Page 1

COLOR TELEVISION RECEIVER

Chassis : K15BD

Model : TK1409

TK2009

TK2009ST

COLOR TELEVISION RECEIVER CONTENTS

Precautions

Specifications and IC Data

Disassembly and Reassembly

Alignment and Adjustment

Troubleshooting

Exploded View and Parts List

Electric Parts List

Block Diagram

PCB Layout Diagram

Wiring Diagram

Schematic Diagrams

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

MAY. 2001

CUBRE TAMBIEN MODELOS GE1400, GE2000 y GE200ST CON NUEVO CHASIS

TK2098

Información reservada a Agentes Autorizados BGH - Por favor conserve este Manual

Page 2

1. Precautions

1-1 Safety Precautions

1. Be sure that all of the built-in protective

devices are replaced. Restore any missing

protective shields.

2. When reinstalling the chassis and its

assemblies, be sure to restore all protective

devices, including: nonmetallic control knobs

and compartment covers.

3. Make sure that there are no cabinet openings

through which people—particularly

children—might insert fingers and contact

dangerous voltages. Such openings include

the spacing between the picture tube and the

cabinet mask, excessively wide cabinet

ventilation slots, and improperly fitted back

covers.

If the measured resistance is less than 1.0

megohm or greater than 5.2 megohms, an

abnormality exists that must be corrected

before the unit is returned to the customer.

4. Leakage Current Hot Check (Figure 1-1):

Warning: Do not use an isolation

transformer during this test. Use a leakagecurrent tester or a metering system that

complies with American National Standards

Institute (ANIS C101.1, Leakage Current for

Appliances), and Underwriters Laboratories

(UL Publication UL1410, 59.7).

5. With the unit completely reassembled, plug

the AC line cord directly into the power

outlet. With the unit’s AC switch first in the

ON position and then OFF, measure the

current between a known earth ground (metal

water pipe, conduit, etc.) and all exposed

metal parts, including: antennas, handle

brackets, metal cabinets, screwheads and

control shafts. The current measured should

not exceed 0.5 milliamp. Reverse the powerplug prongs in the AC outlet and repeat the

test.

Fig. 1-1 AC Leakage Test

6. Antenna Cold Check:

With the unit’s AC plug disconnected from the

AC source, connect an electrical jumper across

the two AC prongs. Connect one lead of the

ohmmeter to an AC prong. Connect the other

lead to the coaxial connector.

7. X-ray Limits:

The picture tube is especially designed to prohibit X-ray emissions. To ensure continued

X-ray protection, replace the picture tube only

with one that is the same type as the original.

Carefully reinstall the picture tube shields and

mounting hardware; these also provide X-ray

protection.

8. High Voltage Limits:

High voltage must be measured each time servicing is done on the B+, horizontal deflection

or high voltage circuits. Correct operation of

the X-ray protection circuits must be

reconfirmed whenever they are serviced.

(X-ray protection circuits also may be called

“horizontal disable” or “hold-down”.)

Heed the high voltage limits. These include

the X–ray Protection Specifications Label, and

the Product Safety and X-ray Warning Note on

the service data schematic.

Precautions

Samaung Electronics 1-1

LEAKAGE

CURRENT

TESTER

DEVICE

UNDER

TEST

TEST ALL

EXPOSED METAL

SURFACES

2-WIRE CORD

ALSO TEST WITH

PLUG REVERSED

(USING AC ADAPTER

PLUG AS REQUIRED)

EARTH

GROUND

(READING SHOULD

NOT BE ABOVE

0.5mA)

Follow these safety, servicing and ESD precautions to prevent damage and protect against potential

hazards such as electrical shock and X-rays.

Page 3

1-1 Safety Precautions (Continued)

9. High voltage is maintained within specified

limits by close-tolerance, safety-related

components and adjustments. If the high

voltage exceeds the specified limits, check

each of the special components.

10. Design Alteration Warning:

Never alter or add to the mechanical or

electrical design of this unit. Example: Do not

add auxiliary audio or video connectors. Such

alterations might create a safety hazard. Also,

any design changes or additions will void the

manufacturer’s warranty.

11. Hot Chassis Warning:

Some TV receiver chassis are electrically

connected directly to one conductor of the AC

power cord. If an isolation transformer is not

used, these units may be safely serviced only

if the AC power plug is inserted so that the

chassis is connected to the ground side of the

AC source.

To confirm that the AC power plug is inserted

correctly, do the following: Using an AC

voltmeter, measure the voltage between the

chassis and a known earth ground. If the

reading is greater than 1.0V, remove the AC

power plug, reverse its polarity and reinsert.

Re-measure the voltage between the chassis

and ground.

12. Some TV chassis are designed to operate with

85 volts AC between chassis and ground,

regardless of the AC plug polarity. These units

can be safely serviced only if an isolation

transformer inserted between the receiver and

the power source.

13. Some TV chassis have a secondary ground

system in addition to the main chassis ground.

This secondary ground system is not

isolated from the AC power line. The two

ground systems are electrically separated by

insulating material that must not be defeated

or altered.

14. Components, parts and wiring that appear to

have overheated or that are otherwise

damaged should be replaced with parts that

meet the original specifications. Always

determine the cause of damage or overheating, and correct any potential hazards.

15. Observe the original lead dress, especially

near the following areas: Antenna wiring,

sharp edges, and especially the AC and high

voltage power supplies. Always inspect for

pinched, out-of-place, or frayed wiring. Do

not change the spacing between components

and the printed circuit board. Check the AC

power cord for damage. Make sure that leads

and components do not touch thermally hot

parts.

16. Picture Tube Implosion Warning:

The picture tube in this receiver employs

“integral implosion” protection. To ensure

continued implosion protection, make sure

that the replacement picture tube is the same

as the original.

17. Do not remove, install or handle the picture

tube without first putting on shatterproof

goggles equipped with side shields. Never

handle the picture tube by its neck. Some

“in-line” picture tubes are equipped with a

permanently attached deflection yoke; do not

try to remove such “permanently attached”

yokes from the picture tube.

18. Product Safety Notice:

Some electrical and mechanical parts have

special safety-related characteristics which

might not be obvious from visual inspection.

These safety features and the protection they

give might be lost if the replacement component differs from the original—even if the

replacement is rated for higher voltage,

wattage, etc.

Components that are critical for safety are

indicated in the circuit diagram by shading,

( ) or ( ).

Use replacement components that have the

same ratings, especially for flame resistance

and dielectric strength specifications.

A replacement part that does not have the

same safety characteristics as the original

might create shock, fire or other hazards.

Precautions

1-2 Samaung Electronics

Page 4

1-2 Servicing Precautions

1. Servicing precautions are printed on the

cabinet. Follow them.

2. Always unplug the unit’s AC power cord from

the AC power source before attempting to: (a)

Remove or reinstall any component or

assembly, (b) Disconnect an electrical plug or

connector, (c) Connect a test component in

parallel with an electrolytic capacitor.

3. Some components are raised above the printed

circuit board for safety. An insulation tube or

tape is sometimes used. The internal wiring is

sometimes clamped to prevent contact with

thermally hot components. Reinstall all such

elements to their original position.

4. After servicing, always check that the screws,

components and wiring have been correctly

reinstalled. Make sure that the portion around

the serviced part has not been damaged.

5. Check the insulation between the blades of the

AC plug and accessible conductive parts

(examples: metal panels, input terminals and

earphone jacks).

6. Insulation Checking Procedure: Disconnect the

power cord from the AC source and turn the

power switch ON. Connect an insulation

resistance meter (500V) to the blades of the AC

plug.

The insulation resistance between each blade

of the AC plug and accessible conductive parts

(see above) should be greater than 1 megohm.

7. Never defeat any of the B+ voltage interlocks.

Do not apply AC power to the unit (or any of

its assemblies) unless all solid-state heat sinks

are correctly installed.

8. Always connect a test instrument’s ground

lead to the instrument chassis ground before

connecting the positive lead; always remove

the instrument’s ground lead last.

Precautions

Samaung Electronics 1-3

Warning1: First read the “Safety Precautions” section of this manual. If some unforeseen circumstance creates a conflict between

the servicing and safety precautions, always follow the safety precautions.

Warning2: An electrolytic capacitor installed with the wrong polarity might explode.

Page 5

1. Some semiconductor (“solid state”) devices

are easily damaged by static electricity. Such

components are called Electrostatically

Sensitive Devices (ESDs); examples include

integrated circuits and some field-effect

transistors. The following techniques will

reduce the occurrence of component damage

caused by static electricity.

2. Immediately before handling any semicon

ductor components or assemblies, drain the

electrostatic charge from your body by

touching a known earth ground. Alternatively,

wear a discharging wrist-strap device. (Be

sure to remove it prior to applying power—

this is an electric shock precaution.)

3. After removing an ESD-equipped assembly,

place it on a conductive surface such as

aluminum foil to prevent accumulation of

electrostatic charge.

4. Do not use freon-propelled chemicals. These

can generate electrical charges that damage

ESDs.

5. Use only a grounded-tip soldering iron when

soldering or unsoldering ESDs.

6. Use only an anti-static solder removal device.

Many solder removal devices are not rated as

“anti-static”; these can accumulate sufficient

electrical charge to damage ESDs.

7. Do not remove a replacement ESD from its

protective package until you are ready to

install it. Most replacement ESDs are

packaged with leads that are electrically

shorted together by conductive foam,

aluminum foil or other conductive materials.

8. Immediately before removing the protective

material from the leads of a replacement ESD,

touch the protective material to the chassis or

circuit assembly into which the device will be

installed.

9. Minimize body motions when handling

unpackaged replacement ESDs. Motions such

as brushing clothes together, or lifting a foot

from a carpeted floor can generate enough

static electricity to damage an ESD.

Precautions

1-4 Samaung Electronics

1-3 Precautions for Electrostatically Sensitive Devices (ESDs)

Page 6

Specifications and IC Data

Samaung Electronics 2-1

2. Specifications and IC Data

2-1 Specifications

Television System

Power Consumption

Picture Tube

Power Requirements

Operating System

Tuning Ranges

Antenna Input Impedance

Intermediate Frequency

Speaker Impedance

14”/20” NTSC, PAL M/N Color TV Signal

14” : 57 Watts Nominal, 20” : 70 Watts Nominal

14” : A34KQV42X 20” : A48KRD82X (H)

AC 100 ~ 240V, 50/60Hz

Remocon System (SSM - 174PT)

VHF CH : 2 ~ 13

UHF CH : 14 ~ 69

CABLE CH : 1, 14~125

75 ohm Unbalanced for VHF/UHF

Picture 45.75 MHz, Sound 41.25 MHz

Color Sub Carrier 42.17 MHz

Single : 8 ohm 2.5W

Dual : 8 ohm 2.5W x 2.5W

Page 7

2-2 IC Line Up

Specifications and IC Data

2-2 Samaung Electronics

Loc. No Specification Description Remark

IC201 TDA8841 SI NTSC, PAL M/N Philips

IC301 TDA8356 VERTICAL OUTPUT

IC501 TDA6107Q RGB DRIVE AMP

IC601 LA4425 SOUND-AMP (2.5W x 1CH)

IC602 LA4425 SOUND-AMP (2.5W x 1CH)

IC801 KA3S0680RF POWER IC (STR)

IC802 KA7630 CUSTOM REGULATOR (5V, 8V)

IC901 SSM-174PT µ-com (OSD Language : English, Spanish, Portuguese)

IC902 24C02/KS24C04O EEPROM

PC802 TCET1108 / LTV817B/PC123Y PHOTO COUPLER

Table 2-1 IC Line-up

Page 8

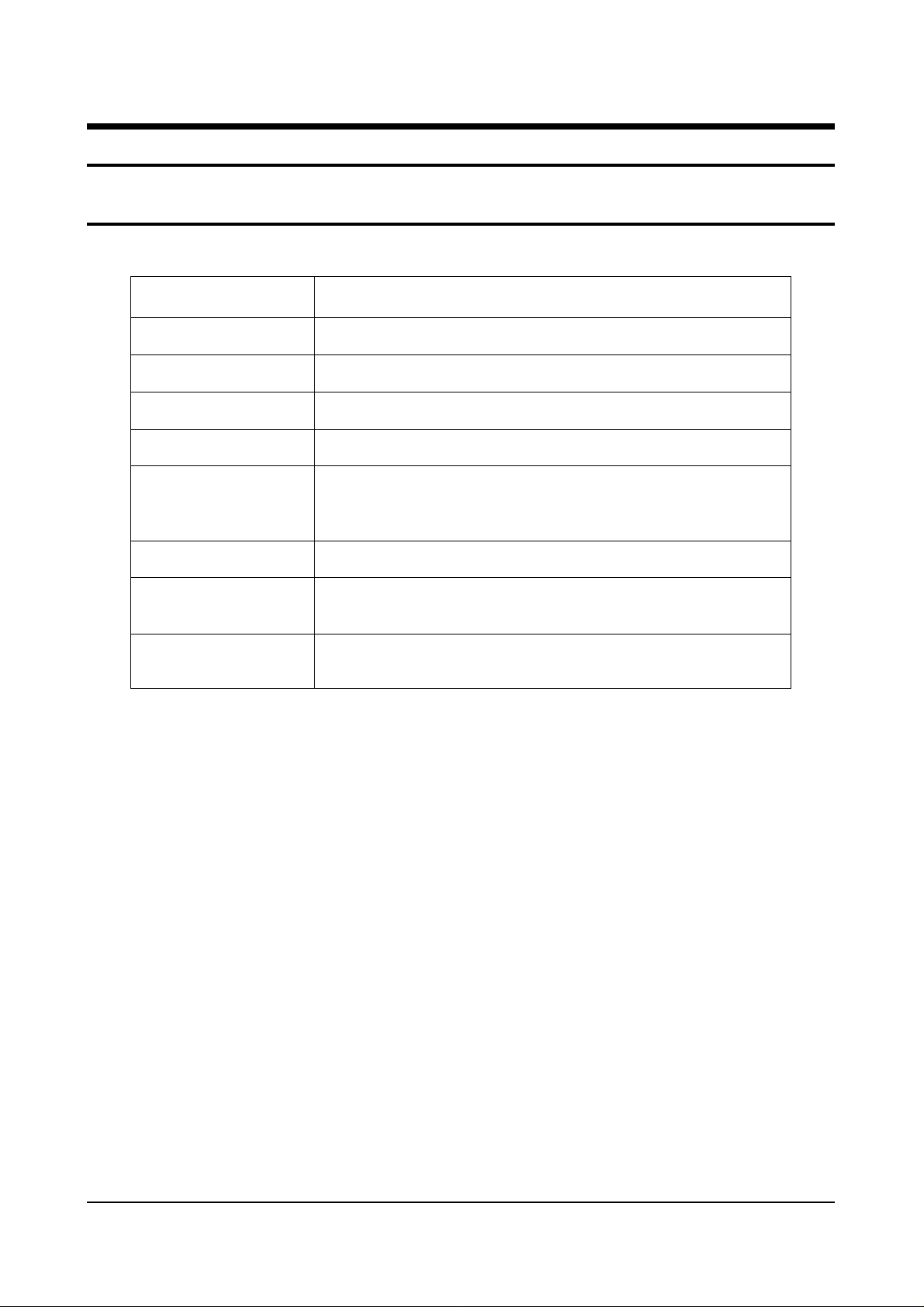

2-3 Semiconductor Base Diagrams

Specifications and IC Data

Samaung Electronics 2-3

Fig. 2-1 Semiconductor Base Diagrams

ELECTROLYTICCONDENSER

TRANSISTOR

2SD1651

2SD1650

KSD5072

KSD5071

KSD1711

KSC5386

DIODE

TRANSISTOR

KSC815-Y

KSA539-Y

BC548

KTC9014

IC

TDA884X(Pin 56)

SSM-174PT(Pin 42)

X24CO2P(Pin 8)

KS24C020(Pin 8)

IC

UPC574J

or

KA33V

SAW-FILTER

1

1

1

M1963M

B

C

E

IC

E B C

TDA8133

TDA8356

TDA6107Q

KA7630

TRANSISTOR

KSR1012

KSR1010

KSR2010

KCT3197

E C B

Page 9

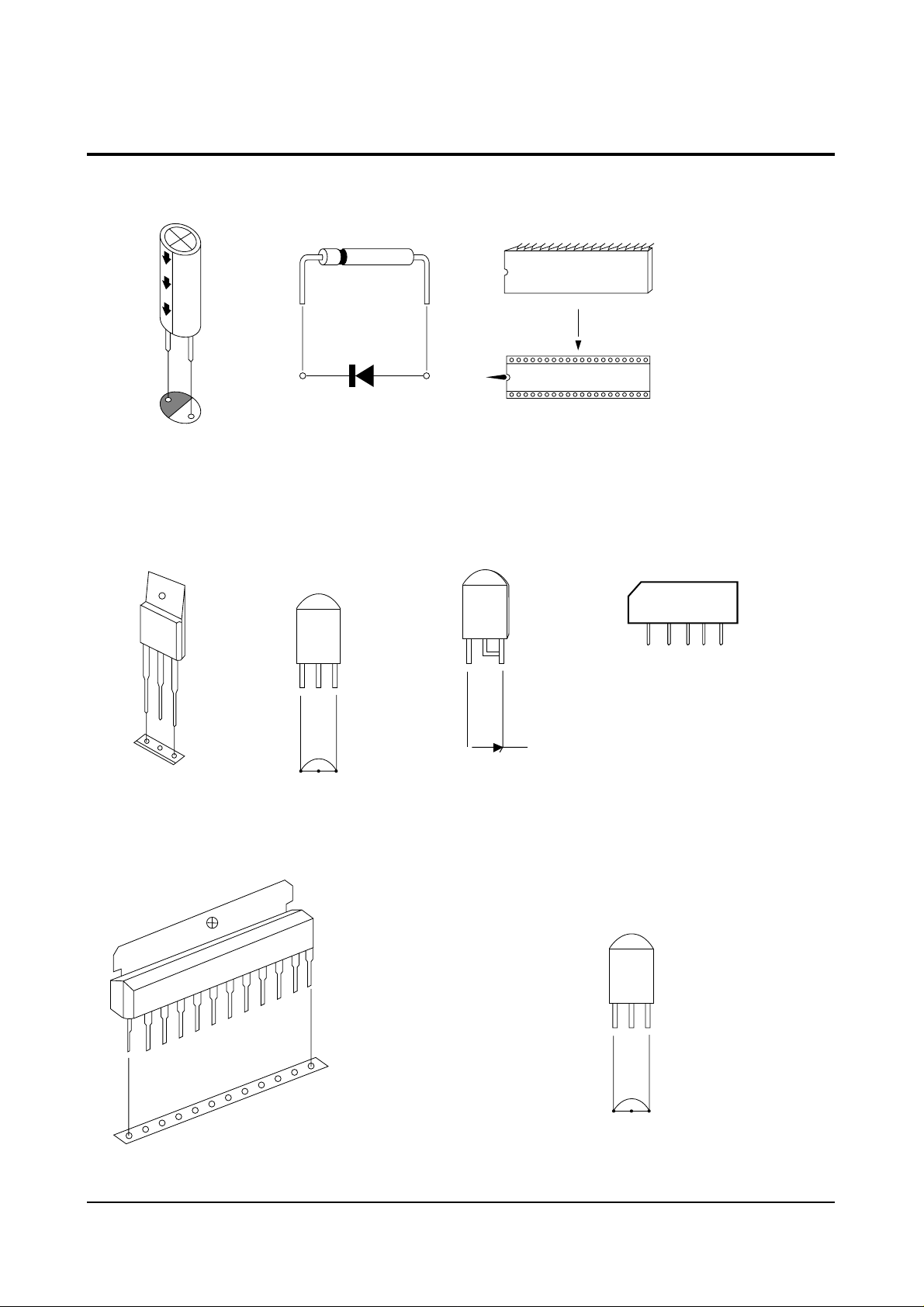

Disassembly and reassembly

Samsung Electronics 3-1

3. Disassembly and Reassembly

3-1 Back Cover Removal

1. After removing the screws, press the tension rib and pull the cabinet backwards.

2. To reassemble, press the tension rib (see diagram).

Page 10

3-2 Main Board Removal

Disassembly and reassembly

3-2 Samsung Electronics

1. Separate the socket board from the CRT neck.

2. Remove the Anode Cap from the CRT.

3. Remove the main board by pulling it with both hands.

Warning: The FBT is charged with high voltage.

Before removing the Anode Cap, discharge the voltage

through one of the heat sinks on the main board.

Page 11

3-3 Speaker Removal

Disassembly and reassembly

Samsung Electronics 3-3

1. Remove the speaker by

pressing the tension rib.

1. Remove the screws.

2. Remove the speaker by

pressing the tension rib.

Page 12

Disassembly and reassembly

3-4 Samsung Electronics

3-4 CRT Removal

1. Spread a soft mat on the floor. Place the TV set face

down.

2. Remove the 4 nuts mounting the CRT to the front cabinet. Lift the CRT.

3. Caution: Because of the high vacuum and large surface

area of the picture tube, be careful while handling it: (1)

Always lift the picture tube by grasping it firmly around

the faceplate, (2) Never lift the tube by its neck. (3) Do

not scratch the picture tube or apply excessive pressure.

Fractures of the glass may cause an implosion.

Page 13

Alignment and Adjustments

4-1

4. Alignment and Adjustments

4-1 Preadjustment

4-1-1 Factory Mode

1. Do not attempt these adjustments in the Video

Mode.

2. The Factory Mode adjustments are necessary

when either the EEPROM (IC902) or the CRT

is replaced.

3. Do not tamper with the “Adjustment” screen

of the Factory Mode menu. This screen is

intended only for factory use.

4-1-2 When EEPROM (IC902) Is Replaced

1. When IC902 is replaced all adjustment data

revert to initial values. It is necessary to

re-program this data.

2. After IC902 is replaced, warm up the TV for

10 seconds.

4-1-3 When CRT Is Replaced

1. Make the following adjustments AFTER setting up after setting up purity and convergence :

White Balance

Sub-Brightness

Vertical Center

Vertical Size

Horizontal Center

4-2 Factory/Service Mode

4-2-1 Procedure for the “Adjustment” Mode

1. This mode uses the standard remote control.

The Service Mode is activated by entering the

following remote-control sequence :

(1) DISPLAY→FACTORY.

(2) STAND-BY→ MUTE→ 1→ 8→ 2

→POWER ON.

2. The “SERVICE (FACTORY)” message will be

displayed. The Service Mode has four components: Adjustment, Option Bytes and Reset.

3. Access the Adjustment Mode by pressing the

“VOLUME” keys ( Up or Down). The adjustment parameters are listed in the accompanying table, and selected by pressing the CHANNEL keys (s ,t).

4. Selection sequences for the PAL N system:

DOWN or UP key:

AGC>VCO>SBT>SCT>RG>GG>BG>SC>

PCR> PSL>PVS>PVA>PHS> HS>CDL

Selection sequences for the NTSC, PAL M

system:

DOWN or UP key:

AGC>VCO>SBT>SCT>RG>GG>BG>SC>STT>

NCR>NSL>NVS>NVA>NHS>CDL

5. The VOLUME keys increase or decrease the

adjustment values (stored in the

non-volatile memory) when Adjustment Mode

is cancelled.

6. Cancel the Adjustment Mode by re-pressing

the “FACTORY” or “Power OFF” keys.

Page 14

4-2-2 Main Adjustment Parameter

NOTE : Once a system (of PAL N/NTSCM, PALM System) is adjusted, another system is

automatically adjusted. (NHS=PHS + HS)

Alignment and Adjustments

4-2

Table 4-1 Main Adjustment Parameter (SSM-174PT, TDA8841)

AUTO GAIN CONTROL

VOLTAGE CONTROL OSCILLATOR

SUB BRIGHT

SUB CONTRAST

RED DRIVE GAIN

GREEN DRIVE GAIN

BLUE DRIVE GAIN

PAL SUB COLOR

S-CORRECTION

PAL VERTICAL SLOPE

PAL VERTICAL SHIFT

PAL VERTICAL AMPLITUDE

OSD ABBREVIATIONFUNCTION

AGC

VCO

SBT

SCT

RG

GG

BG

PCR

SC

PSL

PVS

PVA

0 ~ 63 STEP

0 ~ 128 STEP

0 ~ 23 STEP

0 ~ 23 STEP

0 ~ 63 STEP

0 ~ 63 STEP

0 ~ 63 STEP

0 ~ 23 STEP

0 ~ 63 STEP

0 ~ 63 STEP

0 ~ 63 STEP

0 ~ 63 STEP

INITIAL DATA REMARKRANGE

05

48

9

8

25

25

25

10

10 (20 INCH)

0 (14 INCH)

34

32

28

FIX

FIX

FIX

FIX

PAL HORIZONTAL SHIFT

HORIZONTAL SHIFT

SUB TINT

NTSC SUB COLOR

NTSC VERTICAL SLOPE

NTSC VERTICAL SHIFT

NTSC VERTICAL AMPLITUDE

NTSC HORIZONTAL SHIFT

PHS

HS

STT

NCR

NSL

NVS

NVA

NHS

0 ~ 63 STEP

0 ~ 7 STEP

1 ~ 23 STEP

0 ~ 23 STEP

0 ~ 63 STEP

0 ~ 63 STEP

0 ~ 63 STEP

0 ~ 63 STEP

42

5

14

00

34

32

28

47

FIX

FIX

FIX

Page 15

Alignment and Adjustments

4-3

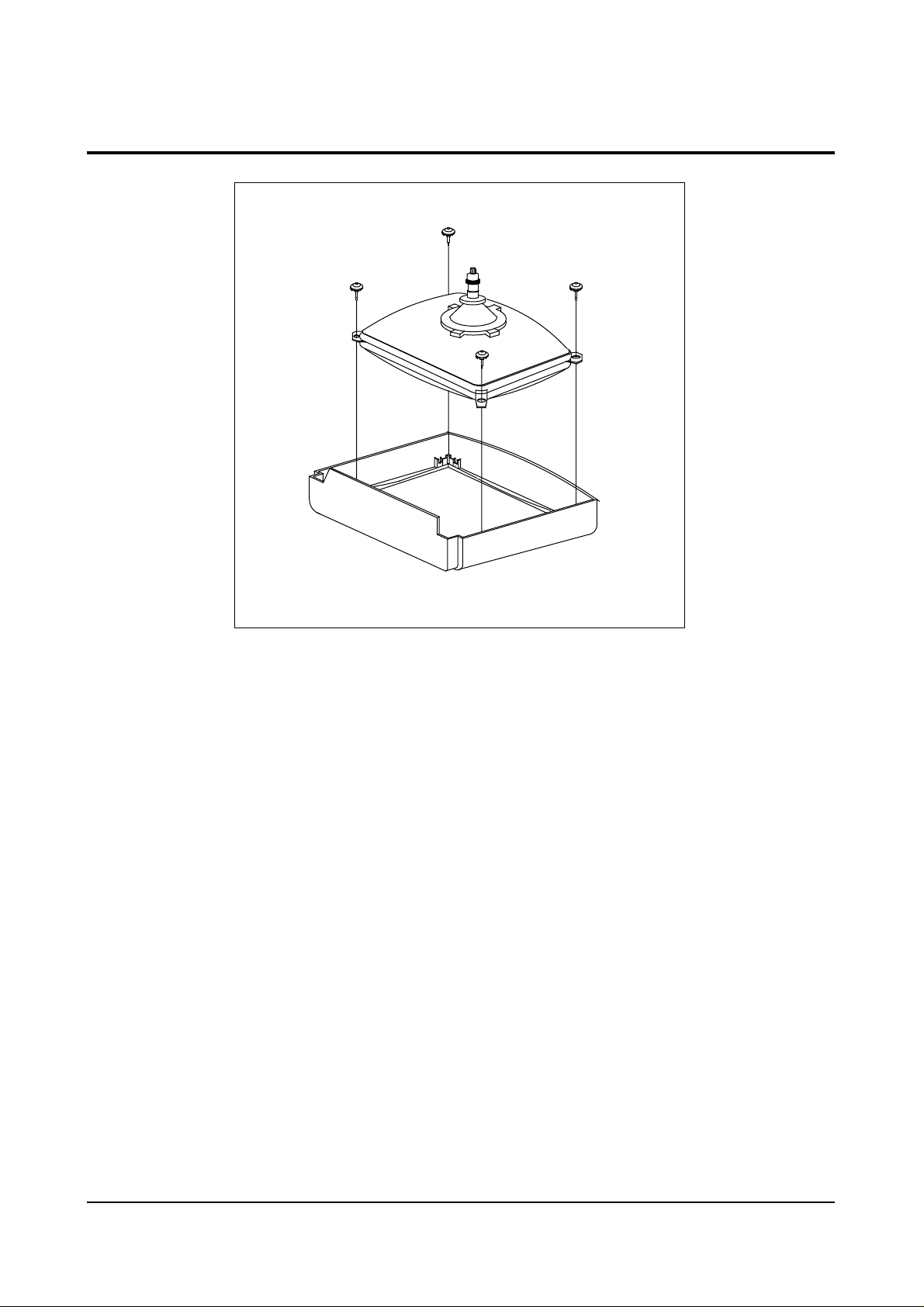

4-2-3 Option Table

543210

< VIDEO MUTE>

0 : VIDEO MUTE ON

1 : VIDEO MUTE OFF

< BLUE-SCREEN OPTION>

0 : BLUE-BACK ON

1 : BLUE-BACK OFF

<AUTO SOUND OPTION>

0 : AUTO SOUND OFF

1 : AUTO SOUND ON

< AUTO ON OPTION >

0 : AUTO POWER ON (LAST MEMORY

1 : DISABLE (STAND-BY)

543210

00110

< BLACK STRECTH >

0 : BLACK STRECTH ON

1 : BLACK STRECTH OFF

< INITIAL LANGUAGE OPTION >

0 : PORTUGUESE

1 : SPANISH

:Basic Option Byte

(Note : No. 5 is a Local Option)

Page 16

4-2-2 Main Adjustment Parameter

N OT E : Once a system (of PA L N / N T SC M , PA L M System) is adjusted, another sy stem is

automatically adjusted. (N H S=PH S + H S)

Alignment and Adjustments

4-2 ST

Table 4-1 Main Adjustment Parameter (Z9036512PSC)

AUTO GAIN CONTROL

SUB BRIGHT

SUB CONTRAST

SUB TINT

NTSC SUB COLOR

PAL SUB COLOR

RED DRIVE GAIN

GREEN DRIVE GAIN

BLUE DRIVE GAIN

S-CORRECTION

HORIZONTAL SHIFT

OSD ABBREVIATIONFUNCTION

AGC

SBT

SCT

STT

NCR

PCR

RG

GG

BG

SCO

CDL

dHS

0 ~ 63 STEP

0 ~ 23 STEP

0 ~ 23 STEP

0 ~ 23 STEP

0 ~ 23 STEP

0 ~ 23 STEP

0 ~ 63 STEP

0 ~ 63 STEP

0 ~ 63 STEP

0 ~ 63 STEP

0 ~ 7 STEP

0 ~ 7 STEP

INITIAL DATA REMARKRANGE

05

9

8

14

00

10

25

25

25

10 (20 INCH)

0 (14 INCH)

4

5

FIX

FIX

FIX

FIX

FIX

NTSC VERTICAL SLOPE

NTSC VERTICAL SHIFT

NTSC VERTICAL AMPLITUDE

NTSC HORIZONTAL SHIFT

PAL VERTICAL SLOPE

PAL VERTICAL SHIFT

PAL VERTICAL AMPLITUDE

PAL HORIZONT

NSL

NVS

NVA

NHS

PSL

PVS

PV

PHS

0 ~ 63 STEP

0 ~ 63 STEP

0 ~ 63 STEP

0 ~ 63 STEP

0 ~ 63 STEP

0 ~ 63 STEP

0 ~ 63 STEP

0 ~ 63 STEP

34

32

28

47

34

32

28

42

Page 17

4-2-3 MTS Table

4-3ST

Table 4-2 MTS Adjustment Parameter (Z9036512PSC)

ATENUATION

SPECTRAL

WIDEBAND

4-2-4 Option

Byte 0 : 51

Byte 1 : 00

OSD ABBREVIATIONFUNCTION

SPECTRAL

WIDEBAND

ATT

0 ~ 15 STEP

0 ~ 63 STEP

0 ~ 63 STEP

INITIAL DATA REMARKRANGE

13

46

32

Page 18

Alignment and Adjustments

4-4

4-3 Other Adjustments

4-3-1 General

1. Usually, a color TV needs only slight touchup adjustment upon installation. Check the

basic characteristics such as height, horizontal

and vertical sync and focus.

2. The picture should have good black and white

details. There should be no objectionable

color shading; if color shading is present, perform the purity and convergence adjustments

described below.

3. Use the specified test equipment or its equivalent.

4. Correct impedance matching is essential.

5. Avoid overload. Excessive signal from a sweep

generator might overload the front-end of the

TV. When inserting signal markers, do not

allow the marker generator to distort test

results.

6. Connect the TV only to an AC power source

with voltage and frequency as specified on the

backcover nameplate.

7. Do not attempt to connect or disconnect any

wires while the TV is turned on. Make sure

that the power cord is disconnected before

replacing any parts.

8. To protect against shock hazard, use an isolation transformer.

4-3-2 Automatic Degaussing

A degaussing coil is mounted around the picture tube, so that external degaussing after

moving the TV should be unnecessary. But

the receiver must be properly degaussed upon

installation.

The degaussing coil operates for about 1 second after the power is switched ON. If the set

has been moved or turned in a different direction, disconnect its AC power for at least 30

minutes.

If the chassis or parts of the cabinet become

magnetized, poor color purity will result. If

this happens, use an external degaussing coil.

Slowly move the degaussing coil around the

faceplate of the picture tube and the sides and

front of the receiver. Slowly withdraw the coil

to a distance of about 6 feet before removing

power.

4-3-3 High Voltage Check

CAUTION: There is no high voltage adjustment on this chassis.

The B+ power supply must be set to +125 volts (Full color bar input

and normal picture level).

1. Connect a digital voltmeter to the second

anode of the picture tube.

2. Turn on the TV. Set the Brightness and

Contrast controls to minimum (zero beam current).

3. The high voltage should not exceed 27.5KV.

4. Adjust the Brightness and contrast controls to

both extremes. Ensure that the high voltage

does not exceed 27.5KV under any conditions.

Page 19

Alignment and Adjustments

4-5

4-3-4 FOCUS Adjustment

1. Input a black and white signal.

2. Adjust the tuning control for the clearest picture.

3. Adjust the FOCUS control for well defined

scanning lines in the center area of the screen.

4-3-5 Cathode Voltage Adjustment

(Screen Adjustment)

1. Connect CRT socket pin GK to an oscilloscope

probe.

2. Input a gray scale pattern. (Use a pattern generator, PM5518)

3. Use the P mode key (on the remote control)

for the STANDARD picture.

4. Adjust the Screen VR (on the FBT) so that the

voltage on the oscilloscope becomes 130+2.5V

(See Fig. 4-1).

4-3-6 Purity Adjustment

1. Warm up the receiver for at least 20 minutes.

2. Plug in the CRT deflection yoke and tighten

the clamp screw.

3. Plug the convergence yoke into the CRT and

set in as shown in Fig. 4-2.

4. Input a black and white signal.

5. Fully demagnetize the receiver by applying an

external degaussing coil.

6. Turn the CONTRAST and BRIGHTNESS controls to maximum.

7. Loosen the clamp screw holding the yoke.

Slide the yoke backward or forward to provide vertical green belt. (Fig. 4-3).

8. Tighten the convergence yoke.

9. Slowly move the deflection yoke forward,

and adjust for the best overall green screen.

10. Temporarily tighten the deflection yoke.

11. Produce blue and red rasters by adjusting the

low-light controls. Check for good purity in

each field.

12. Tighten the deflection yoke.

Fig. 4-1

130 2.5V

+

_

GND

14, 16" :120 2.5V

20, 21" : 130 2.5V

+

_

+

_

_

Page 20

Alignment and Adjustments

4-6

4-3-7 White Balance Adjustment

Fig. 4-2 Convergence Magnet Assembly

Fig. 4-3 Center Convergence Adjustment

Fig. 4-4

(a) Set up

1. Warm up the TV for at least 30 minutes in the

Aging Mode (OSD White). This mode is displayed by entering the following sequence:

DISPLAY

→FACTORY → FACTORY

2. Input a Toshiba pattern.

(b) Low-Light Adjustment

1. Set SBT to 1.3 ± 0.2 fL in the Factory Service

Mode with using CA100. See Fig. 4-4

¡.

2. Adjust RG,BG so that the levels are suitable to

each local area.

(c) High-Light Adjustment

1. Set SCT to 55 FL (20”), 65 FL(14”) in the

Factory Service Mode with using CA100. See

Fig. 4-4

¨.

6 Pole Magnet

Clamper

Screw

4 Pole Magnet

2 Pole Magnet

2 POLE

PURITY

6 POLE

CONVERGENCE

4 POLE

CONVERGENCE

YOKE

CLAMP

SCREW

ADJUST THE ANG

(VERTICAL LINES)

31m/m

Vertical Green Belt

1

2

Page 21

Alignment and Adjustments

4-7

4-3-8 Center Convergence Adjustment

1. Warm up the receiver for at least 20 minutes.

2. Adjust the two tabs of the 4 pole magnets to

change the angle between them. Superimpose

the red and blue vertical lines in the center

area of the screen.

3. Adjust the Brightness and Contrast controls

for a well defined picture.

4. Adjust the two-tab pairs of the 4 pole magnets, and change the angle between them.

Superimpose the red and the blue vertical

lines in the center area of the screen.

5. Turn the both tabs at the same time, keeping

the angle constant, and superimpose the red

and blue horizontal line in the center of the

screen.

6. Adjust the two-tab pairs of the 6-pole magnets

to superimpose the red and blue line onto the

green. (Changing the angle affects the vertical

lines, and rotating both magnets affects the

horizontal lines.)

7. Repeat adjustments 2~6, if necessary.

8. Since the 4-pole magnets and 6-pole magnets

interact, the dot movement is complex

(Fig. 4-5).

4-3-9 VCO Adjustment

Fig. 4-5 Center Convergence Adjustment

Set the vco data to 48 (Factory Mode).

BLUE

BLUE

RED

RED

RED/BLUE

RED/BLUE

GREEN

GREEN

4-Pole Magnet Movement

6-Pole Magnet Movement

Page 22

4-3-10 RF AGC Adjustment

Set the AGC data to 5.0 (Factory Mode).

4-3-11 Sub-Color Adjustment

Set SCR data to 10 (Factory Mode).

4-3-12 Geometry Adjustment

SC →PSL (NSL)→PVS (NVS)→ PVA(NVA)

→PHS (NHS)

1. Input a lion head pattern.

2. Adjust “PVA (NVA)”, “PSL (VSL)” so that the

top and bottom margirns of the screen are 4.0.

If the top and bottom values are different,

adjust “PVA (NVA)”, “PSL (NSL)”, “PVS

(NVS)” so that the sum of the two values is

8.0.

Fig. 4-7

3. Adjust with PHS/NHS (Horizontal Shift) so

that the lion-head pattern and CRT centers are

aligned.

Fig. 4-9

4. Adjust PHS/NHS (using the width coil) so

that the left and right margins of the picture

are 5.

Alignment and Adjustments

4-8

4

5

5

4

Page 23

4-2-3 Test Pattern (Aging Mode)

1. This mode can be used during servicing, or for

confirming that the convergence and purity

adjustments are correct.

2. Access the Test Pattern parameters by pressing

a CHANNEL keys (s ,t) while the Service

Mode is on. The cursor will move to the test

pattern. Press the VOLUME keys. On-screen

display:

• WHITE

• AGING

3. AGING Mode (Reference Only)

This pattern is used for pre-heating the CRT

during manufacturing

—it is accessed in the factory by twice pressing the “SLEEP → FACTORY→FACTORY “

key, then white pattern will be displayed.

Even if the TV power is cut off, the Aging

Mode is not cancelled, The aging mode is cancelled by repressing the “FACTORY” key or

pressing the local “CH UP/DOWN” keys.

Alignment and Adjustments

4-9

Page 24

Troubleshooting

Samaung Electronics 5-1

5. Troubleshooting

5-1 No Video (Raster On, No Sound)

Open the IF Pin of Tuner

Measure the

Voltage of Each Pin

of TU01

Yes

Check IC901

Pins 39, 40

Yes

See "No Video"

(Sound OK)

No

No

Check/Replace

TU01,

Check/Replace

IC901, IC201

See "No Sound"

(Video OK)

Page 25

5-2 No Power

Troubleshooting

5-2 Samaung Electronics

Check the 125V,

13.0V B+ Lines

Yes

Check IC802

Pin 9 (5V)

Check IC901

Pin 10(4V).

Yes

Check IC901

Pin 20 ; Stand-by : 0V

Normal : 5V

No

No

No

No

Check/Replace

IC801, D807,D808,

D809,D810,D802

Check/Replace

IC802 (KA7630)

Check/Replace

IC901, D902

Check/Replace

IC901, (µ-com).

Check IC201,

Pin 40 (H-out)

No

Check/Replace

IC201, Q401, Q402.

Page 26

5-3 No Video (Sound OK)

Troubleshooting

Samaung Electronics 5-3

Check IC201

Pin 12,37 (8V)

Yes

Check IC201

Pin 6 (CVBS)

Yes

Check IC201

Pins 19, 20, 21

Check IC201

pin 27 (Y-IN)

No

No

No

No

Check/Replace

IC802 KA7630

Check/Replace

IC201

Check/Replace

IC201, Q203

Yes

Check IC501

on the CRT PCB

Check/Replace

R419, R505 (HEATER 6.3Vrms)

D501 (CRT G1 pin)

CRT, V999

No

Check/Replace

IC501

Page 27

Troubleshooting

5-4 Samaung Electronics

5-4 No Sound (Video OK)

Check IC201

Pin 15 (Sound Out)

Yes

Check IC601/IC602

Pins 1, (SOUND IN)

No

Check IC601/IC602

Pin 3 (B+ 10-12.5V)

Yes

Check IC601/IC602

No

Yes

No

No

Check/Replace

IC201

Check/Replace

Q902, IC601, IC602

Check/Replace

Q601, Q602, R819

Check/Replace

IC601/IC602

Yes

Check/Replace

A/V Front assembly.

Page 28

Exploded Views & Parts List

Samaung Electronics 6-1

6. Exploded Views & Parts List

No Code No Description Specification Q’ty Remark

1 AA92-00732B ASSY CABINET FRONT ;TK1409SC/TCE 1

AA64-01489F CABINET FRONT ;14H3,SV808P EWN,HIPS HB,G4 1

1-1 AA64-00474B BADGE BRAND ;14INCH,AL,-,-,40(22),SILVER, 1

1-2 AA64-01492B KNOB POWER ;14H3,ABS HB,G3676,NO-SILK 1

1-3 AA64-01493B WINDOW REMOCON ;14H3,PC,VIOLET 1

1-4 AA64-01494B INDICATOR LED ;14H3,ACRYL HB,CLR 1

1-5 AA61-60003J SPRING-CS ;-,SUS304,0.5,OD6,H12,N7,-,-,- 1

1-6 AA41-00227B PCB-A/V ;CT-20S4,FR-1,1L,B,1.6T,245X245 1

1-7 6006-001095 SCREW-ASS’Y TAPT ;WP,BH,+,M4,L12,ZPC(YEL) 2 PA+CF

1-8 AA61-40113A STOPPER-PCB ;501H,HIPS,-,-,HB,NTR,- 1

1-9 AA96-00610A ASSY SPEAKER ;,16OHM,3W,3001-001039,AA39- 1

1-10 6003-001026 SCREW-TAPTITE ;RH,+,B,M4,L15,ZPC(BLK),SWR 8 SPK+CF

1-11 AA64-01491B KNOB CONTROL ;14H3,ABS HB,G3676 1

1-12 6003-001026 SCREW-TAPTITE ;RH,+,B,M4,L15,ZPC(BLK),SWR 1 KC+CF

2 AA97-00277A ASSY-CRT ;A34KQV42X,0MG,14,BARE,TFK1440 1

2-1 AA65-30106A CLAMP-D,COIL ;NYLON 66,V2,NTR,-,14 INCH,- 2

2-2 AA60-10050R SCREW-ASSY ;-,SWRCH18A,M5,L31.5,HH,+,WC,- 4

2-3 3704-001112 SOCKET-CRT ;8P,12PI,22.5PI,NI,- 1 V999S

3 AA64-01490D CABINET-BACK ;14H3,HIPS V2,G4309 1

3-1 AA60-10050T SCREW-TAPPING ;-,SWRCH18A,M4,L20,RH,+,2S, 4 CB+CF

3-2 AA96-70170A ASSY-POWER,CORD ;-,KKP419C,AP2/YES,H/C300 1

6-1 TK1409SC/TCE

Page 29

Exploded Views & Parts List

6-2 Samaung Electronics

No Code No Description Specification Q’ty Remark

1 AA92-00730B ASSY CABINET FRONT ;TK2009SC/TCE 1

AA64-01438G CABINET FRONT ;20H3,SV808P EWN,HIPS,HB,G4 1

1-1 AA64-00475B BADGE BRAND ;20INCH,AL,-,-,50(25),SILVER, 1

1-2 AA64-01338B KNOB POWER ;20H3,ABS,G3676,NO-SILK 1

1-3 AA64-01339B WINDOW REMOCON ;20H3,PC,VIOLET 1

1-4 AA64-01340B INDICATOR LED ;20H3,ACRYL 1

1-5 AA61-60003J SPRING-CS; -,SUS304,0.5,OD6,H12,N7,-,-,- 1

1-6 AA41-00227B PCB-A/V ;CT-20S4,FR-1,1L,B,1.6T,245X245 1

1-7 6006-001095 SCREW-ASS’Y TAPT ;WP,BH,+,M4,L12,ZPC(YEL) 2 AV+CF

1-8 AA61-40113A STOPPER-PCB ;501H,HIPS,-,-,HB,NTR,- 1

1-9 AA96-00676A ASSY SPEAKER ;,16OHM,5W,3001-000280,AA39- 1

1-10 6003-001026 SCREW-TAPTITE ;RH,+,B,M4,L15,ZPC(BLK),SWR 8 SPK+CF

1-11 AA64-01337B KNOB CONTROL ;20H3,ABS,G3676 1

1-12 6003-001026 SCREW-TAPTITE ;RH,+,B,M4,L15,ZPC(BLK),SWR 1 KC+CF

1-13 6006-001095 SCREW-ASS’Y TAPT ;WP,BH,+,M4,L12,ZPC(YEL) 2 AV+CF

1-14 AA97-01312A ASSY-PCB,A/V FRONT ;,14H3,K15B,NTSC,MONO 1

2 AA97-00338B ASSY CRT ;AA03-10029X,0mG,A48KRD82X(H),B 1

2-1 AA65-30107A CLAMP-D,COIL ;NYLON 66,V2,NTR,-,20~22 INC 4

2-2 3704-001105 SOCKET-CRT ;11P,20PI,26.5PI,NI,- 1 V999S

3 AA64-01439E CABINET BACK ;20H3,HIPS,V2,G4309 1

3-1 AA60-10050T SCREW-TAPPING ;-,SWRCH18A,M4,L20,RH,+,2S, 4 CB+CF

3-2 AA96-70170A ASSY-POWER,CORD ;-,KKP419C,AP2/YES,H/C300 1

6-2 TK2009SC/TCE

Page 30

Exploded Views & Parts List

Samaung Electronics 6-3

No Code No Description Specification Q’ty Remark

1 AA92-00730C ASSY CABINET FRONT ;TK2009STSC/TCE 1

AA64-01438H CABINET FRONT ;20H3,SV808P EWS,HIPS,HB,G4 1

1-1 AA64-00475B BADGE BRAND ;20INCH,AL,-,-,50(25),SILVER, 1

1-2 AA64-01338B KNOB POWER ;20H3,ABS,G3676,NO-SILK 1

1-3 AA64-01339B WINDOW REMOCON ;20H3,PC,VIOLET 1

1-4 AA64-01340B INDICATOR LED ;20H3,ACRYL 1

1-5 AA61-60003J SPRING-CS ;-,SUS304,0.5,OD6,H12,N7,-,-,- 1

1-6 AA41-00227B PCB-A/V ;CT-20S4,FR-1,1L,B,1.6T,245X245 1

1-7 6006-001095 SCREW-ASS’Y TAPT ;WP,BH,+,M4,L12,ZPC(YEL) 2 AV+CF

1-8 AA61-40113A STOPPER-PCB ;501H,HIPS,-,-,HB,NTR,- 1

1-9 AA96-00675A ASSY SPEAKER ;,8OHM,5W,3001-000274,AA39-2 1

1-10 6003-001026 SCREW-TAPTITE ;RH,+,B,M4,L15,ZPC(BLK),SWR 8 SPK+CF

1-11 AA64-01337B KNOB CONTROL ;20H3,ABS,G3676 1

1-12 6003-001026 SCREW-TAPTITE ;RH,+,B,M4,L15,ZPC(BLK),SWR 1 KC+CF

1-13 6006-001095 SCREW-ASS’Y TAPT ;WP,BH,+,M4,L12,ZPC(YEL) 2 AV+CF

1-14 AA97-01336A ASSY-PCB,A/V FRONT ;,20H3,K15B,NTSC,STERE 1

2 AA97-00338B ASSY CRT ;AA03-10029X,0mG,A48KRD82X(H),B 1

2-1 AA65-30107A CLAMP-D,COIL ;NYLON 66,V2,NTR,-,20~22 INC 4

2-2 3704-001105 SOCKET-CRT ;11P,20PI,26.5PI,NI,- 1 V999S

3 AA64-01439E CABINET BACK ;20H3,HIPS,V2,G4309 1

3-1 AA60-10050T SCREW-TAPPING ;-,SWRCH18A,M4,L20,RH,+,2S, 4 CB+CF

3-2 AA96-70170A ASSY-POWER,CORD ;-,KKP419C,AP2/YES,H/C300 1

6-3 TK2009STSC/TCE

Page 31

6-4 Samsung Electronics

MEMO

Page 32

ASSY PCB MAIN(COM)

1 * AA97-00650D ASSY PCB MAIN(COM);TK1409SC/TCE,K15B,ARG S.N.A

..2 C102 2401-000962 C-AL;22uF,20%,50V,GP,TP,5x11,5

..2 C104 2202-000127 C-CERAMIC,MLC-AXIAL;10nF,+80-20%,25V,Y5V

..2 C108 2401-000480 C-AL;10uF,20%,50V,GP,TP,5x11,5

..2 C110 2401-001363 C-AL;470uF,20%,16V,GP,TP,10x12.5,5

..2 C151 2202-000127 C-CERAMIC,MLC-AXIAL;10nF,+80-20%,25V,Y5V

..2 C153 2202-000127 C-CERAMIC,MLC-AXIAL;10nF,+80-20%,25V,Y5V

..2 C201 2306-000122 C-FILM,MPPF;100nF,5%,50V,TP,7.3x4.0x5.0m

..2 C202 2401-001840 C-AL;100uF,20%,16V,GP,TP,6.3x11,5

..2 C203 2401-000660 C-AL;2.2uF,20%,50V,GP,TP,5x11,5

..2 C204 2401-001333 C-AL;470nF,20%,50V,GP,TP,5x11,5

..2 C205 2305-000411 C-FILM,MPEF;470nF,5%,50V,TP,7.3x4.8x5.5m

..2 C206 2202-000632 C-CERAMIC,MLC-AXIAL;100nF,20%,50V,Z5U,TP

..2 C207 2305-000196 C-FILM,MPEF;150nF,5%,63V,TP,-,5mm

..2 C208 2401-000027 C-AL;4.7uF,20%,50V,GP,TP,5x11,5

..2 C209 2202-000849 C-CERAMIC,MLC-AXIAL;18pF,5%,50V,CH,TP,3.

..2 C210 2301-000445 C-FILM,PEF;4.7nF,5%,50V,TP,5.5x7x3mm,5mm

..2 C211 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0m

..2 C212 2301-000192 C-FILM,PEF;1nF,5%,50V,TP,5.3x10mm,5mm

..2 C213 2201-000258 C-CERAMIC,DISC;0.017nF,5%,50V,NP0,TP,5x3

..2 C214 2301-000356 C-FILM,PEF;47nF,5%,50V,TP,7.5x4.0x6.5,5m

..2 C215 2301-000383 C-FILM,PEF;10nF,5%,50V,TP,6x7x3.2mm,5mm

..2 C216 2401-001840 C-AL;100uF,20%,16V,GP,TP,6.3x11,5

..2 C218 2202-000791 C-CERAMIC,MLC-AXIAL;150pF,10%,50V,Y5P,TP

..2 C219 2401-000603 C-AL;1uF,20%,50V,GP,TP,5x11,5

..2 C222 2401-000480 C-AL;10uF,20%,50V,GP,TP,5x11,5

..2 C226 2301-000224 C-FILM,PEF;22nF,5%,50V,TP,7.4x3.9x13mm,5

..2 C231 2401-000480 C-AL;10uF,20%,50V,GP,TP,5x11,5

..2 C232 2401-001840 C-AL;100uF,20%,16V,GP,TP,6.3x11,5

..2 C238 2401-002144 C-AL;47uF,20%,16V,GP,TP,5x11,5

..2 C239 2202-000632 C-CERAMIC,MLC-AXIAL;100nF,20%,50V,Z5U,TP

..2 C240 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0m

..2 C247 2202-000632 C-CERAMIC,MLC-AXIAL;100nF,20%,50V,Z5U,TP

..2 C248 2309-000138 C-FILM,PE-PPF;100nF,5%,50V,TP,20x16x8.5,

..2 C249 2401-000603 C-AL;1uF,20%,50V,GP,TP,5x11,5

..2 C250 2301-000224 C-FILM,PEF;22nF,5%,50V,TP,7.4x3.9x13mm,5

..2 C251 2301-000445 C-FILM,PEF;4.7nF,5%,50V,TP,5.5x7x3mm,5mm

..2 C252 2301-000192 C-FILM,PEF;1nF,5%,50V,TP,5.3x10mm,5mm

..2 C253 2202-000632 C-CERAMIC,MLC-AXIAL;100nF,20%,50V,Z5U,TP

..2 C301 2202-000183 C-CERAMIC,MLC-AXIAL;2.2NF,20%,16V,Y5R,TP

..2 C302 2202-000183 C-CERAMIC,MLC-AXIAL;2.2NF,20%,16V,Y5R,TP

..2 C303 2401-003028 C-AL;100uF,20%,25V,WT,TP,6.3x11,5

..2 C304 2401-000901 C-AL;22uF,20%,160V,GP,TP,10x20,5

..2 C307 2305-000708 C-FILM,MPEF;150nF,5%,100V,TP,16.5x10.3x5

..2 C308 2305-000470 C-FILM,MPEF;68nF,5%,100V,TP,-,5mm

..2 C309 2305-000149 C-FILM,MPEF;100nF,5%,100V,TP,12x12.5x6.5

..2 C310 2305-000285 C-FILM,MPEF;220NF,5%,100V,TP,10.5X5.5X15

..2 C401 2201-000600 C-CERAMIC,DISC;0.56nF,10%,50V,Y5P,TP,5x3

..2 C405 2301-001065 C-FILM,MPPF;47nF,5%,630V,TP,19x15.5x7,7.

..2 C406 2201-000556 C-CERAMIC,DISC;0.47nF,10%,500V,Y5P,TP,5.

..2 C407 2401-001661 C-AL;68uF,20%,100V,GP,TP,10x16,5

..2 C408 2201-000556 C-CERAMIC,DISC;0.47nF,10%,500V,Y5P,TP,5.

..2 C409 2401-001397 C-AL;470uF,20%,25V,GP,TP,10x16,5

..2 C410 2301-000383 C-FILM,PEF;10nF,5%,50V,TP,6x7x3.2mm,5mm

..2 C411 2201-000556 C-CERAMIC,DISC;0.47nF,10%,500V,Y5P,TP,5.

..2 C412 2401-000927 C-AL;22uF,20%,250V,GP,TP,13x20,5

..2 C413 2401-002268 C-AL;2.2uF,20%,250V,LZ,TP,8X11,5

..2 C419 2201-000639 C-CERAMIC,DISC;0.68nF,10%,2kV,Y5P,TP,9x5

..2 C445 2305-000382 C-FILM,MPEF;4.7nF,5%,400V,TP,-,5mm

..2 C501 2201-000192 C-CERAMIC,DISC;0.01nF,0.25pF,500V,NP0,TP

..2 C502 2301-000213 C-FILM,PEF;220nF,5%,250V,TP,21.5x11,7.5

..2 C503 2201-000723 C-CERAMIC,DISC;4.7nF,20%,3KV,Y5U,TP,16x5

..2 C504 2401-001232 C-AL;4.7uF,20%,250V,GP,TP,10x12.5,5

..2 C506 2401-000430 C-AL;10uF,20%,250V,GP,TP,10x16mm,5m

..2 C601 2401-001998 C-AL;1000uF,20%,25V,GP,TP,10x20,5mm

..2 C602 2201-000292 C-CERAMIC,DISC;1nF,10%,50V,Y5P,TP,5x3.5,

..2 C603 2401-000603 C-AL;1uF,20%,50V,GP,TP,5x11,5

..2 C604 2401-000603 C-AL;1uF,20%,50V,GP,TP,5x11,5

..2 C605 2202-000279 C-CERAMIC,MLC-AXIAL;47pF,5%,50V,SL,TP,3.

..2 C606 2202-000279 C-CERAMIC,MLC-AXIAL;47pF,5%,50V,SL,TP,3.

..2 C702 2401-000471 C-AL;10uF,20%,50V,BP,TP,5x11,5mm

..2 C703 2202-000183 C-CERAMIC,MLC-AXIAL;2.2NF,20%,16V,Y5R,TP

..2 C705 2202-000183 C-CERAMIC,MLC-AXIAL;2.2NF,20%,16V,Y5R,TP

..2 C801 2401-002219 C-AL;220uF,20%,400V,GP,ST,25x40,10

..2 C802 2201-000119 C-CERAMIC,DISC;100nF,+80-20%,50V,Y5V,TP,

..2 C803 2301-001435 C-FILM,PPF;1.5nF,5%,1.2kV,TP,15x8x12.5mm

..2 C805 2201-000991 C-CERAMIC,DISC;0.56nF,10%,2kV,Y5P,TP,7.5

..2 C806 2401-000262 C-AL;100uF,20%,160V,HR,TP,16x25,7.5

..2 C807 2201-000599 C-CERAMIC,DISC;0.56nF,10%,500V,Y5P,TP,5.

..2 C808 2301-000016 C-FILM,PEF;22nF,5%,100V,TP,7.2x4.5x9.0mm

..2 C809 2401-001998 C-AL;1000uF,20%,25V,GP,TP,10x20,5mm

..2 C810 2306-000122 C-FILM,MPPF;100nF,5%,50V,TP,7.3x4.0x5.0m

..2 C812 2401-001840 C-AL;100uF,20%,16V,GP,TP,6.3x11,5

..2 C813 2401-002144 C-AL;47uF,20%,16V,GP,TP,5x11,5

..2 C816 2401-000480 C-AL;10uF,20%,50V,GP,TP,5x11,5

..2 C817 2401-001840 C-AL;100uF,20%,16V,GP,TP,6.3x11,5

..2 C820 2401-001998 C-AL;1000uF,20%,25V,GP,TP,10x20,5mm

..2 C821 2401-001486 C-AL;47uF,20%,160V,HR,TP,13x20mm,5m

..2 C822 2301-000192 C-FILM,PEF;1nF,5%,50V,TP,5.3x10mm,5mm

..2 C823 2201-000370 C-CERAMIC,DISC;0.22nF,10%,50V,Y5P,TP,4x3

..2 C851 2401-001192 C-AL;33uF,20%,50V,GP,TP,6.3x11,5

..2 C852 2301-000235 C-FILM,PEF;3.9nF,5%,50V,TP,6.5x3.0x5.5mm

..2 C901 2401-002144 C-AL;47uF,20%,16V,GP,TP,5x11,5

..2 C902 2202-000796 C-CERAMIC,MLC-AXIAL;1NF,10%,50V,Y5P,TP,3

..2 C903 2401-000480 C-AL;10uF,20%,50V,GP,TP,5x11,5

..2 C904 2202-000796 C-CERAMIC,MLC-AXIAL;1NF,10%,50V,Y5P,TP,3

..2 C906 2201-000258 C-CERAMIC,DISC;0.017nF,5%,50V,NP0,TP,5x3

..2 C907 2201-000258 C-CERAMIC,DISC;0.017nF,5%,50V,NP0,TP,5x3

..2 C908 2201-000962 C-CERAMIC,DISC;0.012nF,5%,50V,RH,TP,5x3,

..2 C909 2201-000962 C-CERAMIC,DISC;0.012nF,5%,50V,RH,TP,5x3,

..2 C910 2201-000292 C-CERAMIC,DISC;1nF,10%,50V,Y5P,TP,5x3.5,

..2 C911 2401-002144 C-AL;47uF,20%,16V,GP,TP,5x11,5

..2 C912 2301-000246 C-FILM,PEF;33nF,5%,100V,TP,7x5.0x9.5mm,5

..2 C915 2202-000127 C-CERAMIC,MLC-AXIAL;10nF,+80-20%,25V,Y5V

..2 C917 2202-000807 C-CERAMIC,MLC-AXIAL;22nF,+80-20%,25V,Y5V

..2 CC01 2201-000247 C-CERAMIC,DISC;0.015nF,5%,50V,NP0,TP,5x3

..2 CC02 2201-000258 C-CERAMIC,DISC;0.017nF,5%,50V,NP0,TP,5x3

..2 CN501 AA39-20109A LEAD CONNECTOR-ASSY;,8P,YBNH025-08,S,400

..2 CN604 3711-002643 CONNECTOR-HEADER;BOX,4P,1R,2.5MM,STRAIGH

..2 CN701 3711-002646 CONNECTOR-HEADER;BOX,7P,1R,2.5mm,STRAIGH

..2 CR401S 2301-001219 C-FILM,MPE-PPF;3.9nF,5%,1.6KV,TP,29x8.5x

..2 CR403S 2306-000179 C-FILM,MPPF;300nF,5%,250V,TP,20x18.5x10.

..2 CS603 2202-000796 C-CERAMIC,MLC-AXIAL;1NF,10%,50V,Y5P,TP,3

..2 CU10 2401-000832 C-AL;220uF,20%,25V,GP,TP,8x11.5,5

..2 CX801S 2306-000318 C-FILM,MPPF;220nF,20%,250V,TP,-,22.5mm

..2 CY801S 2201-000446 C-CERAMIC,DISC;3.3nF,20%,400V,Y5U,TP,15x

..2 D101 0403-000700 DIODE-ZENER;TZP33A,33V,31-35V,1W,DO-41,T

..2 D102 0403-000508 DIODE-ZENER;MTZJ5.6B,5.6V,5.45-5.73V,500

..2 D201 0401-000005 DIODE-SWITCHING;1N4148,100V,200mA,DO-35,

..2 D202 0401-000005 DIODE-SWITCHING;1N4148,100V,200mA,DO-35,

..2 D209 0401-000005 DIODE-SWITCHING;1N4148,100V,200mA,DO-35,

..2 D210 0401-000005 DIODE-SWITCHING;1N4148,100V,200mA,DO-35,

..2 D301 0402-000132 DIODE-RECTIFIER;1N4004,400V,1A,DO-41,TP

..2 D401 0402-000132 DIODE-RECTIFIER;1N4004,400V,1A,DO-41,TP

..2 D402 0402-000132 DIODE-RECTIFIER;1N4004,400V,1A,DO-41,TP

..2 D403 0402-001105 DIODE-RECTIFIER;ERB43-04SV1,400V,1.0A,-,

..2 D404 0402-000534 DIODE-RECTIFIER;RG10V,400V,1.2A,DO-201,T

..2 D405 0402-000546 DIODE-RECTIFIER;TVR10G,400V,1.0A,DO-41,T

..2 D407 0402-001105 DIODE-RECTIFIER;ERB43-04SV1,400V,1.0A,-,

..2 D501 0402-000254 DIODE-RECTIFIER;RGP10J,600V,1A,DO-41,TP

..2 D502 0402-000546 DIODE-RECTIFIER;TVR10G,400V,1.0A,DO-41,T

..2 D503 0402-000546 DIODE-RECTIFIER;TVR10G,400V,1.0A,DO-41,T

Electric Parts List

Samsung Electronics 7-1

7-1 TK1409SC/TCE

Loc. No. Code No. Description ; Specification Remark Loc. No. Code No. Description ; Specification Remark

7. Electric Parts List

Page 33

..2 D504 0402-000546 DIODE-RECTIFIER;TVR10G,400V,1.0A,DO-41,T

..2 D601 0401-000005 DIODE-SWITCHING;1N4148,100V,200mA,DO-35,

..2 D801S 0402-001111 DIODE-RECTIFIER;1N5397GP,600V,1.5A,DO-20

..2 D802 0402-000540 DIODE-RECTIFIER;RU20A,600V,1.5A,-,TP

..2 D802S 0402-001111 DIODE-RECTIFIER;1N5397GP,600V,1.5A,DO-20

..2 D803 0402-001105 DIODE-RECTIFIER;ERB43-04SV1,400V,1.0A,-,

..2 D803S 0402-001111 DIODE-RECTIFIER;1N5397GP,600V,1.5A,DO-20

..2 D804S 0402-001111 DIODE-RECTIFIER;1N5397GP,600V,1.5A,DO-20

..2 D805 0402-001111 DIODE-RECTIFIER;1N5397GP,600V,1.5A,DO-20

..2 D806 0401-000005 DIODE-SWITCHING;1N4148,100V,200mA,DO-35,

..2 D814 0404-001056 DIODE-SCHOTTKY;RK16,60V,1.5A,DO-204AC,TP

..2 D855 0403-000510 DIODE-ZENER;MTZJ6.2B,6.2V,5.96-6.27V,500

..2 D856 0403-000508 DIODE-ZENER;MTZJ5.6B,5.6V,5.45-5.73V,500

..2 D901 0401-000005 DIODE-SWITCHING;1N4148,100V,200mA,DO-35,

..2 D902 0403-000508 DIODE-ZENER;MTZJ5.6B,5.6V,5.45-5.73V,500

..2 D903 0401-000005 DIODE-SWITCHING;1N4148,100V,200mA,DO-35,

..2 D905 0403-000508 DIODE-ZENER;MTZJ5.6B,5.6V,5.45-5.73V,500

..2 D906 0401-000005 DIODE-SWITCHING;1N4148,100V,200mA,DO-35,

..2 D907 0401-000005 DIODE-SWITCHING;1N4148,100V,200mA,DO-35,

..2 D908 0401-000005 DIODE-SWITCHING;1N4148,100V,200mA,DO-35,

..2 DU01 0402-000132 DIODE-RECTIFIER;1N4004,400V,1A,DO-41,TP

..2 DZ201 0403-001322 DIODE-ZENER;MTZJ8.2B,7.78-8.19V,500mW,DO

..2 DZ202 0403-000714 DIODE-ZENER;MTZJ3.3B,3.3V,3.32-3.53V,500

..2 DZ203 0403-000720 DIODE-ZENER;MTZJ9.1B,9.1V,8.57-9.01V,500

..2 DZ204 2001-000812 R-CARBON;5.6KOHM,5%,1/8W,AA,TP,1.8X3.2M

..2 DZ205 0403-001319 DIODE-ZENER;MTZJ4.7C,4.68-4.93V,500mW,DO

..2 DZ206 0403-000714 DIODE-ZENER;MTZJ3.3B,3.3V,3.32-3.53V,500

..2 DZ207 0403-000720 DIODE-ZENER;MTZJ9.1B,9.1V,8.57-9.01V,500

..2 DZ208 0403-000720 DIODE-ZENER;MTZJ9.1B,9.1V,8.57-9.01V,500

..2 DZ301 0403-001328 DIODE-ZENER;MTZJ22A,20.15-21.20V,500mW,D

..2 DZ302 0403-001039 DIODE-ZENER;MA2560,56V,52-60V,1W,DO-41,T

..2 DZ303 0403-000700 DIODE-ZENER;TZP33A,33V,31-35V,1W,DO-41,T

..2 DZ501 0403-000720 DIODE-ZENER;MTZJ9.1B,9.1V,8.57-9.01V,500

..2 DZ502 0403-000720 DIODE-ZENER;MTZJ9.1B,9.1V,8.57-9.01V,500

..2 DZ503 0403-000720 DIODE-ZENER;MTZJ9.1B,9.1V,8.57-9.01V,500

..2 DZ504 0403-000720 DIODE-ZENER;MTZJ9.1B,9.1V,8.57-9.01V,500

..2 DZ601 0403-001322 DIODE-ZENER;MTZJ8.2B,7.78-8.19V,500mW,DO

..2 DZ602 0403-001325 DIODE-ZENER;MTZJ15C,14.35-15.09V,500mW,D

..2 DZ603 0403-001325 DIODE-ZENER;MTZJ15C,14.35-15.09V,500mW,D

..2 DZ606 0403-001211 DIODE-ZENER;MTZJ12B,11.44-12.03V,500MW,D

..2 DZ607 0403-001211 DIODE-ZENER;MTZJ12B,11.44-12.03V,500MW,D

..2 DZ608 0403-001211 DIODE-ZENER;MTZJ12B,11.44-12.03V,500MW,D

..2 DZ802 0403-001327 DIODE-ZENER;MTZJ18A,16.22-17.06V,500mW,D

..2 DZ806 0403-001318 DIODE-ZENER;MTZJ4.3B,4.17-4.43V,500mW,DO

..2 DZ807 0403-001211 DIODE-ZENER;MTZJ12B,11.44-12.03V,500MW,D

..2 DZ808 0403-000699 DIODE-ZENER;TZP27B,27V,27-30.8V,1W,DO-41

..2 DZ901 0403-000508 DIODE-ZENER;MTZJ5.6B,5.6V,5.45-5.73V,500

..2 DZ902 0403-000508 DIODE-ZENER;MTZJ5.6B,5.6V,5.45-5.73V,500

..2 DZ904 0403-000508 DIODE-ZENER;MTZJ5.6B,5.6V,5.45-5.73V,500

..2 DZ906 0403-000508 DIODE-ZENER;MTZJ5.6B,5.6V,5.45-5.73V,500

..2 F801A 3602-000114 FUSE-HOLDER;-,-,30mohm

..2 F801B 3602-000114 FUSE-HOLDER;-,-,30mohm

..2 FA801S 3601-001086 FUSE-AXIAL LEAD;125V,5A,FAST-ACTING,GLAS

..2 FP801S 3601-000281 FUSE-CARTRIDGE;250V,4A,TIME-LAG,GLASS,5.

..2 IC201S 1204-001439 IC-VIDEO PROCESS;TDA8841,DIP,56P,-,PLAST

..2 IC301 AA96-00193A ASSY-H/S;-,DP,-,AA96-50345E,- S.N.A

...3 AA96-50345E ASSY-H/S;-,VERT,AA62-30174A,TDA8356/N6A S.N.A

....4 AA62-30174A HEAT SINK-PS;-,SPC,T1.0,-,33X20X50,-,FT-

....4 AA61-10162A BRACKET-IC;-,SBHG-1,T1.0,-,-,-,-

....4 6003-000334 SCREW-TAPTITE;RH,+,2S,M3,L6,ZPC(YEL),SWR

....4 1204-001541 IC-VERTICAL DEF.;TDA8356/N6A,SIP,9P,-,PL

....4 0205-000129 GREASE-SILICON;SC102,JAPAN S.N.A

..2 IC501 AA96-00192A ASSY-H/S;-,DP,-,AA96-50311A,- S.N.A

...3 AA96-50311A ASSY-H/S;-,VIDEO,AA62-30175D,TDA6107Q,- S.N.A

....4 1201-001159 IC-VIDEO AMP;6107,ZSIP,9P,-,SINGLE,-,PLA

....4 6003-000334 SCREW-TAPTITE;RH,+,2S,M3,L6,ZPC(YEL),SWR

....4 AA62-30175D HEAT SINK-PS;-,SECC,T1.0,-,33X15X30 FT-2

..2 IC601 AA96-00201A ASSY-H/S;-,DP,-,AA96-50397B,- S.N.A

...3 AA96-50397A ASSY-H/S;-,-,AA62-30180J,TDA7266S,- S.N.A

....4 0205-000129 GREASE-SILICON;SC102,JAPAN S.N.A

....4 1201-001308 IC-POWER AMP;7266,ZIP,15P,-,DUAL,26dB,PL

....4 6003-000333 SCREW-TAPTITE;RH,+,2S,M3,L10,ZPC(YEL),SW

....4 AA62-30180J HEAT SINK-ES;-,A6063 EXTR,-,WHT,-,-,-,40

..2 IC801S AA96-00294A ASSY H/S;DP,-,-,-,AA96-00242A S.N.A

...3 AA96-00242A ASSY H/S;-,-,AA62-30186B,KA5Q0765R,- S.N.A

....4 0205-000129 GREASE-SILICON;SC102,JAPAN S.N.A

....4 1203-001932 IC-PWM CONTROLLER;5Q0765,TO-220F,5P,185M

....4 6003-000333 SCREW-TAPTITE;RH,+,2S,M3,L10,ZPC(YEL),SW

....4 AA62-30186B HEAT SINK-ES;-,-,-,SILVER,171J + COVER-H

..2 IC802 1203-001531 IC-POSI.FIXED REG.;7630,SIP,10P,-,PLASTI

..2 IC901 AA13-00022A IC-MCU;KS88C8316-16D,SSM-174PT,ST,16k

..2 IC902 1103-001107 IC-EEPROM;C21DC,256x8Bit,DIP,8P,300MIL,..2 JA701 3722-000162 JACK-PIN;2P,3.4mm,SN,BLK,..2 L102 2701-001070 INDUCTOR-AXIAL;68UH,10%,4.2X9.8MM

..2 L152 2701-000101 INDUCTOR-AXIAL;1.2uH,10%,2.5x3.4mm

..2 L201 2701-000114 INDUCTOR-AXIAL;10uH,10%,2.5x3.4mm

..2 L206 2701-000114 INDUCTOR-AXIAL;10uH,10%,2.5x3.4mm

..2 L301 2701-000115 INDUCTOR-AXIAL;10uH,10%,3x7mm

..2 L302 2701-000114 INDUCTOR-AXIAL;10uH,10%,2.5x3.4mm

..2 L303 2701-000114 INDUCTOR-AXIAL;10uH,10%,2.5x3.4mm

..2 L304 2701-000159 INDUCTOR-AXIAL;22uH,10%,4.2x9.8mm

..2 L305 2701-000116 INDUCTOR-AXIAL;10uH,10%,4.2x9.8mm

..2 L402 2701-001032 INDUCTOR-AXIAL;100uH,10%,5x14mm

..2 L601 2701-000158 INDUCTOR-AXIAL;22uH,10%,2.5x3.4mm

..2 L802 3301-001223 CORE-FERRITE BEAD;AA,62ohm,3.5x0.8x5mm,..2 L803 2901-000299 FILTER-EMI ON BOARD;-,6A,UL/CSA,-,9x7.5,

..2 L804 3301-001223 CORE-FERRITE BEAD;AA,62ohm,3.5x0.8x5mm,..2 L809 2901-000299 FILTER-EMI ON BOARD;-,6A,UL/CSA,-,9x7.5,

..2 L810 2701-001032 INDUCTOR-AXIAL;100uH,10%,5x14mm

..2 L811 2901-000299 FILTER-EMI ON BOARD;-,6A,UL/CSA,-,9x7.5,

..2 L901 2701-000197 INDUCTOR-AXIAL;5.6uH,10%,2.5x3.4mm

..2 L902 2701-000114 INDUCTOR-AXIAL;10uH,10%,2.5x3.4mm

..2 LC801S AA27-20003U COIL-DEGAUSSING;-,14,16.4ohm,75T,890mm,D

..2 LD901 AA96-30001C ASSY-LED,GUIDE;-,AA61-50055A,DL-G7RA,- S.N.A

..2 LR401S AA27-30003R COIL-LINEARLITY;-,220uH,YL10x10,0.35mm,2

..2 LWU01 2701-000158 INDUCTOR-AXIAL;22uH,10%,2.5x3.4mm

..2 LX801S AA29-30001D FILTER-LINE NOISE;SQ1913,-,6.0MH,0.8A,..2 NT801S 1404-001045 THERMISTOR-NTC;4.7ohm,15%,2900K,35.0mW,T

..2 P803S 1404-001087 THERMISTOR-PTC;7ohm,30%,220V,270V,19A,-,

..2 PC801S 0604-001038 PHOTO-COUPLER;TR,130-260%,200mW,DIP-4,ST

..2 Q151 0501-000436 TR-SMALL SIGNAL;KTC3197,NPN,625mW,TO-92,

..2 Q201 0501-000389 TR-SMALL SIGNAL;KSC815,NPN,400mW,TO-92,T

..2 Q202 0501-000389 TR-SMALL SIGNAL;KSC815,NPN,400mW,TO-92,T

..2 Q205 0501-000389 TR-SMALL SIGNAL;KSC815,NPN,400mW,TO-92,T

..2 Q401 0502-001115 TR-POWER;KSC5386,NPN,50W,TO-3PF,ST,8..2 Q402 0501-000369 TR-SMALL SIGNAL;KSC2331-Y,NPN,1000mW,TO..2 Q601 0501-002183 TR-SMALL SIGNAL;KTC9014,NPN,625mW,TO-92,

..2 Q801 1203-001217 IC-POSI.ADJUST REG.;431,TO-92,3P,4.58MIL

..2 QC01 0504-000123 TR-DIGITAL;KSR1010,NPN,300mW,10K,TO-92,T

..2 QC02 0504-000123 TR-DIGITAL;KSR1010,NPN,300mW,10K,TO-92,T

..2 QU10 0501-000369 TR-SMALL SIGNAL;KSC2331-Y,NPN,1000mW,TO..2 R101 2001-000221 R-CARBON;1.2KOHM,5%,1/8W,AA,TP,1.8X3.2M

..2 R102 2001-000660 R-CARBON;33KOHM,5%,1/8W,AA,TP,1.8X3.2MM

..2 R103 2001-000591 R-CARBON;3.3KOHM,5%,1/8W,AA,TP,1.8X3.2M

..2 R104 2003-000502 R-METAL OXIDE(S);150ohm,5%,2W,AA,TP,4x12

..2 R105 2003-000502 R-METAL OXIDE(S);150ohm,5%,2W,AA,TP,4x12

..2 R106 2003-000664 R-METAL OXIDE(S);33ohm,5%,2W,AF,TP,4x12m

..2 R152 2001-000221 R-CARBON;1.2KOHM,5%,1/8W,AA,TP,1.8X3.2M

..2 R153 2001-000734 R-CARBON;4.7KOHM,5%,1/8W,AA,TP,1.8X3.2M

..2 R154 2001-000515 R-CARBON;220OHM,5%,1/8W,AA,TP,1.8X3.2MM

..2 R155 2001-000362 R-CARBON;150OHM,5%,1/8W,AA,TP,1.8X3.2MM

..2 R156 2001-000666 R-CARBON;33OHM,5%,1/8W,AA,TP,1.8X3.2MM

..2 R157 2001-000793 R-CARBON;47OHM,5%,1/8W,AA,TP,1.8X3.2MM

..2 R158 2001-000007 R-CARBON;3KOHM,5%,1/8W,AA,TP,1.8X3.2MM

..2 R159 2001-000007 R-CARBON;3KOHM,5%,1/8W,AA,TP,1.8X3.2MM

..2 R200 2001-000780 R-CARBON;470OHM,5%,1/8W,AA,TP,1.8X3.2MM

..2 R201 2001-000005 R-CARBON;390ohm,5%,1/8W,AA,TP,1.8x3.2mm

..2 R202 2001-000281 R-CARBON;100OHM,5%,1/8W,AA,TP,1.8X3.2MM

..2 R203 2001-000281 R-CARBON;100OHM,5%,1/8W,AA,TP,1.8X3.2MM

..2 R207 2001-000008 R-CARBON;15KOHM,5%,1/8W,AA,TP,1.8X3.2MM

..2 R208 2001-000674 R-CARBON;360OHM,5%,1/8W,AA,TP,1.8X3.2MM

..2 R209 2001-000016 R-CARBON(S);1OHM,5%,1/2W,AA,TP,2.4X6.4MM

..2 R210 2001-000429 R-CARBON;1KOHM,5%,1/8W,AA,TP,1.8X3.2MM

..2 R212 2001-000003 R-CARBON;330ohm,5%,1/8W,AA,TP,1.8x3.2mm

..2 R213 2001-000003 R-CARBON;330ohm,5%,1/8W,AA,TP,1.8x3.2mm

..2 R214 2001-000003 R-CARBON;330ohm,5%,1/8W,AA,TP,1.8x3.2mm

..2 R215 2001-000273 R-CARBON;100KOHM,5%,1/8W,AA,TP,1.8X3.2M

..2 R218 2001-000591 R-CARBON;3.3KOHM,5%,1/8W,AA,TP,1.8X3.2M

..2 R219 2001-000008 R-CARBON;15KOHM,5%,1/8W,AA,TP,1.8X3.2MM

..2 R224 2001-000563 R-CARBON;27KOHM,5%,1/8W,AA,TP,1.8X3.2MM

..2 R225 2001-000515 R-CARBON;220OHM,5%,1/8W,AA,TP,1.8X3.2MM

..2 R226 2001-000281 R-CARBON;100OHM,5%,1/8W,AA,TP,1.8X3.2MM

..2 R227 2001-000011 R-CARBON;75KOHM,5%,1/8W,AA,TP,1.8X3.2MM

..2 R230 2001-000890 R-CARBON;6.8KOHM,5%,1/8W,AA,TP,1.8X3.2M

Electric Parts List

7-2 Samsung Electronics

Loc. No. Code No. Description ; Specification Remark Loc. No. Code No. Description ; Specification Remark

Page 34

..2 R231 2001-000563 R-CARBON;27KOHM,5%,1/8W,AA,TP,1.8X3.2MM

..2 R232 2001-000356 R-CARBON;150KOHM,5%,1/8W,AA,TP,1.8X3.2M

..2 R234 2001-000281 R-CARBON;100OHM,5%,1/8W,AA,TP,1.8X3.2MM

..2 R235 2001-000633 R-CARBON;30KOHM,5%,1/8W,AA,TP,1.8X3.2MM

..2 R236 2003-000634 R-METAL OXIDE(S);3.9Kohm,5%,1W,AA,TP,3.3

..2 R237 2001-000793 R-CARBON;47OHM,5%,1/8W,AA,TP,1.8X3.2MM

..2 R240 2001-000577 R-CARBON;2KOHM,5%,1/8W,AA,TP,1.8X3.2MM

..2 R243 2001-000343 R-CARBON;130OHM,5%,1/8W,AA,TP,1.8X3.2MM

..2 R244 2001-000780 R-CARBON;470OHM,5%,1/8W,AA,TP,1.8X3.2MM

..2 R245 2001-000832 R-CARBON;510OHM,5%,1/8W,AA,TP,1.8X3.2MM

..2 R246 2001-000613 R-CARBON;3.9KOHM,5%,1/8W,AA,TP,1.8X3.2M

..2 R247 2001-000577 R-CARBON;2KOHM,5%,1/8W,AA,TP,1.8X3.2MM

..2 R252 2004-001914 R-METAL;39Kohm,2%,1/8W,AA,TP,1.8x3.5mm

..2 R258 2001-000449 R-CARBON;2.2KOHM,5%,1/8W,AA,TP,1.8X3.2M

..2 R262 2001-000429 R-CARBON;1KOHM,5%,1/8W,AA,TP,1.8X3.2MM

..2 R301 2004-000500 R-METAL;2.7Kohm,1%,1/8W,AA,TP,1.8x3.2m

..2 R302 2003-002010 R-METAL OXIDE(S);680ohm,5%,1W,AF,TP,3.9x

..2 R303 2001-000085 R-CARBON(S);100KOHM,5%,1/2W,AA,TP,2.4X6.

..2 R305 2004-004087 R-METAL(S);1.5ohm,1%,1/2W,AA,TP,2.5x6.5m

..2 R306 2008-000254 R-FUSIBLE(S);0.68ohm,5%,2W,AF,TP,3.9x10m

..2 R307 2003-000652 R-METAL OXIDE(S);330ohm,5%,2W,AF,TP,4x12

..2 R403 2001-001114 R-CARBON(S);270OHM,5%,1/2W,AA,TP,2.4X6.4

..2 R404 2001-001410 R-CARBON(S);43OHM,5%,1/2W,AA,TP,2.4X6.4M

..2 R405 2003-002173 R-METAL OXIDE(S);7.5Kohm,5%,2W,AG,TP,3.9

..2 R406 2003-000455 R-METAL OXIDE(S);100ohm,5%,2W,AA,TP,4x12

..2 R407 2003-002193 R-METAL OXIDE(S);33Kohm,5%,2W,AG,TP,3.9X

..2 R409 2008-000206 R-FUSIBLE(S);1ohm,5%,1/2W,AF,TP,2.5x6.5m

..2 R410 2008-000204 R-FUSIBLE(S);0.22ohm,10%,1/2W,AF,TP,2.5x

..2 R413 2001-001037 R-CARBON(S);0.39OHM,5%,1/2W,AA,TP,2.4X6.

..2 R415 2003-002178 R-METAL OXIDE(S);1Kohm,5%,2W,AG,TP,3.9x1

..2 R416 2001-000022 R-CARBON(S);33OHM,5%,1/2W,AA,TP,2.4X6.4M

..2 R417 2001-000028 R-CARBON(S);100OHM,5%,1/2W,AA,TP,2.4X6.4

..2 R419 2008-000264 R-FUSIBLE(S);1ohm,5%,1W,AF,TP,3.9x10mm

..2 R420 2004-001377 R-METAL(S);120Kohm,1%,1/2W,AA,TP,2.4x6.4

..2 R501M 2002-001008 R-COMPOSITION;1.8Kohm,10%,1/2W,AA,TP,3.7

..2 R502M 2002-001008 R-COMPOSITION;1.8Kohm,10%,1/2W,AA,TP,3.7

..2 R503 2002-001008 R-COMPOSITION;1.8Kohm,10%,1/2W,AA,TP,3.7

..2 R504 2001-001062 R-CARBON(S);10MOHM,5%,1/2W,AA,TP,2.4X6.4

..2 R505 2008-001015 R-FUSIBLE(S);1.5ohm,5%,2W,AF,TP,3.9x10mm

..2 R510 2001-000281 R-CARBON;100OHM,5%,1/8W,AA,TP,1.8X3.2MM

..2 R511 2001-000281 R-CARBON;100OHM,5%,1/8W,AA,TP,1.8X3.2MM

..2 R512 2001-000281 R-CARBON;100OHM,5%,1/8W,AA,TP,1.8X3.2MM

..2 R601 2001-000429 R-CARBON;1KOHM,5%,1/8W,AA,TP,1.8X3.2MM

..2 R602 2001-000290 R-CARBON;10KOHM,5%,1/8W,AA,TP,1.8X3.2MM

..2 R603 2004-000195 R-METAL;100Kohm,1%,1/8W,AA,TP,1.8x3.2m

..2 R604 2001-000947 R-CARBON;7.5KOHM,5%,1/8W,AA,TP,1.8X3.2M

..2 R606 2001-000734 R-CARBON;4.7KOHM,5%,1/8W,AA,TP,1.8X3.2M

..2 R607 2001-000006 R-CARBON;2.4KOHM,5%,1/8W,AA,TP,1.8X3.2M

..2 R701 2001-001187 R-CARBON(S);75OHM,5%,1/2W,AA,TP,2.4X6.4M

..2 R702 2001-000085 R-CARBON(S);100KOHM,5%,1/2W,AA,TP,2.4X6.

..2 R703 2001-000734 R-CARBON;4.7KOHM,5%,1/8W,AA,TP,1.8X3.2M

..2 R801 2001-001150 R-CARBON(S);470KOHM,5%,1/2W,AA,TP,2.4X6.

..2 R802 2003-000994 R-METAL OXIDE(S);33Kohm,5%,2W,AF,TP,3.9x

..2 R803 2003-000994 R-METAL OXIDE(S);33Kohm,5%,2W,AF,TP,3.9x

..2 R807 2003-000994 R-METAL OXIDE(S);33Kohm,5%,2W,AF,TP,3.9x

..2 R808 2001-001150 R-CARBON(S);470KOHM,5%,1/2W,AA,TP,2.4X6.

..2 R809 2008-000205 R-FUSIBLE(S);10ohm,5%,1/2W,AF,TP,2.5x6.5

..2 R811 2001-001170 R-CARBON(S);6.8OHM,5%,1/2W,AA,TP,2.4X6.4

..2 R812 2008-000264 R-FUSIBLE(S);1ohm,5%,1W,AF,TP,3.9x10mm

..2 R816 2001-001192 R-CARBON(S);820OHM,5%,1/2W,AA,TP,2.4X6.4

..2 R817 2001-001170 R-CARBON(S);6.8OHM,5%,1/2W,AA,TP,2.4X6.4

..2 R819 2008-001049 R-FUSIBLE(S);3.9OHM,5%,2W,AF,TP,3.9X10MM

..2 R819A 2008-001049 R-FUSIBLE(S);3.9OHM,5%,2W,AF,TP,3.9X10MM

..2 R820 2001-000019 R-CARBON(S);10OHM,5%,1/2W,AA,TP,2.4X6.4M

..2 R821 2004-004089 R-METAL(S);123Kohm,1%,1/2W,AA,TP,2.5x6.5

..2 R823 2001-000109 R-CARBON(S);470OHM,5%,1/2W,AA,TP,2.4X6.4

..2 R824 2004-001983 R-METAL(S);2.49Kohm,1%,1/2W,AA,TP,2.4x6.

..2 R825 2001-001108 R-CARBON(S);22KOHM,5%,1/2W,AA,TP,2.4X6.4

..2 R852 2004-001371 R-METAL(S);1.5Kohm,1%,1/2W,AA,TP,2.4x6.4

..2 R853 2004-001390 R-METAL(S);1Kohm,2%,1/2W,AA,TP,2.4x6.4mm

..2 R854 2001-001125 R-CARBON(S);300KOHM,5%,1/2W,AA,TP,2.4X6.

..2 R901 2001-000793 R-CARBON;47OHM,5%,1/8W,AA,TP,1.8X3.2MM

..2 R902 2001-000429 R-CARBON;1KOHM,5%,1/8W,AA,TP,1.8X3.2MM

..2 R903 2001-000281 R-CARBON;100OHM,5%,1/8W,AA,TP,1.8X3.2MM

..2 R904 2001-000281 R-CARBON;100OHM,5%,1/8W,AA,TP,1.8X3.2MM

..2 R905 2001-000241 R-CARBON;1.5KOHM,5%,1/8W,AA,TP,1.8X3.2M

..2 R906 2004-000187 R-METAL;10.5Kohm,1%,1/4W,AA,TP,2.4x6.4

..2 R907 2001-000007 R-CARBON;3KOHM,5%,1/8W,AA,TP,1.8X3.2MM

..2 R908 2001-000006 R-CARBON;2.4KOHM,5%,1/8W,AA,TP,1.8X3.2M

..2 R909 2001-000613 R-CARBON;3.9KOHM,5%,1/8W,AA,TP,1.8X3.2M

..2 R910 2001-000878 R-CARBON;6.2KOHM,5%,1/8W,AA,TP,1.8X3.2M

..2 R911 2001-000290 R-CARBON;10KOHM,5%,1/8W,AA,TP,1.8X3.2MM

..2 R913 2001-000924 R-CARBON;680OHM,5%,1/8W,AA,TP,1.8X3.2MM

..2 R914 2001-000429 R-CARBON;1KOHM,5%,1/8W,AA,TP,1.8X3.2MM

..2 R915 2001-000577 R-CARBON;2KOHM,5%,1/8W,AA,TP,1.8X3.2MM

..2 R916 2001-000281 R-CARBON;100OHM,5%,1/8W,AA,TP,1.8X3.2MM

..2 R917 2001-000281 R-CARBON;100OHM,5%,1/8W,AA,TP,1.8X3.2MM

..2 R918 2001-000281 R-CARBON;100OHM,5%,1/8W,AA,TP,1.8X3.2MM

..2 R919 2001-000281 R-CARBON;100OHM,5%,1/8W,AA,TP,1.8X3.2MM

..2 R921 2001-000429 R-CARBON;1KOHM,5%,1/8W,AA,TP,1.8X3.2MM

..2 R922 2001-000281 R-CARBON;100OHM,5%,1/8W,AA,TP,1.8X3.2MM

..2 R923 2001-000281 R-CARBON;100OHM,5%,1/8W,AA,TP,1.8X3.2MM

..2 R924 2001-000449 R-CARBON;2.2KOHM,5%,1/8W,AA,TP,1.8X3.2M

..2 R925 2001-000449 R-CARBON;2.2KOHM,5%,1/8W,AA,TP,1.8X3.2M

..2 R926 2001-000449 R-CARBON;2.2KOHM,5%,1/8W,AA,TP,1.8X3.2M

..2 R927 2001-000290 R-CARBON;10KOHM,5%,1/8W,AA,TP,1.8X3.2MM

..2 R928 2001-000864 R-CARBON;56KOHM,5%,1/8W,AA,TP,1.8X3.2MM

..2 R929 2001-000331 R-CARBON;12KOHM,5%,1/8W,AA,TP,1.8X3.2MM

..2 R930 2001-000290 R-CARBON;10KOHM,5%,1/8W,AA,TP,1.8X3.2MM

..2 R931 2001-000429 R-CARBON;1KOHM,5%,1/8W,AA,TP,1.8X3.2MM

..2 R937 2001-000290 R-CARBON;10KOHM,5%,1/8W,AA,TP,1.8X3.2MM

..2 R940 2001-000591 R-CARBON;3.3KOHM,5%,1/8W,AA,TP,1.8X3.2M

..2 R941 2001-000723 R-CARBON;4.3KOHM,5%,1/8W,AA,TP,1.8X3.2M

..2 R942 2001-000723 R-CARBON;4.3KOHM,5%,1/8W,AA,TP,1.8X3.2M

..2 R951 2001-000723 R-CARBON;4.3KOHM,5%,1/8W,AA,TP,1.8X3.2M

..2 R968 2001-000273 R-CARBON;100KOHM,5%,1/8W,AA,TP,1.8X3.2M

..2 R988 2001-000397 R-CARBON;180KOHM,5%,1/8W,AA,TP,1.8X3.2M

..2 RC01 2001-000290 R-CARBON;10KOHM,5%,1/8W,AA,TP,1.8X3.2MM

..2 RC02 2001-000290 R-CARBON;10KOHM,5%,1/8W,AA,TP,1.8X3.2MM

..2 RL801S 3501-001040 RELAY-POWER;12VDC,500mW,10A,1FormA,15mS,

..2 RM901 AA59-60001U MODULE-REMOCON;-,ORC-50VF/SR-12V,38KHz,9

..2 RR401S 2004-001390 R-METAL(S);1Kohm,2%,1/2W,AA,TP,2.4x6.4mm

..2 RS606 2001-000429 R-CARBON;1KOHM,5%,1/8W,AA,TP,1.8X3.2MM

..2 RU11 2001-000290 R-CARBON;10KOHM,5%,1/8W,AA,TP,1.8X3.2MM

..2 RU12 2001-000734 R-CARBON;4.7KOHM,5%,1/8W,AA,TP,1.8X3.2M

..2 RU13 2001-000022 R-CARBON(S);33OHM,5%,1/2W,AA,TP,2.4X6.4M

..2 RX801S 2002-001013 R-COMPOSITION;4.7Mohm,5%,1/2W,AA,TP,3.7x

..2 RY801S 2002-001012 R-COMPOSITION;8.2Mohm,5%,1/2W,AA,TP,3.7x

..2 SF101S 2904-000286 FILTER-SAW AV;45.75MHz,SIP5K,ST,13dB,M/N

..2 SW801S3403-000179 SWITCH-PUSH;250V,5A,DPST,-,JPW-2104B

..2 SW901 3404-000244 SWITCH-TACT;15V,20mA,90-170gf,7.5x7mm,SP

..2 SW902 3404-000244 SWITCH-TACT;15V,20mA,90-170gf,7.5x7mm,SP

..2 SW903 3404-000244 SWITCH-TACT;15V,20mA,90-170gf,7.5x7mm,SP

..2 SW904 3404-000244 SWITCH-TACT;15V,20mA,90-170gf,7.5x7mm,SP

..2 SW905 3404-000244 SWITCH-TACT;15V,20mA,90-170gf,7.5x7mm,SP

..2 T401 AA26-50001B TRANS-HORIZ.DRIVE;-,7.1mH,102uH,10-20uH,

..2 T444S AA26-30005S TRANS-FLYBACK;-,FSV-14A004(S),14’,125V

..2 T801S AA26-00043A TRANS SWITCHING;-,-,-,AC90~260V,125/12.5

..2 TU01S AA40-10005Y TUNER-F/S;TECC1970PG26A(S),NTSC/USA,TR,1

..2 V999S 3704-001112 SOCKET-CRT;8P,12PI,22.5PI,NI,..2 VX801S 1405-000152 VARISTOR;560V,2500A,14x8.5mm,TP

..2 X203 2801-003298 CRYSTAL-UNIT;3.579545MHz,30ppm,28-AAM,20

..2 X901 2801-000724 CRYSTAL-UNIT;6MHz,50ppm,28-AAM,20pF,40oh

..2 XC01 2801-003300 CRYSTAL-UNIT;3.575611MHz,30ppm,28-AAM,20

..2 XC02 2801-003299 CRYSTAL-UNIT;3.582056MHz,30ppm,28-AAM,20

..2 Z201 2903-001022 FILTER-CERAMIC;BR,4.5MHz,-,-,-,TP,..2 Z601 2903-000135 FILTER-CERAMIC;BP,4.5MHz,120KHz,6dB,-,TP

..2 AA41-10955D PCB-MAIN;K15B,1L,FR-1,330x245x1.6T,1A,- S.N.A

..2 AA65-30009A CLAMP-FBT;ABS,V0,BLK,-,-,- S.N.A

..2 AA65-30104C CLAMP-WIRE;NYLON 66,V2,NTR,W1 Z4,ALL MOD S.N.A

..2 AA65-30109A CLAMP-FBT;NYLON-66,V2,BLK,-,-,- S.N.A

ASSY-PCB,A/V FRONT

1 * AA97-01312A ASSY-PCB,A/V FRONT;,14H3,K15B,NTSC,MONO S.N.A

..2 CE01 2401-000480 C-AL;10uF,20%,50V,GP,TP,5x11,5

..2 CE02 2401-000480 C-AL;10uF,20%,50V,GP,TP,5x11,5

..2 CN701A AA39-20070E LEAD CONNECTOR-ASSY;,7P,YBNH025-07,67096

..2 JE601 3722-000143 JACK-PHONE;1P(VER),3.4mm,AG,BLK,NO

..2 JR01 3722-001282 JACK-RCA;2P(3P),3.2mm,AU,BLK,..2 RE01 2001-001077 R-CARBON(S);150OHM,5%,1/2W,AA,TP,2.4X6.4

Electric Parts List

Samsung Electronics 7-3

Loc. No. Code No. Description ; Specification Remark Loc. No. Code No. Description ; Specification Remark

Page 35

..2 RE02 2001-001077 R-CARBON(S);150OHM,5%,1/2W,AA,TP,2.4X6.4

..2 AA41-00227B PCB-A/V;CT-20S4,FR-1,1L,B,1.6T,245X245 S.N.A

..2 0202-000187 SOLDER-WIRE FLUX;-,RS60S,D1.2,63Sn/37Pb S.N.A

ASSY-PACKING,CKD

1 * AA92-90001A ASSY-PACKING,CKD;ALL MODEL S.N.A

..2 AA69-60002A WOODEN-BOX;WOOD,1060,800,480,45%,- S.N.A

..2 AA69-60002B WOODEN-BOX;WOOD,1060,560,400,45%,- S.N.A

..2 AA69-60002C WOODEN-BOX;WOOD,530,560,400,45%,- S.N.A

..2 AA69-90001A SILICAGEL;M2,5GR,-,-,- S.N.A

..2 AA61-30009A LOCKER-BAND,CLIP;-,SPC-1,-,-,18MM T0.5,- S.N.A

..2 AA69-30010A BAG-SHEET;LDPE,T0.08,W220,L300,-,-,- S.N.A

ASSY-SUB,MATERIAL

1 * AA97-00291A ASSY-SUB,MATERIAL;TFK14400,K15B,ARGENTIN S.N.A

..2 0202-000187 SOLDER-WIRE FLUX;-,RS60S,D1.2,63Sn/37Pb S.N.A

ASSY-TBC,WIRE(P)

1 * AA98-70032A ASSY-TBC,WIRE(P);DP,14,AA98-70014A,1P,T S.N.A

ASSY CABINET FRONT

1 * AA92-00732B ASSY CABINET FRONT;TK1409SC/TCE S.N.A

..2 KC+CF 6003-001026 SCREW-TAPTITE;RH,+,B,M4,L15,ZPC(BLK),SWR

..2 SPK+CF 6003-001026 SCREW-TAPTITE;RH,+,B,M4,L15,ZPC(BLK),SWR

..2 AA64-01493B WINDOW REMOCON;14H3,PC,VIOLET

..2 AA64-01494B INDICATOR LED;14H3,ACRYL HB,CLR

..2 AA64-01834B CABINET FRONT;DP,14H3,64-01489F,HB S.N.A

...3 AA64-01489F CABINET FRONT;14H3,SV808P EWN,HIPS HB,G4

..2 AA64-01835A KNOB CONTROL;DP,14H3,64-01491B

...3 AA64-01491B KNOB CONTROL;14H3,ABS HB,G3676

..2 AA65-30105A CLAMP-WIRE;NYLON 66,V2,NTR,15MM,ALL MODE S.N.A

..2 AA64-01492B KNOB POWER;14H3,ABS HB,G3676,NO-SILK

..2 AA61-40113A STOPPER-PCB;501H,HIPS,-,-,HB,NTR,..2 AA61-60003J SPRING-CS;-,SUS304,0.5,OD6,H12,N7,-,-,..2 AA64-00474B BADGE BRAND;14INCH,AL,-,-,40(22),SILVER, S.N.A

..2 AA64-00738Q INLAY AV;14H3,PS SHEET,BLK,K15B D/GRY W S.N.A

ASSY CABINET(COM)

1 * AA92-00731B ASSY CABINET(COM);TK1409SC/TCE S.N.A

..2 CB+CF AA60-10050T SCREW-TAPPING;-,SWRCH18A,M4,L20,RH,+,2S,

..2 CB+RJ 6003-001026 SCREW-TAPTITE;RH,+,B,M4,L15,ZPC(BLK),SWR

..2 PA+CF 6006-001095 SCREW-ASS’Y TAPT;WP,BH,+,M4,L12,ZPC(YEL)

..2 AA65-30106A CLAMP-D,COIL;NYLON 66,V2,NTR,-,14 INCH,- S.N.A

..2 AA65-30008A CLAMP-CORD;PE,HB,BLK,-,-,..2 AA64-01832B CABINET-BACK;DP,14H3,64-01490D,V2 S.N.A

...3 AA64-01490D CABINET-BACK;14H3,HIPS V2,G4309

..2 AA60-10050R SCREW-ASSY;-,SWRCH18A,M5,L31.5,HH,+,WC,..2 AA60-00091J SPACER-FELT;-,FELT,330X10,-,-,BLK,T0.5,- S.N.A

ASSY-CRT

1 * AA97-00277A ASSY-CRT;A34KQV42X,0MG,14,BARE,TFK1440 S.N.A

..2 AA27-00041A DEFLECTION-YOKE;-,QPC-E3704,14INCH,-,3.1

..2 AA03-10002M CRT-COLOR;-,A34KQV42X,0MG,14,90DEG,57%,

..2 AA63-60028A SPACER-DY;-,NEOPRENE,-,-,-,BLK,-,-,V0 W1

..2 AA27-00001A MAGNET-CONVERGENCE;-,JH225-06A,22.5MM

ASSY SPEAKER

1 * AA96-00610A ASSY SPEAKER;,16OHM,3W,3001-001039,AA39- S.N.A

..2 3001-001039 SPEAKER;3W,16ohm,90dB,180Hz S.N.A

..2 AA39-20505N LEAD CONNECTOR-ASSY;,4P,YSH025-04,REC,35

ASSY-POWER,CORD

1 * AA96-70170A ASSY-POWER,CORD;-,KKP419C,AP2/YES,H/C300 S.N.A

..2 AA39-10005Q POWER-CORD;-,KKP-560N,H03VVH2-F,2.4m,3P,

..2 AA61-20284A HOLDER;-,P-CORD,PP,VO,BLK,KE-002 S.N.A

ASSY-ACCESSORY

1 * AA97-00268A ASSY-ACCESSORY;-,TFK14000,K15B,TELEFUNKE S.N.A

..2 AA42-10001V ANT-ROD;-,3S,620mm,BRN,UL/CSA

..2 AA68-00410A MANUAL-USERS;K15B,W/P100(G),-,SPA,TELEFU

..2 AA26-90001C TRANS-MATCHING;-,300ohm/75ohm,PAL,40-890

REMOCON

1 * AA59-00021E REMOCON;-,TM59,SSM174PT,27,L/GRAY,TELE

Electric Parts List

7-4 Samsung Electronics

Loc. No. Code No. Description ; Specification Remark Loc. No. Code No. Description ; Specification Remark

Page 36

ASSY PCB MAIN(COM)

1 * AA97-00650E ASSY PCB MAIN(COM);TK2009SC/TCE,K15B,ARG S.N.A

..2 C102 2401-000962 C-AL;22uF,20%,50V,GP,TP,5x11,5

..2 C104 2202-000127 C-CERAMIC,MLC-AXIAL;10nF,+80-20%,25V,Y5V

..2 C108 2401-000480 C-AL;10uF,20%,50V,GP,TP,5x11,5

..2 C110 2401-001363 C-AL;470uF,20%,16V,GP,TP,10x12.5,5

..2 C151 2202-000127 C-CERAMIC,MLC-AXIAL;10nF,+80-20%,25V,Y5V

..2 C153 2202-000127 C-CERAMIC,MLC-AXIAL;10nF,+80-20%,25V,Y5V

..2 C201 2306-000122 C-FILM,MPPF;100nF,5%,50V,TP,7.3x4.0x5.0m

..2 C202 2401-001840 C-AL;100uF,20%,16V,GP,TP,6.3x11,5

..2 C203 2401-000660 C-AL;2.2uF,20%,50V,GP,TP,5x11,5

..2 C204 2401-001333 C-AL;470nF,20%,50V,GP,TP,5x11,5

..2 C205 2305-000411 C-FILM,MPEF;470nF,5%,50V,TP,7.3x4.8x5.5m

..2 C206 2202-000632 C-CERAMIC,MLC-AXIAL;100nF,20%,50V,Z5U,TP

..2 C207 2305-000196 C-FILM,MPEF;150nF,5%,63V,TP,-,5mm

..2 C208 2401-000027 C-AL;4.7uF,20%,50V,GP,TP,5x11,5

..2 C209 2202-000849 C-CERAMIC,MLC-AXIAL;18pF,5%,50V,CH,TP,3.

..2 C210 2301-000445 C-FILM,PEF;4.7nF,5%,50V,TP,5.5x7x3mm,5mm

..2 C211 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0m

..2 C212 2301-000192 C-FILM,PEF;1nF,5%,50V,TP,5.3x10mm,5mm

..2 C213 2201-000258 C-CERAMIC,DISC;0.017nF,5%,50V,NP0,TP,5x3

..2 C214 2301-000356 C-FILM,PEF;47nF,5%,50V,TP,7.5x4.0x6.5,5m

..2 C215 2301-000383 C-FILM,PEF;10nF,5%,50V,TP,6x7x3.2mm,5mm

..2 C216 2401-001840 C-AL;100uF,20%,16V,GP,TP,6.3x11,5

..2 C218 2202-000791 C-CERAMIC,MLC-AXIAL;150pF,10%,50V,Y5P,TP

..2 C219 2401-000603 C-AL;1uF,20%,50V,GP,TP,5x11,5

..2 C222 2401-000480 C-AL;10uF,20%,50V,GP,TP,5x11,5

..2 C226 2301-000224 C-FILM,PEF;22nF,5%,50V,TP,7.4x3.9x13mm,5

..2 C231 2401-000480 C-AL;10uF,20%,50V,GP,TP,5x11,5

..2 C232 2401-001840 C-AL;100uF,20%,16V,GP,TP,6.3x11,5

..2 C238 2401-002144 C-AL;47uF,20%,16V,GP,TP,5x11,5

..2 C239 2202-000632 C-CERAMIC,MLC-AXIAL;100nF,20%,50V,Z5U,TP

..2 C240 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0m

..2 C247 2202-000632 C-CERAMIC,MLC-AXIAL;100nF,20%,50V,Z5U,TP

..2 C248 2309-000138 C-FILM,PE-PPF;100nF,5%,50V,TP,20x16x8.5,

..2 C249 2401-000603 C-AL;1uF,20%,50V,GP,TP,5x11,5

..2 C250 2301-000224 C-FILM,PEF;22nF,5%,50V,TP,7.4x3.9x13mm,5

..2 C251 2301-000445 C-FILM,PEF;4.7nF,5%,50V,TP,5.5x7x3mm,5mm

..2 C252 2301-000192 C-FILM,PEF;1nF,5%,50V,TP,5.3x10mm,5mm

..2 C253 2202-000632 C-CERAMIC,MLC-AXIAL;100nF,20%,50V,Z5U,TP

..2 C301 2202-000183 C-CERAMIC,MLC-AXIAL;2.2NF,20%,16V,Y5R,TP

..2 C302 2202-000183 C-CERAMIC,MLC-AXIAL;2.2NF,20%,16V,Y5R,TP

..2 C303 2401-003028 C-AL;100uF,20%,25V,WT,TP,6.3x11,5

..2 C304 2401-000901 C-AL;22uF,20%,160V,GP,TP,10x20,5

..2 C307 2305-000708 C-FILM,MPEF;150nF,5%,100V,TP,16.5x10.3x5

..2 C308 2305-000470 C-FILM,MPEF;68nF,5%,100V,TP,-,5mm

..2 C309 2305-000149 C-FILM,MPEF;100nF,5%,100V,TP,12x12.5x6.5

..2 C310 2305-000285 C-FILM,MPEF;220NF,5%,100V,TP,10.5X5.5X15

..2 C401 2201-000600 C-CERAMIC,DISC;0.56nF,10%,50V,Y5P,TP,5x3

..2 C405 2301-001065 C-FILM,MPPF;47nF,5%,630V,TP,19x15.5x7,7.

..2 C406 2201-000556 C-CERAMIC,DISC;0.47nF,10%,500V,Y5P,TP,5.

..2 C407 2401-001661 C-AL;68uF,20%,100V,GP,TP,10x16,5

..2 C408 2201-000556 C-CERAMIC,DISC;0.47nF,10%,500V,Y5P,TP,5.

..2 C409 2401-001397 C-AL;470uF,20%,25V,GP,TP,10x16,5

..2 C410 2301-000383 C-FILM,PEF;10nF,5%,50V,TP,6x7x3.2mm,5mm

..2 C411 2201-000556 C-CERAMIC,DISC;0.47nF,10%,500V,Y5P,TP,5.

..2 C412 2401-000927 C-AL;22uF,20%,250V,GP,TP,13x20,5

..2 C413 2401-002267 C-AL;2.2uF,20%,250V,GP,TP,8x11.5,5

..2 C419 2201-000639 C-CERAMIC,DISC;0.68nF,10%,2kV,Y5P,TP,9x5

..2 C445 2305-000382 C-FILM,MPEF;4.7nF,5%,400V,TP,-,5mm

..2 C501 2201-000192 C-CERAMIC,DISC;0.01nF,0.25pF,500V,NP0,TP

..2 C502 2301-000213 C-FILM,PEF;220nF,5%,250V,TP,21.5x11,7.5

..2 C503 2201-000723 C-CERAMIC,DISC;4.7nF,20%,3KV,Y5U,TP,16x5

..2 C504 2401-001232 C-AL;4.7uF,20%,250V,GP,TP,10x12.5,5

..2 C506 2401-000430 C-AL;10uF,20%,250V,GP,TP,10x16mm,5m

..2 C601 2401-001998 C-AL;1000uF,20%,25V,GP,TP,10x20,5mm

..2 C602 2201-000292 C-CERAMIC,DISC;1nF,10%,50V,Y5P,TP,5x3.5,

..2 C603 2401-000603 C-AL;1uF,20%,50V,GP,TP,5x11,5

..2 C604 2401-000603 C-AL;1uF,20%,50V,GP,TP,5x11,5

..2 C605 2202-000279 C-CERAMIC,MLC-AXIAL;47pF,5%,50V,SL,TP,3.

..2 C606 2202-000279 C-CERAMIC,MLC-AXIAL;47pF,5%,50V,SL,TP,3.

..2 C702 2401-000471 C-AL;10uF,20%,50V,BP,TP,5x11,5mm

..2 C703 2202-000183 C-CERAMIC,MLC-AXIAL;2.2NF,20%,16V,Y5R,TP

..2 C705 2202-000183 C-CERAMIC,MLC-AXIAL;2.2NF,20%,16V,Y5R,TP

..2 C801 2401-002219 C-AL;220uF,20%,400V,GP,ST,25x40,10

..2 C802 2201-000119 C-CERAMIC,DISC;100nF,+80-20%,50V,Y5V,TP,

..2 C803 2301-001435 C-FILM,PPF;1.5nF,5%,1.2kV,TP,15x8x12.5mm

..2 C805 2201-000991 C-CERAMIC,DISC;0.56nF,10%,2kV,Y5P,TP,7.5

..2 C806 2401-000262 C-AL;100uF,20%,160V,HR,TP,16x25,7.5

..2 C807 2201-000599 C-CERAMIC,DISC;0.56nF,10%,500V,Y5P,TP,5.

..2 C808 2301-000016 C-FILM,PEF;22nF,5%,100V,TP,7.2x4.5x9.0mm

..2 C809 2401-001998 C-AL;1000uF,20%,25V,GP,TP,10x20,5mm

..2 C810 2306-000122 C-FILM,MPPF;100nF,5%,50V,TP,7.3x4.0x5.0m

..2 C812 2401-001840 C-AL;100uF,20%,16V,GP,TP,6.3x11,5

..2 C813 2401-002144 C-AL;47uF,20%,16V,GP,TP,5x11,5

..2 C816 2401-000480 C-AL;10uF,20%,50V,GP,TP,5x11,5

..2 C817 2401-001840 C-AL;100uF,20%,16V,GP,TP,6.3x11,5

..2 C820 2401-001998 C-AL;1000uF,20%,25V,GP,TP,10x20,5mm

..2 C821 2401-001486 C-AL;47uF,20%,160V,HR,TP,13x20mm,5m

..2 C822 2301-000192 C-FILM,PEF;1nF,5%,50V,TP,5.3x10mm,5mm

..2 C823 2201-000370 C-CERAMIC,DISC;0.22nF,10%,50V,Y5P,TP,4x3

..2 C851 2401-001192 C-AL;33uF,20%,50V,GP,TP,6.3x11,5

..2 C852 2301-000235 C-FILM,PEF;3.9nF,5%,50V,TP,6.5x3.0x5.5mm

..2 C901 2401-002144 C-AL;47uF,20%,16V,GP,TP,5x11,5

..2 C902 2202-000796 C-CERAMIC,MLC-AXIAL;1NF,10%,50V,Y5P,TP,3

..2 C903 2401-000480 C-AL;10uF,20%,50V,GP,TP,5x11,5

..2 C904 2202-000796 C-CERAMIC,MLC-AXIAL;1NF,10%,50V,Y5P,TP,3

..2 C906 2201-000258 C-CERAMIC,DISC;0.017nF,5%,50V,NP0,TP,5x3

..2 C907 2201-000258 C-CERAMIC,DISC;0.017nF,5%,50V,NP0,TP,5x3

..2 C908 2201-000962 C-CERAMIC,DISC;0.012nF,5%,50V,RH,TP,5x3,

..2 C909 2201-000962 C-CERAMIC,DISC;0.012nF,5%,50V,RH,TP,5x3,

..2 C910 2201-000292 C-CERAMIC,DISC;1nF,10%,50V,Y5P,TP,5x3.5,

..2 C911 2401-002144 C-AL;47uF,20%,16V,GP,TP,5x11,5

..2 C912 2301-000246 C-FILM,PEF;33nF,5%,100V,TP,7x5.0x9.5mm,5

..2 C915 2202-000127 C-CERAMIC,MLC-AXIAL;10nF,+80-20%,25V,Y5V

..2 C917 2202-000807 C-CERAMIC,MLC-AXIAL;22nF,+80-20%,25V,Y5V

..2 CC01 2201-000247 C-CERAMIC,DISC;0.015nF,5%,50V,NP0,TP,5x3

..2 CC02 2201-000258 C-CERAMIC,DISC;0.017nF,5%,50V,NP0,TP,5x3

..2 CN501 AA39-20109B LEAD CONNECTOR-ASSY;,8P,YBNH025-08,S,500

..2 CN604 3711-002643 CONNECTOR-HEADER;BOX,4P,1R,2.5MM,STRAIGH

..2 CN701 3711-002646 CONNECTOR-HEADER;BOX,7P,1R,2.5mm,STRAIGH

..2 CR401S 2306-000327 C-FILM,MPPF;6.3nF,3%,1.6KV,TP,28.5x18x10

..2 CR402S 2201-000639 C-CERAMIC,DISC;0.68nF,10%,2kV,Y5P,TP,9x5

..2 CR403S 2306-000004 C-FILM,MPPF;330nF,5%,250V,TP,20x18.5x10.

..2 CS603 2202-000796 C-CERAMIC,MLC-AXIAL;1NF,10%,50V,Y5P,TP,3