Page 1

AC CIRCUIT ANALYZER

USER’S MANUAL

CA10

Please read this manual carefully and thoroughly before using this product.

Page 2

TABLE OF CONTENTS

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Key Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

What's in the Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Setup Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Install Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Attach Test Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Operating Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 – 13

Measuring Voltage Parameters . . . . . . . . . . . . . . . . . . . . . . 5 –7

Measuring Voltage Drop. . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 –8

Measuring Conductor Impedance . . . . . . . . . . . . . . . . . . . 9 – 11

Testing Residual Current Devices (RCDs). . . . . . . . . . . . . . . . . 11

Testing Ground Fault Circuit Interrupters (GFCIs). . . . . . . . . . . 12

Testing Outlet Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 – 13

Other Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Operating & Maintenance Tips . . . . . . . . . . . . . . . . . . . . . . . . 14 – 15

Replacing the Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Housekeeping Hints. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 – 15

Warranty Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Return for Repair Policy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

INTRODUCTION

The CA10 is a special-purpose electrical tester designed to quickly identify and

locate single faults in low-voltage (120VAC) distribution lines (branch circuits).

It can also test the reliability and response time of GFCIs (ground fault circuit

interrupters) and RCDs (residual current devices) and check the wiring of outlet

sockets. The instrument’s ease of use, versatility and accuracy make it the ideal

electrician’s tool for preventing shocks, sparks, electrical fires, equipment

damage and poor equipment performance.

2

Page 3

KEY FEATURES

• Measures a branch circuit’s line voltage, peak voltage, neutral-to-ground

voltage and frequency

• Calculates a circuit’s voltage drop in response to a 12A, 15A or 20A load in

order to check the circuit's integrity

• Measures the impedance of hot, neutral and ground conductors as well as

available short-circuit current (ASCC)

• Tests the reliability and response time of GFCIs (ground fault circuit

interrupters) and RCDs (residual current devices)

• Measures and displays True RMS values of all voltages except peak

voltages

• Identifies wiring configurations and detects wiring faults and missing

ground wires

• Compatible with 2- and 3-phase circuits

• 2.4 in. diagonal LCD with 30-second backlight

• Familiar menu/sub-menu operation

• Data hold and 30-minute auto power off functions

• Includes 6 ft. long test cable and standard tripod mount

• Powered by six “AAA” batteries (included)

SAFETY INSTRUCTIONS

WARNING!

Exercise caution when working with exposed wiring.

Do not use this instrument on circuits carrying voltages higher than 120VAC.

WHAT’S IN THE BOX

The CA10 comes in an illustrated box containing a soft canvas carrying case.

Inside the case are the instrument, a 6 ft. (1.83m) long test cable, six “AAA”

batteries and this user’s manual.

3

Page 4

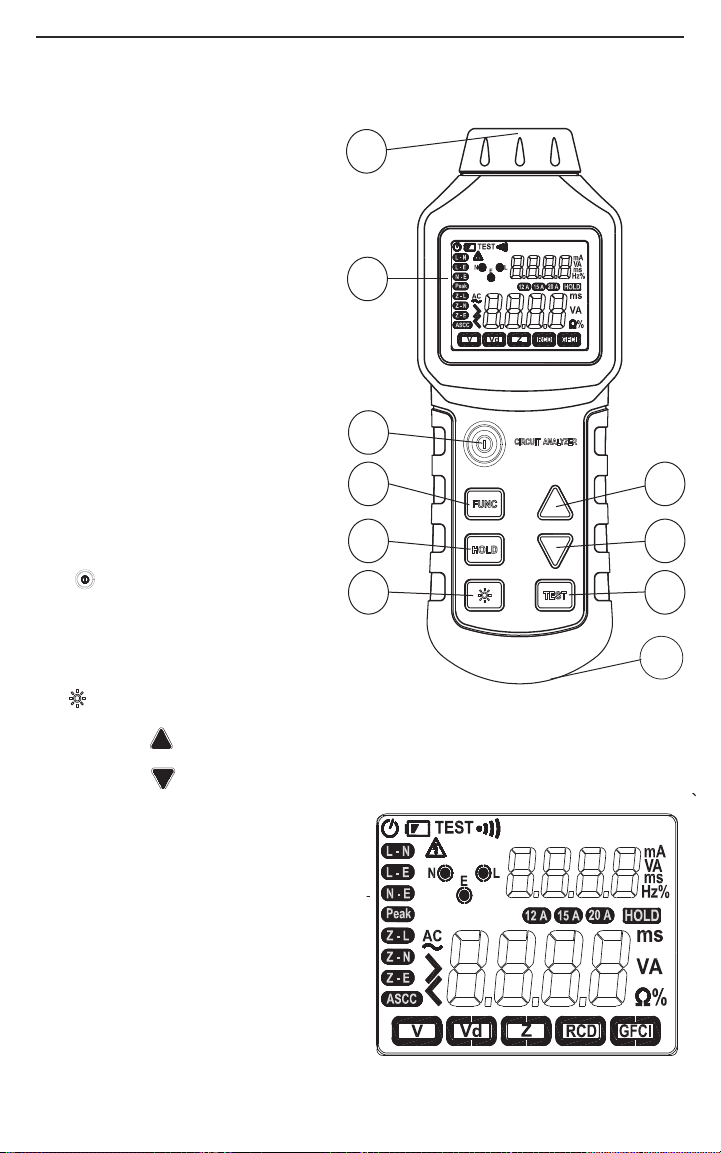

PRODUCT OVERVIEW

1

2

3

4

5

6

7

8

9

Fig. 1 shows the controls, indicators

and physical features of the CA10.

Familiarize yourself with their names

and functions before moving on to

the Setup Instructions and Operating

Instructions.

Fig. 2 shows all possible indications

on the CA10’s LCD.

1. Test cable socket

2. LCD

3. (POWER on/off) button

4. FUNC button

5. HOLD button

6. (Backlight) button

7. Submenu (up one line) button

8. Submenu (down one line) button

9. TEST button

10. Battery compartment (on back)

4

10

Fig. 1. The controls, display and

physical features of the CA10

Fig. 2. All possible indications

on the CA10’s LCD

Page 5

SETUP INSTRUCTIONS

INSTALL BATTERIES

The CA10 is powered by six “AAA” batteries (included).

To install the batteries:

1. Turn the unit over.

2. Remove the one Philips-head screw securing the battery compartment cover

(Figure 1, Callout 10) and set it aside.

3. Remove the battery compartment cover and set it aside as well.

4. Install the six supplied “AAA” batteries in the compartment, making sure to

match the polarity marks on the batteries with the marks stenciled inside the

compartment.

5. Replace the battery compartment cover and secure it with the Philips-head

screw.

ATTACH TEST CABLE

The test cable included with the CA10 has a plug compatible with Americanstyle 110VAC sockets. To attach the cable, plug it into the three-pronged socket

at the top of the CA10 (Fig. 1, Callout 1).

OPERATING INSTRUCTIONS

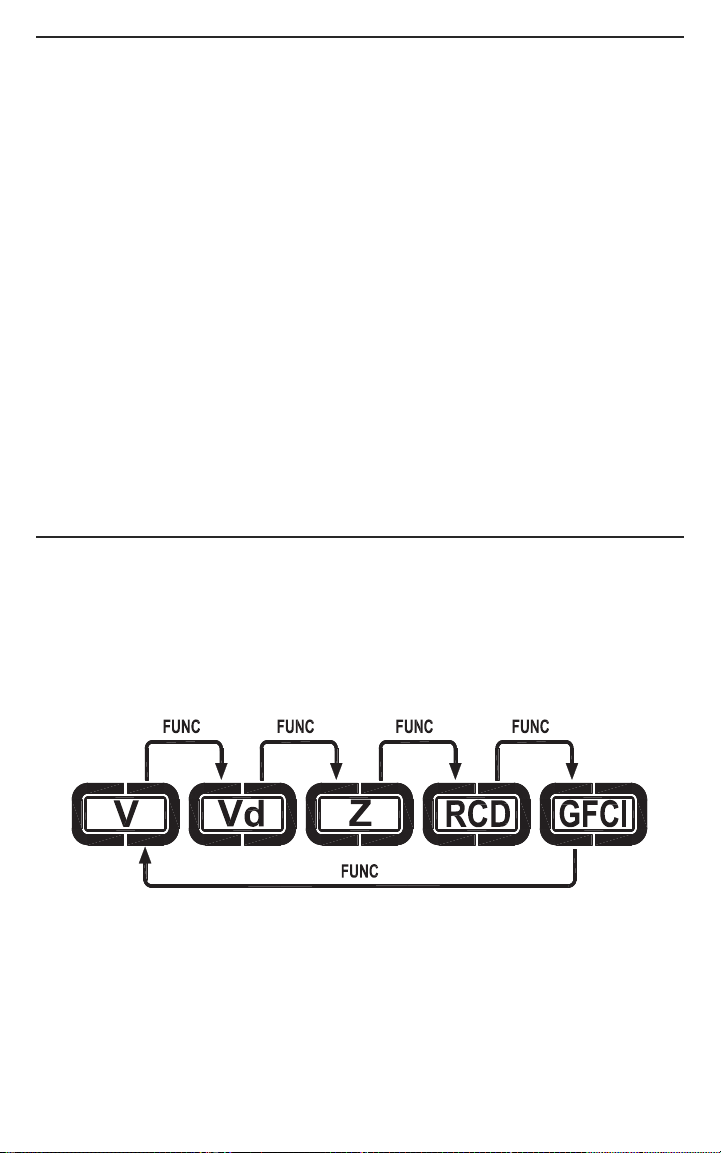

The symbols of the five main parameters/functions tested by the CA10—

voltage (V), voltage drop (Vd), conductor impedance (Z), RCD performance and

GFCI performance—are shown below as they appear on the bottom line of the

LCD. Use the FUNC button to move from any test to the test on its right. When a

test is selected, the border around its text icon is highlighted.

MEASURING VOLTAGE PARAMETERS

The CA10 can measure four parameters of an AC circuit voltage: 1) the True

RMS value of its phase voltage (L-N), 2) the True RMS voltage to earth (ground)

of its neutral line (N-E), 3) the peak value of the voltage (Peak), and 4) the

frequency of the voltage. Each of the first three parameters is measured and

displayed by choosing it from a submenu made available after the FUNC button

has been used to select V. By contrast, the frequency of each of the three

parameters is displayed on the top line of the LCD.

5

Page 6

To begin, plug the free end of the test cable into any outlet of the circuit to be

tested. Press the or button to cycle through the three submenu options

in either direction, as shown in the figure below. The text icon of the parameter

being measured appears at the left of the display. The table below the figure

shows the normal measurement result for each of the four parameters. It also

lists possible causes of, and remedies for, abnormal results.

Parameter

Phase Voltage

L-N (Nominal

Voltage ± 10%)

Voltage to earth

of neutral line

N-E

Peak Voltage

(1.414 x Phase

Voltage, or T

value of Phase

Voltage)

Frequency

6

RMS

Normal

Measurement

Result

108 to 132V

<2V

121 to 262V

60Hz

Actual Result

Voltage is too

high or too low

>2V

Voltage is too

high or too low

Frequency is too

high or too low

Possible Cause

of Abnormal

Result

Circuit is overloaded

High impedance

point(s) in breaker

box or circuit

Supply voltage is

too high or too low

Leakage current

Three-phase

imbalance

Harmonic

interference

Supply voltage is

too high or too low

Electronic device in

circuit is distorting

the AC sine wave

Supply frequency is

too high or too low

Remedy

Redistribute circuit load

Visually inspect all

connection points to detect

or rule out loose

connections and defective

outlets. If none are

apparent, locate points of

high impedance using an

infrared thermometer (IRT)

to detect their heat, or a

voltmeter to detect

excessive voltage drops

across parts. Repair or

replace defective

wiring/parts.

Consult your electricity

provider

Find source of leakage

(a multi-point ground,

a device or piece of

equipment) and repair

or replace

Check and redistribute load

Install spectral filter or take

other steps to reduce

interference

Consult your electricity

provider

Identify and relocate (if

necessary) the device

Consult your electricity

provider

Page 7

Troubleshooting tips: 1) In a single-phase circuit, if the value of L-N is high

the leakage current in the neutral line or the earth line will also be high. 2) In a

three-phase circuit with a neutral line, if the value of N-E is high the threephase load is either unbalanced or the neutral line is affected by harmonic

interference.

MEASURING VOLTAGE DROP

The CA10 can calculate and display a circuit’s voltage drop in response to

application of a 12A, 15A or 20A dummy load. In all three cases, the voltage

drop displayed on-screen as a percentage is based on the True RMS value of

the drop on the circuit’s phase (live) line.

To select the voltage drop test, press the FUNC button until Vd is highlighted.

Then, for 120V circuits, press the or button to select the 15A or 20A

test (see figure below) to match the rating (maximum load) of the circuit.

Alternatively, select the 12A test for a 15A or 20A circuit to avoid tripping the

breaker of a “preloaded” circuit (i.e., a circuit serving other loads during the

load test).

To begin, plug the free end of the test cable into the branch circuit’s outlet that

is furthest from the breaker box (distribution panel). Press the TEST button

(Fig. 1, Callout 9) to initiate the test. The test result, a percentage, will appear

on the lower readout of the display.

The normal measurement result of the voltage drop test is a number less than

8%. If your result for the most distant outlet in the circuit is <8%, there is no

need to check any other outlet(s) of the circuit closer to the breaker box. If your

result is greater than 8%, repeat the test on the outlet that is next-closest to

the breaker box. Keep repeating the test until you get a normal measurement

result. A voltage drop of more than 8% is usually caused by loose connections,

poorly spliced conductors, or conductors that are too thin for the circuit’s load.

7

Page 8

The table below lists the possible causes of an abnormal result and suggests

remedies and additional troubleshooting steps to take.

Parameter

Voltage drop

Normal

Measurement

Result

0 to 8%

Actual Result

Voltage drop is

too high

Possible Cause

of Abnormal

Result

Circuit is overloaded

Conductors are too

thin for circuit

length and/or

circuit’s current

High impedance

point(s) in breaker

box or circuit

Remedy

Redistribute load

Replace wiring with

heavier-gauge conductors

suitable for circuit’s rating

Visually inspect all

connection points to detect

or rule out loose

connections and splices,

broken or improperly

attached twist-on

connectors (wire nuts), and

defective outlets. If none

are apparent, locate points

of high impedance using an

infrared thermometer (IRT)

to detect their heat, or a

voltmeter to detect

excessive voltage drops

across parts. Alternatively,

run the Z-L and Z-N

impedance tests described

in the next section on the

hot and neutral conductors;

if one conductor produces

a much higher reading than

the other, it is defective.

Repair or replace defective

wiring/parts.

8

Page 9

MEASURING CONDUCTOR IMPEDANCE

The CA10 can measure and display the impedance of all three circuit

conductors as well as one impedance-related parameter (available short-circuit

current, or ASCC). The three impedance values represent the impedances of the

phase (live) line (Z-L), the neutral line (Z-N), and the earth (ground) line (Z-E).

Available short-circuit current is a measure of the amount of current that would

pass through the circuit’s breaker if all of its conductors were to be shortcircuited. It is calculated as Phase Voltage/(Live line impedance + Neutral line

impedance). Using the terminology of the CA10: ASCC = (L-N)/(Z-L) + (Z-N).

Each of the four impedance parameters is measured and displayed by choosing

it from a submenu made available after the FUNC button has been used to

select Z.

To begin, plug the free end of the test cable into any outlet of the circuit to be

tested. Press the or button to cycle through the four submenu options

in either direction, as shown in the figure below. The text icon of the parameter

selected for measurement appears at the left of the display. To initiate any test,

press the TEST button.

9

Page 10

The table below the figure shows the normal measurement result for each of

the four parameters. It also lists possible causes of, and remedies for, abnormal

results.

Parameter

Impedance of

live and neutral

conductors

(Z-L and Z-N)

Impedance of

ground

conductor (Z-E)

Normal

Measurement

Result

<0.15Ω/m for

14AWG conductor

<0.1Ω/m for

12AWG conductor

<0.03Ω/m for

10AWG line

<1Ω for personnel

safety

<0.25Ω for

equipment safety

Actual Result

Impedance is too

high

Impedance is

too high

Possible Cause

of Abnormal

Result

Circuit is overloaded

Conductor is too thin

for circuit length

and/or circuit’s

current rating

High impedance

point(s) in circuit or

breaker box

Conductor is too thin

for circuit length

and/or circuit’s

current rating

High impedance

point(s) in circuit or

breaker box

Remedy

Redistribute circuit load

Replace wiring with

heavier-gauge conductors

suitable for circuit’s rating

Visually inspect all

connection points to detect

or rule out loose

connections and defective

outlets. If none are

apparent, locate points of

high impedance using an

infrared thermometer (IRT)

to detect their heat, or a

voltmeter to detect

excessive voltage drops

across parts. Repair or

replace defective

wiring/parts.

Replace wiring with

heavier-gauge conductors

suitable for circuit’s

rating

Visually inspect all

connection points to detect

or rule out loose

connections and defective

outlets. If none are

apparent, locate points of

high impedance using an

infrared thermometer (IRT)

to detect their heat, or a

voltmeter to detect

excessive voltage drops

across parts. Alternatively,

run the Z-L and Z-N

impedance tests on the

hot and neutral conductors;

if one conductor produces

a much higher reading

than the other, it is

defective. Repair or

replace defective

wiring/parts.

10

Page 11

Notes: 1) Be sure any surge suppression system used is properly grounded so it

can continue to protect loads during transient overvoltage conditions. 2) Before

measuring any parameter, remove any heavy loads from the circuit to avoid

producing an inaccurate test result. 3) Before measuring Z-E, be sure to

disconnect any RCDs from the circuit to avoid triggering them. 4) A ground

connection is required to test the impedance of conductors in 2-wire systems.

TESTING RESIDUAL CURRENT DEVICES (RCDs)

The CA10 can measure how much current it takes to trip an RCD, and how

quickly it responds to an event that should cause a trip. It does so by placing a

resistance across the circuit’s live and ground lines, generating a current

between them. According to UL, it should take no more than 30mA to cause a

trip. The CA10 measures and displays the triggering current (in mA) and the

response time (in ms).

To select the RCD test, press the FUNC button until RCD is highlighted. Then

plug the free end of the test cable into any outlet equipped with an RCD. To

initiate the test, press the TEST button. During testing, the display will show the

word TEST on the top line. If the device fails to be triggered, the analyzer will

stop testing automatically after 6.5 seconds.

The table below shows the normal measurement result of RCD testing. It also

lists possible causes of, and remedies for, an abnormal result.

Parameter

RCD reliability

and response

time

Normal

Measurement

Result

RCD trips within

specified time

Actual Result

RCD is too slow

to trip

RCD fails to trip

Possible Cause

of Abnormal

Result

RCD is installed

improperly

RCD is defective

Remedy

Check that installation

complies with

manufacturer’s

requirement and relevant

standards

Repair or replace RCD

Notes: 1) Before testing, remove any heavy loads from the circuit to avoid

producing an inaccurate test result. 2) A ground connection is required to test

RCDs in 2-wire systems. 3) Another common name for a residual current

device (RCD) is a residual current circuit breaker (RCCB).

11

Page 12

TESTING GROUND FAULT CIRCUIT INTERRUPTERS (GFCIs)

The CA10 can measure how much current it takes to trip a GFCI, and how

quickly it responds to a condition that should cause a trip. It does so by placing

a resistance across the circuit’s live and ground lines, generating a current

between them. According to UL, it should take no more than 5mA to trigger a

trip. The CA10 measures and displays the level of triggering current (in mA) and

the response time (in ms).

To select the GFCI test, press the FUNC button until GFCI is highlighted. Then

plug the free end of the test cable into any outlet equipped with a GFCI. To

initiate the test, press the TEST button. During testing, the display will show the

word TEST on the top line. If the device fails to be triggered, the analyzer will

stop testing automatically after 6.5 seconds.

The table below shows the normal measurement result of GFCI testing. It also

lists possible causes of, and remedies for, an abnormal result.

Parameter

GFCI reliability

and response

time

Normal

Measurement

Result

GFCI trips within

specified time

Actual Result

GFCI is too slow

to trip

GFCI fails to trip

Possible Cause

of Abnormal

Result

GFCI is installed

improperly

GFCI is defective

Remedy

Check that installation

complies with

manufacturer’s

requirement and relevant

standards

Repair or replace GFCI

Notes: 1) Before testing, remove any heavy loads from the circuit to avoid

producing an inaccurate test result. 2) A ground connection is required to test

GFCIs in 2-wire systems.

TESTING OUTLET WIRING

The CA10 automatically checks the wiring of any outlet it is plugged into. The

upper part of the display contains the following arrangement of three circles: N

stands for the neutral conductor, L for the live conductor, and E for the earth

(ground) conductor.

If the outlet’s wiring is normal, all three circles will be filled in, as shown in the

table on the next page. Different combinations of filled in (on), empty (off) and

flashing circles indicate specific faults.

12

Page 13

Wiring Condition

Normal

No ground wire detected

Live and neutral conductors are reversed

Screen Display

L E N

Legend

Off

On

Flashing

Other conditions

Any wiring abnormality will prevent the CA10 from performing tests to the full

extent of its abilities. For example, in the absence of a ground wire the analyzer

can only measure the circuit’s phase voltage and voltage drop. Furthermore,

the CA10 cannot detect the voltage between two live lines, multiple concurrent

faults, or reversed neutral and ground conductors.

OTHER FUNCTIONS

Backlight. Pressing the button while the CA10 is powered on turns on the

display backlight. If no button is pushed for 30 seconds, the backlight will turn

off automatically. You can turn off the backlight manually by pressing the

button again.

Auto Power Off (APO). A 30-minute APO function is automatically enabled

when the CA10 is powered on. When APO is enabled (indicated by a clock icon

( ) at the upper left of the display), if no button is pushed for 30 minutes the

CA10 will automatically power off to extend battery life.

To disable the APO function, press and hold the FUNC button while pressing the

button to power on the unit. The clock icon will not be displayed.

Data Hold. Pressing the HOLD button freezes measurements of voltage

parameters on the larger, lower readout. Other measurements cannot be held.

To release the hold, press the HOLD button again.

13

Page 14

SPECIFICATIONS

Parameter or Component Measurement Measurement Resolution

Range Accuracy

Line Voltage 85 to 185VAC ±1% of reading ± 0.2V 0.1V

Peak Voltage 121 to 262VAC ±1% of reading ± 0.2V 0.1V

Line Frequency 45 to 65Hz ±1% of reading ± 0.2Hz 0.1Hz

Voltage Drop 0.1 to 99.9% ±2.5% of reading ± 0.2% 0.1%

Load Voltage 10 to 185VAC ±2.5% of reading ± 0.2V 0.1V

Neutral-to-Earth Voltage 0 to 10VAC ±2.5% of reading ± 0.2V 0.1V

Live, Neutral and 0 to 3Ω ±2.5% of reading ± 0.02Ω 0.01Ω

Ground Line Impedance >3Ω NA

RCD Trip Time 1 ms to 6.5 sec. ±1% of reading ± 2 ms 1 ms

RCD Trip Current 30 to 37mA ±1% of reading ± 0.2mA 0.1mA

GFCI Trip Time 1 ms to 6.5 sec. ±1% of reading ± 2 ms 1 ms

Display Backlit 2.4 in. (61mm) diagonal LCD

Test Cable 18 AWG diameter, 6 ft. (1.83m) long

Auto Power Off Trigger 30 minutes of inactivity

Display Backlight Duration 30 seconds

Operating/Storage 32° to 122°F (0° to 50°C) @ <80% RH

Temperature

Dimensions 7.6 x 3.1 x 1.5 in. (193 x 78 x 39mm)

Weight (Without Batteries) 10.4 oz. (295g)

Power Source Six “AAA” batteries

OPERATING & MAINTENANCE TIPS

REPLACING THE BATTERIES

When the (low battery) icon appears on the top line of the display, it’s time

to replace the unit’s six “AAA” batteries. Follow the instructions on p. 5 for

opening and closing the battery compartment and installing the batteries.

HOUSEKEEPING HINTS

DO NOT expose the CA10 to:

• Direct sunlight

• High humidity or temperatures (above 104°F/40°C during operation or

140°F/60°C in storage)

• Corrosive or explosive gas

• Excessive dust

• Strong mechanical vibration or stress (dropping, for example) or

electromagnetic radiation

14

Page 15

If the instrument has been exposed to extreme temperatures, allow several

hours for it to acclimate to your local conditions before using it.

Do not open the housing of the unit. Doing so voids its limited warranty and

could disable its safety circuitry.

You may clean the housing of the CA10 with a soft, clean cloth and water or a

mild detergent. Never use benzene, alcohol, acetone, ether, ketone, paint

thinner, gasoline or an organic solvent. After cleaning, dry the CA10 thoroughly

with a clean cloth before using it again.

WARRANTY INFORMATION

General Tools & Instruments’ (General’s) CA10 AC Circuit Analyzer is warranted

to the original purchaser to be free from defects in material and workmanship

for a period of three years. Subject to certain restrictions, General will repair or

replace this instrument if, after examination, the company determines it to be

defective in material or workmanship.

This warranty does not apply to damages that General determines to be from

an attempted repair by non-authorized personnel or misuse, alterations, normal

wear and tear, or accidental damage. The defective unit must be returned to

General Tools & Instruments or to a General-authorized service center, freight

prepaid and insured.

Acceptance of the exclusive repair and replacement remedies described herein

is a condition of the contract for purchase of this product. In no event shall

General be liable for any incidental, special, consequential or punitive damages,

or for any cost, attorneys’ fees, expenses, or losses alleged to be a

consequence of damage due to failure of, or defect in any product including,

but not limited to, any claims for loss of profits.

RETURN FOR REPAIR POLICY

Every effort has been made to provide you with a reliable product of superior

quality. However, in the event your instrument requires repair, please contact

our Customer Service to obtain an RGA (Return Goods Authorization) number

before forwarding the unit via prepaid freight to the attention of our Service

Center at this address:

General Tools & Instruments

75 Seaview Drive

Secaucus, NJ 07094-1806

212-431-6100

Remember to include a copy of your proof of purchase, your return address,

and your phone number and/or e-mail address.

15

Page 16

General Tools & Instruments

GeneralToolsNYC

GENERAL TOOLS & INSTRUMENTS

75 Seaview Drive

Secaucus, NJ 07094-1806

PHONE (212) 431-6100

FAX (212) 431-6499

TOLL FREE (800) 697-8665

e-mail: sales@generaltools.com

www.generaltools.com

CA10 User’s Manual

Specifications subject to change without notice

NOTICE - WE ARE NOT RESPONSIBLE FOR TYPOGRAPHICAL ERRORS.

©2016 GENERAL TOOLS & INSTRUMENTS

MAN#CA10

3/17/16

Loading...

Loading...