Page 1

L

...

/'v. '

rTT^n

ii

*

V

ii

■■

' '

POWER SYSTEMS, INC

Owner’s Manual and

Installation Instructions

Liquid-cooled Recreational Vehicle Generator

®

Model: 04270-0

QUIETPACT™ 75D

Page 2

INTRODUaiON

Thank you for purchasing this model of the

QUIETPACT™ product line by Generac Power Systems

Inc. This model is designed and manufactured to sup

ply electrical power for recreational vehicles.

♦ READ THIS MANUAL THOROUGHLY

If you do not understand any portion of this

manual, contact Generac or your nearest

Generac Authorized Service Dealer for starting,

operating and servicing procedures.

Throughout this publication, and on tags and

decals affixed to the generator, DANGER, WARN

ING, CAUTION and NOTE blocks are used to alert

you to special instruction about a particular opera

tion that may be hazardous if performed incorrect

ly or carelessly. Observe them carefully. Their defin

itions are as follows:

DANGER

After this heading, you can read instructions that,

if not strictly complied with, will result in personal

injury or property damage.

---

A WARNING A

After this heading, you can read instructions that,

if not strictly complied with, may result in personal

injury or property damage.

--------

ik CAUTION Mr

After this heading, you can read instructions that, if

not strictly complied with, could result in damage to

equipment and/or property.

NOTE:

After this heading, you can read explanatory

statements that require special emphasis.

These safety warnings cannot eUminate the hazards

that they indicate. Common sense and strict compli

ance with the special instructions while performing the

service are essential to preventing accidents.

Four commonly used safety symbols accompany the

DANGER, WARNING and CAUTION blocks. The type

of information each indicates follows:

This symbol points out important safety informa

A

tion that, if not followed, could endanger personal

safety and/or property of you and others.

This symbol points out potential explosion hazard.

______________

-----

-----------------

The operator (driver) is responsible for proper and

safe use of the vehicle and its equipment, and the safe

ty of all vehicle occupants. We strongly recommend

that the operator read this manual and thoroughly

understand all instructions before using this equip

ment. We also strongly recommend instructing other

occupants in the vehicle to properly start and operate

the generator. This prepares them if they need to oper

ate the equipment in an emergency.

♦ CONTENTS

This manual contains pertinent owner’s Information,

including warranty, electrical diagrams, exploded

views and lists of repair parts for generator model

number 04270-0. In addition, the latter portion of

this manual contains information necessary for the

proper installation of these generators.

♦ OPERATION AND MAINTENANCE

It is the operator's responsibility to perform all

safety checks, to make sure that all maintenance

for safe operation is performed promptly, and to

have the equipment checked periodically by a

Generac Authorized Service Dealer. Normal main

tenance service and replacement of parts are the

responsibility of the owner/operator and, as such,

are not considered defects in materials or work

manship within the terms of the warranty.

Individual operating habits and usage contribute to

the need for maintenance service.

Proper maintenance and care of your generator

ensure a minimum number of problems and keep

operating expenses at a minimum. See your

Generac Authorized Service Dealer for service aids

and accessories.

♦ HOW TO OBTAIN SERVICE

When your generator requires servicing or repairs,

simply contact a Generac Authorized Service Dealer

for assistance. Service technicians are factory-trained

and are capable of handling all of your

service needs.

When contacting a Generac Authorized Service

Dealer or the factory about parts and service, always

supply the complete model number and serial num

ber of your unit as given on its data decal, which is

located on your generator.

Model No.

__________________________________

_______________

Serial No.

This symbol points out potential fire hazard.

This symbol points out potential electrical shock

A

hazard.

Generac* Power Systems, Inc.

AUTHORIZED SERVICE

DEALER LOCATION

To locate the GENERAC AUTHORIZED SERVICE

DEALER nearest you, please call this number:

1-800-33S-1322

ONLY DEALER LOCATION INFORMATION

CAN BE OBTAINED AT THIS NUMBER.

Page 3

Table of Contents

QUIETPACT™ 75D Recreational Vehicle Generator

Part I ~ Owner's Manual

Introduction

Read This Manual Thoroughly ....................................... IFC

Contents

Operation and Maintenance ..............................................IFC

How to Obtain Service........................................................IFC

Authorized Service Dealer Locator Number

Safety Rules

Section 1 - General Information

1.1 Generator Identification..................................................4

1.2 Generator Applicability...................................................5

1.3 Safely.... 5

1.4 Generator AC Connection System

1.5 Specifications ................................................................... 5

Section 2 - Operation...............................................................7

2.1 Generator Control Panel ................................................7

2.2 Optional Remote Start/Stop ...........................................7

2.3 Before Starting the Engine

2.4 Starting the Generator.....................................................8

2.5 Stopping the Generator

2.6 Applying Loads to Generator..........................................9

2.7 Protection Systems

2.8 Additional Information .................................................10

Section 3 - Maintenance

3.1 Checking the Engine OH Level

3.2 Changing the Engine OH and/or OH FUter

3.3 Servicing the Engine Air FHter

3.4 Spark Arrestor Muffler ................................................13

3.5 Cleaning the Generator

3.6 Battery Maintenance

3.7 Cooling System.................................................................14

3.8 Engine Coolant...............................................................14

3.9 Major Service Manual ..................................................15

3.10 Drive Belt

3.11 Exercising tlie Generator...............................................15

3.12 Out of Service Procedure

3.13 Service SchediHe............................................................16

............................

...............................................................................

.............

.............................................................

.................Inside Front Cover

IFC

....................

..........................................

IFC

4

.................................

1.5.1 Fuel Requirements

1.5.2 Fuel Consumption

1.5.3 Engine OH Requirements

...........................................

............................................

...............................

1.5.4 Coolant .............................................................6

1.5.5 Engine................................................................6

1.5.6 Generator .........................................................6

2.1.1 Hourmeter

2.1.2 Start/Stop Switch

........................................................

.............................................

2.1.3 Fuse....................................................................7

2.1.4 Line Breaker.....................................................7

2.1.5 Preheat Switch..................................................7

..............................................

2.3.1 Installation 7

2.3.2 Engine Lubrication

..........................................

2.3.3 Fuel Supply ......................................................8

2.3.4 Coolant Level....................................................8

2.3.5 Cooling and Ventilating Air

...........................

2.3.6 Engine Exhaust Gas.........................................8

...................................................

2.6.1 Letting the Engine Stabilize

2.6.2 Do Not Overload the Generator

2.7.1 Low OH Pressure Switch..................................9

...........................................................

2.7.2 High Temperature Switch

2.7.3 Over speed Shutdown

2.7.4 Overvoltage Protection

............................

.....................

..............................

....................................

..................................

2.8.1 25-Hour Break-in Period...............................10

2.8.2 25-Hour Check-up

2.8.3 Attention Required After Submersion

2.8.4 Operation In High Grass or Brush

2.8.5 Effects of Moisture and Dirt

..................................................... 12

.........................................

........

..............

........................

......................................

...............

....................................

................................................

....................................................

........................................................................

..............................................

3.12.1 Removal From Service

3.12.2 Return to Service

..................................

...........................................

10

10

11

11

11

11

12

12

12

13

14

15

15

15

15

Part II - installation Instructions

Safety Rules

Section 1 - General Information

............................................................................18

............................................

20

1.1 Purpose and Scope of the Manual..................................20

1.2 Safety................................................................................20

1.3 Standards Booklets......................................................... 20

1.4 Equipment Description

.2

1.5 Generator Engine Operating Speed..............................20

1.6 Generator AC Connection System

Section 2 - Installation...........................................................

..................................................

................................

20

20

22

2.1 Location and Support.....................................................22

2.1.1 Generator Location

5

5

6

6

2.1.2 Generator Support

2.1.3 Suspended Moimtlng......................................22

2.1.4 Generator Restraint

2.2 Generator Compartments .............................................23

2.2.1 Compartment Construction

2.2.2 Sound Insulating Materials

2.2.3 Acoustics

..........................................................

2.2.4 Compartment Floor Cutouts

2.3 Cooling and VentHattng Air

2.3.1 Generator Airflow

7

7

2.3.2 Cooling Air Inlet Openings

2.3.3 Compensating for Restrictions

2.3.4 Testing the Installation...................................27

2.4 Diesel Fuel System

2.4.1 Fuel Tank

..........................................................

........................................................

2.4.2 Generator Fuel Supply Line

7

8

2.5 Exhaust System

2.5.1 Mufflers and Speirk Arrestors

2.4.2.1 Rigid Fuel Lines

2.4.2.2 Flexible Fuel Line

........

29

.......................................

........................................

.......................................

..........................

..........................

.........................

........................................

.........................................

............................

......................

..........................

..........................

.......................

.....................

22

22

23

23

24

24

25

26

26

26

27

27

28

28

28

28

29

2.5.2 Exhaust System Safely....................................29

8

9

9

9

9

9

2.6 Electrical Connections....................................................30

2.6.1 Electrical Junction Box

2.6.2 Wiring

..............................................................

..................................

30

30

2.6.3 Generator AC Connections ...........................30

2.6.3.1 Generator Coversion to 120

2.6.4 Conduit

Volts Only - Dual Circuits

............................................................

...........

32

2.6.5 Power Supply Cord.........................................32

2.6.6 Ground Fault Circuit Interrupters

2.6.7 Isolating Different Power Sources

...............

................

32

32

2.7 Battery Installation.........................................................33

2.7.1 Recommended Battery

...................................

33

31

2.7.2 Battery Cables.................................................33

2.7.3 Battery Cable Connections

2.7.4 Battery Compartment

2.8 Optional Accessories.......................................................34

2.8.1 Remote Start/Stop Connections......................34

Section 3 - Post-installation Start-up

Checks 35

............................

...................................

33

34

3.1 Post Installation Tests.....................................................35

3.2 Before Initial Start-up

...................................................

35

3.3 Initial Start ..................................................................... 35

3.4 Testing Under Load........................................................35

3.5 Installation Checklist

Appendix 1 - Troubleshooting

Appendix 2 - Electrical Data

Appendix 3 - Exploded Views and Parts Lists

Appendix 4 - Notes

Appendix 5 - Warranty

.......................................................

..............................................

..................................................

.....................

..............................................................

...........................................................

36

37

38

40

61

64

Generac* Power Systems, Inc.

Page 4

SAFETY RULES

Safety Rules

QUIETPACT™ 75D Recreational Vehicle Generator

SAVE THESE INSTRUCTIONS - The manufacturer suggests that these rules for scfe .

operation be copied and posted in potential hazard areas of the recreational vehicle.

Safety should be stressed to all operators and potential operators of this equipment. ““

A

• The engine exhaust fumes contain carbon monox

WARNING;

The engine exhaust from this product

contains chemicals known to the state

of California to cause cancer, birth

Study these SAFETY RULES carefully before

installing, operating or servicing this equipment.

Become familiar with this manual and with the unit.

The generator can operate safely, efficiently and reli

ably only if it is properly installed, operated and main

tained. Many accidents are caused by failing to follow

simple and fundamental rules or precautions.

Generac cannot possibly anticipate every possible cir

cumstance that might Involve a hazard. The warn

ings in this manual, and on tags and decals

affixed to the unit, are, therefore, not all-inclusive. If

you use a procedure, work method or operating tech

nique Generac does not specifically recommend, you

must satisfy yourself that it is safe for you and others.

You also must make sure the procedure, work

method or operating technique that you choose does

not render the generator unsafe.

DANGER

Despite the safe design of this generator,

operating this equipment imprudently, neglecting

its maintenance or being careless can cause

possible injury or death. Permit only responsible

and capable persons to operate or maintain this

equipment.

Parts of the generator are rotating and/or hot

during operation. Exercise care near running

generators.

Potentially lethal voltages are generated by

A

these machines. Ensure all steps are taken to

render the machine safe before attempting to

work on the generator.

A GENERAL HAZARDS A

For safety reasons, Generac recommends

that the installation, initial start-up and mainte

nance of this equipment is carried out by a

Generac Authorized Service Dealer.

ide, which can be DEADLY. This dangerous gas, if

breathed in sufficient concentrations, can cause

unconsciousness or even death. This exhaust sys

tem must be installed properly, in strict compli

ance with applicable codes and standards.

Following installation, you must do nothing that

might render the system unsafe or in noncompli

ance with such codes and standards. The genera

tor compartment must be completely vapor sealed

from the vehicle interior. There must be no possi

bility of exhaust fumes entering the vehicle interi

or. Never operate this equipment with a leaking or

defective exhaust system.

• Keep hands, feet, clothing, etc., away from drive

belts, fans, and other moving or hot parts. Never

remove any drive belt or fan guard while the unit

is operating.

• Adequate, unobstructed flow of cooling and ven

tilating air is critical to correct generator opera

tion and is required to expel toxic fumes and fuel

vapors from the generator compartment. Without

sufficient cooling airflow, the engine/gener ator

quickly overheats, which causes serious damage

to the generator. Do not alter the installation or

permit even partial blockage of ventilation provi

sions, as this can seriously affect safe operation

of the generator.

• When working on this equipment, remain alert at

all times. Never work on the equipment when you

are physically or mentally fatigued.

• Inspect the generator regularly, and contact your

nearest Generac Authorized Service Dealer immedi

ately for parts needing repair or replacement.

• Before performing any maintenance on the genera

tor, disconnect its battery cables to prevent acci

dental start up. Disconnect the cable from the bat

tery post indicated by a NEGATIVE, NEG or {-)

first. Reconnect that cable last.

• Never use the generator or any of its parts as a

step. Stepping on the unit can stress and break

parts, and may result in dangerous operating con

ditions from leaking exhaust gases, fuel leakage,

oil leakage, etc.

• Never insert any tool or other object through open

ings in the generator interior, even if the unit is not

running. You might seriously Injure yourself or

damage the equipment.

Generac* Power Systems, Inc.

Page 5

Safety Rules

QUIETPACT™ 75D Recreational Vehicle Generator

SAFETY RULES

A

A

ELECTRICAL HAZARDS

• The generator covered by this manual produces

dangerous electrical voltages and can cause fatal

electrical shock. Avoid contact with bare wires, ter

minals, connections, etc., while the unit is running.

Ensure all appropriate covers, guards and barriers

are in place before operating the generator. If you

must work around an operating unit, stand on an

insulated, dry surface to reduce shock hazard.

• Do not handle any kind of electrical device while

standing in water, while barefoot, or while hands

or feet are wet. DANGEROUS ELECTRICAL

SHOCK MAY RESULT.

• During installation onto the vehicle, have the genera

tor properly groimded (bonded) either by soUd

mounting to the vehicle frame or chassis, or by

means of an approved bonding conductor. DO NOT

dlscormect the bonding conductor, if so equipped.

DO NOT reconnect the bonding conductor to any

generator part that might be removed or disassem

bled dming routine maintenance. If the groimding

conductor must be replaced, use only a flexible con

ductor that is of No. 8 American Wire Gauge (AWG)

copper wire minimum.

• In case of accident caused by electric shock,

immediately shut down the source of electrical

power. If this is not possible, attempt to free the

victim from the live conductor. AVOID DIRECT

CONTACT WITH THE VICTIM. Use a noncon

ducting Implement, such as a dry rope or board,

to free the victim from the live conductor. If the

victim is unconscious, apply first aid and get

immediate medical help.

• Never wear jewelry when working on this equip

ment. Jewelry can conduct electricity resulting in

electric shock, or may get caught in moving com

ponents causing injury.

A

A FIRE HAZARDS A

For fire safety, the generator must be installed and

maintained properly. Installation must always

comply with ANSI 119.2-1975/NFPA 501C-1974,

“Standard for Recreational Vehicles, Part III Installation of Electrical Systems," along with all

applicable codes, standards, laws and regulations.

Adhere strictly to local, state and national electri

cal and building codes. Comply with regulations

the Occupational Safety and Health Administration

(OSHA) has established. Also, ensure that the gen

erator is Installed in accordance with the manufac

turer’s Instructions and recommendations.

Following proper installation, do nothing that

might alter a safe installation and render the unit

in noncompliance with the aforementioned codes,

standards, laws and regulations.

Keep a fire extinguisher in the vehicle at all times.

Extinguishers rated “ABC” by the National Fire

Protection Association are appropriate for use on

the recreational vehicle generator electrical sys

tem. Keep the extinguisher properly charged and

be familiar with its use. If you have any question

pertaining to Are extinguishers, consult your local

fire department.

A EXPLOSION HAZARDS A

Do not smoke around the generator. Wipe up any

fuel or oil spills Immediately. Ensure that no com

bustible materials are left in the generator com

partment, or on or near the generator, as FIRE or

EXPLOSION may result. Keep the area surround

ing the generator clean and free from debris.

All fuel types are potentially FLAMMABLE and/or

EXPLOSR^ and should be handled with care.

Comply with all laws regulaüng the storage and han

dling of fuels. Inspect the unit’s fuel system frequent

ly and correct any leaks immediately. Fuel supply

lines must be properly installed, purged and leak

tested according to apphcable fuel-gas codes before

placing this equipment into service.

Generac* Power Systems, Inc.

Page 6

GENERAL

INFORMATION

Section 1 - General Information

QUIETPACT™ 75D Recreational Vehicle Generator

1.1 GENERATOR IDENTIFICATION

Please record the following information from the generator DATA DECAL or information decal,

located below the user control panel.

1. Model Number ___________________________ 2. Serial Number

3. kW Rating

_______________________________

15 1 2 3

22

FRONT VIEW

_______________________________

4. Rated Voltage _______________________________

Model: 04270-0

QUIETPACT™ 75D

1. 2-Pole, 35-amp Circuit

Breaker

2. Hour meter

3. Oil Fill Opening and Plug

4. Oil Dipstick

5. Engine StartyStop Switch

6. 14-amp Fuse

7. Engine Preheat Switch

8. Fuel Filter

9. Air Filter

10. Oil Filter

11. Starter Motor

12. Preheat Contactor

13. Starter Contactor

14. Radiator

15. Coolant Recovery Tank

16. Muffler

17. Battery Connections

18. Fuel Connections

19. Alternator

20. Fuel Pump

21. Centrifugal Cooling Fan

and Housing

22. Alternator Drive Belt

23. Alternator Drive Belt

Tensioner

24. Cooling Fan Drive Belt

25. Cooling Fan Drive Belt

Tensioner

26. Engine

REARVIEW

Generac* Power Syateme, Inc.

Page 7

Section 1 - General Information

QUIETPACT™ 75D Recreational Vehicle Generator

GENERAL

INFORMATION

1.2 GENERATOIIAPPLIGIBILITY

These generators have been designed and manu

factured for supplying electrical power for recre

ational vehicles. You should not modify the gener

ator or use it for any application other than for

what it was designed. If there are any questions

pertaining to its application, write or call the fac

tory. Do not use the unit until you have been

advised by a competent authority.

DANGER

For fire safety, the generator must have been

A

properly installed in compliance with ANSI

119.2-1975/NFPA 501C-1974, "Standard for

Recreational Vehicles, Part III - Installation of

Electrical Systems." The generator also must

have been installed in strict compliance with

the manufacturer's detailed installation instruc

tions. After installation, do nothing that might

render the unit in noncompliance with such

codes, standards and instructions.

You can use this generator to supply electrical power

for operating 120/240-volt, single-phase, 60 Hertz,

AC electrical loads. These loads can require up to

7,500 watts (7.5 kW) of power, but cannot exceed

62.5 AC amps of current at 120 volts, or 31.2 AC

amps at 240 volts.

----------

Mk CAUTION Jk

Do not overload the generator. Some installa

A

tions may require that electrical loads be alter

nated to avoid overloading. Applying excessive

ly high electrical loads may damage the genera

tor and may shorten its life. Add up the rated

watts of all electrical lighting, appliance, tool

and motor loads the generator will power at

one time. This total should not be greater than

the wattage capacity of the generator. If an

electrical device nameplate gives only volts and

amps, multiply volts times amps to obtain watts

(volts X amps = watts). Some electric motors

require more watts of power (or amps of cur

rent) for starting than ifor continuous operation.

13 SAFETY

Before attempting to use the generator set, carefully

read the “Safety Rules” section of this manual.

Comply strictly with these rules to prevent accidents

and damage to equipment and/or property. We sug

gest copying and posting the “Safety Rules” in poten

tial hazard areas of the vehicle. Stress safety to all

operators and potential operators of this equipment.

------------------------

1.4 GENERATOR AC CONNEQION SYSTEM

This generator is equipped with dual stator AC power

windings. These two-stator windings supply electri

cal power to customer electrical loads by means of a

dual two-wire connection system. Note, however, that

the neutral is grounded.

The generator may have been installed so that it pow

ers 120- and/or 240-volt AC electrical loads (Figure

1.1). It can be rewired to connect 120-volt AC electri

cal loads only. This procedure should be done by a

Generac Authorized Service Dealer or other qualified

installer. Refer to the installation portion of this man

ual for more information.

Figure 1.1 - Connections for 120/240 Dual

Voltage

BLUKl

c

‘-f

(

HjUUUUlH '-TJUUUUU-'

1.S SPECIFICATIONS

♦ 1.5.1 FUEL REQUIREMENTS

The generator is equipped with a diesel fuel system.

Use clean, fresh No. ID or No. 2D diesel fuel with min

imum Cetane number of 40. It also must conform to

American Society of Testing and Materials (ASTM)

specifications. Never use any dirty or contaminated

fuel. When adding fuel, DO NOT overfill the tank. Allow

room at the top of the tank for fuel expansion.

Depending on the Installation, the generator may have

either a separate fuel tank, or it may “share” the vehi

cle engine’s fuel tank.

NOTE:

Some installations using a “shared” fuel tank may

have a generator fuel pickup tube that is shorter

than the vehicle engine’s pickup tube. Such an

arrangement causes the generator engine to “run

out of gas” while adequate fuel for the vehicle

remain in the tank.

Also, appropriate care should be taken in applica

tions where extremely low ambient temperatures

are possible to ensure the temperature of the

diesel fuel is not allowed to fall below levels where

“gelling” could occur.

9

p

Generac* Power Systems, Inc.

Page 8

GENERAL

INFORMATION

Section 1 - Generai Information

QUIETPACT™ 75D Recreational Vehicle Generator

♦ 1.5.2 FUEL CONSUMPTION (GAl/HR)

Modd No Load Half Load

QUTETPACT™ 75D

0.28 0.45 0.78

ЕШ Load

(04270-0)

♦ 1.5.3 ENGINE OIL REQUIREMENTS

_______________

Use a high-quality detergent oil with American

Petroleum Institute (API) classification ‘‘For Service

CC.” Detergent oils keep the engine cleaner and reduce

carbon deposits. Use oil having the following SAE vis

cosity rating, based on the amMent temperature range

anticipated before the next oil change:

Temperature Oil Grade (Recommended)

Above 100° F (38° C)

40° to 100° F (4.4° to 38° C) SAE 10W-30 or SAE 30

Below 40° F (4.4° C) SAE 5W-20 or 5W-30

SAE 15W-40 or SAE 40

Crankcase and oil filter capacity is approximately 3.5

L or 3.7 U.S. quarts. Do NOT use special additives.

See Sections 3.1 and 3.2 (Page 12) for oil level check

ing and changing procedures.

♦ 1.5.4 COOLANT

____________________

_________

__

Use a mixture of half low silicate, ethylene glycol base

antifreeze and half soft water. Use only soft water and

only low silicate antifreeze. If desired, you may add a

high quality rust inhibitor to the recommended

coolant mixture. When adding coolant, always add

the recommended 50-50 mixture.

DANGER

Do not remove the radiator pressure cap while

A

the engine is hot or serious burns from boiling

liquid or steam could result.

Ethylene glycol base antifreeze is poisonous. Do

A

not use your mouth to siphon coolant from the

radiator, recovery bottle or any container. Wash

your hands thoroughly after handling. Never store

used antifreeze in an open container because ani

mals are attracted to the smell and taste of

antifreeze even though it is poisonous to them.

---------

Ik CAUTION

Do not use any chromate base rust inhibitor with

ethylene glycol base antifreeze, or chromium

hydroxide ("green slime") will form and cause

overheating. Engines that have been operated

with a chromate base rust inhibitor must be

chemically cleaned before adding ethylene glycol

base antifreeze. Using any high silicate antifreeze

boosters or additives also will cause overheating.

We also recommend that you DO NOT use any

soluble oil inhibitor for this equipment.

Generac*

Power Systems, Inc.

------------------------

-

♦ 1.5.5 ENGINE_________________________________

туре of Engtae

Cylinder Arrangement ......................................................3, in-line

Displacement........................................................58.2 in. (954 cc)

Bore

........................................................................

Stroke.....................................................................2.83 in. (72 mm)

Compression Ratio................................................................23-to-l

Combustion Chamber Type

Rated Horsepower...............................................13 @ 1,950 rpm

Cylinder Block...................................................................Cast Iron

Number of Main Bearings..............................................................4

Number of Tteeth on Flywheel

Type of Governor

Fhel Filter...............................FbU Flow Spln-On (Part # 69858)

Oil Filter

Oil Pressure.......................................................................29-71 psl

туре of Cooling System

Cooling Method

туре of Cooling Fhn

Cooling System Capaclly

Air Cleaner...............................Disposable Filter (Part # C4880)

Starter

Recommended Battery........................70 Ah, 360 Cold-cranking

Maximum Cranking Current

Ground Polarity

................................................................

................................

..................................................

..................................

............................................

.................

.........................................................

...........................................

..............................

...............................................................

.........................................

..................................................................

Mechanical, Fixed Speed

Pull Flow with Bypass Valve

Pressurized, Closed Recovery

Amps

ISM Diesel

2.95 in. (75 mm)

Pre-Combustion

104

(Part # 126-70939)

Liquid-cooled

Centrifu^ Puller

1.4 U.S. gals (5.3 L)

12-volt DC Electric

220 Amps

Negative

♦ 1.5.6 GENERATOR

Rated Maximum Continuous AC Output at...

85° F (29° C) Ambient

100° F (38° C) Ambient ..........................7,000 Watts (7.0 kW)

120° F (49° C) Ambient

Rated Voltage

Rated Maximum Continuous AC Current at...

7,500 Watts

7.000 Watts

6.000 Watts

Phase

.....................................................................................

Rotor Speed at No Load

Number of Rotor Poles................................................................. 2

Engine RPM........................................................................

Rated AC Frequency ............................................................

Batteiy Charge Voltage

Battery Charge Current

Weight...........................................................................

Length.........................................................

Width...

Height..........................................................

*A11 units are reconnectable to 120-volt-only AC output.

....................................................

120 Volts.............................................................62.5 Amps

240 Volts

120 Volts.............................................................58.3 Amps

240 Volts

120 Volts

240 Volts

.......................................................

..............................

..........................

.............................................................

.............................................................

.............................................................50.0 Amps

.............................................................

...

............................................3,780 rpm

................................................

...........................................

7,500 Watts (7.5 kW)

6,000 Watts (6.0 kW)

120/240 Volts AC*

31.2 Amps

29.2 Amps

25.0 Amps

Single

1,950

60 Hz

14 Volts DC

2 Amps (max)

486 Pounds

36.6 inches (929 mm|

23.8 Inches (604 mm)

22.3 Inches (567 mm)

Page 9

Section 2 - Operation

QUIETPACT™ 75D Recreational Vehicle Generator

OPERATION

(Jti

2.1 GENERATOR CONTROL PANEL

The following features are mounted on the generator

control panel (Figure 2.1):

Figure 2.1 - Generator Control Panel

UNE

BREAKER

♦ 2.1.1 HOURMETER

This indicates the time the engine-generator has

operated, in hours and tenths of hours. Use

the hourmeter to ensure that the periodic mainte

nance tasks for your generator are completed on a

timely basis.

♦ 2.1.2 START/STOP SWITCH

To crank and start the engine, hold this switch in the

START position. Release the switch when the engine

starts. To stop an operating engine, press emd hold

the switch in the STOP position until the engine shuts

off. The switch center position is the RUN position.

♦ 2.1.3 FUSE

The 14 amp fuse protects the engine’s DC control cir

cuit against electrical overload. If the fuse element

has melted open due to overloading, the engine can

not be cranked. If you must replace the fuse, use only

an identical replacement (SFE-14).

--------

ik CAUTION ik

If a fuse element melts, you should find the

A

cause of the overload before replacing the fuse.

-------------------

FUSE

PREHEAT

♦ 2.1.4 LINE BREAKER

The line (main) breaker protects the generator’s AC

output circuit against overload and provides a

method of turning OFF the generator’s 120/240-volt

AC output to the vehicle circuits. The QUIETPACT™

75D has two 35-amp breakers.

NOTE:

Refer to Section 1.4, “Generator AC Connection

System,” (Page 5). Individual installations will

differ. If an overload occurs, the dual breakers

will open the ungrounded(hot) stator leads (11

and 44). When the generator has been connected

for 120 volts only, the line breakers will operate

independently on the ungrounded (hot) stator

leads (11 and 33).

♦ 2.1.5 PREHEAT SWITCH

The diesel engine is equipped with glow plugs, one

for each cylinder. When you press the preheat

switch, the glow plugs heat the engine combustion

chamber for quicker starts when the engine is

cold. Pressing the preheat switch also operates the

fuel pump.

_______________________

2.2 OPTIONAL REMOTE START/STOP

This generator is equipped with a plug-in connector

which can be interfaced with an optional remote

panel provided inside the vehicle. This option allows

you to start and stop the generator conveniently from

within the vehicle. Refer to Part II - Installation

Instructions, Section 2.8 for details on the remote

start/stop option.

23 BEFORE STARTING THE ENGINE

NOTE:

Instructions and information in this manual

assume the generator has been properly

installed, connected, serviced, tested and

adjusted by a qualified installation technician or

installation contractor.

♦ 2.3.1 INSTALLATION

Generator installation must have been properly

completed so it complies with all applicable codes,

standards and regulations and with the manufac

turer's recommendations.

___________________________

Generac* Power Systems, Inc.

Page 10

OPERATION

QCe

Section 2 - Operation

QUIETPACT™ 75D Recreational Vehicle Generator

♦ 2.3.2 ENGINE LUBRICATION

Have the engine crankcase properly serviced with the

recommended oil before starting. Refer to Section 1.5.3

(Page 6) and Sections 3.1 and 3.2 (Page 12) for oil ser

vicing procedures and recommendations.

----------

-Jà CAUTION Jk-----------------------

Any attempt to crank or start the engine before

▲

you have properly serviced it with the recom

mended oil may result in an engine failure.

♦ 2.3.3 FUEL SUPPLY

The engine must have an adequate supply of proper

fuel to operate. Before starting it, check tiiat sufficient

fuel is available.

____________________________

NOTE:

Depending on the installation, the generator may

have either a separate fuel tank, or it may “share”

the vehicle engine’s fuel tank.

Some installations using a “shared” iiiel tank may

have a generator fuel pickup tube that is shorter

than the vehicle engine’s pickup tube. Such an

arrangement causes the generator engine to “run

out of fuel” while adequate fuel for the vehicle

remains in the tank.

♦ 2.3.4 COOLANT LEVEL__________________________

Check the engine coolant level prior to initial use and

at recommended intervals. Refer to Section 1.5.4,

"Coolant” (Page 6), and the “Maintenance" portion of

this manual for procedures and recommendations.

♦ 2.3.5 COOLING AND VENTILATING AIR

Air inlet and outlet openings in the generator com

partment must be open and unobstructed for con

tinued proper operation. Without sufficient cooling

and ventilating airflow, the engine/generator may

overheat, which causes it to shut down and may

damage the generator.

♦ 2.3.6 ENGINE EXHAUST GAS

Before starting the generator engine, you should be

sure there is no way for exhaust gases to enter the

vehicle interior and endanger people or animals.

Close windows, doors and other openings in the

vehicle that, if open, might permit exhaust gases to

enter the vehicle.

DANGER

The generator engine gives off DEADLY carbon

monoxide gas through its exhaust system. This

dangerous gas, if breathed in sufficient concentra

tions. can cause unconsciousness or even death.

Never operate the generator set with the vehicle

inside any garage or other enclosed area. DO NOT

OPERATE THE GENERATOR IF THE EXHAUST SYS

TEM IS LEAKING OR HAS BEEN DAMAGED. SYMP

TOMS OF CARBON MONOXIDE POISONING ARE

(a) inability to think coherently; (b) vomiting; (c)

twitching muscles; (d) throbbing temples; (e) dizzi

ness; (f) headaches; (g) weakness; and (h) sleepi

ness. IF YOU FEEL ANY OF THESE SYMPTOMS,

MOVE INTO FRESH AIR IMMEDIATELY. IF SYMP

TOMS PERSIST, GET MEDICAL HELP.

2.4

STARTING THE GENERATOR

NOTE:

Read the vehicle manufacturer’s instructions. The

owner/operator should become familiar with the

vehicle in which this generator is installed.

Differences exist between vehicles. For example,

some vehicles may use a transfer switch to isolate

dockside power from the generator, while other

vehicles may use an isolating receptacle. Some

vehicles may be equipped with a DC converter,

which allows the generator to power certain DC

lighting and other DC loads.

To start the generator from either the generator con

trol panel or from the optional remote panel, proceed

as follows:

1. Turn OFF electrical loads using the means pro

vided in your vehicle (such as a main line circuit

breaker or transfer switch).

NOTE:

If starting from the generator control panel, turn

OFF loads by setting the generator’s main line

breaker to the OFF (or open) position. If starting

from a remote panel, turn OFF loads using the

means provided in the vehicle (such as a main cir

cuit breaker). Electrical load circuits will be

turned ON after the generator has started, stabi

lized and warmed up.

Generac* Power Systems, Inc.

Page 11

QUIETPACT™ 75D Recreational Vehicle Generator

2.

if the engine Is cold, press the Preheat switch for

15 to 30 seconds maximum.

3.

Hold the engine Start/Stop switch in the START

position while pressing the Preheat switch to

crank the engine. Release the switches when the

engine starts.

CAUTION

If the engine does not start after it has been

^ cranking for 15 seconds, release the Start/Stop

switch, wait 15 seconds, and try again. Holding

the switch for longer than 15 seconds can

damage the starter motor.

4.

Let the engine rim at no-load for a few minutes to

stabilize and warm up.

5.

Turn ON electrical loads using the means

provided in your vehicle (such as a main line cir

cuit breaker or transfer switch).

2.5 STOPPING THE GENERATOR

1. Turn OFF all electrical loads using the means

provided in your vehicle (such as a main line cir

cuit breaker or transfer switch).

2. Let generator run at no-load for a few minutes, to

stabilize Internal engine generator temperatures.

CAUTION

Do not stop the engine/generator immediately

^ after running under load. This can overheat

and damage the engine and/or generator.

3.

Press and hold the Start/Stop switch in the STOP

position imtll the engine shuts off.

2.6 APPLYING LOADS TO GENERATOR

When applying electrical loads to the generator,

observe these guideUnes:

• Before applying electrical loads, let the generator

stabilize and warm up for a minute or two.

• DO NOT overload the generator.

• 2.6.1 LEHING THE ENGINE STABILIZE

The generator supplies correct rated voltage only at

the proper governed speed. Some electrical appli

ances may be extremely sensitive to voltage. Incorrect

voltages can damage such appliances.

If electrical loads are applied at reduced operating

speeds, such loads Imposed on the engine when suffi

cient power is not available may shorten engine life.

Never turn ON electrical loads until after the generator

engine has started and stabilized at no-load.

Section 2 - Operation

OPERATION

0tt

• 2.6.2 DO NOT OVERLOAD THE GENERATOR

You can read the rated wattage/amperage capacity of

your generator on the generator data decal located

below the user control panel.

Appl}dng electrical loads in excess of the unit’s rated

capacity may trip the line breaker or cause the

engine/generator to shut down.

To avoid overloading, add up the wattage of all con

nected electrical lighting, appliance, tool and motor

loads. This total should not be greater than the gen

erator’s rated wattage capacity.

• Most lighting, appliance, tool and motor loads indi

cate their required watts on their nameplate or

data plate. For light bulbs, simply note the wattage

rating of the bulb.

• If a load does not show its rated wattage, multi

ply that load’s rated VOLTS times AMPS to

obtain WATTS.

• Induction type motors (such as those that run the

vehicle’s furnace fan, refrigerator, air conditioner,

etc.) need about 2-1/2 time more watts of power for

starting than for running (for a few seconds during

motor starting). Be sure to allow for this when con

necting electrical loads to the generator. First, fig

ure the watts needed to start electric motors in the

system. To that figure, add the running wattages of

other items that will be operated by the generator.

• Do not apply electrical loads over 75 percent of

the unit’s rating for the first two or three hours

of operation.

2.7 PROTEOION SYSTEMS

The engine has several safety switches that cause

it to automatically shut down under the following con

ditions: low oil pressure, high coolant temperature, and

engine overspeed. See Figure 2.2 (Page 10) for the loca

tion of these devices. If automatic shut down does

occur, refer to ‘Troubleshooting Guide” on page 39.

• 2.7.1 LOW OIL PRESSURE SWITCH

This switch is normally closed (N.C.) but is held open

by engine oil pressure during engine running. Should

operating oil pressure drop below approximately 10

psi, the switch contacts close, and the engine shuts

down automatically.

• 2.7.2 HIGH COOLANT TEMPERATURE SWITCH

This normally open (N.O.) thermostatic switch has a

sensing tip that is Immersed in captive coolant. Should

the coolant temperature exceed approximately 110° C

(230° F), the switch contacts close, which causes the

engine to shut down automatically.

______________

1C* Power Systems, Inc.

Page 12

OPERATION

(jet

Section 2 - Operation

QUIETPACT™ 75D Recreational Vehicle Generator

Figure 2.2 - Engine Protective Devices

♦ 2.7.3 OVERSPEED SHUTDOWN

The DC control circuit board (inside control panel)

senses engine speed from the frequency of the alter

nator AC output. Should the alternator output fre

quency exceed approximately 72 Hertz (4,320 alter

nator rpm), circuit board action initiates an automat

ic engine shutdown.

♦ 2.7.4 OVERVOLTAGE PROTEQION

A solid-state voltage regulator (Figure 2.3) controls

the generator’s AC output voltage. This regulator sup

plies an excitation current to the rotor. By regulating

the rotor’s excitation current, the strength of its mag

netic field is regulated and, in turn, the voltage deliv

ered to connected electrical loads is controlled. When

the AC frequency is 60 Hertz, voltage is regulated at

120 volts (voltage-to-frequency ratio is 2-to-l).

_________________

Figure 2.3 - Soiid-state Voitage Regulator

__

_ (nuaanwGiinni

Cr3=-«(+)-l_™i

BKnmiiitMMK

(NlBUnKClBmi)

The voltage regulator also incorporates a “voltage

surge protection circuit.” This circuit prevents trou

blesome surges in the generator AC output voltage.

Voltage surge is a common cause of damage to elec

tronic equipment.

2.8 ADDITIONAL INFORMATION

• 2.8.1 25-HOUR BREAK-IN PERIOD

The first 25 hours of operation is the break-in period

for the generator. Properly breaking in the generator

is essential to minimize oil consumption and maxi

mize engine performance. During this 25-hour break-

in period, observe the following rules:

• Run the unit at varying electrical loads to help seat

the engine piston rings properly.

• After operating the unit for 25 hours, complete

the tasks recommended under Section 2.8.2

(Page 11).

• For the next 75 hours of operation following the

break-in period, avoid light electrical loads. Load

the generator at 50 percent (or more) of its rated

wattage capacity. Repeated light loads during

these 75 hours can cause improper seating of

engine piston rings, resulting in blowby and high

oil consumption.

• Check the engine oil level frequently. Add oil if

needed. It is normal for the generator engine to

consume more oil than is normal until the piston

rings have properly seated.

_______________

i O Generac* Power Systems, Inc.

Page 13

Section 2 - Operation

QUIETPACT" 75D Recreational Vehicle Generator

OPERATION

♦ 2.8.2 25-HOUR CHECK-UP

After the 25-hour break-ln period, contact a Generac

Authorized Service Dealer for the following mainte

nance. The vehicle owner is responsible for all

charges:

• Change the engine crankcase oil and oil filter.

• Check all fluid levels (engine coolant, fuel,

battery electrolyte fluid).

• Visually inspect the unit for any leaks or loose

hardware.

• Inspect the exhaust tailpipe for any leaks or

damage.

♦ 2.8.3 ATTENTION REQUIRED

AFTER SUBMERSION

If the recreational vehicle generator has been sub

merged in water, it MUST NOT be started and oper

ated. Following any submersion in water, have a

Generac Authorized Service Dealer thoroughly clean

and dry the generator.

♦ 2.8.4 OPERATION IN HIGH GRASS

________

OR BRUSH

_____________________________

Never operate the generator while the vehicle is

parked over high grass, weeds, brush, leaves or any

other combustible substance. Such materials can

ignite and burn from the heat of the exhaust system.

The generator exhaust system becomes extremely hot

during operation and remains hot for a long time

after it has shut down.

♦ 2.8.5 EFFECTS OF MOISTURE AND DIRT

Keep the generator set as clean and dry as possible.

Protect the unit against excessive dust, dirt, corro

sive vapors, road splash, etc. Permitting dirt and

moisture to accumulate on generator windings will

have an adverse effect on the insulation resistance

of those windings.

When moisture is allowed to remain in contact with

windings, some of the moisture will be retained in

voids and cracks in the insulation. This causes a

reduced insulation resistance and will eventually

cause problems. Dirt will make the problem worse,

since dirt tends to hold moisture in contact with

windings. Salt (as from sea air) also will worsen the

problem since it tends to absorb moisture from the

air. Salt and moisture, when combined, form a good

electrical conductor.

Generac* Power Systems, Inc. 1 1

Page 14

MAINTENANCE

Section 3 - Maintenance

QUIETPACT™ 75D Recreational Vehicle Generator

3.1 CHECKING THE ENGINE OIL LEVEL

After the 25-hour break-in period, check the engine

crankcase oil level every eight hours of operation or

at least once daily before using the generator. For oil

capacities and requirements, see “Engine Oil

Requirements,” Section 1.5.3 (Page 6). To check the

engine oil level, proceed as follows (see Figure 3.1):

1.

Be sure the generator is as level as possible.

2.

Remove the dipstick and wipe it dry with a clean,

lint-free cloth.

3.

Install the dipstick and fully seat the T-handle;

then, remove it again. The oil level should be at

the dipstick “Full” mark.

If necessary, remove the oil fill plug and slowly

4.

add oil until it reaches the dipstick “Full” mark.

DO NOT FILL ABOVE THE “FULL’ MARK.

----------ik CAUTION Jk--------------------------

Never operate the engine with the oil level

i. below the "Add" mark on the dipstick. Doing

this could damage the engine.

5.

Install the oil fill plug and the dipstick before

operating the engine.

Figure 3.1 - Oil Maintenance Features

OiL FILL

OIL DIPSTICK

To change the oil and/or oil filter, proceed as

follows (see Figure 3.1):

1. Run the engine until it is thoroughly warmed up

(at least five minutes) then shut OFF

the engine.

2. Immediately after the engine shuts OFF, remove

the front service door located beneath the unit

by retracting the two latches and pivoting the

door downward.

3. Remove the air filter (see Section 3.3).

4. Remove the oil drain plug and drain the oil into a

suitable container. Removing the oil fill plug will

allow the crankcase to drain faster.

5. After the oil has drained, replace the oil drain plug.

GO TO STEP 8 IF CHANGING OIL ONLY.

6. With the oil drained, remove the old oil filter by

turning it counterclockwise.

7. Apply a light coating of clean engine oil to the gas

ket of the new filter.

8. Screw the new filter on by hand until its gasket

lightly contacts the oil filter adapter. Then, tight

en the filter an additional 3/4 to one turn.

9. Remove the dipstick and wipe it dry with a

clean, lint-free cloth. This will be used later to

check the oil level.

10. Remove the oil fill plug and slowly add the proper

type and amount of recommended oil (see Section

1.5.3, Page 6). Periodically use the dipstick to check

the oil level and continue to fill the crankcase until

the oil reaches the dipstick “Full” mark. DO NOT

FILL ABOVE THE “FULL MARK.

11. Install the oil fill plug and the dipstick before

operating the engine.

12. Reinstall the air filter.

13. Reattach the front service door; make sure the

latches are fully engaged.

14. Start the engine and check for leaks.

NOTE:

Check the oil level and fill to the “FULL" mark

after checking for leaks. The filter will retain

some oil.

3.2 CHANGING THE ENGINE OIL

AND/OR OIL FILTER

Change the engine oil and oil filter after the first 25

hours of operation (after the 25-hour break-in peri

od, see Section 2.8.1, Page 10). See the “Service

Schedule,” Section 3.13 (Page 16), for subsequent oil

and filter changes. Change the oil more frequently if

operating consistently under heavy load or at high

ambient temperatures.

1 a Generac* Power Systems, Inc.

3.3 SERVICING THE ENGINE

AIR FILTER

To access the engine air filter (Figure 3.2, Page 13),

remove the front service door located beneath the

unit by retracting the two latches and pivoting the

door downward. Loosen the hose clamp at the base

of the air filter and remove the filter. Place the hose

clamp on the new filter and install it, making sure

it is positioned properly before reattaching the ser

vice door. Make sure the service door latches are

fully engaged.

Page 15

Section 3 - Maintenance

QUIETPACT" 75D Recreational Vehicle Generator

MAINTENANCE

Figure 3.2 - Engine Air Filter

See the “Service Schedule,” Section 3.13 (Page 16), for

recommended air cleaner maintenance.

3.4 SPARK ARRESTOR MUFFLER

The exhaust muffler supplied with the QUIETPACT™

75D is a spark arrestor type. Generac exhaust muf

flers for recreational vehicle generators do not have a

spark arrestor screen, but are of the more efficient

“toroid” or “swirl” type. To remove carbon and com

bustion deposits from the muffler, proceed as follows

(see Figure 3.3):

1. Locate the unit above a non-combustable sur

face and ensure that the generator exhaust pip

ing is cool.

2. Remove the two screws holding the spark

arrestor access plate to the rear floor pan.

3. Remove the spark arrestor access plate and gasket.

4. Remove the hex pipe cap from the end of the

spark arrestor cleanout pipe.

5. Thread on a 3/8” NPT pipe coupling and pipe

nipple to extend the cleanout pipe at least 10

inches (250 mm) below the rear floor pan; addi

tional piping may be added to direct the muffler

exhaust away from the cooling air discharge flow

beneath the unit.

6. Start and run the engine for approximately 15

minutes.

7. Shut down the engine and allow the piping to

cool.

8. Remove the 3/8” NPT coupling and piping.

9. Apply a graphite-base anti-seize compound to the

cleanout pipe threads.

10. Reinstall the hex pipe cap, spark arrestor access

plate, gasket and two screws.

-A WARNING A~

The exhaust system of this product gets extreme

A

ly hot and remains hot after shutdown. High

grass, weeds, brush, leaves, etc. must remain

clear of the exhaust. Such materials may ignite

and burn from the heat of the exhaust system.

-------

-ik WARNING ik

Be sure to reinstall the the hex pipe cap tightly to

A

the spark arrestor cleanout pipe. Vibration could

cause a loose cap to fall out, resulting in hot

engine exhaust being drawn through the centrifu

gal cooling fan and out beneath the unit. This

could result in damage to the generator or dis

charge of hot exhaust sparks beneath the unit.

----------------

Figure 3.3 - Spark Arrestor

Muffler Maintenance

3.5 CLEANING THE GENERATOR

Keep your generator as clean and as dry as possi

ble. Dirt and moisture that accumulate on internal

generator windings have an adverse effect on insu

lation resistance.

Periodically, clean the generator’s exterior surfaces.

A soft brush may be used to loosen caked-on dirt.

You can use a vacuum system or dry, low pressure

air to remove any accumulations of dirt. The gener

ator is housed inside an all-weather enclosure;

clean the enclosure with a soft, damp cloth or

sponge and water.

Once each year, have the generator cleaned and

inspected by a Generac Authorized Service Dealer.

Service technicians will use dry, low pressure air to

clean internal windings. Parts inside the control

console should be cleaned and inspected at this

time as well.

Finally, have the insulation resistance of stator and

rotor windings checked. If insulation resistances are

excessively low, the generator may require drying.

----------

-ik CAUTION ik--------------------------

Do NOT use a forceful spray of water to clean

the generator. Water will enter the generator

interior and cause problems, and may also

contaminate the generator fuel system.

Generac® Power Systems, Inc. 1 3

Page 16

iX)=

MAINTENANCE

Section 3 - Maintenance

QUIETPACT™ 75D Recreational Vehicle Generator

3.6 BATTERY MAINTENANCE

All lead-acid batteries will discharge when not in use.

The generator battery should be inspected per the

“Service Schedule,” Section 3.13 (Page 16). The fol

lowing procedure should be used for inspection:

• Inspect the battery posts and cables for tightness

and corrosion. Tighten and clean as necessary.

• Check the battery fluid level of unsealed batteries

and, if necessary, fill with Distilled Water Only. Do

not use tap water in batteries.

• Have the state of charge and condition checked by

a Generac authorized Service Dealer.

NOTE:

Servicing of the battery is to be performed or

supervised by personnel knowledgeable of batter

ies and the required precautions. Keep unautho

rized personnel away from batteries.

Damage will result if the battery connections are

made in reverse.

DANGER

Do not dispose of the battery in a fire. The

battery is capable of exploding. Storage batter

ies give off explosive hydrogen gas. This gas

can form an explosive mixture around the bat

tery for several hours after charging. The

slightest spark can ignite the gas and cause an

explosion. Such an explosion can shatter the

battery and cause blindness or other injury.

Any area that houses a storage battery must be

properly ventilated. Do not allow smoking,

open flame, sparks, or any spark producing

tools or equipment near the battery. Discharge

static electricity from your body before touch

ing the battery by first touching a grounded

metal surface.

A battery presents a risk of electrical shock

A

and high short circuit current. The following

precautions are to be observed when working

on batteries:

• Remove watches, rings or other metal objects;

• Use tools with insulated handles;

• Wear rubber gloves and boots;

• Do not lay tools or metal parts on top of the

battery;

• Disconnect any charging source prior to connecting

or disconnecting battery terminals; and

• Do not use any jumper cables or booster battery to

crank and start the generator engine. If any battery

has discharged, remove it for recharging.

-A WARNING A-

Do not open or mutilate the battery. Released

electrolyte has been known to be harmful to

A

the skin and eyes, and to be toxic.

The electrolyte is a dilute sulfuric acid that is

A

harmful to the skin and eyes. It is electrically

conductive and corrosive. The following

procedures are to be observed:

• Wear full eye protection and protective clothing;

• Where electrolyte contacts the skin, wash it off

immediately with water;

• Where electrolyte contacts the eyes, flush

thoroughly and immediately with water and seek

medical attention.

• Spilled electrolyte is to be washed down with an

acid neutralizing agent. A common practice is to

use a solution of 1 pound (500 grams) bicarbonate

of soda to 1 gallon (4 liters) of water. The bicar

bonate of soda solution is to be added until the

evidence of reaction (foaming) has ceased. The

resulting liquid is to be flushed with water and the

area dried.

3.7 COOLING SYSTEM

Air intake and outlet openings in the generator com

partment must be open and unobstructed for contin

ued proper operation. This includes such obstructions

as high grass, weeds, brush, leaves and snow.

Without sufficient cooUng and ventilating air flow, the

engine/generator quickly overheats, which causes it to

shut down.

3.8 ENGINE COOLANT

Check the coolant level in the coolant recovery tank at

least once daily or prior to use. Add the recommended

coolant mixture (see Section 1.5.4, Page 6) as neces

sary; the bottle should be kept half full. If desired, you

may add a high quality rust inhibitor to the recom

mended 50-50 coolant mixture. If added consistently,

the recommended mixture will protect the unit against

freezing temperatures.

Periodically remove the radiator pressure cap to

make sure the coolant recovery system is functioning

properly. Coolant should be at the bottom of the radi

ator filler neck. If the coolant level is low. Inspect the

gasket in the radiator pressure cap. Replace the cap,

if necessary. To have the pressure cap tested, contact

a Generac Authorized Service Deader. Inspect the

cooling system and coolant recovery system for leaks.

II Generac* Power Systems, Inc.

Page 17

Section 3 - Maintenance

QUIETPAOT” 75 D Recreational Vehicle Generator

MAINTENANCE

DANGER

Do not remove the radiator pressure cap while

the engine is hot or serious burns from boiling

liquid or steam could result.

Ethylene glycol base antifreeze is poisonous.

Do not use your mouth to siphon coolant from

the radiator, recovery bottle or any container.

Wash your hands thoroughly after handling.

Never store used antifreeze in an open contain

er because animals are attracted to the smell

and taste of antifreeze even though it is poiso

nous to them.

----------Ék CAUTION ià

Do not use any chromate base rust inhibitor with

A

ethylene glycol base antifreeze, or chromium

hydroxide ("green slime") will form and cause

overheating. Engines that have been operated

with a chromate base rust inhibitor must be

chemically cleaned before adding ethylene glycol

base antifreeze. Using any high silicate antifreeze

boosters or additives also will cause overheating.

We also recommend that you DO NOT use any

soluble oil inhibitor for this equipment.

3.9 MAJOR SERVICE MANUAL

To obtain a service manual for your generator, con

tact Generac or your nearest Generac Authorized

Service Dealer. Make sure to identify your MODEL

NUMBER and SERIES.

3.10 DRIVE BELT

The engine drives the generator rotor by means of

a pulley and drive belt arrangement. Drive belt ten

sion was properly adjusted before the unit was

shipped from the factory. If you suspect that drive

belt tension is incorrect, contact a Generac

Authorized Service Dealer.

3.11 EXERCISING THE GENERATOR

Generac recommends that you start and operate the

generator at least once every seven days. Let

the unit run for at least 30 minutes to “exercise”

the engine. If you cannot exercise the generator every

seven days, and it is to be out of service longer than

30 days, see Section 3.12.

-------------------------

3.12 OUT OF SERVICE PROCEDURE

♦ 5.12.1 REMOVAL FROM SERVICE

_______________

Prepare the generator for storage as follows:

1. Start the engine and let it run until it is thor

oughly warmed up (at least five minutes), then

shut off the engine.

2. While the engine is still warm from running,

drain the oil completely. Refill the crankcase with

the recommended oil (see Section 1.5.3, Page 6).

3. Attach a tag to the engine indicating the viscosity

and classification of the oil in the crankcase.

4. Remove the battery and store it in a cool, dry

room on a wooden board. Never store the battery

on any concrete or earthen floor.

5. Clean and wipe the entire generator.

♦ 3.12.2 RETURN TO SERVICE____________________

To return the unit to service after storage, proceed

as follows;

Check the tag on the engine for oil viscosity and

1.

classification. Verify that the correct recommend

ed oil is used in the engine (see Section 1.5.3,

Page 6). If necessary, drain and refill with the

proper oil.

2.

Check the state of the battery. Fill all cells of

unsealed batteries to the proper level with distilled

water. DO NOT USE TAP WATER IN THE BAT

TERY Recharge the battery to 100 percent state of

charge, or, if defective, replace the battery.

Clean and wipe the entire generator.

3.

Reconnect the battery. Observe battery polarity.

4.

Damage may occur if the battery is connected

incorrectly.

Turn OFF all electrical loads. Add fuel if neces

sary and then start the engine.

Allow the unit to warm up thoroughly.

6.

7.

Apply electrical loads to at least 50 percent of the

unit’s rated wattage capacity.

When the engine is thoroughly warmed up, shut

it down.

9.

Your generator is now ready for service.

Generac* Power Systems, Inc. 1 5

Page 18

Section 3 - Maintenance

MAINTENANCE

QUIETPACT™ 75D Recreational Vehicle Generator

3.13 SERVICE SCHEDULE

ATTENTION: It is recommended that all service work

be performed by your nearest Generac Authorized Service Dealer.

SYSTEM/COMPONENT PROCEDURE

X = Action

R = Replace/Adjnst as Needed

* = To Be Completed by a

Generac Authorized

Service Dealer.

FUEL

Fuel level

Fuel lines and connections* X

Füel Filter*

LUBRICATION

Oil level

Oil

Oil filter

Oil line leakage*

COOLING

Engine cooling system*

Coolant level

Coolant*

Enclosure louvers

EXHAUST

Exhaust system X

Retorque Exhaust Manifold*

Clean out MuiUer/Spark Arrestor

BATTERY

Electrolyte fluid level

Charge and condition

FAN/ALTERNATOR BELTS

Tension and condition* I X R

ENGINE

Retorque cylinder head* X

Retorque intake manifold*

Starter motor* X EVERY 750 H

Air filter X R EVERY 500 H

Compression* X EVERY 750 H

Valve clearance*

Governor* X R EVERY 750 H

Safety devices* X R EVERY 750 H

Injection system*

GENERAL

Overall condition

Exercise system

COMPLETE TUNE-UP* X X X Y

Inspect

X

X

X

X

X

X

X

X

X R X

X EVERY 750 H

X R EVERY 750 H

X

X X AFTER 25-H BREAK-IN, W

Change

X

X

X

X

R EVERY 750 H

Clean

X 1

X

FREQUENCY

D = Dally W = Weekly

M = Monthly Y = Yearly

H = Hours

AFTER 25-H BREAK-IN,

D / BEFORE USE

AFTER 25-H BREAK-IN,

EVERY 250 H / 6 M

EVERY 250 H / 6 M

EVERY 8 H/D

AFTER 25-H BREAK-IN,

EVERY 250 H / 6 M

AFTER 25-H BREAK-IN,

EVERY 250 H / 6 M

EVERY 100 H

AFTER 25-H BREAK-IN,

EVERY 100 H/M

AFTER 25-H BREAK-IN,

D / BEFORE USE

EVERY 500 H / Y

EVERY 250 H/6 M

EVERY 100 H/M

EVERY 750 H

EVERY 5œH

AFTER 25-H BREAK-IN, W

W, EVERY 250 H / 6 M

EVERY 750H

EVERY 750 H

W

1 B Generac* Power Systems, Inc.

Page 19

PART II -

INSTALLATION

INSTRUaiONS

DANGER

ONLY QUALIFIED ELECTRICIANS OR CONTRACTORS

SHOULD ATTEMPT INSTALLATION!!

Page 20

SAFETY RULES

strictly with article 551, NFPA 70; ANSI Cl-1975; AND, ANSIAl 19.2-1975/NFPA 501C “Standcwd iV

for Recreational Vehicles" (Part 3, “Installation of Electrical Systems"). In addition, installation

A

must comply with the manufacturer’s instructions and recommendations.

Safety Rules

QUIETPACT™ 75D Recreational Vehicle Generator

DANGER: For fire safety, installation of a generator into a recreational vehicle must comply

NOTICE TO INSTALLER

These Installation Instructions have been published

by Generac to aid in the installation of the products

described in this manual. Generac assumes that

installation personnel are familiar with the procedures

for installing such products, or similar products that

Generac manufactures. Generac also assumes that

personnel have been trained in the recommended

installation procedures for these products and that

such training includes (a) use of common hand tools,

(b) use of special Generac tools, and (c) use of any

tools and/or equipment from other suppliers.

Generac cannot possibly know of and advise the

recreational vehicle trade of all conceivable methods,

procedures or techniques by which to perform an

installation. Nor can Generac anticipate every possi

ble hazard that might result from each installation

method, procedure or technique. Generac has not

undertaken any such wide evaluation. Therefore,

people who use a method, procedure or technique

that Generac does not specifically recommend must

first completely satisfy themselves that their safety,

the safety of the vehicle's occupants and the product's

safety is not endangered by the method, procedure or

technique selected.

Information, illustrations, specifications, etc., con

tained in these Installation Instructions are based on

the latest information available at the time of publi

cation. Every effort has been expended to be sure that

such data is both accurate and current. However, the

manufacturer reserves the right to change, alter or

otherwise improve this product at any time without

prior notice.

DANGER

Despite the safe design of this generator,

operating this equipment imprudently, neglecting

its maintenance or being careless can cause

possible injury or death. Permit only responsible

and capable persons to operate or maintain this

equipment.

Parts of the generator are rotating and/or hot

during operation. Exercise care near running

generators.

Potentially lethal voltages are generated by

A

these machines. Ensure all steps are taken to

render the machine safe before attempting to

work on the generator.

A GENERAL HAZARDS ^

• For safety reasons, Generac recommends

that the installation, initial start-up and mainte

nance of this equipment is carried out by a

Generac Authorized Service Dealer.

• The engine exhaust fumes contain carbon monox

ide, which can be DE/UDLY. This dangerous gas, if

breathed in sufficient concentrations, can cause

unconsciousness or even death. This exhaust sys

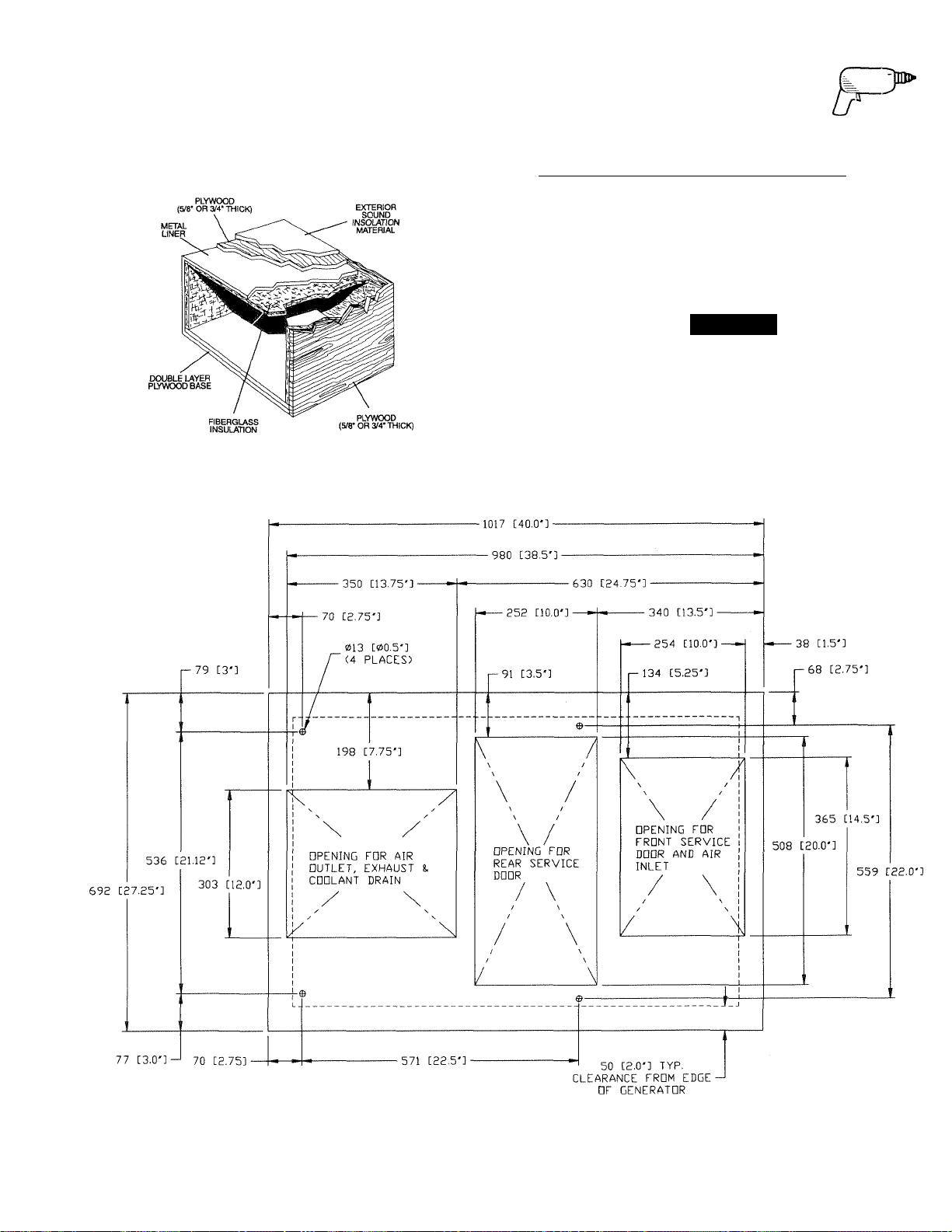

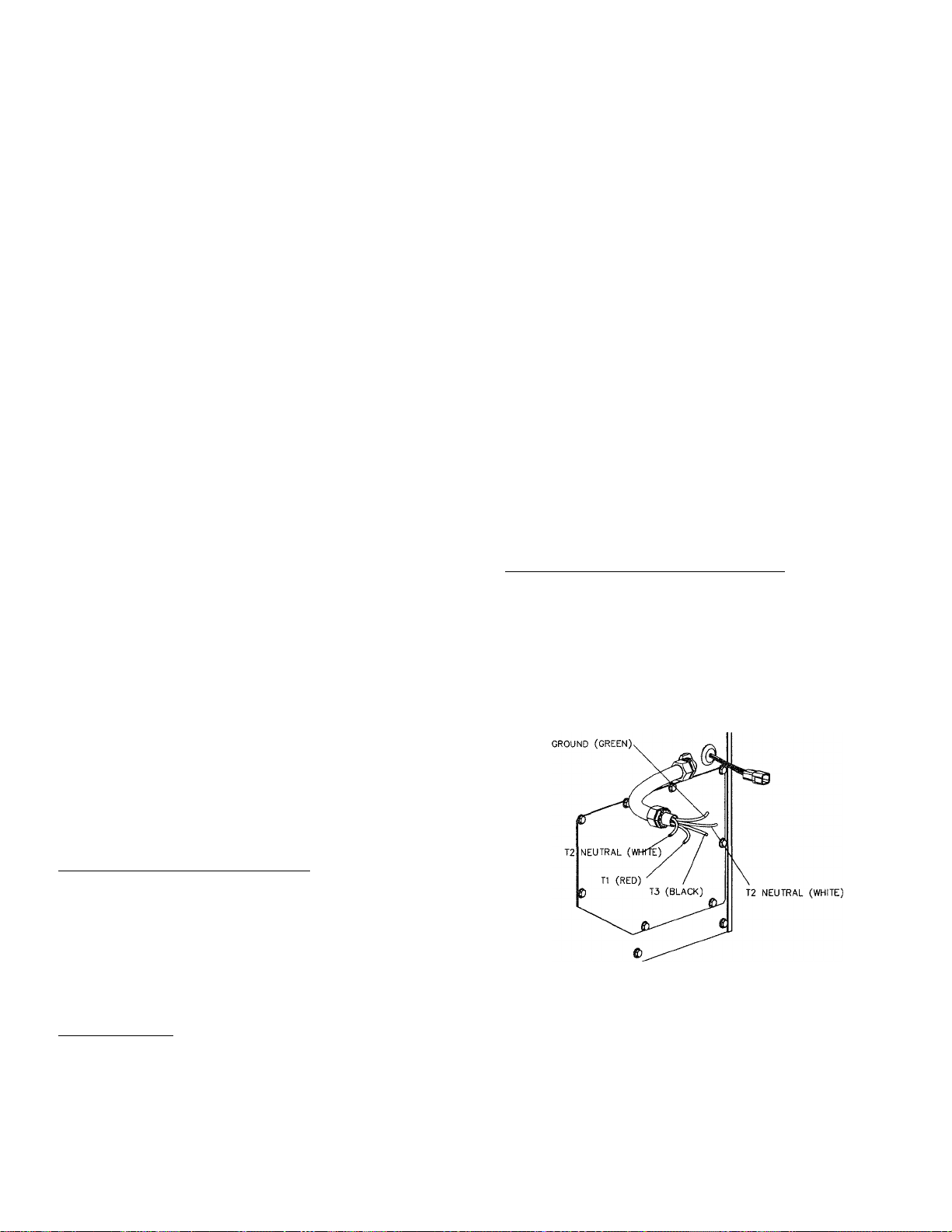

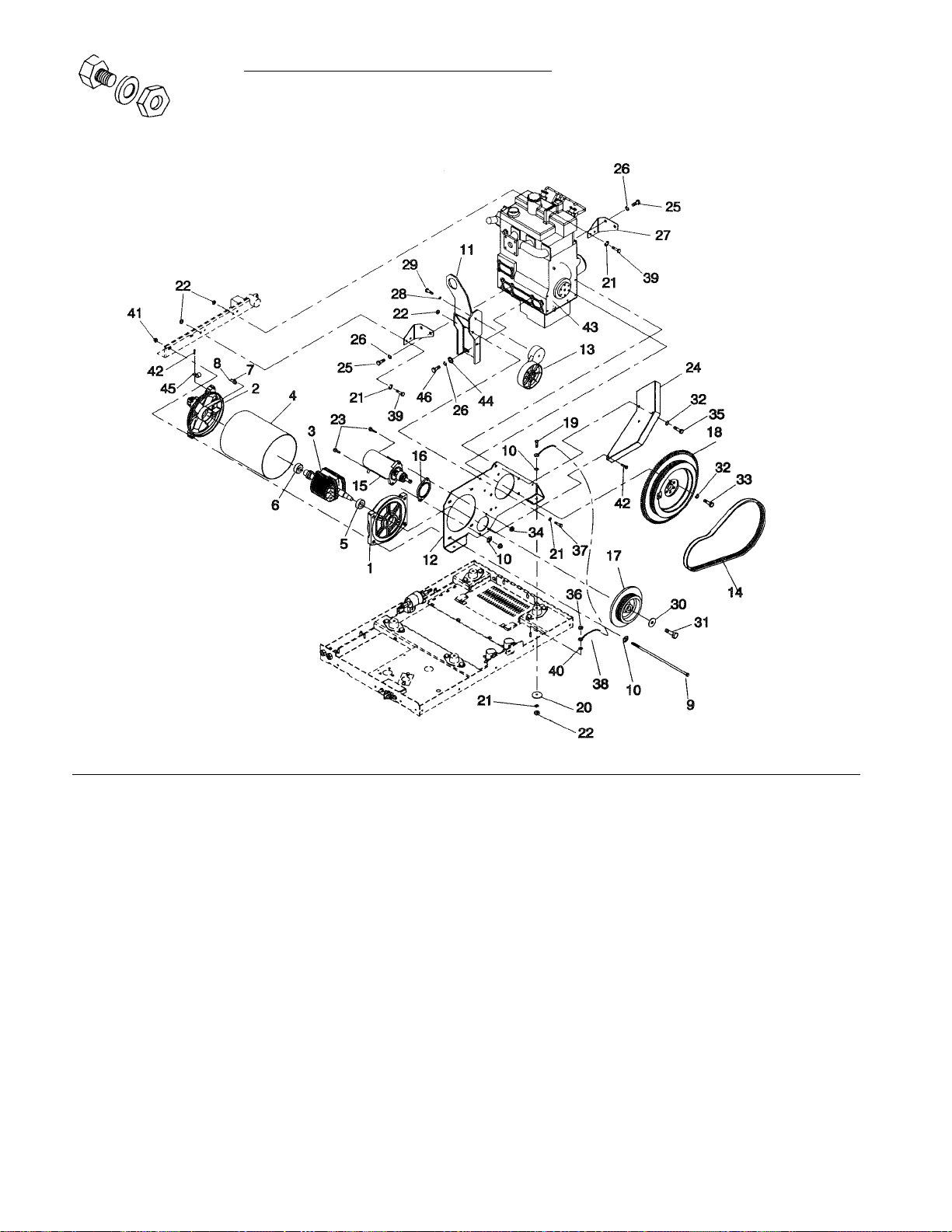

tem must be installed properly, in strict compli