Page 1

POWER SYSTEMS, INC

Owner’s Manual

SUARDIAry

by GENERAC- POWER SYSTEMS

Liquid-cooied, Prepackaged

Standby Generators

Models:

04136- 0 (8 kW/Singie-phase)

04137- 0 (8 kW/Three-phase)

Page 2

INTRODUCTION

Thank you for purchasing the Guardian product

line by Generac Power Systems. This model is a

compact, high performance, liquid-cooled, enginedriven generator designed to automatically supply

electrical power to operate critical loads during a

utility power failure.

This unit is factory installed in an all-weather, metal

enclosure that is intended exclusively for outdoor

installation.

» READ THIS MANUAL THOROUGHLY

______________

If you do not understand any portion of this manual,

contact Generac or your nearest Generac/Guardian

Authorized Dealer for starting, operating and servic

ing procedures.

Throughout this publication, and on tags and

decals affixed to the generator, DANGER, WARNING,

CAUTION and NOTE blocks are used to alert you to

special instruction about a particular operation that

may be hazardous if performed incorrectly or care

lessly. Observe them carefully. Their definitions are

as follorvs;

-AEŒ3 A-

After this heading, you can read instructions that,

if not strictly complied with, wiil result in personal

injury or property damage.

—A WARNING A—

After this heading, you can read instructions that,

if not strictly complied with, may result in persona!

injury or property damage.

------

M CAUTION M

After this heading, you can read instructions that,

if not strictly complied with, could result in damage

to equipment and/or property.

NOTE:

After this heading, you can read explanatory

statements that require special emphasis.

These safety warnings cannot eliminate the hazards

that they indicate. Common sense and strict com

pliance with the special instructions whUe perform

ing the seiwice are essential to preventing accidents.

Four commonlv used safety symbols accompany

tire DANGER. WARNING and CAUTION blocks. The

type of information each indicates is as follows:

This symbol points out important safety informa

A

tion that, if not followed, could endanger persona!

safety and/or property of you and others.

This symbol points out potential explosion hazard.

This symbol points out potential fire hazard.

A This symbol points out potential electrical shock

hazard.

Generac® Power Systems, Inc.

-----------

,

The operator is responsible for proper and safe use

of the equipment. We strongly recommend that the

operator read this Owner’s Manual and thoroughly

understand all instructions before using this equip

ment. We also strongly recommend instructing

other users to properly start and operate the unit.

This prepares them if they need to operate the

equipment in an emergency.

# CONTENTS

________________ ______________________

This manual contains pertinent owner’s informa

tion, including warranty, electrical diagrams,

exploded views and lists of repair parts, for the fol

lowing Guardian models;

04136-0 and 04137-0

4 OPERATION AND MAINTENANCE_____________

_

It is the operator's responsibility to perform all safety

checks, to malce sure that all maintenance for sale

operation is performed promptly and to have the

equipment checked periodically by a Generac/

Guardian Authorized Dealer. Normal maintenance

service and replacement of maintenance parts are the

responsibility of the owner/operator and, as such,

are not considered defects in materials or workman

ship within the terms of the warranty. Indirfdual

operating habits and usage contribute to the need for

maintenance service.

Proper maintenance and care of your generator ensure

a ininimumi number of problems and keep operating

expenses at a rnlniaium. See your Generac/Guardian

Autiiorized Dealer for service aids and accessories.

^ HOW TO OBTAIN SERVICE_______________________

V.'Tien your generator requires servicing or repairs,

simply contact a Generac/Guardian Authorized

Dealer for assistance. Sendee technicians are facto

ry-trained and are capable of handling all of your

sendee needs.

WTien contacting a Generac/Guardian Autlrorized

Dealer or tlie factoiy about parts and service,

always supply the complete model number and

serial number of your unit as grfen on its data

decal, which is located on your generator.

Model No. Serial No.

AUTHORIZED

DEALER LOCATION

To locate the GENERAC/GUARDIAN AUTHORIZED

DEALER nearest you, please call this number:

1-800-747-1530

DEALER LOCATION INFORMdTION

CNN BE OBTAINED AT THIS NUMBER.

Page 3

SAFETY RULES

SAVE THESE INSTRUCTIONS - The manufacturer suggests that these rules for safe

operation be copied and posted in potential hazard areas. Safety should be stressed to all

A

operators and potential operators of this equipment. Mm.

important Safety instructions

Guardian Llquid-cooied 8 kW Generators

WARNING:

The engine exhaust from this product

contains chemicals known to the state

of California to cause cancer, birth

Study these SAf'ETY RULES carefully before

installing, operating or servicing this equipment.

Become familiar with this Oiuner's Manual and with

the unit. The generator can operate safely, effi

ciently and reliably only If it is properly installed,

operated and maintained. Many accidents are

caused by failing to follow simple and fundamental

rules or precautions.

Generac cannot possibly anticipate every possi

ble circumstance that might involve a hazard. The

warnings in this manual, and on tags and decals

afffxed to the unit are, therefore, not all-inclusive. If

you use a procedure, work method or operating

technique Generac does not specificaJly recom

mend, you must satisfy yourself that it is safe for

you and others. You also must make sure the pro

cedure. work method or operating technique that

you choose does not render the generator unsafe.

-A0UE33 A-

Despite the safe design of this ' generator,

A

operating this equipment imprudently, neglecting

its maintenance or being careless can cause

possible injury or death. Permit only responsible

and capable persons to operate or maintain this

equipment.

Potentially lethal voltages are generated by

A

these machines. Ensure ai! steps are taken to

render the machine safe before attempting to

work on the generator.

Parts of the generator are rotating and/or hot

during operation. Exercise care near running

generators.

M GEIMERAL HAZARDS M

For safety reasons, Generac recommends

that the installation, inihal start-up and mainte

nance of this equipment is carried out by a

Generac/Guardian Authorized Dealer.

The engine exhaust fumes contain carbon

monoxicTe, which can be DEADLY. This danger

ous gas, If breathed in sufficient concenhations,

can cause unconsciousness or even death. This

exliaust system must be installed properly, in

strict compliance with applicable codes and stan

dards. Following installation, you must do noth

ing that might render the system unsafe or in

noncompliance with such codes and standards.

Keep hands, feet, clothing, etc., away from drive

belts, fans, and other moving or hot parts. Never

remove any drive belt or fan guard while the unit

is operating.

Adequate, unobstructed flow of cooling and venti

lating air is critical to comect generator operation.

Do not alter the installation or permit even partial

blockage of ventilation provisions, as tliis can

seriously affect safe operation of the generator.

When working on this equipment, remain alert at

all times. Never work on the equipment when you

are physically or mentally fatigued.

Inspect the generator regularly, and repair or

replace all damaged or defective parts irrumedi-

ately. Always use factory-authorized parts.

Turn off the AC power to the batterv' charger

before disconnecting the battery to minimize the

chance of equipment damage.

Before performing any maintenance on the gen

erator, disconnect Its battery cables to prevent

accidental start-up. Disconnect the cable from

tlie battery post indicated by a NEGATIYTD. NEG

or H first. Reconnect that cable last.

Never use the generator or any of its parts as a

step. Stepping on the unit can stress and break

parts, and may result in dangerous operating

conditions from leaking etdaaust gases, fuel leak

age, oil leakage, etc.

Generac® Power Systems, Jnc.

Page 4

Table of Contents

Guardian Liquíd-cooied 8 kW Generators

Introduction

Read This Manual Thoroughly

Contents

Operation and Maintenance

....

....................inside Front Cover

.........................

...........................................................

..............................

IFC

IFC

IFC

How, to Obtain Service ....................................IFC

Authorized Dealer Locator Number

Safety Rules

.....

.................................................

..................

.......2

IFC

Section Ì - General Information..................................

1.1 Unpacking/Inspection

1.1.1 Lifting the Generator

1.2

The Generator .................................................4

1.3

Generator AC Connection Systems

Automatic System Operation

1.4

Main Circuit Breaker

1.5

Engine Protective Devices

1.6

....................................

.........................

................

.........................

......................................

..................1...........

1.6.1 Low Oil Pressure Switch....................5

1.6.2

1.6.3

1.6.4

1.6.5

Specifications

1.7

High Coolant

Temperature Switch

..........................

Low Coolant Level Switch ................6

Overspeed Shutdovm

Or’ercrank Shutdown

........................

........................

..................................................

1.7.1 Generator............................................6

1.7.2 Engine ................................................6

Fuel Requirements

1

and Recommendations

.............'..................

1.9 Engine Oil Recommendations.........................7

1.10 The Barterv .....................................................7

2.4 Automatic Transfer Operation

2.5 Sequence of Automatic Operation

.......................

..................

Q

9

2.6 Engine Heater................................................10

2.7 Weeldy Exercise Cycle .................................10

2.8 Optional GTS Transfer Switch .....................10

2.8.1 Using an Optional GTS

Transfer Switch

Section 3 - Maintenance

4

4

4

4

5

5

5

3.1 25-Hour Break-in Period

3.2 25-Hour Checkup

3.3 Checldng the Engine Oil Level

3.4 Changing the Engine Oil and Filter ..............12

3.5 Changing the Engine Air Cleaner

3.6 Вatteiy Maintenance

3.7 Cooling System

............................................

3.8 Overload Protection for

Engine DC Electrical System

................................

..........

.................................12

..............................

..........................................

....................

.................

.....................................

.......................

11

12

12

12

13

13

14

14

3.9 Fuse................................^...............................14

5

6

6

6

3.10 Engine Coolant

3.11 Miscellaneous Maintenance

3.11.1 Cleaning the Generator

3.11.2 Rodent Protection

3.12 Out of Sendee Procedure

3.12.1 Removal From Service

3.12.2 Return to Service

3.13 Service Schedule

..............................................

.........................

....................

.............................

...............................

.....................

.............................

..........................................

14

15

15

15

15

15

15

16

7

Section 4 - Troubleshooting

...........................17

4.1 Troubleshooting Guide.................................17

Section 2 - Operation

2.1 Control Console Components

2.1.1 AC Voltmeter

2.1.2 AC Ammeter

2.1.3 AC Frequency Meter

....

.................................8

.........................

.....................................

.......................................

..........................

2.1.4 DC Voltmeter .....................................8

2.1.5 Hourmeter

2.1.6 Auto/Off/Manual Switch

2.1.7 Fault Indicator Lamp

.........................................

...................

.........................

2.1.8 30-amp Fuse.......................................8

2.1.9 Voltage-phase Selector Switch

2.1.10 Set Exercise Time Switch

2.1.11 Main Circuit Breaker .........................8

2.2 Preparation Before Start-up

............................

2.3 Using the Auto/Off/Manual Switch

2.3.1 “Auto" Position

2.3.2 “Off Position

2.3.3 “Manual" Position

.................................

......................................

..............................

.............

.................

................

Section 5- Electrical Data................................18

S

8

8

Section 6 - Exploded Views and

Parts Lists.....................................................22

S

Section 7 - Installation Drawings

..................

34

S

8

Section 8 - Warranty

......................................

36

8

8

8

8

8

8

9

9

еЗепегас® Power Systems, ¡nc.

Page 5

/k

ELECTRICAL HAZARDS

Important Safety Instructions

Guardian Liquid-cooled 8 kW Generators

FIRE HAZARDS

SAFETY RULES

All generators covered by this manual produce

dangerous electrical voltages and can cause fatal

electrical shock. Utility power delivers extremely

high and dangerous voltages to the transfer

switch as does the standby generator when it is

in operation. Avoid contact with bare wires, ter

minals, connections, etc., while the unit is run

ning, Ensure all appropriate covers, guards and

barriers are in place before operating the genera

tor. If you must work around an operating unit,

stand on an insulated, diy surface to reduce

shock hazard.

Do not handle any kind of electrical device while

standing in water, while barefoot, or while hands

or feet'^are wet. DANGEROUS ELECTRICAX

SHOCK my RESULT.

The National Electrical Code (NEC) requires the

frame and emernal electrically conductive parts

of the generator to be connected to an approved

earth ground. Local electrical codes also may

require proper grounding of the generator electri

cal system.

ATter installing this standby electrical system, the

generator may crank and start at any time vdthout warning. Wlien this occurs, load circuits are

transferred to the STANDBY (generator] power

source. To prevent possible injury if such a start

and transfer occur, always set the generator’s

Auto/Off/Manual switch to its OFF position

before working on equipment.

In case of accident caused by electric shock,

immediately shut down the source of electrical

power. If this is not possible, attempt to free the

victim from the live conductor. AVOID DIRECT

CONTACT WITH THE VICTIM. Use a noncon

ducting implement, such as a rope or board, to

free the victim from the live conductor. If the vic

tim is unconscious, apply first aid and get imme

diate medical help.

Never wear jewelry when working on this equip

ment. Jewelry can conduct electricity resulting in

electric shock, or may get caught in moving com

ponents causing injun/.

For fire safety, the generator must be installed

and maintained properly. Installation altvays

must comply with applicable codes, standards,

laws and regulations. Adhere strictly to local,

state and national electrical and building codes.

Comply with regulations the Occupational Safety

and Health Administration (OSHA) has estab

lished. Also, ensure that the generator is

installed in accordance with the manufacturer's

instructions and recommendations. Following

proper installation, do nothing that might alter a

safe installation and render the unit in noncom

pliance mth the aforementioned codes, stan

dards, laws and regulations.

Keep a fire extinguisher near the generator at ail

times. Extinguishers rated JABC" by the National

Fire Protection Association are appropriate for

use on the standby electric system. Keep the

extinguisher properly charged and be familiar

with its use. If you have any question pertaining

to fire extinguishers, consult your local fire

department.

A

EXPLOSION HAZARDS

A

Do not smoke around the generator. Wipe up any

fuel or oil spills immediately. Ensure that no

combustible materials are left in the generator

compartment, or on or near the generator, as

FIRE' or EXPLOSION may result. Keep the area

surrounding tlie generator clean and free from

debris.

Although using diesel fuel is safer than using gaso

line or gaseous fluids, which are are extremely

EXPLOSIVE, diesel stiU. presents the danger of

possible FIRE. Install the fuel supply system

according to applicable fuel-gas codes. Before plac

ing the standby electric system into sertlce, fuel

system lines must be properly purged and lecJt

tested according to applicable code. After installa

tion, you must inspect the fuel system periodically

for leaks. No lealtage is permitted.

Generac® Power Systiems, inc.

Page 6

GENERAL

INFORMATION

Section 1 — General Information

Guardian Liquid-cooied 8 kW Generators

1,1 UNPACKlNG/iNSPECTiON

After unpacldng, carefully inspect the contents

for damage.

« This standby generator set has been factory

installed in an all-weather, metal enclosure that

is intended exclusively for outdoor installation.

-A WARNING A-

lf this generator is used to power electrical load

A

circuits normally powered by a utility power

source, you are required by code to install a

transfer switch. The transfer switch must effec

tively isolate the electrical system from the util

ity distribution system when the generator is

operating (NEC 701). Failure to isolate an elec

trical system by such means will result in dam

age to the generator and also may result in

injury or death to utility power workers due to

backfeed of electrical energy.

If. any loss or damage is noted at time of delivery,

have the person(s) making the delivery note all

damage on the freight bill or affix his or her signa

ture under the consignor's memo of loss or damage.

If you note loss or damage after delivery, separate

the damaged materials and contact the carrier for

claim procedures.

“Concealed damage” is understood to mean damage

to the contents of a package that is not in evidence

at the time of delivery, but is discovered later.

# 1.1.1 LIFTING THE GENERATOR

-A WARNING A-

When lifting or hoisting equipment is used, be

A

careful not to touch overhead power lines.

The generator's weight of more than 1,500

A

pounds requires proper tools and equipment,

and qualified personnel to be used in all phases

of handling and unpacking.

1.2 THE GENERATOR ..

This liquid-cooled, Guardian generator set is

designed to supply electrical power to operate criti

cal electrical loads during utility power failure. The

unit has a four-pole revolving field (rotor) and uti

lizes long-life brushes and slip rings to deliver exci

tation current to the rotor windings. The rotor is

directly connected to the engine shaft by a highstrength flexible disc. The engine governor holds

the diesel engine and rotor speeds at a constant

factory setting of approximately 1,860 rpm.

Use this generator as a source of electrical power

for tlie operation of 120- and/or 240-volt, singleor three-phase loads; or 120- and/or 208-volt,

three-phase loads.

These models are available, rated as follows;

04136- 0: Provides 8,000 watts (8 kW) of single

phase power.

04137- 0: Provides 8,000 rvatts (8 kVV) of three-

phase power.

1.3 GENER.ATORAC

CONNECTION SYSTEMS

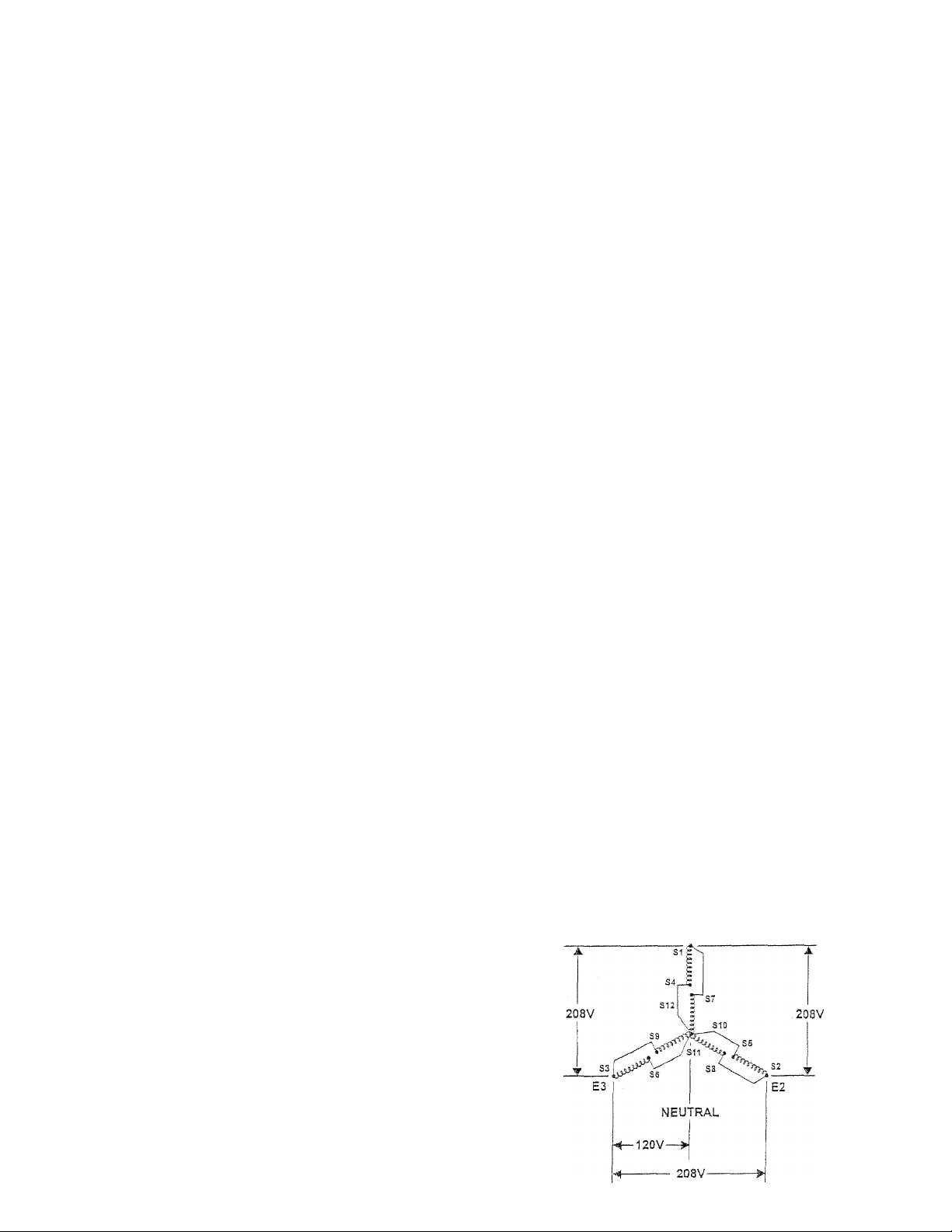

Ttie three-phase generators are shipped from tlie fac

tory with their stator AC output leads connected in a

12-lead low we configuration (Figure 1.1). This tyq)e

of connection system wül supply a 120- and/or 208volt, three-phase output as showm in tire illustration.

If, however, load voltage requires a 120/240-voIt,

single- or three-phase output, the stator's output

leads will need to be reconnected (Figure 1.2). This

task should be performed only by a qualified

Generac/Guardian Authorized Technician. Refer to

the

Guardian Installamn, Start-up and Adjustment

Manual (Part No, 79699) for details.

Figure 1.1 - 12-!ead Low Wye

Generator AC Connection System

E1

Page 7

Section 1 — Generai Information

Guardian Liquid-cooied 8 kW Generators

GENERAL

INFORMATION

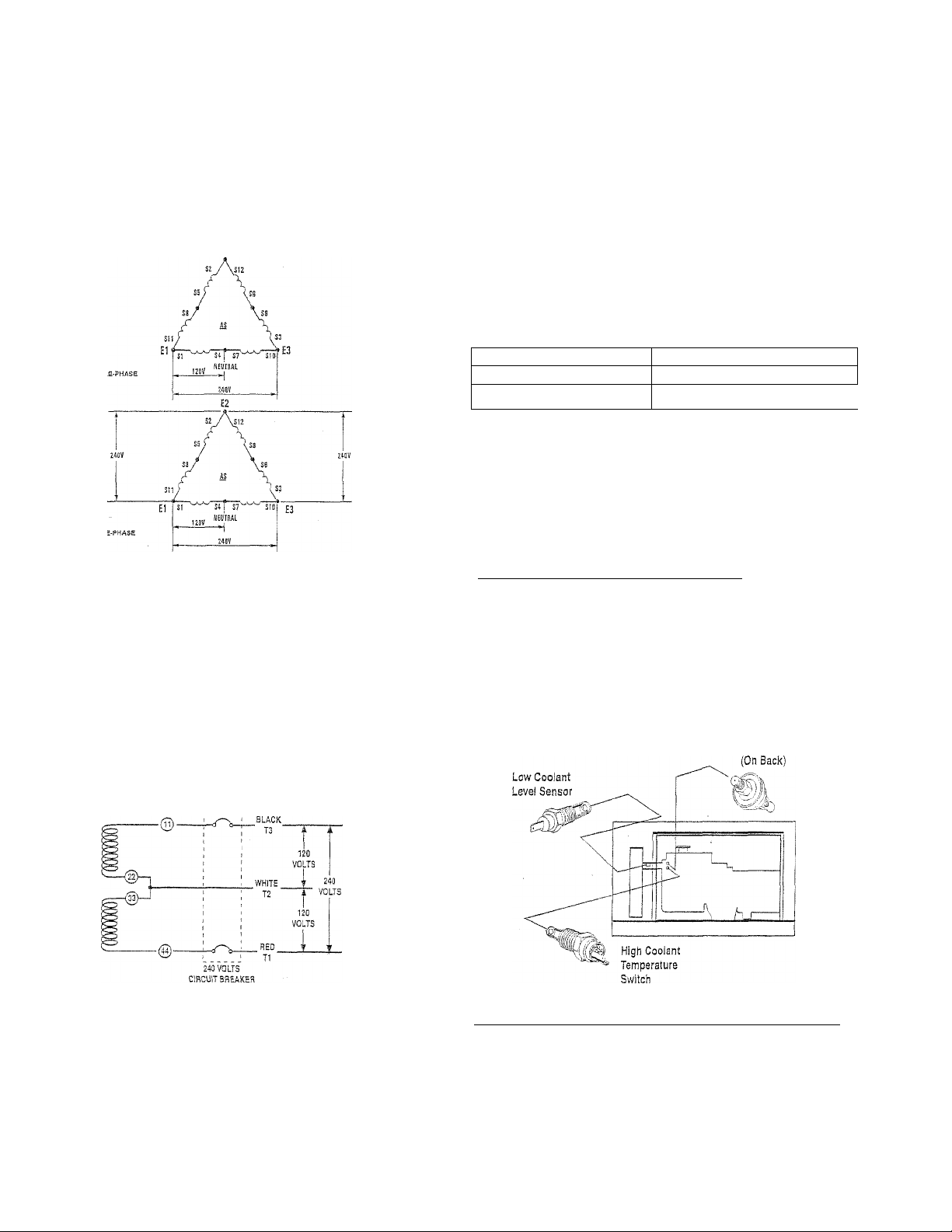

Figure 1.2 - Single- and Three-phase Delta

Generator AC Connection System

Figure 1.3 represents a single-phase, threenvlre

generator AC connection system. The stator assem

bly in this system consists of a pair of stationaiy

windings with Pan leads brought out of each wincl-

ing. Each single nhnding can supply a 120-volt, 60Hertz AC output. When the two windings are con

nected in series, a 240-volt, 60-Hertz AC output

results. Typically, the two "hot” leads in the circuit

are Wires 11 and 44. The neutral leads are the

junction of Wires 22 and 33.

Figure 1.3 - Single-phase

Generator AC Connection System

When utility source voltage has been restored, the

switch transfers back to the utility source voltage,

and the generator then shuts down,

1.5 MAIN CIRCUIT BREAKER

The generator’s main circuit breaker is included with

the unit as shipped from the factory. The breaker for

each unit is described as follows:

Mode! Number Circuit Breaker Ratinq

04135-0

04137-0 35A-3P-BQ3

35A-2P-BQ2

1.6 ENGINE PROTECTIVE DEVICES

The engine has several safely switches tliat cause

it to automatically shut down under the following con

ditions: low oil pressure, high coolant temperature,

low coolant level, and engine overspeed or overcrank.

See Figure 1.4 for the location of these devices.

4 1.6.1 LOW Oil PRESSURE SWITCH

This switch is normally closed {N.C.] but is held open

by engine oil pressure during engine running. Should

operating oU pressure drop below apprommately 15

psi, the switch contacts close, and die engine shuts

down automatically.

Figure 1.4 - Engine Protective Devices

________________

Low Oil

Pressure Switch

1.4 , AUTOMATIC SYSTEM OPERATION

Wnen this generator, along with its transfer switch,

has been Installed and interconnected, a circuit

board in the generator panel continuously monitors

utility power source voltage. Should that voltage

drop below a preset value, and remain at such a low

state for a preset amount of time, the generator

cranks and starts. After the generator starts, the

transfer switch transfers load circuits so the genera

tor can power them.

4 1.6.2 HIGH COOLANT TEMPERATURE SWITCH

This normally open (N.O.) thermostatic switch has

a sensing tip that is immersed in captive coolant.

Should the coolant temperature exceed approzdmately 124° C (256° F), the switch contacts close,

wTich causes the engine to shut clown automatically.

Generac® Power Systems, !nc.

Page 8

GENERAL

INFORMATION

Section 1 — General information

Guardian Liquid-cooied 8 kW Generators

» 1.6.3 LOW COOLANT LEVEL SWITCH

Should tlie .engine coolant level drop below tloe level

of’the high coolant temperature switch, it is possible

for the engine to overheat wltlaout automatic shut

down. To prevent such overheating without automat

ic shut down, the engine has a low coolant level sen

sor. If the engine coolant drops too low, the engine

_____________

_

# 1.6.4 0¥ERSPEE0 SHUTDOWN

______________

The DC control circuit board (inside control panel)

senses engine speed from the frequency of the

alternator AC output. Should the alternator output

frequency exceed approximately 72 Hertz (2,160

alternator rpm), circuit board action initiates an

automatic engine shutdown.

automatically shuts down.

# 1.6.5 OVERCRANK SHUTDOWN

After 90 seconds of crank-rest cycles (while in Auto

mode], this function ends cranking if the engine

fails to start in that 90-second span.

1.7 SPECIFICATIONS

♦ 1.7.] GENERATOR

SINGLE-PHASE

Model

Rated Maximum Continuous

AC Power Outnut (kW)*

Rated Voltage (volts)

Rated Ma:d.mum Continuous

Current at ...

»240 Volts, Single-phase (amps)

»240 Volts. Tlcxee-phase (amps)

•208 Volts, Three-phase (amps) NA

Power Factor

Rated AC Frequency

Number of Rotor Poles

Rotor Speed at No Load

Type of Stator

Rotor Excitation Svstem Direct Excited Brush-h/pe Svstem

Rotor and Stator Insulation

'“Rated p)wer of geneiator is subjeci to and limited by such iactom as ambient leinperature, altitude, engine condition and otiier factoi-s. Engine power will deci-ease about 3.5

percent for eacti 1,000 feet above sea le/el; and also will dettrease an additional 1 percent for each 12° C (10° F) above 15.5° C (60° Fj. Maximum output power of the generator is

hmited by maximum engine power.

04136-0

8

120/240

33.3

NA 24,1

1.0

60 Hertz at 1,800 rpm

4

1,860 rpm

'Four-wire

Class “F”

♦ 1.7.2 engine’

Make ............................................................................ISM Diesel

Cylinder Arrangement

Displacement.................................................58.2 inches (954 cc)

Bore ............................................................2.95 inches (75 mm)

Stroke..............................................................2.85 inches (72 mm)

Compression Ratio...............................................................23-to-l

Compression Pressure ar 200 rpm

Standard......................................................................426.7 psi

Minimum Limit..........................................................2S4.5 psi

Combustion Chamber Type ..................................Pre-Combustion

Firing Order

Direction of Rotation ...........................................Counterdodvvise

NumAer of Main Bearings

No. of Teeth on Flywheel..........................................................104

Ground Polariw ................................................................Negative

Oil Filter.......................................Full flow, woth byptass valve

Oil Pressure ....................................................................29-71 psi

Crankcase Oil Capacity

With Filter Change

Whthout Filter Change

Recoznmended .Engine Oil.................See Section 1,9 (Pcige 7)

Type of Cooling System ....Pressurized, closed recovery

...........................................................................

....................................................

...........................................................

...........................

......................

4.0 U.S. quarts (3.8 L)

3.7 U.S. quarts (3.5 L)

3, in-line

1-2-3

Type of Cooling Fan

Cooling System Capacity

Recommended Coolant ..................Use a 50-50 rnimire of low

Type of Fuel System

Recommended Fuel

Fuel Filter......................................................................10 micron

Fuel Injection Pump

Injection Spray Angle

Injection Pressure ...........................................................1,707 psi

4

Fuel Consumption - 60 Hz (gal/h)

25% Load 50%Load 75% Load 100% Load

0.35 0,52 0.63 0.S4

Actual fuel consumption obtained may vary

depending on such variables as applied load, ambi

ent temperature, engine conditions and other

environmental factors.

..........................................................

....................

.............................................................

.............................

...........................................

............................................

S Generac^ Power Svstems, !nc.

THREE-PHASE

04137-0

120/208

NA

27.8

0.8

12-'wire Reconnectable

2.5 U.S. gallons (9.5 L)

silicate, ethylene glycol base

anti.iTeeze and soft water. See

Section 3.10 (Page 14),

See Section 1.8 (Page 7)

NOTE:

__

________________

Pusher

Diesel

Bosch “M” Type

20°-21° BTDC

Page 9

Section 1 - General Information

Guardian Liquid-cooled 8 kW Generators

GENERAL

INFORMATION

.8 FUEL REQUIREMENTS

AND RECOMMENDATIONS

Г-se clean, fresh No. 2D diesel fuel with minimum

htane number of 40. It also must conform to

merican Society of Testing and Materials (ASTM)

pecifications. The iiiel should be stored in sealed

.3ntainers that have low point drains which permit

Viter to be drained from the fuel periodically. Never

se any dirty or contaminated fuel.

his unit has a 46-gallon fuel tank. When adding

lel, DO NOT overfill the tank. Allow room at the

)p of the tank for fuel expansion.

NOTE:

ppropriate care should be taken in applications

here extremely low ambient temperatures are

ossible to ensure the temperature of the diesel

lel is not allowed to fall below levels where

felling” could occur.

-A WARNING A-

y Although using diesel fuel is safer than using

A gasoline or gaseous fluids, which are are

extremely EXPLOSIVE, diesel stiil presents the

danger of possible FIRE. The fuel supply system

must be installed according to applicable

fuel-gas codes. After installation, you must

inspect the fuel system periodically for leaks.

No leakage is permitted.

9 ENGINE GIL RECOMMENDATIONS

;e a high-quality detergent oil with American

croleum Institute (API) classification “For Service

A’ Detergent oils keep the engine cleaner and

Jiice carbon deposits. Use oil having the follovdng

ciety of Automotive Engineers (SAE) viscosity' rati, based on the ambient temperature range anticLied before the next oil change:

Temperature

Above 70° F (21° C)

3° to 70° F (-7° to 21° C)

Below 20° F (-7° C)

------

M. CAUTION

Any attempt to crank or start the engine before

^ it has been properly serviced with the recom

mended oil may result in an engine failure.

Oil Grade (Recommended)

SAE 30W

SAE 20W

SÀE 10W or 10W-30

A-

1.10 THE BATTERY

Use a 12-volt, automotive-type storage battery

(Group 26F) rated 75 amp hours or more and capar

bie of a minimum of 530 cold-cranking amps at

'17,8° C (0° F). When using a maintenance-free bat

tery, it is not necessaiy to check the specific gravity

or electrolyte level. Have these procedures per

formed at the intervals specified in the service

schedule. A negative ground system is used. Battery

connections ai'e shown on the wiring diagrams.

Make sure the battery is correctly connected and

terminals are tight. Observe battery polarity when

connecting the battery to the generator set.

NOTE:

Damage will result if the battery connections are

made in reverse.

Your generator is equipped with a battery triclde

charger that is active when ypur unit is set up for

automatic operation. The trickle charge is designed

to help extend the life of your battery by maintain

ing the battery when the unit is not running.

-АСШШЭ A-

Storage batteries give off explosive hydrogen

gas. This gas can form an explosive mixture

around the battery for several hours after

charging. The slightest spark can ignite the gas

and cause an explosion. Such an explosion can

shatter the battery and cause blindness or other

injury. Any area that houses a storage battery

must be properly ventilated. Do not allow

smoking, open flame, sparks or any spark pro

ducing tools or equipment near the battery.

Battery electrolyte fluid is an extremely caustic

sulfuric acid solution that can cause severe

burns. Do not permit fluid to contact eyes, skin,

clothing, painted surfaces, etc. Wear protective

goggles, protective clothing and gloves when

handling a battery. If you spill the fluid, flush

the affected area immediately with clear water.

WARNING

Do not dispose of the battery in a fire. The

A

battery is capable of exploding.

Do not open or mutilate the battery. Released

A

electrolyte can be toxic and harmful to the skin

and eyes.

The battery represents a risk of high short circuit

current. When working on the battery, always

remove watches, rings or other metal objects,

and only use tools that have insulated handles.

A-

Generac® Power Systems, Inc.

Page 10

OPERATION

(jo

Section 2 - Operation

Guardian Liquid-cooled 8 kW Generators

2.1 CONTROL CONSOLE COMPONENTS

The components of a liquid-cooled generator con

trol console (Figure 2.1) are as follows:

Figure 2.1 - Control Console

♦ 2.1.1 AC VOLTIVI EIER

The voltmeter displays generator AC output voltage

during operation. Voltage is regulated by a solidstate voltage regulator and is proportional to AC

frequency. Refer to your unit's DATA PLATE for

rated AC voltage.

# 2.1.5 HGURMETER

This indicates the time the engine-generator has

operated, in hours and tenths of hours. Use the

hourmeter along with the periodic maintenance

schedule for your generator set.

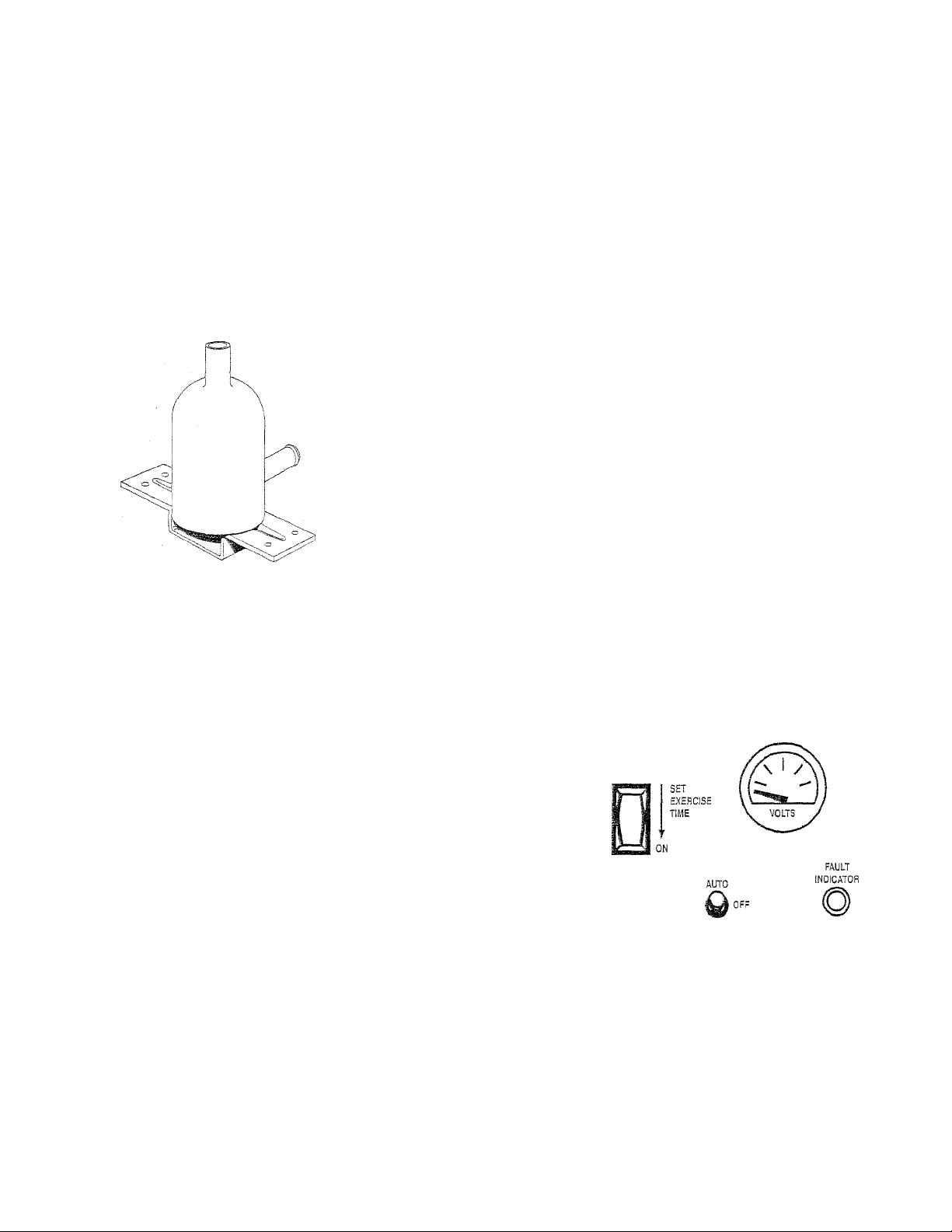

» 2.1.6 AUTO/OFF/MANUAL SWITCH

See Section 2.3.

» 2.1.7 FAULT INDICATOR LAMP

This lamp goes ON when one or more of the following

engine faults occurs and when engine shuts down.

<> Low oil pressure « High coolant temperature

® Low coolant level ® Overcrank

» Overspeed

♦ 2.1.8 30-AiVIP FUSE

This fuse protects the contrcd console’s DC control

circuit against electrical overload. If the fuse has

melted open because of an overload, engine crank

ing and start-up cannot occur. Should you need to

replace the fuse, use only an identical 30-amp

replacement fuse.

______________

___________________

4 2.1.2 AC AMMETER

This indicates current draw of connected electrical

loads during operation. DO NOT EXCEED YOUR

UNIT’S RxCTED MAXIMUM CONTINUOUS CUR

RENT. Refer to th,e unit DATA PLATE.

# 2.1.3 AC FREQUENCY METER

This indicates generator AC output frequency in

Hertz (cycles per second). Frequency is proportion

al to engine speed. Units vlth a four-pole rotor sup

ply 60 Hertz at 1,800 rpm. The frequency reading

with no electrical loads connected (no-load condi

tion) should be between 61-6.3 Hertz. With full

rated wattage/amperage load applied to the gener

ator, frequency should not droop below approxi

mately 58 Hertz.

♦ 2.1.4 DC VOLTMETER

The generator is equipped with a belt-driven DC

alternator, which maintains batten/ state of charge

when the engine operates. The control module

assembly also incorporates a triclde charge circuit

that maintains battery state of charge during non

operating periods. Battery voltage should read

approximately 12.5 to 14.5 volts DC. A low battery

voltage indicates the battery is discharging.

» 2.1.9 VOLTAGE-PHASE SELECTOR SWITCH

This switch permits you to select either line-to-llne

or line-to-neutral voltage and amperage readings

on the console AC voltmeter and ammeter.

♦ 2.1.10 SET EXERCISE TIME SWITCH

This switch allows you to program the generator to

start and exercise automatically.

4 2.1.11 MAIN CIRCUIT BREAKER

The generator’s main circuit breaker is included

with the unit as shipped from the factory. See

“Main Circuit Breaker." Section 1.5 (Page 5), for the

appropriate breaker.

______________

___________________

2.2 PREPARATION BEFORE START-UP

Before starting the generator, check that oil,

coolant and fuel levels are correct (see

“Specifications,” Section 1.7, Page 6).

2.3 USING THE AUTO/OFF/MANUAL

SWITCH

♦ 2.3.1 "AUTO" POSITION

vSelecting this switch position activates fully automat

ic system operation. It also allows the unit to start

and exercise the engine every seven days with the set

ting of tire exercise timer (see Section 2.7, Page 10).

Gensrac* Power Systems, ine.

Page 11

Section 2 ~ Operation

Guardian Liquid-cooled 8 kW Generators

OPERATiON

(pix

^ 2.3.2 "OFF" POSITION

This switch position shuts down the engine. This

position also prevents operation.

# 2.3.3 "MANUAL" POSITION

Set the switch to Manual to crank and start the

engine. Transfer to standby power will not automaticallv occur unless there is a utility failure.

-A WARMING A-

With the switch set to AUTO, the engine may

crank and start at any time without warning.

Such automatic starting normally occurs when

utility power source voltage drops below a pre

set level or during the normal exercise cycle. To

prevent possible Injury that might be caused by

such sudden starts, always set the switch to

OFF and remove the fuse before working on or

around the generator or transfer switch. Then,

place a "Do Not Operate" tag on the generator

panel and on the transfer switch.

2.4

AUTOMATIC TRANSFER

OPERATION

To select automatic operation, do the following:

1. Make sure the transfer switch main contacts

are set to their “Utility" position, i.e., loads con

nected to the utility power source.

2. Be sure tfiat normal utility power source voltage is

available to transfer switch terrninal lugs N1 and

N2. {See the electrical data in the applicable trans

fer switch manual.)

3. Set the generator’s Auto/Otl/Manuai switch to

AUTO.

4. Set the generator's main circuit breaker to Its

ON (or closed) position.

With the preceding steps complete, the generator

will start automatically when utility source voltage

drops below a preset level. After the unit starts,

loads are transferred to the standby power source.

Refer to “Sequence of Automatic Operation.”

Upon restoration of utility source voltage above a

preset level, generator circuit board action signals

the transfer switch to transfer loads back to that

power supply. After retransfer, the engine is sig

nalled to shut down.

The actual sequence of operation is controlled by

sensors and timers on a control logic circuit board",

as follows:

A. Utility Voltage Dropout Sensor

o This sensor monitors utility source voltage.

® If utility source voltage drops below about 60

percent of the nominal supply voltage, the sen

sor energizes a 15-second timer.

® Once the timer has expired, the engine v/ill

crank and start.

B. Engine Warm-up Time Delay

• This mechanism lets the engine warm up for

about 10 seconds before the load is transferred

to a standby source.

C. Standby Voltage Sensor

» This sensor monitors generator .EC output volt

age. 'Wlien the vtytage has reached 50 percent

of the nom.incJ rated voltage, transfer to stand

by can occur.

D. Utiliw Voltage Pickup Sensor

® This sensor monitors utillbv power supply volt

age, When that voltage is restored above SO per

cent of the nominal source volta.ge, a retrcmsfer,

time delay starts timing,

E. Retransfer Time Delay

= This timer runs for about 15 seconds.

® AT end of a 15-second delay, circuit board

acrioii de-energizes transfer relay in the trans

fer switch.

» Retransfer to utility power source tlien occurs.

F. Engine Cool-down Timer

• When the load is transferred back to utility"

power source, tihe engine cool-down timer

starts timing,

• The timer will run for about one minute, and

the generator will then shut down.

2.5 SEQUENCE OF

AUTOMATIC OPERATION

The generator’s control panel houses a control logic

circuit board. This board constantly monitors utllibv* power source voltage. Should tiiat voltage drop

below a preset level, circuit board action will signal

the engine to crank and stmt. .After the engine

starts, the circuit board signals the transfer switch

to activate and connect load circuits to the standby

power supply (load terminal lugs T1/T2 connect to

terminal lugs E1/E2). (See tlie electrical data in tire

applicable transfer switch manual.)

Generac® Power Systems, Inc.

Page 12

OPERATION

-On

Section 2 - Operation

Guardian Liquid-cooled 8 kW Generators

2.6 ENGINE HEATER

Your Generac standby generator comes equipped

with a block heater (Figure 2.2) that is similar to

the block hea.ters used in automotive applications.

Figure 2.2 - Engine Block Heater

Refer to applicable wring diagram(s) and electrical

schematic(s) at the back of this manual for wiring

connections.

2.7- WEEKLY EXERCISE CYCLE

The generator wll start and exercise once ever/

seven days. During this weekly exercise, the unit

runs for approximately 20 minutes and shuts

dotvn. Transfer of loads to generator oucput does

not occur during the exercise unless power is lost

during the exercise period.

To select the day of the tveek and time of day for

exercising, proceed as follov/s:

« Set the Auto/Off/Manual switch to OFF.

« Set generator's main circuit breaker to its OFF (or

open) position.

» Locate 'the rocker swatch on the control panel

identified wdtli the wnrds “Set Exercise Time”

(Figure 2.3).

» Push “Set Exercise Time” swdtch to the ON posi

tion for 20 to 30 seconds and dien release. The

swdtch will spring back into its original positLo.n

wdien released.

» Wait 30 seconds before setting the Auto/Off/

Manual swdtch to the AUTO position.

NOTE;

The unit -will exercise 20 minutes after it is set.

Example: Set - Noon; Exercise - 12:20 p.m.

-A CAUTION A-

If you switch the Auto/Off/Manual switch too

A

soon, the engine may start. If engine does

start, it will shut down automatically in about

two (2) minutes.

® Set the generator's main circuit breaker to its ON

(or closed) position.

• The generator is now programmed to start and

exercise eveiy seven days thereafter, on the day

and at the time of day the swdtch was activched.

0 Place a sign on tlie generator’s control panel and

on the transfer sv/itch that indicates the day and

time the generator tvill be exercising.

NOTE:

If the battery terminals are disconnected or the

control panel fuse is removed, the exercise

timer needs to be reset for automatic exercise

operation.

Figure 2.3 - "Set Exercise" Switch on Control Panel

MANUAL

2.8 OPTIONAL GTS TRANSFER SWITCH

This generator can be installed in conjunction wdth

a Generac GTS-type automatic transfer switch, if

desired.

The standard ATS-type transfer swdtch has no

sensing or controlling circuit boards. Instead, the

generator control console houses a control module

assembly (CfVLA), which controls all phases of oper

ation, including engine start-up and load transfer.

Page 13

Section 2 — Operation

Guardian Liquid-cooied 8 kW Generators

OPERATION

6

&

# 2.8.1 USING AN OPTIONAL GTS

_________

When you use a GTS-type transfer swatch, it con

trols automatic operation and automatic transfer

as follows:

• Solid-state circuits in the transfer switch monitor

utility power source voltage.

• When utilitjr source voltage drops below a preset

level, transfer swdtch action closes the engine cir

cuit. The engine then cranks and starts as con

trolled by the generator's control module circuit

board.

* After the engine starts and when the generator

A.C output voltage and frequency have reached a

preset value, transfer switch circuits signal the

transfer switch main contacts to move to the

standby power source side. Generator AC output

then pownrs load circuits.

TRANSFER SWITCH

_______________________

® When the utiliW power source voltage is restored

above a preset level and the return to utility

timer has timed out. the transfer switch solidstate circuits signal the switch main contacts to

move back to their utility power source side.

» The engine cooldown timer stains and times out.

Then, the transfer switch circuit board action

opens the engine run circuit. The engine then

shuts down.

NOTE:

If yonr generator is installed in conjunction

with an optional GTS-type transfer switch, refer

to the applicable transfer switch manual for

exact operating parameters and timing

sequences.

Page 14

MAINTENANCE

5izz=:0

Section 3 - Maintenance

Guardian Liquid-cooled 8 kW Generators

3.1 25-HOUR BREAK-IN PERIOD

The first 25 hours of operation constitute the breakn period for the standicy generator. Correctly breakng in the generator is essential to mitiiiriize oil connimption and macdmize engine performance. During

he break-in period, observe the ibllowing rules:

. Run the generator at va.rious elecuical loads for

the first 25 hours of operation, to help seat

engine piston rings properly.

For the next 75 operating hours, avoid light

electrical loads.

' During this period, load the unit at 50 percent or

more of its rated capacity (4,000 watts or more).

Repeated light electrical loads during the break-

in period can cause improper seating of engine

piston rings, resulting in blowb\^ and high oil

consumption.

. Check the engine crankcase oil level frequently

during the break-in period. It is normal for oil

consumption to be high during this period.

, xkfter the 25 hour break-in period is completed,

perform the tasks recommended under "25

Hour Checkup.”

.2 25-HOUR CHECKUP

tlloiving the first 25 hours of operation, contact an

tithorized sendee facility for tlie following mainte-

ince. The generator ovmer is responsible for all

targes.

Change the engine crankcase oil and filter.

Check all fluid levels (engine coolant, fuel, bat-

ter\" electrolyte fluid).

Inspect cooling system hoses for deterioration

and leaks, all hose clamps for tightness and

security.

Check fuel system lines for leaks, tightness and

condition.

Check fuel injection timing,

Check/Adjust engine governed speed (frequency).

Inspect engine belts for condition, proper tension.

Check for correct AC voltage output.

Check all generator receptacles and circuit

brealcers for condition and proper operation.

3 CHECKING THE ENGINE

OIL LEVEL

ter the 25-hour break-in period, check the engine oU

'el eveiy" eight hours or operation or at least once

ily before using the generator. For oil capacities, see

oecltications,” Section 1,7 (Page 6). For engine oil rec-

iinendations. see Section 1,9 (Page 7). To check the

gine oil level, proceed as follows (Figure 3.1):

Remove tlae dipstick and rvlpe it dry rvlth a

clean clotli.

S, Generac* Power Systems, !nc.

Install the dipstick cap; then, remove it again.

The oil level should be at the dipstick “Full”

mark. If necessary, add oil to the “Full” mark

only. DO NOT FILL ABOVE THE “FULL” MARK.

3.

Install the dipstick.

CAUTION M.

-A

Never operate the engine with the oil level

below the "Add" mark on the dipstick. Doing

this could damage the engine.

Figure 3.1 - Engine OH Servicing Points

Oil Filler

Cap

--------

3.4 CHANGING THE ENGINE

GIL AND FILTER

See Section 1.9, “Engine Oil Recommendsfoons” (Page

7), for die proper oil grade for your application.

NOTE;

The engine oil and filter should be changed after

the 25-hour break-in period. See the “Service

Schedule,” Section 3.13 (Page 16), for subse

quent oil and filter changes.

-A

.Any attempt to crank or start the engine before

A

it has been properly serviced with the recom

mended oil may result in an engine failure.

To change tiie oil and filter, proceed as follows:

Refer to tlie “Sendee Schedule,” Section 3.13 (Page

16), for engine oU and filter change frequencies.

Drain the oil while the eng,ine is still warm from run

ning. This means you should warm up the engine,

shut it down and drain It immediately as follows:

1. Remove tlie oil drain hose from its retaining clip,

located on the generator base frame.

2. Loosen and remove tlie oil drain hose cap, locat

ed on tlie base frame end of tlie hose. Drain tlie

oil completely into a suitable container.

CAUTiON

A-

Page 15

Section 3 — Maintenance

Guardian Liquid-cooled 8 kW Generators

MAINTENANCE

3. When aJl of the oil has drained, install and tight

en the oil drain hose cap.

4. Turn tile oil filter (Figure 3.1) countercloclcwise

and remove it. Dispose of the old filter.

5. Apply a light coating of engine oil to the seal of

new oil filter. Install tire filter and tighten by

hand only. DO NOT OVERTIGHTEN,

6. Remove the oil filler cap (Figure 3.1). Add the rec

ommended oil (see Section 1.9, Page 7). DO NOT

FILL ABOVE THE DIPSTICK ■‘FULL” MARK.

CAUTION A

-A

After refilling the crankcase with oii, always

check the oil level on the dipstick. Never

operate the engine with the oil level below the

"Add" mark on the dipstick. Doing this could

damage the engine.

--------

7. Start the engine and check for oil leaks.

8. Check the oil level after checking for leaks to

ensure that the oil is filled to the proper level.

3.5 CHANGING THE ENGINE

AIR CLEANER

To replace the engine air cleaner, (Generac part

number 70941), simply remove the air cleaner

cover and replace the air filter making sure it is

positioned properly before reattaching the cover.

Figure 3.2 - Engine Air Cleaner

AIR CLEANER

3.6 BATTERY MAINTENANCE

The battery should be inspected per the “Service

Schedule,” Section 3.13 (Page 16). The following

procedure should be followed for inspection:

1. Inspect the battery posts and cables for tight

ness and corrosion. Tighten and clean as

necessary.

2. Check the battery fluid level of unsealed batter

ies and, if necessar/, fill wth DISTILLED

WATER ONLY. DO NOT USE TAP WATER IN

BATTERIES.

3. Have the s tate of charge and condition checked.

This should be done mth an automotive-type

battery hydrometer or load test.

-АЕВШЗ A-

Storage batteries give off explosive hydrogen

gas. This gas can form an explosive mixture

around the battery for several hours after

charging. The slightest spark can ignite the gas

and cause an explosion. Such an explosion can

shatter the battery and cause blindness or

other injury. Any area that houses a storage

battery must be properly ventilated. Do not

allow smoking, open flame, sparks or any spark

producing tools or equipment near the battery.

Battery electrolyte fluid is an extremely caustic

A

sulfuric add solution that can cause severe

burns. Do not permit fluid to contact eyes, skin,

clothing, painted surfaces, etc. Wear protective

goggles, protective clothing and gloves when

handling a battery, if you spill the fluid, flush

the affected area immediately with clear water.

Do not use any jumper cables or booster bat

A

tery to crank and start the generator engine, if

the battery has completely discharged, remove

it from the generator for recharging.

(TPANSPAREMT ENCLOSURE FOR CLARITY)

See tile “Service Schedule," Section 3.13 (Page 16),

for recommended air cleaner maintenance.

-----

Ak WARNING

Be sure the utility power supply is turned off,

A

or sparking may occur at the battery posts as

you attach the cables and cause an explosion.

Be sure the Auto/Off/Manual switch is set to

the OFF position before connecting the battery

cables. If the switch is set to AUTO or MANUAL,

the generator can crank and start as soon as

the battery cables are connected.

Generac® Power Systems, inc. 13

---------

Page 16

MAINTENANCE

AIH OUTLET

Section 3 - Maintenance

Guardian Liquid-cooled 8 kW Generators

Figure 3.3 - Cooling Vent Locations

GJJTHnH

AIR INTAKE

CT

3.7 COOLING SYSTEM

Air Intalce and outlet openings in the generator com

partment must be open and unobstructed for contin

ued proper operation. This includes such obstruc

tions as high grass, weeds, brush, leaves and snow.

Witiiout sufficient cooling and ventilating air flow, the

engine/generator quiclfly overheats, which causes it

to shut down. (See Figure 3.3 for vent locations.)

-A WARNING A-

The exhaust system of this product gets extreme

ly hot and remains hot after shutdown. High

grass, weeds, brush, leaves, etc. must remain

clear of the exhaust. Such materials may ignite

and burn from the heat of the exhaust system.

3.8

OVERLOAD PROTECTION FOR

ENGINE DC ELECTRICAL SYSTEM

Engine cranlting, start-up and running are con

trolled by a solid-state engine controller circuit

board. Battery voltage is delivered to that circuit

board via a 30-arnp fuse. These overcuiTent protec

tion devices will open if the circuit is overloaded,

-A CAUTION A"

A !f a circuit breaker opens or a fuse element melts,

you should find the cause of the overioad before

resetting the circuit breaker or replacing the fuse.

3.9 FUSE

The generator panel's 30-amp fuse (Figure 2.1, Page

8) protects the DC control circuit against overload.

The fuse is wired in series with the battery output

lead to the panel. If the fuse element has melted

open, you cannot crank or start the engine. You

siiould replace the fuse using only an identical 30amp replacement.

3.10 ENGINE COOLANT

Check the coolant level in the coolant recovery bot

tle at least once daily or prior to use. Add the rec

ommended coolant rruxture (see Section 1.7.2, Page

6) as necessary; the bottle should he kept half full. If

desired, you may add a high quality rust inliibitor to

the recommended ,50-,50 coolant rruxture. If added

consistently, the recommended rnixture will protect

the unit against freezing temperatures.

Periodically remove the radiator pressure cap to

make sure the coolant recover}' system is function

ing properly. Coolant should be at the bottom of tire

radiator filler neck. If the coolant level is low,

inspect the gasket in the radiator pressure cap.

Replace the cap, if necessary'. To have the pressure

cap tested, contact a Generac/Guardian

Authorized Dealer, inspect the cooling system and

coolant recovery system for leaks.

-A A-

Do not remove the radiator pressure cap while

the engine is hot or serious burns from boiling

liquid or steam could result.

Ethylene glycol base antifreeze is poisonous.

A

Do not use your mouth to siphon coolant from

the radiator, recovery bottle or any container,

Wash your hands thoroughly after handling.

Never store used antifreeze in an open contain

er because animals are attracted to the smell

and taste of antifreeze even though it is poi

sonous to them.

-A CAUTION A-

Do not use any chromate base rust inhibitor with

ethylene glycol base antifreeze, or chromium

hydroxide ("green slime") will form and cause

overheating. Engines that have been operated

with a chromate base rust inhibitor must be

chemically cleaned before adding ethylene glycol

base antifreeze. Using any high silicate antifreeze

boosters or additives also will cause overheating.

We also recommend that you DO NOT use any

soluble oil inhibitor for this equipment.

Page 17

Section 3 — Maintenance

Guardian liquid-cooled 8 kW Generators

MAINTENANCE

3.11 MISCELLANEOUS MAINTENANCE

# 5.11.1 CLEANING THE GENERATOR

Keep your generator as clean and as diy^ as possi

ble. Dirt and moisture that accumulate on internal

generator windings have an adverse effect on insu

lation resistance.

Periodically, clean the generator’s exterior surfaces.

soft brush may be used to loosen caked on dirt.

You can use a vacuum system or clr/, low pressure

air to remove any accumulations of dirt. The gener

ator is housed inside an all-weather enclosure:

clean the enclosure with a soft, damp cloth or

sponge and water.

Once each year, have tlie generator cleaned and

inspected t3V a Generac/Guardian Authorized

Dealer. Sertdce technicians wall use diy, low pres

sure air to clean internal windings. Parts Inside the

control console should be cleaned and inspected at

this time as w^ell.

F'ina.lly, have the insulation resistance of stator and

rotor wdndings checked. If insulation resistances are

excessively low. the generator may require diydng.

^ 3.11.2 RODENT PROTECTION

____________________

The intrusion of rodents into the generator set can

cause a wide range of problems, from failure of the

unit to start, to personal injury and, in extreme circumsta.nces, short circuit or fire. .Although the unit

wms designed to limit this problem, you can take

further precautions to help minimize both the

chance of rodent entry and the extent of any dam

age, You should inspect the unit at regular inter

vals for signs of rodent intrusion. In addition,

ensure that all access doors are tightly closed and

secured at all times. If you detect intrusion and/or

damage, contact your nearest Generac Authorized

Service Dealer immediately.

_____________

3.12 GUT OF SERVICE PROCEDURE

♦ 5.12.1 REMOVAL FROM SERVICE

If you cannot exercise the generator even/ seven

days, and it is to be out of sertdce longer than 90

days, prepare the generator for storage as follows:

1. Start the engine and let it warm up.

2. Close the fuel shutoff valve in the fuel supply

line and allow the unit to shut dowm.

_______________

3. Once the unit has shut downs, it will signal a

fault on the control panel.

4. Set tlie Auto/Off/Manual switch to OFF and

turn off the utility powder to tlie transfer switch.

5. While ttie engine is still warm from n.m,ning, drain

the oil completely. Reiill the cranitcase witli the

recommended oil (see Section 1.9, Page 7).

6. Attach a tag to tlie engine indicating the viscos

ity and classification of the oil in the crankcase.

7. Remove the battery and store it in a cool, dry

room on a wooden boa.rd. Never store the batter>' on any concrete or earthen floor.

8. Clean and wipe the entire generator.

# 5.12.2 RETURN TO SERVICE______________________

To return the unit to sendee after storage, proceed

as follows:

1. Verify that utility' power is turned off to the

transfer switch and that the Auto/Off/Manual

switch is set to OFF.

2. Check the tag on the engine for oil viscosify and

classi,fication. Verify that the correct recom

mended oil is used in engine (see Section 1.9.

Page 7). If necessa.r>i clradn and refill with the

proper oil.

3. Check the barterv. Fill all ceils to the proper

level witli distilled water. DO NOT USE TAP

WATER IN THE BATTERY. Remove the batteiy

before charging. Recharge the batteiy' to 100

percent state of charge, or. if defective, replace

the batteiy' with a 12-volt DC Group 26F battery

rated for 75 amp hours (part # 77483).

4. Clean and wipe the entire generator.

5. Reconnect the battery. Obsen'e battery pokirity.

Damage will occur if tlie battery is connected

incorrectly.

6. Open the fuel shutoff valve.

7. Start the unit by moving the Auto/Off/Manual

switch to MANUAL. Allow the unit to warm up

thoroughly.

8. Stop the unit and set tlie Auto/Off/Manual

switch to OFF.

9. Turn on the utility power to the transfer switch.

10. Set the Auto/Off/Manual switc.h to AUTO.

11. Your generator is now ready for sendee.

Generac® Power Systems, Inc. 1 5

Page 18

Section 3 - Maintenance

MAINTEMANCE

Guardian Liquîd-cooied 3 kW Generators

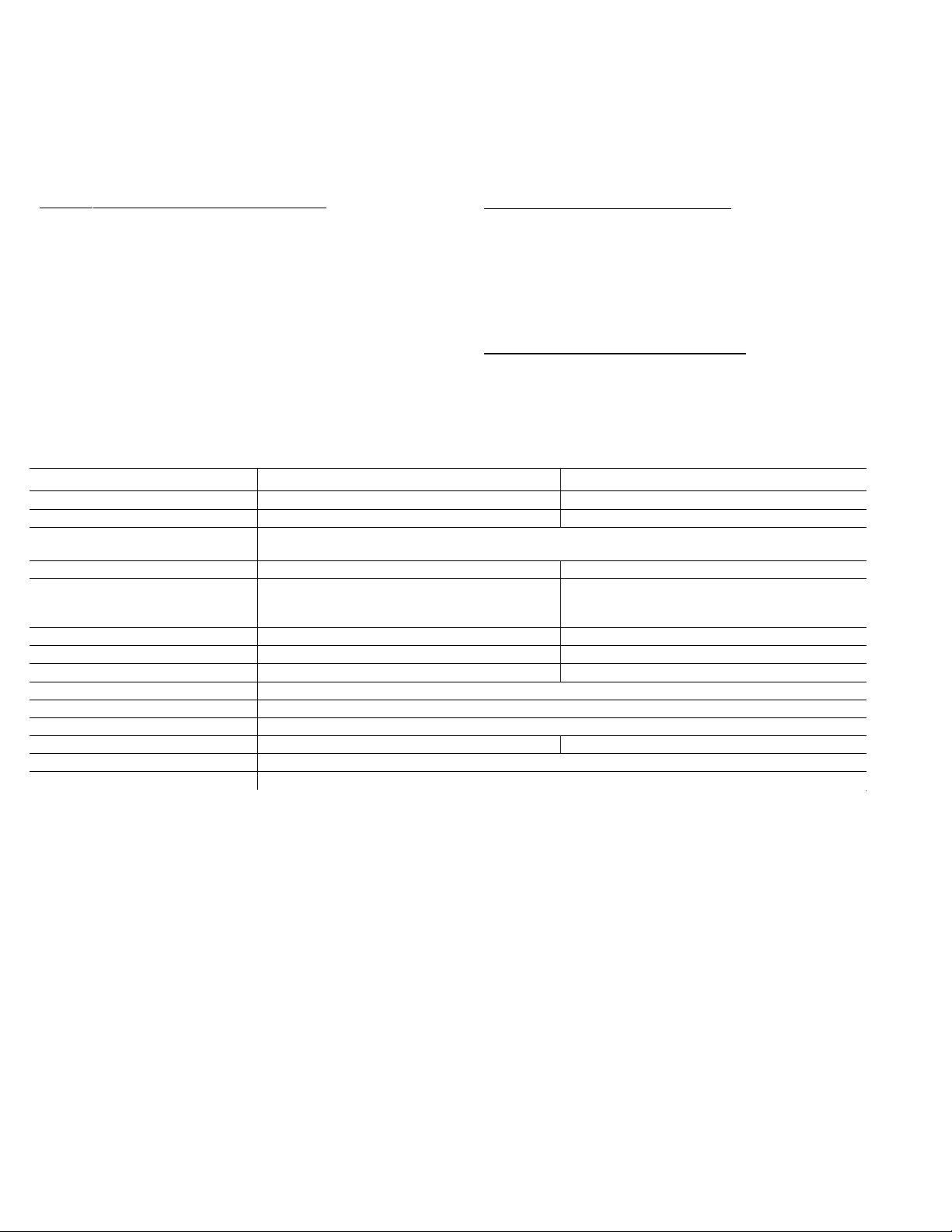

|3J3 SERVICE SCHEDULE

ATTENTiON: !t is recommended that a!! service work

be performed by your nearest Generac/Guardian Authorized Dealer.

SYSTEM/COMPONENT

X = Action

R = Replace/Adjust as Needed

* = Notify Dealer

if R.epair is Needed.

■FUEL

Fuel level

;

Fuel lines, connections

and filters*

LUBRICATION

Oil level

; Oil

1 Oil filter

: Oil line leakage* 1 X

! COOLING

Engine cooling -system*

; Coolant level

Coolant* X

1 Enclosure louvers X

: EXHAUST

Eichaust svstem

Retorque Exhaust Manifold* X

BATTERY

Electrolyte fluid level

Charge and condition

FAN BELT

Tension and condition*

ENGINE

Retorque cylinder head*

Retorque intake manifold*

Starter motor* X

DC alternator* X

Air cleaner X R 1

Compression*

Valve clearance*

Governor* X

SafeA detdces*

Iniection svstem*

GENERAL

Overall condition

Exercise svstem

COMPLETE TUNE-UP*

inspect

X

A'

X i

X

X

X

X i 1 j AFTER 25-H BRE.AK-IN, W

X ! R 1 X i W, EVERT 250 H / 6 M

X

X

X

X

X

X

X ! R

X

TO BE COMPLETED BY A GENERAC/

GUARDIAN AUTHORIZED DEALER

PROCEDURE

Change

X'

X

R

R

R

R i

R

R

R

Clean

X

X

FREQUENCY

D = DaiN W = Weekly

M = Monthly Y = Y'early

H = Hours

AFTER 25-H BRE.AK-IN,

D / BEFORE USE

AVTER 25-H BRE.MÎ-IN,

EVERY 250 H / 6 M

EVERY 8 H /D

AFTER 25-H BRE.AK-IN.

EVERY 250 H / 6 M

AFTER 25-H BREAK-IN,

EVERY 250 H / 6 M

: EVERY 100 H

AFTER 25-H BREAK-IN,

EVERY iOO H / M

AFTER 25-H BRE-.AK-IN,

D / BEFORE USE

EVERY 500 H / Y

EVERY 250 H / 6 M

EVERY 100 H / M

FIRST 100 H ANE

EVERY 800 H

1 AFTER 25-H BREAK-IN,

! EYERY 250 H / 6 M

FIRST 100 H AND

EVERY 800 H

FIRST 100 H AND

EVERY 800 H

EVERY 500 H

EVERY 500 H ARiD Y

EVERY 500 H

EVERY 800 H

EVERY 800 H

AFTER 25-H BRE-AK-IN,

EVERY 250 H/6 M

EVERY 6 M

EVERY 3 M

AFTER 25-H BREAGIN, W

W

Y

Page 19

4.1 TROUBLESHOOTING GUIDE

Section 4 — Troubleshooting

Guardian Liquid-cooled 8 kW Generators

TROUBLESHOOTING

PROBLEM

CAUSE CORRECTION

The engine will not crank. 1. Fuse blown

2. Loose, corroded or defective

battery cables

3. Defective starter contactor

4. Defective starter motor

5. Dead Battery

The engine cranks but

will not start.

1. Out of fuel

2. ' Defective fuel solenoid (FS)

3. Open #14 wire from

engine control board

4. Dirty/Blocked air filter

5. Amto/Off/Manual Switch

in OFF position

The engine starts hard

and runs rough.

1. Air cleaner

plugged or damaged

2. Dlrty/Blocked air filter

The engine starts, but then

shuts doLTO.

1. Engine oil level low

2. Defective low oil

pressure switch

3. Defective high temperature

switch

4. Defective control board

5. Low coolcmt level

6. Defective low coolant switch

7. Engine temperature high

8. Loss of AC sensing to

control boa.rd

1. Replace fuse.

2. Tighten, clean or replace

as necessary.

3. *

4. *

5. Charge or replace battery.

1. Replenish fuel.

2. *

3. *

4. Clean or replace as required.

5. Reset to AUTO or IvLwMUAL.

1. Check, clea.n or replace air cleaner.

2. Clean or replace as required.

1. Check oil and add oil as needed.

2 *

O .1.

o.

4. *

5. Check coolant level, repair leaks

and refill.

6. *

7. Check engine cooling airflow.

R ^

The Auto/Off/Manual switch

is set to OFF, but the engine

continues to run.

There is no AC output from

tlie generator.

There is no transfer to

standby after utility

source failure.

*Contact your nearest Generac/Guardian Authorized Dealer for assistance.

1. Defective switch

2. Defective control board

1. Generator main line circuit

breaker open

2, Generator internal failure

1. Generator main line circuit

breaker open

2. Defective transfer svfitch coil

3. Defective transfer relay

4. Transfer relay circuit open

5. Defective control logic board

1. *

0

1, Reset circuit breaker

to ON (or closed].

2. *

1. Reset circuit breaker

to ON (or closed).

2. *

3. *

4.

5. *

Generac* Power Systems, Inc. '1 *7

Page 20

oWiTi'l fCTOW

_r ELECTRICAL

DATA

Section 5 — Electrical Data

Guardian Liquid-cooled 8 kW Generators

Wiring Diagram (Control Pane!) - Drawing No. C2516-A

Page 21

Section 5 - Electrica! Data

Guardian Liquid-coded 8 kW Generators

Electrical Schematic (Control Panel) - Drawing No. C2669-A

WiTm nrmT]

ELECTRICAL

DATA

Page 22

Tini {HPi piFoinn

ELECTRICAL

DATA

-L

Section 5 — Electrical Data

Guardian Liquid-cooled 8 kW Generators

Wiring Diagram (1.0 Liter Engine) - Drawing No. C4954-

On \A/ r

hWT- HIGH G/ATEH TEMP.

lOS- low oil press SW.

SC - STARTER CONTACTOR

SM - STARTER MOTOR

SWT- SENDER VVATER TEMP

WLS- WATER LEVEL SENSOR

5\/^t:i=rr»5=;. Inc.

Page 23

Section 5 — Electrical Data

Guardian Liquid-cooled 8 kW Generators

Electrical Schematic (1,0 Liter Engine) - Drawing No. C4955-

CUSTOMER

120V/i5A UTILITY

CONNECTIDN

niFoTri rifiJoTir

ELECTRICAL

DATA

EZL

■rr \

'iZy

BLACK-

DCA

DCR

EH

FP

GP

HW

lDS

SC

SM

S W T

WLS

- DC ALTERMATDR

- DC vdltagl regulator

“ lNCINE Hl_A i EK

- ^UEL SHIJTOF“ SQlENGID

- FUEL PUMP

- Glow plug

- HIGH WATER TEMP,

- SWITCH, caw GIL PRESSURE

- STARTER CGMTACTuR

- starter METER

- SLMDER water temp

- WATER _EVEL SENSaP

Generac” Power Systems. Inc. ST

Page 24

^PARTS

LISTS

Section 5 — Exploded Views and Parts Lists

Guardian Liquid-cooled 8 kW Generators

Compartment - Drawing No. C2436-B

2S CBenerac® Power Systems, Inc.

Page 25

Section 6 — Exploded Views and Paris Lists

Guardian Liquid-cooled 8 kW Generators

Compartment - Drawing No. C2436-B

’’EM

PART NO.

*02433 1 CORNER POST, LH. REAR

1

*02434

2

A3443

3

4 A3444 1

5 A3445

6 A3446

A3447 1

7

A7198 1

8

A3449 2 DOOR, SIDE

9

11

A3451

12 A7197 1

13 A3453

14 A3454

*02435

16

*C2435A 1 DUCT, LH. REAR CORNER

C2755A

17

C2755B 1 DOOR, REAR (INSUL.)

18

C2755C

19

C2755D

20

C2755E

21

C2755F

22

C2755N VENTURI, TOP (INSUL.)

23

QTY.

DESCRIPTION

ITEM

24

CORNER POST, RH. REAR 25

1

1 PANEL. REAR BOTTOM

PANEL, REAR TOP

PANEL. SIDE

3

PANEL, RH. SIDE BOTTOM

1

26

27

28

CORNER POST, LH. FRONT 29

CORNER POST, RH. FRONT

30

1 PANEL, FRONT TOP

PANEL, FRONT

1 DOOR, REAR

31

32

33

1 TOR ROOF 34

DUCT, RH. REAR CORNER 35

1

POST

36

POST

37

1 PANEL, REAR BOTTOM 38

(INSUL.) 39

40

1

DOOR, FRONT (INSUL.)

2 CORNER POST, FRONT

(INSUL.)

1 DOOR, LEFT SIDE (INSUL.)

4 PANEL, SIDE (INSUL.)

41

42

FOR REF. ONLY (SEE 02438 CONTROL PANEL FOR

DE \lLSi

PART NO. QTY.

DESCRIPTION

C2755P 1 ROOF, TOP (INSUL.)

C2755M

C2755G 1

C2755H 1

1 DOOR, RIGHT SIDE (INSUL)

AIR DUCT, BOTTOM (INSUL.)

AIR DUCT. FRONT RH,

(INSUL.)

C2755J

C2755K

1

AIR DUCT, LH. SIDE (INSUL.)

AIR DUCT, FRONT LH.

1

(INSUL.)

C2755L 1

22473

AIR DUCT, RH. SIDE (INSUL.)

50 FLAT WASHER-M6-1/4"

22097 32 LOCK WASHER-M6-1/4"

22127 6

49813

42568 18

NUT. HEX-1 M"-20

NUT, HEX-M6-1.0

18

CAPSCR..HEX HD.-M6-1,0 x 20

LONG

67577

22413

67042

78115

A3133A 2

A3133B

A3133C

A3133D

A3359 40

A3360 40

SPEED NUO1/4"-20

16

16 CAPSCR., HEX HD,-1/4"-20 x 1

4

LATCH & CAM

4

WASHER. SELF LOCK/DOME

HINGE, SLIP-MALE L.H.

HINGE, SLIP-FEMALE L.H.

2

d

HINGE, SLIP-MALE R.H.

d

HINGE, SLIP-FEMALE R.H,

BHSCS-M6 X 16 S.S.

SHAKEPROOF, INT.-M6 S.S.

ör-iVA/pan S V «=; ft {= m «=:. inrt.

Page 26

.PARTS

LISTS

Section 6 — Exoioded Views and Parts Lists

Guardian Liquid-cooled 8 kW Generators

Controi Pane! - Drawing No. C2438-3

©

iS^^ooo.;

1©;

»67680 VOLT. RlG, shown IN THIS VIEW

IS USED ON 30 UNIT DMLY

2^4 Generac® Power Systems, Inc.

Page 27

Section 6 - Exploded Views and Parts Lists

Guardian Liquid-cooled 8 kW Generators

Control Pane! - Drawing No. C2438-8

:'E!V! PART NO,

1

C2430 1 CONTROL PANEL BACK/

QTY. DESCRIPTION ITEM PART NO.

BOTTOM

2 C2719

SILKSCREEN-CONTROL 37

1 '

PANEL 38

3 C2431

C2431A

4

83048

CONTROL PANEL L.H, SIDE 39

1

1 CONTROL PANEL R.H, SIDE

VOLTAGE REGULATOR

1

41

1-PHASE 60HZ

67680

VOLTAGE REGULATOR

1

3-PHASE BOHZ 43

C2434

5

CORNER POST, RH REAR 45

1

(PANEL SUPPORT) 46

6 C2433

CORNER POST, LH REAR 47

1

(PANEL SUPPORT

7 77906 1 CIRCUIT BREAKER-MAIN 48

(35A-2P-BQ2) 49

57906

CIRCUIT BREAKER-MAIN

(35A-3P-BQ3)

S C2435 1 DUCT. R.H. R.R, CORNER 53

75589 1 BRACKET, VOLTAGE

9

REGULATOR

76039

10

11 51716 2

12 90426

90427

13

14 40295

40292

15

C2435A

16

о

SCREW, PPHM M5-.8 x 40MM

HEX NUT M5-0.8

PPHMS #10-32 X 3/8“ S.S.

О

FLAT WASHER #10

3

n

LOCK WASHER #10 58 C2428

0

HEX NUT #10-32

5

DUCT, LH REAR ICORNER

1

POST)

17 C2515 1 HARNESS, CONTROL 61

PANEL “P“

18 29333 4 TIE WRAP T LG.

19 76061 1

81988 1

20

21 82573

DECAL. TERMINAL STRIP 64

DECAL SET EXERCISE TIME 65

1

SWITCH ROCKE.R(SET

EXERCISE TIME) 67 C2265 9

22 76020

64009 LIGHT FAULT INDICATOR

23

24 61945

A2560

25

C5454

26

27 22473

55349

28

58568

29

58568

1

SWITCH-AUTO/MANUAL/OFF

1

SWITCH, VOLTAGE SELECTOR

1 RELAY IP 50A/12V

1 CABLE, NYLON CONTROL

PANEL

2

WASHER. FLAT 1/4"

1 INSULATOR

2 CURRENT TRANSFORMER

50/5 n PHASE)

CURRENT TRANSFORMER

3

73 36935

75

76

77

78

79

50/5 (3 PHASE)

70081

30

70043

31

32 32300

49939 RECTIFIER

33

34

22668

1 HOUR METER

1 VOLTMETER DC (BATTERY)

HOLDER, FUSE

1

FUSE. 30A.

1

30

81

82 22473

83

70042 1

35

36 700-^5 1

71668

70370 1

30468

71938A 1

40

23762 1

22097 22

42

C1914A

48766

56967 2

79246

48468 1

14

51

22155

22142

52 22145

33121

22152

54

23897

55

22158

56

57 A2419

24 SWG FASTENER 1/4"-20 x

12

34616

59

57335

60

46669 7

57907 1

62

C2484 2

63

22264 7

39782

75545 1

66

61979

68

69 57073

33530 2

70

22129

72

22259

54199

C2512

75595

A7215

C2473

22287

22127

DESCRIPTION

QTY.

HERTZ METER 60HZ

AC AMMETER 0-200

AC VOLTMETER 0-500

1

WASHER, MICA

STEP, WASHER NYLON

1

VOLTAGE REGULATOR, D.C.

WASHER, EXTERNAL SHAKEPROOF

WASHER. LOCK 1/4"

HINGE CONTROL PANEL

1

BLOCK TERMINAL (2)

1

PLUG, PLASTIC .37

4