Generac Power Systems 00940-2, 00941-2, IMPACT-36G plus II, IMPACT-36LPG plus II Owner's Manual And Installation Instructions

Page 1

POWER SYSTEMS, INC.

®

Owner’s Manual and

Installation Instructions

Air-cooled Recreational Vehicle Generator

• Model Nos: 00940-2 & 00941-2

IMPACT-36 plus II with Inverter

Page 2

Generac®Power Systems, Inc.

INTRODUCTION

Thank you for purchasing this generator by Generac

Power Systems, Inc. This model is designed and manufactured to supply electrical power for recreational

vehicles.

READ THIS MANUAL THOROUGHLY

If you do not understand any portion of this

manual, contact Generac or your nearest

Generac Authorized Service Dealer for starting,

operating, and servicing procedures.

Throughout this publication, and on tags and

decals affixed to the generator, DANGER, WARNING, CAUTION, and NOTE blocks are used to alert

you to special instructions about a particular operation that may be hazardous if performed incorrectly or carelessly. Observe them carefully. Their definitions are as follows:

After this heading, you can read instructions that,

if not strictly complied with, will result in personal

injury or property damage.

After this heading, you can read instructions that,

if not strictly complied with, may result in personal

injury or property damage.

After this heading, you can read instructions that, if

not strictly complied with, could result in damage to

equipment and/or property.

NOTE:

After this heading, you can read explanatory

statements that require special emphasis.

These safety warnings cannot eliminate the hazards

that they indicate. Common sense and strict compliance with the special instructions while performing the

service are essential for preventing accidents.

Four commonly used safety symbols accompany the

DANGER, WARNING, and CAUTION blocks. Here are

the types of information indicated by each symbol:

This symbol points out important safety information that, if not followed, could endanger personal

safety and/or property to self and others.

This symbol points out potential explosion hazard.

This symbol points out potential fire hazard.

This symbol points out potential electrical shock

hazard.

The operator (i.e., the driver) is responsible for the

proper and safe use of the vehicle and its equipment,

and for the safety of all vehicle occupants. Before

using this equipment, we strongly recommend that

the operator read this manual and thoroughly understand all instructions. We also strongly recommend

instructing other occupants in the vehicle to properly

start and operate the generator. This prepares them to

operate the equipment in case of an emergency.

CONTENTS

This manual contains pertinent owner’s information,

including warranty, electrical diagrams, exploded

views, and lists of repair parts for generator models

00940-2 and 00941-2. In addition, the latter portion

of this manual contains information necessary for the

proper installation of these generators.

OPERATION AND MAINTENANCE

It is the operator's responsibility to perform all

safety checks, to make sure that all maintenance

for safe operation is performed promptly, and to

have the equipment checked periodically by a

Generac Authorized Service Dealer. Normal maintenance service and replacement of parts are the

responsibilities of the owner/operator and, as such,

are not considered defects in materials or workmanship within the terms of the warranty.

Individual operating habits and usage contribute to

the need for maintenance service.

Proper maintenance and care of your generator

minimize problems and operating expenses. See

your Generac Authorized Service Dealer for service

aids and accessories.

HOW TO OBTAIN SERVICE

When your generator requires servicing or repairs,

simply contact a Generac Authorized Service Dealer

for assistance. Service technicians are factory-trained

and are capable of handling all of your service needs.

When contacting a Generac Authorized Service

Dealer or the factory about parts and service, always

supply the complete model number and serial number of your unit, as given on its data decal, which is

located on your generator.

Model No. ____________ Serial No. ______________

◆

◆

◆

◆

AUTHORIZED SERVICE

DEALER LOCATION

To locate the GENERAC AUTHORIZED SERVICE

DEALER nearest you, please call this number:

1-800-333-1322

ONLY DEALER LOCATION INFORMATION

CAN BE OBTAINED AT THIS NUMBER.

Page 3

Table of Contents

IMPACT-36 plus II Recreational Vehicle Generator

Generac®Power Systems, Inc. 1

Part I – Owner’s Manual

Introduction ....................................................Inside Front Cover

Read This Manual Thoroughly ............................................IFC

Contents ..............................................................................IFC

Operation and Maintenance ................................................IFC

How to Obtain Service ........................................................IFC

Authorized Service Dealer Locator Number ............................IFC

Safety Rules ....................................................................................2

Section 1 – General Information ..............................................4

1.1 Generator Identification ..................................................4

1.1.1 Impact-36G plus Features ..................................4

1.1.2 Impact-36LPG plus Features ..............................5

1.1.3 Inverter Features ................................................6

1.2 Generator Applicability ....................................................7

1.3 Safety ..............................................................................7

1.4 Generator Control Panel ..................................................7

1.4.1 Fuel Primer ........................................................7

1.4.2 Start/Stop Switch................................................7

1.4.3 Fuse ....................................................................7

1.4.4 Circuit Breakers ................................................7

1.4.5 Hour Meter ........................................................8

1.5 Automatic Choke (Gasoline Only) ....................................8

1.5.1 Choke Solenoid (Gasoline Only) ........................8

1.5.2 Prechoke (Gasoline Only)....................................8

1.6 Engine Protective Devices ................................................8

1.6.1 Automatic Low Oil Pressure Shutdown ..............8

1.6.2 High Temperature Shutdown..............................8

1.6.3 Overspeed ..........................................................8

1.6.4 Low Voltage ........................................................8

Section 2 – Operation ..................................................................9

2.1 Before Starting the Engine ..............................................9

2.1.1 Installation..........................................................9

2.1.2 Engine Lubrication ............................................9

2.1.3 Fuel Supply ........................................................9

2.1.4 Cooling and Ventilating Air ................................9

2.1.5 Engine Exhaust Gas............................................9

2.2 Starting the Generator ....................................................9

2.3 Stopping the Generator ................................................10

2.4 Applying Loads to Generator ........................................10

2.4.1 Letting the Engine Stabilize ..............................10

2.5 Attention Required After Submersion ............................10

2.6 Operation in High Grass or Brush ................................10

2.7 Operating Precautions ..................................................10

2.8 Fuel Requirements (Gasoling Units) ..............................10

2.9 Fuel Requirements (LP Units) ........................................11

2.10 Engine Oil Requirements ..............................................11

2.11 Gas Generator Specifications ........................................11

2.12 LP Generator Specifications ..........................................11

2.13 Engine Specifications ....................................................11

Section 3 – Maintenance ..........................................................12

3.1 Maintenance ..................................................................12

3.2 Checking the Engine Oil Level ......................................12

3.3 Change Engine Oil ........................................................12

3.4 Change Oil Filter............................................................12

3.5 Engine Air Cleaner ........................................................13

3.6 Clean Air Intake Screen ................................................13

3.7 Engine Spark Plug ........................................................13

3.8 Fuel Filter ......................................................................13

3.9 Inverter..........................................................................14

3.10 Cleaning the Generator ..................................................14

3.11 Battery ..........................................................................14

3.11.1 Once Weekly......................................................14

3.11.2 Every Six Months ..............................................14

3.12 Service and Adjustments ..............................................14

3.12.1 Engine Speed ....................................................14

3.13 Adjusting the Carburetor ..............................................14

3.14 Adjusting Valve Clearance ..............................................15

3.15 Major Service Manual ....................................................15

3.16 Exercising the Generator ..............................................15

3.17 Out of Service Protection ..............................................15

3.18 Return Unit to Service After Storage ..............................15

Notes ..............................................................................................16

PartII – Installation Instructions

Safety Rules..................................................................................18

Section 1 – General Information ............................................20

1.1 Purpose and Scope of the Manual ............................20

1.2 Safety ......................................................................20

1.3 Standards Booklets ..................................................20

1.4 Equipment Description ............................................20

1.5 Engine Generator Operating Speed ..........................20

Section 2 – Installation ............................................................21

2.1 Location and Support ....................................................21

2.1.1 Generator Location ..........................................21

2.1.2 Generator Support............................................21

2.1.3 Suspended Mounting ........................................21

2.1.4 Generator Restraint ..........................................22

2.2 Generator Compartments ..............................................22

2.2.1 Compartment Size ............................................23

2.2.2 Compartment Construction ..............................23

2.2.3 Sound Insulating Materials ..............................24

2.2.4 Compartment Floor Cutouts ............................24

2.2.5 Acoustics ..........................................................25

2.3 Cooling and Ventilating Air ............................................25

2.3.1 Generator Airflow ............................................25

2.3.2 Cooling Air Inlet Openings ................................26

2.3.3 Compensating for Restrictions ..........................27

2.3.4 Inverter Location ..............................................27

2.3.5 Testing the Installation......................................27

2.4 Gasoline Fuel System ....................................................27

2.4.1 Fuel Tank .........................................................27

2.4.2 Generator Fuel Supply Lines ............................28

2.5 Propane Gas Fuel System ..............................................28

2.5.1 Parts Not Included in Fuel System ....................28

2.5.2 Some Important Considerations ......................29

2.5.3 Vapor Withdrawal ............................................29

2.5.4 Primary Regulator ............................................29

2.5.5 Gaseous Carburetion ........................................29

2.5.6 Fuel Supply Lines ............................................30

2.5.7 Excess Flow Valve ............................................30

2.5.8 Leakage Tests....................................................30

2.6 Exhaust System ............................................................30

2.6.1 Muffler and Spark Arrestors ............................30

2.6.2 Type of Exhaust System....................................31

2.6.3 Exhaust System Safety......................................31

2.7 Electrical Connections ..................................................31

2.7.1 Wiring ..............................................................32

2.7.2 Generator AC Connection System ....................32

2.7.3 Isolating Different Power Sources ....................32

2.7.4 Power Supply Cord ..........................................32

2.7.5 Gound Fault Circuit Interrupters......................32

2.7.6 Sensing Harnesses ............................................34

2.8 Battery Installation ........................................................34

2.8.1 Recommended Battery......................................34

2.8.2 Battery Cables ..................................................34

2.8.3 Battery Cable Connections ................................35

2.8.4 Battery Compartment ......................................35

2.9 Optional Accessories......................................................35

2.9.1 Remote Plug-in Receptacle ................................35

2.9.2 Remote Start/Stop Panel ..................................35

Section3–Post-installation Startup Checks ......................36

3.1 Post Installation Tests ....................................................36

3.2 Before Initial Startup ....................................................36

3.3 Initial Start ....................................................................36

3.4 Testing Under Load ......................................................36

3.5 Installation Checklist ....................................................37

Section4–Troubleshooting ....................................................38

4.1 Troubleshooting Guide ..................................................38

Section 5 – Electrical Data........................................................39

Section 6 – Exploded Views and Parts Lists ........................42

Section7–Warranty..................................................................52

Page 4

2 Generac®Power Systems, Inc.

Study these SAFETY RULES carefully before

installing, operating, or servicing this equipment.

Become familiar with this manual and with the unit.

The generator can operate safely, efficiently, and reliably only if it is properly installed, operated, and

maintained. Many accidents are caused by failing to

follow simple and fundamental rules or precautions.

Generac cannot possibly anticipate every possible cir

cumstance that might involve a hazard. The warnings in this manual, and on tags and decals

affixed to the unit, are, therefore, not all-inclusive. If

you use a procedure, work method, or operating

technique that Generac does not specifically recommend, you must satisfy yourself that it is safe for you

and others. You also must make sure the procedure,

work method, or operating technique that you choose

does not render the generator unsafe.

Despite the safe design of this generator,

operating this equipment imprudently, neglecting its maintenance, or being careless can cause

possible injury or death. Permit only responsible and capable persons to operate and maintain this equipment.

Parts of the generator are rotating and/or hot

during operation. Exercise care near running

generators.

Potentially lethal voltages are generated by

these machines. Ensure all steps are taken to

render the machine safe before attempting to

work on the generator.

GENERAL HAZARDS

• For safety reasons, Generac recommends

that the installation, initial startup, and maintenance of this equipment be performed by a

Generac Authorized Service Dealer.

• The engine exhaust fumes contain carbon monoxide, which can be DEADLY. This dangerous gas, if

breathed in sufficient concentrations, can cause

unconsciousness or even death. Thus, the exhaust

system must be installed properly, in strict compliance with applicable codes and standards.

Following installation, you must do nothing that

might render the system unsafe or in noncompliance with such codes and standards. The generator compartment must be completely vapor-sealed

from the vehicle interior. There must be no possibility of exhaust fumes entering the vehicle interior. Never operate this equipment with a leaking or

defective exhaust system.

• Keep hands, feet, clothing, etc., away from drive

belts, fans, and other moving or hot parts. Never

remove any drive belt or fan guard while the unit is

operating.

• Adequate, unobstructed flow of cooling and ventilating air is critical to correct generator operation

and is required to expel toxic fumes and fuel

vapors from the generator compartment. Without

sufficient cooling airflow, the engine/generator

quickly overheats, which seriously damages the

generator. Do not alter the installation or permit

even partial blockage of ventilation provisions, as

this can also seriously affect the safe operation of

the generator.

• When working on this equipment, remain alert at

all times. Never work on the equipment when you

are physically or mentally fatigued.

• Inspect the generator regularly, and contact your

nearest Generac Authorized Service Dealer immediately for parts needing repair or replacement.

• Before performing any maintenance on the generator, disconnect its battery cables to prevent accidental startup. First, disconnect the cable from the

battery post, indicated by a NEGATIVE, NEG, or

(–). Reconnect this cable last.

• Never use the generator, or any of its parts, as a

step. Stepping on the unit can stress and break

parts, resulting in dangerous operating conditions

due to leaking exhaust gases, fuel leakage, oil leakage, etc.

• Never insert any tool or other object through openings in the generator interior, even if the unit is not

running. You might seriously injure yourself or

damage the equipment.

Safety Rules

IMPACT-36 plus II Recreational Vehicle Generator

SAVE THESE INSTRUCTIONS – The manufacturer suggests that these rules for safe

operation be copied and posted in potential hazard areas of the recreational vehicle.

Safety should be stressed to all operators and potential operators of this equipment.

The engine exhaust from this product

contains chemicals known to the state

of California to cause cancer, birth

defects, or other reproductive harm.

WARNING:

Page 5

Generac®Power Systems, Inc. 3

ELECTRICAL HAZARDS

• The generator covered by this manual produces

dangerous electrical voltages and can cause fatal

electrical shock. Avoid contact with bare wires, terminals, connections, etc., while the unit is running.

Before operating the generator, ensure all appropriate covers, guards, and barriers are in place . If

you must work around an operating unit, stand on

an insulated, dry surface to reduce shock hazard.

• Do not handle any kind of electrical device while

standing in water, while barefoot, or while hands

or feet are wet. DANGEROUS ELECTRICAL

SHOCK MAY RESULT.

• During installation onto the vehicle, have the generator properly grounded (bonded), either by solid

mounting to the vehicle frame or chassis, or by

means of an approved bonding conductor. DO

NOT disconnect the bonding conductor, if so

equipped. DO NOT reconnect the bonding conductor to any generator part that might be removed or

disassembled during routine maintenance. If the

grounding conductor must be replaced, use only a

flexible conductor that is of No. 8 American Wire

Gauge (AWG) copper wire minimum.

• In case of an accident caused by electric shock,

immediately shut down the source of electrical

power. If this is not possible, attempt to free the

victim from the live conductor. AVOID DIRECT

CONTACT WITH THE VICTIM. Use a nonconducting implement, such as, a dry rope or board, to

free the victim from the live conductor. If the victim

is unconscious, apply first aid and get immediate

medical help.

• Never wear jewelry when working on this equipment. Jewelry can conduct electricity, resulting in

electric shock, or may get caught in moving components, causing, injury.

FIREHAZARDS

• For fire safety, the generator must be installed and

maintained properly. Installation must always

comply with NFPA 70 (latest edition), “National

Electrical Code”, Article 551, and NFPA 1192 (latest edition), “Standard for Recreational Vehicles”,

along with all applicable codes, standards, laws,

and regulations. Adhere strictly to local, state, and

federal electrical and building codes. Comply with

regulations the Occupational Safety and Health

Administration (OSHA) has established. Also,

ensure that the generator is installed in accordance with the manufacturer’s instructions and

recommendations. After proper installation, do

nothing that might alter the installation and render

the unit in noncompliance with the aforementioned codes, standards, laws, and regulations.

• Keep a fire extinguisher in the vehicle at all times.

Extinguishers rated “ABC” by the National Fire

Protection Association are appropriate for use on

the recreational vehicle generator electrical system. Keep the extinguisher properly charged and

be familiar with its use. If you have any question

pertaining to fire extinguishers, consult your local

fire department.

EXPLOSION HAZARDS

• Do not smoke around the generator. Wipe off any

fuel or oil spills immediately. Ensure that no combustible material is left in the generator compartment, or on or near the generator, as FIRE or

EXPLOSION may result. Keep the area surrounding the generator clean and free of debris.

• All fuel types are potentially FLAMMABLE and/or

EXPLOSIVE and should be handled with care.

Comply with all laws regulating the storage and

handling of fuels. Inspect the unit’s fuel system frequently and correct any leaks immediately. Before

placing this equipment into service, the fuel supply

lines must be properly installed, purged, and leaktested according to applicable fuel-gas codes.

Safety Rules

IMPACT-36 plus II Recreational Vehicle Generator

Page 6

4 Generac®Power Systems, Inc.

Section 1 – General Information

IMPACT-36 plus II Recreational Vehicle Generator

Please record the following information from the generator DATA DECAL or information decal,

located below the user control panel.

1. Model Number ____________________ 2. Serial Number __________________

3. kW Rating__________________________ 4. Rated Voltage __________________

5. Phase ______________________________ 6. Hertz __________________________

1.1 GENERATOR IDENTIFICATION

1.1.1 IMPACT-36G PLUS II FEATURES

◆

1. Generator Air Intake Screen

2. Air Cleaner

3. Air Intake Tube

4. Oil Dipstick and Filler Tube

5. Fuel Pump

6. Gasoline Carburetor

7. Fuel Primer Switch

8. Data Decal

9. 12 Volt Battery Connection

10. Engine Start/Stop Switch

11. Generator DC Output Leads

12. Circuit Breaker

13. Fuse

14. Hour Meter

REFERENCE NUMBER IDENTIFICATION

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Page 7

Generac®Power Systems, Inc. 5

Section 1 – General Information

IMPACT-36 plus II Recreational Vehicle Generator

Please record the following information from the generator DATA DECAL or information decal,

located below the user control panel.

1. Model Number ____________________ 2. Serial Number __________________

3. kW Rating__________________________ 4. Rated Voltage __________________

5. Phase ______________________________ 6. Hertz __________________________

1.1.2 IMPACT-36LPG PLUS II FEATURES

◆

1. Generator Air Intake Screen

2. Air Cleaner

3. Air Intake Tube

4. LP Fuel Regulator

5. Oil Dipstick and Filler Tube

6. LP Carburetor

7. LP Fuel Solenoid

8. Fuel Primer Switch

9. Data Decal

10. 12 Volt Battery Connection

11. Engine Start/Stop Switch

12. Generator DC Output Leads

13. Circuit Breaker

14. Fuse

15. Hour Meter

REFERENCE NUMBER IDENTIFICATION

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Page 8

6 Generac®Power Systems, Inc.

Section 1 – General Information

IMPACT-36 plus II Recreational Vehicle Generator

1.1.3 INVERTER FEATURES (PART NO. 0D4885)

◆

1. Inverter

2. 12 Pin Connection

3. Customer AC Output

4. DC Input

5. Cooling Fan

REFERENCE NUMBER IDENTIFICATION

3

5

2

4

1

Page 9

Generac®Power Systems, Inc. 7

Section 1 – General Information

IMPACT-36 plus II Recreational Vehicle Generator

1.2 GENERATOR APPLICABILITY

These generators have been designed and manufactured for supplying electrical power for recreational

vehicles. You should not modify the generator or use

it for any application other than for what it was

designed. If there are questions pertaining to its

application, write or call the factory. Do not use the

unit until you have been advised by a competent

authority.

For fire safety, the generator must have been

properly installed in compliance with (1) ANSI

119.2-1975/NFPA 501C-1974 “Standard for

Recreational Vehicles”, Part III, “Installation of

Electrical Systems.” The generator also must

have been installed in strict compliance with

the manufacturer’s detailed installation

instructions. After installation, do nothing

that might render the unit in non-compliance

with such codes, standards and instructions.

This generator has been designed to work with an

inverter (P/N 0D4885). The inverter changes the voltage from the generator from a DC to an AC voltage.

This generator will not operate properly without the

inverter box connected. All repairs of the inverter

must be handled by an authorized service dealer (see

Page 12 in “Maintenance”).

You can use this generator to supply electrical power

for operating 120 volts, single phase, 60 Hertz, electrical loads. These loads can require up to 3400

watts (3.4 kW) for the Impact-34 plus II, or 3600

watts (3.6 kW) for the Impact-36 plus II. The maximum current at 120 volts is 28.3 amperes for the

Impact-34 plus II, or 30 amperes for the Impact-36

plus II.

CAUTION: Do not overload the generator.

Some installations may require that electrical

loads be alternated to avoid overloading.

Applying excessively high electrical loads may

damage the generator and may shorten its

life. Add up the rated watts of all electrical

lighting, appliance, tool and motor loads the

generator will power at one time. This total

should not be greater than the wattage

capacity of the generator. If an electrical

device nameplate gives only volts and amps,

multiply volts times amps to obtain watts

(volts x amps = watts). Some electric motors

require more amps of current for starting than

for continuous operation.

1.3 SAFETY

Before using the generator set, carefully read GENERAL SAFETY RULES inside the cover. Comply with

these RULES to prevent accidents and damage to

equipment and/or property. Generac suggests copying and posting the GENERAL SAFETY RULES in

potential hazard areas of the recreational vehicle.

Safety should be stressed to all operators of this

equipment.

1.4 GENERATOR CONTROL PANEL

Mounted on the generator control panel (Figure 1.1)

are the following features:

Figure 1.1 — Typical Control Panel

1.4.1 FUEL PRIMER

Before starting a cold engine (if it has not been started in more than two weeks), you must press this

switch to bring fuel from the tank to the fuel carburetor. This rocker type switch springs back into its

original position when you release it.

1.4.2 START/STOP SWITCH

To crank and start the engine, hold this switch at its

START position. Release the switch when the engine

starts. To stop an operating engine, press and hold

the switch in its STOP position until the engine shuts

off. The switch center position is the RUN position.

1.4.3 FUSE

Protects the engine DC control circuit against electrical overload. If the fuse element has melted open due

to overloading, the engine cannot be cranked. If you

must replace it, use only an identical replacement

fuse.

1.4.4 CIRCUIT BREAKERS

Protects generator's AC output circuit against

overload, i.e., prevents unit from exceeding

wattage/amperage capacity.

◆

◆

◆

◆

Circuit Breaker Fuse

Start/Stop

Switch

Fuel Primer

Hour Meter

Page 10

8 Generac®Power Systems, Inc.

Section 1 – General Information

IMPACT-36 plus II Recreational Vehicle Generator

1.4.5 HOUR METER

Indicates the time the engine-generator has operated,

in hours and tenths of hours. Use the hourmeter

along with the periodic maintenance schedule for

your generator set.

1.5 AUTOMATIC CHOKE (GASOLINE

ONLY)

The engine is equipped with an automatic choke (not

shown) that consists of two main components —

choke solenoid and prechoke.

1.5.1 CHOKE SOLENOID (GASOLINE ONLY)

During engine cranking (start/stop switch at START),

a solid state control circuit board signals the choke

solenoid to actuate and cycle (choke on/choke off)

until engine starts. The choke solenoid thus opens

and closes the carburetor choke valve only when the

engine is cranking. When the engine starts, the choke

cycling stops.

1.5.2 PRECHOKE (GASOLINE ONLY)

The choke system also has a temperature sensitive

metal strip that adjusts the choke valve angle according to ambient temperatures (i.e., in cold ambient

temperatures the choke valve closes more). Once the

engine starts, an element heats the temperature-sensitive strip to a normal operating condition, opening

the choke valve. This may take about 3 minutes in

cooler weather.

1.6 ENGINE PROTECTIVE DEVICES

This generator has a computer that monitors low oil

pressure, oil temperature, engine speed, and low

voltage output. This section discusses those protective devices.

1.6.1 AUTOMATIC LOW OIL PRESSURE

SHUTDOWN

The engine is equipped with an oil pressure sensor

that shuts down the engine automatically when oil

pressure is too low. If the engine shuts down by itself

and the fuel tank has enough fuel, check the engine

oil level.

1.6.1.1 Initial Startup

During initial startup, a time delay built into the shutdown control system allows oil pressure to build. The

delay allows the engine to run for about 10 seconds

before sensing oil pressure.

1.6.1.2 Sensing low pressure

If the system senses low oil pressure during operation, the engine shuts down. If you do restart the

engine after a low oil pressure shutdown and have

not corrected the low oil level, the engine runs for

about 10 seconds as described above then stops.

1.6.2 HIGH TEMPERATURE SHUTDOWN

A temperature switch with normally-open (N.O.) contacts is mounted near the oil filter. If engine temperature were to exceed a preset temperature, the switch

contacts close and the engine shuts down.

1.6.3 OVERSPEED

If engine speed is increased manually (or otherwise)

beyond the control of the computer control system,

the computer disables the load capability of the generator and shuts down the engine.

Do not attempt to physically adjust or control

the engine speed. Equipment damage or personal injury may result.

1.6.4 LOW VOLTAGE

The computer monitors the voltage output of the generator. If voltage sensors indicate that voltage has

dropped below a preset level, the engine will automatically shut down. Once the unit has shutdown,

the computer is automatically reset when you restart

the engine.

NOTE:

The computer allows for the low voltage output

that occurs during startup. A time delay that

allows the engine to start and warm up is programmed into the monitoring system.

Before restarting a generator that has been

shutdown, disconnect all loads the generator

might power by whatever means provided,

such as the recreational vehicle’s main circuit

breaker.

◆

◆

◆

▼

▼

◆

◆

◆

◆

Page 11

Generac®Power Systems, Inc. 9

Section 2 – Operation

IMPACT-36 plus II Recreational Vehicle Generator

2.1 BEFORE STARTING THE ENGINE

IMPORTANT: INSTRUCTIONS AND INFORMATION

IN THIS MANUAL ASSUME THE GENERATOR HAS

BEEN PROPERLY INSTALLED, CONNECTED, SERVICED, TESTED AND ADJUSTED BY A QUALIFIED

INSTALLATION TECHNICIAN OR INSTALLATION

CONTRACTOR.

2.1.1 INSTALLATION

Generator installation must have been properly completed so it complies with all applicable codes, standards and regulations and with the manufacturer's

recommendations.

2.1.2 ENGINE LUBRICATION

Have engine crankcase properly serviced with recommended oil before starting. Refer to "Maintenance"

and "Specifications" sections for oil servicing procedures and recommendations.

Any attempt to crank or start the engine

before you have properly serviced it with the

recommended oil may result in engine failure.

2.1.3 FUEL SUPPLY

The engine must have adequate supply of proper fuel

to operate. Before starting, check that sufficient fuel

is available.

NOTE:

On some gasoline installations, the generator

engine may “share” the vehicle’s gasoline fuel

tank with the vehicle engine. Some installations

may provide separate fuel tanks for generator and

vehicle engine.

2.1.4 COOLING AND VENTILATING AIR

Air inlet and outlet openings in the generator compartment must be open and unobstructed for continued proper operation. Without sufficient cooling and

ventilating air flow, the engine-generator quickly overheats, which causes it to automatically shutdown.

Overheating could also damage the unit or your vehicle.

2.1.5 ENGINE EXHAUST GAS

Before starting the generator engine, you should be

sure there is no way for exhaust gases to enter the

vehicle interior and endangering people or animals.

Close windows, doors and other openings in the vehicle that, if open, might permit exhaust gases to enter

the vehicle.

The generator engine gives off deadly carbon

monoxide gas through its exhaust system.

This dangerous gas, if breathed in sufficient

concentrations, can cause unconsciousness or

even death. Do not operate the generator if

its exhaust system is leaking or has been

damaged. Symptoms of carbon monoxide poisoning are (a) inability to think coherently, (b)

vomiting, (c) twitching muscles, (d) throbbing

temples, (e) dizziness, (f) headache, (g) weakness and sleepiness. If you feel any of these

symptoms, move into fresh air immediately. If

symptoms persist, get medical help.

2.2 STARTING THE GENERATOR

IMPORTANT: READ THE VEHICLE MANUFACTURER’S INSTRUCTIONS. THE OWNER/OPERATOR

SHOULD BECOME FAMILIAR WITH THE VEHICLE

IN WHICH THIS GENERATOR IS INSTALLED.

DIFFERENCES EXIST BETWEEN VEHICLES. FOR

EXAMPLE, SOME VEHICLES MAY USE A TRANSFER SWITCH TO ISOLATE DOCKSIDE POWER

FROM THE GENERATOR, WHILE OTHER VEHICLES MAY USE AN ISOLATING RECEPTACLE.

SOME VEHICLES MAY BE EQUIPPED WITH A DC

CONVERTER WHICH ALLOWS THE GENERATOR

TO POWER CERTAIN DC LIGHTING AND OTHER

DC LOADS.

To crank and start the generator engine, proceed as

follows:

1. Turn OFF electrical loads, using whatever means

provided in your vehicle (such as a main line circuit breaker or transfer switch).

NOTE:

If you start the engine with the start/stop switch

on the generator control panel, turn OFF loads by

setting the panel’s main breaker to its “OFF” or

“OPEN” position. Electrical load circuits may be

turned ON after the generator has started, stabilized and warmed up.

NOTE:

On gas units you only need to use the fuel primer

during the initial startup, after the unit has not

been used for an extended period of time (two

weeks) or the fuel line has been disconnected. The

primer is used to prime the fuel pump and carburetor.

2. To crank and start the engine, hold the start/stop

switch at START. Release the switch when the

engine starts.

◆

◆

◆

◆

◆

Page 12

10 Generac®Power Systems, Inc.

Section 2 – Operation

IMPACT-36 plus II Recreational Vehicle Generator

If the engine does not start after it has been

cranking for 15 seconds, release the start/stop

switch and try again. Holding the switch for

longer than 15 seconds may damage the

starter motor.

3. Let the engine run at no-load for a few minutes to

stabilize and warm up the engine.

4. Turn ON electrical loads, using whatever means

provided (such as a main circuit breaker or

transfer switch).

NOTE:

If you start a warm generator engine, you may

press the start switch only slightly to engage the

ignition system. However, you should press and

hold the starter switch for a minimum of two (2)

seconds to energize the field boost system. If you

start the engine without energizing the field boost

system, the generator produces no output.

2.3 STOPPING THE GENERATOR

1. Turn OFF all electrical loads, using whatever

means provided (such as a main circuit breaker

or transfer switch).

2. Let the generator run at no-load for a few minutes, to stabilize internal engine-generator temperatures.

3. Hold Start/Stop switch in its STOP position.

2.4 APPLYING LOADS TO GENERATOR

When applying electrical loads to the generator,

observe these guidelines:

• Before applying electrical loads, let the generator

stabilize and warm up for a minute or two.

• DO NOT overload the generator.

2.4.1 LETTING ENGINE STABILIZE

The generator supplies correctly rated frequency and

voltage only at the proper governed speed. Some electrical appliances may be extremely sensitive to voltage and frequency. Incorrect frequencies and/or voltages can damage those appliances.

If electrical loads are applied at reduced operating

speeds, such loads imposed on the engine when sufficient power is not available may shorten engine life.

Never turn ON electrical loads until after the generator engine has started and stabilized ON-speed.

2.5 ATTENTION REQUIRED AFTER

SUBMERSION

If the motor home generator has been submerged in

water, it must NOT be started or operated. Following

any submersion in water, have an authorized

Generac Service Facility thoroughly clean and dry the

generator.

2.6 OPERATION IN HIGH GRASS OR

BRUSH

Never operate the generator while the vehicle is

parked in high grass, weeds, brush or leaves. Such

materials can ignite and burn from the heat of the

exhaust system. The generator exhaust system

becomes extremely hot during operation and remains

hot for a long time after it has shut down.

2.7 OPERATING PRECAUTIONS

Never operate the motor home generator set while the

vehicle is parked over dry leaves, dry grass or any

other combustible substance. The generator’s

exhaust system becomes extremely hot and can cause

a fire if it is too close to combustible materials.

2.8 FUEL REQUIREMENTS (GASOLINE

UNITS)

These generators are equipped with gasoline fuel systems as standard equipment. Specific installations

may provide either a separate fuel tank for the generator, or the generator may “share” the vehicle engine’s

fuel tank.

NOTE:

Installations using a “shared” fuel tank may have

a generator fuel pickup tube that is shorter than

the vehicle engine’s pickup tube. Such an

arrangement causes the generator engine to “run

out of gas” while adequate fuel for the vehicle

remains in the tank.

To reduce lead and carbon deposits use high quality

UNLEADED gasoline with the generator. Leaded

REGULAR grade gasoline is an acceptable substitute.

NOTE:

Using “Unleaded” gasoline contributes to longer

engine valve life by reducing lead and carbon

deposits.

◆

Page 13

Generac®Power Systems, Inc. 11

Section 2 – Operation

IMPACT-36 plus II Recreational Vehicle Generator

Generac does not recommend using any gasoline containing alcohol, it must not contain

more than 10 percent ethanol and it must be

removed from the generator during storage.

Do NOT use any gasoline containing

methanol. If you use gasoline with alcohol,

inspect more frequently for fuel leaks and

other abnormalities.

FUEL CONSUMPTION (IN GALLONS PER HOUR):

2.9 FUEL REQUIREMENTS (LP UNITS)

These generators are equipped with a liquefied petroleum (LP) gas fuel system. LP gas is usually supplied

as a liquid in pressure tanks.

These generators require a “vapor withdrawal” type

fuel system. This type of gaseous fuel system uses

the vapors forming above the liquid fuel in the storage tank. Air temperature around the storage tank

must be high enough to sustain adequate fuel vaporization. In colder climates, you may need to use an

independent heat source to be sure the fuel sufficiently vaporizes in the storage tank.

LP gas may consist of propane, butane or a mixture

of the two gases. Propane vaporizes at temperatures

as low as -20°F (-29°C), but butane returns to its liquid state when the temperature drops below about

32°F (0°C). For that reason, a higher ratio of propane

is desired in the gas mixture when temperatures

drop below freezing.

2.10 ENGINE OIL REQUIREMENTS

The recommended oils include the following:

• During summer months: SAE 30. An acceptable

substitute is SAE 10W-30.

• During winter months: SAE 5W30. DO NOT USE

SAE 10W-40.

Crankcase and oil filter capacity is about 950ml or

one (1) quart. Use no special additives. See

“Maintenance” section for oil level check and fill procedures.

2.11 GAS GENERATOR SPECIFICATIONS

Model ..................................................Impact-36G plus II

Rated Maximum Continuous

AC Power Output ..............................3600 watts (3.6 kW)

Rated Voltage ................................................120 volts AC

Rated Maximum Continuous

Current at 120 volts ..................................30 AC amperes

Phase ............................................................Single Phase

Rated AC Frequency ................................................60 Hz.

Recommended Battery

Cranking Current ..............................................400 amps

Gross Weight ............................................................97 lbs

Maximum Cranking Current..............................250 Amps

Maximum Charging Current ..................................2 Amps

2.12 LP GENERATOR SPECIFICATIONS

Model ..............................................Impact-36LPG plus II

Rated Maximum Continuous

AC Power Output ..............................3400 watts (3.4 kW)

Rated Voltage ................................................120 volts AC

Rated Maximum Continuous

Current at 120 volts................................28.3 AC amperes

Phase ............................................................Single Phase

Rated AC Frequency ................................................60 Hz.

Recommended Battery

Cranking Current ..............................................400 amps

Gross Weight ............................................................99 lbs

Maximum Cranking Current..............................250 Amps

Maximum Charging Current ..................................2 Amps

2.13 ENGINE SPECIFICATIONS

Type of Engine ......................................................GN-220

Cooling Method ..................................................Air-cooled

Displacement............................................................220cc

Type of Governor ..............................................Electronic

Air Cleaner ..................................................Paper element

Starter ..................................................12 volt DC electric

Ignition System ................................................Solid state

Recommended Spark Plugs ................Champion RC12YC

Spark Plug Gap ..................................0.030 inch (0.8mm)

LOAD GASOLINE LP

NO 0.14 0.20

HALF 0.32 0.41

FULL 0.54 0.77

Page 14

12 Generac®Power Systems, Inc.

Section 3 – Maintenance

IMPACT-36 plus II Recreational Vehicle Generator

3.1 MAINTENANCE

This section includes information about simple

maintenance which includes the following tasks:

• Checking engine oil level.

• Changing engine oil.

• Changing oil filter.

• Air cleaner maintenance.

• Cleaning the air intake screen.

Cleaning spark arrestor.

• Cleaning spark plug.

Replacing fuel filter.

Servicing inverter.

3.2 CHECKING ENGINE OIL LEVEL

Check engine crankcase oil level at least every eight

hours of operation, or before each use (Figure 3.1).

• Be sure the generator is as level as possible.

• Remove oil dipstick and wipe dry with clean, lint-

free cloth.

• Install and tighten oil dipstick, then remove again.

• Oil should be at dipstick FULL mark. If necessary,

add the recommended oil to the FULL mark only.

DO NOT FILL ABOVE “FULL” MARK.

• Install and tighten oil dipstick cap before operating

the engine.

Figure 3.1 — Oil Dipstick and Fill Tube

NOTE:

See “Engine Oil Requirements” on Page 11 for

recommended oils.

3.3 CHANGE ENGINE OIL

Change engine oil after the first 8 hours of operation.

Thereafter, change oil every 100 operating hours.

Change oil more frequently if operating consistently

under heavy load or at high ambient temperatures.

• Warm up engine for at least five minutes, then shut

down.

• With engine still warm from running, clean area

around oil drain plug and remove oil drain plug

(Figure 3.2). Drain oil completely into a suitable

container.

• When oil has drained, install and tighten drain

plug.

• Remove oil dipstick and fill crankcase with the

recommended oil (See Page 11). The engine

crankcase can hold about 1 quart (950ml). DO

NOT FILL ABOVE “FULL” MARK.

• Install and tighten dipstick cap before operating

engine.

3.4 CHANGE OIL FILTER

Replace the engine oil filter after the first 8 hours of

operation, every 100 operating hours thereafter.

• Turn oil filter counterclockwise to remove (Figure

3.2).

Figure 3.2 — Oil Drain Plug and Engine Oil

Filter

• Coat gasket of new filter with engine oil.

• Turn new filter clockwise until its gasket contacts

lightly with the filter adapter. Then tighten an additional 3/4 to one turn by hand.

• Run engine and check for leaks.

NOTE:

Check oil level and fill to full mark after checking

for leaks. Filter will retain some oil.

Oil Dipstick and Fill Tube

Page 15

Generac®Power Systems, Inc. 13

Section 3 – Maintenance

IMPACT-36 plus II Recreational Vehicle Generator

3.5 ENGINE AIR CLEANER

Paper Filter: Once every 25 operating hours or once

each year (whichever comes first), clean or replace

the paper filter (Figure 3.3). Follow the steps on page

12.

Figure 3.3 — Engine Air Cleaner Assembly

• Remove air cleaner cover, then remove paper filter.

• Clean air filter by gently tapping it on a solid surface. If the filter is too dirty, replace it with a new

one. Dispose of the old filter properly.

• Clean air cleaner cover then insert new paper filter

into cover and assemble to the base of the air

cleaner.

3.6 CLEAN AIR INTAKE SCREEN

Clean all foreign material from the air intake screen

(Figure 3.4) at lease once every 100 hours of operation. Clean more often if necessary.

Inspect the area around the generator exhaust muffler periodically and remove all grass, leaves, dirt,

etc. from this area.

Figure 3.4 — Clean Air Intake Screen

3.7 ENGINE SPARK PLUG

Clean engine spark plug and set gap to 0.030 inch

(0.76mm) every 100 hours of operation (Figure 3.5).

Clean by scraping or wire brushing and washing with

commercial solvent. DO NOT BLAST CLEAN SPARK

PLUG.

Figure 3.5 — Setting Gap on Spark Plug

Sparking can occur if wire terminal does not

fit firmly over spark plug terminal end. If necessary, reform wire terminal to obtain a tight

fit.

3.8 FUEL FILTER

Remove and replace fuel filter (Figure 3.6) every 100

hours of operation or once each year, whichever

occurs first.

Figure 3.6 — Fuel Filter

Air Intake Screen

To Fuel Pump

Fuel Filter

Customer Fuel Connection

Page 16

14 Generac®Power Systems, Inc.

Section 3 – Maintenance

IMPACT-36 plus II Recreational Vehicle Generator

3.9 INVERTER

All repairs of the inverter must be handled by an

authorized service dealer (see Figure 3.7).

Figure 3.7 — Inverter Warning Label

3.10 CLEANING THE GENERATOR

Keep your generator set as clean and dry as possible.

Dirt and moisture that are permitted to accumulate

on electrical windings have an adverse affect on the

insulation resistance of those windings.

Moisture that is allowed to remain in contact with

windings will be retained in voids and cracks of the

windings. Dirt makes the problem worse, since it

tends to hold the moisture into contact with the windings. Salt, as from sea air, worsens the problem since

it tends to absorb moisture from the air. The combination of salt and moisture makes a good electrical

conductor.

Do NOT use a forceful spray of water to clean

the generator. Water will enter the generator

interior and cause problems, and may also

contaminate the generator fuel system.

3.11 BATTERY

All lead-acid storage batteries will discharge when

not in use. Inspect the generator battery as follows:

3.11.1 ONCE WEEKLY

Inspect battery posts and cables for tightness, corrosion. Clean and/or tighten as necessary.

Also check battery fluid level, and, if necessary, fill

with DISTILLED WATER ONLY. DO NOT USE TAP

WATER IN BATTERY.

3.11.2 EVERY SIX MONTHS

Have the battery state of charge and condition

checked by an automotive service facility. This should

be done with an automotive type battery hydrometer.

Storage batteries give off explosive hydrogen

gas. This can form an explosive mixture

around the battery for several hours after

charging. The slightest spark can ignite the

gas and cause an explosion. Such an explosion can shatter the battery and cause blindness or other injury. Any area that houses a

storage battery must be properly ventilated.

Do not allow smoking, open flame, sparks or

any spark producing tools or equipment near

the battery.

Battery electrolyte fluid is an extremely caustic sulfuric acid solution that can cause severe

burns. Do not permit fluid to contact eyes,

skin, clothing, painted surfaces, etc. Wear

protective goggles, protective clothing and

gloves when handling a battery. If you spill

the fluid, flush the affected area immediately

with clear water.

Do not use any jumper cables or booster battery to crank and start the generator engine.

If any battery has discharged, remove it from

the vehicle for recharging.

3.12 SERVICE AND ADJUSTMENTS

3.12.1 ENGINE SPEED

Engine speed is completely computer-controlled.

There is no adjustment for speed on the unit. The

computer adjusts the engine speed using an electronic governor throttle control. The computer monitors

the demand for power and adjusts the engine speed

accordingly. This allows the engine to produce only

the power required, resulting in fuel economy as well

as lowering the overall noise emitted.

NOTE:

The computer will disable the electrical load capabilities of the generator and enter a fault condition

if you accelerate the throttle manually or any

other way.

3.13 ADJUSTING THE CARBURETOR

The carburetor of your generator is preset at the factory. The carburetor should not be tampered with, as

this will void the emission control system warranty. If

your generator is used at altitudes in excess of 5,000

feet, consult your Generac Authorized Service Facility

regarding high altitude jetting changes.

◆

◆

◆

Page 17

Section 3 – Maintenance

IMPACT-36 plus II Recreational Vehicle Generator

3.14 ADJUSTING VALVE CLEARANCE

After the first 50 hours of operation, you should

adjust the valve clearance in the engine.

When adjusting valve clearance, the engine should be

at room temperature and the piston should be at Top

Dead Center (TDC) of its compression stroke (both

valves closed). Correct clearance is 0.001-0.003 inch

(0.03-0.07mm). Adjust valve clearance as follows:

1. Loosen the rocker arm jam nut. Use an allen

wrench to turn the pivot ball stud while checking

clearance between the rocker arm and the valve

stem with a feeler gauge (Figure 3.8).

Figure 3.8 — Adjusting Valve Clearance

2. When valve clearance is correct, hold the pivot

ball stud with the allen wrench and tighten the

rocker arm jam nut with a crows foot. Tighten the

jam nut to 65-85 inch-pounds torque. After tightening the jam nut, recheck valve clearance to

make sure it did not change (Figure 3.9).

Figure 3.9 — Tightening Jam Nut

3.15 MAJOR SERVICE MANUAL

To obtain a service manual for your generator, order

it from your dealer/distributor or contact the factory.

Be sure to identify your unit’s MODEL NUMBER and

SERIAL NUMBER.

3.16 EXERCISING THE GENERATOR

Generac recommends that you start and operate the

generator at least once every seven days. Let the unit

run for at least 30 minutes to “exercise” the engine.

3.17 OUT OF SERVICE PROTECTION

If you cannot exercise the generator every seven days

and it is to be out of service longer than 30 days, prepare the generator for storage as follows:

• Start the engine and let it warm up.

• While the engine is still warm from running, drain

the oil completely. Refill crankcase with recommended oil. See “Specifications.”

• Attach a tag to the engine indicating the viscosity

and classification of the oil in the crankcase.

• Remove spark plug and add about 1/2 ounce

(15ml) of clean, fresh engine oil into spark plug

threaded opening. Crank engine several times to

distribute oil, then install and tighten spark plug.

• Remove the battery and store in a cool, dry room

on a wooden board. Never store the battery on any

concrete or earthen floor.

• Clean and wipe the entire generator.

3.18 RETURN UNIT TO SERVICE AFTER

STORAGE

To return the unit to service after storage, proceed as

follows:

• Check tag on engine for oil viscosity and classification. Verify that the correct recommended oil is

used in engine. If necessary, drain and refill with

proper oil.

• Check battery. Fill all cells to the proper level with

distilled water. DO NOT USE TAP WATER IN THE

BATTERY. Recharge battery to 100% state of

charge, or, if defective, replace the battery.

• Turn OFF all electrical loads, then start the engine.

• Let engine warm up.

• Apply electrical loads up to at least 50% of the

unit’s rated wattage capacity.

• When engine is thoroughly warmed up, shut it

down.

THE GENERATOR IS NOW READY FOR SERVICE.

Generac®Power Systems, Inc. 15

Page 18

16 Generac®Power Systems, Inc.

Notes

IMPACT-36 plus II Recreational Vehicle Generator

EJ

Page 19

PART II –

INSTALLATION

INSTRUCTIONS

ONLY QUALIFIED ELECTRICIANS OR CONTRACTORS

SHOULD ATTEMPT INSTALLATION!!

Page 20

18 Generac®Power Systems, Inc.

NOTICE TO INSTALLER

These Installation Instructions have been published

by Generac to aid in the installation of the products

described in this manual. Generac assumes that

installation personnel are familiar with the procedures

for installing such products, or similar products that

Generac manufactures. Generac also assumes that

personnel have been trained in the recommended

installation procedures for these products and that

such training includes (a) use of common hand tools,

(b) use of special Generac tools, and (c) use of any

tools and/or equipment from other suppliers.

Generac cannot possibly know of, nor advise the

recreational vehicle trade of, all conceivable methods,

procedures, or techniques by which to perform an

installation. Nor can Generac anticipate every possible hazard that might result from each installation

method, procedure, or technique. Generac has not

undertaken any such wide evaluation. Therefore,

people who use a method, procedure, or technique

that Generac does not specifically recommend must

first completely satisfy themselves that their safety,

the safety of the vehicle's occupants, and the product's safety are not endangered by the method, procedure, or technique selected.

Information, illustrations, specifications, etc., contained in these Installation Instructions are based on

the latest information available at the time of publication. Every effort has been expended to be sure that

such data are both accurate and current. However,

the manufacturer reserves the right to change, alter,

or otherwise improve this product at any time, without prior notice.

Despite the safe design of this generator,

operating this equipment imprudently, neglecting

its maintenance, or being careless can cause

possible injury or death. Permit only responsible

and capable persons to operate or maintain this

equipment.

Parts of the generator are rotating and/or hot

during operation. Exercise care near running

generators.

Potentially lethal voltages are generated by

these machines. Ensure all steps are taken to

render the machine safe before attempting to

work on the generator.

GENERAL HA

ZARDS

• For safety reasons, Generac recommends

that the installation, initial startup, and maintenance of this equipment is carried out by a

Generac Authorized Service Dealer.

• The engine exhaust fumes contain carbon monoxide, which can be DEADLY. This dangerous gas, if

breathed in sufficient concentrations, can cause

unconsciousness or even death. This exhaust system must be installed properly, in strict compliance with applicable codes and standards.

Following installation, you must do nothing that

might render the system unsafe or in noncompliance with such codes and standards. The generator compartment must be completely vapor-sealed

from the vehicle interior. There must be no possibility of exhaust fumes entering the vehicle interior. Never operate this equipment with a leaking or

defective exhaust system.

• Keep hands, feet, clothing, etc., away from drive

belts, fans, and other moving or hot parts.

Never remove any drive belt or fan guard while

the unit is operating.

• Adequate, unobstructed flow of cooling and ventilating air is critical to correct generator operation and is required to expel toxic fumes and

fuel vapors from the generator compartment.

Without sufficient cooling airflow, the

engine/generator quickly overheats, which causes serious damage to the generator. Do not alter

the installation or permit even partial blockage

of ventilation provisions, as this can seriously

affect safe operation of the generator.

• When working on this equipment, remain alert at

all times. Never work on the equipment when you

are physically or mentally fatigued.

• Before performing any maintenance on the generator, disconnect its battery cables to prevent accidental startup. First, disconnect the cable from the

battery post, indicated by a NEGATIVE, NEG, or

(–). Reconnect that cable last.

• Never use the generator or any of its parts as a

step. Stepping on the unit can stress and break

parts, and may result in dangerous operating conditions from leaking exhaust gases, fuel leakage,

oil leakage, etc.

• Never insert any tool or other object through openings in the generator interior, even if the unit is not

running. You might seriously injure yourself or

damage the equipment.

Safety Rules

IMPACT-36 plus II Recreational Vehicle Generator

DANGER: For fire safety, installation of a generator into a recreational vehicle must comply

strictly with NFPA 70 (latest edition), “National Electrical Code”, Article 551, and NFPA 1192

(latest edition), “Standard for Recreational Vehicles”. In addition, installation must comply with

the manufacturer’s instructions and recommendations.

Page 21

Generac®Power Systems, Inc. 19

ELECTRICAL HAZARDS

• The generator covered by this manual produces

dangerous electrical voltages that can cause fatal

electrical shock. Avoid contact with bare wires, terminals, connections, etc., while the unit is running.

Ensure all appropriate covers, guards, and barriers are in place before operating the generator. If

you must work around an operating unit, stand on

an insulated, dry surface to reduce shock hazard.

• Do not handle any kind of electrical device while

standing in water, while barefoot, or while hands

or feet are wet. DANGEROUS ELECTRICAL

SHOCK MAY RESULT.

• During installation onto the vehicle, properly

ground (bond) the generator either by solid mounting to the vehicle frame or chassis, or by means of

an approved bonding conductor. DO NOT connect

the bonding conductor to any generator part that

might be removed or disassembled during routine

maintenance. If the grounding conductor must be

replaced, use only a flexible conductor that is of

No. 8 American Wire Gauge (AWG) copper wire

minimum.

• If the vehicle electrical circuits can be powered by

any other source of electricity (such as, a “dockside”

power receptacle), there must be no possibility of

connecting the different power sources to the vehicle’s circuits at the same time. The dockside (utility)

power source must be positively isolated from the

vehicle’s circuits whenever the generator is operating. Failure to isolate the vehicle’s circuits from the

dockside power supply when the generator is running may result in damage to the generator or in

serious injury or death to dockside (utility) power

workers due to backfeed of electrical energy.

• In case of an accident caused by electric shock,

immediately shut down the source of electrical

power. If this is not possible, attempt to free the

victim from the live conductor. AVOID DIRECT

CONTACT WITH THE VICTIM. Use a nonconducting implement, such as, a rope or board, to

free the victim from the live conductor. If the victim is unconscious, apply first aid, and get

immediate medical help.

• Never wear jewelry when working on this equipment. Jewelry can conduct electricity, resulting in

electric shock, or may get caught in moving components, causing injury.

FIREHAZARDS

• For fire safety, the generator must be installed

and maintained properly. Installation always

must comply with applicable codes, standards,

laws, and regulations. Adhere strictly to local,

state and national electrical and building codes.

Comply with regulations the Occupational Safety

and Health Administration (OSHA) has established. Also, ensure that the generator is

installed in accordance with the manufacturer’s

instructions and recommendations. Following

proper installation, do nothing that might alter a

safe installation and render the unit in noncompliance with the aforementioned codes, standards, laws, and regulations.

• Keep a fire extinguisher in the vehicle at all times.

Extinguishers rated “ABC” by the National Fire

Protection Association are appropriate for use on

the recreational vehicle generator electrical system.

Keep the extinguisher properly charged, and be

familiar with its use. If you have any question pertaining to fire extinguishers, consult your local fire

department.

EXP

LOSION HAZARDS

• Do not smoke around the generator. Wipe up any

fuel or oil spills immediately. Ensure that no combustible materials are left in the generator compartment, or on or near the generator, as FIRE or

EXPLOSION may result. Keep the area surrounding the generator clean and free from debris.

• All fuel types are potentially FLAMMABLE and/or

EXPLOSIVE and should be handled with care.

Comply with all laws regulating the storage and handling of fuels.

• Fuel supply lines must be properly installed, purged

and leak-tested according to applicable fuel-gas

codes, before placing this equipment into service.

There must be no possibility of fuel vapors entering the vehicle interior.

• You are required to install an approved, flexible,

nonconductive fuel line between the generator fuel

connection point and the rigid fuel lines.

Safety Rules

IMPACT-36 plus II Recreational Vehicle Generator

Page 22

20 Generac®Power Systems, Inc.

1.1 PURPOSE AND SCOPE

OF THE MANUAL

These Installation Instructions have been prepared

especially for the purpose of familiarizing installers

and owners of the applicable equipment with the

product's installation requirements. Give serious

consideration to all information and instructions in

the manual, both for safety and for continued reliable

operation of the equipment.

Because of the different recreational vehicle models

and the variations between the models, it would be

extremely difficult, if not impractical, to provide

detailed instructions for every possible installation.

For that reason, instructions and illustrations in this

manual are general in nature. Illustrations are not

intended to serve as detailed installation blueprints.

The installation should comply strictly with all

applicable codes, standards, and regulations pertaining to the installation and use of this product. If any

portion of this manual appears to be in conflict with

such codes, standards, or regulations, the applicable

codes, standards, or regulations must take precedence over the manual.

1.2 SAFETY

Before handling, installing, operating, or servicing

this equipment, carefully read the “Notice to

Installer” and “Safety Rules” on Pages 18 and 19.

Comply with all safety rules to prevent death, personal injury, or damage to equipment and/or property. Stress safety to all installers, operators, and service technicians who work on this equipment.

1.3 STANDARDS BOOKLETS

Installation, use, and servicing of this equipment

should comply strictly with published standards, as

well as the manufacturer's recommendations. The

following standards booklets (latest revision) are

available from the sources indicated:

1. NFPA 1192, “Standard for Recreational Vehicles”

(replaces ANSI A119.2/NFPA 501C), available

from the National Fire Protection Association,

Batterymarch Park, Quincy, MA 02269.

2. NFPA 70, “NFPA Handbook of the National

Electric Code,” available same as Item 1.

3. ANSI/RVIA EGS-1, “Engine Generator Sets for

Recreational Vehicle Safety Requirements”, avaialable from the Recreational Vehicle Industry

Association, 1896 Preston White Drive, Reston,

VA 22090.

4. California Administrative Code, Title 25, available from the State of California, Documents

Section, P.O. Box 1015, North Highlands,

CA 95660.

5. CSA Electrical Bulletin 946, available from the

Canadian Standards Association, Housing and

Constructions Materials Section, 178 Rexdale

Boulevard, Rexdale, Ontario, Canada, M9W 1R3.

1.4 EQUIPMENT DESCRIPTION

Instructions and information in this section pertain

to Generac Impact air-cooled generators — more

specifically, the installation of Impact-34 plus II and

IMPACT-36 plus II Recreational Vehicle Generators.

These generators are designed specifically for

installing in recreational vehicles.

1.5 ENGINE GENERATOR OPERATING

SPEED

The generators are driven by gasoline-powered, single-cylinder engines. The engines drive revolving

fields (rotors), high frequency, permanent magnet

alternators. The generators supply 120 volts AC at 60

Hertz with DC inverter. The generators revolving

fields are driven at a variable speed depending on the

demand for power. Computers monitor that demand

and adjust the engine speed to provide adequate

power to the connected loads.

Section 1 – General Information

IMPACT-36 plus II Recreational Vehicle Generator

Page 23

Generac®Power Systems, Inc. 21

Section 2 – Installation

IMPACT-36 plus II Recreational Vehicle Generator

2.1 LOCATION AND SUPPORT

2.1.1 GENERATOR LOCATION

The most desirable location for the generator set is

between the vehicle's main frame members However,

this is seldom possible. Most units must be installed

on the side of the vehicle and are difficult to reinforce.

Many recreational vehicles have been factory

equipped with an area for the generator set. Some

vehicles may even have a generator compartment,

provided by the vehicle manufacturer.

Plan the generator location based on the following:

• The generator set must be installed on a framework

that is part of the recreational vehicle, as outlined in

the paragraph entitled “Generator Support.”

• The location must provide an access opening that

is large enough to permit generator removal

(unless the generator is to be removed from underneath the supporting framework.

• The location must provide easy access to frequently

serviced components, such as filters, oil drains,

spark plugs and other common maintenance parts.

• The location must provide sufficient room to allow

minimum clearance of at least 1 inch between all

sides and 1-1/2 inches on top of the generator. If

sound insulation is to be used on compartment

walls and ceiling, the minimum recommended

applies to the space between the generator and

such insulation.

• The location must provide adequate cooling and

ventilating air flow for the generator without a

great deal of work and expense.

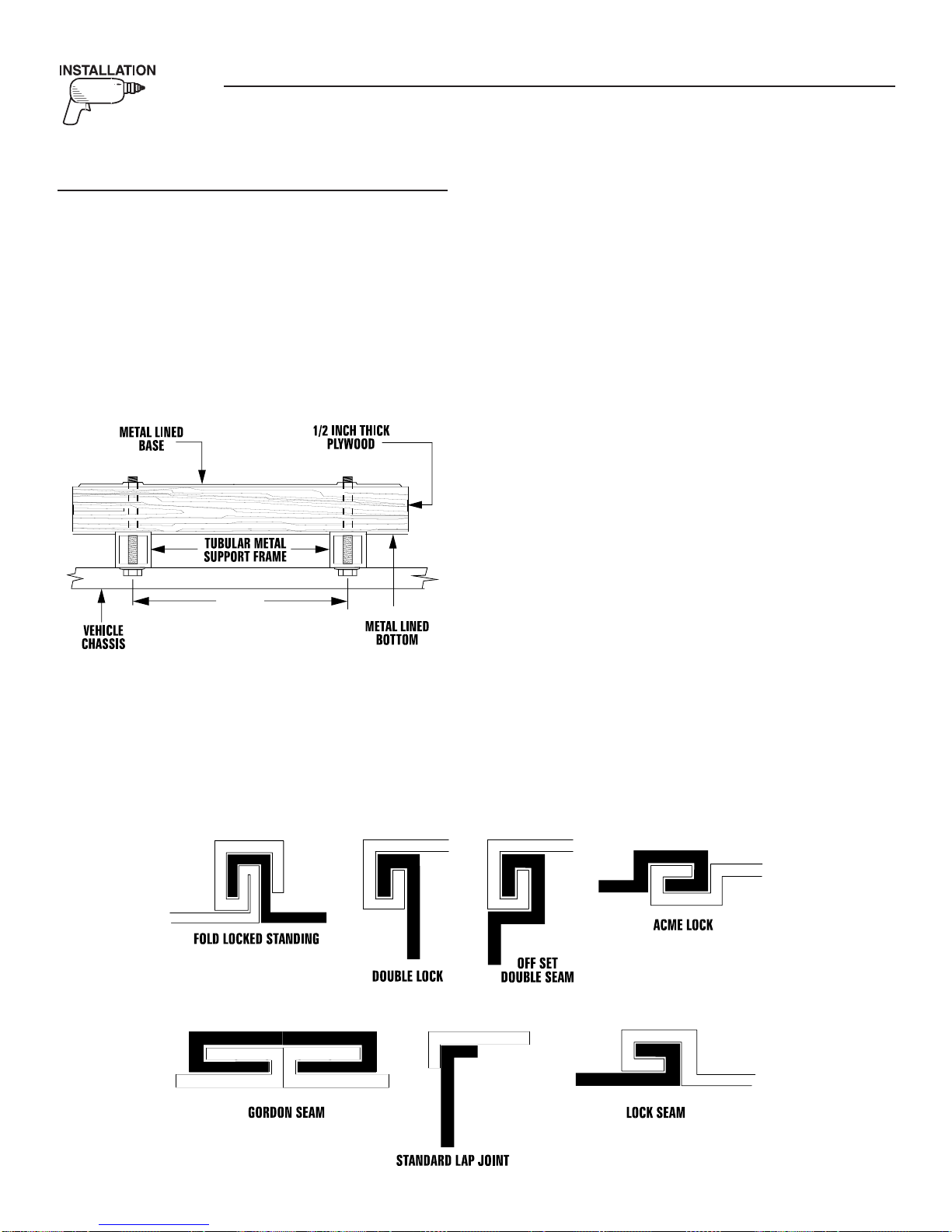

2.1.2 GENERATOR SUPPORT

The generator must be securely attached to a metal

framework that has been made part of the vehicle

frame structure by bolting or welding. The metal

framework on which the generator will rest and

which will restrain the generator set should consist of

at least two horizontal beams. These beams should

consist of (a) 1-1/2 inch square, 11 gauge steel tubing

OR (b) 1-1/2 inch, 11 gauge angle iron. A typical supporting frame with horizontal support tubing, is

shown in Figure 2.1.

The generator can be installed so that it sits on top of

the horizontal support tubing, if the vehicle design

permits. Another method is to suspend the generator

below the horizontal support tubing by means of suitable, structurally sound metal framework. The following general rules apply:

• Vehicle construction MUST be capable of supporting the weight of the generator.

• Whether the generator is mounted above the horizontal support tubing or suspended below the tubing, the supporting frame used must be structurally sound.

• If the generator cannot be bolted directly to the

supporting frame or support tubing, consider

using additional tubing, angle brackets or other

supports to give the supporting frame sufficient

strength.

Figure 2.1 —Typical Horizontal Support Frame

2.1.3 SUSPENDED MOUNTING

If you are going to suspend the generator below the

horizontal support tubing, the suspension method

you use with the vehicle frame members must have

the following: (a) be able to support the weight of the

generator; and (b) provide sufficient restraint for the

generator. One typical suspended mounting system is

shown in Figure 2.2. The location of a suspended

mounting system must be carefully planned, keeping

the following general rules in mind:

• Protect the generator against road splash and

debris. Baffles or splash guards may be required

to protect certain areas of the generator. To make

sure the generator is adequately protected, road

test the installation through mud, water and slush.

Figure 2.2 — Typical Suspended Mounting

System

• The installer must make certain that selected location will permit adequate cooling and ventilating

air flow to be supplied.

◆

◆

◆

Page 24

22 Generac®Power Systems, Inc.

Section 2 – Installation

IMPACT-36 plus II Recreational Vehicle Generator

2.1.4 GENERATOR RESTRAINT

Use four 3/8"-16 hardened steel bolts (Grade 5) to

fasten the generator to the supporting frame or the

support tubing. These bolts must pass through (a)

the generator mounting base, (b) the compartment