Page 1

®

Protector™

Series

INCLUDES:

• Two Line LCD Multilingual Digital

Evolution™ Controller (English/Spanish/

French/Portuguese) with external viewing

window for easy indication of generator

status and breaker position.

• Isochronous Electronic Governor

• Sound Attenuated Enclosure

• Smart Battery Charger

• UV/Ozone Resistant Hoses

• ±1% Voltage Regulation

• Integrated Base Tank Provides 24 Hour

Run Time Minimum at 1/2 Load

Standby Generators

Diesel Engine

Protector™ Series

1 of 6

Not for sale outside of US/CA

Standby Power Rating

Model RD015 (Gray) - 15 kW 60 Hz

Model RD020 (Gray) - 20 kW 60 Hz

Model RD030 (Gray) - 30 kW 60 Hz

Model RD048 (Gray) - 48 kW 60 Hz (single phase only)

Model RD050 (Gray) - 50 kW 60 Hz (three phase only)

• 5 Year Limited Warranty

• UL/CUL2200/UL 142 Listed

• Meets code requirements for External

Vent and Fill

FEATURES

¡ INNOVATIVE DESIGN & PROTOTYPE TESTING are key components of

GENERAC’S success in “IMPROVING POWER BY DESIGN.” But it

doesn’t stop there. Total commitment to component testing, reliability

testing, environmental testing, destruction and life testing, plus testing

to applicable CSA, NEMA, EGSA, and other standards, allows you to

choose GENERAC POWER SYSTEMS with the confidence that these

systems will provide superior performance.

¡ TEST CRITERIA:

PROTOTYPE TESTED NEMA MG1-22 EVALUATION

SYSTEM TORSIONAL TESTED MOTOR STARTING ABILITY

Meets EPA Emission Regulations

CA/MA Emissions Compliant

¡ SOLID-STATE, FREQUENCY COMPENSATED VOLTAGE REGULATION.

This state-of-the-art power maximizing regulation system is standard on

all Generac models. It provides optimized FAST RESPONSE to changing

load conditions and MAXIMUM MOTOR STARTING CAPABILITY by

electronically torque-matching the surge loads to the engine. Digital

voltage regulation at ±1%.

¡ SINGLE SOURCE SERVICE RESPONSE from Generac’s extensive dealer

network provides parts and service know-how for the entire unit, from the

engine to the smallest electronic component.

¡ GENERAC TRANSFER SWITCHES. Long life and reliability are

synonymous with GENERAC POWER SYSTEMS. One reason for this

confidence is that the GENERAC product line includes its own transfer

systems and controls for total system compatibility.

Page 2

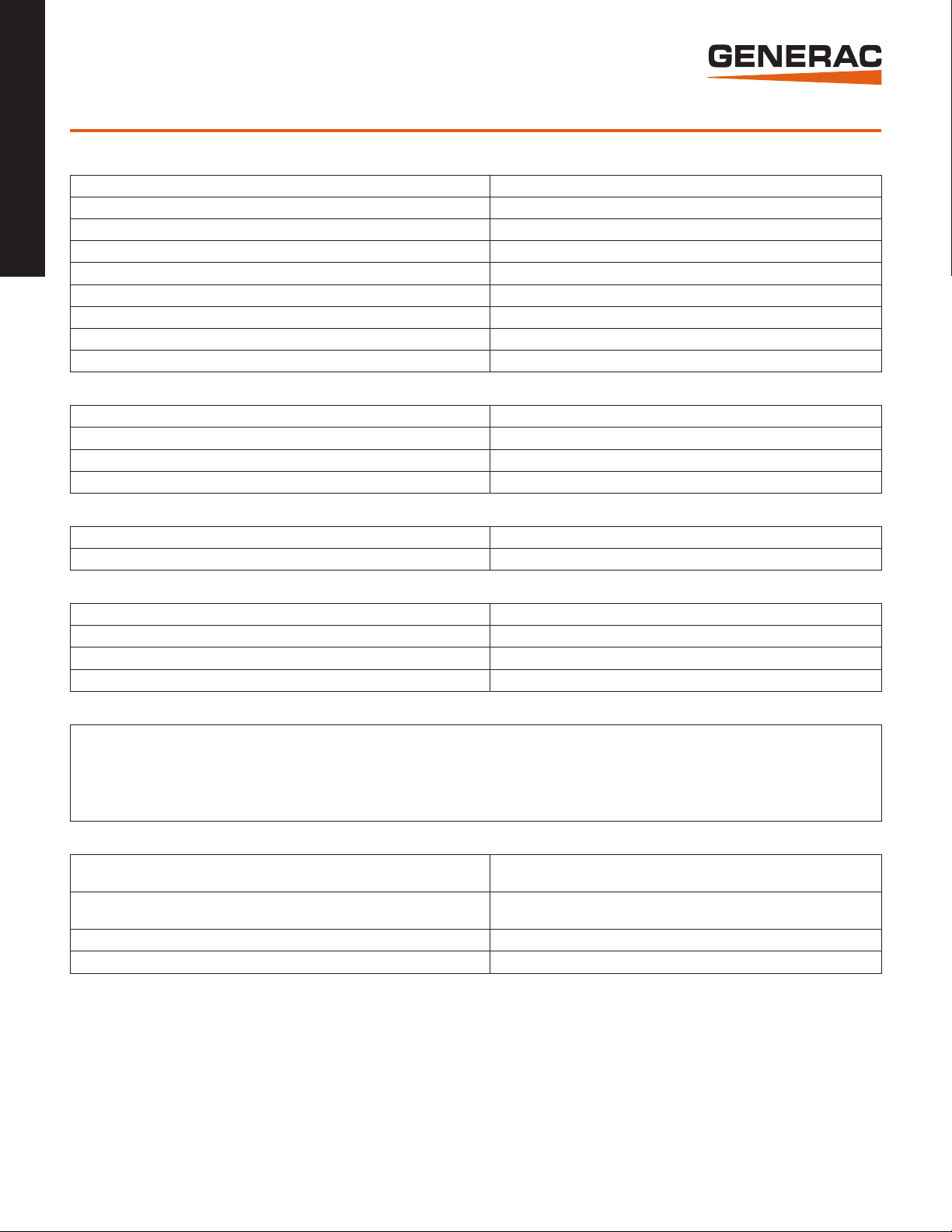

15 • 20 • 30 • 48 • 50 kW application & engineering data

GENERATOR SPECIFICATIONS

Type Synchronous

Protector™ Series

Rotor Insulation Class H (15 & 20 kW) or F (30 & 50 kW)

2 of 6

Stator Insulation Class H

Telephone Interference Factor (TIF) <50

Alternator Output Leads 1-Phase 3 wire

Alternator Output Leads 3-Phase 6 wire

Bearings Single Sealed Cartridge

Coupling Direct, Flexible Disc

Excitation System Direct

VOLTAGE REGULATION

Type Electronic

Sensing Single Phase

Regulation ± 1%

Features Adjustable Voltage & Gain

®

GOVERNOR SPECIFICATIONS

Type Electronic Isochronous

Steady State Regulation ± 0.25%

ELECTRICAL SYSTEM

Battery Charge Alternator 50 Amp (15 & 20 kW) or 70 Amp (30, & & 50 kW)

Smart Battery Charger 2 Amp

Recommended Battery

System Voltage 12 Volts

Group 27F, 700 CCA

GENERATOR FEATURES

Revolving field heavy duty generator

Directly connected to the engine

Operating temperature rise 120°C above a 40°C ambient

Class H insulation is rated at 150°C rise at 25°C ambient

Class F insulation is rated at 145°C rise at 25°C ambient

All models fully prototype tested

ENCLOSURE FEATURES

Steel weather protective enclosure with aluminum roof

Enclosed critical grade muffler Quiet, critical grade muffler is mounted inside the unit to prevent injuries and

Small, compact, attractive Makes for an easy, eye appealing installation.

SAE Sound attenuated enclosure ensures quiet operation.

Ensures protection against mother nature. Electrostatically applied textured epoxy paint

for added durability.

maximize sound dampening.

(All ratings in accordance with BS5514, ISO3046, ISO8528, SAE J1349 and DIN6271)

Page 3

15 • 20 • 30 • 48 • 50 kW application & engineering data

®

ENGINE SPECIFICATIONS: 15 & 20 kW

Make Generac

Model In-line

Cylinders 4

Displacement (Liters) 2.28

Bore (in./mm) 3.46/88

Stroke (in./mm) 3.70/94

Compression Ratio 21.3:1

Intake Air System Naturally Aspirated

Cylinder Head Type Cast Iron OHV

Piston Type Aluminum

EPA Emissions Compliance Emergency Stationary

ENGINE SPECIFICATIONS: 30 kW

Make Generac

Model In-line

Cylinders 4

Displacement (Liters) 2.4

Bore (in/mm) 3.54/90

Stroke (in/mm) 3.70/94

Compression Ratio 21.3:1

Intake Air System Turbocharged

Cylinder Head Type Cast Iron OHV

Piston Type Aluminum

EPA Emissions Compliance Emergency Stationary

ENGINE SPECIFICATIONS: 48/50 kW

Make Generac

Model In-Line

Cylinders 4

Displacement (Liters) 3.4

Bore in/mm 3.86/98

Stroke in/mm 4.45/113

Compression Ratio 18.5:1

Intake Air System Turbocharged/Aftercooled

Cylinder Head Type Cast Iron OHV

Piston Type Aluminum

EPA Emissions Compliance Emergency Stationary

ENGINE LUBRICATION SYSTEM

Oil Pump Type Gear

Oil Filter Type Full flow spin-on canister

6.87/6.5 - 15 & 20 kW

Crankcase Capacity (quarts/liters)

6.8/6.4 - 30 kW

7.4/7 - 48 & 50 kW

ENGINE COOLING SYSTEM

Type

Water Pump Pre-lubed, self-seating

Fan Speed (rpm)

Fan Diameter (in/mm)

Fan Mode Pusher

Pressurized radiator - 15 & 20 kW

Closed recovery - 30, 48 & 50 kW

1800 - 15 & 20 kW

2061 - 30 kW

2029 - 48 & 50 kW

18.11/460 (15 & 20 kW) or

22/559 (30, 48 & 50 kW)

FUEL SYSTEM

Fuel Type Ultra Low Sulfur Diesel Fuel

Fuel Pump Type Mechanical Engine Driven Gear

Injector Type Mechanical

Fuel Supply Line (mm/in) 7.94/0.31 (ID)

Fuel Return Line (mm/in) 7.94/0.31(ID)

Fuel Specification ASTM

Fuel Filtering (microns) 5 (15, 20 & 30 kW)

or 10 (48 & 50 kW)

TANK SPECIFICATIONS

Total Size (gallons/liters) 34/128.7 - 15 & 20 kW

62/234.7 - 30, 48 & 50 kW

Usable Size (gallons/liters) 32/121.1 - 15 & 20 kW

57/215.8 - 30, 48 & 50 kW

Run Time @ 1/2 Load (hrs) 38 - 15 kW

28.6 - 20 kW

36.7 - 30 kW

24 - 48 & 50 kW

Listings UL142

Protector™ Series

3 of 6

Page 4

15 • 20 • 30 • 48 • 50 kW operating data

GENERATOR OUTPUT VOLTAGE/kW - 60 Hz

Protector™ Series

4 of 6

RD015

RD020

RD030

RD048/RD050

®

kW (Standby) Amp (Standby) CB Size

120/240 V, 1Ø, 1.0 pf 15 62 70

120/208 V, 3Ø, 0.8 pf 15 52 60

120/240 V, 3Ø, 0.8 pf 15 45 50

120/240 V, 1Ø, 1.0 pf 20 83 100

120/208 V, 3Ø, 0.8 pf 20 69 80

120/240 V, 3Ø, 0.8 pf 20 60 70

120/240 V, 1Ø, 1.0 pf 30 125 150

120/208 V, 3Ø, 0.8 pf 30 104 125

120/240 V, 3Ø, 0.8 pf 30 90 100

277/480 V, 3Ø, 0.8 pf 30 45 50

120/240 V, 1Ø, 1.0 pf 48 200 200

120/208 V, 3Ø, 0.8 pf 50 173 200

120/240 V, 3Ø, 0.8 pf 50 150 175

277/480 V, 3Ø, 0.8 pf 50 75 90

SURGE CAPACITY IN AMPS

120/240 V, 1Ø 53 129

RD015

RD020

RD030

RD048/RD050

120/208 V, 3Ø 37 90

120/240 V, 3Ø 32 78

120/240 V, 1Ø 87 211

120/208 V, 3Ø 59 143

120/240 V, 3Ø 51 124

120/240 V, 1Ø 66 168

120/208 V, 3Ø 59 144

120/240 V, 3Ø 51 125

277/480 V, 3Ø 26 64

120/240 V, 1Ø 69 189

120/208 V, 3Ø 90 218

120/240 V, 3Ø 78 189

277/480 V, 3Ø 36 87

Voltage Dip @ < .4 pf

15% 30%

ENGINE FUEL CONSUMPTION

25% of rated load 0.51 1.93

RD015

RD020

RD030

RD048/RD050

50% of rated load 0.79 2.99

75% of rated load 1.14 4.31

100% of rated load 1.48 5.58

25% of rated load 0.67 2.6

50% of rated load 1.05 3.97

75% of rated load 1.52 5.32

100% of rated load 1.98 7.48

25% of rated load 0.92 3.5

50% of rated load 1.45 5.5

75% of rated load 1.96 7.4

100% of rated load 2.74 10.4

25% of rated load 1.35 4.92

50% of rated load 2.15 8.71

75% of rated load 3.06 12.5

100% of rated load 3.98 16.36

gal/hr L/hr

STANDBY RATING: Standby ratings apply to installations served by a reliable utility source. The standby rating is applicable to varying loads for the duration of a power outage. There

is no overload capability for this rating. Ratings are in accordance with ISO-3046-1. Design and specifications are subject to change without notice.

Page 5

15 • 20 • 30 • 48 • 50 kW operating data

ENGINE COOLING

15 kW 20 kW 30 kW 48/50 kW

Air flow (inlet air including alternator and combustion air in cfm/cmm) 2824/80 2824/80 3038/86 2824/80

System coolant capacity (gal/liters) 2.8/10.6 2.8/10.6 2.8/10.6 2.8/10.6

Heat rejection to coolant (BTU per hr/MJ per hr) 63,535/67 63,535/67 111,000/117.1 135,900/143.4

Maximum operation air temperature on radiator (°C/°F) 50/122

Maximum ambient temperature (°C/°F) 50/122

COMBUSTION REQUIREMENTS

Flow at rated power (cfm/cmm) 190/5.38 190/5.38 190/2.55 190/5.38

SOUND EMISSIONS

Exercising at 7 meters/23 feet (dB(A)) 65

Normal operation at 7 meters/23 feet (dB(A)) 70

*Sound levels are taken from the front of the generator. Sound levels taken from other sides of the generator may be higher depending on installation parameters.

EXHAUST

®

Protector™ Series

5 of 6

Exhaust flow at rated output (cfm/cmm) 448/12.7 448/12.7 230/6.51 448/12.7

Exhaust temperature at rated output (°C/°F) 604.4/1120 604.4/1120 454.4/850 604.4/1120

ENGINE PARAMETERS

Rated Synchronous RPM 1800

HP at rated kW 26.4 33.5 49 85

POWER ADJUSTMENT FOR AMBIENT CONDITIONS

Temperature Deration .................................................................................................................3% for every 5 °C above 25 °C or 1.7% for every 5 °F above 77 °F

Altitude Deration (15, 30, 48 & 50 kW) .............................................................................1% for every 100 m above 915 m or 3% for every 1000 ft above 3000 ft

Altitude Deration (20 kW) ................................................................................................ 1% for every 100 m above 305 m or 3% for every 1000 ft above 1000 ft

CONTROLLER FEATURES

2-Line Plain Text Multilingual LCD Display .....................................................................................................................Simple user interface for ease of operation.

Mode Buttons: Auto ............................................................................................................................................Automatic Start on Utility failure. 7 day exerciser.

Manual ....................................................................................... Start with starter control, unit stays on. If utility fails, transfer to load takes place.

Off .........................................................................................................................Stops unit. Power is removed. Control and charger still operate.

Ready to Run/Maintenance Messages ................................................................................................................................................................................ Standard

Engine Run Hours Indication .............................................................................................................................................................................................. Standard

Programmable start delay between 2-1500 seconds .........................................................................................................Standard (programmable by dealer only)

Utility Voltage Loss/Return to Utility Adjustable .................................................................................................................................... From 140-171 V/190-216 V

Future Set Capable Exerciser/Exercise Set Error Warning .................................................................................................................................................... Standard

Run/Alarm/Maintenance Logs .................................................................................................................................................................................50 Events Each

Engine Start Sequence ................................................................................................................... Cyclic cranking: 16 sec on, 7 rest (90 sec maximum duration).

Starter Lock-out ...............................................................................................................................Starter cannot re-engage until 5 sec after engine has stopped.

Smart Battery Charger ....................................................................................................................................................................................................... Standard

Charger Fault/Missing AC Warning ..................................................................................................................................................................................... Standard

Low Battery/Battery Problem Protection and Battery Condition Indication ........................................................................................................................... Standard

Automatic Voltage Regulation with Over and Under Voltage Protection ............................................................................................................................... Standard

Under-Frequency/Overload/Stepper Overcurrent Protection ................................................................................................................................................. Standard

Safety Fused/Fuse Problem Protection ............................................................................................................................................................................... Standard

Automatic Low Oil Pressure/High Oil Temperature Shutdown ............................................................................................................................................. Standard

Overcrank/Overspeed (@ 72 Hz)/RPM Sense Loss Shutdown ........................................................................................................................................... Standard

High Engine Temperature Shutdown .................................................................................................................................................................................. Standard

Internal Fault/Incorrect Wiring Protection ........................................................................................................................................................................... Standard

Common External Fault Capability ..................................................................................................................................................................................... Standard

Field Upgradable Firmware ................................................................................................................................................................................................Standard

Page 6

15 • 20 • 30 • 48 • 50 kW available accessories

®

Model # Product Description

006502-0 Spill Box

Protector™ Series

6 of 6

006504-0 90% Fuel Level Alarm

006505-0 - 15 & 20 kW

006506-0 - 30 & 50 kW

006507-0 Fuel Fill Drop Tube

006513-0 - 15 & 20 kW

006517-0 - 30 kW

006516-0 - 50 kW

006510-0 E-Stop

006511-0 Spill Box Drainback Kit

006512-0 Lockable Fuel Cap

006572-0 - 15 & 20 kW

006571-0 - 30 kW

006570-0 - 50 kW

006560-0 - 15 & 20 kW

006559-0 - 30 kW

006558-0 - 50 kW

006576-0 Fuel Maintenance Kit

005704-0 Paint Kit

Tank Risers

Stainless Steel Fuel Lines

Maintenance Kits

Cold Weather Kits

®

The 5-gallon spill box screws into the existing fuel fill port of the base tank. It captures and

contains fuel if over fueling or spilling occurs during the fill process.

The 90% fuel level alarm alerts the fuel fill operator when the tank reaches a 90% fill level by

sounding an audible alarm and triggering an LED warning light.

Tank risers are required in some municipalities to help avoid potential base tank corrosion

caused by mounting on rough surfaces.

A powder coat painted, steel fuel fill drop tube is required in some municipalities to prevent

sparking due to static electricity buildup, which can be caused by the fuel dropping into the

tank from the fill area. Using a drop tube also results in submerged filling, which increases

the fuel delivery flow rate and reduces vapors, foam and potential tank evaporation.

Some municipalities require the use of stainless steel fuel lines instead of the standard hoses

provided with the diesel generator products. These stainless steel lines are fire resistant for

additional safety.

E-stop allows for immediate fuel shutoff and generator shutdown in the event of an

emergency.

The spill box drainback kit allows fuel that was captured in the 5-gallon spill box to be drained

directly back into the fuel tank to avoid vapors.

The cast iron, lockable fuel cap provides the ability to lock the fuel system to prevent

unwanted fuel tampering or fuel siphoning.

The Protector Maintenance Kits offer all the hardware necessary to perform complete

maintenance on Generac Protector generators.

Recommended for generators installed in regions where the temperature regularly falls below

32 °F (0 °C). The Cold Weather Kits consist of a block heater with all necessary mounting

hardware and a battery warmer with a thermostat built into the battery wrap.

The Fuel Maintenance Kit contains everything needed to maintain and clean a diesel fuel

system

If the generator enclosure is scratched or damaged, it is important to touch-up the paint to

protect from future corrosion. The paint kit includes the necessary paint to properly maintain

or touch-up a generator enclosure.

005928-0 Basic Wireless Remote

005951-0

006199-0 PMM Starter Kit

006186-0

Advanced Wireless

Remote

Power Management

Module (50 Amps)

006463-0 Mobile Link™

006478-0 Harness Adapter Kit

Generac Power Systems, Inc. • S45 W29290 HWY. 59, Waukesha, WI 53189 • generac.com

©2013 Generac Power Systems, Inc. All rights reserved. All specifications are subject to change without notice. Bulletin 0K4729-A Printed in U.S.A. 07/19/13

Completely wireless and battery powered, Generac's wireless remote monitor provides you

with instant status information without ever leaving the house.

Remotely control generator functions with the advanced model's LCD display. In addition to

remote testing of the generator, set the exercise cycle and maintenance interval reminders.

The PMM Starter Kit consists of a 24 VAC, field installed transformer that enables the use

of the 24 VAC Power Management Modules (PMMs) and one PMM. The standard controller

(without starter kit) can control two HVAC loads with no additional hardware. Not compatible

with pre-wired switches.

Power Management Modules are used in conjunction with the Smart Switch to increase its

power management capabilities. It gives the Smart Switch additional power management

flexibility not found in any other transfer switch. Not compatible with pre-wired switches.

Note: PMM Starter Kit required.

Generac's Mobile Link allows you to check the status of your generator from

anywhere that you have access to an Internet connection from a PC or with any

smart device. You will even be notified when a change in the generator’s status

occurs via e-mail or text message. Note: Harness Adapter Kit required.

The Harness Adapter Kit is required to make liquid-cooled units compatible with

Mobile Link™.

Loading...

Loading...