Page 1

POWER SYSTEMS, INC.

®

Operator’s Manual

“E” Option Control Panels

This manual should remain with the unit.

This manual contains standard drawings and schematics.

For specific drawings, please refer to the Owner’s Manual of the unit.

Page 2

Generac®Power Systems, Inc.

Important Safety Instructions

E Option Control Panels

SAVE THESE INSTRUCTIONS – The manufacturer suggests that these rules for safe

operation be copied and posted in potential hazard areas. Safety should be stressed to all

operators and potential operators of this equipment.

!

!

Study these SAFETY RULES carefully before

installing, operating or servicing this equipment.

Become familiar with this manual and all literature

pertaining to your generator set and related equipment. This equipment can operate safely, efficiently

and reliably only if it is properly installed, operated

and maintained. Many accidents are caused by failing

to follow simple and fundamental rules or precautions.

Generac cannot possibly anticipate every possible circumstance that might involve a hazard. The warnings in this manual, and on tags and decals

affixed to your equipment are, therefore, not

all-inclusive. If you use a procedure, work method or

operating technique Generac does not specifically recommend, you must satisfy yourself that it is safe for you

and others. You also must make sure the procedure,

work method or operating technique that you choose

does not render the equipment unsafe.

GENERAL HAZARDS

• For safety reasons, Generac recommends that this

equipment be installed and serviced by a Generac

Authorized Service Dealer or other competent, qualified electrician or installation technician who is familiar with applicable codes, standards and regulations.

The operator also must comply with all such codes,

standards and regulations.

• When working on this equipment, remain alert at all

times. Never work on the equipment when you are

physically or mentally fatigued.

• Inspect the equipment regularly, and promptly repair

or replace all worn, damaged or defective parts using

only factory-approved parts.

• Before performing any maintenance on the generator

or any related equipment, disable the generator to

prevent accidental start-up. Remove the control

panel fuse and then disconnect the battery cables by

removing the one indicated by a NEGATIVE, NEG or

(–) first. To re-enable the generator, reconnect the

battery cables connecting the one indicated by a

NEGATIVE, NEG or (–) last, then re-install the control panel fuse.

ELECTRICAL HAZARDS

• Generators produce dangerous electrical voltages

and can cause fatal electrical shock. Avoid contact

with bare wires, terminals, connections, etc., while

the generator and related equipment are running.

Ensure all appropriate covers, guards and barriers

are in place before operating the equipment. If you

must work around an operating unit, stand on an

insulated, dry surface to reduce shock hazard.

• Do not handle any kind of electrical device while

standing in water, while barefoot, or while hands or

feet are wet. DANGEROUS ELECTRICAL SHOCK

MAY RESULT.

• If people must stand on metal or concrete while

installing, operating, servicing, adjusting or repairing

this equipment, place insulative mats over a dry

wooden platform. Work on the equipment only while

standing on such insulative mats.

• Wire gauge sizes of electrical wiring, cables and cord

sets must be adequate to handle the maximum electrical current (ampacity) to which they will be subjected.

• Before installing or servicing this equipment, make

sure that all power voltage supplies are positively

TURNED OFF at their source. Failure to do so will

result in hazardous and possibly fatal electrical

shock.

• When installed with an automatic transfer switch, the

generator may crank and start anytime without

warning. To prevent injuries caused by sudden startup, disable the generator’s automatic start circuit

before working on or around the unit. Then, place a

“Do Not Operate” tag on the generator control panel

and on the transfer switch.

• In case of accident caused by electric shock, immediately shut down the source of electrical power. If

this is not possible, attempt to free the victim from

the live conductor. AVOID DIRECT CONTACT WITH

THE VICTIM. Use a nonconducting implement,

such as a rope or board, to free the victim from the

live conductor. If the victim is unconscious, apply

first aid and get immediate medical help.

• Never wear jewelry when working on this equipment.

Jewelry can conduct electricity resulting in electric

shock, or may get caught in moving components

causing injury.

FIRE HAZARDS

• For fire safety, the generator and related equipment

must be installed and maintained properly.

Installation always must comply with applicable

codes, standards, laws and regulations. Adhere

strictly to local, state and national electrical and

building codes. Comply with regulations the

Occupational Safety and Health Administration

(OSHA) has established. Also, ensure that the

equipment is installed in accordance with the manufacturer’s instructions and recommendations.

Following proper installation, do nothing that

might alter a safe installation and render the unit

in noncompliance with the aforementioned codes,

standards, laws and regulations.

!!

Page 3

Table of Contents

E Option Control Panels

Generac®Power Systems, Inc. 1

Safety Rules ..............Inside Front Cover

Section 1 — General Information..........2

Overview ................................................................2

Engine Control ......................................................2

E Option Control Module ......................................2

Alarms....................................................................4

Alarm Processing....................................................5

Programmable Parameters ....................................6

E Panel Modem Setup Procedure ..........................9

E Panel RS 232 Cables ..........................................9

Additional Panel Components ..............................10

Checking/Replacing the E Panel Control Module

Internal Fuse ....................................................11

User Programmable Inputs ..................................11

Wiring Examples ..................................................12

Programming Examples ......................................13

Section 2 — Operation........................14

Output Function Table ............................................14

E Panel Master Control Box Configuration Settings15

E Panel Display Map ............................................18

Section 3 — Troubleshooting and

Diagnosis ........................20

Oil Pressure Sensing ..............................................20

Low Coolant Level ..................................................22

Coolant Temperature Sensing ................................25

Oil Temperature Sensing ........................................27

AC Voltage Display ..................................................29

RPM Sensor and Engine Speed Alarms ..................29

Engine Does Not Crank ..........................................31

Overcrank................................................................34

Appendix — Phoenix and

Deutsch Connectors ........35

Section 4 — Glossary..........................38

E Control Panel Definitions ....................................38

Section 5 — Electrical Data ................39

E Panel Drawing Application Matrix ......................39

Section 6 — Exploded Views and

Parts Lists ......................60

Section 7 — Notes ..............................76

AUTHORIZED SERVICE DEALER LOCATION

To locate the GENERAC AUTHORIZED SERVICE

DEALER nearest you, please call this number:

1-800-333-1322

DEALER LOCATION INFORMATION

CAN BE OBTAINED AT THIS NUMBER.

Page 4

OVERVIEW

The “E” option control panel is a programmable

engine control and monitoring system. It allows the

user to customize the generator starting and running

sequence, monitor engine parameters and configure

the alarms. This can be done either through its own

control module, featuring liquid-crystal display

(LCD) and keypad, or using a PC and RS232 serial

communications. The module includes user programmable inputs and outputs that allow it to be tailored to a vast range of applications. All of the setup

information is stored in nonvolatile (permanent)

memory.

ENGINE CONTROL

The module has a three-position selector switch that

selects between “Auto” mode, “Off” and “Manual” start

mode. When the switch is in the OFF position, the

generator will not start, and it will stop if it is running.

When the switch is turned to MANUAL, the generator

will start immediately and will continue to run until

the switch is turned to the OFF position or a shutdown alarm is activated. With the switch in the AUTO

position, the generator will wait for either the remote

start contacts to close or for a start command to be

sent from the serial link. The generator will run until

the remote start contacts open, a stop command is

sent down the serial link, a shutdown alarm is activated or the switch is turned to the OFF position. The

remote start contacts always will have priority over

the serial link commands so that the serial link cannot stop the generator if the remote start contacts are

closed. When GenLink®software, which may be

obtained from a Generac Authorized Service Dealer, is

connected to the E panel via modem, the panel will

monitor the connection to ensure that the line has not

dropped. If the E panel detects that the line has been

dropped, it will disconnect the modem so that it is

ready for another incoming call. If the generator had

been started via the modem connection, then it will be

stopped immediately unless the remote start contacts

are closed or the generator is in manual. However, if

the GenLink®software disconnected cleanly (as a

result of a user command) with the generator running,

then the generator will continue to run for a another

three hours unless it receives a stop command.

When a start command is received, the engine preheat

will be engaged, if it is selected. The user can program

the preheat to engage for a programmable time before

engaging the starter motor, to engage while the engine is

attempting to start, or to do both. In order to protect

the engine from trying to start while it is already running (if the rpm sensor is damaged), an alarm is generated if there is oil pressure when the start command is

sent. An alarm also is generated if there is a voltage

output from the generator but the rpm sensor detects

zero engine speed.

The user can program the length of time that the starter

motor is engaged during a start attempt. After the first

attempt, the generator will pause for a programmable

length of time before the next attempt. The number of

attempts also is programmable, after which the failed

to start alarm is activated.

The user can program a warm-up time that is active

after the generator has started. This could be used in

conjunction with a programmable relay output to

inhibit the transfer switch from applying load until

the generator is ready. The warm-up time can be set

to zero if this function is not required. This timer is

separate from the alarm hold off timer, which allows

the generator to run for a time before certain alarms

(such as low oil pressure) are active.

If the generator is in the AUTO mode and a stop command is received, a programmable cool-down timer

can be used to keep the generator running with no

load for a fixed time. This also can work in conjunction with a relay output to inhibit the transfer switch.

If the timer is set to zero, this function is disabled. If

the selector switch is turned to OFF, then the generator will stop immediately without waiting for the cooldown time.

Certain alarm functions are designated as shutdown

alarms. These alarms will stop the generator and

inhibit it from starting until the alarm condition has

cleared and the alarm has been reset.

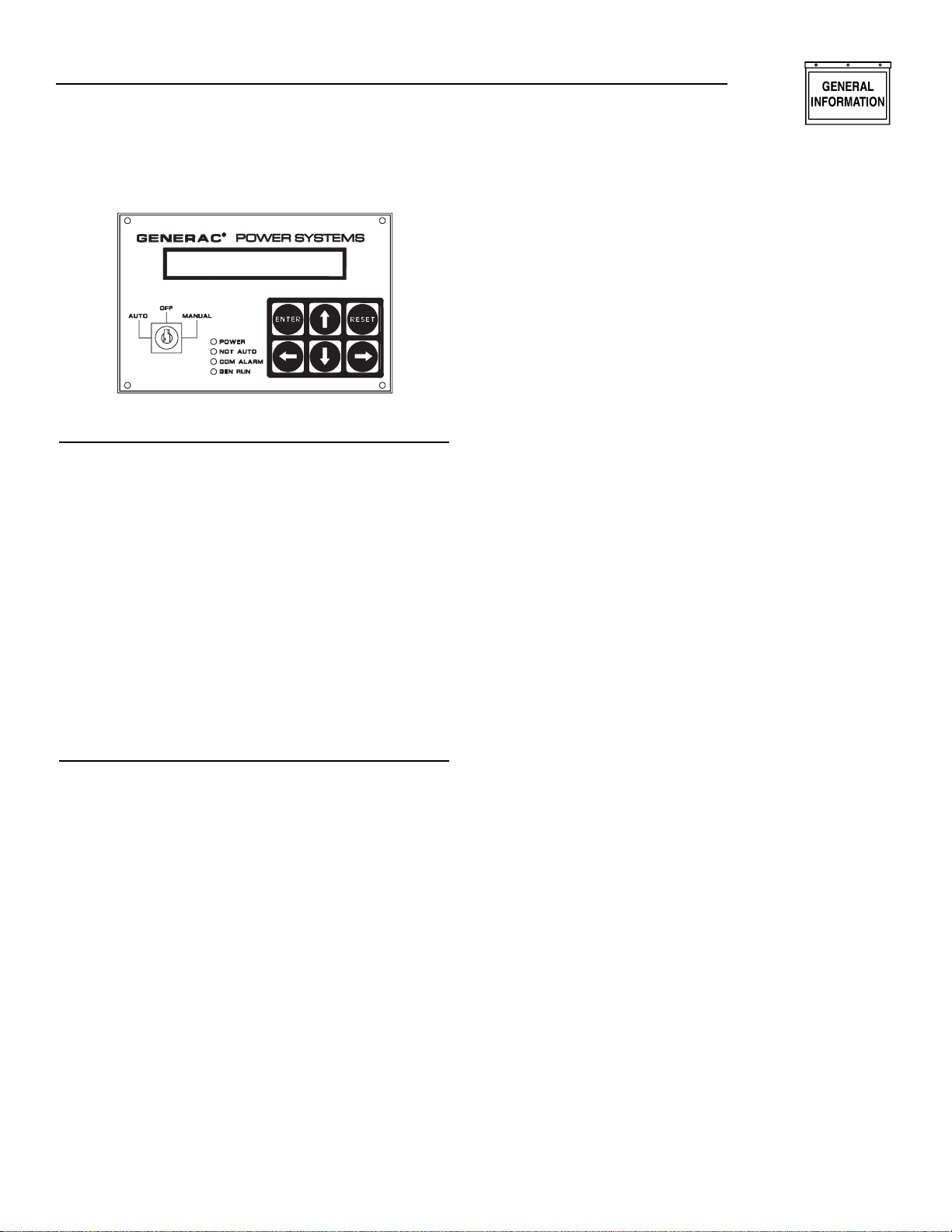

E OPTION CONTROL MODULE

OVERVIEW

The LCD on the front of the module (Figure 1.1) features a 24-character by two-line display screen that will

show one of seven pages. There is a keypad with six

keys that are used for operating the display and selecting the various pages. A key-activated switch allows the

user to select whether the generator is in the “Auto”

mode, “Off” mode or “Manual” run mode. Four LEDs

indicate the following conditions:

• “Power” – Battery power is OK.

• “Not Auto” – The generator is not in the automatic

mode.

• “Com Alarm” – A common alarm condition has

occurred.

• “Gen Run” – The generator is running.

NOTE:

The “Power” LED will go out immediately if the

battery voltage dips below the alarm limit, but the

alarm will not be triggered unless the voltage is

low for more than five minutes.

Section 1 — General Information

E Option Control Panels

2 Generac®Power Systems, Inc.

Page 5

Generac®Power Systems, Inc. 3

Figure 1.1 – Control Module Layout

KEYPAD

The keypad consists of six keys labeled as follows:

↑ (up), ↓ (down), ← (left), → (right)

,

Enter, and Reset.

The left and right arrow keys are used to select the different pages on the display. The up and down arrow

keys are used to scroll between options within a page.

They also are used for selecting characters when the

user is entering messages or parameters for the

alarms. The left and right arrow keys move the cursor

when the user is entering data. The enter key takes the

user into a page on the display to change data (when

applicable) and also accepts data that has been entered.

It also is used to accept an alarm. The reset key ignores

data that has been entered and returns the original

value. It also is used to return from the parameter entry

mode once the user has finished changing the data, and

to reset any latched alarms that have cleared.

DISPLAY

The display is organized into a series of pages, each

page displays information about the status of the generator. For example, the “Alarm Status Message Page”

displays the highest priority current alarm or status

condition. The user will be able to scroll between the

pages using the left and right arrow keys. Certain

actions also cause the display to change pages, e.g.,

when an alarm becomes active, the display automatically will go to the alarm status page and display the

alarm message.

The back light for the display is normally off. If the

user presses any key, the back light will come on

automatically and remain on for five minutes after

the last key was pressed. It also will come on if any

status message is current, which means the display

will switch to the alarm status page. The back light

will flash when an alarm or shutdown message is

active, and the audible alarm will sound.

When the display is showing certain pages, the user

is able to scroll between relevant items within the

page using the up and down arrow keys. For example,

if the display is showing the “Alarm Log Page,” the

user can use the up and down arrow keys to scroll

between the entries on the alarm log. A description of

each page is given below.

Software Version Page

This page displays the software revision. Pressing the

enter key in this page will perform a display and LED

test.

Generator Command Page

This page displays the command sent to the generator. The possible commands are as follows:

• Generator switched off

• Generator in manual mode

• Generator in auto mode – stop command

• Generator in auto mode – remote run command

• Generator in auto mode – serial link run

command

Generator Status Page

This page displays the current status of the generator.

Options will be as follows:

• Stopped – ready to run

• Stopped – start inhibit active

• Pre-heating (with timer counting down)

• Attempting to start (with timer counting down and

number of attempts)

• Pausing before start attempt (with timer counting

down and number of attempts)

• Started – running up to speed

• Warming up

• Ready to accept load

• All alarms enabled

• Cooling down

• Stopping

• Stopped due to alarm

If the user has not pressed a key for some time, any

change in status will cause this page to be displayed

provided that there are no active alarms or status

messages from other inputs. If an alarm condition

occurs, the alarm status page will be displayed automatically.

Alarm Status Message Page

This page displays alarm messages and programmable status messages. Messages are displayed

according to priority, with the shutdown alarms

having highest priority, and status messages having

lowest priority.

Section 1 — General Information

E Option Control Panels

Page 6

4 Generac®Power Systems, Inc.

If an alarm becomes active, the display will switch to

this page and display the highest priority alarm message. The back light and alarm LED will flash, and the

audible alarm will be activated. The user must press

the enter key to accept the alarm, at which time the

back light will be on continuously. If the alarm is nonlatching, the alarm message will clear as soon as the

condition is cleared. If the alarm is a latching alarm,

then the user must press the reset key to clear the message. Once a message has cleared, the display will show

the next priority alarm message.

After an alarm has been accepted, the user is able to

scroll through other active alarm and message

screens using the up and down arrow keys.

Alarm Log Page

This page displays the last 50 alarm messages. When

the user selects this page, it displays the latest alarm

message. Pressing the up or down arrow keys will

allow the user to scroll up and down the list of messages.

Instrumentation Page

This page displays one of the analog signal values.

Pressing the up or down arrow keys will scroll to

other analog display screens.

Parameter Entry Page

This page allows the user to modify the various set

points and programmable options. See the

“Programmable Parameters” section of this manual

for more specific option information. The user must

press the Enter key when this page is displayed and

will then be prompted for a password. The password

is a six-digit number and the default value is 000000.

However, the user will be able to change the password. Digits will be selected using up and down

arrow keys, and the cursor will be moved by the left

and right arrow keys. When the user presses the

Enter key, the password will be checked. If the password is correct, the display will show one of the data

entry screens.

There are four parameter entry menus: “Engine

Parameter,” “System Alarm,” “Digital I/O” and “Analog

Input.” The user will be able to scroll through the various parameters in each menu using the up and down

arrow keys. The left and right arrow keys are used to

switch between the four menus. When a parameter that

requires changing is displayed, the user presses the

Enter key to enable data entry. A cursor will appear at

the first character that can be altered. The user can

then change the character using the up and down arrow

keys. The user can move to the next character or previous character using the left and right arrow keys.

Pressing the Enter key will accept the new setting.

Pressing the Reset key will ignore the new setting.

If an alarm condition occurs when the user is entering data, the data will be ignored, and the display will

show the alarm screen. If a status condition occurs

when data is being entered, the display will not

change.

Once the user has finished entering data by pressing

the Enter key, pressing the Reset key will allow the

user to select other pages using the left and right

arrow keys.

ALARMS

All analog channels have alarms associated with

them. There is also a coolant level alarm, an emergency stop alarm and eight user definable inputs that

can be used to generate alarms. Alarms can be status

messages, non-latching alarms, latching alarms or

shutdown alarms. When a new alarm condition

occurs, the alarm LED and the display back light will

flash. Also, the alarm relay contacts will close (operating the audible alarm), and the display will show

the alarm message. The user will be able to accept the

alarm (turn off the audible alarm) from the keypad,

and if the alarm condition has cleared, he or she also

will be able to clear the alarm. Non-latching alarms

will clear themselves if the alarm condition is no

longer present. Latching alarms require the user to

clear the alarm from the keypad even if the alarm

condition is no longer present. Shutdown alarms are

similar to latched alarms, but they also cause the

generator to stop and will not allow it to start again

until the key-switch has been turned to the OFF position to reset the alarm. Status messages are similar

to non-latching alarms except that they do not activate the alarm relay or the alarm LED and are not

recorded on the alarm log.

Alarms can be always active, immediately active when

the generator is commanded to run, or active after

the hold off timer has expired. This timer delays the

operation of certain alarms until a programmable

time after the engine has started. Some alarms allow

the user to define the type of alarm and when it is

active.

The following chart is a summary of the alarms and

the programmable options:

Section 1 — General Information

E Option Control Panels

Page 7

Generac®Power Systems, Inc. 5

ALARM PROCESSING

INPUT ALARM FUNCTIONS

The E option panel will monitor the status of the analog and digital inputs, and generate alarm messages

as required. Digital alarms and user-defined analog

alarms are fully programmable. The user is able to

select the type of alarm, the state of the input that will

trigger the alarm, and the alarm message when it is

active. The configurations are defined as follows:

Alarm Active

The user is able to select when the alarm is active.

The options will be as follows:

• Disabled: If this option is selected, the alarm is

disabled and has no effect.

• Always: With this option selected, the alarm is

active regardless of the state of the generator.

• Immediate: In this mode, the alarm is not active

when the generator is stationary. It becomes active

as soon as the generator starts to crank and

remains active until the generator stops.

• Hold Off: This option waits until a preset time

after the generator is running before becoming

active. The hold off time can be set by the user.

Note that the hold off time is common to

all alarms.

Section 1 — General Information

E Option Control Panels

Alarm Message Alarm Active Options Alarm Type Options

Pre-Low Oil Pressure Warning Hold Off Non-Latch

Low Oil Pressure Shutdown Alarm Hold Off Shutdown

Pre-High Coolant Temp. Warning Hold Off Non-Latch

High Coolant Temp. Shutdown Alarm Hold Off Shutdown

Low Coolant Temp.Warning Always Non-Latch

Pre-High Oil Temp. Warning Immediate, Hold Off, Disabled Non-Latch

High Oil Temp. Shutdown Alarm Immediate, Hold Off, Disabled Shutdown

Low Battery Voltage Warning* Always Non-Latch

Overspeed Alarm Immediate Shutdown

Underspeed Hold Off Status, Non-Latch, Latch, or Shutdown

Overcrank Alarm Immediate Shutdown

Over Voltage Hold Off Status, Non-Latch, Latch, or Shutdown

Under Voltage Hold Off Status, Non-Latch, Latch, or Shutdown

Over Frequency Hold Off Status, Non-Latch, Latch, or Shutdown

Under Frequency Hold Off Status, Non-Latch, Latch, or Shutdown

High Fuel Warning Always, Disabled Non-Latch

Low Fuel Warning Always, Disabled Non-Latch

Low Fuel Shutdown Alarm Always, Disabled Shutdown

User Analog Alarms** All Options Available All Options Available

Low Coolant Level Alarm Hold Off Shutdown

Emergency Stop Always Shutdown

RPM Sensor Failure Alarm Always Shutdown

Start Inhibit – Oil Pressure Immediate Shutdown

Oil Pressure Sensor Failure Always Shutdown

Oil Temp.Sensor Failure Always, Disabled Shutdown

Coolant Temp.Sensor Failure Always Shutdown

User Digital Input Alarms*** All Options Available All Options Available

High Battery Voltage Warning Always Non-Latch

* Battery voltage must be below alarm limit for 5 minutes to trigger alarm.

** Each user analog input channel has a high and low alarm.

*** Each user digital input can be programmed to trigger an alarm on high or low level.

Page 8

6 Generac®Power Systems, Inc.

ALARM TYPE

Status

This type of alarm will display a message on the

screen. The message will not be logged. This is the

lowest priority of alarm types.

Warning – Non-Latched

This type of warning will activate the audible alarm,

and flash the alarm LED and display back light. The

associated message will be displayed on the screen.

When the user accepts the warning (by pressing the

Enter key), the back light will stop flashing, and the

alarm LED will be on continuously. The message will be

displayed on the alarm screen, but the user will be able

to scroll through other screens. The LED and message

will clear when the warning condition clears. This type

of warning is logged.

Alarm – Latched

This type of alarm will act similarly to the non-latched

warning, except that the alarm does not clear when the

alarm condition clears. When the alarm condition

occurs, the audible alarm sounds, the LED and back

light flash as before, and the user must accept the

alarm to stop them. The alarm will continue to be displayed on the screen even after the alarm condition has

cleared. The user must either press the Reset key or

turn the key-switch to the OFF position to clear the

alarm after the alarm condition has cleared. This type

of alarm is logged.

Shutdown

This type of alarm will act similar to the latched

alarm, but it also will stop the engine when the alarm

condition occurs. It can be reset only by turning the

key-switch to the OFF position. All shutdown alarms

are latching, and this type of alarm is logged.

Alarm Status

This is the value at which the alarm is active. For analog alarms, it is a number corresponding to the alarm

limit. Digital alarms are either “normally open” or

“normally closed,” and an alarm is generated when

the input is not in the normal state.

Alarm Message

Each alarm will have a message associated with it. The

analog alarm messages will be preset, and the digital

alarm messages and user-defined analog messages will

be entered via the keypad or the serial link.

OTHER ALARMS

Overcrank

This alarm is unlike other alarms as it is not associated with an analog or digital signal. The user is able

to define the number of crank attempts, the length of

each crank attempt and the rest time between

cranks. After the last attempt has been made, an

overcrank alarm will be generated. The user must

turn the key-switch to the OFF position to clear the

alarm.

Coolant Level

This alarm is generated by the coolant level detector.

This device senses whether coolant is present or not.

It has no user-definable level setting and is a shutdown alarm that is active after the hold off time.

There are no user-definable parameters for this

alarm.

PROGRAMMABLE PARAMETERS

The E option panel allows the user to configure various options to control the generator starting and

stopping cycles, and the way that the alarms operate.

Parameters are entered either from the control module or via the serial link. A description of the programmable parameters follows:

PREHEAT ENABLED

This parameter determines how the preheat function

works. The preheat can be fully disabled, enabled

before starting only (for the duration of the preheat

time), or before and during starting (for the duration

of the preheat time and also while the starter is

engaged). Note that if the user wishes to engage the

preheat during starting but not to have a preheat

before starting, it is possible to set the preheat time

to zero.

PREHEAT TIME

When a start command is received, some engines

require preheating before the generator attempts to

start. When the preheat function is enabled, this

parameter allows the user to determine the time that

the preheat contact closes before activating the

starter solenoid.

START TIME

Once a start command has been received and

the preheat time has expired (if enabled), the starter

solenoid will be engaged. This parameter allows the

user to determine how long the starter solenoid is

engaged before the start attempt is regarded as having failed. If the generator does not start within this

time, the generator will wait for a preset time before

attempting to start again. The user also can program

the number of start attempts the generator tries.

Section 1 — General Information

E Option Control Panels

Page 9

Generac®Power Systems, Inc. 7

PAUSE TIME

If the generator does not start within the programmed start time, it will pause before trying to

start again. This parameter determines the length of

that pause.

START ATTEMPTS

This parameter determines the number of times that

the generator tries to start. If the generator has not

started after this number of attempts, an alarm is

generated.

STARTER DISENGAGE SPEED

While the starter is engaged, the engine speed is monitored. Once it reaches this value, the starter motor is

disengaged, and the engine is regarded as having

started.

HOLD OFF TIME

Once the engine has started, some alarm functions

(such as low oil pressure and under speed) are not

activated immediately since the engine must be given

time to reach a stable condition. This parameter

determines the time that elapses before the hold off

alarms are activated.

COOL-DOWN TIME

It is sometimes desirable to run the generator for a

given time with no load before stopping to allow the

engine to cool down. This parameter determines the

length of time that the generator continues to run

after a stop command is sent in AUTO mode. Note

that if the key-switch is turned to the OFF position

when the generator is running, it will stop immediately regardless of this setting. This value also should

be set to zero if this function is controlled by the

transfer switch.

LOAD ACCEPT VOLTAGE AND FREQUENCY

Once the generator has started, the voltage and frequency will ramp up until they reach the values at

which the generator can accept load. These parameters allow the user to set the values. The values

should be set slightly lower than the nominal values

to allow for a margin of error in the regulator and

governor settings. Once the values have been

reached, the warm-up timer is started.

WARM-UP TIME

Some applications require that the generator is

allowed to run for a given time before a load is

applied. This parameter allows the user to set that

time. Note that if this function is controlled elsewhere

(e.g., within a transfer switch), this time should be set

to zero. The generator is ready to accept load when

this timer expires. This parameter can be assigned to

an output relay.

VOLTAGE SCALING FACTOR

The voltage scaling factor is used to scale the sensing

voltage applied to CON4-4 and CON4-6.

On generators manufactured prior to the second

quarter of 2000: Sensing voltage was measured from

line-to-line, so the scaling factor was primarily set to

1.0. On generators manufactured starting the second

quarter of 2000: Sensing voltage is measured from

the frequency meter, in this case the scaling factor is

used so the “E” panel displays line-to-line voltage.

This scaling factor can also be used to “calibrate” the

“E” panel display.

FLYWHEEL TEETH

This parameter holds the number of flywheel teeth.

This value is used to determine the engine speed

from the magnetic pickup signal.

USER-DEFINED OUTPUT FUNCTIONS

There are three user-defined outputs, and the preheat

output also can be used as a user-defined output if the

preheat function is disabled. Each output can be programmed to signal that an alarm is active, to indicate

one specific alarm or input condition, to indicate the

status of the key-switch, or to indicate the current status of the generator. These relay contacts can be used

to switch up to 30 volts AC or DC at 1 amp.

Programming example for user output #2 to be active

on any generator alarm shutdown:

1. Press the left or right arrow key until the display

reads “Parameter entry” and press ENTER.

2. Enter your password and press ENTER.

3. Use the left and right arrow keys to find the

“Digital I/O Menu”.

4. Use the up and down arrow keys to locate “Output

2 Function”. The bottom line of the display will

read the current setting. Press ENTER.

5. Use the up and down arrows to scroll through the

list until “Generator Alarm Shutdown” is displayed in the bottom line. Press ENTER.

6. User output #2 is now programmed to become

active (relay energized) on any generator shutdown

alarm.

7. Press RESET. This exits the programming mode

and returns you back to the parameter entry

screen.

NOTE:

See the “Output Function Table” on Page 14 and

the “E” Panel Display Map on pages 18-19 for

more detail.

Section 1 — General Information

E Option Control Panels

Page 10

8 Generac®Power Systems, Inc.

ANALOG INPUT SCALING FACTORS

The two user-defined analog inputs can be scaled so

that the display uses meaningful values rather than the

voltage level at the input. The user enters the value to

be displayed when the input voltage is zero and when it

is at the maximum value. (An analog input to the E

panel is a voltage sourced input with a zero- to 10-volt

range.) All alarm settings are based on this scaling, and

the instrumentation display shows the input value

based on this scaling too.

ANALOG INPUT MESSAGES

This is a message up to 24 characters long that is displayed on the instrumentation display when the corresponding value is being shown.

ANALOG INPUT ALARM MESSAGES

There is a user-definable message for each alarm

condition on each analog input. This message is

shown on the alarm display when the alarm condition is active and is stored in the alarm log.

ANALOG INPUT ALARM SETTINGS

Each analog input has two alarms associated with it.

One is activated when the input value is higher than

the high set-point, and the other is active when the

input is lower than the low set-point. The user also

can define when the alarm is active (or disable it) and

the severity of the alarm (from simply displaying a

status message to shutting down the generator – see

“Alarm Processing” on Page 5).

DIGITAL INPUT ALARM SETTINGS

Each digital input also can generate an alarm. The

user can program the alarm message, the input state

that generates the alarm, when the alarm is active,

and the alarm type. A digital input to the E panel is

NOT a voltage sourced input, but a dry contact closure to ground. Voltage never should be sourced to a

digital input. The signal options to a digital input are

as follows:

• Open: This signal is an open circuit.

• Closed: This signal is a contact closure to ground.

OIL PRESSURE ALARMS

The oil pressure input has two associated alarm

functions. The pre-low oil pressure warning is a nonlatched, hold off alarm with a user-definable setpoint. The low oil pressure shutdown is a shutdown,

hold off alarm with a user-definable set-point. The

shutdown alarm set-point should be the lowest of the

two settings so that the user will have some warning

of a low oil condition before the generator is shut

down.

OIL TEMPERATURE ALARMS

The oil temperature has a non-latched warning and a

shutdown alarm associated with it. The set-points are

programmable, and the alarms can be immediate,

hold off or disabled.

COOLANT TEMPERATURE ALARMS

The coolant temperature input has three associated

alarms. The pre-high coolant temperature alarm is a

non-latched, hold-off alarm. The high coolant temperature alarm is a shutdown, hold-off alarm. The

low coolant temperature warning is a non-latched,

always active alarm. Set-points for each alarm are

programmable.

BATTERY VOLTAGE ALARMS

The low battery voltage warning set-point is programmable. The warning will be activated if the battery voltage is below this value for more than five

minutes. This is a non-latched, always active alarm.

Note that the “Power” LED on the front panel is extinguished immediately if the battery voltage is less than

this value. The high battery voltage alarm set-point is

also programmable. The warning is active immediately when the battery voltage is higher than this

value.

ENGINE SPEED ALARMS

The user can program the overspeed and the underspeed alarm. The overspeed alarm is an immediate

shutdown alarm. Underspeed is a hold off alarm that

can either be non-latched, latched or shutdown.

GENERATOR VOLTAGE ALARMS

An alarm can be generated for high voltage and low

voltage. The set-points are user-definable, and the

alarms can be either non-latching, latching or shutdown.

GENERATOR FREQUENCY ALARMS

An alarm can be generated for high frequency and

low frequency. The set-points are user-definable, and

the alarms can be either non-latching, latching or

shutdown.

FUEL LEVEL ALARMS

Alarms can be generated by an optional fuel level sensor. The high fuel level warning is non-latching. There

is also a low fuel level warning that is non-latching

and a low fuel shutdown alarm. Each of these alarms

has a set-point and can be always active or disabled.

Section 1 — General Information

E Option Control Panels

Page 11

Generac®Power Systems, Inc. 9

E PANEL MODEM SETUP PROCEDURE

NOTE:

Generac only supports the US Robotics 56k V90

Sportster modem for connection of the “E” Panel

to the phone line. Other modems may work in this

application, but have not been tested by Generac.

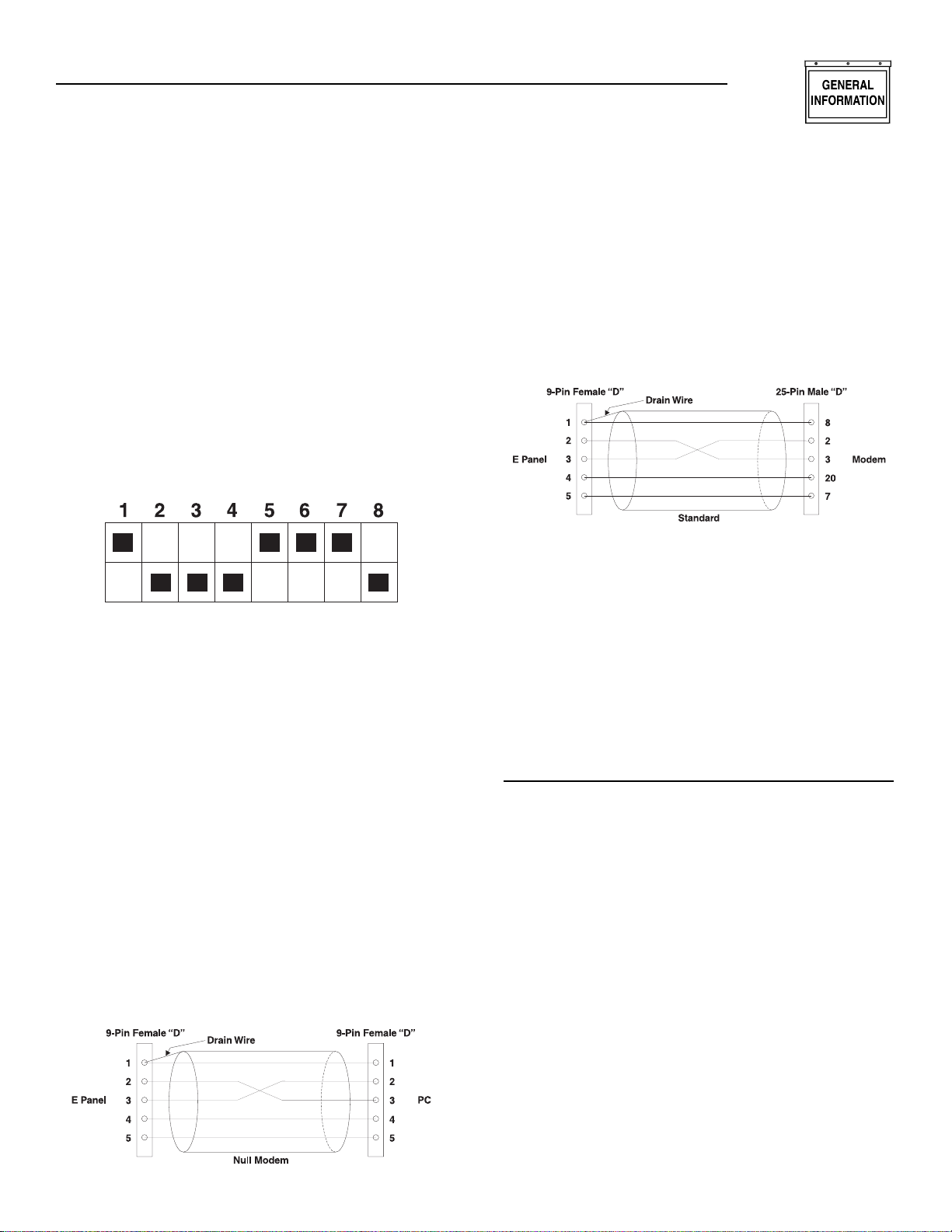

1. Set modem Dip switches as shown in Figure 1.2.

Power cycle the modem (turn modem off, then on).

2. Connect the cable between the “E” panel and the

modem (see Figure 1.4).

3. Set the “E” panel for “modem connection and

setup”. Power cycle the “E” panel (remove and

relace front panel fuse).

4. In GenLink, select the proper setup string for the

modem at the PC end (not the “E” panel).

Figure 1.2 — US Robotics 56k V90 Sportster

Dip Switch Settings

E PANEL RS232 CABLES

The “E” panel can communicate via its RS232 port to

a remote PC. The connection is made either directly

to the serial port on a PC, or via a modem and telephone line.

The “E” panel has a 9-pin male “D” type connector,

and is configured as DTE (Data Terminal

Equipment). The serial ports on most PCs also have

a DTE configuration, and are usually 9-pin “D” type

male connectors. Most modems have a DCE configuration (Data Communication Equipment) and a 25pin female connector.

Connecting an “E” panel directly to a PC requires a

“Null Modem” connection. This can be achieved with

either a null modem cable, or a standard serial cable

with a null modem adapter. Figure 1.3 shows the

required pin connections between the two cables for

a 9-pin serial connector on the PC.

Figure 1.3 — “E” Panel to PC Cable

Configuration

NOTE:

Use shielded cable, 100 feet maximum in length.

Connect the shield drain wire to Pin 1 on the E

panel end only.

Connecting the “E” panel to a modem requires a standard modem cable. The cable supplied with the

modem should work. If a longer cable is required, the

connectors should be wired as shown in Figure 4.

Figure 1.4 — “E” Panel to Modem Cable

Configuration

NOTE:

The modem is not intended to be mounted inside

the control panel. It should be mounted inside the

enclosure (no vibration) or inside a nearby building or shelter if the generator does not have an

enclosure.

NOTE:

Use shielded cable, 100 feet maximum in length.

Connect the shield drain wire to Pin 1 on the E

panel end only.

SERIAL COMMUNICATIONS

Serial Communication Via Modem

(Also refer to the appropriate Genlink Manual)

The control panel has the ability to communicate to a

PC via an RS232 serial port. The PC software will be

able to interrogate the module. The user also will be

able to program the parameters on the PC and download them to the module if using the Pro version. The

user will be able to start and stop the generator if it is

in AUTO mode.

The module does not have a built-in modem.

However, software will include the ability to interface

with an external modem. The user can initialize the

modem from the panel. Generac offers a remote

annunciator (models #’s 004391-0, 004392-0 and

004391-1, 004392-1) which allows the E panel to

communicate with both a modem and a remote

annunciator. See the Remote Annunciator Panel manual (part number 0A7450) for a complete description

of these panels.

Section 1 — General Information

E Option Control Panels

Page 12

10 Generac®Power Systems, Inc.

Section 1 — General Information

E Option Control Panels

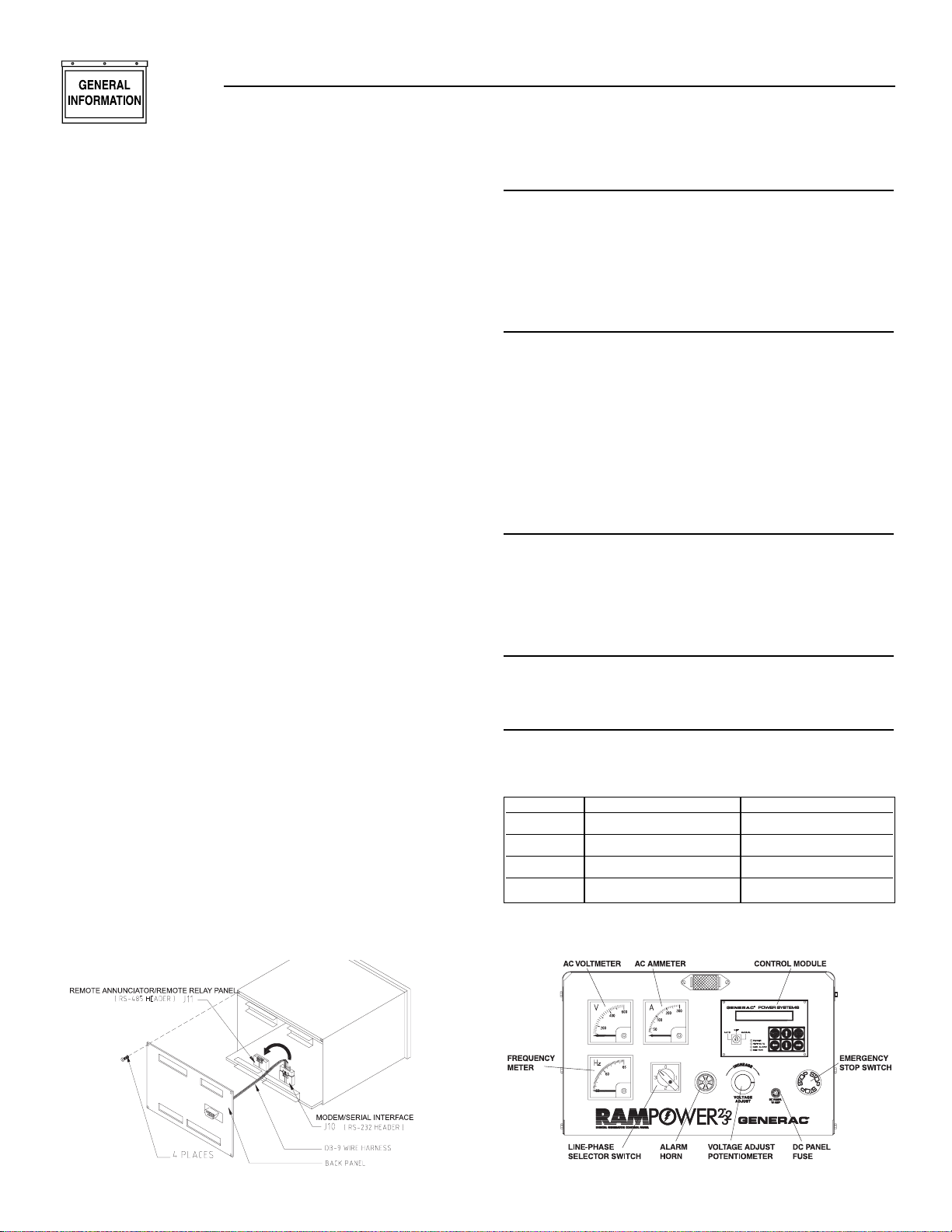

Remote Annunciator Panel

(Refer to manuals 0A7450 and 0A9825)

The serial connections can be configured to allow the

control panel to connect to a remote

annunciator/remote relay panel, which is configured

as RS485, to meet NFPA 110. Only one communication port is available for either a modem or remote

annunciator.

NOTE:

The following diagram and instructions apply only

to those units manufactured before January 2000.

Units manufactured after January 2000 incorporate a selector switch on the back of the control

module. This switch will allow selection of either

RS232 or RS485 without opening the module.

Altering the Serial Communications Setup

The E option control panel is capable of being used

with either a modem or a remote annunciator/

remote relay panel, depending on the configuration of

the serial connections. The unit comes set up for connection to a modem (RS232). In order to use the control panel with a remote annunciator/remote relay

panel (RS485), adhere to Figure 1.5 and the instructions that follow.

1. Remove harness retaining screws, then unplug all

five wire harnesses from the back of the E panel

control module.

2. Remove the four phillips head screws retaining the

rear cover of the control module.

3. Open the back of the control module.

4. Locate the DB-9 wire harness that runs from the

DB-9 connector on the back panel to the black

header on the lower circuit board inside the control module.

5. Carefully remove the black connector from

the header by pressing the locking tab and

lifting up.

6. Insert the black connector into the RS485

header (J11). Make sure that the connector is fully

inserted and that the locking tab snaps into place.

7. Replace the back panel and the four screws.

Figure 1.5 – E Panel Serial Communications

Setup Modification

USER PASSWORD

The user can set the password. This is a six-digit

number and is initially set to 000000.

ADDITIONAL PANEL COMPONENTS

In addition to the control module, the E option panel

contains the following components (see Figure 1.6):

AC VOLTMETER

This meter indicates the generator AC output voltage.

To determine the nominal rated AC voltage of the

unit, refer to the unit’s data plate.

NOTE:

Some generators are re-connectable to a variety of

voltages. Some units may be equipped with a

rotary “Voltage Selector Switch.” Be sure to read

the “Generator AC Lead Connections” section in

the Owner’s Manual.

AC AMMETER

This meter indicates the current draw of connected

electrical loads, in amps. Also see “Line-phase

Selector Switch.” For continuous operation, never

exceed the rated maximum continuous current

capacity of the generator.

FREQUENCY METER

This meter indicates the generator’s AC output frequency in “Hertz” (cycles per second).

LINE-PHASE SELECTOR SWITCH

This four-position switch permits selection of either

line-to-line or line-to-neutral readings on the panel voltmeter and ammeter. Switch positions are as follows:

Figure 1.6 – E Option Panel Components

Switch Single-phase Units Three-phase units

1 Line E1 to Neutral Line E1 to E2

2 Line E3 to Neutral Line E2 to E3

3 Line E1 to E3 Line E3 to E1

OFF No Reading No Reading

Page 13

Generac®Power Systems, Inc. 11

VOLTAGE ADJUST POTENTIOMETER

This potentiometer permits the operator to “fine

adjust” the generator’s AC output voltage on units

rated below 400 kW. Adjustment range is plus or

minus five percent. Turn the knob clockwise to

increase voltage, counterclockwise to decrease voltage.

ALARM HORN

This horn sounds an audible warning when an alarm

condition exists. See the “Alarms” section for further

information.

DC PANEL FUSE

This 15-amp fuse protects the panel components.

This fuse is not to be confused with the control module internal fuse discussed in “Checking/Replacing

the E Panel Control Module Internal Fuse.”

EMERGENCY STOP SWITCH

When pressed, this switch will automatically shut

down the entire generator set. The operator must pull

the switch out to its original position to reset it and

allow for generator operation.

CHECKING/REPLACING THE E PANEL

CONTROL MODULE INTERNAL FUSE

Typically, the main indication of fuse failure is the

absence of any illuminated front panel LEDs (even

with the key in the OFF position, the “Power” LED

will be illuminated) and no text visible on the module

display. It should be noted however, that these conditions can exist if either:

a. The generator start battery is dead (less than five

volts) or disconnected.

b. The main panel fuse (15 amp) is blown.

c. The battery supply wires (#13 and #0) to the

panel control module are open circuit (disconnected).

d. The “Power” connector (CON4) is disconnected

from the rear of the control module.

e. The generator start battery connections have been

reversed. Reversal of the battery connections

WILL blow the internal fuse and is the most likely reason for its failure.

Before removing or disconnecting the E panel control

module, check that none of the above conditions (ae) exist.

If you are satisfied that the problem lies with the

control module:

1. Disconnect the generator start battery.

2. Unplug all four wire harnesses from the back of

the control module.

3. Loosen, then detach, the two retaining clips securing the control module and remove the module.

4. Using a multimeter (e.g., Fluke 87) set to the diode

range, measure between pins 1 (BAT+) and 2 (BAT) of connector CON4 on the module.

• With the positive meter lead connected to pin

2 and the negative lead to pin 1, the meter

should read between 0.4 and 0.6 volts, which

indicates that the internal fuse is OK.

• Reversing the meter leads would give a slowly

increasing voltage reading on the meter, which

also indicates a good fuse.

• An open circuit fuse will give an open circuit

meter reading (.OL on Fluke 87).

If the meter reads open circuit:

5. Remove the four phillips head screws retaining the

rear cover of the control module.

3. Open the back of the control module.

4. Locate the internal printed-circuit board mounted

fuse, which is behind and to the left of CON4.

5. Remove the white plastic cover from the fuse holder and remove the fuse.

6. If the fuse has blown, replace the fuse (part

#0A5705), reassemble the control module, and

reinstall the control module and its connections.

7. Reconnect the generator start battery and check if

the control module now functions.

If the fuse blows again, or was not blown when the

module was opened, or the module still does not

function, the E panel control module must be

replaced.

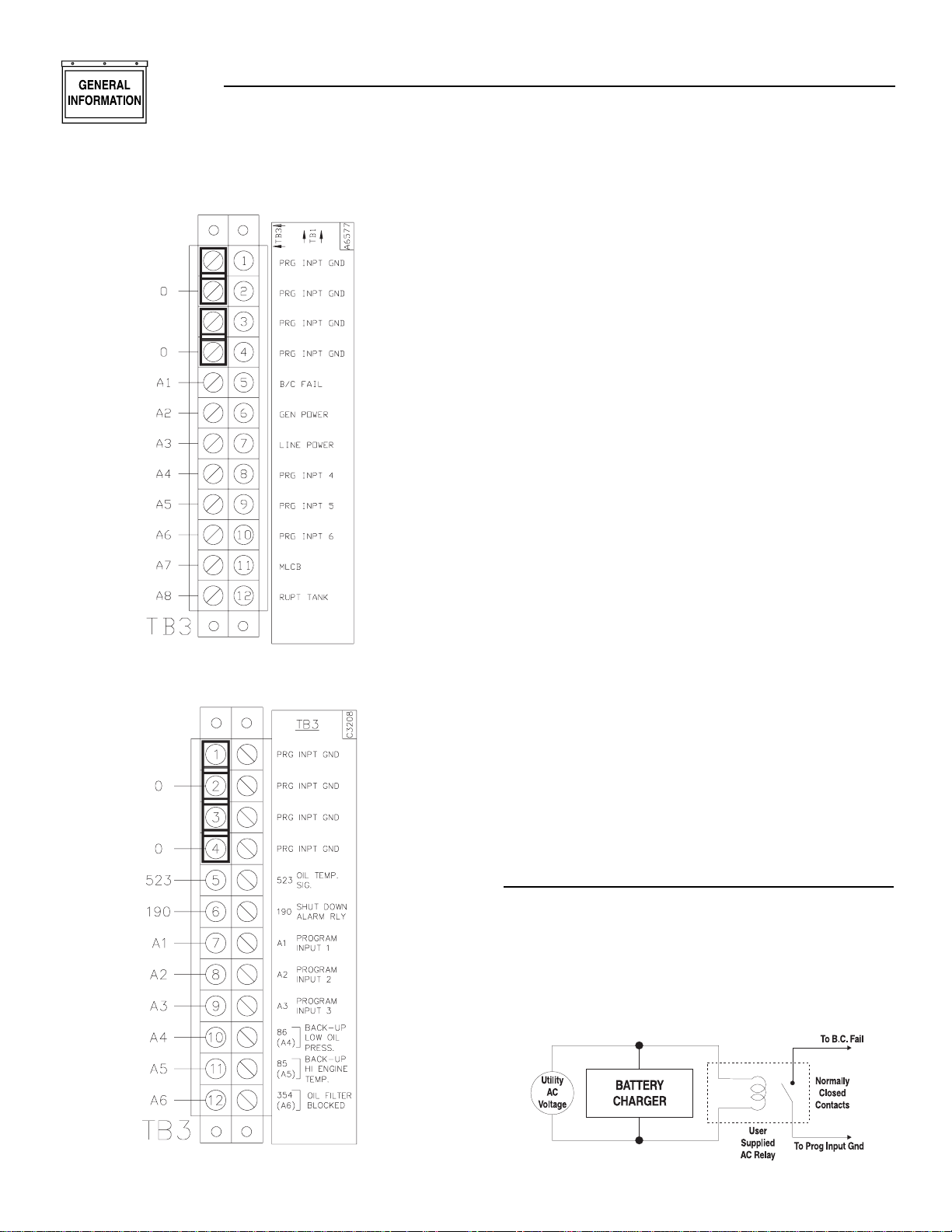

USER PROGRAMMABLE INPUTS

The E panel has eight (8) user programmable inputs.

These inputs can be used for annunciation, prealarm, or shutdown alarms. Four of the inputs,

Battery Charge Fail, Gen Power, Line Power, and

Programmable Input 4 are set up to annunciate on

the control panel display and at the optional 20 Light

Remote Annunciator (Programmable Input 4 will

light the unlabeled “spare” LED). These four inputs

can be used for other connections if a remote annunciator is not used. The other four inputs, if utilized,

will annunciate at the control panel only.

The user programmable input connection points are

located inside the E option control panel on a 12position strip labeled TB3 (refer to Figures 1.7 and

1.8 on page 12.). The first four terminals are labeled

“prog input gnd”. These are the common ground connection points for the user supplied switch devices to

be used for the programmable annunciation.

NOTE:

These ground terminals are for user programmable input use only. The are not to be used for

grounding any other circuits.

Section 1 — General Information

E Option Control Panels

Page 14

12 Generac®Power Systems, Inc.

Figure 1.7 — TB3 Units Up to 400 kW

Figure 1.8 — TB3 Units Over 400 kW

The remaining eight terminals on TB3 are for the “positive” side of each user programmable input switch circuit. These eight terminals have a five VDC potential

available in an open-circuit condition (whether the

control panel key switch is in the off, manual, or auto

position). The inputs can be programmed to annunciate upon either an open circuit condition (five VDC

potential at the terminal) or a grounded condition

(zero VDC potential at the terminal). This voltage state

is determined by the user supplied switch either opening or closing to cause an annunciation.

Program set-up for the user programmable inputs is

carried out in the Digital I/O Menu of the E module

(please refer to the Display Map on pages 18-19). Each

of the eight inputs has four parameters in which specific options must be selected to make the annunciation function properly. These four parameters are

labeled Input Channel Message, Input Channel Setting,

Input Channel Alarm Enable, and Input Channel

Alarm Type. Following is a brief description of each:

• Input Channel Message — for selecting letters and

numbers to spell out what the display will read

upon activation of that specific input.

• Input Channel Setting — for selecting whether

annunciation should activate upon that specific

circuit opening or closing to ground.

• Input Channel Alarm Enable — for enabling or dis-

abling annunciation function of that specific input.

Also, if enabled, for selecting when annunciation

will be active. The choices are: Disabled, Always,

Immediate and Hold-off. See E Control Panel

Definitions on page 38.

• Input Channel Alarm Type — for selecting the type

of alarm annunciation and the effect it has on the

generators control system. The four choices are:

Status, Non-latched, Latched and Shutdown. See

E Control Panel Definitions on page 14.

WIRING EXAMPLES

USER PROGRAMMABLE INPUT NUMBER 1

On units rated below 400 kW, input number 1 is programmed for “Battery Charge Fail” annunciation at

the control panel display, and the LED on the 20 Light

Remote Annunciator (if used). A user supplied AC

relay is wired in to be powered up by AC voltage that

supplies the unit Battery Charger (see Figure 1.9).

Figure 1.9 — Battery Charge Fail Wiring

◆

Section 1 — General Information

E Option Control Panels

Page 15

Generac®Power Systems, Inc. 13

Upon loss of this AC supply voltage, the relay will deenergize. The normally closed contacts on the relay

are to be connected to TB3 in the control panel. One

wire connects to any of the four “Prog Input Gnd”

terminals, the other wire connects to terminal number 5 (B/C Fail). With the relay de-energized, terminal

5 will be grounded, signaling the E module to activate

on Programmable Input 1.

USER PROGRAMMABLE INPUTS NUMBERS

2 AND 3

On units rated below 400 kW, input numbers 2 and 3

are programmed for “Gen Power” and “Line Power”

respectively, indicating the transfer switch position

(Standby or Utility). Annunciation will occur at the

control panel display and at the Remote Annunciator

(if used). These signals will come from a set of spare

auxiliary contacts located on the main contactor

assembly in the transfer switch. The auxiliary contact

switch is a set of dry contacts with three terminals:

Common, Normally Open, and Normally Closed.

Wires must be connected to these three terminals and

routed to the generator control panel. These three

wires must not be run in the same conduit as the generator’s main output conductors. The wire connected

to the Common terminal on the auxiliary contacts

will connect to any of the Prog Input Gnd terminals

on TB3. The wire connected to the Normally Open

terminal on the auxiliary contacts will connect to terminal 6 (Gen Power) on TB3. The wire connected to

the Normally Closed terminal on the auxiliary contacts will connect to terminal 7 (Line Power) on TB3.

ALL USER PROGRAMMABLE INPUTS

On units rated below 400 kW, input numbers 4

through 8, and units rated over 400 kW, input numbers 1 through 8 can be used for virtually any kind of

annunciation the user wishes to set up, within the

parameters previously described, via an opened or

closed switch device. Proper wiring consists of two

wires from the user supplied switch: one wire connects to one of the “Prg Inpt Gnd” terminals (1

through 4 on TB3), the other wire connects to a

Programmable Input terminal on TB3.

PROGRAMMING EXAMPLES

USER PROGRAMMABLE INPUT NUMBER 1

To be used for Battery Charge Fail annunciation.

After properly wiring the circuit as described in

Wiring Examples, program as follows:

1. Power up the E panel by connecting unit battery

(ies) and inserting control panel fuse. The module

will run through a self-test mode. Once it has completed its self-test, it will display the generator status (Stopped, ready to run).

2. Use the LEFT or RIGHT arrow keys to scroll over

to the PARAMETER ENTRY column.

3. Once at the PARAMETER ENTRY column, press

ENTER. Enter the password (if different from the

factory set password 000000) and press ENTER.

From the ENGINE PARAMETER MENU, press the

RIGHT arrow to get to the DIGITAL I/O MENU.

4. Using the UP or DOWN arrows (the column is a

continuous loop), scroll to INPUT CHANNEL 1

MESSAGE and press ENTER. Up to 24 letters,

numbers and other characters can be entered to

spell out what will be displayed upon this input

becoming active. In this case, enter Battery Charge

Fail. After entering the message, press ENTER.

5. Press the UP arrow to display INPUT CHANNEL 1

SETTING. Press ENTER, the display will read

Input Function, OPEN=ALARM. The Battery

Charge Fail annunciation should occur upon the

user supplied relay de-energizing and its normally-closed contact closing, therefore, select

CLOSED=ALARM by pressing the UP or DOWN

arrow. Press ENTER, the display will read Input

Channel 1 Setting, CLOSED=ALARM.

6. Press the UP arrow, the display will read Input 1

Alarm Enable, DISABLED, press ENTER. The

choices are DISABLED, ALWAYS, IMMEDIATE,

and HOLD OFF. This alarm should always be

active, therefore, scroll up or down and select

ALWAYS, and press ENTER.

7. Press the UP arrow, the display will read Input

Channel 1 Alarm Type, STATUS MESSAGE, press

ENTER. The choices are STATUS MESSAGE,

NON LATCHING ALARM, LATCHING ALARM and

SHUTDOWN ALARM. This annunciation for

Battery Charge Fail should be a STATUS message,

therefore, scroll up or down and select STATUS

MESSAGE by pressing ENTER.

Programming for User Input Channel 1, Battery

Charge Fail is now complete. The E module has been

programmed for a STATUS alarm message that is

ALWAYS active. Upon loss of AC supply voltage to the

generators battery charger, the user supplied relay

will de-energize, its normally closed contacts will

close, grounding TB3 terminal 5 to Prg Input Gnd.

The E module will display BATTERY CHARGE FAIL.

Because it was programmed as a STATUS alarm and

not a LATCHING or SHUTDOWN alarm, the status

message will clear when AC power is restored to the

battery charger.

NOTE:

The Battery Charger Fail LED on the 20 Light

Remote Annunciator (if connected) will also turn

on when Input Channel 1 is activated.

◆

◆

◆

Section 1 — General Information

E Option Control Panels

Page 16

14 Generac®Power Systems, Inc.

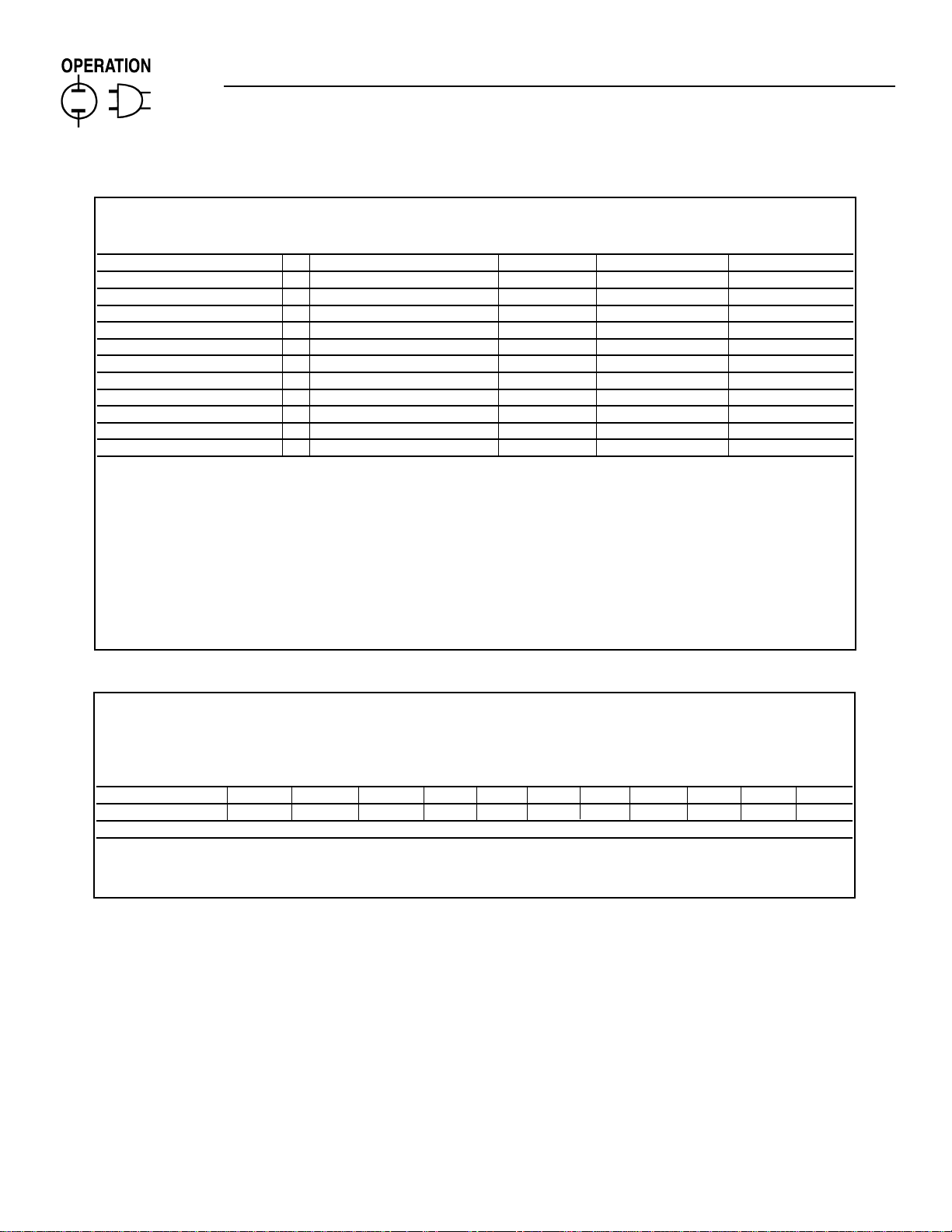

Section 2 — Operation

E Option Control Panels

Output Function Name Description

Function ID

00 Output Disabled Output not in use

01 Common Alarm Active for all latched, non-latched and shutdown alarms

02 Low Oil Pressure Warning Active after hold off time

03 Oil Pressure Shutdown Active after hold off time, low oil pressure

04 High Coolant Temp. Warning Active after hold off time

05 Coolant Temp. Shutdown Active after hold off time, high coolant temperature

06 Low Coolant Temp. Alarm

07 High Oil Temp. Warning

08 Oil Temp. Shutdown High oil temperature

09 Low Battery Voltage Must be below set value for five minutes

10 High Battery Voltage

11 Overspeed Shutdown

12 Underspeed Alarm Active after hold off time

13 Over Voltage Alarm Active after hold off time

14 Under Voltage Alarm Active after hold off time

15 Over Frequency Alarm Active after hold off time

16 Under Frequency Alarm Active after hold off time

17 High Fuel Alarm Above the warning set-point

18 Low Fuel Alarm Below the warning set-point

19 Low Fuel & Shutdown Below the shutdown set-point

20 Failed to Start Alarm Overcrank

21 Coolant Level Alarm Low coolant level

22 RPM Sensor Failed Alarm Magnetic pickup failure

23 Start Inhibit Alarm Oil pressure was present at start request

24 Emergency Stop Alarm Emergency stop active

25 Oil Press. Sense Fault Sensor is either open or short circuit

26 Oil Temp. Sense Fault Sensor is either open or short circuit

27 Coolant Temp. Sense Fault Sensor is either open or short circuit

28 Analog Channel 1 High Input at user analog channel 1 is above programmed high set-point

29 Analog Channel 1 Low Input at user analog channel 1 is below programmed low set-point

30 Analog Channel 2 High Input at user analog channel 2 is above programmed high set-point

31 Analog Channel 2 Low Input at user analog channel 2 is below programmed low set-point

32 Digital Channel 1 Active User programmable digital input 1 is active

33 Digital Channel 2 Active User programmable digital input 2 is active

34 Digital Channel 3 Active User programmable digital input 3 is active

35 Digital Channel 4 Active User programmable digital input 4 is active

36 Digital Channel 5 Active User programmable digital input 5 is active

37 Digital Channel 6 Active User programmable digital input 6 is active

38 Digital Channel 7 Active User programmable digital input 7 is active

39 Digital Channel 8 Active User programmable digital input 8 is active

40 Generator in Auto Key switch in auto position

41 Generator in Manual Key switch in manual position

42 Generator Off Key switch in off position

43 Stopped Generator stopped

44 Shutdown Due to Alarm Generator shutdown

45 Stopped Ready to Run Generator ready to start

46 Running Generator running

47 Ready to Accept Load Generator has reached load accept voltage and frequency set-points, and

the warm-up timer has expired

48 All Alarms Active Generator running

OUTPUT FUNCTION TABLE

Page 17

Generac®Power Systems, Inc. 15

Section 2 — Operation

E Option Control Panels

E PANEL MASTER CONTROL BOX CONFIGURATION SETTINGS

ENGINE PARAMETER MENU

Parameter Value Units

RS232 Port

or RS485 Port

Restore All Values to

Default Settings

Voltage Scaling Factor

Flywheel Teeth Number

Panel I.D.

User Password

Preheat Option

Load Accept Frequency Hz

Load Accept Voltage V

Starter Disengage Speed RPM

Number of Start Attempts Number

Generator Cool Down Time min.

Generator Warm Up Time sec.

Alarm Hold Off Time sec.

Start Attempt Pause Time sec.

Start Timer sec.

Preheat Timer sec.

Available Options: P1 = No Preheat, Before Start, Before and During Star t

C1 = Direct Connection, Modem Connection, Modem Connection & Setup

Connection Mode (C1)

Direct Connection Only

Master Password

Required (Factory Only)

.05 to 300

30 to 200

000000 to 999999

000000 to 999999

(P1)

0to90

0 to 2000

0 to 4000

0to10

0 to 600

0 to 600

0to15

5 to 600

3to15

0to30

SYSTEM ALARM MENU

Parameter Value Units Active Type

Low Fuel Shutdown Alarm % Shutdown Alarm

Fuel Level Low Warning % Non-latching Alarm

Fuel Level High Warning % Non-latching Alarm

Under Freq. Hz Hold Off

Over Freq. Hz Hold Off

Under V oltage V Hold Off

Over Voltage V Hold Off

Engine Underspeed Alarm RPM Hold Off

Engine Overspeed Alarm RPM Immediate Shutdown Alarm

Battery Volts High Warning V Always Non-latching Alarm

Battery Volts Low Warning V Always Non-latching Alarm

Oil Temp. Shutdown Alarm Deg. F Shutdown Alarm

Oil Temp.Warning Deg. F Non-latching Alarm

Coolant Temp. Shutdown Alarm Deg. F Hold Off Shutdown Alarm

Coolant Temp. High Warning Deg. F Hold Off Non-latching Alarm

Coolant Temp.Low W arning Deg. F Always Non-latching Alarm

Oil Press. Shutdown Alarm PSI Hold Off Shutdown Alarm

Oil Press.Warning PSI Hold Off Non-latching Alarm

Available Options: A1 = Disable, Hold off, Immediate

A2 = Disable, Always

T1 = Shutdown Alarm, Latching Alarm, Non-latching Alarm, Status Message

0 to 100

0 to 100

0 to 100

0 to 100

0 to 100

0 to 2000

0 to 2000

0 to 4500

1000 to 4500

4to30

4to30

-5 to 275

-5 to 275

-5 to 275

-5 to 275

0 to 245

0 to 100

0 to 100

(A2)

(A2)

(A2)

(T1)

(T1)

(T1)

(T1)

(T1)

(A1)

(A1)

Page 18

16 Generac®Power Systems, Inc.

Section 2 — Operation

E Option Control Panels

DIGITAL I/O MENU

Channel Message Setting Alarm Enable Alarm Type

Output 1 (F1)

Output 2 (F1)

Output 3 (F1)

Preheat Output Function (F1)

User Input 1 *1 Battery Charge Fail (S1) (A1) (T1)

User Input 2 *1 Generator Power (S1) (A1) (T1)

User Input 3 *1 Line Power (S1) (A1) (T1)

User Input 4 *2 Backup Low Oil Pressure (S1) (A1) (T1)

User Input 5 *2 Backup High Engine Temp. (S1) (A1) (T1)

User Input 6 *2 Oil Filter Blocked (S1) (A1) (T1)

User Input 7 *2 MLCB (S1) (A1) (T1)

User Input 8 *2 Ruptured Tank (S1) (A1) (T1)

Messages can be a maximum of 24 characters including spaces.

Available Options: A1 = Disabled, Hold Off, Immediate, Always

F1 = See output function table for available options.

S1 = Closed (Low Signal/Contact Closure to Ground), Open (High signal/Open Circuit)

T1 = Shutdown Alarm, Latching Alarm, Non-latching alarm, Status Message

*1 Assigned if used with 20 light Remote Annunciator or Remote Relay Panel Otherwise available for any

customer options.

*2 Factory wired if unit is equipped with these options.Otherwise these inputs are available for any

customer requirements.

ANALOG INPUT MENU

Alarm Msg. (Alarm) (Alarm)

Value at Value at (Display) Message Setpoint Enable Type

0V 10V Title High Low High Low High Low High Low

Analog Channel 1 (A1) (A1) (T1) (T1)

Analog Channel 1 (A1) (A1) (T1) (T1)

Messages can be a maximum of 24 characters including spaces.

Available Options: A1 = Disabled, Hold Off, Immediate, Always

T1 = Shutdown Alarm, Latching Alarm, Non-latching alarm, Status Message

Page 19

Generac®Power Systems, Inc. 17

Section 2 — Operation

E Option Control Panels

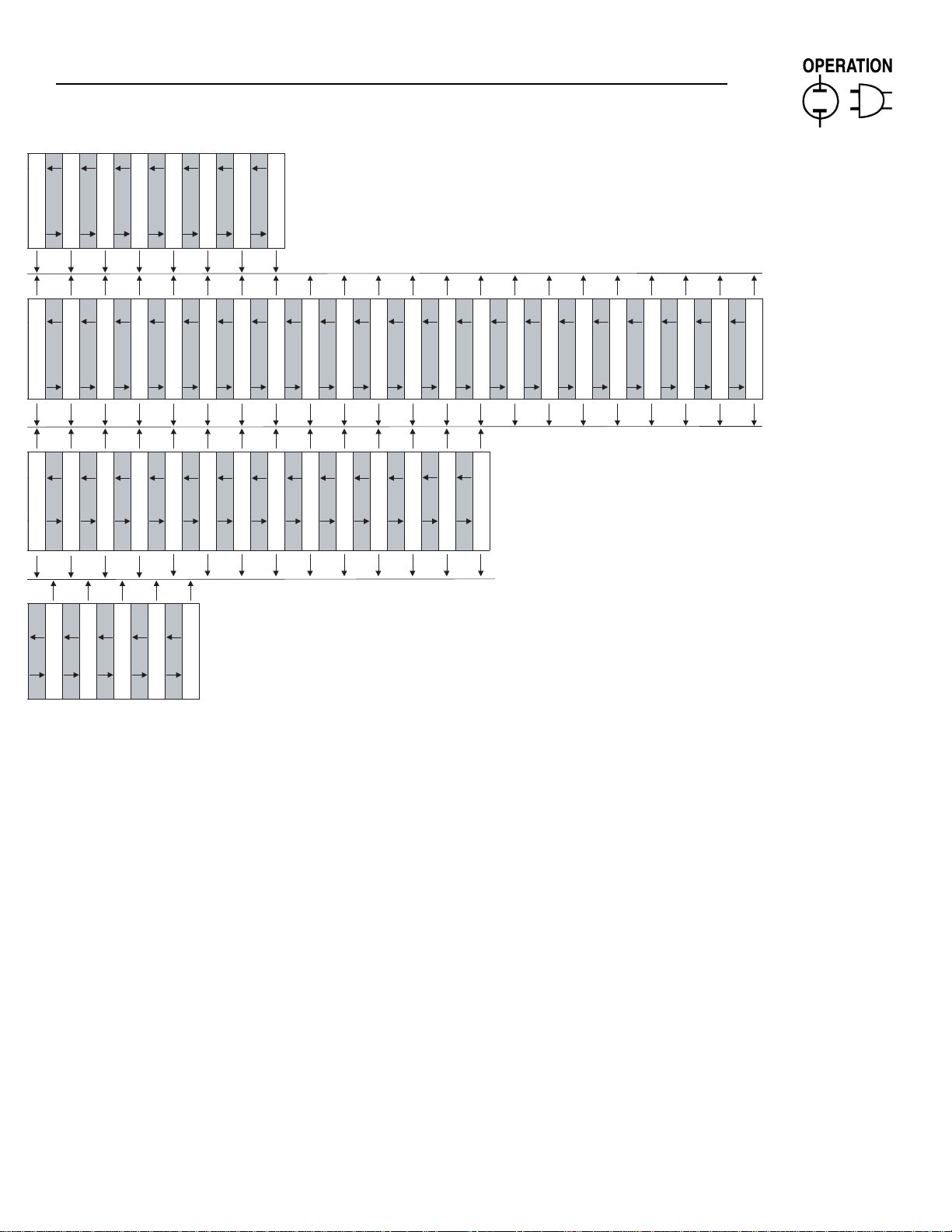

GenLink®Communications Flowchart

Dip Switch Setting

1Up

2Down

3Down

4Down

5Up

6Up

7Up

8Down

TABLE A

“E” Panel Pin Modem Pin

18

23

32

420

57

TABLE B

Page 20

18 Generac®Power Systems, Inc.

Section 2 — Operation

E Option Control Panels

E PANEL DISPLAY MAP

Generac digital panel Generator switch off

Software version X.XX Generator switch off

will be on Attempting to start

X.X

or or or

or or or

or or or

or or or

or or or

Fuel Level High Enable Input Ch 7 Alarm Type Analog Ch 2 low Setpoint

Fuel Level Low Setpoint Input Channel 8 Message Analog Ch 2 High Enable

or or or

Under Freq Alarm Type Input Channel 7 Setting Analog 2 Low Alarm Msg

Fuel Level High Setpoint Input Ch 7 Alarm Enable Analog Ch 2 High Setpoint

or or or

or or or

XX.X Hz

Under Freq Setpoint Input Channel 7 Message Analog Ch 2 High Alarm Msg

Over Freq Alarm Type Input Ch 6 Alarm Type Analog Channel 2 Title

or or or

or or or

XX.X Hz X.X

Over Freq Setpoint Input Ch 6 Alarm enable Analog Ch 2 Value at 10V

Under Voltage Alarm Type Input Channel 6 Setting Analog Ch 2 value at 0V

or or or

or or or

XXX Volts

Under Voltage Setpoint Input Channel 6 Message Analog Ch 1 Low Type

or or or

or or or

XXX Volts

Over Voltage Setpoint Input Ch 5 Alarm Enable Analog Ch 1 Low Enable

Over Voltage Alarm Type Input Ch 5 Alarm Type Analog Ch 1 High Type

Parameter entry

Press Enter to Continue

Password Attempt number X

Or Enter Or Enter * Or Turn key to auto mode: Or

E-PANEL DISPLAY MAP

or

or

or

or or or or

X.X Enter

XXX Volts

Or

or

Thru Hours Run * Display test, stop command

Logged Alarm Number 50 XXXXX.X Hrs all pixels black, all 4 LEDs Turn key to manual mode:

ALARM STATUS ALARM LOG INSTRUMENTATION PARAMETER ENTRY SOFTWARE VERSION GENERATOR COMMAND

there are no messages Generator in auto mode

Analog Input 2 XXXXXX

X.X

Analog Input 1 Engine Parameter Menu Or System Alarm Menu Or Digital I/O Menu Or Analog Input menu

or

or

Direct Connection only

X RS485 Port

or

Fuel Level Low Fuel Shutdown Enable Input Ch 8 Alarm Type Analog Ch 2 Low Type

Battery Voltage RS 232 Port Low Fuel Shutdown Setpt Input Ch 8 Alarm enable Analog Ch 2 High Type

or

RS 232 Port

or

XXX p.s.I or

XX.X Volts Direct conection XX %

Oil Pressure Modem connection Fuel Level Low Enable Input Channel 8 Setting Analog Ch 2 Low Enable

or

or

RS 232 Port

to default settings

Restore all values

Modem connection & Setup

or

or

XXX deg F XX%

XXX deg. F X.X

Oil Temperature

Coolant Temperature

or

or

XXX

XXX.XX

Flywheel Teeth

Voltage Scaling Factor

or

or

XXXX Rpm XX% X.X

Engine Speed

Generator Frequency

Panel I.D.

XX.XHz

or

XXXXXX

or

XXXXXX

User Password

or

Preheat Option

or

or

XX.X Hz

XXX Volts

Load Accept Voltage

Load Accept Frequency

X

or

or

XXX RPM

Starter Disengage Speed

Number of Start Attempts

X Min

Generator Cool Down Time

STATUS

GENERATOR

Stopped ready to run No active messages * Logged Alarm Number 1 Generator Voltage

Or Or * this is true as long as Or

Page 21

Generac®Power Systems, Inc. 19

Section 2 — Operation

E Option Control Panels

X.X

or or or

or or or

XXXX Rpm

Underspeed Alarm Type Input Channel 5 Message Analog Ch 1 low Setpoint

Overspeed Shutdown Setpt Input Channel 5 Setting Analog Ch 1 High Enable

or or or

or or or

XX.X V

XXXX Rpm X.X

Underspeed Alarm Setpt Input Ch 4 Alarm Type Analog Ch 1 High Setpoint

Battery Volts Low Setpt Input Channel 4 Setting Analog Ch 1 High Alarm Msg

Battery Volts High Setpt Input Ch 4 Alarm Enable Analog 1 Low Alarm Msg

or or or

XX.X V

Coolant Temp low Setpt Input Channel 4 Message Analog Channel 1 Title

Analog Ch 1 Value at 10V

Input Ch 3 Alarm Type

or or or

or or or

XXX Deg F

XXX Deg F X.X

Coolant Temp Shutdn Setpt.

Analog Ch 1 value at 0V

Input Ch 3 Alarm Enable

or or

or or

XXX Deg F X.X

Coolant Temp High Setpt

Oil Temp Shutdown Enable Input Channel 3 Setting

or or

or or

XX Deg F

Oil Temp Warn Enable Input Ch 2 Alarm Type

Oil Temp. Shutdown Setpt Input Channel 3 Message

or or

or or

XX Psi

XX Deg F

Oil Temp. Warn Setpt Input Ch 2 Alarm Enable

Oil Press Shutdown Setpt Input Channel 2 Setting

or

or

Input Ch 1 Alarm Type

XX Psi

Oil Press Warn Setpt Input Channel 2 Message

or

or

or

or

Input Channel 1 Setting

Input Ch 1 Alarm Enable

Preheat Output Function

Input Channel 1 Message

or

Output 3 FunctionorOutput 2 Function

Output 1 Function

or

or

X Sec

Gen. Warm Up Time

or

XX Sec

XX Sec

Alarm Hold Off Time

Start Attempt Pause Time

or

or

XX Sec

Start Timer

XX Sec

Preheat Timer

Page 22

20 Generac®Power Systems, Inc.

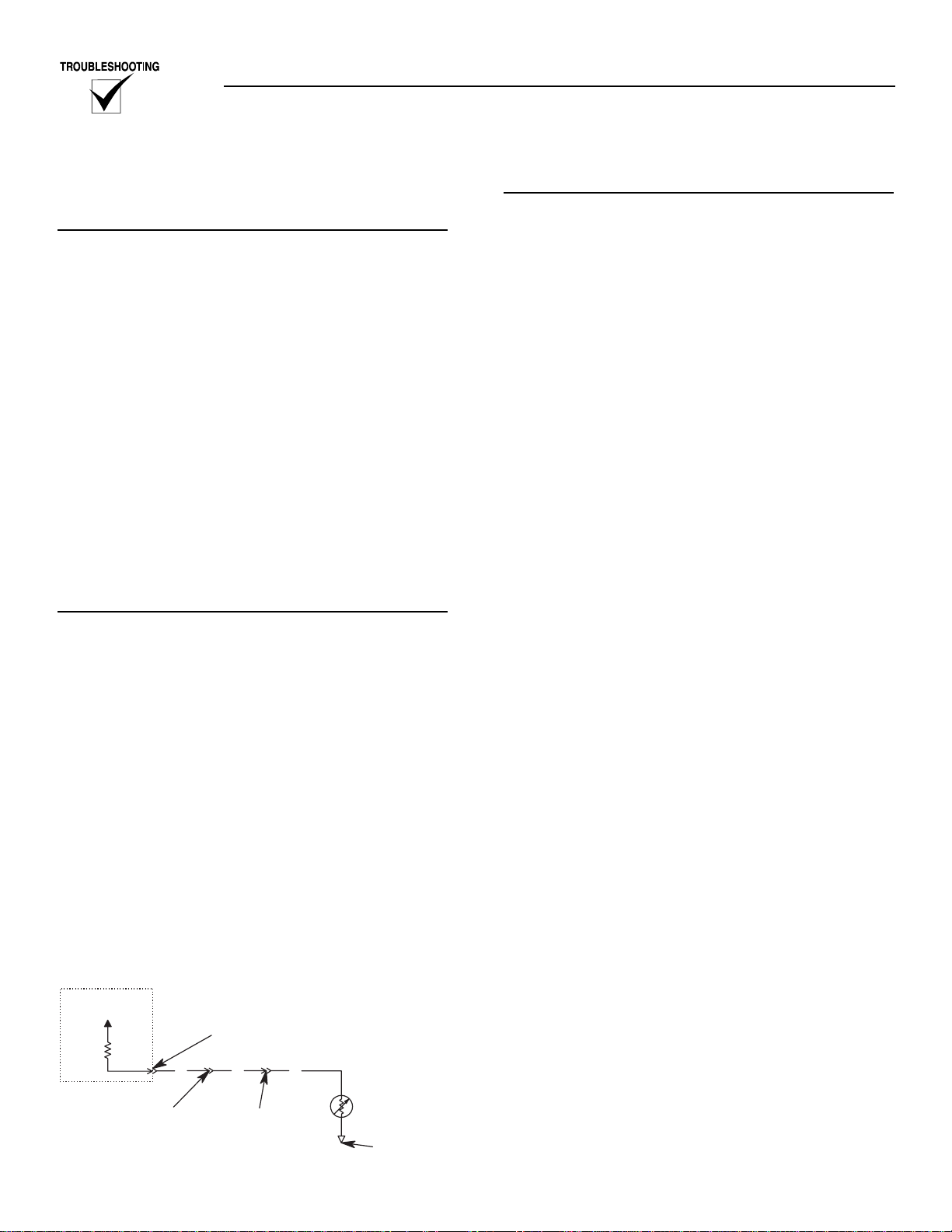

OIL PRESSURE SENSING (Refer to Figure 3.1)

OVERVIEW

An analog Oil Pressure Sender (OPS) is used for

monitoring the engine oil pressure. This sender

allows the E panel to measure and display the Engine

oil pressure.

Refer to the owners manual for the OPS part number

and mounting location.

Wire number 69 is used to connect the OPS to the E

Panel. The Ground for the OPS is made through the

engine block.

The OPS is a resistive device, whose resistance

changes based on engine oil pressure. The resistance

of the sender results in a voltage being developed

across the sender. As the oil pressure increases, the

resistance will decrease, causing the voltage to

decrease. This changing voltage is read by the E Panel

and converted into the engine Oil Pressure.

The E Panel will monitor and display oil pressure

anytime the DC input to the E Panel is present.

TROUBLESHOOTING

Prior to any troubleshooting, the oil pressure parameters programmed into the E Panel should be

checked and verified. The oil pressure input has two

different set points associated with it. They are:

Pre-Low Oil Pressure Warning: This is the warning

set point. The generator's alarm will sound, but the

generator will continue to run.

Critical Low Oil Pressure Alarm: This is the alarm

set point. The generator will shut down and sound

the alarm.

It is important to verify that these parameters are set

correctly for the specific unit. Check the E Panel settings against the Generator setup sheet. If the generator setup sheet is not available, contact Generac's

service department for the recommended settings.

Figure 3.1 — Oil Pressure Sender Connections

TESTING THE CONTROL PANEL

It is relatively easy to do a thorough test of the E

Panel's Oil Pressure input.

Place the Auto/Off/Manual switch to the Off position

during this testing.

Open circuit testing

This test checks the high end of the oil pressure input

of the E Panel.

1. Remove the 69 wire from the control panel terminal strip. This simulates a sender open circuit

condition.

2. Look for the following response from the E Panel:

The back light will flash, the Com Alarm LED will

flash, and the display will read as follows:

OIL PRESS SENSE FAULT

PRESS ENTER TO ACCEPT

3. Press enter to accept the alarm.

Short circuit testing

This test checks the low end of the oil pressure input

of the E Panel.

1. Reconnect the 69 wire to the control panel terminal strip.

Connect a jumper wire between the 69 and 0

positions on the control panel terminal strip. This

simulates a sender short circuit condition

2. Look for the following response from the E Panel

2.1 For units with software version V1.11 and

earlier: The back light will flash, the Com

Alarm LED will flash, and the display will

read as follows:

OIL PRESS SENSE FAULT

PRESS ENTER TO ACCEPT

Press enter to accept the alarm.

2.2 For units with software version V1.12 and

later:

Use the arrow keys to go to the Oil pressure

display screen.

The screen should display oil pressure as

125 p.s.i.

Control panel testing complete

1. Remove the jumper between the 69 and 0 locations on the control panel terminal strip.

2. If any E Panel alarms are present, press enter to

accept.

Test Results

1. Tests 1and 2 Pass:

Move on to the next test "Testing the Oil Pressure

Sender".

Section 3 — Troubleshooting and Diagnosis

E Option Control Panels