Page 1

R-200A Digital Controller

TECHNICAL

MANUAL

A new standard of reliability

This manual should remain with the unit.

Page 2

IMPORTANT SAFETY INSTRUCTIONS

R-panel Technical Manual

SAVE THESE INSTRUCTIONS – The manufacturer suggests that these rules for safe

operation be copied and posted in potential hazard areas. Safety should be stressed to all

operators and potential operators of this equipment.

Study these SAFETY RULES carefully before installing, operating, or servicing this equipment. Become

familiar with this manual and all literature pertaining to the generator set and related equipment. This

equipment can operate safely, efficiently, and reliably

only if it is properly installed, operated, and maintained. Many accidents are caused by failing to follow

simple and fundamental rules or precautions.

The manufacturer cannot anticipate every possible

circumstance that might involve a hazard. The warnings in this manual, and on tags and decals affixed

to the equipment, are, therefore, not all-inclusive. If

using a procedure, work method, or operating technique the manufacturer does not specifically recommend, ensure that it is safe for others. Also make sure

the procedure, work method, or operating technique

utilized does not render the equipment unsafe.

GENERAL HAZARDS

For safety reasons, the manufacturer recommends

•

that this equipment be installed and serviced by

an Authorized Service Dealer or other qualified

electrician or installation technician who is familiar with applicable codes, standards, and regulations. The operator also must comply with all such

codes, standards, and regulations.

When working on this equipment, remain alert

•

at all times. Never work on the equipment when

physically or mentally fatigued.

Inspect the equipment regularly, and promptly

•

repair or replace all worn, damaged or defective

parts, using only factory-approved parts.

Before performing any maintenance on the gen-

•

erator or any related equipment, disconnect the

generator’s battery cables and remove panel fuse

to prevent accidental startup. Disconnect the cable

from the battery post, indicated by a NEGATIVE,

NEG, or (–) first. Reconnect that cable last.

ELECTRICAL HAZARDS

Generators produce dangerous electrical voltages

•

and can cause fatal electrical shock. Avoid contact

with bare wires, terminals, connections, etc., while

the generator and related equipment are running.

Ensure all appropriate covers, guards, and barriers are in place before operating the equipment.

If working around an operating unit, stand on an

insulated, dry surface to reduce potential shock

hazards.

Do not handle any kind of electrical device while

•

standing in water, while barefoot, or while hands or

feet are wet. DANGEROUS ELECTRICAL SHOCK

MAY RESULT.

If people must stand on metal or concrete while

•

installing, operating, servicing, adjusting, or repairing this equipment, place insulative mats over a

dry wooden platform. Work on the equipment only

while standing on such insulative mats.

Wire gauge sizes of electrical wiring, cables, and

•

cord sets must be adequate to handle the maximum electrical current (amperage) to which they

will be subjected to.

Before installing or servicing this equipment, make

•

sure that all power voltage supplies are positively

turned off at their source. Failure to do so will result

in hazardous and possibly fatal electrical shock.

When installed with an automatic transfer switch,

•

the generator may crank and start anytime, without warning. To prevent injuries caused by sudden

start-up, disable the generator’s automatic start

circuit before working on, or around, the unit.

Then, place a “Do Not Operate” tag on the generator control panel and on the transfer switch.

In case of an accident caused by electric shock,

•

immediately shut down the source of electrical

power. If this is not possible, attempt to free the

victim from the live conductor. AVOID DIRECT

CONTACT WITH THE VICTIM. Use a nonconducting implement, such as, a rope or board, to free

the victim from the live conductor. If the victim

is unconscious, apply first aid and get immediate

medical help.

Never wear jewelry when working on this equip-

•

ment. Jewelry can conduct electricity, resulting in

electric shock, or may get caught in moving components, causing injury.

FIRE HAZARDS

For fire safety, the generator and related equip-

•

ment must be installed and maintained properly.

Installation always must comply with applicable

codes, standards, laws, and regulations. Adhere

strictly to local, state, and national electrical

and building codes. Comply with regulations the

Occupational Safety and Health Administration

(OSHA) has established. Also, ensure that the

equipment is installed in accordance with the

manufacturer’s instructions and recommendations. Following proper installation, do nothing

that might alter a safe installation and render the

unit in noncompliance with the aforementioned

codes, standards, laws, and regulations.

Page 3

Table of Contents

Table of Contents

R-panel Technical Manual

Safety Rules ........................................ Inside Front Cover

General Information ......................................................... 2

Introduction ........................................................... 2

Control Board Dip Switch & Jumper Settings .......2

Generator Operation ..............................................5

Engine Timing ........................................................ 5

Utility Failure .........................................................5

Manual Mode ...................................................... 5

Auto Mode ........................................................... 5

Exercise Mode .....................................................5

Utility Restored ...................................................... 5

Initial Cranking ......................................................5

Active Alarm ........................................................... 6

Re-crank ................................................................6

Normal Exercise Mode ...........................................6

Low Speed Exercise ...............................................6

Auto Start ..............................................................6

Manual Start ..........................................................7

System Ready (Green LED Indicator) ....................7

Low Fuel Pressure (Yellow LED Indicator) ............. 7

Low Battery (Red LED Indicator) ...........................7

Low Oil Pressure (Red LED Indicator) ................... 7

High Coolant Temp (Red LED Indicator) ................ 7

Low Coolant Level (Flashing Red

High Coolant Temp LED Indicator) .....................7

Overspeed (Red LED Indicator) ............................. 7

RPM Signal Failure

(Flashing Red Overspeed Indicator) .................... 8

RPM Signal Failure During Cranking ..................8

RPM Signal Failure During Running .................... 8

Overcrank (Red LED Indicator) ............................. 8

Invalid Dip Switch Setting (All Red LED's On) .......8

Alarm Cancel .........................................................8

Automatic Transfer Switch (ATS Mode) ................. 8

Engineered Transfer Switch

(2-wire Start GTS Mode) ..................................... 9

Voltage Regulator Adjustment ..............................10

R-200A J1 Connector (23 Pin,

Gray=1800 rpm, White=3600 rpm) ..............11

R-200A J2 Connector (14 Pin White) ................11

2A and 10A Battery Chargers ............................... 11

2A, 12VDC Battery Charger .............................. 12

10A, 12VDC Battery Charger ............................ 12

Notes ................................................................................... 13

AUTHORIZED SERVICE

DEALER LOCATION

To locate the nearest AUTHORIZED

SERVICE DEALER, please call this number:

1-800-333-1322

DEALER LOCATION INFORMATION

CAN BE OBTAINED AT THIS NUMBER,

or visit the website at www.generac.com.

1

Page 4

General Information

R-panel Technical Manual

INTRODUCTION

The R-200A Controller incorporates the generator

control circuitry, the ignition coil driver circuitry and

the interface circuitry to an external governor driver.

The R-200A Controller can control a;

4-cylinder, 1.6L, 1800 rpm or 3600 rpm engine

•

4-cylinder, 2.4L, 1800 rpm or 3600 rpm engine

•

6-cylinder, 4.2L, 1800 rpm engine (with separate

•

ignition coil driver)

The R-200A controller will monitor the utility voltage

to determine if stand-by power is required. Should

the utility voltage fail, the unit will start and run,

detaching from the utility and supplying the customer

load from the generator.

Both the 1.6L and 2.4L engines use a magnetic

pickup on the flywheel gear to provide speed information. A cam sensor is used to provide engine position

information. Each engine uses two coil drivers in a

waste spark coil pack for ignition. With a waste spark

coil, each high-voltage coil output is connected to two

spark plugs resulting in each spark plug being fired

during both the compression and exhaust cycle.

The 4.2L engine uses a magnetic pickup on the flywheel gear to provide speed information. A cam sensor and a crankshaft sensor provide information to a

separate ignition coil driver that fires each spark plug

independently.

The above generators are configured, at the factory,

to use either LP Vapor or Natural Gas (NG). The governor gains have been pre-set and are not adjustable.

The output frequency of the generator main alternator is 60Hz.

The controller PCB, located on the inside door of

the R-200A, may have one of several part numbers.

Early 1.6L units will have part number 0G1505A.

Early 2.4L units will have part number 0G1505B.

Later units have part number 0G1303A for 1800

rpm or, 0G1303B for 3600 rpm. The 0G1303B is a

suitable replacement for the 0G1505A and 0G1505B.

In later units, or if the engine has emission controls,

part number 0G1303C is used for 1800 rpm and

0G1303D is used for 3600 rpm. The latest versions

include 30kW, 3600 rpm, 1.6L control and 18kW,

1800 rpm, 1.6L control. Part number 0G1303E is

used for 1800 rpm and 0G1303F is used for 3600

rpm. The 0G1303C or 0G1303E will work in place

of 0G1303A. The 0G1303D or 0G1303F will work in

place of 0G1303B, 0G1505A or 0G1505B.

The addition of the 4.2L engine required creation of

a new series of controller (see Figure 2). This controller is part number 0G3958C for 1800 rpm units and

0G3958D for 3600 rpm units. All previous part numbers are replacable with these new controllers.

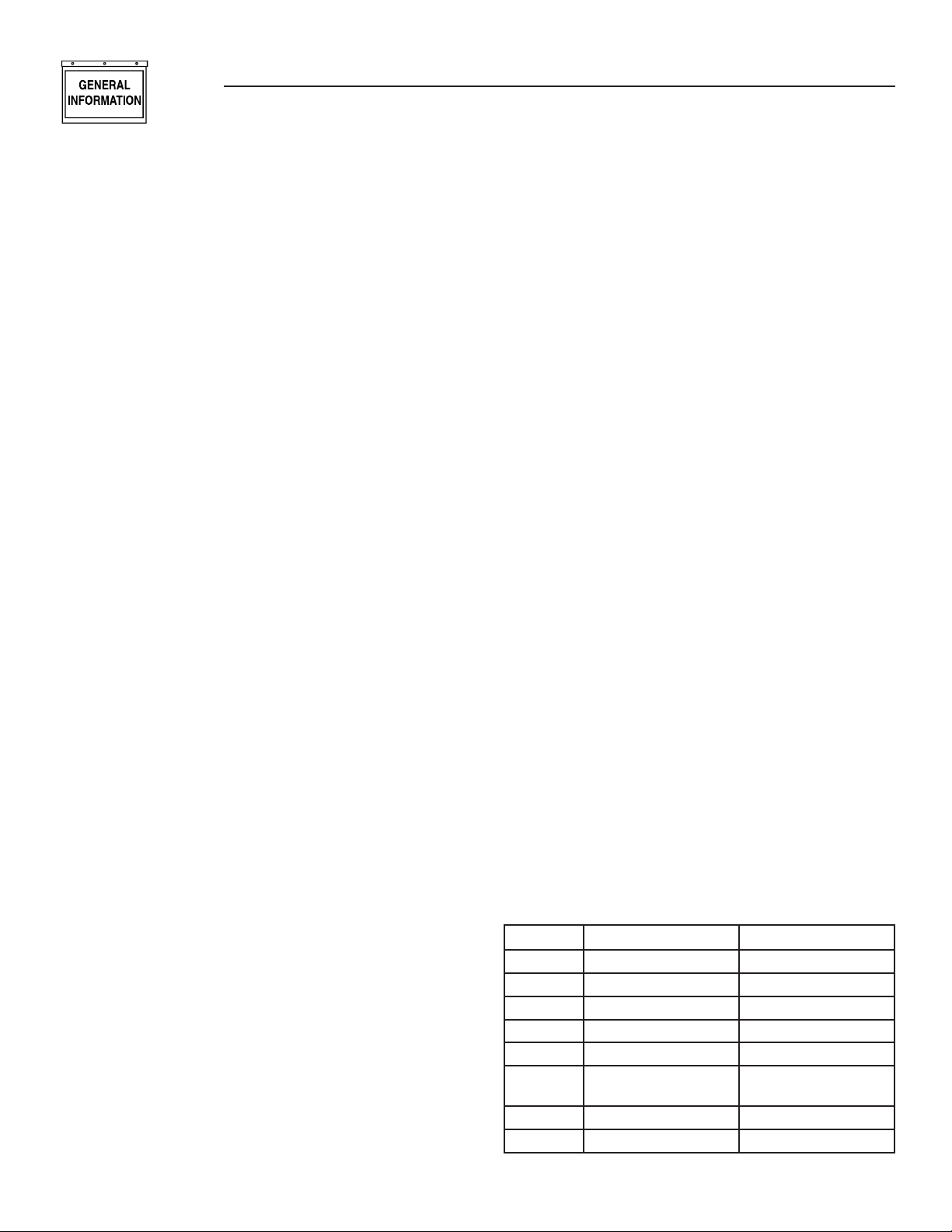

CONTROL BOARD DIP SWITCH &

JUMPER SETTINGS

The Switch "ON" position location is marked on the

DIP switch housing (see Figures 1 and 2.) To activate

the DIP Switch settings place the AUTO/OFF/MANUAL

switch in the OFF Mode, make the DIP switch changes and then push and hold the Set Exercise Switch

for five seconds.

DIP Switch Position 1: Reserved for future use. The

position of this DIP Switch does not affect generator

operation.

DIP Switch Position 2: Selects the type of transfer

switch to be used with the generator. When an "HS" or

RTS-type transfer switch is used (ATS Mode) this DIP

Switch should be in the OFF Position. When a W-type

transfer switch is used (GTS Mode) the generator

2-wire start inputs can be used to control the generator operation. The 2-wire start inputs are labeled

as 178 and 183 on the wiring terminals inside the

generator's customer connection panel.

DIP Switch Position 3: Selects the engine operating

speed in exercise mode.

DIP Switch Position 4: Selects the type of Fuel used

by the generator. The fuel regulator must also be configured for the correct fuel type.

DIP Switch Position 5: Selects the engine displacement when Switch Position 7 is OFF. This position is

ignored when Switch Position 7 is ON.

DIP Switch Position 6: Selects the alternator kW

rating for the 2.4L at 3600 rpm and the 4.2L at 1800

rpm. The position of this DIP switch does not affect

generator operation for the 1.6L, or the 1800 rpm

2.4L.

DIP Switch Position 7: Selects 4.2L displacement

when ON. When OFF, Switch Position 5 selects displacement.

DIP Switch Position 8: Reserved for future use. The

position of this DIP switch does not affect generator

operation.

Switch OFF Switch ON

Position 1 Reserved Reserved

Position 2 ATS Mode GTS Mode

Position 3 Low Speed Exercise Normal Speed Exercise

Position 4 LP Vapor Fuel (LP) Natural Gas Fuel (NG)

Position 5 2.4L 1.6L

Position 6 45kW (2.4L, 3600 rpm and

4.2L, 1800 rpm)

Position 7 1.6L, 2.4L 4.2L

Position 8 Reserved Reserved

35kW (2.4L, 3600 rpm and

4.2L, 1800 rpm)

2

Page 5

General Information

R-panel Technical Manual

Jumper JMP1/S2: Selects the engine displacement.

Set to position 1 and 2 for 1.6L. Set to position 2

and 3 for 2.4L. The jumper is not used on PCB's

0G1505A or 0G1505B. On later revisions, JMP1 is

replaced by S2. S2 has no effect on 4.2L operation

and is ignored when DIP Switch Position 7 is ON.

Figure 1 — Dip Switch & Jumper Settings

(Old Revision)

JUMPER - JMP1

J1

DIP SWITCH

3

1

SOFTWARE P/N

REV #

DATE XXXX

J5

RL1

POS

1

2

43LP

5

6

7

8

LOW SPD

45kW

ON

1

2

3

4

5

6

7

8

OFF

ON

ATS GTS

NORMAL

NG

1.6L

2.4L

35kW

J4

U7

TRANSFER SWITCH MODE

EXERCISE MODE

kW RATING FOR 2.4L, 3600rpm

DESCRIPTION

RESERVED

FUEL TYPE

ENGINE TYPE

RESERVED

RESERVED

U9

J2

J3

Jumper Position* Description

1 & 2 1.6L Selected

2 & 3 2.4L Selected

* When S2 is used, see decal adjacent to S2. Ignored when Pos 7 is ON.

If the DIP switch and jumper settings are not set

correctly, the generator engine may run rough,

not start or not provide rated power. When LP

fuel is used it is very important that DIP Switch

Position 4 be in the LP fuel position (switch

OFF).

LED Indicators visible through front panel (see Table

1 and Figure 3).

Table 1

System Ready Green LED

•

Low Fuel Pressure Yellow LED

•

Low Battery Red LED

•

Low Oil Pressure Red LED

•

Hi Coolant Temp/Low Coolant Level Red LED

•

Over Speed/RPM Sensor Loss Red LED

•

Over Crank Red LED

•

Figure 3 — LED Indicators on Front Panel

Figure 2 — Dip Switch & Jumper Settings

(New Revision)

8 7 6 5 4 3 2 1

S1

J5

ON

J1

RL1

2.4

1.6

S2

U6

S2

C13C14C15

POS OFF ON DESCRIPTION

DIP

SWITCH

1

2

ATS

3

LOW SPD

4

LP

5

2.4L

6

45kW

7

1.6L, 2.4L 4.2L

8

RESERVED

GTS

TRANSFER SW. MODE

NORMAL

EXERCISE MODE

NG

FUEL TYPE

1.6L

ENGINE TYPE WHEN POS 7 IS OFF

35kW

kW RATING FOR 2.4L 3600 RPM AND 4.2L, 1800 RPM

ENGINE SELECT FOR 4.2L

RESERVED

J3

U12

OVERCRANK

OVERSPEED

LOW COOLANT LEVEL

HI COOLANT TEMPERATURE

LOW OIL PRESSURE

LOW BATTERY

LOW FUEL PRESSURE

SYSTEM READY

J2

3

Page 6

General Information

R-panel Technical Manual

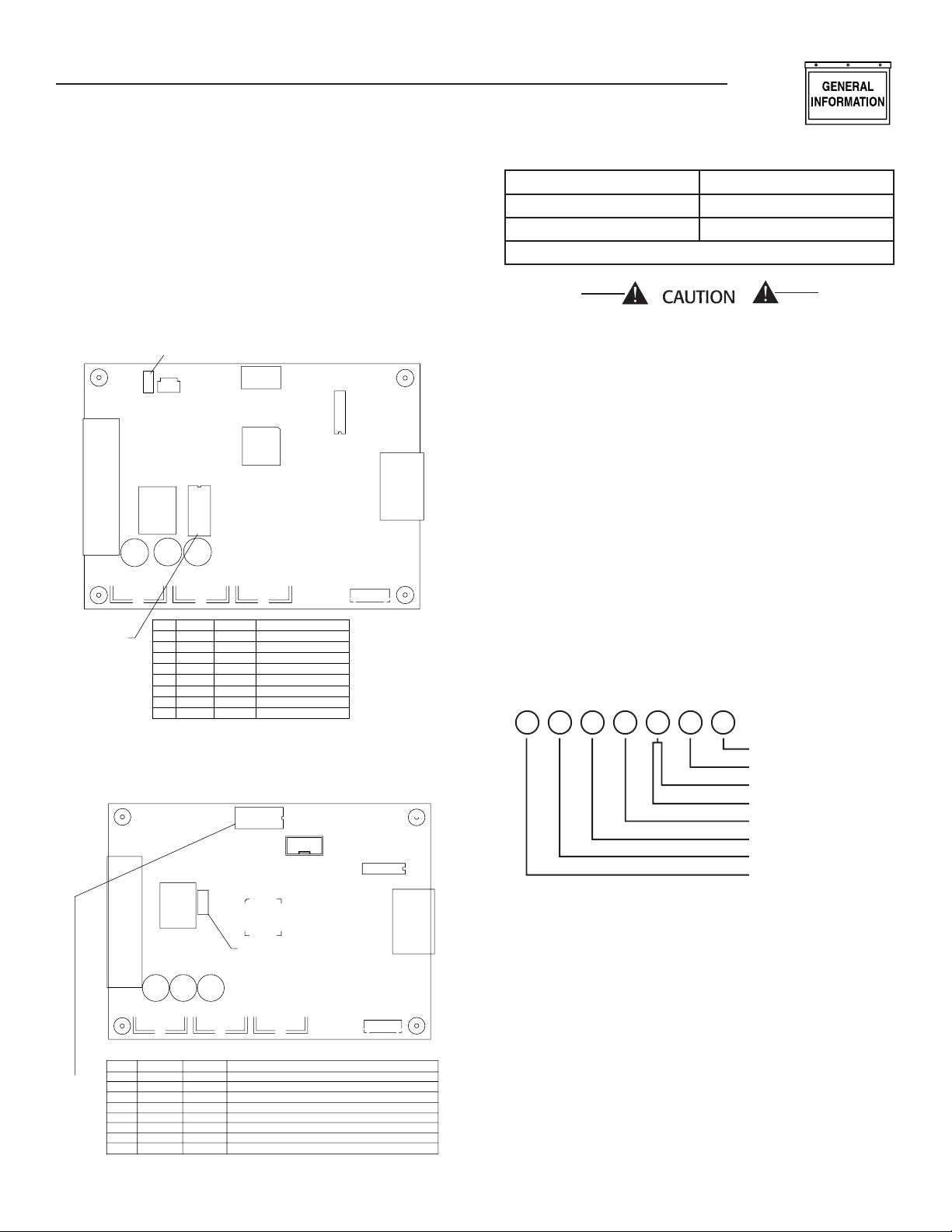

Switch Position

Condition System Low Low Low High Over Over Manual Auto Off

Ready Fuel Bat Oil Temp Speed Crank

Generator Switch is OFF @ X OFF OFF OFF OFF O

in the OFF Mode

System Ready for ON @ X OFF OFF OFF OFF O

Automatic Start

Generator Switch is OFF @ X OFF OFF OFF OFF O

in the MANUAL Mode

Weekly Exerciser X @ Flashing Flashing Flashing Flashing Flashing O O O

is not Set (Note A)

Battery Voltage <12.2V X @ ON O O O

for > 1 minute (Non-Latching)

Battery Voltage <6V OFF @ ON O O

For > 0.05 seconds

(---------------------------------------1 sec rate -------------------------------------)

Unit Shutdown due OFF @ X ON O O

To Low Oil Pressure

Unit Shutdown due OFF @ X ON O O

To High Cooant Temp

Unit Shutdown due OFF @ X ON O O

To Engine Overspeed

Unit Failed to Start OFF @ X ON O O

During it's Crank Cycle

Utility Voltage is Flashing @ X O O

< 60% of Nominal 1 sec rate

Unit Shutdown due OFF @ X Flashing O O

To Low Coolant Level

Engine Speed Signal OFF @ X Flashing O O

Fault/RPM Signal Loss

Control Board is Flashing @ X O O O

In GTS Mode 5 sec ON, 1 sec OFF

DIP Switch #5 is OFF @ ON ON ON ON ON O O O

not set correctly

@ = Low Fuel Pressure is a Yellow LED and will be ON when fuel pressure is less than 5 inches Water Column

X = indicates that the LED can be ON or OFF depending on the Operating Mode (i.e. Manual, OFF or Auto)

Note A: a RED LED fault indication has priority over the flashing LED's used to indicate exercise time not set

4

Page 7

General Information

R-panel Technical Manual

GENERATOR OPERATION

The R-200A controller monitors the front panel

switch position and reads the DIP switch position settings when the control board is initially powered-up.

In the OFF position the controller will only be incrementing the exercise timer and monitoring the battery voltage and low fuel pressure sensor.

In the MANUAL position the controller will start and

run the generator.

In the AUTO position the controller will go into a

"standby" mode, where the controller will monitor

the utility voltage and the exercise timer, and determine if the generator needs to be started and the load

transferred.

Battery voltage is continuously monitored and a

warning LED is lit if the battery voltage drops below

approximately 12.2 volts for longer than one (1) minute. The LED will turn off when the battery voltage

goes back above approximately 12.5 volts.

If, however, the battery voltage drops below 6V during

cranking the low battery LED will stay lit.

While starting and running the engine, the controller

will monitor the engine condition and shut the engine

down on;

Over Crank

•

Over Speed

•

High Coolant Temperature

•

Low Coolant Level

•

Low Oil Pressure

•

Engine Speed Signal Loss/RPM Sensor Loss (the

•

overspeed LED flashes to indicate this fault)

Dead Battery (battery voltage < 6V during crank-

•

ing)

ENGINE TIMING

Nominal engine timing when Natural Gas (NG) fuel

is selected is:

1.6L engine is 34 degrees BTDC at 3600 rpm; 28

•

degrees BTDC at 1800 rpm

2.4L engine is 30 degrees BTDC

•

4.2L engine is 15 degrees BTDC

•

Nominal engine timing when LP fuel is selected is:

1.6L engine is 22 degrees BTDC at 3600 rpm; 20

•

degrees BTDC at 1800 rpm

2.4L engine is 21 degrees BTDC

•

4.2L engine is 15 degrees BTDC

•

UTILITY FAILURE

When the utility fails, a 15 second timer will start.

If the utility is still gone when the timer expires the

engine will crank and start. Once started a 10 second engine warm-up timer will be initiated. When

the warm-up timer expires, the R-200A controller

will transfer the load to the generator (ATS Mode).

The transfer of load when the generator is running is

dependent upon the operating conditions as follows:

MANUAL MODE

The unit will not transfer if the utility is present, it

will un-transfer if the utility voltage is above 80% of

nominal for > 15 seconds and will re-transfer if the

utility voltage drops below 60% of nominal for >15

seconds.

AUTO MODE

The engine will run if the utility fails for >15 seconds, will not transfer if the utility is present, will

un-transfer if the utility is above 80% of nominal for

>15 seconds, and will stop the engine after a one 1

minute cool-down time.

EXERCISE MODE

The unit will not exercise if the generator is already

running (in manual or auto mode). The generator

will only transfer if the utility fails during the exercise period for >15 seconds, and the switch is in the

AUTO mode above.

UTILITY RESTORED

When the utility returns, a 15 second timer will start.

At the completion of this time, if the utility supply has

been above 80% of nominal voltage for the previous

15 seconds, the control will transfer the load back to

the utility. When the load is transferred a one (1) minute cool down timer will start, after which the engine

will be shutdown.

INITIAL CRANKING

The initial crank cycle will be a 15 second crank followed by a seven (7) second rest. This will be followed

by 5 additional cycles of seven (7) second cranks followed by seven (7) second rests. If the engine still

fails to start, the overcrank LED will be illuminated.

Based on the above, the maximum number of engine

crank events is six (6), which is approximately 90

seconds, prior to illuminating the overcrank LED.

5

Page 8

General Information

R-panel Technical Manual

ACTIVE ALARM

Low Oil Pressure, High Coolant Temp, Low Coolant

Level, Overspeed, Overcrank, Engine Speed Signal

Loss and a Dead Battery indication will all be latched

shutdowns. In the event one of these conditions

occurs, the unit will be shut down, the appropriate

LED will be illuminated, and the unit will not start

again without manual intervention (see Re-Crank

below).

RE-CRANK

If an engine speed signal failure occurs while the generator is running the engine will shutdown and then

attempt a re-crank. A maximum of two re-cranks will

be attempted after which the overcrank LED will be

set. If the engine speed signal failure occurred during

the engine exercise mode the exercise timer will continue from where it was at the start of the re-crank

and is not reset.

NORMAL EXERCISE MODE

To select this mode, place DIP switch position 3 in

the ON position.

In Normal Exercise Mode the generators will exercise

at their normal running speed.

The R-200A controller will start and run the generator once every seven (7) days for approximately 12

minutes. If the utility fails during the exercise period,

this exercise period is aborted and the R-200A

Controller transfers the load to the generator output,

assumes automatic operation and continues to run

until the utility is returned.

The weekly exercise cycle is set as follows:

1. Place the AUTO/OFF/MANUAL switch in the

AUTO position.

2. Press and hold the "Set Exercise Time " switch for

five (5) seconds and then release.

At this time all five (5) red LED's will flash for 10

seconds, then the engine will start and run for it's

12 minute exercise period, then shut down. The generator will now start and run each week at approximately the same time.

If battery power to the R-200A Controller is lost, the

weekly exercise time setting will be lost. This is indicated by all five (5) red LED's continually flashing in

ATS mode. In this state the generator will still start

and run in MANUAL mode, or automatically start and

run if utility voltage is lost while in AUTO mode, but

it will NOT perform a weekly exercise cycle.

In the event of a failure while running in this mode,

the five (5) red LED's will stop flashing, the individual fault LED will turn on and the engine will be

shut down. Once the AUTO/OFF/MANUAL switch is

switched to OFF, the individual fault LED will turn off

and the five (5) red LED's will begin flashing to show

that the exercise mode has not yet been set.

6

LOW SPEED EXERCISE

To select this mode place DIP switch position 3 in the

OFF position.

In Low Speed Exercise mode the normal speed 3600

rpm generators will exercise at 1800 rpm. The normal 1800 rpm generators will exercise at 1400 rpm

in this mode.

If the utility fails during the low speed exercise period,

a 10 second timer will start. If the utility returns to

a normal operating level, during this 10 second time

interval the low speed exercise operation will continue. If the utility is still not present (i.e. utility voltage

less than 60% of nominal) when the above 10 second

timer expires then the low speed exercise mode is

terminated and the engine will ramp up to its normal

running speed within five (5) seconds. If the utility

returns during the five (5) second ramp-up period

the generator will terminate the exercise mode. If the

utility is still not present, once the generator is up

to its normal running speed, then the controller will

transfer the load to the generator. When the utility

returns the generator will shutdown.

If battery power to the R-200A Controller is lost, the

weekly exercise time setting will be lost. This is indicated by all 5 red LED's continually flashing in ATS

mode. In this state the generator will still start and

run in MANUAL mode, or automatically start and run

if utility voltage is lost while in AUTO mode, but it will

NOT perform a weekly exercise cycle.

In the event of a failure while running in this mode,

the five (5) red LED's will stop flashing, the individual fault LED will turn on and the engine will be

shut down. Once the AUTO/OFF/MANUAL switch is

switched to OFF, the individual fault LED will turn off

and the five (5) red LED's will begin flashing to show

that the exercise mode has not yet been set.

AUTO START

This unit is designed to automatically start in the

event of a utility failure. A utility failure is defined as

the utility voltage being less than approximately 60%

of nominal, while the utility is considered good when

it is restored to approximately 80% of its nominal

value.

If the generator is already running under exercise

when an auto start is required, it will simply transfer

the load after a 15 second delay and then switch to

auto operation.

Page 9

General Information

R-panel Technical Manual

DANGER

With the switch set to AUTO, the engine can

crank and start suddenly without warning. Such

automatic start up normally occurs when utility

source voltage drops below a pre-set level. To

prevent possible injury that might be caused by

such sudden starts, set the AUTO/ OFF/MANUAL

switch to OFF and remove the NEGATIVE battery

cable from the battery before working on or

around the unit. Then, place a “DO NOT OPERATE” tag on the control console.

MANUAL START

Allows the user to start and run the generator manually. Transfer of the load to the generator will occur

if the utility is lost while the engine is running in the

manual mode.

SYSTEM READY (GREEN LED

INDICATOR)

Is a positive status indicator and dependent upon the

following conditions being true:

1. Switch in the AUTO position.

2. No other warning indicator present.

3. Controller is functional.

The System Ready LED will also indicate if utility

voltage is present at the control board. The system

ready LED will flash every second (at a 0.5 second

ON and a 0.5 second OFF rate) when utility voltage is

not present at the control board when the switch is in

either the AUTO or MANUAL position. This function

is ONLY available with DIP Switch Position 2 in the

OFF position (ATS application).

The system ready LED will also indicate if the generator is in the GTS Mode (i.e. DIP Switch Position 2 in

the ON Position). The system ready LED will flash at

a five (5) seconds ON and one (1) second OFF rate in

GTS Mode.

LOW BATTERY (RED LED INDICATOR)

The R-200A controller continually monitors the battery voltage and turns on the low battery LED if the

battery voltage falls below approximately 12.2VDC

for one minute. A low battery voltage is a non-latching alarm and will not shut down the engine, however,

it is a possible indication of a potential issue with

the battery or battery charger and should be investigated.

The low battery LED will automatically turn off if the

battery voltage rises above approximately 12.5VDC.

If the engine is running when the low battery condition occurs, the engine will continue to run as long

as possible.

If the battery voltage drops below 6V at any time during cranking, the crank cycle will be terminated and

the low battery LED will remain lit. This is a latched

fault and will shut down the engine.

LOW OIL PRESSURE (RED LED

INDICATOR)

Occurs if the oil pressure switch closes while the

engine is running after the 10 second hold off timer

expires. This is a latched fault and will shutdown the

engine.

HIGH COOLANT TEMP (RED LED

INDICATOR)

Occurs if the high coolant temp switch closes. Checks

are made after the 10 second hold off timer expires.

This is a latched fault and will shutdown the engine.

LOW COOLANT LEVEL (FLASHING RED

HIGH COOLANT TEMP LED INDICATOR)

Occurs if the coolant level is low. Checks are made

after the 10 second hold off timer expires. This is a

latched fault and will shutdown the engine.

LOW FUEL PRESSURE (YELLOW LED

INDICATOR)

The yellow low fuel pressure LED will turn ON if the

fuel supply pressure drops below approximately five

(5) inches water column (i.e. occurs when the low fuel

pressure sensing switch on the fuel regulator opens).

This is a non-latched fault (visual LED warning only)

and does not trigger the controller alarm output. Low

fuel pressure sensing is active in all generator operating modes (i.e. MANUAL, OFF and AUTO).

OVERSPEED (RED LED INDICATOR)

An overspeed shutdown will occur if the engine speed

is greater than 4300 rpm for a 3600 rpm engine;

2160 rpm for an 1800 rpm engine; 2250 rpm for an

1800 rpm engine, for three (3) seconds. An overspeed

condition will shutdown the engine and activate the

over speed LED. An immediate overspeed shutdown

will occur if the engine speed is greater than 4500

rpm for a 3600 rpm engine.

7

Page 10

General Information

R-panel Technical Manual

RPM SIGNAL FAILURE (FLASHING RED

OVERSPEED INDICATOR)

If the R-200A controller does not receive a signal

from the engine flywheel sensor, the R-200A controller cannot maintain the generator output frequency

or monitor for an overspeed condition. If this signal is lost the R-200A controller will shut down the

engine as follows:

RPM SIGNAL FAILURE DURING CRANKING

The engine control board (R-200A controller) will

monitor the engine speed signal during engine cranking. If the control board does not see a valid signal

within the first four seconds of each crank cycle it

will stop the crank cycle, lock out on a shut down

fault and flash the overspeed LED.

RPM SIGNAL FAILURE DURING RUNNING

Running mode is handled differently because there

is always the possibility the engine could slow down

or stop running due to a temporary overload. To

avoid shutting down and latching out on a temporary

problem the following is done. If the engine is up and

running, and the control board stops receiving a valid

engine speed input signal it will respond as follows:

1. It will close the throttle.

2. It will shut down the engine by turning off the fuel

supply.

3. It will wait for 15 seconds to ensure the engine

has stopped.

4. It will then energize the starter and monitor the

engine speed signal.

A. If the control board does not see the engine

speed signal it will stop the crank cycle, lock out

on fault, and flash the overspeed LED.

B. If the control board does see the engine speed

input signal during cranking it will start and run

the engine normally. If the engine speed signal is

again lost while running it will repeat the above

procedure one more time.

C. If the failure should repeat a third time, the con-

trol board will shut down the engine, lock out on

fault, and flash the over speed LED.

OVERCRANK (RED LED INDICATOR)

Occurs if the engine has not started within the total

90 second crank cycle. This is a latched fault and will

shut down the engine.

INVALID DIP SWITCH SETTING

(ALL RED LED’S ON)

All five (5) RED LED’s on the front panel will be ON

all the time if DIP switch position 5 is not set correctly.

ALARM CANCEL

When the generator is shut down on a latched fault or

latching alarm, the AUTO/OFF/MANUAL switch must

be set to the OFF position to turn off the corresponding fault LED. Prior to moving the switch to the OFF

position, record which LEDs are ON or FLASHING

and the date on the back cover of this manual.

AUTOMATIC TRANSFER SWITCH (ATS

MODE)

When this generator, along with an RTS-type or HStype automatic transfer switch has been installed and

connected, a circuit board in the generator control

panel constantly monitors the utility voltage and controls the operation of the transfer switch.

To implement this mode of operation, Position 2 of

the eight-position DIP switch, which is located on the

generator circuit board (see Figures 1 and 2), must

be in the OFF position. In ATS Mode utility voltage

sensing, weekly exercising, and load transferring is

under the control of the generator.

Should the utility voltage drop below a preset value,

and remain at this low voltage for a preset amount

of time, the generator cranks and starts. After the

generator starts, the transfer switch transfers the

load circuits to the generator so the generator can

power them. When the utility source voltage has been

restored, the transfer switch re-transfers the load

circuits back to the utility source voltage and the generator shuts down.

The transfer switch is controlled by the generator

circuit board via control wires 23 and 194. Wire 23

connects the collector of an NPN transistor on the

generator circuit board to the “low side” (Terminal

23) of the transfer relay coil in the transfer switch.

Wire 194 connects positive battery voltage from the

generator circuit board to the “high side” (Terminal

194) of the transfer relay coil in the transfer switch.

In order for the generator utility voltage sensing

function to work, it is necessary to provide a 5 amp

fused 240VAC for 240V or 480V systems or 208VAC

utility source connection (depending on the generator

being used) from the transfer switch main N1 and N2

terminals to the generator wiring panel N1 and N2

terminals (See Figure 4).

8

Page 11

General Information

R-panel Technical Manual

Figure 4 - Connection Diagram (ATS Mode)

FUSE

N1

N2

FUSE

RTS-TYPE

OR

HS-TYPE

TRANSFER

SWITCH

FROM UTILITY

N1 N2 (N3)

194

23

E1 E2 (E3)

MAIN LINE

CIRCUIT

BREAKER

OR FUSE

T1

T2

(T3)

TO LOAD

FEEDER CIRCUITS

LOAD

DISTRIBUTION

PA NE L

GENERATOR

CHARGER

120 VAC

LINE

NEU

GND

194

23

178

183

E1 E2 (E3)

N2 N1

Be very careful when connecting high-voltage

wires labeled N1 and N2 and low-voltage wires

labeled 23 and 194 in both the generator wiring

panel and the transfer switch wiring panel. The

control board will be damaged if these wires are

not connected correctly.

In order for the generator battery charger function

to work, it is necessary to provide a 120VAC utility source connection to the generator wiring panel

LINE, NEUTRAL and GND terminals (see Figure 4).

ENGINEERED TRANSFER SWITCH

(2-WIRE START GTS MODE)

When required, the generator can be installed with

an engineered W-type transfer switch which controls

utility voltage sensing, weekly exercising and load

transferring.

When Position 2 of the eight-position DIP switch,

which is located on the generator circuit board (see

Figures 1 and 2), is in the ON position then utility

voltage sensing, weekly exercising and load transferring is under the control of the engineered W-type

transfer switch (GTS Mode).

Generator control board DIP switch position 2 ON =

2-wire Start GTS Mode:

The generator control board will NOT monitor the

•

utility.

The generator control board will NOT perform a

•

weekly exercise. (In GTS mode the green system

ready LED will be ON for five (5) seconds and OFF

for one (1) second).

The generator control board will NOT activate the

•

transfer output.

The generator control board WILL monitor all

•

engine conditions and shut down on all the faults

listed in this document.

For the W-type transfer switch to control utility voltage sensing, weekly exercising and load transferring,

suitable wiring must also be connected from the

transfer switch 178 and 183, 2-wire start terminals

to the corresponding generator 178 and 183 2-wire

start terminals. Recommended wire gauge sizes for

the 2-wire start wiring depend on the length of the

wire (see wiring length chart).

MAXIMUM WIRE LENGTH RECOMMENDED WIRE SIZE

460 feet (140M) No. 18 AWG.

461 TO 730 feet (223M) No 16 AWG.

731 to 1,160 feet (354m) No 14 AWG.

1,161 to 1,850 feet (565m) No 12 AWG.

9

Page 12

General Information

R-panel Technical Manual

Figure 5 - Connection Diagram (GTS Mode)

FROM UTILITY

N1 N2 (N3)

W-TYPE

TRANSFER

SWITCH

E1 E2 (E3)

MAIN LINE

CIRCUIT

BREAKER

OR FUSE

T1

T2

(T3)

178

183

TO LOAD

FEEDER CIRCUITS

LOAD

DISTRIBUTION

PANEL

GENERATOR

CHARGER

LINE

NEU

GND

194

23

178

183

E1 E2 (E3)

120 VAC

N2 N1

Route the 2-wire start control wires through suitable, approved conduit which is separate from the

AC power leads. Connection of wire 178 to wire 183

by relay contact closure action (volt free switch contacts) in the transfer switch must result in generator

engine cranking and startup (see Figure 5).

Do NOT connect battery voltage, utility voltage

(N1/N2) or load voltage (T1/T2) to either the

178 or the 183 2-wire start terminals as this will

damage the generator control board.

In order for the generator battery charger function

to work, it is necessary to provide a 120Vac utility source connection to the generator wiring panel

LINE, NEUTRAL and GND terminals (see Figure 5).

When in GTS mode, the control board will respond

as follows based on the AUTO/OFF/MANUAL switch

position.

OFF: The generator will not start and run in this

position. Only the System Ready LED and the Low

Battery LED are active in the GTS OFF mode.

10

MANUAL: The control board will start and run the

generator whenever the switch is in the manual position.

AUTO: The control board will monitor the 2-wire

start circuit. When the 2-wire start wire 178 is connected to 2-wire start wire 183, via a relay contact

closure in the W-type transfer switch, the control

board will start and run the generator. When the

2-wire start wire connection is opened the control

board will stop the generator.

When the control board is in AUTO, MANUAL or OFF

(GTS mode) the GREEN System Ready LED will flash

(five (5) seconds ON, one (1) second OFF) to indicate that the transfer switch is performing the utility

monitoring and transfer functions.

VOLTAGE REGULATOR ADJUSTMENT

Although adjustment potentiometers are provided on

the voltage regulator installed in the control panel,

the voltage regulator potentiometers have been set at

the factory and should NOT be re-adjusted.

Page 13

R-200A J1 CONNECTOR (23 PIN, GRAY=1800

RPM, WHITE=3600 RPM)

Pin #

1 Governor 12V Supply

2 Reserved (Do not connect any wires to this

pin.)

3 GND-B to Governor Driver

4 Hi-Coolant Temp Input

5 0V to Governor Driver

6 5V Supply to Governor Driver

7 Distributor (Hall Sensor) 12V Sensor Supply

8 Low Coolant Level Input

9 Crank Signal Input

10 Crank Signal Return

11 Low Fuel Pressure Input

12 Governor Position Feedback Input

13 Reserved (Do not connect any wires to this

pin.)

14 Coil + (Supply voltage to engine coil pack.)

15 Coil A Driver

16 2.4L Distributor Sensor Return

17 2.4L Distributor Sensor Input

18 Governor PWM Output

19 Governor Enable Output

20 Lo Oil Pressure Input

21 2.4L Flywheel Sensor Screen

22 Coil C Driver

23 Coil B Driver

R-200A J2 CONNECTOR (14 PIN WHITE)

Pin #

1 Reserved

2 Start (Crank) Relay Driver Output (minimum

coil resistance is 90 ohms)

3 Fuel (Run) Relay Driver Output (minimum

coil resistance is 90 ohms)

4 2-wire Start Input (from relay contact in W-

type transfer switch)

5 Momentary Open Switch Input (B+)

6 2-wire Start Return (from relay contact in W-

type transfer switch)

7 Manual/Auto Input (+BS)

8 19.5VAC Utility Sense Input

9 Reserved

10 Transfer Switch Relay Driver Output (mini-

mum coil resistance is 60 ohms)

11 Manual Input

12 19.5VAC Utility Sense Return

13 Reserved

14 GND-B (Battery Ground)

General Information

R-panel Technical Manual

Refer to the individual generator wiring dia-

grams and schematics for additional information.

2A AND 10A BATTERY CHARGERS

There are two types of battery chargers. A 2 Amp battery charger and a 10 Amp battery charger.

The 2 Amp battery charger is a "float" type charger. A

"float" type charger will charge the battery at its maximum output current rating until the battery voltage

reaches a "float" voltage and then the charge current

will decrease to maintain the battery at that "float"

voltage.

The 10 Amp battery charger is an "equalize" type

charger. An "equalize" type charger will charge the

battery at its maximum output current rating until

the battery voltage reaches an "equalize" voltage and

then the charge current will decrease to maintain the

battery at a lower "float" voltage.

The 2 Amp charger incorporates fuses on both the

input AC line and the battery charger output. The

input AC line fuse is a Littelfuse 2 Amp, Slo-Blo Fuse,

5x20mm, P/N 218002. The AC line fuse is located on

the charger printed-circuit board. The output DC battery fuse is a Littelfuse 5 Amp, Mini-Blade Fuse, P/N

297005. The battery fuse is located on the charger

printed-circuit board.

The 10 Amp charger incorporates fuses on both the

input ac line and the battery charger output. The

input AC line fuse is a Littelfuse 5 Amp, Slo-Blo Fuse,

5x20mm, P/N 218005. The AC line fuse is located

on the charger printed-circuit board. The output DC

battery fuse is a Littelfuse 15 Amp, ATO Fuse, P/N

257015. The battery fuse is located on the charger

printed-circuit board.

These chargers require that the battery be connected

to the charger in order to turn on. The battery voltage

must also be above a certain "boost" voltage for the

charger to turn-on.

The boost voltage required is approximately 11 volts

for a 12V system. If the battery open-circuit voltage is

less than the above boost voltage, it is recommended

that the battery be checked.

If the voltage of the generator's 12V battery exceeds

15VDC, during normal charging operation, the battery should be checked. Typical battery voltages,

when a 12V battery is being charged, should be in the

13VDC to 15VDC range.

The 2 Amp and 10 Amp chargers are UL recognized

for use in the R-panel enclosure and are not to be

operated outside the R-panel enclosure.

11

Page 14

General Information

R-panel Technical Manual

DANGER

Storage batteries give off explosive hydrogen

gas. This gas can form an explosive mixture

around the battery for several hours after charging. The slightest spark can ignite the gas and

cause an explosion. Such an explosion can shatter the battery and cause blindness or other

injury. Any area that houses a storage battery

must be properly ventilated. Do not allow smoking, open flame, sparks or any spark producing

tools or equipment near the battery.

Battery electrolyte fluid is an extremely corro-

sive sulfuric acid solution that can cause severe

burns. Do not permit fluid to contact eyes, skin,

clothing, painted surfaces, etc. Wear protective

goggles, protective clothing and gloves when

handling a battery. If fluid is spilled, flush the

affected area immediately with clear water.

Do not use any jumper cables or booster battery

to crank and start the generator engine. If the

battery has completely discharged, remove it

from the generator for recharging.

2A, 12VDC BATTERY CHARGER

Nominal Input AC Line Voltage .......................... 120Vac

Operating AC Line Voltage Range ................... 108Vac to

Input AC Line Frequency ..............................50 or 60Hz

AC Line Fuse ......................... 2 Amp Slo-Blo, 5x20mm,

Littelfuse P/N 218002

Battery Fuse ........................................5 Amp, Littelfuse

Mini-Blade Fuse P/N 297005

Nominal Charge Rate ........................................ 2 Amps

Float Voltage (type) .........................................13.4 Volts

Battery Undervoltage Shutdown (typ) .............. 11 Volts

LED Indicators

AC Line Voltage > 108Vac ................Green LED ON

Battery Connected & Charging .........Yellow LED ON

(the Green LED must be ON to obtain a valid bat-

tery charging indication,

Yellow LED ON if charge current > approx 0.5

Amps)

Battery Current Drain (AC Power OFF) ........ 30mA (typ)

AC Line Connection........................... via terminal block

(AC Hot, AC Neut & GND)

Battery Connections ..........................via terminal block

132Vac

(Pos +, Neg -)

Be sure the AUTO/OFF/MANUAL switch is set to

the OFF position, before connecting the battery

cables. If the switch is set to AUTO or MANUAL,

the generator can crank and start as soon as the

battery cables are connected.

Be sure the utility power supply to the battery

charger is turned off, or sparking may occur at

the battery posts as the cables are attached and

cause an explosion.

10A, 12VDC BATTERY CHARGER

Nominal Input AC Line Voltage ........................ 120Vac

Operating AC Line Voltage Range ......108Vac to 132Vac

Input AC Line Frequency .............................50 or 60Hz

AC Line Fuse ...................................... 5 Amp, 5x20mm,

Littelfuse P/N 218005

Battery Fuse ..............................15 Amp, Littelfuse ATO

Blade P/N 257015

Nominal Charge Rate ..................................... 10 Amps

Equalize Voltage (typ) ....................................13.8 Volts

Float Voltage (typ) .........................................13.0 Volts

Current at Equalize to Float Transition (typ) .. 5 Amps

Battery Undervoltage Shutdown (typ) ...............11 Volts

LED Indicators

AC Line Voltage > 108Vac ...............Green LED ON

Battery Connected & Charging ........Yellow LED ON

the Green LED must be ON to obtain a valid

battery charging indication,

Yellow LED ON if charge current > approx 2

Amps)

Battery Current Drain (AC Power OFF) ....... 30mA (typ)

AC Line Connections ......................... via terminal block

(AC Hot, AC Neut & GND)

Battery Connections ..........................via terminal block

(Pos +, Neg -)

Control Connections ......................AC Power Fail Relay,

Form C, 2Amps, 12Vdc

(N.O. Contact closes when ac line voltage is applied)

(N.O. Contact opens when ac line voltage is removed)

12

Page 15

Notes

R-panel Technical Manual

13

Page 16

GENERAC® POWER SYSTEMS, INC.

P.O. BOX 8

WAUKESHA, WI 53187

Part No. 0G1341

Revision E (06/19/07) Printed in U.S.A.

Loading...

Loading...