Page 1

Standby

Generators

Standby Generators

Liquid-Cooled Gas Engine

Standby Generators

1 of 9

INCLUDES:

• Two Line LCD Tri-Lingual Digital Nexus™

Controller

• Isochronous Electronic Governor

• Sound Attenuated Enclosure

• Closed Coolant Recovery System

• Smart Battery Charger

• UV/Ozone Resistant Hoses

• ±1% Voltage Regulation

• Natural Gas or LP Operation

• 2 Year Limited Warranty

• UL 2200 Listed

70, 100, 130 & 150 kW meet CA/MA emissions requirement with optional catalyst

Standby Power Rating

Model QT070 (Aluminum - Bisque) - 70 kW 60 Hz

Model QT080 (Aluminum - Bisque) - 80 kW 60 Hz

Model QT100 (Aluminum - Bisque) - 100 kW 60 Hz

Model QT130 (Aluminum - Bisque) - 130 kW 60 Hz

Model QT150 (Aluminum - Bisque) - 150 kW 60 Hz

Meets EPA Emission Regulations

80 kW not for sale in CA/MA

FEATURES

¡ INNOVATIVE DESIGN & PROTOTYPE TESTING are key components of

GENERAC’S success in “IMPROVING POWER BY DESIGN.” But it

doesn’t stop there. Total commitment to component testing, reliability

testing, environmental testing, destruction and life testing, plus testing

to applicable CSA, NEMA, EGSA, and other standards, allows you to

choose GENERAC POWER SYSTEMS with the confidence that these

systems will provide superior performance.

¡ TEST CRITERIA:

PROTOTYPE TESTED NEMA MG1-22 EVALUATION

SYSTEM TORSIONAL TESTED MOTOR STARTING ABILITY

¡ SOLID-STATE, FREQUENCY COMPENSATED VOLTAGE REGULATION.

This state-of-the-art power maximizing regulation system is standard on

all Generac models. It provides optimized FAST RESPONSE to changing

load conditions and MAXIMUM MOTOR STARTING CAPABILITY by

electronically torque-matching the surge loads to the engine. Digital

voltage regulation at ±1%.

¡ SINGLE SOURCE SERVICE RESPONSE from Generac’s extensive dealer

network provides parts and service know-how for the entire unit, from the

engine to the smallest electronic component.

¡ GENERAC TRANSFER SWITCHES. Long life and reliability are

synonymous with GENERAC POWER SYSTEMS. One reason for this

confidence is that the GENERAC product line includes its own transfer

systems and controls for total system compatibility.

Page 2

70 • 80 • 100 • 130 • 150 kW application & engineering data

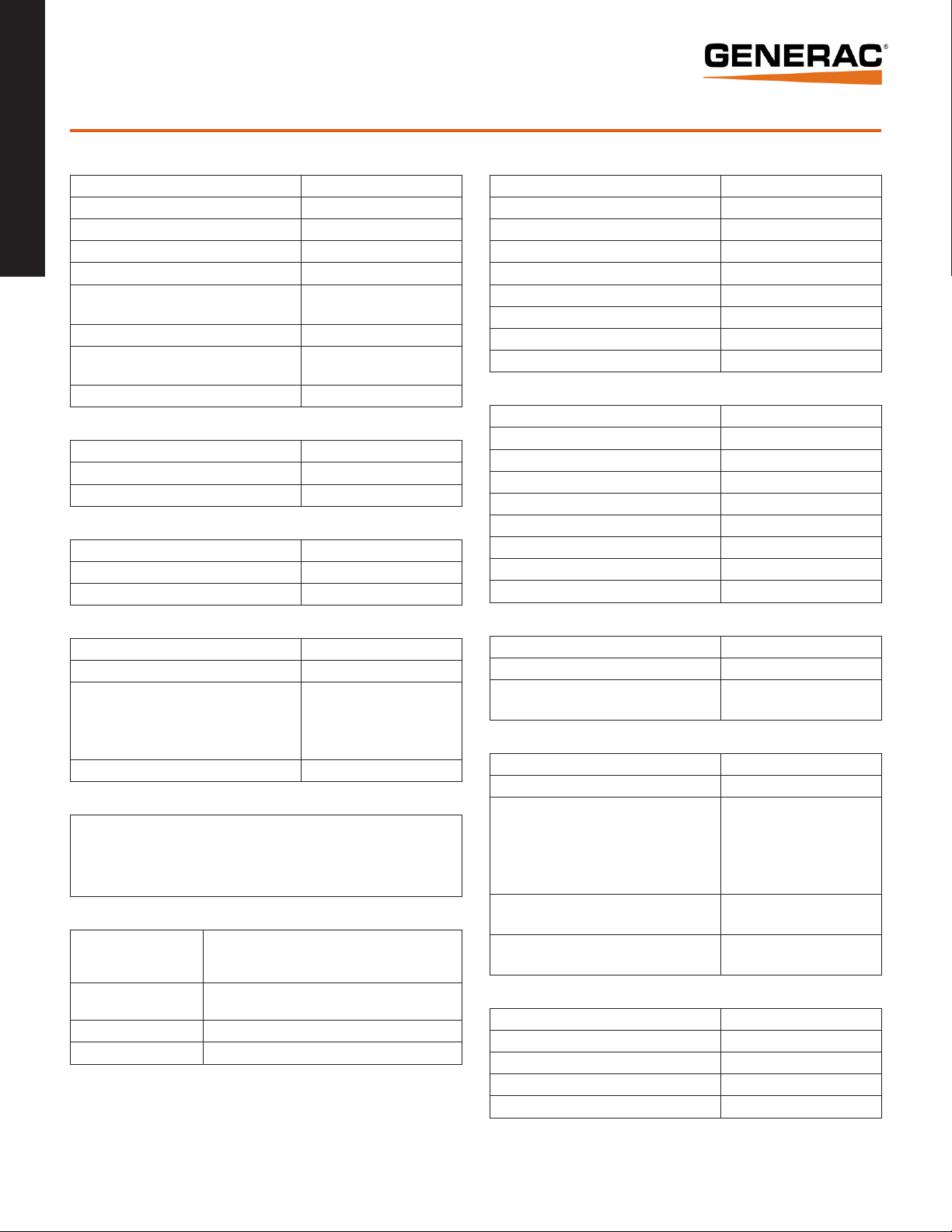

GENERATOR SPECIFICATIONS

Type Synchronous

Rotor Insulation Class H

Standby Generators

2 of 9

Stator Insulation Class H

Telephone Interference Factor (TIF) <50

Alternator Output Leads 1-Phase 4 wire

Alternator Output Leads 3-Phase

Bearings Sealed Ball

Coupling

Excitation System Brushless

VOLTAGE REGULATION

Type Electronic

Sensing Single Phase

Regulation ± 1%

GOVERNOR SPECIFICATIONS

Type Electronic

Frequency Regulation Isochronous

Steady State Regulation ± 0.25%

6 wire (70, 80 & 150 kW) or

12 wire (100 & 130 kW)

Flexible Disc (70, 80 & 150 kW)

or Gear Drive (100 & 130 kW)

ENGINE SPECIFICATIONS: 80 kW

Make Generac

Model V-Type

Cylinders 8

Displacement (Liters) 4.6

Bore (in/mm) 3.55/90.2

Stroke (in/mm) 3.54/89.9

Compression Ratio 9.4:1

Intake Air System Naturally Aspirated

Lifter Type Hydraulic

ENGINE SPECIFICATIONS: 70, 100, 130 & 150 kW

Make Generac

Model V-Type

Cylinders 10

Displacement (Liters) 6.8

Bore (in/mm) 3.55/90.2

Stroke (in/mm) 4.17/105.9

Compression Ratio 9:1

Intake Air System Naturally Aspirated

Lifter Type Hydraulic

ELECTRICAL SYSTEM

Battery Charge Alternator 12 Volt 30 Amp

Static Battery Charger 2 Amp

Group 24F, 525 CCA

Recommended Battery

System Voltage 12 Volts

(70, 80 & 150 kW)

or Group 27F, 700 CCA

(100 & 130 kW)

GENERATOR FEATURES

Revolving field heavy duty generator

Directly connected to the engine

Operating temperature rise 120 °C above a 40 °C ambient

Class H insulation is rated at 150 °C rise at 25 °C ambient

All models fully prototyped tested

ENCLOSURE FEATURES

Aluminum weather

protective enclosure

Enclosed critical grade

muffler

Small, compact, attractive Makes for an easy, eye appealing installation.

SAE Sound attenuated enclosure ensures quiet operation.

Ensures protection against mother nature.

Electrostatically applied textured epoxy paint for added

durability.

Quiet, critical grade muffler is mounted inside the unit

to prevent injuries.

ENGINE LUBRICATION SYSTEM

Oil Pump Type Gear

Oil Filter Type Full flow spin-on cartridge

Crankcase Capacity (quarts/liters)

5/4.7 (70, 100, 130 & 150 kW)

or 6/5.7 (80 kW)

ENGINE COOLING SYSTEM

Type Closed

Water Pump Belt driven

2300 - 70 kW

1600 - 80 kW

Fan Speed (rpm)

Fan Diameter (in/mm)

Fan Mode

26/660.4 (80, 100, 130 & 150 kW)

Puller (80, 100, 130 & 150 kW)

1670 - 100 kW

1950 - 130 kW

2200 - 150 kW

22/558.8 (70 kW) or

Pusher (70 kW) or

FUEL SYSTEM

Fuel Type Natural gas, propane vapor

Carburetor Down Draft

Secondary Fuel Regulator Standard

Fuel Shut Off Solenoid Standard

Operating Fuel Pressure 11” - 14” H2O

(All ratings in accordance with BS5514, ISO3046, ISO8528, SAE J1349 and DIN6271)

Page 3

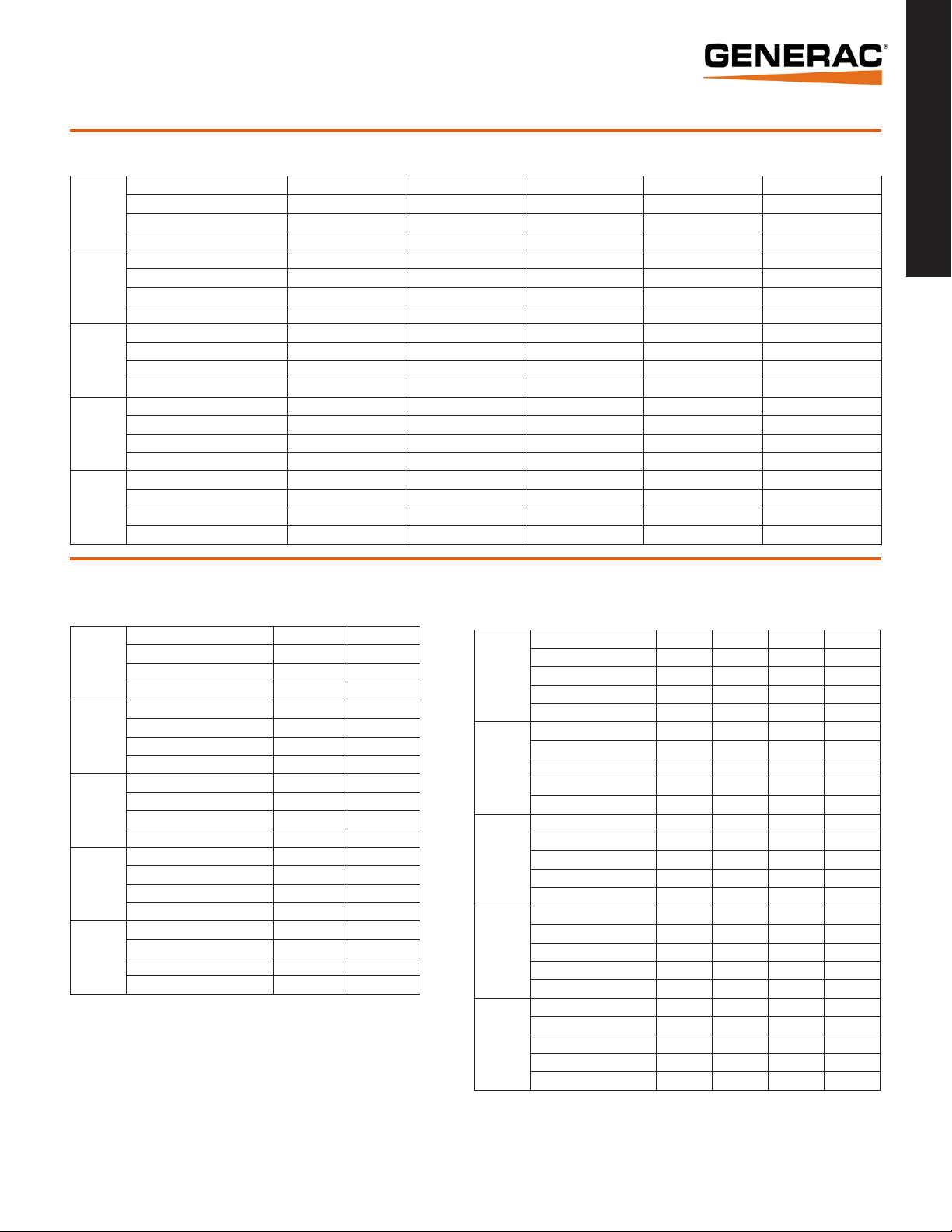

70 • 80 • 100 • 130 • 150 kW operating data

GENERATOR OUTPUT VOLTAGE/kW - 60Hz

kW LPG Amp LPG kW Nat. Gas Amp Nat. Gas CB Size (Both)

120/240 V, 1Ø, 1.0 pf 67 292 64 267 300

QT070

QT080

QT100

QT130

QT150

120/208 V, 3Ø, 0.8 pf 70 243 67 232 300

120/240 V, 3Ø, 0.8 pf 70 211 67 201 250

277/480 V, 3Ø, 0.8 pf 70 105 67 101 125

120/240 V, 1Ø, 1.0 pf 77 333 77 333 400

120/208 V, 3Ø, 0.8 pf 80 278 80 278 300

120/240 V, 3Ø, 0.8 pf 80 241 80 240 300

277/480 V, 3Ø, 0.8 pf 80 120 80 120 150

120/240 V, 1Ø, 1.0 pf 100 417 89 371 500

120/208 V, 3Ø, 0.8 pf 100 347 94 326 400

120/240 V, 3Ø, 0.8 pf 100 301 94 283 350

277/480 V, 3Ø, 0.8 pf 100 150 94 141 175

120/240 V, 1Ø, 1.0 pf 130 542 117 488 600

120/208 V, 3Ø, 0.8 pf 130 451 122 423 500

120/240 V, 3Ø, 0.8 pf 130 391 122 367 450

277/480 V, 3Ø, 0.8 pf 130 195 122 183 225

120/240 V, 1Ø, 1.0 pf 144 625 136 567 700

120/208 V, 3Ø, 0.8 pf 150 520 142 493 600

120/240 V, 3Ø, 0.8 pf 150 451 142 427 500

277/480 V, 3Ø, 0.8 pf 150 225 142 214 250

Standby Generators

3 of 9

SURGE CAPACITY IN AMPS

Voltage Dip @ < .4 pf

15% 30%

120/240 V, 1Ø 129 356

QT070

QT080

QT100

QT130

QT150

Note: Fuel pipe must be sized for full load.

For Btu content, multiply ft3/hr x 2520 (LP) or ft3/hr x 1000 (NG).

For megajoule content, multiple m³/hr x 93.89 (LP) or m³/hr x 37.26 (NG).

Refer to "Emissions Data Sheets" for maximum fuel flow for EPA and SCAQMD permitting purposes.

STANDBY RATING: Standby ratings apply to installations served by a reliable utility source. The standby rating is applicable to varying loads for the duration of a power outage. There

is no overload capability for this rating. Ratings are in accordance with ISO-3046-1. Design and specifications are subject to change without notice.

120/208 V, 3Ø 194 471

120/240 V, 3Ø 168 408

277/480 V, 3Ø 83 201

120/240 V, 1Ø 174 435

120/208 V, 3Ø 186 466

120/240 V, 3Ø 161 404

277/480 V, 3Ø 70 175

120/240 V, 1Ø 150 413

120/208 V, 3Ø 186 452

120/240 V, 3Ø 161 392

277/480 V, 3Ø 107 261

120/240 V, 1Ø 236 648

120/208 V, 3Ø 364 885

120/240 V, 3Ø 315 767

277/480 V, 3Ø 161 390

120/240 V, 1Ø 486 1214

120/208 V, 3Ø 534 1334

120/240 V, 3Ø 463 1156

277/480 V, 3Ø 250 624

ENGINE FUEL CONSUMPTION

Exercise cycle 110 3.1 1.2 4.6

25% of rated load 260 7.4 2.85 10.8

QT070

QT080

QT100

QT130

QT150

50% of rated load 500 14.2 5.46 20.8

75% of rated load 696 19.8 7.62 29.1

100% of rated load 1020 29 11.17 42.6

Exercise cycle 131 3.7 1.45 5.5

25% of rated load 312 8.9 3.45 13.1

50% of rated load 600 17.1 6.64 25

75% of rated load 835 23.7 9.25 34.9

100% of rated load 1154 32.8 12.78 48.2

Exercise cycle 130 3.7 1.4 5.4

25% of rated load 371 10.5 4.1 15.5

50% of rated load 713 20.3 7.9 29.8

75% of rated load 991 28.2 11 41.5

100% of rated load 1260 35.8 13.9 52.6

Exercise cycle 135 3.8 1.4 5.7

25% of rated load 482 13.7 5.3 20

50% of rated load 927 26.3 10.3 38.7

75% of rated load 1292 36.7 14.3 54

100% of rated load 1786 50.8 19.8 74.6

Exercise cycle 155 4.4 1.7 6.5

25% of rated load 556 15.8 6.09 23.2

50% of rated load 1070 30.4 11.72 44.7

75% of rated load 1491 42.4 16.33 62.3

100% of rated load 2061 58.6 22.57 86.1

Natural Gas Propane

(ft³/hr) (m³/hr) (gal/hr) (l/hr)

Page 4

70 • 80 • 100 • 130 • 150 kW operating data

ENGINE COOLING

Air flow (inlet air including alternator and combustion air in ft³/min) 5200/147.2 5300/150.1 5500/155.7 6450/182.6 7800/220.9

Standby Generators

System coolant capacity (gal/liters) 4.5/17 4/15.1 4.5/17 4.5/17 4.5/17

4 of 9

Heat rejection to coolant (BTU/hr) 287,000/302.8 316,000/333.4 342,000/360.8 496,000/523.3 568,000/599.3

Maximum operation air temperature on radiator (°C/°F) 60/150

Maximum ambient temperature (°C/°F) 50/140

COMBUSTION REQUIREMENTS

Flow at rated power (cfm/cmm) 205/5.8 250/7.1 262/7.4 336/9.5 410/11.6

SOUND EMISSIONS

Sound output in dB(A) at 23 ft (7 m) with generator in exercise mode* 67 64 61 65 66

Sound output in dB(A) at 23 ft (7 m) with generator operating at normal load* 72 74 72 75 79

*Sound levels are taken from the front of the generator. Sound levels taken from other sides of the generator may be higher depending on installation parameters.

EXHAUST

Exhaust flow at rated output (cfm/cmm) 557/15.8 720/20.4 888/25.1 1119/31.7 1535/43.5

Exhaust temperature at muffler outlet (°C/°F) 477/890 449/840 516/960 521/970 593/1100

70 kW 80 kW 100 kW 130 kW 150 kW

ENGINE PARAMETERS

Rated Synchronous rpm 1800 3600 2300 2970 3600

POWER ADJUSTMENT FOR AMBIENT CONDITIONS

Temperature Deration ...........................................................................................................3% for every 10 °C above 25 °C or 1.65% for every 10 °F above 77 °F

Altitude Deration (70,100,130 & 150) .................................................................................1% for every 100 m above 183 m or 3% for every 1000 ft above 600 ft

Altitude Deration (80 kW) ................................................................................................ 1% for every 100 m above 915 m or 3% for every 1000 ft above 3000 ft

CONTROLLER FEATURES

2-Line Plain Text LCD Display ........................................................................................................................................Simple user interface for ease of operation.

Mode Switch: Auto ..............................................................................................................................................Automatic Start on Utility failure. 7 day exerciser

Off ...........................................................................................................................Stops unit. Power is removed. Control and charger still operate.

Manual ......................................................................................... Start with starter control, unit stays on. If utility fails, transfer to load takes place.

Programmable start delay between 10-30 seconds ............................................................................................................................................................ Standard

Engine Start Sequence ..................................................................................................................... Cyclic cranking: 16 sec on, 7 rest (90 sec maximum duration)

Engine Warm-up ..................................................................................................................................................................................................................... 5 sec

Engine Cool-Down ..................................................................................................................................................................................................................1 min

Starter Lock-out ................................................................................................................................Starter cannot re-engage until 5 sec after engine has stopped.

Smart Battery Charger ........................................................................................................................................................................................................ Standard

Automatic Voltage Regulation with Over and Under Voltage Protection ................................................................................................................................ Standard

Automatic Low Oil Pressure Shutdown ............................................................................................................................................................................... Standard

Overspeed Shutdown .............................................................................................................................................................................................. Standard, 72 Hz

High Temperature Shutdown ............................................................................................................................................................................................... Standard

Overcrank Protection ..........................................................................................................................................................................................................Standard

Safety Fused ...................................................................................................................................................................................................................... Standard

Failure to Transfer Protection .............................................................................................................................................................................................. Standard

Low Battery Protection ........................................................................................................................................................................................................ Standard

50 Event Run Log ...............................................................................................................................................................................................................Standard

Future Set Capable Exerciser .............................................................................................................................................................................................. Standard

Incorrect Wiring Protection ................................................................................................................................................................................................. Standard

Internal Fault Protection .....................................................................................................................................................................................................Standard

Common External Fault Capability ...................................................................................................................................................................................... Standard

Governor Failure Protection ................................................................................................................................................................................................ Standard

Page 5

70 • 80 • 100 • 130 • 150 kW available accessories

Model # Product Description

005632-0 - 70, 80 & 150 kW

005633-0 - 100 & 130 kW

005620-0 - 70, 100 & 130 kW

005619-0 - 80 kW

005667-0 - 150 kW

005651-0 Base Plug Kit Add base plugs to the base of the generator to keep out debris.

005703-0 Paint Kit

005660-0 - 70, 100, 130 & 150 kW

005985-0 - 80 kW

005928-0 Wireless Remote

005951-0

Cold Weather Kit

Extreme Cold Weather

Kit

Scheduled

Maintenance Kit

Advanced Wireless

Remote

If the temperature regularly falls below 32 °F (0 °C), install a cold

weather kit to maintain optimal battery temperature. Kit consists of

battery warmer with thermostat built into the wrap.

Recommended where the temperature regularly falls below 32 °F (0 °C)

for extended periods of time. For liquid cooled units only.

If the generator enclosure is scratched or damaged, it is important

to touch-up the paint to protect from future corrosion. The paint

kit includes the necessary paint to properly maintain or touch-up a

generator enclosure.

The Liquid-Cooled Scheduled Maintenance Kits offer all the hardware

necessary to perform complete maintenance on Generac liquid-cooled

generators.

Completely wireless and battery powered, Generac's wireless remote

monitor provides you with instant status information without ever

leaving the house.

Remotely control generator functions with the advanced model’s LCD

display. In addition to remote testing of the generator, set the exercise

cycle and maintenance interval reminders.

Standby Generators

5 of 9

006199-0 PMM Starter Kit

006186-0

006463-0 Mobile Link™

006478-0 Harness Adapter Kit

Power Management

Module (50 Amps)

The PMM Starter Kit consists of a 24 VAC, field installed transformer

that enables the use of the 24 VAC Power Management Modules

(PMMs) and one PMM. The standard controller (without starter kit) can

control two HVAC loads with no additional hardware. Not compatible

with pre-wired switches.

Power Management Modules are used in conjunction with the Smart

Switch to increase its power management capabilities. It gives the

Smart Switch additional power management flexibility not found in any

other transfer switch. Not compatible with pre-wired switches. Note:

PMM Starter Kit required.

Generac's Mobile Link allows you to check the status of your generator

from anywhere that you have access to an Internet connection from a

PC or with any smart device. You will even be notified when a change in

the generator’s status occurs via e-mail or text message. Note: Harness

Adapter Kit required.

The Harness Adapter Kit is required to make liquid-cooled units

compatible with Mobile Link™.

Page 6

70 • 80 • 100 • 130 • 150 kW interconnections

Standby Generators

6 of 9

Page 7

70 kW installation layout

Standby Generators

7 of 9

Page 8

80 kW installation layout

Standby Generators

8 of 9

Page 9

100 • 130 • 150 kW installation layout

Standby Generators

9 of 9

Generac Power Systems, Inc. • S45 W29290 HWY. 59, Waukesha, WI 53189 • generac.com

©2013 Generac Power Systems, Inc. All rights reserved. All specifications are subject to change without notice. Bulletin 0199370SBY-B Printed in U.S.A. 07/30/13

Loading...

Loading...