Page 1

GENERAC®ENGINES

Overhead Valve

Industrial

Owner’s Manual

Manual No.A8926

Model No. 190/220 (6.5/7.8 Horsepower)

TTHHIISS SSYYMMBBOOLL PPOOIINNTTSS OOUUTT IIMMPPOORRTTAANNTT SSAAFFEETTYY IINNSSTTRRUUCCTTIIOONNSS,, WWHHIICCHH,, IIFF NNOOTT FFOOLLLLOOWWEEDD,, CCOOUULLDD EENNDDAANNGGEERR

TTHHEE PPEERRSSOONNAALL SSAAFFEETTYY AANNDD//OORR PPRROOPPEERRTTYY OOFF YYOOUURRSSEELLFF AANNDD OOTTHHEERRSS.. RREEAADD AANNDD FFOOLLLLOOWW AALLLL

IINNSSTTRRUUCCTTIIOONNSS IINN TTHHEE MMAANNUUAALL BBEEFFOORREE AATTTTEEMMPPTTIINNGG TTOO OOPPEERRAATTEE TTHHIISS UUNNIITT..

Revision 0 (11/16/98) Printed in U.S.A.

Page 2

GGeenneerraacc GGNN--119900//222200 EEnnggiinnee

If you don’t understand any portion of this manual, contact

Generac for a demonstration of actual starting, operating and

servicing procedures.

Throughout this publication and on tags and decals affixed to

the generator, DANGER,WARNING and CAUTION blocks are

used to alert you to special instruction about a particular

operation that may be hazardous if performed incorrectly or

carelessly. Observe them carefully.

These safety warnings cannot eliminate the hazards that they

indicate. Strict compliance with the special instructions while

performing the service plus “common sense” are major

measures to prevent accidents.

The following definitions apply to DANGER, WARNING,

CAUTION and NOT E blocks found throughout the manual.

These safety symbols indicate the following:

DANGER: After this heading you can read handling,

installing, operating or servicing instructions that, if not

strictly complied with, will result in personal injury.

WARNING: After this heading you can read handling,

installing, operating or servicing instructions that, if not

strictly complied with, may result in personal injury.

CAUTION: After this heading you can read instructions for

handling, installing, operating or servicing the g enerator

that, if not strictly complied with, may result in damage to

equipment and/or property.

NOTE: After this heading you can read explanatory statements that

require special emphasis.

These symbols indicate the following:

Points out important safety infor mation and, if not followed, could

endanger personal safety and/or property of yourself and others.

P

otential explosion hazard.

RULES FOR SAFE OPERATION

Study these RULES FOR SAFE OPERATION carefully before

operating or servicing this equipment. Become familiar with the

OWNER’S MANUAL and with the engine.The engine can

operate safely, efficiently and reliably only if it is properly

operated and maintained. Many accidents are caused by failing

to follow simple and fundamental rules or precautions.

Generac cannot possibly anticipate ever y possible circumstance

that might involve a hazard. The warnings in this manual and on

tags and decals affixed to the equipment, are therefore, not allinclusive.If you use a procedure, work method or operating

technique Generac does not specifically recommend, you must

satisfy yourself that it is safe for you and others.You must also

make sure the procedure, work method or operating technique

that you choose does not render the engine to be unsafe.

DANGER: Do not tamper with the engine governed speed.

High operating speeds are dangerous and increase the

risk of personal injury or damage to the equipment.

Operating at low speeds with heavy load may shorten the

engine’s life.

BEFORE OPERATING

• Gasoline is highly FLAMMABLE and its vapors are

EXPLOSIVE. Do not permit smoking, open flames, sparks or

heat in the area while handling gasoline. Avoid spilling

gasoline on a hot engine. Comply with all of the laws

regulating storage and handling of gasoline.

• Store gasoline and other fuels only in containers designed

and approved for the storage of such materials.

• Pressure can build up in the fuel tank. Loosen the fuel tank

slowly to relieve any pressure in the tank.

• Add gasoline and other fuels in a clean, well-ventilated area.

Wipe up any spilled gasoline immediately. If gasoline has

been spilled, let it dry completely before starting the engine.

Potential fire hazard.

Potential electrical shock hazard.

WWAARRNNIINNGG::

The engine exhaust from this product

contains chemicals known to the State

of California to cause cancer, birth

defects, or other reproductive harm.

— 2 —

Page 3

GGeenneerraacc GGNN--119900//222200 EEnnggiinnee

• Do not overfill the fuel tank.Always allow room for fuel

expansion. If the tank is overfilled, the fuel can overflow onto

a hot engine and cause a FIRE or an EXPLOSION.

• Allow at least two (2) feet of clearance on all sides of the

engine, even while operating it outdoors, or you could damage

the engine.

• Thoroughly inspect the engine for loose or damaged parts

before each use.Do not use the engine until adjustments or

repairs are made.

• Check the oil level in the engine before each use.

• Inspect the engine periodically. Repair or replace all damaged

or defective parts immediately.

• Inspect fuel system frequently for leaks or damage.Repair or

replace any damaged or leaking component immediately.

Never attempt to change, alter or modify the engine fuel

system in any way that might affect safety or compliance with

applicable codes and standards.

• Do not insert any object through the cooling slots of the

• Do not operate the engine faster than the speed necessary to

• This engine requires an adequate flow of cooling air for its

• Do not smoke around the engine.Wipe up any fuel or oil spills

• Keep hands, feet, clothing, etc., away from moving parts of this

• Never operate the engine (a) in the rain; (b) in any enclosed

WHILE OPERATING

• This engine was designed and manufactured for specific

applications. Do not attempt to modify the equipment or

use it for any application for which it was not designed.

• Engine exhaust gases contain DEADLY carbon monoxide

gas.This dangerous gas, if breathed in sufficient

concentrations, can cause unconsciousness or even death.

Operate this equipment only in the open air where adequate

ventilation is available.

• Never wor k on this engine or handle any electrical device while

engine.You could damage the equipment or injure yourself.

operate the equipment. Do not run the engine at high speed

when not operating the equipment.

continued proper operation. Never operate the equipment

inside any room or enclosure where the free flow of cooling air

into and out of the equipment might be obstructed. Without

sufficient cooling air flow, the engine quickly overheats,

damaging the engine or nearby property.

immediately. Never leave oily or fuel soaked rags around the

engine. Keep the area around the engine clean and free of

debris.

engine.

compartment; (c) if the engine speed changes; (d) if the engine

sparks; (e) if flame or smoke is obser ved while the engine is

running.

standing in water, while barefoot, or while hands or feet are

wet. DANGEROUS ELECTRIC SHOCK will result.

— 3 —

Page 4

GGeenneerraacc GGNN--119900//222200 EEnnggiinnee

This engine meets the 1998 and later California emissions

regulations. To ensure that your engine continues to meet

these regulations, refer to the following information and

instructions in this owner’s manual.

SERVICE INFORMATION

Service on this engine within and after the warranty

period can be performed by any authorized service

dealer.Ser vice technicians are factory trained and

capable of handling all service needs.

When contacting an authorized service dealer or the

factory about parts and ser vice, always supply the

complete model number and serial number of your unit as

given on its data plate decal.

The warranty and replacement parts for this engine are

included in the owner’s manual.

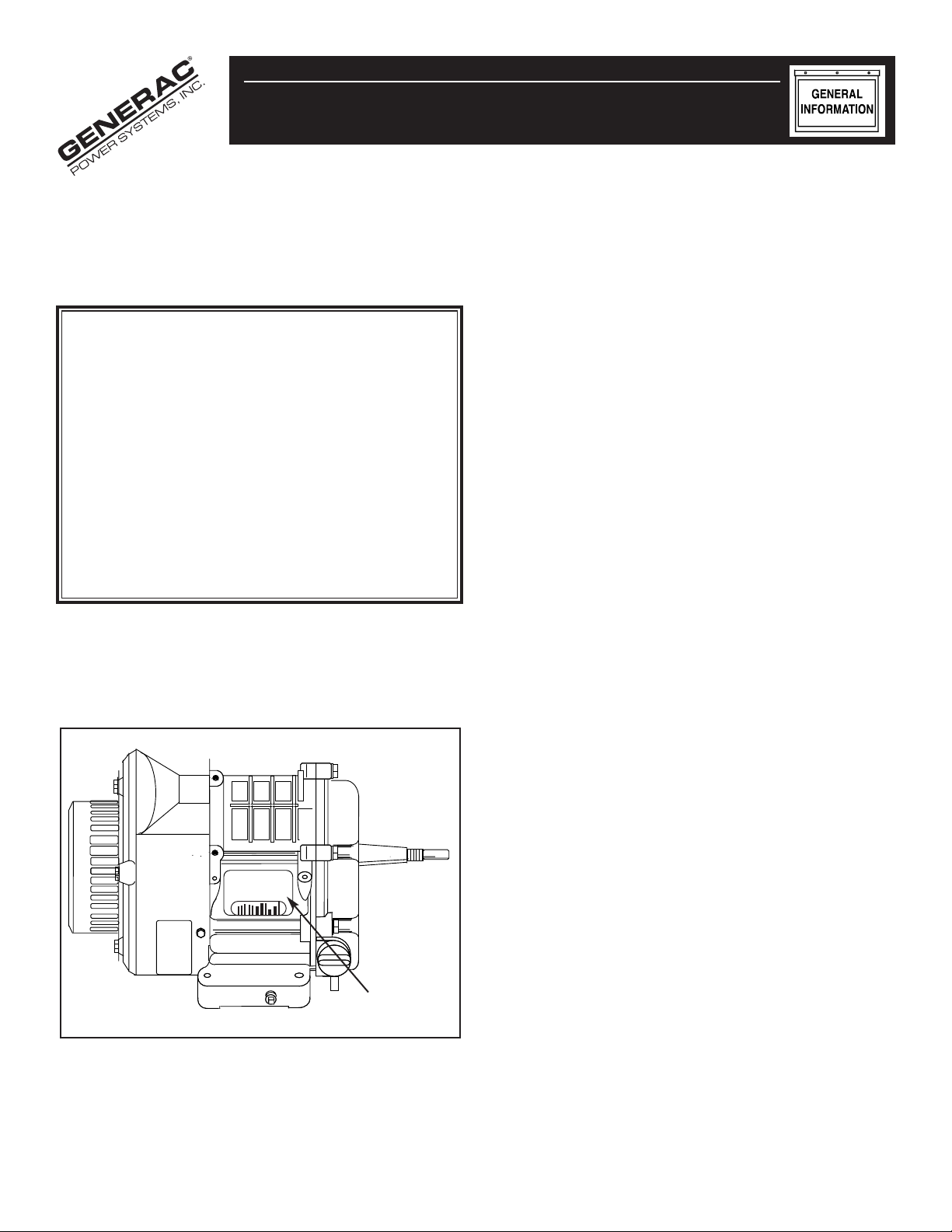

When ordering engine components, you must provide the

authorized service dealer with the engine identification number,

which is located on the engine identification decal. See the

illustration below for the location of the decal.

TABLE OF CONTENTS

RULES FOR SAFE OPERATION ........................................2-3

GENERAL INFORMATION..................................................4-5

Service Information ..................................................................4

Engine Identification Decal Location ........................................4

Oil and Fuel Information............................................................5

OPERATION ........................................................................6-7

Before Starting the Engine........................................................6

Starting the Engine ................................................................6-7

Stopping the Engine..................................................................7

Low Pressure Shutdown System ..............................................7

MAINTENANCE ................................................................8-13

General Maintenance Recommendations ................................8

Service and Adjustments ....................................................8-10

Carburetor Adjustments ..........................................................11

Checking/Adjusting Valve to Rocker Ar m Clearance ..............11

Retorquing Head Bolts ............................................................12

Maintenance Schedule............................................................12

Storage Instructions ................................................................13

Specifications ..........................................................................13

Generac Corporation

Eng. Identif. No. XXXXXX

Displacement XXXXXX

PARTS LISTS & EXPLODED VIEWS ....................14-21

WARRANTIES ................................................................22-24

California Emission Control Warranty Statement ....................22

Emission Control System Warranty ........................................23

Generac Engine Warranty ........................................Back Cover

Decal

— 4 —

Page 5

GGeenneerraacc GGNN-- 119900//222200 EEnnggiinnee

OIL AND FUEL INFORMATION

NOTE: BE SURE TO READ THESE INSTRUCTIONS

CAREFULLY BEFORE ATTEMPTING TO START OR

OPERATE THIS EQUIPMENT. Using old or improper oil or

fuel can cause engine damage.

CAUTION: Any attempt to crank or star t the engine

before it has been properly serviced with the

recommended oil may result in engine damage.

RECOMMENDED OIL TYPE

Using the proper type and weight of oil in the crankcase is

extremely important. Check the oil before each use and change

the oil regularly. Failure to use the correct oil, or using dir ty oil,

can cause premature engine wear and failure.

The recommended oils include the following:

• During summer months: SAE 10W-30,

• During winter months: SAE 5W-20 or 5W-30. DO NOT USE

SAE 10W-40.

The crankcase oil capacity is about 770 ml (29 oz.) with the oil

filter.Without the filter, the oil capacity is 620ml (21 oz.). Use no

special additives.

RECOMMENDED FUEL TYPE

Use clean, fresh, regular UNLEADED gasoline with this engine.

CAUTION: Do not overfill the fuel tank. Always allow

room for fuel expansion.

WARNING: NEVER FILL THE FUEL TANK INDOORS. OR

WHEN THE ENGINE IS RUNNING OR HOT. DO NOT

LIGHT A CIGARETTE OR SMOKE WHEN FILLING THE

FUEL T ANK.

— 5 —

Page 6

GGeenneerraacc GGNN--119900//222200 EEnnggiinnee

OPERATION AND MAINTENANCE

It is the owner’s/operator's responsibility to perform all safety

checks; to make sure that all maintenance for safe operation is

performed promptly; and to have the engine checked by an

authorized dealer periodically. Normal maintenance service and

replacement of parts are the responsibility of the owner/operator

and, as such, are not considered defects in materials or

workmanship within the terms of the warranty. Individual

operating habits and usage contribute to the need for

maintenance service.

Proper maintenance and care of your engine assures a minimum

number of problems and keeps your operating expenses at a

minimum. See your authorized dealer/distributor for service aids

and accessories.

BEFORE STARTING THE ENGINE

Perfor m the following tasks before trying to start the engine:

ADDING ENGINE OIL

1. Remove the yellow oil fill cap from the crankcase (Figure 1).

2. Add engine oil until the oil level is to the point of overflowing.

STARTING THE ENGINE

1. Open the fuel shut-off valve, if so equipped.

2. If your unit is equipped with the IDLE/CONTROL feature,

locate the IDLE/CONTROL ON/OFF SWITCH on the control

panel, and set it to the OFF (O) position.

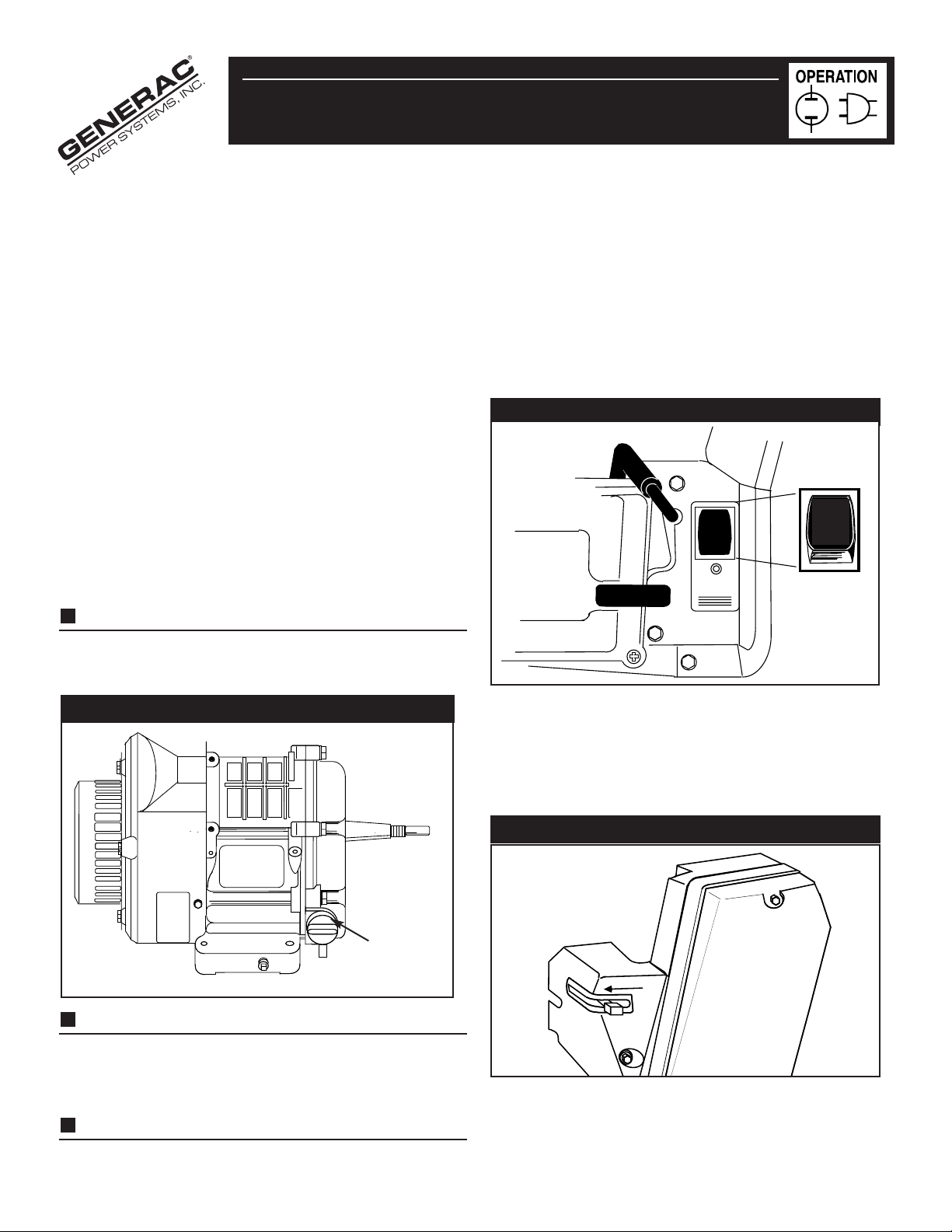

3. Locate the RUN/STOP SWITCH (Figure 2) next to the

engine cylinder head and push it to RUN.

Figure 2 — RUN/STOP SWITCH

RUN

RUN

STOP

STOP

LOW OIL

LOW OIL

INDICATOR

INDICATOR

Figure 1 — Oil Fill Cap

Oil Fill

Cap

CHECKING ENGINE OIL

1. Check the engine oil level before starting the engine each

time after the initial start. If the oil level is below the point of

overflowing, fill to the proper level.

ADDING FUEL

1. Fill the fuel tank using clean, fresh UNLEADED gasoline.

If your engine is equipped with a choke, use the

following instructions:

1. Place the choke lever in the FULL CHOKE POSITION

(Figure 3) by sliding it to the left (towards the valve cover),

in the direction indicated by the arrow.

Figure 3 — Choke Positions

CHOKE

2. Grasp the recoil handle (Figure 4) and pull it slowly until you

feel slight resistance, then PULL QUICKLY.

— 6 —

Page 7

GGeenneerraacc GGNN--119900//220000 EEnnggiinnee

A If the engine FAILS TO START, go to Step 3.

B. If the engine STARTS, go to Step 4.

Figure 4 — Recoil Handle

Recoil

Handle

3. Move the choke lever to the HALF CHOKE POSITION,

and pull the recoil handle (Figure 4) two (2) times.

• If the engine STILL F AILS T O ST ART, repeat

Steps 1-3.

4. Move the choke lever to the RUN POSITION by sliding it

to the right (away from the valve cover and under the

arrow).

5. Allow the engine to warm up for two (2) minutes before

using the equipment.

If this engine is equipped with a primer bulb, use

the following instructions.

1. Press the primer bulb three (3) times, waiting two (2)

seconds between each push (Figure 5).

Figure 5 — Pressing the Primer Bulb

H

V

OOHH VV II

I

R

UN

S

O

T

P

L

O

W

O

I

L

IND

ICATOR

2. Grasp the recoil handle (see Figure 4) and pull it slowly until

you feel slight resistance, then PULL QUICKLY. Repeat

pulling the recoil handle three (3) times, if necessary.

3. If the engine FAILS TO ST ART, repeat Steps 1 and 2.

4. Allow the engine to warm up for two (2) minutes before using

the equipment.

STOPPING THE ENGINE

1. Remove the load on the engine, and let it run for 30

seconds.

2. Turn off the engine by moving the RUN/STOP SWITCH to

the STOP position.

3. Close the fuel shut-off valve, if so equipped.

LOW PRESSURE SHUTDOWN SYSTEM

The engine is equipped with a low oil pressure sensor that shuts

down the engine automatically when the oil pressure drops below 8

psi. If the engine shuts down by itself and the fuel tank has enough

gasoline, check the engine oil level.

INITIAL STARTUP

A delay built in the shutdown system allows oil pressure to build

during starting. The delay allows the engine to run for about 10

seconds before sensing oil pressure.

SENSING LOW PRESSURE

If the system senses low oil pressure during operation, the

engine shuts down. As the system shuts down, the low oil light

comes ON (see Figure 2, page 6 ). However, once the engine

stops rotating, this light will go OFF.

RESTARTING THE ENGINE

If you try to restart the engine within 5 seconds after it shuts

down, the engine may NOT star t. The system needs 5 to 10

seconds to reset.

NOTE: If you do restart engine after a shutdown and have not

corrected the low oil pressure, the engine will run for

about 10 seconds as described above,and then it will stop.

— 7 —

Page 8

GGeenneerraacc GGNN--119900//222200 EEnnggiinnee

GENERAL MAINTENANCE

2. When the oil is drained, install and tighten the oil drain

RECOMMENDATIONS

3. If your engine is equipped with an oil filter, use the

The owner/operator is responsible for making sure that all per iodic

maintenance tasks are completed on a timely basis; that all

discrepancies are corrected; and that the equipment is kept clean

and properly stored. Never operate a damaged or defective

engine.

CAUTION: Disconnect the spark plug wire from the spark

plug, and place the wire where it cannot come in contact with

the spark plug before working on this engine.

CHECKING THE OIL LEVEL

See the BEFORE STARTING THE ENGINE section on page 6 for

information on checking the oil level. The oil level should be

checked before each use, or at least every eight (8) hours of

operation. Keep the oil level maintained.

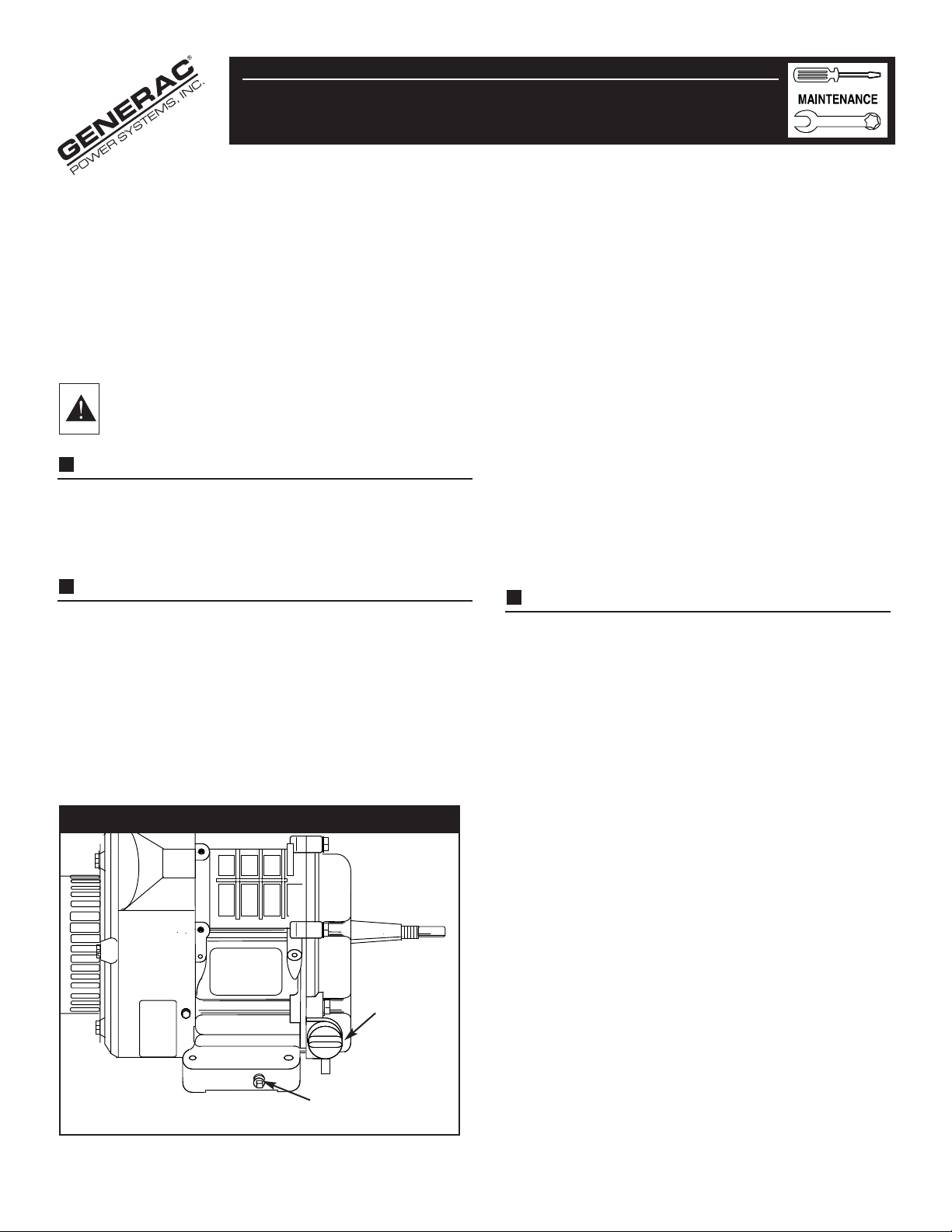

CHANGING THE OIL AND OIL FILTER

Your engine may be equipped with an oil filter. Change the oil and

filter after the first eight (8) hours of operation. Change the oil

and oil filter (if so equipped) every 50 hours thereafter. If you are

using this engine under dirty or dusty conditions, or in extremely

hot weather, change the oil more often.

Use the following instructions to change the oil while the engine is

still warm:

1. Clean the area around the oil drain plug, remove the plug and

drain the oil completely into a suitable container (Figure 6).

4. Remove the oil fill plug and insert a clean funnel into the

5. When the crankcase is filled to the proper level, install

Your equipment’s air cleaner is one of the most important

areas to maintain.This engine will not r un properly and may

get damaged if it is run with a dirty air cleaner system.

Clean or replace the paper air filter (Figure 7) every 50

hours of operation or once a year, whichever comes first.

Clean or replace the filter more often if the engine is operated

under dusty or dirty conditions. Clean the foam pre-filter

every 25 hours of operation, or sooner under dusty or dirty

conditions.

plug.

following instructions:

A. Place a suitable container beneath the oil filter and

turn the filter counterclockwise to remove the filter.

B. Coat the gasket of a new filter with engine oil. Turn

the new filter clockwise until the gasket contacts the

filter adapter, then tighten an additional 3/4 turn.

plug opening. Fill the crankcase with the recommended

oil until the oil level is at point of overflowing. Approximately 620ml (21 oz.) are required without an oil filter;

770ml (29 oz.) with an oil filter.POUR SLOWLY.

and tighten the oil fill plug.

SERVICING THE AIR CLEANER

.

Figure 6 — Oil Filter and Drain Plug

Oil Filter

Drain Plug

— 8 —

Page 9

GGeenneerraacc GGNN--119900//222200 EEnnggiinnee

CAUTION: Never run this equipment without the complete

air cleaner system installed on the engine.This could result

in premature wear to the engine.

Use the following instructions to clean or replace the

air cleaner components.

1. Loosen the two screws on the air cleaner cover. Remove the

air cleaner cover (Figure 7).

Figure 7 — Removing the Air Cleaner Cover

Foam

Pre-Filter may

stick to cover

CHOKE

2. Remove the paper air filter and the foam pre-filter from the

air cleaner cover (Figure 8).

Figure 8 — Air Cleaner Components

Foam

Pre-Filter

CHOKE

3. To clean or replace the foam pre-filter:

A. Wash the pre-filter in soapy water.

B. Squeeze the pre-filter dry with a clean cloth. DO

NOT TWIST.

NOTE: If the pre-filter is still dirty after washing and drying it,

replace it with a new one.

C. Apply enough clean engine oil to saturate the pre-

filter.

D. Wrap the pre-filter in a clean dry cloth and squeeze

out the excess oil. DO NOT TWIST. Set the pre-filter

aside.

4. To clean or replace the paper air filter:

A. Clean the air filter by tapping it gently on a solid

surface.

NOTE: If the filter is too dirty, replace it with a new one.

Dispose of the old filter properly.

5. Clean the air cleaner cover.

6. Insert the pre-filter into the cover, then the paper air

filter (see Figure 8).

7. Reinstall the air cleaner cover and tighten the two (2)

screws (see Figure 7).

REPLACING THE SPARK PLUG

Use a Champion RC12YC spark plug or equivalent.The

correct air gap is 0.76mm (0.030 in.). Remove the plug ever y

100 hours of operation or once each year, whichever comes

first.This will help your engine to star t easier and r un better.

Paper

Filter

1. Stop the engine and pull the spark plug wire off of the

spark plug.

2. Clean around the spark plug and remove it from the

cylinder head.

— 9 —

Page 10

Generac GN-190/220 Engine

3. Set the spark plug gap (Figure 8) to 0.76mm (0.030 in.).

Install a correctly gapped spark plug into the cylinder head.

Figure 8 — Setting Spark Plug Gap

SET PLUG GAP AT 0.76 mm

(0.030 inch)

Figure 9 — Removing Heat Shield

Spark

Arrestor

Screen

83083

CLEANING THE SPARK ARRESTOR

SCREEN

The engine exhaust muffler has a spark arrestor screen. Inspect

and clean the screen every 100 hours of operation or once

each year, whichever comes first.

NOTE: If you use your engine on any forest-covered, brush-

covered or grass-covered unimproved land, it must

have a spark arrestor. The spark arrestor must be

maintained in good condition by the owner/operator.

Clean and inspect the spark arrestor screen as follows:

Inspect the screen and replace if it is torn, perforated or otherwise

damaged (see Steps 1-4 below).DO NOT USE a def ectiv e screen.If

the screen is not damaged, clean it with a commercial solvent.

If the spark arrestor is found to be damaged or defective, replace it

as follows:

1. Remove the four (4) screws that connect the heat shield to

the muffler (Figure 9).

2. Remove the four (4) screws that attach the spark arrestor

screen (Figure 9).

3. Replace damaged screen with new screen (Part No.83083).

4. Reattach the screen and the heat shield with the four (4)

screws. Resintall the heat shield to the muffler with the four

(4) screws.

SERVICE AND ADJUSTMENTS

Your engine r uns at a constant speed. This constant operating

speed is maintained by a mechanical, flyweight type, fixed

speed governor.DO NOT try to adjust the governed speed

setting for the following reasons:

• Operating the engine at high engine speeds is dangerous and

• Operating the engine at low engine speeds with heavy loads may

Heat Shield

ENGINE SPEED

CAUTION: The engine speed was properly adjusted at

the factory and should require no additional adjustment.

Do not attempt to change engine speed. If you believe the

engine is running too fast or too slow, take your engine to

an authorized service center for repair and adjustment.

CHANGING THE ENGINE GOVERNED SPEED WILL

VOID THE ENGINE W ARRANTY.

increases the risk of personal injury or damage to the

equipment.

shorten the engine’s life.

— 10 —

Page 11

Tighten Jam Nut to

65-85 inch-pounds

Allen Wrench

Feeler Gauge

Loosen Jam Nut,

GGeenneerraacc GGNN--119900//222200 EEnnggiinnee

OHVI

LOW

OI

CARBURETOR ADJUSTMENTS

The carburetor of your engine is pre-set at the factor y.The

carburetor should not be tampered with because this will VOID

THE EMISSION CONTROL SYSTEM WARRANTY. If you

experience problems and your engine is used at an altitude in

excess of 5000 feet, contact the nearest authorized dealer

regarding high altitude setting changes.

CHECKING/ADJUSTING VALVE TO

ROCKER ARM CLEARANCE

Every 50 hours of operation, remove the rocker cover and

check the valve to rocker arm clearance.

When adjusting the clearance, the engine should be at room

temperature, and the piston should be at Top Dead Center

(TDC) of its compression stroke (both valves are closed). The

correct clearance is 0.05-0.1mm (0.002-0.004 in.). Check and

adjust the valve to rocker arm clearance as follows:

1. Remove the four (4) screws from the rocker cover

(Figure 10).

2. Remove the rocker cover and rocker cover gasket.

Figure 10 —Removing the Valve Cover

3. Loosen the rocker arm jam nut. Using an allen wrench to turn

the pivot ball stud, check the clearance between the rocker

arm and the valve stem with a flat feeler gauge (Figure 11).

Figure 11 — Adjusting Valve to Rocker Arm Clearance

4. When the valve clearance is correct, hold the pivot ball stud

with the allen wrench and tighten the rocker arm jam nut.

Torque the jam nut to 7.15-9.35 N-m (65-85 in-lb). After

tightening the jam nut, recheck the valve clearance to make

sure it did not change (see Figure 11).

5. Reinstall the rocker cover gasket, rocker cover and

the four (4) screws (see Figure 10).

— 11 —

Page 12

E

B

D

C

A

GGeenneerraacc GGNN--119900//222200 EEnnggiinnee

RETORQUING THE HEAD BOLTS

After the first 50 hours of operation, retorque the head bolts.

NOTE: Only perform this adjustment after the first 50 hours of

operation.The head bolts will need no fur ther adjustment.

1. Remove the four (4) screws from the rocker cover

(see Figure 10).

2. Remove the rocker cover and rocker cover gasket.

3. Torque the bolts to 4.0 kg-m. (22 ft-lb).

4. Torque the bolts in the following sequence: A, B, C, D, E

(star pattern). See Figure 12.

Figure 12 — Tightening Sequence

MAINTENANCE SCHEDULE

Every 8 Hours or 25 Hours or Every 50 Hours or Every 100 Hours or Every

MAINTENANCE OPERATION or Daily Season Season Season

Check Oil Level X

Change Oil See Note 1

Change Oil Filter (if so equipped) See Note 1

Service Air Filter Foam Pre-Filter Paper Filter (Note 2)

Replace or Clean Spark Plug X

Clean Spark Arrestor Screen X

Adjust Valv e Clearance X

Retorque Head Bolts See Note 3

NOTE 1:Change oil and filter after first 8 hours of operation and then every 50 hours thereafter. Change sooner when operating under heavy load or in

dusty or dirty environment or in high ambient temperature.

NOTE 2: Clean more often when operating under dirty or dusty conditions.

NOTE 3: Perform this task ONLY after first 50 hours of operation. Head bolts will NOT need further retorquing.

— 12 —

Page 13

GGeenneerraacc GGNN--119900//222200 EEnnggiinnee

STORAGE INSTRUCTIONS

This engine should be started at least once a week and run for at

least 30 minutes. If this cannot be done and the equipment must

be stored for more than 30 days, use the following guidelines to

prepare it for storage.

WARNING: Never store the engine with the fuel in the tank

indoors or in an enclosed, poorly ventilated areas, where

fumes can reach an open flame spark or pilot light as on a

furnace, water heater, or clothes dryer.

1. Run the engine for about five (5) minutes to war m it.

NOTE: Alcohol-blended fuel, or “gasohol”, attracts moisture which

can lead to the separation and formation of acids during

storage.This acidic gas can damage internal engine parts.

Methanol, ethanol and grain alcohol all are forms of

gasohol. If you did use “gasohol,” drain the fuel tank, then

run the engine until it stops from lack of fuel.

WARNING: Drain the fuel into approved container

outdoors, away from open flame. Be sure the engine is cool.

OTHER STORAGE TIPS

1. Do not store gasoline from one season to another.

2. Replace the gasoline can if it starts to rust. Rust and/or dirt

in a gasoline can cause problems when you use that fuel

with this equipment.

3. Store the equipment in a clean and dry area.

SPECIFICATIONS

Model GN-190 GN-220

Bore 70mm 75mm

Stroke 49mm 49mm

Valve Clearance 0.05–0.10mm 0.05–0.10mm

Displacement 190cc 220cc

Maximum Tilt Angle

While Operating 15° 15°

Oil Capacity with Oil Filter 770ml (29 oz.) 770ml (29 oz.)

Oil Capacity without Oil Filter 620ml (21 oz.) 620ml (21 oz.)

NOTE: Using a fuel additive such as STA-BIL® fuel stabilizer, or an

equivalent, will prevent gum deposits from forming in the

engine’s fuel system.

2. While the engine is still warm, drain the oil from the

crankcase. Refill with it with fresh oil. See BEFORE

STARTING ENGINE on Page 6 for oil recommendations.

3. Remove spark plug and pour about 1/2 ounce (15ml) of

engine oil into the cylinder. Crank slowly to distribute oil.

CAUTION: Avoid spray from the spark plug hole when

cranking the engine slowly.

4. Install the spark plug. Do not connect the spark plug wire.

5. Clean the dirt, oil and grease from the cylinder, cylinder head,

fins, blower housing, rotating screen and muffler area.

6. Close the fuel shut-off valve.

— 13 —

Page 14

Generac GN-190/220 Engine

EEXXPPLLOODDEEDD VVIIEEWW —— SSHHOORRTT BBLLOOCCKK

— 14 —

Page 15

GGeenneerraacc GGNN--119900//222200 EEnnggiinnee

SSHHOORRTT BBLLOOCCKK

ITEM DESCRIPTION PART NO. QTY.

N/A Long Block Assembly 21942E 1

(190cc used with Item 8A)

Long Block Assembly 21943E 1

(190cc used with Item 8B)

Long Block Assembly 21944E 1

(220cc used with Item 8A)

Long Block Assembly 21945E 1

(220cc used with Item 8B)

1 Control Rod Assembly 78621 1

2 Piston Pin 76389 1

3A Piston Ring Set [190cc

3B Piston Ring Set [220cc] 88411 1

4 Gear Cover Assembly A8897A 1

5 M8 x 52mm Head Bolt 77168 5

6A Piston [190cc] 90325 1

6B Piston [220cc] 88057 1

7 Pin Retainer Ring 76390 2

8A Tapered Crankshaft Assm. 83337A 1

8B Straight Crankshaft Assm. 83338A 1

9 Governor “R” Pin 78658 1

10 Gov .Arm Thrust Washer 78659 1

11A Crankcase Assm. [190cc] 89213K 1

11B Crankcase Assm. [220cc] 89213J 1

12 Governor Arm A7637 1

13 Oil Seal 81695 2

14 Governor Gear Assembly A8929 1

15 Governor Gear C-Ring 78645 1

16 Governor Spool A7811 1

17 1/8” NPT Pipe Plug 72683 1

18 Camshaft Assembly 98752 1

19 Crankcase Gasket 89096 1

20 Valve Stem Seal 88156 1

21 Cylinder Head Gasket A8822 1

22 Oil Pressure Relief Cover 78691 1

23 Oil Pressure Spring A5772 1

24 11/32” Ball A5776 1

25 M5 Form Screw 74908 1

26 M6-1.0 x 12mm Screw 78606 4

27 Gov.Gear Thrust Washer 76361 1

]

78660

1

ITEM DESCRIPTION

28 M8-1.25 x 35mm Screw 89230 6

29 Spring Washer 99922 1

30 Valve Spr ing Retainer A1720 2

31 Valve Spr ing 88401 2

32 Valv e Spring Wear Washer 84186 2

33 Geroter Set 83192 1

34 “O” Ring 86254 1

36 Cylinder Head Assembly 21705B 1

37 Exhaust Valv e 90082 1

38 Intake V alve 90081 1

39 Push Rod 88396A 2

40 Tappet 83235 2

41 Oil Pick-up Assembly 80336 1

42 Rocker Cover Gasket 96362 1

43 Pivot Ball Stud 77161 2

44 GN-190/220 Rocker Arm 77160 2

45 Rocker Arm Jam Nut 76307 2

46 Push Rod Guide Plate 88403 1

47 1/4” NPT Pipe Plug 72657 2

48 Rocker Cover Assembly 88412 1

49 Plastic Oil Fill Plug 76329 1

PART NO. QTY.

— 15 —

Page 16

GGeenneerraacc GGNN--119900//222200 EEnnggiinnee

EEXXPPLLOODDEEDD VVIIEEWW —— AAIIRR CCLLEEAANNEERR AANNDD CCAARRBBUURREETTOORR

ITEM DESCRIPTION PART NO. QTY.

31 Breather Hose 90947 1

32 Manifold Head Gasket 90051 1

33 M6 x 55mm Capscrew 57058 1

34 M6 x 25mm Capscrew 80318 1

35 M6 x 30mm Screw 80316 2

36A Intake Manifold 20136 1

37 M6 Lock Washer 22097 2

38 M6 Hex Nut 49813 2

39A Carburetor/Air Box 21202 1

Gasket

40 #10-32 x 3/4” Screw 36935 2

41 Canal Cover 80303 1

42 Carburetor/Manifold 21201 1

Gasket

43A Dellorto Carburetor 21203 1

44A Air Cleaner Base 21200 1

45 M6 x 12mm Capscrew 66476 1

46 #8 x 3/8" Plastite 59635 1

Screw

47 Air Filter 78601 1

48 Precleaner 78602 1

— 16 —

Page 17

GGeenneerraacc GGNN--119900//222200 EEnnggiinnee

AAIIRR CCLLEEAANNEERR AANNDD CCAARRBBUURREETTOORR

ITEM DESCRIPTION PART NO. QTY.

31 Breather Hose 90947 1

32 Manifold Head 90051 1

Gasket

35 M6 x 30mm Screw 80316 2

36B Intake Manifold 90948 1

39B Carburetor /Air Box 91846 1

Gasket

41 Canal Cover 80303 1

42 Carburetor Manifold 78631 1

Gasket

43B Carburetor (190cc) 98469 1

43C Carburetor (220cc) 97747 1

44B Air Cleaner Base 78607 1

45 M6 x 12mm Capscrew 66476 1

46 #8 x 3/8" Plastite 59635 1

Screw

47 Air Filter 78601 1

48 Precleaner 78602 1

49 Choke Knob 83504 1

50 Curb Bolt 78643 2

— 17 —

Page 18

GGeenneerraacc GGNN--119900//222200 EEnnggiinnee

EEXXPPLLOODDEEDD VVIIEEWW —— GGAASS TTAANNKK

ITEM PART # QTY. DESCRIPTION

55 83512 2 M6 X 15 Taptite

57 95213 1 Tank Bracket

58 77395 2 M6 Flange Nut

59 95214 1 Tank Cradle

60 30340 12” 1/4” ID Hose

61 48031C 1 Hose Clamp

— 18 —

Page 19

GGeenneerraacc GGNN--119900//222200 EEnnggiinnee

EEXXPPLLOODDEEDD VVIIEEWW —— OOIILL FFIILLTTEERR AANNDD OOPPTTIIOONNAALL OOIILL FFIILLLL TTUUBBEE

ITEM PART # QTY. DESCRIPTION

1 94820 1 Expansion Plug

2 91848 1 Oil Filter Gasket

3A 88758 1 Oil Blockoff

3B 84982 1 Oil Filter Adapter

4 92978 2 M6 X 18 Taptite

5 99236 1 Oil Press Switch

6 70185 1 Oil Filter

ITEM PART # QTY. DESCRIPTION

64 74908 2 M5 X 12 Taptite

65 91475 1 Dipstick ASM

66 90388 1 M6 X 12 Taptite

67 22473 1 M6 Flat Washer

68 47411 1 M6 X 16 HHCS

69 91230 1 Rubber Washer

70 91041 1 Fill Tube

71 95997 1 Oil Fill Brkt

72 77395 1 M6 Flange Nut

— 19 —

Page 20

GGeenneerraacc GGNN--119900//222200 EEnnggiinnee

EEXXPPLLOODDEEDD VVIIEEWW —— LLOOWW OOIILL SSHHUUTTDDOOWWNN AANNDD GGOOVVEERRNNOORR

ITEM PART # QTY. DESCRIPTION

7 78653 1 Run/Stop Switch

8 85272 1 LED Assembly

8A 86753 1 LED Assembly

9 84195 1 L.O.S. Decal

10 85620 1 Black Sleeving

11 00285271 1 Black Wire Assembly

12 84329 1 3 Pin Male HSG

13 00185271 1 White Wire Assembly

14 22097 2 M6 Lockwasher

15 82981 2 M6 X 30 Taptite

16 81675 1 Ignition Coil

17 84274 1 Tinnerman Clamp

18 87221A 1 L.O.S. Module

19 45756 1 M6 x 10mm Screw

20 72347 1 Sparkplug

ITEM PART # QTY. DESCRIPTION

21 86962 1 Governor Lever

22 85953 1 Wear Washer

23 83502 1 Adjust Screw

24 83512 1 M8 X 15 Taptite

25A 78604 1 60Hz Gov. Spring

25B 86643 1 50Hz Gov. Spring

26 66476 1 M6 X 12 HHCS

27 83503 1 M5 Lock Nut

28 83781 1 Governor Brkt.

29 86384 1 Governor Rod

30 86037 1 Anti-Lash Spring

100 83782 1 Idle Coil ASM

101 66311 1 M8 — 1.25 Jam Nut

— 20 —

Page 21

GGeenneerraacc GGNN--119900//222200 EEnnggiinnee

EEXXPPLLOODDEEDD VVIIEEWW —— SSTTEEPPPPEERR MMOOTTOORR,, FFLLYYWWHHEEEELL,, RREECCOOIILL SSTTAARRTTEERR

ITEM PART # QTY. DESCRIPTION

55 83512 2 M8 X 15 Taptite

78 82774 1 Woodruff Key

79A SRV77182T 1 191 Flywheel

79B SRV77182E 1 220 Flywheel

80 83312 1 Conical Washer

81 81810 1 M16 Hex Nut

82 92984 1 Top Wrapper

83 45756 4 M6 X 10 Taptite

84 78609 2 Cover Bolts

ITEM PART # QTY. DESCRIPTION

85 78608A 1 Air Box Cover

86 90695A 1 Blower Housing

87 89739 1 Lower Wrapper

88 66476 9 M6 X 12 HHCS

89 A2799 1 Recoil Assembly

90 A2842 1 Recoil Cup

91 78651C 1 Backplate

92 59636 1 #4 X 3.37 Long

93 86296 1 Governor Rod

94 88905 1 Extension Spring

95 89477 1 Spring Clip

96 89478 1 Snap Button

97 40976 1 SHCS M8—1.25 X 20

98 90192 1 Carb Wear Washer

99 92059 1 Stepper Motor

— 21 —

Page 22

GGeenneerraacc GGNN--119900//222200 EEnnggiinnee

CALIFORNIA EMISSION CONTROL WARRANTY STATEMENT

YOUR WARRANTY RIGHTS AND OBLIGATIONS

The California Air Resources Board ("CARB") and Generac Corporation are pleased to explain the Emission Control System

Warranty on your new utility or lawn and garden equipment engine. In California, new utility and lawn and garden

equipment engines must be designed, built and equipped to meet the State's stringent anti-smog standards. Generac

Corporation will warrant the emission control system on your utility or lawn and garden equipment for the periods of time

listed below provided there has been no abuse, neglect, unapproved modification, or improper maintenance of your utility or

lawn and garden equipment engine.

Your emission control system may include parts such as the carburetor, ignition system and exhaust system. Also included may

be the compression release system and other emission-related assemblies.

Where a warrantable condition exists, Generac Corporation will repair your utility or lawn and garden equipment engine at

no cost to you for diagnosis, parts and labor.

MANUFACTURER'S EMISSION CONTROL SYSTEM WARRANTY COVERAGE:

Emissions control systems on 1995 and later model year utility and lawn and garden equipment engines are warranted for two

years as hereinafter noted. If, during such warranty period, any emission-related part on your engine is defective in materials

or workmanship, the part will be repaired or replaced by Generac Corporation.

OWNER'S WARRANTY RESPONSIBILITIES:

As the utility or lawn and garden equipment engine owner, you are responsible for the performance of the required

maintenance listed in your owners manual. Generac Corporation recommends that you retain all receipts covering

maintenance on your utility or lawn and garden equipment engine, but Generac Corporation will not deny warranty solely

due to the lack of receipts or for your failure to provide written evidence of the performance of all scheduled maintenance.

As the utility or lawn and garden equipment engine owner, you should, however, be aware that Generac Corporation may

deny you warranty coverage if your utility or lawn and garden equipment engine or a part thereof has failed due to abuse,

neglect , improper maintenance or unapproved modifications.

You are responsible for presenting your utility or lawn and garden equipment engine to a Generac Corporation Authorized

Service Outlet as soon as a problem exists. The warranty repairs should be completed in a reasonable amount of time, not to

exceed 30 days.

Warranty service can be arranged by contacting either a Generac Corporation Authorized Service Outlet or by contacting

Generac Corporation at:

GENERAC CORPORATION PH: (414) 544-4811

P.O. BOX 8 FAX: (414) 544-0179

WAUKESHA, WI 53187

IMPORTANT NOTE: This warranty statement explains your rights and obligations under the Emission Control System

Warranty ("ECS Warranty") which is provided to you by Generac Corporation pursuant to California law. See also the Generac

Corporation Limited Warranties for Generac Corporation which is enclosed herewith on a separate sheet and also is provided

to you by Generac Corporation. The ECS Warranty applies only to the emission control system of your new engine. To the

extent that there is any conflict in terms between the ECS Warranty and the Generac Corporation Warranty, the ECS Warranty

shall apply except in any circumstances in which the Generac Corporation Warranty may provide a longer warranty period.

Both the ECS Warranty and the Generac Corporation Warranty describe important rights and obligations with respect to your

new engine.

Warranty service can only be performed by a Generac Corporation Authorized Service Outlet. At the time of requesting

warranty service, evidence must be presented of the date of the sale to the original purchaser. The purchaser shall pay any

charges for making service calls and/or for transporting the products to and from the place where the inspection and/or

warranty work is performed. The purchaser shall be responsible for any damage or loss incurred in connection with the

transportation of any engine or any part(s) thereof submitted for inspection and/or warranty work.

IF YOU HAVE ANY QUESTIONS REGARDING YOUR WARRANTY RIGHTS AND RESPONSIBILITIES, YOU SHOULD CONTACT

GENERAC CORPORATION AT 1-800-222-3136.

— 22 —

Page 23

GGeenneerraacc GGNN--119900//222200 EEnnggiinnee

EMISSION CONTROL SYSTEM WARRANTY

Emission Control System Warranty ("ECS Warranty") for 1995 and Later Model Year Utility and Lawn and Garden Equipment Engines:

A. Applicability: This warranty shall apply to 1995 and later model year utility and lawn and garden equipment engines. The ECS Warranty

Period ("ECS Warranty Period") shall begin on the date the new engine or equipment is delivered to its original, end-use purchaser and shall

begin on the date the new engine or equipment is delivered to its original, end-use purchaser and shall continue for 24 consecutive months

thereafter.

B. General Emissions Warranty Coverage: Generac Corporation warrants to the original, end-use purchaser of the new engine or equipment

and to each subsequent purchaser that each of its utility and lawn and garden equipment engines is:

1. Designed, built and equipped so as to conform with all applicable regulations adopted by the Air Resources Board pursuant to its

authority, and

2. Free from defects in materials and workmanship which, at any time during the ECS Warranty Period, will cause a warranted emissions related part to fail to be identical in all material respects to the part as described in the engine manufacturer's application for certification.

C. The ECS Warranty only pertains to emissions-related parts on your engine, as follows:

1. Any warranted, emissions-related parts which are not scheduled for replacement as required maintenance in the Owner's Manual shall be

warranted for the ECS Warranty Period. If any such part fails during the ECS Warranty Period, it shall be repaired or replaced by Generac

Corporation according to Subsection (4) below. Any such part repaired or replaced under the ECS Warranty shall be warranted for any

remainder of the ECS Warranty Period.

2. Any warranted, emissions-related part which is scheduled only for regular inspection as specified in the Owner's Manual shall be

warranted for the ECS Warranty Period. A statement in such written instructions to the effect of "repair or replace as necessary" shall not

reduce the ECS Warranty Period. Any such part repaired or replaced under the ECS Warranty shall be warranted for any remainder of the

ECS Warranty Period.

3. Any warranted, emissions-related part which is scheduled for replacement as required maintenance in the Owner's Manual shall be

warranted for the period of time prior to first scheduled replacement point for that part. If the part fails prior to the first scheduled

replacement, the part shall be repaired or replaced by Generac Corporation according to Subsection (4) below. Any such emissions-related

part repaired or replaced under the ECS Warranty shall be warranted for the remainder of the ECS Warranty Period prior to the first

scheduled replacement point for such emissions-related part.

4. Repair or Replacement of any warranted, emissions-related part under this ECS Warranty shall be performed at no charge to the owner

at a Generac Corporation Authorized Service Outlet.

5. The owner shall not be charged for diagnostic labor which leads to the determination that a part covered by the ECS Warranty is in fact

defective, provided that such diagnostic work is performed at a Generac Corporation Authorized Service Outlet.

6. Generac Corporation shall be liable for damages to other original engine components or approved modifications proximately caused by

a failure under warranty of any emission-related part covered by the ECS Warranty.

7. Throughout the ECS Warranty Period, Generac shall maintain a supply of warranted emission-related parts sufficient to meet the expected

demand for such emission-related parts.

8. Any Generac Corporation authorized and approved emission-related replacement part may be used in the performance of any ECS

warranty maintenance or repairs and will be provided without charge to the owner. Such use shall not reduce Generac Corporation ECS

warranty obligations.

9. Unapproved add-on modified parts may not be used to modify or repair a Generac Corporation engine. Such use voids this ECS Warranty

and shall be sufficient grounds for disallowing an ECS Warranty claim. Generac Corporation shall not be liable hereunder for failures of

any warranted parts of a Generac Corporation engine caused by the use of such an unapproved add-on or modified part.

EMISSION RELATED PARTS INCLUDE THE FOLLOWING:

1. Carburetor assembly and it's internal components.

a. Fuel filter

b. Carburetor gaskets

c. Intake pipe

2. Air cleaner assembly

a. Air filter element

3. Ignition system including:

a. Spark plug

b. Ignition module

4. Catalytic muffler (if so equipped)

a. Muffler gasket (if so equipped)

b. Exhaust manifold (if so equipped)

5. Crankcase breather assembly and its components.

a. Breather connection tube

— 23 —

Page 24

GGeenneerraacc GGNN--119900//222200 EEnnggiinnee

GENERAC POWER SYSTEMS, INC.

TWO YEAR LIMITED WARRANTY FOR “GN” ENGINES

Generac Power Systems, Inc. warrants to the original purchaser that the engine will be trouble free from defects in material

or workmanship for the items and period set forth below from the date of original purchase. This warranty is not transferable.

This warranty pertains to “GN” engines utilized to power equipment within the lawn and garden industry. Examples are, but

not limited to generators, pressure washers, air compressors, welders, lawn tractors, snow blowers, mowers, edgers and

pumps.

ENGINE COVERAGE CONSUMER* COMMERCIAL*

2 YEARS (2 YEAR PARTS ONLY) 1 YEAR

With the exception of European Community Countries, all engines bound for export shall be warranted for one (1) year in

consumer applications, and 90 days in commercial applications as defined below.

NOTE: For the purpose of this warranty, “consumer use” means personal residential household use by original purchaser. This

does not apply to engines used in generators used for prime power in place of utility. “Commercial use” means all other uses,

including rental, construction and income producing purposes. Once an engine has experienced commercial use, it shall

thereafter be considered a commercial use for the purpose of this warranty.

DURING SAID WARRANTY PERIOD, GENERAC POWER SYSTEMS, INC. WILL, AT ITS OPTION, REPAIR OR REPLACE ANY PART

WHICH, UPON EXAMINATION BY GENERAC POWER SYSTEMS, INC. IS FOUND TO BE DEFECTIVE UNDER NORMAL USE AND

SERVICE. Starting batteries are not warranted by Generac Power Systems, Inc. All transportation costs under warranty,

including return to the factory if necessary, are borne by the purchaser and paid by him. This warranty does not include normal

maintenance and service and does not apply to engines or parts which have been subjected to improper or unauthorized

installation, misuse, negligence, accident, overloading, over speeding, improper maintenance, improper repair or improper

storage so as, in Generac Power Systems, Inc.’s judgement, to adversely affect its performance and reliability.

NORMAL WEAR: As with all mechanical devices, the “GN” Series engines requires periodic service and parts replacement

(example: oil filter) in accordance with the owner’s manual schedules maintenance to insure proper performance of the

engine. This warranty will not cover repair when normal use has exhausted the life of a part or engine.

There is no other expressed warranty. GENERAC POWER SYSTEMS, INC. HEREBY DISCLAIMS ANY AND ALL IMPLIED

WARRANTIES, INCLUDING, BUT NOT LIMITED TO, THOSE OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE

TO THE EXTENT PERMITTED BY LAW. The duration of any implied warranties which cannot be disclaimed is limited to the time

period (one year) as specified in the expressed warranty. Liability for consequential, incidental, or special damages under any

and all warranties is excluded to the extent permitted by law. Some states do not allow limitations on how long an implied

warranty lasts, or the exclusions or limitations of consequential or incidental damages, so the limitations or exclusions do not

apply. This warranty provides the original purchaser specific legal rights and the original purchaser may also have other rights,

which vary state to state.

For service, please see your nearest Generac Power Systems, Inc. Authorized Service Dealer or call 414-544-4811. Warranty

service can only be performed by a Generac Power Systems, Inc. Authorized Service Dealer. This warranty does not apply to

service performed at any other facility or dealership. At the time of requesting warranty service, evidence of the original

purchase date must be presented.

GENERAC CORPORATION

P.O. BOX 8 WAUKESHA,WI 53187 TELEPHONE: (414) 544-4811 FAX: (414) 544-4851

Loading...

Loading...