Page 1

Owner’s Manual / Manual del Propietario

Questions? Help is just a moment away!

Preguntas? La ayuda es justa un momento lejos!

Call: Generac Generator Helpline - 1-800-270-1408 M-F 8-5 CT

Llamada: Generador Helpline De Generac - 1-800-270-1408 M-F 8-5 CT

Web: www.generac-portables.com or www.briggsandstratton.com

Model No. 1654-0 (5,500 Watt AC Generator) Manual No. 189828GS Revision 1 (02/05/2002)

Safety Rules / Reglas De Seguridad . . . . . . . . . . . . 2-3 / 20-21

Assembly / Ensamblaje . . . . . . . . . . . . . . . . . . . . . 4-5 / 22-23

Know Your Generator / Conozca Su Generador. . . . . . 6 / 24

Operation / Funcionamiento . . . . . . . . . . . . . . . . . 7-9 / 25-27

Product Specifications / Especificaciones Del Producto 10 / 28

Maintenance / Mantenimiento . . . . . . . . . . . . . . . . . . . 10 / 28

Storage / Almacenamiento. . . . . . . . . . . . . . . . . . . . . . 11 / 29

Troubleshooting / Diagnosticos De Averías . . . . . . . . . 12 / 30

Schematic / Esquemático . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Wiring Diagram / Digrama Eléctrico. . . . . . . . . . . . . . . . . . 15

Replacement Parts / Piezas De Recambio . . . . . . . . . . . 16-19

Notes / Notas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Garantia . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Last Page

• Generator / Generador

• Wheel Kit / Juego de Llantas

• Locking 30 Amp Plug / Tapone de Fijación

• Engine Oil / Aceite para Motor

• Owner's Manual / Manual del Propietario

• Engine Manual / Manual del Motor

*If any parts are missing or damaged, call 1-800-270-1408.

*Si alguna de las partes no está presente o está dañada, llame

1-800-270-1408.

Parts Included* / Piezas Incluidas*

Table of Contents / Tabla de Contenidos

Page 2

2

5500 Watt Heavy Duty Generator

EQUIPMENT

DESCRIPTION

Read this manual carefully and become familiar

with your generator. Know its applications, its

limitations and any hazards involved.

This generator is an engine–driven, revolving field, alternating

current (AC) generator.It was designed to supply electrical

power for operating compatible electrical lighting, appliances,

tools and motor loads.The generator’s revolving field is

driven at about 3,600 rpm by a single-cylinder engine.

CAUTION! Do Not exceed the generator’s

wattage/amperage capacity. See “Don’t Overload the

Generator” on page 9.

Every effort has been made to ensure that information in this

manual is accurate and current. However, Generac reserves

the right to change, alter or otherwise improve the product

and this document at any time without prior notice.

The Emission Control System for this generator is warranted

for standards set by the Environmental Protection Agency. For

warranty information refer to the engine owner’s manual.

SAFETY RULES

The safety alert symbol ( ) is used with a signal word

(DANGER, CAUTION,WARNING), a pictorial and/or a

safety message to alert you to hazards. DANGER indicates

a hazard which, if not avoided, will result in death or serious

injury. WARNING indicates a hazard which, if not avoided,

could result in death or serious injury. CAUTION

indicates a hazard which, if not avoided, might result in

minor or moderate injury. CAUTION, when used

without the alert symbol, indicates a situation that could

result in equipment damage. Follow safety messages to

avoid or reduce the risk of injury or death.

The engine exhaust from this product contains

chemicals known to the State of California to cause

cancer, birth defects, or other reproductive harm.

WARNING

• Operate generator ONLY outdoors.

• Keep at least 2 feet of clearance on all sides of generator for

adaquate ventilation.

• Do not operate generator inside any building or enclosure,

including the generator compartment of a recreational vehicle

(RV).

Running generator gives off carbon monoxide,

an ordorless, colorless, poison gas.

Breathing carbon monoxide will cause nausea,

fainting or death.

DANGER

WHEN ADDING FUEL

• Turn generator OFF and let it cool at least 2 minutes before

removing gas cap.Loosen cap slowly to relieve pressure in tank.

• Fill fuel tank outdoors.

• Do not overfill tank.Allow space for fuel expansion.

• Keep gasoline away from sparks, open flames, pilot lights, heat,

and other ignition sources.

• Do not light a cigarette or smoke.

WHEN OPERATING EQUIPMENT

• Do not tip engine or equipment at angle which causes

gasoline to spill.

WHEN TRANSPORTING OR REPAIRING EQUIPMENT

• Transport/repair with fuel tank EMPTY or with fuel shutoff

valve OFF.

• Disconnect spark plug wire.

WHEN STORING GASOLINE OR EQUIPMENT WITH

FUEL IN TANK

• Store away from furnaces, stoves, water heaters,clothes

dryers or other appliances that have pilot light or other

ignition source because they can ignite gasoline vapors.

Gasoline and its vapors are extremely flammable

and explosive.

Fire or explosion can cause severe burns or

death.

WARNING

Page 3

3

5500 Watt Heavy Duty Generator

• When using generator for backup power, notify utility

company. Use approved transfer equipment to isolate

generator from electric utility.

• National Electric Code requires generator to be properly

grounded to an approved earth ground. Call an electrician for

local grounding requirements.

• Use a ground fault circuit interrupter (GFCI) in any damp or

highly conductive area, such as metal decking or steel work.

• Do not touch bare wires or receptacles.

• Do not use generator with electrical cords which are worn,

frayed, bare or otherwise damaged.

• Do not operate generator in the rain.

• Do not handle generator or electrical cords while standing in

water, while barefoot, or while hands or feet are wet.

• Do not allow unqualified persons or children to operate or

service generator.

Generator produces powerful voltage.

Failure to properly ground generator can result

in electrocution.

Failure to isolate generator from power utility

can result in death or injury to electric utility

workers due to backfeed of electrical energy.

WARNING

• Do not allow any open flame, spark, heat, or lit cigarette

during and for several minutes after charging a battery.

• Wear protective goggles, rubber apron, and rubber gloves.

Storage batteries give off explosive hydrogen gas

during recharging.

Hydrogen gas stays around battery for a long

time after battery has been charged.

Slightest spark will ignite hydrogen and cause

explosion.

You can be blinded or severely injured.

Battery electrolyte fluid contains acid and is

extremely caustic.

Contact with battery fluid will cause severe

chemical burns.

DANGER

• Do not touch hot surfaces.

• Allow equipment to cool before touching.

Running engines produce heat.Temperature of

muffler and nearby areas can reach or exceed

150°F (65°C).

Severe burns can occur on contact.

WARNING

• Do not tamper with governed speed. Generator supplies

correct rated frequency and voltage when running at governed

speed.

• Do not modify generator in any way.

Excessively high operating speeds increase risk of injury

and damage to generator.

Excessively low speeds impose a heavy load.

CAUTION

• See “Don’t Overload Your Generator” on page 9.

• Start generator and let engine stabilize before connecting

electrical loads.

• Connect electrical loads in OFF position, then turn ON for

operation.

• Turn electrical loads OFF and disconnect from generator

before stopping generator.

Exceeding generators wattage/amperage cappacity can

damage generator and/or electrical devices connected

to it.

CAUTION

• Use generator only for intended uses.

• If you have questions about intended use, ask dealer or

contact Generac.

• Operate generator only on level surfaces.

• Do not expose generator to excessive moisture, dust, dirt, or

corrosive vapors.

• Do not insert any objects through cooling slots.

• If connected devices overheat, turn them off and disconnect

them from generator.

• Shut off generator if:

-electrical output is lost;

-equipment sparks, smokes, or emits flames;

-unit vibrates excessively.

Improper treatment of generator can damage it and

shorten its life.

CAUTION

Page 4

4

5500 Watt Heavy Duty Generator

Your generator requires some assembly and is ready for

use after it has been properly serviced with the

recommended oil and fuel.

If you have any problems with the assembly of your

generator, please call the generator helpline at

1-800-270-1408.

IMPORTANT: Any attempt to run the unit before it has

been serviced with the recommended oil will result in an

engine failure.

REMOVE GENERATOR

FROM CARTON

• Set the carton on a rigid flat surface with “This Side Up”

arrows pointing upward.

• Carefully open the top flaps of the shipping carton.

• Cut down corners at one end of carton from top to

bottom and lay that side of carton down flat.

• Remove all packing material, carton fillers, etc.

• Remove the generator from the shipping carton.

CARTON CONTENTS

Check all contents. If any parts are missing or damaged, call

the generator helpline at 1-800-270-1408.

• The generator

• Generator and engine owner’s manuals

• Locking 30 Amp plug

• Engine oil

• Wheel kit

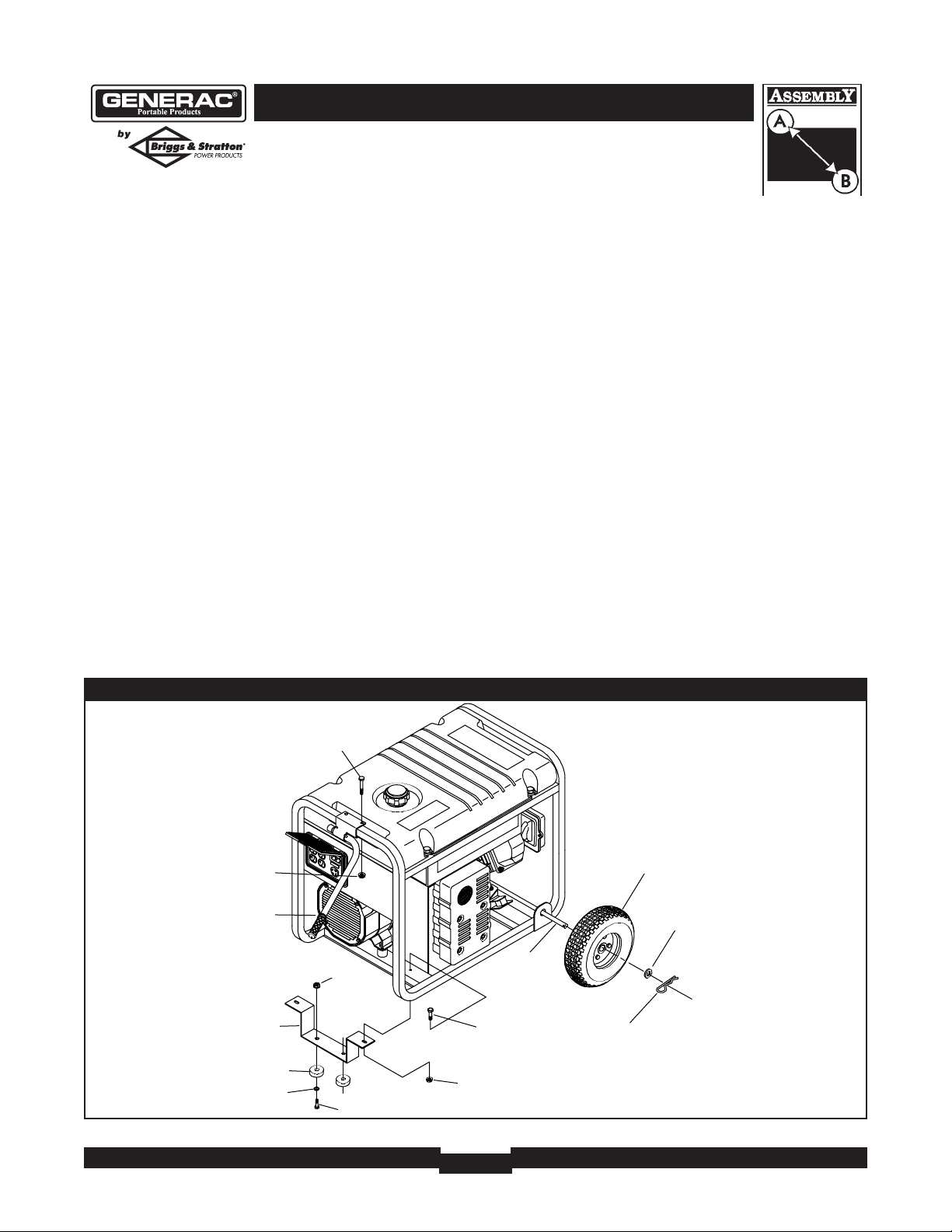

INSTALL WHEEL KIT

The wheel kit is designed to greatly improve the portability

of your generator.

NOTE:Wheel kit is not intended for over-the-road use.

You will need a socket wrench with 1/2" or 13mm sockets

and a needle-nose pliers to install this kit.

Refer to Figure 1 and install the wheel kit as

follows:

1. Place the generator on a hard flat surface.

2. Stand at the engine end of the generator and gently tilt

the generator forward, high enough to place wooden

blocks beneath the cradle.This will allow you to add

the wheels.

Support Leg

Hex Nut

Axle

Flat Washer

Cap Screw

Handle Assembly

Hex Nut

Wheel

Retaining Pin

Figure 1 — Install Wheel Kit

Cap Screw

Hex Nut

Flat Washer

Cap Screw

Vibration Mount

Use existing hardware

to attach left side of

support leg to unit

Page 5

5

5500 Watt Heavy Duty Generator

3. Slide the axle through the holes in the brackets

provided on the generator cradle.

4. Slide a wheel and flat washer on one end of the axle.

Make sure the air inflation valve is outward. Insert the

retaining pin.

5. Slide the axle through until wheel is tight against

bracket.

6. Slide the other wheel and flat washer on the other end

of the axle. Make sure the air inflation valve is outward.

Insert the retaining pin using the needle-nose plier.

Remove the wooden blocks.

7. Attach the vibration mounts to the support leg with

30mm capscrews, washers and lock nuts.

8. To aid support leg assembly, rest generator on cradle,

engine end down. Remove the existing hardware from

the left unit vibration mount with 13mm wrench. Use

the same hardware to attach the support leg.

9. Attach the other side of the support leg with a 20mm

cap screw and lock nut. Rest generator on wheels and

support leg.

10. Center the handle bracket on generator frame at

support leg end of cradle, as shown.

11. Attach handle bracket with two M8 x 45mm cap

screws and two locking hex nuts.

12. Check each fastener to ensure it is secure and the

tires are inflated between 15-40 PSI.

BEFORE STARTING THE

ENGINE

Add Oil

CAUTION! Any attempt to crank or start the engine

before it has been properly filled with the recommended

oil may result in an engine failure.

To fill your engine with oil:

• Place generator on a level surface.

• Follow the oil grade recommendations and oil fill

instructions given in the engine owner’s manual.

NOTE:The generator’s revolving field rides on a

prelubricated and sealed ball bearing that requires no

additional lubrication for the life of the bearing.

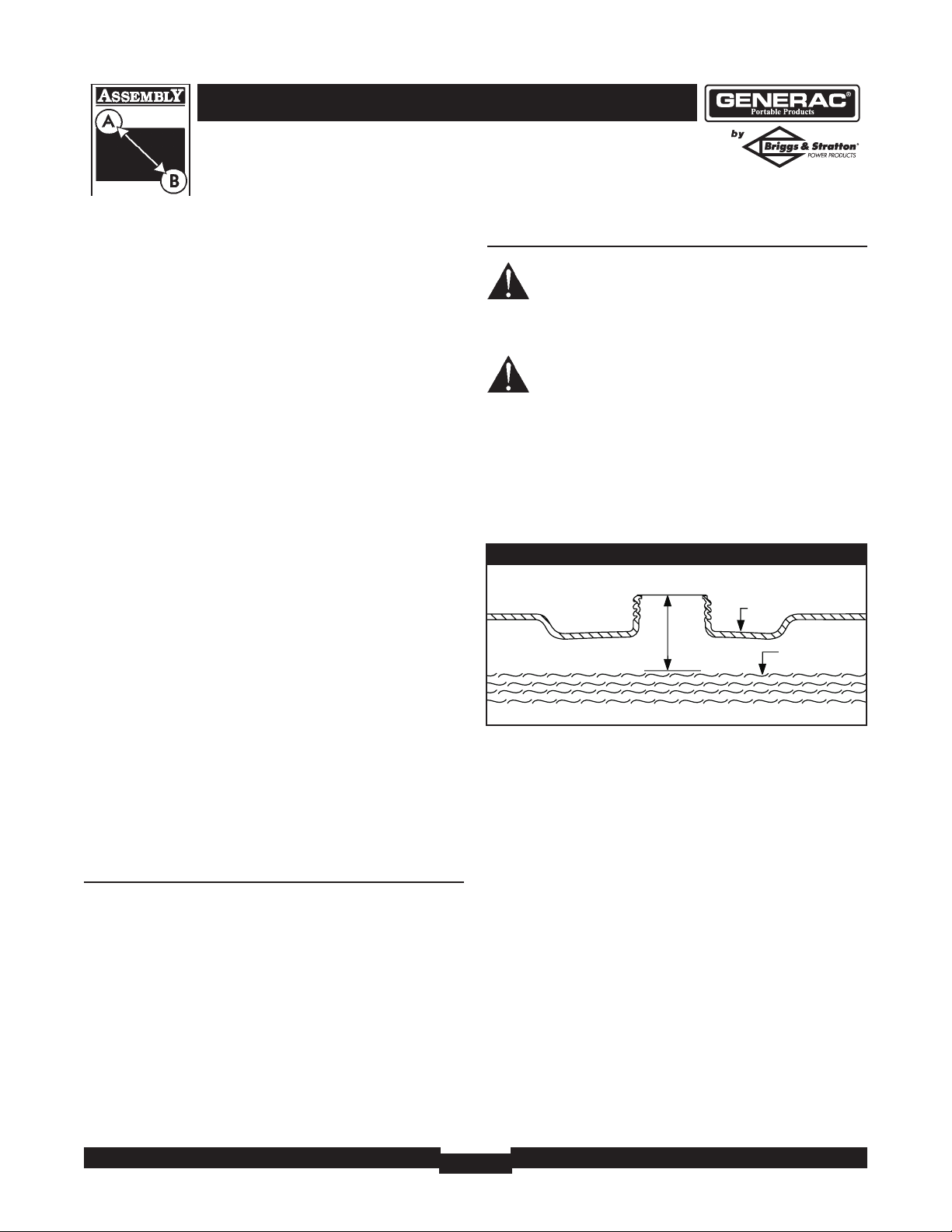

Add Gasoline

WARNING! Never fill fuel tank indoors. Never

fill fuel tank when engine is running or hot.Allow unit

to cool for two minutes before refueling. Do Not

light a cigarette or smoke when filling the fuel tank.

WARNING! Do Not overfill the fuel tank.

Always allow room for fuel expansion.

• Use regular UNLEADED gasoline with the generator

engine. Do Not use premium gasoline. Do Not mix oil

with gasoline.

• Clean area around fuel fill cap, remove cap.

• Slowly add unleaded regular gasoline to fuel tank. Be

careful not to overfill.Allow about 1.5" of tank space for

fuel expansion (Figure 2).

• Install fuel cap and wipe up any spilled gasoline.

IMPORTANT: It is important to prevent gum deposits

from forming in essential fuel system parts, such as the

carburetor, fuel filter, fuel hose or tank during storage. Also,

experience indicates that alcohol–blended fuels (called

gasohol, ethanol or methanol) can attract moisture, which

leads to separation and formation of acids during storage.

Acidic fuel can damage the fuel system of an engine while in

storage.

To avoid engine problems, the fuel system should be

emptied before storage of 30 days or longer.See “Storage”

on page 11. Never use engine or carburetor cleaner

products in the fuel tank or permanent damage may occur.

Figure 2 — Typical Fuel Expansion Space

Fuel

Tank

1.5” Airspace

Page 6

5500 Watt Heavy Duty Generator

6

120 Volt AC, 20 Amp, Duplex Receptacles — May be

used to supply electrical power for the operation of

120 Volt AC, 20 Amp, single phase, 60 Hz electrical, lighting,

appliance, tool and motor loads.

120/240 Volt AC, 30 Amp Locking Receptacle — May

be used to supply electrical power for the operation of

120 and/or 240 Volt AC, 30 Amp, single phase, 60 Hz

electrical, lighting, appliance, tool and motor loads.

Air Cleaner — Uses a dry type filter element to limit the

amount of dirt and dust sucked into the engine.

Choke Lever — Used when starting a cold engine.

Circuit Breakers (AC) — Push to reset circuit breakers

are provided to protect the generator against electrical

overload.

Fuel Tank — Capacity of seven (7) U.S. gallons.

Grounding Wing Nut — Used for proper grounding of

unit (see page 7).

Oil Fill — Add engine oil here.

Recoil starter — Used to start the engine.

Rocker Switch — Set this switch to "On" before using

recoil starter. Set switch to "Off" to switch off engine.

Spark Arrester Muffler — Exhaust muffler lowers

engine noise and is equipped with a spark arrester screen.

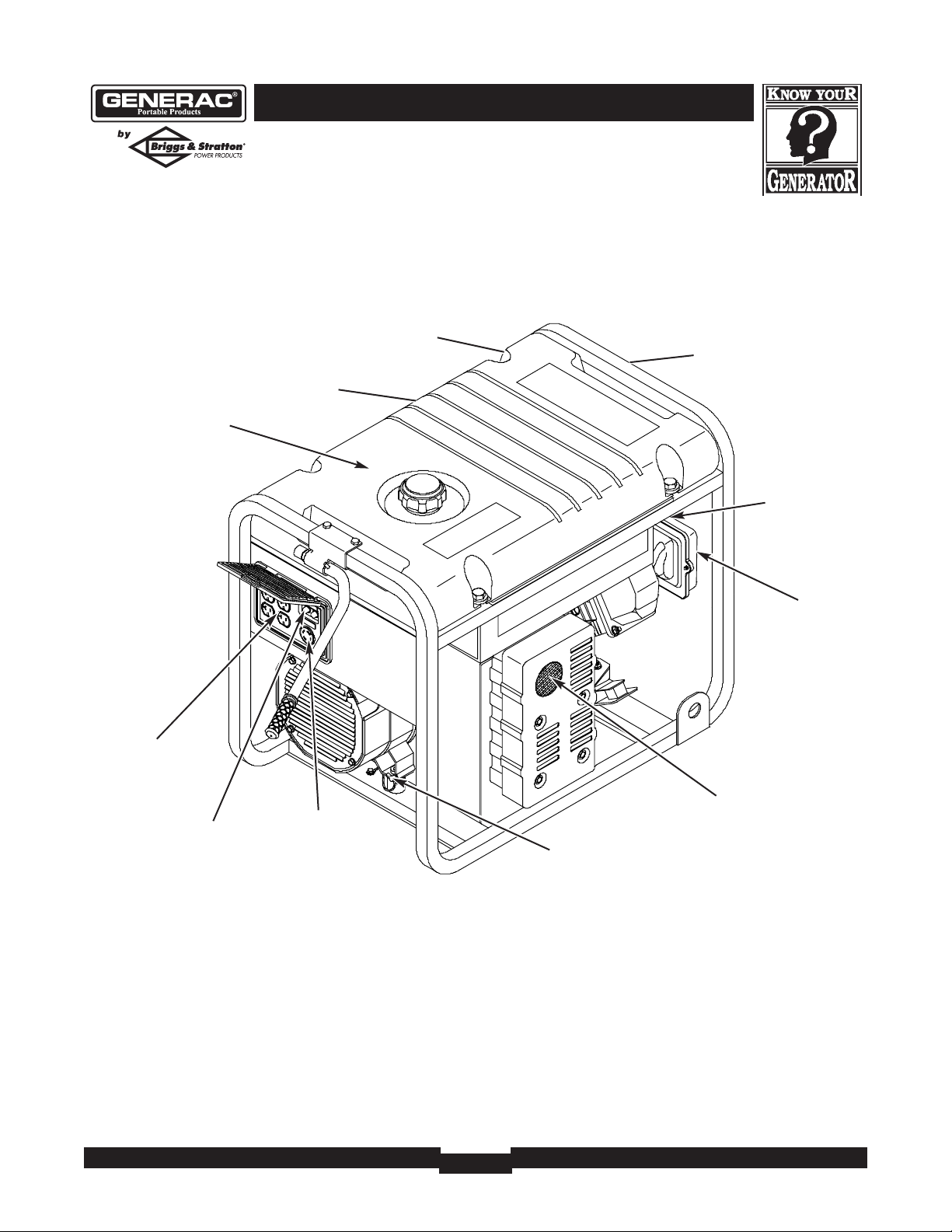

KNOW YOUR GENERATOR

Read this owner’s manual and safety rules before operating your generator.

Compare the illustrations with your generator, to familiarize yourself with the locations of various controls and

adjustments. Save this manual for future reference.

120 Volt AC, 20 Amp

Duplex Receptacles

Fuel Tank

Choke Lever

Recoil Starter

Rocker Switch

(on engine shroud)

Circuit

Breakers (AC)

120/240 Volt AC,

30 Amp

Receptacle

Spark Arrester Muffler

Air Cleaner

Grounding Wing Nut

Oil Fill

Page 7

7

5500 Watt Heavy Duty Generator

GROUNDING THE

GENERATOR

The National Electrical Code requires that the frame and

external electrically conductive parts of this generator be

properly connected to an approved earth ground. Local

electrical codes may also require proper grounding of the

unit. For that purpose, a GROUNDING WING NUT is

provided on the generator end (Figure 3).

Generally, connecting a No. 12 AWG (American Wire

Gauge) stranded copper wire to the grounding wing nut

and to an earth–driven copper or brass grounding rod

(electrode) provides adequate protection against electrical

shock. Be careful to keep the grounding wire attached after

connecting the stranded copper wire. However, local codes

may vary widely. Consult with a local electrician for

grounding requirements in your area.

Properly grounding the generator helps prevent electrical

shock if a ground fault condition exists in the generator or

in connected electrical devices. Proper grounding also helps

dissipate static electricity, which often builds up in

ungrounded devices.

OPERATING THE

GENERATOR

CAUTION! Never start or stop the engine with

electrical loads connected to the receptacles AND

with the connected devices turned ON.

Starting the Engine

Disconnect all electrical loads from the generator. Use the

following start instruction steps by numerical order:

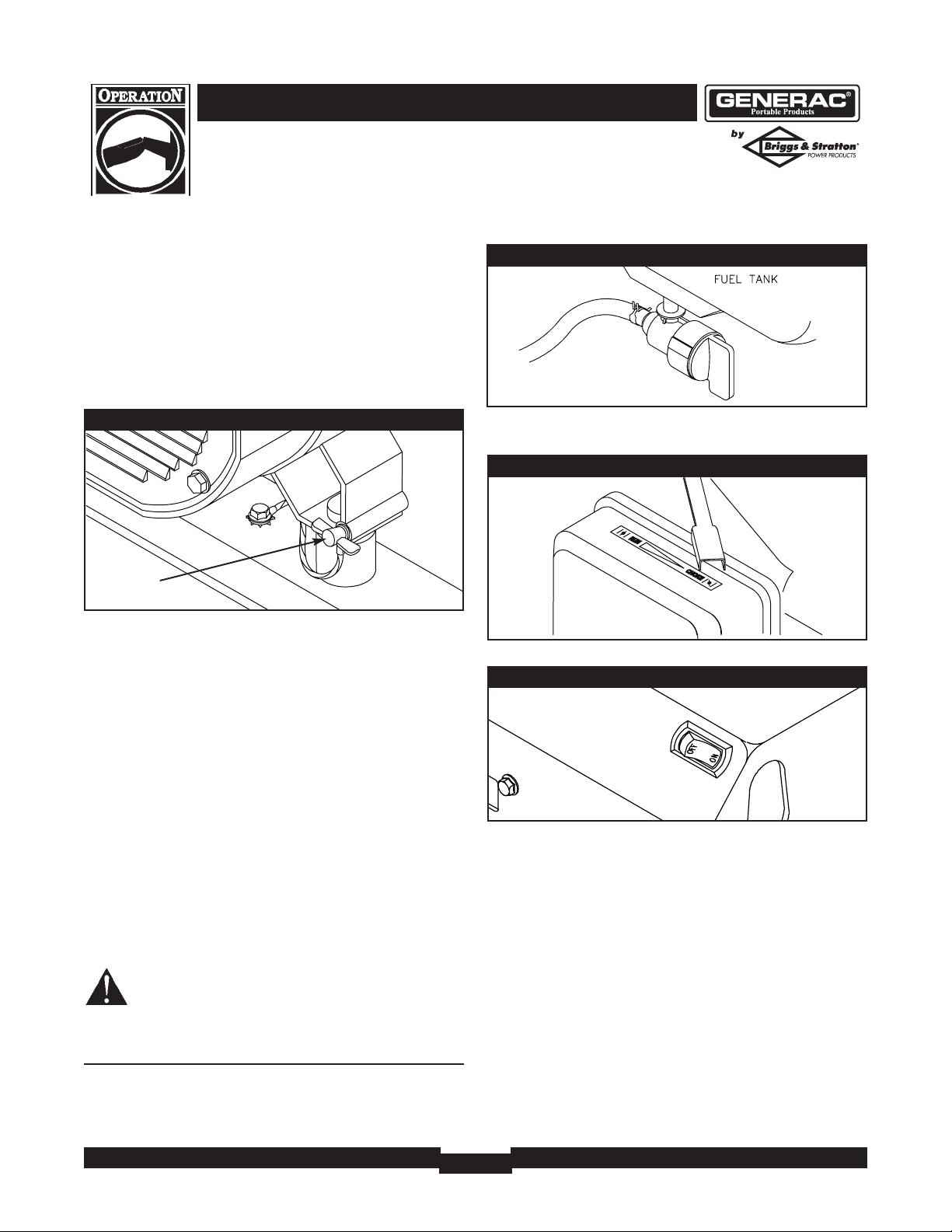

1. Turn the fuel valve to the “On” position (Figure 4).

2. Place the choke lever in the “Choke” position

(Figure 5).

3. Set the rocker switch to “On” position (Figure 6).

4. Grasp the recoil handle and pull slowly until slight

resistance is felt.Then pull rapidly to start engine.

5. Move choke lever to “Run” position a short distance at

a time over several seconds in warm weather or

minutes in cold weather. Let engine run smoothly before

each change. Operate with choke in “Run” position.

NOTE: If engine still fails to start, see engine manual.This

engine may be equipped with a low oil device.

Refer to the engine owner’s manual for more

detailed starting instructions.

Fuel Valve is shown

in the On position

Figure 4 — Fuel Valve

Figure 5 — Choke Lever

Figure 6 — Rocker Switch

Figure 3 — Grounding Wing Nut

Grounding

Wing Nut

Page 8

5500 Watt Heavy Duty Generator

8

Connecting Electrical Loads

• Let engine stabilize and warm up for a few minutes after

starting.

• Plug in and turn on the desired 120 and/or 240 Volt AC,

single phase, 60 Hz electrical loads.

• Do Not connect 240 Volt loads to the 120 Volt duplex

receptacles.

• Do Not connect 3–phase loads to the generator.

• Do Not connect 50 Hz loads to the generator.

• DO NOT OVERLOAD THE GENERATOR. See

“Don’t Overload the Generator” on page 9.

Stopping the Engine

• Unplug all electrical loads from generator panel

receptacles. Never start or stop engine with electrical

devices plugged in and turned ON.

• Let engine run at no-load for several minutes to stabilize

the internal temperatures of engine and generator.

• Move rocker switch to “Off” position.

• Move the fuel valve to the “Off” position.

RECEPTACLES

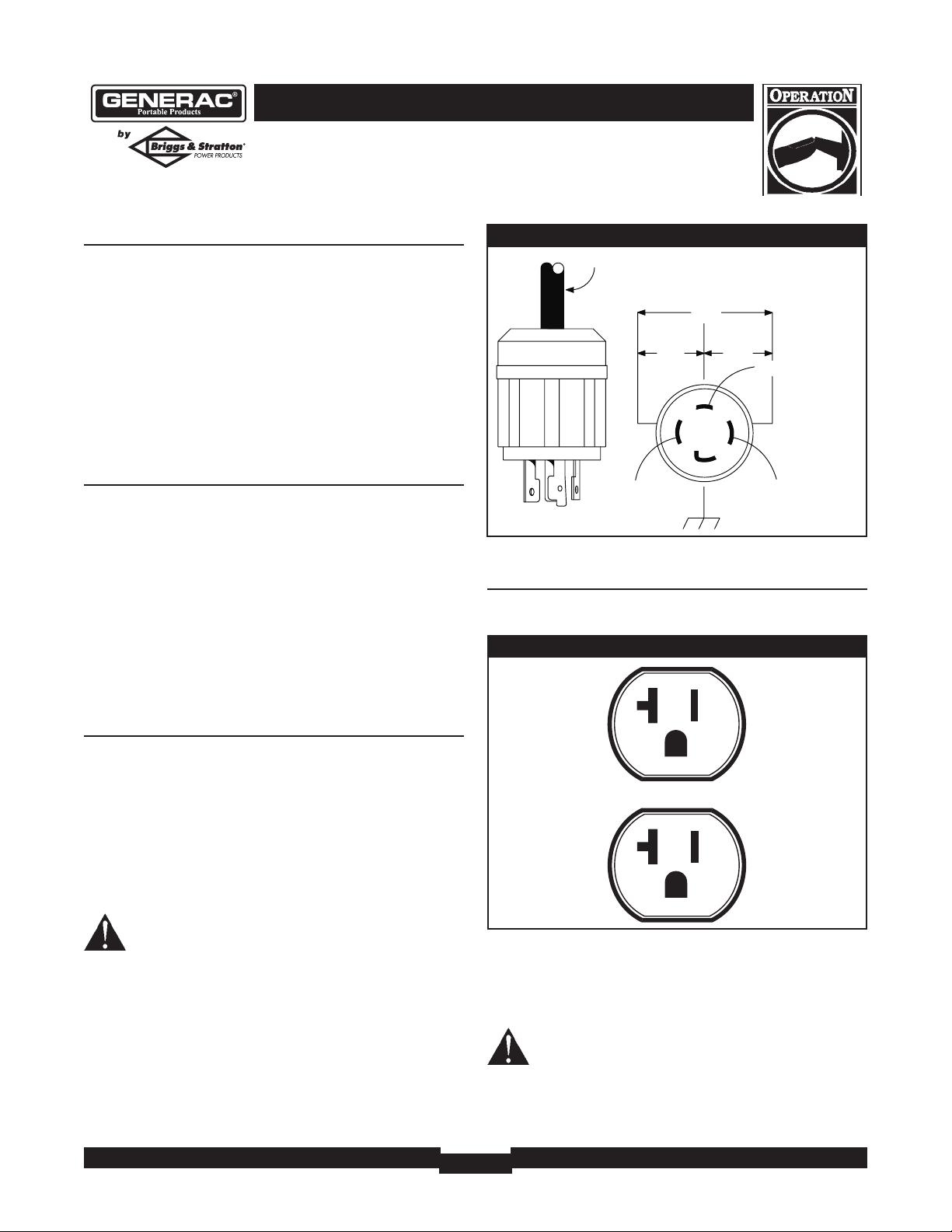

120/240 Volt AC, 30 Amp, Locking

Receptacle

Use a NEMA L14–30 plug with this receptacle. Connect a

4–wire cord set rated for 250 Volt AC loads at 30 Amps (or

greater) (Figure 7).You can use the same 4–wire cord if you

plan to run a 120 Volt load.

This receptacle powers 120/240 Volt AC, 60 Hz, single

phase loads requiring up to 5,500 watts of power (5.5 kW)

at 30 Amps for 120 Volts or 240 Volts.The outlet is

protected by a push–to–reset circuit breaker.

CAUTION! Although this outlet states it has a

120/240 Volt 30 Amp rating (up to 7,200 watts), the

generator is only rated for 5,500 watts. Powering

loads that exceed the wattage/amperage capacity of

the generator can damage it or cause serious

injuries.

120 Volt AC, 20 Amp, Duplex

Receptacles

Each duplex receptacle (Figure 8) is protected against

overload by a push–to–reset circuit breaker.

Use each receptacle to operate 120 Volt AC, single–phase,

60 Hz electrical loads requiring up to 2,400 watts (2.4 kW)

at 20 Amps of current. Use cord sets that are rated for

125 Volt AC loads at 20 Amps (or greater).

CAUTION!These outlets are rated at 120 Volt

20 Amp each (up to 80 Amps).The generator is only

rated for up to 45.8 Amps. Powering loads that

exceed the wattage/amperage capacity of the

generator can damage it or cause serious injuries.

Figure 8 — 120 Volt, 20 Amp Duplex Receptacle

Figure 7 — 120/240 Volt AC, 30 Amp Receptacle

4-Wire Cord Set

240V

120V

120V

W (Neutral)

X (Hot)

Y (Hot)

NEMA L14-30

Ground (Green)

Page 9

9

5500 Watt Heavy Duty Generator

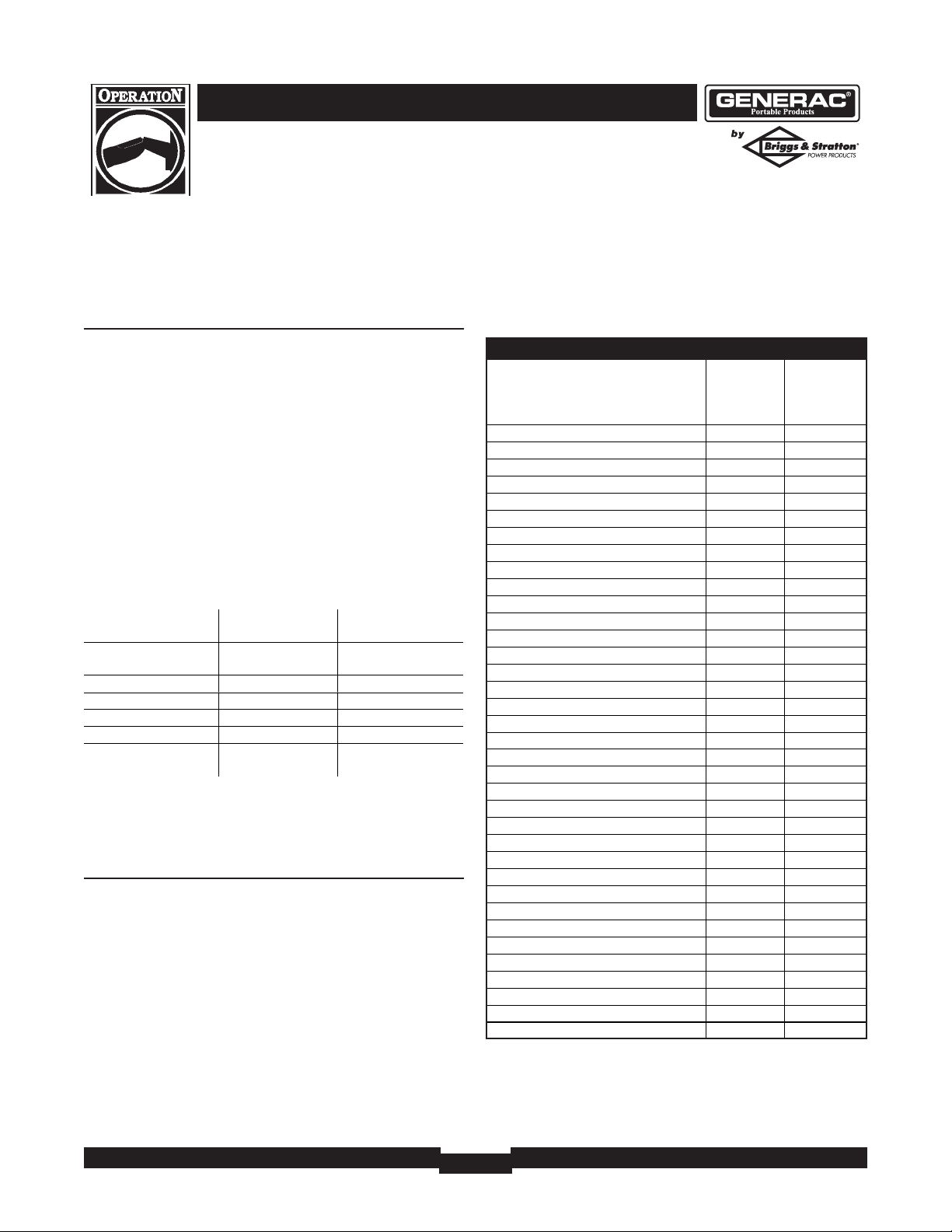

DON'T OVERLOAD YOUR

GENERATOR

Capacity

You must make sure your generator can supply enough

rated (running) and surge (starting) watts for the items you

will power at the same time. Follow these simple steps:

1. Select the items you will power at the same time.

2. Total the rated (running) watts of these items.This is

the amount of power your generator must produce to

keep your items running. See Figure 9.

3. Estimate how many surge (starting) watts you will

need. Surge wattage is the short burst of power

needed to start electric motor-driven tools or

appliances such as a circular saw or refrigerator.

Because not all motors start at the same time, total

surge watts can be estimated by adding only the

item(s) with the highest additional surge watts to the

total rated watts from step 2.

Example:

Total Rated (Running) Watts = 3075

Highest Additional Surge Watts = 1800

Total Generator Output Required = 4875

Power Management

To prolong the life of your generator and attached devices,

it is important to take care when adding electrical loads to

your generator.There should be nothing connected to the

generator outlets before starting it's engine.The correct

and safe way to manage generator power is to sequentially

add loads as follows:

1. With nothing connected to the generator, start the

engine as described in this manual.

2. Plug in and turn on the first load, preferably the largest

load you have.

3. Permit the generator output to stabilize (engine runs

smoothly and attached device operates properly.

4. Plug in and turn on the next load.

5. Again, permit the generator to stabilize.

6. Repeat steps 4 and 5 for each additional load.

Never add more loads than the generator capacity.Take

special care to consider surge loads in generator capacity,

as described above.

*Wattages listed are approximate only. Check tool or

appliance for actual wattage.

Tool or Appliance

Rated (Running)

Watts

Additional Surge

(Starting) Watts

Window Air

Conditioner

1200 1800

Refrigerator 800 1600

Deep Freezer 500 500

Television 500 Light (75 Watts) 75 -

3075 Total

Running Watts

1800 Highest

Surge Watts

Tool or Appliance

Rated*

(Running)

Watts

Additional

Surge

(Starting)

Watts

Essentials

Light Bulb - 75 watt

75

-

Deep Freezer

500

500

Sump Pump

800

1200

Refrigerator/Freezer - 18 Cu. Ft.

800

1600

Water Well Pump - 1/3 HP

1000

2000

Heating/Cooling

Window AC - 10,000 BTU

1200

1800

Window Fan

300

600

Furnace Fan Blower - 1/2 HP

800

1300

Kitchen

Microwave Oven - 1000 Watt

1000

-

Coffee Maker

1500

-

Electric Stove - Single Element

1500

-

Hot Plate

2500

-

Family Room

DVD/CD Player

100

-

VCR

100

-

Stereo Receiver

450

-

Color Television - 27”

500

-

Personal Computer w/17” monitor

800

-

Other

Security System

180

-

AM/FM Clock Radio

300

-

Garage Door Opener - 1/2 HP

480

520

Electric Water Heater - 40 Gallon

4000

-

DIY/Job Site

Quartz Halogen Work Light

1000

-

Airless Sprayer - 1/3 HP

600

1200

Reciprocating Saw

960

960

Electric Drill - 1/2 HP

1000

1000

Circular Saw - 7 1/4”

1500

1500

Miter Saw - 10”

1800

1800

Table Planer - 6”

1800

1800

Table Saw/Radial Arm Saw - 10”

2000

2000

Air Compressor - 1-1/2 HP

2500

2500

Figure 9 - Wattage Reference Chart

Page 10

5500 Watt Heavy Duty Generator

10

SPECIFICATIONS

Maximum Surge Watts . . . . . . . . . . . . . . . . .8,500 watts

Continuous Wattage Capacity . . . . . . . . . . .5,500 watts

Power Factor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.0

Rated Maximum Continuous AC Load Current:

At 120 Volts . . . . . . . . . . . . . . . . . . . . . . .45.8 Amps

At 240 Volts . . . . . . . . . . . . . . . . . . . . . . .22.9 Amps

Phase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–phase

Rated Frequency . . . . . . . . . . . . . . . . . . . . . . .60 Hertz

Fuel Tank Capacity . . . . . . . . . . . . . . . . . . . 7 U.S. gallons

Shipping Weight . . . . . . . . . . . . . . . . . . . . . . . . . 175 lbs.

GENERAL MAINTENANCE

RECOMMENDATIONS

The Owner/Operator is responsible for making sure that

all periodic maintenance tasks are completed on a timely

basis; that all discrepancies are corrected; and that the unit

is kept clean and properly stored. Never operate a

damaged or defective generator.

Engine Maintenance

See engine owner’s manual for instructions.

If you need service for your engine, you need to determine

the engine identification number.To do so, remove the

rocker arm cover hood, item number 55 shown on

page 16, by removing the four nuts and washers holding it

in place.The engine model-type-trim number is stamped on

the side of the inner cover attached to the engine. Have

this number in hand when you call the engine service

center for assistance.

CAUTION! Avoid prolonged or repeated skin

contact with used motor oil. Used motor oil has

been shown to cause skin cancer in certain

laboratory animals.Thoroughly wash exposed areas

with soap and water.

KEEP OUT OF REACH OF CHILDREN. DON'T

POLLUTE. CONSERVE RESOURCES. RETURN

USED OIL TO COLLECTION CENTERS.

Generator Maintenance

Generator maintenance consists of keeping the unit clean

and dry. Operate and store the unit in a clean dry

environment where it will not be exposed to excessive

dust, dirt, moisture or any corrosive vapors. Cooling air

slots in the generator must not become clogged with snow,

leaves or any other foreign material.

NOTE: Do Not use a garden hose to clean generator.

Water can enter engine fuel system and cause problems. In

addition, if water enters generator through cooling air slots,

some of the water will be retained in voids and cracks of

the rotor and stator winding insulation.Water and dirt

buildup on the generator internal windings will eventually

decrease the insulation resistance of these windings.

To Clean the Generator

CAUTION! Never insert any object or tool

through the air cooling slots, even if the engine is

not running.

• Use a damp cloth to wipe exterior surfaces clean.

• A soft bristle brush may be used to loosen caked on dirt

or oil.

• A vacuum cleaner may be used to pick up loose dirt and

debris.

• Low pressure air (not to exceed 25 psi) may be used to

blow away dirt. Inspect cooling air slots and opening on

generator.These openings must be kept clean and

unobstructed.

Page 11

11

5500 Watt Heavy Duty Generator

STORAGE

The generator should be started at least once every seven

days and allowed to run at least 30 minutes. If this cannot

be done and you must store the unit for more than

30 days, use the following guidelines to prepare it for

storage.

Generator Storage

• Clean the generator as outlined in “To Clean the

Generator.”

• Check that cooling air slots and openings on generator

are open and unobstructed.

CAUTION! Storage covers can be flammable.

Do Not place a storage cover over a hot

generator. Let the unit cool for a sufficient time

before placing the cover on the unit.

Engine Storage

See engine owner’s manual for instructions.

Other Storage Tips

• Do Not store gasoline from one season to another.

• Replace fuel container if it starts to rust. Rust and/or dirt

in fuel can cause problems if it's used with this unit.

• Store in clean and dry area.

Page 12

12

5500 Watt Heavy Duty Generator

TROUBLESHOOTING

Problem

Cause

Solution

Engine is running, but

no AC output is

available.

1. Circuit breaker is open.

2. Poor connection or defective cord set.

3. Connected device is bad.

4. Fault in generator.

1. Reset circuit breaker.

2. Check and repair.

3. Connect another device that is in good

condition.

4. Contact Generac service facility.

Engine runs good but

bogs down when

loads are connected.

1. Short circuit in a connected load.

2. Generator is overloaded.

3. Engine speed is too slow.

4. Shorted generator circuit.

1. Disconnect shorted electrical load.

2. See “Don’t Overload the Generator” on

page 9.

3. Contact Briggs and Stratton service

facility.

4. Contact Generac service facility.

Engine will not start;

or starts and runs

rough.

1. Rocker switch set to “Off”.

2. Fuel valve is in the “Closed” position.

3. Low oil level.

4. Dirty air cleaner.

5. Out of gasoline.

6. Stale gasoline.

7. Spark plug wire not connected to

spark plug.

8. Bad spark plug.

9. Water in gasoline.

10. Overchoking.

11. Excessively rich fuel mixture.

12. Intake valve stuck open or closed.

13. Engine has lost compression.

1. Set switch to “On”.

2. Turn fuel valve to the “Open” position.

3. Fill crankcase to proper level.

4. Clean or replace air cleaner.

5. Fill fuel tank.

6. Drain gas tank and fill with fresh fuel.

7. Connect wire to spark plug.

8. Replace spark plug.

9. Drain gas tank; fill with fresh fuel.

10. Set choke to “Off” position.

11. Contact Briggs service facility.

12. Contact Briggs service facility.

13. Contact Briggs service facility.

Engine shuts down

during operation.

1. Out of gasoline.

2. Fault in engine.

1. Fill fuel tank.

2. Contact Briggs service facility.

Engine lacks power.

1. Load is too high.

2. Dirty air filter.

1. See “Don’t Overload the Generator” on

page 9.

2. Replace air filter.

Engine “hunts” or

falters.

1. Choke is opened too soon.

2. Carburetor is running too rich or too

lean.

1. Move choke to halfway position till engine

runs smoothly.

2. Contact Briggs service facility.

Page 13

13

5500 Watt Heavy Duty Generator

NOTES

Page 14

5500 Watt Heavy Duty Generator

14

SCHEMATIC

Page 15

15

5500 Watt Heavy Duty Generator

WIRING DIAGRAM

Page 16

5500 Watt Heavy Duty Generator

16

EXPLODED VIEW – MAIN UNIT

Page 17

17

5500 Watt Heavy Duty Generator

PARTS LIST – MAIN UNIT

Item Part # Qty Description

1 A189503GS 1 CRADLE

2 70642GS 2 MOUNT,Vibration, 45°

3 76222GS 4 PPHMS, M8 - 1.25 x 40 mm

4 66365GGS 1 HOUSING, Engine Adapter

5 187746GS 1 ASSEMBLY, Rotor (Inclds Item 7)

6 187745GS 1 ASSEMBLY, Stator

7 65791GS 1 BEARING

8 96796GS 1 WASHER, M8 Flat

9 189949GS 1 DECAL, Cover,Air Cleaner

10 86307GS 4 SCREW, SEMS

11 99383GS 1 SCREW

12 67022GS 1 GROMMET, Rubber

13 189127GS 1 GROMMET, Rubber

14 189009GS 1 BRACKET, Muffler

15 188551GS 1 GASKET, Exhaust

16 66476GS 2 SCREW, w/Lock Washer

17 189008GS 1 MUFFLER

18 60706GS 2 SCREW

19 83083GS 1 SCREEN, Spark Arrest

20 81917GS 1 PIN, 4mm x 10 Roll

21 67989GS 10 NUT, Flange Serrated

22 20566GS 1 DECAL, 1-800 #

23 86292GS 1 SCREW, Self Drilling

24 J190061GS 1 SHIELD, Heat

25 SRV66825DGS 1 CARRIER, Rear Bearing

26 74908GS 5 TAPTITE

27 86308AGS 4 BOLT,Stator

28 84409GS 1 SLEEVING, Flexo

29 22695GS 1 FASTEN,On Tab Housing 6P

30 84242GS 1 GROMMET, Plastic

31 77816GS 1 DECAL, Hot Muffler

32 91825GS 1 ASSEMBLY, Brush Holder

33 66849GS 2 TAPTITE

34 B4871GS 1 COVER, Bearing Carrier

35 23762GS 2 WASHER, Ext. Shakeproof

36 86494GS 1 SCREW,Wing

Item Part # Qty Description

37 B2153GS 2 SCREW, Self Drilling

38 56893GS 5 SCREW, Crimptite

39 189948GS 2 DECAL, Heat Shield

40 77395GS 4 NUT, M6 Flange Lock

41 80270GS 1 VALVE,Tank

42 78299GS 1 BUSHING, Plastic Tank

43 83465GS 4 GROMMET,Tank

44 78831BGS 4 HHCS, SEMS

45 B4363GS 1 CAP, Fuel Gauge

46 22097GS 4 WASHER, Lock

47 22127GS 4 NUT

48 14353621GS 1 WIRE, Ground

49 26850GS 2 WASHER, M6 Shakeproof

50 B4986GS 1 DECAL, Ground, Green

51 92982GS 1 DECAL, Danger

52 189235GS 1 DECAL, Start Instructions

53 85652GS 2 MOUNT,Vibration

54 92665GS 1 INSULATION

55 187330GS 1 HOOD, Rocker Arm Cover

56 85000GS 1 CLIP, Insulation

57 B1998GS 1 ASSY.,Tank, Fuel 7-Gallon

(Includes Items 41 & 42)

58 189157GS 1 ASSEMBLY, Control Panel

59 189164GS 4 NUT, Palnut

60 J92039GS 1 SHIELD, Heat

61 189828GS 1 MANUAL, Owners

62 BB3061GS 1 BOTTLE, Oil, 28 oz

63 43438GS 1 PLUG, 250V, 30A

64 189521AGS 1 WIRE, Ground, Panel

65 188826GS 1 MANUAL, Engine

66 189949GS 1 DECAL, Panel, Control

67 73054GS 1 DECAL, Fuel Shut-off

68 L190018GS 1 PLATE, Stiffener

69 28739AGS 1 TIE WRAP

900 NSP 1 ENGINE

Page 18

5500 Watt Heavy Duty Generator

18

EXPLODED VIEW AND PARTS LIST – WHEEL KIT

Item Part # Qty Description

1 189715GS 1 ASSEMBLY, Handle

2 B187101GS 1 LEG, Mounting

3 52858GS 5 NUT, Locking Hex

4 39287GS 2 HHCS, M8 - 1.25 x 45

5 93693GGS 1 AXLE

6 B4966GS 2 WHEEL

7 87005AGS 2 PIN, Retaining

8 22247GS 2 WASHER, Flat

9 39253GS 1 HHCS, M8 - 1.25 x 20

10 42909GS 2 HHCS, M8 - 1.25 x 30

11 22145GS 2 WASHER, Flat

12 27007GS 2 MOUNT,Vibration

Page 19

19

5500 Watt Heavy Duty Generator

EXPLODED VIEW AND PARTS LIST – CONTROL PANEL

Item Part # Qty Description

1 188914GS 1 COVER, Lid, Control Panel

2 188889GS 1 CONTROL PANEL, Compact

3 189167GS 2 CLIP, Hinge Pin Retainer

4 189182GS 2 SPRING, Hinge, Pin

5 189166GS 2 PIN, Hinge, Cover, Compact

6 68759GS 2 OUTLET, 120V, 20Amp, Duplex

7 189165GS 4 NUT, Palnut, Pushnut

8 84198GS 2 CAP, Circuit Breaker

9 75207GS 2 CIRCUIT BREAKER

10 43437GS 1 OUTLET, 120/240 Locking, 30A

11 189164GS 2 NUT, Palnut, Pushnut

12 84543CGS 2 SCREW, Phillips, Head

13 93857GS 1 BAR, Retaining

14 188890GS 1 COVER, Back, Control Panel

15 82308GS 6 SCREW, Self Tapping

16 22694GS 1 HOUSING, Receptacle

Page 20

5500 Watt Pesado Generador

20

DESCRIPCIÓN DEL EQUIPO

Lea este manual de manera cuidadosa y familiarícese con

su generador. Conozca sus usos, sus limitaciones y

cualquier peligro relacionado con el mismo.

Este generador funciona en base a un motor, de campo eléctrico

giratorio y de corriente alterna (AC). Fue diseñado con la

finalidad de proveer energía eléctrica para luces eléctricas,

aparatos, herramientas compatibles y cargas de motor. El campo

giratorio del generador funciona a una velocidad de 3,6000 rpm

usando un motor con un solo cilindro.

¡PRECAUCIÓN! No sobrepase la capacidad de vataje y

amperaje del generador. Revise "No Sobrecargue el Generador"

en la página 27.

Se ha hecho cada esfuerzo posible para asegurarse que la

información que aparece en este manual es exacta y se encuentra

actualizada. Sin embargo, Generac se reserva el derecho a

cambiar, alterar o de otra manera mejorar, el producto y este

documento en cualquier momento, sin previo aviso.

El Sistema de Control de Emisiones para este generador está

garantizado para juegos estándares por la Agencia de Protección

Ambiental. Para mayor información acerca de la garantía, consulte

con el manual del propietario del motor.

INSTRUCCIONES DE SEGURIDAD

El símbolo de alerta de seguridad ( ) es usado con una palabra

(PELIGRO,ADVERTENCIA,PRECAUCIÓN), un mensaje por

escrito o una ilustración, para alertarlo acerca de cualquier

situación de peligro que pueda existir. PELIGRO indica un riesgo

el cual, si no se evita, causará la muerte o una herida grave.

ADVERTENCIA indica un riesgo el cual, si no se evita, puede

causar la muerte o una herida grave. PRECAUCIÓN indica un

riesgo, el cual, si no se evita, puede causar heridas menores o

moderadas. PRECAUCIÓN, cuando se usa sin el símbolo de

alerta, indica una situación que podría resultar en el daño del

equipo. Siga los mensajes de seguridad para evitar o reducir los

riesgos de heridas e inclusive la muerte.

El escape del motor de este producto contiene

elementos químicos reconocidos en el Estado de

California por producir cáncer, defectos de nacimiento u

otros daños de tipo reproductivo.

ADVERTENCIA

• Opere el generador SOLAMENTE al aire libre.

• Mantenga al menos 2 pies de espacio libre alrededor del

generador, para la adecuada ventilación.

• No opere el generador dentro de un edificio o lugar cerrado,

incluyendo el compartimiento del generador en un vehículo

recreativo o RV.

Al generador funcionar, se produce monóxido de

carbono, un gas inodoro y venenoso.

El respirar el monóxido de carbono, producirá

náusea, desmayo o la muerte.

PELIGRO

CUANDO AÑADA COMBUSTIBLE

• Apague el generador (posición OFF) y déjelo enfriar al menos por

2 minutos antes de remover la tapa de la gasolina.Afloje la tapa

lentamente para dejar que la presión salga del tanque.

• Llene el tanque al aire libre.

• No llene demasiado el tanque. Permita al menos espacio para la

expansión del combustible.

• Mantenga la gasolina alejada de chispas, llamas abiertas, pilotos, calor y

otras fuentes de ignición.

• No encienda un cigarrillo o fume.

CUANDO OPERE EL EQUIPO

• No incline el motor o el equipo, de tal manera que la gasolina se

pueda derramar.

CUANDO TRANSPORTE O REPARE EL EQUIPO

• Transporte o repare el equipo con el tanque de combustible vacío, o

con la válvula para apagar el combustible, apagada (posición OFF).

• Desconecte el cable de la bujía.

CUANDO ALMACENE O GUARDE EL EQUIPO CON

COMBUSTIBLE EN EL TANQUE

• Almacene alejado de calderas, estufas, calentadores de agua, secadoras

de ropa u otros aparatos electrodomésticos que posean pilotos u

otras fuentes de ignición, porque ellos pueden encender los vapores

de la gasolina.

La gasolina y sus vapores son extremadamente

inflamables y explosivos.

El fuego o una explosión pueden causar quemaduras

severas e inclusive la muerte.

ADVERTENCIA

Page 21

21

5500 Watt Pesado Generador

• No permita ninguna llama abierta, chispa, calor, o encienda un

cigarrillo durante y por varios minutos después de haber recargado la

batería.

• Lleve puestos las gafas protectoras, delantal y guantes de goma.

Las baterías almacenadas producen hidrógeno

explosivo mientras estén siendo recargadas.

El hidrógeno puede permanecer cerca de la batería

por un periodo largo de tiempo, después que la

batería haya sido recargada.

Una pequeña chispa puede encender el hidrógeno y

causar una explosión.

Usted puede quedar ciego o sufrir heridas muy graves.

El fluido de electrolito de la batería contiene ácido y

es extremadamente cáustico.

El contacto con el fluido de la batería puede causar

quemaduras químicas severas.

PELIGRO

• Cuando use un generador como poder de energía auxiliar, notifique a

la compañía de utilidades. Use el equipo de transferencia aprobado

para aislar el generador de otra utilidad eléctrica.

• Los Códigos Nacionales para la Electricidad, requieren que los

generadores estén haciendo tierra de una manera aprobada.Llame a

un electricista para conocer los requisitos locales para hacer tierra.

• Use un interruptor para la falla del circuito de tierra (GFCI) en

cualquier área bastante húmeda o que sea altamente conductiva, tales

como terrazas de metal o trabajo hecho con acero.

• No toque los alambres pelados o receptáculos.

• No use un generador con cables eléctricos que estén malgastados,

rotos, pelados o dañados de cualquier forma.

• No opere el generador bajo la lluvia.

• No maneje el generador o cables eléctricos mientras esté parado en

agua, descalzo o cuando las manos y los pies estén mojados.

• No permita que personas descalificadas o niños operen o sirvan al

generador.

Los generadores producen un voltaje muy poderoso.

Si no hace tierra apropiadamente con un generador,

puede hacer que ocurra un electrocutamiento.

Si no aísla el generador de utilidades de energía,

puede hacer que los trabajadores de electricidad

sufran heridas graves e inclusive la muerte, debido a

la retroalimentación de la energía eléctrica.

ADVERTENCIA

• No toque las superficies calientes.

• Permita que el equipo se enfríe antes de tocarlo.

Los motores al funcionar producen calor. La

temperatura del silenciador y de las áreas cercanas

puede alcanzar o pasar los 150°F (65°C).

Quemaduras severas pueden ocurrir al hacer contacto.

ADVERTENCIA

• No cambie ninguna velocidad determinada. El generador suministra

una frecuencia y un voltaje calificado cuando funciona a una velocidad

determinada.

• No modifique al generador en ninguna forma.

Las velocidades de operación en exceso, aumentan los

riesgos de heridas y daños al generador.

Las velocidades bajan en exceso,imponen una carga muy pesada.

PRECAUCIÓN

• Vea "No sobrecargue su generador" en la página 27.

• Encienda su generador y deje que el motor se estabilice antes de

conectar las cargas eléctricas.

• Conecte las cargas eléctricas en la posición de apagado (OFF), luego

encienda (ON) para su operación.

• Apague (OFF) las cargas eléctricas y desconéctelas del generador

antes de parar el generador.

El sobrepasar la capacidad del amperaje y vataje del

generador, puede dañar al generador y los aparatos eléctricos

conectados al mismo.

PRECAUCIÓN

• Use el generador solamente con la finalidad para el cual fue diseñado.

• Si usted tiene alguna pregunta acerca de las finalidades de uso del

generador, pregúntele a su concesionario o contacte a Generac.

• Opere el generador solamente en superficies niveladas.

• No exponga al generador a una humedad excesiva, polvo, suciedad o

vapores corrosivos.

• No inserte cualquier objeto a través de las ranuras de enfriamiento.

• Si los aparatos conectados se sobrecalientan, apáguelos y

desconéctelos del generador.

• Apague el generador si:

-Se pierde la salida eléctrica;

-El equipo produce chispas, humo o emite llamas;

-La unidad vibra de una manera excesiva.

El tratamiento inadecuado del generador puede dañarlo y

acortar su vida productiva.

PRECAUCIÓN

Page 22

5500 Watt Pesado Generador

22

Su generador requiere de ciertos procedimientos de montaje y

solo estará listo para ser utilizado después de haberle

suministrado servicio con el combustible y aceite recomendados.

Si usted tiene problemas con el montaje de su generador, por

favor llame a la línea de ayuda para generadores al

1-800-270-1408.

IMPORTANTE: Cualquier intento de encender el motor antes

de haber colocado el aceite recomendado resultará daño del

motor.

PARA RETIRAR EL GENERADOR

DE LA CAJA

• Coloque la caja sobre una superficie plana y rigida, con las

flechas que dicen "this side up" hacia arriba.

• Abra con cuidado las tapas superiores de la caja de envío.

• Corte de arriba a abajo las esquinas de uno de los lados de la

caja y coloque ese lado de la caja sobre el suelo.

• Retire todo el material de empaque, relleno, etc.

• Saque el generador de la caja de envío.

CONTENIDO DE LA CAJA

Revise todo el contenido. Si alguna de las partes no está presente

o está dañada, por favor llame a la linea de ayuda para

generadores al 1-800-270-1408.

• La unidad principal

• Manual del propietario

• Aceite para motor

• Tapones de fijación

• Juego de llantas

INSTALE EL JUEGO DE RUEDAS

El juego de ruedas está diseñado para mejorar el transporte del

generador.

NOTA: Este Juego de Ruedas no ha sido diseñado para ser usado

en la carretera.

Necesitará una llave de cubos con cubos de ½" o 13mm y unas

pinsas de punta para instalar el juego de ruedas.

Consulte la Figura 10 y instale el juego de ruedas como

se describe a continuación:

1. Coloque el generador sobre una superficie plana y dura.

Pata de Apoyo

Tuercas

Eje

Arandela

Tornillos

Manilla

Tuercas

Rueda

Pasador de Seguridad

Figura 10 — Instale el Juego de Ruedas

Tornillos

Tornillos

Arandela

Montajes Antivibratorios

Use hardware existente

para conectar el lado

izquierdo de pierna de

apoyo a la unidad

Tuercas

Page 23

23

5500 Watt Pesado Generador

2. Párese en el extremo del motor del generador e incline el

generador cuidadosamente hacia adelante, lo suficiente como

para colocar bloques por debajo del armazón. Esto le

permitirá colocar las ruedas.

3. Pase el eje a través de los orificios de las ménsulas del

armazón del generador.

4. Coloque las ruedas y las arandelas planas en cada extremo

del eje.Asegúrese de instalar ambas ruedas con la válvula de

aire hacia el lado de afuera. Insertar los pasadores de

retención.

5. Deslice el eje por hasta que la rueda sea apretada contra

paréntesis.

6. Deslice la otra rueda y arandela plana en el otro fin del eje.

Insertar los pasadores de retención usa unas pinsas de punta.

Remover los bloques madera.

7. Instale los montajes antivibratorios a la pata de soporte

utilizando dos tornillos prisioneros 30mm, arandelas y

tuercas de seguridad.

8. Para ayudar al ensamblaje de la pata de apoyo, haga

descansar el generador en la camilla, con la parte del motor

hacia abajo. Quite el hardware existente del monte izquierdo

de la vibración de la unidad con 13mm llave inglesa. Use el

mismo hardware para conectar la pierna de apoyo.

9. Conecte el otro lado de la pierna de apoyo con un 20mm

tornillo de la tapa y nuez de cerradura. Descanse el

generador en la pierna de ruedas y apoyo.

10. Coloque el soporte de la manilla en el centro del marco del

generador al extremo de la pata de apoyo, como se muestra.

11. Anexe el soporte de la manilla con dos tornillos 45mm y dos

tuercas de seguridad.

12. Verifique que todas las piezas estén apretadas y las llantas

estén infladas con aire entre 15-40 PSI.

ANTES DE DARLE ARRANQUE AL

MOTOR

Agregar Aceite al Motor

CAUTION! Cualquier intento para arancar el motor antes de

haberle proporcionado el mantenimiento apropiado con el aceite

recomendado,podría ocasionar la falla del motor.

• Coloque la generador sobre una superficie nivelada.

• Consulte el manual del propietario del motor para añadir al

motor el aceite recomendado.

NOTA: El campo giratorio del generador se encuentra en un

cojinete pre-lubricado y sellado que no requiere lubricación

adicional por la vida útil del cojinete.

Agregue Gasolina

¡ADVERTENCIA! Nunca llene el tanque del

combustible en recintos cerrados. Nunca llene el tanque

del combustible cuando el motor esté en funcionamiento

o caliente. No encienda cigarrillos o fume cuando esté

llenando el tanque del combustible.

¡ADVERTENCIA! No llene excesivamente el tanque

de combustible. Deje suficiente espacio para la expansión

del combustible.

• Use gasolina regular SIN CONTENIDO DE PLOMO en

el generador. No use gasolina premium. No mezcle aceite con

gasolina.

• Limpie el área alrededor del llenado de gasolina; retire la tapa.

• Llene lentamente el tanque con gasolina sin contenido de

plomo. Sea cuidadoso de no llenar excesivamente. Deje

1.5" de espacio en el tanque para que la expansión del

combustible, como se muestra en esta ilustración (Figura 11).

• Instale la tapa del combustible y limpie cualquier derrame de

gasolina.

IMPORTANTE: Es importante evitar la formación de depósitos

de goma en las partes esenciales del sistema de combustible

como en el carburador, filtro del combustible, manguera del

combustible o tanque, durante su almacenamiento. Los

combustibles mezclados con alcohol (llamados gasohol, etanol o

metanol) pueden atraer la humedad, la cual produce la separación

y formación de ácidos durante el almacenamiento. La gasolina

ácida puede dañar el sistema de combustible de un motor

durante su almacenamiento.

Para evitar problemas en el motor, deberá vaciar el sistema de

combustible antes de períodos de almacenamiento de 30 días o

más.Vea "Almacenamiento" en la página 28. Nunca use productos

para limpiar motores o carburadores en el tanque del

combustible; si lo hace ocurrirán daños permanentes.

Figura 11 — Espacio Típico para la Expansión del

Combustible

Combustible

Tanque

Espacio de 1.5"

Page 24

5500 Watt Pesado Generador

24

CONOZCA SU GENERADOR

LEA ESTE MANUAL DEL PROPIETARIO Y LAS REGLAS DE SEGURIDAD ANTES DE OPERAR SU GENERADOR.

Compare las ilustraciones con su Generador para familiarizarse con las ubicaciones de los diferentes controles y ajustes.Conserve este

manual para referencias futuras.

Cortacircuitos (AC) — Cada tomacorriente posee un

cortacircuito para proteger el generador contra sobrecargas

eléctricas. Los cortacircuitos son del tipo “oprimir para

reposicionar”.

Culatazo el Principio — Usó para comenzar motor.

Depurador de Aire — Filtra el aire de entrada a medida que

penetra en el motor.

Interruptor Balancín — Deberá estar en la posición “On” (En)

para darle arranque al motor. Colóquelo en la posición “Off”

(Apagado) para detener un motor en funcionamiento.

Palanca del Cebador — Usada cuando se está dando arranque

a un motor frío.

Silenciador Apagachispas — El silenciador disminuye el ruido

del motor y está equipado con una pantalla apagachispas.

Tanque del Combustible — El tanque tiene una capacidad de

7 galones americanos de gasolina sin contenido de plomo.

Terraplén del aceite -- Agregue el aceite de motor aquí.

Tomacorriente Dobles de 120 Voltios AC, 20 Amp —

Pueden ser utilizados para suministrar alimentación eléctrica para

el funcionamiento de cargas del motor, herramientas, aparatos

especiales e iluminación eléctrica de 120 Voltios AC a

20 Amperios, monofásica de 60 Hz.

Tomacorriente con Dispositivo de Seguridad de

120/240 Voltios, 30 Amp — Puede ser utilizado para

suministrar alimentación eléctrica para el funcionamiento de

cargas del motor, herramientas, aparatos especiales e iluminación

eléctrica de 120 y/o 240 Voltios AC a 30 Amperios, monofásica de

60 Hz.

Tuerca Mariposa para Conexión a Tierra — Usado para

apropiado molió de la unidad (vea página 25).

Depurador

de Aire

Interruptor

Balancín

Palanca del Cebador

Tomacorrientes con

Dispositivo de

Seguridad de

120/240 Voltios AC,

30 Amp

Tomacorrientes Doble de

120 Voltios AC, 20 Amp

Silenciador

Apagachispas

Tanque de Combustible

Cortacircuitos

Culatazo el Principio

Tuerca Mariposa para

Conexión a Tierra

Terraplén del aceite

Page 25

25

5500 Watt Pesado Generador

CONEXION A TIERRA DEL

GENERADOR

El Código Nacional de Electricidad exige que el marco y las

partes exteriores del generador conductoras de electricidad,

estén conectadas a tierra adecuadamente. Los códigos eléctricos

locales también pueden exigir que la unidad esté conectada a

tierra correctamente. Para tal propósito, se ha instalado una

tuerca mariposa para conexión a tierra en la base del bastidor

(Figura 12).

Por lo general, la conexión de un alambre de cobre trenzado No.

12 AWG (American Wire Gauge) a la aleta de conexión a tierra y

a una barra de conexión a tierra de cobre o bronce (electrodo)

proporciona una protección adecuada contra las descargas

eléctricas. Sin embargo, los códigos locales pueden variar

substancialmente. Consulte con un electricista local para conocer

los requisitos de conexión a tierra de su área.

La conexión a tierra adecuada del generador ayudará a evitar las

descargas eléctricas en el caso de que exista una condición de

falla a tierra en el generador o en los dispositivos eléctricos

conectados. La conexión a tierra adecuada también ayuda a

disipar la electricidad estática, la cual se acumula frecuentemente

en dispositivos no conectados a tierra.

OPERANDO EL GENERADOR

¡PRECAUCIÓN! Nunca encienda o pare el motor

con las cargas eléctricas conectadas a los receptáculos Y

con los aparatos conectados ENCENDIDOS.

Encienda el Motor

Desconecte todas las cargas eléctricas del generador. Use las

siguientes instrucciones para encender, paso por paso, en orden

numérico.

1. Gire la válvula del combustible a la posición "On" (Figura 13).

2. Coloque la palanca de choke en la posición "Choke"

(Figura 14).

3. Coloque el interruptor balancín a la posición "On"

(Figura 15).

4. Agarre la manilla de retroceso y hale lentamente hasta que

puede sentir un poco de resistencia. Luego hale rápidamente

para encender el motor.

5. Mueva la palanca de choke a la posición "Run" una distancia

corta a la vez por algunos segundos en un clima cálido, o

algunos minutos en un clima frío. Deje que el motor corra

suavemente antes de cada cambio. Opere con el choke en la

posición "Run".

NOTA: Si el motor aún no puede encender después de halarla

tres veces, verifique el nivel adecuado de aceite en el cigüeñal.

Esta unidad está equipada con un aparato para detectar el nivel

bajo de aceite, que no permitirá que el motor se encienda.Vea el

manual del motor.

Consulte con el manual del propietario del motor para

las instrucciones completas de encendido.

Válvula del Combustible

en posición “On”

Figura 13 — Válvula de Combustible

Figura 14 — Palanca Choke

Figura 15 — Interruptor Balancín

Figura 12 — Tuerca Para Tierra

Tuerca Mariposa

para Conexión a

Tierra

Page 26

5500 Watt Pesado Generador

26

Conexion De Cargas Electricas

• Deje que el motor se estabilice y se caliente por unos

minutos después del arranque.

• Conecte y encienda las cargas eléctricas de 120 y/o

240 Voltios AC monofásicas de 60 Hz que desse.

• No conecte cargas de 240 Voltios a tomacorrientes de

120 Voltios.

• No conecte cargas trifásicas al generador.

• No conecte cargas de 50 Hz al generador.

• NO SOBRECARGUE EL GENERADOR.Vea "No

Sobrecargue el Generador" en la página 27.

Parado Del Motor

• Desconecte todas las cargas eléctricas de los tomaco-rrientes

del panel del generador. Nunca de arranque o detenga el

motor con todos los dispositivos eléctricos conectados y

encendidos.

• Deje que el motor funcione sin cargas por algunos minutos

para estabilizar las temperaturas internas del motor y el

generador.

• Mueva el interruptor balancín a la posición “Off” (Apagado).

• Cierre la válvula del combustible.

RECEPTÁCULOS

120/240 Voltios AC, 30 Amp, Receptáculo

de Seguridad

Use un tapón NEMA L14-30 con este receptáculo. Conecte un

juego de cable de 4 alambres, clasificado como 250 Voltios AC a

30 Amps (o mayor) (Figura 16). Usted puede usar el mismo cable

de 4-alambres si planea trabajar con una carga de 120 Voltios.

Este receptáculo le provee poder a cargas de 120/240 Voltios AC,

de 60 Hz, fase sencilla, que requieren hasta 5,500 vatios de

energía (5.5 kW) a 30 Amps, para 120 Voltios o 240 Voltios.La

salida está protegida por un corto-circuito de, del tipo "empuje

para reposicionar".

¡PRECAUCIÓN! Aunque esta salida tiene una

clasificación de 120/240 Voltios 30 Amps (hasta

7,200 vatios), el generador está clasificado solamente para

5,500 vatios. Cargas que pasen la capacidad de amperaje y

vataje del generador pueden dañarlo o causar accidentes

muy serios.

120 Volt AC, 20 Amp, Receptáculos Dobles

Cada receptáculo (Figura 17) está protegido en contra de

sobrecargas por un corto-circuitos de, del tipo "empuje para

reposicionar".

Use cada receptáculo para operar 120 Voltios AC, de fase sencilla,

de cargas de 60Hz que requieren hasta 2,400 vatios (2.4 kW) a

corrientes de 20 Amps. Use los juegos de cables que son

calificados para cargas de 125 Voltios AC, a 20 Amps (o mayores).

¡PRECAUCIÓN! Estas salidas se valoran en

120Voltios 20 Amps (hasta 80 Amps). El generador es sólo

valorado hasta 45.8 Amps. Las cargas que accionan que

excede el wattage/la capacidad de amperaje del generador

lo puede dañar o causar las heridas gravas.

Figura 17 — 120 Volt AC, 20 Amp Receptáculo Doble

Figura 16 — 120/240 Volt AC, 30 Amp, Receptáculo de

Seguridad

Juego de Cable de 4 Alambres

240V

120V

120V

W (Neutro)

X (Cargado)

Y (Cargado)

NEMA L14-30

Tierra (Verde)

Page 27

27

5500 Watt Pesado Generador

NO SOBRECARGUE EL

GENERADOR

Capacidad

Usted debe asegurarse que su generador puede proveer el

suficiente vataje calificado (cuando esté funcionando) y de carga

(al encender) para los aparatos a los cuales va a proveer la

energía, al mismo tiempo. Siga estos pasos:

1. Seleccione los aparatos que recibirán la energía, al mismo

tiempo.

2. Totalice los vatios calificados (cuando esté funcionando) de

estos aparatos. Esta es la cantidad de energía que su

generador debe producir para mantener eso aparatos

funcionando adecuadamente.Vea la Figura 18.

3. Calcule la cantidad de vatios de carga (al encender) que

usted necesitará. El vataje de carga es la cantidad mínima de

electricidad, necesaria para encender herramientas o

aparatos con motores eléctricos, tales como, sierras

circulares o refrigeradores. Debido a que no todos los

motores se encienden al mismo momento, el vataje total de

carga se puede estimar al añadir solamente el(los) aparato(s)

con el vataje adicional más alto, al total del vataje calificado,

obtenido en el paso 2.

Ejemplo:

Vataje Total Calificado (cuando esté funcionando)= 3075

Vataje de Carga Adicional más alto = 1800

Salida Total Requerida del Generador = 4875

Control de la Energía

Para prolongar la vida de su generador y los aparatos que estén

conectados al mismo, es muy importante cuidarlo cuando se le

añaden cargas eléctricas. Nada debería estar conectado a los

tomacorrientes del generador antes de que su motor sea

encendido. La forma correcta y más segura para controlar la

energía del generador, es la de añadir en secuencias las cargas,

como se describe a continuación:

1. Sin tener nada conectado al generador, encienda el motor de

la manera descrita en este manual.

2. Conecte y encienda la primera carga, preferiblemente la

mayor que usted tenga.

3. Permita que la salida del generador se estabilice (el motor

funciona suavemente y el aparato conectado al mismo

trabaja adecuadamente).

4. Conecte y encienda la próxima carga.

5. De nuevo, permita que el generador se estabilice.

6. Repita los pasos 4 y 5 para cada carga adicional que usted

tenga.

Nunca añada más cargas sobre la capacidad del generador.Tome

una atención especial en considerar las cargas de corriente según

la capacidad del generador, como se describe arriba.

*El vataje que aparece en la lista es solamente una cantidad

aproximada.Verifique la herramienta o aparato eléctrico para

obtener el vataje verdadero.

Herramienta o

Aparato Eléctrico

Vatios Calificados

(cuando esté

funcionando)

Vatios Adicionales de

Carga (al encender)

Aire Acondicionado

de Ventana

1200 1800

Refrigerador 800 1600

Congelador industrial 500 500

Televisión 500 Luz (75 Vatios) 75 -

Total = 3075

Vatios para funcionar

1800 (Vatios de

Carga más alto)

Herramienta o Aparato Eléctrico

Vatios

Calificados*

(cuando esté

funcionando)

Vatios

Adicionales

de Carga (al

encender)

Esenciales

Bombilla - 75 vatios 75 Congelador industrial 500 500

Bomba de aguas negras 800 1200

Refrigerador / congelador - 18 pies

cúbicos

800 1600

Bomba de agua - 1/3 HP 1000 2000

Calefacción / enfriamiento

Aire Acond. de ventana – 10.000 BTU 1200 1800

Ventilador de ventana 300 600

Calefactor de caldera - 1/2 HP 800 1300

Cocina

Horno de microondas – 1.000 Vatios 1000 Cafetera 1500 Cocina eléctrica – Elemento simple 1500 Calientaplatos 2500 -

Habitación Familiar

Tocador de DVD/CD 100 VCR 100 Receptor estéreo 450 Televisor a color – 27 pulg. 500 Computadora personal con monitor de

17 pulg.

800 -

Otros

Sistema de seguridad 180 Radio-Reloj AM/FM 300 Abridor de garaje - 1/2 HP 480 520

Calentador eléctrico de agua - 40

galones

4000 -

Taller

Luz de halógeno para trabajar 1000 Rociador sin aire - 1/3 HP 600 1200

Sierra intercambiable 960 960

Taladro eléctrico - 1/2 HP 1000 1000

Sierra circular - 7 ¼ pulg. 1500 1500

Sierra inglete- 10 pulg. 1800 1800

Mesa de planificación – 6 pulg. 1800 1800

Sierra de mesa / sierra de brazo radial

– 10 pulg.

2000 2000

Compresor de aire - 1-1/2 HP HP =

Caballo de fuerza.

2500 2500

Figura 18 - Guia de Referencia de Vatiaje

Page 28

5500 Watt Pesado Generador

28

ESPECIFICACIONES

Potencia Máxima. . . . . . . . . . . . . . . . . . . . . 8,500 Vatios (8.5 kW)

Potencia de Sobretensión . . . . . . . . . . . . . . 5,500 Vatios (5.5 kW)

Voltaje Nominal AC . . . . . . . . . . . . . . . . . . . . . . . 120/240 Voltios

Corriente Máxima a 240 Voltios. . . . . . . . . . . . . . . 22.9 Amperios

Corriente Máxima a 120 Voltios. . . . . . . . . . . . . . . 45.8 Amperios

Frecuencia Nominal. . . . . . . . . . . . . . . . . . . . . . 60Hz a 3600 rpm

Fase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Monofásica

Tanque del Combustible . . . . . . . . . . . . . . 7 Galones Americanos

Peso que Embarca. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175 lbs.

RECOMENDACIONES

GENERALES DE

MANTENIMIENTO

El propietario / operador es responsable por asegurarse de que

todos los trabajos periódicos de mantenimiento se lleven a cabo

adecuadamente; que todos los problemas son resueltos; y que la

unidad se mantiene limpia y adecuadamente almacenada. Nunca

opere un generador que esté dañado o defectuoso.

Mantenimiento del Motor

Consulte el manual del propietario del motor para las

instrucciones de cómo mantener adecuadamente el motor.

¡PRECAUCIÓN! Evite el contacto prolongado o

repetido de piel con aceite usado de motor. El aceite usado

del motor ha sido mostrado al cancer de la piel de la causa

en ciertos animales del laboratorio. Completamente lavado

expuso áreas con el jabón y el agua.

MANTENGA FUERA DE ALCANCE DE NIÑOS. NO

CONTAMINE. CONSERVE los RECURSOS.VUELVA

ACEITE USADO A la COLECCION CENTRA.

Mantenimiento del Generador

El mantenimiento del generador consiste en conservar la unidad

limpia y seca. Opere y almacene la unidad en un ambiente limpio

y seco donde no será expuesta al polvo, suciedad, humedad o

vapores corrosivos. Las ranuras del aire de enfriamiento del

generador no deben estar tapadas con nieve, hojas, o cualquier

otro material extraños. Revise frecuentemente la limpieza del

generador y límpielo cuando esté con polvo, sucio, con aceite,

humedad, o cuando otras substancias extrañas sean visibles en su

superficie exterior.

NOTA: No recomendamos el uso de mangueras de jardín para

limpiar el generador. El agua podría introducirse en el sistema de

combustible del motor y causar problemas.Además,si el agua se

introduce al generador a través de las ranuras para aire de

enfriamiento, algo del agua quedará retenida en los espacios

vacíos y grietas del aislamiento del devanado del estator y rotor.

La acumulación de agua y suciedad en los devanados internos del

generador disminuirá eventualmente la resistencia del aislamiento

de estos devanados.

Para Limpiar el Generador

¡PRECAUCION! Nunca inserte objetos o

herramientas a través de las ranuras de enfriamiento de

aire, incluso si el motor no está en funcionamiento.

• Utilice un trapo húmedo para limpiar las superficies

exteriores.

• Puede usar un cepillo de cerdas suaves para retirar la

suciedad endurecida, aceite, etc.

• Puede usar una máquina aspiradora para eliminar suciedad y

residuos sueltos.

• Puede usar aire a baja presión (que no exceda los 25 psi) para

eliminar la suciedad. Inspeccione las ranuras para aire de

enfriamiento y la apertura del generador. Estas aperturas

deberán mantenerse limpias y despejadas.

ALMACENAMIENTO

El generador deberá ser encendido al menos una vez cada siete

días y deberá dejarlo funcionar al menos durante 30 minutos. Si

no puede hacer esto y debe almacenar la unidad por más de

30 días, siga las siguientes instrucciones para preparar su unidad

para almacenamiento.

Almacenando el Generador

• Limpie el generador como está descrito en (“Para Limpiar el

Generador”).

• Revise que las ranuras para el aire de enfriamiento y las

aperturas del generador se encuentren abiertas y despejadas.

¡PRECAUCIÓN! Las cubiertas para almacenamiento

pueden ser inflamables. No coloque una cubierta encima

de un generador caliente. Deje que la unidad se enfríe lo

suficientemente antes de que le coloque la cubierta.

Almacenando el Motor

Consulte el manual del propietario del motor para las

instrucciones de cómo preparar adecuadamente el motor para su

almacenamiento.

Otras Sugerencias Para el Almacenando

• No almacene gasolina de una estación a otra.

• Reemplace la caneca de gasolina si comienza a oxidarse. El

óxido y/o la suciedad en la gasolina le causará problemas.

• Almacene la unidad en un área limpia y seca.

Page 29

29

5500 Watt Pesado Generador

NOTAS

Page 30

5500 Watt Pesado Generador

30

DIAGNOSITICOS DE AVERÍAS

Problemo

Causa

Accion

El motor está

funcionando pero no

existe salida de AC

disponsible.

1. El interruptor automático de circuito está

abierto.

2. Conexión mal o defectuosa del juego de

cables.

3. El dispositivo conectado está dañado.

4. Avería en el generador.

1. Reposicione el interruptor.

2. Revise y repare.

3. Conecte otro dispositivo que esté buenas

condiciones.

4. Contacte el Departmento de Servicio

Generac.

El motor funciona bien

sin carga pero “funciona

mal” cuando se le

contectan cargas.

1. Corto circuito en una de las cargas

conectadas.

2. El generador está sobrecarga.

3. Velocidad del motor es muy lenta.

4. Circuito del generador en corto.

1. Desconecte la carga eléctrica en corto.

2. Vea “No Sobrerecarque el Generador” en la

página 27.

3. Contacte el Departmento de Servicio Briggs

and Stratton.

4. Contacte el Departmento de Servicio

Generac.

El motor no se

enciende; o se enciende

y funciona mal.

1. Interruptor Run/Stop poscioando en “Off”.

2. Válvula del Combustible en posición “Off”.

3. Depurador de aire sucio.

4. Sin gasolina.

5. Gasolina vieja.

6. El cable de la bujía no está en malas la bujía.

7. Bujía defectuosa.

8. Agua en la gasolina.

9. Sobrecebado.

10. Mezcla de combustible excesivamente rica.

11. La válvula de corte de combustible.

12. La válvula de entrada está atascada está

cerrada.

13. El motor ha perdido compresión.

1. Coloque del interruptor en “On”.

2. Gire la válvula del combustible a la posición

"On".

3. Limpie o reemplace el depurador de aire.

4. Llénelo con combustible fresco.

5. Drene el tanque de gasolina; llénelo con

combustible fresco.

6. Conecte el cable a la bujía.

7. Reemplace la bujía.

8. Drene el tanque de gasolina; llénelo con

combustible fresco.

9. Abra por completo el cebador y haga girar el

motor.

10. Contacte el Departmento de Servicio Briggs.

11. Contacte el Departmento de Servicio Briggs.

12. Contacte el Departmento de Servicio Briggs.

13. Contacte el Departmento de Servicio Briggs.

El motor se apaga en

pleno funcionamiento.

1. Sin gasolina.

2. Nivel de aceite bajo.

1. Llene el tanque de combustible.

2. Llene de caja del cigüeñal al nivel correcto.

Al motor le hace falta

potencia.

1. La carga es muy alta.

2. Filtro de aire sucio.

1. Vea “No Sobrerecarque el Generador” la

página 27.

2. Reemplace el filtro de aire.

El motor “no funciona

continuamente” o se

detiene.

1. El cebador fue abierto muy rápidamente.

2. Carburador con mezcla de aire-combustible

muy rica o muy pobre.

1. Mueva el cebador a la posición intermedia

hasta que el motor funcione suavemente.

2. Contacte el Departmento de Servicio Briggs.

Page 31

GARANTÍA LIMITADA

PÓLIZA DE GARANTÍA PARA LOS PROPIETARIOS DE PRODUCTOS PORTÁTILES GENERAC Efectiva desde el 1ro de Octubre, 2001

PERIODO DE GARANTÍA*

* El periodo de garantía comienza en la fecha de compra hecha por el primer consumidor al detal o usuario comercial, y continúa por el periodo de tiempo que

aparece en la tabla arriba mencionada. "Para uso del consumidor" significa, uso residencial por un consumidor al detal. "Para uso comercial" significa, todos los otros

casos, incluyendo el uso comercial, para generar un ingreso o por propósitos de alquiler. Una vez que el equipo ha sido usado comercialmente, debería ser

considerado como de uso comercial para las finalidades de esta garantía. El equipo usado, el equipo de demostración y el equipo usado como energía primaria en

lugares donde las utilidades públicas no están garantizados. Los accesorios tales como pistolas, mangueras,varillas y boquillas están excluidos de la garantía del

producto.

** El motor a gasolina y las baterías para el encendido, están garantizados por el fabricante de esos productos.

EL REGISTRO DE LA GARANTÍA NO ES NECESARIO PARA OBTENER LA GARANTÍA EN LOS EQUIPOS PORTÁTILES DE GENERAC.

GUARDE SU RECIBO DE COMPRA. SI USTED NO PROVEE LA PRUEBA DE LA FECHA DE LA COMPRA INICIAL,AL MOMENTO EN

QUE SE REQUIERA USAR LA GARANTÍA, LA FECHA DE LA FABRICACIÓN DEL EQUIPO SERÁ USADA PARA DETERMINAR EL

PERIODO DE GARANTÍA.

Acerca de la seguridad de su equipo:

Los Productos Portátiles Generac, reciben las reparaciones bajo la garantía y le pide disculpas por cualquier inconveniencia causada. Cualquier Concesionario de

Servicio Autorizado puede llevar a cabo reparaciones bajo la garantía. La mayoría de las reparaciones bajo la garantía son manejadas normalmente, pero algunas

veces la solicitud del servicio de garantía es posible que no sea apropiada. Por ejemplo, la garantía no será válida si el daño al equipo ocurrió debido al mal uso, falta

de mantenimiento adecuado, manejo, envío, almacenamiento o una instalación inadecuada. Similarmente, la garantía es anulada si el número de serial del equipo ha

sido removido o el equipo ha sido alterado o modificado.

Si un cliente no está de acuerdo con la decisión hecha por el Concesionario de Servicio, se llevará a cabo una investigación para determinar si la garantía se puede

aplicar. Pida al Concesionario de Servicio que entregue todos los hechos que soportan su decisión a su Distribuidor, para que éste los revise. Si el Distribuidor

decide que el reclamo es justificado, al cliente se le reembolsará completamente por todos esos artículos que están defectuosos. Para evitar un malentendido que

pueda ocurrir entre el Concesionario y el cliente, abajo aparecen algunos de las razones por las cuales el equipo puede fallar, y que la garantía no cubre:

Desgaste normal:

Equipo eléctrico al aire libre, como todos los aparatos mecánicos, necesita partes, servicio y reemplazo, periódicamente, para que funcione bien.Esta garantía

no cubre la reparación cuando el uso normal ha acabado con la vida de una parte en particular o del equipo.

Instalación y mantenimiento:

Esta garantía no se aplica al equipo o parte que ha estado sujeta a una instalación inadecuada, que no haya sido autorizada o a cualquier tipo de alteración, el

mal uso, negligencia, accidentes, sobrecarga, velocidad excesiva, mantenimiento inadecuado, reparación o almacenamiento, que según la opinión de los Productos

Portátiles Generac, han afectado desfavorablemente su rendimiento y fiabilidad. Esta garantía también no cubre el mantenimiento normal tales como ajustes,

limpieza del sistema de combustión y la obstrucción (debido a materias químicas, suciedad, carbón o cal, etc.)

Otras exclusiones:

También se encuentran excluidos de está garantía, el desgaste de los artículos tales como, conectadores,medidores de aceite, correas, anillos O, filtros,

empaque de la bomba, etc. las bombas que se hagan funcionar o trabajar sin agua, o daños y malfuncionamientos que resulten de accidentes, abusos,

modificaciones, alteraciones, un servicio inadecuado, congelamiento o deterioro químico.