Page 1

Portable Generator Owner's Manual

A his is the safety alert symbol. It is usedto alert you to potential personal injury hazards.Obey all safety messagesthat follow this symbol to avoid possible injury or death.

Questions? Help is just a moment away!

Call: Generac Generator Helpline - 1-800-270-1408 M-F 8-5 CT; Sat.8-4 CT

Web: www.generac-portables.com or www.briggsandstratton.com

Model No. 1642-0 (5,500Watt AC Generator) Manual No. 189027 Revision 2 (06/01/2001)

Page 2

EQUIPMENT

SAFETY RULES

DESCRIPTION

This generator is anengine-driven, revolving field,alternating

current (AC) generator. It was designedto supply electrical

power for operating compatible electrical lighting, appliance,

tool and motor loads.

This manual contains informationfor a generator that

operates 120and/or 240Volt AC, singlephase,60Hz devices

that require up to 5,500 watts (5.5 kW) of power that pull

up to 45.8 Amps at 120Vottsor 22.9 Amps at 240Volts.

CAUTION! Do Not exceed the generator's

wattage/amperage capacity.Add up the rated watts of all

devicesyou will connect to generator receptacles at one

time.This total should not be greater than 5,500 watts for

this generator. Review"Don't Overload the Generator" on

page 9.

The generator's revolvingfield isdriven at about 3,600 rpm

by a single-cylinder engine.

Every effort hasbeen made to ensure that informationin

this manual isaccurate and current However, Generac

reservesthe right to change,alter or otherwise improvethe

product and this document at any time without prior

notice.

Thisgenerator set was designed and manufactured for

specific applications. Do Not attempt to modify the unitor

use it for anyapplication it was not designed for. If you have

anyquestions about your generator's application, askyour

dealer or consult the factory.

The manufacturer could not possibly anticipate every

circumstance that might involvea hazard.For that reason

warnings in the manualand warnings on tags or decals

affixed to the unit are not all-inclusive. If you intendto

handle,operate or service the unit by a procedure or

method not specifically recommended by the manufacturer,

first make sure that such a procedure or method will not

render this equipment unsafeor pose a threat to you and

others.

Read this manual carefully and become familiar

with your generator set. Know its applications, its

limitations and any hazards involved.

_ AUTION! Do Not tamper with engine

The Emission Control System for this generator is

warranted for standards set by the Environmental

Protection Agency.For warranty informationrefer to the

engine owner's manual.

governed speed.High operating speeds are

dangerousand increaserisk of personal injuryor

damageto equipment.The generator supplies

correct rated frequency and voltage only when

running at proper governed speed.Incorrect

frequency and/or voltage can damagesome

connected electrical loads.Operating at excessively

low speedsimposesa heavy load.When adequate

engine power isnot availableengine life may be

shortened.

_, ARNING! You must isolatethe generator

from the electric utility usingapproved transfer

equipment if this unit isused for backup power.

Failure to isolate the generator from the

power utility may result in injury or death to

electric utility workers and damage to the

generator due to a backfeed of electrical energy.

Whenever the unit is providing backup power, the

electric utility must be notified.

_|k DANGER! Generator exhaust gases contain

DEADLY carbon monoxide gas. If breathed in

sufficient concentrations, carbon monoxide

can cause unconsciousness or death. Operate

this equipment outdoors where adequate ventilation

isavailable.

/

2

Page 3

• The generator produces avery powerful voltage that can

cause serious injury or death by electrocution. Never

touch bare wires or receptacles.Never permit a child or

any unqualified person to operate the generator.

• Never handle any kind of electrical cord or device while

standing in water, while barefoot or while hands or feet

are wet Death or serious injury from electrocution may

result.

• Use a ground fault circuit interrupter (GFCI) in any damp

or highly conductive area (such as metal decking or steel

work).

• Never useworn, bare,frayed or otherwise damaged

electrical cords with the generator. Death, serious injury

and property damagefrom electrical shock may result

• Gasoline is highly FLAMMABLE and its vapors are

EXPLOSIVE. Never allow smoking, open flames,

sparks or heat in the vicinity while handling

gasoline. Avoid spielinggasolineon a hot engine. Comply

with all laws regulating storage and handlingof gasoline.

• Do Not overfill the fuel tank.Always allow room for fuel

expansion.If tank is overfllled, fuel can overflow

onto a hot engine and cause a FIRE or an

EXPLOSION.

• Never store a generator with fuel in the tank where

gasolinevapors might reach an open flame, spark or pilot

light (ason a furnace, water heater,clothes dryer). FIRE

or an EXPLOSION may result.

• The unit requires an adequateflow of cooling air for its

continued proper operation. Never operate the unit

inside anyroom or enclosure where the free flow of

cooling air into and out of the unit might be obstructed.

Allow at least2 feet of clearanceon all sidesof generator,

evenwhile operating unit outdoors, or you could damage

the unit

• Never start, or stop the unit with electrical loads

connected to receptacles with the connected devices

turned ON. Start the engine and let it stabilize before

connecting any electrical loads. Disconnect all electrical

loads before shutting down the generator.

• Do Not insert anyobject through cooling slots of the

engine.Youcould damagethe unit or injure yourself.

• Never operate the generator:

in rain; in any enclosed compartment; when connected

electrical devices overheat; if electrical output is lost; if

engine or generator sparks; if flame or smoke is observed

while unit is running; if unit vibrates excessively.

GROUNDING THE

G EN ERATO R

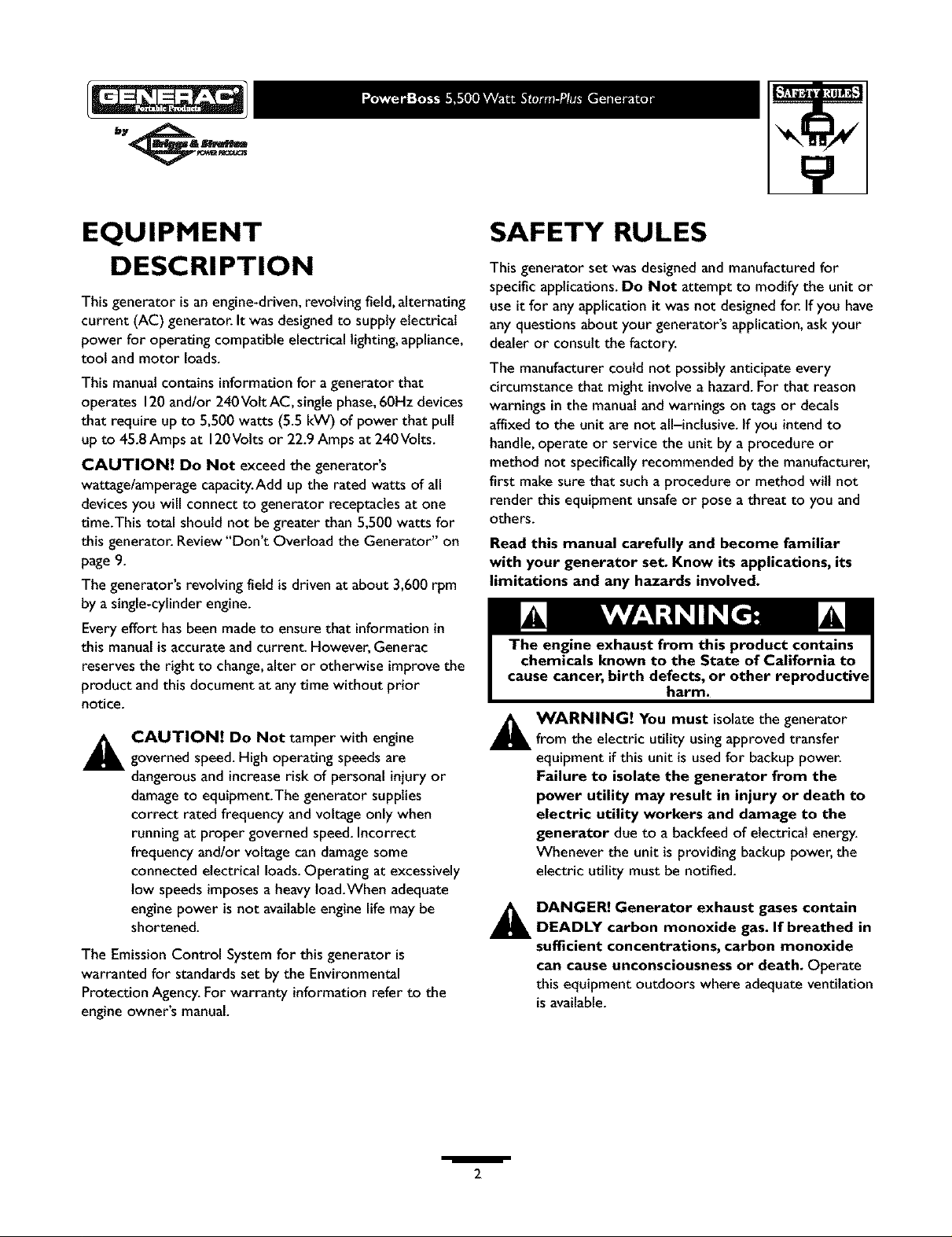

The National Electrical Code requires that the frame and

external electrically conductive parts of this generator be

properly connected to an approved earth ground. Local

electrical codes may also require proper grounding of the

unit. For that purpose, a GROUNDING WING NUT is

provided on the generator end (Figure I).

Generally,connecting a No. 12AWG (American Wire

Gauge) stranded copper wire to the grounding wing nut

and to an earth-driven copper or brassgrounding rod

(electrode) provides adequateprotection againstelectrical

shock. Be careful to keep the grounding wire attached after

connecting the stranded copper wire. However, local codes

may vary widely.Consult with a local electrician for

grounding requirements in your area.

Properly grounding the generator helps prevent electrical

shock if a ground fault condition exists in the generator or

in connected electrical devices.Proper grounding also helps

dissipatestatic electricity, which often builds up in

ungrounded devices.

/

3

Page 4

Yourgeneratorrequiressomeassemblyandis ready for

use after it has been properly serviced with the

recommended oil and fuel.

If you have any problems with the assembly of your

generator, please call the generator helpline at

1-800-270-1408.

IMPORTANT: Any attempt to run the unit before it has

been serviced with the recommended oil will result in an

engine failure.

CARTON CONTENTS

Check all contents. If anyparts aremissingor damaged,call

the generator helpline at 1-800-270-1408.

• The generator

• Generator and engine owner's manuals

• Locking 30Amp plug

• Engineoil

• Wheel kit

REMOVE G EN ERATOR

FROM CARTON

• Set the carton on arigid flat surfacewith "This SideUp"

arrows pointing upward.

• Carefully open the top flaps of the shippingcarton.

• Cut down corners at one end of carton from top to

bottom and laythat side of carton down flat

• Removeall packingmaterial, carton fillers, etc.

• Removethe generator from the shipping carton.

Cap Screw

\

\

Handle Assembly

\

\

INSTALL WHEEL KIT

IMPORTANT:This wheel kit is not intended for

over-the-road use.

To installyour wheel kit you need the followingtools:

• Two 13mm box, openend, or socket wrenches

Install Wheel Kit as follows:

I. Placethe bottom of the generator cradle on a flat,

even surface.Temporarily place uniton blocks to ease

assembly.

2. Slide axle through both axle mounting brackets on

cradle frame, as shown in Figure 2.

Hex

Mounting Leg J

Use Existing Fasteners

FlatWasher

Axle

/

Wheel

Retaining Pin

/

4

O_

/

F

/

Page 5

3. Slideawheel over the axle.

NOTE: Be sure to installboth wheelswith the air

pressure valve on the outboard side.

4. Retain wheel on axle with the retaining pin.You may

acidthe fiat washer if desired.

5. Repeat step 3 and 4 to secure second wheel.

6. Removethe existing hardware from the vibration

mounts with 13mm wrench. Use the samehardware to

attach the mounting leg.

7. Removethe temporary blocks.

8. Center the handle bracket on generator frame at

control panel end of cradle.

9. Attach handle bracket with two cap screws and two

hex nuts. Use two 13mm wrenches to tighten

hardware.

Add Gasoline

_hL WARNING! Never fill fuel tank indoors. Never

fill fuel tank when engine is running or hot. Do Not

light a cigarette or smoke when filling the fuel tank.

_ WARNING! Do Not overfill the fuel tank.

Always allow room for fuel expansion.

• Use regular UNLEADED gasoline with the generator

engine.Do Not use premium gasoline.Do Not mix oil

with gasoline.

• Clean area around fuel fill cap,remove cap.

• Add unleaded regular gasoline,slowly to fuel tank. Be

careful not to overfill.Allow about I/2" of tank spacefor

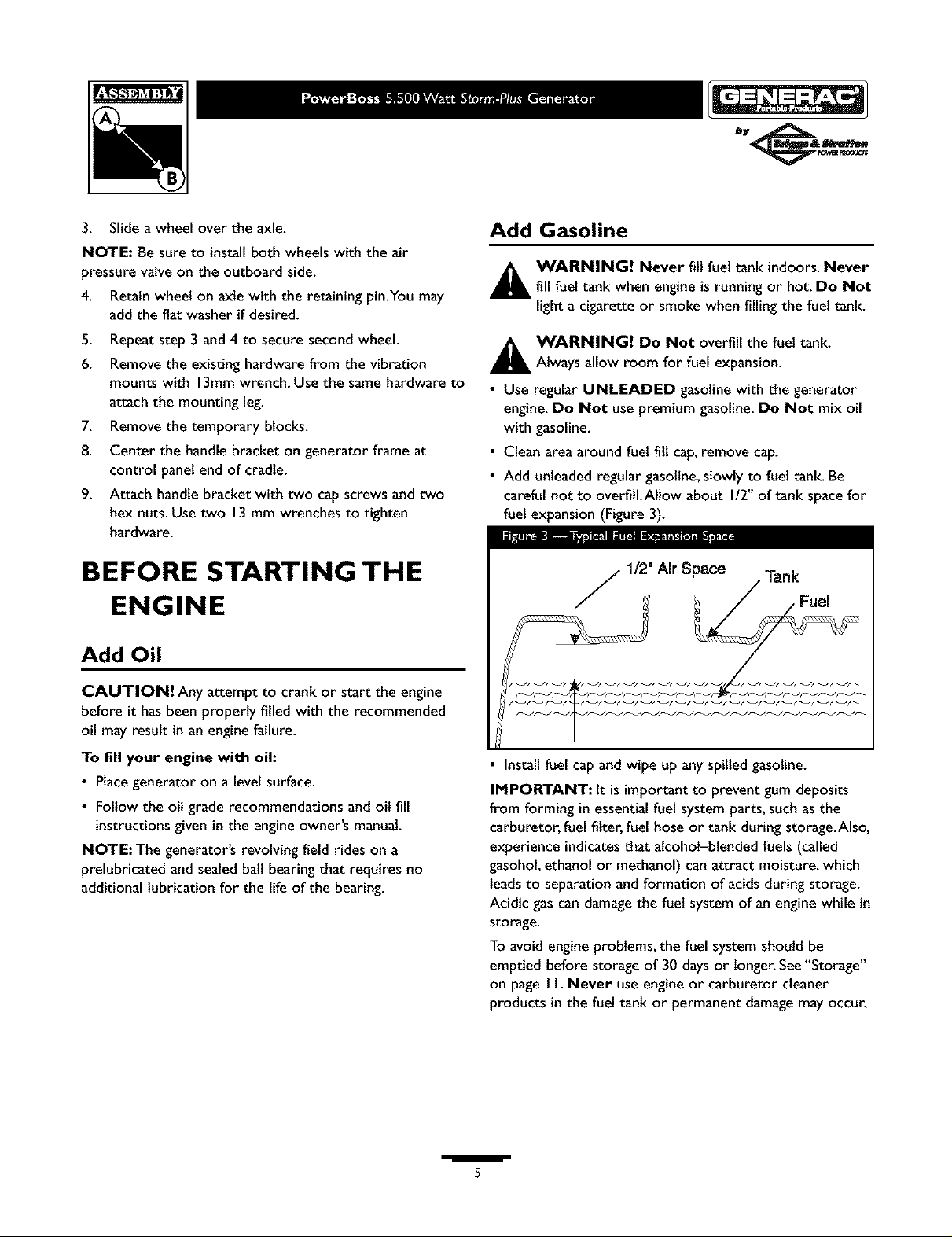

fuel expansion (Figure 3).

BEFORE STARTING THE

ENGINE

Add Oil

CAUTION! Any attempt to crank or start the engine

before it has been properly filled with the recommended

oil may result in an engine failure.

To fill your engine with oil:

• Place generator on a level surface.

• Follow the oil grade recommendations and oil fill

instructions given in the engine owner's manual.

NOTE:The generator's revolving field rides on a

prelubricated and sealed ball bearing that requires no

additional lubrication for the life of the bearing.

1/2" Air Space Tank

• Install fuel cap and wipe up any spilled gasoline.

IMPORTANT: It is important to prevent gum deposits

from forming in essential fuel system parts, such asthe

carburetor, fuel filter, fuel hose or tank during storage.Also,

experience indicates that alcohol-blended fuels (called

gasohol, ethanol or methanol) can attract moisture, which

leads to separation and formation of acids during storage.

Acidic gas can damage the fuel system of an engine while in

storage.

To avoid engine problems, the fuel system should be

emptied before storage of 30 days or longer. See "Storage"

on page I I. Never use engine or carburetor cleaner

products in the fuel tank or permanent damage may occur.

/

5

Page 6

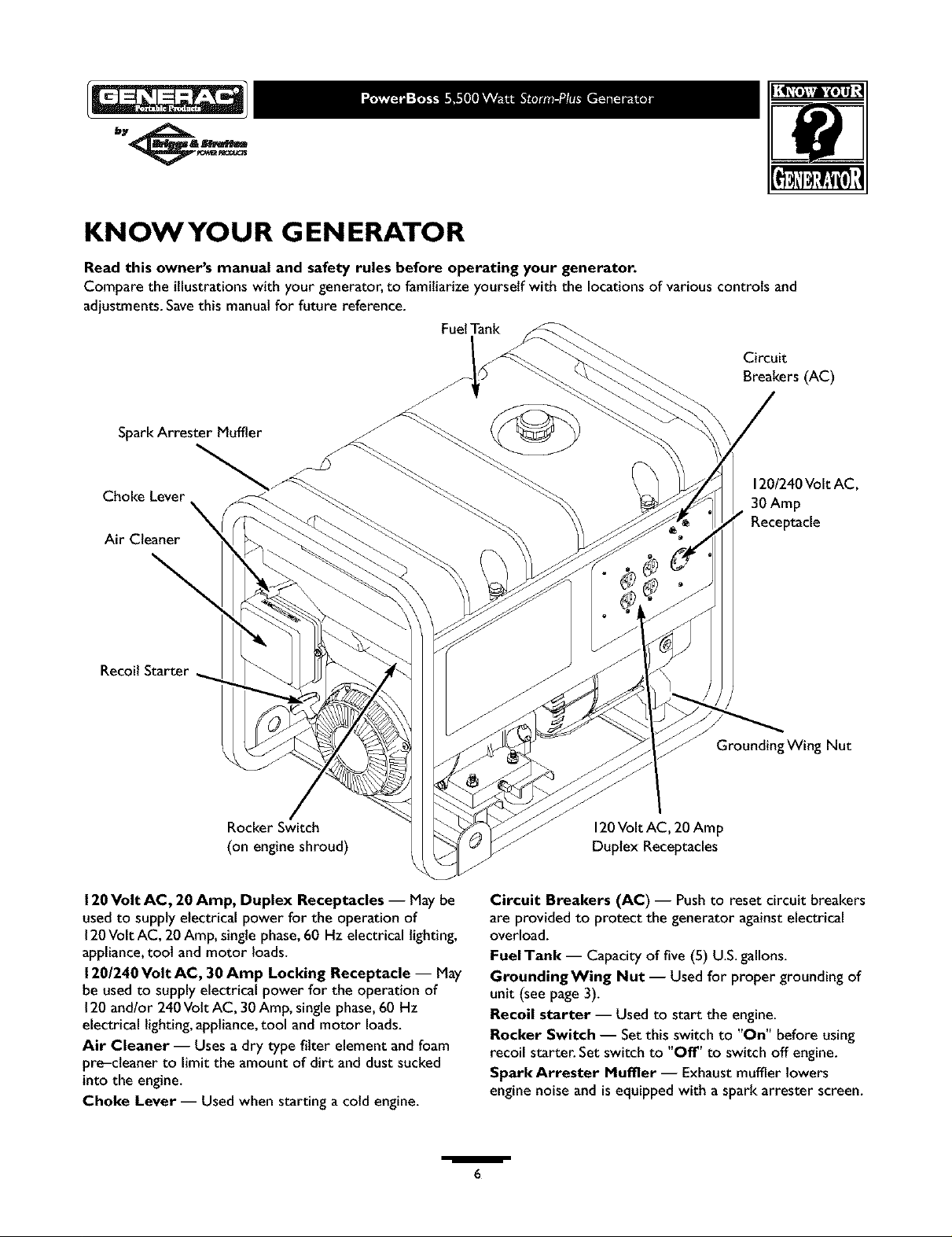

KNOWYOUR GENERATOR

Read this owner's manual and safety rules before operating your generator.

Compare the illustrations with your generator, to familiarize yourself with the locations of various controls and

adjustments. Save this manual for future reference.

FuelTank

Circuit

Breakers (AC)

SparkArrester Muffler

Choke Lever

Air Cleaner

Recoil Starter

Rocker Switch

(on engine shroud)

120Volt AC, 20 Amp, Duplex Receptacles -- May be

usedto supply electrical power for the operation of

120Volt AC, 20 Amp, singlephase,60 Hz electrical lighting,

appliance,toot and motor loads.

120/240 Volt AC, 30 Amp Locking Receptacle -- May

be usedto supply electrical power for the operation of

120and/or 240Volt AC, 30Amp, singlephase,60 Hz

electrical lighting,appliance,tool and motor loads.

Air Cleaner -- Uses a dry type filter element and foam

pre-cteaner to limit the amount of dirt and dust sucked

into the engine.

Choke Lever -- Usedwhen starting a cold engine.

120/240Volt AC,

30 Amp

Receptacle

Grounding Wing Nut

120Volt AC, 20 Amp

Duplex Receptacles

Circuit Breakers (AC) -- Pushto reset circuit breakers

are provided to protect the generator againstelectrical

overload.

Fuel Tank -- Capacity of five (5) U.S.gallons.

GroundingWing Nut -- Used for proper grounding of

unit (seepage 3).

Recoil starter -- Used to start the engine.

Rocker Switch -- Set this switch to "On" before using

recoil starter. Set switch to "Off" to switch off engine.

Spark Arrester Muffler -- Exhaust muffler lowers

engine noise and is equipped with a spark arrester screen.

/

6

Page 7

OPERATING THE

G EN ERATO R

,_ CAUTION! Never start or stop the engine with

electrical loadsconnectedto the receptaclesAND

with the connected devices turned ON.

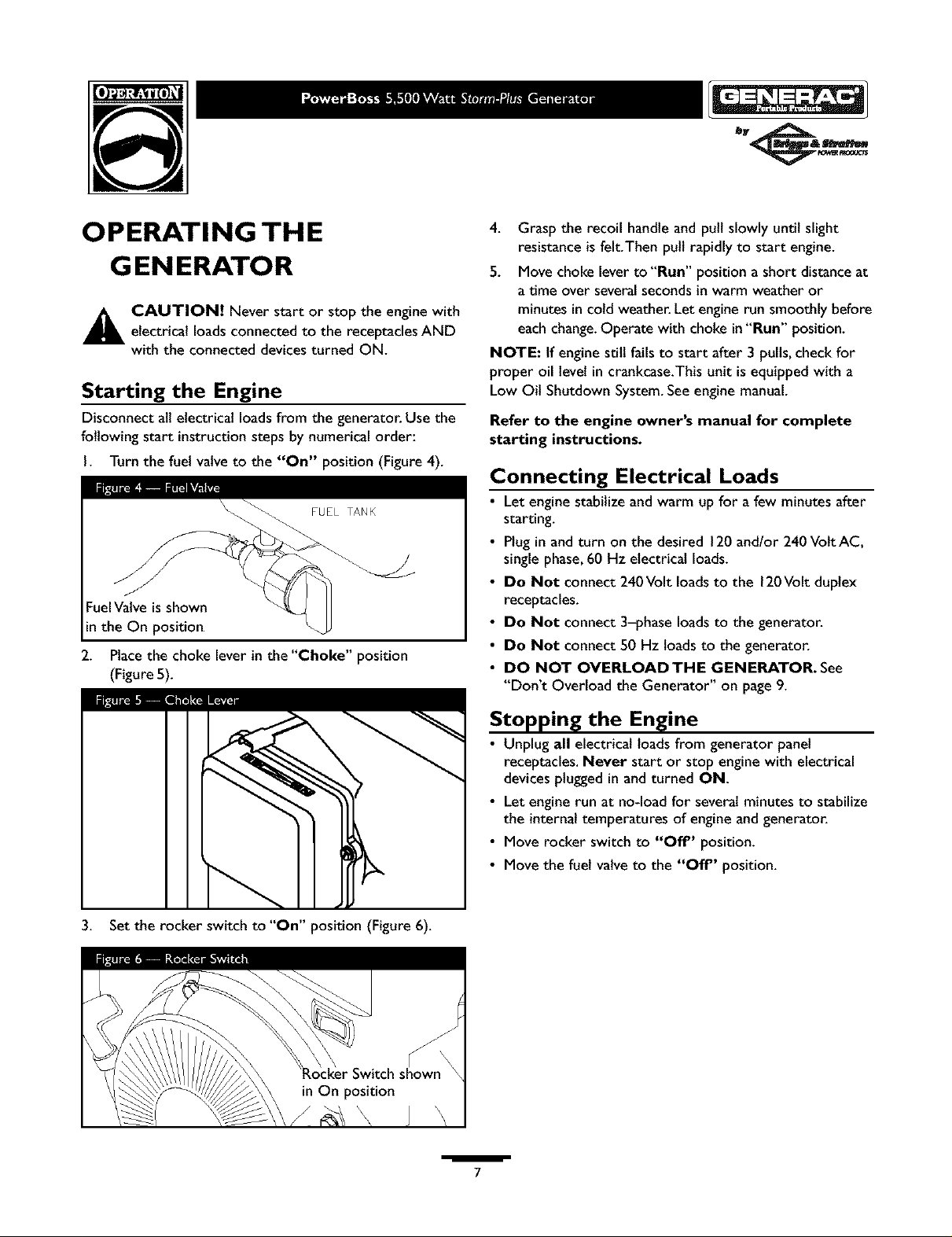

Starting the Engine

Disconnect all electrical loadsfrom the generator. Use the

following start instructionsteps by numerical order:

I. Turn the fuel valve to the "On" position (Figure 4).

FuelValveisshown

in the On position

2. Placethe choke leverin the "Choke" position

(Figure5).

mu

4. Grasp the recoil handle and pull slowly untilslight

resistance isfelt.Then pull rapidly to start engine.

5. Move choke leverto "Run" position a short distanceat

a time over severalsecondsin warm weather or

minutes in cold weather.Let engine run smoothly before

eachchange.Operate with choke in"Run" position.

NOTE: If engine still failsto start after 3 pulls,check for

proper oil level in crankcase.This unit isequipped with a

Low Oil Shutdown System.Seeengine manual.

Refer to the engine owner's manual for complete

starting instructions.

Connecting Electrical Loads

• Let engine stabilize and warm up for a few minutes after

starting.

• Plug in and turn on the desired 120and/or 240 VottAC,

singlephase,60 Hz electrical loads.

• Do Not connect 240Volt loads to the 120Volt duplex

receptacles.

• Do Not connect 3_hase loadsto the generator.

• Do Not connect 50 Hz loads to the generator.

• DO NOT OVERLOADTHE GENERATOR. See

"Don't Overload the Generator" on page9.

Stopping the Engine

• Unplug all electrical loads from generator panel

receptacles.Never start or stop engine with electrical

devicesplugged in and turned ON.

• Let engine run at no-load for several minutes to stabilize

the internal temperatures of engine andgenerator.

• Move rocker switch to "Off" position.

• Move the fuel valve to the "Off" position.

3. Set the rocker switch to "On" position (Figure 6).

in On

I

7

Page 8

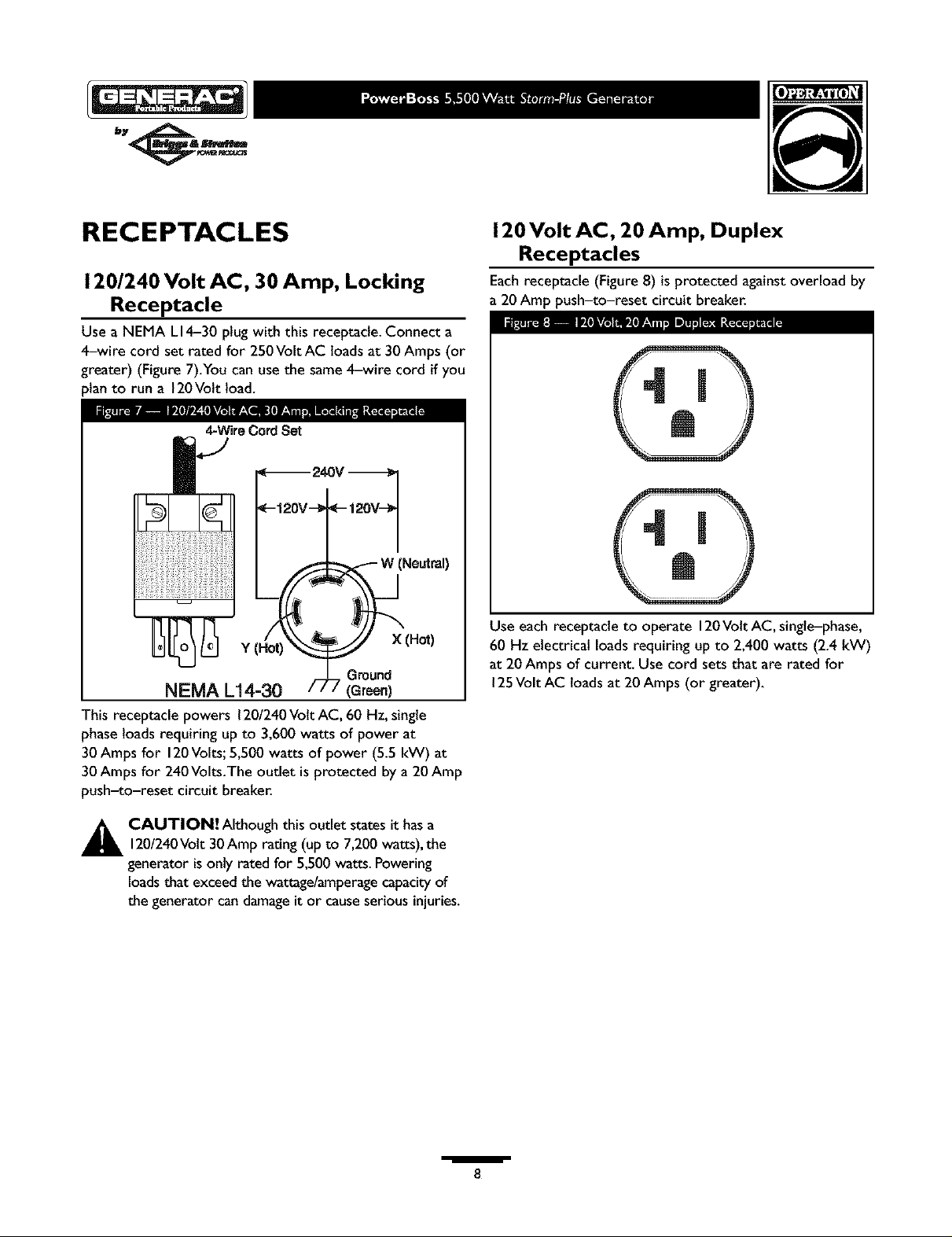

RECEPTACLES

120/240 Volt AC, 30 Amp, Locking

Receptacle

Use a NEMA LI4-30 plugwith this receptacle.Connect a

4-wire cord set rated for 250Volt AC loads at 30 Amps (or

greater) (Figure 7).You can usethe same 4-wire cord if you

_lanto run a 120Volt load.

4-Wire CordSet

Y (Hot) X (H_)

Ground

NEMA L14=30 (Green)

This receptacle powers 120/240Volt AC, 60 Hz,single

phaseloads requiring up to 3,600 watts of power at

30 Amps for 120Volts;5,500 watts of power (5.5 kW) at

30 Amps for 240Volts.The outlet isprotected bya 20 Amp

push-to-reset circuit breaken

120 Volt AC, 20 Amp, Duplex

Receptacles

Eachreceptacle (Figure 8) isprotected against overload by

a 20 Amp push-to-reset circuit breaker.

Use each receptacle to operate 120Volt AC, single-phase,

60 Hz electrical loadsrequiring up to 2,400 watts (2.4 kW)

at 20Amps of current. Use cord sets that are rated for

125Volt AC loadsat 20Amps (or greater).

_, AUTION! Although this outlet states it has a

120/240 Volt 30 Amp rating (up to 7,200 watts), the

generator isonly rated for 5,500 watts. Powering

loads that exceed the wattage/amperage capacity of

the generator can damage it or cause serious injuries.

/

8

Page 9

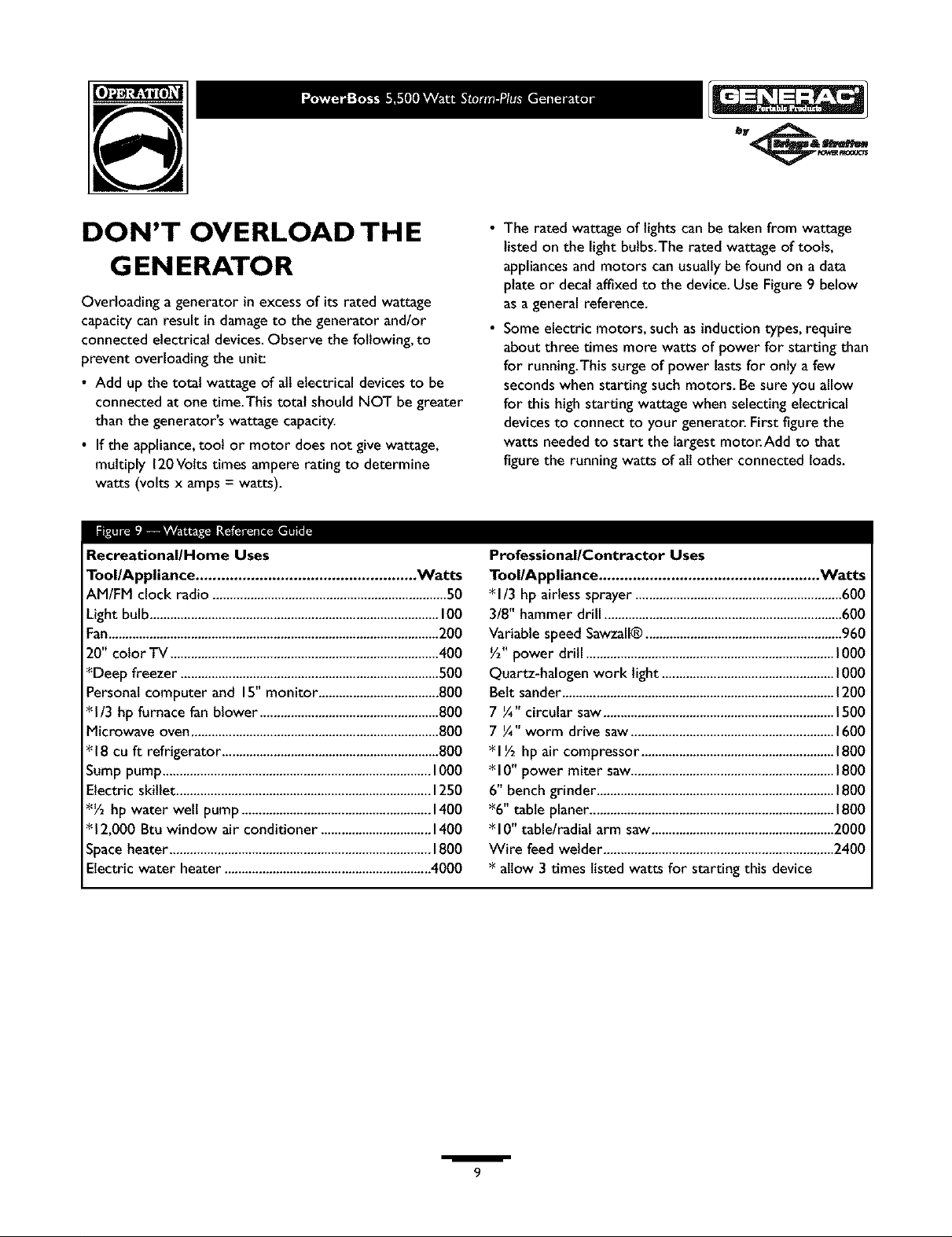

DON'T OVERLOAD TH E

G EN ERATO R

Overloading a generator in excess of its rated wattage

capacity can result in damageto the generator and/or

connected electrical devices.Observe the following, to

prevent overloading the unit:

• Add up the total wattage of all electrical devices to be

connected at one time.This total should NOT be greater

than the generator's wattage capacity.

• Ifthe appliance,tool or motor does not give wattage,

multiply 120Volts times ampere rating to determine

watts (volts x amps = watts).

The rated wattageof lights can be taken from wattage

listed on the lightbulbs.The rated wattageof tools,

appliancesand motors can usually be found on adata

plate or decal affixed to the device. Use Figure 9 below

asa general reference.

Someelectric motors, such asinductiontypes, require

about three times more watts of power for starting than

for running.This surge of power lastsfor only afew

secondswhen starting such motors. Be sure you allow

for this high starting wattage when selectingelectrical

devicesto connect to your generator. First figure the

watts needed to start the largest motor.Add to that

figure the running watts of all other connected loads.

Recreational/Home Uses

Tool/Appliance .................................................... Watts

AM/FM clock radio ....................................................................50

Light bulb....................................................................................100

Fan................................................................................................200

20" color TV ..............................................................................400

*Deep freezer ...........................................................................500

Personal computer and 15" monitor ...................................800

*1/3 hp furnace fan blower ....................................................800

Microwave oven ........................................................................800

*18 cu ft refrigerator ...............................................................800

Sump pump ..............................................................................1000

Electric skillet ..........................................................................1250

*Y2 hp water well pump .......................................................1400

*12,000 Btu window air conditioner ................................1400

Space heater ............................................................................1800

Electric water heater ............................................................4000

Professional/Contractor Uses

Tool/Appliance .................................................... Watts

"1/3 hp airless sprayer ............................................................600

3/8" hammer drill .....................................................................600

Variable speed Sawzall® .........................................................960

Y2" power drill ........................................................................1000

Quartz-halogen work light ..................................................1000

Belt sander ...............................................................................1200

7 ¼" circular saw ...................................................................1500

7 ¼" worm drive saw ...........................................................1600

*1/2 hp air compressor ........................................................1800

* I 0" power miter saw ...........................................................1800

6" bench grinder .....................................................................1800

*6" table planer.......................................................................1800

* I 0" table/radial arm saw .....................................................2000

Wire feed welder ...................................................................2400

* allow 3 times listed watts for starting this device

I

9

Page 10

SPECIFICATIONS

Maximum SurgeWatts ................. 8,500 watts

Continuous Wattage Capacity ........... 5,500 watts

Power Factor .............................. 1.0

Rated Maximum Continuous AC LoadCurrent:

At 120Volts ....................... 45.8Amps

At 240 Volts ....................... 22.9Amps

Phase................................. I-phase

Rated Frequency ....................... 60 Hertz

FuelTank Capacity................... 5 U.S.gallons

ShippingWeight ......................... 148 Ibs.

GENERAL MAINTENANCE

RECOMMENDATIONS

The Owner/Operator is responsible for making sure that

all periodic maintenance tasks are completed on atimely

basis;that all discrepancies are corrected; and that the unit

is kept clean and properly stored. Never operate a

damaged or defective generator.

Engine Maintenance

See engine owner's manual for instructions.

If you need service for your engine, you need to determine

the engine identification number.To do so, remove the

rocker arm cover hood, item number 55 shown on page

16, by removing the four nuts and washers holding it in

place.The engine model-type-trim number is stamped on

the side of the inner cover attached to the engine. Have

this number in hand when you call the engine service

center for assistance.

Generator Maintenance

Generator maintenance consists of keeping the unit clean

and dry. Operate and store the unit in a clean dry

environment where it will not be exposed to excessive

dust, dirt, moisture or any corrosive vapors. Cooling air

slots in the generator must not become clogged with snow,

leaves or any other foreign material.

NOTE: Do Not use a garden hose to clean generator.

Water can enter engine fuel system and cause problems. In

addition, if water enters generator through cooling air slots,

some of the water wilt be retained in voids and cracks of

the rotor and stator winding insulation.Water and dirt

buildup on the generator internal windings will eventually

decrease the insulation resistance of these windings.

To Clean the Generator

_, AUTION! Never insert anyobject or tool

through the air cooling slots, even ifthe engine is

not running.

• Use a damp cloth to wipe exterior surfaces clean.

• A soft bristle brush may be used to loosen caked on dirt

or oil.

• A vacuum cleaner may be used to pick up loose dirt and

debris.

• Low pressure air (not to exceed 25 psi) may be used to

blow awaydirt. Inspect cooling air slots and opening on

generator.These openings must be kept clean and

unobstructed.

_, AUTION! Avoid prolonged or repeated skincontact with used motor oil. Used motor oil has

been shown to causeskin cancer in certain

laboratory animals.Thoroughly wash exposed areas

with soap and water.

KEEPOUT OF REACH OF CHILDREN. DON'T

POLLUTE.CONSERVE RESOURCES.RETURN

USED OIL TO COLLECTION CENTERS.

/

10

Page 11

STO RAG E

The generator should be started at least once every seven

days and allowed to run at least 30 minutes. If this cannot

be done and you must store the unit for more than

30 days,usethe following guidelinesto prepare it for

storage.

_ CAUTION! Storage covers can be flammable.

Oo Not place a storage cover over a hot

generator. Let the unit cool for a sufficient time

before placingthe cover on the unit.

Engine Storage

Seeengine owner's manualfor instructions.

Generator Storage

• Clean the generator asoutlined in"To Clean the

Generator"

• Check that cooling air slots and openings on generator

are open and unobstructed.

Other Storage Tips

• Do Not store gasolinefrom one seasonto another.

• Replacegasoline can if it starts to rust. Rust and/or dirt

in gasoline can causeproblems when that fuel is used

with this unit.

• Store in clean and dry area.

/

II

Page 12

TROUBLESHOOTING

Problem

Engine is running, but

no AC output is

available.

Engine runs good but

bogs clown when

loads are connected.

Engine will not start;

or starts and runs

rough.

Cause

I. Circuit breaker is open.

2. Poor connection or defective cord set.

3. Connected device is bad.

4. Fault ingenerator.

I. Short circuit in a connected load.

2. Generator is overloaded.

3. Engine speed is too slow.

4. Shorted generator circuit.

I. Rocker switch set to "Off'.

2. Low oil level.

3. Dirty air cleaner.

4. Out of gasoline.

5. Stalegasoline.

6. Sparkplug wire not connected to

spark plug.

7. Badspark plug.

8. Water in gasoline.

9. Overchoking.

10. Excessivelyrich fuel mixture.

I I. Intake valve stuck open or closed.

12. Enginehaslostcompression.

Solution

I. Reset circuitbreaker.

2. Check and repair.

3. Connect another device that isingood

condition.

4. Contact Generac service facility.

I. Disconnectshorted electrical load.

2. See"Don't Overload the Generator" on

page9.

3. Contact Briggsservice facility.

4. Contact Generac service facility.

I. Setswitch to "On".

2. Fill crankcaseto proper level.

3. Cleanor replace air cleaner.

4. Fillfuel tank.

5. Drain gastank and fill with fresh fuel.

6. Connect wire to spark plug.

7. Replacespark plug.

8. Drain gastank; fill with fresh fuel.

9. Setchoke to "Off' position.

10. Contact Briggsservice facility.

I I. Contact Briggsservice facility.

12. Contact Briggsservice facility.

Engine shuts down I. Out of gasoline. I. Fill fuel tank.

during operation. 2. Fault in engine. 2. Contact Briggs service facility.

I. Load istoo high. See "Don't Overload the Generator" on

Engine lacks power. 2. Dirty air filter. Replace air filter.

3. Engine needs to be serviced. Contact Briggs service facility.

I. Choke is opened too soon.

Engine "hunts" or

falters.

2. Carburetor is running too rich or too

lean.

/

12

I.

page 9.

2.

3.

I.

Move choke to halfway position till engine

runs smoothly.

2.

Contact Briggs service facility.

Page 13

NOTES

/

13

Page 14

SCHEMATIC

BRIDGE

RECTIFIER

÷

CB

2OA

BLUE

BLUE

(ii>

BLUE

(IIA)

(i>

BLUE (2)

RED

(22)

RED

RED

(22)

(22)

RED

(22)

GREEN

(0)

EXCITATION

FIELD

120V/20A

RED (6)

BLUE

(IIA)

(4)

GRAY

(44)

GRAY

(44)

GRAY

(44A)

BLUE_

(IIA)

BLUE

(IIA)

120/240V/30A

(22)

/

14

Page 15

÷

WIRING DIAGRAM

ii IIA

CIRCUIT

BREAKER

)

20A

CIRCUIT

BREAKER

120V

20A

22

WARNING!

TAB MUSTNOT BE BROKEN

NDTE_ POSITIVE BRUSH [2 CLOSEST TO BEARING

_ _LUE

RED (2)

(6)

/

15

SIX LUG

CONNECTOR

HOU£ING

Page 16

EXPLODED VIEW

45

\

- MAIN UNIT

56

57

68

\

N

41

59

\

65

\

37

57

29

8 7,

28

62

15

27

6

\

10

5

$

18 17 _

_55

46

/47

3O

16_ _9

26

33

64

67

/

16

61

23

21

J65

Page 17

PARTS LIST - MAIN UNIT

Item Part#

I BI89010

2 B92531

3 B92731

4 66365G

5 187746

6 187745

7 65791

8 96796

9 22129

10 86307

II 99383

12 92609

13 189127

14 92532

15 188551

16 66476

17 188213

18 60706

19 83083

20 81917

21 67989

22 189027

23 189160

24 JI89011

25 66825B

26 74908

27 86308A

28 84409

29 22695

30 84242

31 188826

32 91825

33 66849

34 B4871

35 22769

36 86494

Qty

Description

CRADLE

SUPPORT,Engine

SUPPORT,Engine& Muffler

HOUSING, EngineAdapter

ASSEMBLY,Rotor (Inclds Item 7)

ASSEMBLY,Stator

BEARING

WASHER, M8 Flat

2

WASHER, M8 Lock

4

SCREW,5/16-24 x 3/4 SEMS

I

SCREW,5/I 6-24 x 7-3/8

2

MOUNT, Vibration

I

GROMMET,Rubber

I

BRACKET,Muffler

I

GASKET,Exhaust

2

SCREW,M6-1 x 12w/Lock

Washer

I

MUFFLER

2

SCREW,5/16 - 18x 3/4"

I

SCREEN,SparkArrest

I

PIN,4mm x 10 Roll

8

NUT, FlangeSerrated

I

MANUAL, Owners

4

NUT, 5/16-18, FlangedSerrated

I

SHIELD,Heat

I

CARRIER,Rear Bearing

4

TAPTITE,M5-0.8 x 10

4

BOLT,M6-1 x 145mm Stator

I

SLEEVING,Flexo, I/2" X 15"

I

FASTEN,On Tab Housing 6P

I

GROMMET,Plastic

I

MANUAL, Engine

I

ASSEMBLY,Brush Holder

2

TAPTITE,M5-0.8 x 16

I

COVER, Bearing Carrier

I

WASHER,#10 Int. Shakeproof

I

SCREW,M6-1.0 x 16Wing

Item Part# Qty

37 B2153 13

38 189155 4

39 188973 4

40 189156 4

41 80270 I

42 78299 I

43 85134 I

44 188817 I

45 189235

46 22097

47 22127

48 14353621

49 26850

50 B4986

51 92982

52 189153

53 B5072

54 BB3061

55 187330

56 189025

57 189024

58 189018

59 NSP

60 39414

61 22142

62 67022

63 189186

64 77816

65 43438

66 73054

67 20566

68 30340

69 48031C

70 J189297

71 86292

Description

SCREW,# I0 Self Drilling

WASHER,Flat,6.6 x 21.6 x 1.9

GROMMET,Tank

HHCS, M6-1.0 x 25

VALVE,Tank

BUSHING, PlasticTank

CAP,Fuel Gauge

TANK, Fuel,5 Gallon

(Includes Items 41 & 42)

DECAL, Start Instructions

WASHER,Lock

NUT, I/4-20

WIRE, Ground

WASHER,M6 Shakeproof

DECAL, Ground, Green

DECAL, Danger

DECAL, Heat Shield

MOUNT, Vibration

BOTTLE,Oil, 28 oz

HOOD, Rocker Arm Cover

DECAL, Panel,Side

DECAL, Control Panel

ASSEMBLY,Control Panel

ENGINE

HHCS, M8 - 1.25x 35

SCREW,5//16 - 18x 3/4"

GROMMET,Rubber

DECAL, Cover,Air Cleaner

DECAL, Hot Muffler

PLUG, 250V,30A

DECAL, Shut-Off, Fuel

DECAL, 1-800#

HOSE, I/4" x 7.5"

CLAMP

STRAP,Tank, Fuel

SCREW,# I0 Self Drilling

/

17

Page 18

EXPLODEDVIEWAND PARTS LIST-WHEEL KIT

3

/

5

e/ c_"

USE EXISTING FASTENERS

TO SECURE ITEM #2

Item Part # Qty Description

I B4217 I ASSEMBLY,Handle

2 BI764 I LEG, Mounting

3 52858 2 NUT, Locking Hex M8 - 1.25

4 39287 2 HHCS, M8 - 1.25x 45

5 93693H I AXLE

6 B4966 2 WHEEL, 10" Diameter

7 87005A 2 PIN, Retaining

8 22247 2 WASHER, Flat

6 /

7

/

18

Page 19

EXPLODED VIEW AND PARTS LIST- CONTROL PANEL

9

11

9

\

\ 7

8

10 13

9

8

7

5

1

\

\_ 2

3

3

Item

2

3

4

5

6

7

8

9

10

II

12

13

I

Part#

BI89015

75475

82308

82881

23365

43437

38150

22264

51715

75207

68759

81919

22694

Qty Description

I PANEL,Control

6 SCREW,M4 - 0.7 x 10mm

6 SCREW,SelfTapping

2 WASHER, InternalLock

6 WASHER, No. 8 Serrated Lock

I OUTLET, 120/240 Locking, 30 Amp

6 WASHER, No. 8 Flat

6 WASHER, No. 8 Lock

6 NUT, M4 0.7 Hex

2 CIRCUIT BREAKER,20 amp

2 OUTLET, 120Volt, 20 amp Duplex

I CONTROL PANEL,Back. Plastic

I CONNECTOR, 6-Pin

/

19

Page 20

DESCRIPCION DEL EQUIPO

Este generador funciona en base a un motor, de campo el_ctrico

giratorio y de corriente alterna (AC). Fue disefiado con la

finalidad de proveer energia el_ctrica para luces el_ctricas,

aparatos,herramientas compatibles y cargas de motor.

Este manual contiene lainformaci6n para un generador que opera

120y/o 240Voltios de corriente alterna (AC), de fase sencilla,

aparatos de 60Hz que requieren hasta5,500 vatios (5.5 kW) de

energia y que necesitan hasta 45.8Amps a 120Voltios o

22.9Amperios a 240Voltios.

|PRECAUCION! No sobrepase la capacidadde vatale y

amperaie del generador. Sumea lavez,todos los ratios de los

aparatos que usted estar_ conectando algenerador. Estetotal no

deberia pasar de 5,500 vatios para estegenerador en particular.

Revise"No sobrecargue el Generador" en la p_gina27.

El campo giratorio del generador funciona a una velocidad de

3,6000 rpm usando un motor con un solo cilindro.

Se ha hecho cada esfuerzo posible para asegurarse que la

informaci6n que aparece en este manual es exacta y se encuentra

actualizada. Sin embargo, Generac se reserva el derecho a

cambiar, alterar o de otra manera mejorar, el producto y este

documento en cualquier momento, sin previo aviso.

INSTRUCCIONES DE SEGURIDAD

Estegenerador rue dise_ado y fabricadopara usosespecificos. No

intente modificar la unidad o usarla para otro uso para el cualno

rue disefiado.Si usted tiene alguna pregunta acercadel uso del

generador,preg_ntele a su vendedor o consulte con el fabricante.

No es posible que el fabricante pueda predecir cadacircunstancia

que pueda representar un peligro. Por esta raz6n, lasadvertencias

colocadasen el manual yen las etiquetas, o calcomanias colocadas

en la unidad, no son inclusivas.Si usted intenta manejar,operar, o

hacerle servicio a la unidad mediante un procedimiento o m_todo

que no es recomendado especiflcamente por el fabricante,

primeramente asegfireseque eseprocedimiento o m_todo no

har_ que la unidad seainsegura o que represente un peligro para

usted y los demos.

Lea este manual de manera cuidadosa y familiaricese con

su generador. Conozca sus usos, sus limitaciones y

cualquier peligro relacionado con el mismo.

_IL iPRECAUCI_N! No intente modificar lavelocidad

que produce el moto_ Lasvelocidades altas de operaci6n

son muy peligrosas,y aumentan el riesgo de accidentes

personales o daffo alequipo.El generador suministra una

frecuencia correcta y elvoltaje solamente cuando funciona

a la velocidad adecuada.Lafrecuencia incorrecta y el

voltaje incorrecto pueden daffaralgunascargasel_ctricas

conectadas al mismo. Sial generador se le hace funcionar a

velocidades excesivamente baias,sele estar_ sometiendo a

unacargamuy pesada.Cuando la energtaadecuadadel

motor no seencuentra disponible, sepuede acortar la

vida fitil del motor.

El Sistema de Control de Emisiones para este generador est_

garantizado para juegos est_ndares por la Agencia de Protecci6n

Ambiental. Para mayor informaci6n acerca de la garantla, consulte

con el manual del propietario del motor.

_ iPELIGRO! Siesta unidad se usapara energta de

refuerzo, usted debe aislar el generador de cualquier

utilidad el_ctrica usando un equipo de transferencia

aprobado. Si no se aisla de la manera adecuada,

puede resultar en un accidente e inclusive la

muerte para los electricistas que trabajen alli y pot

Io tanto, dafio al generador debido a la

retroalimentaci6n de energtael_ctriea.Entodo momento

que la unidadest_ proveyendo energiade refuerzo, la

compa_tael_ctricade utilidadesdebeser notificada.

_ PELIGRO! Los gases provenientes del generadorcontienen mon6xido de carbono, el cual puede

causar la MUERTE. Si se respira en

concentraciones sufidentes, el mon6xido de

carbono puede hacer que la persona quede

inconsciente o a_n pierda la vida. Opere este equipo

al aire fibre donde haya bastante ventilaci6n.

I

20

Page 21

El generador produce un voltaje muy alto, el cual puede

ocasionar descargasel_ctricas extremamente peligrosas.Evite

el contacto con terminales, alambres pelados o sin

recubrimiento, etc. Nunca permita que personas no

calificadasoperen o proporcionen servicio al generador.

Nunca manipule dispositivos o cordones el_ctricos cuando

se encuentre parado en agua,descalzoo con los pies o las

manos moiadas.

Use un interruptor de circuito de fallaa tierra en _reas

h_medas o de alta conductividad (como en pisos met_licos o

estructuras de acero).

Nunca utilice en el generador juegos de cordones el_ctricos

que est_n desgastados,pelados,raidos o da_ados de cualquier

manera.

La gasolina es altamente INFLAMABLE y susvapores

son EXPLOSIVOS. No permita que lumen, que

existan llamas abiertas, chispas o calor a su alrededor

cuando manipule gasolina. Evite regar gasolina sobre

un motor caliente. Cumpla con todas las regulaciones que

requieran almacenamiento y manejode gasolina.

No Ilene el tanque de combustible excesivamente.Siempre

permita que exista espacio para la expansi6n del combustible.

Si el tanque estg demasiado Ileno, el combustible

podria rebosarse y caer sobre el motor caliente y

ocasionar un INCENDIO o una EXPLOSION.

Nunca almacene el generador con combustible en el tanque,

donde los vapores de la gasolinapuedan entrar en contacto

con llamasabiertas, chispaso luces de piloto (como en

hornos, calentadores de agua o secadoras de ropa). Podrian

ocurrir iNCENDIOS o EXPLOSIONES.

El motor-generador requiere de un fluio de aire de

enfriamento adecuado para tener un funcionamiento continuo

adecuado.Nunca opere la unidad en el interior de

habitaciones o recintos encerrados donde el fluio de aire que

entra o sale de la unidad pueda ser obstruido. Deie por Io

menos 2 pies de distancia alrededor del generador, incluso

cuando la unidad est_ funcionando en exteriores, de otra

forma podrta dahar la unidad.

Nunca arranque o detenga el motor-generador cuando tenga

cargas el_ctricas conectadas a los tomacorrientes y los

dispositivos conectados est_n ENCENDtDOS.Arranque el

motor y permita que se estabilice antes de conectar lascargas

el_ctricas. Oesconecte todas las cargas el_ctricas antes de

apagarel generador.

No introduzcaobietos a trav_s de las ranuras de

enfriamiento del motor-generador.

Nunca opere el generador:

en la Iluvia; en compartimiento encerrados; si se recalientan

los dispositivos el_ctricos conectados; si se pierde la salida

el_ctrica; si se presentan chispasen el motor o generador; si

seobservan llamaso humo cuando la unidad est_

funcionando; si la unidad vibra excesivamente.

CONEXION ATIERRA DEL

GENERADOR

ElC6digo Nacional de Electricidadexige que el marco y las

partes exteriores del generador conductoras de electricidad,

est_n conectadas a tierra adecuadamente.Los cbdigos el_ctricos

locales tambi_n pueden exigir que la unidad est_ conectada a

tierra correctamente. Paratal propbsito, se ha instaladouna

tuerca mariposa para conexibn a tierra en la base del bastidor

(Figura 10).

Por Io general, la conexibn de un alambre de cobre trenzado No.

12AWG (American Wire Gauge) a la aleta de conexibn a tierra y

a una barra de conexibn a tierra de cobre o bronce (electrodo)

proporciona una protecci6n adecuadacontra las descargas

el_ctricas. Sinembargo, los cbdigos locales pueden variar

substancialmente.Consulte con un electricista local para conocer

los requisitos de conexi6n a tierra de su _rea.

La conexi6n a tierra adecuadadel generador ayudar_a evitar las

descargasel_ctricas en el caso de que exista una condici6n de

fallaa tierra en el generador o en los dispositivos el_ctricos

conectados. La conexibn a tierra adecuadatambi_n ayudaa

disipar la electricidad est_tica,la cual se acumula frecuentemente

en dispositivos no conectados atierra.

/

21

Page 22

Sugeneradorrequieredeciertosprocedimientosdemontajey

soloestar_listoparaserutilizadodespu_sdehaberle

suministradoservicioconelcombustibleyaceiterecomendados.

Siustedtieneproblemasconelmontajedesugenerador,por

favorIlamealaIfneadeayudaparageneradoresal

1-800-270-1408.

IMPORTANTE: Cualquier intentode encender el motor antes

de haber colocado el aceite recomendado resultar_ da_o del

motor.

PARA RETIRAR EL GENERADOR

DE LA CAJA

Coloque la caja sobre una superficie planay rigida, con las

flechasque dicen "this side up" haciaarriba.

Abra con cuidado lastapas superiores de la cajade envio.

Corte de arriba a abajo las esquinasde uno de los lados de la

caja y coloque ese lado de la caja sobre el suelo.

Retire todo el material de empaque, relleno, etc.

Saque el generador de la cajade envto.

CONTENIDO DE LA CAJA

Revisetodo el contenido. Si alguna de las partes no est_ presente

o es_ da_ada,por favor Ilame a la linea de ayuda para

generadores al 1-800-270-1408.

La unidad principal

Manual del propietario

Aceite para motor

Tapones de fijaci6n

Juegode Ilantas

INSTALE EL JUEGO DE RUEDAS

IMPORTANTE: EsteJuegode Ruedas no ha sidodisehado para

ser usado en la cari_etera.

Para instalarsuJuegode Ruedas,usted necesitar_ las siguientes

herramientas:

Dos cajasde 13rambox, extremo abierto, o Ilave de tubo.

Instale el Juego de Ruedas como sigue (Figura I I):

I. Coloque el fondo de la camilla del generadoren una

superficie plana.Temporalmente, coloque la unidad en

bloques para ensamblarla f_cilmente.

2. Deslice el eje a trav_s de los soportes de montaje, en el

marco de la camilla,como semuestra.

_ lib i'_,_ll'l_ll_,,m _.llt"_m

Tornillos

Manilla

\

\

\

Montaje de Patas/

Use PiezasExistentes

\

Arandela

/

Eie

Rueda

/

/

/

Pasador de Seguridad

I

22

Page 23

3. Deslice una rueda en el eie.

NOTA: Aseg_rese de instalarambasruedas con la v_lvulade aire

hacia el lado de afuera.

4. Suiete la rueda al eje con el pas_dor de seguridad.Usted

puede a_adir la arandelasi asf Io desea.

5. Repita los pasos 3 y 4 para asegurar la segundarueda.

6. Remuevalas piezas existentes del montaje de vibraci6n con

la Ilavede 13mm.Use lasmismas piezaspara conectar las

patas.

7. Remuevalos bloques temporales.

8. Coloque los soportes de la manilla en el centro del marco

del generador y en el extremo del panel de control de la

camilla.

9. Sujete el soporte de la manilla con dos tornillos y dos

tuercas. Use dos Ilavesde 13mm para apretar las piezas.

ANTES DE DARLE ARRANQUE AL

MOTOR

Agregar Aceite al Motor

Use gasolinaregular SIN CONTENIDO DE PLOMO en

el generador.No use gasolina premium. No mezcle aceite con

gasolina.

Limpie el _rea alrededor del Ilenado de gasolina;retire la tapa.

Llene lentamente eltanque con gasolinasin contenido de

plomo. Seacuidadoso de no Ilenar excesivamente. Deje

I/2" de espacio en el tanque para que la expansibn del

combustible, como se muestra en esta ilustraci6n (Figura 12).

Espacio de Aire

de I/2" Tanque

CAUTION! Cualquier intento para arancar el motor antes de

haberle proporcionado el mantenimiento apropiado con el aceite

recomendado, podrta ocasionar la falla del motor.

Coloque la generador sobre una superficie nivelada.

Consulte el manual del propietario del motor para ahadir al

motor el aceite recomendado.

NOTA: Elcampo giratorio del generador se encuentra en un

coiinete pre-lubricado y sellado que no requiere lubricacibn

adicional por la vida atil del coiinete.

Agregue Gasolina

_ ADVERTENCIA! Nunca Ileneel tanque delcombustible en recintos cerrados. Nunca Ilene el tanque

del combustible cuando el motor est_ en funcionamiento

o caliente. No encienda cigarrillos o fume cuandoest_

Ilenando el tanque del combustible.

_ iADVERTENCIAt No Ilene excesivamente eltanque

de combustible. Deje suficiente espacio para la expansi6n

del combustible.

Instalela tapa del combustibley limpie cualquier derrame de

gasolina.

IRPORTANTE: Esimportante evitar laformacibn de dep6sitos

de goma en las partes esencialesdel sistema de combustible

como en el carburador, filtro del combustible, manguera del

combustible o tanque, durante sualmacenamiento. Los

combustibles mezclados con alcohol (llamados gasohol,etanol o

metanol) pueden atraer la humedad,la cual produce la separacibn

y formaci6n de _cidos durante el almacenamiento. Lagasolina

_cida puede da_ar el sistema de combustible de un motor

durante su almacenamiento.

Paraevitar problemas en el motor, deber_ vaciar el sistema de

combustible antes de pertodos de almacenamiento de 30 dias o

m_s.Vea"Almacenamiento" en la p_gina 28. Nunca useproductos

para limpiar motores o carburadores en el tanque del

combustible; si Io hace ocurrir_n dahos permanentes.

/

23

Page 24

CONOZCA SU GENERADOR

LEA ESTE MANUAl DE/PROPIETARIOY LAS REGLAS DE SEGURIDAD ANTES DE OPERAR SU GENERADOR.

Compare las ilustracionescon su Generador para familiarizarse con las ubicaciones de los diferentes controles y ajustes. Conserve este

manual para referencias futuras.

Tanque de Combustible

Cortacircuitos

Silenciador

Apagachispas

Tomacorrientes con

Dispositivo de

Seguridad de

Palancadel Cebador

Depurador de

Aire

120/240Voltios AC,

30 Amp

Culatazo el Principio

lnterruptor

B_landn

Cortacireuitos (AC) -- Cada tomacorriente posee un

cortacircuito para proteger el generador contra sobrecargas

el_ctricas. Los cortacircuitos son del tipo "oprimir para

reposicionar".

Culatazo el Principio -- Us6 para comenzar motor.

Depurador deAire -- Filtra el aire de entrada a medida que

penetra en el motor.

Interruptor Balancin -- Deber_ estar en la posicibn "On" (En)

para darle arranque al moto_ Colbquelo en la posicibn"Off'

(Apagado) para detener un motor en funcionamiento.

Palanca del Cebador -- Us_dacuando se est_ dando arranque

a un motor frio.

Sileneiador Apagachispas -- El silenciador disminuye el ruido

del motor y est_ equipado con una pantalla apagachispas.

Tuerca Mariposa

para Conexibn

aTierra

Tomacorrientes Doble de

120Voltios AC, 20 Amp

Tanque del Combustible -- El tanque tiene unacapacidadde

5 galones americanos de gasolina sin contenido de plomo.

TomacorHente Dobles de 120VoltiosAC, 20Amp --

Puedenser utilizados para suministrar alimentaci6n el_ctrica para

el funcionamiento de cargas del motor, herramientas, aparatos

especialese iluminaci6n el_ctrica de 120Voltios AC a

20Amperios, monof_sica de 60 Hz.

Tomacorriente con Dispositivo de Seguridad de

1201240 Voltios, 30 Amp -- Puede set utilizadopara

suministrar alimentaci6n el_ctrica para el funcionamiento de

cargasdel motor, herramientas, aparatos especialese iluminaci6n

el_ctrica de 120 y/o 240Voltios AC a 30Amperios, monofLsica de

60 Hz.

Tuerca Mariposa para Conexi6n aTierra -- Usado para

apropiado moli6 de la unidad (veap_gina21).

I

24

Page 25

OPERANDO EL GENERADOR

_ iPRECAUCI_N! Nunca encienda o pare el motor

con las cargas el_etricas coneetadas a los recept_culosY

con los aparatos conectados ENCENDIDOS.

Encienda el Motor

Desconectetodas las cargasel_ctricas del generador. Use las

siguientes instrucciones para encender,paso por paso,en orden

num_rico.

I. Gire la v_lvula del combustible a la posici6n "On" (Rgura 13).

Vglvula del Combustible

en posici6n "On"

2. Coloque la palancade choke en la posid6n "Choke"

(Rgura 14).

m|

4. Agarre la manilla de retroceso y halelentamente hastaque

puede sentir un poco de resistencia. Luego hale r_pidamente

para encender el moto_

5. Mueva la palancade choke a la posicibn "Run" una distancia

corta a la vez por algunos segundos en un clima c_lido, o

algunos minutos en un clima frio. Deje que el motor corra

suavementeantes de cadacambio. Opere con el choke en la

posicibn"Run".

NOTA: Siel motor atln falla en encender despu_sde halartres

veces,verifique el nivel adecuado del aceite en el cig_iehaLEsta

unidad est_ equipada con un Sistema que seapagacuando el

aceite est_ bajo. Consulte con el manual del moton

Consulte con el manual del propietario del motor para

las instrucciones completas de encendido.

Conexion De Cargas Electricas

Deje que el motor se estabilice y secaliente pot unos

minutos despu_s del arranque.

Conecte y encienda lascargas el_ctricas de 120y/o

240Voltios AC monof_sicas de 60 Hz que desse.

No conecte cargasde 240Voltios atomacorrientes de

120Voltios.

No conecte cargastrif_sicas al generador.

No conecte cargasde 50 Hz al generador.

NO SOBRECARGUE EL GENERADOR.Vea "No

Sobrecargueel Generador" en la p_gina 27.

3. Coloque el interruptor balandn a la posicibn"On"

(Figura 15).

Parado Del Motor

Desconecte todas las cargasel_ctricas de los tomaco-rrientes

del paneldel generador.Nunca de arranque o detenga el

motor con todos los dispositivos el&ctricos conectados y

encendidos.

Deje que el motor funcione sin cargaspor algunos minutos

para estabilizar lastemperaturas internas del motor y el

generador.

Mueva el interruptor balanctna la posicibn "Off" (Apagado).

Cierre lavdlvula del combustible.

/

25

Page 26

RECEPTACULOS

120/240 Voltios AC, 30 Amp, Recept_culo

de Seguridad

Use un tap6n NEMA LI4-30 con este receptSculo. Conecte un

juego de cable de 4 alambres, clasificado como 250Voltios AC a

30Amps (o mayor) (Figura 16).Usted puede usar el mismo cable

de 4-alambres si planeatrabajar con una carga de 120Voltios.

240V-_>

120V--><,- 120V-->

_ ___, (Neutro)

(Ca rgado)

Tierra

NEMA L14-30 F_ (Verde)

EstereceprSculo le provee poder a cargasde 120/240Voltios AC,

de 60 Hz, fasesencilla,que requieren hasta 3,600 vatios de

energia a 30Amps, para 120Voltios;5,500vatios de energia

(5.5 kW) a 30Amps para 240Voltios. La salidaesr5 protegida por

un corto*circuito de 30 Amp, del tipo "empuje para reposicionar".

120 Volt AC, 20 Amp, Receptgculos Dobles

Cada recept_culo (Figura 17)est5 protegido en contra de

sobrecargas por un corto-circuitos de 20 Amp, del tipo "empuie

para reposicionar".

Use cada recept_culo para operar 120Voltios AC, de fase sencilla,

de cargas de 60Hz que requieren hasta 2,400 vatios (2.4 kW) a

corrientes de 20 Amps.Use los juegos de cables que son

calificados para cargasde 125Voltios AC, a 20 Amps (o mayores).

_ PRECAUCI(_N! Aunque esta salidatiene una

clasificacibn de 120/240Voltios 30Amps (hasta

7,200 ratios), el generador est_ clasificadosolamente para

5,500 ratios. Cargasque pasen la capacidadde amperaje y

vataje del generador pueden daharlo o causaraccidentes

muy serios.

/

26

Page 27

NO SOBRECARGUE EL

GENERADOR

Sobrecargar el generador m_s allg de su capacidadde vatiaie

puede ocasionar daSosal mismo y a los dispositivos el_ctricos

conectados. Siga1assiguientesinstruccionespara evitar

sobrecargar launidad:

Sume el vatiaje total de todos losdispositivos el_ctricos que

van a ser conectados al mismo tiempo. Estetotal NO deber_

ser mayor que la capacidadde vatiaie del generador.

Si el aparato especial,herramienta o motor no suministra el

vatiaje,multiplique los voltios pot la clasificaci6n de amperaie

para determinar los vatios (voltios x amperios = ratios).

El vatiaje nominal de las luces puede ser tomado de los

bombillos. El vatiaie nominal de herramientas, aparatos

especialesy motores se puede encontrar, por Io general,en la

calcomantao placa de datos del dispositivo (Figura 18).

Algunos motores el_ctricos, como losde induccibn,requieren

aproximadamente tres veces m_svatios de poder para su

arranque que para sufuncionamiento. Esta onda irrupdvade

poder dura tan solo unos segundos durante elarranque de

dichos motores.Aseg_rese de tener en cuenta este alto

vatiaie de arranque cuando seleccione los dispositivos

el_ctricos que va aconectar a sugenerador. Primero, conozca

la cantidad de ratios necesarios para dar arranque al motor

m_s grande. Sumelea ese n_mero los vatios de

funcionamiento de todas las otras cargasconectadas.

Uso Recreativo/Dom6stico

H erramientaJAr tefacto ....................... Watts

RadioAM/FM con reloi................................. 50

Bombillo de luz...................................... 100

Vendlador .......................................... 200

Televisor de color, 20" . ............................... 400

*Congeladora ....................................... 500

Computadora personal y monitor de 15". ................ 800

*Ventilador de homo de I/3 hp ......................... 800

Homo de microondas ................................ 800

*Refrigeradora de 18pies c_bicos ....................... 800

Bomba de sumidero ................................. 1000

Sart_n el_ctrica ..................................... 1250

*Bomba de aguade pozo de I/2 hp ..................... 1400

*Acondicionador de aire tipo ventana,12.000 Btu ......... 1400

Calefactor de ambiente .............................. 1800

Calentador el_ctrico de agua.......................... 4000

Uso de Profesiona|es/Contratistas

Herramienta/Ar tefacto ....................... Watts

*Pulverizador no neum_tico de 113 hp ................... 600

Taladro de percusi6n de 3/8". .......................... 600

Sawzall® de velocidad variable .......................... 960

Taladro el_ctrico de 112" . ............................ 1000

L_mpara de trabaio de cuarzo-halSgeno ................. 1000

Lijadora de correa .................................. 1200

Sierra circular de 7.1/4". ............................. 1500

Sierra a tornillo sin fin de 7. I/4" . ...................... 1600

*Compresor de aire de I.I/2 hp ....................... 1800

*Sierra el_ctrica tipo inglete de 10". .................... 1800

Amoladora de banco de 6" . .......................... 1800

*Cepilladora de mesa de 6". .......................... 1800

*Sierra de brazo radiallde mesa de 10". ................. 2000

Soldadora de alambre ................................ 2400

*para el arranque de este dispositivo, tome en cuenta 3 veces los

watts listados

/

27

Page 28

ESPECIFICAClONES

Potencia M_xima..................... 8,500Vatios (8.5 kW)

Potencia de Sobretensibn .............. 5,500Vatios (5.5 kW)

Voltaie Nominal AC ....................... 120/240Voltios

Corriente M_xima a 240Voltios ............... 22.9 Amperios

Corriente M_xima a 120Voltios ............... 45.8 Amperios

Frecuencia Nominal ...................... 60Hz a 3600 rpm

Fase ...................................... Monof_sica

Tanque del Combustible .............. 5 GalonesAmericanos

Peso que Embarca............................... 148 Ibs.

RECOMENDACIONES

GENERALES DE

MANTENIMIENTO

El propietario / operador es responsable por asegurarse de que

todos los trabaios peri6dicos de mantenimiento se Ilevena cabo

adecuadamente;que todos los problemas son resueltos; y que la

unidad se mantiene limpia y adecuadamente almacenada.Nunca

opere un generador que est6 da_ado o defectuoso.

Mantenimiento del Motor

Consulte el manual del propietario del motor para las

instruccionesde cbmo mantener adecuadamente el motor.

_ iPRECAUCI_N! Eviteel contacto prolongado o

repetido de pielcon aceite usadode motor. El aceite usado

del motor hasido mostrado al cancer de la piel de la causa

en ciertos animales del laboratorio. Completamente lavado

expuso greascon el iabbn y el agua.

MANTENGA FUERADEALCANCE DE Nli_OS. NO

CONTAMINE. CONSERVElos RECURSOS.VUELVA

ACEtTE USADO A la COLECCION CENTRA.

Mantenimiento del Generador

El mantenimiento del generador consiste en conservar launidad

limpia y seca.Opere y almacenela unidad en un ambiente limpio

y seco donde no ser_ expuesta al polvo, suciedad,humedad o

vapores corrosivos. Lasranuras del aire de enfriamiento del

generador no deben estar tapadas con nieve,hoias, o cualquier

otro material extrahos.

Revisefrecuentemente la limpieza del generador y limpielo

cuando est6 con polvo, sucio, con aceite, humedad, o cuando otras

substancias extra_as sean visibles en su superficie exterio_

NOTA: No recomendamos el uso de manguerasde jardIn para

limpiar el generador. El agua podria introducirseen el sistema de

combustible del motor y causar problemas.Adem_s, si el aguase

introduceal generador a trav6s de las ranuras para aire de

enfriamiento, algo del aguaquedar_ retenida en los espacios

vactosy grietas del aislamiento del devanado del estator y rotor.

La acumulacibn de aguay suciedad en los devanados internos del

generador disminuir_ eventualmente la resistencia del aislamiento

de estos devanados.

Para Limpiar el Generador

Utilice un trapo h_medo para limpiar lassuperficies

exteriores.

Puede usar un cepillo de cerdas suavespara reti_r la

sudedad endurecida,aceite, etc.

Puede usar una m_quinaaspiradora para eliminar suciedad y

residuos sueltos.

Puede usar aire a baja presi6n (que no exceda los 25 psi) para

eliminar la suciedad, tnspeccione las ranuras para aire de

enfriamiento y la apertura del generado_ Estasaperturas

deber_n mantenerse limpias y despejadas.

ALMACENAMIENTO

Elgeneradordeber_ ser encendido al menos unavez cada siete

dtasy deber_ dejarlo funcionar al menos durante 30 minutos.Si

no puede hacer esto y debe almacenar la unidad por mgs de

30 dtas,sigalas siguientes instruccionespara preparar su unidad

para almacenamiento.

Almacenando el Generador

Limpieel generador como est_descrito en ("Para Limpiarel

Generador").

Reviseque lasranuras para el aire de enfriamiento y las

aperturas del generador se encuentren abiertas y despejadas.

_ PRECAUCION! Lascubiertas para almacenamiento

pueden ser inflamables.No coloque una cubierta encima

de un generador caliente. Deje que la unidad se enfrle Io

suficientemente antes de que le coloque lacubierta.

Almacenando el Motor

Consulte el manual del propietario del motor para las

instruccionesdecbmo preparar adecuadamente el motor para su

almacenamiento.

Otras Sugerencias Para el Almacenando

No almacene gasoiina de una es_ci6n aotra.

Reemplacela canecade gasolinasi comienza aoxidarse. El

bxido y/o la suciedad en la gasolina le causar_problemas.

Almacene la unidad en un _rea limpia y seca.

i

28

Page 29

NOTAS

/

29

Page 30

DIAGNOSITICOS DE AVERJAS

Problemo

El motor est_

funcionando pero no

existe salida de AC

Causa

I, El interruptor autom_tico de circuito est_

abierto.

2. Conexi6n mal o defectuosa del juego de

cables.

3. El dispositivo conectado est_ dahado.

disponsible.

4, Aver_ en el generador.

I, Corto circuitoen unade lascargasconectadas.

El motor funciona bien

sin carga pero "funciona

mar' cuando se le

contectan cargas.

2, Elgeneradorest_ sobrecarga.

3. Velocidad del motor es muy lenta.

4, Circuito del generador en corto.

I. Interruptor RunlStop poscioando en "Off'.

2, Depurador de aire sucio.

3. Sin gasolina.

4. Gasolina vieja.

5. Elcable de la bulia no est_ en malas la bulia.

El motor no se

enciende; o se enciende

y funciona mal.

El motor se apaga en

pleno funcionamiento.

AI motor le hace falta

potencia. 2. Filtro de aire sucio. 2.

El motor "no funciona

contirluamente" 0 se

detiene.

6. Buiiadefectuosa.

7. Agua en la gasolina.

8. Sobrecebado.

9,

Mezcla de combustible excesivamente rica.

10.

La v_Ivula de corte de combustible.

II.

La v_Ivula de entrada est_ atascada est_

cerrada.

12.

El motor ha perdido compresi6n.

I.

Sin gasolina.

2.

Nivel de aceite balo.

I.

La carga es muy alta.

I. El cebador fue abierto muy r_pidamente. I.

2, Carburador con mezcla de aire-combustible

muy rica o muy pobre.

Accion

I. Reposicione el interruptor.

2. Revisey repare.

3. Conecte otro dispositivo que est_ buenas

condiciones.

4. Contacte el Departmento de Servicio

Generac.

I. Desconecte la carga el_ctrica en corto.

2. Vea"No Sobrerecarque el Generador" en la

p_gina27.

3. Contacte el Departmento de Servicio Briggs

andStratton.

4. Contacte el Departmento de Servicio

Generac.

I. Coloque del interruptor en "On".

2. Limpie o reemplace el depurador de aire.

3. Ll_nelo con combustible fresco.

4. Drene el tanque de gasolina; ll_nelo con

combustible fresco.

5. Conecte el cable a la bujia.

6. Reemplace la bujia.

7. Drene el tanque de gasolina; ll_nelo con

combustible fresco.

8. Abra por completo el cebador y haga girar el

motor.

9. Contacte el Departmento de Servicio Briggs.

I0. Contacte el Depar tmento de Servico Briggs.

I I. Contacte el Departmento de Servicio Briggs.

12.

Contacte el Departmento de Servicio Bri_s.

I.

Llene el tanque de combustible.

2.

Llene de caja del cig_iehal al nivel correcto.

I.

Vea "No Sobrerecarque el Generador" la

p_gina 27.

Reemplace el filtro de aire.

Mueva el cebador a la posici6n intermedia

hasta que el motor funcione suavemente.

2.

Contacte el Departmento de Servicio Briggs.

I

30

Page 31

GARANTiA LIM ITADA

PARA GENERADORES PORTATILES

Los ProductosPort,tiles Generac (referidos aqufcomo la COMPAI_iA) garantiza al comprador original que el alternador para su

generador port_til estar_n libres de defectos en los materiales o la mano de obra para las piezasy el perfodo establecido a partir de la

fecha de compra original. Esta garantfa no incluyelos motores de gasolina cuando se encuentran anexados o comprados, porque tales

motores se encuentran cubiertos solamente por losfabricantes de dichos motores. Estagarantia no es transferible y seaplica

_nicamente a los generadores port,tiles impulsadospor el motor garantizado motor de arriba de la v_lvula.

Horatio De la Garantia_

CONSUMIDOR* COMERCIAL*

Motor Solamente por los fabricantes de dichos motores

Todo 2 ahos (el sugundo a_o unicamente partes) I aho

*NOTA: Las unidades de alquiler, para demostracibn, usos comerciales,tales como de construccibn o productores de ingresos,se

encuentran garantizadaspor 90 dfas.Las unidades de alquiler, para demostracibn, o usos comerciales tales como para laconstruccibn o

de utilidades, las cuales han sido vendidas de nuevo,no se encuentran cubiertas bajo esta garantta por la COMPANiA. Cualquier

garantta,bien sea expresada o implicada,es responsabilidad _nicadel vendedor.

Durante el periodo de la garantia mencionada, la COMPANiA, a su opcibn, reparar_ o reemplazar_ cualquier parte, que despu_sde ser

examinada,sehayadeterminado que posee un defecto bajo un uso y servicio normaI.Todos los gastos de transporte bajo la garantta,

incluyendopara regresarlo a la COMPAI_iA, si esnecesario,ser_ responsabilidad del comprador y pagados de antemano por el

comprador. Estagarantia no incluyeel mantenimiento nominal y el servicio, y no se aplicaal juego del generador, o partes, las cuales hart

sido sometidas a una instalacibninadecuadao no autorizada, mal uso, negligencia,accidentes,sobrecarga,exceso de velocidad,

mantenimiento inadecuado,reparacibn o almacenamiento,que seg_n el punto de vista de la COMPANiA, afecte de una manera negativa

su rendimiento y flabilidad.

NO EXISTEOTRA GARANTiA EXPRESA.LA COMPANiA POR LO TANTO, NIEGA CUALQUIER O TODAS LAS

GARANTiAS IMPLICADAS, INCLUYENDO PERO NO LIMITADAS A AQUELLAS DE MERCADEO Y ESTADO

FiSICO PARA UN PROP_SITO EN PARTICULARA LA EXTENSION DE LA LE'fiLA DURACI_N DE

CUALESQUIERA GARANTiAS IMPLtCADAS,LAS CUALES NO PUEDEN SERDESCARGADAS DE

RESPONSABtLIDAD,ESTA LIMITADA AL PERIODO ESPECtFICADO EN LA GARANTiA EXPRESA.

RESPONSABtLIDAD POR DAI_OS INCIDENTES, CONSECUENTES, O ESPECIALESBAJO CUALQUIER O TODAS

LAS GARANTiAS EST', EXCLUIDA HASTA LA EXTENSION DE LA LE_ LA COMPANiATAMBIEN NO SEHACE

RESPONSABLEPOR DANOS INCIDENTES O CONSECUENTES TALES COMO PERDIDA DE TIEMPO O EL USO

DEL EQUIPO DE ENERGiA, O CUALQUIER PERDIDA COMERCIAL DEBIDO A LA FALLA DEL EQUIPO;Y

CUALESQUIERA GARANTiAS IMPLICADASSEENCUENTRAN LIMITADAS A LA DURACI_N DE ESTA

GARANTiA ESCRITA.

AIgunos estados no permiten limitaciones en el tiempo que una garantia implicadadura, o las exclusiones o limitaciones de los da_os

incidenteso consecuentes, por Io que las limitaciones y exclusiones mencionadas arriba, esposible que no se apliquen a usted.Esta

garantta le da austed derechos legalesespectficos yes posible que por otro lado usted tenga otros derechos legales,los cuales pueden

variar de estado a estado.

Estagarantta se aplica para todos los productos fabricados despu_s de iunio de 1998,y sustituye todas las garantias anteriores de la

COMPANiA.

Para servicio, contacte su centro de servicio de garantta autorizado de la COMPANiA, o Ilame al 1-877-544-0982. O la mirada en el

internet en www.generac-potables.com. El servicio de garantia puede ser Ilevado a cabo solamente por un centro de servicio autorizado

por la COMPANiA.AI momento de solicitar un servicio de garantta,se debe presentar evidencia de la compra original del producto.

PRODUCTOS PORTATILES GENERAC

Jefferson,Wisconsin U.S.A.

Page 32

PORTABLE GENERATOR LIMITED WARRANTY

GENERAC PORTABLEPRODUCTS (hereafter referred to as the COMPANY) warrants to the original purchaser that the

components in its portable generator will be free from defects in materials or workmanship for the items and period set

forth below from the date of original purchase.This warranty does not includethe gasoline engine when furnished or

attached becausesuch engine iscovered solely by the engine manufacturer's warranty. Starting batteries are not warranted

by the COMPANY.The term "original purchaser" means the person for whom the generator is originally purchased.This

warranty isnot transferable and applies only to portable generators driven by an overhead valve engine.

Warranty Schedule:

Consumer* Commercial*

Engine Warranted solely by the engine manufacturer

All other parts 2 years (2rid year parts only) I Year

With the exception of European Community Countries, all units bound for export shall be warranted for One (I)

Yearin Consumer applications, and 90 days in Commercial applications as defined below.

*NOTE: For the purpose of this warranty "consumer use" means personal residential household use by

original purchaser.This warranty does not apply to units used for Prime Power in place of utility.

"Commercial Use" means all other uses, including rental, construction, commercial and income producing

purposes. Once a generator has experienced commercial use, it shall thereafter be considered a

commercial use generator for the purposes of this warranty.

During saidwarranty period, the COMPANY will, at isoption, repair or replace any part which, upon examination by the

COMPANY, is found to be defective under normal useand service**.AII transportation costs under warranty, including

return to the factory if necessary,are to be borne by the purchaser and prepaid by the purchaser.This warranty does not

cover normal maintenance and service and does not apply to a generator set, alternator, or parts which have been

subjected to improper or unauthorized installation or alteration, misuse,negligence,accident,overloading, overspeeding,

improper maintenance, repair or storage so as,in the COMPANY's judgement, to adverselyaffect its performance and

reliability.

**NORMAL WEAR: As with all mechanical devices, the generator needs periodic parts service and

replacement to perform well.This warranty will not cover repair when normal use has exhausted the life of

a part or generator.

THERE ISNO OTHER EXPRESSWARRANTY.THECOMPANY HEREBYDISCLAIMSANYANDALL

IMPLIEDWARRANTIES, INCLUDING BUT NOT LIMITEDTOTHOSE OF MERCHANTABILITY AND

FITNESSEORA PARTICULAR PURPOSETOTHE EXTENT PERMITTED BY LAW.THE DURATION OF

ANY IMPLIEDWARRANTIESWHICH CANNOT BE DISCLAIMED IS LIMITEDTOTHETIME PERIODAS

SPECIFIEDINTHE EXPRESSWARRANTY. LIABILITY FOR CONSEQUENTIAL, INCIDENTAL OR SPECIAL

DAMAGES UNDER ANY AND ALLWARRANTIES ISEXCLUDED. THE COMPANY ALSO DISCLAIMSANY

RESPONSIBILITYFOR INCIDENTAL OR CONSEQUENTIAL DAMAGES, SUCHASTHE LOSSOETIME OR

THE USEOETHE POWER EQUIPMENT,ORANY COMMERCIAL LOSSDUETOTHE FAILUREOETHE

EQUIPMENT:AND ANY IMPLIEDWARRANTIESARE LIMITEDTOTHE DURATION OETHISWRITTEN

WARRANTY.

Some states do not allow limitations on how long an implied warranty lasts, or the exclusion or limitation of incidental or

consequential damages, so the above limitations or exclusions may not apply to you.This warranty gives you specific legal

rights and you may also have other rights, which vary from state to state.

For service, see your nearest COMPANY authorized warranty service facility or call 1-877-544-0982. Or look on the

internet at www.generac-portables.com.Warranty service can be performed only by a COMPANY authorized service

facility.This warranty will not apply to service at any other facility.At the time of requesting warranty service, evidence of

original purchase date must be presented.

GENERAC PORTABLE PRODUCTS

Jefferson,Wisconsin U.S.A.

Loading...

Loading...