Page 1

POWER SYSTEMS, INC.

®

Installation, Start-up

and Adjustment Manual

Air-cooled, Prepackaged

Standby Generators

Models:

Nonsound Attenuated (Non-SA)

04077-1 (6 kW)

04109-1 (8 kW)

04079-1 (10 kW)

Sound Attenuated (SA)

00789-1 (8 kW)

00844-1 (8 kW)

ONLY QUALIFIED ELECTRICIANS OR CONTRACTORS

SHOULD ATTEMPT INSTALLATION!!

Page 2

Generac®Power Systems, Inc.

INTRODUCTION

Thank you for purchasing a model of the Guardian

product line by Generac Power Systems Inc. These

models are compact, high performance, air-cooled,

engine-driven generators designed to automatically

supply electrical power to operate critical loads during a utility power failure.

This unit is factory installed in an all-weather, metal

enclosure that is intended exclusively for outdoor

installation. This generator will operate using either

vapor withdrawn liquid propane (LP) or

natural gas (NG).

READ THIS MANUAL THOROUGHLY

If you do not understand any portion of this manual,

contact Generac or your nearest Generac/Guardian

Authorized Dealer for starting, operating and

servicing procedures.

Throughout this publication, and on tags and

decals affixed to the generator, DANGER, WARNING,

CAUTION and NOTE blocks are used to alert you to

special instructions about a particular operation that

may be hazardous if performed incorrectly or carelessly. Observe them carefully. Their definitions are

as follows:

After this heading, you can read instructions that,

if not strictly complied with, will result in personal

injury or property damage.

After this heading, you can read instructions that,

if not strictly complied with, may result in personal

injury or property damage.

After this heading, you can read instructions that, if

not strictly complied with, could result in damage to

equipment and/or property.

NOTE:

After this heading, you can read explanatory

statements that require special emphasis.

These safety warnings cannot eliminate the hazards

that they indicate. Common sense and strict compliance with the special instructions while performing the

service are essential to preventing accidents.

Four commonly used safety symbols accompany the

DANGER, WARNING and CAUTION blocks. The type

of information each indicates follows:

This symbol points out important safety information that, if not followed, could endanger personal

safety and/or property of you and others.

This symbol points out potential explosion hazard.

This symbol points out potential fire hazard.

This symbol points out potential electrical shock

hazard.

The operator is responsible for proper and safe use

of the equipment. We strongly recommend that the

operator read the Owner's Manual and thoroughly

understand all instructions before using this equipment. We also strongly recommend instructing other

users to properly start and operate the unit. This prepares them if they need to operate the equipment in

an emergency.

OPERATION AND MAINTENANCE

It is the operator's responsibility to perform all safety checks, to make sure that all maintenance for safe

operation is performed promptly, and to have the

equipment checked periodically by a

Generac/Guardian Authorized Dealer. Normal maintenance service and replacement of parts are the

responsibility of the owner/operator and, as such, are

not considered defects in materials or workmanship

within the terms of the warranty. Individual operating

habits and usage contribute to the need for maintenance service.

Proper maintenance and care of your generator

ensure a minimum number of problems and keep

operating expenses at a minimum. See your

Generac/Guardian Authorized Dealer for service aids

and accessories.

HOW TO OBTAIN SERVICE

When your generator requires servicing or repairs,

simply contact a Generac/Guardian Authorized

Dealer for assistance. Service technicians are factorytrained and are capable of handling all of your

service needs.

When contacting a Generac/Guardian Authorized

Dealer or the factory about parts and service, always

supply the complete model number and serial number of your unit as given on its data decal, which is

located on the generator’s engine.

◆

◆

◆

AUTHORIZED

DEALER LOCATION

To locate the GENERAC/GUARDIAN AUTHORIZED

DEALER nearest you, please call this number:

1-800-747-1530

DEALER LOCATION INFORMATION

CAN BE OBTAINED AT THIS NUMBER.

Page 3

Table of Contents

Guardian Air-cooled Generators

Generac® Power Systems, Inc. 1

Introduction ......................Inside Front Cover

Read This Manual Thoroughly ......................IFC

Operation and Maintenance............................IFC

How to Obtain Service....................................IFC

Authorized Dealer Location Number..................IFC

Safety Rules ......................................................2

Section 1 – Installation ..................................4

1.1 Introduction to Installation ..........................4

1.1.1 Installation Assistance......................4

1.1.2 Standards Index ..............................4

1.2 Unpacking....................................................4

1.2.1 Precautions ......................................4

1.2.2 Inspection ........................................4

1.3 Before Installation........................................5

1.4 Lifting the Generator....................................5

1.5 Engine Oil Recommendations ......................5

1.6 Gaseous Fuel System ..................................5

1.6.1 Fuel System Requirements

and Recommendations ....................5

1.6.2 Fuel Consumption ............................6

1.6.3 Fuel Pipe Sizing ................................6

1.6.4 Reconfiguring the Fuel System ........6

1.7 Location and Mounting ................................7

1.7.1 Generator ........................................7

1.7.1.1 6 kW, 8 kW and

10 kW Units (Non-SA) ......7

1.7.1.2

Sound Attenuated Units

....7

1.7.2 Transfer Switch................................7

1.7.2.1 6 Kw, 8 kW and

10 kW Units (Non-SA) ......7

1.7.2.2 Sound Attenuated Units ....7

1.8 Emergency Circuit Isolation Method ..........11

1.9 Total Circuit Isolation Method....................11

1.10 Generator AC Connection System..............12

1.11 Wiring Interconnections ..............................12

1.11.1 6 kW, 8 kW and

10 kW Units (Non-SA) ....................12

1.11.2 Sound Attenuated Units ................12

1.12 Generators and GTS Transfer Switches ....14

1.13 Control Circuit Interconnections................14

1.14 Adapting Three-phase Transfer Switch ......15

1.15 Control Board Configuration......................15

1.16 Grounding the Generator ..........................15

1.17 The Battery.................................................16

1.17.1 Battery Installation ........................17

1.18 The Fuse.............. ......................................17

1.19 Post Installation Inspection ........................17

Section 2 – Operation ..................................18

2.1 Using the Auto/Off/Manual Switch..............18

2.1.1 “Auto” Position................................18

2.1.2 “Off” Position..................................18

2.1.3 “Manual” Position ..........................18

2.2 Automatic Transfer Operation....................18

2.3 Sequence of Automatic Operation ..............19

2.4 Manual Transfer Operation........................19

2.4.1 Transfer to Generator

Power Source ..................................19

2.4.2 Transfer Back to Utility

Power Source ..................................20

2.5 Protection Systems ....................................20

2.5.1 Low Oil Pressure Switch ................20

2.5.2 High Temperature Switch ..............20

2.5.3 Overcrank ......................................20

2.5.3.1 Approximate Crank

Cycle Times ....................21

2.5.4 Overspeed ......................................21

2.6 Additional Generator Features ..................21

2.6.1 6 kW, 8 kW and

10 kW Units (Non-SA) ....................21

2.6.2 Sound Attenuated Units ................21

Section 3 – Post-installation Start-up

Adjustments..............................22

3.1 Before Initial Start-up ................................22

3.2 Check Transfer Switch Operation ..............22

3.3 Electrical Checks ......................................22

3.4 Generator Tests Under Load......................22

3.5 Checking Automatic Operation ..................23

3.6 Adjusting the Load Block ..........................23

3.7 Engine Governor Adjustment ....................24

3.7.1 6 kW Units (Non-SA) ......................24

3.7.2 8 kW and 10 kW Units (Non-SA)....24

3.7.3 Sound Attenuated Units ................25

3.8 Voltage Regulator Adjustment ....................25

3.9 Overspeed Calibration................................25

3.9.1 6 kW, 8 kW and

10 kW Units (Non-SA) ....................26

3.9.2 Sound Attenuated Units ................26

3.10 Setting the Exercise Timer ........................26

3.10.1 6 kW, 8 kW and

10 kW Units (Non-SA) ....................26

3.10.2 Sound Attenuated Units ................26

Section 4 – Troubleshooting ......................27

4.1 Troubleshooting Guide ..............................27

4.2 Installation Checklist ................................28

Section 5 – Notes ..........................................29

Page 4

2 Generac®Power Systems, Inc.

Study these SAFETY RULES carefully before

installing, operating or servicing this equipment.

Become familiar with this Installation, Start-up and

Adjustment Manual and with the unit. The generator

can operate safely, efficiently and reliably only if it is

properly installed, operated and maintained. Many

accidents are caused by failing to follow simple and

fundamental rules or precautions.

Generac cannot possibly anticipate every possible cir

cumstance that might involve a hazard. The warnings in this manual, and on tags and decals

affixed to the unit are, therefore, not all-inclusive. If

you use a procedure, work method or operating technique Generac does not specifically recommend, you

must satisfy yourself that it is safe for you and others.

You also must make sure the procedure, work

method or operating technique that you choose does

not render the generator unsafe.

Despite the safe design of this generator,

operating this equipment imprudently, neglecting

its maintenance or being careless can cause

possible injury or death. Permit only responsible

and capable persons to operate or maintain this

equipment.

Potentially lethal voltages are generated by

these machines. Ensure all steps are taken to

render the machine safe before attempting to

work on the generator.

Parts of the generator are rotating and/or hot

during operation. Exercise care near running

generators.

GENERAL HAZ

ARDS

• For safety reasons, Generac recommends

that the installation, initial start-up and maintenance of this equipment is carried out by a

Generac/Guardian Authorized Dealer.

• The engine exhaust fumes contain carbon monoxide, which can be DEADLY. This dangerous gas, if

breathed in sufficient concentrations, can cause

unconsciousness or even death. This exhaust system must be installed properly, in strict compliance with applicable codes and standards.

Following installation, you must do nothing that

might render the system unsafe or in noncompliance with such codes and standards.

• Keep hands, feet, clothing, etc., away from drive

belts, fans, and other moving or hot parts. Never

remove any drive belt or fan guard while the unit is

operating.

• Adequate, unobstructed flow of cooling and ventilating air is critical to correct generator operation.

Do not alter the installation or permit even partial

blockage of ventilation provisions, as this can seriously affect safe operation of the generator. The

generator MUST be installed outdoors.

• When working on this equipment, remain alert at

all times. Never work on the equipment when you

are physically or mentally fatigued.

• Inspect the generator regularly, and contact your

nearest Generac/Guardian Authorized Dealer for

parts needing repair or replacement.

• Before performing any maintenance on the generator, disconnect its battery cables to prevent accidental start up. Disconnect the cable from the battery post indicated by a NEGATIVE, NEG or (–)

first. Reconnect that cable last.

• Never use the generator or any of its parts as a

step. Stepping on the unit can stress and break

parts, and may result in dangerous operating conditions from leaking exhaust gases, fuel leakage,

oil leakage, etc.

Important Safety Instructions

Guardian Air-cooled Generators

SAVE THESE INSTRUCTIONS – The manufacturer suggests that these rules for safe

operation be copied and posted near the unit’s installation site. Safety should be stressed to

all operators and potential operators of this equipment.

The engine exhaust from this product

contains chemicals known to the state

of California to cause cancer, birth

defects or other reproductive harm.

WARNING:

Page 5

Generac®Power Systems, Inc. 3

ELECTRICAL HAZARDS

• All generators covered by this manual produce

dangerous electrical voltages and can cause fatal

electrical shock. Utility power delivers extremely

high and dangerous voltages to the transfer switch

as does the standby generator when it is in operation. Avoid contact with bare wires, terminals, connections, etc., while the unit is running. Ensure all

appropriate covers, guards and barriers are in

place before operating the generator. If you must

work around an operating unit, stand on an insulated, dry surface to reduce shock hazard.

• Do not handle any kind of electrical device while

standing in water, while barefoot, or while hands

or feet are wet. DANGEROUS ELECTRICAL

SHOCK WILL RESULT.

• The National Electrical Code (NEC) requires the

frame and external electrically conductive parts of

the generator to be connected to an approved earth

ground. Local electrical codes also may require

proper grounding of the generator electrical system.

• After installing this home standby electrical system, the generator may crank and start at any time

without warning. When this occurs, load circuits

are transferred to the STANDBY (generator) power

source. To prevent possible injury if such a start

and transfer occur, always set the generator’s

Auto/Off/Manual switch to its OFF position before

working on equipment and remove the fuse.

• In case of accident caused by electric shock, immediately shut down the source of electrical power. If

this is not possible, attempt to free the victim from

the live conductor. AVOID DIRECT CONTACT

WITH THE VICTIM. Use a nonconducting implement, such as a rope or board, to free the victim

from the live conductor. If the victim is unconscious, apply first aid and get immediate medical

help.

• Never wear jewelry when working on this equipment. Jewelry can conduct electricity resulting in

electric shock, or may get caught in moving components causing injury.

FIRE HAZARDS

• For fire safety, the generator must be installed and

maintained properly. Installation always must

comply with applicable codes, standards, laws and

regulations. Adhere strictly to local, state and

national electrical and building codes. Comply

with regulations the Occupational Safety and

Health Administration (OSHA) has established.

Also, ensure that the generator is installed in

accordance with the manufacturer’s instructions

and recommendations. Following proper installation, do nothing that might alter a safe installation

and render the unit in noncompliance with the

aforementioned codes, standards, laws and regulations.

• Keep a fire extinguisher near the generator at all

times. Extinguishers rated “ABC” by the National

Fire Protection Association are appropriate for use

on the standby electric system. Keep the extinguisher properly charged and be familiar with its

use. If you have any question pertaining to fire

extinguishers, consult your local fire department.

EXPL

OSION HAZARDS

• Do not smoke around the generator. Wipe up any

fuel or oil spills immediately. Ensure that no combustible materials are left in the generator compartment, or on or near the generator, as FIRE or

EXPLOSION may result. Keep the area surrounding the generator clean and free from debris.

• Gaseous fluids such as natural gas and liquid

propane (LP) gas are extremely EXPLOSIVE.

Install the fuel supply system according to applicable fuel-gas codes. Before placing the home standby electric system into service, fuel system lines

must be properly purged and leak tested according

to applicable code. After installation, you must

inspect the fuel system periodically for leaks. No

leakage is permitted.

Important Safety Instructions

Guardian Air-cooled Generators

Page 6

1.1 INTRODUCTION TO INSTALLATION

NOTE:

Read the entire manual before starting the installation. Ensure that the model number of the unit

being installed matches a model on the front cover.

Generac cannot possibly know of and advise the home

standby trade of all conceivable procedures and methods by which installation of this equipment might be

achieved. Neither can Generac know of possible hazards

and/or results of each method or procedure. We have

not undertaken any such wide evaluation.

1.1.1 INSTALLATION ASSISTANCE

1. For the Homeowner or Business Owner: You need

to have a certified electrician or contractor to

install this product. To arrange for proper installation, contact one of the following sources:

• Generac/Guardian Authorized Dealer: Look for

“Generac” or “Guardian” in your local Yellow

Pages under the classification “Generators –

Electric.”

• Heating and A/C Contractors: Look in your local

Yellow Pages under the classifications “Heating

Contractors” or “Air Conditioning Contractors.”

• Call us direct at (262) 544-4811 between the

hours of 8 a.m. and 5 p.m. CST. We will gladly

assist you in finding a local qualified installer.

2. For the Installing Dealer/Contractor: This manual

contains all the information required to properly

install and start a Guardian Power Systems generator in most applications. If you do need more

information, contact us directly at

(262) 544-4811, between the hours of 8 a.m. and

5 p.m., CST.

1.1.2 STANDARDS INDEX

In the absence of pertinent standards, codes, regulations and laws, the published information listed

below may be used as installation guide for this

equipment.

1. NFPA No. 37, STATIONARY COMBUSTION

ENGINES AND GAS TURBINES, available from

the National Fire Protection Association, 470

Atlantic Avenue, Boston, MA 02210.

2. NFPA No. 76A, ESSENTIAL ELECTRICAL SYSTEMS FOR HEALTH CARE FACILITIES, available

same as Item 1.

3. NFPA No. 54, NATIONAL FUEL GAS CODE, available same as Item 1.

4. NFPA No. 58, AMERICAN NATIONAL STANDARD

FOR STORAGE AND HANDLING OF LIQUEFIED

PETROLEUM GAS, available same as Item 1.

5. NFPA No. 70, NFPA HANDBOOK OF NATIONAL

ELECTRIC CODE, available same as Item 1.

6. Article X, NATIONAL BUILDING CODE, available

from the American Insurance Association, 85

John Street, New York, N.Y. 10038.

7. AGRICULTURAL WIRING HANDBOOK, available

from the Food and Energy Council, 909 University

Avenue, Columbia, MO 65201.

8. ASAE EP-3634, INSTALLATION AND MAINTENANCE OF FARM STANDBY ELECTRICAL SYSTEMS, available from the American Society of

Agricultural Engineers, 2950 Niles Road, St.

Joseph, MI 49085.

9. NFPA No. 30, FLAMMABLE AND COMBUSTIBLE

LIQUIDS CODE, available same as Item 1.

1.2 UNPACKING

1.2.1 PRECAUTIONS

Handle shipping cartons and crates with care. Use

care to avoid damage from dropping, bumping, collision, etc. Store and unpack crates and cartons with

the proper side up, as noted on the shipping carton.

1.2.2 INSPECTION

After unpacking, carefully inspect the contents

for damage that may have occurred during shipment

• This standby generator set has been factory sup-

plied with a weather protective enclosure that is

intended for outdoor installation only.

• The 6 kW, 8 kW and 10 kW standby generator sets

are packaged with an automatic transfer switch.

• This UL listed, two-pole switch is rated at 100 AC

amperes at 250 volts maximum. This transfer

switch is for indoor use only.

• All sound attenuated models have a built-in trans-

fer switch.

If this generator is used to power electrical load

circuits normally powered by a utility power

source, you are required by code to install a transfer switch. The transfer switch must effectively isolate the electrical system from the utility distribution system when the generator is operating (NEC

701). Failure to isolate an electrical system by such

means will result in damage to the generator and

also may result in injury or death to utility power

workers due to backfeed of electrical energy.

If any loss or damage is noted at time of delivery, have

the person(s) making the delivery note all damage on

the freight bill or affix his or her signature under the

consignor's memo of loss or damage.

If you note loss or damage after delivery, separate the

damaged materials and contact the carrier for claim

procedures.

“Concealed damage” is understood to mean damage

to the contents of a package that is not in evidence at

the time of delivery, but is discovered later.

◆

◆

◆

◆

Section 1 — Installation

Guardian Air-cooled Generators

Only qualified electricians or contractors

should attempt such installations, which

must comply strictly with applicable

codes, standards and regulations.

DANGER:

4 Generac®Power Systems, Inc.

Page 7

1.3 BEFORE INSTALLATION

Before installing this equipment, check the ratings of both

the generator and the transfer switch. Read “Emergency

Circuit Isolation Method” and “Total Circuit Isolation

Method” in Sections 1.8 and 1.9 (Page 11) carefully.

The generator's rated wattage/amperage capacity

must be adequate to handle all electrical loads that

the unit will power. You may have to group the critical (essential) electrical loads together and wire them

into a separate emergency distribution panel.

NOTE:

In some areas, you may need to acquire electrical

permits for installing an emergency system, building permits for installing gas lines, and permits for

noise allowances. Check your local codes before

installing the unit.

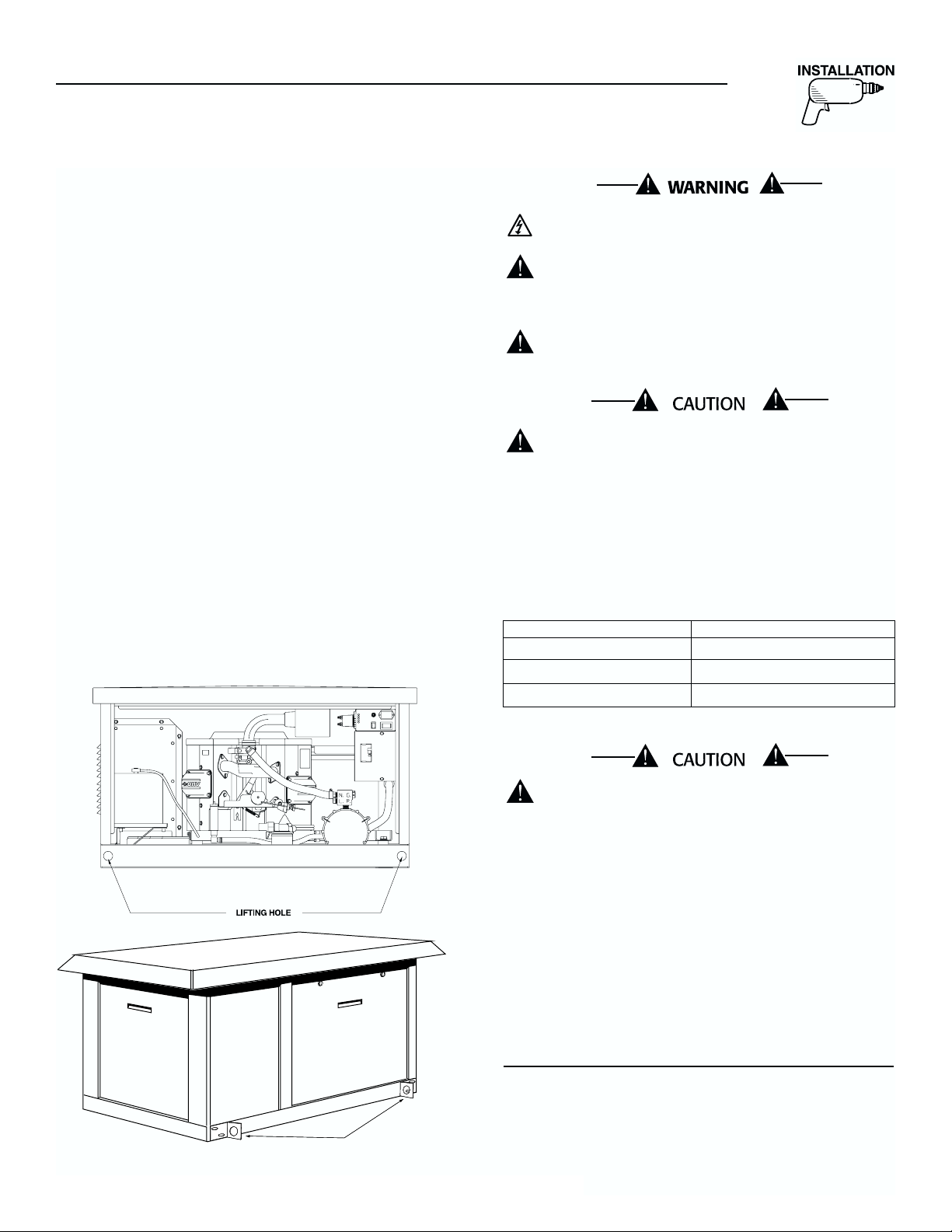

1.4 LIFTING THE GENERATOR

To lift a nonsound attenuated generator, insert pipe

having sufficient strength and diameter through the lifting holes (lifting brackets are provided with sound

attenuated units), which are located near the unit’s base

(see Figure 1.1). You also may lift the unit using a hook

and hoist method provided you use a spreader bar to

ensure that the lines clear the roof.

Figure 1.1 – Location of Lifting Holes/Brackets

When lifting or hoisting equipment is used, be

careful not to touch overhead power lines.

The generator’s weight of more than 300

pounds requires proper tools and equipment,

and qualified personnel to be used in all phases

of handling and unpacking.

Exercise caution when lifting the unit

manually as it may shift on lifting pipes during

transportation, which may result in injury.

The generator was not designed to be lifted by

its roof. Use the lifting holes or brackets provided

near the base of the unit. If using a hook and

hoist lifting method, you must employ a spreader

bar to prevent from crushing the roof.

1.5 ENGINE OIL RECOMMENDATIONS

Use oil of American Petroleum Institute (API) Service

Class SG, SH or SJ. Select the viscosity based on the

air temperature at the time of operation. See the following chart:

*Organic break-in oil is required before using synthetic oil.

Any attempt to crank or start the engine before

it has been properly serviced with the recommended oil may result in an engine failure.

1.6 GASEOUS FUEL SYSTEM

NOTE:

The following information pertaining to gaseous

fuel systems is provided to assist gaseous fuel

technicians in planning installations. In no way

should this information be interpreted to conflict

with applicable fuel gas codes. Consult with your

local fuel supplier or fire marshall if questions or

problems arise.

1.6.1 FUEL SYSTEM REQUIREMENTS

AND RECOMMENDATIONS

When installing the fuel system, install a flexible

length of line between the generator fuel connection and the rigid piping. The flexible hose must

be approved for use with gaseous fuels. It is recommended that an emergency manual fuel shutoff

valve be placed in-line.

◆

Section 1 — Installation

Guardian Air-cooled Generators

Generac®Power Systems, Inc. 5

Temperature Oil Grade (Recommended)

Above -7º C (20º F) SAE 10W-30 or SAE 30

Below -7º C (20º F) SAE 5W-20 or 5W-30

All Seasons SAE 5W-30 Synthetic*

(6 kW, 8 kW and 10 kW)

(Sound Attenuated)

LIFTING BRACKET

Page 8

6 Generac®Power Systems, Inc.

With LP gas, use only the vapor withdrawal system.

This type of system uses the vapors formed above the liquid fuel in the storage tank.

The engine has been fitted with a fuel carburetion system that meets the specifications of the 1997 California

Air Resources Board for tamper-proof dual fuel systems. The unit will run on natural gas or LP gas, but it

has been factory set to run on natural gas. Should the

primary fuel need to be changed to LP gas, the fuel system needs to be reconfigured. See Section 1.6.4 (Page

6) for instructions on reconfiguration of the fuel system.

Recommended fuels should have a Btu content of at

least 1,000 Btus per cubic foot for natural gas; or at

least 2,520 Btus per cubic foot for LP gas. Ask your fuel

supplier for the Btu content of your fuel.

Fuel pressure for both natural gas and liquid propane

(LP) vapor set ups MUST be 11 inches to 14 inches of

water column (0.6 psi) at all load ranges.

1.6.2 FUEL CONSUMPTION

See the following chart for fuel supply requirements at

half and full load for both natural gas and LP vapor.

*Natural gas is in cubic feet per hour.

**LP is in gallons per hour/cubic feet per hour.

Gaseous fuels such as natural gas and liquid

propane (LP) gas are highly explosive. Even the

slightest spark can ignite such fuels and cause

an explosion. No leakage of fuel is permitted.

Natural gas, which is lighter than air, tends to

collect in high areas. LP gas is heavier than air

and tends to settle in low areas.

1.6.3 FUEL PIPE SIZING

See the following chart for proper sizing of fuel supply

piping. Insufficient fuel pipe size can cause hard starting, poor engine performance and inability to carry

load.

NG and LP Vapor Pipe Sizing Chart:

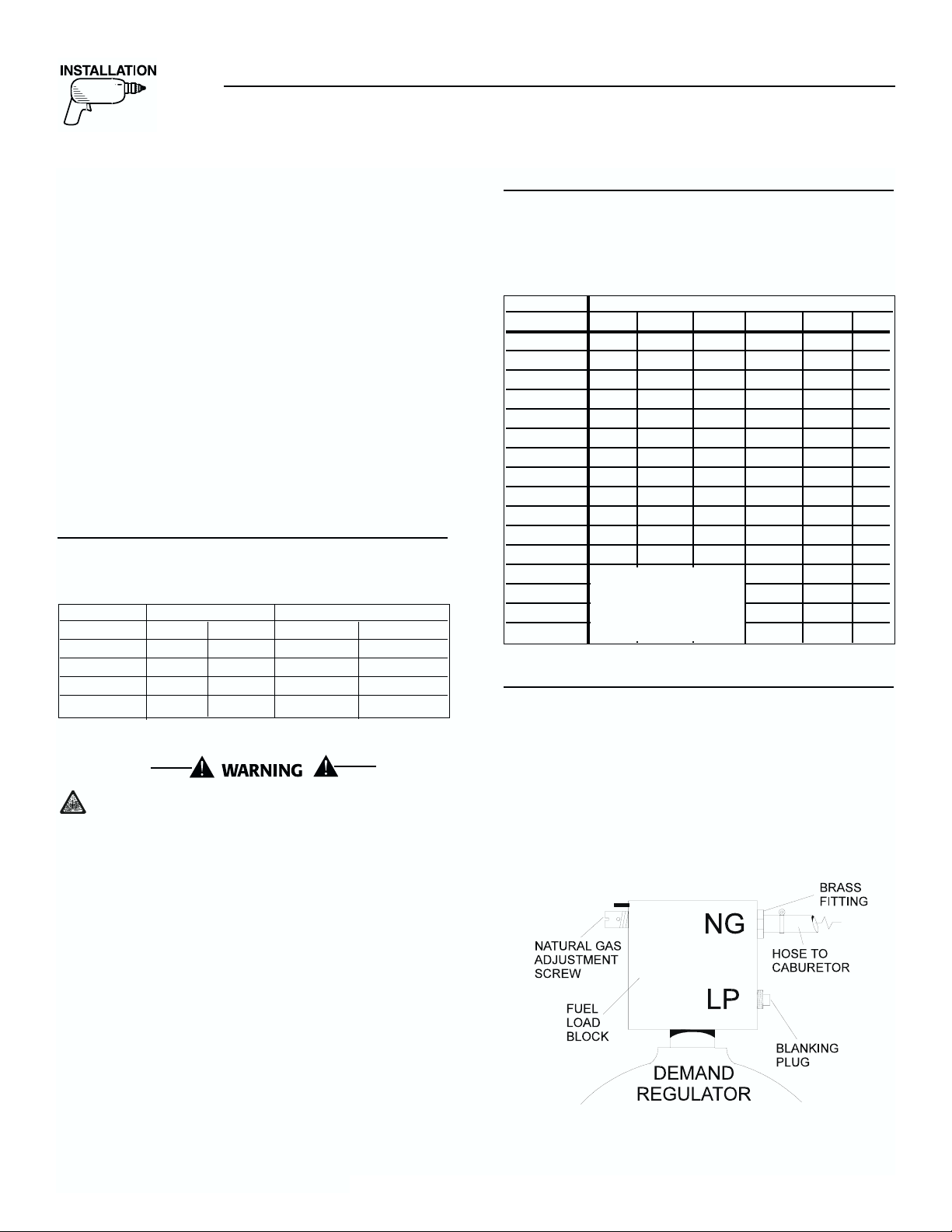

1.6.4 RECONFIGURING THE FUEL SYSTEM

To reconfigure the fuel system from NG to LP,

follow these steps:

1. Remove the carburetor fuel hose from the natural

gas port of the fuel load block and the brass fitting (Figure 1.2).

2. Remove the blanking plug from the LP port of the

load block (Figure 1.2).

Figure 1.2 – Natural Gas Setup`

◆

◆

◆

Section 1 — Installation

Guardian Air-cooled Generators

Model # Nat. Gas (*) LP Vapor (**)

1/2 Load Full Load 1/2 Load Full Load

6 kW 74.1 105.3 0.86/31.30 1.08/39.30

8 kW 79.7 140.0 1.07/38.94 1.56/56.77

10 kW 100.8 177.9 1.16/42.21 2.15/78.24

Sound Attn. 84.6 126.6 1.06/38.57 1.7/61.86

Length of Pipe Iron Pipe Size (IPS Inches)

½" ¾" 1" 1 ¼" 1 ½" 2"

15' 76 172 345 750 1,220 2,480

30' 52 120 241 535 850 1,780

45' 43 99 199 435 700 1,475

60' 38 86 173 380 610 1,290

75' 77 155 345 545 1,120

90' 70 141 310 490 1,000

105 65 131 285 450 920

120 120 270 420 860

150 109 242 380 780

180 100 225 350 720

210 92 205 320 660

240 190 300 620

270 178 285 580

300 170 270 545

450 140 226 450

600 119 192 390

Consumption in

Cubic Feet Per Hour

Page 9

Generac®Power Systems, Inc. 7

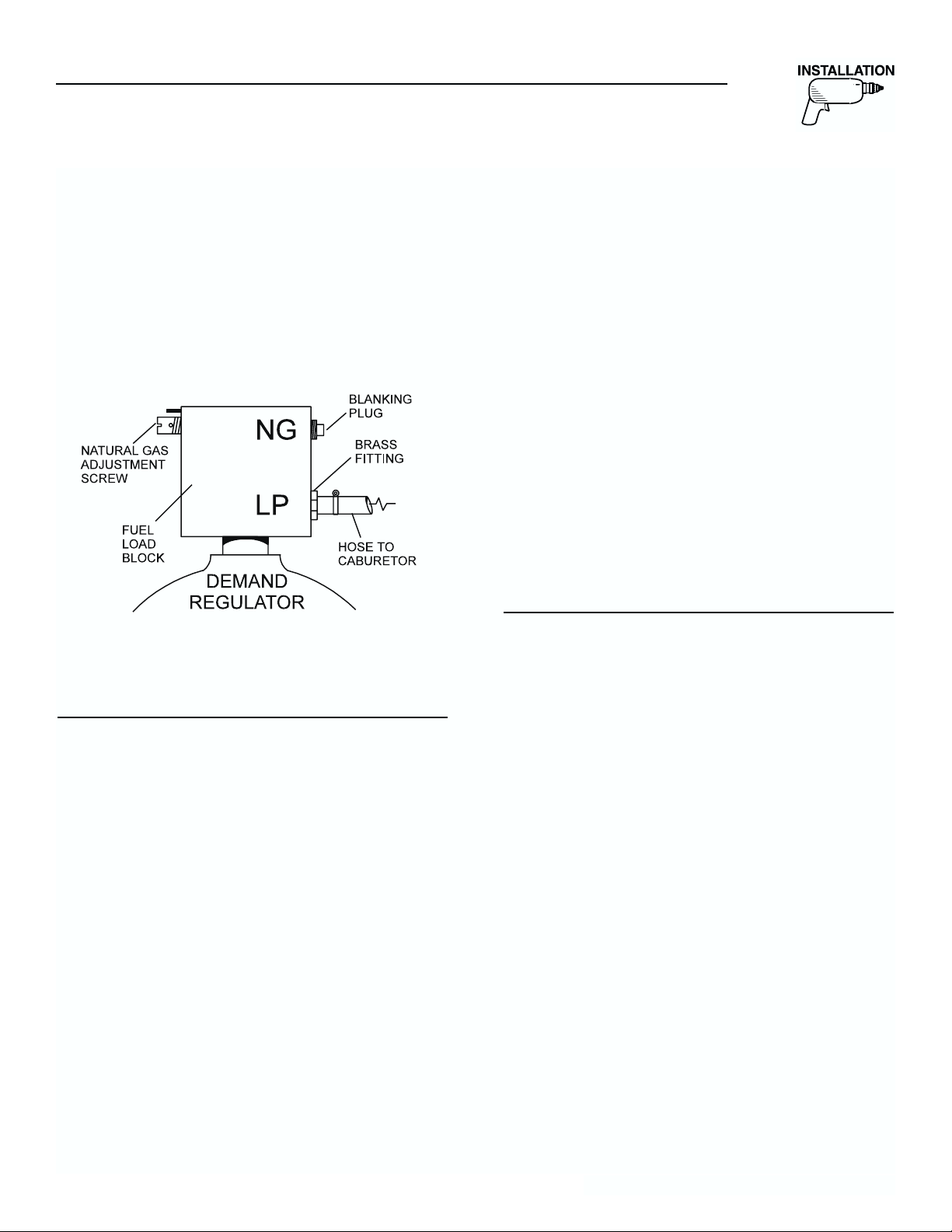

3. Refit the fitting and hose to the LP port and

the blanking plug to the natural gas port

(Figure 1.3).

4. Reverse the procedure to convert back to

natural gas.

NOTE:

The natural gas adjustment screw is preset during

installation and should not need any further

adjustment.

Figure 1.3 – LP Gas Setup

1.7 LOCATION AND MOUNTING

1.7.1 GENERATOR

Install the generator set, in its protective enclosure,

outdoors, where adequate cooling and ventilating air

always is available. Consider these factors:

• Install the unit where air inlet and outlet openings

will not become obstructed by leaves, grass, snow,

etc. If prevailing winds will cause blowing or drifting, you may need to consider using a windbreak

to protect the unit.

• Install the generator on high ground where water

levels will not rise and endanger it.

• Allow sufficient room on all sides of the generator

for maintenance and servicing. A good rule is to

allow 3 feet of space on all sides.

• Where strong prevailing winds blow from one

direction, face the generator air inlet openings into

the prevailing winds.

• Install the generator as close as possible to the

transfer switch. This reduces the length of wiring

and conduit.

• Install the generator as close as possible to the fuel

supply, to reduce the length of piping. HOWEVER,

REMEMBER THAT LAWS OR CODES MAY REGULATE THE DISTANCE.

1.7.1.1 6 kW, 8 kW and 10 kW Units (Non-SA)

These Guardian units are supplied with their own

mounting pads and DO NOT require a concrete pad.

Remove the packing material from the unit and unbolt

the two 4-inch by 4-inch wooden blocks from the

underside of the mounting base. Plug the holes with the

plugs provided. Prepare the installation site to accept

the mounting base. Provide adequate substrate to give

sufficient drainage, i.e., a 3-inch deep section of pea

gravel scattered under the mounting base.

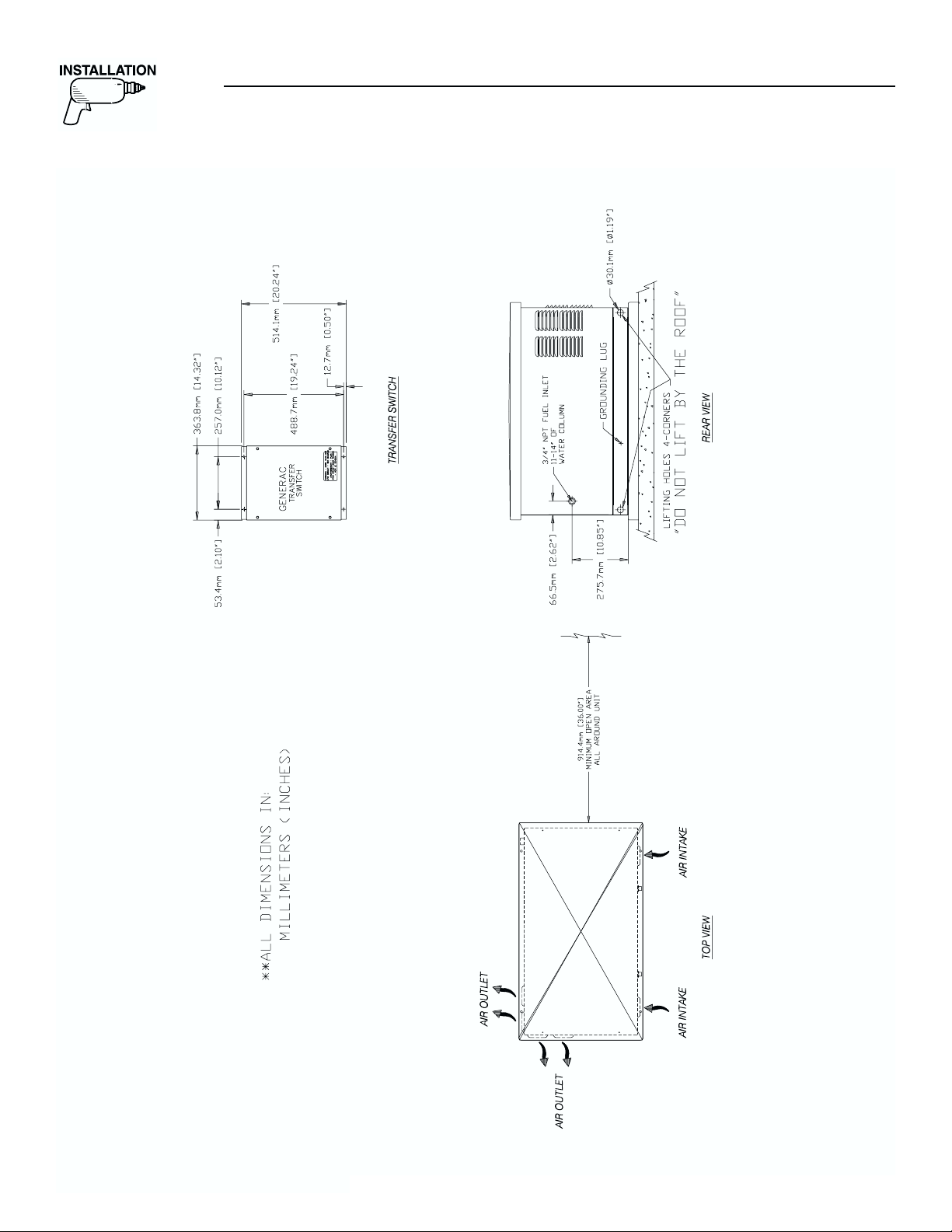

See Figure 1.4 (Pages 8-9) for generator and transfer

switch major dimensions.

1.7.1.2 Sound Attenuated Units

Retain the generator compartment to a concrete slab

with 1/4-inch masonry type anchor bolts. Be sure the

bolts are long enough to retain the compartment. The

slab should be at least 3 inches thick and should

extend beyond the enclosure to a distance of at least

3 inches on all sides.

See Figure 1.5 (Page 10) for generator major

dimensions.

1.7.2 TRANSFER SWITCH

1.7.2.1 6 kW, 8 kW and 10 kW Units (Non-SA)

The transfer switch shipped with this generator is

enclosed in a NEMA 1 enclosure. This type of enclosure is intended for indoor use only. Follow these

rules:

• Install the transfer switch indoors on a firm, sturdy supporting structure.

• To prevent switch distortion, level the switch

if necessary. This can be done by placing

washers between the switch enclosure and

mounting surface.

• Never install the switch where water or any corrosive substance might drip onto the enclosure.

• Protect the switch at all times against excessive

moisture, dust, dirt, lint, construction grit and

corrosive vapors.

1.7.2.2 Sound Attenuated Units

All sound attenuated models have a transfer switch

built into the enclosure and do not require a separate

switch attachment.

◆

◆

Section 1 — Installation

Guardian Air-cooled Generators

Page 10

8 Generac®Power Systems, Inc.

Figure 1.4 – Generator and Transfer Switch Mounting Dimensions (6 kW, 8 kW and 10 kW Non-SA)

Section 1 — Installation

Guardian Air-cooled Generators

Page 11

Generac®Power Systems, Inc. 9

Figure 1.4 (Continued)

Section 1 — Installation

Guardian Air-cooled Generators

Page 12

10 Generac®Power Systems, Inc.

Figure 1.5 – Generator Mounting Dimensions (Sound Attenuated)

Section 1 — Installation

Guardian Air-cooled Generators

Page 13

Generac®Power Systems, Inc. 11

1.8 EMERGENCY CIRCUIT

ISOLATION METHOD

One effective way of preventing the generator from

being overloaded is to use the “Emergency Circuit

Isolation Method” (Figure 1.6).

Essential electrical loads are grouped together and

wired into a separate emergency distribution panel.

Load circuits fed by the emergency distribution panel

must be within the unit's rated wattage capacity. The

following apply to this type of isolation system:

• The transfer switch is installed between the main

and the emergency distribution panels as shown.

• The transfer switch must have an ampere rating

equal to the ampere rating of the emergency circuit.

Figure 1.6 – Emergency Circuit Isolation Method

* Ampere rating must equal or exceed the ampere

rating of the emergency distribution system.

** Ampere capacity is not to exceed the alternator

rating. Only these items will be powered by the

standby alternator. If the electrician sizes the load

properly, the alternator cannot be overloaded.

All wiring must conform to the National Electrical

Code, and all state and local codes. Consult a qualified, licensed electrician.

The above illustration assumes the utility is supplying 120/240-volt, single-phase electrical service.

1.9 TOTAL CIRCUIT

ISOLATION METHOD

If essential electrical loads cannot be grouped together and wired into an emergency distribution panel,

you will have to select load circuits that the generator

will power during a utility power outage.

Be careful to avoid overloading the generator. The following apply to the “Total Circuit Isolation Method”

(Figure 1.7):

• The transfer switch is installed between the utility

service entrance and the distribution panel.

• The transfer switch ampere rating must be equal to

the main electrical service entrance rating.

Figure 1.7 – Total Circuit Isolation Method

* Ampere rating is equal to or larger than main (nor-

mal) power source.

** Use caution with this system to prevent overload of

the alternator during utility power failure. All load

items in the distribution panel must be individually turned off. Only certain items can be turned

back on during alternator operation. These items

should be specified by your electrician so as not to

overload the alternator.

All wiring must conform to the National Electrical

Code, and all state and local codes. Consult a qualified, licensed electrician.

The above illustration assumes the utility is supplying 120/240-volt, single-phase electrical service.

Section 1 — Installation

Guardian Air-cooled Generators

Service Disconnect

Page 14

12 Generac®Power Systems, Inc.

1.10 GENERATOR AC

CONNECTION SYSTEM

Figure 1.8 represents a single-phase, three-wire generator AC connection system. The stator assembly in

this system consists of a pair of stationary windings

with two leads brought out of each winding. Each single winding can supply a 120-volt, 60-Hertz AC output. When the two windings are connected in series,

a 240-volt, 60-Hertz AC output results. Stator AC output leads 11 and 44 are the two “hot” leads; the junction of leads 22 and 33 forms the neutral lead.

Figure 1.8 – Generator AC Connection System

1.11 WIRING INTERCONNECTIONS

This generator uses an UNGROUNDED neutral

line consisting of the junction of stator leads 22

and 33. Figure 1.9 and Figure 1.10 (Page 13) are

interconnection diagrams of home standby

electrical systems. Power voltage leads and

transfer switch “signal” leads must be run in

separate conduit.

All wiring must be the proper size, properly supported, of approved insulative qualities, and protected by

NEC approved conduit. Use a length of flexible conduit

between the generator and any rigid conduit.

NOTE:

See also “Emergency Circuit Isolation Method,”

Section 1.8, and “Total Circuit Isolation Method,”

Section 1.9, on Page 11.

1.11.1 6 KW, 8 KW AND 10 KW UNITS (NON-SA)

Complete the following AC power lead connections

for single-phase units (Figure 1.9, Page 13):

1. Connect utility power supply leads to transfer

switch terminals N1, N2 and the neutral lug.

2. Connect generator AC output leads from the generator’s main circuit breaker (CB1) and the generator neutral lug to transfer switch terminals

E1, E2 and the neutral lug.

3. Connect circuit load leads to customer load,

and to transfer switch terminals T1, T2 and the

neutral lug.

1.11.2 SOUND ATTENUATED UNITS

The sound attenuated unit utilizes an internal

100-amp “V”-type transfer switch. The control and

generator AC wires are prewired from the factory.

Complete the following AC power lead connections

for single-phase units (Figure 1.10, Page 13):

1. Connect utility power supply leads to transfer

switch terminals N1, N2 and the neutral lug.

2. Connect circuit load leads to customer load,

and to transfer switch terminals T1, T2 and the

neutral lug.

◆

◆

Section 1 — Installation

Guardian Air-cooled Generators

Page 15

Generac®Power Systems, Inc. 13

Section 1 — Installation

Guardian Air-cooled Generators

Figure 1.10 – Interconnection Diagram for Single-Phase Power System (Sound Attenuated)

Figure 1.9 – Interconnection Diagram for Single-Phase Power System (6 kW, 8 kW and 10 kW Non-SA)

Page 16

14 Generac®Power Systems, Inc.

1.12 GENERATORS AND GTS

TRANSFER SWITCHES

Guardian generators (this DOES NOT APPLY to singlephase sound attenuated units) may be installed with

either a prepackaged transfer switch or with a standard GTS-type automatic transfer switch (Figure

1.11). You can do this by connecting generator control

console terminals 178 and 183 to identically numbered terminals in the GTS switch. Turn dip switch #2

“Remote Not Auto” to the ON position on the generator

control printed circuit board.

NOTE:

The enclosure roof will need to be removed to gain

access to the printed circuit board.

When a Guardian generator is installed with a standard GTS-type switch, solid-state circuit boards in

the transfer switch control automatic operation.

For automatic operating sequences, parameters

and timing, refer to the appropriate GTS transfer

switch manual.

Automatic operation for Guardian generators

installed with prepackaged transfer switches is

controlled by a control module circuit board in the

control panel. Refer to the “Operation” section of

this manual.

1.13 CONTROL CIRCUIT

INTERCONNECTIONS

For 6 kw, 8 kW and 10 kW units (not including

sound attenuated), these interconnections consist

of “Utility” and leads 23 and 194 (see Figure 1.9,

Page 13). These four leads must be routed in conduit that is separate from the generator AC power

leads. Control lead functions may be briefly

described as follows:

1. Utility 1 and Utility 2: Deliver utility source power

to the generator's logic circuit board.

2. Leads 23 and 194: After the generator starts, the

logic circuit board in control panel delivers a

“transfer” signal via these two leads.

• When logic circuit board action closes this circuit,

it causes transfer switch main contacts to activate

and connect load circuits to generator output.

• When utility source voltage is restored, logic board

opens leads 23 and 194 circuit. Loads are then

transferred back to utility circuit.

NOTE:

Recommended size of control circuit leads (Utility

1 and 2, and 23 and 194) is No. 14 AWG stranded

copper wire.

Section 1 — Installation

Guardian Air-cooled Generators

Figure 1.11 – Interconnection With GTS Transfer Switch (100A, y-type)

Page 17

Generac®Power Systems, Inc. 15

1.14 ADAPTING THREE-PHASE

TRANSFER SWITCH

The generator you are installing may include a

prepackaged transfer switch configured for threephase loads. If you want to adapt this kind of transfer

switch for single-phase loads, proceed as follows:

1. Discard the three-phase power monitor (PM)

found inside the enclosure. You will not use it

with a single-phase system.

2. Locate the eight-pin octal relay socket in the lower

left corner of the transfer switch enclosure.

3. Move Wire N1A from Terminal 8 to Terminal 1 by

cutting the lug off of N1A , stripping wire 5/16"

from end, and inserting the wire under screw of

Terminal 1.

NOTE:

Moving N1A from Terminal 8 to Terminal 1 takes

the three-phase voltage monitor out of the sensing

circuit. Now, the control circuit board in the control module assembly (CMA) senses utility voltage.

4. Now, connect the control wires as follows:

• Connect Utility Supply to lugs N1 and N2.

• Connect the Customer Load lugs T1 and T2.

• Connect the Standby Supply to lugs E1 and E2.

1.15 CONTROL BOARD CONFIGURATION

The control board for the 6 kW, 8 kW and 10 kw has

four dip switches (see Figure 1.12), which may be set

up differently during installation.

1. Dip switch 1: When in the ON position, the board

requires 20 Vac from the step down transformer

to the control board to determine if utility is

present. This switch is factory preset and should

not need to be changed. This switch should be set

in the OFF position.

2. Dip switch 2: When in the ON position, it will

disable the automatic starting of these units.

This should be set when utility is not present at

the installation location. This is the only switch

that may need to be set to the ON position for

these models.

3. Dip switch 3: It will allow for 50 Hertz opera-

tion and is not applicable to these models. This

switch is factory preset and should not need to

be changed. This switch should be set in the

OFF position.

4. Dip switch 4: It has no function at this time.

Figure 1.12 – Control Board Configuration

1.16 GROUNDING THE GENERATOR

Generally, connecting a No. 12 AWG stranded copper

wire to the grounding lug (Figure 1.13) and to an earthdriven copper or brass grounding rod (electrode) will

adequately ground the generator. However, local codes

may vary widely. Consult with a local electrician for

grounding requirements in your area.

Figure 1.13 – Grounding the Generator

Section 1 — Installation

Guardian Air-cooled Generators

Page 18

16 Generac®Power Systems, Inc.

1.17 THE BATTERY

Servicing of the battery is to be performed or supervised by personnel knowledgeable of batteries and

the required precautions. Keep unauthorized personnel away from batteries.

When replacing the battery, use the following type of

battery: Group 26/26R 12-volt battery with a rating of

350 cold-cranking amps at -17.8º C (0º F) minimum.

When using a maintenance-free battery, it is not necessary to check the specific gravity or electrolyte level.

Have these procedures performed at the intervals

specified in the Owner’s Manual “Service Schedule.”

A negative ground system is used. Battery connections are shown on the wiring diagrams. Make sure

the battery is correctly connected and terminals are

tight. Observe battery polarity when connecting the

battery to the generator set.

NOTE:

Damage will result if the battery connections are

made in reverse.

Your generator is equipped with a battery trickle

charger that is active when your unit is set up for

automatic operation. The trickle charger is

designed to help extend the life of your battery by

maintaining the battery when the unit is

not running.

Do not dispose of the battery in a fire. The

battery is capable of exploding.

A battery presents a risk of electrical shock

and high short circuit current. The following

precautions are to be observed when working

on batteries:

• Remove watches, rings or other metal objects;

• Use tools with insulated handles;

• Wear rubber gloves and boots;

• Do not lay tools or metal parts on top of the

battery; and

• Disconnect charging source prior to connecting or dis-

connecting battery terminals.

Do not open or mutilate the battery. Released

electrolyte has been known to be harmful to

the skin and eyes, and to be toxic.

The electrolyte is a dilute sulfuric acid that is

harmful to the skin and eyes. It is electrically

conductive and corrosive. The following

procedures are to be observed:

• Wear full eye protection and protective clothing;

• Where electrolyte contacts the skin, wash it off

immediately with water;

• Where electrolyte contacts the eyes, flush

thoroughly and immediately with water and seek

medical attention; and

• Spilled electrolyte is to be washed down with an

acid neutralizing agent. A common practice is to

use a solution of 1 pound (500 grams) bicarbonate

of soda to 1 gallon (4 liters) or water. The bicarbonate of soda solution is to be added until the

evidence of reaction (foaming) has ceased. The

resulting liquid is to be flushed with water and the

area dried.

Lead-acid batteries present a risk of fire

because they generate hydrogen gas. The

following procedures are to be followed:

• DO NOT SMOKE when near the battery;

• DO NOT cause flame or spark in battery area; and

• Discharge static electricity from your body before

touching the battery by first touching a grounded

metal surface.

Be sure the Auto/Off/Manual switch is set to

the OFF position before connecting the battery

cables. If the switch is set to AUTO or MANUAL,

the generator can crank and start as soon as

the battery cables are connected.

Be sure the utility power supply is turned off,

or sparking may occur at the battery posts as

you attach the cables and cause an explosion.

Section 1 — Installation

Guardian Air-cooled Generators

Page 19

Generac®Power Systems, Inc. 17

1.17.1 BATTERY INSTALLATION

Fill the battery with the proper electrolyte fluid if necessary and have the battery fully charged before

installing it.

Before installing and connecting the battery, complete

the following steps:

1. Set the generator's Auto/Off/Manual switch

to OFF.

2. Turn off utility power supply to the transfer

switch.

If the Auto/Off/Manual switch is not set to its

OFF position, the generator can crank and start

as soon as the battery cables are connected. If

the utility power supply is not turned off,

sparking can occur at the battery posts and

cause an explosion.

Battery cables were factory connected at the generator (Figure 1.14). Connect cables to battery posts as

follows:

1. Connect the red battery cable (from starter contactor) to the battery post indicated by a positive,

POS or (+).

2. Connect the black battery cable (from frame

ground) to the battery post indicated by a negative, NEG or (—).

Figure 1.14 – Battery Cable Connections

NOTE:

With the battery installed and utility power source

voltage available to the transfer switch, the battery

receives a trickle charge while the engine is not

running, to prevent self-discharge. The trickle

charge feature cannot be used to recharge a discharged battery.

1.18 THE FUSE

The generator panel’s 15-amp fuse protects the DC

control circuit against overload. The fuse is wired in

series with the battery output lead to the panel. If the

fuse element has melted open, you cannot crank or

start the engine. You should replace the fuse using

only an identical 15-amp replacement.

1.19 POST INSTALLATION INSPECTION

Before placing the home standby electrical system

into service, inspect the entire installation carefully.

Some areas may require that an inspection be performed by a building or electrical inspector.

◆

Section 1 — Installation

Guardian Air-cooled Generators

Figure 1.15 – Typical Emergency Power System

Page 20

18 Generac®Power Systems, Inc.

NOTE:

Throughout the “Operation” section, differences

in procedures specific to sound attenuated units

will be denoted as follows: (SA = information).

2.1 USING THE AUTO/OFF/MANUAL

SWITCH

(FIGURE 2.1/2.2)

2.1.1 “AUTO” POSITION

Selecting this switch position activates fully automatic system operation. It also allows you to start and

exercise the engine every seven days with the setting

of the exercise timer (see Section 3.10, Page 26). This

position also is used for remote starting, when it is

set up.

2.1.2 “OFF” POSITION

This switch position shuts down the engine. This

position also prevents automatic operation.

2.1.3 “MANUAL” POSITION

Set the switch to MANUAL to crank and start the

engine. Transfer to standby power will not occur

unless there is a utility failure.

With the switch set to AUTO, the engine may

crank and start at any time without warning.

Such automatic starting normally occurs when

utility power source voltage drops below a

preset level or during the normal exercise cycle.

To prevent possible injury that might be caused

by such sudden starts, always set the switch to

OFF and remove the fuse before working on or

around the generator or transfer switch. Then,

place a “Do Not Operate” tag on the generator

panel and on the transfer switch.

Figure 2.1 – Generator Control Panel

(6 kW, 8 kW, 10 kW Non-SA)

Figure 2.2 – Generator Control Panel

(Sound Attenuated)

2.2 AUTOMATIC TRANSFER

OPERATION

To select automatic operation, do the following:

1. Make sure the transfer switch main contacts are

set to their “Utility” position, i.e., loads connected

to the utility power source (Figure 2.3, Page 19).

2. Be sure that normal utility power source voltage is

available to transfer switch terminal lugs N1 and N2.

3. Set the generator’s Auto/Off/Manual switch to

AUTO.

4. Set the generator’s main circuit breaker to its ON

(or closed) position.

With the preceding steps complete, the generator will

start automatically when utility source voltage drops

below a preset level. After the unit starts, loads are

transferred to the standby power source. Refer to

“Sequence of Automatic Operation.”

◆

◆

◆

Section 2 — Operation

Guardian Air-cooled Generators

Page 21

Generac®Power Systems, Inc. 19

2.3 SEQUENCE OF

AUTOMATIC OPERATION

The generator’s control panel houses a control logic

circuit board. This board constantly monitors utility power source voltage. Should that voltage drop

below a preset level, circuit board action will signal

the engine to crank and start. After the engine

starts, the circuit board signals the transfer switch

to activate and connect load circuits to the standby

power supply (load terminal lugs T1/T2 connect to

terminal lugs E1/E2).

Upon restoration of utility source voltage above a

preset level, generator circuit board action signals

the transfer switch to transfer loads back to that

power supply. After retransfer, the engine is signalled

to shut down.

The actual sequence of operation is controlled by

sensors and timers on a control logic circuit board,

as follows:

A.Utility Voltage Dropout Sensor

• This sensor monitors utility source voltage.

• If utility source voltage drops below about 60 percent of the nominal supply voltage, the sensor

energizes a 15-second (SA = six-second) timer.

• Once the timer has expired, the engine will crank

and start.

B.Engine Warm-up Time Delay

• This mechanism lets the engine warm up for

about 10 (SA = 15) seconds before the load is

transferred to a standby source.

C.Standby Voltage Sensor

• This sensor monitors generator AC output voltage. When the voltage has reached 50 percent of

the nominal rated voltage, transfer to standby

can occur.

D.Utility Voltage Pickup Sensor

• This sensor monitors utility power supply voltage. When that voltage is restored above 80 percent of the nominal source voltage, a retransfer

time delay starts timing.

E.Retransfer Time Delay

• This timer runs for about 15 (SA = six) seconds.

• At end of a 15-second (SA = six-second) delay,

circuit board action de-energizes transfer relay in

the transfer switch.

• Retransfer to utility power source then occurs.

F. Engine Cool-down Timer

• When the load is transferred back to utility power

source, the engine cool-down timer starts timing.

• The timer will run for about one minute, and the

generator will then shut down.

NOTE:

Sound attenuated units have a control module

assembly (CMA) board that reads frequency signals from the stator battery charge windings and

relates them to engine speed or rpm. When AC frequency reaches about 30 Hertz, cranking is terminated and an engine warmup timer goes ON, running for approximately 15 seconds.

2.4 MANUAL TRANSFER OPERATION

2.4.1 TRANSFER TO GENERATOR

POWER SOURCE

To start the generator and activate the transfer switch

manually, proceed as follows:

1. Set the generator’s Auto/Off/Manual switch to

OFF.

2. Set the generator’s main circuit breaker to its

OFF (or open) position.

3. Turn OFF the utility power supply to the transfer

switch using the means provided (such as a

utility main line circuit breaker).

Do not attempt to activate the transfer switch

manually until all power voltage supplies

to the switch have been positively turned off.

Failure to turn off all power voltage supplies

may result in extremely hazardous and possibly

fatal electrical shock.

Figure 2.3 – Manual Transfer Switch Operation

4. Use the manual transfer handle inside the transfer switch to move the main contacts to their

“Standby” position, i.e., loads connected to the

standby power source (Figure 2.3).

5. Turn ON the utility power supply to the transfer

switch using the means provided (such as a

utility main line circuit breaker).

◆

Section 2 — Operation

Guardian Air-cooled Generators

Page 22

20 Generac®Power Systems, Inc.

6. To crank and start the engine, set the

Auto/Off/Manual switch to MANUAL.

7. Let the engine stabilize and warm up for a few

minutes.

8. Set the generator’s main circuit breaker to its ON

(or closed) position. The standby power source

now powers the loads.

2.4.2 TRANSFER BACK TO UTILITY

POWER SOURCE

When utility power has been restored, you will want

to transfer back to that source and shut down the

generator. This can be accomplished as follows:

1. Set the generator’s main circuit breaker to its

OFF (or open) position.

2. Let the engine run for a minute or two at no-load

to stabilize the internal temperatures.

3. Set the generator’s Auto/Off/Manual switch to

its OFF (or open) position. The engine should

shut down.

4. Check that utility power supply to the transfer

switch is turned OFF.

Do not attempt to activate the transfer switch

manually until all power voltage supplies

to the switch have been positively turned off.

Failure to turn off all power voltage supplies

may result in extremely hazardous and possibly

fatal electrical shock.

5. Use the manual transfer handle inside the transfer switch to move the main contacts back to their

“Utility” position, i.e., loads connected to the utility power source (Figure 2.3, Page 19).

6. Turn ON the utility power supply to the transfer

switch using the means provided.

7. Set the system to automatic operation as

outlined in “Automatic Transfer Operation,”

Section 2.2 (Page 18).

2.5 PROTECTION SYSTEMS

Unlike an automobile engine, the generator may have

to run for long periods of time with no operator present to monitor engine conditions. For that reason, the

engine is equipped with the following systems that

protect it against potentially damaging conditions:

1. Low Oil Pressure Sensor

2. High Temperature Sensor

3. Overcrank

4. Overspeed

On sound attenuated models, there are LED readouts on the control panel to notify you that one of

these faults has occurred. There is also a “System

Set” LED that is lit when all of the following conditions are true:

1. The Auto/Off/Manual switch is set to the AUTO

position.

2. The “Not In Auto” dip switch is set to the OFF

position on the control board.

3. No alarms are present.

2.5.1 LOW OIL PRESSURE SWITCH

This switch (Figure 2.4) has normally closed contacts

that are held open by engine oil pressure during

cranking and operating. Should oil pressure drop

below the 8 psi range, switch contacts close, and the

engine shuts down. The unit should not

be restarted until oil is added, and the

Auto/Off/Manual switch must be turned to OFF and

then back to AUTO.

2.5.2 HIGH TEMPERATURE SWITCH

This switch’s (Figure 2.4) contacts close if the temperature should exceed approximately 140º C (284º

F), initiating an engine shutdown. Your generator will

automatically restart and the LED will reset once the

temperature has returned to a safe operating level.

Figure 2.4 – Low Oil Pressure and

High Temperature Switches

2.5.3 OVERCRANK

This feature prevents the generator from damaging itself

when it continually attempts to start and another problem, such as no fuel supply, prevents it from starting.

The unit will crank and rest for a preset time limit.

Then, it will stop cranking, and the LED will light indicating an overcrank failure. The Auto/ Off/Manual switch

will need to be set to OFF and then back to AUTO to

reset the generator control board.

NOTE:

If the fault is not repaired, the overcrank feature

will continue to activate.

◆

◆

◆

◆

Section 2 — Operation

Guardian Air-cooled Generators

Page 23

2.5.3.1 Approximate Crank Cycle Times

• 15 seconds ON

• 15 seconds OFF

• 7 seconds ON

• 7 seconds OFF

• Repeat for 45 seconds

Approximately 90 seconds total

2.5.4 OVERSPEED

This feature protects the generator from damage by

shutting it down if it happens to run faster than the preset limit. This protection also prevents the generator

from supplying an output that could potentially damage

appliances connected to the generator circuit. The overspeed feature will activate as follows:

1. If the generator runs at 72 Hertz for five seconds,

the generator will shut down.

2. If the generator reaches 75 Hertz, it will shut

down instantly.

2.6 ADDITIONAL GENERATOR

FEATURES

2.6.1 6 KW, 8 KW AND 10 KW UNITS (NON-SA)

The standard 6 kW, 8 kW and 10 kW air-cooled

Guardians offer additional features that are not

factory preset:

1. Remote Start – This allows for remote starting of

the generator by means of the #183 (common)

and #178 (normally open) lines with the

Auto/Off/Manual switch set to AUTO. Closure of

the circuit starts the unit; opening of the circuit

stops the unit. See Figure 2.5.

NOTE:

This function will work ONLY with the unit in the

AUTO mode.

Figure 2.5 – Remote Start/Alarm Options

–Type 14 AWG wire is recommended.

–These options should be wired to the unit by a qualified electrician or

Generac/Guardian Authorized Dealer.

2. Remote/Common Alarm – This allows for an

alarm, light, horn, etc., to activate when any fault

has occurred. Lines #210 (common) and #211

(normally open) provide a “closure” on common

fault, which can be used for 120 volts, 10 amps

maximum. See Figure 2.5.

3. Remote Not Auto – The generator will not automatically start during a utility failure.

2.6.2 SOUND ATTENUATED UNITS

Model 00844 of the sound attenuated air-cooled

Guardians offers additional features that are not factory

preset (see Figure 2.6):

1. Remote Start – This allows for remote starting of the

generator by means of the #183 and #178 lines with

the Auto/Off/Manual switch set to AUTO.

2. Engine Run Signal – The engine run signal is controlled by the #14 line. The “volt free” engine run

signal relay closes when the #14 line is “hot.”

3. Automatic Transfer Switch (ATS) in Emergency –

For this to be active, a microswitch on the transfer

switch sends a signal along the #231 line to close

the “volt free” contact relay.

4. Shutdown Fault – This signal is controlled by the

main printed circuit board along the #229 line.

When a common fault occurs (low oil pressure,

high temperature, overspeed, overcrank), the

control board will send a signal along the #229

line to close the "volt free" contact relay.

Figure 2.6 – Remote Alarms

◆

◆

◆

Section 2 — Operation

Guardian Air-cooled Generators

Generac®Power Systems, Inc. 21

Page 24

22 Generac®Power Systems, Inc.

3.1 BEFORE INITIAL START-UP

Before starting, complete the following:

1. Set the generator's Auto/Off/Manual switch to the

OFF position.

2. Turn OFF the utility power supply to the transfer

switch using the means provided (such as the

utility main line circuit breaker).

3. Check the engine crankcase oil level and, if necessary, fill to the dipstick FULL mark with the recommended oil. Do not fill above the FULL mark.

4. Check the fuel supply. Gaseous fuel lines must

have been properly purged and leak tested in

accordance with applicable fuel-gas codes. All

fuel shutoff valves in the fuel supply lines must

be open.

Never operate the engine with the oil level

below the “Add” mark on the dipstick. Doing

this could damage the engine.

3.2 CHECK TRANSFER

SWITCH OPERATION

Refer to Section 2.4 (Page 19) for manual operation

procedures.

Do not attempt manual transfer switch

operation until all power voltage supplies to

the transfer switch have been positively turned

off. Failure to turn off all power voltage

supplies will result in extremely hazardous

and possibly fatal electrical shock.

3.3 ELECTRICAL CHECKS

Complete electrical checks as follows:

1. Turn on the utility power supply to the transfer

switch using the means provided (such as a utility main line circuit breaker).

The transfer switch is now electrically “hot.”

Contact with “hot” parts will result in extremely

hazardous and possibly fatal electrical shock.

Proceed with caution.

2. Use an accurate AC voltmeter to check utility

power source voltage across terminals N1 and

N2. Nominal line-to-line voltage should be 240

volts AC.

3. Check utility power source voltage across terminals N1 and the transfer switch neutral lug; then

across terminal N2 and neutral. Nominal line-toneutral voltage should be 120 volts AC.

4. When certain that utility supply voltage is compatible with transfer switch and load circuit ratings, turn OFF the utility power supply to the

transfer switch.

5. Set the generator's main circuit breaker to its

OFF (or open) position. Initial tests will be conducted at no-load condition.

6. On the generator panel, set the Auto/Off/Manual

switch to MANUAL. The engine should crank

and start.

7. Let the engine warm up for about five minutes to

allow internal temperatures to stabilize. Then, set

the generator’s main circuit breaker to its ON (or

closed) position.

Proceed with caution! Generator power voltage

is now supplied to the transfer switch. Contact

with live transfer switch parts will result in

dangerous and possibly fatal electrical shock.

8. Connect an accurate AC voltmeter and an AC frequency meter across transfer switch terminal

lugs E1 and E2. Voltage should be 242-252 volts;

frequency should read about 61-63 Hertz.

9. Connect the AC voltmeter test leads across terminal lug E1 and neutral; then across E2 and neutral. In both cases, voltage reading should be 121126 volts AC.

10. Set the generator’s main circuit breaker to its

OFF (or open) position. Let the engine run at noload for a few minutes to stabilize internal engine

generator temperatures.

11. Set the generator's Auto/Off/Manual switch to

OFF. The engine should shut down.

NOTE:

It is important that you DO NOT proceed until you

are certain that generator AC voltage and frequency are correct and within the stated limits.

Generally, if both AC frequency and voltage are

high or low, the engine governor requires adjustment. If frequency is correct, but voltage is high or

low, the generator’s voltage regulator requires

adjustment.

3.4 GENERATOR TESTS UNDER LOAD

To test the generator set with electrical loads applied,

proceed as follows:

1. Set generator’s main circuit breaker to its OFF

(or open) position.

2. Set the generator's Auto/Off/Manual switch

to OFF.

3. Turn OFF the utility power supply to the transfer

switch, using the means provided (such as a utility main line circuit breaker).

Section 3 — Post-installation Start-up Adjustments

Guardian Air-cooled Generators

Page 25

Generac®Power Systems, Inc. 23

Do not attempt manual transfer switch

operation until all power voltage supplies to

the transfer switch have been positively turned

off. Failure to turn off all power voltage

supplies will result in extremely hazardous

and possibly fatal electrical shock.

4. Manually set the transfer switch to the STANDBY

position, i.e., load terminals connected to the

generator's E1/E2 terminals. The transfer switch

operating lever should be down.

5. Set the generator's Auto/Off/Manual switch to

MANUAL. The engine should crank and start

immediately.

6. Let the engine stabilize and warm up for a few

minutes.

7. Set the generator’s main circuit breaker to its ON

(or closed) position. Loads are now powered by

the standby generator.

8. Turn ON electrical loads. Apply an electrical load

equal to the full rated wattage/amperage capacity

of the installed generator.

9. Connect an accurate AC frequency meter across

terminal lugs E1 and E2. Voltage should be

greater than 230 volts; frequency should be

greater than 58 Hertz.

10. Let the generator run at full rated load for 20-30

minutes. Listen for unusual noises, vibration or

other indications of abnormal operation. Check

for oil leaks, evidence of overheating, etc.

11. When testing under load is complete, turn OFF

electrical loads.

12. Set the generator's main circuit breakers to their

OFF (or open) positions.

13. Let the engine run at no-load for a few minutes.

14. Set the Auto/Off/Manual switch to OFF. The

engine should shut down.

3.5 CHECKING AUTOMATIC

OPERATION

To check the system for proper automatic operation,

proceed as follows:

1. Check that the Auto/Off/Manual switch is set

to OFF.

2. Manually set the transfer switch to the UTILITY

position, i.e., load terminals connected to the utility power source side.

3. Turn ON the utility power supply to the transfer

switch, using the means provided (such as a utility main line circuit breaker).

4. Set the Auto/Off/Manual switch to AUTO. The system is now ready for automatic operation.

5. Turn OFF the utility power supply to the transfer

switch.

With the Auto/Off/Manual switch at AUTO, the engine

should crank and start when the utility source power

is turned OFF. After starting, the transfer switch

should connect load circuits to the standby side. Let

the system go through its entire automatic sequence

of operation.

With the generator running and loads powered by

generator AC output, turn ON the utility power supply to the transfer switch. The following should

occur:

• After about six seconds, the switch should transfer

loads back to the utility power source.

• About one minute after retransfer, the engine

should shut down.

3.6 ADJUSTING THE LOAD BLOCK

When the natural gas system is being used, the load

block is fitted with an adjustment screw that has

been calibrated to provide maximum power.

However, because of variations in the Btu content of

natural gas across the country, it may be necessary to

readjust the load block.

• Connect a frequency meter to the output of the

generator.

• Start the unit and apply full load according to the

following chart:

• Allow the unit to stabilize; then, turn the adjustment screw slowly clockwise or counterclockwise

and watch the frequency.

• When the highest frequency is reached, turn the

adjustment screw counterclockwise 1/4 turn.

• The fuel system is now set.

• For LP gas operations, the hose and blanking plug

must be reconfigured as shown in Figure 1.3, Page

7. The unit is set to provide maximum power

using LP gas.

Do not make any unnecessary adjustments.

Factory settings are correct for most applications. However, when making adjustments, be

careful to avoid overspeeding the engine.

Section 3 — Post-installation Start-up Adjustments

Guardian Air-cooled Generators

Unit 120 Volts 240 Volts

6 kW (Non-SA): 50 amps 25 amps

8 kW (Non-SA)

: 66.7 amps 33.3 amps

10 kW (Non-SA): 83.3 amps 41.6 amps

Sound Attn.: 66.7 amps 33.3 amps

Page 26

24 Generac®Power Systems, Inc.

3.7 ENGINE GOVERNOR ADJUSTMENT

If both AC frequency and voltage are correspondingly

high or low, adjust the engine governor as follows:

3.7.1 6 KW UNITS (NON-SA)

1. Loosen the governor clamp bolt (Figure 3.1).

2. Push the spring end of the governor lever clockwise to the wide open throttle position of

the lever.

• Hold the governor lever at wide open throttle and,

with a pair of pliers, rotate the governor shaft

fully clockwise.

• While holding the governor shaft fully clockwise

and the governor lever at wide open throttle,

tighten the governor clamp bolt to 70 inchpounds (8 N-m).

3. Start the engine; let it stabilize and warm up at

no-load.

4. Turn the adjuster nut to obtain a frequency reading of 62 Hertz.

5. Determine if the governor spring is properly

located in the slot of the governor lever as

follows:

• If droop is excessive, move the governor spring

down one slot on the lever.

• For greater stability, move the governor spring up

one slot on the lever.

6. After repositioning the spring on a lever slot,

recheck the frequency reading and, if necessary,

readjust the adjuster nut to obtain 62 Hertz at

no-load.

7. When frequency is correct at no-load, check the

AC voltage reading. If voltage is incorrect, the voltage regulator may require adjustment.

Figure 3.1 – 6 kW

Engine Governor Adjustment

3.7.2 8 KW AND 10 KW UNITS (NON-SA)

1. Loosen the governor clamp bolt (Figure 3.2).

2. Push the spring end of the governor lever clockwise to the wide open throttle position of

the lever.

• Hold the governor lever at wide open throttle

and, with a screwdriver, rotate the governor

shaft fully clockwise.

• Before tightening, verify that the governor lever is

pushed all the way onto the governor shaft.

• While holding the governor shaft fully clockwise

and the governor lever at wide open throttle,

tighten the governor clamp bolt to 70 inchpounds (8 N-m).

3. Start the engine; let it stabilize and warm up at

no-load.

4. Turn the speed adjust nut to obtain a frequency

reading of 62 Hertz.

5. When frequency is correct at no-load, check the

AC voltage reading. If voltage is incorrect, the voltage regulator may require adjustment.

Figure 3.2 – 8 kW and 10 kW

Engine Governor Adjustment

NOTE:

If the engine continues to run fast, use a pair of

pliers to bend the bend tab clockwise to release

tension on the lower governor spring.

◆

◆

Section 3 — Post-installation Start-up Adjustments

Guardian Air-cooled Generators

Page 27

Generac®Power Systems, Inc. 25

3.7.3 SOUND ATTENUATED UNITS

1. Carefully inspect the governor anti-lash

spring (Figure 3.3). Be sure it is not broken

or disengaged.

2. Loosen the governor clamp nut. Then, push the

spring end of the governor lever all the way up

(wide open throttle).

3. Hold the governor lever at wide open throttle and

insert the tip of a screwdriver into the slotted end

of the governor shaft.

• Hold the governor lever at wide open throttle and

rotate the governor shaft fully counterclockwise.

• Hold the governor shaft fully counterclockwise

and tighten the governor clamp nut to 70 inchpounds (8 N-m) torque.

Figure 3.3 – Sound Attenuated

Engine Governor Adjustment

3.8 VOLTAGE REGULATOR

ADJUSTMENT

With the frequency between 61-62 Hertz, slowly turn

the slotted potentiometer (Figure 3.4) until line voltage reads 244-252 volts.

NOTE:

You must remove the roof to adjust the voltage

regulator on nonsound attenuated units.

Figure 3.4 – Voltage Adjustment Potentiometer

NOTE:

The voltage regulator is housed in the generator's

control panel. The regulator maintains

a voltage in direct proportion to frequency at a 2to-1 ratio. For example, at 62 Hertz, line-to-neutral voltage will be 124 volts.

3.9 OVERSPEED ADJUSTMENT

3.9.1 6 KW, 8 KW AND 10 KW UNITS (NON-SA)

See item 3 of Section 1.15 on Page 15 for overspeed

adjustment information for these units.

3.9.2 SOUND ATTENUATED UNITS

Use the following overspeed adjustment procedure: