Page 1

GENERAC _

0

erator'sIVianual

I

Page 2

introduction.............................................................1

Safety Rules...........................................................1

SafetySymbols and Meanings.......................................1

Generalinformation................................................4

KnowYourPowerWasher.........................................................4

ProductSpecifications..............................................................5

EmissionsInformation..............................................................5

HighAltitudeOperation..............................................................5

Unpacking.................................................................................6

Set-up.....................................................................6

Assembly..................................................................................6

Add EngineOil..........................................................................7

Add Fuel...................................................................................7

ConnectHoseand WaterSupplyto Pump.................................8

How to Use Nozzles..................................................................9

CleaningandApplying Detergent..................................10

PowerWasherRinsing.................................................11

CleaningDetergentSiphoningTube...............................11

Operation..............................................................12

Operation................................................................................12

PowerWasherLocation..........................................................12

ChecklistBefore StartingEngine..............................................12

How to Start YourPowerWasher............................................12

AutomaticCoolDown System (ThermalRelief).......................14

How to Stop YourPowerWasher.............................................14

Maintenance.........................................................14

MaintenanceRecommendations..............................................14

MaintenanceSchedule............................................................15

PumpOil.................................................................................15

EmissionsControl...................................................................15

PowerWasherMaintenance....................................................15

Checkand CleanInletScreen..................................................15

CheckHigh PressureHoses....................................................15

CheckDetergentSiphoningTube.............................................15

CheckSpray Gun....................................................................15

NozzleMaintenance................................................................15

EngineMaintenance................................................................16

EngineOil Recommendations..................................................16

CheckOil Level............................................................17

AddingEngineOil.........................................................17

ChangingEngineOil.....................................................17

ServiceAir Cleaner.................................................................18

ServiceSparkPlug..................................................................18

InspectMufflerand SparkArrestor..........................................18

RemoveSparkArresterScreen.....................................18

After EachUse........................................................................19

WinterStorage........................................................................19

LongTermStorage..................................................................20

ProtectFuelSystem.....................................................20

ProtectEngine..............................................................20

ChangeOil...................................................................20

Protectingthe Pump.....................................................20

OtherStorageInstructions.......................................................20

Transporting/Tippingofthe Unit..............................................20

Troubleshooting....................................................21

TroubleshootingGuide.............................................................21

Manueldel propietario..........................................23

Manueld'entretien................................................47

Page 3

iNTRODUCTION

Thank you for purchasing this power washer manufactured by

GeneracPower Systems, Inc.This modelis a high performance,

air-cooled, engine-driven power washer that operates between

2500 and 3100 psi dependingon which model you purchased.

The units feature custom designed wheels, axial cam pump

with stainless steel pistons, automatic cool down system, quick

connect nozzles,high pressure hose, detergentsiphoning hose

and chemicaltank(s) dependingon unit model.

Commonsenseandstrictcompliancewiththespecialinstructions

are essentialto preventingaccidents. The operatormust read

this manual and thoroughly understand all of the instructions

and warnings before usingthe equipment.If any portion of the

manualis not understood,contact the nearestAuthorizedDealer

for starting, operating and servicing procedures.The owner is

responsiblefor properandsafe use of the equipment.

Thepowerwashercanoperatesafely,efficientlyandreliablyonly if

it is properlylocated,operatedand maintained. Beforeoperating,

servicingor storing:

• Studyall warnings in this manualand on the productcarefully.

• Becomefamiliar with this manual andthe unit beforeuse.

• Referto theAssemblysection of the manualfor instructionson

final assembly procedures.Followthe instructions completely.

Themanufacturercannot anticipateevery possible circumstance

that might involvea hazard.The warnings in this manual,and on

tags and decals affixedto the unit are,therefore,not all inclusive.

If usingaprocedure,workmethodoroperatingtechniquethat the

manufacturerdoes not specifically recommend,ensurethat it is

safe for others. Also makesure the procedure,work methodor

operatingtechnique utilized does not renderthe power washer

unsafe.

THE INFORMATIONCONTAINEDHEREIN WAS BASED ON

MACHINESIN PRODUCTIONAT THE TIME OF PUBLICATION.

GENERACRESERVESTHERIGHTTO MODIFYTHIS MANUALAT

ANYTIME.

Save these instructionsfor future reference. If you loan this

device to someone,ALWAYSloan these instructionsAND the

Owner's Manualto the individualas well.

WHERETOFiNDUS

You can contact GeneracCustomerService by phoneat 1-888-

436-3722, or on the internet at www.generac.com.Record the

important information of the unit in the following chart for future

referenceand/orservice inquiries.

SAFETYRULES

Throughout this publication, and on tags and decals affixed to

the power washer, DANGER,WARNING,CAUTIONand NOTE

blocks are used to alert personnelto special instructions about

a particular operation that may be hazardous if performed

incorrectly or carelessly.Observethemcarefully.Theirdefinitions

areas follows:

Indicatesa hazardoussituationor action which,if notavoided,

will resultin death or seriousinjury.

Indicatesa hazardoussituationor actionwhich, if not avoided,

couldresultin deathor seriousinjury.

ACAUTION!

Indicatesa hazardoussituationor actionwhich, if not avoided,

couldresultin minoror moderateinjury.

NOTE:

Notescontainadditional informationimportanttoa procedure

and will be found withinthe regulartextbody of thismanual.

These safety warnings cannot eliminate the hazardsthat they

indicate. Common sense and strict compliancewith the special

instructionswhile performingtheaction or serviceareessentialto

preventingaccidents.

SAFETYSYMBOLSANDMEAN/NGS

ToxicFumes Kickback ElectricalShock

Slippery Surface Fall Fluid injection

D

Fire

Explosion Operator's Manual

ModelNumber

Serial Number

DatePurchased

MovingParts

Flying Objects Hot Surface

Page 4

,_ DANGER:CarbonmonoxideproducedduringuseCANKiLL

inminutes.NEVERuseindoors,ina vehicle,orinother

shelteredareas,EVENiFdoorsandwindowsareopen.Only

useOUTSIDEandfarawayfrom windows,doorsandvents.

Somechemicalsor detergents may beharmfulif inhaled

oringested,causingseverenausea, fainting, or poisoning.

• Operatepower washer ONLYoutdoors.

• A runningenginegivesoff carbon monoxide.

• Carbonmonoxideis an odorless,colorless, poisonousgas.

Breathingcarbonmonoxidecan causeheadache,fatigue,

dizziness,vomiting, confusion,seizures,nausea,fainting

or death.If you start experiencingany of these symptoms,

IMMEDIATELYmoveto fresh air. Seekmedicalattention.

• Keep exhaustgasfrom enteringa confined areathrough

windows, doors, ventilationintakes,or other openings.Warnany

occupantsinside aboutthe symptoms of carbon monoxideso

they know to move to fresh air if they beginto feel ill.

• The use of a carbon monoxidedetector insideany occupied

premisesbetweenthe powerwasher andthe occupant is

recommended.

• NEVERstart or run engineindoors,in a vehicle, or in an

enclosedarea, EVENIFwindows anddoors are open.

• Use a respiratoror maskwheneverthere is a chancethat

harmful gas or vapors may beinhaled.

• Readall instructions with respiratoror mask so you arecertain

the respiratoror mask will providethe necessaryprotection

againstinhalingharmful gasor vapors. Ifyou beginto

experienceany ofthe COsymptoms listedabove,IMMEDIATELY

moveto fresh air.

,_DANGER: spray gun people, or

electrical devices. Serious injury or deathwill result.

ALWAYSpointspraygunin safedirection, squeezespraygun

trigger to release highpressure,every time you stopengine.

Engagetrigger lockwhen not inuse.

,_ produces cancut through skin andits underlyingtissues,leadingto serious injury,possible amputationor death.

• NEVERallow CHILDRENto operatepowerwasher or playnearby.

This is NOTa toy.

• NEVERrepairhigh pressure hose. Replaceit.

• NEVERrepairleaking connectionswith sealantof any kind.

Replaceo-ring or seal.

• NEVERconnecthigh pressurehoseto nozzleextension.

• Keep high pressurehose connectedto pump andspray gun

while system is pressurized.

• NEVERsecurespray gun in openposition.

• NEVERleavespraygun unattendedwhile machineis running.

• NEVERusea spray gun which does not haveatrigger lock or

triggerguard in placeandin working order.

• ALWAYSbe certain spraygun, nozzlesand accessoriesare

correctly attached.

NEVERaim at

• The highpressurestream ofwater that this equipment

Spray guntraps high water pressure,EVENWHENengine

is stoppedandwater is disconnected,which can cause

injury.

animals,

,_WARNING: Riskofelectrocution.

burn.

'_ Contactwithpowersourcecancauseelectricshockor

• NEVERspraynearpower source.

,_WARNING: Contactwith muffler area can result in serious

burns. Exhaustheat/gasescanignitecombustibles,

structuresor damage fuel tank causing a fire.

• DONOTtouch hot parts and AVOIDhot exhaustgases.

• Allow equipmentto cool beforetouching.

• Keepat leastfive (5) feet (152 cm) of clearanceon all

sidesof powerwasherincluding overhead.

• It is a violation of CaliforniaPublicResourceCode,Section

4442, to use or operatethe engineon anyforest-covered,

brush-covered,or grass-coveredland unlessthe exhaust

systemis equippedwith aspark arrester,as definedin

Section4442, maintainedin effectiveworking order.Other

statesor federaljurisdictions may havesimilar laws.

Contactthe original equipmentmanufacturer,retailer,or dealerto

obtaina sparkarrester designedfor the exhaustsystem installed

onthis engine.

• Replacementparts must bethe same and installedin the same

position as the originalparts.

,_ WARNING:Fuel and its vaporsare extremelyflammable and

explosive. Fire or explosion cancausesevere burns or death.

WHENADDINGDR DRAININGFUEL

• Turnpower washerOFFand let it cool atleast two (2)

minutes beforeremovingfuel cap. Loosencap slowly to

relievepressurein tank.

_j_ • Fill ordrainfuel tank outdoors.

WHENSTARTINGEQUIPMENT

WHENOPERATINGEQUIPMENT

WHENTRANSPORTINGORREPAIRINGEQUIPMENT

WHENSTORINGFUELDREQUIPMENTWITH FUELiN TANK

• DONOToverfill tank. Allow spacefor fuel expansion.

• If fuel spills, wait until it evaporatesbeforestarting

engine.

• Keepfuel awayfrom sparks, openflames,pilot lights, heat, and

other ignitionsources.

• DONOTfighta cigaretteor smoke.

• Ensuresparkplug, muffler,fuel cap, andair cleanerare in place.

• DONOTcrank enginewith spark plug removed.

• DONOTtip engineor equipment at anglewhich causesfuel to

spill.

• DONOTsprayflammable liquids.

• Transport/repairwith fuel tank EMPTYor withfuel shutoff valve

OFF.

• Disconnect sparkplug wire.

• Store away from furnaces, stoves,water heaters,clothes dryers,

or otherappliancesthat havepilot light or otherignition source

becausetheycan ignitefuel vapors.

Page 5

_ll WARNING:Useofpowerwashercancreatepuddlesand

slipperysurfaces.Kickbackfromsprayguncancauseyouto

fall.

Useonly on a levelsurface.

The cleaning area should have adequate slopes and

drainageto reducethe possibility of afall due to slippery

surfaces.

Donot useon elevatedsurfaceswhere chanceof kickback

could resultin a seriousfall.

®

Firmlygrasp spraygun with both handswhen using high

pressure spray to avoid injury when spray gun kicks

back.

,AWARNING: Starter and otherrotatingpartscan

entangle hands,hair,clothing,or accessories.

or covers.

• NEVERoperatepowerwasherwithoutprotectivehousing

• DONOTwearlooseclothing,jewelryoranythingthat

maybecaughtinthestarterorotherrotatingparts.

• Tieuplonghairandremovejewelry.

_ll ARNING:Starter cordkickback(rapid retraction) can result

in bodilyinjury.Kickbackwill pull handand arm toward

engine faster than you can let go. Brokenbones,fractures,

bruises,or sprains couldresult.

• NEVERpull starter cord withoutfirst relievingspraygun

_. pressure.

• To relievetrappedpressure, point gunin safe directionand

releasepressureby pulling/actuatingtrigger on spraygun.

• Whenstarting engine, pull cord slowly until resistanceis felt and

then pull rapidlyto avoidkickback.

• After eachstarting attempt,where enginefails to run, always

pointspray gun in safedirection, and squeezespray gun trigger

to releasehigh pressure.

• Firmly grasp spraygun with both handswhen using high

pressuresprayto avoid injurywhen spraygunkicks back.

_ll ARNING:Unintentionalsparking canresult in fire or electric

shock.

WHENADJUSTINGORMAKINGREPAIRSTO YOURPOWER

WASHER.

• Disconnectthe sparkplug wire from the spark plug and

place the wire whereit cannotcontact sparkplug.

• Useapprovedsparkplug tester.

_$ WHENTESTINGFORENGINESPARK

• DONOTcheck for spark with spark plug removed.

,,I_WARNING: The engine exhaust from this productcontains

chemicalsknownto the State ofCaliforniato causecancer,

birthdefects, or otherreproductive harm.

,,I_WARNING: This containslead and lead

knownto the State of Californiato causebirth defects or

otherreproductive harm.Wash your handsafter handlingthis

product.

product compounds,

NOTE:

Highpressurespraymay damage fragile itemsincluding

glass.

DO NOTpoint spray gun at glasswhen using red (0°) MAX

nozzle.

NEVERaim spray gun at people,animals,electricaldevicesor

plants.

NOTE:

Impropertreatmentof powerwashercan damageit and

shortenits life.

• If you havequestionsaboutintendeduse,ask dealeror contact

qualifiedservice center.

• NEVERoperateunits with brokenor missing parts, or without

protectivehousingor covers.

• DONOTby-passanysafetydeviceonthismachine.

• DONOToperatepowerwasheraboveratedpressure.

• DONOTmodify power washerin anyway.

• Beforestartingpowerwasherincold weather,checkallparts of

the equipmentto be sure icehas notformed there.

• NEVERmovemachinebypullingon hoses.Usehandleprovided

on unit.

• Checkfuel system for leaksor signsof deterioration,such as

chafed or spongy hose, looseormissing clamps, or damaged

tank or cap. Correctall defectsbefore operatingpowerwasher.

• Thisequipmentisdesignedto be usedwith Generacauthorized

parts ONLY.If equipment is used with parts that DO NOT

comply with minimum specifications, user assumes all risks

and liabilities.

CALIFORNIAPROPOSiTiON55 WARNING

Engineexhaustandsomeof its constituentsareknown

to the Stateof Californiato causecancer,birth defects

andotherreproductiveharm.

,A WARNING:Risk of eye injury.Spray cansplash backor

propelobjects.

0 • Always wearsafetygoggleswhen using this equipmentor

•. in vicinity of where equipmentis in use.

• Beforestartingthepower washer,be sureyou are

wearing adequatesafetygoggles.

• NEVERsubstitute safety glassesfor safety goggles.

CAUFORNIAPROPOSITION55 WARNING

This productcontainsor emits chemicalsknown tothe

Stateof Californiato causecancer,birth defectsand

otherreproductiveharm.

Page 6

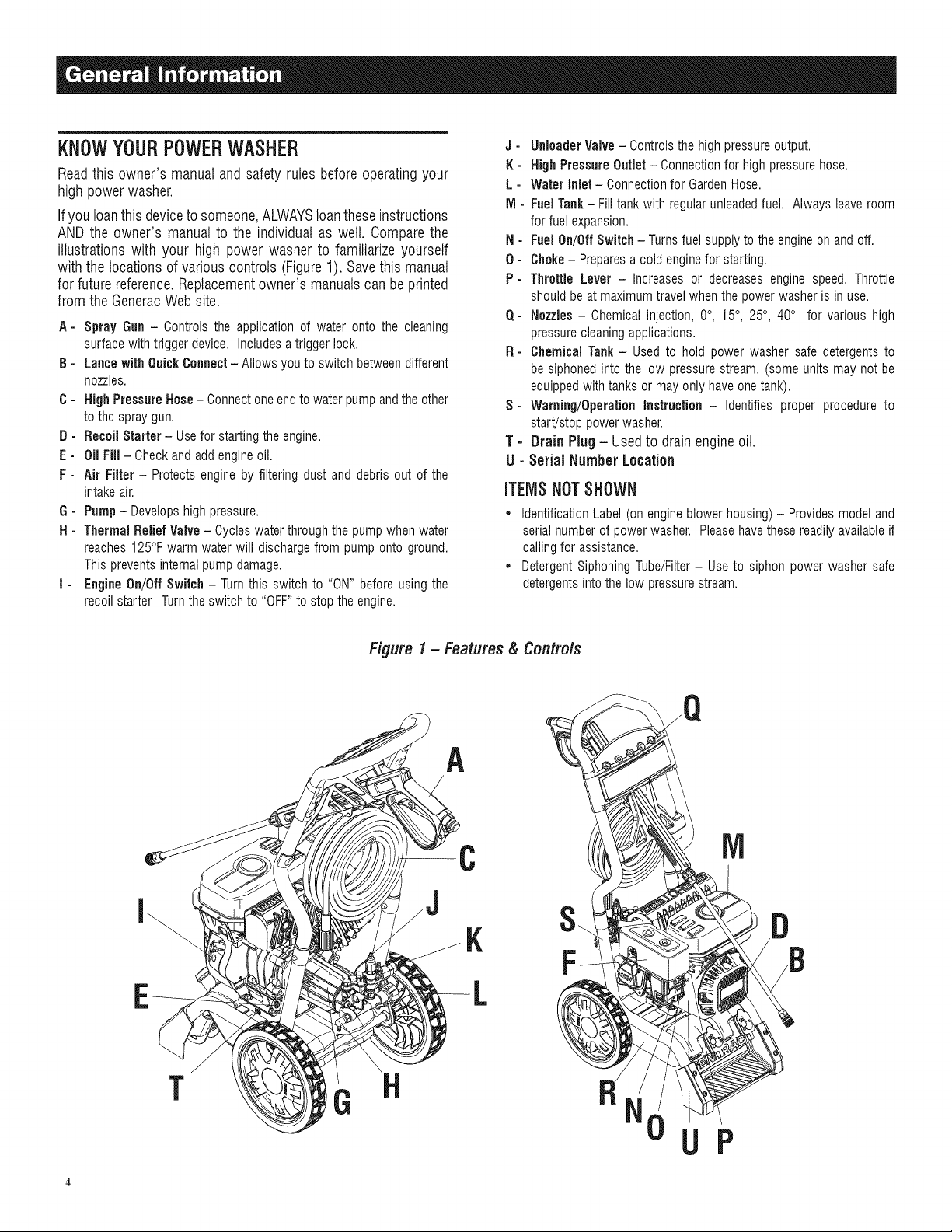

KNOWYOURPOWERWASHER

Readthis owner's manualand safety rules beforeoperatingyour

high powerwasher.

Ifyou loanthis deviceto someone,ALWAYSloantheseinstructions

ANDthe owner's manualto the individualas well. Comparethe

illustrations with your high power washer to familiarize yourself

with the locations of variouscontrols (Figure1). Savethismanual

for future reference.Replacementowner's manualscan beprinted

from the GeneracWebsite.

A- Spray Gun- Controls the application of water onto the cleaning

surface withtrigger device. Includesatrigger lock.

B- LancewithQuickConnect- Allows you to switch betweendifferent

nozzles.

C- HighPressure Hose - Connectone endto waterpumpandthe other

to the spraygun.

D - Recoil Starter - Usefor starting the engine.

E- Oil Fill - Checkand add engineoil.

F - Air Filter - Protects engine by filtering dust and debris out of the

intakeair.

G - Pump- Developshigh pressure.

H - Thermal Relief Valve- Cycleswater through the pump when water

reaches125°F warm water will dischargefrom pump onto ground.

This preventsinternal pump damage.

I - Engine On/Off Switch - Turnthis switch to "ON" before using the

recoil starter. Turn theswitch to "OFF"to stop the engine.

J - UnloaderValve- Controlsthe highpressureoutput.

K- High Pressure Outlet- Connectionfor high pressure hose.

L - Water Inlet - Connectionfor GardenHose.

M - FuelTank- Filltankwith regularunleadedfuel. Always leaveroom

forfuel expansion.

N - Fuel On/OffSwitch - Turnsfuel supply to the engineon and off.

O - Choke- Preparesacold enginefor starting.

P- Throttle Lever - Increases or decreases engine speed. Throttle

shouldbe at maximumtravel whenthe powerwasher is inuse.

Q- Nozzles - Chemical injection, 0°, 15°, 25°, 40° for various high

pressurecleaningapplications.

R- Chemical Tank- Used to hold power washer safe detergents to

be siphonedinto the low pressurestream. (some units may not be

equippedwith tanks or may only have onetank).

S- Warning/OperationInstruction - Identifies proper procedure to

start!stop powerwasher.

T - Brain Plug - Used to drain engine oil.

U - Serial Number Location

ITEMSNOTSHOWN

• IdentificationLabel (on engineblower housing)- Providesmodel and

serial numberof power washer. Pleasehavethese readilyavailableif

callingfor assistance.

• DetergentSiphoning Tube/Filter- Use to siphon power washer safe

detergentsinto the low pressurestream.

T

Figure1- Features& Controls

A

C

D

/

R

U

P

Page 7

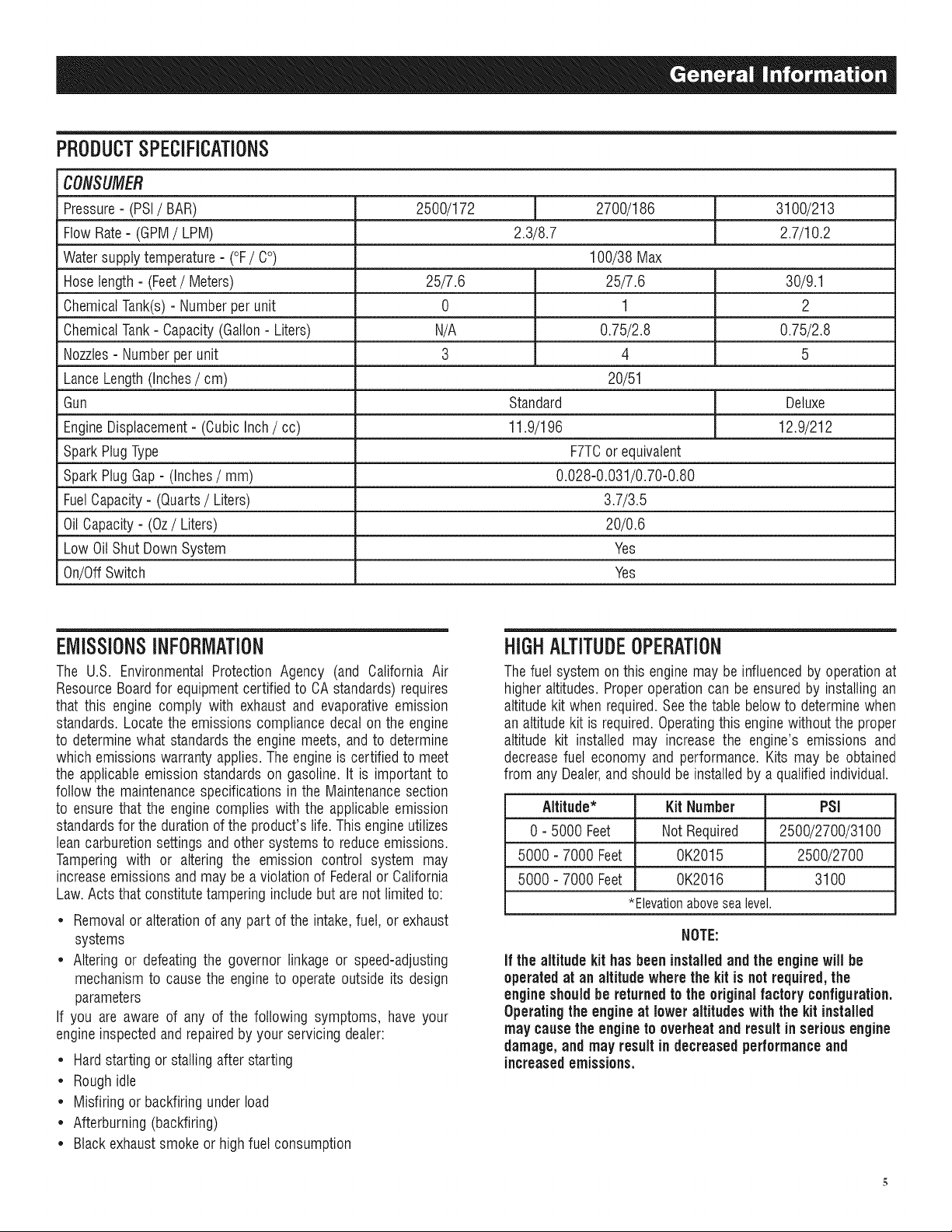

PRODUCTSPECiFiCATiONS

CONSUMER

Pressure- (PSI/ BAR) 2500/172 2700/186 3100/213

FlowRate- (GPM/ LPM) 2.3/8.7 2.7/10.2

Watersupplytemperature- (°F/ C°) 100/38 Max

Hoselength- (Feet/Meters) 25/7.6 25/7.6 30/9.1

ChemicalTank(s)- Numberper unit 0 1 2

ChemicalTank- Capacity(Gallon- Liters) N/A 0.75/2.8 0.75/2.8

Nozzles- Numberperunit 3 4 5

LanceLength (Inches/ cm) 20/51

Gun Standard Deluxe

EngineDisplacement- (Cubic Inch/ cc) 11.9/196 12.9/212

SparkPlugType F7TCorequivalent

SparkPlugGap- (Inches/ mm) 0.028-0.031/0.70-0.80

FuelCapacity- (Quarts/ Liters) 3.7/3.5

OilCapacity- (Oz/ Liters) 20/0.6

Low OilShut Down System Yes

On/OffSwitch Yes

EMISSIONSINFORMATION

The U.S. EnvironmentalProtection Agency (and California Air

ResourceBoardfor equipmentcertifiedto CAstandards) requires

that this engine comply with exhaust and evaporative emission

standards.Locate the emissions compliance decalon the engine

to determinewhat standards the enginemeets, and to determine

which emissions warrantyapplies.The engineis certified to meet

the applicable emission standards on gasoline.It is important to

follow the maintenancespecificationsin the Maintenancesection

to ensurethat the enginecomplies with the applicableemission

standardsfor theduration ofthe product's life. Thisengineutilizes

leancarburetionsettings and other systemsto reduceemissions.

Tampering with or altering the emission control system may

increaseemissionsand may be a violation of Federalor California

Law.Acts that constitutetampering includebut are notlimited to:

• Removalor alterationof anypart of the intake,fuel, or exhaust

systems

• Altering or defeatingthe governor linkage or speed-adjusting

mechanismto causethe engineto operate outside its design

parameters

If you are aware of any of the following symptoms, have your

engineinspectedand repairedby your servicing dealer:

• Hardstartingor stallingafter starting

• Roughidle

• Misfiring or backfiringunderload

• Afterburning(backfiring)

• Blackexhaustsmoke or highfuel consumption

HIGHALTITUDEOPERATION

Thefuel systemonthis enginemay be influencedby operationat

higher altitudes.Properoperationcan be ensuredby installing an

altitudekit when required.Seethetable belowto determinewhen

an altitudekit is required.Operatingthis enginewithoutthe proper

altitude kit installed may increase the engine's emissions and

decreasefuel economy and performance. Kits may be obtained

from anyDealer,and shouldbeinstalledby a qualifiedindividual.

Altitude* Kit Number PSI

0 - 5000 Feet NotRequired 2500/2700/3100

5000 - 7000 Feet 0K2015 2500/2700

5000 - 7000 Feet 0K2016 31O0

*Elevationabovesealevel.

NOTE:

If thealtitude kit hasbeen installedandthe enginewill be

operated at an altitudewherethe kit is notrequired, the

engineshould be returned tothe original factory configuration.

Operatingthe engineat loweraltitudes with the kit installed

may causethe engineto overheat andresult in seriousengine

damage, and may result in decreased performanceand

increasedemissions.

Page 8

UNPACKING

1. Removethe parts bag, accessories,andinserts includedwith

powerwasher.

2. Opencarton completely by cutting each corner from top to

bottom.

3. Ensureyou haveall includeditems priorto assembly.

• MainUnit

• HandleAssembly

• HighPressureHose

• SiphonHose&Filter

• SprayGun

• LancewithQuickConnectFitting

• OilBottle

• HoseHookWireform

• PartsBag(whichincludesthefollowing):

- ChemicalTankCapwith hole if model is equippedwith a

ChemicalTank

- Operator'sManual

- Owner'sRegistrationCard

- BagcontainingColor-codedNozzles

4. If you are missing any items from your carton, pleasecall

GeneracCustomerServiceat 1-888-436-3722. Whencalling

for assistance,pleasehavethe modeland serial numberfrom

the datatag available.

5. Fill out and send in registrationcard. Write Modet number,

Serialnumber & dateof purchasein the table locatedin the

"Whereto FindUs" section.

ASSEMBLY

Readentireoperator'smanualbeforeyouattempttoassembleorIf

you haveany problemswith the assemblyof your powerwasher,

pleasecall GeneracCustomerServiceat 1-888-436-3722. When

calling for assistance, pleasehavethe model and serial number

from the data tag available.

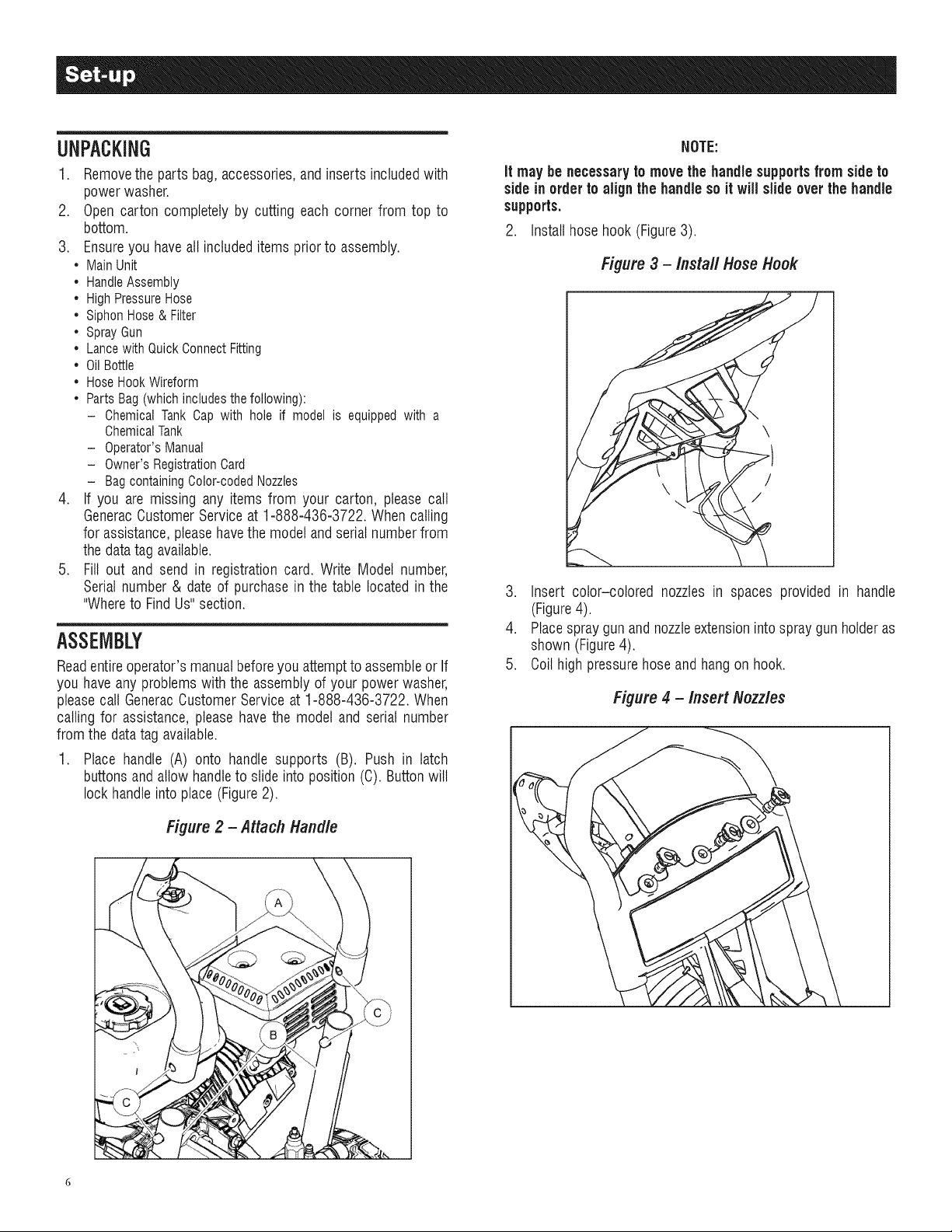

1. Place handle (A) onto handle supports (B). Push in latch

buttonsand allow handleto slide intoposition(C).Buttonwill

lock handleintoplace (Figure2).

NOTE:

it may benecessaryto move the handlesupportsfrom sideto

sidein order to alignthe handle so it will slideover the handle

supports.

2. Installhose hook (Figure3).

Figure3 - Install HoseHook

/

\

/

f

3. Insert color-colored nozzles in spaces provided in handle

(Figure4).

4. Placespraygun andnozzleextensionintospraygun holderas

shown (Figure4).

5. Coilhigh pressurehose andhang on hook.

Figure4 - InsertNozzles

Figure 2- Attach Handle

Page 9

.

Attachsiphontube to location A (Figure5).

Figure 5 - Siphon TubeLocation

.===_

ADDFUEL

Fuelmust meettheserequirements:

* Clean,fresh, unleadedgasoline.

* A minimum of 87 octane/87AKI (91 RON).

* Gasolinewith up to 10% ethanol(gasohol)is acceptable.

NOTE:

Avoid powerwasherdamage. Failureto follow Operator's

Manualfor fuel recommendationsvoidswarranty.

* DONOTuse unapprovedgasolinesuch asE85.

* DONOTmix oil ingasoline.

* DONOTmodify engineto runonalternatefuels.

Toprotectthefuel systemfrom gelling,mix in afuelstabilizerwhen

addingfuel. SeeStorage.All fuel isnotthe same.If youexperience

starting or performance problems after using fuel, switch to a

differentfuel provideror changebrands.

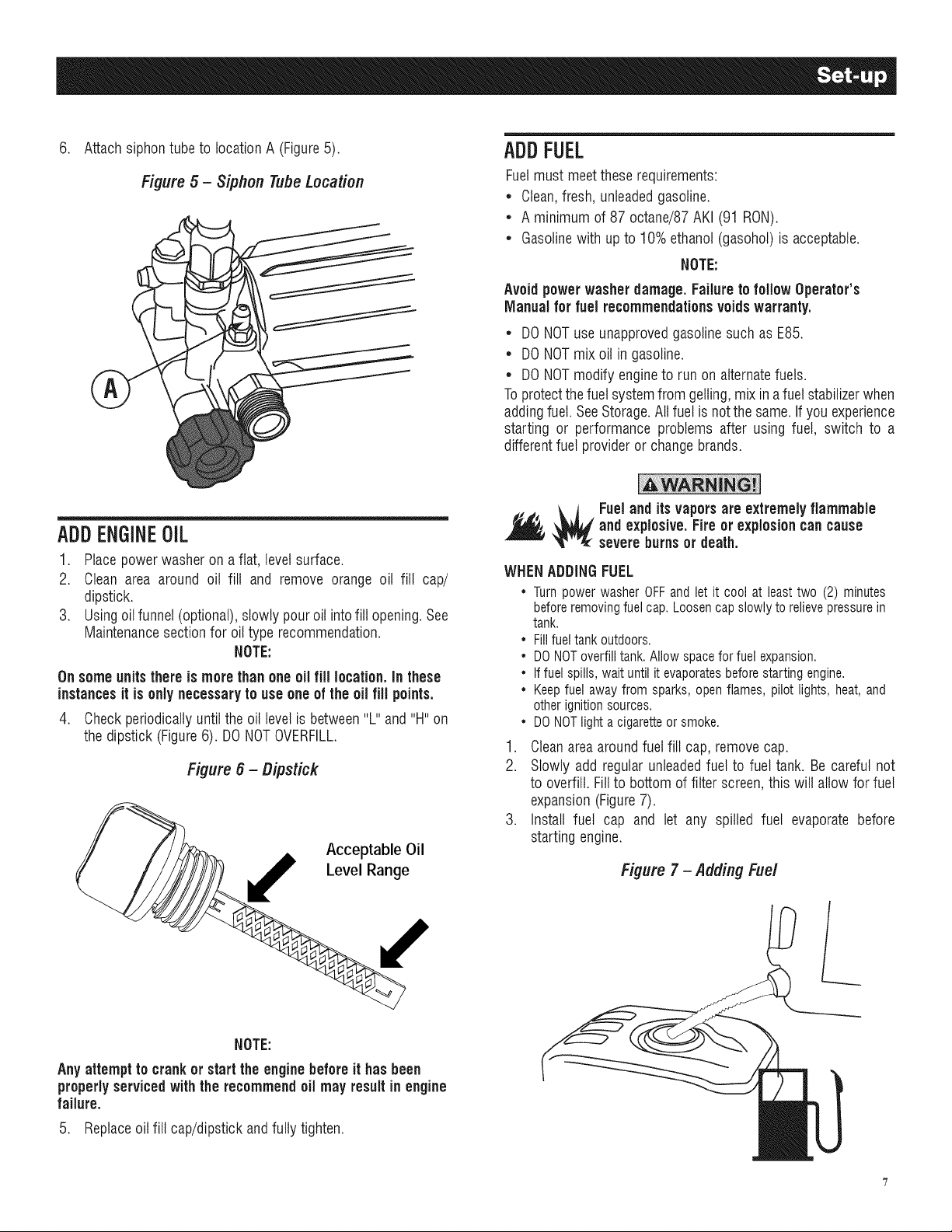

ADDENGINEOIL

1. Placepowerwasher on a flat, level surface.

2. Clean area around oil fill and remove orange oil fill cap/

dipstick.

3. Usingoilfunnel(optional),slowly pouroil intofill opening.See

Maintenancesectionfor oil type recommendation.

NOTE:

Onsomeunits there is morethan one oil fill location,inthese

instancesitis only necessaryto use one of theoil fill points.

4. Checkperiodicallyuntil the oil levelis between"L" and "H"on

thedipstick (Figure6). DONOTOVERFILL.

Figure6 - Dipstick

Acceptable Oil

Level Range

and explosive.Fire or explosion cancause

Fueland itsvaporsare extremelyflammable

severe burns or death.

WHEN ADDING FUEL

* Turnpower washer OFFand let it cool at least two (2) minutes

beforeremovingfuel cap. Loosen capslowly to relievepressurein

tank.

* Fillfuel tankoutdoors.

* DONOToverfill tank.Allow spacefor fuel expansion.

* Iffuel spills,wait until it evaporatesbeforestarting engine.

* Keepfuel away from sparks, open flames, pilot lights, heat, and

other ignitionsources.

* DONOTlight a cigaretteor smoke.

1. Clean area around fuel fill cap, remove cap.

2. Slowly add regular unleaded fuel to fuel tank. Be careful not

to overfill. Fill to bottom of filter screen, this will allow for fuel

expansion (Figure 7).

3. Install fuel cap and let any spilled fuel evaporate before

starting engine.

Figure 7- Adding Fuel

NOTE:

Anyattempt to crankor start the engine before ithas been

properlyserviced with the recommendoil mayresultin engine

failure.

5. Replaceoil fill cap/dipstickandfully tighten.

/

Page 10

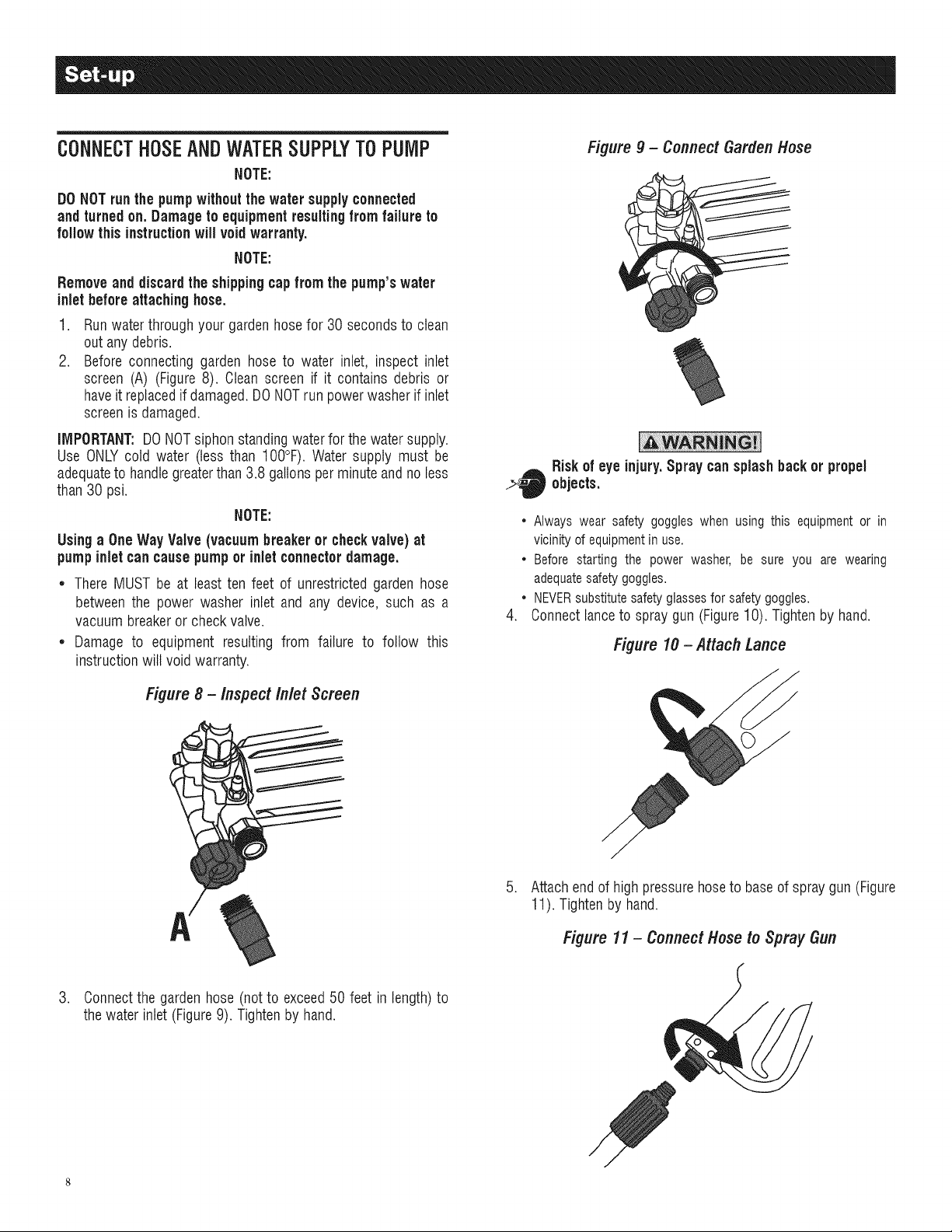

CONNECTHOSEANDWATERSUPPLYTOPUMP

NOTE:

DONOTrunthe pumpwithoutthe water supplyconnected

andturnedon. Damageto equipmentresultingfrom failureto

followthisinstructionwill voidwarranty.

NOTE:

Removeand discardthe shippingcap from the pump'swater

inletbefore attachinghose.

1. Runwater through your gardenhose for 30 secondsto clean

outany debris.

2. Before connecting garden hose to water inlet, inspect inlet

screen (A) (Figure8). Clean screen if it contains debris or

haveit replacedif damaged.DONOTrun powerwasherif inlet

screenis damaged.

IMPORTANT:DONOTsiphonstandingwaterfor the watersupply.

Use ONLYcold water (less than 100°F). Water supply must be

adequateto handlegreaterthan 3.8 gallons perminuteandno less

than 30 psi.

NOTE:

Using a OneWayValve(vacuum breaker or checkvalve) at

pumpinletcancause pumpor inlet connectordamage.

• ThereMUST be at least ten feet of unrestricted garden hose

betweenthe power washer inlet and any device, such as a

vacuum breakeror checkvalve.

• Damage to equipment resulting from failure to follow this

instructionwill voidwarranty.

Figure9 - ConnectGardenHose

Riskof eyeinjury.Spray cansplashback or propel

..>d_ objects.

• Always wear safety goggles when using this equipment or in

vicinity of equipment in use.

• Before starting the power washer, be sure you are wearing

adequatesafety goggles.

• NEVERsubstitutesafety glassesfor safety goggles.

.

Connect lance to spray gun (Figure 10). Tighten by hand.

Figure10 - Attach Lance

Figure 8 - Inspect Inlet Screen

3. Connectthe gardenhose (not to exceed50 feet in length)to

the water inlet (Figure9). Tightenby hand.

/

.

Attachendof high pressurehoseto baseof spray gun (Figure

11).Tightenby hand.

figure11 - Connect Hose toSpray Gun

Page 11

producescancutthroughskinand its underlying

The highpressurestreamof waterthat this equipment

tissues,leadingto seriousinjuryand possible

amputation.

• NEVERconnecthighpressurehosetolance.

• Keephighpressurehoseconnectedto pumpandspraygunwhile

systemispressurized.

• Alwaysbe certain spray gun, nozzlesand accessoriesare

correctlyattached.

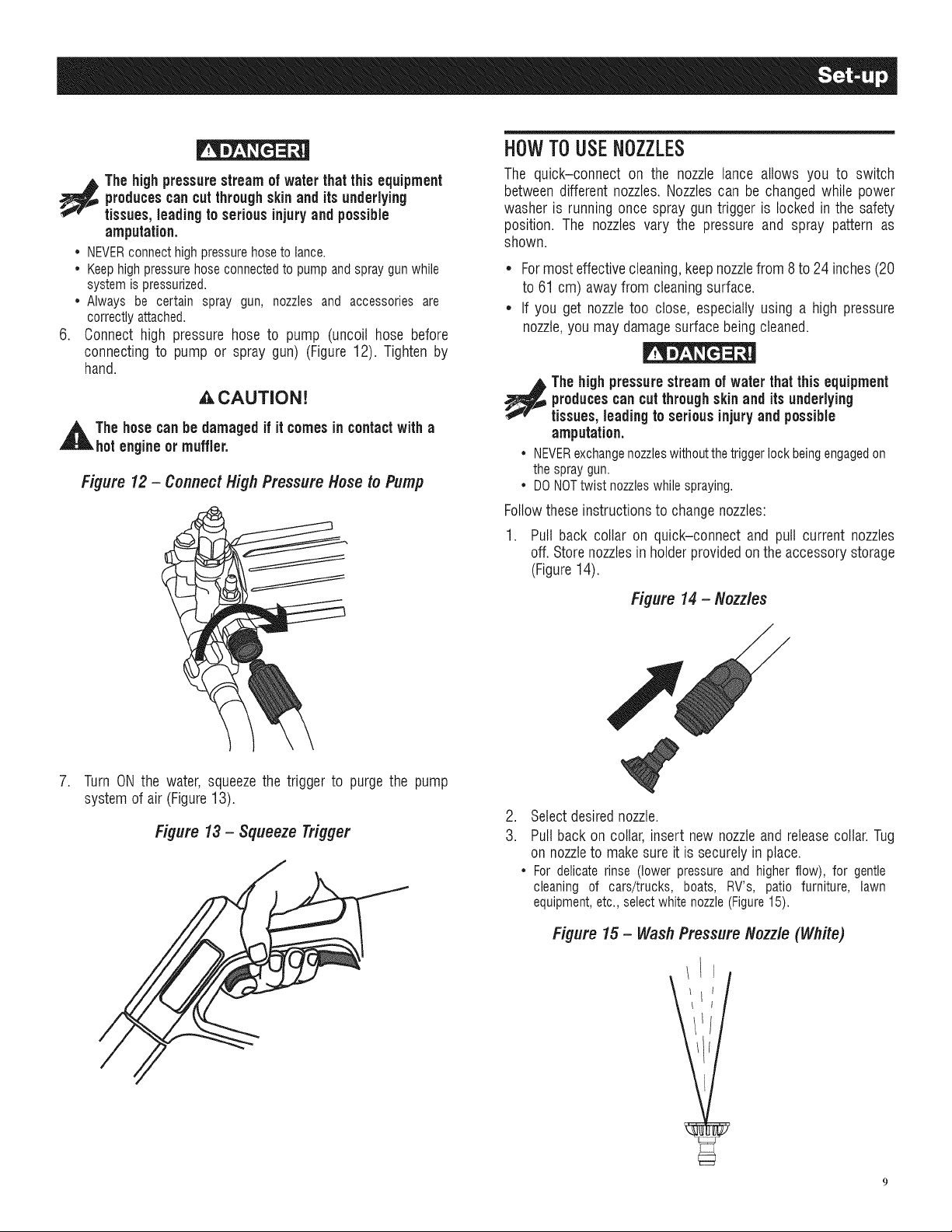

6. Connect high pressure hose to pump (uncoil hose before

connecting to pump or spray gun) (Figure12). Tighten by

hand.

HOW TOUSENOZZLES

The quick-connect on the nozzle lance allows you to switch

between differentnozzles. Nozzlescan be changedwhile power

washer is runningonce spray gun trigger is lockedin the safety

position. The nozzles vary the pressure and spray pattern as

shown.

• Formosteffectivecleaning,keepnozzlefrom 8 to 24inches(20

to 61 cm) awayfrom cleaningsurface.

• If you get nozzletoo close, especiallyusing a high pressure

nozzle,you may damagesurfacebeingcleaned.

,ACAUTiON!

,_The hosecanbe damagedif it comesin contactwith a

hot engineor muffler.

Figure12 - ConnectHighPressureHoseto Pump

.

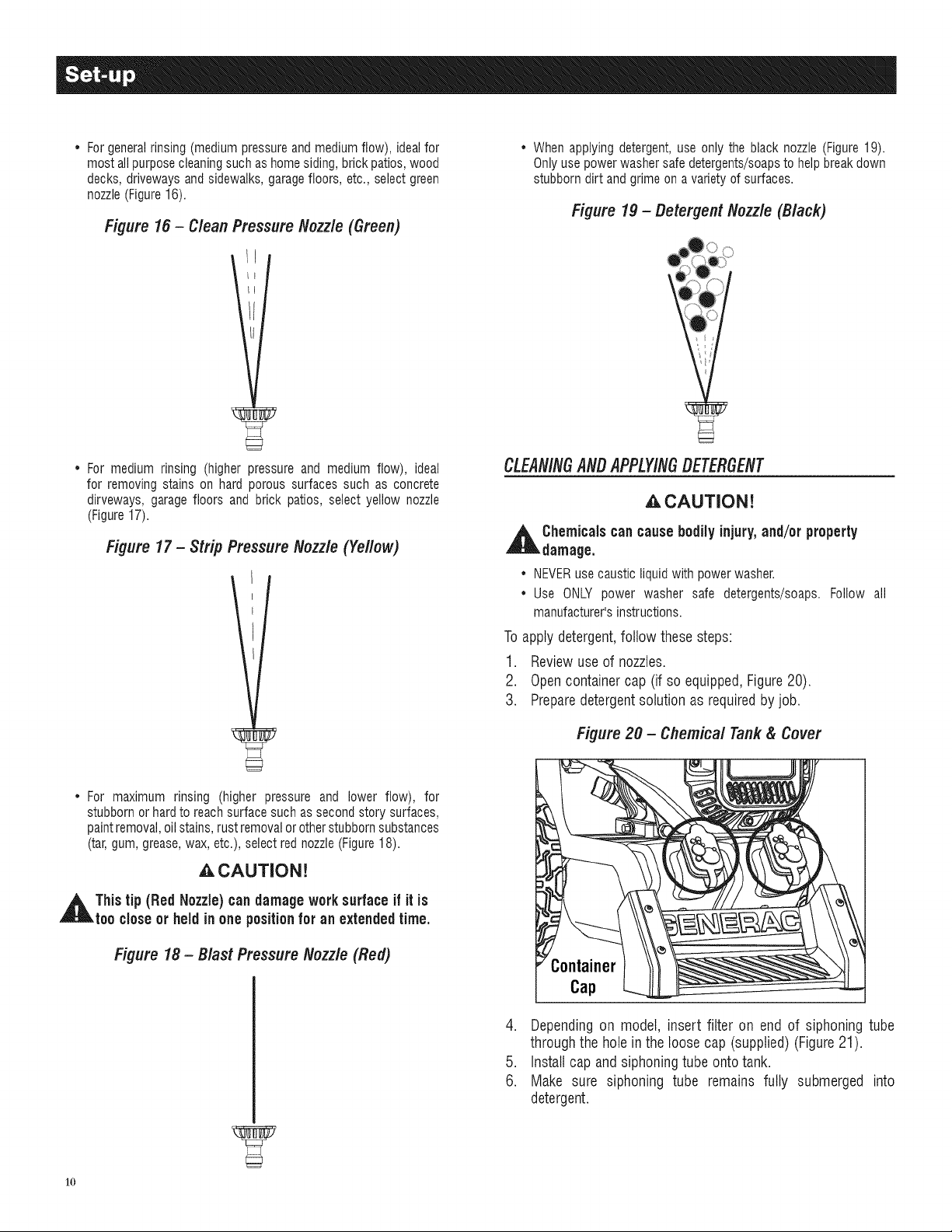

Turn ON the water, squeezethe trigger to purgethe pump

systemof air (Figure13).

Figure 13-Squeeze Trigger

producescancutthrough skinand its underlying

The highpressurestreamof waterthat this equipment

tissues,leadingto serious injury and possible

amputation.

• NEVERexchangenozzleswithoutthetriggerlockbeingengagedon

thespraygun.

• DONOTtwistnozzleswhilespraying.

Followtheseinstructionsto changenozzles:

1. Pull back collar on quick-connect and pull current nozzles

off. Storenozzlesin holderprovidedonthe accessory storage

(Figure14).

Figure 14- Nozzles

.

Selectdesirednozzle.

3.

Pull back on collar, insert new nozzleand releasecollar.Tug

on nozzleto makesure it is securelyin place.

• Fordelicaterinse (lowerpressureandhigherflow), for gentle

cleaningof cars/trucks, boats, RV's, patio furniture, lawn

equipment,etc.,selectwhitenozzle(Figure15).

Figure 15 - Wash Pressure Nozzle (White)

/

Page 12

• Forgeneralrinsing (medium pressureandmedium flow), idealfor

mostall purposecleaningsuch as homesiding, brickpatios,wood

decks, driveways and sidewalks,garagefloors, etc., select green

nozzle(Figure16).

Figure 16 - Clean Pressure Nozzle (Green)

,, Whenapplying detergent,use only the black nozzle (Figure19).

Onlyuse powerwasher safe detergents/soapsto helpbreakdown

stubborn dirt andgrime on avariety of surfaces.

Figure lg - Detergent Nozzle (Black)

• For medium rinsing (higher pressure and medium flow), ideal

for removing stains on hard porous surfaces such as concrete

dirveways, garage floors and brick patios, select yellow nozzle

(Figure17).

Figure 17- Strip Pressure Nozzle (Yellow)

• For maximum rinsing (higher pressure and lower flow), for

stubborn or hardto reach surface such assecond story surfaces,

paintremoval,oil stains,rustremovalor otherstubbornsubstances

(tar, gum,grease,wax, etc.), select red nozzle(Figure18).

,A CAUTION!

,_This tip (RedNozzle) candamage worksurfaceif it is

too closeor held in one positionfor an extendedtime.

CLEANINGANDAPPLYINGDETERGENT

,A CAUTION!

,_ Chemicals cancause bodilyinjury,and/orproperty

damage.

• NEVERusecausticliquidwithpowerwasher.

• Use ONLYpower washer safe detergents/soaps.Follow all

manufacturer'sinstructions.

Toapply detergent,followthese steps:

1. Reviewuse of nozzles.

2. Opencontainercap (if so equipped,Figure20).

3. Preparedetergentsolutionas requiredby job.

Figure 20 - Chemical Tank & Cover

Figure 18- Blast Pressure Nozzle (Red)

Container

Cap

4. Dependingon model, insert filter on end of siphoning tube

throughthe hole in theloose cap (supplied)(Figure21).

5. Installcap andsiphoningtube ontotank.

6. Make sure siphoning tube remains fully submerged into

detergent.

1o

Page 13

Figure 21 -/nsta//Siphoning Tube

NOTE:

Makesurethe filter remainsfully submergedin detergent

while applying detergent.

NOTE:

Contactwith the hotmuffler candamagedetergentsiphoning

tube.

• Wheninsertingthesiphonintoadetergentsolutionbottle,routethe

tubeso asto keepitfrominadvertentlycontactingthe hotmuffler.

.

Makesure blackdetergentnozzleis installed.

NOTE:

Detergentcannotbe appliedwiththe highpressurenozzle

(Yellow,White,Greenor Bed). Only usethe Black nozzlewith

detergent.

8. Confirmset-up instructions havebeenfollowed.

NOTE:

Youmustattachall hosesbefore youstart the engine.

= Startingtheenginewithoutallthehosesconnectedandwithoutthe

waterturnedONwilldamagethe pump.

• Damagetoequipmentresultingfromfailuretofollowthisinstruction

willvoidwarranty.

9. Start enginefollowing instructions Howto Start Your Power

Washer.

10. Apply detergentto a dry surface, starting at lower portion

of area to be washed and work upward using long, even,

overlappingstrokes.

11. Allow detergentto "soak in" for 3-5 minutes before washing

and rinsing. Reapply as needed to prevent surface from

drying. DO NOT allow detergent to dry on surface being

cleaned(preventsstreaking).

IMPORTANT:Youmustflush the detergentsiphoningsystem after

eachuse byplacing thefilter into a bucketof cleanwater,then run

the powerwasher in low pressurefor 1-2 minutes.

POWERWASHERR/NS/NG

1. Removeblackdetergentnozzlefrom lance.

2. Select and install desired high pressure nozzle following

instructions Howto UseNozzles.

3. Point spray gun in safe direction and away from people,

animals and plants. Squeezetrigger to flush any remaining

chemicalfrom system.

4. Keepspraygun a safe distancefrom areayou planto spray.

"_ Im_,_ Kickback fromspraygun cancauseyouto fall.• Useonlyonalevelsurface.

• Donotuseonelevatedsurfaceto preventthe risk

ofa seriousfall.

• Beextremelycarefulif youmustusethepowerwasherfrom a

ladder,scaffolding,or anyothersimilarlocation.

• Firmlygraspspraygunwithbothhandswhenusinghighpressure

sprayto avoidinjurywhenspraygunkicksback.

5. Apply a highpressurespray to a small area andthen check

surfacefor damage.If no damageis found, you can assume

it is okay to continuerinsing.

6. Start at top of areato be rinsed, working down with same

overlappingstrokesas you usedfor cleaning.

CLEANINGDETERGENTSIPHONINGTUBE

If you used the detergentsiphoningtube, you must flush it with

cleanwater beforestoppingthe engine.

1. Placedetergentsiphoning tube/filter in a bucketfull of clean

water.

2. Removehigh pressurenozzlefrom nozzleextension.

3. Selectandinstall blackdetergentnozzlefollowing instructions

How to Use Nozzles.

4. Flushfor 1-2 minutes.

5. Shut off engine following instructions How to Stop Power

Washerand turn off water supply.

6. ALWAYSpoint spray gun in a safedirection, squeezespray

gun trigger to release retainedhigh water pressure. Engage

triggerlock when not inuse.

IMPORTANT: Spray gun traps high water pressure, evenwhen

engineis stoppedandwater is disconnected.

producescancutthroughskinand its underlying

The highpressurestreamof waterthat this equipment

tissues,leadingto seriousinjuryand possible

amputation.Spray guntrapshighwaterpressure,even

whenengine isstoppedandwater is disconnected,

whichcan causeinjury.

• Keephighpressurehoseconnectedto pumpandspraygunwhile

systemispressurized.

• ALWAYSpointspraygun in safe direction,andsqueezespray

guntriggerto releasehighpressure,everytimeyou stopengine.

Engagetriggerlockwhennotin use.

11

Page 14

OPERATION

If you haveanyproblemsoperatingyour powerwasher,pleasecall

Generaccustomerservice at 1-888-436-3722.

POWERWASHERLOCATION

ClearancesandAir Movement

Runningenginegivesoff carbonmonoxide,an

odorless, colorless,poisonousgas. Breathing carbon

monoxidecancauseheadache,fatigue, dizziness,

vomiting,confusion, seizures,nausea,fainting or

death. Formore information,referencethe CO

warnings in the SafetyRules section.

Placepower washer outdoors in an areathat will not accumulate

deadly exhaust gas. NEVERplace power washer where exhaust

gas could accumulate and enter inside or be drawn into a

potentially occupied building. Ensureexhaust gas is kept away

from any windows, doors, ventilation intakes, or other openings

that canallow exhaustgasto collect in a confinedarea. Prevailing

winds and air currents should betaken into considerationwhen

positioningpowerwasher (Figure22).

• OperatepowerwasherONLYoutdoors.

• Keepexhaustgasfromenteringaconfinedareathroughwindows,

doors,ventilationintakes,orotheropenings.

• NEVERstartor runengineindoors,in avehicleorinan enclosed

area,EVENIFwindowsanddoorsareopen.

CHECKLISTBEFORESTARTINGENGINE

1. Be sure to read and understandthe OperatorSafety section

and Operationsectionbeforeusing powerwasher.

2. Checkthatoil is atthe properlevelintheenginecrankcaseand

thatfuel has been addedto the fuel tank.

3. Reviewthe unit's assembly and ensure fitting are properly

securedandmakesurethere areno kinks,cuts, or damageto

high pressurehose.

4. Provide a proper water supply at an adequateflow, clear

screensof debris,andconfirmthatthe system ispurgedof air.

5. Confirm unit is secureon levelground and surroundingwork

areais clear.

HOWTOSTARTYOURPOWERWASHER

NOTE:

DONOTrun the pumpwithout the watersupplyconnected

andturned on. Damage to equipmentresultingfrom failure to

follow this instructionwill voidwarranty.

1. Movethefuel valve leverto theONposition (Figure23).

Figure 23 - Fuel Valve

Off

_ Exhaustheat/gasescanignitecombustibles,

Keepatleast 5ft. (152cm) clearanceon allsidesof power washer

includingoverhead.

structuresor damage fuel tankcausinga fire.

Figure22 - Building Clearances

5 Foot Minimum

2. Move chokeleverto "CLOSE"position (Figure24).

NOTE:

For a warm engine,be surethe chokeleveris inthe "OPEN"

position.

Figure 24 - Choke Lever

Choke

Open

Close

12

Page 15

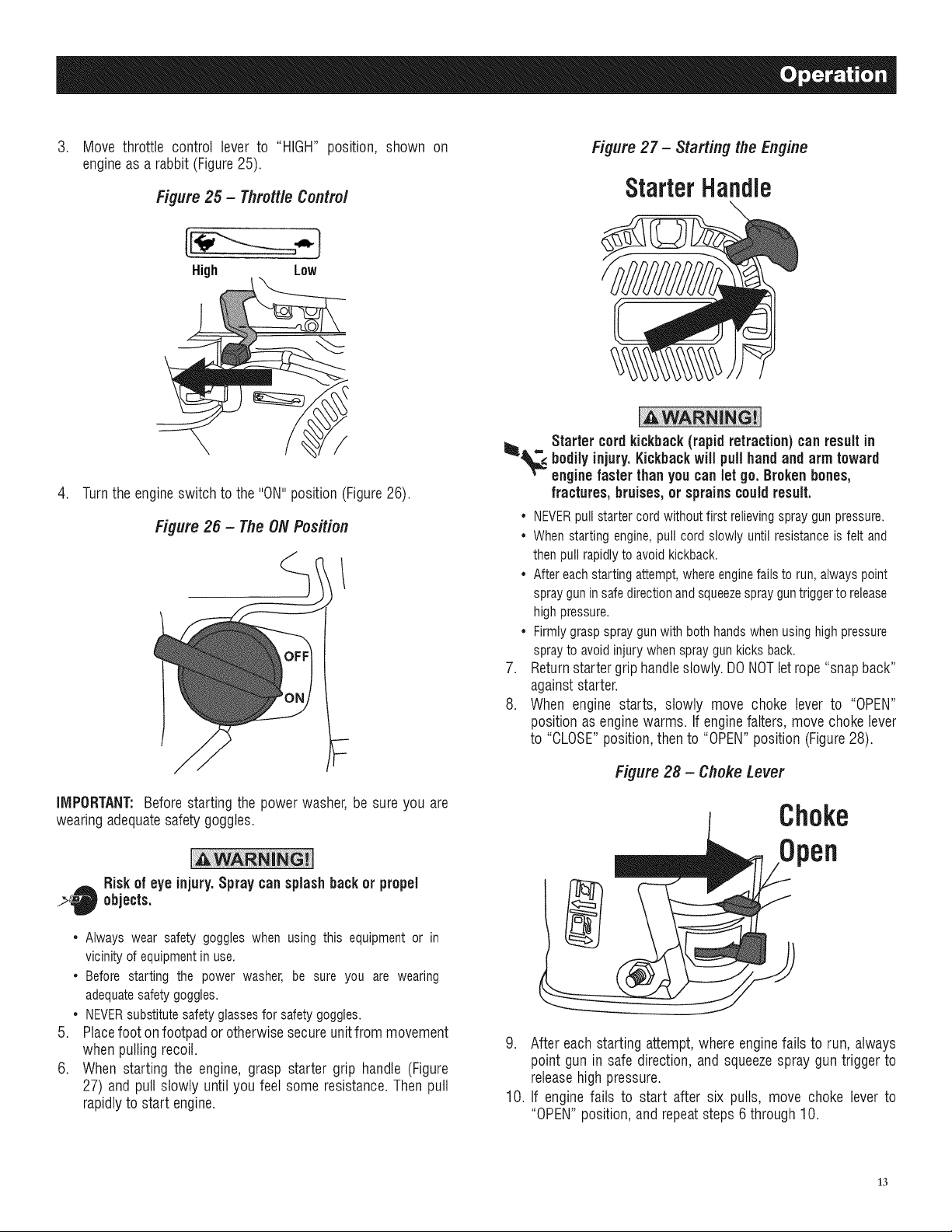

.

Move throttle control lever to "HIGH" position, shown on

engineasa rabbit (Figure25).

Figure 25 - Thrott/e Contro/

High Low

.

Turnthe engineswitch to the "ON"position (Figure26).

Figure26 - TheONPosition

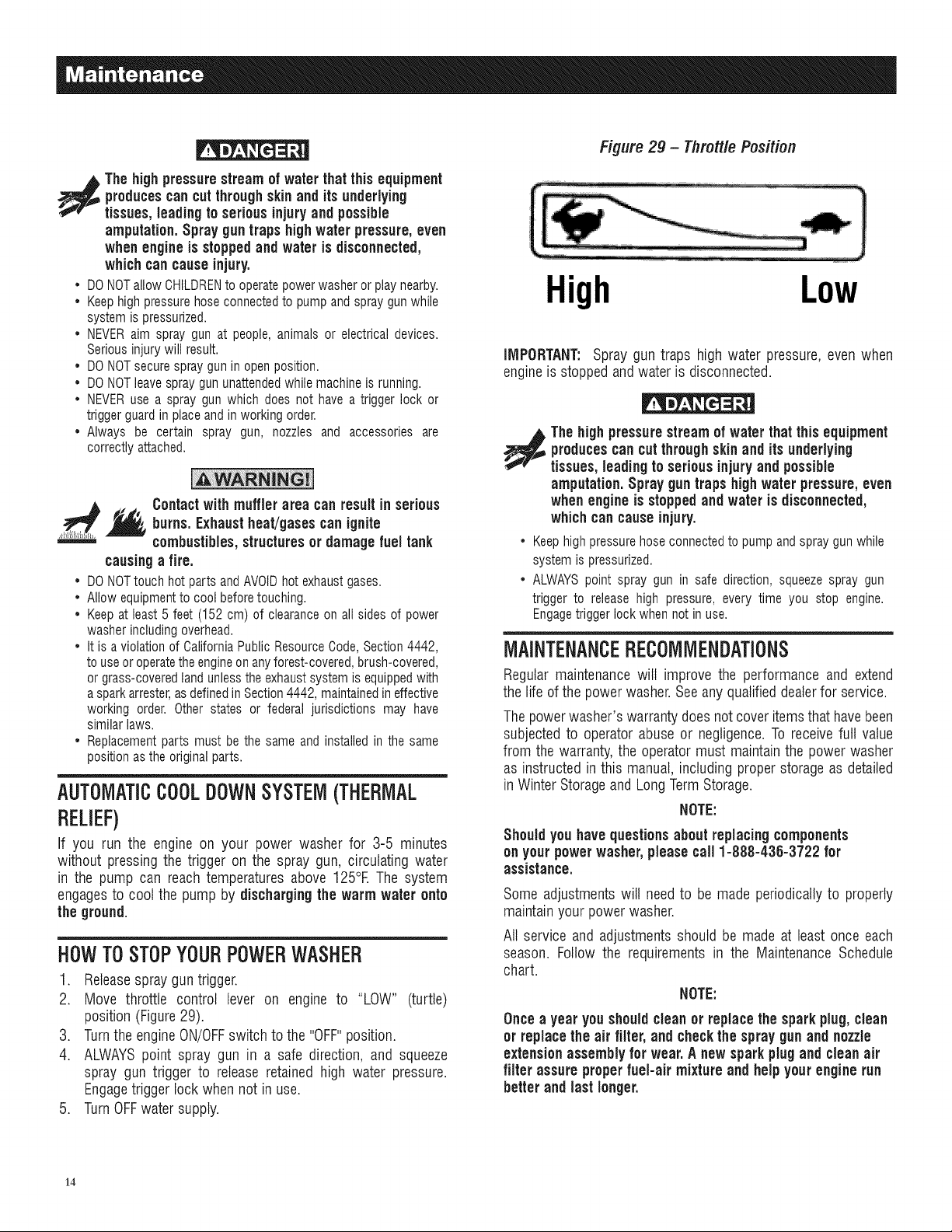

Figure27- Starting the Engine

Starter Handle

Starter cordkickback(rapid retraction)canresultin

,_. bodilyinjury.Kickbackwill pullhandand arm toward

engine faster thanyoucanlet go.Brokenbones,

fractures,bruises,or sprainscouldresult.

* NEVERpullstartercordwithoutfirstrelievingspraygunpressure.

* Whenstartingengine,pullcord slowlyuntilresistanceis felt and

thenpullrapidlyto avoidkickback.

* Aftereachstartingattempt,whereenginefailsto run,alwayspoint

sprayguninsafedirectionandsqueezesprayguntriggertorelease

highpressure.

* Firmlygraspspraygunwithbothhandswhenusinghighpressure

sprayto avoidinjurywhenspraygunkicksback.

7. Returnstartergrip handleslowly.DONOTletrope"snapback"

againststarter.

8. When engine starts, slowly move choke lever to "OPEN"

position asenginewarms. Ifenginefalters, move chokelever

to "CLOSE"position,thento "OPEN"position (Figure28).

IMPORTANT:Beforestarting the powerwasher, be sure you are

wearingadequatesafetygoggles.

Riskof eye injury.Spray cansplashbackorpropel

objects.

* Alwayswearsafetygoggleswhenusingthis equipmentor in

vicinityof equipmentin use.

* Beforestartingthe powerwasher,be sure you are wearing

adequatesafetygoggles.

* NEVERsubstitutesafetyglassesforsafetygoggles.

.

Placefoot onfootpador otherwise secureunitfrom movement

whenpulling recoil.

6.

When starting the engine,grasp starter grip handle (Figure

27) and pull slowly until you feel some resistance.Then pull

rapidlyto start engine.

Figure28 - Choke Lever

Choke

9. After eachstarting attempt,where enginefails to run, always

point gun insafe direction,and squeezespray gun triggerto

releasehigh pressure.

10. If enginefails to start after six pulls, move choke leverto

"OPEN"position,and repeatsteps 6 through 10.

13

Page 16

producescancutthroughskinand its underlying

The highpressurestreamof waterthat this equipment

tissues,leadingto seriousinjuryand possible

amputation.Spray guntrapshighwaterpressure,even

whenengineis stoppedandwater is disconnected,

whichcan causeinjury.

• DONOTallow CHILDRENto operatepowerwasher or play nearby.

• Keephigh pressure hose connectedto pumpand spray gunwhile

systemis pressurized.

• NEVERaim spray gun at people, animals or electrical devices.

Seriousinjury will result.

• DONOTsecure spray gunin openposition.

• DONOTleavespray gun unattendedwhile machine is running.

• NEVERuse a spray gun which does not have a trigger lock or

trigger guard in placeandin working order.

• Always be certain spray gun, nozzles and accessories are

correctly attached.

Contactwith muffler area canresultin seriousburns.Exhaustheat/gasescanignite

combustibles,structuresor damage fuel tank

causinga fire.

• DONOTtouchhotpartsandAVOIDhotexhaustgases.

• Allowequipmenttocoolbeforetouching.

• Keepatleast5feet(152cm)of clearanceonallsidesof power

washerincludingoverhead.

• Itisaviolationof CaliforniaPublicResourceCode,Section4442,

touseoroperatetheengineonanyforest-covered,brush-covered,

orgrass-coveredlandunlesstheexhaustsystemisequippedwith

asparkarrester,asdefinedinSection4442,maintainedineffective

workingorder.Otherstatesor federaljurisdictionsmay have

similarlaws.

• Replacementpartsmustbethe sameandinstalledinthesame

positionastheoriginalparts.

AUTOMATICCOOLDOWNSYSTEM(THERMAL

RELIEF)

If you run the engine on your power washer for 3-5 minutes

without pressing the trigger on the spray gun, circulating water

in the pump can reach temperatures above 125°E The system

engages to cool the pump by discharging the warm water onto

the ground.

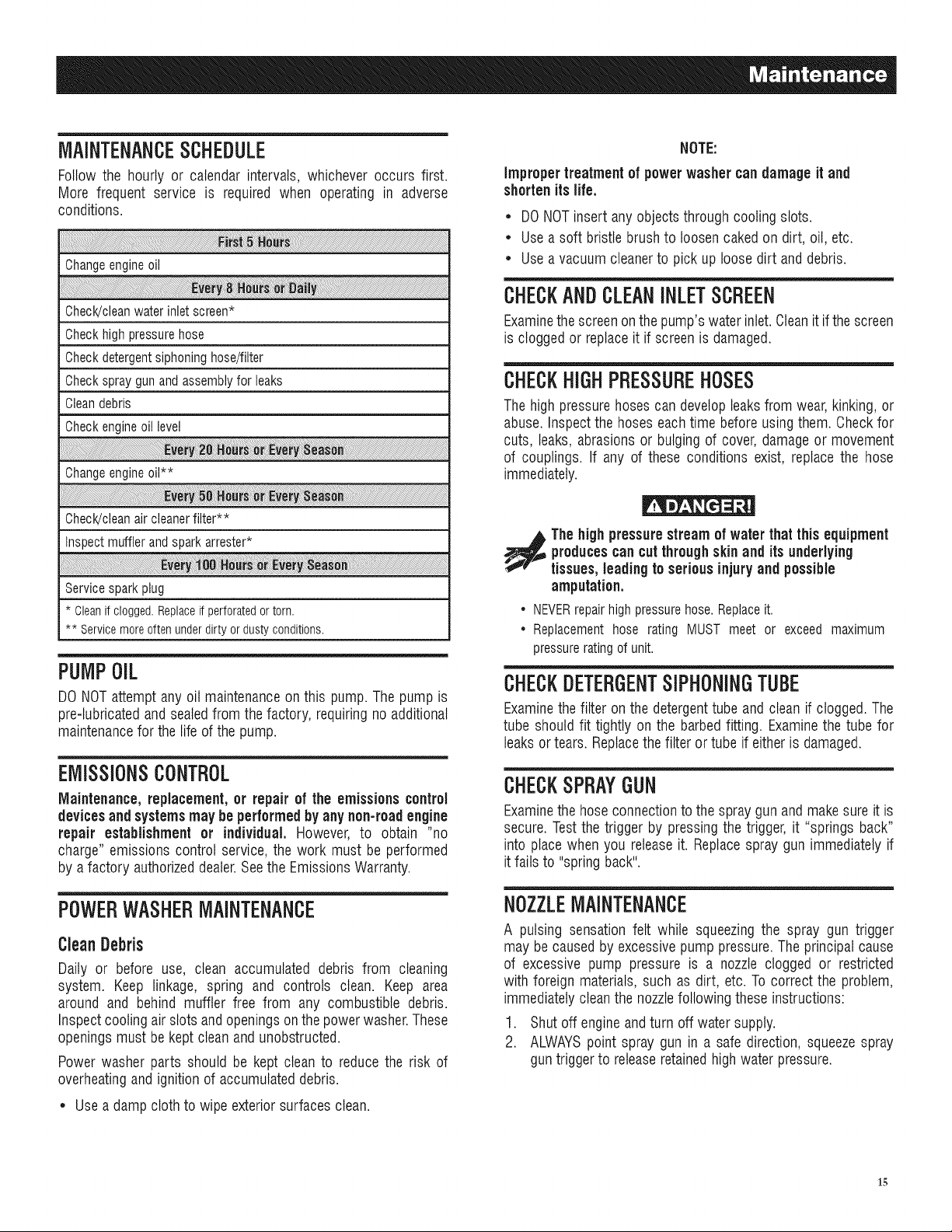

HOWTOSTOPYOURPOWERWASHER

1. Release spray gun trigger.

2. Move throttle control lever on engine to "LOW" (turtle)

position (Figure 29).

3. Turn the engine ON/OFF switch to the "OFF" position.

4. ALWAYS point spray gun in a safe direction, and squeeze

spray gun trigger to release retained high water pressure.

Engage trigger lock when not in use.

5. Turn OFFwater supply.

Figure 2g- Throttle Position

High Low

IMPORTANT:Spray gun traps high water pressure, evenwhen

engineis stopped andwater is disconnected.

producescancut through skinandits underlying

Thehighpressurestream of water that this equipment

tissues, leadingto seriousinjuryand possible

amputation.Spray gun traps highwaterpressure,even

when engineis stoppedand water isdisconnected,

which cancauseinjury.

• Keephigh pressurehose connectedto pump andspray gunwhile

system is pressurized.

• ALWAYSpoint spray gun in safe direction, squeeze spray gun

trigger to release high pressure, every time you stop engine.

Engagetriggerlock when not in use.

MAINTENANCERECOMMENDATIONS

Regular maintenance wilt improve the performance and extend

the life of the power washer. See any qualified dealer for service.

The power washer's warranty does not cover items that have been

subjected to operator abuse or negligence. To receive full value

from the warranty, the operator must maintain the power washer

as instructed in this manual, including proper storage as detailed

in Winter Storage and Long Term Storage.

NOTE:

Shouldyouhavequestions aboutreplacingcomponents

on yourpowerwasher,pleasecall 1-888-435-3722 for

assistance.

Someadjustments will needto be made periodicallyto properly

maintainyour power washer.

All service andadjustmentsshould be made at least once each

season. Follow the requirementsin the MaintenanceSchedule

chart.

NOTE:

Oncea yearyoushouldcleanor replacethe sparkplug,clean

or replacethe air filter, and checkthe spraygun and nozzle

extensionassembly for wear. Anew sparkplugand cleanair

filter assure properfuel-air mixture andhelp yourenginerun

better and lastlonger.

I[4

Page 17

MAINTENANCESCHEDULE

Follow the hourly or calendar intervals, whichever occurs first.

More frequent service is required when operating in adverse

conditions.

Changeengineoil

Check!cleanwaterinletscreen*

Checkhighpressurehose

Checkdetergentsiphoninghose/filter

Checkspraygunandassemblyforleaks

Cleandebris

Checkengineoil level

Changeengineoil**

Check/cleanaircleanerfilter**

Inspectmufflerandspark arrester*

Servicesparkplug

* Cleanif clogged.Replace ifperforated or torn.

** Service more often under dirty or dusty conditions.

PUlVIPOIL

DONOTattemptany oil maintenanceonthis pump. The pump is

pre-lubricatedandsealedfrom the factory, requiringnoadditional

maintenancefor the life of the pump.

NOTE:

impropertreatment of powerwasher candamageit and

shortenits life.

• DONOTinsertanyobjectsthroughcooling slots.

• Usea soft bristlebrushto loosencakedon dirt, oil,etc.

• Usea vacuumcleanerto pickuploosedirt anddebris.

CHECKANDCLEANINLETSCREEN

Examinethe screenonthe pump'swater inlet.Cleanit if the screen

is clogged or replaceit if screenis damaged.

CHECKHiGHPRESSUREHOSES

Thehighpressurehosescan developleaksfrom wear,kinking, or

abuse.Inspectthe hoses eachtime beforeusing them.Check for

cuts, leaks,abrasionsor bulgingof cover,damageor movement

of couplings. If any of these conditions exist, replacethe hose

immediately.

producescancut throughskinand its underlying

Thehighpressurestreamof waterthat thisequipment

tissues,leadingto seriousinjuryand possible

amputation.

• NEVERrepair highpressurehose. Replaceit.

• Replacement hose rating MUST meet or exceed maximum

pressureratingof unit.

CHECKDETERGENTSIPHONINGTUBE

Examinethe filter on the detergenttube and cleanif clogged.The

tube shouldfit tightly on the barbedfitting. Examinethe tube for

leaksor tears. Replacethefilter or tube if eitheris damaged.

EMISSIONSCONTROL

Maintenance,replacement,or repair of the emissionscontrol

devicesandsystemsmay be performedbyanynon-roadengine

repair establishmentor individual. However, to obtain "no

charge" emissions control service, the work must beperformed

by a factory authorizeddealer.Seethe EmissionsWarranty.

POWERWASHERMAINTENANCE

CleanDebris

Daily or before use, clean accumulated debris from cleaning

system. Keep linkage, spring and controls clean. Keep area

around and behind muffler free from any combustible debris.

Inspectcoolingair slots andopeningsonthe powerwasher.These

openingsmust be kept cleanandunobstructed.

Power washer parts should be kept clean to reducethe risk of

overheatingand ignitionof accumulateddebris.

• Use a dampcloth to wipe exteriorsurfacesclean.

CHECKSPRAYGUN

Examinethe hoseconnectionto the spraygun and makesureit is

secure.Testthe trigger by pressingthe trigger,it "springs back"

into place when you releaseit. Replacespraygun immediatelyif

itfails to "spring back".

NOZZLEMAINTENANCE

A pulsing sensationfelt while squeezingthe spray gun trigger

may be causedby excessivepump pressure.Theprincipal cause

of excessive pump pressure is a nozzle clogged or restricted

with foreign materials, such as dirt, etc. To correct the problem,

immediatelycleanthe nozzlefollowing these instructions:

1. Shutoff engineandturn off water supply.

2. ALWAYSpoint spray gun in a safe direction, squeezespray

guntriggerto releaseretainedhigh water pressure.

15

Page 18

producescancutthroughskinand its underlying

The highpressurestreamof waterthat this equipment

tissues,leadingto seriousinjuryand possible

amputation.Spray guntrapshighwaterpressure,even

whenengineisstoppedandwater is disconnected,

whichcan causeinjury.

* Keephighpressurehoseconnectedtopumpandspraygunwhile

systemispressurized.

* ALWAYSpointsprayguninsafedirection,andsqueezespraygun

triggertoreleasehighpressureeverytimeyoustopengine.Engage

triggerlockwhennotinuse.

3. Removenozzlefrom endof nozzleextension.

4. Usea small paperclip to freeanyforeignmaterialcloggingor

restricting nozzle(Figure30).

ENGINEMAINTENANCE

'_/f Unintentional sparkingcanresultin fire or

WHENADJUSTINGORMAKINGREPAIRSTOYOURPOWER

WASHER

* Disconnectthesparkplugwirefromthe sparkplugandplacethe

wirewhereit cannotcontactsparkplug.

WHENTESTINGFORENGINESPARK

* Useapprovedsparkplugtester.

* DONOTcheckfor sparkwithsparkplugremoved.

electric shock.

ENGINEOILRECOMMENDATIONS

Figure30 - Free ForeignMaterial

5. Removelancefrom spray gun.

6. Using a garden hose, remove additional debris by back

flushing waterthrough lance (Figure31). Backflush between

30 to 60seconds.

7. Reinstallnozzleinto lance.

8. Reconnectlanceto spray gun.

Figure31 - Back FlushLance

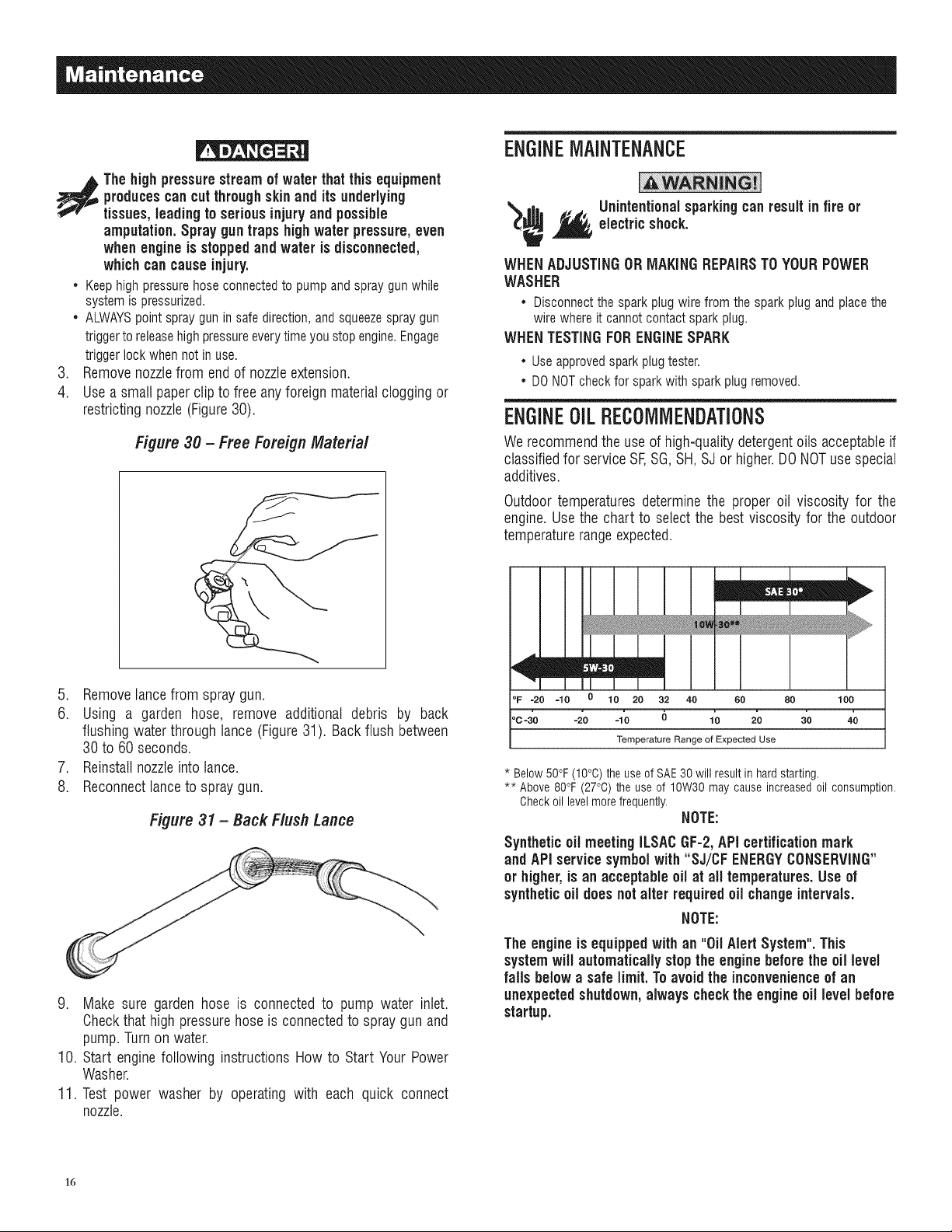

Werecommendthe use of high=qualitydetergentoils acceptableif

classifiedfor service SF,SG,SH,SJor higher.DO NOTusespecial

additives.

Outdoortemperatures determinethe proper oil viscosity for the

engine.Usethe chart to select the best viscosity for the outdoor

temperaturerangeexpected.

mEm

lm| zmm

°F =20 =10 0 10 20 32 40 60

oc/o -2'o -1'o 6 lo 2'o

Temperature Range of Expected Use

* Below 50°F (10°C) the use of SAE 30 will result in hard starting.

** Above 80°F (27°C) the use of 10W30 may cause increased oil consumption.

Checkoil levelmore frequently.

NOTE:

Synthetic oil meeting &SAC GF-2,API certificationmark

and API servicesymbolwith "SJ/CFENERGYCONSERVING"

or higher,is an acceptable oil at all temperatures.Use of

syntheticoil doesnotalter requiredoil changeintervals.

NOTE:

9. Make sure gardenhose is connectedto pump water inlet.

Checkthat high pressurehose is connectedto spray gun and

pump. Turnon water.

10. Start enginefollowing instructions How to StartYour Power

Washer.

11. Test power washer by operating with each quick connect

nozzle.

16

Theengine is equipped withan "OilAlert System". This

systemwill automatically stopthe engine beforethe oil level

fails below a safe limit.Toavoidtheinconvenienceof an

unexpectedshutdown,always checkthe engine oil levelbefore

startup.

Page 19

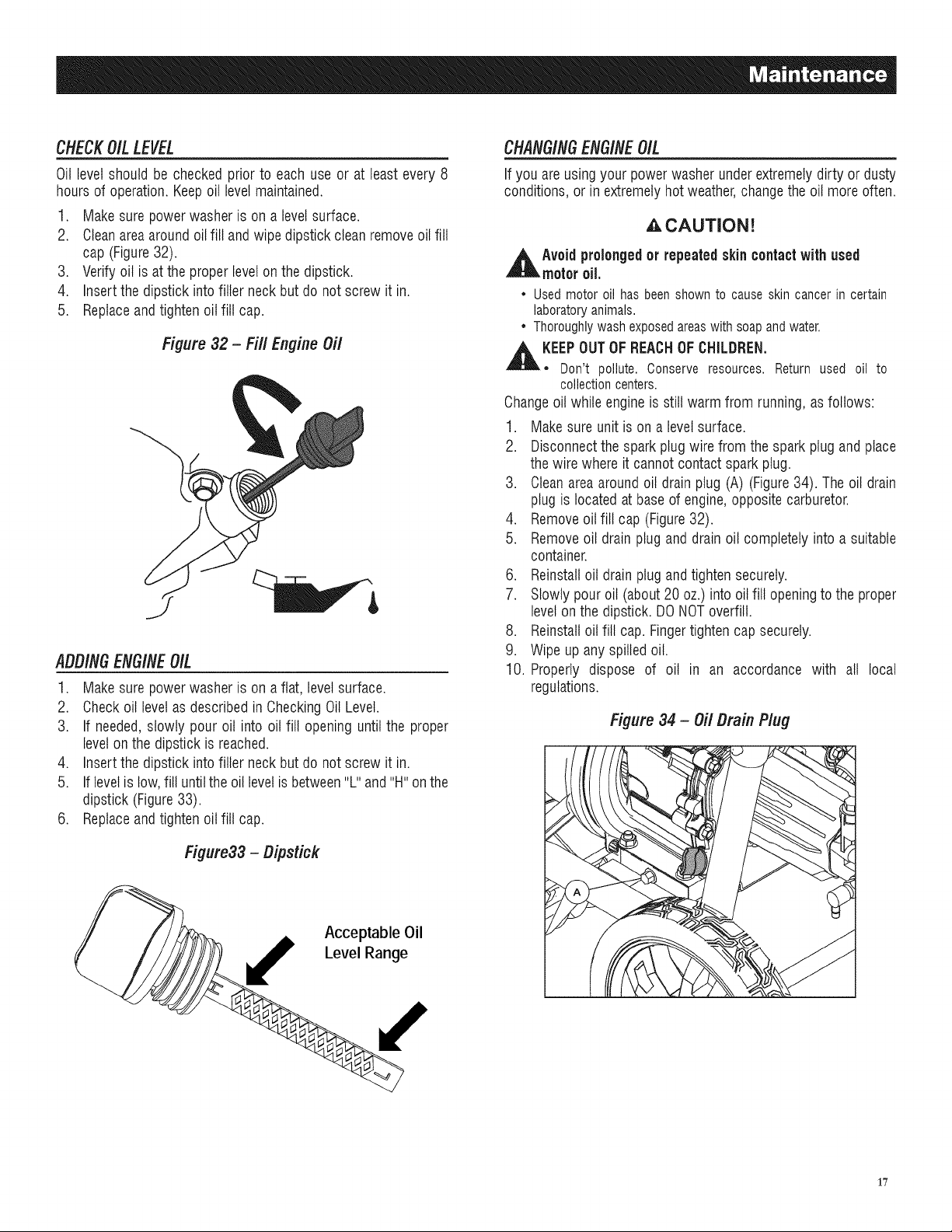

CHECKOILLEVEL

CHANGINGENGINEOIL

Oil level should be checkedprior to each use or at least every 8

hoursof operation.Keepoil levelmaintained.

1. Makesure powerwasher is on alevelsurface.

2. Cleanareaaroundoil fill and wipedipstickcleanremoveoil fill

cap (Figure32).

3. Verifyoil is atthe properlevelonthe dipstick.

4. Insertthe dipstick intofiller neck butdo not screw it in.

5. Replaceandtighten oil fill cap.

Figure32- Fill EngineOil

ADDINGENGINEOIL

1. Makesure powerwasher is on aflat, levelsurface.

2. Checkoil levelasdescribedin CheckingOil Level.

3. If needed,slowly pour oil into oil fill openinguntilthe proper

levelonthe dipstick is reached.

4. Insertthe dipstick intofiller neck butdo not screw it in.

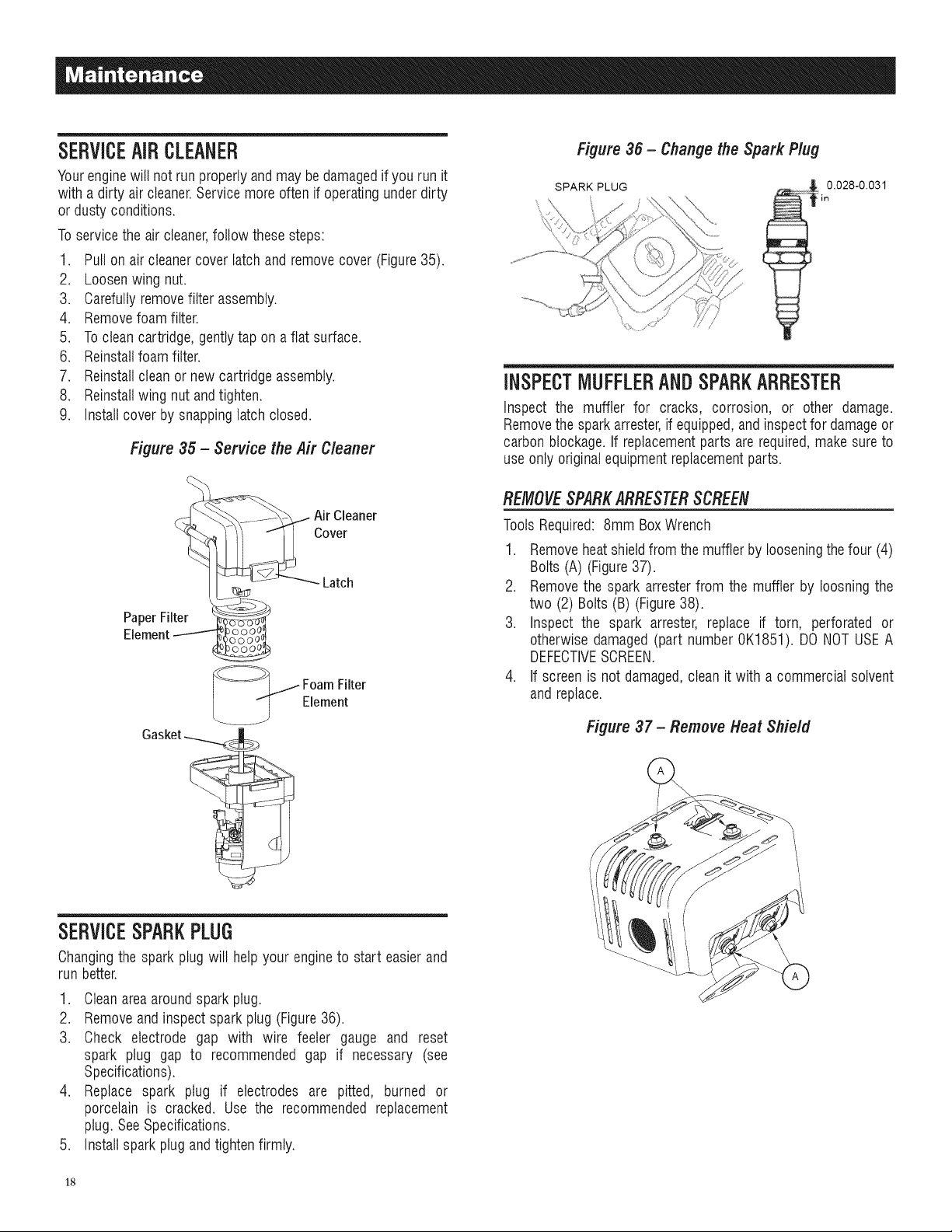

5. If levelis low,fill untiltheoillevelisbetween"L"and "H"onthe

dipstick (Figure33).

6. Replaceandtighten oil fill cap.

If you are usingyour power washer underextremelydirty or dusty

conditions,or in extremelyhot weather,changethe oil moreoften.

,ACAUTION!

,_ Avoidprolongedor repeatedskin contactwith used

motoroil.

• Usedmotoroil hasbeenshownto causeskincancerin certain

laboratoryanimals.

• Thoroughlywashexposedareaswithsoapandwater.

,_ KEEPOUTOF REACHOF CHILDREN.

• Don't pollute. Conserveresources.Return used oil to

collectioncenters.

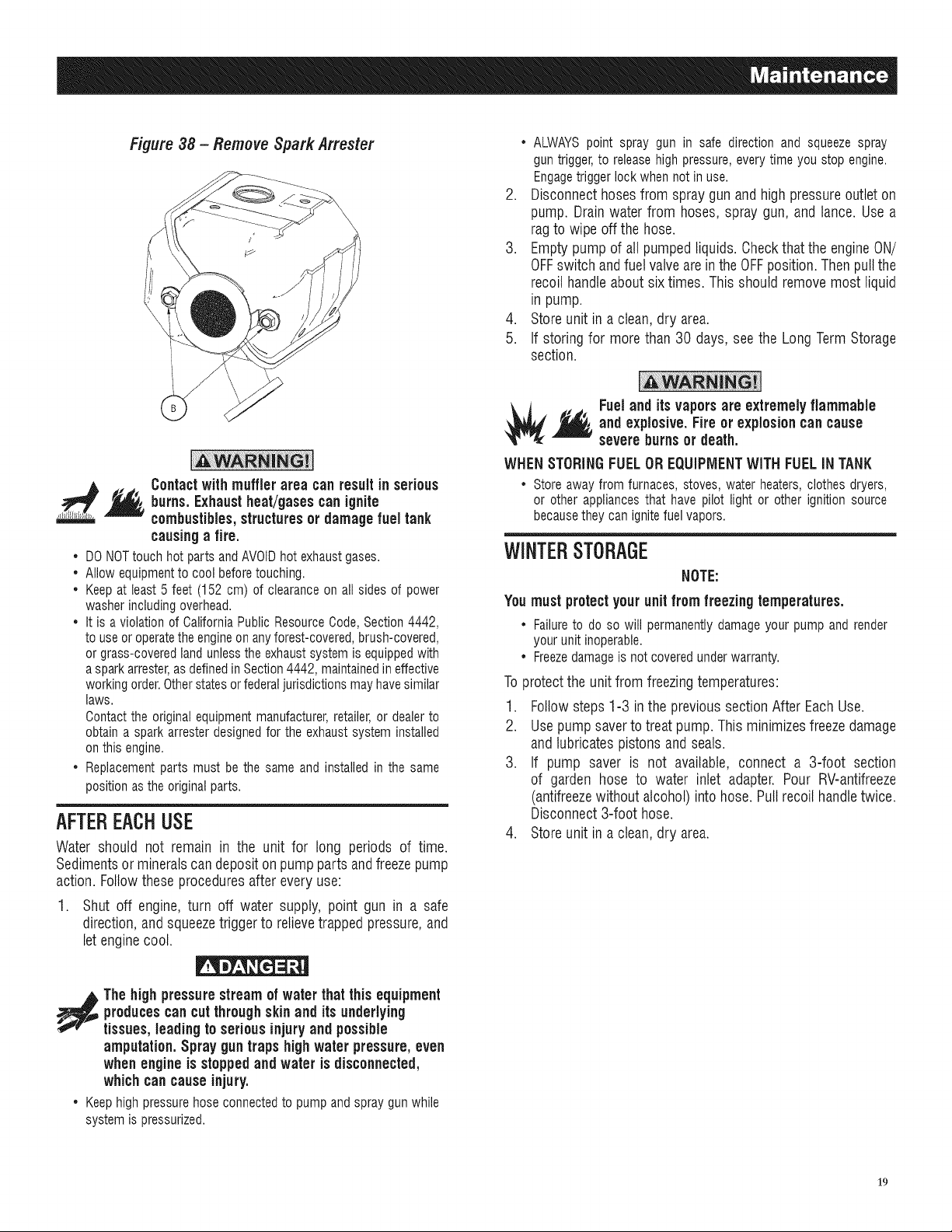

Changeoil while engineis still warmfrom running,asfollows:

1. Makesure unit is on a levelsurface.

2. Disconnectthe sparkplug wirefrom the spark plugand place

thewire whereit cannot contactspark plug.

3. Cleanareaaround oil drain plug (A)(Figure34). The oil drain

plug is locatedat baseof engine,oppositecarburetor.

4. Removeoil fill cap (Figure32).

5. Removeoil drainplug anddrain oil completelyinto a suitable

container.

6. Reinstalloil drain plug andtighten securely.

7. Slowly pour oil (about20 oz.) into oilfill openingto the proper

levelonthe dipstick. DONOToverfill.

8. Reinstalloil fill cap. Fingertightencap securely.

9. Wipeup any spilledoil.

10. Properly dispose of oil in an accordance with all local

regulations.

Figure 34 - Oil Drain Plug

Figure33 - Dipstick

i_' Level Range

Acceptable Oil

1"7

Page 20

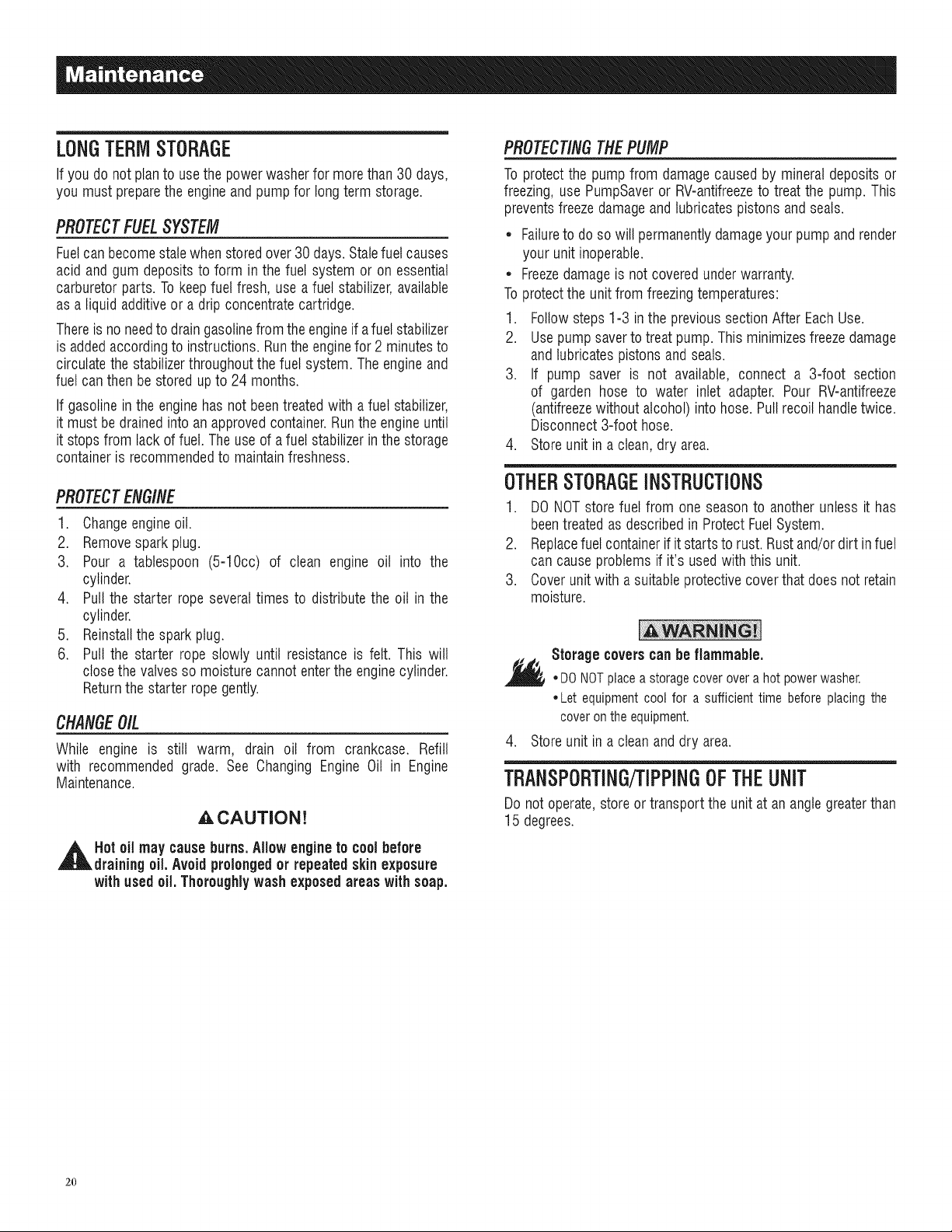

SERVICEAiRCLEANER

Yourenginewill notrun properlyandmay be damagedif you run it

with a dirty air cleaner.Servicemoreoftenif operatingunderdirty

or dustyconditions.

Toservicethe air cleaner,follow these steps:

1. Pull on air cleanercover latch and removecover (Figure35).

2. Loosenwing nut.

3. Carefullyremovefilter assembly.

4. Removefoamfilter.

5. Toclean cartridge,gentlytap on aflat surface.

6. Reinstallfoamfilter.

7. Reinstallclean or new cartridgeassembly.

8. Reinstallwing nutandtighten.

9. Installcover by snappinglatchclosed.

Figure 35 - Service the Air Cleaner

Figure 36- Change the Spark Plug

SPARK PLUG

_o_ m0.028-0.031

iNSPECTMUFFLERANDSPARKARRESTER

Inspect the muffler for cracks, corrosion, or other damage.

Removethespark arrester,if equipped,andinspectfor damageor

carbonblockage. If replacementparts arerequired,makesureto

useonly originalequipmentreplacementparts.

_-__- -__/Air Cleaner

Paper Filter

Element

_06ooo_

£--__ oamFilter

Element

SERVICESPARKPLUG

Changingthe spark plug will helpyour engineto start easier and

run better.

1. Cleanareaaroundspark plug.

2. Removeandinspect sparkplug (Figure36).

3. Check electrode gap with wire feeler gauge and reset

spark plug gap to recommended gap if necessary (see

Specifications).

4. Replace spark plug if electrodes are pitted, burned or

porcelain is cracked. Use the recommended replacement

plug. SeeSpecifications.

5. Installspark plugand tightenfirmly.

REMOVESPARKARRESTERSCREEN

Tools Required: 8mm BoxWrench

1. Removeheatshieldfrom the muffler by looseningthe four (4)

Bolts (A) (Figure37).

2. Removethe spark arresterfrom the muffler by Ioosningthe

two (2) Bolts (B) (Figure38).

3. Inspect the spark arrester, replace if torn, perforated or

otherwisedamaged (part number0K1851). DO NOTUSEA

DEFECTIVESCREEN.

4. If screen is not damaged,clean it with a commercial solvent

and replace.

Figure 37 - Remove Heat Shield

18

Page 21

Figure 38 - Remove Spark Arrester

:_ f_, Contact with muffler area can result in seriousburns. Exhaustheat/gasescan ignite

combustibles,structures or damagefuel tank

causinga fire.

* DONOTtouch hot parts and AVOIDhot exhaustgases.

* Allow equipmentto cool beforetouching.

* Keepat least 5 feet (152 cm) of clearance on all sides of power

washerincludingoverhead.

* It is a violation of CaliforniaPublic ResourceCode,Section 4442,

to useor operatethe engineon anyforest-covered,brush-covered,

or grass-coveredland unlessthe exhaustsystemis equippedwith

aspark arrester,asdefinedin Section4442, maintainedin effective

workingorder.Otherstatesorfederaljurisdictions mayhavesimilar

laws.

Contactthe original equipmentmanufacturer,retailer,or dealerto

obtain a spark arrester designedfor the exhaustsystem installed

on this engine.

* Replacementparts must be the same and installed in the same

positionas the originalparts.

AFTEREACHUSE

Water should not remain in the unit for long periods of time.

Sedimentsormineralscan depositon pumpparts andfreezepump

action. Followthese proceduresafter every use:

1. Shut off engine,turn off water supply, point gun in a safe

direction,andsqueezetriggerto relievetrappedpressure,and

let enginecool.

ALWAYSpointspraygun in safe directionand squeezespray

guntrigger,to releasehighpressure,everytimeyoustopengine.

Engagetriggerlockwhennotin use.

.

Disconnecthosesfrom spray gunandhighpressureoutleton

pump. Drainwater from hoses,spray gun, and lance. Usea

ragto wipeoff the hose.

.

Emptypump of all pumpedliquids. Checkthatthe engineON/

OFFswitch andfuel valvearein theOFFposition.Thenpullthe

recoil handleabout six times. Thisshould removemost liquid

in pump.

.

Storeunit in a clean,dry area.

5.

If storing for morethan 30 days, see the LongTerm Storage

section.

Fueland itsvaporsare extremelyflammable

and explosive. Fireor explosioncan cause

severeburnsor death.

WHENSTORINGFUELOREQUIPMENTWiTHFUELiN TANK

* Storeawayfromfurnaces,stoves,waterheaters,clothesdryers,

or otherappliancesthathavepilotlightor otherignitionsource

becausetheycanignitefuelvapors.

WINTERSTORAGE

NOTE:

Youmustprotectyourunitfrom freezing temperatures.

, Failureto do sowill permanentlydamageyourpumpandrender

yourunitinoperable.

* Freezedamageisnotcoveredunderwarranty.

Toprotectthe unit from freezingtemperatures:

1. Followsteps1-3 inthe previoussectionAfter Each Use.

2. Usepumpsaverto treatpump. This minimizesfreezedamage

and lubricatespistons and seals.

3. If pump saver is not available, connect a 3-foot section

of garden hose to water inlet adapter. Pour RV-antifreeze

(antifreezewithoutalcohol) intohose.Pullrecoilhandletwice.

Disconnect3-foot hose.

4. Storeunit in a clean,dry area.

producescancutthroughskinand its underlying

The highpressurestreamof waterthat this equipment

tissues,leadingto seriousinjuryand possible

amputation.Spray guntrapshighwaterpressure,even

whenengineisstoppedandwater is disconnected,

whichcan causeinjury.

* Keephighpressurehoseconnectedtopumpandspraygunwhile

systemispressurized.

19

Page 22

LONGTERMSTORAGE

If you do not planto usethe power washerfor more than30 days,

you must preparethe engineandpump for longterm storage.

PROTECTFUELSYSTEM

Fuelcan becomestalewhenstoredover30 days.Stalefuelcauses

acid and gum depositsto form in the fuel system or on essential

carburetorparts. To keepfuel fresh, usea fuel stabilizer,available

as a liquid additiveor adrip concentratecartridge.

Thereis no needto draingasolinefrom theengineif afuel stabilizer

is addedaccordingto instructions. Runthe enginefor 2minutesto

circulatethe stabilizerthroughoutthe fuel system. The engineand

fuelcan then be storedup to 24 months.

If gasolinein the enginehasnot beentreatedwith a fuel stabilizer,

it must be drainedinto anapprovedcontainer.Runthe engineuntil

it stops from lack of fuel.Theuse of afuel stabilizerin the storage

containeris recommendedto maintainfreshness.

PROTECTENG/NE

1. Changeengineoil.

2. Removespark plug.

3. Pour a tablespoon (5-10cc) of clean engine oil into the

cylinder.

4. Pull the starter rope severaltimes to distributethe oil in the

cylinder.

5. Reinstallthe spark plug.

6. Pull the starter rope slowly until resistanceis felt. This will

closethe valves so moisture cannotenterthe enginecylinder.

Returnthe starter ropegently.

CHANGEO/L

While engine is still warm, drain oil from crankcase. Refill

with recommended grade. See Changing Engine Oil in Engine

Maintenance.

_,CAUTION!

PROTECtiNGTHEPUMP

Toprotect the pump from damagecaused by mineraldepositsor

freezing,use PumpSaveror RV-antifreezeto treat the pump.This

preventsfreezedamageand lubricatespistons and seals.

* Failureto doso will permanentlydamageyour pumpandrender

your unit inoperable.

* Freezedamageis not coveredunderwarranty.

Toprotectthe unit from freezingtemperatures:

1. Followsteps1-3 inthe previoussectionAfter Each Use.

2. Usepumpsaverto treatpump. This minimizesfreezedamage

and lubricatespistons and seals.

3. If pump saver is not available, connect a 3-foot section

of garden hose to water inlet adapter. Pour RV-antifreeze

(antifreezewithoutalcohol) intohose.Pullrecoilhandletwice.

Disconnect3-foot hose.

4. Storeunit in a clean,dry area.

OTHERSTORAGEINSTRUCTIONS

1. DONOTstore fuel from one seasonto anotherunless it has

beentreated asdescribedin ProtectFuelSystem.

2. Replacefuel containerif it startsto rust. Rustand/ordirt infuel

can causeproblemsif it's usedwith this unit.

3. Coverunitwith asuitableprotectivecoverthat does notretain

moisture.

Storage coverscan beflammable.

*DONOTplaceastoragecoveroverahotpowerwasher.

*Let equipmentcool for a sufficienttime beforeplacingthe

coverontheequipment.

.

Storeunit in a cleananddry area.

TRANSPORTING/TIPPINGOFTHEUNIT

Do not operate,storeor transport the unitat an anglegreaterthan

15 degrees.

,_Hot oil may causeburns.Allow engineto coolbefore

draining oil. Avoid prolongedor repeatedskin exposure

with usedoil. Thoroughlywash exposedareaswith soap.

2O

Page 23

TBOUBLESHOOTiNGGUIDE

1. Low pressurenozzleinstalled. 1. Replacewith high pressurenozzle.

2. Water inletis blocked. 2. Clearinlet.

3. Inadequatewater supply.

Pumphasfollowingproblems:

failuretoproducepressure,erratic

pressure,chattering,lossofpres-

sure,lowwatervolume.

Detergent fails to mix with spray, cracked.

Engineruns well at no-load but 1. Enginespeedis too slow. 1. Move throttlecontrol to FASTposition.If engine

"bogs" when load isadded, still "bogs down", contact local servicefacility.

4. Inlet hose is kinked or leaking.

5. Cloggedinlet hosescreen.

6. Water supplyis over lO0°E

7. High pressurehose is blockedor leaks.

8. Spray gun leaks.

9. Nozzleis obstructed.

10. Pumpis faulty.

1. Detergentsiphoning tubeis not submerged. 1. Insert detergentsiphoningtubeinto detergent.

2. Detergentsiphoning tube/filteris cloggedor 2. Cleanor replacefilter/detergentsiphoningtube.

3. High pressurenozzleinstalled. 3. Replacewith low pressurenozzle.

! I

3. Provideadequatewaterflow.

4. Straighteninlethose,patch leak.

5. Checkand cleaninlet hose screen.

6. Providecoolerwater supply.

7. Clearblocks in outlet hoseor replacehose.

8. Replacespraygun.

9. Cleannozzle.

10. Contactlocal servicefacility.

1. Low oil level,"OilAlert System".

2. Dirty air cleaner.

3. Outof fuel.

Enginewill notstart;orstartsand

runsrough.

Engineshutsdownduring 1. Outof fuel. 1. Fillfuel tank.

operation.

Enginelacks power. 1. Dirty air filter. 1. Replaceairfilter.

4. Stalefuel.

5. Sparkplug wire not connectedto spark plug.

6. Bad sparkplug.

7. Water infuel.

8. Excessivelyrich fuel mixture.

J !

1. Fill crankcaseto proper level.

2. Cleanor replaceair cleaner.

3. Fillfuel tank.

4. Drainfuel tank; fill with fresh fuel.

5. Connectwire to spark plug.

6. Replacesparkplug.

7. Drainfuel tank; fill with fresh fuel.

8. Contact localservice facility.

21

Page 24

Manual PartNo. 0K1393 RevisionA (10/30/12) Printedin U.S.A.

Page 25

GENERAC _

IVianualdelProietario

I

23

Page 26

Introducci6n..........................................................25

Dondenos encuentran.................................................25

ReglasdeSeguridad............................................25

Simbolosde seguridady su significado........................25

Informaci6n general..............................................28

Conozcasu hidrolavadora.......................................................28

Articulos que no se muestran.......................................28

Especificacionesdet producto.................................................29

Informaci6nsobreemisiones..................................................29

Funcionamientoa granaltitud..................................................29

Desempaque...........................................................................30

Ensarnbiar.............................................................30

Ensambtar...............................................................................30

Agregueaceitepara motor......................................................31

Agregadode combustible........................................................31

Conectelamangueray etsuministrodeaguaalabomba.........32

Como usarlas boquillas..........................................................33

Limpiezay aplicacionde detergente.............................34

Enjuaguede la hidrolavadora........................................35

Limpiezadeltubo de descargade detergente...............35

Operaci6n.............................................................36

Operaci6n...............................................................................36

Localizaci6nde la hidrolavadora..............................................36

Lista de verificacionantesde encenderet motor.....................36

C6mo arrancarsu hidrolavadora.............................................36

Sistemade enfriamientoautom_,tico(aliviotermico)................38

Como apagarsu hidrolavadora................................................38

lVlantenirniento......................................................39

Recomendacionesde mantenimiento......................................39

Conogramade mantenimiento.................................................39

Bombade aceite.....................................................................39

Controlde emisiones..............................................................39

Mantenimientode la hidrolavadora..........................................39

Verifiqueel estadoy limpieetfiltro de latoma.........................39

Verifiqueet estadode las manguerasde alta presion...............39

Verifiqueet estadodel tubo de descargade detergente............40

Verifiqueet estadode la pistolarociadora................................40

Mantenimientode la boquilla...................................................40

Mantenimientodelmotor.........................................................40

Recomendacionessobreet aceitedel motor............................40

Verificaci6ndet nivelde aceite......................................41

C6moagregaraceiteal motor ......................................41

Cambiodel aceitede motor..........................................41

Serviciodetfiltro deaire..........................................................42

Servicioa la bujia...................................................................42

Inspecciondel silenciadory delsupresor dechispas .............42

Retireel tamizdet supresorde chispas.........................42

Luegode cadauso .................................................................43

Almacenamientoen invierno...................................................43

Almacenamientoa largo plazo.................................................44

Protecci6ndel sistemade combustible.........................44

Protecciondet motor....................................................44

Cambiode aceite.........................................................44

Protecci6nde la bomba................................................44

Otrascondicionesde almacenamiento....................................44

Transportee inctinaci6nde la unidad......................................44

Locaiizaci6ny correcci6nde fallas ......................45

Guiade Iocalizaci6ny correcci6ndefaltas..............................45

24

Page 27

INTRODUCCION

Gracias por comprar esta hidrolavadorafabricada por Generac

PowerSystems, Inc. Estemodetoesunahidrolavadoraimpulsada

por motor enfriada por aire, de alto rendimiento que opera

entre 2500 y 3100 psi, dependiendo de que modeto haya

comprado.Lasunidadescuentancon ruedasdisehadasa medida,

bomba de excentrica axial con pistones de acero inoxidable,

sistemaautomaticode enfriamiento,boquillasde conexionrapida,

manguerade alta presion,manguerade succion de detergentey

tanque(s) para sustanciasquimicas,dependiendodetmodelo de

la unidad.

EIsentidocomunyelcumpiimientoestricto deestasinstrucciones

especialessonesencialesparapreveniraccidentes.Eloperador

debeleerestemanualy entenderendetalletodas lasinstrucciones

y advertenciasantesde usar el equipo.Sicualquierpartedeeste

manual no se entiende,contacte al DistribuidorAutorizadomas

cercano para obtener informacion sobre los procedimientosde

arranque,operaciony mantenimiento.Eloperadores responsable

detuso apropiadoy segurodel equipo.

La hidrolavadora puede operar de forma segura, eficiente y

confiablesolamentesi se situa, opera y mantienecorrectamente.

Antesde operar,usar o guardar:

* Estudiecuidadosamentetodas las advertencias de seguridad

en estemanualyen etproducto.

* Familiaricesecon estemanualy con la unidadantesde usarla.

* Consulte la seccion Montaje de este manual para obtener

instrucciones acercade los procedimientosde montaje.Siga

todas lasinstrucciones.

Etfabricante no puede anticipar cada circunstancia posible que

pueda implicar un riesgo. Las advertenciasen este manual, y

en las etiquetasy calcomaniasen la unidadson, porIo tanto, no

exhaustivas.Si usaunprocedimiento,m_tododetrabajo otecnica

de operacion que el fabricante no recomiende especificamente,

segurese de que es seguro para otros. Tambienasegurese de

que et procedimiento,m_todo de trabajo o tecnica de operacion

utilizadano hagaque la hidrolavadoraseainsegura.

LA INFORMACIONINCLUIDAENELPRESENTESEBASAENLAS

MAQUINASEN PRODUCCIONA LA HORADELA PUBLICACION.

GENERACSE RESERVAEL DERECHODE MODIFICARESTE

MANUALENCUALQUIERMOMENTO.

Conserve estas instruccionespara futuras referencias. Si

prestaeste dispositivo a alguien,siempreentreguetambiena la

personaestas instruccionesy el Manualdel Propietario.

REGLASDESEGURIDAD

En toda esta publicacion, en los rotulos yen las etiquetas

adhesivasfijadas en la hidrolavadora,los bloques de PELIGRO,

ADVERTENCIA,PRECAUCIONy NOTAse usan para alertar al

personalsobre instruccionesespecialesacerca de una operacion

en particular que puede ser peligrosa si se efectua de manera

incorrecta o imprudente. Observelos cuidadosamente. Sus

definicionesson lassiguientes:

Indica una situacionoaccion peligrosaque,si no se evita,

puedeocasionar la muerte o una lesiongrave.

Indica una situacionoaccion peligrosaque,si no se evita,

podriaocasionar la muerte o una lesiongrave.

_. CUIDADO

Indicauna situacionoaccion peligrosaque, si nose evita,

podriaocasionar una lesionmenoro moderada.

NOTA:

LasNotas contieneninformacionadicional importantepara

un procedimientoy se incluyendentro del cuerpodeltextode

este manual.

Estasadvertenciasde seguridadno puedeneliminar los peligros

que indican. El sentido comun y etestricto cumplimiento con las

instrucciones especiales mientras realizala accion o el servicio

son esencialesparala prevencionde accidentes.

SiMBOLOSDESEGUR/DADYSU SlGN/F/CADO

Gases tSxicos Retroceso Shock electrico

Superficie resbaladiza Caida lnyecci6n de liquido

DONDE NOS ENCUENTRAN

Puede comunicarse con el Servicio at Cliente de Generac al

1-888-436-3722, o enInterneten www.generac.com.Registrela

informacion importante de la unidad en el siguiente cuadro para

futuras referenciasy/o solicitudes deservicio.

Numerode modelo

Numerode serie

Fechadecompra

Fuego Explosi6n Manual del Propietario

Partes m6viles

Objetos voladores Superficie caliente

25

Page 28

,_ PELIGRO:Elmoo6xidodecarboooquasegeneradurante

el usepuedematarenminutes.NUNCAusareninteriores,

enunvehiculo,oareascubierlas,INCLUSOSIventanasy

puerlasasianabierlas.UsarSOLOal aire fibre,y lejosde

ventanas,puertasyventilaciones.

AIgunosproductosquimicosodetergentespuedenser

_ erjudicialessiseinhalano ingieren,causandonauseas,

desmayosoenvenenamiento.

• Operarla hidrolavadoraSOLOal aire libre.

• Un motor enfuncionamientoliberamonoxide decarbono.

• Elmonoxidedecarbonoes ungasvenenososin colorniaroma.

Respirarelmonoxidedecarbonopuedecausardolordecabeza,

fatiga,mareos,vomitos,confusion,convulsiones,nauseas,

desmayos,o lamuerte.Siexperimentaestossintomas,retiresea un

lugarconairefrescoINMEDtATAMENTE.Busqueasistenciamedica.

• Evite quelos gases de escapeentrena un a.reacerradaatraves

de ventanas,puertas,tomas deventilacionu otras aberturas.

Expliquealas personas quese encuentrenen el interioracerca