Page 1

Automatic Transfer Switch

Owner’s Manual

ATS Service Entrance

HS Type Transfer Switch

Models: 005036-0, 100 Amp, 250 Volts

and 004945-1, 200 Amp, 250 Volts

This manual should remain with the unit.

Page 2

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS - This manual contains important instructions that should be

followed during installation and maintenance of the generator and batteries.

SAVE THESE INSTRUCTIONS! Read the following information carefully before attempting to

install, operate or service this equipment. Also read the instructions and information on tags,

decals, and labels that may be affixed to the transfer switch. Replace any decal or label that

is no longer legible.

DANGER! Connection of a generator to an electrical system normally supplied by an electric

utility shall be by means of suitable transfer equipment so as to isolate the electric system

from utility distribution system when the generator is operating (Article 701 Legally Required

Standby Systems or Article 702 Optional Standby Systems, as applicable). Failure to isolate

electric system by these means may result in damage to generator and may result in injury

or death to utility workers due to backfeed of electrical energy.

Generac Power Systems, Inc., hereafter referred to as

the “manufacturer”, cannot anticipate every possible

circumstance that might involve a hazard. The warnings in this manual, and on tags and decals affixed

to the unit are, therefore, not all-inclusive. If using

a procedure, work method or operating technique

the manufacturer does not specifically recommend,

ensure that it is safe for others. Also make sure the

procedure, work method or operating technique chosen does not render the transfer switch unsafe.

Throughout this publication, and on tags and decals

affixed to the generator, DANGER, WARNING,

CAUTION and NOTE blocks are used to alert personnel to special instructions about a particular operation that may be hazardous if performed incorrectly

or carelessly. Observe them carefully. Their definitions are as follows:

DANGER

After this heading, read instructions that, if not

strictly complied with, will result in personal injury, including without limitation, death, or property

damage.

After this heading, read instructions that, if not

strictly complied with, may result in personal injury or property damage.

After this heading, read instructions that, if not

strictly complied with, could result in damage to

equipment and/or property.

NOTE:

After this heading, read explanatory statements

that require special emphasis.

These safety warnings cannot eliminate the hazards

that they indicate. Common sense and strict compliance with the special instructions while performing

the service are essential to preventing accidents.

Four commonly used safety symbols accompany the

DANGER, WARNING and CAUTION blocks. The type

of information each indicates follows:

This symbol points out important safety infor-

mation that, if not followed, could endanger

personal safety and/or property.

This symbol points out potential explosion haz-

ard.

This symbol points out potential fire hazard.

This symbol points out potential electrical shock

hazard.

GENERAL HAZARDS

• Any AC generator that is used for backup power if

a NORMAL (UTILITY) power source failure occurs,

must be isolated from the NORMAL (UTILITY)

power source by means of an approved transfer

switch. Failure to properly isolate the NORMAL

and STANDBY power sources from each other may

result in injury or death to electric utility workers,

due to backfeed of electrical energy.

• Improper or unauthorized installation, operation,

service or repair of the equipment is extremely

dangerous and may result in death, serious personal injury, or damage to equipment and/or personal property.

• Extremely high and dangerous power voltages are

present inside an installed transfer switch. Any

contact with high voltage terminals, contacts or

wires will result in extremely hazardous, and possibly LETHAL, electric shock. DO NOT WORK ON

THE TRANSFER SWITCH UNTIL ALL POWER

VOLTAGE SUPPLIES TO THE SWITCH HAVE

BEEN POSITIVELY TURNED OFF.

Page 3

Table of Contents

• Competent, qualified personnel should install,

operate and service this equipment. Adhere strictly

to local, state and national electrical and building

codes. When using this equipment, comply with

regulations the National Electrical Code (NEC),

CSA Standard; C22.1 Canadian Electric Code and

Occupational Safety and Health Administration

(OSHA) have established.

• Never handle any kind of electrical device while

standing in water, while barefoot, or while hands or

feet are wet. DANGEROUS ELECTRICAL SHOCK

MAY RESULT.

• Jewelry conducts electricity and wearing it may

cause dangerous electrical shock. Remove all jewelry (such as rings, watches, bracelets, etc.) before

working on this equipment.

• If work must be done on this equipment while

standing on metal or concrete, place insulative

mats over a dry wood platform. Work on this

equipment only while standing on such insulative

mats.

• Never work on this equipment while physically or

mentally fatigued.

• Keep the transfer switch enclosure door closed

and bolted at all times. Only qualified personnel

should be permitted access to the switch interior.

• In case of an accident caused by electric shock,

immediately shut down the source of electrical

power. If this is not possible, attempt to free the

victim from the live conductor but AVOID DIRECT

CONTACT WITH THE VICTIM. Use a nonconducting implement, such as a dry rope or board, to free

the victim from the live conductor. If the victim is

unconscious, apply first aid and get immediate

medical help.

• When an automatic transfer switch is installed for

a standby generator set, the generator engine may

crank and start at any time without warning. To

avoid possible injury that might be caused by such

sudden start-ups, the system’s automatic start circuit must be disabled before working on or around

the generator or transfer switch. For that purpose,

a SAFETY DISCONNECT is provided inside the

transfer switch. Always set that switch to its OFF

position before working on the equipment. Then

place a “DO NOT OPERATE” tag on the transfer

switch and on the generator. Remove the Negative

(Neg) or (–) battery cable.

Safety Rules .........................................Inside Front Cover

Section 1 — General Information ...................................2

1.1 Introduction............................................................. 2

1.2 Equipment Description ........................................... 2

1.2.1 Transfer Switch Mechanism .......................... 2

1.2.2 Service Disconnect Circuit Breaker ............... 2

1.3 Transfer Switch Data Decal ..................................... 2

1.4 Transfer Switch Enclosure ...................................... 3

1.5 Safe Use Of Transfer Switch .................................... 3

Section 2 — Installation ....................................................3

2.1 Introduction to Installation ...................................... 3

2.2 Unpacking ............................................................... 3

2.3 Mounting ................................................................. 3

2.4 Connecting Power Source and Load Lines ............... 3

2.5 Connecting Start Circuit Wires ................................ 4

Section 3 — Operation .......................................................4

3.1 Functional Tests & Adjustments .............................. 4

3.2 Manual Operation .................................................... 4

3.2.1 Close to Normal Source Side ........................ 5

3.2.2 Close to Emergency Source Side ................... 5

3.2.3 Return to Normal Source Side ...................... 5

3.3 Voltage Checks ......................................................... 6

3.4 Generator Tests Under Load ................................... 6

Section 4 – Installation Diagram ....................................7

Section 5 – Electrical Data ...............................................8

Section 6 – Exploded Views & Parts Lists ..................12

Section 7 – Notes .............................................................16

Section 8 – Warranty ...................................... Back Cover

For authorized service,

reference the dealer locator

number found in the generator

owner’s manual.

1

Page 4

Section 1 — General Information

ATS “HS” Type Transfer Switch

1.1 INTRODUCTION

This manual has been prepared especially for the

purpose of familiarizing personnel with the design,

application, installation, operation and servicing of

the applicable equipment. Read the manual carefully

and comply with all instructions. This will help to

prevent accidents or damage to equipment that might

otherwise be caused by carelessness, incorrect application, or improper procedures.

Every effort has been expended to make sure that the

contents of this manual are both accurate and current. The manufacturer, however, reserves the right

to change, alter or otherwise improve the product at

any time without prior notice.

1.2 EQUIPMENT DESCRIPTION

The automatic transfer switch is used for transferring electrical load from a UTILITY (NORMAL) power

source to an EMERGENCY (STANDBY) power source.

Such a transfer of electrical loads occurs automatically when the UTILITY power source has failed or is

substantially reduced and the EMERGENCY source

voltage and frequency have reached an acceptable

level. The transfer switch prevents electrical feedback

between two different power sources (such as the

UTILITY and EMERGENCY sources) and, for that

reason, codes require it in all standby electric system

installations.

The transfer switch consists of a transfer mechanism, service disconnect circuit breaker, a relay

control, fuses, and a terminal strip for connection of

sensing wires.

This transfer switch is suitable for use as service

entrance equipment.

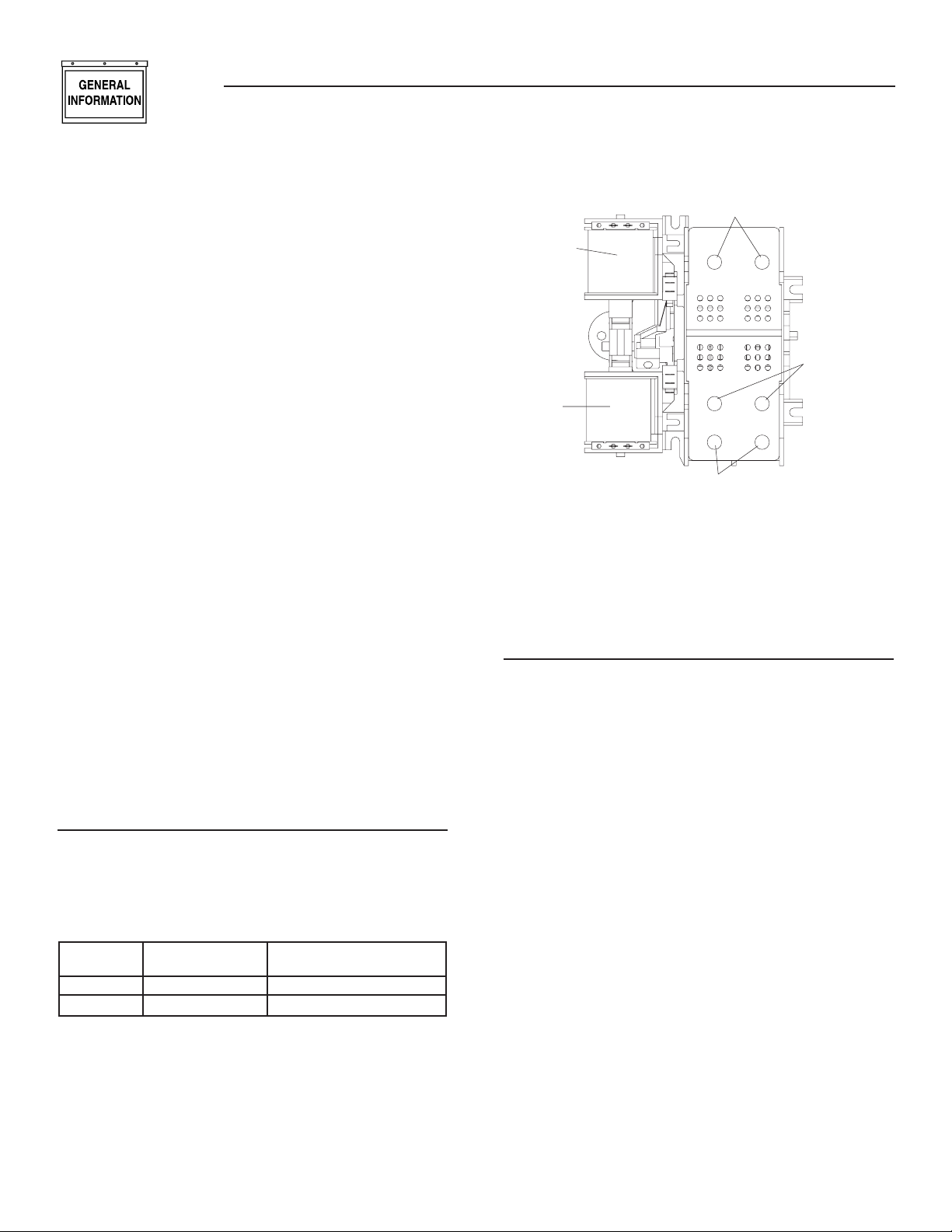

1.2.1 TRANSFER SWITCH MECHANISM

These switches (Figure 1.1) are used with a singlephase system, when the single-phase NEUTRAL line

is to be connected to a Neutral Lug and is not to be

switched.

Solderless, screw-type terminal lugs are standard.

Switch Wire Conductor Tightening

Rating Range Torque

100A #14-1/0 AWG 50 in-lbs.

200A #6-250 MCM 275 in-lbs.

This transfer switch is suitable for control of motors,

electric discharge lamps, tungsten filament and electric heating equipment where the sum of motor full

load ampere ratings and the ampere ratings of other

loads do not exceed the ampere rating of the switch

and the tungsten load does not exceed 30 percent of

the switch rating.

2

Figure 1.1 — Typical ATS Transfer Mechanism

UTILITY LUGS

UTILITY

CLOSING

COIL

GENERATOR

LUGS (E1 & E2)

GENERATOR

CLOSING

COIL

LOAD LUGS (T1 & T2)

This transfer switch is for use in optional standby

systems only.

This transfer switch is suitable for use on a circuit

capable of 10,000 rms symmetrical amperes, 240

VAC maximum.

1.2.2 SERVICE DISCONNECT CIRCUIT

BREAKER

The service disconnect circuit breaker for the 100

amp models are:

• Siemens, Type BQ, 2-pole

• 120/240VAC, 100A

• 50/60 Hertz

• Heating, Air Conditioning and Refrigeration (HACR)

rated

• Wire range: #1 - #8 AWG.

• The conductor tightening torque is 50 in-lbs.

The service disconnect circuit breaker for the 200

amp models are:

• Siemens, Type QN, 2-pole

• 120/240VAC, 200A

• 50/60 Hertz

• Heating, Air Conditioning and Refrigeration (HACR)

rated

• Wire range: 300 KCMIL - 4 AWG

• The conductor tightening torque is 250 in-lbs.

1.3 TRANSFER SWITCH DATA DECAL

A DATA DECAL is permanently affixed to the transfer

switch enclosure. Use this transfer switch only with

the specific limits shown on the DATA DECAL and

on other decals and labels that may be affixed to the

switch. This will prevent damage to equipment and

property.

Page 5

Section 2 — Installation

GTS “HS” Type Transfer Switch

When requesting information or ordering parts for this

equipment, make sure to include all information from

the DATA DECAL.

Record the Model and Serial numbers in the space

provided below for future reference.

MODEL #

SERIAL #

1.4 TRANSFER SWITCH ENCLOSURE

The standard switch enclosure is a National

Electrical Manufacturer’s Association (NEMA) 3R

type. NEMA 3R type enclosures primarily provide

a degree of protection against falling rain and sleet

and is undamaged by the formation of ice on the

enclosure.

1.5 SAFE USE OF TRANSFER SWITCH

Before installing, operating or servicing this equipment, read the SAFETY RULES (inside front cover)

carefully. Comply strictly with all SAFETY RULES to

prevent accidents and/or damage to the equipment.

The manufacturer recommends that a copy of the

SAFETY RULES are posted near the transfer switch.

Also, be sure to read all instructions and information

found on tags, labels and decals affixed to the equipment.

Two publications that outline the safe use of transfer

switches are the following:

• NFPA 70; National Electrical Code

• UL 1008, STANDARD FOR SAFETY-AUTOMATIC

TRANSFER SWITCHES

2.1 INTRODUCTION TO INSTALLATION

This equipment has been wired and tested at the

factory. Installing the switch includes the following

procedures:

• Mounting the enclosure.

• Connecting power source and load leads.

• Connecting the generator sensing and transfer

relay circuits.

• Connecting any auxiliary contact (if needed)

• Testing functions.

2.2 UNPACKING

Carefully unpack the transfer switch. Inspect closely

for any damage that might have occurred during shipment. The purchaser must file with the carrier any

claims for loss or damage incurred while in transit.

Check that all packing material is completely removed

from the switch prior to installation.

2.3 MOUNTING

Mounting dimensions for the transfer switch enclosure are in this manual. Enclosures are typically

wall-mounted. See “Installation Diagram”, Section 5.

Handle transfer switches carefully when install-

ing. Do not drop the switch. Protect the switch

against impact at all times, and against construction grit and metal chips. Never install a transfer

switch that has been damaged.

This transfer switch is mounted in a NEMA 3R enclosure. It can be mounted outside or inside and should

be based on the layout of installation, convenience

and proximity to the utility supply and load center.

Install the transfer switch as close as possible to the

electrical loads that are to be connected to it. Mount

the switch vertically to a rigid supporting structure.

To prevent switch distortion, level all mounting

points. If necessary, use washers behind mounting

holes to level the unit.

2.4 CONNECTING POWER SOURCE

AND LOAD LINES

DANGER

Make sure to turn OFF both the UTILITY

(NORMAL) and EMERGENCY ( STANDBY) power

supplies before trying to connect power source

and load lines to the transfer switch. Supply

voltages are extremely high and dangerous.

Contact with such high voltage power supply lines causes extremely hazardous, possibly

lethal, electrical shock.

Wiring diagrams and electrical schematics are provided in this manual.

Two suggested installation methods are shown. One

for new installations and/or retrofit and one for retrofit.

NOTE:

All installations must comply with national, state

and local codes. It is the responsibility of the

installer to perform an installation that will pass

the final electrical inspection.

The utility supply connection is made at the circuit

breaker terminals. The generator supply and customer load connections are made at the transfer switch

mechanism, inside the switch enclosure.

3

Page 6

Section 3 — Operation

ATS “HS” Type Transfer Switch

Conductor sizes must be adequate to handle the

maximum current to which they will be subjected to,

based on the 75°C column of tables, charts, etc. used

to size conductors. The installation must comply fully

with all applicable codes, standards and regulations.

Before connecting wiring cables to terminals, remove

any surface oxides from the cable ends with a wire

brush. All power cables must enter the enclosure

through the knockouts. If not using the knockouts,

entry must be at or below knockouts. If ALUMINUM

conductors are used, apply corrosion inhibitor to

conductors. Tighten terminal lugs to the torque

values as noted in Section 1.2.2, and on the decal

located on the inside of the door. After tightening terminal lugs, carefully wipe away any excess corrosion

inhibitor.

Use a torque wrench to tighten the conduc-

tors, being sure not to overtighten, or damage

to the switch base could occur. If not tightened

enough, a loose connection would result, causing excess heat which could damage the switch

base.

Connect power source load conductors to clearly

marked transfer mechanism terminal lugs as follows

1. Connect UTILITY (NORMAL) power source cables

to circuit breaker.

2. Connect EMERGENCY (STANDBY) source power

cables to transfer switch terminals E1, E2.

3. Connect customer LOAD leads to switch terminals T1, T2.

Conductors must be properly supported, of approved

insulative qualities, protected by approved conduit,

and of the correct wire gauge size in accordance with

applicable codes.

Be sure to maintain proper electrical clearance

between live metal parts and grounded metal. Allow

at least 1/2 inch for 100-400 amp circuits.

2.5 CONNECTING START CIRCUIT

WIRES

Control system interconnections consist of N1 and

N2, T1 and T2, and leads 23 and 194. Control system

interconnection leads must be run in a conduit that

is separate from the AC power lead. Recommended

wire gauge sizes for this wiring depends on the length

of the wire, as recommended below:

MAXIMUM WIRE LENGTH RECOMMENDED WIRE

SIZE

460 feet (140m) No. 18 AWG.

461 to 730 feet (223m) No. 16 AWG.

731 to 1,160 feet (354m) No. 14 AWG.

1,160 to 1,850 feet (565m) No. 12 AWG.

4

NOTE:

When this ATS is used with an air-cooled generator, the LOAD 1 and LOAD 2 wires are not used.

3.1 FUNCTIONAL TESTS AND

ADJUSTMENTS

Following transfer switch installation and interconnection, inspect the entire installation carefully. A competent, qualified electrician should

inspect it. The installation should comply strictly

with all applicable codes, standards, and regulations. When absolutely certain the installation is

proper and correct, complete a functional test of

the system.

Perform functional tests in the exact order pre-

sented in this manual, or damage could be done

to the switch.

IMPORTANT: Before proceeding with functional tests,

read and make sure all instructions and information

in this section are understood. Also read the information and instructions of labels and decals affixed

to the switch. Note any options or accessories that

might be installed and review their operation.

3.2 MANUAL OPERATION

DANGER

Do NOT manually transfer under load.

Disconnect transfer switch from all power sources by approved means, such as the main circuit

breaker(s).

A manual HANDLE is shipped with the transfer

switch. Manual operation must be checked BEFORE

the transfer switch is operated electrically. To check

manual operation, proceed as follows:

1. Turn the generator’s AUTO/OFF/MANUAL switch

to OFF.

2. Turn OFF both UTILITY (service disconnect cir-

cuit breaker) and EMERGENCY (generator main

line to circuit breaker) power supplies to the

transfer switch.

3. Turn the GENERATOR DISCONNECT SWITCH

to the OFF position.

4. Note position of transfer mechanism main con-

tacts by observing the moveable contact carrier

arm. This can be viewed through the long narrow

slot in the inside cover of the ATS. The top of the

moveable contact carrier arm is yellow to be easily identified.

• Manual operation handle in the UP position LOAD terminals (T1, T2) are connected to UTILITY terminals (N1, N2).

Page 7

Figure 3.1 — Actuating Transfer Switch

Attach handle to

the moveable contact

carrier arm.

Move handle UP for the

NORMAL (UTILITY) position.

Section 3 — Operation

ATS “HS” Type Transfer Switch

NOTE: Return handle to

storage position in enclosure

when finished with manual transfer.

Move handle DOWN for the

STANDBY (EMERGENCY)

position.

• Manual operation handle in the DOWN position - LOAD terminals (T1, T2) are connected to

EMERGENCY terminals (E1, E2).

Do not use excessive force when operating the

transfer switch manually or damage could be

done to the manual handle.

3.2.1 CLOSE TO NORMAL SOURCE SIDE

Before proceeding, verify the position of the switch by

observing the position of manual operation handle in

Figure 3.1. If the handle is UP, the contacts are closed

in the NORMAL (UTILITY) position, no further action

is required. If the handle is DOWN, proceed with Step

1.

Step 1: With the handle inserted into the moveable

contact carrier arm, move handle UP. Be

sure to hold on to the handle as it will move

quickly after the center of travel.

Step 2: Remove manual operating handle from move-

able contact carrier arm. Return handle to

storage bracket.

3.2.2 CLOSE TO EMERGENCY SOURCE SIDE

Before proceeding, verify the position of the switch

by observing the position of the manual operation

handle in Figure 3.1. If the handle is DOWN, the

contacts are closed in the EMERGENCY (STANDBY)

position. No further action is required. If the handle

is UP, proceed with Step 1.

Step 1: With the handle inserted into the moveable

contact carrier arm, move the handle DOWN.

Be sure to hold on to the handle as it will

move quickly after the center of travel.

Step 2: Remove manual operating handle from move-

able contact carrier arm. Return handle to

storage bracket.

3.2.3 RETURN TO NORMAL SOURCE SIDE

Step 1: Manually actuate switch to return manual

operating handle to the UP position.

Step 2: Remove manual operating handle from move-

able contact carrier arm. Return handle to

storage bracket.

5

Page 8

Section 3 — Operation

ATS “HS” Type Transfer Switch

3.3 VOLTAGE CHECKS

1. Turn ON the UTILITY power supply to the transfer switch using the service disconnect circuit

breaker.

DANGER

PROCEED WITH CAUTION. THE TRANSFER

SWITCH IS NOW ELECTRICALLY HOT. CONTACT

WITH LIVE TERMINALS RESULTS IN EXTREMELY

HAZARDOUS AND POSSIBLY FATAL ELECTRICAL

SHOCK.

2. With an accurate AC voltmeter, check for correct

voltage. Measure across ATS terminal lugs N1

and N2. Also check N1 to NEUTRAL and N2 to

NEUTRAL.

3. When certain that UTILITY supply voltage is correct and compatible with transfer switch ratings,

turn OFF the UTILITY supply to the transfer

switch.

4. On the generator panel, set the AUTO/OFF/

MANUAL switch to MANUAL position. The generator should crank and start.

5. Let the generator stabilize and warm up at noload for at least five minutes.

6. Turn the GENERATOR DISCONNECT SWITCH

to the ON position.

7. Set the generator's main circuit breaker (CB1) to

its ON or CLOSED position.

DANGER

PROCEED WITH CAUTION. GENERATOR

OUTPUT VOLTAGE IS NOW BEING DELIVERED

TO TRANSFER SWITCH TERMINALS. CONTACT

WITH LIVE TERMINALS RESULTS IN EXTREMELY

DANGEROUS AND POSSIBLY FATAL ELECTRICAL

SHOCK.

8. With an accurate AC voltmeter and frequency

meter, check the no-load, voltage and frequency.

Measure across ATS terminal lugs E1 to E2. Also

check E1 to NEUTRAL and E2 to NEUTRAL.

a. Frequency ....................................... 60-62 Hertz

b. Terminals E1 to E2 ........................ 240-246 VAC

c. Terminals E1 to NEUTRAL ............. 120-123 VAC

d. Terminals E2 to NEUTRAL ............. 120-123 VAC

9. Set the generator’s main circuit breaker (CB1) to

its OFF or OPEN position.

10. Set the AUTO/OFF/MANUAL switch to the

OFF position to shut down the generator.

NOTE:

Do NOT proceed until generator AC output voltage and frequency are correct and within stated

limits. If the no-load voltage is correct but no-load

frequency is incorrect, the engine governed speed

may require adjustment. If no-load frequency is

correct but voltage is not, the voltage regulator

may require adjustment.

3.4 GENERATOR TESTS UNDER LOAD

1. Set the generator's main circuit breaker to its

OFF or OPEN position.

2. Manually actuate the transfer switch main contacts to their EMERGENCY (STANDBY) position.

Refer to Manual Operation (Section 3.2).

3. To start the generator, set the AUTO/OFF/ MANUAL

switch to MANUAL. When engine starts, let it stabilize for a few minutes.

4. Turn the generator's main circuit breaker to its

ON or CLOSED position. The generator now powers all LOAD circuits. Check generator operation

under load as follows:

• Turn ON electrical loads to the full rated wattage/amperage capacity of the generator. DO

NOT OVERLOAD.

• With maximum rated load applied, check

voltage and frequency across transfer switch

terminals E1 and E2. Voltage should be

greater than 230VAC and frequency should be

greater than 59 Hertz.

• Let the generator run under rated load for at

least 30 minutes. With unit running, listen for

unusual noises, vibration, overheating, etc.,

that might indicate a problem.

5. When checkout under load is complete, set main

circuit breaker of the generator to its OFF or

OPEN position.

6. Let the generator run at no-load for several

minutes. Then, shut down by setting the AUTO/

OFF/MANUAL switch to its OFF position.

7. Move the switch's main contacts back to their

UTILITY position. For example, LOAD connected to UTILITY power supply. Refer to Manual

Operation (Section 3.2). Handle and operating

lever of transfer switch should be in UP position.

8. Turn on the utility power supply to transfer

switch, using whatever means provided (such

as a utility main line circuit breaker). The utility

power source now powers the loads.

9. Set the generator's AUTO/OFF/MANUAL switch to

its AUTO position.

10. Set the GENERATOR DISCONNECT SWITCH to

the ON position. The system is now set for fully

automatic operation.

6

Page 9

]

]

]

OR

E

3

S

]

0A6599tv

"

]

E

E

E

E

S

]

OCK

)

ON

0A6599tv

]

Section 4 — Installation Diagram

ATS “HS” Type Transfer Switch

Drawing No. 0F0016-B

597mm[23.50"

271mm[10.67"

MOUNTING HOLE

6.3mm[0.25"

26.5mm[1.04"

561mm[22.09

PADL

CUSTOMER SUPPLIED

LOCATI

34mm[1.34"

179.5mm[7.07"

KNOCKOUT SUITABL

FOR 3/4" & 1" CONDUIT SIZ

KNOCKOUT SUITABLE F

1", 1-1/4", 1-1/2" CONDUIT SIZ

PLACE

KNOCKOUT SUITABL

FOR 1", 1-1/4", 1-1/2" CONDUIT SIZ

324mm[12.76"

7

Page 10

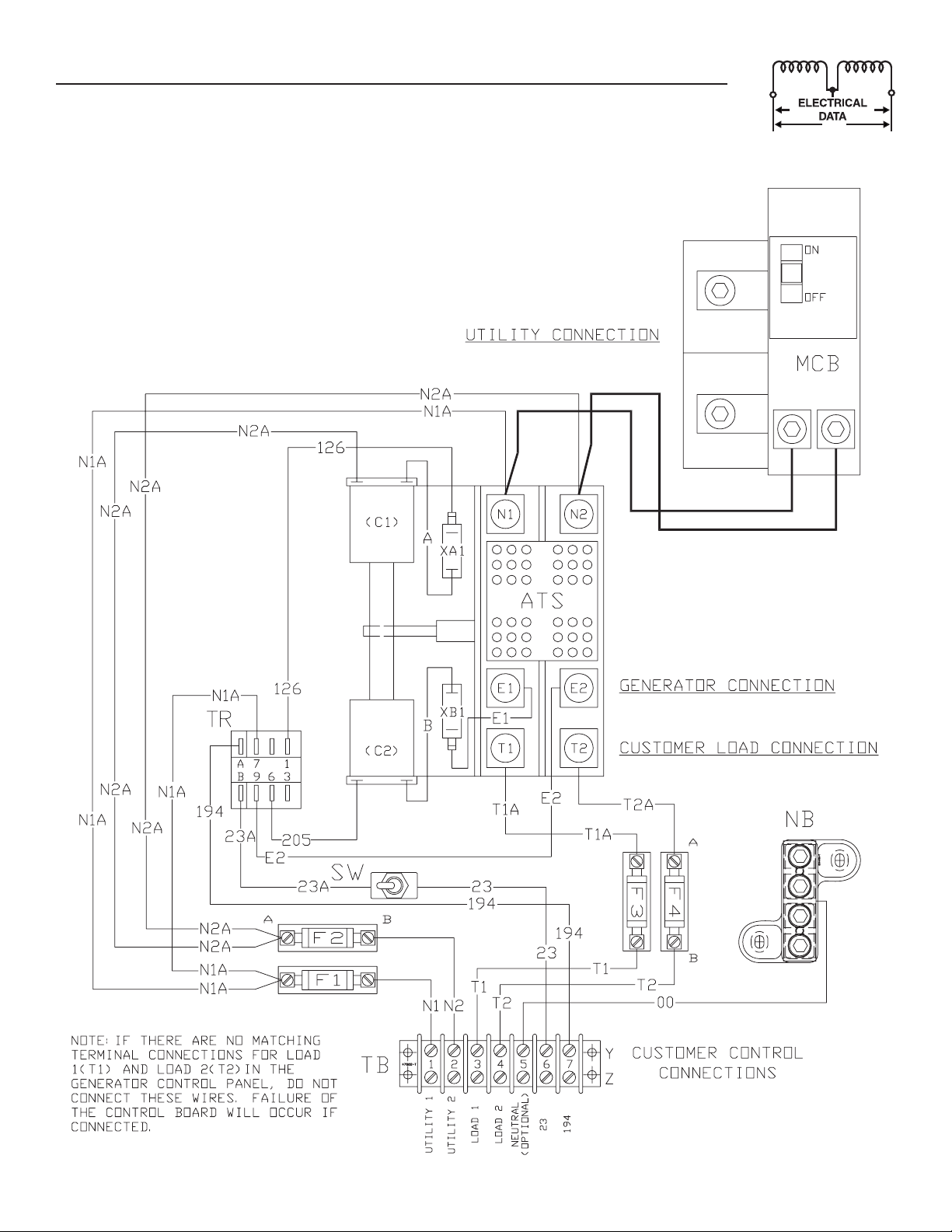

Section 5 — Electrical Data

G

O

O

O

O

COO

U

S

S

O

SCO

C

C

O

O

O

S

O

U

OU

G

Y

O

O

O

OU

C

C

CO

S

,

C

S

C

C

US

S

O

O

O

C

SCO

C

S

S

US

S

S

C

C

C

O

G

JU

S

S

O

O

OC

CO

S

S

ATS “HS” Type Transfer Switch

Transfer Switch Interconnections - Drawing No. 0F0017-A

E

MEET

.

E ENTRAN

DE

MPER WILL NEED

ERVI

IZED T

AL

NDIN

ED A

TALLED

I

NAL & L

E A B

BE IN

ATI

EVI

F AT

T

NNE

E DI

ERVI

T

.

NE BY A

DE

STATE AND

IAN AND M

BE D

AL

TRI

N T

TRI

ED ELE

AL ELE

EN

TALLATI

EET ALL NATIONAL

I

T

NNE

NDIN

I

ND BAR

R

ARD

N

TI

NNE

N PANELB

TRAL BAR

E

N

FIT

TALLATI

R RETR

EW IN

TE: IN

ARD

ANELB

NIT

LED

R

R

M

LTERNAT

TAT

R

T

T

N AIR

T1 & T2 N

ED

ND SOME LIQUID COOLED UNITS

-WIRE

4

R

L PANEL

ND BAR

R

ENERAT

NTR

KET

TILIT

8

Page 11

L

R

R

D

SCO

CT

ON

G

D

OT

COO

S

T

CE

D

T

S.

O

D

)

G

OR

E

&

).

TILIT

Y

T

UST

OR

OR

OM

33

OC

S.

D

SCO

CT

S

S

KE

Section 5 — Electrical Data

ATS “HS” Type Transfer Switch

Transfer Switch Interconnections - Drawing No. 0F0017-A

IF ATS IS USED AS SERVICE ENTRAN

DEVICE A BONDING JUMPER WILL NEE

TO BE INSTALLED SIZED TO MEE

ATIONAL & LOCAL CODE

EXISTING WIRES T

PANELBOAR

SEE ABOVE NOTE

INSULATED SPLICIN

NNECTOR

NEW WIRES CAN B

PULLED FROM ATS

PANELBOARD

ERVICE DI

NNE

AT

NOTE: INSTALLATION TO BE DONE BY A

LICENSED ELECTRICIAN AND M

MEET ALL NATIONAL, STATE AN

L

AL ELECTRICAL CODE

FR

ALTERNAT

TAT

*-WIRES T1 & T2 N

DI

NNE

BONDIN

NNECTI

IN PANELBOAR

NEUTRAL BA

ROUND BA

PANELBOAR

AC GENERATOR

NTROL PANE

ED ON AIR

AND SOME LIQUID COOLED UNIT

LED UNIT

RETROFI

9

Page 12

Section 5 — Electrical Data

ATS “HS” Type Transfer Switch

Wiring Diagram/Schematic - Drawing No. 0F0015-A

10

Page 13

Section 5 — Electrical Data

ATS “HS” Type Transfer Switch

Wiring Diagram/Schematic - Drawing No. 0F0015-A

11

Page 14

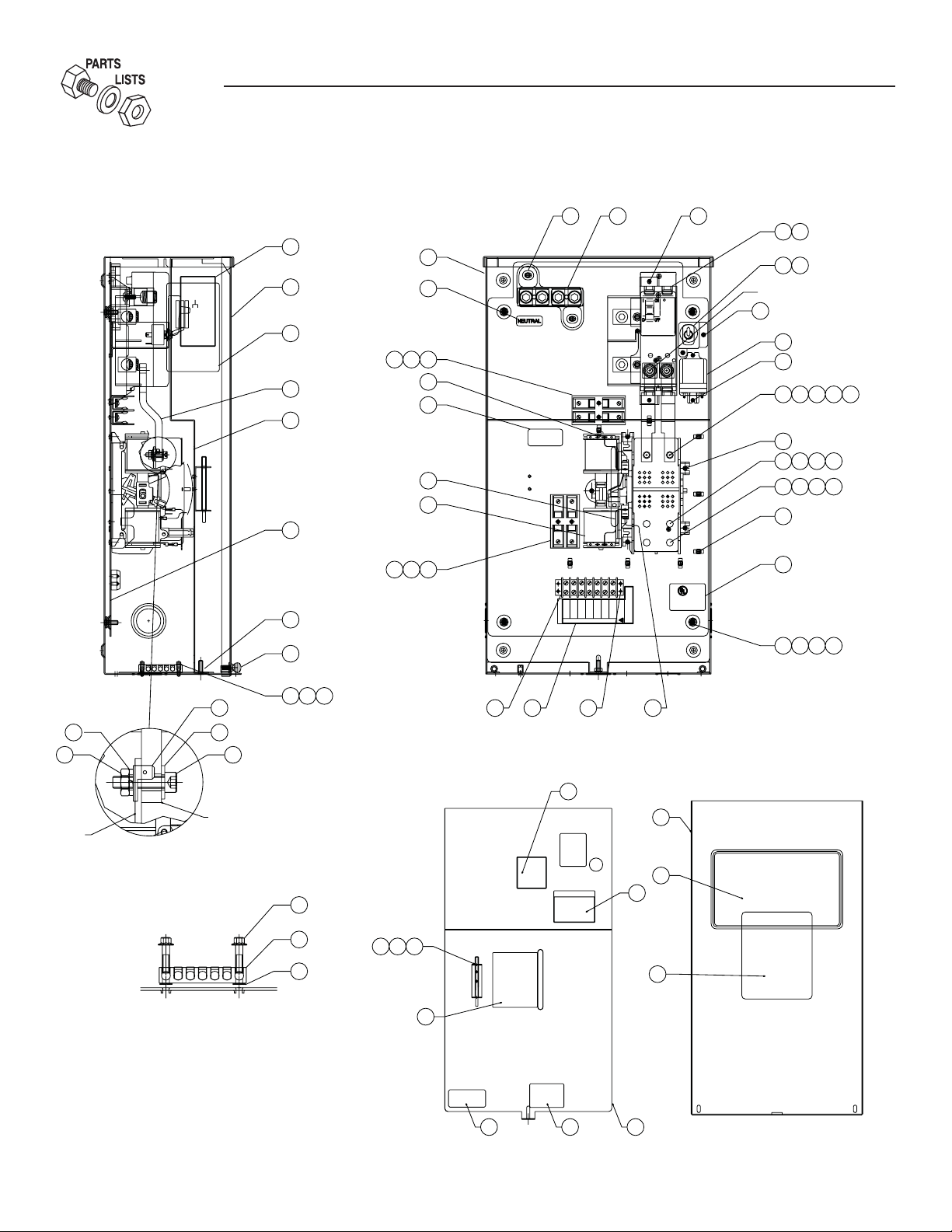

Section 6 — Exploded Views and Parts List

ATS “HS” Type Transfer Switch

100A Transfer Switch Assembly – Drawing No. 0F0466$-D

46

44

DETAIL A-A

(POWER TERMINAL LUG ASSY)

TIGHTEN ITEM #43: 24-30 IN/LBS

NOTE:

43

44

43

DETAIL B-B

(POWER TERMINAL LUG ASSY)

TIGHTEN ITEM #43: 24-30 IN/LBS

46

NOTE:

33

3

2

15

16

6

TERMINAL TIGHTENING

TORQUE 50 INCH-POUNDS

!

32

4

10

31

47

48

TERM. XA1

TERM. XA2

TERMINAL TIGHTENING

TORQUE 50 INCH-POUNDS

SWITCH XA

TERM. XA3

SWITCH LEVER

SWITCH LEVER

TERM. XB1

SWITCH XB

TERM. XB3

51

54

NOTE:

TERM. XB2

ASSEMBLE SENSING WIRE

CLEARANCE IS GIVEN FOR

RING TERMINALS SO

5

ACCESS TO LOWER LUG

SCREWS.

!

0A6599tv

0A6599tv0A6599tv

63378-T

0A9457

63378-T

A

A

63378-T

A

30A, 600V

D2806-T

63378-T

0D3587

Replace with UL

listed fuse of same

600 Volt, 5 amp.

type and rating

63378-T63378-T

LISTED

US

64NL

63378-T

B

B

E1

B

D2806-T

30A, 600V

R

STAND-BY SYSTEMS

FOR USE IN OPTIONAL

C

AUTOMATIC TRANSFER SWITCH

63378-T

194WIRE

23WIRE

T2

T1

N2WIRE

N1

47822-T

38

30

378 37

QTY. 1 ITEM #37 ABOVE SUBPLATE

QTY. 2 ITEM #37's BELOW SUBPLATE

4 PLACES

0A6599tv

19

7

24

P/N 0A2595

NOTE WIRE ORIENTATION

WARNING

(12 VDC)

(12 VDC)

(OPTIONAL)

NEUTRAL

(240 VAC)

WIRE

(240 VAC)

WIRE

(240 VAC)

CUSTOMER CONNECTIONS

(240 VAC)

WIRE

DECAL DETAILS

(NOT TO SCALE)

VIEWS SHOWN WITH ITEMS #18 & #19 FULLY ASSEMBLED

20

0E9999

0E3485

OF

29

COVER

INSIDE

0E3484

18

0C8308

49 45

23

41 4240

28

0A6599tv0A6599tv

0A6599tv

0A6599tv

VIEW SHOWN WITH ITEMS #18 & #19 REMOVED

17

INSIDE RIGHT SIDE

50

OR ALUUMINUM WIRE OF AT LEAST 75° c RATING

ALL TERMINALS LUGS ARE SUITABLE FOR COPPER

#0C1026 OR #0D8440 0R #0E0117 OR #0E5241A

SWITCH IS FOR USE WITH CONTROL PANEL ASSEMBLY

RATING

SWITCH

INSIDE LEFT SIDE

22

WAUKESHA, WI.

GENERAC POWER SYSTEMS, INC.

MAXIMUM VOLTS - 240

MAXIMUM AMPS - 100

TRANSFER SYSTEM DATA

1/4 STL

22097-S

22473-S

1-4X20STL

22473-S

1-4X20STL

!

13

26

27

52

53

1211 31

19

0F2710

MODEL NUMBER

SERIAL NUMBER

SYSTEM VOLTAGE

0C4449A-RS

18

D2806-E

30A, 600V

1

1211 31

21

30A, 600V

D2806-S

48850-E

14

TERMINAL TIGHTENING

TORQUE 45 INCH-POUNDS

B

35

8

36

1/4 STL

22097-S

22473-S

1-4X20STL

22473-S

1-4X20STL

934

DETAIL "A"

9

34

35

DETAIL A

(GROUND LUG ASSEMBLY)

ENCLOSURE

12

Page 15

Section 6 — Exploded Views and Parts List

ATS “HS” Type Transfer Switch

100A Transfer Switch Assembly – Drawing No. 0F0466$-D

ITEM PART NO. QTY. DESCRIPTION

1 0C2237 1 TRANSFER SW- HSB 100A 2P 250V

2 0E7886H 1 CB 0100A 2P 240V S BQ2 LB

3 0E7890 1 BRKT CB MTG BACK

4 0E9906 1 BRACKET, DISCONNECT SWITCH 100A

5 063378 8 HOLDER, CABLE TIE

6 0D3728 1 SWITCH TOG SPST 15A @ 125V

7 0E9999 1 DECAL SERVICE DISCONNECT SWITCH

8 049813 4 NUT HEX M6 X 1.0 G8 YEL CHR

9 0E6523 1 GROUND BAR (5)4-14 AWG CONN

10 *** 063617 1 RELAY PNL 12VDC DPDT 10A@240VA

11 *** 0D2806 2 FUSEBLOCK 30A 600V 2POS W/SQ

12 073590A 4 FUSE 5A X BUSS

1 3 *** 047822 1 BLOCK TERM 20A 7 X 6 X 1100V

14 0A1661 2 RIVET POP .156 X .675 AL

15 0C4449 1 ASS’Y-NTRL BL 150-200A

16 090388 2 SCREW HHTT M6-1.0 X 12 ZINC

17 0E1473 1 WELDMENT TRANSFER SWITCH BOX

18 0E9907 1 COVER INSIDE XFER SWITCH BOX

19 0E1477 1 COVER TRANSFER SWITCH BOX

20 0F0668 1 DECALTRANSFER SWITCH

21 0E3070 1 SUBPLT XFER SW HSB

22 0E9734 REF DECAL SWITCH RATING

23 0E3484 1 DECAL WARN MANUAL OPER HANDLE

24 0E3485 1 DECAL SERVICE DISCONNECT

25 067210A 1 DECAL GROUND LUG (NOT SHOWN)

26 0A9457 1 DECAL NEUTRAL

27 0D3587 1 DECAL FUSE REPLACEMENT

28 0A2595 1 DECAL TERMINAL STRIP

29 0F0776 1 DECAL TEST SEQ. 2P TS HS 3R

30 081221 1 DECAL-UL LIST HSB

31 045764 6 SCREW HHTT M4-0.7 X 8 BP

32 074908 2 SCREW HHTT M5-0.8 X 10 BP

33 066849

34 0C3992 2 SCREW HHTT M4-0.7 X 16 BP

35 026579 2 WASHER SHAKEPROOF EXT #8 STEEL

36 0E7213 2 SCREW THUMB 1/4-20 X 1/2 W/SHLD

37 022473 8 WASHER FLAT 1/4-M6 ZINC

38 022097 4 WASHER LOCK M6-1/4

39 0E9987 1 WIRE HARNESS HSB (NOT SHOWN)

40 0E6193 1 BRACKET ARM EXTENDER

41 064526 2 SCREW HWHS #6-25 X 3/8 ZNC

42 ** 0E6155 1 ARM EXTENDER PIN

43 036933 6 SCREW PPHM #10-32 X 3/8

44 077033 6 LUG SLDLSS 1/0-#14X9/16 AL/CU

45 0C8308 1 DECAL TERMINAL SHOCK HAZARD

46 022152 6 WASHER LOCK #10

47 0912

48 0912970086 1 WIRE ASSY 2AWG 100A 2-P T/S N2A

49 095282 1 DECAL LIVE-CIRCUIT

50 0F2710 1 DECAL XFER SWITCH DATA SE 100A

51 066849 4 SCREW HHTT M5-0.8 X 16

52 0E6303 1 WIRE – A

53 0E6303A 1 WIRE – B

54 0E6303C 1 WIRE – E1

B 2 SCREW HHTT M5-0.8 X 8 BP

970085 1 WIRE ASSY 2AWG 100A 2-P T/S N1A

*** SUPPLIED WITH WIRE HARNESS ITEM #39

** SUPPLIED WITH TRANSFER SWITCH (ITEM #1)

13

Page 16

Section 6 — Exploded Views and Parts List

ATS “HS” Type Transfer Switch

200A Transfer Switch Assembly – Drawing No. 0E9801$-F

38

8

SWITCH

22097-S

1/4 STL

22473-S

22473-S

1-4X20STL

1-4X20STL

0C4449A-RS

30A, 600V

D2806-E

22097-S

1/4 STL

22473-S

1-4X20STL

D2806-S

30A, 600V

48850-E

22097-S

1/4 STL

22473-S

22473-S

1-4X20STL

1-4X20STL

22097-S

1/4 STL

22473-S

1-4X20STL

BUSBAR HARDWARE

DETAIL

ENCLOSURE

RATING

SWITCH

SWITCH IS FOR USE WITH CONTROL PANEL ASSEMBLY

#0C1026 OR #0D8440 0R #0E0117 OR #0E5241A

MAXIMUM AMPS - 200

MAXIMUM VOLTS - 240

TRANSFER SYSTEM DATA

120/240

SYSTEM VOLTAGE

MODEL NUMBER

SERIAL NUMBER

DETAIL A

(GROUND LUG ASSEMBLY)

ALL TERMINALS LUGS ARE SUITABLE FOR COPPER

OR ALUUMINUM WIRE OF AT LEAST 75° c RATING

0F2712

BUSBAR

16

INSIDE RIGHT SIDE

55

19

GENERAC POWER SYSTEMS, INC.

WAUKESHA, WI.

INSIDE LEFT SIDE

22

17

26

0A6599tv0A6599tv0A6599tv

0A9457

3111 12

4

46

27

18

Replace with UL

listed fuse of same

type and rating

600 Volt, 5 amp.

0D3587

47

15

0C4449A-T

31

3

2

53

52

NOTE:LOCATE HOLE IN BUSBAR

UNDER BALL END OF SCREW

0A6599tv0A6599tv0A6599tv

TIGHTENING TORQUE 250 IN-LBS

33

31

UTILITY

(C1 & VR1)

71037 388

D2806-T

30A, 600V

63378-T

AA

63378-T

63378-T

SEE SIDE VIEW FOR HARDWARE DETAIL

TORQUE ITEM #8 TO 12 FT-LBS

56

53038

63378-T

5

386645

43

44

TORQUE ITEM #6

TO 72 IN-LBS.

1

STANDBY

D2806-T

30A, 600V

21

(C2 & VR2)

63378-T

11 3112

47822-T

T2

T1N2N1

(240 VAC)

(240 VAC)

(240 VAC)

WIRE

WIRE

WIRE

WIRE

32

0A6599tv0A6599tv0A6599tv

CUSTOMER CONNECTIONS

36

43

DETAIL "A"

35349

13

28 14

E1E1

BB

63378-T

194

23

(12 VDC)

(12 VDC)

(240 VAC)

NEUTRAL

WIRE

WIRE

(OPTIONAL)

WARNING

P/N 0A2595

NOTE WIRE ORIENTATION

R

C

AUTOMATIC TRANSFER SWITCH

FOR USE IN OPTIONAL

STAND-BY SYSTEMS

63378-T

63378-T

LISTED

US

64NL

0A6599tv0A6599tv0A6599tv

0A6599tv

50

32 3737 38

QTY. 2 ITEM #37's BELOW SUBPLATE

QTY. 1 ITEM #37 ABOVE SUBPLATE

4 PLACES

48

37

7

DECAL DETAILS

VIEWS SHOWN WITH ITEMS #18 & #19 FULLY ASSEMBLED

(NOT TO SCALE)

24

19

0E3485

34

0E9999

9

40 4241

35

0E3484

20

51

29

INSIDE

OF

COVER

AUTOMATIC

TRANSFER SWITCH

NEMA 3R - INDOOR/OUTDOOR USE

23

14

0C8308

54 49

18

Page 17

Section 6 — Exploded Views and Parts List

ATS “HS” Type Transfer Switch

200A Transfer Switch Assembly – Drawing No. 0E9801$-F

ITEM PART NO. QTY. DESCRIPTION

1 0D9618 1 TRANSFER SW- HSB 200A 2P 250V

2 0E3628 1 CIRCUIT BREAKER 0200A 2P 120/240V S QN

3 0E3664 1 BASE QN CIRCUIT BREAKER

4 0E3553 2 BUSBAR 200A HSB XFER SW

5 0E3375 4 LUG SLDLSS 250-#6 AL/CU

6 0F1252 4 SCREW BHSC 1/4-20 X 3/8

7 036656 2 SCREW SHC 1/4-20 X 1 G8.8 NZ

8 022127 2 NUT HEX 1/4-20 STEEL

9 0E6523 1 GROUND BAR (5)4-14 AWG CONN

10 063617 1 RELAY PNL 12VDC DPDT 10A@240VA

11 0D2806 2 FUSEBLOCK 30A 600V 2POS W/SQ

12 073590A 4 FUSE 5A X BUSS

13 047822 1 BLOCK TERM 20A 7 X 6 X 1100V

14 0A1661 2 RIVET POP .156 X .675 AL

15 0C4449A 1 ASS’Y-NTRL BL150-200A

16 090388 2 SCREW HHTT M6-1.0 X 12 ZINC

17 0E1473 1 WELDMENT TRANSFER

18 0E9989 1 COVER INSIDE XFER SWITCH BOX

19 0E1477 1 COVER TRANSFER SWITCH BOX

20 0F0668 1 DECALTRANSFER SWITCH

21 0E3070 1 SUBPLT XFER SW HSB

22 0E3477 REF DECAL SWITCH RATING

23 0E3484 1 DECAL WARN MANUAL OPER HANDLE

24 0E3485 1 DECAL SERVICE DISCONNECT

25 067210A 1 DECAL GROUND LUG (NOT SHOWN)

26 0A9457 1 DECAL NEUTRAL

27 0D3587 1 DECAL FUSE REPLACEMENT

28 0A2595 1 DECAL TERMINAL STRIP

29 0E7109 1 DECAL TEST SEQ.2P TS HS 3R

30 063378 8 HOLDER CABLE TIE

31 045764 8 SCREW HHTT M4-0.7 X 8 BP

32 049813 5 NUT HEX M6 X 1.0 G8 YEL CHR

33 0749

34 0C3992 2 SCREW HHTT M4-0.7 X 16 BP

35 026579 2 WASHER SHAKEPROOF EXT #8 STEEL

36 0E7213 2 SCREW THUMB 1/4-20 X 1/2 W/SHLD

37 022473 14 WASHER FLAT 1/4-M6 ZINC

38 022097 10 WASHER LOCK M6-1/4

39 0E9987 1 WIRE HARNESS HSB (NOT SHOWN)

40 0E6193 1 BRACKET ARM EXTENDER

41 064526 2 SCREW HWHS #6-25 X 3/8

42 * 0E6155 1 ARM EXTENDER PIN

43 * 0E6032 2 90 DEGREE UP SPADE CONNECTOR

44 * 0E6033 2 90 DEGREE DN SPADE CONNECTOR

45 * 0E6034 2 STRAIGHT SPADE CONNECTOR

46 0E6303

47 0E6303A 1 WIRE B

48 0E6303B 1 WIRE E1

49 0C8308 1 DECAL TERMINAL SHOCK HAZARD

50 081221 1 DECAL-UL LIST HSB

51 0E9999 1 DECAL-SERVICE DISCONNECT SWITCH

52 0E9988 1 BRACKET SERVICE SWITCH

53 0D3728 1 TOBBLE SWITCH, SERVICE

54 095282 1 DECAL LIVE-CIRCUIT

55 0F2712 1 DECAL XFER SWITCH DATA SE 200A

56 066849 5 SCREW HHTT M5-0.8 X 16

08 2 SCREW HHTT M5-0.8 X 10 BP

1 WIRE A

SWITCH BOX

* SUPPLIED WITH TRANSFER SWITCH ITEM #1

15

Page 18

Section 7 — Notes

ATS “HS” Type Transfer Switch

16 Generac® Power Systems, Inc.

Page 19

Section 7 — Notes

ATS “HS” Type Transfer Switch

Generac® Power Systems, Inc. 17

Page 20

Section 8 — Warranty

ATS “HS” Type Transfer Switch

GENERAC POWER SYSTEMS, INC. WARRANTY/SERVICE

Generac Power Systems, Inc. will warrant that from the date of purchase, our transfer

switch will be free from defects in material and workmanship for the items and periods set

forth in the warranty statement found in the owners manual of the Generac Power Systems

Inc. generator that this transfer switch will be utilized with.

Any equipment that the purchaser/owner claims to be defective must be examined by the

nearest Generac Authorized Warranty Service Dealer by visiting our website at www.generac.com or by calling the dealer locator number at 1-800-333-1322. Select the prompt that

describes the brand name of the generator.

THIS WARRANTY IS IN PLACE OF ALL OTHER WARRANTIES, EXPRESSED OR

IMPLIED, SPECIFICALLY, GENERAC MAKES NO OTHER WARRANTIES AS TO THE

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

Some states do not allow limitations on how long an implied warranty lasts, so the above

limitation may not apply to you.

GENERAC’S ONLY LIABILITY SHALL BE THE REPAIR OR REPLACEMENT OF PART(S)

AS STATED ABOVE. IN NO EVENT SHALL GENERAC POWER SYSTEMS, INC. BE

LIABLE FOR ANY INCIDENTAL, OR CONSEQUENTIAL DAMAGES, EVEN IF SUCH

DAMAGES ARE A DIRECT RESULT OF GENERAC’S NEGLIGENCE.

Some states do not allow the exclusion or limitation of incidental or consequential dam-

ages, so the above limitations may not apply to you.

This warranty gives you specific legal rights. You also may have other rights that vary from

state to state.

GENERAC® POWER SYSTEMS, INC.

P.O. BOX 297 • WHITEWATER, WI 53190

Part No. 0E9905 Revision F (07/21/05) Printed in U.S.A.

Loading...

Loading...