Microwave Data Systems Inc.

MDS T ransNET OEM

Transceiver Model EL806

™

Spread Spectrum Data Transceiver

Including Instructions for

03-4053A01 Evaluation Development Kit

OEM Integration Guide

Installation & Operation Guide

MDS 05-3946A01, Rev. A

APRIL 2003

QUICK START GUIDE

The steps below contain the essential information needed to place the OEM transceiver in service. Because the transceiver is designed for use in other pieces of

equipment, these steps assume that prior testing and evaluation have been

conducted with the host device. If not, please refer to Section 3.0, Benchtop Setup

and Evaluation for proper interface wiring and configuration.

1. Mount the transceiver module using the four holes provided.

• If possible, select a mounting location that allo ws vie wing the status LEDs and

provides ready access to the antenna connector.

• Use standoff hardware to secure the board to the host device.

• When mounting the board, use care to align the transceiver’s 16-pin header

connector with the mating pins in the host device.

2. Connect the antenna system to the transceiver

• Use only with antenna/feedline assemblies that have been expressly tested

and approved for such service by Microwave Data Systems Inc.

• Use an MMCX-type male connector to attach the antenna to the transceiver.

• For best performance, antennas should be mounted in the clear, with an

unobstructed path in the direction of desired transmission/reception.

3. Apply power and observe the LEDs for proper operation. The LED

command must be set to ON (LEDS ON).

After 16 seconds...

• The GP lamp should be lit continuously

• The DCD lamp should be lit continuously—if synchronization with another unit

has been achieved

• The Remote radio(s) should be transmitting data (TXD) and receiving data

(RXD) with its associated station

LED Indicator Descriptions

LED Name Description

RXD (CR3)

Receive Data

TXD (CR4)

Transmit Data

DCD (CR5)

Data Carrier Detect

GP (CR6)

General Purpose

Serial receive data activity. Payload data from connected device.

Serial transmit data activity. Payload data to connected device.

Continuous—Radio is receiving/sending synchronization frames

On within 10 seconds of power-up under normal

conditions

• Continuous—Power is applied to the radio; no

problems detected

• Flashing (5 times-per-second)—Fault indication.

See “TROUBLESHOOTING” on Page 52

• Off—Radio is unpowered or in Sleep mode

RXD

TXD

DCD

GP

CONTENTS

1.0 ABOUT THIS MANUAL..........................................................1

2.0 PRODUCT DESCRIPTION....................................................1

2.1 Transceiver Features .......................................................2

2.2 Model Configuration Codes ............................................2

2.3 Spread Spectrum Transmission ......................................3

2.4 Typical Applications .........................................................3

Multiple Address Systems (MAS)....................................3

Point-to-Point System ......................................................4

Tail-End Link to an Existing Network ...............................5

Store-and-Forward Repeater...........................................5

2.5 Transceiver Accessories .................................................6

3.0 BENCHTOP SETUP & EVALUATION....................................7

3.1 Evaluation Development Kit (P/N 03-4053A01) ..............7

Evaluation Board .............................................................8

Connecting the Eval. Board & Transceiver (Figure 8)......9

3.2 Cable Connections for Benchtop Testing ........................10

Antenna Connection (J200 on the transceiver module)...10

Diagnostic Connection (J4)..............................................11

Data Connector (J5) ........................................................12

DC Power Connector (J3)................................................14

Jumper Block J1 (DC Power Configuration) ....................15

3.3 Initial Power-Up & Configuration .....................................15

Configuration Settings .....................................................16

LED Indicators.................................................................17

4.0 EVALUATION BOARD DOCUMENTATION ...........................18

4.1 Assembly Drawing ..........................................................18

4.2 Parts List .........................................................................18

4.3 Evaluation Board Fuse Replacement .............................20

5.0 TRANSCEIVER MOUNTING.................................................21

MDS 05-3946A01, Rev. A TransNET OEM Integration Guide i

5.1 Mounting Dimensions .....................................................21

5.2 Antennas & Feedlines ....................................................21

Feedlines.........................................................................22

6.0 OPTIMIZING PERFORMANCE.............................................23

6.1 Antenna Aiming .............................................................. 23

6.2 Antenna SWR Check ..................................................... 23

6.3 Data Buffer Setting ......................................................... 23

6.4 Hoptime Setting ..............................................................23

6.5 Operation at 115200 bps ................................................24

6.6 Baud Rate Setting ..........................................................24

6.7 Radio Interference Checks .............................................24

6.8 RF Output Setting ...........................................................24

7.0 OPERATING PRINCIPLES & SPECIAL

CONFIGURATIONS ......................................................................25

7.1 How Remotes Acquire Synchronization ......................... 25

7.2 Establishing a Tail-End Link ............................................ 25

7.3 Store & Forward (SAF) Operation with Extension Radios 26

Simple Extended SAF Network.......................................26

Extended SAF Network...................................................27

Retransmission and ARQ operation................................28

Synchronization in SAF Networks...................................28

Configuration Parameters for Store-and Forward Services29

7.4 Sleep Mode Operation (Remote units only) ...................31

Sleep Mode Example...................................................... 32

8.0 DEALING WITH INTERFERENCE........................................32

9.0 PROGRAMMING REFERENCE ...........................................34

9.1 Programming Methods ................................................... 34

Terminal Interface Mode..................................................34

PC-Based Configuration Software..................................34

9.2 User Commands ............................................................ 34

Entering Commands ....................................................... 35

9.3 Detailed Command Descriptions ....................................40

ADDR [1–65000]............................................................. 40

AMASK [0000 0000–FFFF FFFF]................................... 41

ii TransNET OEM Integration Guide MDS 05-3946A01, Rev. A

ASENSE [HI/LO]..............................................................41

BAUD [xxxxx abc]............................................................41

BUFF [ON, OFF]..............................................................41

CODE [NONE, 1…255] ...................................................42

CTS [0–255].....................................................................42

CTSHOLD [0–60000].......................................................43

DEVICE [DCE, CTS KEY] ..............................................43

DLINK [xxxxx/ON/OFF]....................................................43

DKEY...............................................................................44

DTYPE [NODE/ROOT]....................................................44

FEC [ON, OFF]................................................................44

HOPTIME [7, 28] .............................................................44

INIT..................................................................................44

HREV...............................................................................45

KEY..................................................................................45

LEDS [ON, OFF]..............................................................45

MODE [M, R, X]...............................................................45

OWM [xxxxx]....................................................................45

OWN [xxxxx]....................................................................45

PORT [RS232, RS485]....................................................45

PWR [20–30] ...................................................................46

REPEAT [0–10]................................................................47

RETRY [0–10]..................................................................47

RSSI ................................................................................47

RTU [ON, OFF, 0-80].......................................................48

RX [xxxx]..........................................................................48

RXTOT [NONE, 0–1440] .................................................48

SAF [ON, OFF]................................................................48

SETUP.............................................................................48

SER .................................................................................49

SHOW PWR....................................................................49

SHOW SYNC...................................................................49

SKIP [NONE, 1...8]..........................................................49

SLEEP [ON, OFF]............................................................50

SREV...............................................................................50

STAT ................................................................................50

TEMP...............................................................................50

TX [xxxx]..........................................................................50

UNIT [10000–65000] .......................................................50

MDS 05-3946A01, Rev. A TransNET OEM Integration Guide iii

XADDR [0–31].................................................................51

XMAP [00000000-FFFFFFFF]........................................51

XPRI [0–31].....................................................................51

XRSSI [NONE, –40...–120]............................................. 51

ZONE CLEAR.................................................................51

ZONE DATA..................................................................... 51

10.0 TROUBLESHOOTING......................................................... 52

10.1 Alarm Codes .................................................................53

Checking for Alarms—STAT command ...........................53

Major Alarms vs. Minor Alarms.......................................53

Alarm Code Definitions ................................................... 53

10.2 LED Indicators ..............................................................54

10.3 Troubleshooting Chart ..................................................54

10.4 Network-Wide Remote Diagnostics ..............................55

11.0 FIRMWARE UPGRADES....................................................57

11.1 Obtaining new firmware ................................................57

Saving a Web-site firmware file to your PC.....................57

11.2 Installing firmware in your radio ....................................57

12.0 Security ...............................................................................57

13.0 Product Specifications.........................................................58

13.1 Detailed Pin Descriptions .............................................59

14.0 dBm-Watts-Volts Conversion Chart.....................................66

To Our Customers

We appreciate your patronage. You are our business. We promise to serve and anticipate your

needs. We strive to give you solutions that are cost effective, innovative, reliable and of the

highest quality possible. We promise to build a relationship that is forthright and ethical, one that

builds confidence and trust.

Copyright Notice

This Installation and Operation Guide and all software described herein are Copyright 2003 by

Microwave Data Systems Inc. All rights reserved. Microwave Data Systems Inc. reserves its

right to correct any errors and omissions in this manual.

iv T r ansNET OEM Integration Guide MDS 05-3946A01, Rev. A

RF Exposure Notice

RF EXPOSURE

The radio equipment described in this guide emits radio frequency energy. Although

the power level is low, the concentrated energy from a directional antenna may pose

a health hazard.

outdoor mounted, must be installed to provide a separation distance of at

least 23 cm (9 inches) from all persons, and must not be co-located or operating in conjunction with any other antenna or transmitter.

In mobile applications (vehicle mounted) the above separation distance must be

maintained at all times. More information on RF exposure is availab le on the Internet

at www.fcc.gov/oet/info/documents/bulletins.

All antenna(s) used with this transmitter, whether indoor or

FCC Part 15 Notice

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to part 15 of the FCC Rules.These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed and used

in accordance with the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his own expense.

FCC Modular Approval Notice

This device is offered as an FCC Part 15 Unlicensed Modular Transmitter. This Modular Transmitter is approved for use only with specific antenna, cable and output power configurations that

have been tested and approved by the manufacturer (Microwave Data Systems Inc.). Modifications to the radio, the antenna system, or power output, that have not been explicitly specified by

the manufacturer are not permitted, and may render the radio non-compliant with applicable regulatory authorities. Refer to Table 7 on Page 24 for more detailed information.

This device employs a unique connector at all connections between the module and the antenna,

including the cable. Consult MDS for approved antenna/cable assemblies in our product offering.

When this device is placed inside an enclosure, a durable label must be affixed to the outside of

that enclosure which includes this module’s FCC ID Number.

Changes or modifications not expressly approved by the party responsible for compliance

could void the user’s authority to operate the equipment.

ISO 9001 Registration

Microwave Data Systems adheres to the internationally-accepted ISO 9001 quality system standard.

Manual Revision and Accuracy

While every reasonable effort has been made to ensure the accuracy of this manual, product

improvements may result in minor differences between the manual and the product shipped to

you. If you have additional questions or need an exact specification for a product, please contact

our Customer Service Team using the information at the back of this guide. In addition, manual

updates can often be found on the MDS Web site at www.microwavedata.com.

MDS 05-3946A01, Rev. A TransNET OEM Integration Guide v

vi T r ansNET OEM Integration Guide MDS 05-3946A01, Rev. A

1.0 ABOUT THIS MANUAL

This manual is intended to guide technical personnel in the integration of

MDS TransNET OEM™ transceivers into existing electronic equipment. The

OEM transceiver is designed for use inside Remote Terminal Units (RTUs),

Programmable Logic Controllers (PLCs) and other equipment associated

with remote data collection, telemetry and control.

The manual provides instructions for interface connections, hardware

mounting, and programming commands. Following integration of the

transceiver, it is recommended that a copy of this manual be retained for

future reference by technical personnel.

2.0 PRODUCT DESCRIPTION

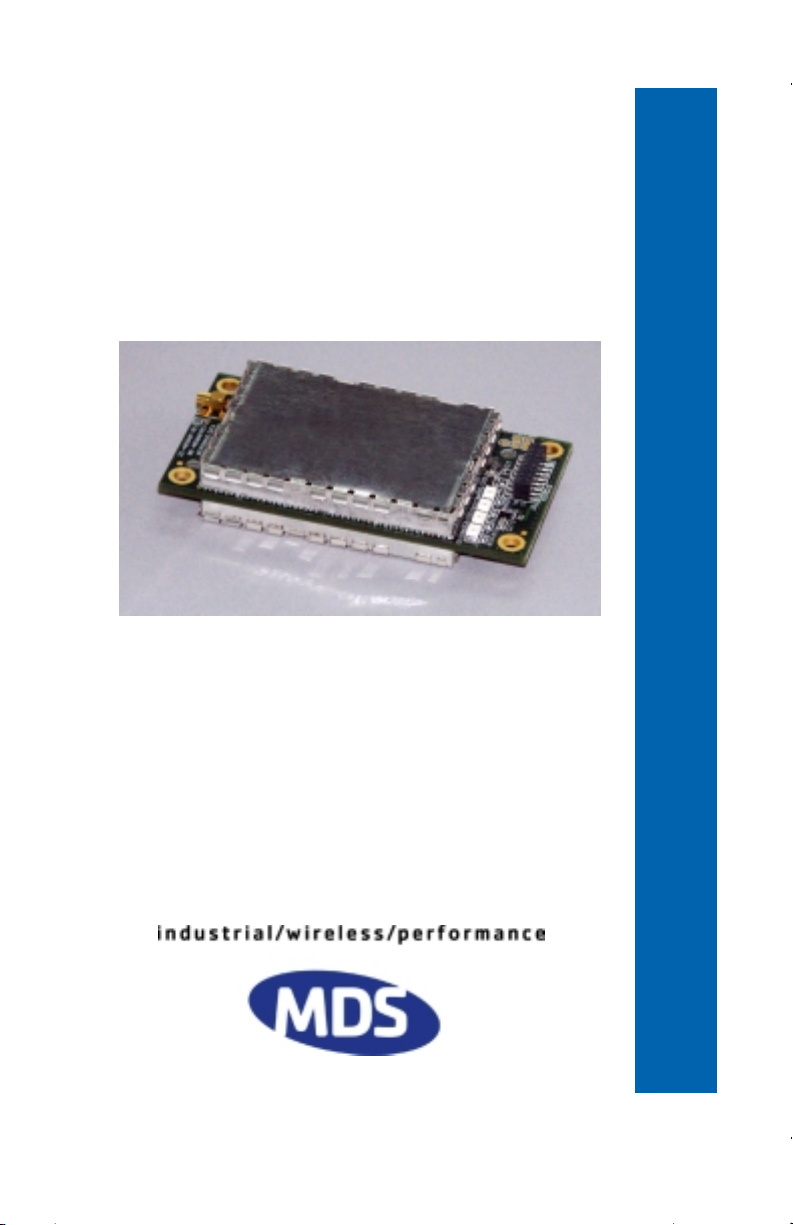

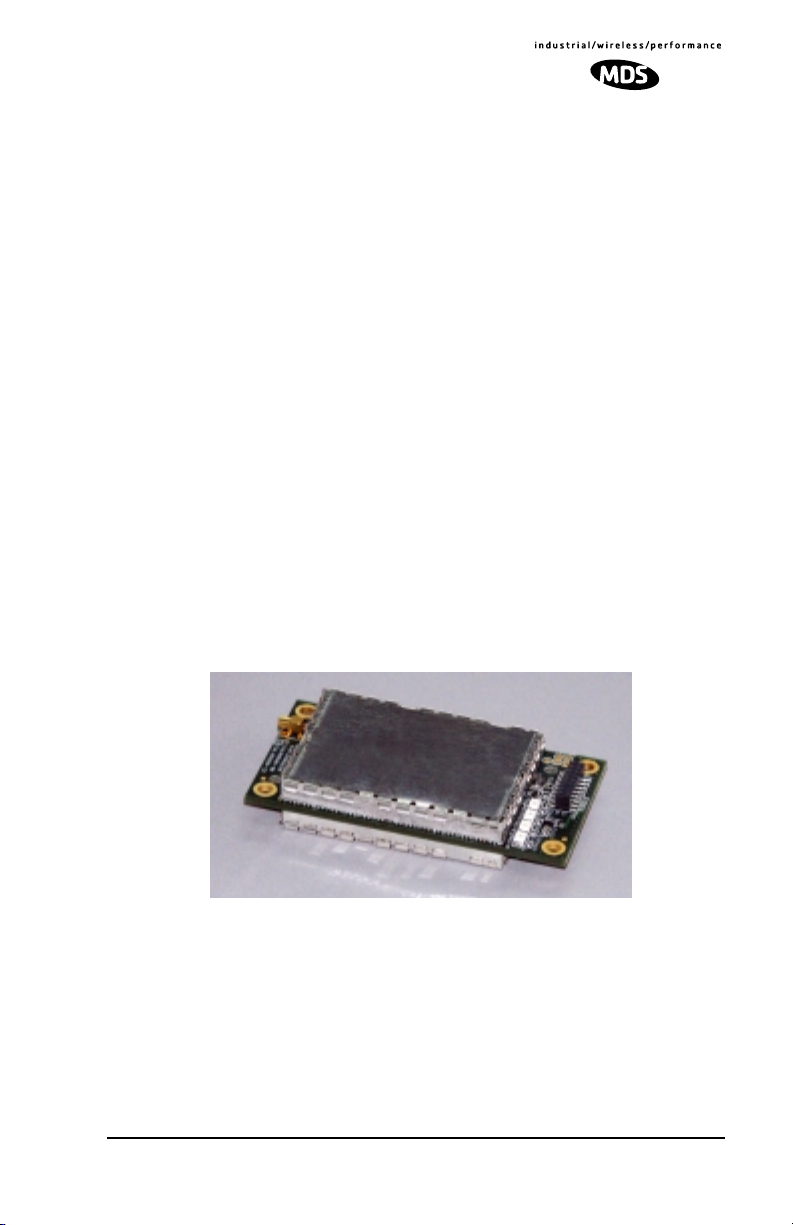

The OEM transceiver, (Figure 1), is a compact, spread spectrum wireless

module designed for license-free operation in the 902-928 MHz frequency

range. It is contained on one double-sided circuit board with all necessary

components and RF shielding included. It need only be protected from direct

exposure to the weather and is designed for rugged service in extreme

temperature environments. The transceiver has full over-the-air compatibility

with standard (non-OEM) TransNET 900TM transceivers manufactured by

MDS.

All transceiver programming is performed via a connected PC terminal. No

jumper settings or manual adjustments are used to configure the transceiver

for operation.

Invisible place holder

Figure 1. TransNET OEM™ Transceiver

The transceiver employs Digital Signal Processing (DSP) technology for

highly reliable data communications, even in the presence of weak or

interfering signals. DSP techniques also make it possible to obtain

information about the radio’s operation and troubleshoot problems, often

eliminating the need for site visits.

Using appropriate software at the master station, diagnostic data can be

retrieved for any radio in the system, even while payload data is being

transmitted. (See “Network-Wide Remote Diagnostics” on Page 55.)

MDS 05-3946A01, Rev. A TransNET OEM Integration Guide 1

2.1 Transceiver Features

The OEM transceiver is designed for easy installation and flexibility in a wide

range of wireless applications. Listed below are several key features of the

transceiver which are described in more detail later in this guide.

• 128 frequencies over 902–928 MHz, subdivided into eight frequency

zones

• Configurable operating zones to omit frequencies with constant

interference

• 65,000 available network addresses to enhance communications

security

• Network-wide configuration from the master station; eliminates most

trips to remote sites

• Data transparency–ensures compatibility with virtually all

asynchronous data terminals

• Peak-hold RSSI, averaged over eight hop cycles

• Operation at up to 115,200 bps continuous data flow

• Store-and-Forward repeater operation

• Data latency typically less than 10 ms

• Same hardware for master or remote configuration

• Supports RS/EIA-232 or RS/EIA-485 interfaces (factory configured)

• Low current consumption—nominal 8 mA in “sleep” mode. Ideal for

solar/battery powered applications.

NOTE:

Some features may not be available on all units, based on the options purchased and the regulatory constraints for the region in which the radio will operate.

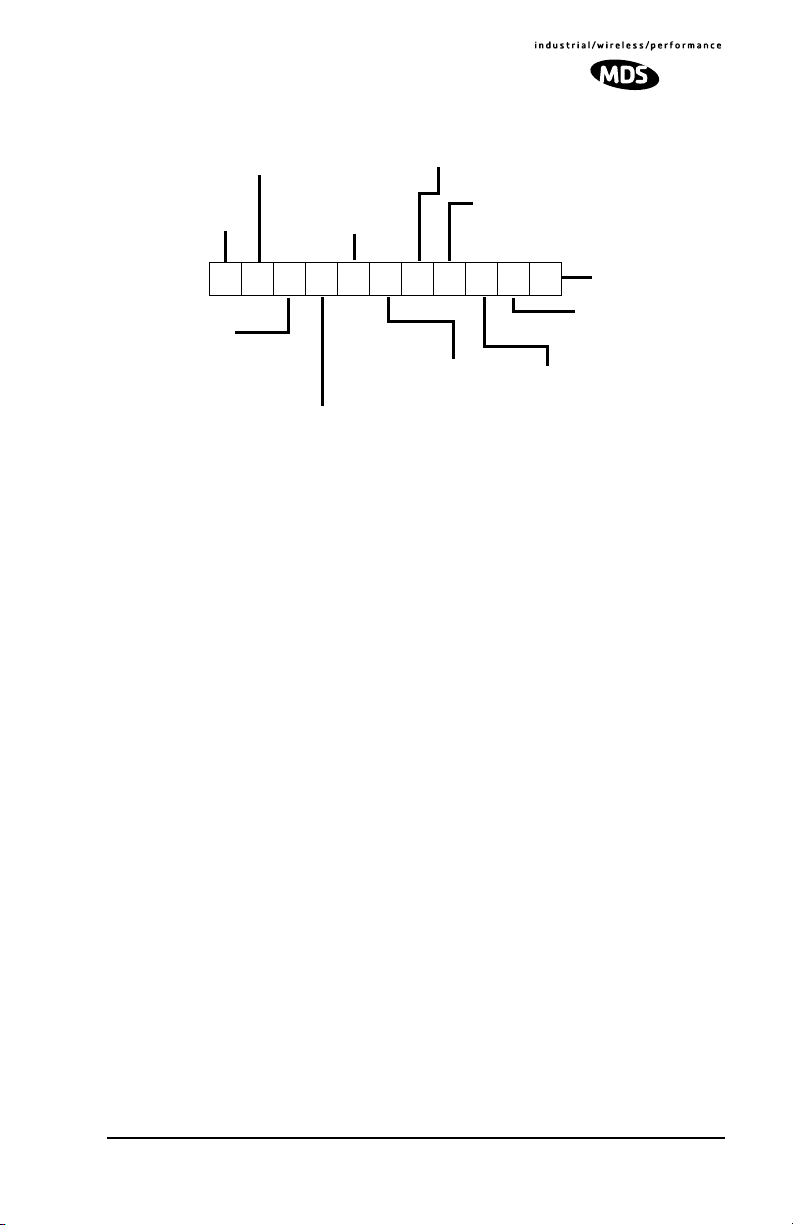

2.2 Model Configuration Codes

The model number code is printed on the radio module, and provides key

information about how it was configured when it left the factory. See Figure 2

for an explanation of the model number codes. (Note: This information is

subject to change and should not be used for ordering additional products.

Your factory representative can assist you with product ordering.)

2 TransNET OEM Integr ation Guide MDS 05-3946A01, Rev. A

OPERATION

(X) Remote/Master

BAND

(9) 900 MHz

EL806

ENCLOSURE

(0) Modular-no enclosure

INTERFACE SIGNALING & INPUT POWER OPTIONS

(0) Payload RS-232/485; Diagnostics RS-232; DC Input +3.3 Vdc

(1) Payload TTL; Diagnostic RS-232; DC Input +3.3 Vdc

(2) Payload TTL; Diagnostic TTL; DC Input 3.3 Vdc

(3) Payload RS-232/485; Diagnostic RS-232; DC Input +5-25 Vdc

(4) Payload TTL; Diagnostic RS-232; Input +5-25 Vdc

(5) Payload TTL, Diagnostic TTL; DC Input +5-25 Vdc

AGENCY

(N) None

(F) FCC/IC

09N

RESERVED

(N) None

INTERFACE MODE

(0) EIA/RS-232

(1) EIA/RS-485

(2) TTL

0

0X

SAFETY CERT.

(N) N/A

W

RESERVED

(N) None

SPARE

(N) None

DIAGNOSTICS

(N) None

(W) Network-wide

Figure 2. Model Number Configuration Codes

2.3 Spread Spectrum Transmission

The transceiver “hops” from channel to channel many times per second using

a specific hop pattern applied to all radios in the network. A distinct hopping

pattern is provided for each of the 65,000 available network addresses,

thereby minimizing the chance of interference with other spread spectrum

systems.

In the USA, and certain other countries, no license is required to install and

operate this type of radio device, provided RF power and antenna gain

restrictions are observed. In the USA and Canada, a maximum of 36 dBm

Effective Isotropic Radiated Power (EIRP) is allowed. The factory offers a set

of approved antennas with special connectors for this radio. Substitutions that

would void the compliance of the device are not permitted.

2.4 Typical Applications

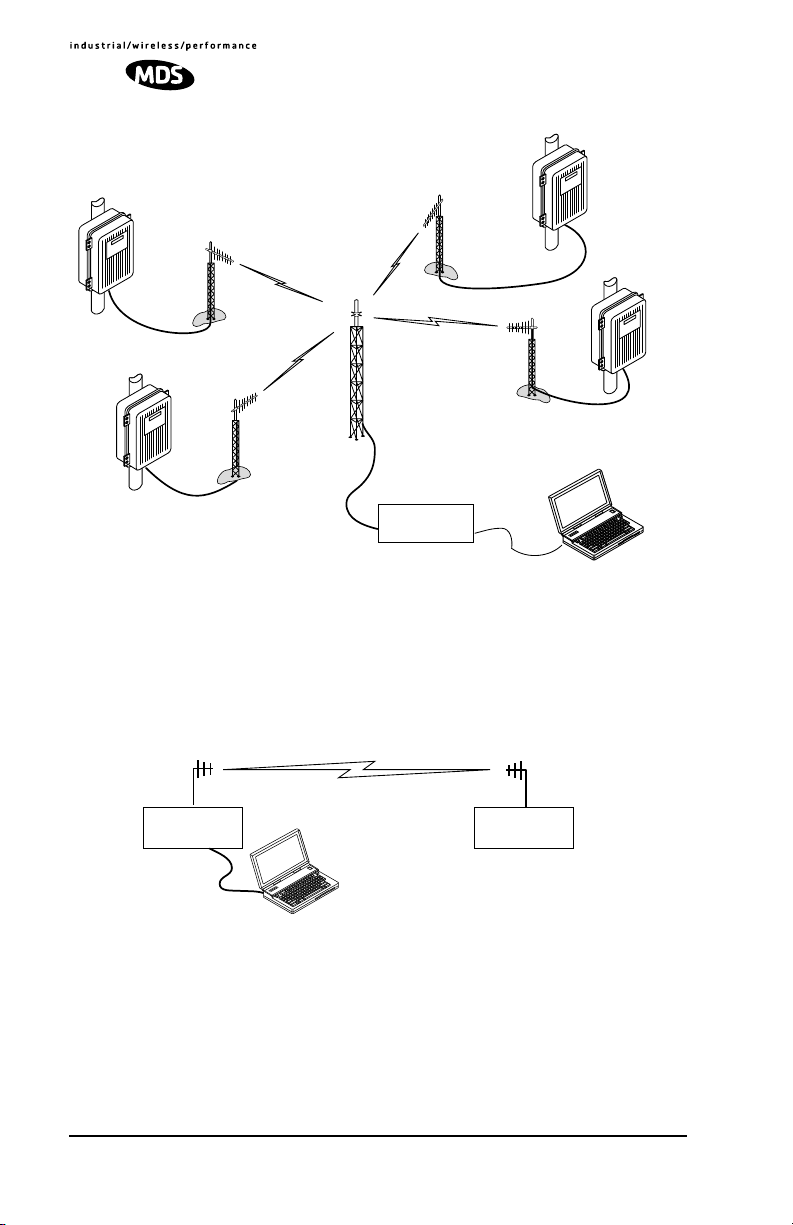

Multiple Address Systems (MAS)

This is the most common application of the transceiver. It consists of a central

control station (master) and two or more associated remote units, as shown in

Figure 3. This type of network provides communications between a central

host computer and remote terminal units (RTUs) or other data collection

devices. The operation of the radio system is transparent to the computer

equipment. This application provides a practical alternative to traditional

(licensed) MAS radio systems.

MDS 05-3946A01, Rev. A TransNET OEM Integration Guide 3

RTU/PLC WITH

TRANSCEIVER

INSTALLED

Invisible place holder

RTU/PLC WITH

TRANSCEIVER

INSTALLED

RTU/PLC WITH

TRANSCEIVER

INSTALLED

MASTER SITE

RTU/PLC WITH

TRANSCEIVER

INSTALLED

DATA

TRANSCEIVER

Figure 3. Typical MAS Network

Point-to-Point System

A point-to-point configuration (Figure 4) is a simple arrangement consisting

of just two radios—a master and a remote. This provides a half-duplex

communications link for the transfer of data between two locations.

Invisible place holder

Master Site Remote Site

DATA

TRANSCEIVER

Host System

Figure 4. Typical Point-to-Point Link

DATA

TRANSCEIVER

4 TransNET OEM Integr ation Guide MDS 05-3946A01, Rev. A

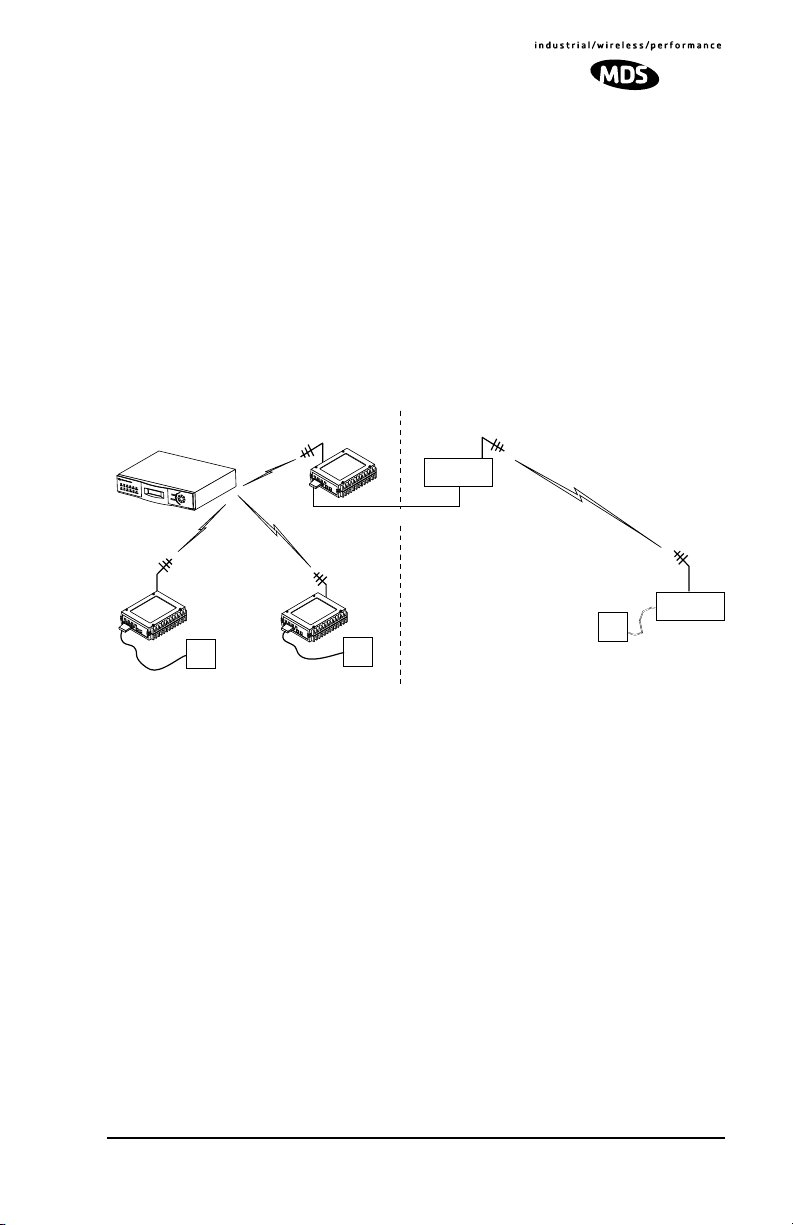

Tail-End Link to an Existing Network

A tail-end link is often used to extend the range of a traditional (licensed)

MAS system without adding another licensed radio. This might be required

if an outlying site is blocked from the MAS master station by a natural or

man-made obstruction. In this arrangement, a spread spectrum transceiver

links the outlying remote site into the rest of the system by sending data from

that site to an associated transceiver installed at one of the licensed remote

sites—usually the one closest to the outlying facility. (See Figure 5).

As the data from the outlying site is received at the associated transceiver, it

is transferred to the co-located licensed radio (via a data crossover cable) and

is transmitted to the MAS master station over the licensed channel.

Additional details for tail-end links are given in Section 7.2 (Page 25).

Invisible place holder

REPEATER STATION

Remote

Radio

Remote Radio

Null-Modem Cable

RTU

S

P

R

E

A

T

DATA

TRANSCEIVER

O

O

LICENSE-FREE SPREAD SPECTRUM SYSTEM

D

S

P

U

E

C

T

L

T

Y

R

I

U

N

M

G

S

L

I

I

N

T

E

K

DATA

TRANSCEIVER

RTU

OUTLYING

REMOTE SITE

Master Station

A

C

T

I

V

E

S

T

B

Y

A

L

A

R

M

R

X

A

L

R

T

X

A

L

R

A

C

T

L

I

I

N

V

E

E

S

T

B

Y

A

L

A

R

M

R

X

A

L

R

T

X

A

L

R

L

I

N

E

E

N

T

E

R

E

S

C

A

P

E

Remote

Radio

RTU

MAS SYSTEM (LICENSED OR UNLICENSED)

Figure 5. Typical Tail-End Link Arrangement

Store-and-Forward Repeater

Similar to a Tail-End Link, Store-and-Forward (SAF) offers a way to

physically extend the range of a network, but in a simplified and economical

manner. SAF operates by storing up the data received from one site, and then

retransmitting it a short time later. Figure 6 shows a typical SAF repeater

arrangement.

SAF operates by dividing a network into a vertical hierarchy of two or more

sub-networks. Extension radios (designated as

MODE X

) serve as single-radio

repeaters that link adjacent sub-networks, and move data from one

sub-network to the next. Additional information on SAF mode is provided in

“Store & Forward (SAF) Operation with Extension Radios” on Page 26.

MDS 05-3946A01, Rev. A TransNET OEM Integration Guide 5

Programmed as

MODE M

DATA

TRANSCEIVER

STORE & FORWARD REPEATER STATION

Invisible place holder

S

P

R

E

A

T

O

RTU

DATA

TRANSCEIVER

Programmed as

MODE X

O

D

S

P

U

E

C

T

L

T

Y

R

I

U

N

M

G

S

L

I

I

N

T

E

K

Programmed as

MODE R

DATA

TRANSCEIVER

Programmed as

MODE R

RTU

DATA

TRANSCEIVER

RTU

Programmed as

MODE R

RTU

DATA

TRANSCEIVER

OUTLYING

REMOTE SITE

Figure 6. Store-and-Forward Repeater Network

2.5 Transceiver Accessories

One or more of the accessories listed in Table 1 may be used with the OEM

transceiver. Contact your factory representative for availability and ordering

details.

Table 1. OEM Transceiver Accessories

Accessory Description Part No.

AC Power Adapter

TransNET Support Package CD

TNC Male-to-N

Male Coax Cable

Assy.

TNC Male-to-N

Male Coax Cable

Assy.

TNC male-to-N

Female Adapter

RJ-11-to-DB9

Adapter Cable

Fuse (for Evaluation Board)

InSite Diagnostic

Software

Omnidirectional

Antennas

Small power supply designed for continuous op-

01-3862A02

eration of the transceiver. UL approved. Input:

120/220; Output: 12 Vdc.

Programming, diagnostic and support files on a

03-2708A01

CD ROM. Includes electronic copy of this guide

(PDF format).

3 ft/1 meter shielded antenna cable 97-1677A159

6 ft/1.8 meter shielded antenna cable 97-1677A160

One-piece RF adaptor plug 97-1677A161

Short cable assembly that converts RJ-11 to

03-3246A01

DB9 connector type

2A SMF Slo-Blo (plugs into FH1 on Evaluation

29-1784A03

Board)

PC-based diagnostic software for MDS radios.

03-3533A01

Supplied on CD.

Rugged antennas suitable for use at Master

Various

stations.

6 TransNET OEM Integr ation Guide MDS 05-3946A01, Rev. A

Table 1. OEM Transceiver Accessories

(Continued)

Yagi Antenna Rugged directional antennas suitable for use at

Whip Antennas Short, flexible antennas suitable for short-range

Bandpass Filter Antenna system filter to aid in eliminating inter-

Evaluation Development Kit

Remote stations.

applications. Available with and without coaxial

feedlines.

ference from high power transmitters, such as

those used in paging systems.

Kit containing two OEM Transceiver modules,

whip antennas, two Evaluation Boards, support

software on CD, cables, power supplies and other accessories needed to operate the transceiver in a benchtop setting.

Various

Various

20-2822A01

32-4051A01

3.0 BENCHTOP SETUP & EVALUATION

As an Integrator, your first task is to verify that the OEM module will function

as intended with the host equipment. This section describes how to test the

unit for operation with host devices such as RTUs, PLCs and similar gear. It

covers the steps for making interface connections, powering up the

transceiver, and setting configuration parameters using a connected PC.

Evaluation of the module is best performed in a controlled environment, such

as a shop or lab facility where you can readily test various hardware and

programming configurations and observe the effects of these changes before

final installation.

Once you are satisfied that the transceiver module operates properly on the

bench, you can plan the installation of the module inside the host device and

be assured of proper operation in the field.

3.1 Evaluation Development Kit (P/N 03-4053A01)

The Evaluation Development Kit is designed to assist integrators who will be

working with the transceiver in a benchtop setting. The kit contains the

following:

• Two OEM Transceiver modules (configured for TTL, or RS-232/485

operation, as requested)

• Two Evaluation Development boards (P/N 03-4051A01)

• Interface Cables

• Two whip antennas

• Two 12 Vdc power supplies

• TransNET Support CD containing software for programming &

diagnostics

MDS 05-3946A01, Rev. A TransNET OEM Integration Guide 7

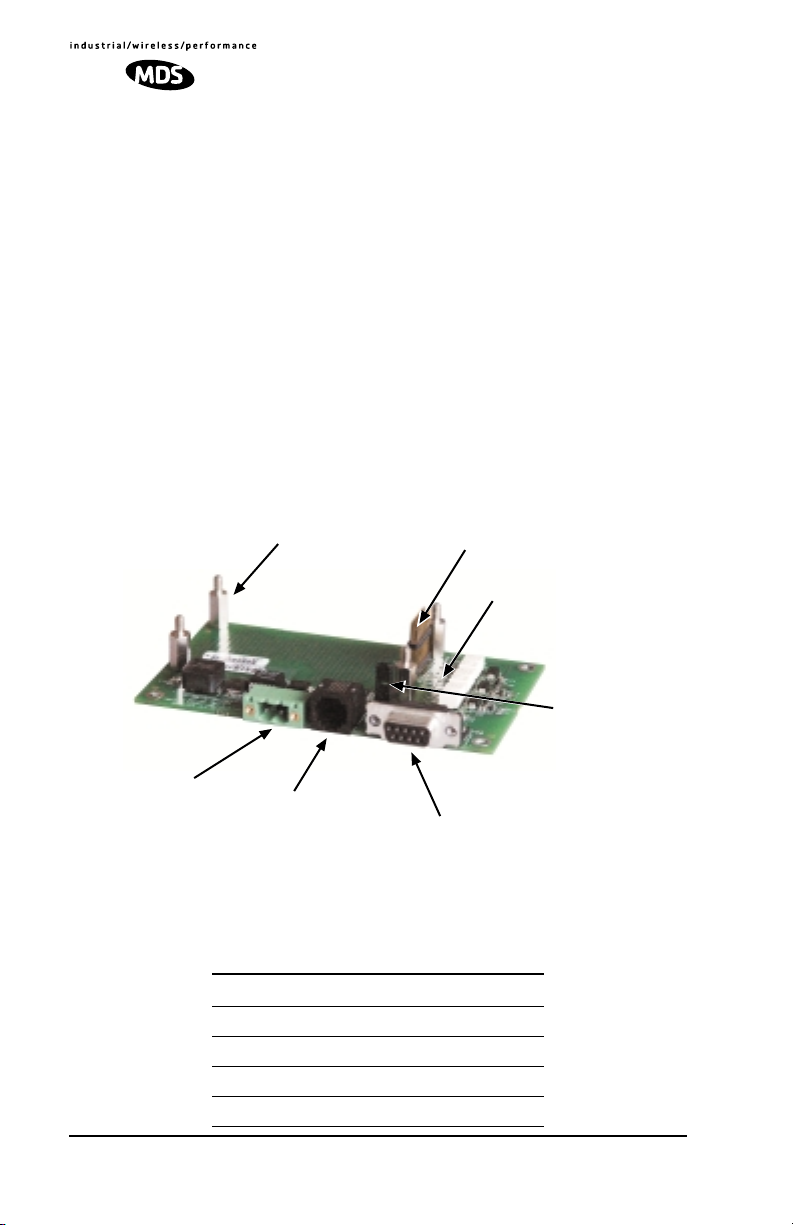

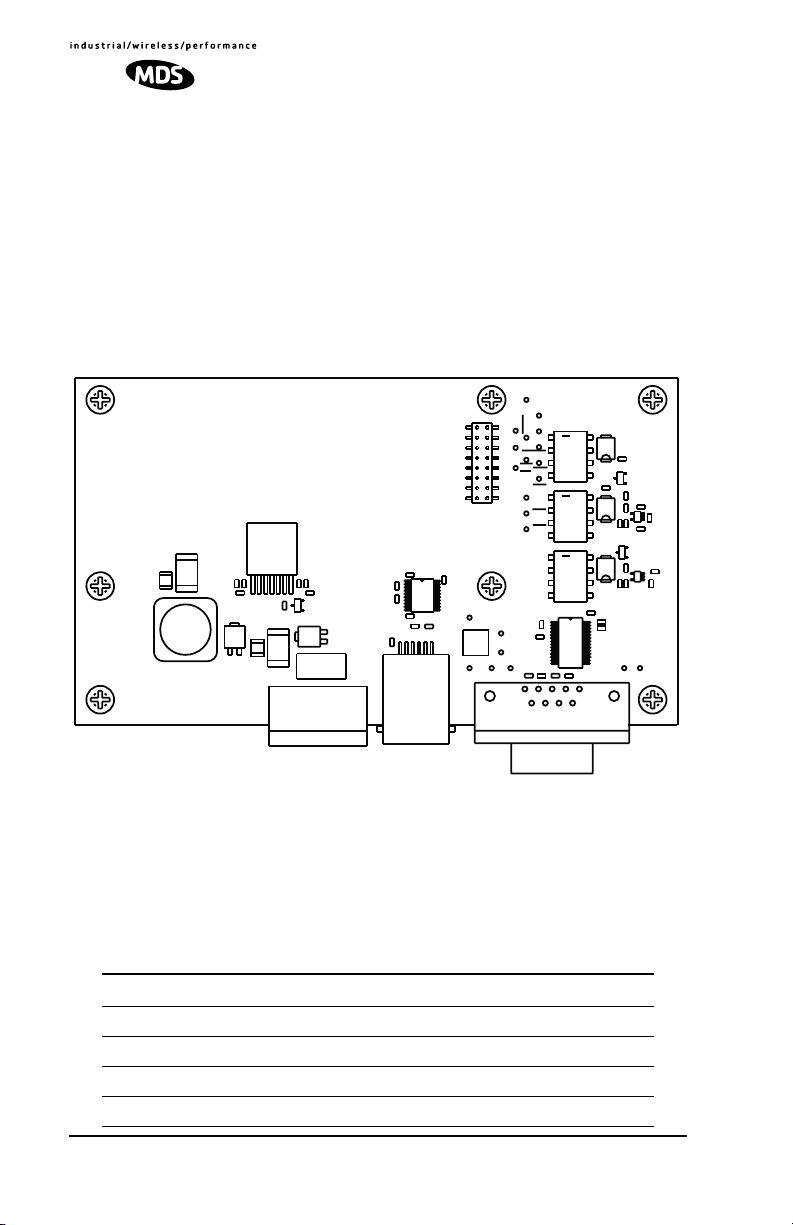

Evaluation Board

A key part of the Evaluation Development Kit is the Evaluation Board shown

in Figure 7. It contains a 16-pin header connector (J2) that mates with female

connector J3 the OEM transceiver board. It carries all signals (except RF)

onto the Evaluation Board. Table 2 lists the basic pin functions of J2. For

more detailed pinout information, including the differences between TTL and

RS-232/485 configured radios, refer to Section 13.1 on Page 59.

The Evaluation Board provides convenient connection points for diagnostics,

payload data, and DC power. Each of these connectors are discussed in this

section. The board also includes a series of test probe points to the left of J2.

These may be used for monitoring logic signal activity with a multimeter or

oscilloscope. The probe points are identified by printed markings on the

board.

The transceiver board’s RF/Antenna connection is

not

brought onto the

Evaluation Board by the 16-pin header. The antenna connection is always

made at J200 on the transceiver module using a male MMCX-type connector.

DC POWER

(5-25 VDC)

Figure 7. OEM Evaluation Board (P/N 03-4051A01)

STANDOFF SPACERS (4)

DIAGNOSTIC

COMMUNICATIONS

(RJ-11)

DATA CONNECTOR

16-PIN HEADER

TEST PROBE

POINTS

JUMPER BLOCK

J1

(DB-9)

Table 2. Basic Pin Functions of J2 (16-Pin Header Connector)

Pin No. Pin Function

1 Ground

2 Diagnostic TXD

3 Alarm Condition

4 Diagnostic RXD

8 TransNET OEM Integr ation Guide MDS 05-3946A01, Rev. A

Table 2. Basic Pin Functions of J2 (16-Pin Header Connector)

5 DC Input

6 Sleep Mode Input

7 Data Carrier Detect (DCD)

8 Power Supply Shutdown Control

9 Reserved—Do not connect.

10 Transmitted Payload Data (TXD)

11 DC Input

12 Request to Send (RTS)

13 Reserved—Do not connect.

14 Received Payload Data (RXD)

15 Ground

16 Clear to Send (CTS)

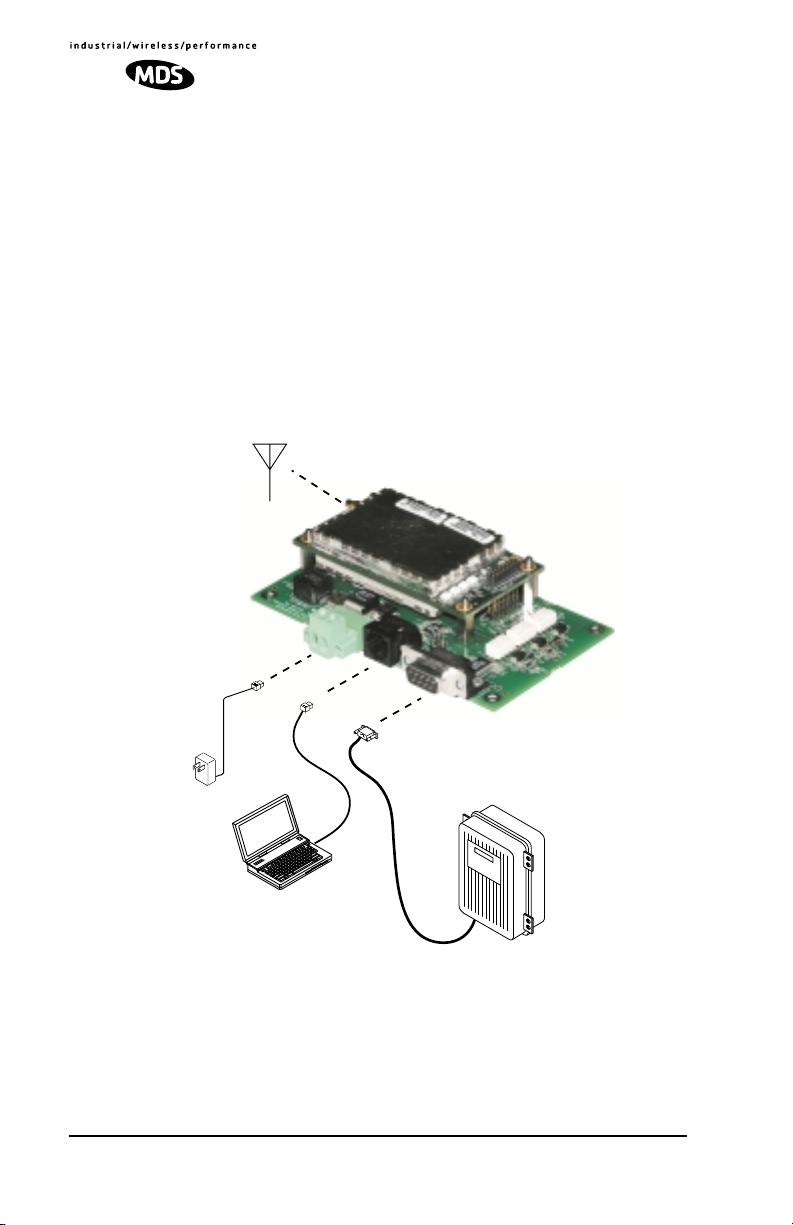

Connecting the Evaluation Board & Transceiver (Figure 8)

To connect the Evaluation Board to the radio, carefully align the pins of the

16-pin header with J3 on the transceiver module and press down firmly. The

radio PC board should seat solidly on the four standoff spacers. Use nuts to

secure the board to the standoffs.

Invisible place holder

Figure 8. Connecting the Evaluation Board and Transceiver Together

CAUTION:

Take care to avoid short-circuiting the underside of the Evaluation PC

board. The bottom of the board is

objects on the work surface could cause damage to the board or connected equipment.

not

insulated, and contact with metallic

MDS 05-3946A01, Rev. A TransNET OEM Integration Guide 9

3.2 Cable Connections for Benchtop Testing

There are four basic requirements for operating the transceiver and evaluation

board in a benchtop test environment. They are:

• Adequate and stable primary power

• A proper antenna system or RF load (50 Ohms)

• The correct interface wiring between the transceiver and the connected

DTE device (RTU, PLC, etc.)

• A connected PC terminal to read/set transceiver parameters.

Figure 9 shows a typical setup for bench testing an OEM Transceiver. Two

such setups will be required if you intend to establish over-the-air

communications with another OEM transceiver.

Invisible place holder

ANTENNA

(OR 50-OHM RF LOAD)

OEM Transceiver

and Evaluation Board

Power Supply

13.6 VDC @

500 mA (min.)

PC TERMINAL

Figure 9. Typical Test Setup

DATA TERMINAL

EQUIPMENT

Antenna Connection (J200 on the transceiver module)

The Antenna connector is located at the upper left corner of the transceiver

module and is a female MMCX-type coaxial connector. Connect an antenna

or other suitable RF load to this connector. Only approved antenna/cable

assemblies may be used with the radio

10 TransNET OEM Integration Guide MDS 05-3946A01, Rev. A

CAUTION

POSSIBLE

EQUIPMENT

DAMAGE

Do not apply DC power to the transceiver without first

attaching a proper RF load, or the transceiver may be

damaged.

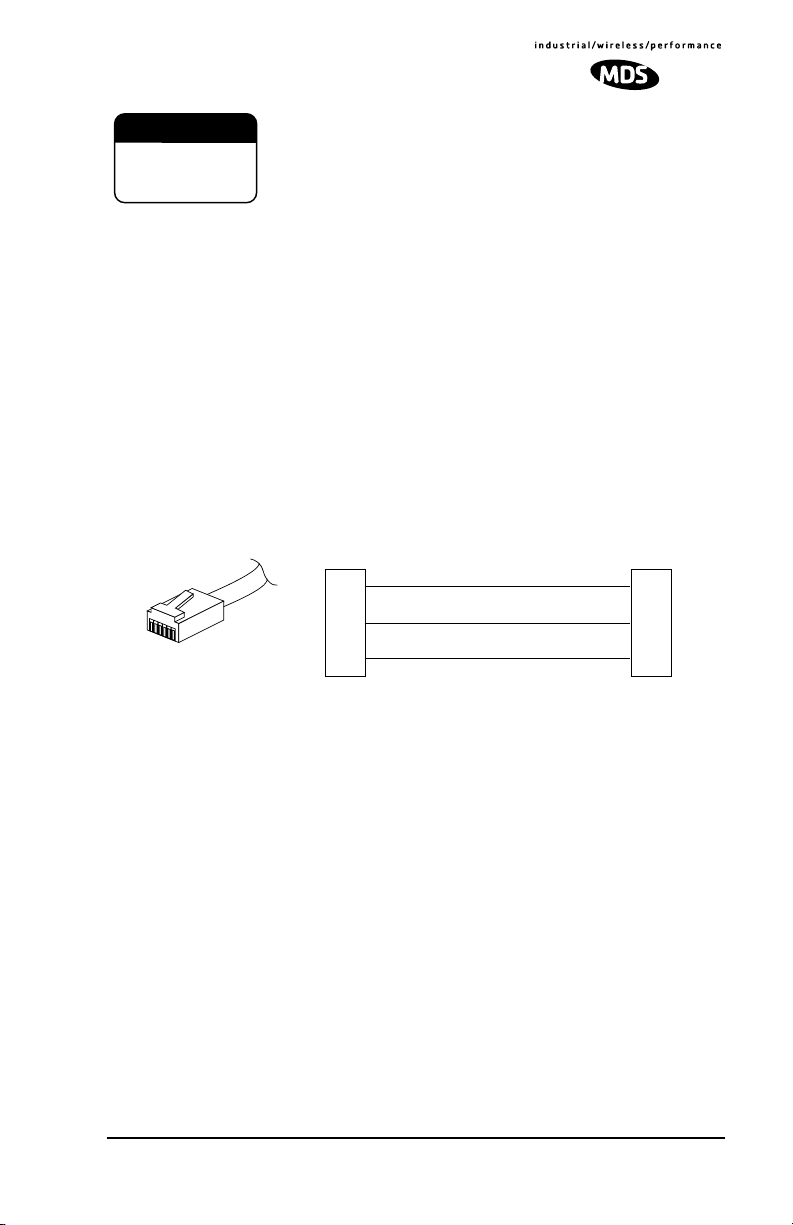

Diagnostic Connection (J4)

J4 is an RJ-11-6 modular connector used to connect the evaluation

board/transceiver to a PC terminal for programming and interrogation. An

RJ-11 to DB-9 Adapter Cable (Part No. 03-3246A01) is required for this

connection. If desired, an cable may be constructed for this purpose as shown

in Figure 10. Only Pins 4, 5, and 6 of the RJ-11 connector should be used.

Pins 1, 2, and 3 are reserved for factory test purposes.)

The data parameters of the diagnostics port are as follows: 8 data bits, 1 stop

bit, and no parity. It automatically configures itself to function at 1200, 2400,

4800, 9600, 19200, 38400, 57600, and 115200 bps, as required.

Invisible place holder

RJ-11 PLUG

(TO TRANSCEIVER)

DB-9 FEMALE

(TO COMPUTER)

RXD

TXD

GND

2

3

5

1

6

RJ-11 PIN LAYOUT

4

TXD

5

RXD

6

GND

Figure 10. RJ-11 to DB-9 Diagnostic Cable—Wiring Details

(A pre-constructed cable is also available, Part No. 03-3246A01)

Diagnostic Communication Modes

Two methods may be used to communicate with the radio’s diagnostic port:

•

Terminal Interface

—The PC is used in its basic terminal emulation

mode, (i.e., HyperTerminal session) and commands are issued as simple

text strings.

•

Radio Configuration Software

—Proprietary software from MDS that

runs under the Windows operating system. It provides a graphical user

interface with “point and click” functionality. The program is included

on the

TransNET Support Package

CD shipped with every radio order.

Both of these control methods are described in more detail in the section titled

“PROGRAMMING REFERENCE” on Page 34. This section also includes a

chart listing all commands for the OEM transceiver.

MDS 05-3946A01, Rev. A TransNET OEM Integration Guide 11

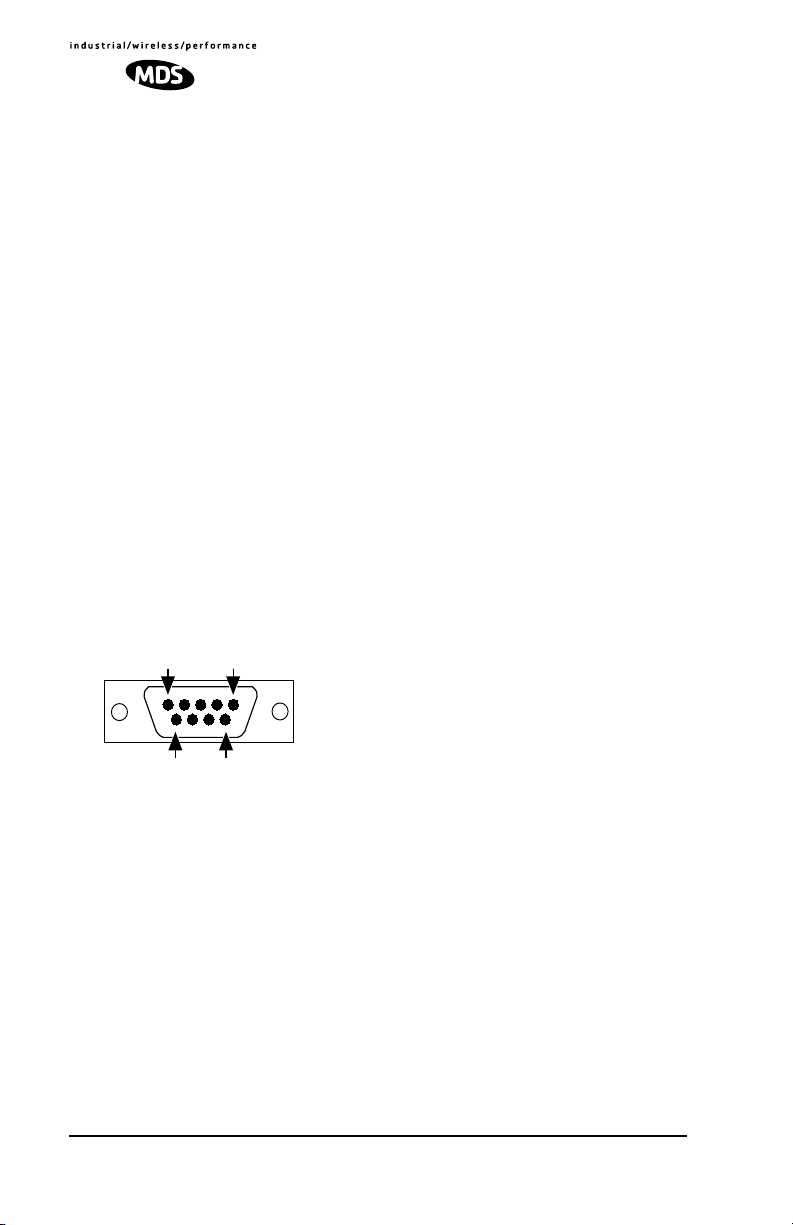

Data Connector (J5)

J5 on the Evaluation Board (Figure 11) is the data interface for the

transceiver. It is used to connect the transceiver to an external DTE terminal

that supports the EIA/RS-232 or EIA/RS-485 format, depending on how the

radio hardware was configured at the factory. The data connector supports

interface data rates of 1200, 2400, 4800, 9600, 19200, 38400, 57600, and

115200 bps (asynchronous only). The connector mates with a standard DB-9

plug available from many electronics parts suppliers.

Data Wiring Connections

The connections made to J5 will depend on the requirements of the DTE

device being used with the transceiver, and the operating functions that you

require. Only the required pins for the application should be used. Do not use

a straight through “computer” type cable that is wired pin-for-pin.

Typical RS/EIA-232 applications require the use of Pin 2 (receive

data—RXD) and Pin 3 (transmit data—TXD). Additionally, some systems

may require the use of Pin 7 (Request-to-send—RTS). If hardware flow

control is desired, Pin 7 (RTS) and Pin 8 (CTS) may also need connection.

Table 3 gives pin details for radios configured for RS/EIA-232 service.

Table 4 gives details for radios configured for RS/EIA-485 service.

NOTE:

from the Evaluation Board.

Radios equipped with a payload TTL interface are presented as RS-232 mode

5

1

96

Figure 11. DATA Connector (DB-9F)

As viewed from outside the device

12 TransNET OEM Integration Guide MDS 05-3946A01, Rev. A

Pin Descriptions—RS/EIA-232 Mode

Table 3 lists the

DATA

connector pin functions for radios configured to

operate in RS/EIA-232 mode.

Table 3. J5 DATA Connector Pinouts—RS/EIA-232

Pin

Number

1 OUT

2 OUT

3IN

4IN

5IN

6 OUT

7IN

8 OUT

9 -- Reserved—Do not connect.

Input/

Output Pin Description

Data Carrier Detect (DCD)—

chronization has been achieved.

Received Data (RXD)—

the connected device.

Transmitted Data (TXD)—

connected device.

Sleep Mode Input—

cuits in a remote radio. This allows for greatly reduced power consumption, yet preserves the radio’s ability to be

brought quickly back on line. See “Sleep Mode Operation

(Remote units only)” on Page 31 for details.

Ground—

Alarm condition—

indicates an alarm. (See ASENSE [HI/LO] command for

more information.)

Request to Send (RTS)—

the programmed CTS delay time has elapsed (DCE).

Clear to Send (CTS)—

CTS delay time has elapsed (DCE), or keys an attached radio when RF data arrives (CTS KEY).

Connects to ground (negative supply potential).

A low indicates hopping syn-

Supplies received payload data to

Accepts payload data from the

A ground on this pin turns off most cir-

A low indicates normal operation. A high

A high causes CTS to follow after

Goes high after the programmed

Pin Descriptions—RS/EIA-422/485 Mode

Table 4 on the following page lists the

DATA

connector pin functions for

radios configured to operate in RS/EIA-422/485 mode. See Figure 12 for

wiring schemes.

NOTE:

Radios equipped with a payload RS-232/485 interface can select

for RS/EIA-485 mode.

PORT RS485

MDS 05-3946A01, Rev. A TransNET OEM Integration Guide 13

Table 4. DATA connector pin descriptions—RS/EIA-485 Mode

Pin

Number

1 — Reserved—Do not connect.

2 OUT

3IN

4IN

5IN

6 -- Reserved—Do not connect.

7IN

8 OUT

9 -- Reserved—Do not connect.

Input/

Output Pin Description

TXD+/TXA (Received Data +)—

RXD+/RXA (Transmitted Data +)—

input.

Sleep Mode Input—

cuits in a remote radio. This allows for greatly reduced power

consumption, yet preserves the radio’s ability to be brought

quickly back on line. See “Sleep Mode Operation (Remote

units only)” on Page 31 for details.

Ground—

RXD–/RXB (Transmitted Data –) —

TXD–/TXB (Received Data –) —

Connects to ground (negative supply potential).

Non-inverting driver output.

Non-inverting receiver

A ground on this pin turns off most cir-

Inverting receiver input.

Inverting driver output.

Table 4 Notes:

• RXD+/RXA and RXD–/RXB are data sent into the radio to be transmitted out

• RXD+/RXA is positive with respect to RXD–/RXB when the line input is a “0”

• TXD+/TXA and TXD–/TXB are data received by the radio and sent to the connected

device

• TXD+/TXA is positive with respect to TXD–/TXB when the line output is a “0”

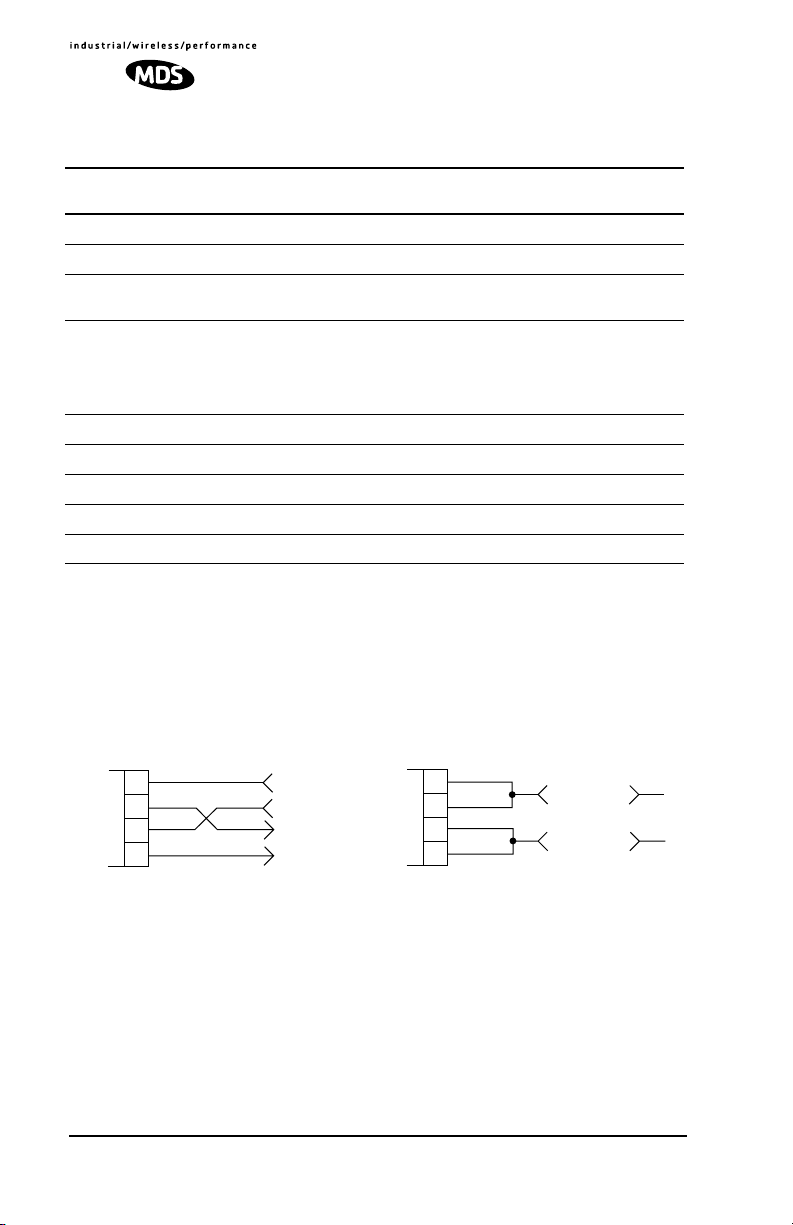

Invisible place holder

4-WIRE CONNECTIONS

2

3

7

8

DATA CONNECTOR

RXD +

RXD –

TXD +

TXD –

2-WIRE CONNECTIONS

2

3

7

8

DATA CONNECTOR

RXD+/TXD+

RXD–/TXD–

Figure 12. EIA-422/485 Wiring Schemes

(Left: EIA-422, Right: EIA-485)

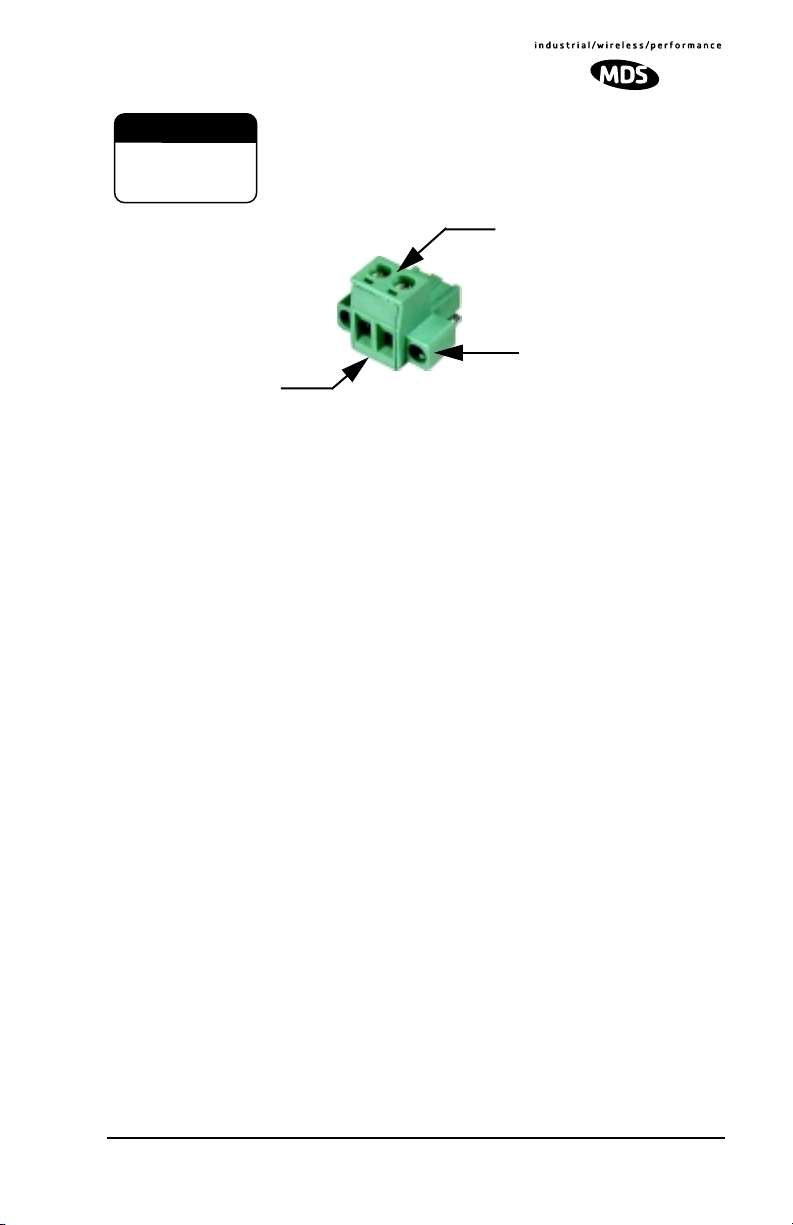

DC Power Connector (J3)

This connector accepts 12 Vdc operating power for the transceiver. A

wall-style AC adapter (Part No. 01-3862A02) is recommended for this

service.

DC connection is made with a 2-pin polarized plug, MDS Part No.

73-1194A39. Be sure to observe proper polarity.

positive (+) and the right is negative (-)

. (See Figure 13).

The left terminal is

14 TransNET OEM Integration Guide MDS 05-3946A01, Rev. A

CAUTION

POSSIBLE

EQUIPMENT

DAMAGE

The transceiver must be used only with negative-g round

systems. Make certain that the polarity of the power

source is correct.

Wire Ports (2)

(Polarity: Left +, Right –)

Figure 13. DC Power Connector (P/N 73-1194A39)

Invisible place holder

Lead

Binding

Screws (2)

Retaining

Screws (2)

NOTE:

resembles those used by some earlier MDS transceivers, such as the MDS

9810 and x710 family, the connectors are

plug will provide unreliable connections. Only the power connector shown in

Figure 13 with screw terminals and two retainer screws should be used with

the OEM Evaluation Board.

Although the power connector used on the OEM Evaluation Board

not

equal and the use of the wrong

Jumper Block J1 (DC Power Configuration)

Jumper J1 does not normally require any change by the user.

The jumper is

used to configure the board for the proper voltage level applied to the

transceiver module.

Both

jumper plugs are normally installed on J1. The plug connecting Pins 3

and 4 may be temporarily removed to insert an ammeter in series with the DC

power line going to the transceiver. This provides a convenient way to

measure the transceiver’s current draw during bench testing.

3.3 Initial Power-Up & Configuration

When all of the cable connections described in Section 3.2 have been made,

the transceiver is ready for initial power-up. Operation begins as soon as

power is applied, and there are no manual adjustments or settings required.

To place the transceiver into operation:

1. Ensure that all cable connections are properly wired and secure. Verify

that no metallic objects are touching the underside of the evaluation board

which might cause a short-circuit.

2. Apply DC power. The GP indicator (CR6) on the transceiver board

should light continuously.

MDS 05-3946A01, Rev. A TransNET OEM Integration Guide 15

3. Using a connected PC terminal, configure the unit with the proper mode

(master or remote), network address and data parameters. See

Configuration Settings

below for programming details.

4. Observe the transceiver’s LED indicators for proper operation. Table 5 on

Page 17 shows the functions and normal indications of the LEDs.

5. Verify that the transceiver is transmitting and recei ving data (TXD, RXD)

in response to the master station and/or connected terminal device.

Configuration Settings

This section explains how to set the essential operating parameters of the

transceiver. For more information on connecting a PC terminal and preparing

it for use, refer to Section see “PROGRAMMING REFERENCE” on Page

34.

The three essential settings for the transceiver are as follows:

Mode—

Network Address—

Data Interface Parameters—

Master, Remote, or Extension

a unique number from 1–65000

bps, data bits, parity, stop bits

Follow these steps to program the transceiver:

1. Set the Mode using the

MODE M

(Master), MODE R (Remote), or MODE X

(Extension) command. (Note: There can be only one master radio in a

system.)

For Extension (SAF) radios only: If any MODE X radios are used in the

network, SAF must be turned on at the Master station. The MODE X radio

must be programmed with an Extended Address (XADDR). Units that

need to hear the MODE X radio must be programmed with an appropriate

XPRI and/or XMAP value. (See “Simple Extended SAF Network” on

Page 26 for more information.)

2. Set a unique Network Address (1–65000) using ADDR command. Each

radio in the system must have the same network address. Tip: Use the last

four digits of the master station’s serial number to help avoid conflicts

with other users.

3. Set the baud rate/data interface parameters. Default setting is 9600 bps, 8

data bits, no parity, 1 stop bit. If changes are required, use the B A UD xxxxx

abc command where xxxxx equals the data speed (1200–115200 bps) and

abc equals the communication parameters as follows:

a = Data bits (7 or 8)

b = Parity (N for None, O for Odd, E for Even)

c = Stop bits (1 or 2)

NOTE:

7N1, 8E2 and 8O2 are invalid interface parameters.

16 TransNET OEM Integration Guide MDS 05-3946A01, Rev. A

Configuring Multiple Remote Units

In most installations, the Remote radios will be programmed with virtually

the same set of parameters. This process can be streamlined by testing key

pieces of equipment—such as the Master, Remote, and any Extensions—on

a benchtop setup prior to installation. This allows you to test various

configurations in a controlled environment.

Once the evaluation network is working satisfactorily, you can save the

configuration of each unit in a data file on your PC’s hard drive through the

use of TransNET Configuration Software. You can then open the Remote

configuration file and install it in the next Remote radio. The software

prevents you from overwriting unit or other mode-specific parameters.

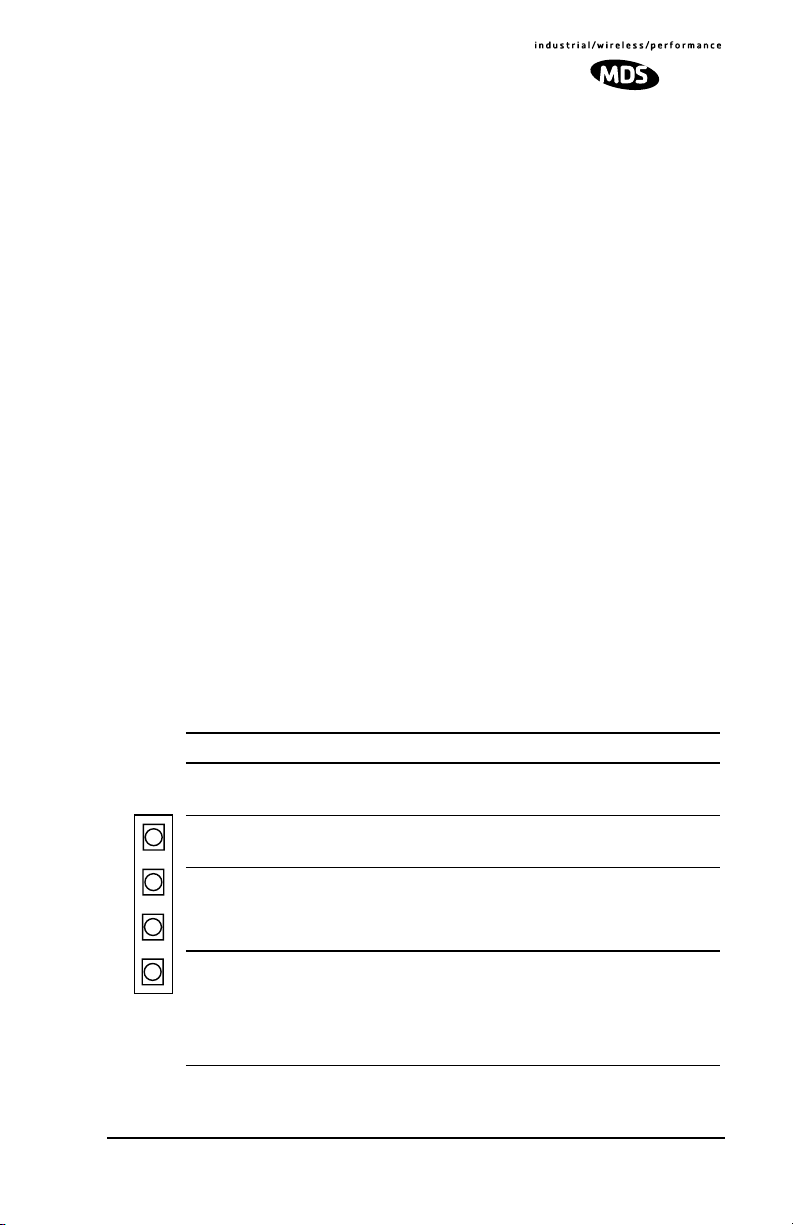

LED Indicators

The LED indicators are located to the right of the transceiver’s shield cover

(near J3) and show important information about status of the module. The

functions of LEDs are explained in Table 5 below.

NOTE: For the LEDs to function, they must be enabled using the LEDS ON command.

Within 16 seconds of power-up, the following indications will be seen if the

unit has been properly configured and is communicating with another

transceiver:

• GP lamp lit continuously

• DCD lamp lit continuously (if unit is synchronized with another station)

• Remote radio(s) transmitting data (TXD) and receiving data (RXD) with

another station.

Table 5. LED indicator descriptions

LED Name Description

RXD

TXD

DCD

GP

RXD (CR3)

Receive Data

TXD (CR4)

Transmit Data

DCD (CR5)

Data Carrier Detect

GP (CR6)

General Purpose

Serial receive data activity. Payload data from connected device.

Serial transmit data activity. Payload data to connected device.

Continuous—Radio is receiving/sending synchronization frames

On within 10 seconds of power-up under normal

conditions

• Continuous—Power is applied to the radio; no

problems detected

• Flashing (5 times-per-second)—Fault indication.

See “TROUBLESHOOTING” on Page 52

• Off—Radio is unpowered or in Sleep mode

MDS 05-3946A01, Rev. A TransNET OEM Integration Guide 17

4.0 EVALUATION BOARD DOCUMENTATION

This section contains an assembly drawing and parts list for the OEM

Evaluation Board. Also, a foldout schematic diagram of the Board is included

at the back of this manual. This documentation is provided to assist

integrators who need to create compatible interface circuitry between the

OEM transceiver and host equipment.

NOTE: The foldout schematic may also be accessed from the TransNET Support

Package CD, or from our website at: www.microwavedata.com.

4.1 Assembly Drawing

Invisible place holder

GND

2

16

J2

U2

o

1

C13

C12

C15

+

C14

R10

L1

CR2

R13

R14

R11

C

NA

C8

A

CR1

+

CR3

C30

C16

FH1

1

J3

C19

o

C17

C18

C20

C31

C21

U3

J1

C7

C6

2

6

1

J4

Figure 14. Evaluation Board Assembly Diagram

DIAG_TXD

1

ALARM

DIAG_RXD

SLEEP

SHUTDN

DCD

UNREG_PWR

RXD

LED

CTS

GND

15

REG_PWR

RTS

TXD

C2

C4

1

C29

51

9

CR6

K3

R15

CR5

K2

C23

CR4

K1

C22

C1

C3

o

28

C5

U1

C11

C10

C9

6

J5

C24

<

C

E

Q2

B

R9

R8

5

<

C26

R5

C

E

Q1

B

R7

5

<

U4

C25

R12

R6

1

U5

R3

1

R4

4.2 Parts List

Table 6 lists the electronic components used on the Evaluation Board.

Table 6. OEM Evaluation Board Parts List

Ref. Desig. Part Description

CR1 DIODE, SOT23 SMALL SIG 914 5D

CR4 CR5 CR6 RECTIFIER, 30V B13

CR2 CR3 DIODE, SCHOTTKY POWER, SMT, SNGL, UPS840

Q1 Q2 TRANSISTOR, SOT23 NPN 6429 M1LR

18 TransNET OEM Integration Guide MDS 05-3946A01, Rev. A

Table 6. OEM Evaluation Board Parts List (Continued)

U4 U5 IC, LINEAR SC70-5 COMPARATOR SNGLE LMV33

U1 IC, IN'FACE SSOP28 RS-232 TXVR SP3238E

U3 IC, IN'FCE 20PIN TSSOP DRIVER SP3222

U2 IC, SWITCHING REG'R ADJ.4.5A LT1374HVIR

K1 K2 K3 RELAY, DPDT

R10 RESISTOR, CHIP 0603 1/16W 5% 2.2K

R4 R5 R13 R14 RESISTOR, CHIP 0603 1/10W 1% 10K

R12 RESISTOR, CHIP O603 1/10W 1% 100K

R7 R9 RESISTOR, CHIP 0603 1/10W 1% 1.5K

R11 RESISTOR, CHIP O603 1/10W 1% 1.82K

R3 RESISTOR, CHIP 0603 1/10W 1% 22.6K

R15 RESISTOR, CHIP O603 1/10W 1% 31.6K

R8 RESISTOR, CHIP 0603 1/10W 1% 470 OHM

R6 RESISTOR, CHIP O603 1/10W 1% 6.81K

C12 CAP, TANT 7343 20% 10V 100uf

C6 C7 C9 C10

C11 C29 C31

C1 C2 C3 C4 C5

C17 C18 C19

C20 C21 C22

C23 C24 C25

C26 C8

C13 CAP, CHIP 0603 X7R 10% 470 pf

C14 CAP, CHIP 0603 X7R 10% 4700pF

C15 Capacitor, Low ESR Chip Ceramic, 1210 22uF

C16 Capacitor, Low ESR Chip Ceramic, 1210 4.7

L1 INDUCTOR, SWITCHING, 20%, 10uH

J1 CONN, HEADER, .100 DUAL STR 4-PIN

P/O J1 1-2, P/O

J1 3-4

FH1 FUSE HOLDER, PCB SMT W/2A SLO-BLO FUSE

CAP, CHIP 0603 50V NPO 5% 100pf

CAP, CHIP 0603 X7R 10% 0.1uF

CONN, JUMPER

MDS 05-3946A01, Rev. A TransNET OEM Integration Guide 19

Table 6. OEM Evaluation Board Parts List (Continued)

J2 CONN, HEADER, PC MOUNT .078, DUAL, 16 PIN

J3 CONN, TERM STRIP, 5MM PCB

J4 CONN, TELE JACK 6POS 6CON RT A SMT W/F

J5 CONN, D-SUB, PCB RCPT 90 DEGREE, 9 PIN

Samtec TW Series, Part No: ASP 103812-01

(Mates with J3 on the OEM radio transceiver)

4.3 Evaluation Board Fuse Replacement

The Evaluation Board is protected by a 2 ampere fuse. The fuse can be blown

by an over-current condition caused by an internal failure or over-voltage.

Follow the procedure below to remove and replace the fuse:

1. Disconnect the primary power cable and all other connections to the

Evaluation Board.

2. Locate the fuse holder assembly , FH1, behind the green power connector,

J3.

3. Loosen the fuse from the holder using a very small screwdriver, then use

a small pair of needle-nose pliers to pull the fuse straight up and out of

the holder.

4. Use an ohmmeter or other continuity tester to verify that the fuse is open.

5. Install a new fuse in the holder. Replacement fuse information: Littelfuse

#0454002; 452 Series, 2 Amp SMF Slo-Blo fuse (MDS Part No.

29-1784A03).

20 TransNET OEM Integration Guide MDS 05-3946A01, Rev. A

5.0 TRANSCEIVER MOUNTING

This section provides details for mounting the OEM transceiver in a host

device. The module need only be protected from direct exposure to the

weather. No additional RF shielding is required.

5.1 Mounting Dimensions

Figure 15 shows the dimensions of the transceiver board and its mounting

holes. If possible, choose a mounting location that provides an unobstructed

view of the radio’s LED status indicators when viewing the board from

outside the host device.

Mount the transceiver module to a stable surface using the four mounting

holes at the corners of the PC board. Standoff spacers should be used to

maintain adequate clearance between the bottom of the circuit board and the

mounting surface. (Fasteners/anchors are not normally supplied.)

3.45”

(87.5 mm)

1.81˝

(46 mm)

T

3.11”

(7.9 cm)

Side View

w

ie

V

p

o

1.49˝

(3.8 cm)

(16 mm)

0.63”

Figure 15. Transceiver Mounting Dimensions

5.2 Antennas & Feedlines

A number of omnidirectional and directional antennas are available for use

with the radio. Contact your factory representative for specific

recommendations on antenna types and hardware sources. In general, an

omnidirectional antenna (Figure 16) is used at master station sites in order to

provide equal coverage to all of the remote units.

MDS 05-3946A01, Rev. A TransNET OEM Integration Guide 21

At remote sites and in many point-to-point systems, a directional Yagi

antenna (Figure 17) is generally recommended to minimize interference to

and from other users and to maximize range.

For systems operating in a very short range environment, small, flexible whip

antennas may also be supplied. Such antennas are available for direct

connection to the transceiver module, or for exterior mounting with various

lengths of feedline.

Figure 16.

Omnidirectional Antenna

(shown mounted to mast)

Invisible place holder

Figure 17. Typical Yagi Antenna (shown mounted to mast)

Feedlines

The feedline supplied with the antenna was carefully selected to minimize RF

loss and ensure regulatory compliance with the antenna being used. Do not

make substitutions or change the lengths of the antenna system feedline. If

you require a different length of feedline for your installation, contact your

factory representative for assistance.

NOTE: Strong fields near the antenna can interfere with the operation of the low level

22 TransNET OEM Integration Guide MDS 05-3946A01, Rev. A

RTU circuits and change the reported values of the data being monitored. If interference is experienced, it may be necessary to re-orient the antenna with respect to the radio, RTU, sensors or other components of the system.

6.0 OPTIMIZING PERFORMANCE

After the basic operation of the radio has been checked, you may wish to

optimize its performance using some of the suggestions given here. The

effectiveness of these techniques will vary with the design of your system and

the format of the data being sent.

Complete instructions for using the commands referenced in this manual are

provided in “PROGRAMMING REFERENCE” on Page 34.

6.1 Antenna Aiming

For optimum performance of directional antennas (yagis), they must be

accurately aimed in the direction of desired transmission. The easiest way to

do this is to point the antenna in the approximate direction, then use the

remote radio’s RSSI command (Received Signal Strength Indicator) to further

refine the heading for maximum received signal strength.

In an MAS system, RSSI readings are only meaningful when initiated from a

remote station. This is because the master station typically receives signals

from several remote sites, and the RSSI would be continually changing as the

master receives from each remote in turn.

6.2 Antenna SWR Check

It is necessary to briefly key the transmitter for this check by placing the radio

in the SETUP mode (Page 48) and using the KEY command. (To unkey the

radio, enter DKEY; to disable the SETUP mode and return the radio to normal

operation, enter Q or QUIT.)

The SWR of the antenna system should be checked before the radio is put into

regular service. For accurate readings, a wattmeter suited for 1000 MHz is

required. One unit meeting this criteria is the Bird Model 43 directional

wattmeter with a 5J element installed.

The reflected power should be less than 10% of the forward power (≈2:1

SWR). Higher readings usually indicate problems with the antenna, feedline

or coaxial connectors.

6.3 Data Buffer Setting

The default setting for the data buffer is OFF. This allows the radio to operate

with the lowest possible latency and improves channel efficiency. MODBUS

and its derivatives are the only protocols that should require the buffer to be

turned on. See “BUFF [ON, OFF]” on Page 41 for details.

6.4 Hoptime Setting

The default hop-time setting is 7 (7 ms). An alternate setting of 28 is used to

increase throughput, but at the cost of increased latency. A detailed

explanation of the HOPTIME command can be found on Page 44.

MDS 05-3946A01, Rev. A TransNET OEM Integration Guide 23

6.5 Operation at 115200 bps

Burst throughput at 115200 bps is supported at all settings. The radio will

always buffer at least 500 characters. Sustained throughput at 115200bps is

only possible when the data path is nearly error free and the operating settings

have been properly selected. For sustained operation at 115200 bps, use the

following settings: SAF OFF, FEC OFF, REPEAT 0, RETRY 0, HOPTIME 28.

6.6 Baud Rate Setting

The default baud rate setting is 19200 bps to accommodate most systems. If

your system will use a different data rate, you should change the radio’s data

interface speed using the BAUD xxxxx abc command (Page 41). It should be

set to the highest speed that can be sent by the data equipment in the system.

(The transceiver supports 1200 to 115200 bps.)

6.7 Radio Interference Checks

The radio operates in eight frequency zones. If interference is found in one or

more of these zones, the SKIP command (Page 49) can be used to omit them

from the hop pattern. You should also review 8.0 DEALING WITH

INTERFERENCE, when interference problems are encountered.

6.8 RF Output Setting

OEM Transceivers are shipped from the factory with a compliant power

setting for the antenna system to be used. This setting limits the maximum

effective isotropic radiated power (EIRP) from the antenna to +36 dBm. For

compliance with FCC and Industry Canada rules, the power level must be

adjusted in accordance with Table 7 below.

NOTE: In some regions, the maximum allowable RF output may differ from those stat-

ed above. Be sure to check for and comply with the requirements for your area

before placing the transceiver in service.

Table 7. Power Setting vs. Antenna System Gain

Required to maintain FCC/IC maximum +36 dBm EIRP

Antenna

(Model No.)

1/2 Wave Whip

Dipole (Z1527)

Omni-directional

Base Station

(Z1526)

Yagi Directional

(Z1523A, B, or C)

Gain

Power Setting

(dBi)

2.1 30 30 18-inch/0.46 meter

7.1 29 29 10 feet/3.05 meters of

8.1 28 28 10 feet/3.05 meters of

(dBm)

Max. Power

(dBm)

Minimum Length of

Feedline Cable

LMR 100A cable assembly

RG-213 cable

with 18-inch/0.46 meter

LMR 100A cable assembly

LMR 400 cable

with 18-inch/0.46 meter

LMR 100A cable assembly

24 TransNET OEM Integration Guide MDS 05-3946A01, Rev. A

7.0 OPERATING PRINCIPLES & SPECIAL CONFIGURATIONS

7.1 How Remotes Acquire Synchronization

Remotes acquire synchronization and configuration information via SYNC

messages sent from the Master (the MODE M unit) or from any valid

Extension (MODE X unit).

The Master will always transmit SYNC messages. An Extension will only

start sending SYNC messages after synchronization is achieved with its

Master.

The ability to synchronize to a given radio is further qualified by the sender’s

Extended Address (XADDR) and by receiver’s Synchronization Qualifiers

(XMAP, XPRI, and XRSSI).

When a primary is specified (XPRI is 0...31), a radio will always attempt to

find the primary first. If 30 seconds elapses and the primary is not found, then

the radio will attempt to synchronize with any non-primary radio in the

list.

Once every 30 minutes, if a primary is defined, the radio will check its

synchronization source. If the radio is synchronized to a unit other than the

primary, then the current RSSI value is compared to the XRSSI value. If RSSI

is less than XRSSI (or if XRSSI is NONE) the radio will force a

loss-of-synchronization, and hunt for the primary again (as described in the

previous paragraph).

By default, Extensions (and the Master) begin with XADDR 0.

Synchronization qualifiers are set to XMAP 0, XPRI 0, and XRSSI NONE,

respectively. This default configuration allows any radio to hear the Master.

When an Extension is added, the extended address of the Extension must be

set to a unique value. All remotes that need to hear that extension can specify

this either by designating the extension as the primary (XPRI), or by including

it in their list of valid synchronization sources (XMAP).

XMAP

7.2 Establishing a Tail-End Link

A tail-end link can be used to bring an outlying remote site into the rest of an

MAS network. Figure 5 on Page 5 shows a diagram of this type of system.

A tail-end link is established by connecting an OEM transceiver

“back-to-back” with another unit such as a licensed MDS x710 Series

transceiver. The wiring connections between the two radios must be made as

shown in Figure 18. In addition, the DEVICE CTS KEY command must be

asserted at the OEM radio.

MDS 05-3946A01, Rev. A TransNET OEM Integration Guide 25

DCE

DB-25

3

RXD

TXD

2

GND

7

RTS

MDS x710 Series

Remote T ransceiver

(or device requiring keyline)

Figure 18. Data Crossover Cable for Tail-End Links

4

If required.

DCE

16-pin header (J3)

10

TXD

RXD

14

5

GND

16

CTS

TransNET OEM

(DEVICE CTS KEY)

Remote T ransceiver

7.3 Store & Forward (SAF) Operation with Extension Radios

The Store-and-Forward (SAF) capability allows individual radios to act as

data repeaters. SAF operates by dividing a network into a vertical hierarchy

of two or more sub-networks. (See Figure 6 on Page 6.) Adjacent

sub-networks are connected via Extension radios operating in “MODE X”

which move data from one sub-network to the next one.

The Store-and-Forward implementation adheres to the general polling

principles used in most multiple-address systems (MAS). Polls originate from

the Master station, broadcast to all radios within the network, and travel

hierarchically downward. All Remotes will hear the same message, but only

one Remote will respond. Messages within a hierarchy only travel in one

direction at a time.

Using SAF will cut the overall data throughput in half, however, multiple

networks can be inter-connected with no additional loss in network

throughput.

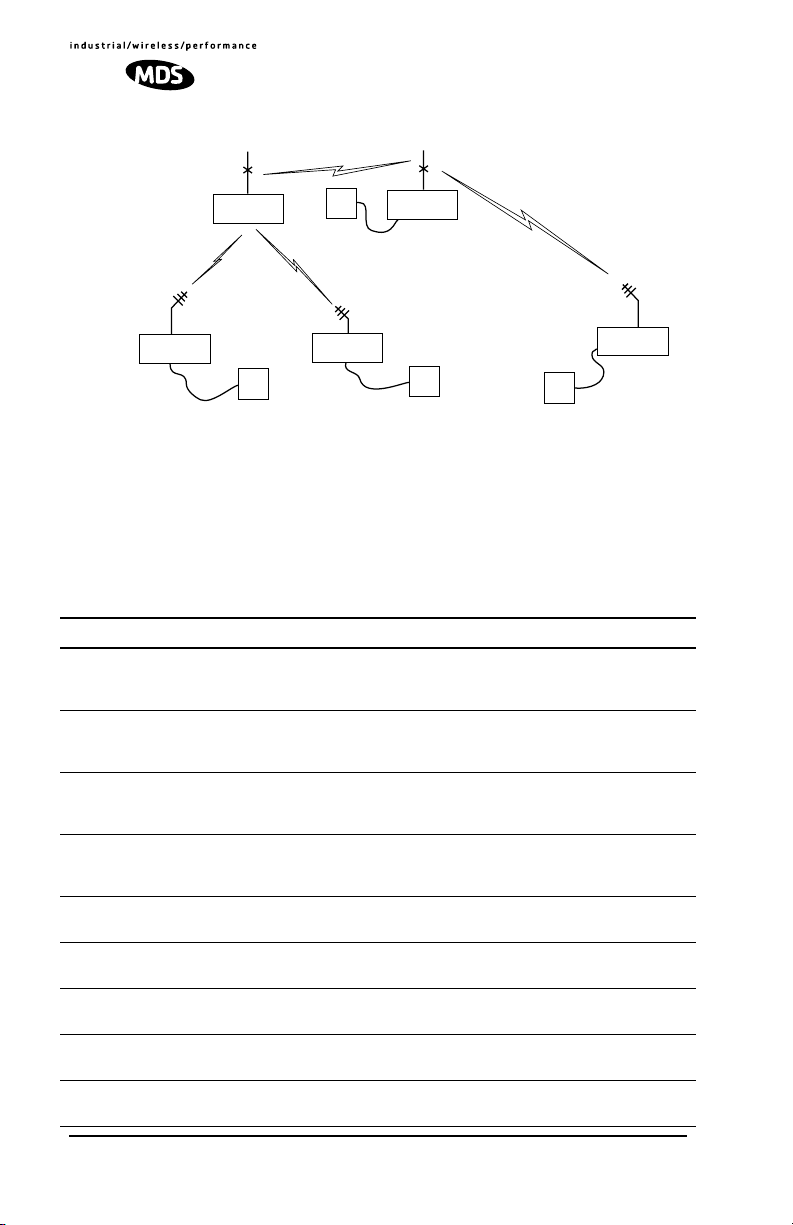

Simple Extended SAF Network

Figure 19 depicts a two-level network utilizing a single Master (M) and an

Extension (X) radio. In this network, messages directed to Remotes in the

“K” sub-network, will be relayed through Extension radio X

to the

j,k

K-Remotes. Any response from a Remote in sub-network “K” will pass back

through Extension radio X

to the Master Mj. Radios in sub-network “J”

j,k

operate on the same set of frequencies and sub-network “K” but with a

different radio-frequency hopping pattern.

26 TransNET OEM Integration Guide MDS 05-3946A01, Rev. A

Invisible place holder

M

J

Sub-Network J

R

R

J

X

J

J,K

R

J

Sub-Network K

KK

Figure 19. Simple Extended SAF Network

R

Networks: J and K

RR

K

In the SAF operation, the Extension radios are set to MODE X

(Details page 45) and operate with a “dual personality”—50% of the time

they serve as a Remote station and 50% of the time as a Master for

sub-network Remotes.

Extended SAF Network

Below is an example of a multilevel network utilizing two repeaters—X

and X

. The example demonstrates the extensibility of the network. In this

K,L

J,K

case, messages directed to Remotes in the sub-network L will be relayed

through Extension radios X

J,K

and X

. As in the previous example, the

K,L

Extension radios will split their operating time equally between their Master

and Remote personalities. This multi-layered network can be extended

indefinitely without degrading system throughput beyond that initially

incurred by placing the network in the SAF mode.

MDS 05-3946A01, Rev. A TransNET OEM Integration Guide 27

Invisible place holder

M

J

Sub-Network J

R

R

J

X

J

J,K

R

J

Sub-Network K

X

K,L

R

K

R

K

Sub-Network L

R

R

L

Figure 20. Extended SAF Network

R

L

L

Networks: J, K, L

Retransmission and ARQ operation

Functionally, the sub-network side of an Extension behaves like a

corresponding connection between a master and a remote.

When an Extension is using its “master personality” it sends

acknowledgments and performs unconditional retransmissions based on its

REPEAT count.

When an Extension is using its “Remote personality”, acknowledgments are

processed and retransmissions occur as needed, up to the number of times

specified by the

RETRY count value.

If new data arrives—from a new source—prior to completion of

retransmissions, then this is considered a violation of the polling model

protocol. The new data takes precedence over the old data and the old data is

lost. In such a situation, new data is likely to be corrupt as it will have some

old data mixed in with it.

Synchronization in SAF Networks

The Master controls the synchronization for a given network for all modes.

Setting the Master to “SAF ON” broadcasts a command from the Master to all

radio units in the associated network either directly or through an Extension

radio. This command puts all radios in the entire system in a special

time-division duplexing mode that alternates between two timeslots. One

time slot for data communications upstream and another for downstream

communications.

28 TransNET OEM Integration Guide MDS 05-3946A01, Rev. A

The Extensions are single radios which serve as bridges between adjacent

sub-network levels. Extensions will undertake a “remote” personality in one

timeslot, and a “master” personality in the alternate timeslot and provide

communications with associated Remotes downstream. Extensions behave

like two radios with their data ports tied together, first synchronizing with

their upstream Master during their Remote personality period, and then

providing synchronization signals to dependent Remotes downstream during

its Master personality period.

All Remotes synchronize to a corresponding Master. This can be the “real

master” (the MODE M unit), or it can be a repeater “Extension” that derives

synchronization from the “real master.”

Payload polls/packets broadcast from the network Master will be repeated to

all levels of the network, either directly to Remotes, or through network

repeaters—the Extensions station. The targeted Remote will respond to the

poll following the same path back to the Master.

Configuration Parameters for Store-and Forward Services

The installation and configuration of a network with an Extension using SAF

is straight-forward with only a few unique parameters that need to be

considered and set at each unit.

In every network there can be only one Master station. It will serve as the sole

gateway to the outside world. The following three tables detail the parameters

that will need to be set on each type of radio in the network.

• Network Master Radio—Table 8 on Page 29

• Extension Radio(s)—Table 9 on Page 30

• Remote Radio(s)—Table 10 on Page 31

Table 8. Configuration Parameters for SAF Services

Network Master Radio

Parameter Command Description

Operating Mode

Network Address

MODE M

Details page 45

ADDR

Details page 40

Set the radio to serve as a

Master

A number between 1 and

65,000 that will serve as a

common network address.

All radios in the network

use the same number.

MDS 05-3946A01, Rev. A TransNET OEM Integration Guide 29

Table 8. Configuration Parameters for SAF Services

Network Master Radio (Continued)

Parameter Command Description

Extended Address

Store and Forward

Mode

XADDR

Details page 51

SAF ON

Details page 48

A number between 0 and

31 that will serve as a

common address for radios that synchronize directly to this master.

Typically, the Master is

set to zero (0).

Enables store and forward capability in the network.

Table 9. Configuration Parameters for SAF Services

Extension Radio(s)

Parameter Command Description

Operating Mode

Network Address

Extended Address

Primary Extended

Address

Extension Map

Extension

Received Signal

Strength Indicator

MODE X

Details page 45

ADDR

Details page 40

XADDR

Details page 51

XPRI

Details page 51

XMAP

Details page 51

XRSSI

Details page 51

Set the radio to serve as an

Extension

A number between 1 and

65,000 that will serve as a

common network address.

All radios in the network use

the same number.

A number between 0 and 31

that will serve as a common

address for radios that synchronize directly to this Extension radio serving as

master for associated

sub-network units.

We recommend using zero

(0) for the Master station.

XADDR number of the primary or preferred radio with

which this radio will synchronize.

Functional list of all XADDR

values with which this radio

can synchronize, excluding

XPRI address

the

The minimum RSSI level re-

quired to preserve synchronization with a non-primary

radio. (Ineffective when

XPRI is NONE)

30 TransNET OEM Integration Guide MDS 05-3946A01, Rev. A

Table 10. Configuration Parameters for SAF Services

Remote Radio(s)

Parameter Command Description

Operating Mode

Network Address

Primary Extended

Address

Extension Map

Extension

Received Signal

Strength Indicator

MODE R

Details page 45

ADDR

Details page 40

XPRI

Details page 51

XMAP

Details page 51

XRSSI

Details page 51

Set the radio to serve

as a Remote station

A number between 1

and 65,000 that will

serve as a common

network address or

name.

Same number for all

units in the same network.

XADDR number of the

primary or preferred

radio with which this

radio will synchronize.

A list of all XADDR values with which this radio can synchronize,

excluding the

address

The minimum RSSI

level required to preserve synchronization

with a non-primary radio. (Ineffective when

XPRI is NONE)

XPRI

7.4 Sleep Mode Operation (Remote units only)

In some installations, such as at solar-powered sites, it may be necessary to

keep the transceiver’s power consumption to an absolute minimum. This can

be accomplished using the radio’s Sleep Mode feature. In this mode, power

consumption is reduced to about 8 mA.

Sleep Mode can be enabled under RTU control by asserting a ground (on Pin

6 of J3, the radio’s header connector. The radio stays in Sleep Mode until the

low is removed, and all normal functions are suspended.

The radio can be “awakened” by your RTU every minute or so to verify

synchronization with the master station. When the ground is removed, the

radio will be ready to receive data within 75 milliseconds.

NOTE: The SLEEP function must be set to ON; otherwise a ground on the Sleep Mode

MDS 05-3946A01, Rev. A TransNET OEM Integration Guide 31

pin will be ignored.

It is important to note that power consumption will increase somewhat as

communication from the master station degrades. This is because the radio

will spend a greater period of time “awake” looking for synchronization

messages from the master radio.

In order for the radio to be controlled by the Sleep Mode pin, the radio must

be set to SLEEP ON. See “SLEEP [ON, OFF]” on Page 50 for more

information.

Sleep Mode Example

The following example describes Sleep Mode implementation in a typical

system. Using this information, you should be able to configure a system that

meets your own particular needs.

Suppose you need communications to each remote site only once per hour.

Program the RTU to raise an EIA/RS-232 line once each hour (DTR for

example) and wait for a poll and response before lowering it again. Connect

this line to Pin 6 of the radio’s header connector. This will allow each RTU