Page 1

GE Digital Energy

Power Quality

Installation, Operation &

Maintenance Manual

Tranquell™Surge Protective Device (SPD)

UL Recognized DIN Rail Mount

• This equipment must be

installed and serviced only by qualified

electrical personnel in accordance with

national and local electrical codes.

• Turn off all power supplying this equipment

before working on equipment.

• Always use a properly rated voltage-sensing

device to confirm power is off.

• Replace all devices, doors and covers before

restoring power to this equipment.

• Do not apply petroleum-based products to

nonmetallic parts.

Improper installation or misapplication of these devices

may result in serious injury to the installer and/or

damage to electrical system or related equipment.

Protective eye wear and clothing should be worn

whenever working around hazardous voltages.

Failure to follow these instructions could result in

serious injury or death.

• Do not attempt to open or

tamper the Tranquell

™

device

in any way as this may compromise performance and

will void the warranty.

• Megger and hi-potential tests may damage

the device. Disconnect all power supplying the

equipment and isolate the Tranquell

™

device

before testing.

• Install for point-of-use Tranquell

™

DIN Rail,

tested for Type 2 applications

• Prior to installation, confirm that the Tranquell

™

SPD is rated for the correct voltage, current

and frequency equivalent to the application.

• Tranquell

™

DIN Rail must be installed within

an enclosure or control cabinet.

• Operating and storage temperature of this device

must be within -13°F to 140°F (-25°C and +60°C).

DANGER

CAUTION

Hazard of Electric Shock,

Burn or Explosion

1. MOUNTING

Tranquell

™

SPD DIN Rail is designed to

mount onto a 35mm DIN rail or top-hat rail

(standard EN 50022, BS 5584) set in the

horizontal position. To install, first hook the

line side over a 35mm DIN rail and then push in

the load side until the spring loaded mounting

clip “clicks” onto the rail (See Figure 1).

3.

AUXILIARY MICROSWITCH INSTALLATION

Remote signaling is available on Tranquell

™

SPD DIN Rail products. #30 AWG to #16 AWG

(.051 mm

2

- 1.31 mm2) signal wire may be used. Maximum torque rating for the terminal

screw is 1.8 in.-lb. (0.113 N-m). The maximum continuous current rating for the microswitch contact is 3 amps. If applicable, install signal wiring as shown in Figure 3.

Figure 3 – Microswitch

NOTE:

Shown with no power applied

Field wiring by others

2. REPLACEMENT/REMOVAL

Replace the module if the RED indicator tab (See Figure 2) is visible

on any of the multiple pole units. To remove: (1) verify that you have the correct replacement

module; (2) disconnect power; (3) pull the pluggable module from the base; (4) push a new

pluggable module into the base. You will hear a “click”, indicating that the module is set

in place (See Figure 1). An insertion “key” built into the unit will help ensure that the module

has been correctly selected.

CAUTION: Use of excessive force, during insertion, can result

in damage to the module or the base.

Figure 2 – Visual Indicator Tab

Figure 1 –

Mounting

Contact between Common + NO

= Product Offline, Not-Protected

Contact between Common + NC

= Product Online, Protected

NC

Common

NO

Signal Wire Range: #30 AWG to #16 AWG (.051 mm2 - 1.31 mm2)

Terminal Torque: 1.8 in.-lb. (0.113 N-m)

Contact

Rating

125 VAC –

3 amp max.

-25°C to 85°C

Page 2

GE Digital Energy – Power Quality

830 W 40th Street, Chicago, IL 60609

USA

800 637 1738 www.gepowerquality.com

Information subject to change without notice. Please verify all details with

GE.

© 2010 General Electric Company All Rights Reserved

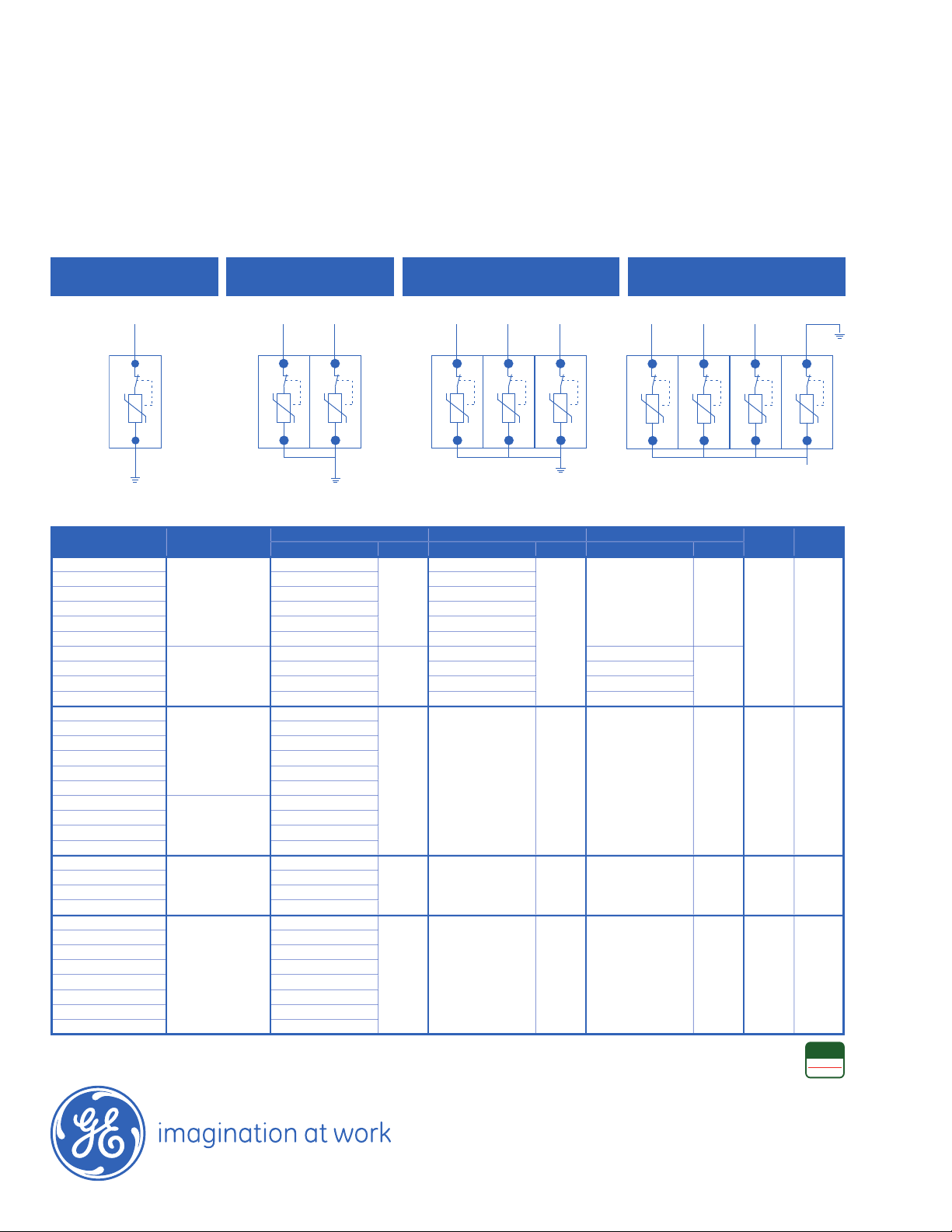

Figure 4 – Wiring Configuration Diagram (NOTE: Shown with no power applied)

NOTE: The Tranquell

™

DIN Rail SPD has been tested for safe operation without any

additional overcurrent protection, when correctly matched to the power system

parameters. A gG 160 Amp NH Fuse may be chosen to meet other requirements in

an

IEC application. Consult local codes and standards for appropriate fuse sizing.

SINGLE

PHASE

3 PHASE DELTA /

3 PHASE WYE, COMMON N/G

L1

L2

L3

N

G

3 PHASE HIGH LEG DELTA /

3 PHASE WYE, PLUS N-G

SPLIT

PHASE

Part Numbers & Specifications

4. WIRE INSTALLATION

#14

AWG to #6 AWG (2.08 mm

2

- 13.3 mm2), 60/75°C Copper

wire shall be used on phase and Neutral/

PE terminals.

Maximum torque to be applied to terminal screws is

14.75 in.-lb. (2.0 N-m). Strip back wire insulation 1/4" (6 mm).

Interconnecting wire should be kept at minimum length. Wire

bending radius should be >4" (100 mm). Do not loop or twist

interconnecting wire. Failure to meet these requirements may

result in higher let-through voltages.

Tranquell

™

SPD is normally installed in parallel with the load or

the electrical system wiring.

Determine electrical voltage configuration and proper modes

of protection and install wiring as shown in Figure 4.

Assembly System

Part Number

Wiring

Configuration

L-N/G Pluggable Module N - G Pluggable Module Hi-Leg Pluggable Module

No. of

Poles

No. of

Wires

Part Number Qty Part Number Qty Part Number Qty

TD120Y4025RMN

3 Phase Wye,

plug N-G

RU-180-25

3

RU-180-25

1

— —

4 5

TD120Y4050RMN RU-180-50 RU-180-50

TD277Y4025RMN RU-320-25 RU-180-25

TD277Y4050RMN RU-320-50 RU-180-50

TD347Y4025RMN RU-420-25 RU-275-25

TD347Y4050RMN RU-420-50 RU-275-50

TD240H4025RMN

3 Phase

High Leg Delta

RU-180-25

2

RU-180-25 RU-275-25

1

TD240H4050RMN RU-180-50 RU-180-50 RU-275-50

TD480H4025RMN RU-275-25 RU-180-25 RU-550-25

TD480H4050RMN RU-275-50 RU-180-50 RU-550-50

TD120Y3025RMP

3 Phase Wye

common N/G

RU-180-25

3 — — — — 3 4

TD120Y3050RMP RU-180-50

TD277Y3025RMP RU-320-25

TD277Y3050RMP RU-320-50

TD347Y3025RMP RU-420-25

TD347Y3050RMP RU-420-50

TD240D3025RMP

3 Phase Delta

RU-275-25

TD240D3050RMP RU-275-50

TD480D3025RMP RU-550-25

TD480D3050RMP RU-550-50

TD120S2025RMP

Split Phase

RU-180-25

2 — — — — 2 3

TD120S2050RMP RU-180-50

TD240S2025RMP RU-275-25

TD240S2050RMP RU-275-50

TD120S1025RMP

Single Phase

RU-180-25

1 — — — — 1 2

TD120S1050RMP RU-180-50

TD240S1025RMP RU-275-25

TD240S1050RMP RU-275-50

TD277S1025RMP RU-320-25

TD277S1050RMP RU-320-50

TD347S1025RMP RU-420-25

TD347S1050RMP RU-420-50

2020007801 (3/10)

L

G/N

L1

L2

G/N

L1

L2

L3

G/N

RoHS

COMPLIANT

2002/95/EC

Loading...

Loading...