Page 1

g

GEK-90214B

GE Lift Truck

User’s Guide

144D2912G1

144D2933G1

144D2911G5

Page 2

GE LIFT TRUCK

EACH USER HAS THE RESPONSIBILITY TO

INSTRUCT ALL PERSONNEL ASSOCIATED

WITH THIS EQUIPMENT ON ALL SAFETY

PRECAUTIONS WHICH MUST BE OBSERVED.

GENERAL

GE offers three styles of lift trucks for handling

Power/Vac circuit breakers, ground and test devices

and transformer and fuse rollouts. The first type is a

95” high double-mast truck (144D2933G1) that is compatible with indoor switchgear and outdoor non-aisle

switchgear. This truck has 2 fixed front wheels and 2

swivel rear wheels. The lifting winch is located on

the rear of the truck. The second style is a 87” high

double-mast truck (144D2912G1) that is compatible

with outdoor aisle switchgear. This truck has 4 swivel

wheels for easy turning in a confined space and has

the winch located on the right side. The third style is a

79” high single mast truck (144D2911G5) that is required for special indoor and outdoor applications.

The lift trucks are provided with interlocks to retain the device being handled and to lock the lift truck

to the switchgear while a device is being inserted or

removed. The carriage which lifts a device is raised or

lowered by means of a winch and cable. When the

winch handle is released the carriage is held in that

position by means of a clutch-brake internal to the

winch.

Two arms are attached to the carriage for engaging the track rollers on the sides of each device. The

following procedures describe the necessary steps to

remove a device from, or insert a device into, the

switchgear equipment. Be sure to read and understand

the safety rules identified in this manual before operating the lift truck.

The lift trucks are functional for both upper and

lower compartments provided the equipment is

mounted on no more than a three inch pad. See Table

2 - Lift Truck Selection (page 11).

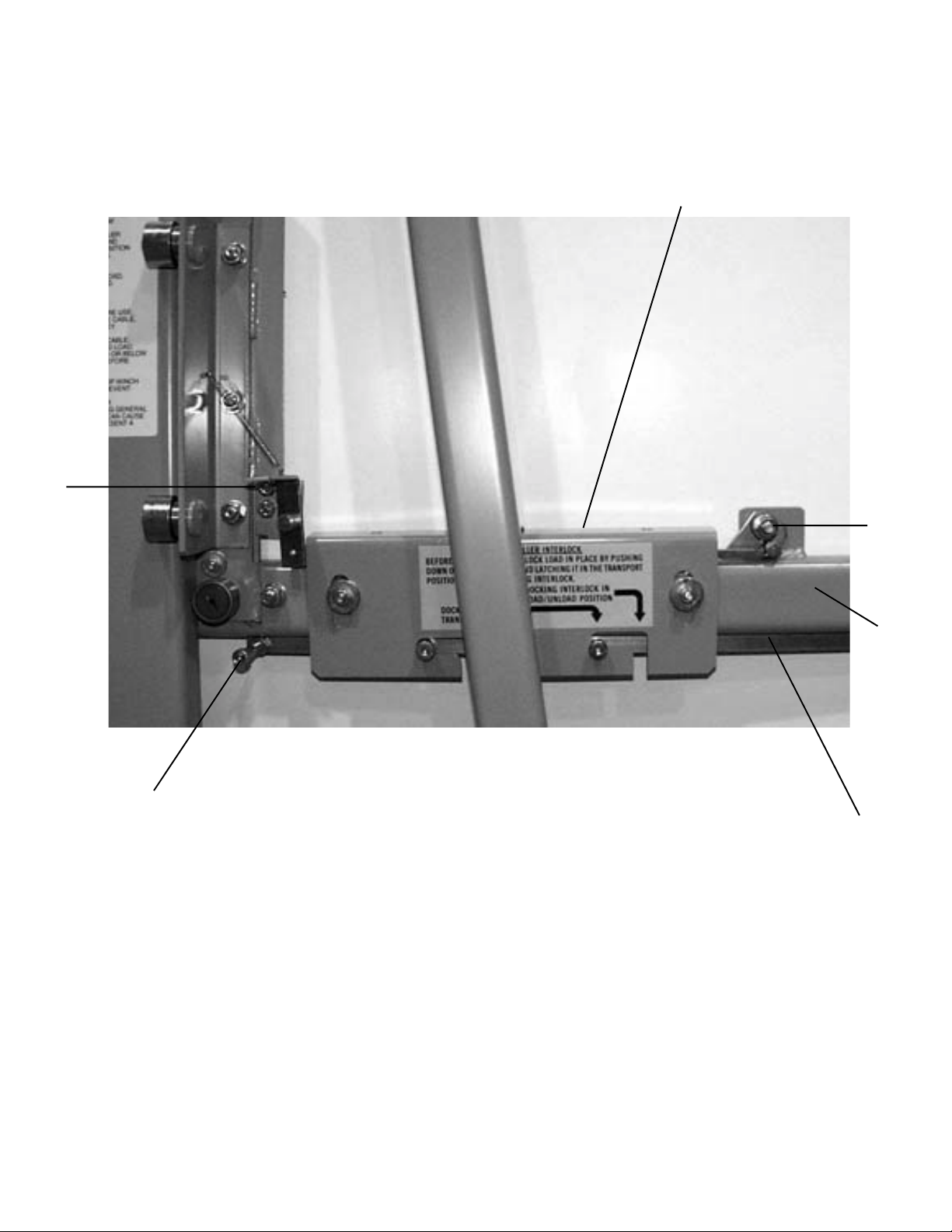

1. Prepare the truck for docking with the switchgear

equipment by making sure that both track roller

interlocks (1, Fig. 1) are in the “Transport” position (Fig. 2). If they are not, depress the track roller

interlocks and slide the docking interlocks (2, Fig.

1) all the way back toward the lift truck masts.

2. Adjust the height of the carriage until the docking

hooks at the ends of the arms are slightly higher

than the rail surface in the equipment. Position the

hooks over the slots in the rails and lower the

hooks into the slots. Place both track roller interlocks (1, Fig. 1) in the “Load/Unload” position (Fig.

3) by depressing them and sliding the docking interlocks (2, Fig. 1) forward, away from the lift truck

masts. The docking interlocks will extend under

the equipment rails and lock the truck arms to the

rails. The track roller interlocks are now in the

raised position so they are no longer blocking the

track rollers. Use the winch to adjust the lift truck’s

arms if they are not approximately level.

3. Release the device from the equipment and roll it

fully onto the lift truck rails until it comes in contact with the stops (3, Fig. 7) on the rails. The

catches that retain a device in the equipment compartment are different for the different devices so

see the instructions for the device being handled

for specific information. Verify that the device

rolled freely and that its rollers have properly engaged the rails. Place both track roller interlocks

(1, Fig. 1) in the “Transport” position (Fig. 2) by

depressing them and sliding the docking interlocks

(2, Fig. 1) all the way back toward the lift truck

masts. Raise the carriage slightly to release the

docking hooks from the slots in the equipment rail.

Pull the lift truck back to just clear the equipment

and lower the carriage to, or below, the maximum

transport position (Fig. 4) before transporting the

device to the desired location.

NOTE: The figures used in this instruction book depict

the 87” high double-mast lift truck. The operating

instructions apply to all three types

TO REMOVE A DEVICE FROM THE

SWITCHGEAR EQUIPMENT:

NOTE: To remove a breaker or instrument rollout from

an outdoor non-aisle switchgear lineup, first open the

outer door on the unit to the right of the one to be

worked on. Open this door to the fist stop location.

Then open the outer door of the unit to be worked on

to the second stop location. This will allow enough

room to access the right side lift truck track interlock.

2

4. To unload the device onto the floor, lower the carriage until the device is resting on the floor and

the load of the track rollers is no longer being supported by the lift truck arms. Place both track roller

interlocks (1, Fig. 1) in the “Load/Unload” position (Fig. 3) by depressing them and sliding the

docking interlocks (2, Fig. 1) forward, away from

the lift truck masts. The track roller interlocks are

now in their raised position. The lift truck can now

be pulled away from the device while holding the

backup track roller interlock handle (4, Fig. 1) in

the released position, away from the lift truck

masts.

Page 3

TO INSTALL A DEVICE INTO THE

SWITCHGEAR EQUIPMENT:

1. To load a device that is on the floor onto the lift

truck place both track roller interlocks (1, Fig. 1) in

the “Load/Unload” position (Fig. 3) by depressing

them and sliding the docking interlocks (2, Fig. 1)

forward, away from the lift truck masts. Adjust

the height of the arms so that they can engage the

track rollers on the sides of the device. Slight readjustments may be necessary as the arms approach

the rollers. It is also common to have to make

minor adjustments to allow the second set of track

rollers to be engaged. Move the lift truck forward,

or pull the device back, so that the device is all the

way towards the lift truck masts and the track rollers are in contact with the stops on the rails. Verify

that the device rolled freely and that all rollers have

properly engaged the rails.

5. To undock the lift truck from the equipment place

both track roller interlocks (1, Fig. 1) in the “Transport “ position (Fig. 2) by depressing them and

sliding the docking interlocks (2, Fig. 1) all the way

back toward the lift truck masts. Raise the carriage

slightly to release the docking hooks from the slots

in the equipment rail. Pull the lift truck back to clear

the equipment and lower the carriage to, or below, the maximum transport position (Fig. 4).

WARNING

As the load is lifted there should be a clicking noise

from the winch pawl. If this noise stops while a device

is being lifted, maintain a grip on the handle and lower

the load to the floor. Investigate why the pawl is not

engaging and make repairs before making any further

attempt to lift the load.

2. To lock the device onto the lift truck, place both

track roller interlocks (1, Fig. 1) into the “Transport” position (Fig. 2) by depressing them down

and sliding the docking interlocks (2, Fig. 1) all the

way back toward the lift truck masts.

3. Raise the carriage so the device is off the floor but

the carriage is at, or below, the maximum transport height before moving the device into position directly in front of the equipment compartment

into which the device is to be installed. The lift

truck should be as close to the equipment as possible, allowing just enough room for the device

and carriage to clear the equipment as it is being

raised. Adjust the height of the carriage until the

docking hooks at the ends of the arms are slightly

higher than the rail surface in the equipment. Position the hooks over the slots in the rails and lower

the hooks into the slots. Place both track roller interlocks (1, Fig. 1) in the “Load/Unload” position

(Fig. 3) by depressing them and sliding the docking interlocks (2, Fig. 1) forward, away from the

lift truck masts. The docking interlocks will extend

under the equipment rails and lock the truck arms

to the rails. The track roller interlocks are now in

the raised position so they are no longer blocking

the track rollers. Use the winch to adjust the lift

trucks’s arms if they are not approximately level.

4. Roll the device into the equipment while holding

the backup track roller interlock handle (4, Fig. 1)

in the released position, away from the lift truck

masts. Make sure that the device has engaged the

latches in the equipment (see the instructions for

the equipment and the device being used).

CAUTION

Although a backup to the track roller interlock is

functional for all but long wheel base devices such as

electrical ground & test devices and fuse rollouts, safe

use of this truck demands locking of both track roller

interlocks in the transport position before winch operation.

SAFETY RULES

1. Maximum load is 900 pounds.

2. Inspect lift truck daily before use. Items inspected

must include cable, cable fittings, pulleys, pulley

hardware and winch.

3. Replace damaged or frayed cable.

4. Stay out from under elevated load.

5. Lower lift truck carriage to or below maximum

transport height before transporting.

6. Use on smooth level surface only.

7. When lowering carriage, stop winch when cable

goes slack to prevent tangling.

8. The use of this lift truck for anything other than

handling GE Power/Vac devices can cause dam-

age to the lift truck and present a safety hazard.

The GE lift truck is included under the Occupation

Safety and Health Administration (OSHA) standard

1910.179 and should be inspected and tested per that

standard.

These instructions do not purport to cover all details or variations in equipment nor to provide for every possible

contingency to be met in connection with installation, operation or maintenance. Should further information be

desired or should particular problems arise which are not covered sufficiently for the purchaser’s purposes, the

matter should be referred to GE.

3

Page 4

1

4

5

6

3

2

Figure 1. Right Side Carriage Arm Assembly

1. Track Roller Interlock (right side)

2. Docking Interlock

3. Docking Interlock Handle

4. Backup Track Roller Interlock Handle

5. Backup Track Roller Interlock

6. Carriage Arm

4

Page 5

Figure 2. Track Roller and Docking Interlocks in Transport Position

Figure 3. Track Roller and Docking Interlocks in Load/Unload Position

5

Page 6

Figure 4. Maximum Transport Height

Table 1. Renewal Parts

Double Mast Single Mast

Lift Truck Lift Truck

144D2912G1/G2 144D2911G5

& 144D2933G1

Fig Item Description Part Number Part Number

1 1 Track Roller Interlock (Right Side) 0282A4397G004 0282A4397G004

5 1 Guide Roller 0282A3747P001

2 Guide Bracket (Right Side) 0282A4161G001

3 Backup Track Roller Interlock Spring 0282A3848P001 0282A3848P001

4 Backup Track roller Interlock 0209B4788G001 0209B4788G001

5 Carriage Roller 0282A4569P001

6 Winch 0282A3764G002

7 Cable (144D2912G1/G2 only) 0282A3575P001

(144D2933G1 only) 0346A9338P001

6 1 Track Roller Interlock (Left Side) 0282A4397G003 0282A4397G003

2 Guide Bracket (Left side) 0282A4161G002

3 Docking Interlock Handle N170P23040B6

4 Shoulder Bolts N94P38012B6 N94P3801B6

5 Docking Interlock 0282A4399P001 0209B5160P001

8 Left Arm 0209B4780G001 0144D2682G001

7 1 Carriage/Right Arm 0177C3744G001 0144D2682G002

2 Pulley 0282A4469P001

Bearing 0282A4556P001

Inner Race 0282A2000P055

3 Stop Block 0282A4349P001 0282A4349P001

4 Track Extrusions (Right Side) 0209B4774P001 0209B4774P001

Track Extrusions (Left Side) 0209B4774P001 0209B4774P002

- - Castor 0282A4555P001

- - Straight Wheel (0144D2912G2 only) 0282A4398P001

(144D2933G1 only) 0346A9338P001

6

Page 7

3

4

2

1

5

6

7

Figure 5. Right Side

1. Guide Bracket Roller

2. Right Side Guide Bracket

3. Backup Track Roller Interlock Return Spring

4. Backup Track Roller Interlock

5. Carriage Roller

6. Winch

7. Cable

7

Page 8

1

2

8

6

5

Figure 6. Left Side

1. Track Roller Interlock (Left Side)

2. Left Side Guide Bracket

3. Docking Interlock Handle

4. Shoulder Bolts

5. Docking Interlock

6. Arm Width Adjustment Access Hole

7. Arm Width Adjustment Nut (1 of 3)

8. Left Arm

3

4

7

8

Page 9

1

2

4

3

Figure 7. Carriage Inside

1.Carriage

2. Pulley

3. Stop Block

4. Track Extrusion

9

Page 10

CARRIAGE ARM ADJUSTMENTS

The arms are adjusted at the factory prior to shipping. Inspect carriage arm spacing if the device being

lifted does not fit on lift truck. The distance between the

two aluminum track extrusions (4, Fig. 7) should be 29.80

inches, plus 0.00, minus 0.03, and they should be vertically parallel within 0.125 inches.

On the double-masted lift truck the spacing between

the arms may be adjusted with three adjusting nuts (7,

Fig. 6), two of which must be reached through the access hole in the left mast (6, Fig. 6). The left arm may be

adjusted vertically parallel to the right arm by loosening the jam nut and turning the adjusting bolt located

underneath the left arm.

The arms are not adjustable vertically on the singlemasted lift truck, but they may be slid closer together or

farther apart. Enlarge the hole for the carriage arm spring

pin if more adjusting distance is required.

HANDLING OF ROLLOUTS:

It is possible that on some early fuse and transformer

rollouts the rear track rollers may extend about 1.5 inches

beyond the end of the lifting arms. Although the front

two sets of rollers engaged by the lifting arms provide

for safe lifting of the rollout, it may not be possible to

dock, or undock the lift truck because of interference between the rear rollers and the top of the front end of the

equipment track. The arms are prevented from being

lifted to release the docking hooks. If this occurs the following action may be required to allow removal of a

rollout.

Temporarily remove the stops on the lift truck arms

so that the rollout can enter the lifting arms farther. The

stops (3, Fig. 7) are rectangular plates on the inside of

the “C” shaped lifting arms (6, Fig. 1), held by a single

bolt. In many cases this will allow for rollout removal.

When reassembling, be sure to place the long end of the

part away from the mast. If rollout removal is not possible after this alteration, either of two options will allow removal of the rollout:

1. A 10 to 12 inch adjustable type wrench may be used

to slightly bend the top front corner of the equipment

rail up approximately 0.25 inch (see illustration be-

low).

2. Remove a piece from the top front of the equipment

rail so that the arm can be lifted to release the hook

without interfering with the top of the rail (see illus-

tration below). Care must be taken to prevent chips

from falling into the equipment.

On new rollouts the rear track rollers have been

moved forward 1.5 inches so they are fully engaged by

the lift truck arms and there is no interference with the

equipment rail.

10

Page 11

TT

able 2. Lift able 2. Lift

T

able 2. Lift

TT

able 2. Lift able 2. Lift

MODEL APPLICATIONS RESTRICTIONS FEATURES

144D2933G1 Indoor Switchgear Will not reach a roof mounted 95” High

Outdoor Weatherproof Switchgear Will not fit inside Outdoor Rear mounted winch

144D2912G1 Outdoor Aisle Switchgear Will not reach the top PT/CPT 87” High

144D2911G5 Roof mounted PT/CPT 79” High when collapsed

Outdoor Aisle Switchgear with Rear mounted winch

two PT/ CPT rollout trays in the Front & rear swivel wheels

upper “A” compartment. 76” Min. front aisle

Raised Switchgear Pads 950 Min. door swing*

TT

ruck Selectionruck Selection

T

ruck Selection

TT

ruck Selectionruck Selection

PT/CPT tray 76.5” Max. reach

Switchgear with an aisle Front fixed wheels

Rear swivel wheels

71” Min. front aisle

18” Min. side clearance

0

110

Min. door swing*

rollout tray when 2 are installed 69.5” Max. reach

in the upper “A” compartment Side mounted winch

Front & rear swivel wheels

58” Min. front aisle

18’ Min. left side clearance

30” Min. right side clearance

1100 Min. left side door swing*

1300 Min. right side door swing*

122.5” Max. reach

18” Min. side clearance

Collapsible for storage

*Note: The minimum door swing requirements are to allow operator access to the lift truck interlocks. If relays are on the door, then a 135

minimum door swing should be provided.

0

11

Page 12

g

GEK-90214B 1001

GE Industrial Systems

General Electric Company

510 East Agency

West Burlington, Iowa 52655

www.indsys.ge.com

Loading...

Loading...