Page 1

GE Healthcare

Dash™ 3000/4000/5000 Patient Monitor

Service Manual

Dash 3000/4000/5000

English

2023909-006C (CD)

2023896-069C (paper)

© 2006 General Electric Company

All Rights Reserved

Page 2

NOTE: The information in this manual only applies to Dash 3000/4000 patient monitors with software

versions 5.4 and Dash 3000/4000/5000 patient monitors with software versions 6 or later. It does not apply to

earlier software versions. Due to continuing product innovation, specifications in this manual are subject to

change without notice.

NOTE: For technical documentation purposes, the abbreviation GE is used for the legal entity name, GE

Medical Systems Information Technologies.

Listed below are GE Medical Systems Information Technologies trademarks. All other trademarks contained

herein are the property of their respective owners.

DASH, DINAMAP, EAGLE, MULTI-LINK, MUSE, SAM, SOLAR, TRIM KNOB, and UNITY NETWORK are

trademarks of GE Medical Systems Information Technologies registered in the United States Patent and

Trademark Office.

12SL, CENTRALSCOPE, INTELLIRATE, MENTOR, and SUPERSTAT are trademarks of GE Medical Systems

Information Technologies.

T-2 Dash 3000/4000/5000 2000966-363C

1 August 2006

Page 3

Contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Manual Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Manual Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Ordering Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Responsibility of the Manufacturer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Warnings, Cautions, and Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Equipment Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Service Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Service Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Equipment Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

2 Equipment Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Monitoring System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Patient Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Controls and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Exchangeable/Compatible Battery Packs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Optional Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Optional Remote Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

Software Packages and Software Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Software Packages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Software Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-13

Ethernet Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

About Ethernet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Twisted Pair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Network Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

2000966-363C Dash 3000/4000/5000 Patient Monitor i

Page 4

Theory Of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Overall Patient Monitor Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Data Acquisition System (DAS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Processor/Power Management Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

Lithium-Ion Battery Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-34

Speaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-39

Handle Subassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-39

Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-39

Storage and Backup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-41

Optional Thermal Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-42

3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Installation Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Before You Begin... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Back Panel Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Power Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Configure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

4 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Before You Begin... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Service Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Boot Loader Service Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

Main Menu Service Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Set Print Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Service Mode Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Set Unit Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Set Bed Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

Patient-Monitor Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Admit Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Confirm/Configure Wireless LAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

ii Dash 3000/4000/5000 Patient Monitor 2000966-363C

Page 5

Boot Code Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

Set Defib Sync Voltage and Pulse Width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

Set Line Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

Set CIC and QS Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

Set MUSE System Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

Transcutaneous Pace Blank Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

Set Country Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Set Language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Enable/Disable AFIB Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

Enable/Disable IntelliRate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-19

Analog Out Buzz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

Completion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

Advanced User Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

Set Time and Date . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

Transfer Monitor Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-22

5 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Visual Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Clean the Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Clean the Exterior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Clean the Print Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Battery Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

How to Charge the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

How to Condition the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

How to Store the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-8

How to Wake Up the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

How to Replace the Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-10

Rechargeable Battery Recycling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

About the Cadex SMart Two+ Charger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Clear the Stored Patient Data Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

2000966-363C Dash 3000/4000/5000 Patient Monitor iii

Page 6

6 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Fault Analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Required Tools/Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Acquisition PCB Symptoms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Processor PCB Symptoms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-4

Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Battery Alarms and Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Battery Messages Displayed in the ECG Waveform Area . . . . . . . . . . . . . . . . . . . 6-7

Battery Messages Displayed in the Battery Status Information Window . . . . . . . . 6-8

Battery Messages Displayed in the Battery Fuel Gauge Icon . . . . . . . . . . . . . . . . 6-8

Writer/Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

External . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Internal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

No Waveform at Central Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

Monitor Defaults Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

Storing Monitor Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-11

Copying Stored Monitor Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

Change Internet Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

Review Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

View Output/Input Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

Useful Error Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

Get Error Logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

Get Logs via PC Using netUpdate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

Get Logs via CIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-21

Get Logs via Centralscope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-21

Wireless LAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-24

Access Service Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-24

Identify the Wireless Technology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-25

802.11b . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-26

802.11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-29

iv Dash 3000/4000/5000 Patient Monitor 2000966-363C

Page 7

7 Field Replaceable Units . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Ordering Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Disassembly Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

Before Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

Hardware Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-8

Electrostatic Discharge (ESD) Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-8

Remove/Replace Handle Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

Remove/Replace Display Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

Replace Display Flex Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-18

Replace Display Assembly Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-20

Open Display Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-21

Replace Dash 4000/5000 Alarm Light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-22

Replace Display Inverter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-23

Replace Key Pad Assembly or Trim Knob Control . . . . . . . . . . . . . . . . . . . . . . .7-24

Replace Display Assembly Without LCD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-25

Replace Main Unit Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-27

Replace DAS Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-27

Replace Wireless Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-31

Replace NBP Pump Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-32

Replace Writer Assembly/Writer Flex . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-33

Replace Speaker Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-34

Replace CPU/Battery Housing Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-35

Replace Power Supply Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-37

Replace Battery Door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-39

Replace Foot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-40

Replace Writer Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-41

Recommended Checkout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-42

2000966-363C Dash 3000/4000/5000 Patient Monitor v

Page 8

8 Checkout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Manufacturer Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Maintenance and Checkout Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

“Visual Inspection” on page 5-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

“Cleaning” on page 5-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

“Battery Maintenance” on page 5-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-3

“Electrical Safety Tests” on page 8-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

“Checkout Procedures” on page 8-17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

Electrical Safety Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

Power Outlet Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

Power Cord and Plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

Ground (Earth) Integrity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-8

Ground (Earth) Wire Leakage Current Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-10

Enclosure Leakage Current Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11

Patient (Source) Leakage Current Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-12

Patient (Sink) Leakage Current Test (Mains Voltage on the Applied Part) . . . . . 8-13

BISx (option) Current Leakage Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-14

Test Completion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-16

Checkout Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-17

Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-17

Identify Enabled Patient Parameters and Software Options . . . . . . . . . . . . . . . . 8-17

Patient Monitor Power-up Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-18

ECG Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-19

Respiration Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-22

Temperature Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-23

Cardiac Output Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-24

Invasive Blood Pressure Tests (option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-26

Pulse Oximetry Tests for GE Ohmeda SPO2 Oximeter . . . . . . . . . . . . . . . . . . . 8-30

Pulse Oximetry Tests for Masimo SET SPO2 . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-32

Pulse Oximetry Tests for Nellcor OxiMax SPO2 . . . . . . . . . . . . . . . . . . . . . . . . . 8-34

Noninvasive Blood Pressure Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-36

NBP Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-38

Analog Output and Defibrillator Synchronization Tests . . . . . . . . . . . . . . . . . . . .8-41

End-tidal CO

Battery Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-45

Graph/Print Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-45

Display Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-46

Speaker Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-46

Network Test (option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-47

Remote Control Test (option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-47

BISx Test (option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-48

Test (option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-44

2

vi Dash 3000/4000/5000 Patient Monitor 2000966-363C

Page 9

Wireless LAN Test (option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-50

Dash Port Docking Station Test (option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-53

RAC 2A Module Housing Peripheral Device Test (option) . . . . . . . . . . . . . . . . .8-53

Data Acquisition Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-54

ECG Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-54

Lead Fail Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-56

Pace Detect Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-56

Invasive Blood Pressure Functions (option) . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-57

Respiration Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-59

Noninvasive Blood Pressure Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-61

Checkout Procedures Completion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-63

Repair Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-64

Appendix A – Technical Specifications . . . . . . . . . . . . . .A-1

Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-2

ECG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-3

Invasive Blood Pressure (BP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-5

Noninvasive Blood Pressure (NBP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-5

Bispectral Index (BIS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-7

GE Pulse Oximetry (SPO2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-7

Masimo SET SPO2 Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-7

Nellcor SPO2 Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-8

Cardiac Output (CO) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-8

Respiration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-9

Temperature (TEMP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-10

Carbon Dioxide (CO2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-10

Analog Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-12

Defibrillator Synchronization Pulse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-12

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-13

Paper Recorder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-13

Wireless LAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-14

Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-14

Physical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-15

Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-15

Appendix B– Electromagnetic Compatibility (EMC) . . . .B-1

Electromagnetic Compatibility (EMC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Guidance and Manufacturer’s Declaration – Electromagnetic Emissions . . . . . . .B-2

Guidance and Manufacturer’s Declaration – Electromagnetic Immunity . . . . . . . .B-3

Guidance and Manufacturer’s Declaration – Electromagnetic Immunity . . . . . . . .B-4

Recommended Separation Distances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-5

Compliant Cables and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-6

2000966-363C Dash 3000/4000/5000 Patient Monitor vii

Page 10

viii Dash 3000/4000/5000 Patient Monitor 2000966-363C

Page 11

1 Introduction

2000966-363C Dash 3000/4000/5000 Patient Monitor 1-1

Page 12

Manual Information

Revision History

Each page of this manual has the document part number and revision

letter at the bottom of the page. The revision letter identifies the

document’s update level. The revision history of this document is

summarized below.

Revision Comment

Manual Purpose

Introduction: Manual Information

A Initial release of this manual.

B Added information for 802.11b wireless and BISx. Updated Technical

Specifications and Checkout.

C Added software version 5.4 information where applicable.

Intended Audience

Ordering Manuals

This manual supplies technical information for service representatives

and technical personnel so they can maintain the equipment to the

assembly level. Use it as a guide for maintenance and electrical repairs

considered field repairable. Where necessary the manual identifies

additional sources of relevant information and technical assistance.

See the operator’s manual for the instructions necessary to operate the

equipment safely in accordance with its function and intended use.

This manual is intended for service representatives and technical

personnel who maintain, troubleshoot, or repair this equipment.

A paper copy of this manual will be provided upon request. Contact your

local GE representative and request the part number on the first page of

the manual.

1-2 Dash 3000/4000/5000 Patient Monitor 2000966-363C

Page 13

Introduction: Safety Information

Safety Information

Responsibility of the Manufacturer

GE is responsible for the effects of safety, reliability, and performance

only if:

Assembly operations, extensions, readjustments, modifications, or

repairs are carried out by persons authorized by GE.

The electrical installation of the relevant room complies with the

requirements of the appropriate regulations.

The equipment is used in accordance with the instructions for use.

General

This device is intended for use under the direct supervision of a licensed

health care practitioner.

This device is not intended for home use.

Federal law restricts this device to be sold by or on the order of a

physician.

Contact GE for information before connecting any devices to the

equipment that are not recommended in this manual.

Parts and accessories used must meet the requirements of the applicable

IEC/EN 60601 series safety standards, and/or the system configuration

must meet the requirements of the IEC 60601-1-1 medical electrical

systems standard.

Periodically, and whenever the integrity of the device is in doubt, test all

functions.

The use of ACCESSORY equipment not complying with the equivalent

safety requirements of this equipment may lead to a reduced level of

safety of the resulting system. Consideration relating to the choice shall

include:

use of the accessory in the PATIENT VICINITY; and

evidence that the safety certification of the ACCESSORY has been

performed in accordance to the appropriate IEC 60601-1 and/or IEC

60601-1-1 harmonized national standard.

If the installation of the equipment, in the USA, will use 240V rather

than 120V, the source must be a center-tapped, 240V, single-phase

circuit.

2000966-363C Dash 3000/4000/5000 Patient Monitor 1-3

Page 14

Introduction: Safety Information

Warnings, Cautions, and Notes

The terms danger, warning, and caution are used throughout this

manual to point out hazards and to designate a degree or level or

seriousness. Familiarize yourself with their definitions and significance.

Hazard is defined as a source of potential injury to a person.

DANGER indicates an imminent hazard which, if not avoided, will

result in death or serious injury.

WARNING indicates a potential hazard or unsafe practice which, if not

avoided, could result in death or serious injury.

CAUTION indicates a potential hazard or unsafe practice which, if not

avoided, could result in minor personal injury or product/property

damage.

NOTE provides application tips or other useful information to assure

that you get the most from your equipment.

1-4 Dash 3000/4000/5000 Patient Monitor 2000966-363C

Page 15

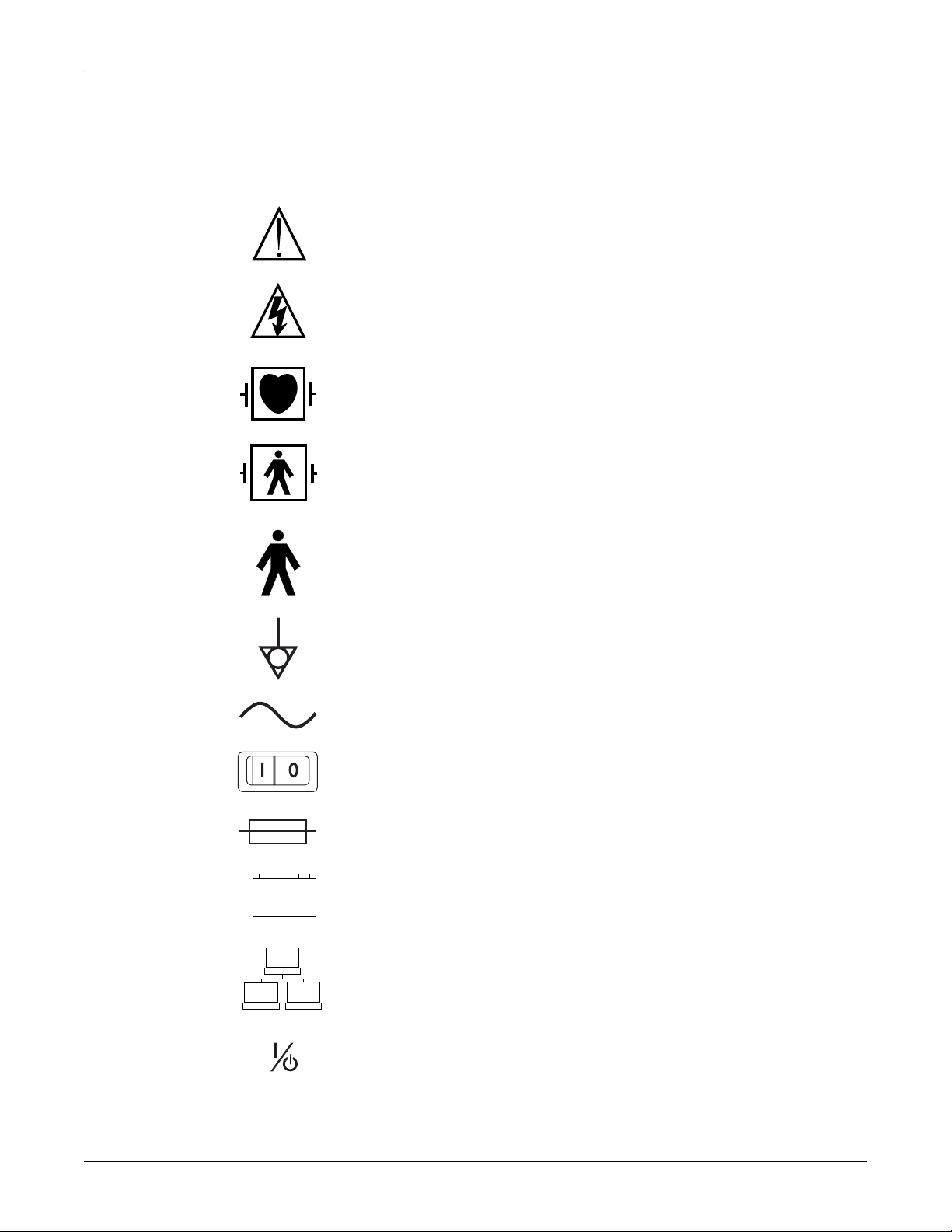

Equipment Symbols

NOTE: Some symbols may not appear on all equipment.

ATTENTION: Consult accompanying documents before using the equipment.

In Europe, this symbol means dangerous or high voltage. In the United States, this symbol

represents the caution notice below:

To reduce the risk of electric shock, do NOT remove cover (or back). Refer servicing to

qualified personnel.

Defibrillator-proof type CF equipment; type CF equipment is specifically designed for

applications where a conductive connection directly to the heart is established. The paddles

indicate the equipment is defibrillator proof.

Defibrillator-proof type BF equipment; type BF equipment is suitable for intentional external

and internal application to the patient, excluding direct cardiac application. Type BF

equipment is type B equipment with an F-type isolated (floating) part. The paddles indicate

the equipment is defibrillator proof.

Introduction: Equipment Symbols

Type B equipment; type B equipment is suitable for intentional external and internal

application to the patient, excluding direct cardiac application.

Equipotential Stud: A ground wire from another device can be tied here to ensure the

devices share a common reference.

Alternating current (AC)

I = ON; O= OFF

Power;

Fuse

Battery

Indicates the Ethernet connection for the patient monitor.

POWER (Dash 3000/4000)

2000966-363C Dash 3000/4000/5000 Patient Monitor 1-5

Page 16

Introduction: Equipment Symbols

Power (Dash 5000)

Standby (Dash 5000)

Main Display (Dash 5000)

Trend (Dash 5000)

Admit/Discharge (Dash 5000)

Print (Graph Go/Stop on older Dash 3000/4000)

4P41

NBP Go/Stop (on older Dash 3000/4000)

NBP Auto (Dash 5000)

Zero All

Silence Alarm/Admit

Medical Equipment

With respect to electric shock, fire and mechanical hazards only in accordance with UL

60601-1, CAN/CSA C22.2 NO. 601.1, IEC 60601-1, IEC 60601-2-27, IEC 60601-2-30. IEC

60601-2-34, and IEC 60601-2-49.

This symbol indicates that the waste of electrical and electronic equipment must not be

disposed as unsorted municipal waste and must be collected separately. Please contact an

authorized representative of the manufacturer for information concerning the

decommissioning of your equipment.

This symbol indicates the date of manufacture of this device. The first four digits identify the

year and the last two digits identify the month.

2005-08

Non-ionizing electromagnetic radiation: To indicate elevated, potentially dangerous, levels

of non-ionizing radiation. Note - In case of application in a warning sign the rules according

to ISO 3864-1 shall be adhered to.

IEC 60878 note: See safety sign ISO 7010 - W005 "Warning, non-ionizing radiation".

1-6 Dash 3000/4000/5000 Patient Monitor 2000966-363C

Page 17

Service Information

Service Requirements

Follow the service requirements listed below.

Refer equipment servicing to GE-authorized service personnel only.

Any unauthorized attempt to repair equipment under warranty voids

It is the user’s responsibility to report the need for service to GE or to

Failure on the part of the responsible individual, hospital, or

Regular maintenance, irrespective of usage, is essential to ensure

Equipment Identification

Introduction: Service Information

that warranty.

one of their authorized agents.

institution using this equipment to implement a satisfactory

maintenance schedule may cause undue equipment failure and

possible health hazards.

that the equipment will always be functional when required.

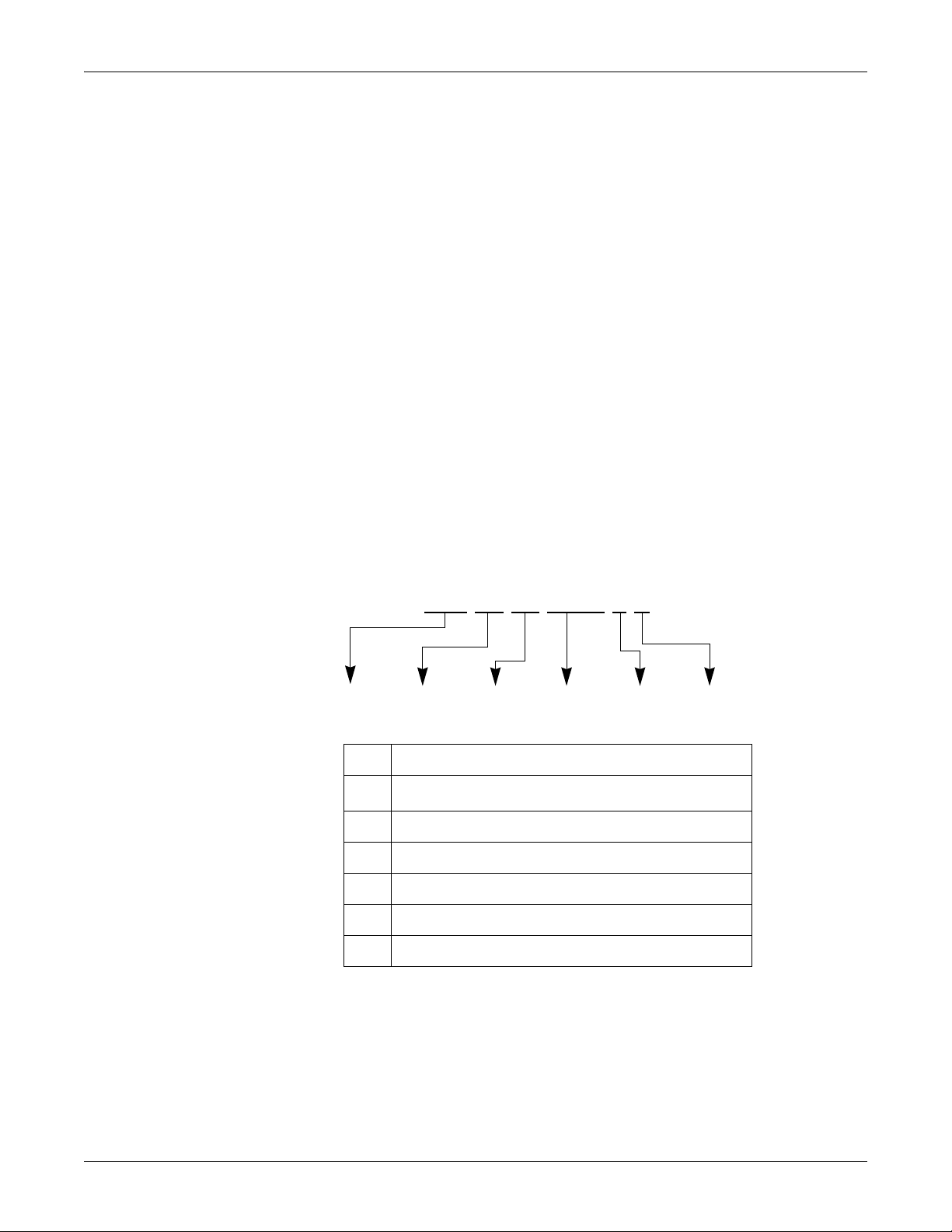

Every GE device has a unique serial number for identification. A sample of the

information found on a serial number label is shown below.

### ## ## #### # #

ABCDEF

Description

A

product code

B year manufactured

C fiscal week manufactured

D production sequence number

E manufacturing site

F miscellaneous characteristic

1. Current Dash patient monitor product code SBG

1

2000966-363C Dash 3000/4000/5000 Patient Monitor 1-7

Page 18

Introduction: Service Information

Dash 3000/4000 patient monitors with DJ product code as shown on the

sample label below, were shipped from the factory with MPC821

processor board. These patient monitors cannot support software

versions later than 5.x.

D 1 DJ 0005 G XX

Product Code

NOTE

If the MPC821 processor board was replaced with an MPC823

processor board, then the patient monitor can run software version 6

or later. The hardware version can be identified in the Boot Loader

program. See “Boot Loader Service Menu” on page 4-4 for steps to

access Boot Loader.

1-8 Dash 3000/4000/5000 Patient Monitor 2000966-363C

Page 19

2 Equipment Overview

2000966-363C Dash 3000/4000/5000 Patient Monitor 2-1

Page 20

Components

Monitoring System

Patient Monitor

Equipment Overview: Components

The Dash patient monitor can function as a portable monitoring device

with a built-in writer, or as a flexible care monitoring device connected to

the optional Unity Network™ via Ethernet. If using the wireless card or

Ethernet connection, optional components are a Clinical Information

Center (CIC Pro™) and a Centralscope™ central station.

This device is designed to monitor a fixed set of parameters including

ECG, noninvasive blood pressure, impedance respiration, SpO2, and

temperature. Invasive pressure, BISx, and EtCO2 are optional features.

Additional specialized features include cardiac output, cardiac

calculations, pulmonary calculations, dose calculations, PA wedge (PA

wedge is only available with the invasive pressure option), ICG module

interface, and SAM™ module interface.

AC Battery

Power

Charging Status

A

B

Graph

NBP Go/Stop

Zero All

Trim Knob

Silence Alarm/

Admit

001C 051D 003A

Dash 4000 MonitorDash 3000 Monitor

Dash 5000 Monitor

NOTE

For compatibility information, contact Technical Support.

2-2 Dash 3000/4000/5000 Patient Monitor 2000966-363C

Page 21

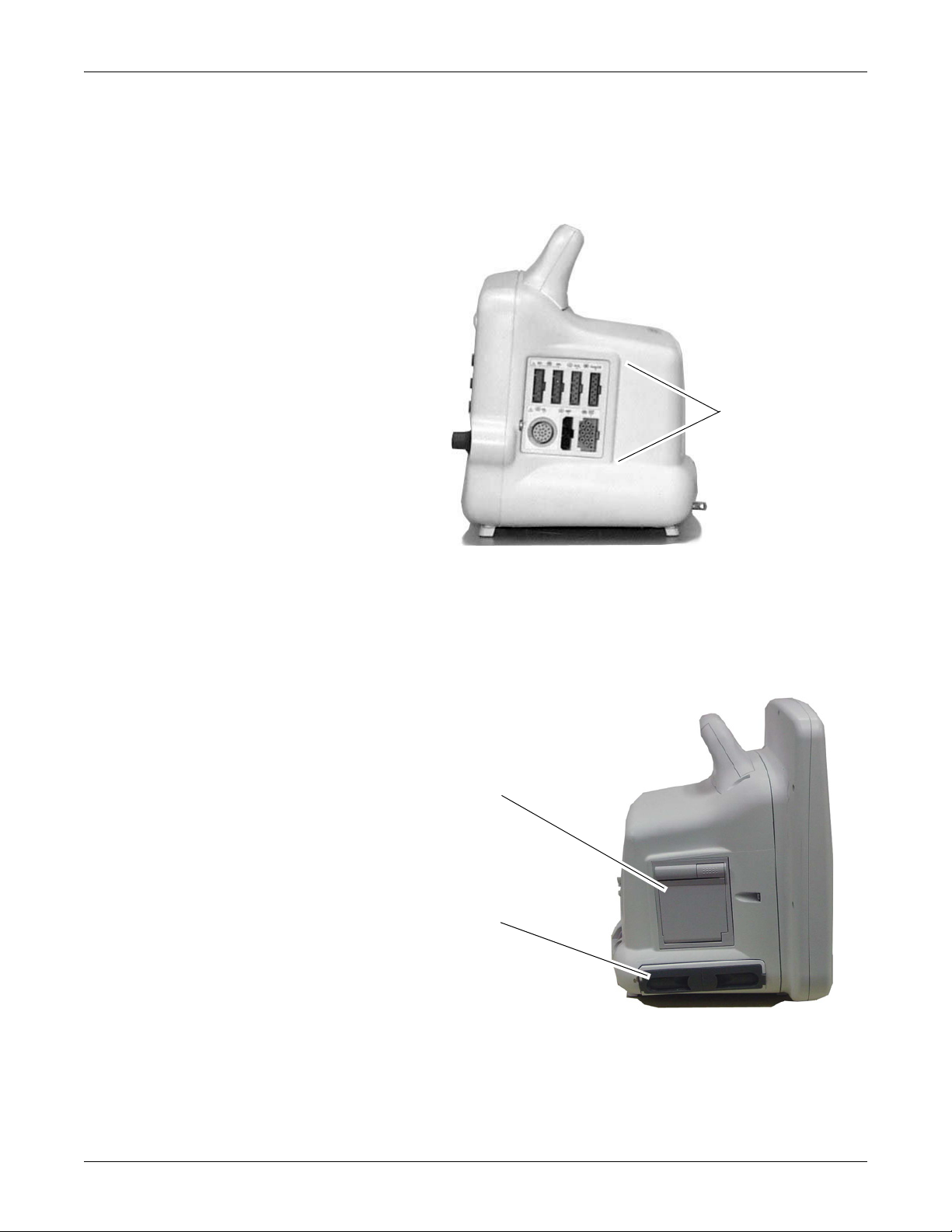

Right Side View

Equipment Overview: Components

All of the patient cable connectors are located on the right side of the

patient monitor. A Trim Knob™ control provides single control

operation of virtually all patient monitor functions.

Patient Cable

Connectors

Left Side View

002A

On the left of the patient monitor, you can find the built-in writer and the

battery compartment.

Optional Built-in Writer—

The built-in, 4 channel

writer is located in the

center of the left side of the

monitor.

Battery Compartment—

The battery packs are

located in this

compartment.

The battery compartment

may be a single plastic

door or two silicone doors.

925B

2000966-363C Dash 3000/4000/5000 Patient Monitor 2-3

Page 22

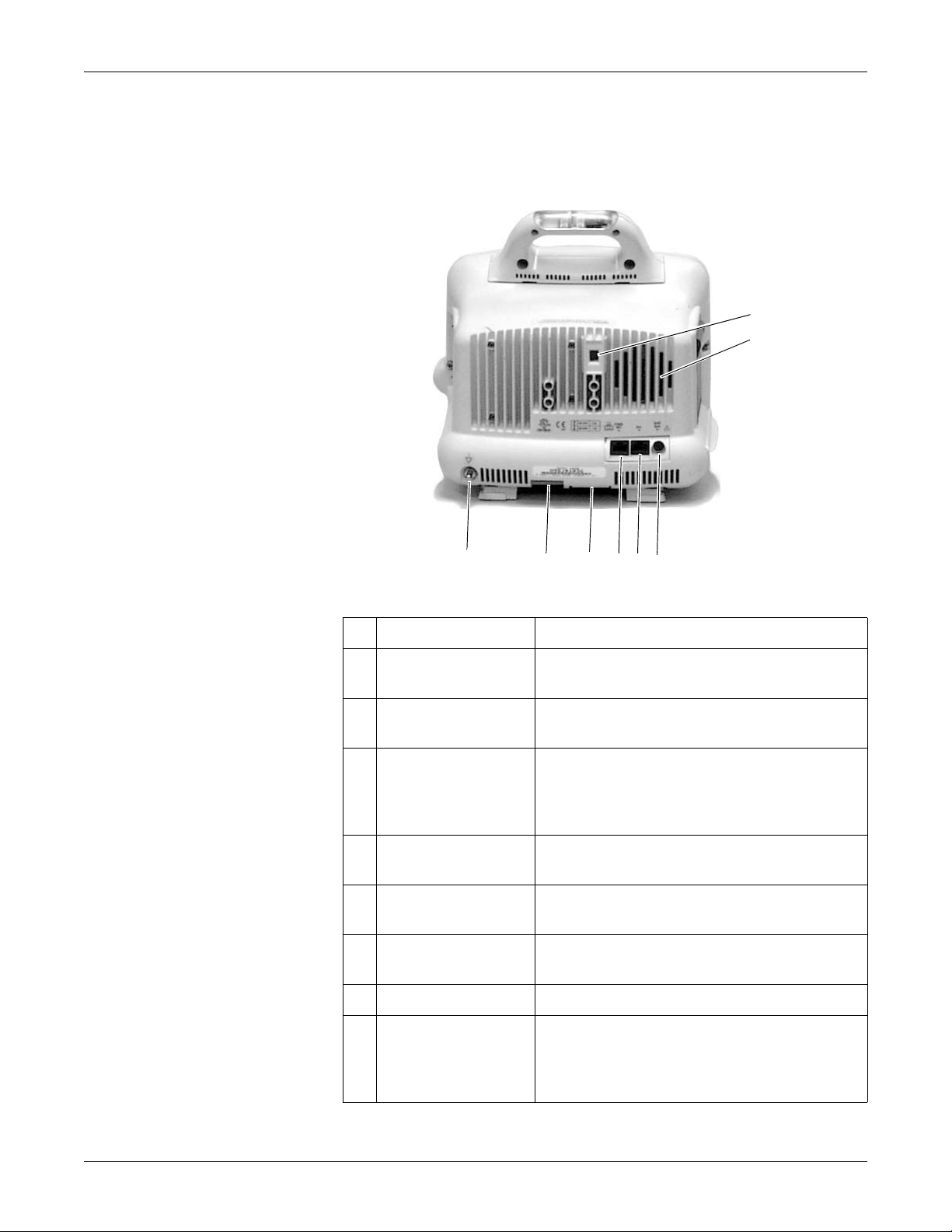

Back View

Equipment Overview: Components

All ports for equipment and network are on the back of the patient

monitor.

A

B

004A

HGFEDC

Name Description

line voltage selector This selector is factory set to match the line voltage

A

audible alarm enunciator The internal speaker provides sound for audible alarms.

B

rating for your country.

For better sound quality do not block speaker.

Defib Sync port Provides ECG analog output signals to user-supplied

C

equipment. A 5-volt, 2-millisecond artificial pacer spike

is added to the analog output when PACE is on and

detection occurs.

Aux port Used for RAC 2A, BISx and other compatible auxiliary

D

Ethernet port Used to connect a monitor to the Unity Network for

E

peripheral expansion

F

port

devices.

patient monitoring or for software installation.

Used for connecting to a Dash Port™

docking station

or other compatible auxiliary devices.

G AC power Used for connecting an AC power cable.

equipotential terminal For measurements in or near the heart we recommend

H

connecting the monitor to the potential equalization

system. Use the green and yellow potential equalization

cable and connect it to this pin.

2-4 Dash 3000/4000/5000 Patient Monitor 2000966-363C

Page 23

Optional Alarm Light Indicator

An optional alarm light indicator may be built into the handle of the

Dash 3000 patient monitor or into the display bezel of the Dash 4000/

5000 patient monitor. When activated, the LED indicator flashes red for

Crisis patient status alarms and yellow for Warning patient status and

system alarms.

Controls and Indicators

Equipment Overview: Components

Alarm Light Indicator

052B536A

Dash 3000 Monitor Dash 4000 and 5000 Monitors

Flat Panel Display

Trim Knob Control

Function/Power Keys

The user interface consists of a flat panel display and the keypad

assembly that includes a Trim Knob control, function keys, and LED

indicators.

The active-matrix color liquid crystal display (LCD) is assembled into a

shock absorbing isolator that fits within the patient monitor’s front bezel

to protect the display from mechanical shock during use.

The acrylic optical filter protects the display panel from impact and

enhances visibility with its non-glare surface coating on the viewing side

of the filter. It also has a scratch-resistance surface coating.

The Trim Knob control is a 24-position rotary control with a push

selection switch.

Dash 3000/4000 Patient Monitors

Power, Print, NBP Go/Stop, Zero All, Silence Alarm/Admit.

Dash 5000 Patient Monitor

Power, Standby, Admit/Discharge, NBP Go/Stop, NBP Auto,

Print, Silence Alarm, Zero All, Trend, Main Display.

2000966-363C Dash 3000/4000/5000 Patient Monitor 2-5

Page 24

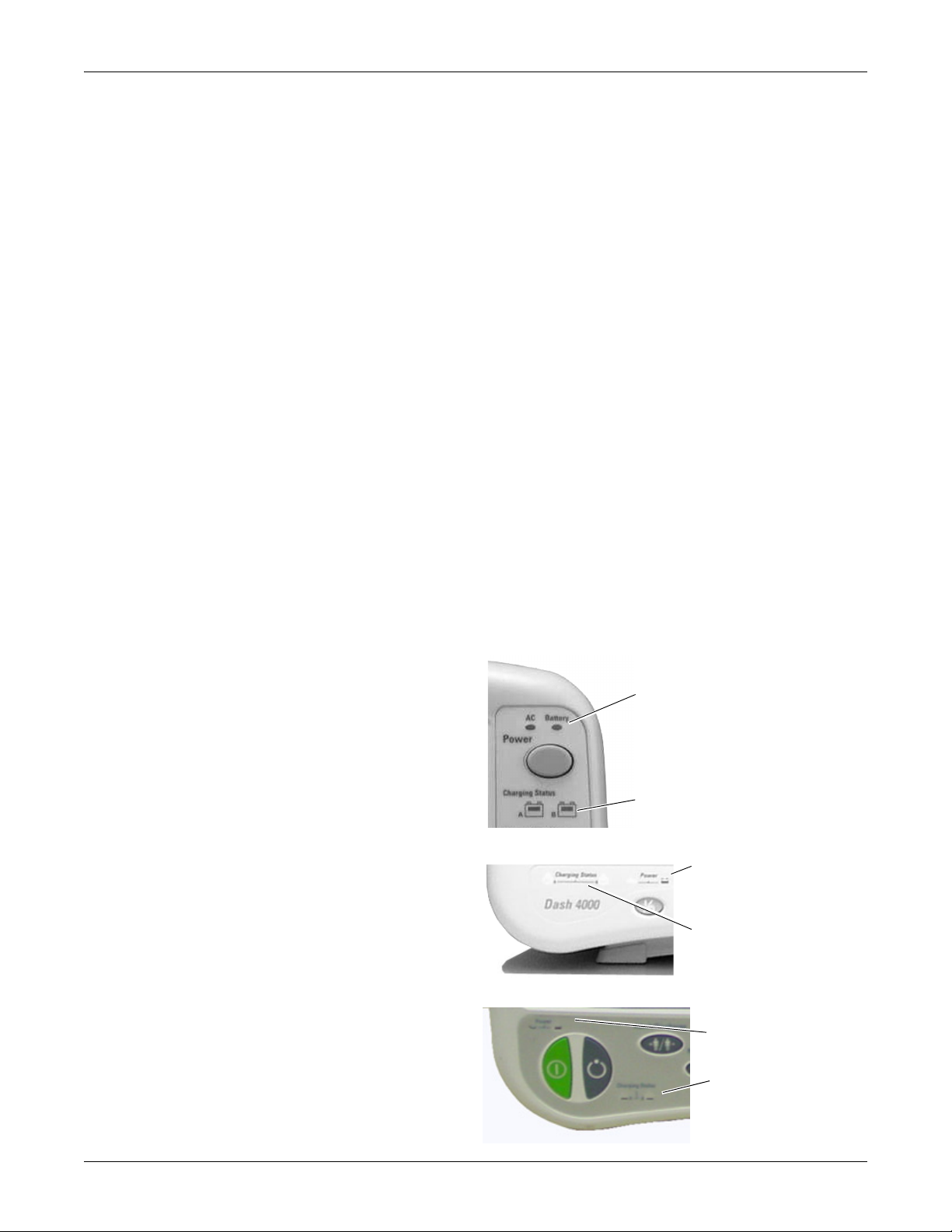

Indicators

Equipment Overview: Components

Power Key

The patient monitor is powered at all times when it is plugged into AC

power. When the patient monitor is not plugged in to AC power, this key

turns the patient monitor On and Off.

When AC power is present, this key toggles the operational mode of the

patient monitor between normal operation and stand-by mode. In

standby mode patient monitoring discontinues. Only the charging

function continues and the charging status indicators operate as

described below.

While the patient monitor powers up or changes between normal mode

and standby mode, all four front panel indicators illuminate.

AC Power Indicator

The indicator lights green when AC mains power is applied to the patient

monitor (including when the patient monitor is in the standby mode).

The indicator does not illuminate when the patient monitor has no AC

mains power.

Battery Power Indicator

The indicator lights yellow when the patient monitor is operating on

battery power. The indicator does not illuminate when the patient

monitor has no battery power. Battery indicators are located on the front

panel of the patient monitor. They indicate when battery power is used

and the battery charging status.

Battery Power Indicators

Dash 3000

Charge Status Indicators

009A

Battery Power

Indicators

Dash 4000

Charge Status

Indicators

053A

Battery Power

Indicators

Dash 5000

2-6 Dash 3000/4000/5000 Patient Monitor 2000966-363C

Charge Status

Indicators

868A

Page 25

Equipment Overview: Components

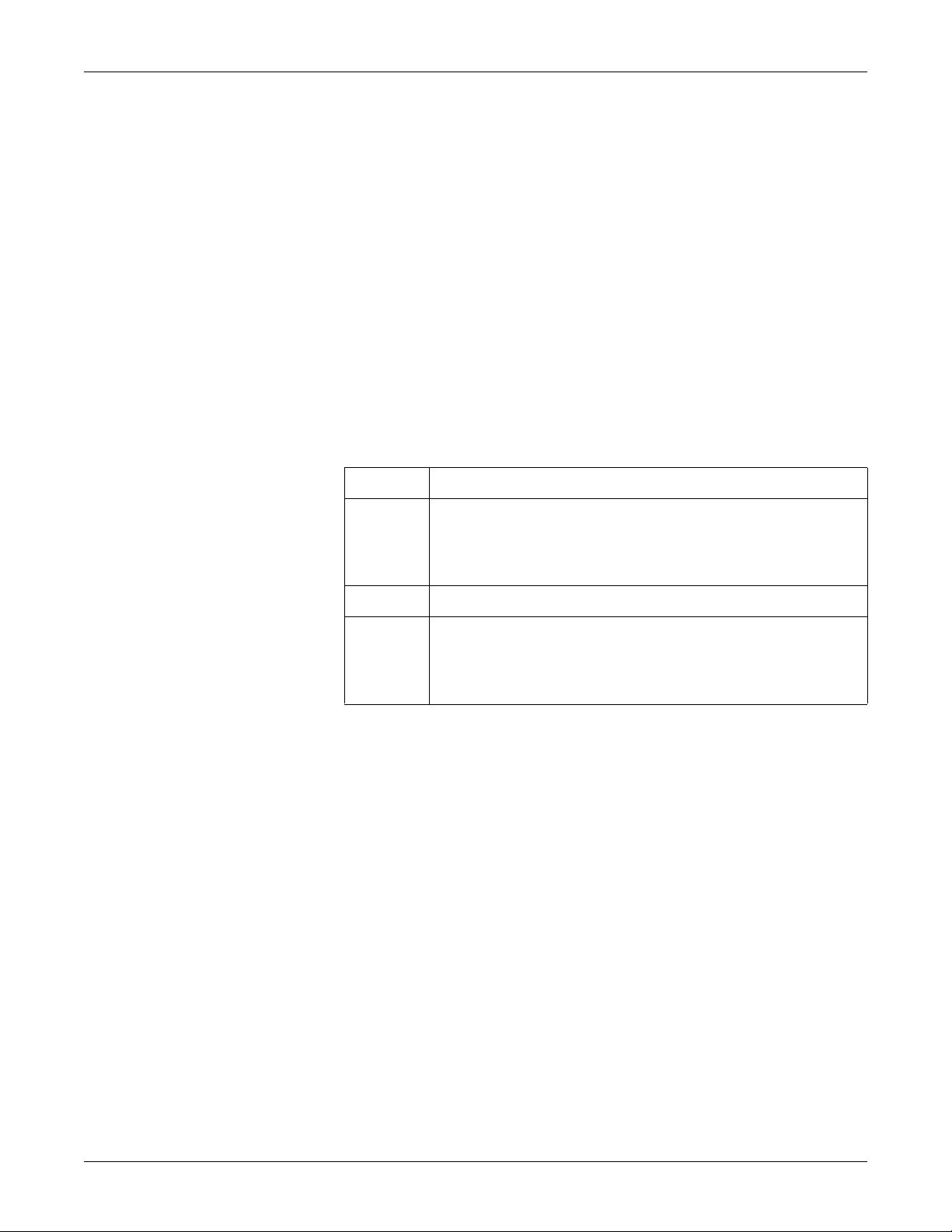

Charging Status Indicators

An icon for each battery indicates its charging status. The battery icon

lights yellow when the respective battery is being charged. If both

batteries are present and require charging, then both icons illuminate

even though they will be charged sequentially. The battery icon lights

green when the respective battery is fully charged.

When the patient monitor is operating under battery power the battery

icons are not illuminated. The icons are also not illuminated when the

respective battery is either not being charged, not installed, or has failed.

The following table explains what the charging status indicators mean.

NOTE

No specific indicator distinguishes a failed battery pack condition

from a condition where the battery is not installed or is not being

charged. Go to the Service Menu for Battery Status. Refer to “Battery

Alarms and Messages” on page 6-7 for further information.

LED Color Explanation

Yellow Two battery icons, labeled Charging Status A and B, illuminate yellow

when the respective battery is being charged. If both batteries are present

and require charging, then both icons illuminate yellow even though they

charge sequentially.

Green The icon lights green when the respective battery is fully charged.

No Light The icon does not illuminate under the following conditions:

The respective battery is not installed.

The patient monitor is operating on battery power.

A failure condition has been detected for the respective battery.

Battery Status Indicators

The battery status indicators are located inside the battery

compartment. One green LED indicator is located above each of the two

battery slots and lights green when the patient monitor is receiving

power solely from the respective battery. The indicators do not

illuminate when the patient monitor is not battery powered.

Neither indicator lights when the patient monitor is operating from both

batteries simultaneously (i.e., in a very low battery charge condition

when both batteries are joined together in order to sustain operation of

the patient monitor).

2000966-363C Dash 3000/4000/5000 Patient Monitor 2-7

Page 26

Equipment Overview: Components

Battery Capacity Gauge

On-screen capacity gauges indicate the battery's current state of health

and charge status. A battery capacity gauge for each battery present

displays below the parameter blocks in the lower right corner of the

display. The capacity gauge indicates the remaining charge capacity

(usable energy left) for each battery.

The capacity gauges fill in from left to right proportional to the battery

charge level. The solid portion represents the full charge capacity of the

battery as a percentage of its design capacity.

Exchangeable/Compatible Battery Packs

809A

Battery Capacity Gauges

WARNING

EXPLOSION OR FIRE - Using non-recommended

batteries could result in injury/burns to patients and

users. Only use batteries recommended or manufactured

by GE. The warranty can be voided if non-recommended

batteries are used.

Dash patient monitors running versions 5.4 or later only recognize and

charge GE recommended batteries. Non-recommended batteries will run,

but not charge, the Dash patient monitor. If battery is labeled GE

Approved, the battery is compatible.

NOTE

Incompatible batteries display an “ERROR” message in the Battery

Capacity Guage on the bottom right corner of the patien monitor

screen.

Verify compatibility of an unmarked battery as follows.

1. Install a battery pack in the patient monitor.

2. Using the Trim Knob control, access the Service Mode menu

starting from the Main Menu. Select MORE MENUS > MONITOR

SETUP > SERVICE MODE.

3. Enter password using the Trim Knob control to select the day and

month from patient monitor screen with leading zeros. (e.g. July 4 =

0407).

4. Select BATTERY SERVICE.

5. Verify that the MANUFACTURER NAME does not display

INCOMPAT, NME, or UNKNOWN for the battery corresponding to

BATTERY A or BATTERY B slot.

2-8 Dash 3000/4000/5000 Patient Monitor 2000966-363C

Page 27

Optional Components

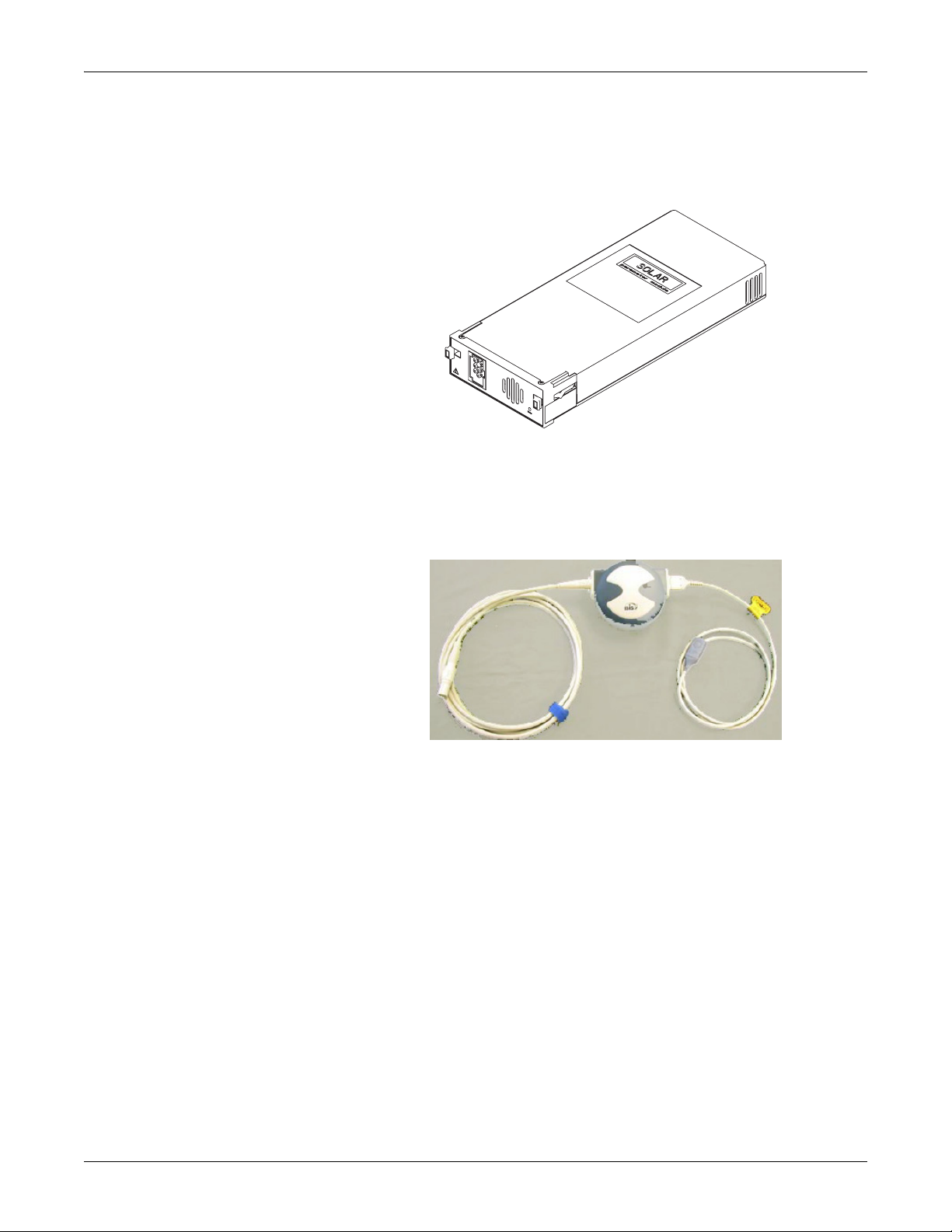

RAC 2A Module Housing

Equipment Overview: Components

The RAC 2A module housing currently supports the SAM and ICG

modules.

797B

An integral power supply is used to run the RAC 2A and support the

needed voltages.

Dash Port 2 Docking Station

The docking station is a quick mount/dismount base for a Dash patient

monitor. It gives the patient monitor easy connect/disconnect access to

AC power, Unity Network

See the Dash Port 2 Docking Station Operating Instructions and the

Dash Port 2 Docking Station Service Manual for additional information.

NOTE

™

, a remote display, and auxiliary devices.

When a Dash patient monitor is connected to the docking station,

only the docking station’s Ethernet port is active. The Dash patient

monitor’s network port remains inactive until the patient monitor is

disconnected from the docking station.

823B

An optional remote display can be connected to the system for viewing on

a larger monitor, or in a separate room. The remote display requires:

Dash Port 2 docking station,

Dash 3000/4000 patient monitor software version 5 or later, or

Dash patient monitor software version 6 with Dash Port 2 software

version 2.0, and

Must be within 150 feet of the Dash patient monitor.

2000966-363C Dash 3000/4000/5000 Patient Monitor 2-9

Page 28

ICG Module

BISx

Equipment Overview: Components

The ICG module (impedance cardiography) measures and processes

patient hemodynamic data.

825A

Available in software version 6 or later, BISx measures the effect of

anesthetics and sedatives on the brain.

935A

2-10 Dash 3000/4000/5000 Patient Monitor 2000966-363C

Page 29

Wireless Connection

Equipment Overview: Components

The flexibility of the optional GE Unity Network is increased by using

the wireless network. The wireless connection allows the user to roam

from one access point to another, maintaining a strong seamless

connection to the Unity Network. GE offers 802.11 and 802.11b wireless

options.

The patient monitor, with its optional built-in wireless card, functionally

performs the same as a patient monitor connected directly to the optional

Unity Network. It can be viewed at the central station and by other GE

monitors on the network (i.e. Dash 3000/4000/5000, Eagle

™

Solar

patient monitors). Patient monitors with a wireless connection

™

4000, and

can send and receive patient data via the access points to the Unity

Network.

NOTE

It is recommended that wireless patient monitors that are moved

from room to room have their patient monitor type configured as

Rover or Rover/Combo monitoring.

To extend the Unity Network to a hospital’s 802.11b wireless network, a

proper installation and configuration needs to be performed. To maintain

continuous wireless patient monitoring, refer to the Wireless LAN

Configuration Guide and contact GE for consultation in integrating the

Unity Network to a 802.11b wireless network.

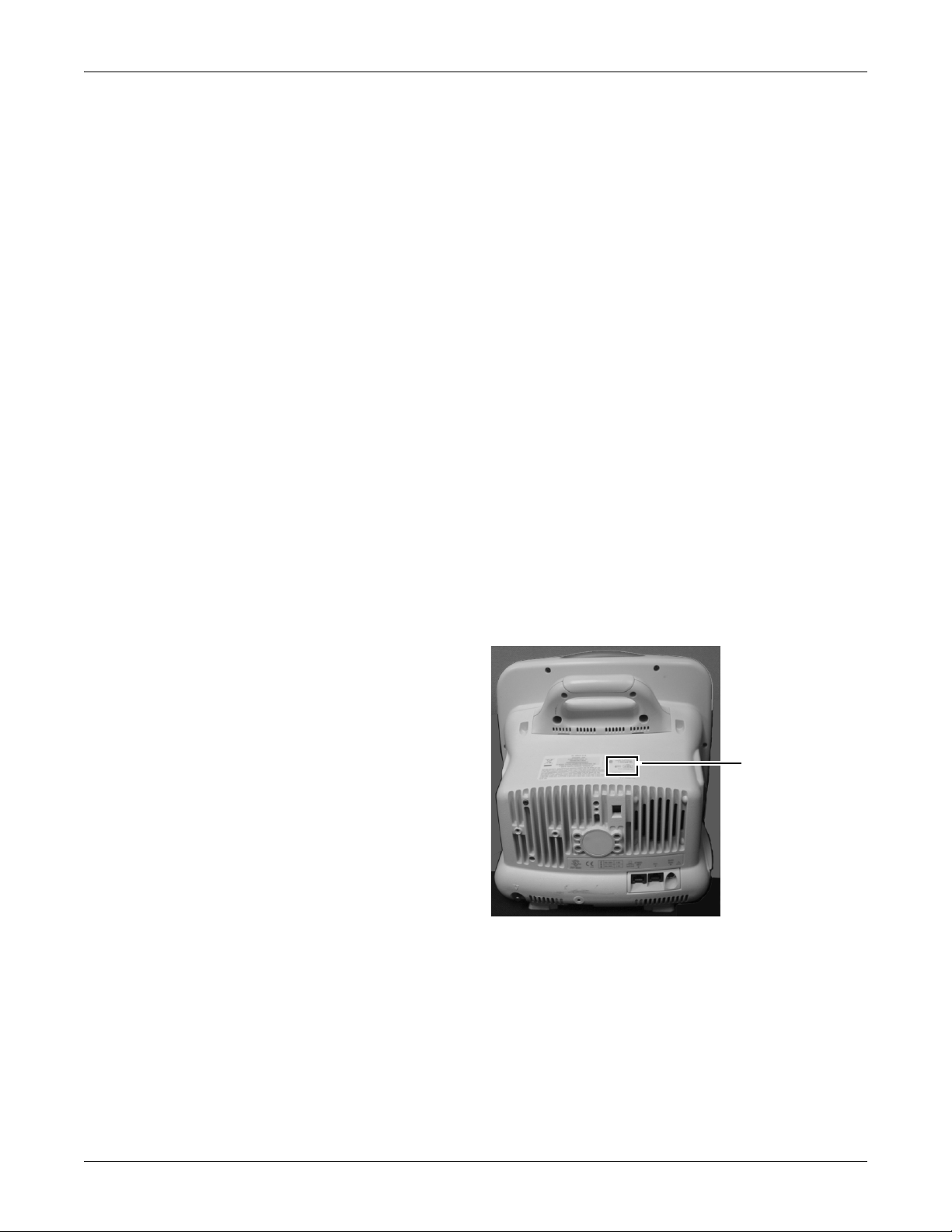

To identify a patient monitor with the wireless option, look for the

wireless LAN label.

Wireless

LAN label

940A

2000966-363C Dash 3000/4000/5000 Patient Monitor 2-11

Page 30

Optional Remote Control

The optional remote control provides all patient monitor controls on a

portable component with a Trim Knob control, and allows the user to

operate the patient monitor from across the room. Eighteen hard keys

are configured for adult, neonatal, or operating room applications.

Equipment Overview: Components

821A

2-12 Dash 3000/4000/5000 Patient Monitor 2000966-363C

Page 31

Equipment Overview: Software Packages and Software Options

Software Packages and Software Options

Software Packages

The Dash patient monitor comes configured with the Basic software

package. This package consists of standard-of-care parameters, lethal

arrhythmia detection, dose calculations, and features required by

clinicians caring for acutely ill patients.

Two additional software packages can be purchased separately or in any

combination. These packages provide a variety of features that allow the

patient monitor to be configured to best meet the needs of its intended

environment.

The Cardiac software package focuses on cardiac conductivity. Its

features include full arrhythmia analysis and storage, as well as ST

segment trending, storage, and templates. The ability to adjust the ST

measurement point is also included in this package.

The Cardiopulmonary software package centers on cardiac and

pulmonary hemodynamics. Features include the PA insert and wedge

algorithms, the intra-aortic balloon pump algorithm, and the

thermodilution cardiac output algorithm, including predefined

computation constants for the catheters of major manufacturers. Also

included are cardiac and pulmonary calculations.

Software Options

Three software options can be purchased separately or in any

combination with the software packages and software options.

The High Resolution CRG Trends option provides storage of up to 100

CRG events, and up to 24 hours of CRG trend data, in addition to the

CRG feature set found in the Basic software package.

The 12SL™ ECG analysis program with Gender Specific Criteria and the

Acute Cardiac Ischemia–Time Insensitive Predictive Instrument (ACITIPI) analysis option uses recorded ECG data to produce a numerical

score which is the predicted probability of acute cardiac ischemia. In

addition, the gender-specific criteria improves the detection of acute

myocardial infarctions (AMI) in women.

The Unity Network option enables you to view other patients on the

network, interface with a central station and other network devices, and

perform Combo or Rover Combo monitoring.

2000966-363C Dash 3000/4000/5000 Patient Monitor 2-13

Page 32

Equipment Overview: Ethernet Communication

Ethernet Communication

About Ethernet

The GE Unity Network uses Ethernet for device to device

communications. This local area network links all patient monitors,

clinical information centers, and other GE equipment throughout the

hospital. Depending on the construction of the hospital, thick-net, thinnet, or CAT-5 twisted pair cabling is used. The Dash patient monitor is

designed to be used with twisted-pair cabling. Consult GE when trying to

interface with either thick-net or thin-net cabling. The real-time GE

Unity Network operates at 10 Mbps, half-duplex.

Twisted Pair

Twisted pair is the most popular cabling because it is easy to install and

flexible to work with. It uses the star topology with a switch as the hub of

the segment. A maximum of 100 meters or 328 feet is the longest length

of twisted pair cable allowed. The maximum number of devices on the GE

Unity Network is 1,000.

CIC Pro

CIC Pro

Dash

Segment

Dash

Switches

1 to n

054B

2-14 Dash 3000/4000/5000 Patient Monitor 2000966-363C

Page 33

Equipment Overview: Ethernet Communication

Network Terms

Node

Each network device or node is assigned a Media Access Control (MAC)

Address number and requires a network connection to interface between

the network device and the network.

Media Access Control (MAC) Address

A 48-bit address assigned by the manufacturer to uniquely identify a

node of the network. This is also known as the Ethernet address.

Switch

To implement the star topology, each network device is connected to a

network switch. The switch passes all network data between each

network device in the star segment. Typically, the switch supports 12 to

48 network devices and may be linked to other switches to form larger

networks.

Segment

IP Address

Subnet

A network segment is comprised of all devices connected to one or many

switches which are in-turn connected together to form a larger network.

The boundaries of the segment are defined by networking equipment

that regulate the flow of packets into and out of the segment (e.g. routers

and switches).

A 32-bit (IPv4) address assigned by the user (either statically or

dynamically from a server) to uniquely identify the packets from a device

for routing purposes.

A subnet is a logical segment of a larger network that shares a common

IP address range as defined by a subnet mask. Proper subnetting can

improve the performance and security of a network.

2000966-363C Dash 3000/4000/5000 Patient Monitor 2-15

Page 34

Equipment Overview: Theory Of Operation

Theory Of Operation

Components

The patient monitor is housed in a single package. The main components

of the assembly are:

Power Supply

Data Acquisition System

Processor/Power Management subsystem (including battery case and

expansion port)

Speaker

Handle subassembly (including the Alarm Light option)

Thermal Printer (optional)

Battery

Overall Patient Monitor Block Diagram

516A

2-16 Dash 3000/4000/5000 Patient Monitor 2000966-363C

Page 35

Equipment Overview: Theory Of Operation

Power Supply

The subsystems within the patient monitor operate from a common 9 to

18 V power bus. Due to the wide variety of voltages required by the

various subsystems, power is converted locally by each subsystem. This

architecture results in an efficient and compact system by reducing the

number of conversions required and optimizing the physical size of each

converter for the specific application.

When operating on AC mains power, the power bus voltage is 18 V,

generated by the offline switching power supply.

No AC mains power switch is provided.

The line voltage range switch must be set to select 115 V or 230 V (90 to

132 VAC or 190 to 264 VAC, respectively).

Data Acquisition System (DAS)

All interfaces to the patient occur through the DAS. The ECG function

uses a direct connection to the patient; therefore it is separately isolated

from the other functions (except respiration, which shares the ECG

patient interface) to substantially reduce coupling of noise and leakage

currents to/from other functions. All remaining DAS functions (i.e., pulse

oximetry, NBP, invasive pressure, temperature, cardiac output, and

) share a common isolation barrier.

CO

2

NOTE

The patient monitor supports three SPO2 configurations, Generic

Ohmeda SPO2, Masimo SET SPO2, and Nellcor OxiMax SPO2.

2000966-363C Dash 3000/4000/5000 Patient Monitor 2-17

Page 36

Equipment Overview: Theory Of Operation

DAS Block Diagram with Generic Ohmeda SPO2

+V_PUMP

PUMP_DRV

GND

PRESSURE

NBP

INTERFACE

NBP

ASIC

INTERFACE

TRANSDUCER

OVERPRESSURE

TO PUMP,VALVES &

H0H1H2H3H4H5H6

8-BIT

HOST

GENERAL

PURPOSE

INTERFACE

H7

HA1

HA0

HA2

HCS*

HRD*

+9-18V

HWR*

PWR_ENABLE*

ACQ_TIMER_IRQ*

HOST_DMA_REQ*

TC_PACER_BLANK*

DC-DC

PRIMARY

CIRCUITRY

CONVERTER

PS FEEDBACK

RESET*

NBP_ENABLE

SERIAL _DATA_IN

SERIAL_DATA_OUT

COUPLER

+5V

+5V

+3.3V

+3.3V

+9-18V

DAS_ID1

DAS_ID0

+9-18V

7.5KV SPARK GAP

+9-18V

+9-18V

GND

GND

DIGITAL DATA

GND

COUPLERS

GND

GND

GND

GND

GND

+5V

+12V_VALVE

VALVE1_DRV

VALVE0_DRV

SIGNAL

TRANSDUCER

CONDITIONING

+9-18V

ISOLATION

BARRIER

DC-DC

PRIMARY

CIRCUITRY

DC-DC

+12V

CONVERTER

CONVERTER

SECONDARY

+5V

-12V

COUPLER

7.5KV SPARK GAP

PS FEEDBACK

CIRCUITRY

CONTROL

COUPLERS

DIGITAL DATA

PACE - BLANKING

TRANSCUTANEOUS

DC-DC

+12V

CONVERTER

SECONDARY

-12V

+5.5V

PROM

Serial

2

4K x 8

CIRCUITRY

+5V

REG

LDO

CIRCUITRY)

(TO DIGITAL

E

FLASH

128K x 16

MHz

22.1184

RESET IC

38.4

KHz

MOTOROLA

68332

SRAM

CO2

128K x 8

LOGIC

CONTROL

VREF

MHz

7.3728

68HSC05

NBP CUFF

(MOUNTED ON

801368-001 HYBRID)

VREF

MUX & A/D

DUAL INVASIVE BP -- 801466-001

OUTPUT

NON-INVASIVE BP -- 2008654-001

PULSE-OXIMETRY -- 801368-001

INV BP1

TEMP CH1 -- 401788-004

TEMP CH2 -- 402100-004

DEFIB PROTECTION MODULE -- 414639-002

RESPIRATION

COUPLING CAP

11 PIN

ECG

INPUT

CONNECTOR

RESPIRATION DEMODULATOR -- 400871-004

RESPIRATION CARRIER -- 400870-001

ECG PREAMP (I,II,III,V/V1) -- 400869-004

ECG PREAMP II (V2-V6) -- 401790-001

PACE DETECT (I,II,III,V/V1,V2-V6)-- 800982-001

FINAL AMP (I,II,III,V/V1) -- 401787-001

PACE REJECT (I,II,III,V/V1) -- 2007009-001

PACE REJECT (V2-V6) -- 401786-001

FINAL AMP (V2-V6) -- 401787-001

CARDIAC

ISOLATION BARRIER ISOLATION BARRIERISOLATION BARRIER

DUAL TEMP/

PRESSURE SENSOR

CO2 IR SOURCE DRIVE / HEATER CONTROL -- 801370-001

CO2 SIGNAL PROCESSING & BARO PRESS -- 801368-001

PRESSURE

SENSOR

BAROMETRIC

NBP

SpO2

INV BP2

ETCO2

MUX & A/D

528B

2-18 Dash 3000/4000/5000 Patient Monitor 2000966-363C

Page 37

Equipment Overview: Theory Of Operation

The DAS block diagram with Generic Ohmeda SPO2 consists of the

following three sections.

Section Description

ECG/Respiration Separately isolated section includes a 7.3728MHz 68HSC05

microcontroller, A/D conversion, signal processing hybrids and

DC-DC isolation converter.

Main DAS Separately isolated section includes a 22.1184MHz 68332

microcontroller with FLASH and SRAM memory, A/D conversion,

signal processing hybrids and DC isolation converter.

Non-Isolated

circuits

Includes serial and parallel host interfaces and NBP pump, valves,

and over-pressure circuitry.

ECG

The ECG function detects heartbeats and arrhythmias, measures heart

rate (HR) and ST segment deviation, and generates a 12SL diagnostic

interpretation. Patient alarms with adjustable high and low limits for

HR and ST segment deviation are provided. Additional patient alarms

are provided for arrhythmias and PVCs. System alarms for individual

lead failure and all leads failure are provided.

The patient monitor accepts the green 3, 5, and 10-leadwire Multi-link

ECG connectors (compatible with Eagle 3000 monitor, Eagle 4000

monitor, and Tram modules).

Respiration

The respiration function measures respiration rate (RR) and detects

apnea through the ECG leadwires using the impedance variation

technique. Patient alarms for RR (with adjustable high and low limits)

and apnea (with adjustable time limit) are provided. System alarms for

lead failure, cardiac artifact, and learning are provided.

Generic Ohmeda Pulse Oximetry (SpO2)

The pulse oximetry function measures arterial oxygen saturation (SpO2)

and peripheral pulse rate (PPR). Patient alarms with adjustable high

and low limits for SpO

off patient, low-quality signal, and pulse search are provided.

and PPR are provided. System alarms for probe

2

The patient monitor accepts the blue color-coded pulse oximetry

connector (compatible with Eagle 3000 monitor, Eagle 4000 monitor, and

the Tram x50-series modules). The patient monitor with Generic

Ohmeda SPO2 supports Nellcor probes.

2000966-363C Dash 3000/4000/5000 Patient Monitor 2-19

Page 38

Equipment Overview: Theory Of Operation

Non-Invasive Blood Pressure

The NBP function measures systolic pressure, diastolic pressure, mean

pressure, and heart rate. Patient alarms with adjustable high and low

limits for systolic, diastolic, and mean pressures are provided. System

alarms for deflation failure, inflation failure, maximum pressure

exceeded, measurement time exceeded, pulse too weak, hardware

malfunction, and system pressure leak are provided.

The NBP function operates in manual, auto, and stat measurement

modes. The patient monitor has backup protections for magnitude and

duration of applied cuff pressure (with different settings in adult and

neonatal modes).

The patient monitor accepts the rectangular NBP connector (compatible

with the Eagle 3000 monitor and some versions of the Tram module).

Invasive Pressure

The invasive pressure function measures two blood pressures and

calculates systolic pressure, diastolic pressure, mean pressure, and

pulsatile pressure rate where applicable. Patient alarms with adjustable

high and low limits for systolic pressure, diastolic pressure, mean

pressure, and pulse rate are provided for each channel. System alarms

for sensor status (failure and disconnected), Smart BP event (artifact),

zeroing status (not zeroed, failure, and pressure sensed), and PA Wedge

status (wait, inflate, processing, complete, and no pulse) are provided.

The user can set an adjustable low-pass filter to 12 or 40 Hz. The 12 Hz

filter is implemented in software; the filter is disabled at the 40 Hz

setting.

The patient monitor accepts the red color-coded invasive pressure

connectors (compatible with the Eagle 3000 monitor, Eagle 4000

monitor, and Tram modules).

Temperature

The temperature function measures two temperatures. Patient alarms

with adjustable high and low limits for temperature are provided.

System alarms for sensor and calibration failures are provided.

The patient monitor accepts the brown color-coded connector (compatible

with the Eagle 3000 monitor, Eagle 4000 monitor, and Tram modules).

The patient monitor supports both YSI Series 400 and 700 thermistor

probes. The probe type is determined by identification signals in the

probe adapter cable.

The temperature connector and measurement circuits are shared with

the cardiac output monitoring function; therefore you cannot use both

functions concurrently. A signal in the patient cable indicates the

appropriate function.

2-20 Dash 3000/4000/5000 Patient Monitor 2000966-363C

Page 39

Equipment Overview: Theory Of Operation

Cardiac Output

The cardiac output function measures blood temperature and injectate

temperature, and uses the thermal dilution method to calculate cardiac

output. Patient alarms with adjustable high and low limits for blood

temperature are provided. System alarms for sensor failure and unstable

blood temperature are provided.

The patient monitor accepts the brown color-coded connector (compatible

with the Eagle 4000 monitor and Tram modules).

The cardiac output connector and measurement circuits are shared with

the temperature monitoring function. You cannot use both functions

concurrently. A signal in the patient cable indicates the appropriate

function.

Carbon Dioxide (CO2)

The CO2 function measures inspired and expired CO2 and respiration

rate using the infrared light absorption technique. The patient monitor

connects to an external CapnoFlex Low Flow Sidestream module or

Novametrix Capnostat III sensor that clips to an airway adapter in the

patient’s ventilation circuit. The circuits to drive the sensor and process

its incoming signal are located within the DAS.

Patient alarms with adjustable high and low limits for inspired CO

expired CO

, and respiration rate are provided. An additional patient

2

alarm for no breath detected is provided. System alarms for various

sensor conditions are provided.

The patient monitor accepts the yellow color-coded connector.

,

2

2000966-363C Dash 3000/4000/5000 Patient Monitor 2-21

Page 40

Equipment Overview: Theory Of Operation

DAS Block Diagram with Masimo SET SPO2

931B

2-22 Dash 3000/4000/5000 Patient Monitor 2000966-363C

Page 41

Equipment Overview: Theory Of Operation

The DAS system block diagram with Masimo SET SPO2 and four

SuperStat BP channels consists of the following three sections.

Section Description

ECG/Respiration Separately isolated section includes a 7.3728MHz Motorola

MC68HSC705C8A microcontroller, A/D conversion, signal

processing hybrids and DC-DC isolation converter.

Main DAS Separately isolated section includes a 22.1184MHz Motorola

MC68332 microcontroller with FLASH and SRAM memory, an

Analog Devices ADSP-21062 32-bit floating point digital signal

processor running at 12.096MHz, A/D conversion, signal

processing hybrids/modules and DC-DC isolation converter.

Non-Isolated

circuits

Includes ECG and Main DAS isolation power conversion circuitry,

serial and parallel host interfaces and NBP pump, valves, and

over-pressure circuitry.

Parameter Functions of the DAS with Masimo SET SPO2,

four BP Channels and Dinamap SuperSTAT NIBP

Except for the SPO2 parameter and additional 2 IBPs, the DAS with the

Masimo SET SPO2 parameter supports the same parameters as DAS

with the GE Ohmeda SPO2 parameter. Refer to 2-19.

Probes and Cable

The Masimo compatible DAS is intended for use exclusively with pulseoximetry probes from Masimo Corporation. An adapter cable is used to

interface the probes to the DAS front panel Nicolay connector. The

Nicolay connector utilizes a key pattern unique to Masimo.

2000966-363C Dash 3000/4000/5000 Patient Monitor 2-23

Page 42

Equipment Overview: Theory Of Operation

001

004

004

p

y

Y

ASSEMBLY

E

C

E

R

R

001

001

R

G

R

Y

DIGITAL

R

R

R

Y

R

R

001

001

004

001

001

001

001

001

001

DAS Block Diagram with Nellcor 05 (OxiMax) SP02

REG

REG

TC_PACER_BLANK*

NBP_ENABLE

PWR_ENABLE*

SERIAL _DATA_IN

SERIAL_DATA_OUT

RESET*

DAS_ID0

+9-18V +9-18V

GND GND GND GND GND

GND

+5V +5V

+3.3V +3.3V

DAS_ID1

+9-18V +9-18V

GND

GND

COUPLERS

DIGITAL DATA

UART

SRAM

128K x 8

PROM

4K x 8

E

CO2

ASIC

INTERFAC

FLASH

512K x 8

MUX & A/D

+3.3V

+5V

COUPLER

PS FEEDBACK

I

I

L

T

S

A

O

O

(TO SPO2

MP100

CONNECTOR)

7.5KV SPARK GAP

N

PCB

Module

(TO

CIRCUITRY)

RESET IC

NBP CUFF

PRESSURE SENSO

BAROMET RIC

MHz

22.1184

68332

MOTOROL

38.4

KHz

Serial

2

VREF

(MOUNTED ON

801368-001 HYBRID)

CO2 IR SOURCE DRIVE / HEATER CONTROL -- 801370-

CO2 SIGNAL PRO CESSING & BARO PRE SS -- 801368-

PRESSURE

SENSOR

H0 H1

H2 H3

ASSEMBL

NBP PUMP

NBP VAL VE/MANIFOL D

H4

H6

H5

H7

HA1

HA0

8-BIT

HOST

GENERAL

PURPOSE

INTERFACE

HA2

HRD*

HCS*

HWR*

I

SIGNAL

TRANSDUCE

OVERPRESSUR

TRANSDUCE

CONDITIONIN

INTERFAC

NBP

+9-18V

DC-DC

PRIMARY

CIRCUITRY

CONVERTE

COUPLER

PS FEEDBACK

7.5KV SPARK GAP

CONTROL

COUPLERS

DIGITAL DATA

PACE - BLANKING

TRANSCUTANEOUS

+9-18V

BARRIE

DC-DC

PRIMARY

CIRCUITRY

CONVERTE

DC-DC

CIRCUITRY

CONVERTE

SECONDAR

DC-DC

+12V

DEFIB PROTECTION MODULE 414639-

ISOLATION

CIRCUITRY

CONVERTE

SECONDAR

+5V

-12V

MHz

7.3728

68HSC05

VREF

MUX & A/D

RESPIRATION

COUPLING CAP

RESPIRATION CARRIER -- 400870-

RESPIRATION DEMODUL AT OR -- 400871-

ECG PREAMP (I,II,III,V/V1) -- 400869-

ECG PREAMP II (V2-V6) -- 401790-

PACE DETECT (I,II,III,V/V1,V2-V6)-- 800982-

FINAL AMP (I,II,III,V/V1) -- 401787-

PACE REJECT (I,II,III,V/V1) -- 401786-

PACE REJECT (V2-V6) -- 401786-

BARRIE

ISOLATION

TEMP CH1 -- 401788-

FINAL AMP (V2-V6) -- 401787-

+12V

TEMP CH2 -- 402100-

LDO

LDO

-12V

+5.5V

t

Em

4-IBP and SU PER BP -- 2013329-

ECG

11 PIN

INPUT

CONNECTOR

BARRIER

ISOLATION

DUAL TEMP/

INV BP1/ BP3 INV BP2/ BP4

SpO2

NBP

ETCO2

OUTPUT

CARDIAC

DETAILED BLOCK DIAGRAM

DASH Nellcor 05 Data

932A

2-24 Dash 3000/4000/5000 Patient Monitor 2000966-363C

Page 43

Equipment Overview: Theory Of Operation

The DAS block diagram with Nellcor 05 DAS PCB assembly consisting of

three sections:

Section Description

ECG/Respiration Separately isolated section includes a 7.3728MHz 68HSC05

Main DAS Separately isolated section includes a 22.1184MHz Motorola

microcontroller, A/D conversion, signal processing hybrids and

DC-DC isolation converter.

MC68332 microcontroller with FLASH and SRAM memory, an

Analog Devices ADSP-21062 32-bit floating point digital signal

processor running at 12.096MHz, A/D conversion, signal

processing hybrids/modules and DC-DC isolation converter.

Non-Isolated