GE Healthcare 3900P, 3800, 3900 Service Manual

GE Healthcare

3800/3900/3900P Pulse Oximeter

With/Without TruTrak®+

Technical Reference Manual

♥

GE Healthcare

3800/3900/3900P Pulse Oximeter

With/Without TruTrak®+

Technical Reference Manual

♥

6050-0006-404

March 2005

Important

Rx Only (USA)

Attention! Consult the accompanying instructions, including all safety

precautions, before using or servicing this device.

Responsibility of the manufacturer

The safety, reliability, and performance of this device can be assured only under the

following conditions:

• Fittings, extensions, readjustments, changes, or repairs are carried out by

authorized personnel.

• The electrical installation complies with relevant standards and regulations.

• The device is used according to the accompanying operating instructions and is

serviced and maintained in accordance with this manual.

Service and repair

Service and repair procedures must be performed by authorized service personnel.

Repair this device or its parts only in accordance with instructions provided by the

manufacturer. To order replacement parts or for assistance, contact an authorized

service office. When shipping the monitor for repair, clean the monitor, allow it to

dry completely, and pack it for shipment in the original shipping container, if

possible.

Trademarks

Datex®, Ohmeda®, OxyTip®, TruTrak®, PerfTrak®, TeleOximetry®, and PIr™ are the

property of GE Healthcare Finland Oy. All other product and company names are the

property of their respective owners.

0537

GE Healthcare Finland Oy

Helsinki, Finland

+358 10 394 11

www.gehealthcare.com

© 2005 General Electric Company. All rights reserved.

1/Overview

Related information..........................................................................................................1-1

Technical competence.....................................................................................................1-1

1.1 General description...........................................................................................................................1-2

1.1.1 Major components, block interconnect diagram.............................................1-2

1.1.2 General subassembly description.............................................................................1-2

Power inlet module............................................................................................................1-2

Power supply.........................................................................................................................1-3

Battery......................................................................................................................................1-3

System board ........................................................................................................................1-3

Oximetry board....................................................................................................................1-3

Sensor filter board..............................................................................................................1-3

Front panel.............................................................................................................................1-3

3900P printer .........................................................................................................................1-3

1.2 Compliance with standards .........................................................................................................1-4

1.2.1 General safety requirements........................................................................................1-4

Safety checks for software.............................................................................................1-4

1.2.2 Electromagnetic compatibility (EMC)......................................................................1-5

Electromagnetic effects ..................................................................................................1-8

1.3 Specifications.......................................................................................................................................1-9

1.3.1 General.....................................................................................................................................1-9

Circuitry...................................................................................................................................1-9

Displays ...................................................................................................................................1-9

Audio indicators..................................................................................................................1-9

Dimensions and weight ...................................................................................................1-9

1.3.2 Factory settings................................................................................................................ 1-10

Mode switches................................................................................................................... 1-10

1.3.3 Measurement.....................................................................................................................1-11

SpO2........................................................................................................................................1-11

Pulse rate .............................................................................................................................1-11

PIr pulsatile value...........................................................................................................1-11

Interfering substances .................................................................................................. 1-11

Sensor emitter wavelength ranges.........................................................................1-11

1.3.4 Alarms....................................................................................................................................1-12

Audible alarms..................................................................................................................1-12

Alarm limits ........................................................................................................................1-12

1.3.5 Environmental...................................................................................................................1-12

1.3.6 Electrical...............................................................................................................................1-12

Power......................................................................................................................................1-12

Current leakage................................................................................................................1-12

Fuse.........................................................................................................................................1-12

Battery...................................................................................................................................1-13

1.3.7 RS-232 connector.............................................................................................................1-13

1.4 Precautions ........................................................................................................................................1-14

1.4.1 Warnings..............................................................................................................................1-14

1.4.2 Cautions................................................................................................................................ 1-15

1.5 Safety guidelines.............................................................................................................................1-16

1.5.1 Cleaning................................................................................................................................ 1-16

Contents

i

Contents

2/Theory of Operations

ii

2.1 Power supply and power inlet module...................................................................................2-1

2.2 System board .......................................................................................................................................2-2

System board functions ..................................................................................................2-2

2.2.1 System board data management..............................................................................2-2

Microprocessor ....................................................................................................................2-3

SRAM..........................................................................................................................................2-3

Flash memory and software upgrade socket ......................................................2-3

RS-232 connector interface ...........................................................................................2-3

Mode switch...........................................................................................................................2-3

Alarm signal and pulse tone generator ..................................................................2-3

Microprocessor supervisor ............................................................................................2-3

Audio amplifier ....................................................................................................................2-4

Front panel interface........................................................................................................2-4

Background debug ............................................................................................................2-4

(3900/3900P) Real-time clock........................................................................................2-4

(3900P) Printer interface ..................................................................................................2-4

2.2.2 System board power management ..........................................................................2-4

+ 5 V supply ............................................................................................................................2-4

Battery charger....................................................................................................................2-5

Battery monitor...................................................................................................................2-5

AC monitor..............................................................................................................................2-5

+ VR supply.............................................................................................................................2-5

Power on/standby circuitry..........................................................................................2-5

2.3 Switch board.........................................................................................................................................2-6

2.4 Oximetry board...................................................................................................................................2- 7

2.4.1 Oximetry board power supply section....................................................................2-7

2.4.2 Oximetry board digital section...................................................................................2-7

Microprocessor ....................................................................................................................2-7

Flash memory.......................................................................................................................2-7

SRAM..........................................................................................................................................2-7

DAC .............................................................................................................................................2-7

Reset circuit...........................................................................................................................2-7

2.4.3 Oximetry board analog section..................................................................................2-8

Detector preamplifier.......................................................................................................2-8

Interference detect .............................................................................................................2-9

Multiplexed low-pass filter............................................................................................2-9

Test circuit..............................................................................................................................2-9

Ambient light subtraction .............................................................................................2-9

Composite gain stage ......................................................................................................2-9

Demultiplex and low-pass filter..................................................................................2-9

High-pass filter and multiplex.....................................................................................2-9

AC gain stage........................................................................................................................2-9

Demultiplex low pass .......................................................................................................2-9

Analog multiplexor and buffer.................................................................................2-10

Multiplexor.......................................................................................................................... 2-10

LED drive ...............................................................................................................................2-11

Sensor monitor.................................................................................................................. 2-11

Sensor identification .....................................................................................................2-11

2.5 Passive filtering (sensor filter board or flex cable).........................................................2-11

2.6 3900P Printer interface .................................................................................................................2-12

2.6.1 Printer board......................................................................................................................2-12

Motor driver........................................................................................................................2-12

Tachometer shaper.........................................................................................................2-12

Head drivers........................................................................................................................2-12

ESD protection...................................................................................................................2-12

Temperature sensor/keypad decoder ..................................................................2-13

2.6.2 Printer button board......................................................................................................2-13

3/Test and Upgrade Procedures

3.1 Functionality test ..............................................................................................................................3-1

3.1.1 Printer test (3900P) ..............................................................................................................3-3

3.1.2 Diagnostic self-test............................................................................................................3-4

3.2 Electrical safety check ....................................................................................................................3-4

3.3 Software upgrade ...............................................................................................................................3-5

3.3.1 Remove the cover and identify the system board ............................................3-6

3.3.2 (Optional) Check the installed software versions...............................................3-6

3.3.3 System software upgrade using the U-LOADER or LOADER chip...............3-7

3.3.4 System software upgrade using the SYS chip......................................................3-9

3.3.5 Oximetry software upgrade (monitors without TruTrak+)......................... 3-11

3.3.6 Install the cover and check the installation .....................................................3-12

Contents

4/Troubleshooting

4.1 Messages.................................................................................................................................................4-1

4.2 System failure error codes.............................................................................................................4-5

4.2.1 Nonfatal errors—the system continues running ...............................................4-5

4.2.2 Fatal errors—the system sounds an alarm tone and halts ..........................4-6

4.3 Troubleshooting guide....................................................................................................................4-8

4.4 3900/3900P TeleOximetry messages and troubleshooting.......................................4-12

4.4.1 TeleOximetry status messages.................................................................................4-12

4.4.2 TeleOximetry troubleshooting guide.................................................................... 4-14

4.5 Test points ...........................................................................................................................................4-15

4.5.1 System board test points .............................................................................................4-15

4.5.2 Oximetry board test points ........................................................................................4-16

Oximetry board in TruTrak+ monitors .................................................................4-16

Oximetry board in monitors without TruTrak+...............................................4-17

5/Repair and Replacement Procedures

5.1 Oximeter cover.....................................................................................................................................5-2

5.1.1 Removing the cover...........................................................................................................5-2

5.1.2 Replacing the cover...........................................................................................................5-2

5.2 Front panel assembly......................................................................................................................5-3

5.2.1 Front panel, remove and disassemble ....................................................................5-3

5.2.2 Sensor filter replacement (board or flex cable) ...................................................5-4

Sensor filter board..............................................................................................................5-4

Sensor filter flex cable......................................................................................................5-4

5.2.3 Sensor connector replacement ...................................................................................5-4

5.2.4 Switch board LCD replacement...................................................................................5-4

5.2.5 Button pad replacement.................................................................................................5-4

iii

Contents

6/Illustrated Parts

5.2.6 Switch board replacement ............................................................................................5-5

5.2.7 Front panel, reassemble and reinstall.....................................................................5-5

5.3 Power-related components..........................................................................................................5-7

5.3.1 Power supply replacement............................................................................................5-7

5.3.2 Equipotential ground connector replacement...................................................5-7

5.3.3 Power inlet module replacement ...............................................................................5-8

5.3.4 Fuse replacement ...............................................................................................................5-9

5.3.5 Battery replacement......................................................................................................5-10

5.4 Speaker replacement ....................................................................................................................5-11

5.5 System board replacement .......................................................................................................5-12

5.6 Oximetry board replacement...................................................................................................5-14

5.7 3900P Printer repair........................................................................................................................ 5-15

5.7.1 Printer board replacement.........................................................................................5-15

5.7.2 Printer button board replacement......................................................................... 5-15

6.1 Service kits.............................................................................................................................................6-2

6.2 Front panel assembly......................................................................................................................6-6

6.2.1 Front panel components ................................................................................................6-6

6.2.2 Front panel assembly drawing (3800)......................................................................6-7

6.2.3 Front panel assembly drawing (3900/3900P)........................................................6-8

6.3 Chassis assembly...............................................................................................................................6-9

6.3.1 Chassis components.........................................................................................................6-9

6.3.2 Chassis assembly drawing .........................................................................................6-10

6.4 Printer/cover assembly (3900P)................................................................................................ 6-11

6.4.1 Printer/cover components..........................................................................................6-11

6.4.2 Printer/cover assembly drawing.............................................................................6-12

6.5 System board ....................................................................................................................................6-13

6.5.1 System board components shown.........................................................................6-13

6.5.2 System board layout (all monitors except 3800 without TruTrak+) ..... 6-13

6.5.3 System board layout (3800 REF 6051-0000-064 and 6051-0000-163).....6-14

6.6 Oximetry board................................................................................................................................6-15

6.6.1 Oximetry board layout (TruTrak+ monitors)..................................................... 6-15

6.6.2 Oximetry board layout (monitors without TruTrak+)...................................6-16

6.7 Switch board......................................................................................................................................6-17

6.8 Sensor filter flex cable (TruTrak+ monitors).......................................................................6-18

6.9 Sensor filter board (monitors without TruTrak+)............................................................6-18

6.9 3900P Printer boards .....................................................................................................................6-19

6.9.1 3900P Printer board........................................................................................................6-19

6.9.2 3900P Printer button board........................................................................................6-19

iv

1/Overview

This manual provides instructions for servicing all Model 3800, Model 3900, and Model

3900P pulse oximeters. This includes models with TruTrak®+ technology, the patented

technology for enhanced performance during conditions of clinical patient motion.

Important: Only OxyTip®+ sensors can be used with TruTrak+ monitors.

The 3900P is identical to the 3900, except that it contains an integral printer. All

references to printer functions and components are for the 3900P only.

This chapter contains:

• A general description of the oximeter and its main components.

• Oximeter specifications.

• Precautions, including specific warnings and cautions you must follow when

• Safety procedures you must follow when handling or repairing equipment that

Related information

For a detailed description of your monitor’s components, functions, general operating

guidelines, and RS-232 interface, see the 3900/3900P Pulse Oximeter User’s Manual or

the 3800 Pulse Oximeter User’s Manual.

servicing the oximeter.

may be contaminated.

If you need to reference printed circuit board schematics and component lists,

purchase and refer to the information contained in the 3800/3900/3900P PCA Drawings

Service Kit. See chapter 6 for a description and order number.

For information related to sensors (sensor application and cleaning, for example), refer

to the instructions for the sensor.

Technical competence

CAUTION: Only qualified service personnel should perform the procedures described in

this manual.

Only trained service personnel or competent individuals who are experienced with

servicing medical devices of this nature should perform the procedures described in

this service manual.

1- 1

3800/3900/3900P Technical Reference Manual

1.1 General description

The 3800, 3900, and 3900P pulse oximeters are noninvasive, arterial oxygen saturation

and pulse rate monitors. Through the use of a sensor applied to the patient and

connected to the monitor, these pulse oximeters measure the absorption of selected

wavelengths of light to calculate pulse rate and arterial oxygen saturation. The light

generated in the sensor passes through the tissue and is converted into an electronic

signal by a photodetector in the sensor. The electronic signal passes to the oximeter

and is amplified. Analog and digital signal processing convert the light intensity

information into SpO2 and pulse rate values.

Both models feature two easy-to-read displays that present patient data and status

information.

• The numeric LEDs (light-emitting diodes) show the SpO2 and pulse rate values.

• The LCD (liquid crystal display) shows alarm messages, the plethysmographic

waveform (or data), and the high and low SpO2 and pulse rate limit settings. This

display also shows the Relative Perfusion Index (PIr®) pulsatile value and menus

as appropriate for the monitor.

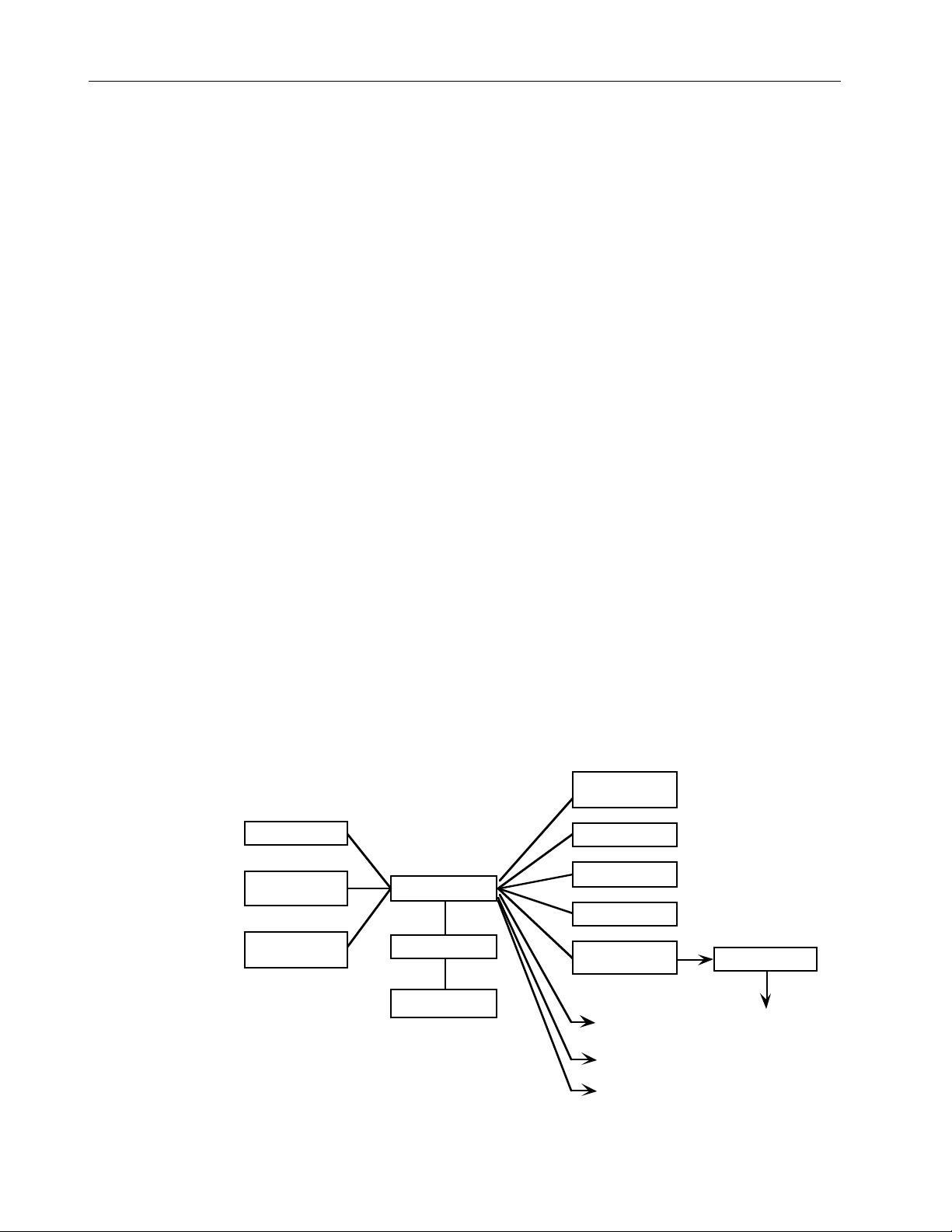

1.1.1 Major components, block interconnect diagram

AC

Power

Power inlet

module

Power supply

+12 V

Mode switches

RS-232 port

System board

Battery

1.1.2 General subassembly description

The descriptions that follow discuss the interaction of major components within the

pulse oximeter. More detailed information for each component is found in chapter 2.

Power inlet module

The primary function of the power inlet module is to allow the oximeter to be

connected to an AC power source. It also serves as a filter for electromagnetic

compatibility (EMC) compliance and contains fuses to limit the current flow. This

module is connected to the power supply.

3900P

Printer board

Oximetry board

3900P Printer

button board

Front panel

Sensor filter

board

Oximetry

sensor

1- 2

1/Overview

Power supply

The power supply converts power from any AC source between 90 and 264 VAC at

47 to 63 Hz to +12 VDC. It also provides the necessary isolation between the patient

and the mains. The +12 VDC is connected to the system board for further conditioning.

Battery

Power for the unit, when it is not connected to the AC mains power, is supplied by the

battery. The nominal battery voltage is 8 V. The battery is connected to the system

board, which conditions the battery and charges the battery when the unit is

connected to the AC mains power.

System board

This board conditions power from the +12 V power supply and the battery. It charges

the battery when supplied with a DC voltage from the power supply. On power up it

reads the position of the mode switches on the back panel. It communicates through

the RS-232 port. The board sends data to the front panel for display and monitors the

button switches. An upgrade socket on the board provides a means of upgrading the

software. The board monitors and sends commands to the oximetry board via a serial

interface and a few discrete digital lines.

The board communicates printer functions to the 3900P printer board. It also contains

a real-time clock for use in 3900/3900P monitors.

Oximetry board

This board drives the LEDs in the oximetry sensor and receives the photodetector

signals. The signals pass through the sensor filter board. The photodetector signal is

conditioned and processed on the oximetry board and the output is used to determine

patient oxygen saturation, perfusion, and pulse rate. The output is sent to the system

board.

Sensor filter board

This board filters out unwanted electrical signals (EMC, surges, noise, etc.). These are

internal signals that should not leave the unit and external signals that should not

enter the unit.

Front panel

This panel displays information sent to it by the system board: saturation, pulse rate,

plethysmographic waveform, alarm messages, and alarm indicators. The panel also

contains the primary user-interface switches. It displays the AC power status and

contains the power/standby switch.

3900P printer

The printer board and printer button board interface to the system board. The system

board controls the 3900P printer to provide printed output of current monitoring data,

stored trend, and summary data.

1- 3

3800/3900/3900P Technical Reference Manual

1.2 Compliance with standards

Compliance with standards The presence on the monitor of any symbol described

below indicates compliance with the standard represented by that symbol.

Medical Device Directive 93/42/EEC of the European Union for a class I

0537

(with a measuring function), IIa, IIb, or III device.

Medical electrical equipment classified in the US and Canada with

respect to electric shock, fire, and mechanical hazards only, in

accordance with the Canadian Standards Association CAN/CSA C22.2 No.

601.1 and Underwriters Laboratories Inc. UL 2601-1.

Medical electrical equipment classified with respect to electric shock,

fire, and mechanical hazards only, in accordance with the Canadian

Standards Association CAN/CSA C22.2 No. 601.1.

Medical electrical equipment classified with respect to electric shock,

fire, and mechanical hazards only, in accordance with Underwriters

Laboratories Inc. UL 2601-1.

1.2.1 General safety requirements

The 3800, 3900, and 3900P pulse oximeters comply with the requirements of EN 606011 Part 1: General requirements for safety of medical electrical equipment.

Type BF applied part.

Type of protection against electric shock: Class I/Internal electrical power source

Degree of protection against ingress of liquids: Ordinary (IPX0)

Mode of operation: Continuous

The oximeter also complies with the following:

EN 865 Pulse oximeters – Particular requirements

EN 475 Medical devices – Electrically-generated alarm signals.

Safety checks for software

Software design controls include performance of a risk analysis using methods

consistent with EN 1441 Medical devices – Risk analysis.

To ensure proper operation of the software, the monitor employs three separate

watchdog circuits for the microprocessors, power-on self-tests (including memory

checksum and calibration verification), and memory tests during monitoring. The

software continuously monitors the patient sensor and, if a failure is detected,

discontinues power to the sensor.

1- 4

1/Overview

1.2.2 Electromagnetic compatibility (EMC)

The 3800, 3900, and 3900P pulse oximeters comply with the requirements of EN 606011-2: Electromagnetic compatibility - Requirements and tests.

Emissions EN 55011 Group I, Class B

The 3800, 3900, and 3900P oximeters were tested with no peripheral devices when

operating on battery power.

The 3800 pulse oximeter was tested with an RS-232 cable attached when operating on

AC power.

The 3900 and 3900P pulse oximeters were tested with an RS-232 cable and analog

output cables attached when operating on AC power. A USRobotics Sportster Fax

Modem was connected to the 3900 when Electrical Safety and EMC testing was

performed. The analog output was measured using a fiber optic link during testing.

When installing and using this monitor, take precautions to ensure electromagnetic

compatibility.

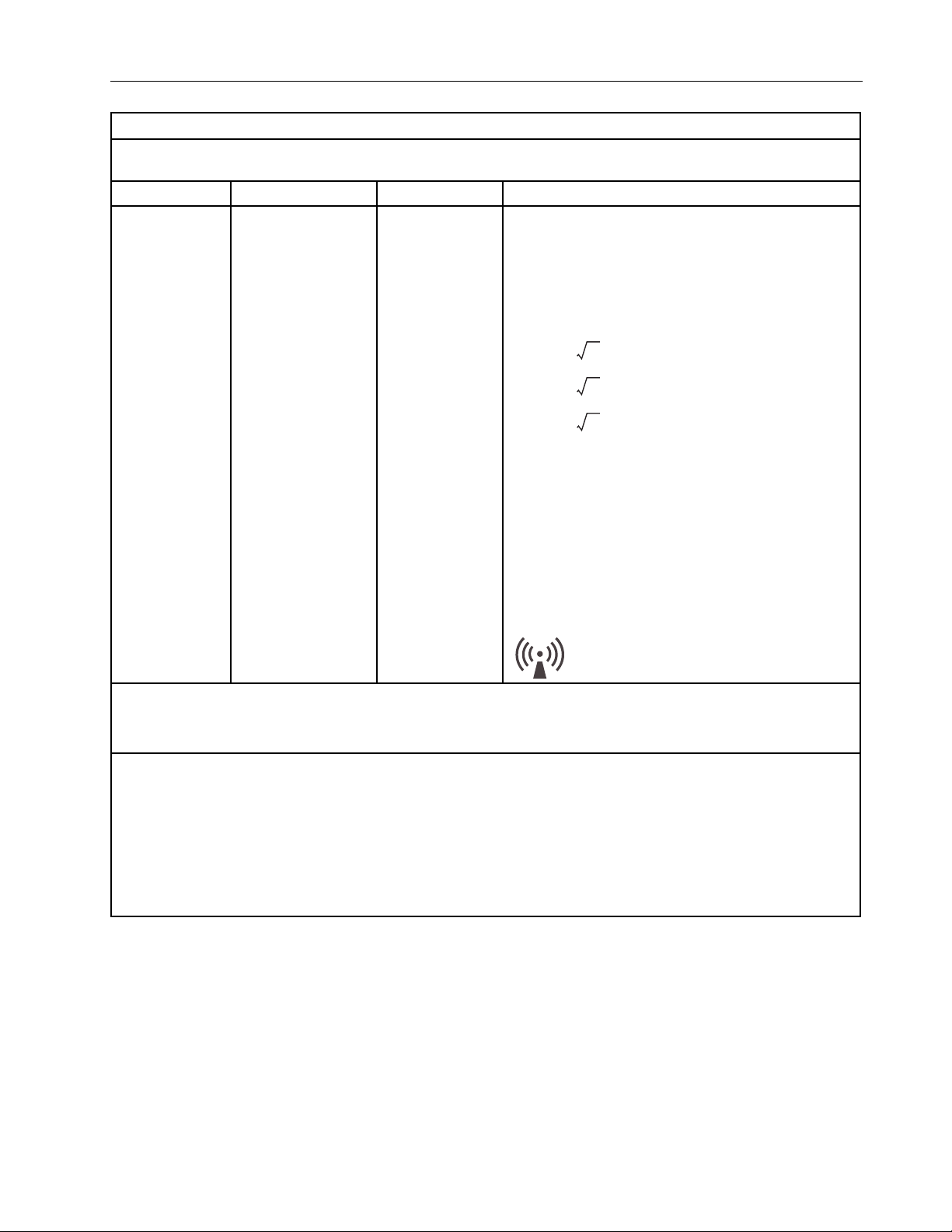

Table 1-1. Guidance and manufacturer’s declaration - electromagnetic emissions

The 3800/3900/3900P TruTrak+ is suitable for use in the electromagnetic environment specified below. The customer

or the user of the 3800/3900/3900P TruTrak+ should assure that it is used in such an environment.

Emissions test Compliance Electromagnetic environment - guidance

RF emissions

Group 1

CISPR 11

RF emissions

Class B

CISPR 11

Harmonic emissions

Class A

IEC 61000-3-2

Voltage fluctuations/flicker emissions

Complies

IEC 61000-3-3

The 3800/3900/3900P TruTrak+ uses RF energy only for its

internal function. Therefore, its RF emissions are very low

and are not likely to cause any interference in nearby

electronic equipment.

The 3800/3900/3900P TruTrak+ is suitable for use in all

establishments, including domestic establishments and

those directly connected to the public low-voltage power

supply network that supplies buildings used for domestic

purposes.

1- 5

3800/3900/3900P Technical Reference Manual

Table 1-2 Guidance and manufacturer’s declaration - electromagnetic immunity

The 3800/3900/3900P TruTrak+ is intended for use in the electromagnetic environment specified below. The customer

or the user of the 3800/3900/3900P TruTrak+ should assure that it is used in such an environment:

Immunity test IEC 60601-1-2 test level Compliance level

Electrostatic

discharge (ESD)

± 6 kV contact

± 8 kV air

± 6 kV contact

± 8 kV air

IEC 61000-4-2

Electrical fast

transient/burst

± 2 kV for power supply lines

± 1 kV for input/output lines

± 2 kV for power supply lines

± 1 kV for input/output lines

IEC 61000-4-4

Surge

IEC 61000-4-5

Voltage dips,

short

interruptions

and voltage

variations on

power supply

input lines

IEC 61000-4-11

Power frequency

± 1 kV differential mode

± 2 kV common mode

< 5 % U

T

(> 95 % dip in UT) for 0,5 cycle

40 % U

T

(60 % dip in UT) for 5 cycles

70 % U

T

(30 % dip in UT) for 25 cycles

< 5 % U

T

(> 95 % dip in UT) for 5 sec

± 1 kV differential mode

± 2 kV common mode

< 5 % U

T

(> 95 % dip in UT) for 0,5 cycle

40 % U

T

(60 % dip in UT) for 5 cycles

70 % U

T

(30 % dip in UT) for 25 cycles

< 5 % U

T

(> 95 % dip in UT) for 5 sec

3 A/m 3 A/m Power frequency magnetic fields

(50/60 Hz)

magnetic field

IEC 61000-4-8

NOTE: UT is the a.c. mains voltage prior to application of the test level.

Electromagnetic environment -

guidance

Floors should be wood,

concrete, or ceramic tile. If

floors are covered with

synthetic material, the relative

humidity should be at least

30%.

Mains power quality should be

that of a typical commercial or

hospital envi ronment

Mains power quality should be

that of a typical commercial or

hospital envi ronment.

Mains power quality should be

that of a typical commercial or

hospital environment. If the

user of the 3800/3900/3900P

TruTrak+ requires continued

operation during power mains

interruptions, it is

recommended that the

3800/3900/3900P TruTrak+ be

powered from an

uninterruptible power supply

or a battery.

should be at levels

characteristic of a typi cal

location in a typical commercial

or hospital environment.

1- 6

1/Overview

Table 1-3 Guidance and manufacturer’s declaration - electromagnetic Immunity

The 3800/3900/3900P TruTrak+ is intended for use in the electromagnetic environment specified below. The customer

or the user of the 3800/3900/3900P TruTrak+ should assure that it is used in such an environment:

Immunity test IEC 60601 test level Compliance level Electromagnetic environment - guidance

Portable and mobile RF communications equipment

should be used no closer to any part of the

3800/3900/3900P TruTrak+, including cables, than the

recommended separation distance calculated from

the equation applicable for the frequency of the

transmitter.

Recommended Separation Distance

Conducted RF

IEC 61000-4-6

Radiated RF

IEC 61000-4-3

3 Vrms

150 kHz to 80 MHz

3 V/m

80 MHz to 2,5 GHz

5 V

5 V/m

where P is the maximum output power rating of the

transmitter in watts (W) according to the transmitter

manufacturer and d is the recommended separation

dis tance in meters (m).

Field strengths from fixed RF transmitters, as determined by an electromagnetic site survey,

be less than the compliance level in each fre quency

range.

Interference may occur in the vicinity of equipment

marked with the following symbol:

Pd = 0.70

Pd = 0.70

80 MHz to 800 MHz

Pd = 1.40

800 MHz to 2,5 GHz

a

should

b

NOTE 1: At 80 MHz and 800 MHz, the separation distance for the higher frequency range applies.

NOTE 2: These guidelines may not apply in all situations. Ele ctromagnetic propagation is affected by absorption

and reflection from structures, objects, and people.

a

Field strengths from fixed transmitters, such as base stations for radio (cellular/cordless) telephones and land

mobile radios, amateur radio, AM and FM radio broadcast, and TV broadcast cannot be predicted theoretically

with accuracy. To assess the electromagnetic environment due to fixed RF trans mitters, an electromagnetic site

survey should be considered. If the measured field strength in the location in which the 3800/3900/3900P TruTrak+

is used exceeds the applicable RF compliance level above, the 3800/3900/3900P TruTrak+ should be observed to

verify normal operation. If abnormal performance is observed, additional measures may be necessary, such as reorienting or relocating the 3800/3900/3900P TruTrak+.

b

Over the frequency range 150 kHz to 80 MHz, field strengths should be less than 5 V/m.

1- 7

3800/3900/3900P Technical Reference Manual

Electromagnetic effects

Electromagnetic interference, including interference from portable and mobile radio

frequency (RF) communications equipment, can affect this monitor.

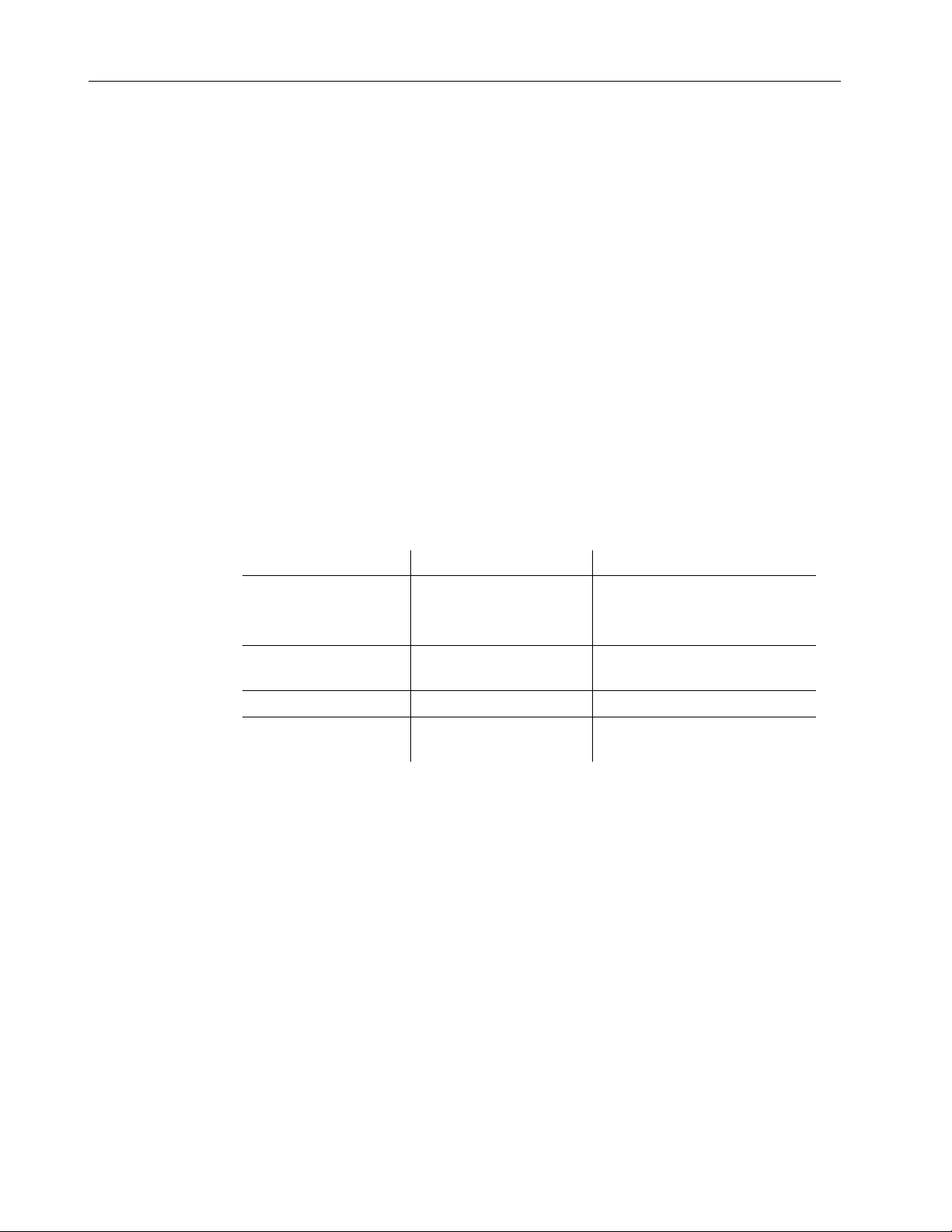

Table 1-4 Recommended Separation Distances between Portable and Mobile RF Communications

Equipment and the 3800/3900/3900P TruTrak+

The 3800/3900/3900P TruTrak+ is intended for use in an electromagnetic environment in which RF disturbances are

controlled. The customer or the user of the 3800/3900/3900P TruTrak+ can prevent electromagnetic interference by

maintaining a minimum distance between portable and mobile RF communications equipment (transmitters) and

the 3800/3900/3900P TruTrak+ as recommended below, according to the maximum output power of the

communications equipment.

Rated maximum output

power of transmitter

W

0.01 0.07 0.07 0.14

0.1 0.22 0.22 0.44

1 0.70 0.70 1.40

10 2.2 2.2 4.4

100 7.0 7.0 14.0

For transmitters rated at a maximum output power not listed above, the recommended separation distance d in

meters (m) can be estimated using the equation applicable to the frequency of the transmitter, where P is the

maximum output power rating of the transmitter in watts (W) according to the transmitter manufacturer.

NOTE 1: At 80 MHz and 800 MHz, the separation distance for the higher frequency range applies.

NOTE 2: These guidelines may not apply in all situations. Electromagnetic propagation is affected by absorption

and reflection from structures, objects, and people.

Separation distance according to the frequency of the transmitter

m

150 kHz to 80 MHz

Pd = 0.70

80 MHz to 800 MHz

Pd = 0.70

800 MHz to 2,5 GHz

Pd = 1.40

1- 8

Indications that the monitor is experiencing electromagnetic interference include the

following:

• Variations in the PerfTrak waveform display.

• Sudden increases or decreases in the waveform height that do not correlate to the

physiological condition of the patient.

• Sensor-related messages that are not resolved by the instructions found in this

manual.

• The display of dashes on numeric LEDs when a valid physiological signal is

present.

• (3900P ) Printed output that is garbled, solid black, or missing.

This interference may be intermittent and careful correlation between the effect and its

possible source is important. Indications of interference should not occur if the

monitor is used within its intended electromagnetic environment.

1.3 Specifications

Unless otherwise indicated, all specifications are nominal and are subject to change

without notice.

1.3.1 General

Circuitry

Microprocessor-controlled

Automatic self-test of oximeter when powered on

Automatic setting of default parameters

Automatic alarm messages

(3800) Up to 12 hours of stored trend data output through the RS-232 serial port for SpO2,

pulse rate, and alarm messages

(3900/3900P) Real-time data output or up to 24 hours of stored trend data output

through the RS-232 port for SpO2, pulse rate, PIr pulsatile value, and alarm messages;

SpO2 and pulse rate output through two analog channels

Displays

The displayed SpO2, pulse rate, and PIr values are updated every second. The

plethysmographic waveform sweep is updated every 4 seconds.

1/Overview

Numeric display (Light Emitting Diodes—LEDs)

Arterial oxygen saturation (SpO2) reading

Pulse rate reading

Graphic display (Liquid Crystal Display—LCD)

Plethysmographic waveform

High and low SpO2 and pulse rate alarm limits settings

Sensor condition alarms

Messages—alarm messages and system operational status messages

Contrast adjustment

(All monitors except 3800 without TruTrak+) PIr pulsatile value

(3900/3900P) SpO2 real-time or stored data graph

(3900/3900P) PIr pulsatile value real-time or stored data graph

Audio indicators

Adjustable-volume pulse beep; pitch modulation reflects changing SpO2 levels

Adjustable-volume alarm tone

Alarm silence (120 seconds); all mute (continuous silence)

Out-of-limits alarms for SpO2 and pulse rate

Sensor-condition, system-failure, and recharge-battery alarms

Dimensions and weight

(3800/3900) height x width x depth: 9.4 cm (3.7 in) x 24.4 cm (9.5 in) x 22.5 cm (8.9 in)

(3900P) height x width x depth: 10.4 cm (4.1 in) x 24.4 cm (9.5 in) x 22.5 cm (8.9 in)

Weight: 3800/3900—2.9 kg (6.5 lbs); 3900P —3.2 kg (7.0 lbs)

1- 9

3800/3900/3900P Technical Reference Manual

1.3.2 Factory settings

Parameter 3900/3900P 3800

High SpO2 limit OFF (appears as – – –) OFF (appears as – – –)

Low SpO2 limit 85% 85%

High pulse rate 130 bpm Adult mode: 130 bpm

Low pulse rate 40 bpm Adult mode: 40 bpm

Alarm volume 3 3

Pulse volume 2 2

Save limits No Not applicable

Data output mode

(printer and modem)

Data output resolution 6-second Not applicable

All mute Yes Not applicable

Serial transmission

baud rate

Analog 0.0 V Not applicable

Print contrast 5 Not applicable

Date format DD/MM/YY Not applicable

Time format HH MM Not applicable

Neonate mode: 200 bpm

Neonate mode: 100 bpm

SpO

2

9600 Not applicable

Not applicable

Mode switches

Switch 3900/3900P options 3800 options

Language Danish, Dutch, English

(factory setting), Finnish,

French, German, Italian,

Japanese, Norwegian,

Portuguese, Polish,

Spanish, and Swedish

Averaging mode Long / TruTrak+ (12 sec.

factory setting), Medium

(6 sec.), and Short (3 sec.)

Patient mode Not applicable Adult (factory setting) and

(TruTrak+ monitors) PI

pulsatile value display

(Monitors without TruTrak+)

SpO2 calibration

EMI line frequency 60 Hz 60 Hz

Yes (factory setting) and No Yes (factory setting) and No

r

Fractional (factory setting)

and functional

English (factory setting),

French, German, Italian,

Japanese, Portuguese,

Spanish, and Swedish

Long / TruTrak+ (12 sec.

factory setting), Medium

(6 sec.), and Short (3 sec.)

Neonate

Fractional (factory setting)

and functional

1- 1 0

1.3.3 Measurement

1/Overview

SpO

2

Calibration Functional Fractional or Functional

Range 0 to 100% 0 to 100%

Accuracy, A

(previously

represented

by 1 SD)

Accuracy, 1 SD 80 to 100% ± 2%

Resolution 1% 1%

rms

Pulse rate

Range 30 to 250 bpm 20 to 255 bpm

Accuracy

(assuming a

constant

pulse rate)

Resolution 1 bpm 1 bpm

TruTrak+ monitors Monitors without TruTrak

70 to 100% ± 2 digits

70 to 100% ± 3 digits during

conditions of clinical patient

motion (with TruTrak+ enabled)

Below 70% unspecified

60 to 79% ± 3%

Below 60% unspecified

TruTrak+ monitors Monitors without TruTrak

± 2% or ± 2 bpm (whichever is

greater)

Accuracy during conditions of

clinical patient motion:

unspecified

40 to 235 bpm ± 1.7% of

reading

+

+

PIr pulsatile value

Range 0.00 to 9.99 Not applicable

Averaging

interval

Resolution 0.01 Not applicable

TruTrak+ monitors

and 3900/3900P without

TruTrak

12 seconds Not applicable

+

3800 without TruTrak

Interfering substances

Carboxyhemoglobin may erroneously increase readings. The level of increase is

approximately equal to the amount of carboxyhemoglobin present. Dyes, or any

substances containing dyes, that change usual arterial pigmentation may cause

erroneous readings.

Sensor emitter wavelength ranges

Red LED peak wavelength range: 650 to 670 nm

Infrared (IR) LED peak wavelength range: 930 to 950 nm

Average power: ≤ 1 mW

+

1- 1 1

3800/3900/3900P Technical Reference Manual

1.3.4 Alarms

Audible alarms

Setting levels available:

Alarm: 1 through 5

Pulse beep: OFF and 1 through 5

Volume intensity at 1-meter distance:

Setting of 1: 45 decibels (minimum)

Setting of 5: 85 decibels (maximum)

Alarm limits

SpO2 alarm limit range:

High = 50 to 100%, or OFF

Low = OFF, or 50 to 100%

Pulse rate alarm limit range in beats per minute (bpm):

TruTrak+ monitors Monitors without TruTrak

High = 30 to 235, or OFF

Low = OFF, or 30 to 235

+

High = 40 to 235, or OFF

Low = OFF, or 40 to 235

1.3.5 Environmental

Parameter Operating Transport and Storage

Temperature 0 to 50 ºC (32 to 122 ºF) –40 to 70 ºC (–40 to 158 ºF)

Relative humidity,

noncondensing

Pressure 1060 to 697 hPa 1060 to 188 hPa

Approximate

elevation

1.3.6 Electrical

Power

Consumption (typical): 15 watts (3900P—20 watts)

Input voltage range: 90 to 264 VAC at 47-63 Hz

Current (typical): 0.45 A

Current leakage

With power on, forward or reverse polarity: 100 microamperes maximum

Ground resistance: less than 0.1 Ω

3900P with printer paper:

–20 to 45 °C (4 to 113 °F)

20% to 95% 5% to 95%

–378 to 3048 m

(–1240 to 10,000 ft.)

at 100 V, 0.37 A

rms

at 120 V, 0.25 A

rms

–378 to 12.2 km

(–1240 to 40,000 ft.)

at 220/230/240 V

rms

1- 1 2

Fuse

T2.0AH/250V, 5mm (OD) x 20 mm (Length)

Battery

Type: 8 volt, sealed lead-acid

Capacity: 3.2 ampere hours

Operation time for a new battery at normal operating temperatures:

At least 5 1/2 hours (with all functions operative from a fully charged battery).

3900P —approximately 4 hours when printing.

Low battery indicator (LOW BATTERY): indicates the remaining battery capacity is

between 5 and 15 minutes.

Important: To prevent permanent damage to the battery, recharge a discharged

battery within eight hours after LOW BATTERY is displayed.

Charge time:

4 hours = 80% capacity

8 hours = 100% capacity

Life: several hundred charge/discharge cycles

Shelf life: 6 months (maximum if not recharged) when stored at room temperature;

batteries stored for extended periods of time should be recharged every six months

to maintain the charging capacity.

1/Overview

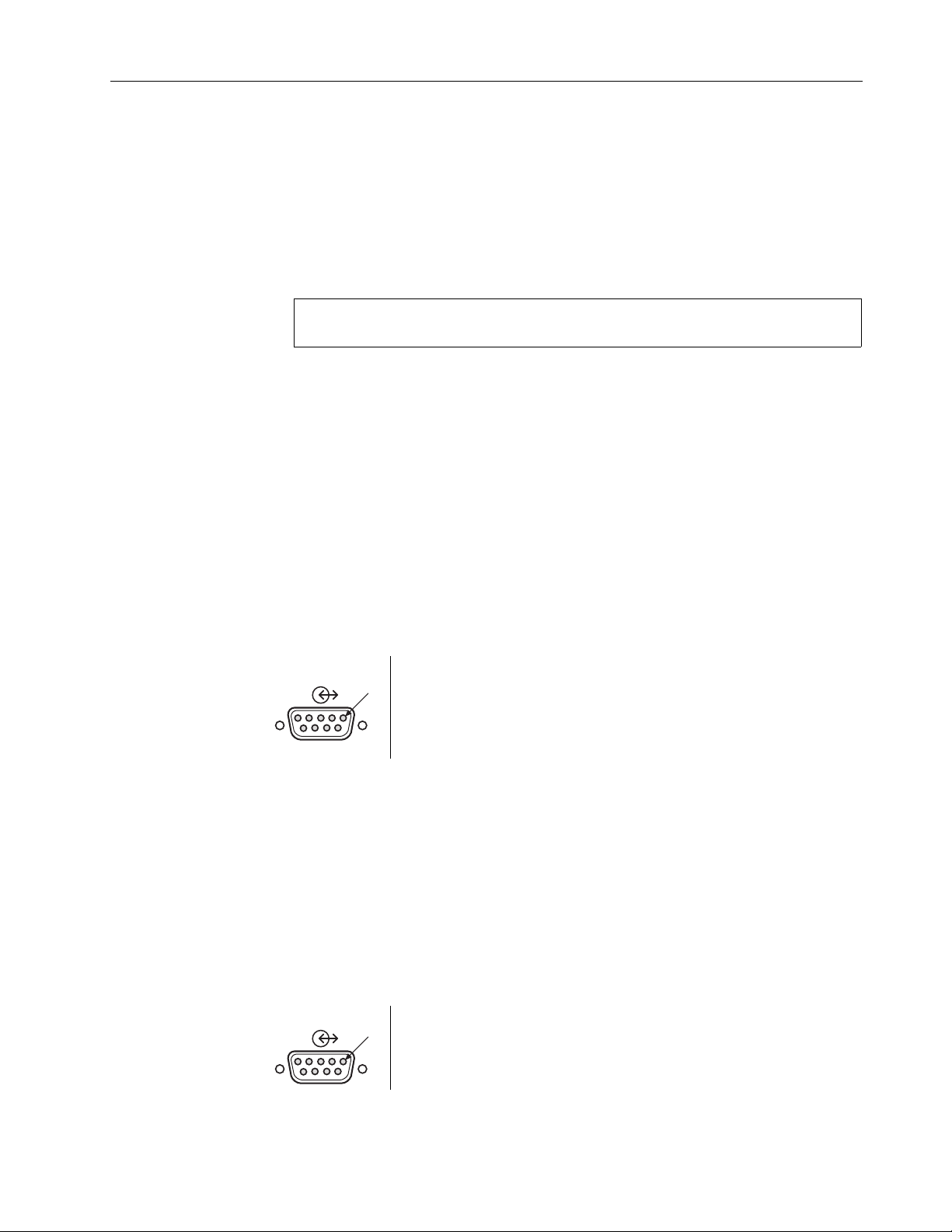

1.3.7 RS-232 connector

Connector type: 9-pin standard D, female

3900/3900P—pins 1 and 4 are not used.

3800—pins 1, 4, 6 and 9 are not used.

Serial output

RS 232

1

Data output every 2 seconds (auto-output mode) or 6 seconds (trend-output mode):

• (All monitors) SpO2, pulse rate, alarm limit violation messages, and displayed

alarm messages

• (3900/3900P) Relative Perfusion Index, time stamp, and custom patient label

Baud rate: 3800—9600 baud; 3900/3900P—9600, 19.2 K, 38.4 K, or 57.6 K baud

Full duplex; no parity

8 bits per character; 1 start bit; 1 stop bit

Handshaking: CTS/RTS

(3900/3900P) Analog output

2 = oximeter receives data

3 = oximeter transmits data

5 = signal ground

7 = RTS (Request To Send)

8 = CTS (Clear To Send)

RS 232

5 = signal ground

1

6 = SpO2 (0 to 1 Vdc ± 20 mV = 0 to 100% ± 2.0%)

9 = Pulse rate (0 to 1 Vdc ± 20 mV = 0 to 255 bpm ± 2.0%)

1- 1 3

3800/3900/3900P Technical Reference Manual

1.4 Precautions

Two types of precautions appear in this manual: Warnings and cautions.

• A WARNING indicates the possibility of injury to the patient or operator.

• A CAUTION indicates a condition that may cause equipment damage or

malfunction.

(3900/3900P) If you connect a modem, refer to the precautions contained in the

instructions that accompanied your modem.

1.4.1 Warnings

Battery replacement

To ensure proper operation, replace only with the recommended battery.

Failure of operation

If the oximeter fails any part of the checkout procedures or current leakage test,

remove it from operation until qualified service personnel have corrected the situation.

Data validity

Conditions that may cause inaccurate readings and impact alarms include interfering

substances, excessive ambient light, electrical interference, excessive motion, low

perfusion, low signal strength, incorrect sensor placement, poor sensor fit, and

movement of the sensor on the patient.

To prevent erroneous readings, do not use an inflated blood pressure cuff or arterial

blood pressure measurement device on the same limb as the oximeter sensor.

Electrical shock hazard

Measure the oximeter’s leakage current in accordance with applicable standards after

completing any repair procedure.

This equipment must be properly grounded.

• Electrical safety specifications (e.g., current leakage and ground resistance) can be

assured only when the oximeter is connected to a three-wire, grounded, receptacle

without the use of extension cords or adapters.

• If there is any doubt about the integrity of the AC power supply protective earth

conductor, operate the oximeter on internal battery power.

• Because the unit is not grounded when it is operating on battery power, do not

connect any equipment to the RS-232 port on the rear panel unless the unit is

connected to the AC power supply.

Before cleaning or repairing the monitor, turn it off and disconnect it from AC mains

power.

Fire/explosion hazard

Replace fuses only with fuses of the same type and voltage rating.

Do not use the monitor in the presence of any flammable anesthetic mixture.

1- 1 4

Patient safety

Never test or perform maintenance on the oximeter while it is being used to monitor a

patient.

Sensors

To prevent injury or equipment damage, use only oximeter sensors approved for use

with this oximeter. For complete information about the safe and appropriate use of a

sensor, consult the instructions for that sensor.

Discard a damaged sensor immediately. Do not repair a damaged sensor or use a

sensor repaired by others.

1.4.2 Cautions

General

US Federal law restricts this device to sale by or on the order of a licensed medical

practitioner.

Only qualified service personnel should perform the procedures described in this

manual.

Handle the monitor with care. Improper handling can cause damage or inaccurate

results.

1/Overview

Static sensitivity

Internal electronic components are susceptible to damage by electrostatic discharge.

To avoid damage when disassembling the oximeter, observe the standard precautions

and procedures for handling static-sensitive components.

(3900P ) To avoid damage to the print head from electrostatic discharge, take special

care when servicing the 3900P printer.

Sensors

Do not apply tension to the sensor cable; sensor damage may result.

Cleaning

Do not autoclave, pressure sterilize, or gas sterilize this oximeter.

Use cleaning solution sparingly. Do not soak or immerse the oximeter in liquid.

Excessive solution can flow into the oximeter and damage internal components.

When cleaning the display area, do not use abrasive cleaning compounds or other

materials that could damage the screen.

Do not use petroleum-based solutions, acetone solutions, or other harsh solvents to

clean the oximeter. These substances may damage the oximeter and cause a

malfunction.

(3900P ) Do not allow cleaning solution to get into the printer mechanism.

Disposal

Dispose of this medical device and its packaging according to local requirements.

Dispose of the battery, which contains lead and acid, through an approved hazardous

materials disposal facility.

1- 1 5

3800/3900/3900P Technical Reference Manual

1.5 Safety guidelines

Before you start any procedure that involves disassembly of the oximeter, review these

guidelines to ensure the proper and safe completion of the procedure.

WARNING: Patient safety. Never test or perform maintenance on the oximeter while it

is being used to monitor a patient.

WARNING: Electrical shock hazard. Before cleaning or repairing the monitor, turn it off

and disconnect it from AC mains power.

1. Power off and disconnect the unit from the AC power supply.

2. Disconnect the sensor from the unit.

3. Clean the unit—see section 1.5.1.

4. Read and follow each step of all test and repair procedures. Give special attention

to all warnings and cautions.

Important: After repairs are complete, test the unit as directed at the end of each

procedure to verify that it is functioning properly.

1.5.1 Cleaning

You must clean the oximeter,

• Before you start any procedure that involves disassembly of the oximeter.

• Before you send the oximeter for repair.

CAUTION: Cleaning

• Do not autoclave, pressure sterilize, or gas sterilize the oximeter.

• Use cleaning solution sparingly. Do not soak or immerse the monitor in liquid.

• When cleaning the display area, do not use abrasive cleaning compounds or other

• Do not use petroleum-based solutions, acetone solutions, or other harsh solvents

• To prevent damage to the 3900P printer, do not allow cleaning solution to get into

1. Turn off the oximeter and disconnect it from AC mains power.

2. Gently wipe the display panel with a cotton swab moistened with isopropyl

3. To clean the out er surface of the oximeter, use a soft cloth dampened with a mild

Excessive solution can flow into the monitor and damage internal components.

materials that could damage the screen.

to clean the oximeter. These substances may damage the oximeter and cause a

malfunction.

the printer mechanism.

alcohol (70 vol%).

soap and water solution or one of the following solutions:

1- 1 6

Mild detergent solution 0.5% sodium hypochlorite (bleach)

70% isopropyl alcohol Quarternary germicides (Virex®)

1.6% phenol (Sporicidin®) 3.4% glutaraldehyde (Cidex® Plus)

2/Theory of Operations

This chapter covers the theory of operations for the following components:

• Power supply and power inlet module

• System board

• Switch board

• Oximetry board

• Passive filtering

• 3900P printer interface

2.1 Power supply and power inlet module

The power supply converts power from an AC power source to +12 VDC. It also provides

the necessary isolation between the patient and the AC power supply. It is connected

to the system board for further conditioning.

The power inlet module contains the three-contact power connector and the fuses.

Block diagram

To AC power supply

Power inlet

module

Off-line switching

power supply

12 VDC

To system board

2- 1

3800/3900/3900P Technical Reference Manual

2.2 System board

The system board has two major components:

• Data management section

• Power management section

System board functions

• Condition power from the AC power supply and the battery.

• Charge the battery when supplied with a DC voltage from the power supply.

• Monitor language mode switch positions.

• Provide bi-directional communication through the RS-232 connector.

• Send data to the front panel for display.

• Monitor front panel button presses.

• Allow for software upgrades.

• Monitor and send commands to the oximetry board via a serial interface and a few

discrete digital lines.

• (3900/3900P) Send analog SpO2 and pulse rate data to analog outputs.

• (3900/3900P) Provide real-time clock capability.

• (3900P) Provide control for printer output.

2.2.1 System board data management

The digital section of the system board provides data management. The digital section

contains the microprocessor, SRAM, Flash memory, a software upgrade socket, the

RS-232 interface, mode switches, alarm signal generator, audio amplifier,

microprocessor supervision, 3900/3900P real-time clock capability, and 3900P printer

interface.

Block diagram

Mode switches

Microprocessor

supervisor

Background

debug

Microprocessor

Isolation

RS-232 connector

(3900/3900P)

Real-time clock

Static memory

Flash memory

Upgrade socket

Alarm tone

generator

To oximetry board

To front panel

Audio driver

Speaker

2- 2

(3900P) To printer board

2/Theory of Operations

Microprocessor

The microprocessor is a Motorola 68332 that operates at 16 MHz. It uses a crystal that

operates at 32.768 KHz. Several ports can be configured by software. A 16-channel timer

processing unit can be programmed to execute various timing functions, including a

serial communication port. A background debug feature allows full access to the

processor through a 10-pin connector. Communication to the oximetry board is

accomplished primarily through a dedicated serial port.

SRAM

The static RAM is 128 K x 8 bits. The SRAM is powered when the unit is in standby mode,

which allows data to be retained when the digital system is powered down.

Flash memory and software upgrade socket

The Flash memory (512 K x 8 bits) contains the application code software, which runs

the oximeter. An upgrade socket allows download of revisions to the application code

software. The software upgrade socket accepts a memory chip with the same pinout as

the onboard Flash memory. A super cap provides flash memory backup while the

battery is disconnected.

RS-232 connector interface

This port, which operates at 9600 baud (3800) or 9600, 19.2K, 38.4K, or 57.6K baud

(3900/3900P), allows for transmission of oximetry data to other serial devices. It has

optoisolators and an isolated power supply so that there is no ohmic connection

between the connector and the digital system.

(3900/3900P) Two analog outputs allow SpO2 and pulse rate outputs in analog form, at

0 to 1 volt full scale.

Mode switch

The mode switch settings determine the modes of operation for the oximeter, such as

the averaging mode, for example. The switches are ESD-protected by a 14-channel dual

SCR chip connected to the power supply. The positions of the switches are read directly

through 8 of the TPU channels.

Alarm signal and pulse tone generator

This is a sawtooth generator. The circuit produces a signal that is rich in harmonics. A

resistor in the feedback loop controls the slope of the rising edge while another resistor

controls the slope of the falling edge. The frequency is set to about 800 Hz. Volume is

controlled by the microprocessor using pulse width modulation (PWM). Another PWM

channel on the microprocessor generates pulse tones; the microprocessor controls the

frequency of this tone. Discrete logic is incorporated to produce an alarm tone at full

volume in the event that the microprocessor is not operating.

Microprocessor supervisor

This chip monitors the power supply, contains a watchdog, has battery switchover

circuitry, generates reset pulses, and disables the SRAM during power down. If the

power supply voltage is too low, this circuit holds the reset on the processor until the

correct voltage is restored. It also switches the SRAM supply power to the Vbatt input

and disables RAM when the supply voltage is low. If the microprocessor does not pulse

the watchdog input occasionally, the chip issues a reset pulse. It also enables the

alarm tones if the watchdog is active.

2- 3

3800/3900/3900P Technical Reference Manual

Audio amplifier

This is a single chip that amplifies the audio tones. It has a bipolar output that allows

for maximum volume with a single supply. The amplifier has a low-pass pole at 17.5

KHz to reduce noise which may be picked up at the input to the amplifier.

Front panel interface

Switches on the front panel are read via various discrete I/O lines on the processor.

They are scanned via an output port on the front panel circuit board (the switch board).

The numeric displays on the front panel are sent data via the serial peripheral interface

of the processor.

Background debug

A 10-pin connector allows direct connection to the microprocessor. All microprocessor

functions can be accessed through this interface.

Boot code and application code can be downloaded via this connector.

(3900/3900P) Real-time clock

This is a single chip connected to the microprocessor. It provides time, month, day, and

year for the display and for printed trend data. A super cap provides backup while the

battery is disconnected.

(3900P) Printer interface

A connector and port allow the microprocessor to control printer functions.

Handshaking lines synchronize the printer to the microprocessor. The microprocessor

directly controls the printhead patterns for text and graphic images.

2.2.2 System board power management

The power management section generates + 5 V, switches between the + 12 V and

battery supplies, charges and monitors the battery voltage, and controls power on and

standby modes.

Block diagram

AC monitor

+ 12 V

input

Battery charger

Battery

input

Battery voltage

monitor

+ 5 V supply

+ 5 V is generated by a buck-switching regulator that operates at 52 KHz. The input

voltage is between about + 6.7 and + 12 V. This supplies power to the digital section, the

front panel, and the oximetry board.

Switchover circuit

Front panel switch

+ VR regulator

+ 5 V switching

regulator

Power on /

standby control

Microprocessor

supervisor

Memory

2- 4

2/Theory of Operations

Battery charger

The battery charger is designed specifically for lead-acid batteries. If the battery

voltage is less than 6.52 V, the circuit charges the battery at a low current. After the

battery reaches voltage 6.52 V, it charges the battery at 625 mA. When the battery

reaches 9.8 V, the charger changes to a constant voltage charger. When the charging

current is less than 31 mA, the charger goes into a float state holding the battery

voltage at 9.4 V.

Battery monitor

The battery is monitored for low voltage and recharge. The low voltage trip point is set

at 7.3 V, and the recharge-battery-voltage trip point is set at 7.0 V. The low battery

signal is sent to the microprocessor. The recharge battery signal is latched with

discrete logic. In the event that a recharge battery condition is reached, the unit must

be connected to AC mains power to reset the recharge battery latch.

AC monitor

+ 12 V is used to indicate that the unit is connected to AC mains power. This signal is

level shifted to + 5 V and sent to the processor.

+ VR supply

+ VR is generated by a low power linear regulator set as about 4 V. This voltage is

routed to the microprocessor supervisor Vbatt input. It supplies power to the power

on/standby circuitry, SRAM, and the recharge battery latch when the unit is in standby

mode. It also supplies power to the real-time clock. This supply is backed up by a super

cap during periods when the battery is disconnected.

Power on/standby circuitry

The input to the + 5 V switching regulator is controlled by a P channel FET. The gate of

the FET is controlled by a transistor whose base is connected to a flip-flop. The state of

this flip-flop determines the on or standby state of the unit. The circuit senses when the

front panel power switch is depressed. When this switch is closed, a flip-flop is toggled.

If the unit was in standby, the unit changes to the on state. If the unit is on, the circuit

generates a power-down request. This signal then goes to the microprocessor.

After the microprocessor finishes any tasks deemed necessary, the microprocessor

issues a power-down command. This signal then clears both flip-flops and puts the unit

in the standby mode. In the event that the microprocessor does not respond with a

power-down command within about 800 ms, the circuit times out and clears the flipflops.

2- 5

3800/3900/3900P Technical Reference Manual

2.3 Switch board

The switch board provides the interface between the system board and the liquid

crystal display (LCD), the drive electronics for the light emitting diode (LED) numeric

displays, and the user interface switches. It also interfaces the bicolor alarm LED, the

power/standby switch, and the LCD contrast adjustment potentiometer.

Block diagram

To system

board

Alarm indicator Saturation display Graphic display

User buttonsPulse rate displayAC power indicator

The LCD is controlled by the system board over the data bus. A hardware line, RESET,

blanks the display. The user controls the contrast (or viewing angle) of the LCD by the

position of potentiometer R6.

The LED numeric displays are driven by an LED interface chip that is controlled by the

system board over a synchronous serial interface. The maximum intensity of the

displays is set by a resistor. One end of the resistor is controlled by a latch to allow the

LEDs to be blanked when the latch is reset.

The alarm LED is bicolor (red and yellow) and is controlled by two bits of a latch.

The mains power indicator is a green LED that is lit when the oximeter is plugged into

AC mains power.

The user interface switches are configured in a matrix and are scanned by the system

board.

The power/standby switch is a momentary contact switch that is wired through to the

system board.

Contrast adjust

2- 6

Loading...

Loading...