Page 1

Geeetech Prusa I3 pro W

User Manual

Page 2

Safety Instructions

Building the printer will require a certain amount of physical dexterity, common sense and a

thorough understanding of what you are doing. We have provided this detailed instruction to help

you assemble it easily.

However ultimately we cannot be responsible for your health and safety whilst building or

operating the printer, with that in mind be sure you are confident with what you are doing prior to

commencing with building or buying. Read the entire manual to enable you to make an informed

decision.

Building and operating involves electricity, so all necessary precautions should be taken and

adhered to, the printer runs on 12V supplied by a certified power supply, so you shouldn’t ever have

to get involved with anything over 12V but bear in mind there can still be high currents involved

and even at 12V they shouldn’t be taken lightly.

High temperatures are involved with 3D Printing, the Extrusion nozzle of the hot end can run about

230°C, the heated bed runs 110°C and the molten plastic extruded will initially be at around 200°C,

so special care and attention should be made when handling these parts of the printer during

operation.

Check the power input of the power supply unit. You can choose either 110V or 220V according to

the Power regulation in your country.

Tear off the yellow sticky note to check it. You can use a hard stick to reach into the power box and

switch it. (依旧保留吗)

We wouldn’t recommend leaving your printer running unattended, or at least until you are confident

to do so. We cannot be held responsible for any loss, damage, threat, hurt or other negligent result

from either building or using the printer.

Page 3

Content

1. Software Resources ..................................................................................................................... 1

1.1 Driver ................................................................................................................................. 1

1.2 Arduino IDE ....................................................Pogreška! Knjižna oznaka nije definirana.

1.3 EasyPrint 3D Installation and Configuration ....................................................................... 1

2. Hotbed Leveling .......................................................................................................................... 5

2.1Homing ............................................................................................................................... 5

2.2 Coarse Tuning of distance between the nozzle and the hotbed............................................. 6

2.3 Fine Tuning ........................................................................................................................ 7

3. Print Settings ............................................................................................................................... 8

3.1 Quick mode ........................................................................................................................ 8

3.2 Custom mode ..................................................................................................................... 9

3.2.1 Create a new configuration/setting ............................................................................ 9

3.2.2 Print settings ........................................................................................................... 10

4. Begin Printing ........................................................................................................................... 21

4.1 Load a Model File ............................................................................................................ 22

4.2 Print Setting...................................................................................................................... 22

4.3 Slicing .............................................................................................................................. 23

4.4 Stand-alone print with SD Card ........................................................................................ 24

4.4.1 Save Job ................................................................................................................. 24

4.4.2 Print ................................................................................................ ........................ 25

5. FAQ ........................................................................................................................................... 27

5.1 How to upgrade firmware? ............................................................................................... 27

5.2 How to change the motor direction in firmware? .............................................................. 30

5.3 User manual of Repetier Host ........................................................................................... 31

5.4 Possible causes for motor’s non-action ............................................................................. 31

5.5 Extruder does not work normally ................................................................ ...................... 31

5.6 The hotbed or extruder can not be heated .......................................................................... 31

5.7 LCD error: MAX/MIN TEMP error ................................................................ .................. 31

Page 4

5.8 No information or displaying black square on LCD .......................................................... 31

5.9 Time.h/endstop hit or other abnormalities ......................................................................... 31

Page 5

www.geeetech.com

ShenZhen GETECH

1

1. Software Resources

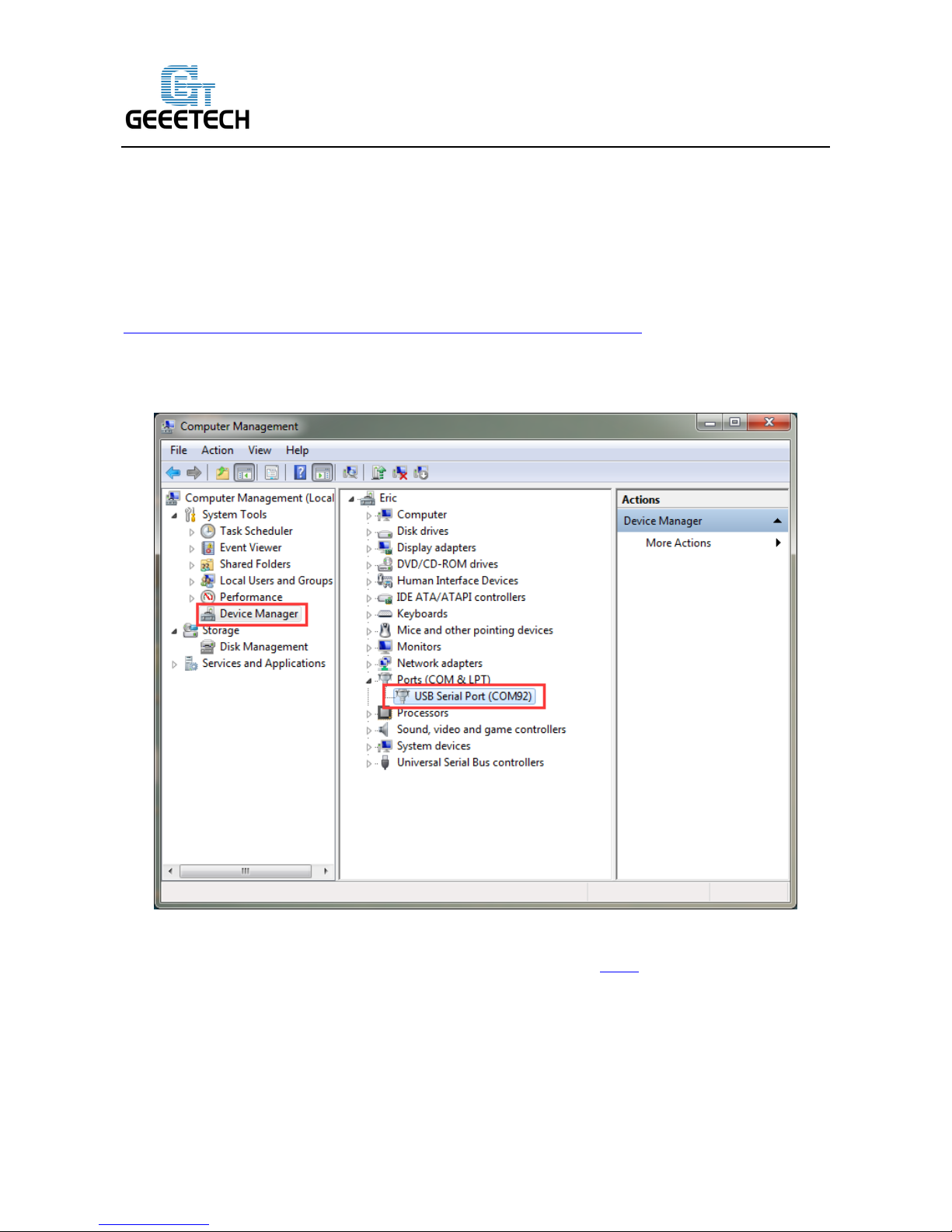

1.1 Driver

Connect the printer to computer with USB cable, the motherboard driver installer will automatically

appear. If not, you can download FT232RQ here, which is the driver of GT2560:

http://www.geeetech.com/wiki/index.php/Prusa_I3_X#Install_the_drivers

Download and install, you can find the corresponding serial port in the Windows "Device

Manager":

If the driver cannot be automatically installed, please download the FTDI or find it in the SD card

and then manually install it.

1.2 EasyPrint 3D Installation and Configuration

EasyPrint 3D is a piece of 3D printing software, engineered for Geeetech products. In addition, it is

Page 6

www.geeetech.com

ShenZhen GETECH

2

also compatible with other printers.

Step1. Install EasyPrint 3D.

You can download it here: http://www.geeetech.net/firmware/EasyPrint.msi

Step2. After the installing is finished, find the icon EasyPrint 3D. Double click it to start the

software.

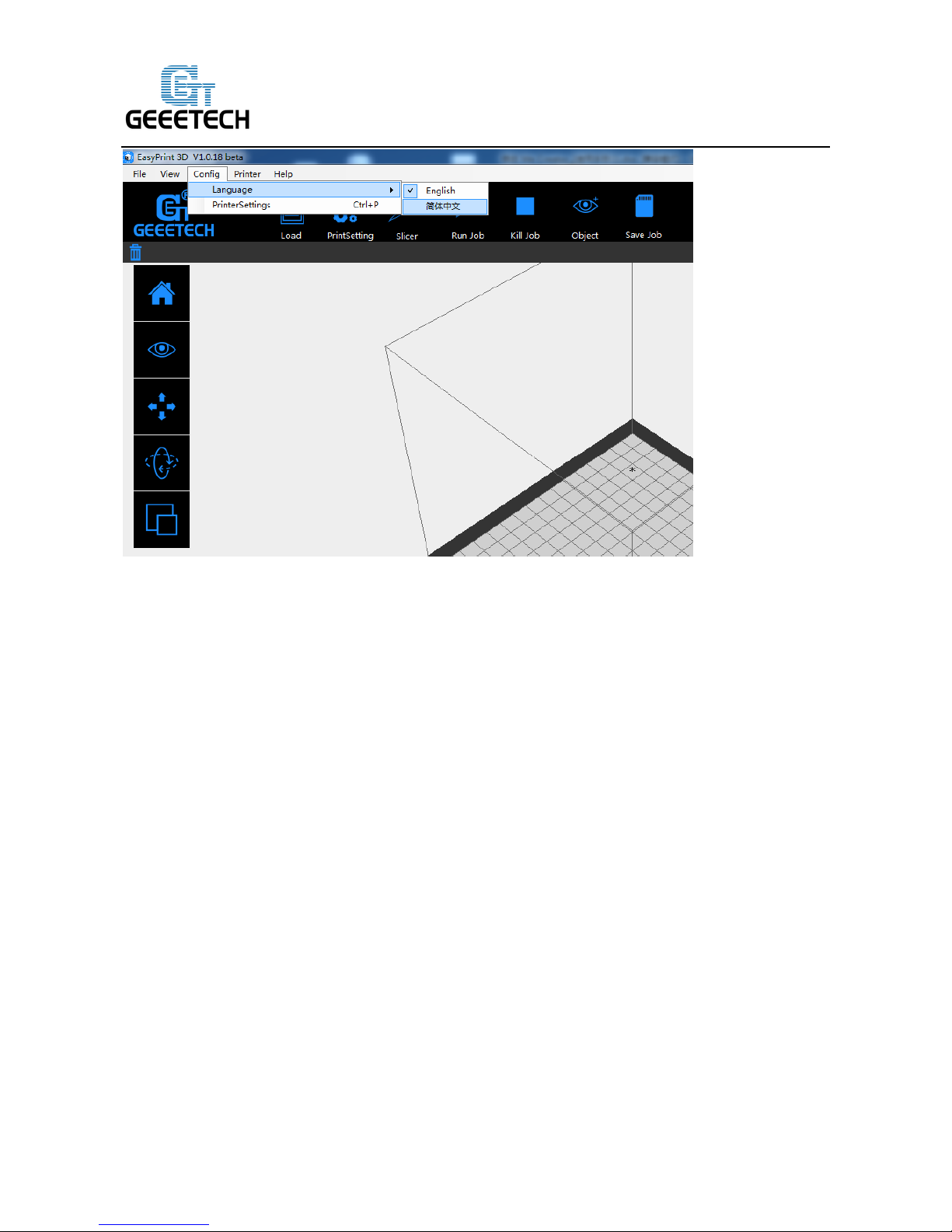

Then you can choose English in Config>Language.

Page 7

www.geeetech.com

ShenZhen GETECH

3

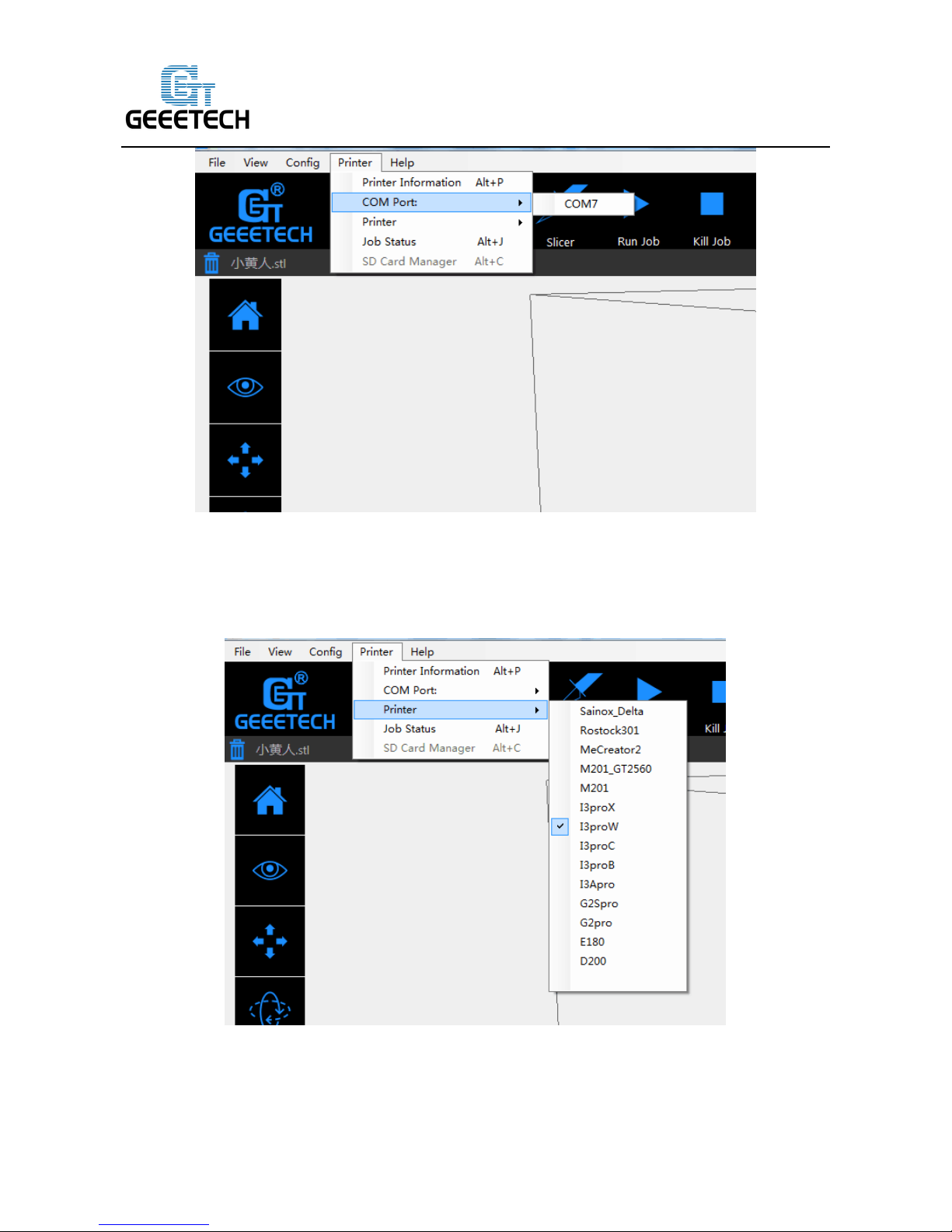

Step 4. Select the COM Port

Click the Printer menu, and then select the corresponding COM Port.

* The COM Port refers to the port that can be used for connecting the printer and your

computer, identical to the USB serial in the device manager.

In case you could not find the COM Port, make sure that the power switch of your printer is

turned on and the USB cable is well connected with the computer.

Page 8

www.geeetech.com

ShenZhen GETECH

4

Step 5. Select the Printer

Click the Printer menu, and then choose the proper printer type: Pro W

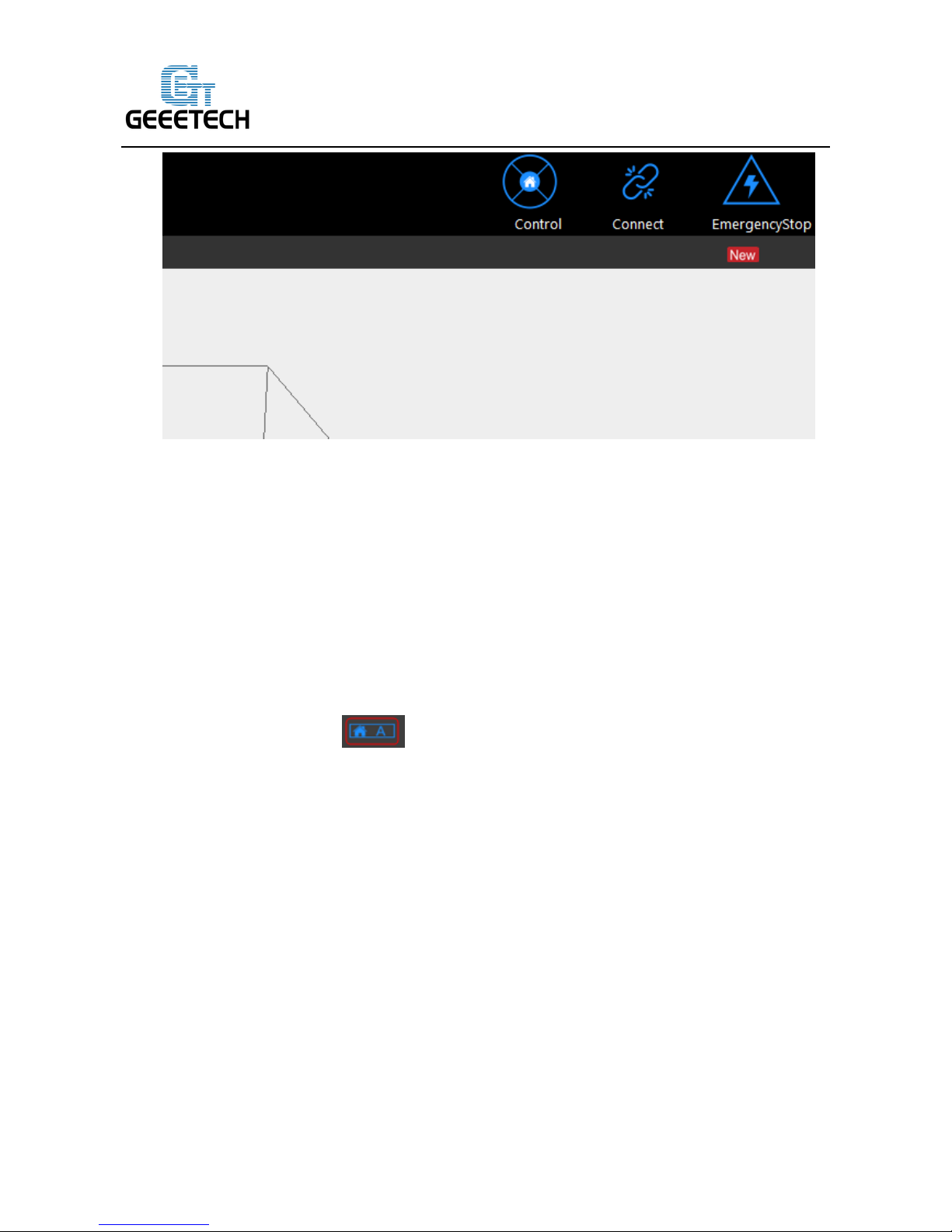

Click the Connect button on the top right. You could observe the real-time status of the printer

on the bottom of the software interface.

Page 9

www.geeetech.com

ShenZhen GETECH

5

2. Hotbed Leveling

Before printing, we need to do hotbed leveling. Only after this step can the quality of printed parts

get improved. Otherwise the un-leveling gap between the hotbed and extrusion head will affect the

filament adhesion to the hotbed, which would cause poor print quality or even not printing.

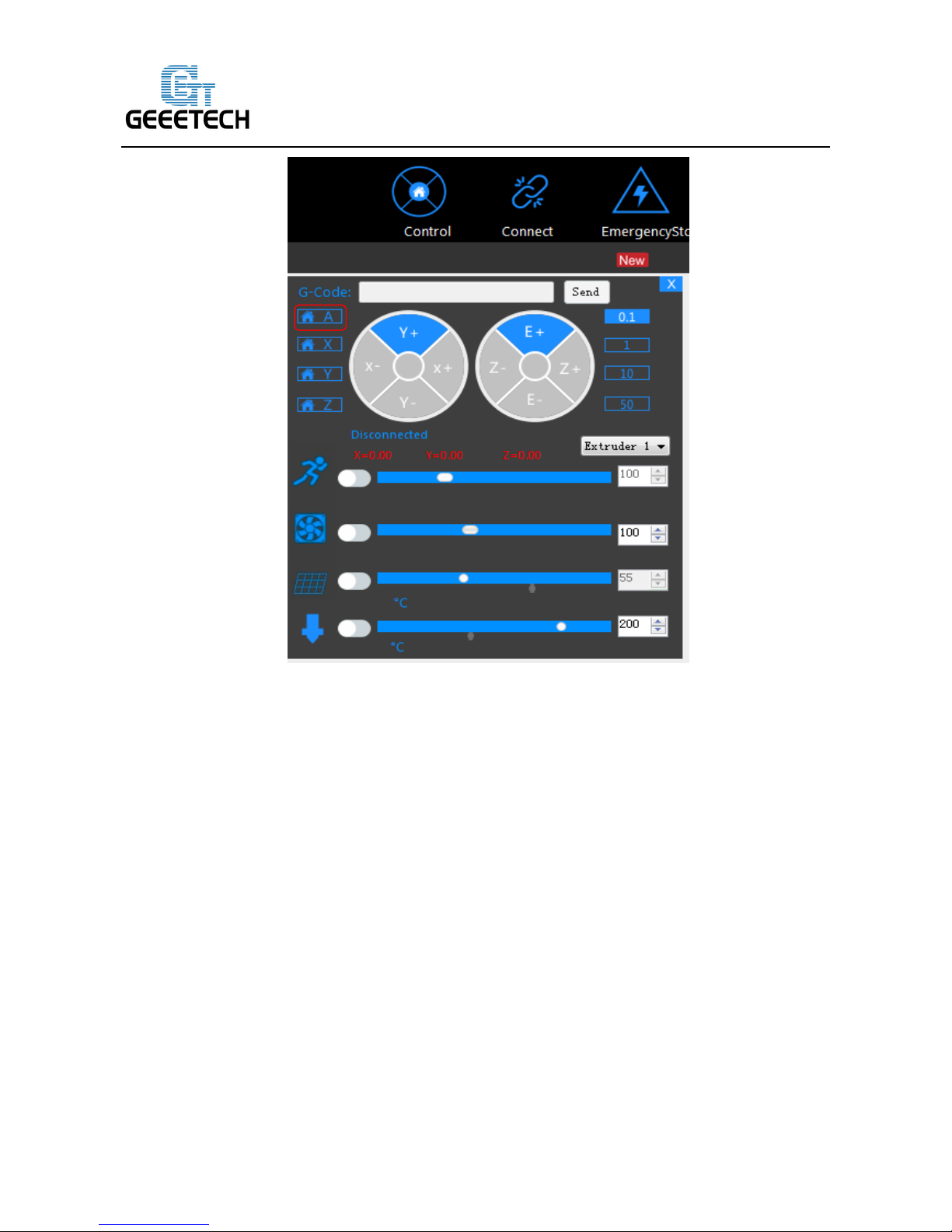

2.1 Homing

Home the printer by clicking

Page 10

www.geeetech.com

ShenZhen GETECH

6

4.

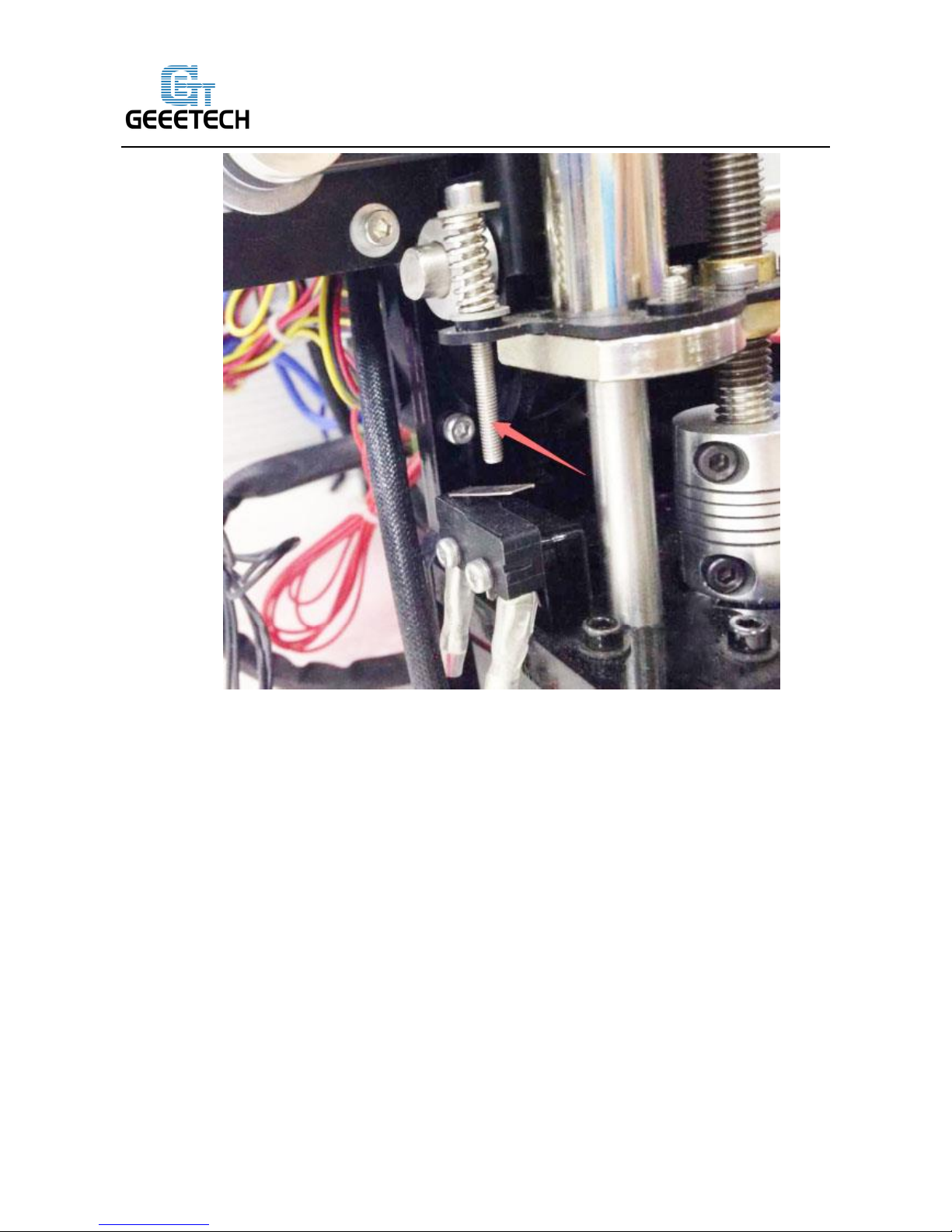

2.2 Coarse Tuning of distance between the nozzle and the hotbed

*If the nozzle is far from the surface of hotbed, loosen the M3x35mm screw to decrease the

distance between the nozzle and the hotbed.

*If the nozzle is too close to the surface of hotbed, tighten the M3x35mm screw to increase the

distance between the nozzle and the hotbed.

You may need to calibrate for many times at this step.

The recommended distance between the nozzle and the hotbed is 0.5-1mm.

Page 11

www.geeetech.com

ShenZhen GETECH

7

2.3 Fine Tuning

After the initial adjustment, home the printer. Disable the stepper motors via LCD control panel,

manually move the extruder to the four corners of the hot bed and fine-tune the wing nut at each

corner to level the distances between the extrusion head and four corners. During adjustment, you

can put a piece of A4 paper (half fold it) between the nozzle and hotbed. If you can feel a bit friction

pulling the paper back and forth, the distance is proper.

After finishing the adjustment of four corners, the entire leveling process is done. You can also

move the extruder to the center of hotbed to verify leveling outcome.

Page 12

www.geeetech.com

ShenZhen GETECH

8

3. Print Settings

EasyPrint 3D provides two print setting modes: quick mode and custom mode. The [quick] mode is

designed for entry-level users, while the [custom] mode is tailored for expert user with finer

printing parameters.

3.1 Quick mode

Choose [quick] tab. Here, we have prepared 3 printing quality settings for you.

Quality

Choose Low, Standard, or High quality to specify the surface quality of your 3D print.

• Objects sliced with the High quality profile will have finer layers and will print more

slowly.

• Objects sliced with the Standard quality profile will be printed using the default settings.

• Objects sliced using the Low quality profile will be printed with thicker layers and will

print faster.

Infill: The density of the infilling structure.

Page 13

www.geeetech.com

ShenZhen GETECH

9

Extruder temperature: Different filament requires different temperature for extruders; please

refer to the suggested temperature.

Layer height: the thickness of each layer. You can leave it as default.

Supports

Select this checkbox to have your object printed with support structures. EasyPrint 3D will

automatically generate supports for any overhanging sections of your object. Supports will be easily

removable once you remove your finished object from the build plate.

When you have finished the setting process, click [Apply]. The current settings will be used to slice

your model next time you print or export a print file.

3.2 Custom mode

For advanced users who want to exert more sophisticated control over the whole printing

process, EasyPrint 3D provides a series of parameters for you to engineer the printing configuration.

3.2.1 Create a new configuration/setting

To customize settings, you need to create a new setting first. Click the [create new conf.] tab

and enter the name of new configuration in the textbox. Click [Ok].

Page 14

www.geeetech.com

ShenZhen GETECH

10

3.2.2 Print settings

Choose the [custom] tab to enjoy the sophisticated print settings.

1) Accuracy:

a. Layer Height:

Page 15

www.geeetech.com

ShenZhen GETECH

11

The layer height is one of the most often adjusted settings. It is the thickness of one printed

layer (in mm). With a thinner layer height you will increase the quality of the print, leading to a

smoother surface and more detail visible in the Z-direction (height) of the model. On the other hand,

by using thicker layers you can decrease the print time substantially.

b. Nozzle diameter: showing the diameter of the current nozzle.

c. Solid layers: The loops needed to finish just one layer.

d. Perimeter: The loops needed to finish printing one layer to make the printout more solid and the

surface finish smoother.

2) Skirt:

A skirt is a line printed around the object on the first layer, but not connected to the object.

This helps prime the extrusion and can also be a good check for bed leveling before the print starts

and it can ensure that the material is flowing smoothly from the extruder before it starts on the

Page 16

www.geeetech.com

ShenZhen GETECH

12

model proper.

a. Loops: The number of skirt lines printed around the model. One loop is usually sufficient.

b. Distance from object: The distance between the object and the skirt. The default of 6mm is

usually sufficient.

c. Skirt height: The number of layers to lay down a skirt for. For ensuring the material is

flowing smoothly, one layer is sufficient, however the skirt function can also be used to build walls

around the object in case it should be protected from draughts.

3) Retraction:

Page 17

www.geeetech.com

ShenZhen GETECH

13

Retraction is used at the places in a print where the printer has to do a travel move between

two printed parts. Without retraction extruded material will hang between the parts. This means that

the filament is pulled back by the feeder, so that it doesn’t leak from the nozzle during the travel

moves. By using retraction, “stringing” (thin threads of plastic in between the printed parts) is

prevented, resulting in a much cleaner final model. You have to be careful with flexible materials or

models that require a lot of retractions, as that might lead to grinding of the filament.

a. Length: The number of millimeters to retract. Note that the measurement is taken from the

raw filament entering the extruder. A value of between 1 and 2mm is usually recommended.

Bowden extruders may need up to 4 or 5mm due to the hysteresis introduced by the tube.

b. Lift Z: Raises the entire extruder on the Z axis by that many millimeters during each travel.

This can be useful to ensure the nozzle will not catch on any already laid filament; however it is

usually not necessary and will slow the print speed. A value of 0.1mm is usually sufficient.

c. Speed: The speed at which the extruder motor will pull back the filament. The value should

be set to as quick as the extruder can handle without skipping steps, and it is worth experimenting

with this value to find the quickest retraction possible.

4) Infill:

Page 18

www.geeetech.com

ShenZhen GETECH

14

a. Fill Density: The infill density defines the amount of plastic used inside the print. A higher

infill density means that there is more plastic on the inside of your print, leading to a stronger object.

An infill density around 20% is used for models with a visual purpose; higher densities can be used

for end-use parts.

c. Fill angle: By default the infill pattern runs at 45° to the model to provide the best adhesion

to wall structures. Infill extrusions that run adjacent to perimeters are liable to delaminate under

stress. Some models may benefit from rotating the fill angle to ensure the optimal direction of the

extrusion.

d. Fill Pattern: It is the pattern of filling shape which effects printing duration.

EasyPrint 3D offers seven infill patterns, including four regular flavors, and three more exotic

Page 19

www.geeetech.com

ShenZhen GETECH

15

ones. The numbers on the right of each figure are a rough estimate of material used and time taken

for a simple 20mm cube model. Note that this is only indicative, as model complexity and other

factors will affect time and material.

1. Line :

350.57mm/5m: 23s

2. Rectilinear

344.51mm/5m: 20s

3. Concentric

344.51mm/5m: 20s

4. Hilbert Curve

Page 20

www.geeetech.com

ShenZhen GETECH

16

332.82mm /5m: 28s

5. Archimedean Chords

333.66mm /5m: 27 s

6. Octagram Spiral

318.63mm/5m: 15 s

7. Honeycomb

362.73mm /5m: 39s

Page 21

www.geeetech.com

ShenZhen GETECH

17

5) Filament:

a. Diameter:

In this field you can enter the diameter of the filament, so that EasyPrint 3D could calculate the

extrusion rate correctly. The most commonly used filament diameters are 1.75mm and 3mm, but it

might be necessary to change this setting when using filament from other suppliers.

b. Extrusion temperature:

This is the temperature of the nozzle that is used during printing. The extrusion temperature

can differ per material. PLA, for example, needs a printing temperature of approximately 180

-230 °C, while ABS needs a higher temperature of 210 - 250 °C to properly extrude the plastic.

c. Hotbed temperature

For printers with a heated bed, the temperature of the heated bed can also be set here. We

recommend using 60 °C for PLA and 90 °C for ABS to ensure that the plastic sticks well to the

build plate.

6) Speed:

Page 22

www.geeetech.com

ShenZhen GETECH

18

The print speed defines at which speed (in mm/s) the print head moves while printing. Based

on this setting, EasyPrint 3D will also calculate how fast the filament must be extruded. A higher

print speed will lead to a shorter print time. But keep in mind that increasing the print speed means

that you might have to increase the temperature as well, to ensure the plastic is properly melted.

Although you can choose one overall print speed for the complete print, it’s also possible to

use different print speeds for specific parts of the print:

a. Max/Min print speed: This parameter defines the max/min speed [60-100mm/s] at which

the printer runs.

b. Travel feed rate: This is the speed at which the print head moves when it’s not extruding,

that is, when the print head is moving from one point to another. A higher travel speed decreases the

chance of filament leaking from the nozzle, producing a cleaner object. On the other hand, a very

high speed means that the nozzle can hit an already printed part so fast that it might be damaged or

deformed by the hot nozzle. This can be prevented by using lift z when retracting though.

c. First layer speed: With this setting you can specifically change the speed for the first layer

of the print. By default a low speed is used for the bottom layer, so that the material sticks well to

the build plate on the first layer. As mentioned in the above section, the first layer is important to lay

down correctly, and a slower pace helps enormously. Setting a value of 50%, or even less can really

help.

Page 23

www.geeetech.com

ShenZhen GETECH

19

d. Perimeter feed rate: The speed at which the walls are printed. You can also set the speed for

the outer and inner wall separately. Printing the outer wall a bit slower usually results in a better

surface finish.

e. Perimeter feed rate: The speed of printing the wall. You can set the speed of printing the

exterior wall and the interior wall respectively. Usually, printing the exterior wall at a low speed

will bring smooth surface for your final product.

f. Infill feed rate: The speed at which the infill material is printed. Since (visual) quality of

the infill is not important, you could use a higher speed for the infill. But keep in mind that this

might affect the strength of your print.

g. Solid infill speed: The speed at which the top layers are printed. A lower speed increases

the reliability of closure of the top layers, especially on large area prints.

7) Support:

Page 24

www.geeetech.com

ShenZhen GETECH

20

Generally, most 3D models will print with overhanging parts by up to a certain degree. The

angle is determined by several factors, most notably layer height and extrusion width, and is usually

around 45°. For models with larger overhangs, a support structure may have to be printed below it.

This incurs the use of more material, longer print times, and post-printing clean-up.

support (the blue part)

a. Generate support material

Some models have overhanging parts, which means that parts of the model float mid-air when

you would print the model. In this case you must use a support structure under the model to prevent

the plastic from falling down. This can be achieved by generating support material. Select this

Page 25

www.geeetech.com

ShenZhen GETECH

21

checkbox to have your object printed with support structures.

b. Extruder

If you are printing with dual extruder, you can select one of them to print the support

material.

c. Pattern

There are different patterns available for printing support structures, resulting in sturdiness or

the easiness to remove the support. You can choose from the following patterns.

(1) Honeycomb (2) Rectilinear

d. Pattern Spacing

Pattern Spacing determines the distance between support lines, and is akin to infill density

apart from being defined only in mm. The adjustment of this attribute by taking into account the

width of the support extrusion and the amount of support material will adhere to the object.

Care should be taken to choose a support pattern which matches the model, where the support

material attaches perpendicularly to the wall of the object, rather than in parallel, so it will be easy

to remove. If the support structure does run along the length of a wall, the Pattern Angle option

allows the direction of the support lines to be rotated.

Now all the parameters are set. Click [Apply] and [OK].

4. Begin Printing

So far, all the preparatory work is completed. The next step is to import the model file for slicing

and printing. For 3D printer, the file format of the model is generally .stl file. We can download for

free and print those models which are shared online, and you can also design your own creative

Page 26

www.geeetech.com

ShenZhen GETECH

22

objects for printing. Here we print a simple plate.

4.1 Load a Model File

Click [load] to load a.stl file from your computer, or you can drag it to the 3D view window. Now

you would see your model at the center of a gray rectangle, the representation of your 3D printer’s

build plate. Then you can use the tools on the left to edit your model.

4.2 Print Setting

Making reference to the setting procedures in chapter 5, you can choose the simple [quick] mode or

the sophisticated [custom] mode to customize your printing quality.

Page 27

www.geeetech.com

ShenZhen GETECH

23

4.3 Slicing

After loading the model file and adjusting printing parameters, you can click the [slicer] icon to

slice. It will take a while; the slicing time depends on the size of the model.

Upon slicing, you get the sliced .gcod file.

Page 28

www.geeetech.com

ShenZhen GETECH

24

When you are ready to print your model, click [Run job] to embark on your printing journey.

4.4 Stand-alone print with SD Card

If you want to print stand-alone , you can save the .gcode file in SD card for printing.

Note: The printer only recognizes .gcode file in the SD card, and the file can not be placed in any

folder!

Steps are as follows:

4.4.1 Save Job

Click [Save job] for SD Print, and select the [save] button in the dialog box.

Page 29

www.geeetech.com

ShenZhen GETECH

25

4.4.2 Print

Insert the SD card into the SD card slot at the back of the LCD control panel, and choose the

corresponding .gcode to print.

Press the knob on LCD, rotate the knob to enter the main menu and choose Print from SD option.

Choose corresponding .gcode file to begin printing.

Page 30

www.geeetech.com

ShenZhen GETECH

26

Heating

When heating is completed, it begins printing automatically.

Page 31

www.geeetech.com

ShenZhen GETECH

27

5. FAQ

If you encounter any problems during use, you can come to our forum:

http://www.geeetech.com/forum/, and there are detailed solutions answer in the forum. Common

problems are as follows:

5.1 How to upgrade firmware?

EasyPrint 3D provides all the users with online service of upgrading firmware to guarantee

perfect printing performance.

The specific method is as follows:

1. Connect your GEEETECH 3D printer to the computer with the USB cable.

2. Turn the printer on.

3. In EasyPrint 3D, choose the COM port and the printer type.

4. Click ’help’> 'Update firmware'.

After clicking the [upgrade firmware] tab, a window will pop up with the information of

Page 32

www.geeetech.com

ShenZhen GETECH

28

printer type and port, the current firmware version installed, the available version and the update

summary of the latest firmware. Take the printer D200 as an example:

Click update and confirm updating, the progress bar will turn green, the firmware will be

updated automatically. This process may take some time.

When the upload is complete the message ‘update sucess’ will be displayed.

Page 33

www.geeetech.com

ShenZhen GETECH

29

Click ‘ok’ and ‘Close’ on the windows to complete the firmware upgrade.

OR you can upgrade firmware by the following ways:

The way of uploading firmware, please refer to:

http://www.geeetech.com/forum/viewtopic.php?f=13&t=17181

Firmware download address, please refer to:

http://www.geeetech.com/forum/viewtopic.php?f=10&t=17046

Page 34

www.geeetech.com

ShenZhen GETECH

30

Common parameters settings of firmware, please refer to:

http://www.geeetech.com/forum/viewtopic.php?f=13&t=17194

5.2 How to change the motor direction in firmware?

In the configuration.h tab of firmware, find the following codes. Change the true of corresponding

axis into false or false into true, and save the firmware and burn into the printer. ( Because you don’t

know the firmware which has been burned by mother board is true or false, it may be necessary to

burn both of the two parameters.)

#define INVERT_X_DIR true

#define INVERT_Y_DIR false

#define INVERT_Z_DIR true

#define INVERT_E0_DIR false

Page 35

www.geeetech.com

ShenZhen GETECH

31

5.3 User manual of Repetier Host

For detailed user manual of Repetier Host, please refer to Wiki:

http://www.geeetech.com/wiki/index.php/Repetier-Host

5.4 Possible causes for motor’s non-action

http://www.geeetech.com/forum/viewtopic.php?f=13&t=17038

5.5 Extruder does not work normally

http://www.geeetech.com/forum/viewtopic.php?f=13&t=17097

5.6 The hotbed or extruder can not be heated

http://www.geeetech.com/forum/viewtopic.php?f=13&t=17039

5.7 LCD error: MAX/MIN TEMP error

http://www.geeetech.com/forum/viewtopic.php?f=13&t=17030

5.8 No information or displaying black square on LCD

http://www.geeetech.com/forum/viewtopic.php?f=13&t=17040

5.9 Time.h/endstop hit or other abnormalities

http://www.geeetech.com/forum/viewtopic.php?f=13&t=17037

Loading...

Loading...