Page 1

1

Geeetech Aluminum Prusa I3

User Manual

Page 2

2

Safety Instructions

Building the printer will require a certain amount of physical dexterity, common sense and a

thorough understanding of what you are doing. We have provided this detailed instruction to help

you assemble it easily.

However ultimately we cannot be responsible for your health and safety whilst building or

operating the printer, with that in mind be sure you are confident with what you are doing prior to

commencing with building or buying. Read the entire manual to enable you to make an informed

decision.

Building and operating involves electricity, so all necessary precautions should be taken and

adhered to, the printer runs on 12V supplied by a certified power supply, so you shouldn’t ever have

to get involved with anything over 12V but bear in mind there can still be high currents involved

and even at 12V they shouldn’t be taken lightly.

High temperatures are involved with 3D Printing, the Extrusion nozzle of the hot end can run

about 230°C, the heated bed runs 110°C and the molten plastic extruded will initially be at around

200°C, so special care and attention should be made when handling these parts of the printer during

operation.

Check the power input of the power supply unit. You can choose either 110V or 220V

according to the Power regulation in your country.

We wouldn’t recommend leaving your printer running unattended, or at least until you are

confident to do so. We cannot be held responsible for any loss, damage, threat, hurt or other

negligent result from either building or using the printer.

Page 3

www.geeetech.com

ShenZhen GETECH CO.,LTD

1

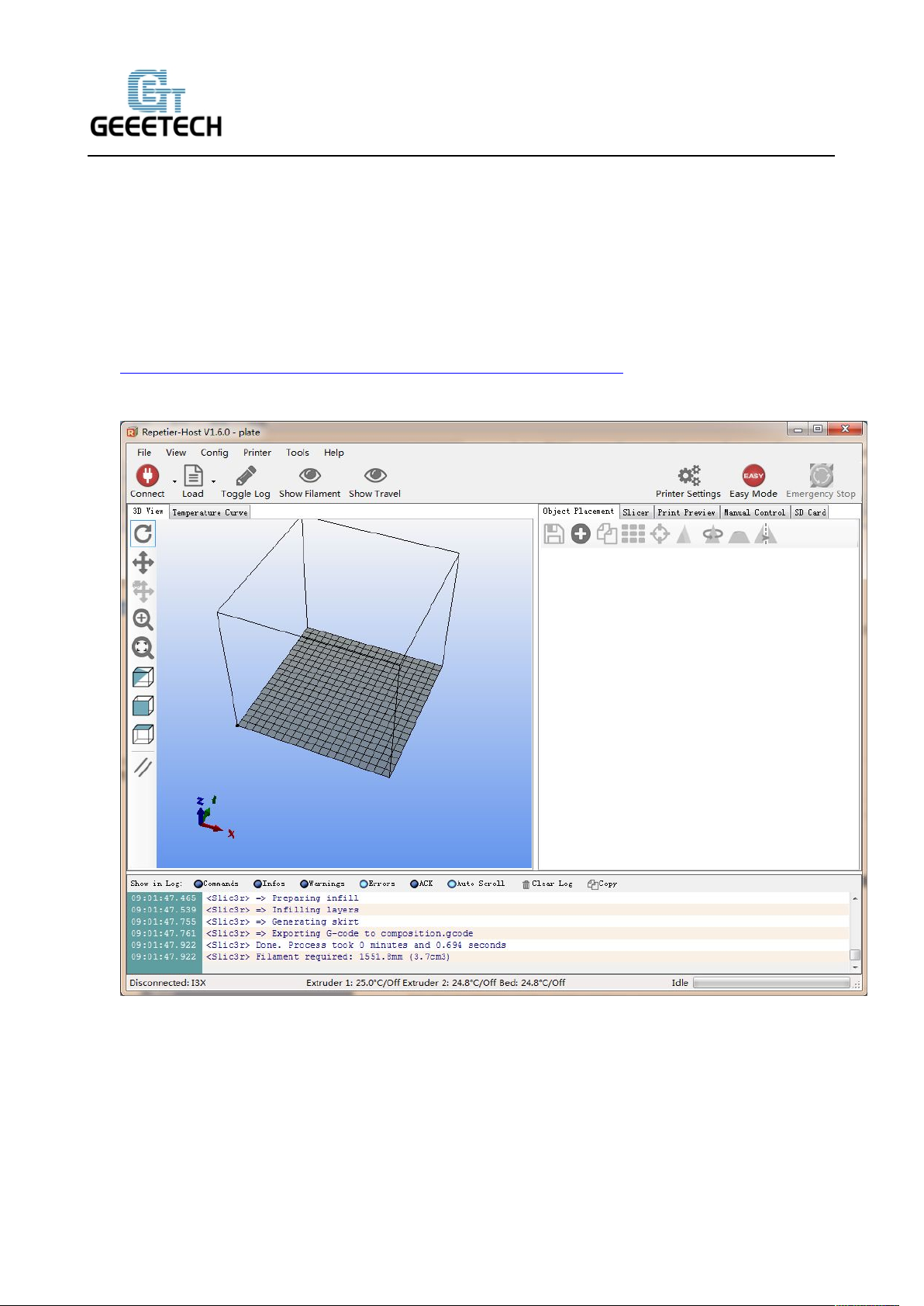

1 Software resources

1.1 Printer control software Repetier-Host

We use the latest Repetier host V1.6.0 as the printer control software, link for downloading:

http://www.geeetech.com/wiki/index.php/Repetier-Host#Download

After downloading and installation, it can be used.

Page 4

www.geeetech.com

ShenZhen GETECH CO.,LTD

2

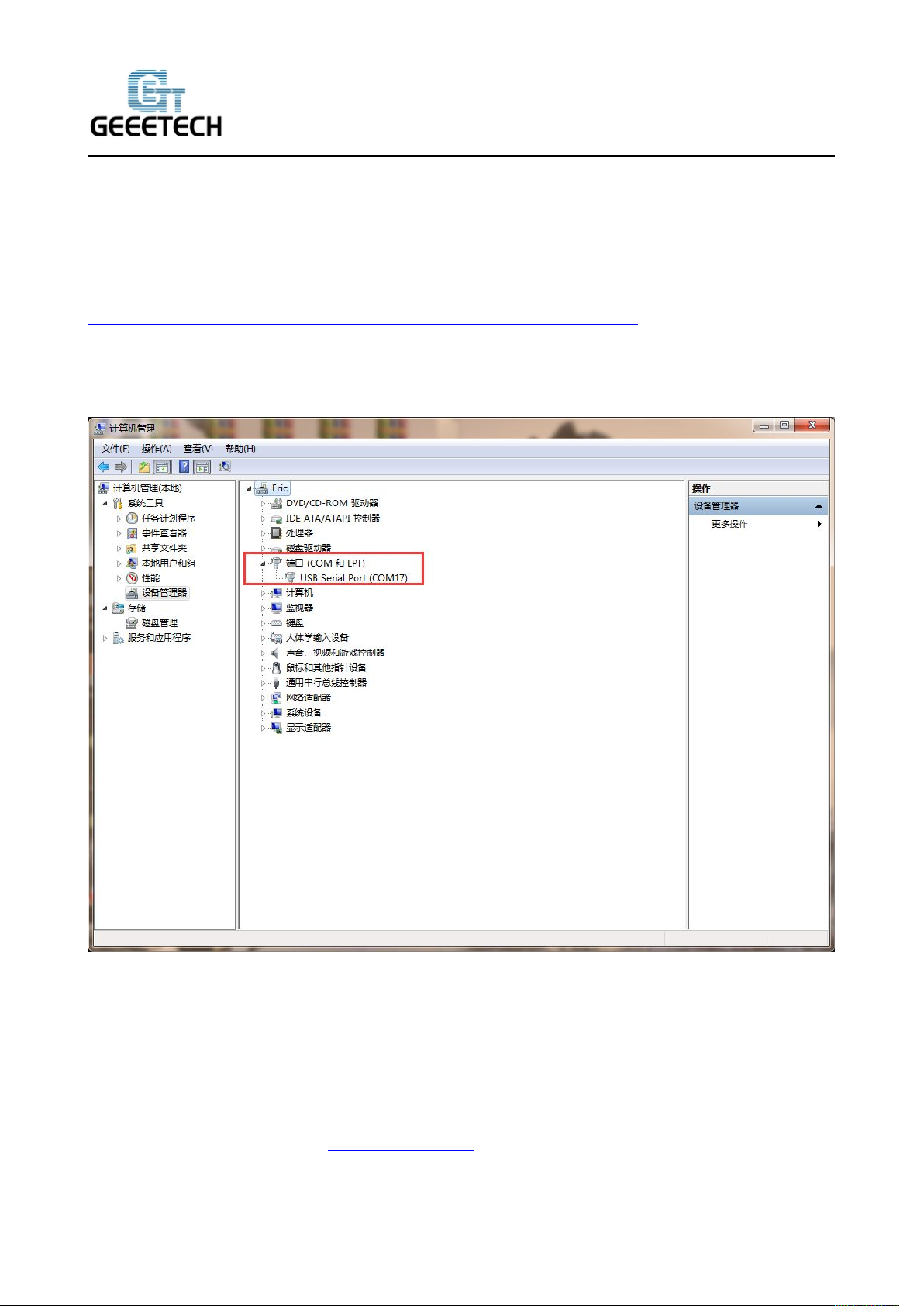

1.2 Driver

Connect the printer to computer with USB cable, the motherboard driver installer will automatically

appear. If not, you can download FT232RQ here, which is the driver of GT2560:

http://www.geeetech.com/wiki/index.php/Prusa_I3_X#Install_the_drivers

Download and install, you can find the corresponding serial port in the Windows "Device

Manager":

1.3 Arduino IDE

In the process of using the printer you may need to re-upload the firmware, and the software you

need to use is Arduino.

About how to upload firmware, please refer to FAQ.

Page 5

www.geeetech.com

ShenZhen GETECH CO.,LTD

3

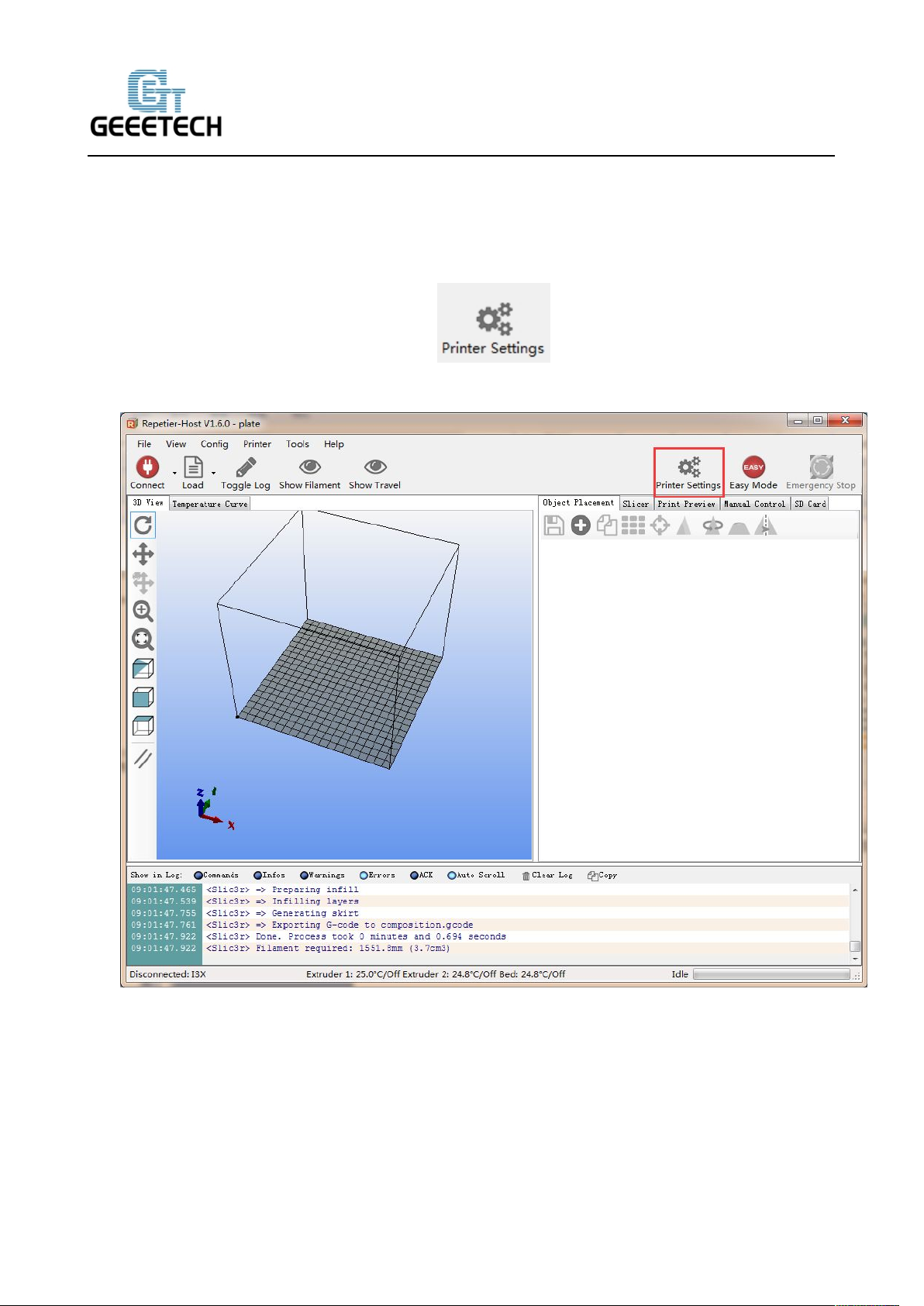

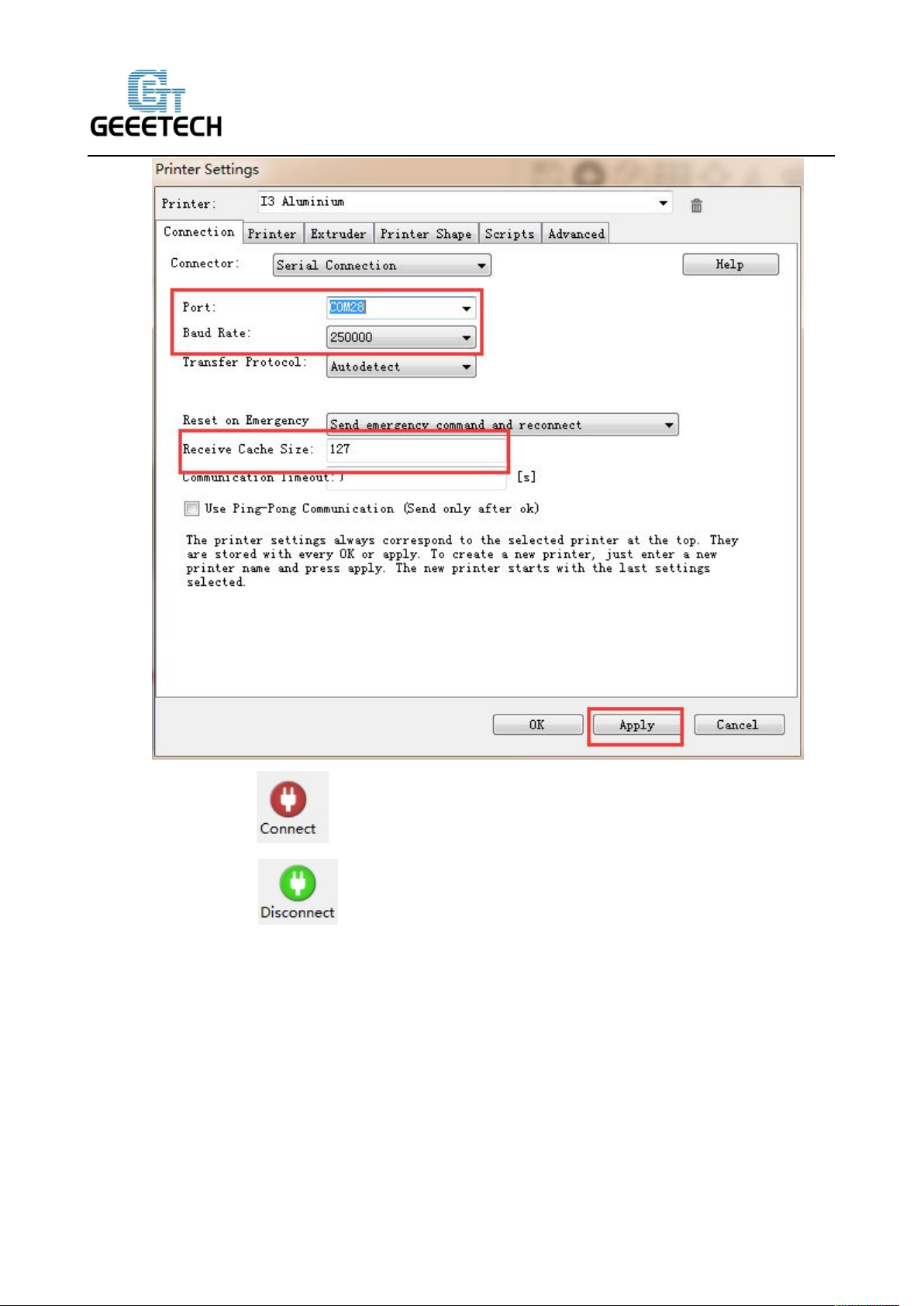

2 Connect the printer

After the above software is installed, we can connect the printer to the computer. Plug the USB into

the computer, open Repetier host, click the icon in the top right corner, and the

dialog box of printer settings will appear.

Select corresponding COM port of the printer and baud rate 250,000 in the dialog box. Click Apply

after the setting. Shown as below.

Page 6

www.geeetech.com

ShenZhen GETECH CO.,LTD

4

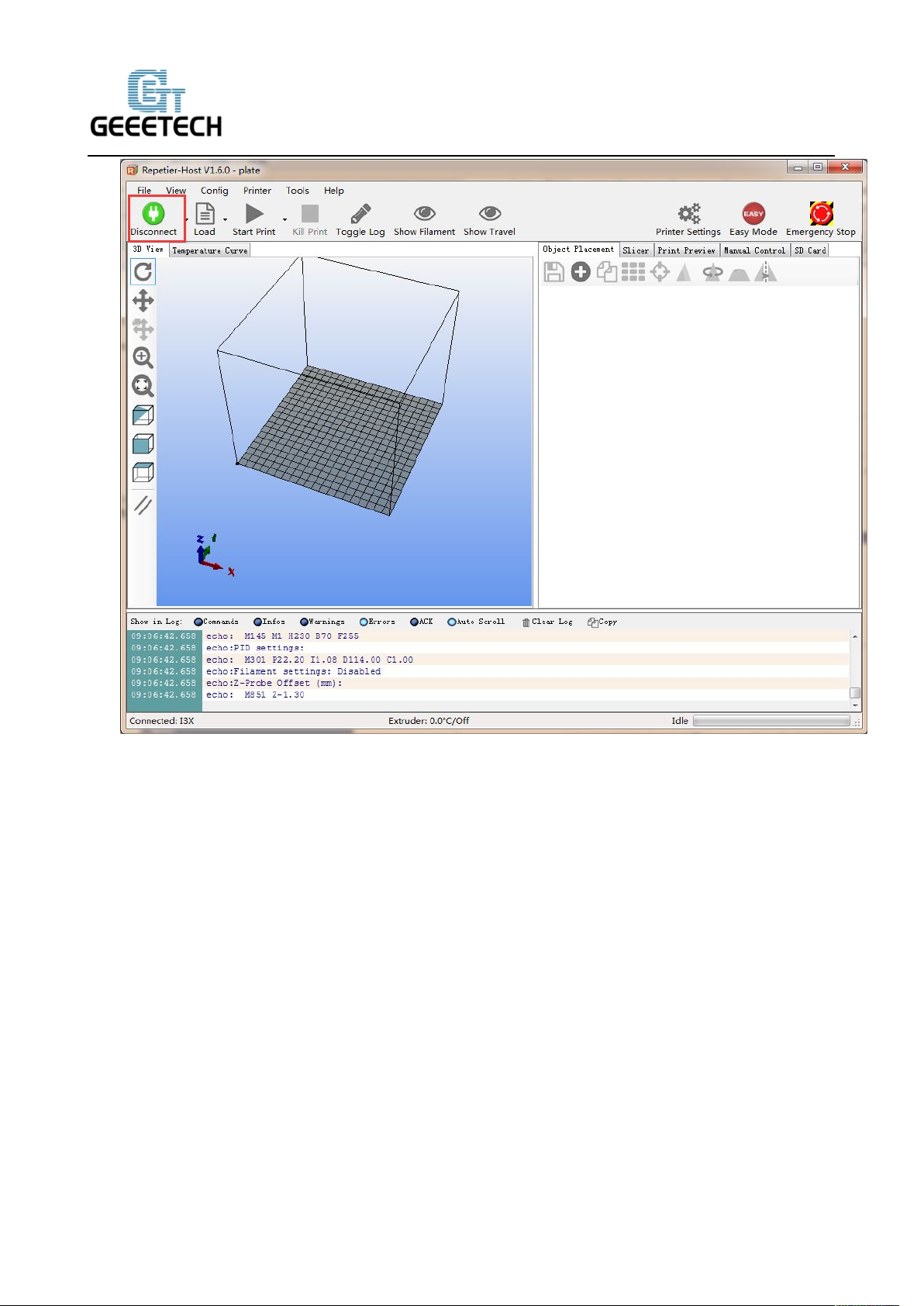

After setting, click the button in the top left corner of Home Page. When the button turns

green and changes into , the printer connection is successful.

Page 7

www.geeetech.com

ShenZhen GETECH CO.,LTD

5

Printer Setting

3

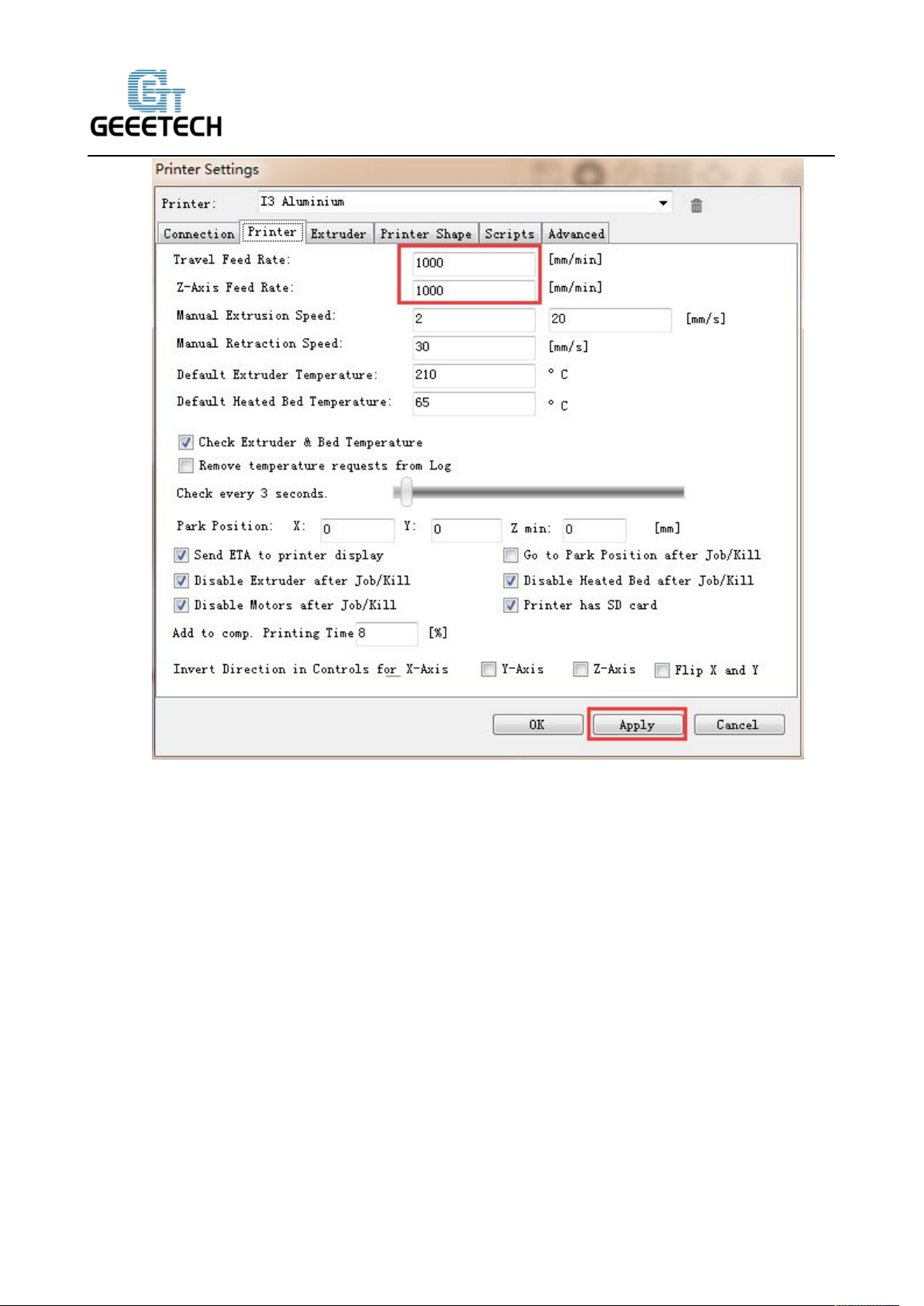

3.1 Printer speed

Set the running speed of printer as 1000 in the printer settings in order to avoid collision because of

high speed during the test. After follow-up tests are completed it can be changed back to the original

value. (Recommend speed of Z-axis should not be too high, 1000 is OK)

Travel feed rate: 1000mm/min

Z-Axis feed rate: 1000mm/min

Page 8

www.geeetech.com

ShenZhen GETECH CO.,LTD

6

3.2 Number of Extruder and Nozzle Diameter

The number of extruders is set to 1. The diameter of nozzle is set according to actual size, here is

0.4mm.

Page 9

www.geeetech.com

ShenZhen GETECH CO.,LTD

7

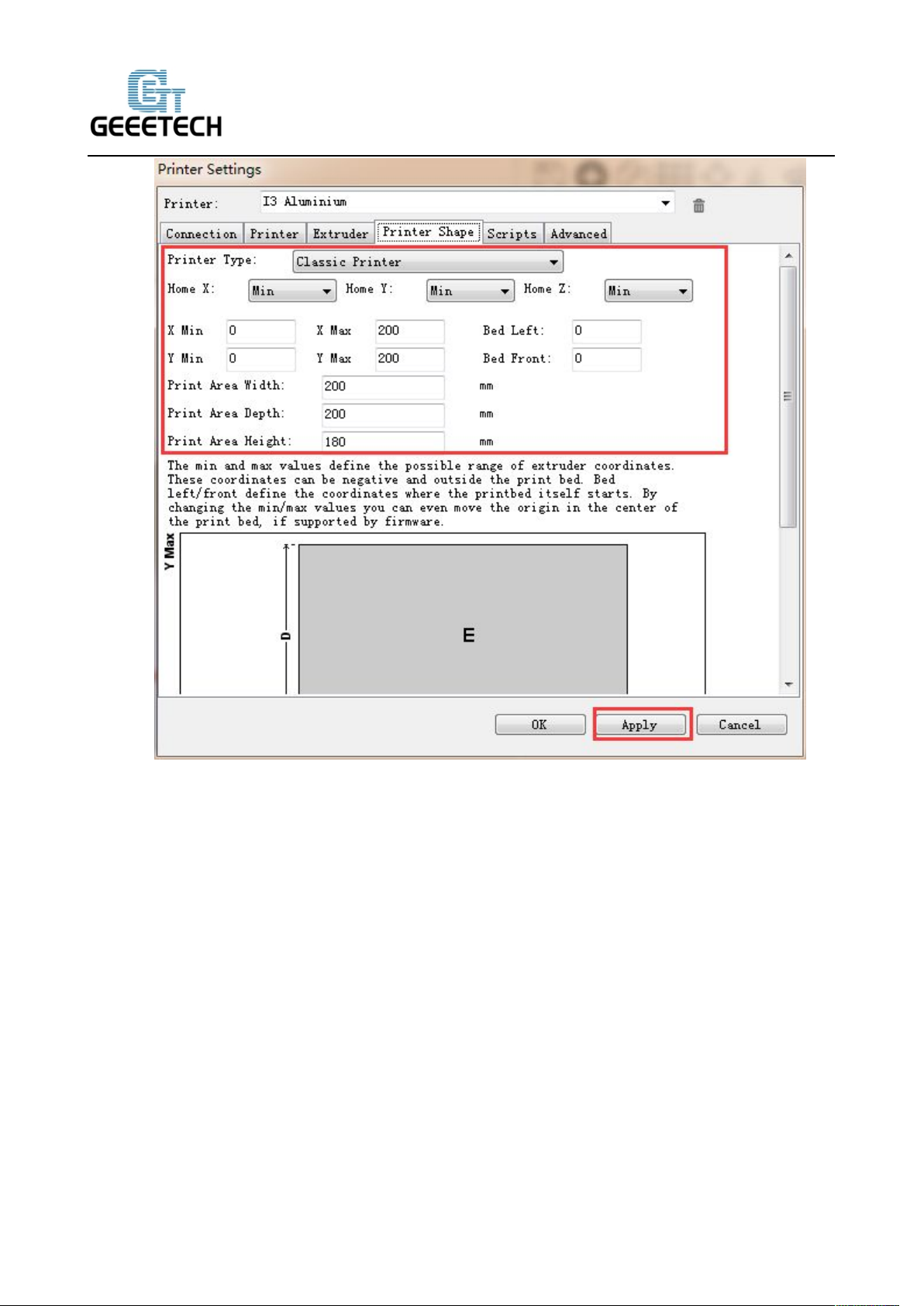

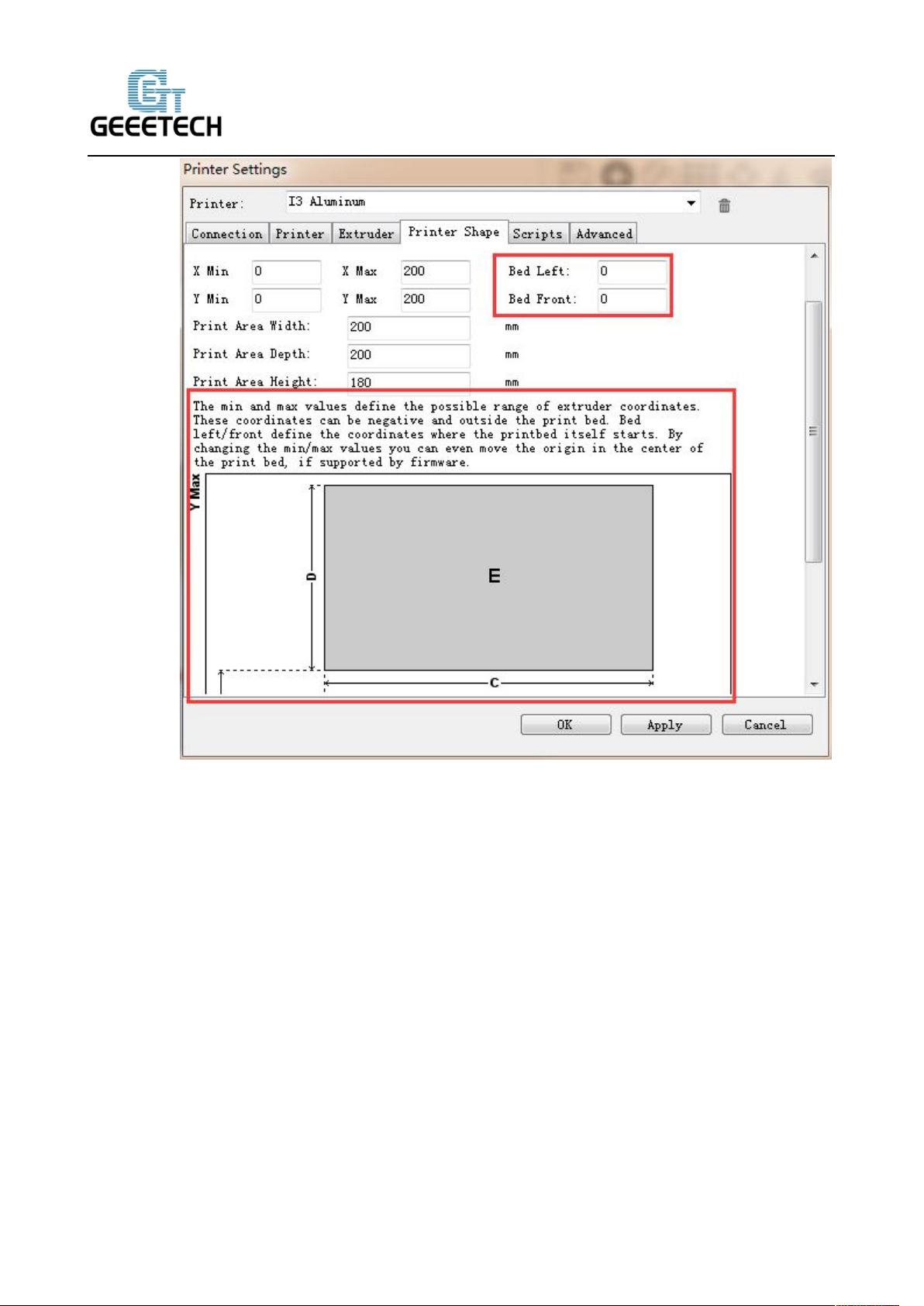

3.3 Printer shape

Here the printer shape of I3 aluminum is Classic Printer;

For home position, choose Min;

The printer's maximum printing volume 200 * 200 * 180 (length / width / height)

Page 10

www.geeetech.com

ShenZhen GETECH CO.,LTD

8

If the object which is being printed is not in the center of the hot bed, you can adjust the following

two values to compensate for the distance deviation of X / Y direction:

Bed Left

Bed Right

Page 11

www.geeetech.com

ShenZhen GETECH CO.,LTD

9

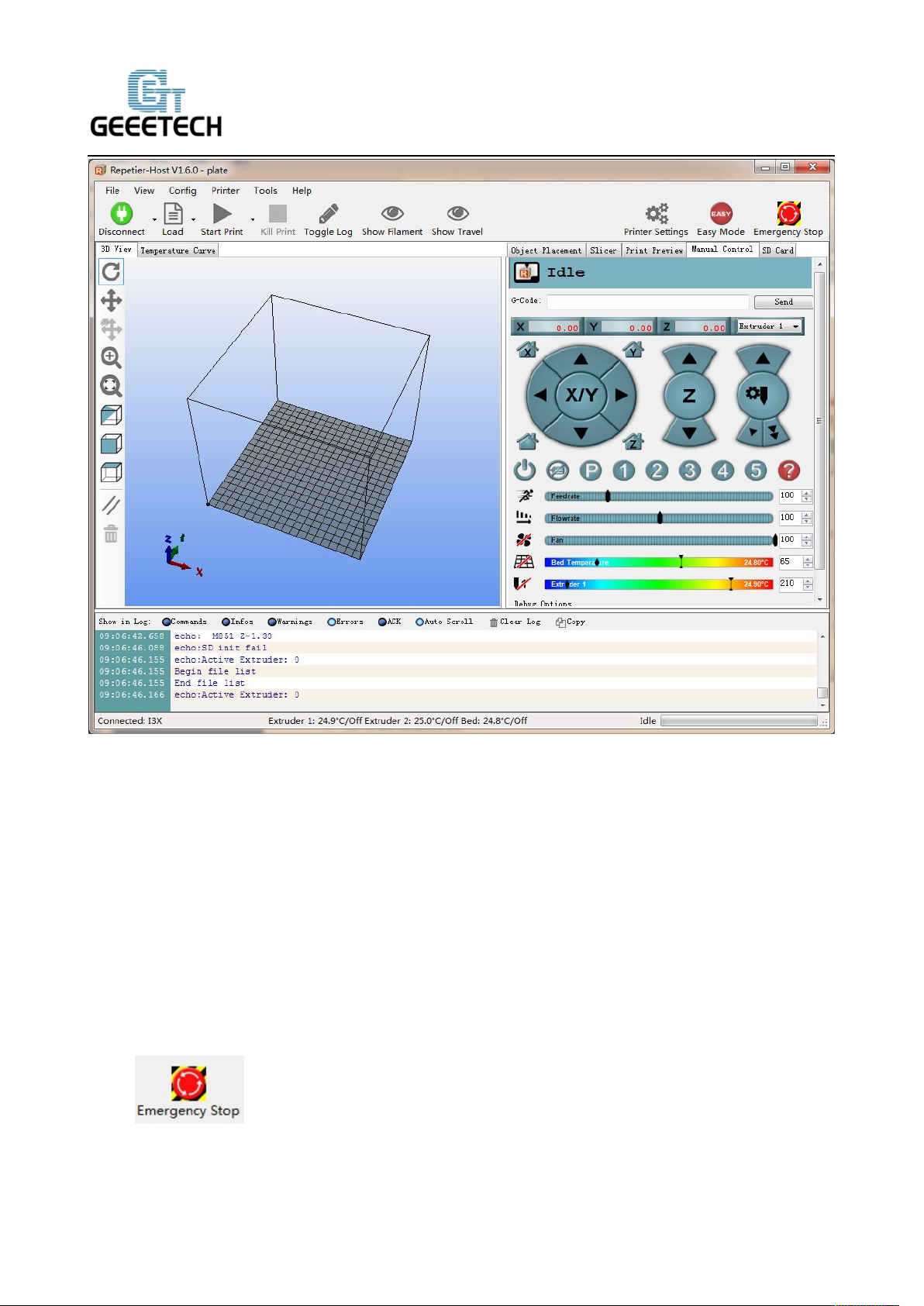

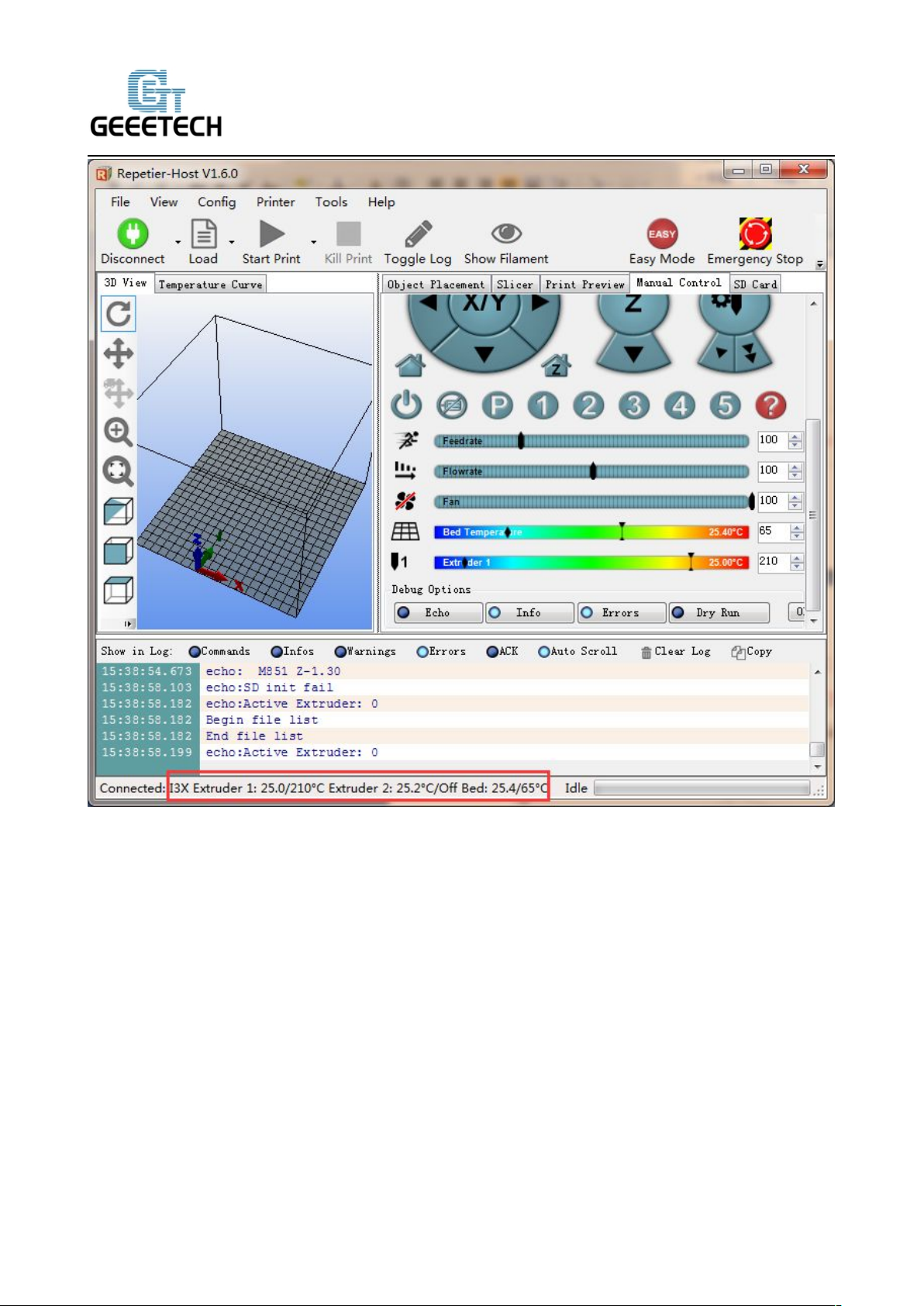

After setting, click Apply>OK

The interface after setting is as following:

Page 12

www.geeetech.com

ShenZhen GETECH CO.,LTD

10

4 Printer Function Test

When we are testing, we can test through LCD control panel or we can also do the test on Repetier

Host. The methods are as followings.

4.1 Use Repetier Host to Test

4.1.1 Motor Direction Test

Before the test, manually set the motors of X / Y / Z axis at the intermediate position of each axis to

avoid accidental collision occurring during the test. There is emergency stop button at the top right

corner , or you can cut off the power. Always be prepared for emergency stop.

Page 13

www.geeetech.com

ShenZhen GETECH CO.,LTD

11

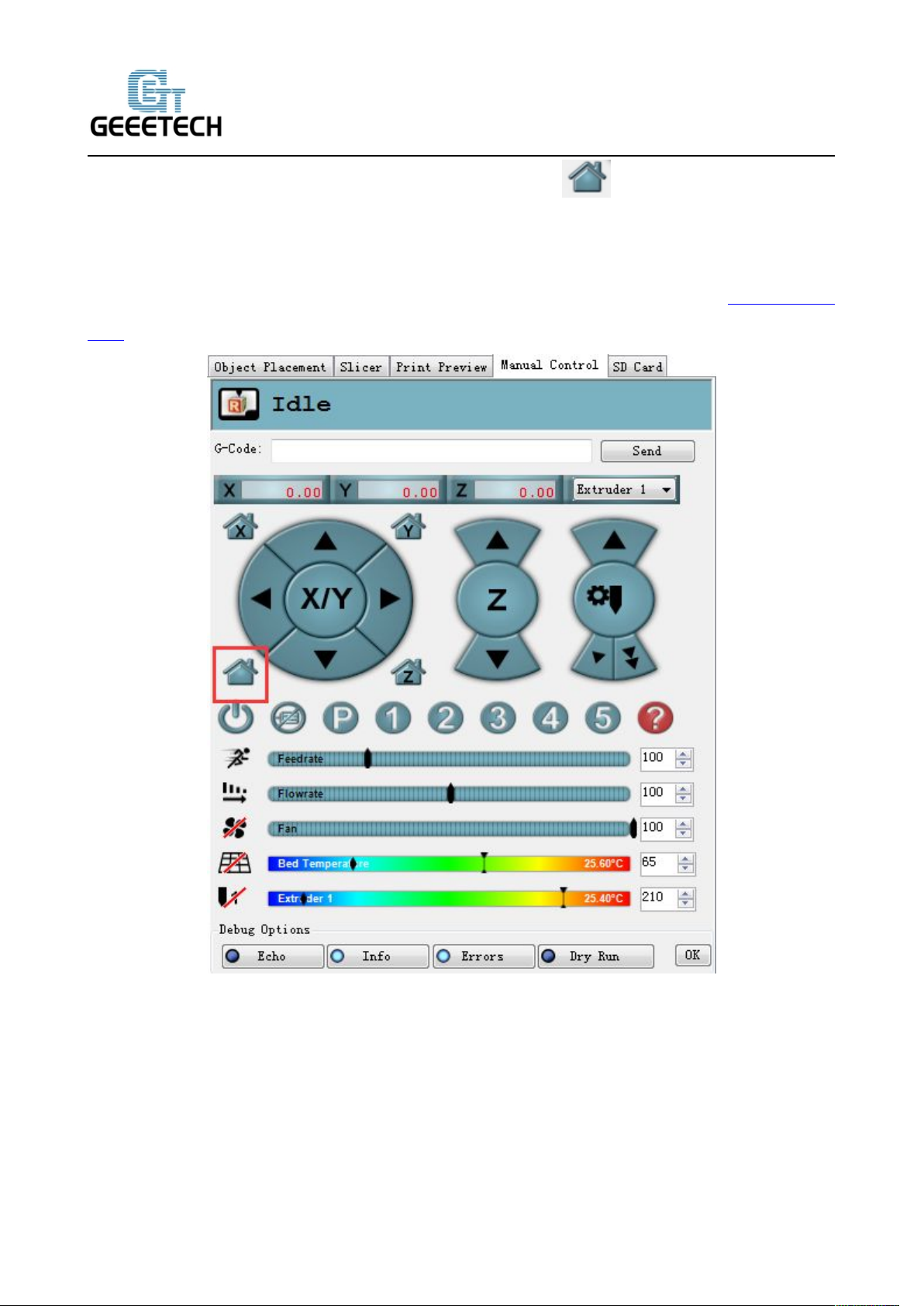

Open Repetier host and connect the printer. Click Home button , then all three axes will move

towards the endstop. After they hit the endstop they will move back for a short distance and then

stop the movement. The origin location should be in the right front corner of the printer platform. If

the moving direction is reversed, you can change the motor direction in firmware.(please refer to

FAQ).

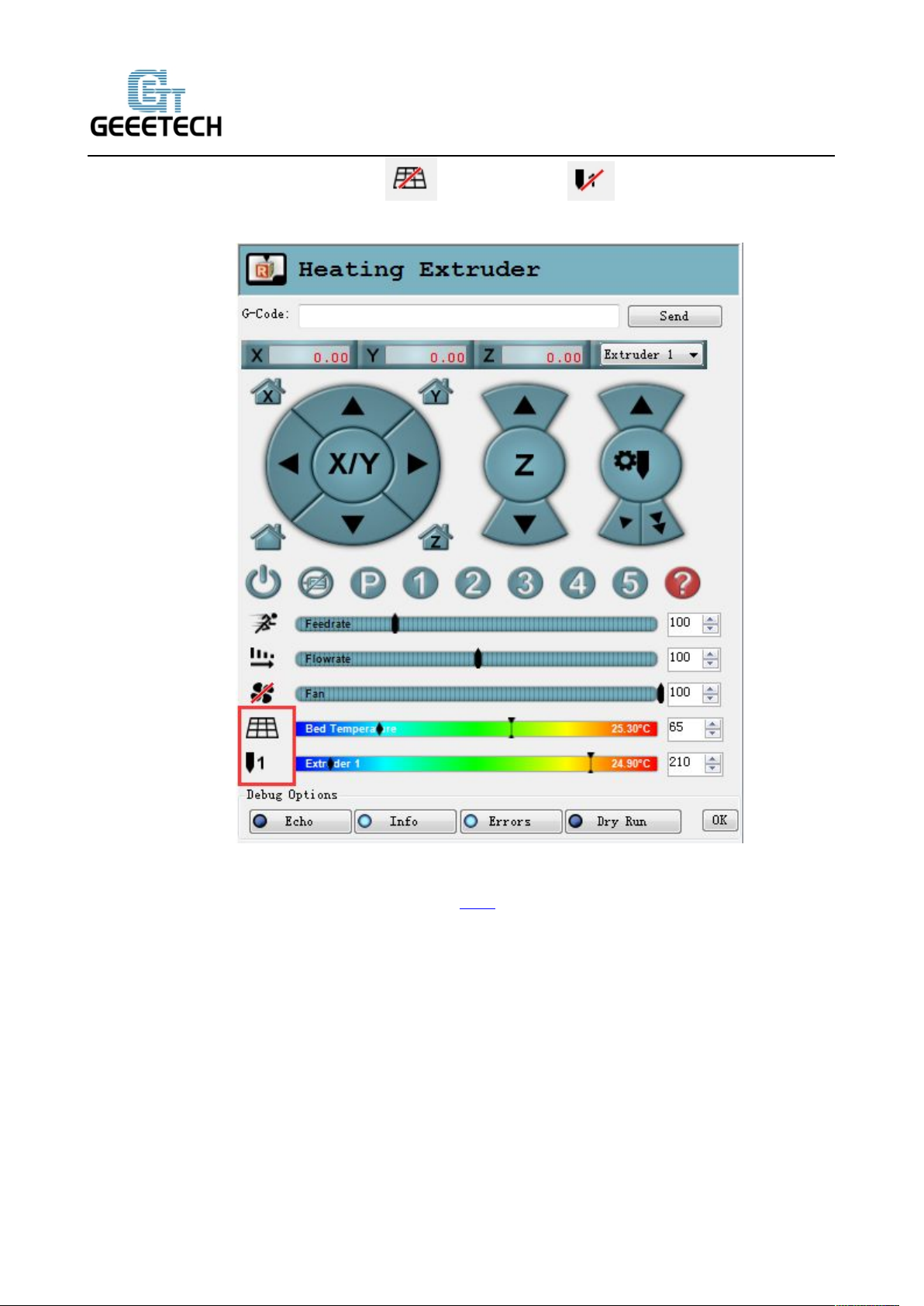

4.1.2 Heating Test

Page 14

www.geeetech.com

ShenZhen GETECH CO.,LTD

12

Click the heating button of the hot bed and the extruder . The slash will disappear and

you will see the temperature rising up.

Meanwhile you can see the temperature changing at the bottom of Repetier.

If the hot bed or extruder can heat, please refer to FAQ.

Page 15

www.geeetech.com

ShenZhen GETECH CO.,LTD

13

4.1.3 Extruder test

Please note: The extruder will not begin working until the temperature reaches above 170 ℃.

Heat the extruder to 200 ℃, and then insert the filament into hotend via push-in fitting. When you

are pushing the filament, press the handle with one hand and push the filament with the other hand.

Please note that the filament must be in the slot of the gear, otherwise feeding will not be fluent.

Page 16

www.geeetech.com

ShenZhen GETECH CO.,LTD

14

Page 17

www.geeetech.com

ShenZhen GETECH CO.,LTD

15

After pushing the filament into the bottom of hotend, use the feeding button on Repetier (as shown

in following picture) to do manual feeding. If the nozzle can extrude filament fluently, the extruder

is working well. If not, please refer to FAQ.

Note: If the moving direction of the motor is reversed, which means you found the filament going

backwards when you click to feed downwards, change the motor direction of the extruder in the

firmware to solve the problem. This method is the same with that for X/Y/Z axis motor.

Page 18

www.geeetech.com

ShenZhen GETECH CO.,LTD

16

1. Press the knob: OK or enter the sub-menu

2. Turn the knob: to scroll through the options, or change parameters

4.2 Use LCD Control Panel to Test

4.2.1 Motor Direction Test

Functions of the knob on LCD:

Note: Turn the knob during printing, you can change the Feed rate in real time.

Page 19

www.geeetech.com

ShenZhen GETECH CO.,LTD

17

After learning about the functions of the knob on the LCD, press the knob to enter sub-menu and

choose Prepare:

Choose Move axis:

Choose Move 1mm:

( Note: the extruder can only support two options: Move 1mm and Move 0.1mm. The 10mm

option is disabled.)

Page 20

www.geeetech.com

ShenZhen GETECH CO.,LTD

18

Choose the axis that you want to move by using Move X/Y/Z options. Turning the knob can make

each axis move left and right or back and forth.

After testing each axis, you can choose Prepare>Auto home in the menu to make it back to home

position.

If you want to manually move the motor, you can unlock the motor. Unlocking method:

Page 21

ShenZhen GETECH CO.,LTD

19

Prepare>Disable steppers:

www.geeetech.com

4.2.2 Heating Test

In the Control menu, you can select temperature setting of hotbed and extruder.

Choose control:

Page 22

ShenZhen GETECH CO.,LTD

20

Choose temperature:

www.geeetech.com

Select the temperature you want to set:

After setting, you can choose Prepare> Preheat PLA to preheat hot bed and extruder.

Page 23

www.geeetech.com

ShenZhen GETECH CO.,LTD

21

So far, function tests of the printer are done.

5 Hotbed Leveling

Before printing, we need to do hotbed leveling. Only after this step can quality of printed parts get

improved. Otherwise the un-leveling gap between the hotbed and extrusion head will affect the

filament adhering to the hotbed thus cause poor print quality or even not printing.

5.1 Homing

Home the printer.

Page 24

www.geeetech.com

ShenZhen GETECH CO.,LTD

22

5.2 Coarse tuning of distance between the nozzle and the hotbed

*If the nozzle is far from the surface of hotbed, loosen the M3x50mm screw to extend the bottom

part.

Then the printer will home at a relatively lower place, the distance between the nozzle and the

hotbed will be decreased.

*If the nozzle is too close to the surface of hotbed, tighten the M3x50mm screw to shorten the

bottom part.

Then the printer will home at a relatively higher place, the distance between the nozzle and the

hotbed will be increased.

You may need to calibrate for many times at this step.

The recommended distance between the nozzle and the hotbed is 0.5-1mm.

Page 25

www.geeetech.com

ShenZhen GETECH CO.,LTD

23

5.3 Fine Tuning

After the initial adjustment, home the printer. Disable the stepper motors( ), manually move the

extruder to the four corners of the hot bed and fine-tuning the wing nut at each corner to level the

distances between the extrusion head and four corners. During adjustment, you can put a piece of

A4 paper(half fold it) between the nozzle and hotbed. If you can feel a bit friction when you pull the

paper back and forth, the distance is proper.

After finishing the adjustment of four corners, the entire leveling process is done. You can also

Page 26

www.geeetech.com

ShenZhen GETECH CO.,LTD

24

move the extrusion head to the center of hotbed to verify leveling outcome.

6 Slice Settings

With one more step, we can start printing,set the slice parameters such as print material diameter,

the speed, the layer height, etc. to achieve better print quality. Open slic3r, which is a slice software

coming with Repetier host. As shown below:

You will be presented with the following interface:

Page 27

www.geeetech.com

ShenZhen GETECH CO.,LTD

25

6.1 Printing Setting

Set layer height and the first layer height in the Print setting tab. Generally speaking, layer height

can be set as 0.1-0.3mm. Considering of accuracy and speed, 0.2mm is the most appropriate layer

height. The layer height is set as 0.35mm by default.

Page 28

www.geeetech.com

ShenZhen GETECH CO.,LTD

26

6.2 Filament Setting

Set filament diameter and print temperature in the Filament setting tab. Filament we use here is

1.75mm PLA. Usually the temperature of the extrusion head is 195-210℃,and the temperature of

hotbed is 60-70℃. Here we separately set them as 200℃ and 65℃.

Page 29

www.geeetech.com

ShenZhen GETECH CO.,LTD

27

6.3 Printer Setting

Set the shape and size of hotbed and the number of extruders in the Printer setting> General tab.

Page 30

www.geeetech.com

ShenZhen GETECH CO.,LTD

28

Page 31

www.geeetech.com

ShenZhen GETECH CO.,LTD

29

Meanwhile set the extrusion head diameter as 0.4mm (input the actual diameter of your own

printer):

Page 32

www.geeetech.com

ShenZhen GETECH CO.,LTD

30

6.4 Other Settings

In addition to the above parameter settings, parameters like the speed of the printer are also very

important to print quality. It requires user’s long-term using experience and exploration.

Here we’d like to give you a setting for reference, please download the attachment config.ini. You

can import it into slic3r to view it through the following steps.

Open slic3r>File>Load Config:

Page 33

www.geeetech.com

ShenZhen GETECH CO.,LTD

31

Find “I3 aluminum PLA config.ini” file in the dialog box and open it.

Page 34

www.geeetech.com

ShenZhen GETECH CO.,LTD

32

Then you can successfully import the config.ini file. Click the Save button to rename and save it.

Page 35

www.geeetech.com

ShenZhen GETECH CO.,LTD

33

7 Begin Printing

So far, all the preparatory work is completed. The next step is to import the model file for slicing

and printing. For 3D printer, the file format of the model is generally .stl file. We can download for

free and print those models which are shared online , and you can also design your own creative

objects for printing. Here we print a simple plate. You can download the model file here: plate.stl.

Page 36

www.geeetech.com

ShenZhen GETECH CO.,LTD

34

7.1 Load print model

In the main interface of Repetier host, click the Load button . Choose the file you have

downloaded and open it.

Page 37

www.geeetech.com

ShenZhen GETECH CO.,LTD

35

7.2 Model Slicing

After the file is loaded, you can use the following buttons to enlarge, shrink or rotate it.

Page 38

www.geeetech.com

ShenZhen GETECH CO.,LTD

36

After the size setting, choose the slicing parameters which were imported previously in the drop-

down menu, and click slice with slic3r.

Page 39

www.geeetech.com

ShenZhen GETECH CO.,LTD

37

In this way, .gcode file which can be recognized by the printer is generated.

Page 40

www.geeetech.com

ShenZhen GETECH CO.,LTD

38

Last step, click button to print.

Page 41

www.geeetech.com

ShenZhen GETECH CO.,LTD

39

7.3 Stand-alone print with SD Card

If you want to print Stand-alone , you can save the .gcode file in SD card for printing.

Note: The printer only recognizes .gcode file in the SD card, and the file can not be placed in any

folder!

Steps are as follows:

7.3.1 Save

Click Save for SD Print, and select the save button in the dialog box.

Page 42

www.geeetech.com

ShenZhen GETECH CO.,LTD

40

7.3.2 Generate file

Choose a save path to save the generated .gcode file which can be used for SD card printing.

Page 43

www.geeetech.com

ShenZhen GETECH CO.,LTD

41

7.3.3 Print

Insert the SD card into the SD card slot at the back of the LCD control panel, and choose the

corresponding .gcode to print.

Press the knob on LCD, rotate the knob to enter the main menu and choose Print from SD option.

Choose corresponding .gcode file to begin printing.

Page 44

ShenZhen GETECH CO.,LTD

42

Heating

www.geeetech.com

When heating is completed, it begins printing automatically.

Page 45

www.geeetech.com

ShenZhen GETECH CO.,LTD

43

8 FAQ

If you encounter any problems during use, you can come to our forum:

http://www.geeetech.com/forum/, and there are detailed solutions answer in the forum. Common

problems are as follows:

8.1 How to upload firmware?

The motherboard of the printer is already burned with firmware when it leaves the factory. If you

have firmware problem when you are using the product and need to upload firmware, you need to

use the Arduino IDE to burn. Arduino1.0.1 is recommended, and the download address is:

https://www.arduino.cc/en/Main/OldSoftwareReleases#1.0.x

Page 46

www.geeetech.com

ShenZhen GETECH CO.,LTD

44

The way of uploading firmware, please refer to:

http://www.geeetech.com/forum/viewtopic.php?f=13&t=17181

Firmware download address, please refer to:

http://www.geeetech.com/forum/viewtopic.php?f=10&t=17046

Common parameters settings of firmware, please refer to:

http://www.geeetech.com/forum/viewtopic.php?f=13&t=17194

8.2 How to change the motor direction in firmware?

In the configuration.h tab of firmware, find the following codes. Change the true of corresponding

axis into false or false into true, and save the firmware and burn into the printer. ( Because you don’t

Page 47

www.geeetech.com

ShenZhen GETECH CO.,LTD

45

8.3 User manual of Repetier Host

know the firmware which has been burned by mother board is true or false, it may be necessary to

burn both of the two parameters.)

#define INVERT_X_DIR true

#define INVERT_Y_DIR false

#define INVERT_Z_DIR true

#define INVERT_E0_DIR false

For detailed user manual of Repetier Host, please refer to Wiki:

http://www.geeetech.com/wiki/index.php/Repetier-Host

Page 48

www.geeetech.com

ShenZhen GETECH CO.,LTD

46

8.4 Possible causes for motor’s non-action

http://www.geeetech.com/forum/viewtopic.php?f=13&t=17038

8.5 Extruder does not work normally

http://www.geeetech.com/forum/viewtopic.php?f=13&t=17097

8.6 The hotbed or extruder can not be heated

http://www.geeetech.com/forum/viewtopic.php?f=13&t=17117

8.7 LCD error: MAX/MIN TEMP error

http://www.geeetech.com/forum/viewtopic.php?f=13&t=17030

8.8 No information or displaying black square on LCD

http://www.geeetech.com/forum/viewtopic.php?f=13&t=17040

8.9 Time.h/endstop hit or other abnormalities

http://www.geeetech.com/forum/viewtopic.php?f=13&t=17037

Loading...

Loading...