Shenzhen Getech Technology Co.,Ltd

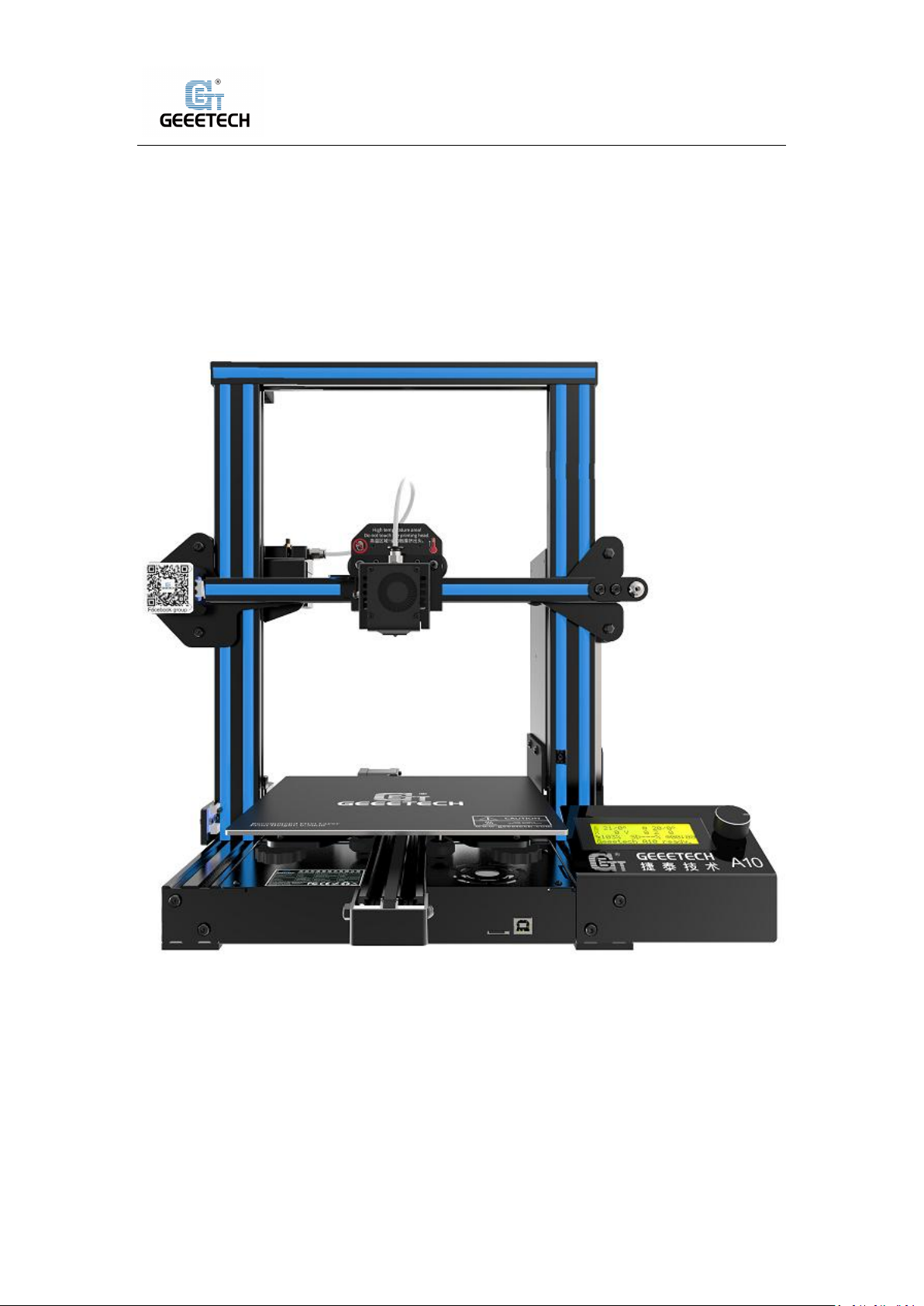

Geeetech A10 3D Printer

User Manual (V0.01)

1

Shenzhen Getech Technology Co.,Ltd

Content

1 Attention ........................................................................................................................................ 4

1.1 Safety instructions ............................................................................................................... 4

1.2 Factory test before delivery ................................................................................................ 4

2 Machine parameters ………………………………………………..…………………………………………………….………..5

3 Packing list ……………………………………………………………………………………………..……………….……………….6

4 Machine Overview …………………………………………………………………………………………………………………..7

5 Assembling ..................................................................................................................................... 8

5.1 Assembling the main frame ................................................................................................ 8

5.2 Wire connection ................................................................................................................ 10

5.3 Check the power input mode ............................................................................................ 13

5.4 Check the filament ............................................................................................................ 13

6 First print ...................................................................................................................................... 16

6.1 Level the print bed ............................................................................................................ 16

6.2 TF card printing ................................................................................................................. 18

7 Introduction to the LCD menu...................................................................................................... 20

7.1 Tree diagram ..................................................................................................................... 20

7.2 Main functions .................................................................................................................. 20

8 Software setting ........................................................................................................................... 24

8.1 Install driver....................................................................................................................... 24

8.2 Install slicing software ....................................................................................................... 26

8.3 USB printing ...................................................................................................................... 33

8.4 TF card printing ................................................................................................................. 38

9 Function introduction .................................................................................................................. 40

9.1 Power loss-resuming capability ......................................................................................... 40

9.2 Reset button ...................................................................................................................... 40

9.3 Filament run-out sensor (Optional) .................................................................................. 41

9.4 3D touch for auto bed leveling (Optional)......................................................................... 41

10 FAQ (Frequently Asked Questions) ............................................................................................. 42

10.1 Abnormal extrusion ......................................................................................................... 42

10.2 The gear of the extruder skips and makes an abnormal noise ....................................... 42

10.3 First layer abnormal ........................................................................................................ 42

10.4 Layer shift ........................................................................................................................ 43

10.5 Print stopped ................................................................................................................... 43

11 Declaration ................................................................................................................................. 44

11.1 Terms ............................................................................................................................... 44

11.2 Disclaimers ...................................................................................................................... 44

V

2

Shenzhen Getech Technology Co.,Ltd

Thank you for choosing Geeetech products!

[Important] Please read the instruction manual

carefully before using this machine.

Official site: https://www.geeetech.com/

Email us for technical support: https://www.geeetech.com/contact_us.htm

Facebook Group:

3

Shenzhen Getech Technology Co.,Ltd

1 Attention

1.1Safety instructions

Please switch to the correct local voltage (110V-220V) before turning on the printer. Be sure

the switch is in the correct position or it will damage the power supply unit (PSU).

Be sure all wires are correctly connected before turning on the printer.

Don’t touch the extruder head or hot bed when printing as they generate high temperature

which may cause burn.

Don’t leave the printer unattended when printing.

1.2Factory test before delivery

In order to ensure the quality, each printer is tested in the factory before delivery. As a result,

there may be residue in the extruder head or on the hot bed, but it should not affect normal use.

We provide the spare nozzle in the accessory kit just in case.

4

Shenzhen Getech Technology Co.,Ltd

2 Parameters

1) Printing parameters

Printing technology: FDM

Printing volume: 220*220*260 mm

Printing accuracy: 0.1~0.2mm

Positioning precision: X/Y: 0.011mm Z: 0.0025mm

Printing speed: 60mm/s

Nozzle quantity: 1-in-1-out single nozzle

Nozzle diameter: 0.4mm

Filament: Diameter 1.75mm;ABS/PLA, etc.

Environment temperature: 10℃-40℃

Operating system: Windows/Mac/Linux

Slicing software: Repetier-Host, EasyPrint 3D, Cura

File format: .STL/.Gcode

2) Electrical parameters

Power input: 115/230V AC,50/60Hz

Power output: DC24V-15A Max,360W

Connectivity: TF card, USB

Display screen: LCD2004 screen

3) Mechanical parameters

Printer size: 478x413x485mm3

Package size: 530x470x230mm3

Net weight: ~7.6kg

Gross weight: ~ 9.5kg

3

5

Shenzhen Getech Technology Co.,Ltd

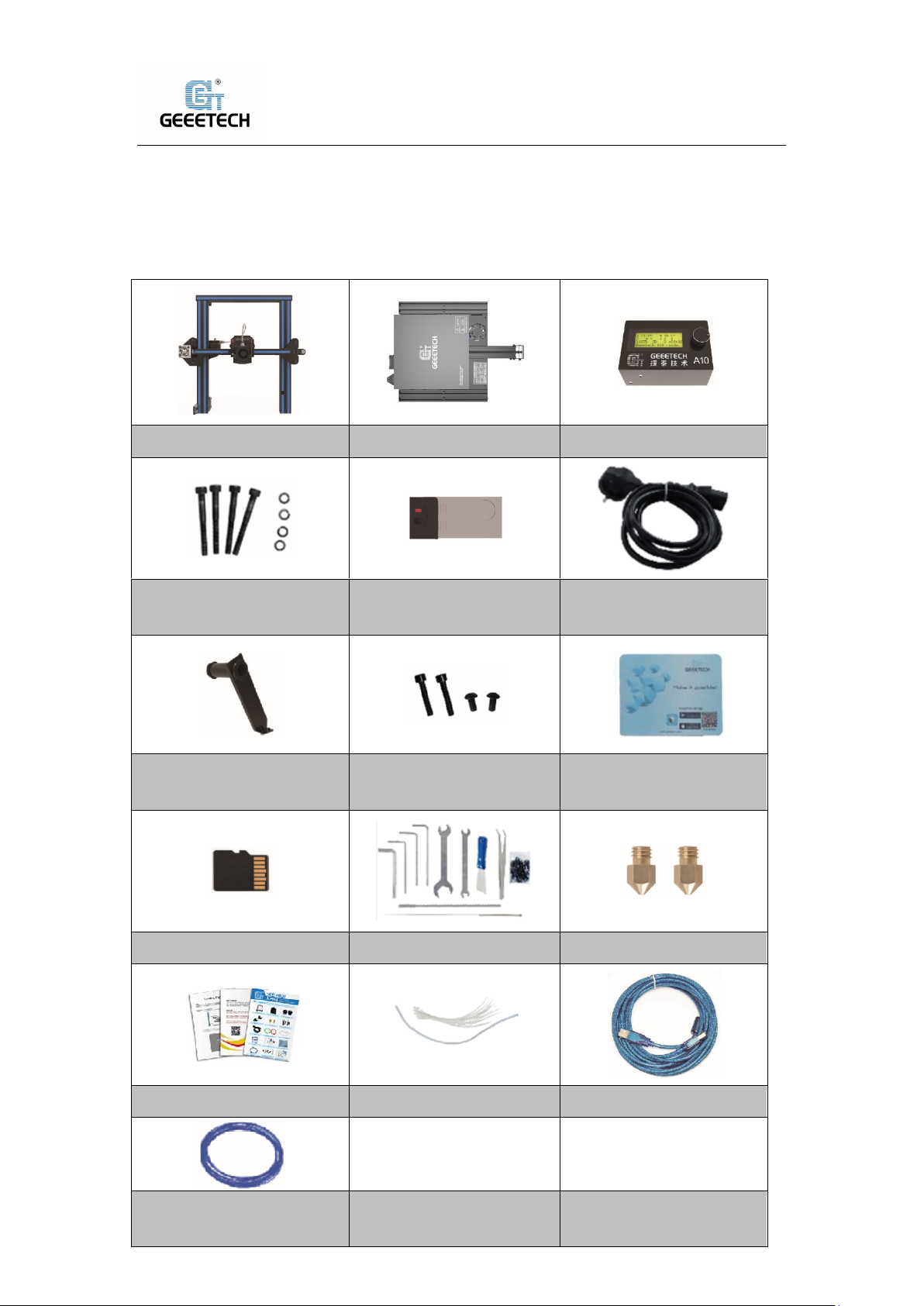

Gantry kit

Bottom kit

LCD display kit

Gantry and base installing

screws

PSU kit

Power cord

Spool holder component

Power and LCD screen

installing screws

Mouse pad

TF Card

Tool kit

Nozzle *2

User guide

Teflon tube & Zip ties

USB cord

Filament(1 random

colors )

3 Packing list

Please check the parts/accessories when you receive the printer (As shown below). If any spare

parts are missing, please contact your sales representative.

6

Shenzhen Getech Technology Co.,Ltd

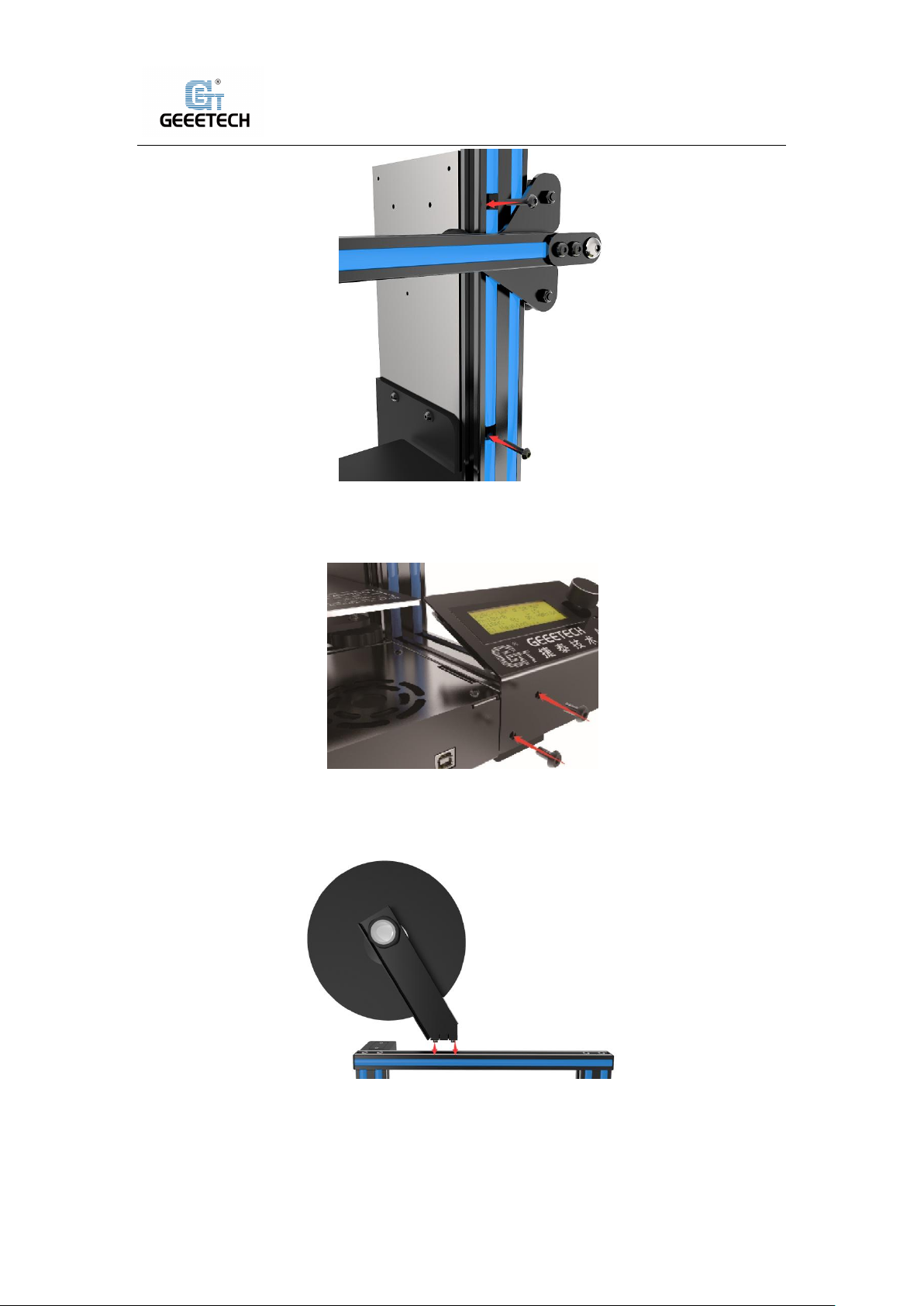

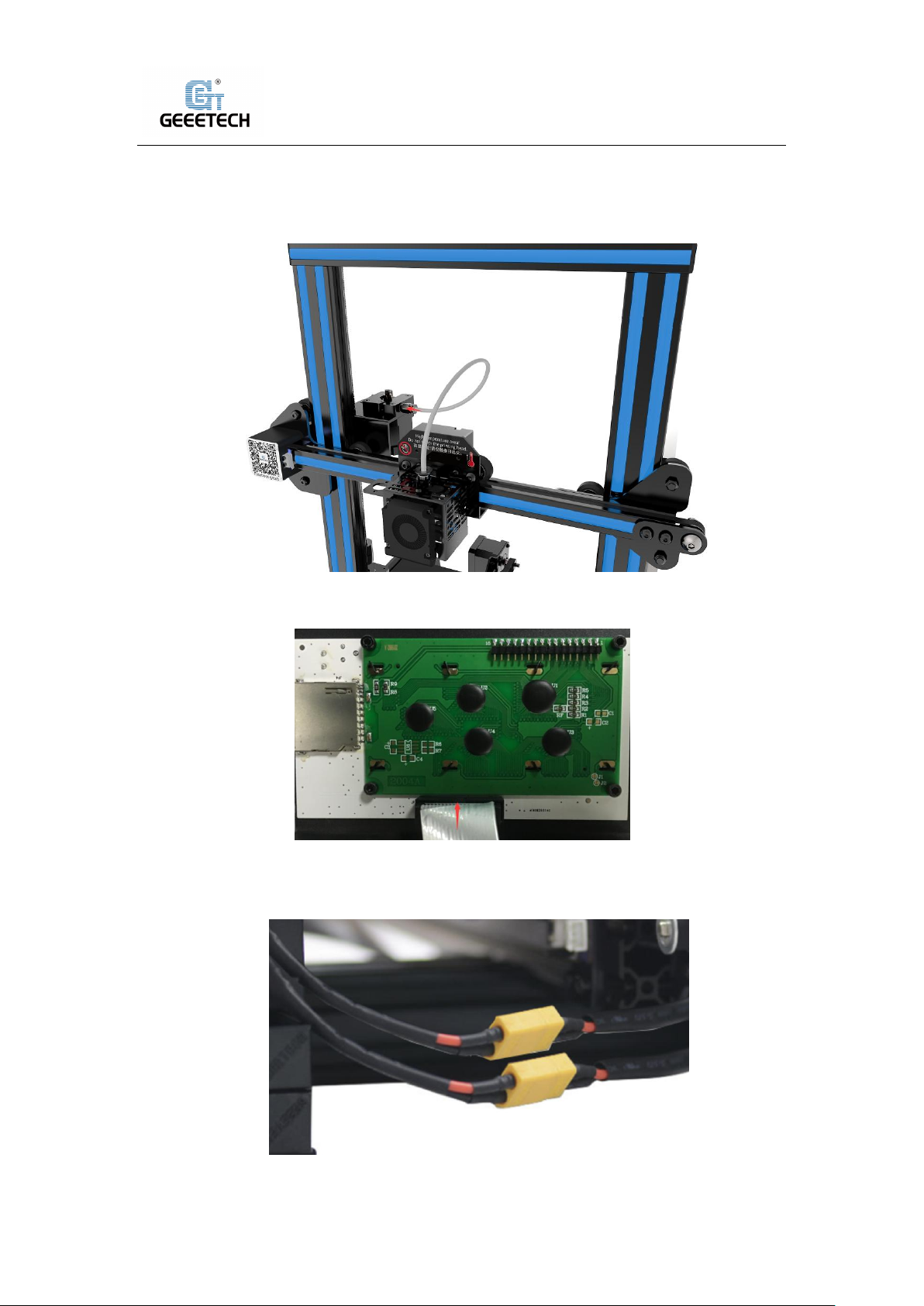

4 Machine Overview

(Picture 4-1) (Picture 4-2)

(Picture 4-3)

① Gantry kit;②LCD2004 screen;③Knob;④Reset button;⑤USB port;

⑥TF card slot;⑦Y axis;⑧Bottom kit;⑨Z axis end stop;⑩X axis end stop;

⑪Spool holder component;⑫Teflon tube;⑬Extruder head;⑭Hot bed;⑮X axis motor;

⑯Z axis motor;⑰Y axis motor;⑱Y axis end stop;⑲PSU;⑳Power voltage selector switch;

㉑Extruder wire connector;㉒Power switch;㉓Power socket

7

Shenzhen Getech Technology Co.,Ltd

Gantry kit

Bottom kit

LCD display kit& PSU kit

Spool holder component

Gantry and base

installing screws

Power and LCD screen

installing screws

5 Assembling

5.1Assembling the main frame

The main frame consists of the following components: Gantry kit, bottom kit, LCD display kit,

PSU kit, Spool holder component, and its associated screws.

See picture (5-1)

(Picture 5-1)

The gantry and bottom frames are assembled from the bottom of the machine with 4

M5x45 screws and 4 spring washers M5. See picture (5-2).

(Picture 5-2)

Fix the PSU to the gantry frame with 2 M4x20 screws. See picture (5-3).

8

Shenzhen Getech Technology Co.,Ltd

(Picture5-3)

Fix the LCD to the correct holes on the right side of the base with 2 M5x10 screws. See

picture (5-4).

(Picture 5-4)

Assemble filament holder and attach to the top of the frame closing to the extruder

side, with 2pcs M3x6 screws and 2 T- nuts M3, as shown picture (5-5).

(Picture 5-5)

9

Shenzhen Getech Technology Co.,Ltd

5.2Wire connection

Insert the Teflon tube into the quick-insert connector. Details see picture (5-6).

(Picture 5-6)

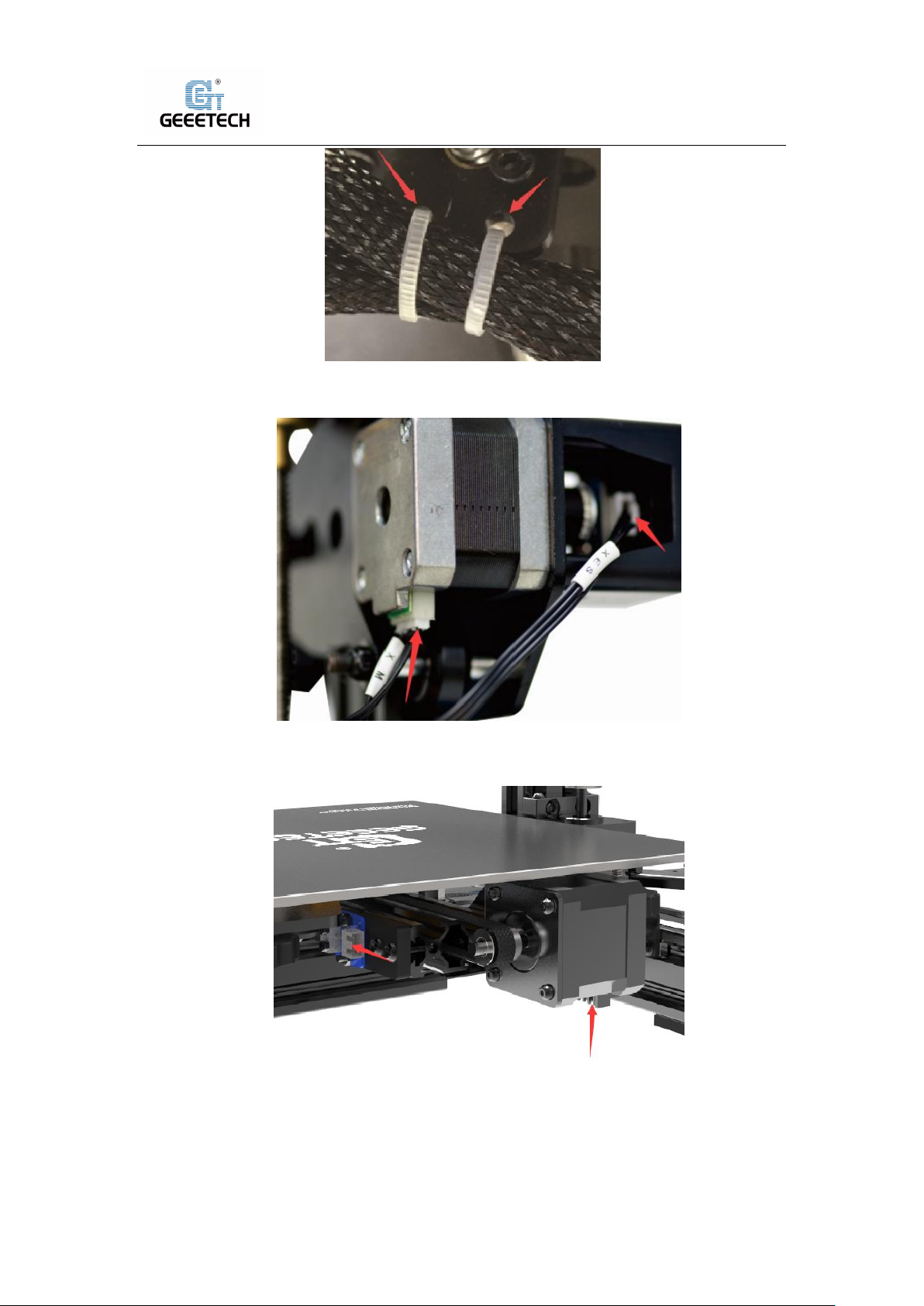

Insert the LCD cable into LCD socket behind the LCD screen. See picture (5-7).

(Picture 5-7)

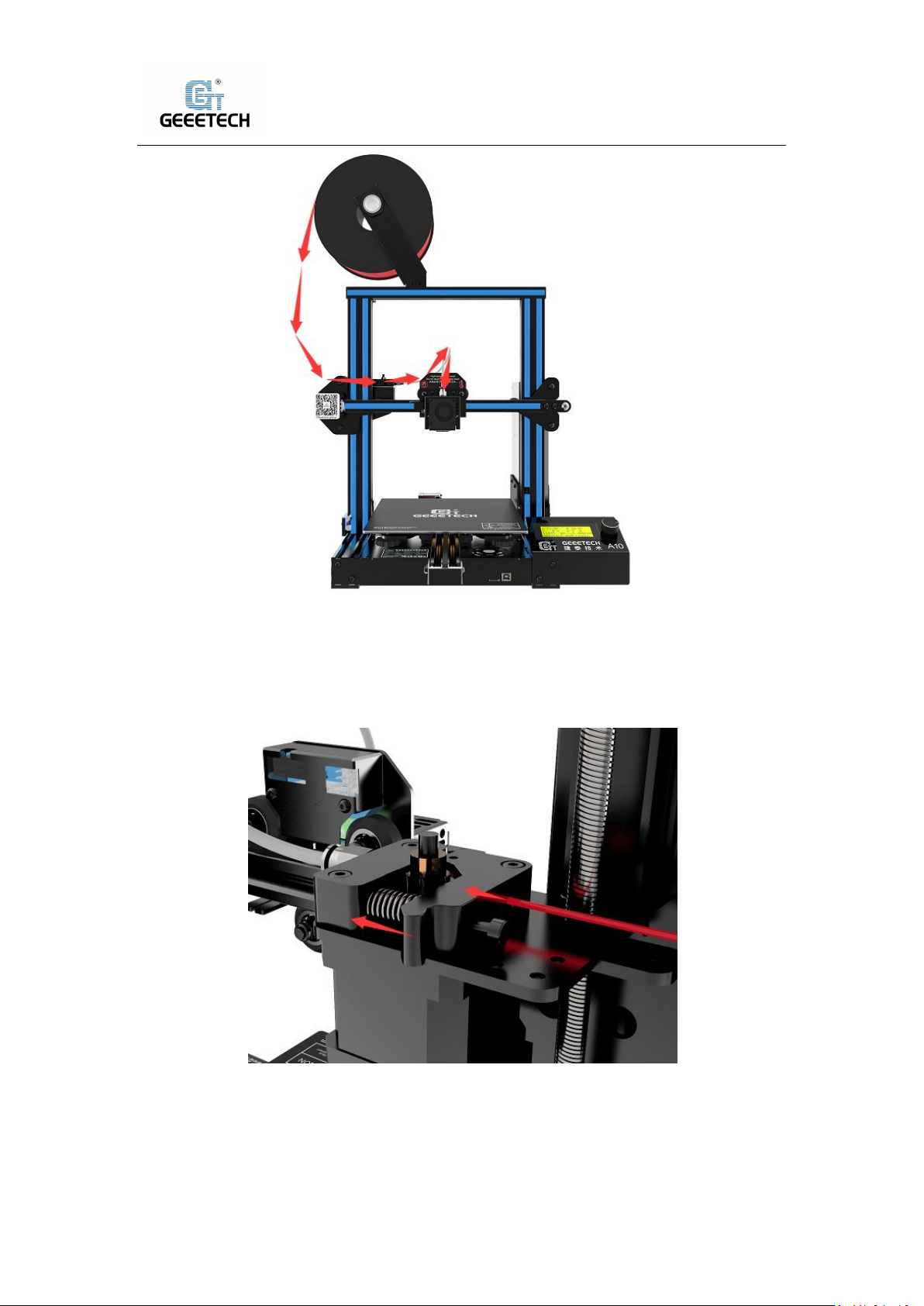

Connect two sets of power cables (note: can be connected arbitrarily without order)

See picture (5-8).

(Picture 5-8)

10

Shenzhen Getech Technology Co.,Ltd

Plug the extruder cables into the socket of the extruder head adapter plate, and the buckle

must be fastened. See picture (5-9)

(Picture 5-9)

Connect the motor wires of E0. See picture (5-10).

(Picture 5-10)

Then the extruder wire and the motor extruder wire are fixed into the small hole on the backside

of the lead screw with the Cable tie to avoid the wire harness touching the model during printing.

In addition, the position the harness fixed needs to reserve the length of the Z-axis at the

maximum height. See picture (5-11).

11

Shenzhen Getech Technology Co.,Ltd

(Picture 5-11)

Connect the X-axis motor and the X-axis limit switch wire. See picture (5-12).

(Picture 5-12)

Connect the Y-axis motor and the Y-axis limit switch wire. See picture (5-13).

(Picture 5-13)

Connect the Z-axis motor and the Z-axis limit switch wire. See picture (5-14).

12

Shenzhen Getech Technology Co.,Ltd

(Picture 5-14)

5.3Check the power input mode

The factory default voltage is 230V. You need to choose the correct voltage according to your

local standard requirement. See picture (5-15)

Note: Be sure the voltage is switched to the correct one.

(Picture 5-15)

5.4Check the filament

Put the filament on the spool holder. Please pay attention to the feeding direction of the filament.

As shown by the arrow in (5-16).

13

Shenzhen Getech Technology Co.,Ltd

(Picture 5-16)

Press down the lever handle of the extruder and insert the filament into the feeding tube until it

reaches the extruder head. Since the filament is bent, so you need to straighten the front of the

filament by hand and sharpen them with diagonal pliers or scissors to make it easier to insert it

into the head. See picture (5-17).

(Picture 5-17)

When print PLA, set the target nozzle temperature about 190-210℃. When the temp is stable,

control the extruder filament feeding on LCD screen (“Move axis”), feed until there is molten

material flowing from the nozzle.

Observe the nozzle, if there is no filament stuck and the filament is coming out smoothly, then

14

Shenzhen Getech Technology Co.,Ltd

stop filament feeding, clear the nozzle with tweezers. See picture (5-18).

(Picture 5-18)

15

Shenzhen Getech Technology Co.,Ltd

6First print

6.1 Level the print bed

The first layer is key to a successfully printed model. The factory default setting is a little high in

order to avoid scratching the hotbed with the nozzle, so users need to adjust the distance

between nozzle and hotbed again. After the first-time bed leveling, users don’t need to level the

bed again.

1) Rough leveling

Home the printer first (“Prepare”> “Auto home”), then it shows the option “Level corners” on

the LCD screen. Put a piece of A4 paper on the platform, click “Next corner”, the extruder head

moves counterclockwise from the bottom left corner to the four corners of the platform. See

picture (6-1).

(Picture 6-1)

When the extruder head moves to the left bottom, adjust the corresponding knob until the

distance between the nozzle and bed is about the thickness of a piece of paper (about

0.1-0.2mm). Slide the paper back and forth to see if you feel a slight resistance. If yes, it means

the leveling of this corner is finished and you can proceed to level the rest corners with the same

method. See picture (6-2).

(Picture 6-2)

16

Shenzhen Getech Technology Co.,Ltd

2) Accurate leveling

If you level the bed with A4 paper, the first layer maybe too high, too low or moderate.

a. Too high: the distance between the nozzle and bed is too far, which may cause the filament to

not stick or not stick well. See picture (6-3).

(Picture 6-3)

b. Too low: the distance between the nozzle and the bed is too close, which prevents the filament

from coming out and causes the extruder gear to click, and even worse, scratch the nozzle on the

bed. See picture (6-4).

(Picture6-4)

c. Moderate: Extrude the filament properly and evenly stick on the bed. See picture (6-5).

(Picture 6-5)

In the case of too low and too high, adjust the knobs under the platform till they are moderate. It

may take some trial and error to achieve the best result. An example of good first layer, see

picture (6-6).

(Picture 6-6)

Note:

If turn the knobs clockwise, the platform will rise, and vice versa.

Avoid the nozzle touching the bed; use a piece of A4 paper. Or it will scratch the bed.

For more details, please refer to this link:

http://geeetech.com/forum/viewtopic.php?f=112&t=62296

17

Shenzhen Getech Technology Co.,Ltd

6.2TF card printing

Insert the TF card into the slot. See picture (6-7)

(Picture 6-7)

Press and rotate the knob to enter the main menu. Select the option of "Print from SD". See

picture (6-8).

(Picture 6-8)

Choose the files in the TF card. See picture (6-9).

(Picture 6-9)

The printer will heat automatically. See picture (6-10).

18

Shenzhen Getech Technology Co.,Ltd

(Picture 6-10)

When heating done, the printer will start printing until the print is complete. See picture (6-11,

6-12).

(Picture 6-11)

(Picture 6-12)

19

Shenzhen Getech Technology Co.,Ltd

7 Introduction to the LCD menu

7.1Tree diagram

7.2Main functions

LCD rotating knob:

Press the knob: Confirm or enter the next menu.

Rotate the knob: Roll the select options or change parameters.

LCD homepage, see picture (7-2)

1. Extruder temperature: Current temp/target temp

(Picture 7-1)

20

Shenzhen Getech Technology Co.,Ltd

2. Hot bed temperature: Current temp/target temp

3. Current X,Y,Z axis value

4. Feed rate: Current print feeding speed

5. Current print time

(Picture 7-2)

Note: Rotating the knob can change the printing feed rate during printing. We suggest users not

changing the feed rate too much or it will make the motors to skip caused by too fast speed

and affect the print quality.

Press the knob to enter the next menu (Picture 7-3):

Prepare: Prepare and test the printer before normal operation

Control: Printer temp and motion parameter setting

Print from SD: TF/SD card printing(No SD card is shown when the card is not

inserted)

About Printer: The printer info

(Picture 7-3)

The main functions of Prepare menu (Picture 7-4, 7-5):

Move axis: Move X/Y/Z axis and Extruder

Auto home: X/Y/Z axis homing

Disable steppers: Unlock motors

Preheat PLA: Manually pre-heat the hot bed and extruder before printing PLA.

Preheat ABS: Manually pre-heat the hot bed and extruder before printing ABS.

(Picture 7-4)

21

Shenzhen Getech Technology Co.,Ltd

(Picture 7-5)

The main functions of Control menu (Picture 7-6, 7-7):

Temperature: Change the temp of the hot bed and extruder in real time

during printing. Customize the temp of preheat PLA and preheat ABS.

Motion: Motion parameter setting in firmware. After modification, choose

“store memory” to save the change.

Filament: Open or close filament detector; set filament diameter.

Store settings: Save the parameters modified.

Load settings: If you need to restore to the original settings, please choose

this option.

Restore failsafe: Restore factory setting.

Initialize EEPROM: Initialize printer Settings

(Picture 7-6)

(Picture 7-7)

Test the motors’ function via LCD

Press the knob to enter the next menu; choose “Prepare”, choose “Auto home” to home the

printer, see picture (7-8).

(Picture 7-8)

22

Shenzhen Getech Technology Co.,Ltd

Choose “Move axis” to move motors. See picture (7-9)

(Picture 7-9)

Choose from “Move X/Y/Z/Extruder “and rotate the knob to move them. See picture (7-10).

(Picture 7-10)

Choose “Move 1mm”, see picture (7-11).

(Picture 7-11)

Note: we suggest using 1mm to test each axis.

After axis’ testing finished, if you want to unlock the motor, choose “Prepare>Disable steppers”,

see picture (7-12).

(Picture 7-12)

When the motors are unlocked, you can move them by hand.

23

Shenzhen Getech Technology Co.,Ltd

8Software setting

8.1Install driver

Two printing choices for A10: TF card printing and USB printing.

TF card printing: After leveling, insert the TF card into the slot, and choose a .gcode file to start

printing.

USB printing: Connect the printer and computer with a USB cable to control the printer with

slicing software such as Repetier-Host. Because of some unstable factors such as signal

interference, the USB printing prone to fail. So we suggest choosing TF card printing.

The details of USB printing are as follows:

Firstly, turn on the printer, and connect the printer to computer with a USB cable. Normally, the

computer will automatically search the install driver. The newest communication chip of A10 is

CH340. See picture (8-1).

(Picture 8-1)

If it fails to automatically install the driver in computer, then check whether the driver is installed

successfully or not. Click to choose “My computer>Property>Device manager”.

If it shows the exclamation mark as picture below (8-2), then you need manually install the driver.

24

Shenzhen Getech Technology Co.,Ltd

(Picture 8-2)

Download link for CH340:

https://www.geeetech.com/index.php?main_page=download&download_id=40

After the driver is installed, check the “Device manager” and see if it is same as the picture below

(8-3). If so, it means the driver is successfully installed.

(Picture 8-3)

25

Shenzhen Getech Technology Co.,Ltd

8.2Install slicing software

Repetier-Host is the default slicing software here. Download address:

https://www.repetier.com/download-software/

Set printer parameters

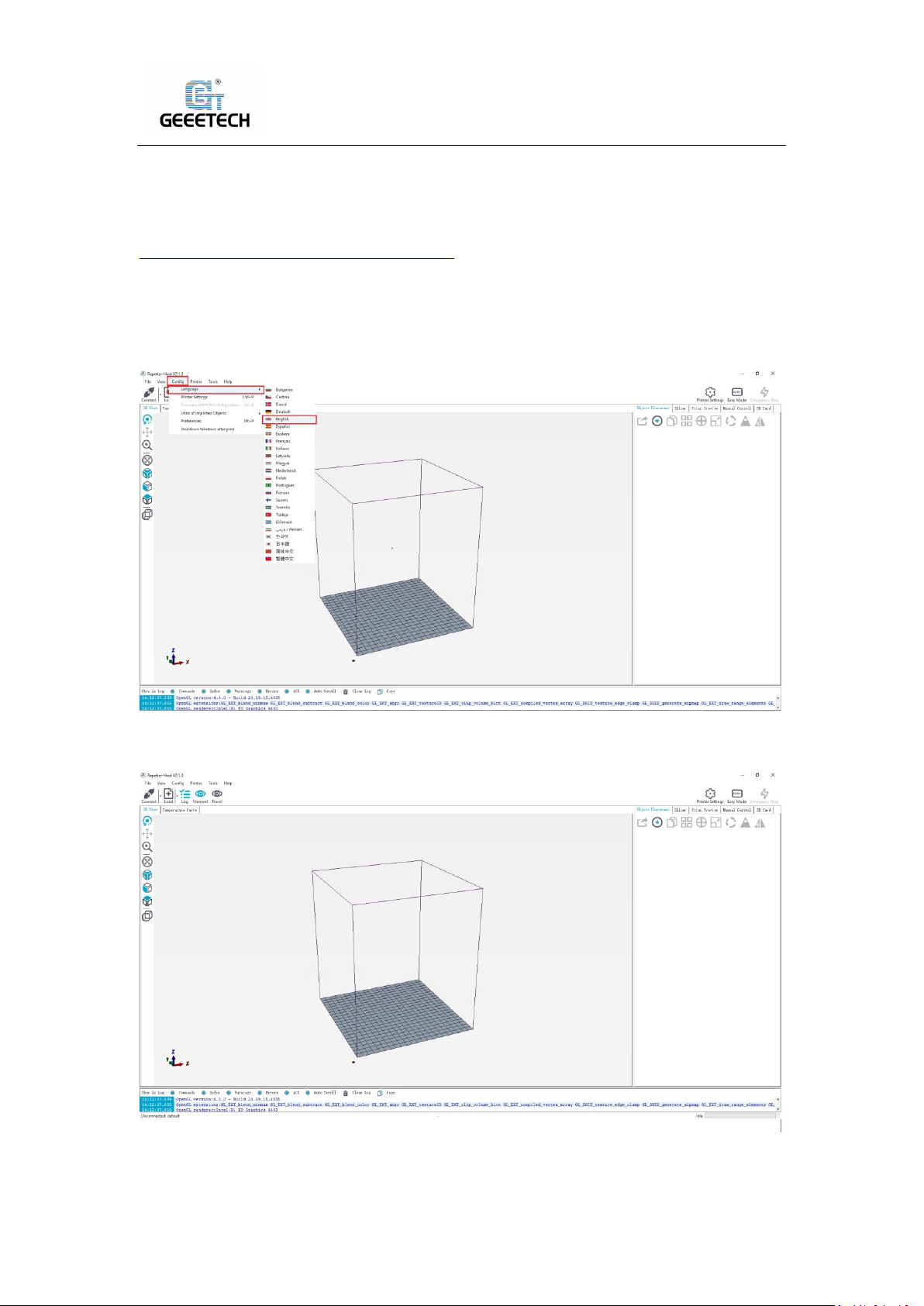

When Repetier-Host is installed, turn on the printer and open the Repetier-Host. Repetier-Host

supports several languages. You can choose your native language from Config>Language (Picture

8-4 for details).

(Picture 8-4)

English interface for your reference (picture 8-5).

(Picture 8-5)

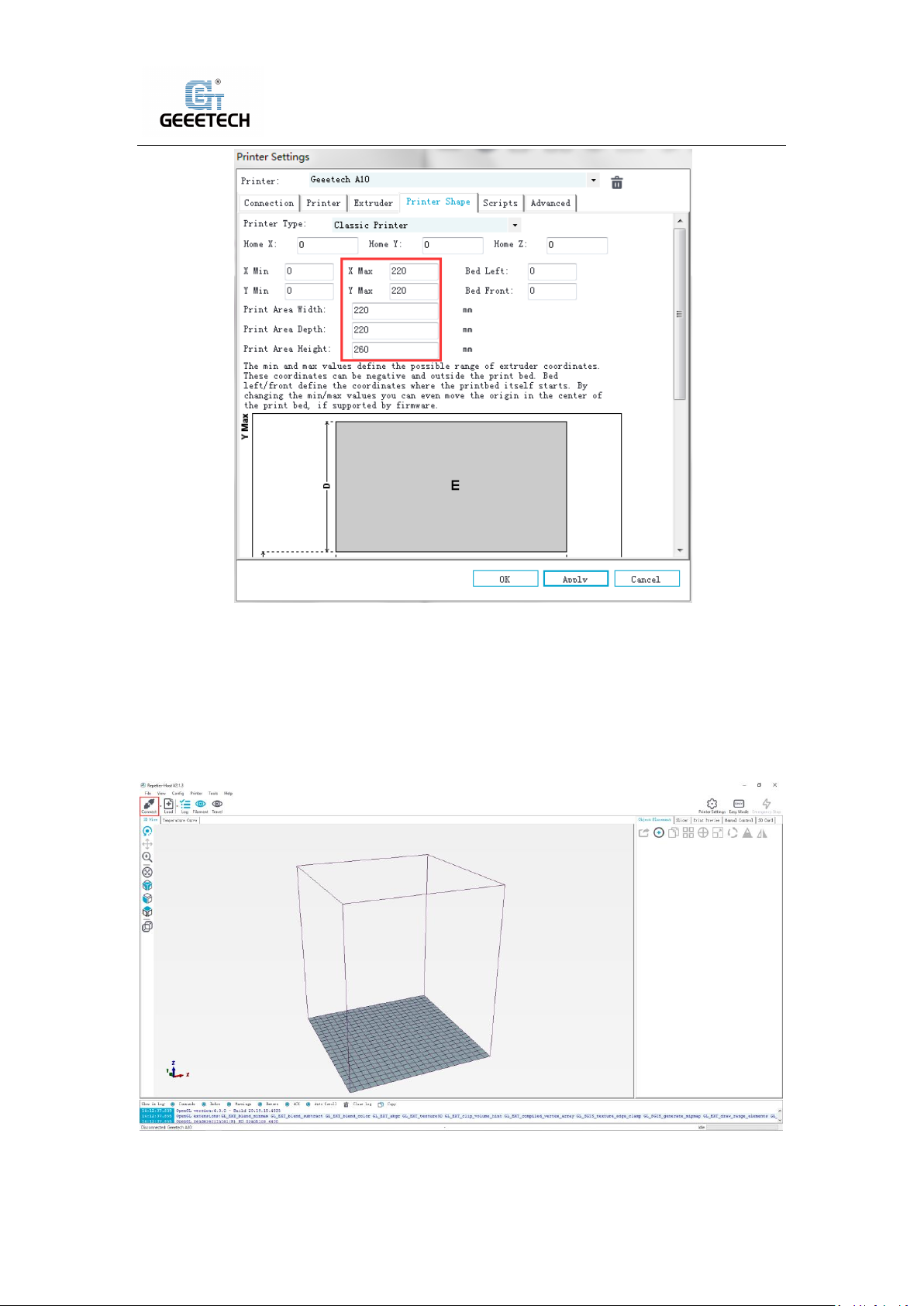

Using the Repetier-Host for the first time, printer parameters need to be configured before

26

Shenzhen Getech Technology Co.,Ltd

connecting. Click “Printer settings” on the top right corner, see picture (8-6).

(Picture 8-6)

It pops up the content as the picture below. Write down the relevant info accordingly.

(Red box is the key content)

a. Connection dialog (Picture 8-7):

(Picture 8-7)

b. Printer dialog (Picture 8-8):

Do not check "Return to the parking position after the end of the task interruption" to prevent

27

Shenzhen Getech Technology Co.,Ltd

the machine from damaging the model after the end of printing.

c. Extruder dialog (Picture 8-9):

(Picture 8-8)

d. Printer shape dialog (Picture 8-10):

(Picture 8-9)

28

Shenzhen Getech Technology Co.,Ltd

(Picture 8-10)

Now the printer parameters are set.

Note: If the operating system is Mac OS, Repetier Host baud rate is also set to 250,000.

Set slicing parameters

After setting the printer parameters, click “Connect” on the top left corner. The color of the icon

changed to green means the printer connects to the Repetier-Host successfully. Click it again to

disconnect. See picture (8-11).

(Picture 8-11)

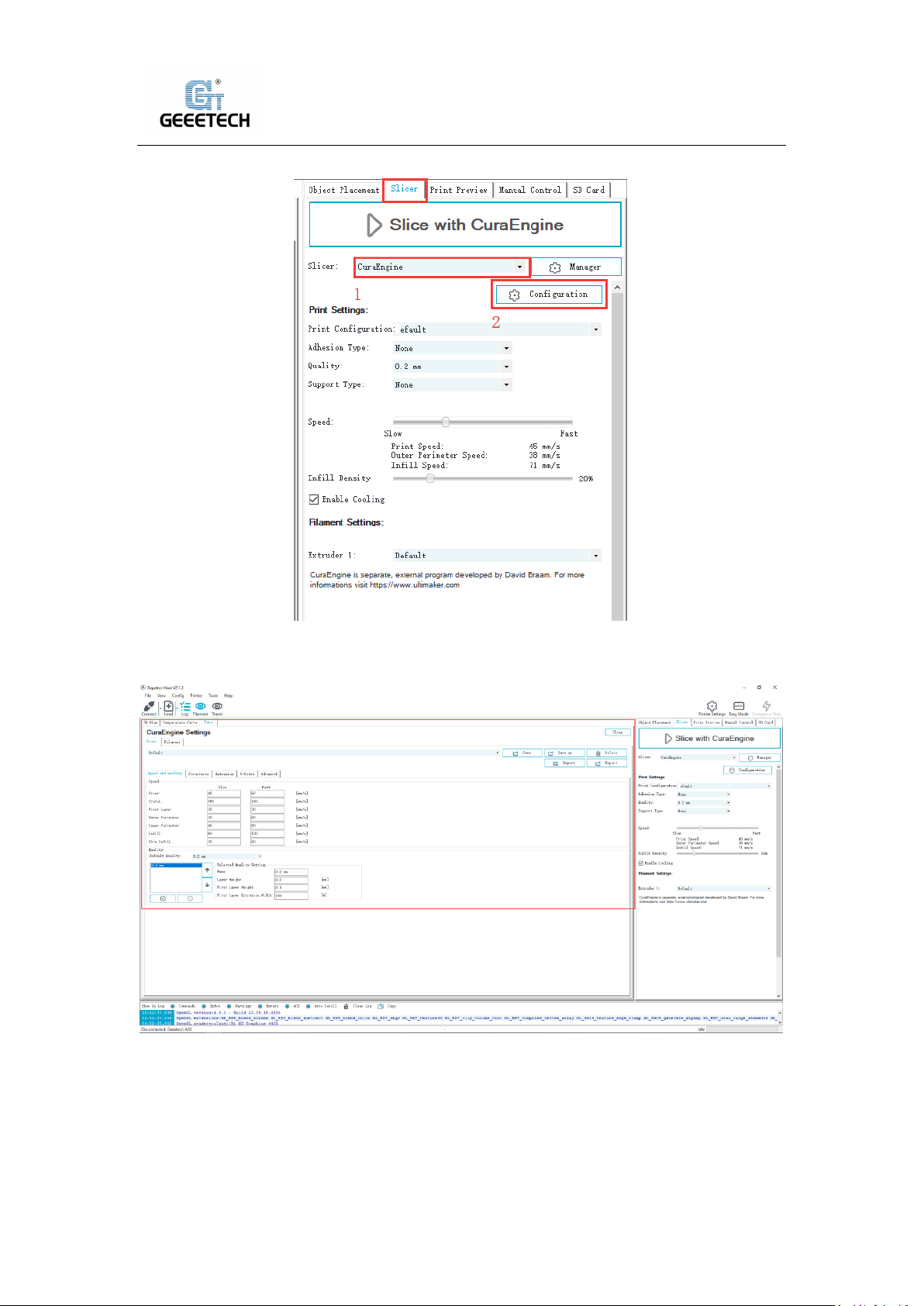

After successfully connected, choose “Slicer> CuraEngine” and open the configuration menu. See

29

picture (8-12).

Shenzhen Getech Technology Co.,Ltd

(Picture 8-12)

It pops up dialog as picture below (8-13):

(Picture 8-13)

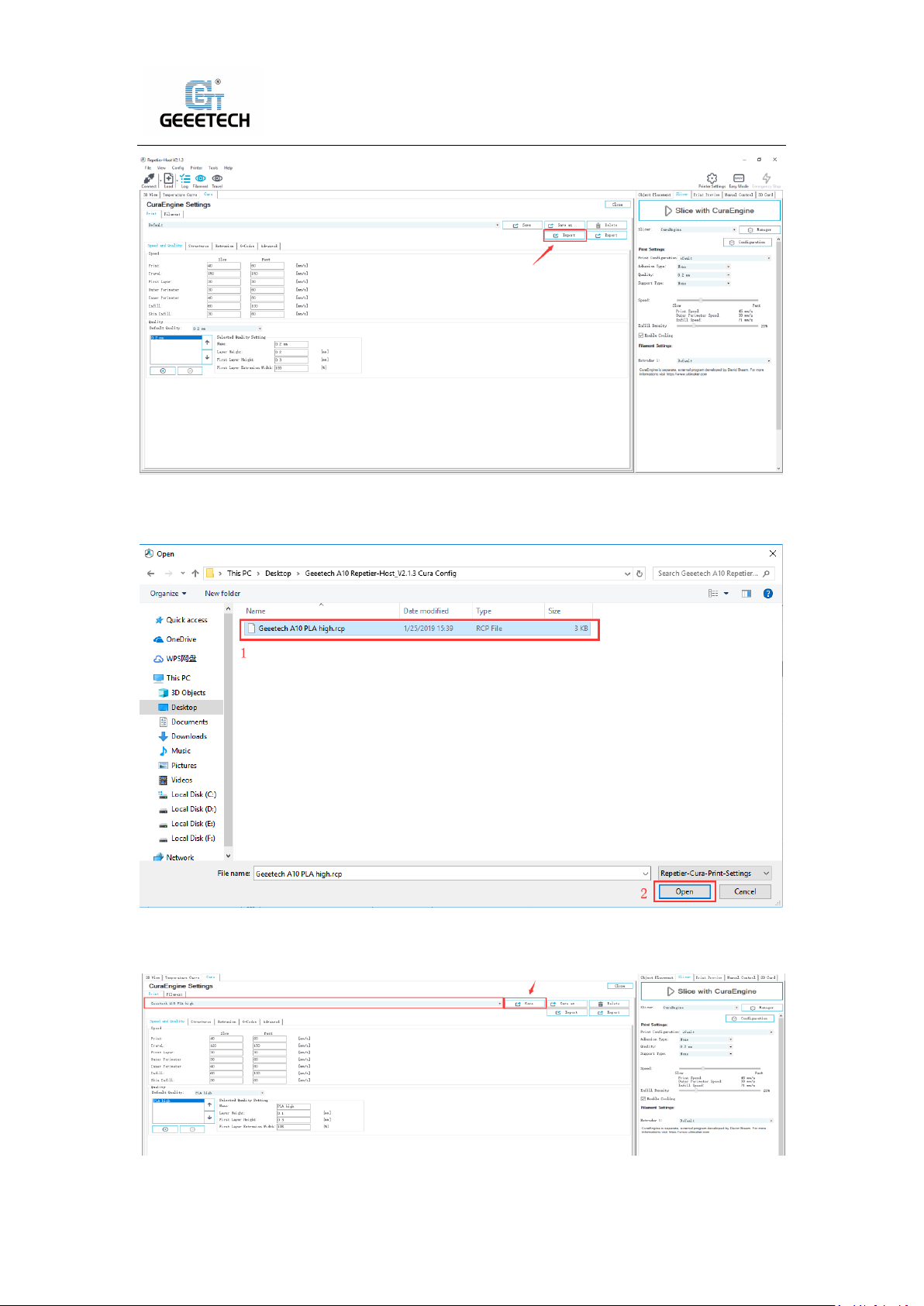

Printer parameters are important to print quality. Customers need to run tests to find the best

parameters for their printers. Here we provide a configuration file for your reference (“Geeetech

A10 PLA high.rcp”). You can import it according to the steps as follows. The following is an

example of parameters for PLA (Picture 8-14):

Click “Print>Import”

30

Shenzhen Getech Technology Co.,Ltd

(Picture 8-14)

It pops up the dialog as below (Picture 8-15). Choose “Geeetech A10 PLA high.rcp” and open it.

(Picture 8-15)

Now, the configuration file is imported, click “Save”. See picture (8-16).

(Picture 8-16)

31

Shenzhen Getech Technology Co.,Ltd

Click “Filament>Import”, see picture (8-17).

(Picture 8-17)

It pops up dialog as below (Picture 8-18); choose “Geeetech A10 PLA high fi.rcf”.

(Picture 8-18)

Now, the configuration file is imported. Click “Save”. See picture (8-19).

32

Shenzhen Getech Technology Co.,Ltd

(Picture 8-19)

Choose “Geeetech A10 PLA high” as print configuration and “Geeetech A10 PLA high fi” as

printing material setting. Details see picture (8-20) below.

(Picture 8-20)

Now parameters setting are finished.

8.3 USB printing

You can start USB printing when the parameters setting are finished.

The model file format is .stl for 3D printer. You can download free models from websites such as

33

Shenzhen Getech Technology Co.,Ltd

thingiverse.com You can also design your own models.

Load the printing model

Open the Repetier-Host and click “load”. Choose a file and open it. See picture (8-21, 8-22).

(Picture 8-21)

(Picture 8-22)

When it is loaded, you can use the buttons as picture below (picture 8-23) to zoom in, zoom out

or rotate the model.

34

Shenzhen Getech Technology Co.,Ltd

(Picture 8-23)

Adjust the direction of the model so that the flat part of the model is touching the hot bed. See

picture below (8-24):

(Picture 8-24)

Note: If the model loaded is too big and beyond the printing platform, you need to zoom out

the model. You can perform a uniform scaling. See picture (8-25):

35

Shenzhen Getech Technology Co.,Ltd

(Picture 8-25)

Or zoom in/out them separately, see picture (8-26).

(Picture 8-26)

Model slicing

When the size and direction of the model are set, choose the imported slicing parameters, and

click “Slice with CuraEngine”. See picture (8-27).

36

Shenzhen Getech Technology Co.,Ltd

(Picture 8-27)

(Picture 8-28)

Waiting for a while after the slice is complete, you can find the model information such as

estimated print time, the amount of filament needed, etc. Click “Print” to start USB printing. The

printer will heat to the target temp and then start printing. Under high temperature, the filament

will flow out of the nozzle, which is normal. You can use tweezers to clean up the residual

material of the nozzle.

37

Shenzhen Getech Technology Co.,Ltd

8.4 TF card printing

(Picture 8-29)

When all parameters are set, click “Save for SD print”. It will pop up a dialog as picture below

(See picture 8-30) and then click the save button to generate a .Gcode file. Copy the Gcode file to

the TF card.

(Picture 8-30)

Insert the TF card into the TF card slot on the front side of the machine. Press the knob to enter

the main menu and choose “Print from SD”. See picture (8-31)

38

Shenzhen Getech Technology Co.,Ltd

(Picture 8-31)

Choose the corresponding Gcode file to start printing.

Note:

The printer can only read gcode file and the file name should be English letters, a space,

an underscore or their combination.

The Gcode file cannot be placed in any folder of the TF card, otherwise it cannot be read.

39

Shenzhen Getech Technology Co.,Ltd

9Function introduction

9.1 Power loss-resuming capability

In the normal printing process, such as accidental power outage, after the power is restarted, the

pop-up prompt option (Power outage), choose “Resume print”. See picture (9-1).

(Picture 9-1)

When it reaches the target temperature, the X and Y axes will auto home. The extruder will

extrude the residue in the nozzle. Use a tweezers to clean the nozzle before starting printing

again.

Note:

When power outage, move the nozzle away from the printing model in case the filament

oozes out on to the print.

Be sure to clean the residue in the nozzle before restarting the print or it would affect the

quality of the print.

9.2 Reset button

The reset button is below the knob. When the printer works abnormally, press the reset button

to reset the printer to avoid any damage. See picture (9-2).

(Picture 9-2)

40

Shenzhen Getech Technology Co.,Ltd

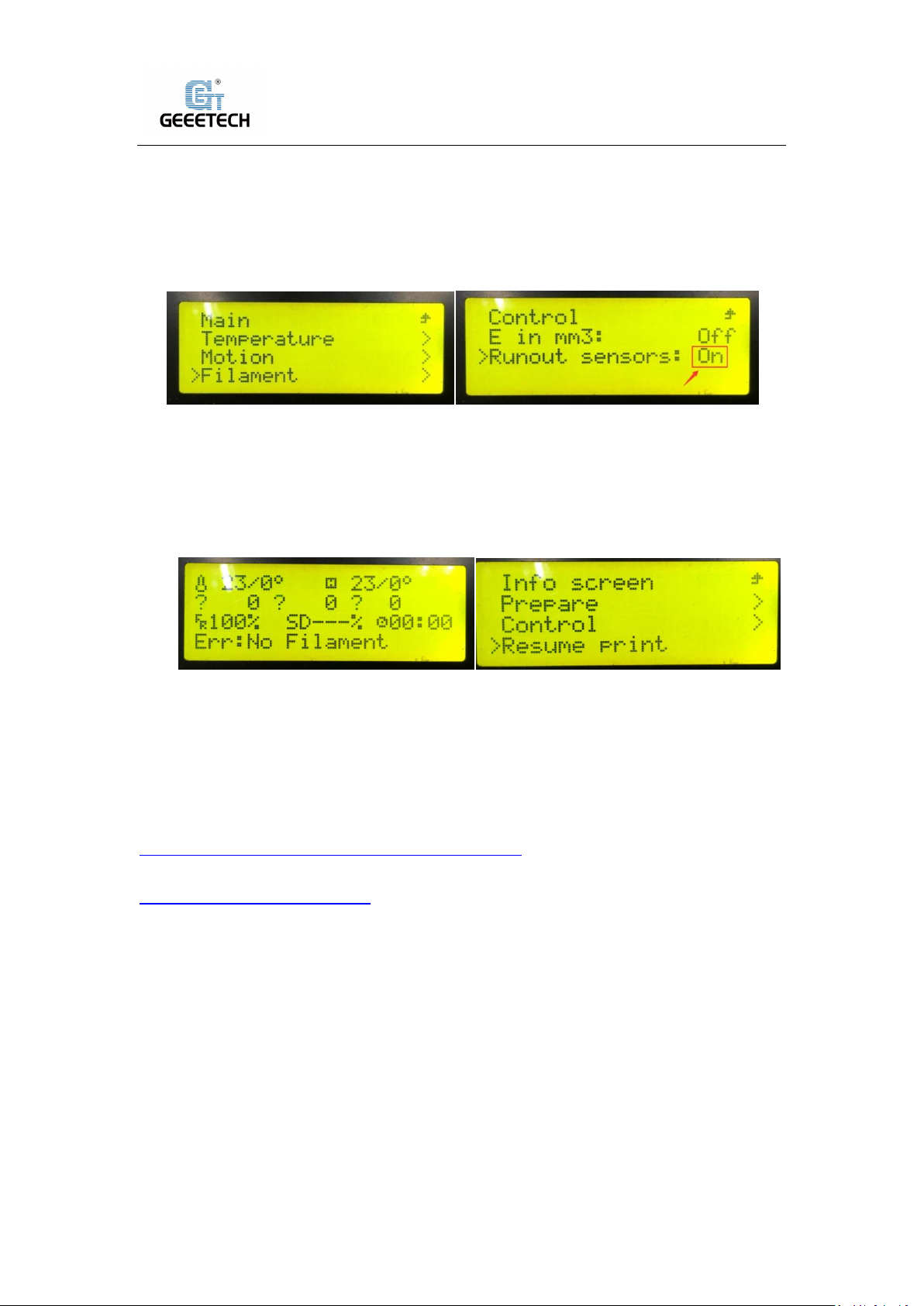

9.3Filament run-out sensor (Optional)

Before using this function, please check whether it is turned on or not. Choose

“Control”>”Filament”>“Runout sensors” and after entering the menu, make sure that "Runout

sensors" is "On". See pictures (9-3, 9-4).

(Picture 9-3) (Picture 9-4)

It will pop up the notification “Err: No Filament” when the filament is run out during

printing and the printer will stop. See picture (9-5).

Press the extruder handle, remove the remaining filament before loading the new filament.

When the filament is loaded, use a tweezers to clean the nozzle. Press the knob to enter the

main menu, and choose “Resume print” to re-start the printing. See picture (9-6).

(Picture 9-5) (Picture 9-6)

9.4 3D touch for auto bed leveling (Optional)

This printer supports auto bed leveling. Refer to the link below to know how to install the 3d

touch sensor.

https://www.youtube.com/watch?v=_RtsZDbR2po&t=66s

Visit our official forum

http://www.geeetech.com/forum/

41

Shenzhen Getech Technology Co.,Ltd

10 FAQ (Frequently Asked Questions)

10.1 Abnormal extrusion

The filament is tangled

The nozzle temp is too low to reach the melting temperature required.

There is carbonized residue inside the nozzle. Please replace it with the spare nozzle

Insufficient heat dissipation of radiator of the extruder head causes the filament in

the tube to melt in advance and the extrusion strength is insufficient. Please check

whether the cooling fan works normally.

The printing speed is so fast that the extruding speed can’t match it. Please reduce

the printing speed.

10.2The gear of the extruder skips and makes an abnormal

noise

The nozzle is clogged; please refer to 10.1 abnormal extrusions.

Check whether the friction force between the extruder gear and the filament is

enough. Please clean the residue.

Check whether the voltage of the driver of the extruder is normal, and try to

increase it by 0.1v until it works normally, max 1.2v.

10.3 First layer abnormal

Non-stick: a. the nozzle is too far from the hot bed. Please re-level the bed, try to

stick masking paper or glue stick on the surface of the hot bed.

Not extruding and the bed scratched: a. the nozzle is too close from the hot bed.

Please re-level the bed; b. check if the nozzle extrusion normal.

42

Shenzhen Getech Technology Co.,Ltd

10.4 Layer shift

The printing speed is too fast. Please slow it down.

The belt of X or Y axis is too lose. Please tighten it.

The X or Y axis synchronization wheel is not fixed firmly. Please adjust the eccentric

nuts.

The voltage of the driver of X/Y axis is too low.

10.5 Print stopped

USB printing: the signal is interfered. Please copy the model to TF card and print via TF card.

TF card printing: the gcode file in the TF card is abnormal, please slice again.

The quality of the TF card is poor. Please try another TF card.

The power supply voltage in the area is not stable; please print after the voltage is

stable.

Visit our official forum for more information:

http://www.geeetech.com/forum/viewtopic.php?f=98&t=61864

43

Shenzhen Getech Technology Co.,Ltd

11Declaration

11.1Terms

Please be advised of the following terms (the “Terms”) regarding this User Manual (this

“Manual”):

All information in this Manual is subject to change at any time without notice and is provided for

convenience purposes only. Geeetech reserves the right to modify or revise this Manual in its

sole discretion and at any time. You agree to be bound by any modifications and/or revisions.

Contact the Geeetech Support Team for up-to-date information.

11.2Disclaimers

Neither Geeetech nor any of our affiliates warrants the accuracy or completeness of the

information, products, or services provided by or through this Manual, which are provided “as is”

and without any express or implied warranties of any kind, including warranties of merchant

ability, fitness for a particular purpose, or non-infringement of intellectual property. To the fullest

extent permissible by the applicable law, we hereby disclaim all liability for product defect or

failure or for claims that are due to normal wear, product misuse or abuse, product modification,

improper product selection, noncompliance with any codes, or misappropriation. To the fullest

extent permissible by the applicable law, we hereby disclaim any and all responsibility, risk,

liability, and damages arising out of death or personal injury resulting from assembly or operation

of our products. Geeetech assumes no responsibility, nor will be liable, for any damages to, or

any viruses or malware that may infect your computer, telecommunication equipment, or other

property caused by or arising from your downloading of any information or materials related to

Geeetech products.

44

Shenzhen Getech Technology Co.,Ltd

Shenzhen Getech Technology Co.,ltd

www.geeetech.com

45

Loading...

Loading...