Page 1

GE

Intelligent Platforms

Programmable Control Products

VersaMotion

Servo Motors and Amplifiers

User’s Manual, GFK-2480A

October 2012

Page 2

GFL-002

Warnings, Cautions, and Notes

as Used in this Publication

Warning

Warning notices are used in this publication to emphasize that hazardous voltages,

currents, temperatures, or other conditions that could cause personal injury exist in this

equipment or may be associated with its use.

In situations where inattention could cause either personal injury or damage to equipment,

a Warning notice is used.

Caution

Caution notices are used where equipment might be damaged if care is not taken.

Note: Notes merely call attention to information that is especially significant to

understanding and operating the equipment.

This document is based on information available at the time of its publication. While efforts

have been made to be accurate, the information contained herein does not purport to cover all

details or variations in hardware or software, nor to provide for every possible contingency in

connection with installation, operation, or maintenance. Features may be described herein

which are not present in all hardware and software systems. GE Intelligent Platforms assumes

no obligation of notice to holders of this document with respect to changes subsequently made.

GE Intelligent Platforms makes no representation or warranty, expressed, implied, or statutory

with respect to, and assumes no responsibility for the accuracy, completeness, sufficiency, or

usefulness of the information contained herein. No warranties of merchantability or fitness for

purpose shall apply.

* indicates a trademark of GE Intelligent Platforms, Inc. and/or its affiliates. All other

trademarks are the property of their respective owners.

©Copyright 2011 GE Intelligent Platforms, Inc.

All Rights Reserved

Page 3

Contact Information

Online technical support and

GlobalCare

http://support.ge-ip.com

Additional information

http://www.ge-ip.com/

Solution Provider

solutionprovider.ip@ge.com

Online Technical Support

http://support.ge-ip.com

Phone

1-800-433-2682

International Americas Direct Dial

1-780-420-2010 (if toll free 800 option is unavailable)

Technical Support Email

support.ip@ge.com

Customer Care Email

customercare.ip@ge.com

Primary language of support

English

Online Technical Support

http://support.ge-ip.com

Phone

+800-1-433-2682

EMEA Direct Dial

+1-780-401-7717 (if toll free 800 option is unavailable or if

dialing from a mobile telephone)

Technical Support Email

support.emea.ip@ge.com

Customer Care Email

customercare.emea.ip@ge.com

Primary languages of support

English, French, German, Italian, Czech, Spanish

Online Technical Support

http://support.ge-ip.com

Phone

+86-400-820-8208

+86-21-3217-4826 (India, Indonesia, and Pakistan)

Technical Support Email

support.cn.ip@ge.com (China)

support.jp.ip@ge.com (Japan)

support.in.ip@ge.com (remaining Asia customers)

Customer Care Email

customercare.apo.ip@ge.com

customercare.cn.ip@ge.com (China)

If you purchased this product through an Authorized Channel Partner, please contact the seller

directly.

General Contact Information

Technical Support

If you have technical problems that cannot be resolved with the information in this manual, please

contact us by telephone or email, or on the web at http://support.ge-ip.com

Americas

Europe, the Middle East, and Africa

Asia Pacific

iii VersaMotionServo Motors and Amplifiers User’s Manual–October 2012 GFK-2480A

Page 4

Page 5

Contents

Introduction .................................................................................................................... 1-1

1.1 Product Overview ....................................................................................................... 1-3

1.2 Servo Drive and Servo Motor Combinations ............................................................ 1-11

1.3 Servo Drive Control Modes ....................................................................................... 1-12

Unpacking and Installation ........................................................................................... 2-1

2.1 Unpacking and Inspection .......................................................................................... 2-2

2.2 Storage Conditions ..................................................................................................... 2-2

2.3 Installation ................................................................................................................... 2-3

2.4 Molded-Case Circuit Breaker, Fuse and Leakage Current ........................................ 2-8

Equipment Connections and Wiring ............................................................................ 3-1

3.1 Equipment Connections .............................................................................................. 3-2

3.2 Basic Wiring ................................................................................................................ 3-9

3.3 Input/Output Interface Connector CN1 ..................................................................... 3-11

3.4 Encoder Connector CN2 ........................................................................................... 3-33

3.5 Serial Communication Connector CN3 ..................................................................... 3-34

3.6 Standard Connection Example ................................................................................. 3-36

Display and Operation ..................................................................................................... 4-1

4.1 Description of the Digital Keypad................................................................................ 4-2

4.2 Display Flowchart ....................................................................................................... 4-3

4.3 Status Display ............................................................................................................. 4-4

4.4 General Function Operation ....................................................................................... 4-8

Trial Run and Tuning Procedure .................................................................................. 5-1

5.1 Trial Run without a Load ............................................................................................. 5-2

5.2 Tuning Procedure ..................................................................................................... 5-15

Control Modes of Operation ................................ ......................................................... 6-1

6.1 Control Mode Summary .............................................................................................. 6-2

6.2 Position Control Mode ................................................................................................ 6-4

6.3 Speed Control Mode ................................................................................................. 6-20

6.4 Torque Control Mode ................................................................................................ 6-38

6.5 Control Mode Selection ............................................................................................ 6-43

6.6 Others ....................................................................................................................... 6-46

Parameters ...................................................................................................................... 7-1

7.1 Definitions ................................................................................................................... 7-2

7.2 Parameter Summary ................................................................................................... 7-3

7.3 Detailed Parameter Listings ...................................................................................... 7-20

7.4 Input Function Definitions ......................................................................................... 7-92

7.5 Output Function Definitions ...................................................................................... 7-97

GFK-2480A v

Page 6

Contents

MODBUS Communications .......................................................................................... 8-1

8.1 Communication Hardware Interface ........................................................................... 8-2

8.2 Communication Parameter Settings ........................................................................... 8-6

8.3 MODBUS Communication Protocol .......................................................................... 8-10

8.4 Communication Parameter Write-in and Read-out ................................................... 8-19

Maintenance and Inspection ........................................................................................ 9-1

9.1 Basic Inspection .......................................................................................................... 9-2

9.2 Maintenance ............................................................................................................... 9-3

9.3 Life of Replacement Components .............................................................................. 9-4

Diagnostics .................................................................................................................... 10-1

10.1 Fault Messages Table ............................................................................................ 10-2

10.2 Potential Causes and Corrective Actions ............................................................... 10-4

10.3 Clearing Faults ...................................................................................................... 10-10

Specifications .............................................................................................................. 11-1

11.1 Servo Drive AC Input Current Ratings .................................................................... 11-2

11.2 Servo Drive Specifications ...................................................................................... 11-3

11.3 Servo Motor Specifications ..................................................................................... 11-5

11.4 Servo Motor Speed-Torque Curves ........................................................................ 11-8

11.5 Overload Characteristics ...................................................................................... 11-10

11.6 Dimensions of Servo Drives ................................................................................. 11-12

11.7 Dimensions of Servo Motors ................................................................................. 11-14

11.8 EMI Filters Selection ............................................................................................. 11-16

Application Examples ................................................................................................. 12-1

12.1 Position Control with Homing Function ................................................................... 12-2

12.2 Roller Feeding......................................................................................................... 12-4

12.3 Connecting to a PLC ............................................................................................... 12-6

12.4 Connecting to an Operator Interface .................................................................... 12-11

12.5 Position Control Mode (Pr Mode) ......................................................................... 12-12

12.6 Feed Step Control ................................................................................................. 12-15

12.7 Internal Auto Running Mode ................................................................................. 12-26

12.8 Homing Function ................................................................................................... 12-30

DSM314 Connections ................................................................................................... A-1

Equipment Needed for One-Axis Connection to DSM314................................................ A-1

Avoiding Electrical Noise in the Installation ...................................................................... A-1

Connection Diagram ......................................................................................................... A-2

VersaMotion Start-up (Do This First) ................................................................................ A-3

DSM314 Start-Up .............................................................................................................. A-3

vi VersaMotion Servo Motors and Amplifiers User’s Manual–October 2012 GFK-2480A

Page 7

Contents

Accessories ..................................................................................................................... B-1

B.1 Power Connectors ...................................................................................................... B-2

B.2 Power Cables ............................................................................................................. B-3

B.3 Encoder Connectors ................................................................................................... B-5

B.4 Encoder Cables .......................................................................................................... B-6

B.5 I/O Signal Connector .................................................................................................. B-7

B.6 Drive- to-Computer Communication Cable ................................................................ B-7

B.7 Terminal Block ............................................................................................................ B-8

GFK-2480A Contents vii

Page 8

Page 9

Chapter

1

Introduction

This chapter provides an overview of VersaMotion servo drives and motors.

Page

1.1 Product Overview 1-3

1.2 Servo Drive and Servo Motor Combinations 1-11

1.3 Servo Drive Control Modes 1-12

The rest of the manual describes VersaMotion products in detail, and explains how to install, operate

and maintain the servo drives and motors.

Chapter 2, Unpacking and Installation. Includes procedures for unpacking, initial inspection and

installation of a VersaMotion system.

Chapter 3, Equipment Connections and Wiring. Provides cable connection and wiring

procedures. Also provides detailed information on I/O signals.

Chapter 4, Display and Operation. Explains how to use the VersaMotion drive’s digital keypad.

Chapter 5, Trial Run and Tuning Procedure. Explains how to perform a trial run without a load

and how to tune the servo system with a load.

Chapter 6, Control Modes of Operation. Explains how to operate the VersaMotion drive in each

control mode. (The VersaMotion drive provides provide six single and five dual control modes,

which are summarized on page 1-12.)

Chapter 7, Parameters. Describes how to use the drive’s operating parameters, which can be

configured using the VersaMotion Configuration software.

Chapter 8, MODBUS Communications. Describes connections and parameter settings for RS232, RS-485 and RS-422 communications.

Chapter 9, Maintenance and Inspection. Explains how to perform preventive maintenance and

inspection of the servo drive.

Chapter 10, Diagnostics. Provides definitions and corrective actions for fault messages.

Chapter 11, Specifications. Provides physical and electrical characteristics of the VersaMotion

drives and servo motors.

Chapter 12, Application Examples. Provides sample applications using VersaMotion drives and

servo motors.

Appendix A, Accessories. Provides a reference to connectors, cables and terminal blocks used

with VersaMotion products.

GFK-2480A 1-1

Page 10

1

VersaMotion Servo Drive and Motor

For additional information about VersaMotion and related products, refer to the following manuals:

VersaMax Micro and Nano PLCs User’s Manual, GFK-1645

VersaMax Micro Two-Axis Servo Motion Expansion Modules User’s Manual, GFK-2471

DSM314 Motion Controller for PACSystems RX3i and Series 90-30 User's Manual, GFK-1742

User manuals, module datasheets, and other product documents are available online at

http://support.ge-ip.com.

1-2 VersaMotion User’s Manual – October 2012 GFK-2480A

Page 11

1

1.1 Product Overview

The VersaMotion family of servo motors offers high servo performance in a compact package. The

range of torque and motor power allows you to optimize performance, size and cost for your

application.

The motors range from 100 W to 3 kW with continuous torque ratings from 0.3 Nm to 19.1-Nm. Most

models are rated for 3000 RPM continuous with an intermittent rating of 5000 RPM. Motor feedback is

provided by a 2500 PPR encoder (10,000 quadrature counts per revolution) for a resolution of 0.036

degrees of a motor revolution. All motors have metric mounting configurations and include a straight

shaft with key and oil seal.

Motors are matched with VersaMotion amplifiers, which support a variety of configurable command

interface and operational modes. They provide simple stand-alone positioning capability using up to

eight stored motion profiles or can be connected to a motion controller using an analog velocity, analog

torque or pulse command interface.

The drives, motors, and accessories that make up the VersaMotion product family are listed on page

1-6.).

VersaMotion servo/amplifier products provide the following features:

Power range: 100 Watt to 3 kW (7 models)

Torque range: Continuous: 0.32-19.1 Nm, Peak: 0.96 – 57.3 Nm

Single and dual control modes: Position, Speed, Torque, Speed/Position, Speed/Torque and

Torque/Position

The RS-232/485/422 serial communications interface supports multi-drop system

configurations and Modbus ASCII or RTU communication protocol.

Encoder position output: A/B/Z with scalable resolution

Homing and jogging functions

Speed and torque limiting functions

Autotuning function

On-the-fly gain switching

Electronic gearing (pulse follower)

Configurable digital I/O: 8 Inputs and 5 Outputs

Analog inputs: 1 Speed or 2 Torque

Built-in touch pad and display provides convenient access to configuration parameters and

system information.

Resonance suppression using notch and low pass filters

Motors with 24 VDC holding brakes are available (except 100 Watt motor) for vertical axes or

applications that need to hold position during power loss.

GFK-2480A Chapter 1 Introduction 1-3

Page 12

1

LED Display

The 5 digit, 7 segment LED displays

the servo status or

fault codes

Heatsink

Used to secure servo drive and for

heat dissipation

Charge LED

A lit LED indicates that either power is

connected to the servo drive OR a

residual charge is present in the drive's

internal power components.

DO NOT TOUCH ANY ELECTRICAL

CONNECTIONS WHILE THIS LED IS LIT.

(Please refer to the Safety Precautions on

page i).

Control Circuit Terminal (L1, L2)

Used to connect

single-phase VAC supply.

50/60Hz

200~230Vac,

Main Circuit Terminal (R, S, T)

Used to connect

commercial power supply

50/60Hz

200~230V,

Ground Terminal

Servo Motor Output (U, V, W)

Used to connect servo motor. Never

connect the output terminal to main

circuit power.

The AC servo drive

may be destroyed beyond repair if

incorrect cables are connected to

the output terminals.

Internal / External Regenerative

Resistor Terminal

1)

resistor, connect P and C to the

regenerative resistor and ensure that

the circuit between P and D

is open.

2) When using the internal regenerative

resistor, ensure that the circuit

between P and D is closed and the

circuit between P and C is open.

When using an external regenerative

Operation Panel

Used function keys to perform status

display, monitor and diagnostic, function

and parameter setting.

Function Keys:

MODE : Press this key to select/change

mode

SHIFT :

Press this key to shift

left

UP : Press this key to increase values

on the display

DOWN :

Press this key to decrease

values on the display

SET : Press this key to store data

Shift Key has several functions:

moving the cursor and indexing

through the parameter groups

cursor to

the

I/O Interface

Used to connect Host Controller (PLC)

or control I/O signal

Encoder Interface

Used to connect Encoder of

Servo Motor

Serial Communication Interface

For RS-485 / 232 / 422 serial

communication

Used to connect personal computer

or other controllers

1.1.1 Servo Drive Features

1-4 VersaMotion User’s Manual – October 2012 GFK-2480A

Page 13

1

1.1.2 VersaMotion System Architectures

The VersaMotion servos can be used in the following types of system architectures:

As a standalone simple position indexer using up to eight stored positions that are selected and

triggered using discrete inputs or the serial communication interface. Positions can be

configured or changed using a teach function or over the serial communication interface.

Simple electronic gearing (pulse follower) using a configurable fixed gear ratio is also

supported.

With the VersaMax Micro 20/40/64 built-in CPU motion functions.

With the VersaMax Micro two-axis motion expansion module using the 500 KHz pulse

command interface for application that require more complex motion sequences, such as basic

positioning with registration control.

With Quick Panel Control and the VersaMax Micro two-axis motion expansion module using

the 500 KHz pulse command interface to provide an integrated motion, logic and view solution.

With a DSM314 Motion Controller using either an analog velocity or analog torque command.

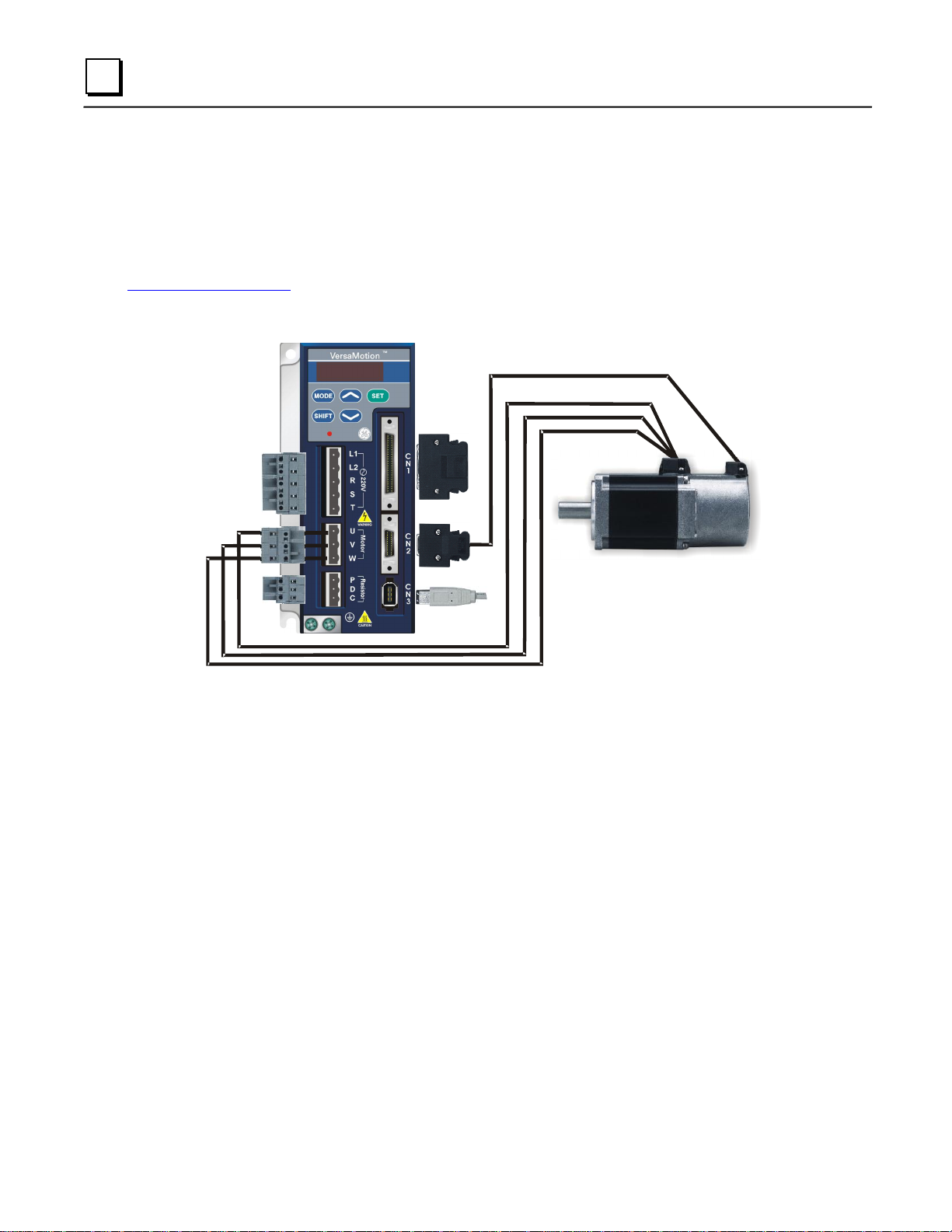

1.1.3 VersaMotion System Components

A complete and workable VersaMotion servo system includes the following parts:

1) Servo amplifier

2) Servo motor

3) One operating lever (for wire to terminal block insertion)

4) One power cable, which is used to connect the servo motor and the servo drive’s U, V,

and W terminals.

5) One encoder cable, which is used to connect the encoder of servo motor and CN2

terminal of servo drive.

6) CN1 I/O connector: 50 pin Connector (IC800VMACONCN1), Breakout Terminal Board

and Cable Kit (IC800VMTBC005), or Flying Lead I/O Cable (IC800VMCI010 — 1

meter) or IC800VMCI030 — 3meter)

7) CN3 serial communication cable (IC800VMCS030)

For 100W — 1KW models:

8) Five-pin Terminal Block for L1, L2, R, S, T (Included with amplifier.)

9) Three-pin Terminal Block for U, V, W (Included with amplifier.)

10) Three-pin Terminal Block for P, D, C (Included with amplifier.

Note: The 2kW and 3kW amplifiers have built-in terminal blocks.

GFK-2480A Chapter 1 Introduction 1-5

Page 14

1

IC800VMA 30 2

VersaMotion Amplifier

Power Rating

01 = 100 Watt 10 = 1000 Watt

02 = 200 Watt 20 = 2000 Watt

04 = 400 Watt 30 = 3000 Watt

07 = 750 Watt

Voltage

2 = 200–230 VAC, 1 or 3 phase (100-750W)

2 = 200–230 VAC, 3 phase (2kW & 3kW)

Part Number

Power Rating (Watts)

IC800VMA012

100

IC800VMA022

200

IC800VMA042

400

IC800VMA072

750

IC800VMA102

1000

IC800VMA202

2000

IC800VMA302

3000

IC800VMM 30 L N KS E25

VersaMotion Motor

Power Rating

01 = 100 Watt

02 = 200 Watt

04 = 400 Watt

07 = 750 Watt

10 = 1000 Watt

20 = 2000 Watt

30 = 3000 Watt

Feedback

E25 = 2500 PPR Encoder

Shaft Configuration

KS= Straight Shaft, Key & Oil Seal

Inertia Type

L = Low Inertia

Brake

N = No Brake

B = 24 VDC Holding Brake

Part Number

Power Rating (Watts)

IC800VMM01LNKSE25

100

IC800VMM02LNKSE25

200

IC800VMM04LNKSE25

400

IC800VMM07LNKSE25

700

IC800VMM10LNKSE25

1000

IC800VMM20LNKSE25

2000

IC800VMM30LNKSE25

3000

Amplifiers

Motors

Without brake

1-6 VersaMotion User’s Manual – October 2012 GFK-2480A

Page 15

1

Part Number

Power Rating (Watts)

IC800VMM01LBKSE25

100

IC800VMM02LBKSE25

200

IC800VMM04LBKSE25

400

IC800VMM07LBKSE25

700

IC800VMM10LBKSE25

1000

IC800VMM20LBKSE25

2000

IC800VMM30LBKSE25

3000

Part Number

Description

IC800VMCExxx

Encoder Cable (100W to 750W)

IC800VMCE1xxx

Encoder Cable (1000W & larger)

Part Number

Description

IC800VMCPxxx

Motor Power Cable (100W to 750W)

IC800VMCP1xxx

Motor Power Cable (1kW)

IC800VMCP2xxx

Motor Power Cable (2kW & 3kW)

Part Number

Description

IC800VMCBxxx

Motor Power & Brake Cable (200W to 750W)

IC800VMCB1xxx

Motor Power & Brake Cable (1kW)

IC800VMCB2xxx

Motor Power & Brake Cable (2kW & 3kW)

With Brake

Accessories

Cables

Note: xxx = length in 0.1 meter increments.

Standard lengths (other lengths available):

xxx=030 3 meters

xxx=050 5 meters

xxx=100 10 meters

xxx=200 20 meters

Encoder Cables

Motor Power Cables

Motor Power & Brake Cables

Note: The 100 Watt motor does not have a brake option.

GFK-2480A Chapter 1 Introduction 1-7

Page 16

1

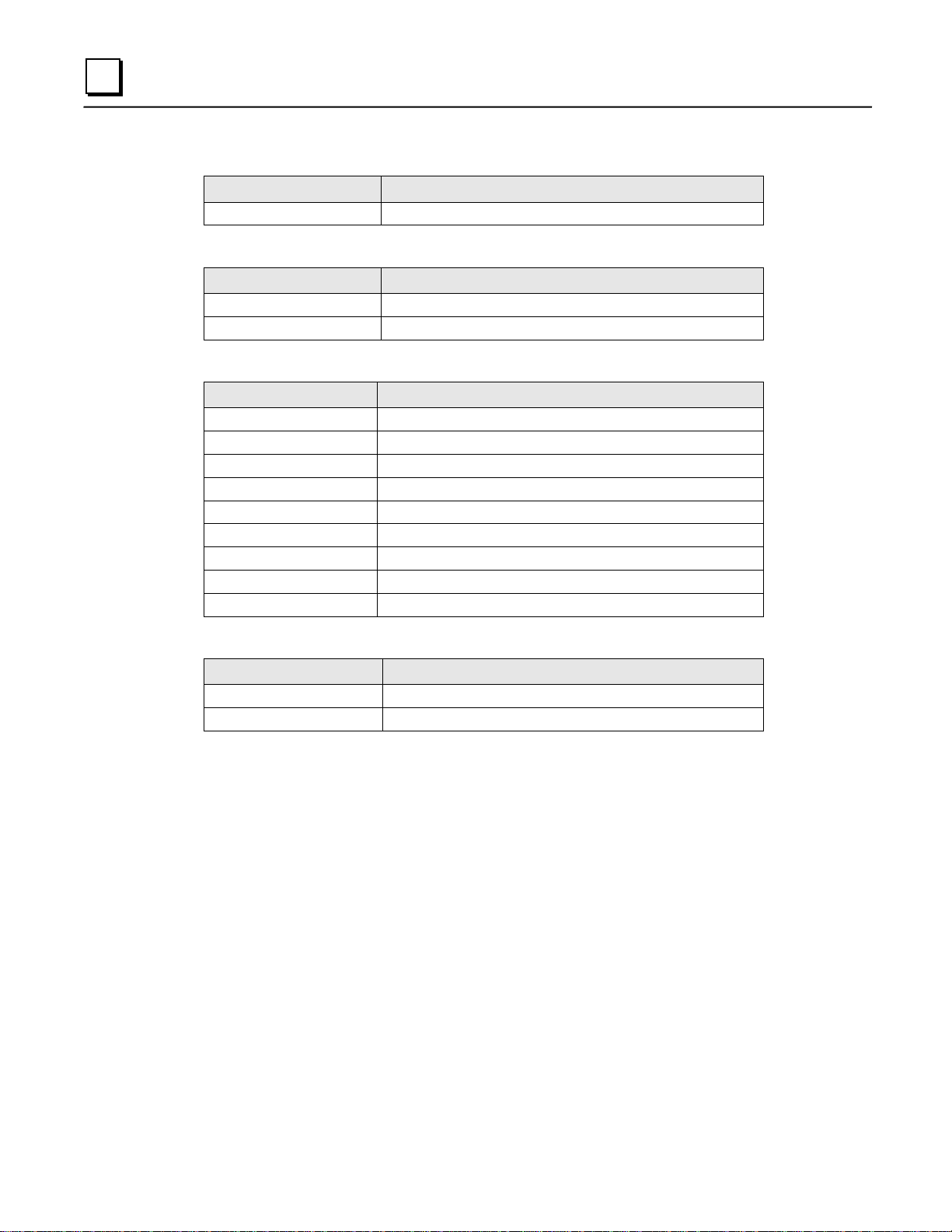

Part Number

Description

IC800VMCS030

Serial Cable, 3 meter

Part Number

Description

IC800VMBR040

40 ohm 400 watt

IC800VMBR020

20 ohm 1000 watt

Part Number

Description

IC800VMACONCN1

Amplifier CN1 Serial Communication Connector

IC800VMACONCN2

Amplifier CN2 Encoder Connector

IC800VMACONCN3

Amplifier CN3 Serial Communications Connector

IC800VMTBC005

Breakout Terminal Board with 0.5 m Cable

IC800VMMCONE001

Motor Encoder Connector (100W-750W)

IC800VMMCONE002

Motor Encoder Connector (1000W & larger)

IC800VMMCONP002

Motor Power Connector (100-750W, With Brake)

IC800VMMCONP001

Motor Power Connector (100-750W, No Brake)

IC800VMMCONP003

Motor Power Connector (1kW-3kW)

Part Number

Description

IC800VMACONMTRP

Amplifier Motor Power Connector

IC800VMADBR001

Amplifier External Braking Resistor Connector

Serial Cable

Regeneration Resistors

Amplifier Connectors

Amplifier Terminal Blocks

1-8 VersaMotion User’s Manual – October 2012 GFK-2480A

Page 17

1

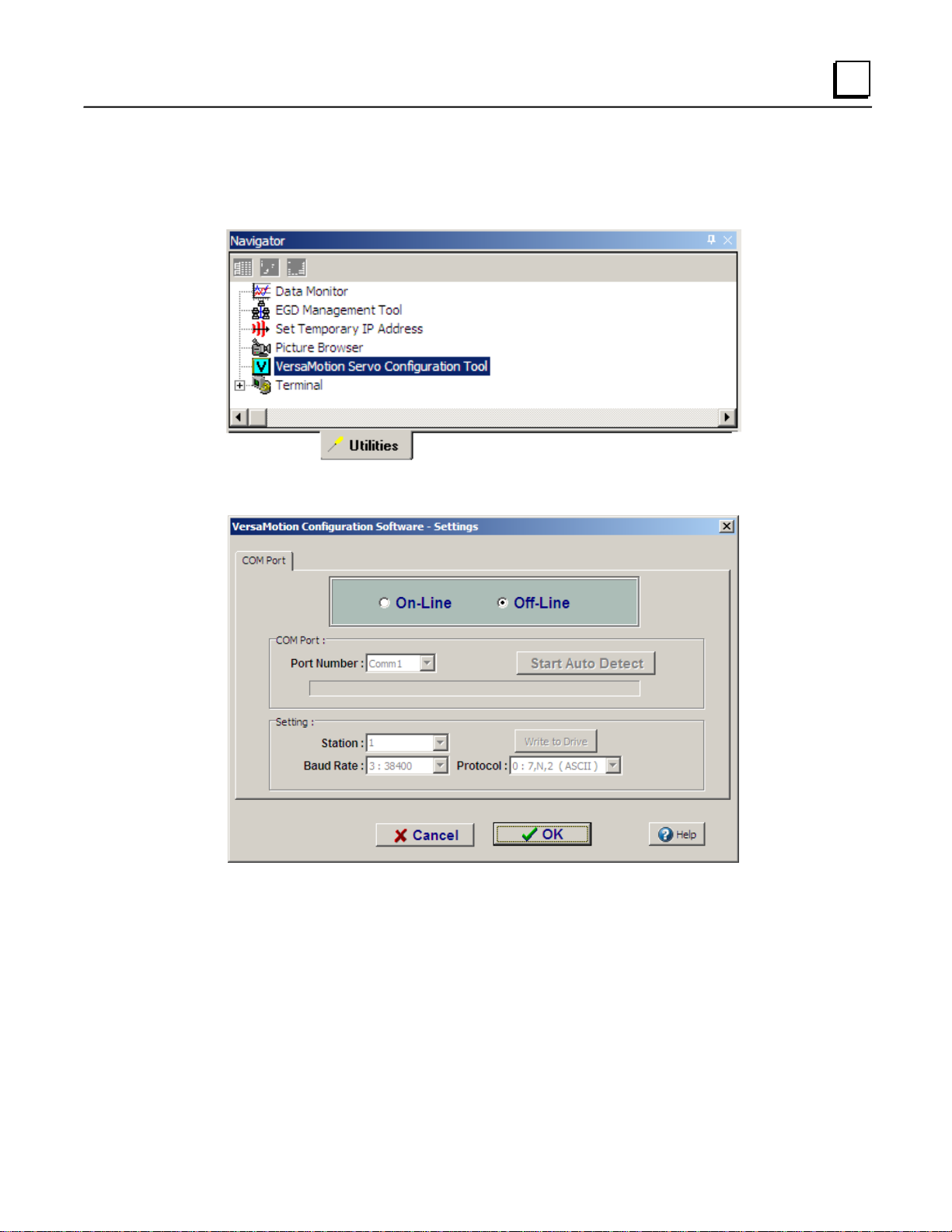

1.1.4 VersaMotion Configuration Software

The VersaMotion servo configuration tool is provided with Proficy Machine Edition version 5.70, SIM 1.

To access the configuration tool, select it on the Utilities tab in the Machine Edition Navigator window.

The VersaMotion Settings dialog box appears. To work in offline mode, click OK. To configure a

communications port for the software tool, select On-Line and click OK.

GFK-2480A Chapter 1 Introduction 1-9

Page 18

1

Settings

Allows you to go online with the VersaMotion drive

Scope

Opens the oscilloscope view

Auto Gain Tuning

Opens tool for calculating servo gain values

Digital IO/Jog Control

Allows you to view and change the digital IO functions in the

servo drive

Status Monitor

Allows you to monitor the servo motor status.

Model Information

Lists communications port information, drive model information,

and motor specifications.

Alarm Information

Displays information for current alarms and alarm history.

Parameter Editor

Allows you to view the values of all servo drive parameters.

Some parameters can be set while online with the servo drive.

Parameter Wizard

Allows you to read the current parameter settings, select the

control mode, edit selected parameter values, or save a set of

parameter values to a file.

User Manual

Online help for the VersaMotion software.

Parameter Manual

Provides a summary of servo drive parameters.

VersaMotion Information

Provides version information for the VersaMotion software.

VersaMotion Software provides the following tools:

1-10 VersaMotion User’s Manual – October 2012 GFK-2480A

Page 19

1

Power

Rating

Servo Drives

Servo Motors

Without Brake

With Brake

100W

IC800VMA012

IC800VMM01LNKSE25

IC800VMM01LBKSE25

200W

IC800VMA022

IC800VMM02LNKSE25

IC800VMM02LBKSE25

400W

IC800VMA042

IC800VMM04LNKSE25

IC800VMM04LBKSE25

750W

IC800VMA072

IC800VMM07LNKSE25

IC800VMM07LBKSE25

1000W

IC800VMA102

IC800VMM10LNKSE25

IC800VMM10LBKSE25

2000W

IC800VMA202

IC800VMM20LNKSE25

IC800VMM20LBKSE25

3000W

IC800VMA302

IC800VMM30LNKSE25

IC800VMM30LBKSE25

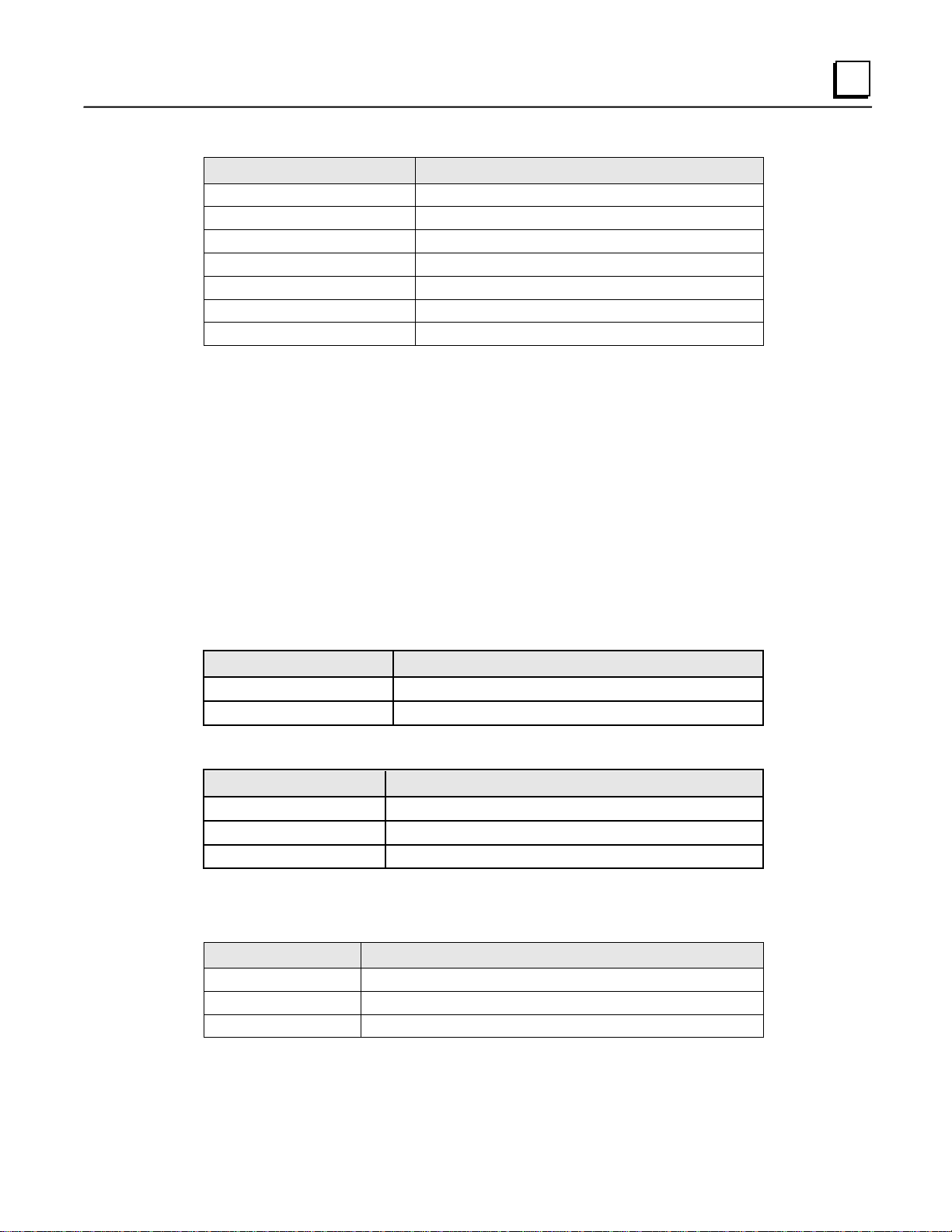

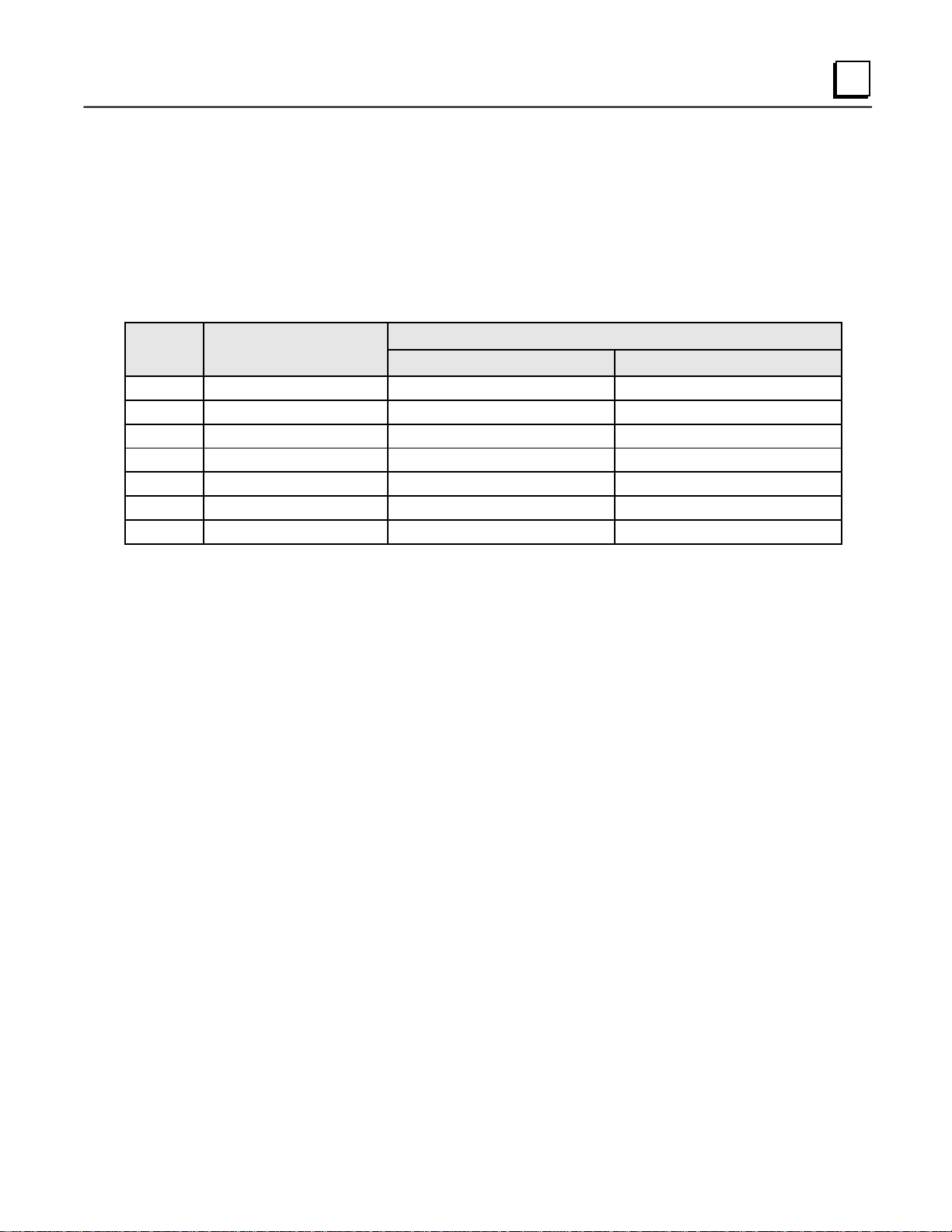

1.2 Servo Drive and Servo Motor Combinations

The servo drives are designed for use in combination with specific servo motors. The table below

shows the possible combinations of VersaMotion servo drives and motors.

The servo drive and motor must be correctly matched for size (power rating). If the power of motor and

drive is not within the specifications, the drive and motor may overheat and servo alarm would be

activated. For detailed specifications of servo drives and motors, please refer to Chapter 11

“Specifications”.

GFK-2480A Chapter 1 Introduction 1-11

Page 20

1

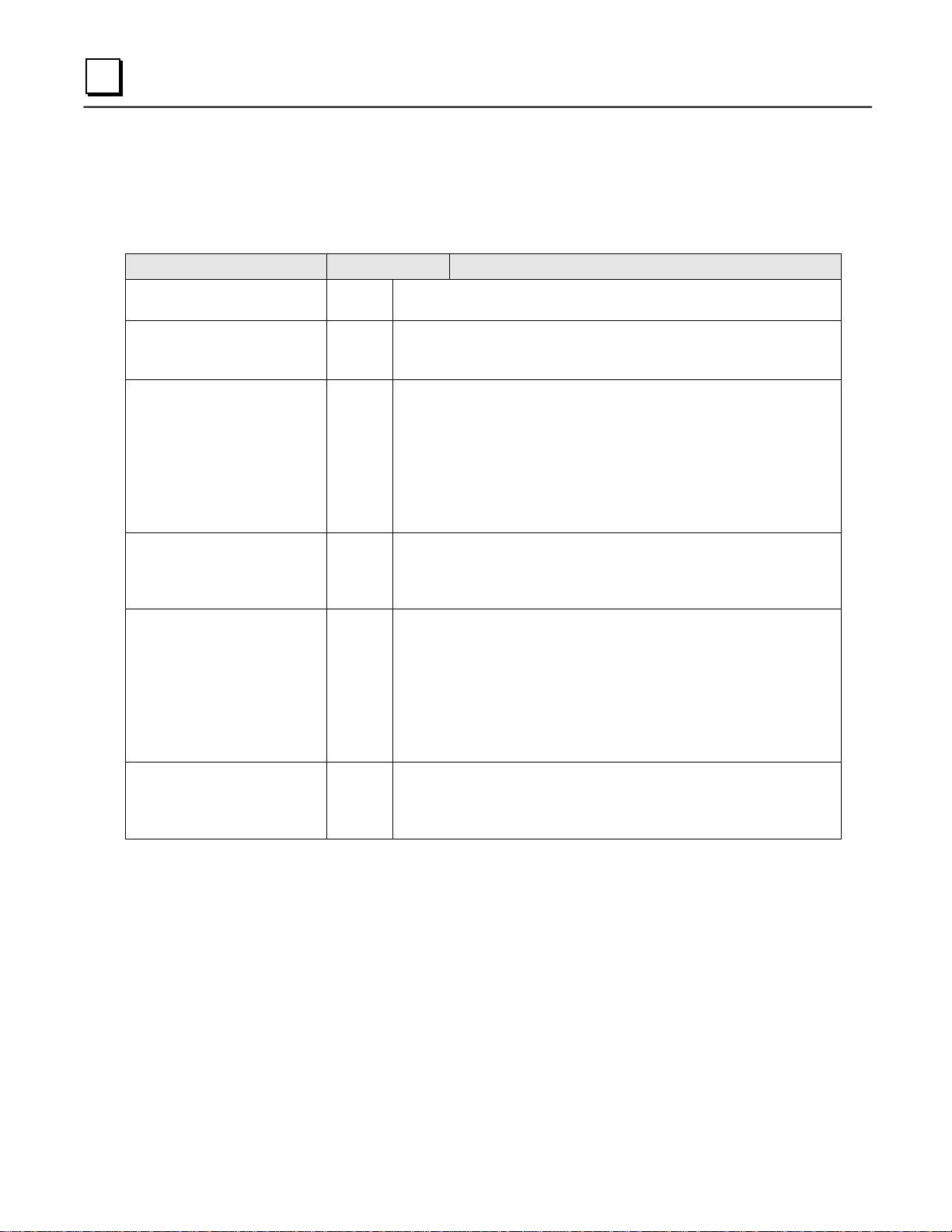

Single Modes

Code

Description

External Position Control

Pt

Position control for the servo motor is achieved via an external

pulse command.

Internal Position Control

Pr

Position control for the servo motor is achieved via by eight

commands stored in the servo controller. Digital Inputs (DI)

control execution of the position commands.

Speed Control

S

Speed control for the servo motor is provided by either Internal

Preset Speed Parameters or External analog -10 to +10VDC

command. If using the Internal Preset Speed Parameters, the

three individual speeds are selected via digital inputs.

Note: S mode is a dual mode. The Internal Preset Speeds have

priority over the analog input. At any point when an Internal

Preset Speed is selected via a digital input, it will take priority

over the incoming External analog command.

Internal Speed Control

Sz

Speed control for the servo motor is provided by Internal Preset

Speed Parameters only. The individual speed commands are

selected via digital inputs. (A maximum of three speeds can be

stored internally).

Torque Control

T

Torque control for the servo motor is provided by either Internal

Preset Torque Parameters or External analog -10 to +10VDC

command. If using the Internal Preset Torque Parameters, the

three individual torques are selected via digital inputs.

Note: T mode is a dual mode. The Internal Preset Torque has

priority over the analog input. At any point when an Internal

Preset Torque command is selected via a digital input, it will

take priority over the incoming External analog command.

Internal Torque Control

Tz

Torque control for the servo motor is provided by Internal Preset

Torque Parameters only. The individual torque commands are

selected via digital inputs. (A maximum of three torque levels

can be stored internally).

1.3 Servo Drive Control Modes

The VersaMotion servo can be programmed to provide six single and five dual modes of operation,

which are described in the following table. For information on operating in each control mode, refer to

chapter 6.

1-12 VersaMotion User’s Manual – October 2012 GFK-2480A

Page 21

1

Dual Modes

Code

Description

Position (pulse train) Speed

Pt-S

Either Pt or S control mode can be selected via the Digital Inputs

(DI)

When switched to Speed mode the user has the option to use

Internal Preset Speed commands or External analog -10 to

+10VDC command as described in the Speed Mode details.

Position (pulse train) Torque

Pt-T

Either Pt or T control mode can be selected via the Digital Inputs

(DI).

When switched to Torque mode the user than has the option to

use Internal Preset Torque commands or External analog -10 to

+10VDC command as described in the Torque Mode details.

Position (internal register) Speed

Pr-S

Either Pr or S control mode can be selected via the Digital

Inputs (DI)

When switched to Speed mode the user has the option to use

Internal Preset Speed commands or External analog -10 to

+10VDC command as described in the Speed Mode details.

Position (internal register) Torque

Pr-T

Either Pr or T control mode can be selected via the Digital Inputs

(DI).

When switched to Torque mode the user than has the option to

use Internal Preset Torque commands or External analog -10 to

+10VDC command as described in the Torque Mode details.

Speed - Torque

S-T

Either S or T control mode can be selected via the Digital Inputs

(DI).

When switched to Speed mode the user than has the option to

use Internal Preset Speed commands or External analog -10 to

+10VDC command as described in the Speed Mode details.

When switched to Torque mode the user than has the option to

use Internal Preset Torque commands or External analog -10 to

+10VDC command as described in the Torque Mode details.

GFK-2480A Chapter 1 Introduction 1-13

Page 22

Page 23

Chapter

2

Unpacking and Installation

This chapter provides the following information:

Page

2.1 Unpacking and Inspection 2-2

2.2 Storage Conditions 2-2

2.3 Installation 2-3

2.4 Molded-Case Circuit Breaker, Fuse and Leakage Current 2-8

Note: In this manual, actual measured values are in metric units. Dimensions in SI units are for

reference only. Please use metric units for precise measurements.

GFK-2480A 2-1

Page 24

2

2.1 Unpacking and Inspection

Warning

Ensure that both the servo drive and motor are correctly matched for size (power

rating). Failure to observe this precaution may cause fire, seriously damage the

drive or motor, or cause personal injury.

After receiving the AC servo drive, please check for the following:

Ensure that the product is what you have ordered.

Verify the part number indicated on the nameplate corresponds with the part number of your order.

Ensure that the servo motor shaft rotates freely.

Rotate the motor shaft by hand; a smooth rotation will indicate a good motor. However, a servo

motor with an electromagnetic brake cannot be rotated manually.

Check for damage.

Inspect the unit to insure it was not damaged during shipment.

Check for loose screws.

Ensure that all necessary screws are tight and secure.

If any items are damaged or incorrect, contact the distributor from whom you purchased the product.

2.2 Storage Conditions

The product should be kept in the shipping carton before installation. In order to retain the warranty

coverage, the servo drive should be stored properly when it is not to be used for an extended period of

time. Some storage suggestions are:

Store in a clean and dry location free from direct sunlight.

Store within an ambient temperature range of -20°C to +65°C (-4°F to 149°F).

Store within a non-condensing relative humidity range of 0% to 90%.

Do not store in a place subjected to corrosive gases and liquids.

The product should be correctly packaged and placed on a solid surface.

2-2 VersaMotionServo Motors and Amplifiers User’s Manual – October 2012 GFK-2480A

Page 25

2

2.3 Installation

2.3.1 Installation Notes

Do not bend or strain the cables between the servo drive and the motor.

When mounting the servo drive, tighten screws to secure the drive in place.

If the servo motor shaft is coupled directly to a rotating device, ensure that the alignment

specifications of the servo motor, coupling, and device are followed. Failure to do so may

cause unexpected loads or premature failure of the servo motor.

If the length of cable connected between servo drive and motor is more than 20m, the wire

gauge of the encoder and motor connection cables (connected to U, V, W terminals) should be

increased. For wire gauge recommendations, refer to chapter 3.

Make sure to properly tighten the motor mounting bolts.

2.3.2 Installation Conditions

Warning

Do not install the product in a location that is outside the stated specification for

the drive and motor. Failure to observe this caution may result in electric shock,

fire, or personal injury.

VersaMotion drives are open type servo drives and must be installed in a NEMA enclosure, such as a

protected control panel, during operation to comply with the requirements of international safety

standards. They provide precise feedback control and high-speed calculation functions incorporating

DSP (Digital Signal Processor) technology, and are intended to drive three-phase permanent magnet

synchronous motors (PMSM) to achieve precise positioning by means of accurate current output

generated by IGBT (Insulated Gate Bipolar Transistor).

VersaMotion drives can be used in industrial applications and for installation in an end-use enclosure

that conforms to the specifications provided in this manual (Drives, cables and motors are for use in a

suitable enclosure with a minimum of a UL Type 1 rating).

GFK-2480A Chapter 2 Unpacking and Installation 2-3

Page 26

2

Operating Temperature

VersaMotion Servo Drives: 0°C to 55°C (32°F to 131°F)

VersaMotion Servo Motors: 0°C to 40°C (32°F to 104°F)

For long-term reliability, the ambient temperature of the servo drive should be less than 45°C (113°F).

If the ambient temperature of servo drive is greater than 45°C (113°F), install the drive in a well-

ventilated location and do not obstruct the airflow of the cooling fan.

Caution

The servo drive and motor will generate heat. If they are installed in a control

panel, allow sufficient space around the units for heat dissipation.

Observe the following precautions when selecting a mounting location.

Do not mount the servo drive or motor adjacent to heat-radiating elements or in direct sunlight.

Do not mount the servo drive or motor in a location subjected to corrosive gases, liquids, or

airborne dust or metallic particles.

Do not mount the servo drive or motor in a location where temperature and humidity will

exceed the specifications.

Do not mount the servo drive or motor in a location where vibration and shock will exceed the

specifications.

Do not mount the servo drive or motor in a location where it will be subjected to high levels of

electromagnetic radiation.

2-4 VersaMotionServo Motors and Amplifiers User’s Manual – October 2012 GFK-2480A

Page 27

2

Correct

Incorrect

2.3.4 Installation Procedure and Minimum Clearances

Incorrect installation may result in a drive malfunction or premature failure of the drive and or motor.

Please follow the guidelines in this manual when installing the servo drive and motor.

The VersaMotion servo drive should be mounted perpendicular to the wall or in the control panel. In

order to ensure the drive is well ventilated, allow sufficient free space surrounding the servo drive and

do not obstruct the ventilation holes. Do not install the drive in a horizontal position or malfunction and

damage will occur.

Drive Mounting

The servo drives must be back-mounted vertically on a dry and solid surface such as a NEMA

enclosure. A minimum spacing of two inches must be maintained above and below the drive for

ventilation and heat dissipation. Additional space may be necessary for wiring and cable connections.

Also, the mounting surface should be able to conduct heat away from the mounting plate and not

conduct into the drive from external sources.

Motor Mounting

The servo motors should be mounted firmly to a dry and solid mounting surface to ensure maximum

heat transfer for maximum power output and to provide a good ground.

For dimensions and weight specifications of the servo drives and motors, refer to Chapter 11,

“Specifications".

GFK-2480A Chapter 2 Unpacking and Installation 2-5

Page 28

2

20mm

(0.8in)

min.

20mm

(0.8in)

min.

50mm

(2.0in)

min.

50mm

(2.0in)

min.

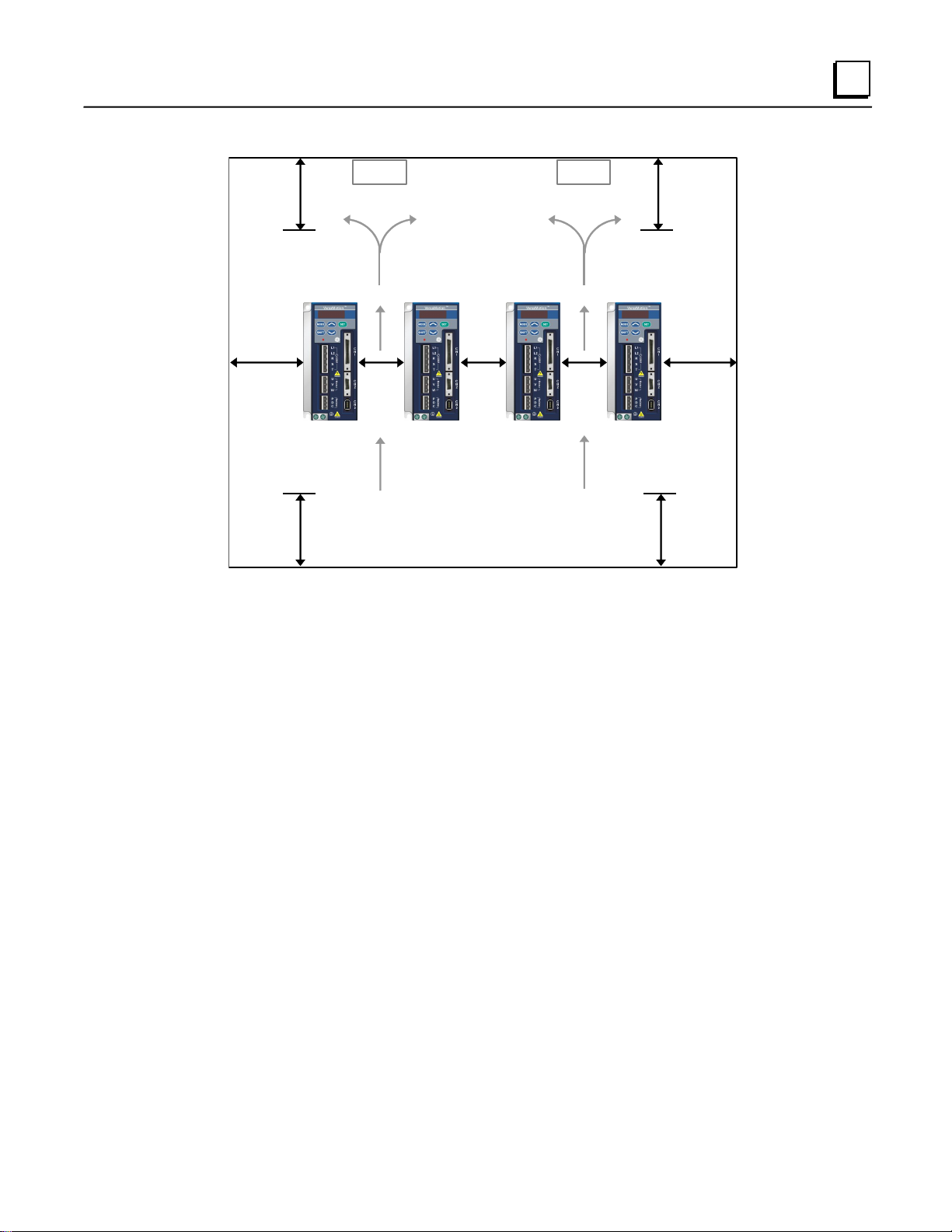

Minimum Clearances

Install a fan to increase ventilation to avoid ambient temperatures that exceed the specification. When

installing two or more drives adjacent to each other, allow clearances as shown in the following

diagram.

Minimum Clearances

2-6 VersaMotionServo Motors and Amplifiers User’s Manual – October 2012 GFK-2480A

Page 29

2

40mm

(1.16 in)

min.

40mm

(1.16 in)

min.

10mm

(0.4 in)

min.

10mm

(0.4 in)

min.

10mm

(0.4 in)

min.

100mm

(4.0 in)

min.

100mm

(4.0 in)

min.

100mm

(4.0 in)

min.

100mm

(4.0 in)

min.

Air flow

Air flow

Fan

Fan

Side by Side Installation

GFK-2480A Chapter 2 Unpacking and Installation 2-7

Page 30

2

Drive Part No.

Output Short

Circuit

Breaker

Fuse

3-Phase

Operation

Leakage Current

1-Phase

Operation

Leakage Current

IC800VMA012

8.4A (peak)

5A

5A

0.06mA

0.16mA

IC800VMA022

8.4A (peak)

5A

5A

0.06mA

0.16mA

IC800VMA042

25A (peak)

10A

20A

0.08mA

0.2mA

IC800VMA072

42A (peak)

10A

20A

0.08mA

0.2mA

IC800VMA102

60A (peak)

15A

25A

0.08mA

0.2mA

IC800VMA202

73A (peak)

30A

60A

0.12mA

-

IC800VMA302

107A (peak)

30A

80A

0.13mA

-

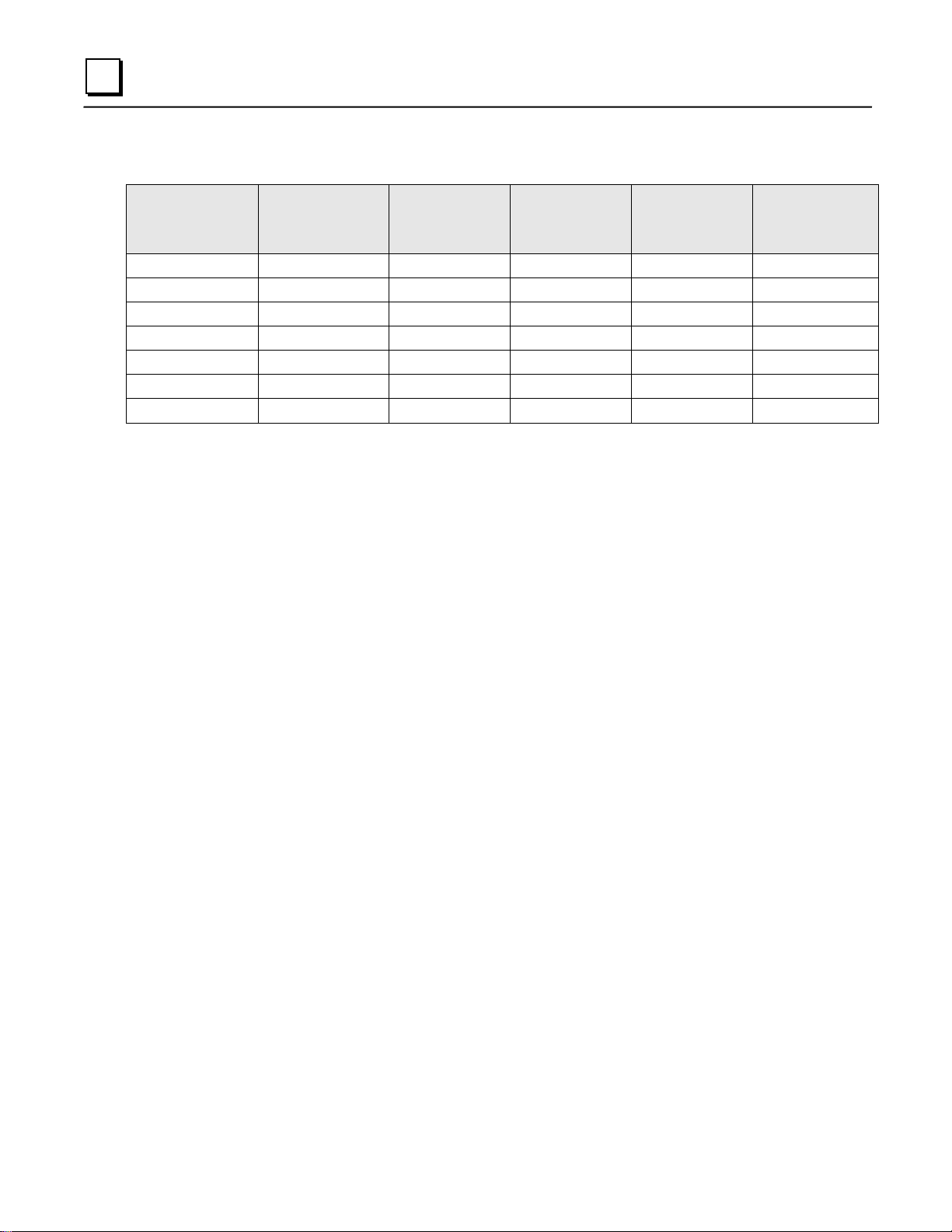

2.4 Molded-Case Circuit Breaker, Fuse and Leakage Current

2-8 VersaMotionServo Motors and Amplifiers User’s Manual – October 2012 GFK-2480A

Page 31

Chapter

3

Equipment Connections and Wiring

This chapter provides information on wiring VersaMotion products, descriptions of I/O signals, and

sample wiring diagrams.

Page

3.1 Equipment Connections 3-2

3.2 Basic Wiring 3-9

3.3 Input / Output Interface Connector CN1 3-11

3.4 Encoder Connector CN2 3-33

3.5 Serial Communication Connector CN3 3-34

3.6 Standard Connection Example 3-36

Warning

Install the encoder cables in a separate conduit or wire tray from the motor

power cables to avoid signal noise. Separate the conduits or trays by 30cm

(11.8inches).

Use multi-stranded twisted-pair wires or multi-core shielded-pair wires for

encoder feedback cables. The maximum length of command input cable is 3m

(9.84ft). The maximum length of encoder feedback cables is20m (66ft).

A charge with hazardous voltages may still remain in the drive after power has

been removed. Wait at least 10 minutes after power has been removed before

performing any wiring and/or inspection.

Caution

Connect wiring after the terminal blocks are all removed from the drive.

Insert only one wire into a terminal on the terminal block.

When inserting wires, ensure that the conductors are not shorted to adjacent

terminals or wires.

Double check the wiring before applying power to the drive. If the wiring is in

error, perform the wiring again with proper tools.

Never use force to remove the terminals or wires. Otherwise, , as it may result in

malfunction or damage.

GFK-2480A 3-1

Page 32

3

3.1 Equipment Connections

3.1.1 Connecting to Peripheral Devices

The following figure illustrates how to connect the peripheral devices.

When using an external regenerative resistor, connect the resistor to terminals P and C on the Servo

Drive, and ensure an open circuit between P and D. When using an internal regenerative resistor,

ensure the connection between P and D is closed, and P and C is open.

3-2 VersaMotionServo Motors and Amplifiers User’s Manual – October 2012 GFK-2480A

Page 33

3

Identification

Terminal

Description

Notes

L1, L2

Control circuit

terminal

The servo Control Circuit requires an independent 220V

single-phase VAC supply.

R, S, T

Main circuit

terminal

The Main Circuit Terminal is used to supply the servo with line

power. If a single-phase supply is used, connect the R and S

terminals to power. If three-phase power is used, connect all three

terminals, R, S, and T. To provide Control Circuit power, add two

jumpers: from R to L1 and S and L2.

U, V, W, FG

Servo motor

output

Used to connect servo motor.

Terminal Symbols:

U

V

W

FG

P, D, C

Regenerative

resistor terminal

Internal

resistor

Ensure the circuit is closed between P and D,

and the circuit is open between P and C.

External

resistor

Connect the regenerative resistor to P and C,

and ensure an open circuit between P and D.

two places

Ground terminal

Used to connect grounding wire of power supply and servo motor.

CN1

I/O connector

Used to connect external controllers. For details, refer to “3.3

Input/Output Interface Connector CN1” on page 3-11.

CN2

Encoder

connector

Used to connect encoder to servo motor and drive I/O. For details,

refer to “3.4 Encoder Connector CN2” on page 3-33.

Terminal Symbols:

A

/A

B

/B

Z

/Z

+5V

GND

CN3

Communication

connector

Used to connect PC. For details, refer to “Serial Communication

Connector CN3” on page 3-34

3.1.2 Servo Drive Connectors and Terminals

Note: U, V, W, CN1, CN2, CN3 terminals provide short circuit protection.

GFK-2480A Chapter 3 Equipment Connections and Wiring 3-3

Page 34

3

3.1.3 Wiring Notes

Warning

Connect the ground terminals to a class-3 ground (Ground resistance should not

exceed 100 Ω). Improper grounding may result in electric shock or fire.

Do not connect a power supply to the U, V and W terminals. Failure to observe

this precaution may result in serious injury, damage to the drive or fire.

Ensure that all screws, connectors and wire terminations are secure on the

power supply, servo drive and motor. Failure to observe this caution may result

in damage, fire or personal injury.

Please observe the following wiring notes while performing wiring and touching any electrical

connections on the servo drive or servo motor.

1. Verify the power supply and wiring of the power terminals (R, S, T, U, V, & W) is correct.

2. Use shielded twisted-pair cables for wiring to prevent voltage coupling and eliminate electrical

noise and interference.

3. Because a residual hazardous voltage may remain inside the drive, do not immediately touch any

of the power terminals (R, S, T, U, V, & W) and/or the cables connected to them after the power

has been turned off and the Charge LED is lit. (Refer to the safety precautions on page 3-1.)

4. The cables connected to R, S, T and U, V, W terminals should be placed in separate conduits from

the encoder or other signal cables. Separate them by at least 12 inches (30cm).

5. The encoder cable should use a twisted-shield signal wire with grounding conductor. The wire

length should be 65.62ft. (20m) or less. For lengths greater than 65.62ft. (20m), the wire gauge

should be doubled in order to lessen any signal attenuation.

6. The motor power cable should use 600V PTFE wire and the wire length should be less than 98.4ft.

(30m). If the wiring distance is longer than 98.4ft. (30m), choose adequate wire size according to

the voltage.

7. The shield of shielded twisted-pair cables should be connected to the ground (terminal marked )

of the servo drive.

8. For connector and cable specifications, refer to “3.1.6 Encoder Connector Specifications” on page

3-7.

3-4 VersaMotionServo Motors and Amplifiers User’s Manual – October 2012 GFK-2480A

Page 35

3

3.1.4 Wiring Methods

For servo drives from 100W to 1.0KW the input power can be either single or three-phase. For servo

drives 2kW and above only three-phase connections are available.

In the following wiring diagram figures:

Power ON: contact “a” (normally open)

Power OFF or Alarm Processing: contact “b” (normally closed)

1MC/x: coil of electromagnetic contactor

1MC/a: self-holding power

1MC: contact of main circuit power

Single-Phase Power Supply Connection

Three-Phase Power Supply Connection

GFK-2480A Chapter 3 Equipment Connections and Wiring 3-5

Page 36

3

Servo Drive

Power Rating

Motor Part Number

Description

U, V, W / Electromagnetic Brake Connector

Terminal

Id.

No Brake

100W

IC800VMM01LNKSE25

A

200W

IC800VMM02LNKSE25

400W

IC800VMM04LNKSE25

750W

IC800VMM07LNKSE25

Brake

200W

IC800VMM02LBKSE25

B

400W

IC800VMM04LBKSE25

750W

IC800VMM07LBKSE25

With or Without Brake

1kW

IC800VMM10LNKSE25

IC800VMM10LBKSE25

3106A-20-18S

C

2kW

IC800VMM20LNKSE25

IC800VMM20LBKSE25

3kW

IC800VMM30LNKSE25

IC800VMM30LBKSE25

3106A-24-11S

D

Terminal

Identification

U

V

W

CASE GROUND

BRAKE1

BRAKE2

A

1 2 3 4 -

-

B

1 2 4 5 3

6

C F I B E

G H D

D E F G A

B

3.1.5 Motor Power Cable Connector Specifications

Note: The brake coil has no polarity. The terminal identification names are BRAKE1 and BRAKE2.

The power supply for the brake is 24 VDC. Never use it for VDD, the +24V source voltage.

3-6 VersaMotionServo Motors and Amplifiers User’s Manual – October 2012 GFK-2480A

Page 37

3

Servo Drive Capacity

Motor Model Name

Encoder Connector

Terminal

Identific

ation

100W

IC800VMM01LNKSE25

HOUSING: AMP (1-172161-9)

A

200W

200WIC800VMM02LNKSE

25 IC800VMM02LBKSE25

200W

IC800VMM02LNKSE25

IC800VMM02LBKSE25

400W

400WIC800VMM04LNKSE

25 IC800VMM04LBKSE25

400W

IC800VMM04LNKSE25

IC800VMM04LBKSE25

750W

750WIC800VMM07LNKSE

25 IC800VMM07LBKSE25

750W

IC800VMM07LNKSE25

IC800VMM07LBKSE25

1kW

IC800VMM10LNKSE25

IC800VMM10LBKSE25

20-29 17-#16

B

2kW

2kWIC800VMM20LNKSE2

5 IC800VMM20LBKSE25

2kW

IC800VMM20LNKSE25

IC800VMM20LBKSE25

3kW

3kWIC800VMM30LNKSE2

5 IC800VMM30LBKSE25

3kW

IC800VMM30LNKSE25

IC800VMM30LBKSE25

Terminal

Identification

AMP (1-

172161-9)

A

/A

B

/B

Z

/Z

+5V

GND

BRAID

SHELD

A

1 4 2 5 3 6 7 8 9

Terminal

Identification

3106A-20-

29S

A

/A

B

/B

Z

/Z

+5V

GND

BRAID

SHELD

B

A B C D F G S R L

3.1.6 Encoder Connector Specifications

GFK-2480A Chapter 3 Equipment Connections and Wiring 3-7

Page 38

3

Servo Drive

Power Cable - Wire Gauge AWG (mm2)

L1, L2

R, S, T

U, V, W

P, C

IC800VMA012

AWG16 (1.31)

AWG14 (2)

AWG14 (2)

AWG14 (2)

IC800VMA022

AWG16 (1.31)

AWG14 (2)

AWG14 (2)

AWG14 (2)

IC800VMA042

AWG16 (1.31)

AWG14 (2)

AWG14 (2)

AWG14 (2)

IC800VMA072

AWG16 (1.31)

AWG14 (2)

AWG14 (2)

AWG14 (2)

IC800VMA102

AWG16 (1.31)

AWG14 (2)

AWG14 (2)

AWG14 (2)

IC800VMA202

AWG16 (1.31)

AWG14 (2)

AWG14 (2)

AWG14 (2)

IC800VMA302

AWG16 (1.31)

AWG12 (3.31)

AWG12 (3.31)

AWG14 (2)

Servo Drive

Encoder Cable - Wire Gauge AWG (mm2)

Wire Size

Core Number

UL Rating

IC800VMA012

AWG26 (0.13)

10 core (4 pair)

UL2464

IC800VMA022

AWG26 (0.13)

10 core (4 pair)

UL2464

IC800VMA042

AWG26 (0.13)

10 core (4 pair)

UL2464

IC800VMA072

AWG26 (0.13)

10 core (4 pair)

UL2464

IC800VMA102

AWG26 (0.13)

10 core (4 pair)

UL2464

IC800VMA202

AWG26 (0.13)

10 core (4 pair)

UL2464

IC800VMA302

AWG26 (0.13)

10 core (4 pair)

UL2464

3.1.7 Cable Specifications Power Cable

Power Cable

The following table lists recommended wire gauges for power cables of 30m (98.4ft.) or less.

Encoder Cable

The following table lists recommended wire gauges for encoder cables of 20m (65.62ft) or less. For

lengths greater than 20m (65.62ft.), the wire gauge should be doubled to avoid signal attenuation.

Notes:

1) Please use shielded twisted-pair cables for wiring to prevent voltage coupling and eliminate

electrical noise and interference.

2) The shield of shielded twisted-pair cables should be connected to the ground terminal (marked

) of the servo drive.

3-8 VersaMotionServo Motors and Amplifiers User’s Manual – October 2012 GFK-2480A

Page 39

3

3.2 Basic Wiring

3.2.1 Basic Wiring Schematic of 100W — 1.0kW Models

GFK-2480A Chapter 3 Equipment Connections and Wiring 3-9

Page 40

3

3.2.2 Basic Wiring Schematic of 2kW — 3kW Models

3-10 VersaMotionServo Motors and Amplifiers User’s Manual – October 2012 GFK-2480A

Page 41

3

3.3 Input/Output Interface Connector CN1

The CN1 Interface Connector provides access to three signal groups:

General interface for the analog speed and torque command, encoder reference signal

from the motor, pulse / direction inputs, and reference voltages.

Eight programmable Digital Inputs (DI), can be set using parameters P2-10 — P2-17

Five programmable Digital Outputs (DO), can be set using parameters P2-18 — P2-22

A detailed explanation of each group is provided in “3.3.3 CN1 Signal Description” on page 3-13

3.3.1 CN1 Terminal Identification

GFK-2480A Chapter 3 Equipment Connections and Wiring 3-11

Page 42

3

2

DO3-

Digital

output

4

DO2-

Digital

output

6

DO1-

Digital

output

8

DI4-

Digital

input

10

DI2-

Digital

input

12

GND

Analog

input

signal

ground

14

NC

NC

16

MON1

Analog

monitor

output 1

18

T_REF

Analog

torque

Input

20

VCC

+12V

power

output (for

analog

command)

22

/OA

Encoder

/A pulse

output

24

/OZ

Encoder

/Z pulse

output

1

DO4+

Digital

output

3

DO3+

Digital

output

5

DO2+

Digital

output

7

DO1+

Digital

output

9

DI1-

Digital

input

11

COM+

Power

input

(12 —

24V)

13

GND

Analog

input

signal

ground

15

MON2

Analog

monitor

output 2

17

VDD

+24V

power

output (for

external

I/O)

19

GND

Analog

input

signal

ground

21

OA

Encoder

A pulse

output

23

/OB

Encoder

/B pulse

output

25

OB

Encoder

B pulse

output

27

DO5-

Digital

output

29

NC

NC

31

DI7-

Digital

input

33

DI5-

Digital

input

35

PULL

HI

Pulse

applied

power

37

SIGN

Position

sign (-)

39

NC

NC

41

PULSE

Pulse

input (-)

43

/PULSE

Pulse

input (+)

45

COM-

VDD(24V)

power

ground

47

COM-

VDD(24V)

power

ground

49

COM-

VDD(24V)

power

ground

26

DO4-

Digital

output

28

DO5+

Digital

output

30

DI8-

Digital

input

32

DI6-

Digital

input

34

DI3-

Digital

input

36

/SIGN

Position

sign (+)

38

NC

NC

40

NC

NC

42

V_REF

Analog

speed

input (+)

44

GND

Analog

input

signal

ground

46

NC

NC

48

OCZ

Encoder

Z pulse

Open-coll

ector

output

50

OZ

Encoder

Z pulse

Line-drive

r output

3.3.2 CN1 Terminal Signal Identification

CAUTION

The terminals marked NC (No Connection) must be left unconnected. The NC

terminals are used within the servo drive. Any outside connection to the NC

terminals will result in damage to the drive.

3-12 VersaMotionServo Motors and Amplifiers User’s Manual – October 2012 GFK-2480A

Page 43

3

Signal

Pin

No.

Details

Wiring

Diagram

Analog

Signal

INPUT

V_REF

42

Motor speed command: -10V to +10V. Corresponds to

the maximum speed programmed. P1-55 Maximum

Speed Limit (Factory default 3000 RPM).

C1

T_REF

18

Motor torque command: -10V to +10V. Corresponds to 100% to +100% rated torque command.

C1

Analog

Monitor

OUTPUT

MON1

16

The MON1 and MON2 can be assigned drive and motor

parameters that can be monitored via an analogue

voltage.

C2

MON2

15

Please refer to parameter P0-03 for monitoring

commands and P1-04 / P1-05 for scaling factors.

Output voltage is reference to the power ground.

Position

Pulse

INPUT

PULSE (A)

41

The drive can accept two types of pulse inputs: Open

Collector and Line Driver.

Three different pulse commands can be selected via

parameter P1-00: Quadrature, CW + CCW pulse, and

Pulse/Direction.

C3/C4

/PULSE (/A)

43

SIGN (B)

37

/SIGN (/B)

36

PULL HI

35

If an Open Collector type of pulse is used, this terminal

must be pulled high to pin 17.

C3

Position

Pulse

OUTPUT

OA

21

The motor encoder signals are available through these

terminals. The encoder output pulse count can be set

using parameter P1-46.

C11/C12

/OA

22

OB

25

/OB

23

OZ

50

/OZ

24

Power

VDD

17

VDD is the +24V source voltage provided by the drive.

Maximum permissible current 500mA.

-

COM+

11

COM+ is the common voltage rail of the Digital Input and

Digital Output signals. Connect VDD to COM+ for source

mode. For external applied power sink mode (+12V to

+24V), the positive terminal should be connected to

COM+ and the negative to COM-.

COM-

45

47

49

3.3.3 CN1 Signal Description

The tables in this section detail the three groups of signals on the CN1 connector: General Signals,

Digital Output (DO) signals and Digital Input (DI) signals. The General Signals are set by the factory

and cannot be changed, reprogrammed or adjusted. The Digital Input and Digital Output signals can be

programmed by the users.

General Signals (non-configurable)

For wiring diagrams, see “3.3.5 Wiring Diagrams of I/O Signals (CN1)” on page 3-29.

GFK-2480A Chapter 3 Equipment Connections and Wiring 3-13

Page 44

3

Signal

Pin

No.

Details

Wiring

Diagram

Power

VCC

20

VCC is a +12V power rail provided by the drive. It can be

used for the input on an analog speed or torque

command. Maximum permissible current 100mA.

-

GND

12,13,

The polarity of VCC is with respect to Ground (GND).

19,44

Other

NC

14,29,

38,39,

40,46,

See previous note for NC terminals CN1 connector on

page 3-12.

-

48

DO

Signal

Name

DO

Parameter

Value

Assigned

Control

Mode

CN1 Pin

No.

(Default)

Details

Associated

Parameters

Wiring

Diagram

+

-

SRDY

01

ALL 7 6

Servo Ready (SRDY) is

activated when the servo

drive is ready to run. All

fault and alarm

conditions, if present,

have been cleared.

P2-51

C5/C6/C7/C8

SON

02

Not

assigned

- - Servo On (SON) is

activated when control

power is applied to the

servo drive.

C5/C6/C7/C8

Caution

Any outside connection to the NC terminals will result in damage to the drive.

Configurable Signals

The Digital Inputs (DI) and Digital Outputs (DO) have factory default settings that correspond to the

servo drive control modes, which are listed in chapter 1. However, both the DI and DO signals can be

configured independently to meet the requirements of the application.

The factory default settings of the DI and DO signals are listed in on pages 3-22 and 3-25.

The DI and DO signals and their corresponding pin numbers are factory set and cannot be changed.

However, the assigned signals and control modes are user configurable. For example, the factory

default function of DO5 (pins 28/27) can be assigned to DO1 (pins 7/6) and vice versa.

Digital Output (DO) Signals

For wiring diagrams, see “3.3.5 Wiring Diagrams of I/O Signals (CN1)” on page 3-29.

Functions of the digital outputs DO1 through DO5 can be selected using parameters P2-18 through

P2-22. For information on setting these parameters, refer to “Output Function Definitions” in chapter 7.

3-14 VersaMotionServo Motors and Amplifiers User’s Manual – October 2012 GFK-2480A

Page 45

3

DO

Signal

Name

DO

Parameter

Value

Assigned

Control

Mode

CN1 Pin

No.

(Default)

Details

Associated

Parameters

Wiring

Diagram

+

-

ZSPD

03

ALL 5 4

Zero Speed (ZSPD) is

activated when the drive

senses the motor speed

is equal to or below the

Zero Speed Range as

defined in parameter P1-

38. For example, at the

factory default setting,

ZSPD will be activated

when the drive detects

the motor rotating at or

below 10 rpm. ZSPD will

remain active until the

motor speed increases

above 10 RPM.

P1-38

C5/C6/C7/C8

TSPD

04

ALL 3 2

Target Speed (TSPD) is

activated once the drive

has detected the motor

has reached the Target

Speed setting as defined

in parameter P1-39.

TSPD will remain active

until the motor speed

drops below the Target

Speed.

P1-39.

C5/C6/C7/C8

TPOS

05

Pt, Pr, PtS, Pt-T,

Pr-S, Pr-T

1

26

When the drive is in Pt

mode, Target Position

(TPOS) will be activated

when the position error is

equal to or less than the

value of parameter P1-

54. When the drive is in

Pr mode, TPOS will be

activated when the drive

detects that the position

of the motor is in the

range between -P1-54

and +P1-54 of the target

position. For example, at

the factory default

setting, TPOS will

activate when the motor

is within -99 pulses of the

target position, then

deactivate after it

reaches +99 pulses of

the desired position.

P1-54

C5/C6/C7/C8

GFK-2480A Chapter 3 Equipment Connections and Wiring 3-15

Page 46

3

DO

Signal

Name

DO

Parameter

Value

Assigned

Control

Mode

CN1 Pin

No.

(Default)

Details

Associated

Parameters

Wiring

Diagram

+

-

TQL

06

Not

assigned

- - Torque Limit (TQL) is

activated when the drive

has detected that the

motor has reached the

torque limits set by either

the parameters P1-12 to

P1-14 or by an external

analog voltage.

P1-12 P1-

13 P1-14

C5/C6/C7/C8

ALRM

07

ALL

28

27

Alarm (ALRM) is

activated when the drive

has detected a fault

condition. However,

when a Reverse limit

error, Forward limit error,

Emergency stop, Serial

communication error, or

Undervoltage fault

occurs, Warning (WARN)

is activated first.

C5/C6/C7/C8

BRKR

08

ALL

1

26

BRKR is used to control

operation of the motor

brake. When BRKR is

ON, the brake is

activated, allowing the

motor to move.

C5/C6/C7/C8

HOME

09

Pt, Pr

3

2

HOME is activated when

the servo drive has

detected that the HOME

sensor (Digital Input 24)

is detected and the home

conditions set in

parameters P1-47, P1-50

and P1-51 are satisfied.

P1-47 P1-

50 P1-51

C5/C6/C7/C8

OLW

10

ALL

- - Output Overload (OLW)

is activated when the

servo drive detects that

the motor has reached

the output overload level

set by the parameter

P1-56.

P1-56

C5/C6/C7/C8

3-16 VersaMotionServo Motors and Amplifiers User’s Manual – October 2012 GFK-2480A

Page 47

3

DO

Signal

Name

DO

Parameter

Value

Assigned

Control

Mode

CN1 Pin

No.

(Default)

Details

Associated

Parameters

Wiring

Diagram

+

-

WARN

11

ALL

- - Warning output (WARN)

is activated when the

drive detects a Reverse

limit error, Forward limit

error, Emergency stop,

Serial communication

error, or an Undervoltage

fault condition.

C5/C6/C7/C8

DI Signal

DI

Parameter

Value

Control

Mode

CN1 Pin

No.

(Default)

Details

Wiring

Diagram

SON

01

ALL

9

Servo On. Switch

servo to "Servo

Ready". Check

parameter P2-51.

C9/C10

ARST

02

ALL

33

A number of Faults

(Alarms) can be

cleared by activating

ARST. For details,

see “Clearing Faults”

in chapter 10. The

cause of the fault

should be

investigated if the

Fault does not clear

or the fault

description warrants

closer inspection of

the drive system.

C9/C10

GAINUP

03

ALL

-

Gain switching

C9/C10

Notes:

Pins 3 and 2 are assigned to either TSPD or HOME, depending upon control mode selected.

Pins 1 and 26 assigned to either BRKR or TPOS, depending on the control mode selected.

Digital Input (DI) Signals

For wiring diagrams, see “3.3.5 Wiring Diagrams of I/O Signals (CN1)” on page 3-29.

Functions of the digital inputs DI1 through DI8 can be selected using parameters P2-10 through P2-18.

For information on setting these parameters, refer to “Input Function Definitions” in chapter 7.

GFK-2480A Chapter 3 Equipment Connections and Wiring 3-17

Page 48

3

DI Signal

DI

Parameter

Value

Control

Mode

CN1 Pin

No.

(Default)

Details

Wiring

Diagram

CCLR

04

Pt

10

When CCLR is

activated the pulse

number is cleared.

The Pulse Clear

Mode is determined

by parameter P2-50.

C9/C10

ZCLAMP

05

ALL

-

When this signal is

On and the motor

speed value is lower

than the value of

P1-38, the motor is

locked in the instant

position.

C9/C10

CMDINV

06

Pr, T, S

-

When this signal is

On, the motor is in

reverse rotation.

C9/C10

HOLD

07

Not

assigned

Internal position

control command

pause

C9/C10

CTRG

08

Pr, Pr-S,

Pr-T

10

When the drive is in

Pr mode and CTRG

is activated, the drive

will command the

motor to move to the

stored position that

corresponds to the

POS 0, POS 1 and

POS 2 settings.

Activation is

triggered on the

rising edge of the

pulse.

C9/C10

TRQLM

09

S, Sz

10

ON indicates the

torque limit

command is valid.

C9/C10

SPDLM

10

T, Tz

10

ON indicates the

speed limit command

is valid.

C9/C10

3-18 VersaMotionServo Motors and Amplifiers User’s Manual – October 2012 GFK-2480A

Page 49

3

DI Signal

DI

Parameter

Value

Control

Mode

CN1 Pin

No.

(Default)

Details

Wiring

Diagram

POS0

11

Pr

34

When the Pr Control

Mode is selected, the

eight stored positions

are selected via a

combination of the

POS 0, POS 1, and

POS 2 commands.

For details, see

“Source of Position

Command (Pr Mode

Only)“ on page 3-21.

C9/C10

POS1 POS112Pr-S, Pr-

T

POS1

12

Pr-S, Pr-

T

8

POS2 POS213--

POS2

13 - -

SPD0

14

S, Sz,

34

Select the source of

speed command.

C9/C10

SPD1

15

Pt-S, PrS, S-T

8

For details, see

“Source of Speed

Command“ on page

3-22.

C9/C10

TCM0

16

Pt, T, Tz,

Pt-T, PrT, S-T

34

Select the source of

torque command.

For details, see

“Source of Torque

Command“ on page

3-22.

C9/C10

TCM1

17

Pt, T, Tz,

Pt-T, PrT, S-T

31

Select the source of

torque command.

For details, see

“Source of Torque

Command“ on page

3-20.

C9/C10

S-P

18

Pt-S, PrS

31

Speed / Position

mode switching OFF:

Speed, ON: Position

C9/C10

S-T

19

S-T

31

Speed / Torque

mode switching OFF:

Speed, ON: Torque

C9/C10

T-P

20

Pt-T, PrT

31

Torque / Position

mode switching OFF:

Torque, ON: Position

C9/C10

TRLM

26

Not

assigned

-

Forward operation

torque limit (Torque

limit function is valid

only when P1-02 is

enabled)

C9/C10

SHOM

27

Not

assigned

-

When SHOM is

activated, the drive

will command the

motor to move to

“Home”.

C9/C10

GFK-2480A Chapter 3 Equipment Connections and Wiring 3-19

Page 50

3

DI Signal

DI

Parameter

Value

Control

Mode

CN1 Pin

No.

(Default)

Details

Wiring

Diagram

INDEX0

28

Not

assigned

-

Feed step selection

input 0 (bit 0)

C9/C10

INDEX1

29

Not

assigned

-

Feed step selection

input 1 (bit 1)

C9/C10

INDEX2

30

Not

assigned

-

Feed step selection

input 2 (bit 2)

C9/C10

INDEX3

31

Not

assigned

-

Feed step selection

input 3 (bit 3)

C9/C10

INDEX4

32

Not

assigned

-

Feed step selection

input 4 (bit 4)

C9/C10

MD0

33

Not

assigned

-

Feed step mode

input 0 (bit 0)

C9/C10

MD1

34

Not

assigned

-

Feed step mode

input 1 (bit 1)

C9/C10

MDP0

35

Not

assigned

-

Manually continuous

operation

C9/C10

MDP1

36

Not

assigned

-

Manually single step

operation

C9/C10

JOGU

37

Not

assigned

-

Forward JOG input.

When JOGU is

activated, the motor

will JOG in forward

direction. (See

parameter P4-05, in

chapter 7.)

C9/C10

JOGD

38

Not

assigned

-

Reverse JOG input.

When JOGD is

activated, the motor

will JOG in reverse

direction. (See

parameter P4-05 in

chapter 7.)

C9/C10

STEPU

39

Not

assigned

-

Step up input. When

STEPU is activated,

the motor will run to

next position.

C9/C10

STEPD

40

Not

assigned

-

Step down input.

When STEPD is

activated, the motor

will run to previous

position.

C9/C10

STEPB

41

Not

assigned

-

Step back input.

When STEPB is

activated, the motor

will return to first

position.

C9/C10

3-20 VersaMotionServo Motors and Amplifiers User’s Manual – October 2012 GFK-2480A

Page 51

3

DI Signal

DI

Parameter

Value

Control

Mode

CN1 Pin

No.

(Default)

Details

Wiring

Diagram

AUTOR

42

Not

assigned

-

Auto run input. When

AUTOR is activated,

the motor will run

automatically

according to internal

position command.

For time interval

setting, please see

the descriptions of

parameters P2-52 to

P259 in chapter 7.

C9/C10

GNUM0

43

Not