Page 1

VersaMax Micro

00813-0100-0113

VersaMaxTM Micro

Scalable Micro PLCs

T

oday’s manufacturing environment faces the

critical need for shorter production runs, quicker

changeovers, and just-in-time manufacturing.

Machines are no longer dedicated to a single

product and long production runs. VersaMax

Micro helps you address this challenge as a

scalable solution with precise and powerful

control in a compact design. With the flexibility

to enhance machine performance, availability,

and profitability, the modular VersaMax Micro

offers the features to match your application

needs.

Application Flexibility and Scalability

VersaMax Micro PLCs provide the scalability and flexibility

to cover a broad range of applications. For applications that

require more I/O, up to four modules can be used to expand

the series of controllers. For smaller machines, units can be

used as a standalone controller with integrated I/O functions.

With I/O expansion modules and support of a portable

program FLASH memory module, the VersaMax Micro PLCs

provide the flexibility to configure a solution to your exact

requirements and budget.

Big Features in a Compact Package

The small footprint VersaMax Micro PLC offers the flexibility

of modular design and a variety of built-in features, including

up to 64 I/O points (expandable to 176 I/O points), fast cycle

times, a robust instruction set and extensive memory that

multiplies your programming options.

A Variety of Communications Options

All units have a RS-232 port that can be used for SNP slave,

Modbus RTU or serial I/O commands, and select units have

an RS-485 port that adds SNP master and Modbus master

commands. The Micro 20, Micro 40 and Micro 64 also have a

second option port that supports either RS-232, RS-485 or USB

communications module. The VersaMax Micro PLCs are easily

networked to Ethernet with the powerful VersaMax SE (Serial

to Ethernet module).

Data Sheet

May 2020

Performance to Improve Productivity

The VersaMax Micro family is designed to provide the

power and performance of customized solutions with the

convenience and economy of off-the-shelf technology.

VersaMax Micro PLCs have two channels of high-speed

control, two independent 65kHz pulse and direction outputs,

and user configurable inputs and outputs to effectively

increase machine performance. With VersaMax Micro PLCs

you can reduce costs and save time on machine configurations

without compromising the ability to customize the features

that are right for your application.

Simplified Programming for PLCs

With PAC Machine Edition software, programming your

VersaMax Micro PLCs is an intuitive process. Mix Relay Ladder

Diagram and Instruction List programming within an

application. Develop and save custom view tables. View PLC

and I/O system fault tables on demand. PAC Machine Edition

deploys HMI, motion, and multi-target control in an integrated

development environment. This provides a common user

interface, drag-and-drop editing, and a rich set of development

tools. The Micro 20, Micro 40 and Micro 64 support a portable

program FLASH Memory Module that provides a simple cost

effective way of upgrading eld controllers.

Page 2

VersaMax Micro

May 2020

Feature Benefit

Single Toolchain

Flexible Communications from Serial to Ethernet

Abundance of Data Storage Capability

Powerful Instruction Set

n Use PAC Machine Edition to program micro (VersaMax),

compact (RSTi-EP), and large (RX3i) PLCs

n Modbus Master, Modbus Slave and Report by exception

n Modem and Ethernet SRTP or Modbus TCP (Server) option

n Up to 32K words of data storage

n Floating point math and PID for process control

n Write and Read data to internal FLASH

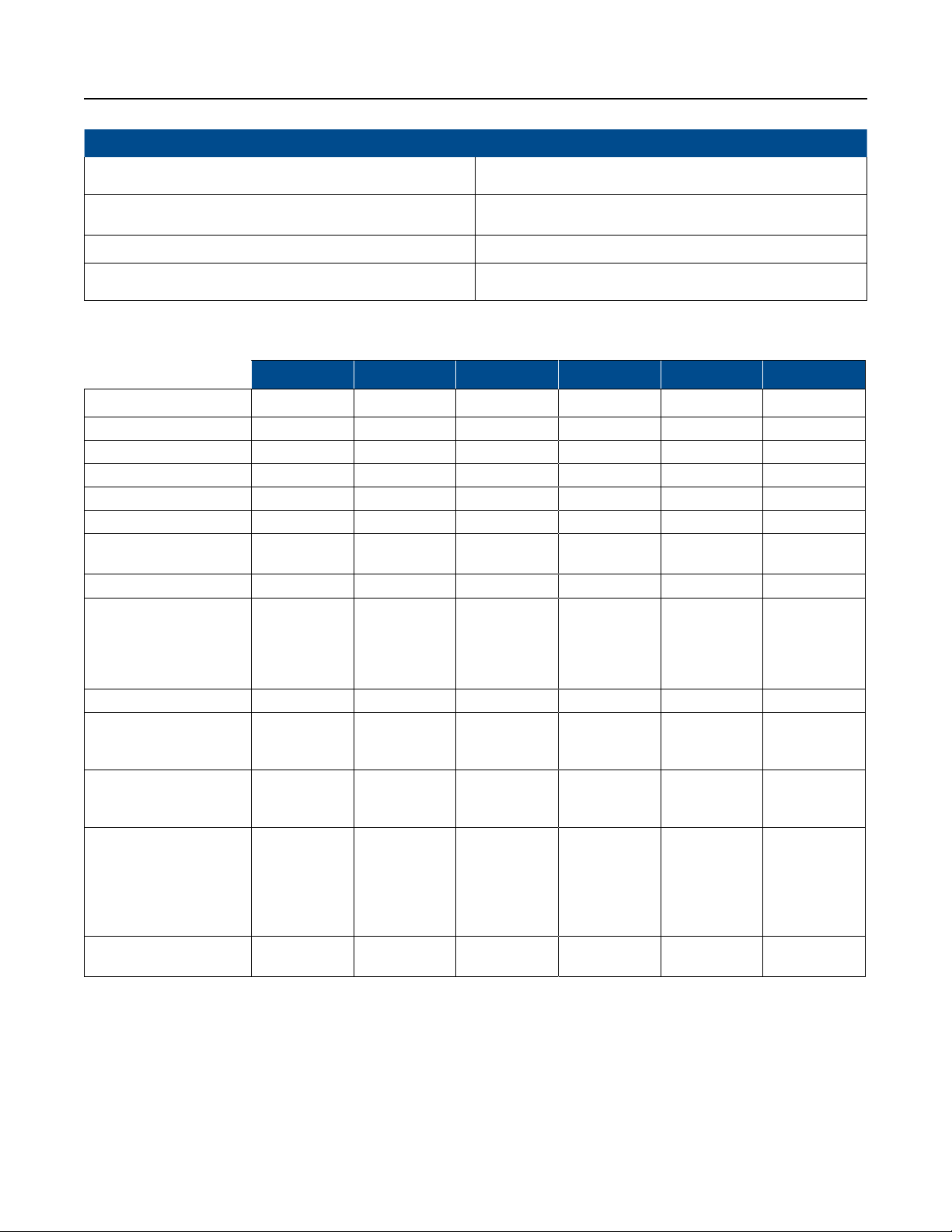

Specifications

Micro 14 Micro 23 Micro 28 Micro 20 Micro 40 Micro 64

Built-in Discrete I/O 8 in/6 out 13 in/10 out 16 in/12 out 12 in/8 out 24 in/16 out 40 in/24 out

Built-in Analog I/O None 2 in/1 out None None None None

I/O Expansion Units Up to 4 Up to 4 Up to 4 Up to 4 Up to 4 Up to 4

Logic Memory (Words) 9K 9K 9K 24K 24K 24K

Data Storage (Words) 256 2K 2K 32K 32K 32K

Scan Time (msec/K) 1.1 msec 1.1 msec 1.1 msec 1.1 msec 1.1 msec 1.1 msec

Battery Backed RAM Super Cap only

Yes, and

Super Cap

Real Time Clock None Included Included Included Included Included

Ports Available 1 RS-232

1 RS-232 and

1 RS-485

Ethernet Option VersaMax SE VersaMax SE VersaMax SE Second port Second port Second port

High Speed Counter

Pulse Train/PWM

Up to 4

at 10Khz

(16 bit)

Up to 4

at 5Khz

(16 bit)

Up to 4

at 10Khz

(16 bit)

Up to 4

at 5Khz

(16 bit)

Motion Commands N/A N/A N/A

Write Register Values

to Internal Flash

Yes Yes Yes Yes Yes Yes

Yes, and

Super Cap

1 RS-232 and

1 RS-485

Up to 4

at 10Khz

(16 bit)

Up to 4

at 5Khz

(32 bit)

Yes, and

Super Cap

1 RS-232 and

second port

(RS-232,

RS-485, USB,

or Ethernet)

Up to 4

at 100Khz

(32 bit)

Up to 4

at 65Khz

(32 bit)

Find Home,

Go Home,

Jog,

Ramp,

Blended

Move

Yes, and

Super Cap

1 RS-232 and

second port

(RS-232,

RS-485, USB,

or Ethernet)

Up to 4

at 100Khz

(32 bit)

Up to 4

at 65Khz

(32 bit)

Find Home,

Go Home,

Jog,

Ramp,

Blended

Move

Yes, and

Super Cap

1 RS-232 and

second port

(RS-232,

RS-485, USB,

or Ethernet)

Up to 4

at 100Khz

(32 bit)

Up to 4

at 65Khz

(32 bit)

Find Home,

Go Home,

Jog,

Ramp,

Blended

Move

www.Emerson.com2

Page 3

May 2020

Part Number Description

Micro 14

IC200UEX013 14 point Exp.(8) 12VDC In, (6) Relay Out

IC200UEX011 14 point Exp.(8) 24VDC In, (6) Relay Out, 120/240VAC Power Supply

IC200UEX012 14 point Exp.(8) 24VDC In, (6) Relay Out, 24VDC Power Supply

IC200UEX010 14 point Expansion (8) 120VAC In, (6) 120VAC Out

IC200UEX009 14 point Expansion (8) 120VAC In, (6) Relay Out

IC200UEX014 14 point Expansion (8) 24VDC In, (6)24VDC Out

IC200UEX122 14 point Expansion (8) 24VDC In, (6)24VDC Out, with ESCP

IC200UAA003 14 point PLC, (8) 120VAC In, (6) 120VAC Out

IC200UAR014 14 point PLC, (8) 120VAC In, (6) Relay Out

IC200UDD112 14 point PLC, (8) 12VDC In, (6) 12VDC Out

IC200UDR003 14 point PLC, (8) 12VDC In, (6) Relay Out

IC200UDD104 14 point PLC, (8) 24VDC In, (6) 24VDC Out

IC200UDR001 14 point PLC, (8) 24VDC In, (6) Relay Out

VersaMax Micro

IC200UDR002 14 point PLC, (8) 24VDC In, (6) Relay Out

Micro 23

IC200UAL004 23 point PLC, (13) 12VDC In, (10) Relay Out

IC200UAL006 23 point PLC, (13) 24VDC In, (1) 24VDC Out, (9) Relay Out, 120/240VAC Power Supply

IC200UAL005 23 point PLC, (13) 24VDC In, (1) 24VDC Out, (9) Relay Out, 24VDC Power Supply

Micro 28

IC200UEX210 28 point Expansion (16) 120VAC In, (12) 120VAC Out,

IC200UEX209 28 point Expansion (16) 120VAC In, (12) Relay Out

IC200UEX215 28 point Expansion (16) 12VDC In, (12) 12 VDC Out

IC200UEX213 28 point Expansion (16) 12VDC In, (12) Relay Out

IC200UEX214 28 point Expansion (16) 24VDC In, (12) 24VDC Out

IC200UEX222 28 point Expansion (16) 24VDC In, (12) 24VDC Out, with ESCP

IC200UEX211 28 point Expansion (16) 24VDC In, (12) Relay Out, 120/240VAC Power Supply

IC200UEX212 28 point Expansion (16) 24VDC In, (12) Relay Out, 24VDC Power Supply

IC200UAA007 28 point PLC, (16) 120VAC In, (12) 120V/240AC Out, 120/240VAC Power Supply

IC200UAR028 28 point PLC, (16) 120VAC In, (12) Relay Out, 120/240VAC Power Supply

IC200UDD212 28 point PLC, (16) 12VDC In, (12) 12VDC Out

IC200UDR006 28 point PLC, (16) 12VDC In, (12) Relay Out, 12VDC Power Supply

IC200UDR228 28 point PLC, (16) 24VDC In, (11) Relay Out, (1) 24VDC Out

IC200UDR005 28 point PLC, (16) 24VDC In, (11) Relay Out, (1) 24VDC Out, 120V/240AC Power Supply

IC200UDR010 28 point PLC, (16) 24VDC In, (11) Relay Out, (1) 24VDC Out, 24VDC Power Supply

3www.Emerson.com

Page 4

VersaMax Micro

IC200UDD110 28 point PLC, (16) 24VDC In, (12) 24VDC Out

IC200UDD120 28 point PLC, (16) 24VDC In, (12) 24VDC Out, with ESCP

Micro 20

IC200UDD020 20 point PLC, (12) 24VDC In, (8) 24VDC Out

IC200UDD220 20 point PLC, (12) 24VDC In, (8) 24VDC Sink Out

IC200UDR120 20 point PLC, (12) 24VDC In, (8) Relay Out, 120/240VAC Power Supply

IC200UDR020 20 point PLC, (12) 24VDC In, (8) Relay Out, 24VDC Power Supply

Micro 40

IC200UDD040 40 point PLC, (24) 24VDC In, (16) 24VDC Out

IC200UDD240 40 point PLC, (24) 24VDC In, (16) 24VDC Sink Out

IC200UDR140 40 point PLC, (24) 24VDC In, (16) Relay Out

IC200UDR440 40 point PLC, (24) 24VDC In, (16) Relay Out, 12/24vDC

IC200UDR040 40 point PLC, (24) 24VDC In, (16) Relay Out, 24VDC

Micro 64

IC200UEX364 64 point Expansion (40) 24VDC In, 24VDC sink Out

May 2020

IC200UEX264 64 point Expansion (40) 24VDC In, 24VDC source outp

IC200UEX064 64 point Expansion (40) 24VDC In, relay Out, 24

IC200UEX164 64 point Expansion (40) 24VDC In, relay Out, AC

IC200UDD164 64 point PLC, (40) 24VDC In, (24) 24VDC Sink Out

IC200UDD064 64 point PLC, (40) 24VDC In, (24) 24VDC source Out

IC200UDR164 64 point PLC, (40) 24VDC In, (24) Relay Out

IC200UDR064 64 point PLC, (40) 24VDC In, (24) Relay Out, 24VDC

Expansion

IC200UEX624 Expansion, 4 channel Analog In

IC200UEX826 Expansion, 4 channel Thermocouple/mV In module

IC200UEX824 Expansion, 4 channel Thermocouple/mV In module, 24VDC

IC200UEX636 Expansion, 6 channel Analog (4) In, (2) Out

IC200UEX616 Expansion, 6 channel Analog (4) In, (2) Out, 12VDC

IC200UEX626 Expansion, 6 channel Analog (4) In, (2) Out, 24VDC

IC200UEO116 Expansion, 16 Out (16) 24VDC Sink Out, 24VDC

IC200UER016 Expansion, 16 Out (16) Relay Out, 24VDC Power

IC200UEO016 Expansion, 16 point (16) 24VDC Source ESCP Out

IC200UEI016 Expansion, 16 point In (16) 24VDC In

IC200UEO008 Expansion, 8 Out (8) 24VDC Out

IC200UER008 Expansion, 8 Out (8) Relay Out, 24VDC Power S

IC200UEO108 Expansion, 8 Out 24VDC Sink Out, 24VDC Power S

www.Emerson.com4

Page 5

May 2020

IC200UEI008 Expansion, 8 point (8) 24VDC In

IC200UEC008 Expansion, 8 point combination (4) 24VDC In, (4) 24VDC Out

IC200UEC108 Expansion, 8 point combination (4) 24VDC In, (4) 24VDC Out, 24VDC

IC200UEC208 Expansion, 8 point combination (4) 24VDC In, (4) Relay Out

IC200UMM102 Expansion, VersaMax MicroMotion, 2 independent axis, 120/240

IC200UMM002 Expansion, VersaMax MicroMotion, 2 independent axis, 24VDC p

IC200UEX724 Expansion, RTD module for Pt 100

IC200UEX726 Expansion, RTD module for Pt 100

IC200UEX734 Expansion, RTD module for Pt 100

IC200UEX736 Expansion, RTD module for Pt 100

Communication

IC200UEM001 Micro Plus 20/40/64 Ethernet module

IC200USB001 Micro Plus 20/40/64, RS-232 communications option

IC200USB002 20/40/64, RS-485 communications option board

IC200UUB001 20/40/64, USB Slave communications option board

VersaMax Micro

IC200UMB001 20/40/64, User Program Memory Module

IC200SET001 Micro 14/23/28 Ethernet to Serial Interface

5www.Emerson.com

Page 6

VersaMax Micro

00813-0100-0113

Data Sheet

May 2020

United State Office

Emerson Automation Solutions

Intelligent Platforms, LLC

2500 Austin Dr

Charlottesville, VA

China Office

Emerson Automation Solutions Intelligent

Platforms (Shanghai) Co., Ltd

No.1277, Xin Jin Qiao Rd, Pudong,

Shanghai, China, 201206

Singapore Office

Emerson Automation Solutions Intelligent

Platforms Asia Pacic Pte. Ltd.

1 Pandan Cres,

Singapore, 128461

Germany Office

Emerson Automation Solutions

ICC Intelligent Platforms GmbH

Memminger Straße 14

Augsburg, DE 86159

Brazil Office

Emerson Automation Solutions

Av. Hollingsworth, 325 – Iporanga

Sorocaba – SP, 18087-105

India Offices

Emerson Automation Solutions

Intelligent Platforms Pvt. Ltd.,

Building No.8, Ground Floor

Velankani Tech Park, No.43

Electronics City Phase I, Hosur Rd

Bangalore-560100

Americas Support – Technical and Commercial

Phone: 1-888-565-4155 or 1-434-214-8532 (if toll free 800 option is unavailable)

Email for Technical Support: support.mas@emerson.com

Email for Commercial Support: customercare.mas@emerson.com

Primary language of support: English

Europe, Middle East, & Africa Support – Technical and Commercial

Phone: +800-4-444-8001

or +420-225-379-328 (if toll free 800 option is unavailable or dialing from a mobile telephone)

Email for Technical Support: support.mas.emea@emerson.com

Email for Commercial Support: customercare.emea.mas@emerson.com

Primary languages of support: English, German, Italian, Spanish

Asia Support – Technical and Commercial

Phone: +86-400-842-8599 for Greater China

+65-6955-9413 (All Other Countries)

Email for Technical Support: support.mas.apac@emerson.com

Email for Commercial Support Asia: customercare.cn.mas@emerson.com

Primary languages of support: Chinese, English

Support Website: www.emerson.com/iac-support

Home Website: www.emerson.com/industria

©2020 Emerson. All rights reserved.

The Emerson logo is a trademark and service mark of Emerson Electric Co. All other marks

are property of their respective owners. The contents of this publication are presented for

information purposes only, and while effort has been made to ensure their accuracy, they are

not to be construed as warranties or guarantees, express or implied, regarding the products

or services describe herein or their use or applicability. All sales are governed by our terms

and conditions, which are available on request, We reserve the right to modify or improve

the designs or specications of our products an any time without notice.

l-automation-controls

Loading...

Loading...