Page 1

GE

Intelligent Platforms

Programmable Control Products

VersaMax*

Modules, Power Supplies and

Carriers

User Manual

August

2014

, GFK-1504N

Page 2

These instructions do not purport to cover all details or variations in equipment, nor to provide for every

possible contingency

to be met

during installation, operation, and maintenance. The information is supplied for informational purposes only, and GE makes no warranty

as to the accuracy of the information included herein. Changes, modifications, and/ or improvements to equipment and specifications are

made periodically and these changes may or may not be reflected herein. It is understood that GE may make changes, modifications, or

improvements to the equipment referenced herein or to the document itself at any time. This document is intended for trained personnel

familiar with the GE products referenced herein.

This document is approved for public disclosure.

GE may have patents or pending patent applications covering subject matter in this document. The furnishing of this document

does not provide any license whatsoever to any of these patents.

GE provides the following document and the information included therein as is and without warranty of any kind, expressed or implied,

including but not limited to any implied statutory warranty of merchantability or fitness for particular purpose.

For further assistance or technical information, contact the nearest GE Sales or Service Office, or an authorized GE Sales

Representative.

Revised: Aug 2014

Issued: Sept 2006

Copyright © 2006 - 2014 General Electric Company, All rights reserved.

* Indicates a trademark of General Electric Company and/or its subsidiaries. All other

trademarks are the property of their respective owners.

Refer to the section, Contact Information for support on this

product

.

Page 3

Online Technical Support

www.ge-ip.com/support

Phone

+800-1-433-2682

or dialing from a mobile telephone)

Technical Support Email

support.emea.ip@ge.com

Custome r Care Email

customercare.emea.ip@ge.com

Primary languages of support

English, French, German, Italian, Czech, Spanish

Phone

+86-400-820-8208

+86-21-3217-4826 (India, Indonesia, and Pakistan)

support.in.ip@ge.com (remaining Asia customers)

customercare.cn.ip@ge.com (China)

Contact Information

If you purchased this product through an Authorized Channel Partner, contact the seller

directly.

General Contact Information

Online technical support and GlobalCar e http://www.ge-ip.com/support

Additional information http://www.ge-ip.com/

Solution Provider solutionprovider.ip@ge.com

Technical Support

If you have technical problems that cannot be resolved with the information in this guide,

contact us by telephone or email, or on the web at www.ge-ip.com/support

Americas

Online Technical Support www.ge-ip.com/support

Phone 1-800-433-2682

International Americas Direct Dial 1-780-420-2010 (if toll free 800 option is unavailable)

Technical Support Email support.ip@ge.com

Customer Care Email customercare.ip@ge.com

Primary language of support English

.

Europe, the Middle East, and Africa

EMEA Direct Dial +420-23-901-5850 (if toll free 800 option is unavailable

Asia Pacific

Online Technical Support www.ge-ip.com/support

Technical Support Email support.cn.ip@ge.com (China)

support.jp.ip@ge.com (Japan)

Custome r Care Email customercare.apo.ip@ge.com

Page 4

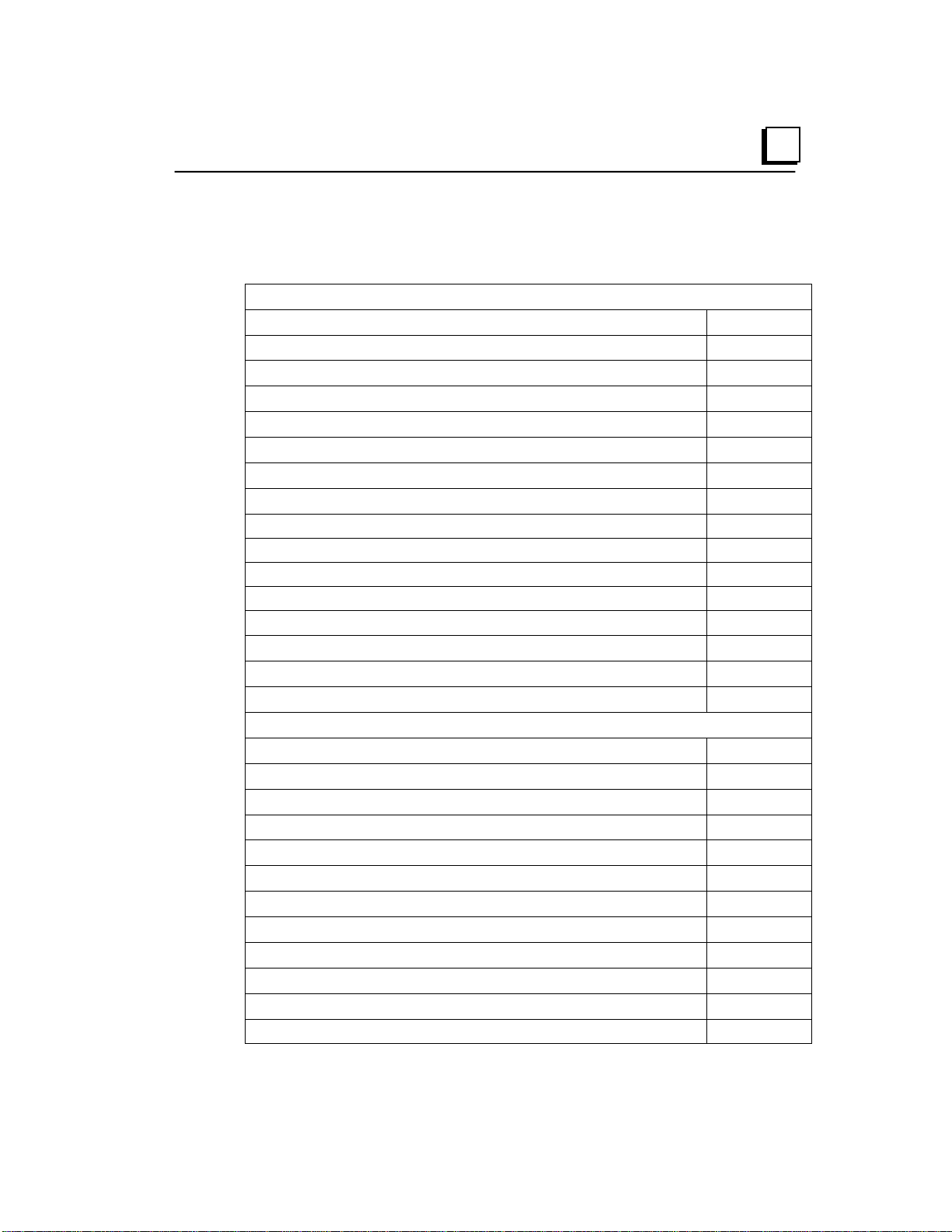

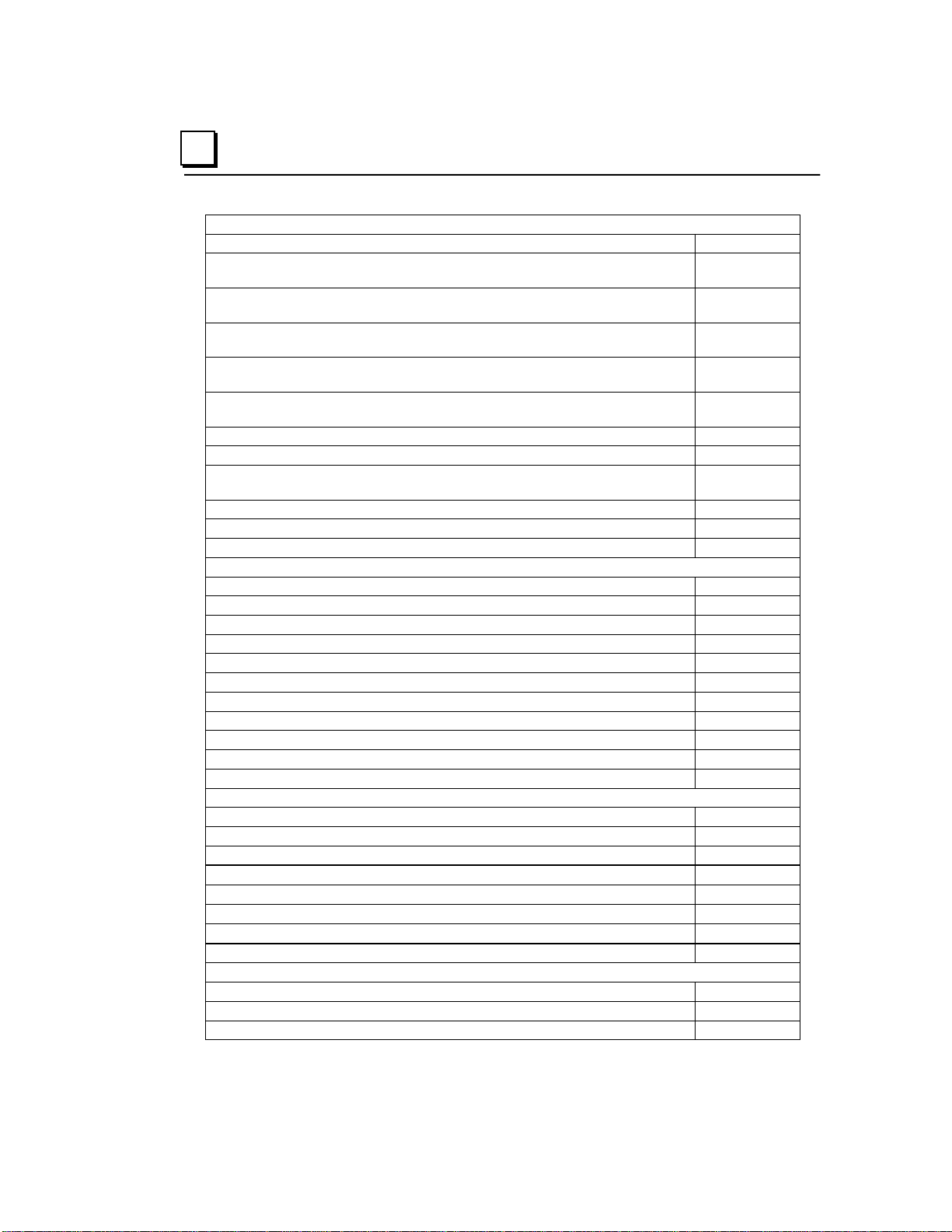

Contents

Introduction .......................................................................................... 1-1

Getting Started ............................................................................................. 1-1

The VersaMax Family of Products ............................................................... 1-3

CPU Modules for VersaMax PLCs............................................................... 1-4

Network Interface Units ................................................................................ 1-6

Power Supplies ............................................................................................ 1-8

I/O Modules .................................................................................................. 1-9

Discrete Module Point LEDs ........................................................................ 1-9

Carriers ...................................................................................................... 1-13

Expansion Modules .................................................................................... 1-15

Communications Modules .......................................................................... 1-17

VersaMax General Product Specifications ................................................ 1-19

Installation ............................................................................................ 2-1

Preinstallation Check ................................................................................... 2-2

Thermal Considerations ............................................................................... 2-4

DIN Rail and Panel Mounting ....................................................................... 2-5

Installing an Expansion Transmitter Module ................................................ 2-7

Installing a Power Supply ........................................................................... 2-12

System Wiring Guidelines .......................................................................... 2-14

System Grounding ..................................................................................... 2-19

Installing Wiring for I/O Devices ................................................................. 2-20

Installing Modules ...................................................................................... 2-39

Power Supplies ....................................................................................... 3-1

IC200PWR001 24VDC Power Supply ......................................................... 3-2

IC200PWR002 24VDC Expanded 3.3 V Power Supply .............................. 3-4

IC200PWR011 and IC200PWR012 24VDC Isolated Power Supplies ........ 3-6

IC200PWR101 120/240VAC Power Supply ................................................ 3-9

IC200PWR102 120/240VAC Expanded 3.3V Power Supply .................... 3-11

IC200PWR201 12VDC Power Supply ....................................................... 3-13

IC200PWR202 12VDC Expanded 3.3 V Power Supply ............................ 3-15

Carriers ................................................................................................. 4-1

IC200CHS001 Barrier-Style I/O Carrier ....................................................... 4-2

IC200CHS002 Box-Style I/O Carrier ........................................................... 4-5

IC200CHS003 Connector-Style I/O Carrier ................................................. 4-8

IC200CHS005 Spring-Style I/O Carrier ..................................................... 4-11

IC200CHS022 Compact Box-Style I/O Carrier .......................................... 4-14

GFK-1504N iii

Page 5

Contents

IC200CHS025 Compact Spring-Style I/O Carrier ...................................... 4-17

IC200CHS006 Communications Carrier .................................................... 4-20

IC200PNS001 and IC200PNS001 PROFINET Scanner Carriers ............. 4-21

IC200PWB001 Power Supply Booster Carrier .......................................... 4-23

Interposing Terminals and Auxiliary I/O Terminal Strips .......................... 5-1

IC200CHS011 Barrier-Style Interposing I/O Terminals .............................. 5-2

IC200CHS012 Box-Style Interposing I/O Terminals .................................... 5-4

IC200CHS014 Thermoc ouple Compensation Box-Style Interposing

I/O Terminals ................................................................................................ 5-6

IC200CHS015 Spring-Style Interposing I/O Terminals................................ 5-8

IC200CHS101, Main Base IC200CHS102, Expansion Base

Disconnect-Style Interposing I/O Terminals .............................................. 5-10

IC200CHS111, Main Base IC200CHS112, Expansion Base

Relay-Style Interposing I/O Terminals ....................................................... 5-14

IC200CHS121, Main Base IC200CHS122, Expansion Base

Fuse-Style Interposing I/O T erminals ........................................................ 5-20

IC200TBM001: Barrier-Style Auxiliary I/O Terminal Strip .......................... 5-24

IC200TBM002 Box-Style Auxiliary I/O Terminal Strip ............................... 5-25

IC200TBM005 Spring-Style Auxiliary I/O Terminal Strip ........................... 5-26

Expansion Modules ................................................................................. 6-1

IC200ETM001 Expansion Transmitter Module ............................................ 6-2

IC200ERM001 Expansion Receiver Module, Isolated ................................. 6-7

IC200ERM002 Expansion Receiver Module, Non-isolated ....................... 6-14

Discrete Input Modules ........................................................................... 7-1

IC200MDL140 Input Module, 120VAC 8 Points .......................................... 7-2

IC200MDL141 Input Module, 240VAC 8 Points .......................................... 7-5

IC200MDL143 Input Module, 120VAC Isolated 8 Points ............................. 7-8

IC200MDL144 Input Module, 240VAC Isolated 4 Points ........................... 7-11

IC200MDL240 Input Module, 120VAC 16 Points ...................................... 7-14

IC200MDL241 Input Module, 240VAC16 Points ....................................... 7-18

IC200MDL243 Input Module, 120VAC Isolated 16 Points ......................... 7-22

IC200MDL244 Input Module, 240VAC Isolated 8 Points ........................... 7-26

IC200MDL631 Input Module, 125VDC Pos/Neg Logic Isolated 8 Points .. 7-29

IC200MDL632 Input Module, 125VDC Pos/Neg Logic Isolated 16 Points 7-32

IC200MDL635 Input Module, 48VDC Pos/Neg Logic Grouped 16 Points. 7-36

IC200MDL636 Input Module, 48VDC Pos/Neg Logic Grouped 32 Points. 7-39

IC200MDL640 Input Module, 24VDC Pos/Neg Logic 16 Points ................ 7-43

iv VersaMax Modules, Power Supplies and Carriers GFK-1504N

Page 6

Contents

IC200MDL643 Input Module, 5/12VDC Pos/Neg Logic Grouped

16 Points .................................................................................................... 7-46

IC200MDL644 Input Module, 5/12VDC Pos/Neg Logic Grouped

32 Point ...................................................................................................... 7-50

IC200MDL650 Input Module, 24VDC Pos/Neg Logic 32 Points ................ 7-54

Discrete Output Modules ........................................................................ 8-1

IC200MDL329 Output Module, 120VAC 0.5 Amp, Isolated 8 Points .......... 8-2

IC200MDL330 Output Module, 120VAC 0.5 Amp, Isolated 16 Points ........ 8-6

IC200MDL331 Output Module, 120VAC 2.0 Amp, Isolated 8 Points ........ 8-10

IC200MDL730 Output Module, 24VDC Posi ti ve Log ic 2.0 Amps,

w/ESCP 8 Points ........................................................................................ 8-14

IC200MDL740 Output Module, 12/24VDC Positive Logic 0.5 Amp,

16 Points .................................................................................................... 8-17

IC200MDL741 Output Module, 24VDC Positive Logic 0.5 Amp,

w/ESCP 16 Points ...................................................................................... 8-21

IC200MDL742 Output Module, 24VDC Positive Logic 0.5 Amp,

w/ESCP 32 Points ...................................................................................... 8-25

IC200MDL743 Output Module, 5/12/24V DC Negative Logic 0.5 Amp,

16 Points .................................................................................................... 8-29

IC200MDL744 Output Module, 5/12/24VDC Negative Logic 0.5 Amp,

32 Points ................................................................................................... 8-32

IC200MDL750 Output Module, 12/24VDC Positive Logic 0.5 Amp,

32 Points .................................................................................................... 8-36

IC200MDL930 Output Module, Relay 2.0 Amp Isolated Form A

8 Points ...................................................................................................... 8-40

IC200MDL940 Output Module, Relay 2.0 Amp, Isolated Form A

16 Points .................................................................................................... 8-44

Discrete Mixed Modules .......................................................................... 9-1

IC200MDD840 Mixed Module, 24VDC Positive Logic Input

20 Points / Output Relay 2.0 Amp 12 Points .............................................. 9-2

IC200MDD842 Mixed Module, Output 24VDC Pos. Logic 0.5A Grouped

w/ESCP 16 Points / Input 24VDC Pos/Neg Logic Grouped 16 Points ....... 9-6

IC200MDD843 Mixed Module, 24VDC Positive Logic Input Grouped

10 Points / Output Relay 2.0A per Point Grouped 6 Points ...................... 9-13

IC200MDD844 Mixed Module, Output 12/24VDC Pos. Logic 0.5A

16 Points / Input 24 VDC Pos/Neg Logic Grouped 16 Points ................... 9-17

IC200MDD845 Mixed Module, Output Relay 2.0A Isolated

8 Points / Input 24VDC Pos/Neg Logic Grouped 16 Points ...................... 9-23

IC200MDD846 Mixed Module, Output Relay 2.0A per Pt Isolated

8 Points / Input 120VAC Grouped 8 Points .............................................. 9-30

GFK-1504N Contents v

Page 7

Contents

IC200MDD847 Mixed Module, Output Relay 2.0A per Pt Isolated

8 Points / Input 240VAC Grouped 8 Points ............................................... 9-34

IC200MDD848 Mixed Module, Output 120VAC 0.5A per Pt Isolated

8 Points / Input 120VAC Grouped 8 Points .............................................. 9-38

IC200MDD849 Mixed Module Output Relay 2.0A per Pt Isolated

8 Points / Input 120VAC Isolated 8 Points ................................................ 9-43

IC200MDD850 Mixed Module, Output Relay 2.0A per Pt Isolated

8 Points / Input 240VAC Isolated 4 Points ................................................ 9-47

IC200MDD851 Mixed Module, Output 12/24VDC Positive Logic Grouped

16 Points / Input 5/12VDC Pos/Neg Logic Grouped 16 Points ................. 9-51

Analog Input Modules ........................................................................... 10-1

IC200ALG230 Analog Input Module, 12 Bit Voltage/Current 4 Channels . 10-2

IC200ALG240 Analog Input Module, 16 Bit Voltage/Current, 1500VAC Isolation,

8 Channels ................................................................................................. 10-9

IC200ALG260 Analog Input Module, 12 Bit Voltage/Current 8 Channels 10-17

IC200ALG261 Analog Input Module, 15 Bit Differential Voltage

8 Channels ............................................................................................... 10-24

IC200ALG262 Analog Input Module, 15 Bit Differential Current

8 Channels ............................................................................................... 10-29

IC200ALG263, IC200ALG265 Analog Input Module, 15 Bit Voltage

15 Channels ............................................................................................. 10-34

IC200ALG264, IC200ALG266 Analog Input Module, 15 Bit Current

15 Channels ............................................................................................. 10-39

Analog Output Modules ........................................................................ 11-1

IC200ALG320 Analog Output Module, 12 Bit Current, 4 Channels ........... 11-2

IC200ALG321 Analog Output Module, 12 Bit Voltage 0 to 10VDC

4 Channels ................................................................................................. 11-9

IC200ALG322 Analog Output Module, 12 Bit Voltage -10 to +10VDC

4 Channels ............................................................................................... 11-15

IC200ALG325 Analog Output Module, 13 Bit Voltage 8 Channels ......... 11-21

IC200ALG326 Analog Output Module, 13 Bit Current, 8 Channels ......... 11-28

IC200ALG327 Analog Output Module, 13 Bit Voltage 12 Channels ....... 11-34

IC200ALG328 Analog Output Module, 13 Bit Current, 12 Channels....... 11-41

IC200ALG331 Analog Output Module, 16 Bit Voltage/Current,

1500VAC Isolation, 4 Channels ............................................................... 11-48

vi VersaMax Modules, Power Supplies and Carriers GFK-1504N

Page 8

Contents

Analog Mixed I/O Modules ..................................................................... 12-1

IC200ALG430 Analog Mixed Module, 12 Bit Input Current 4 Channels

and Output Current 2 Channels ................................................................ 12-2

IC200ALG431 Analog Mixed Module, 12 Bit 0 to 10VDC Input

4 Channels and Output 2 Channels ........................................................... 12-9

IC200ALG432 Analog Mixed Module, 12 Bit +/-10VDC Input 4 Channels

and Output 2 Channels ............................................................................ 12-17

Mixed Discrete/High-Speed Counter Module ......................................... 13-1

IC200MDD841: Mixed Module, 24VDC Positive Logic Input

20 Points / Output 12 Point / (4) High Speed Counter,

PWM, or Pulse Train Configurable Points ................................................. 13-2

Temperature Sensing Modules ......................................................... 14-1

IC200ALG620 Analog Input, 16 Bit RTD, 4 Channels ............................... 14-2

IC200ALG630 Analog Input, 16 Bit Thermocouple, 7 Channels ............. 14-10

Accessories ........................................................................................... 15-1

IC200ACC301 I/O Filler Module ................................................................ 15-2

IC200ACC302 Input Simulator ................................................................... 15-3

IC200ACC303 I/O Shorting Bar ................................................................. 15-4

Panel Mounting Dimensions ................................................................... A-1

Thermal Considerations ............................................................................... A-2

Panel-Mounting Details ................................................................................ A-3

Module Space Requirements ....................................................................... A-4

Module Sizes ................................................................................................ A-5

Mounting Dimensions Example ................................................................. A-11

Relay Contact Ratings ............................................................................ B-1

Power Supply Load Requirements .......................................................... C-1

I/O Module Keying Summary .................................................................. D-1

Compatibility Matrix .............................................................................. E-1

GFK-1504N Contents vii

Page 9

Chapter

1

Introduction

Getting Started

Read this chapter first to learn about the basics of VersaMax I/O. To locate

detailed information, refer to the following section, Guide to the VersaMax

Document Set.

Guide to the VersaMax Document Set

This manual contains descriptions of the many VersaMax I/O and option

modules, power supplies, and carriers.

Installation procedures are described in Chapter 2.

The rest of the chapters in this manual describe the wide variety of VersaMax

I/O modules, carriers, and accessories that are available.

Power Supplies: chapter 3

Carriers: chapter 4

Interposing Terminals and Terminal Strips: chapter 5

Expansion Modules: chapter 6

Discrete Input Modules: chapter 7

Discrete Output Modules: chapter 8

Discrete Mixed Modules: chapter 9

Analog Input Modules: chapter 10

Analog Output Modules: chapter 11

Analog Mixed Modules: chapter 12

Discrete Mixed/High Speed Counter Module: chapter 13

Temperature-sensing Modules: chapter 14

Accessories: chapter 15

The appendices to this manual contain detailed reference information.

GFK-1504N 1-1

Page 10

Describes the installation and operation of the VersaMax PROFINET

1

Related VersaMax Manuals

For more information about VersaMax products, consult the following manuals.

GFK-1503, VersaMax PLC

System Manual

GFK-1860, VersaMax Ethernet

Network Interface Unit User’s

Manual

GFK-1533, VersaMax

DeviceNet Modules User’s

Manual

GFK-1534, VersaMax Profibus

Network Modules User’s

Manual

Describes the installation and operation of the PLC System. This

manual also contains general information about CPU operation and

program features.

Describes the installation and operation of the Ethernet NIU. The

Ethernet NIU interfaces an I/O station of VersaMax modules to an

Ethernet Network.

Describes the installation and operation of the DeviceNet NIU and

DeviceNet Network Communications Module.

The DeviceNet NIU interfaces an I/O station of VersaMax modules to

a DeviceNet Network. It operates as a slave on the network.

The DeviceNet Network Communications Module can operate as a

master or slave on the DeviceNet network.

Describes the installation and operation of the Profibus Network

Interface Unit and Profibus Network Slave Module.

The Profibus NIU interfaces an I/O station of VersaMax modules to a

Profibus Network. It operates as a slave on the network.

The Profibus Network Slave Module operates as a slave on the

Profibus network.

GFK-1535, VersaMax Genius

Network Interface Unit User’s

Manual

GFK-1697, VersaMax AS-i

Network Master Module User’s

Manual

GFK-2571, VersaMax

PROFINET Scanner Manual

1-2 VersaMax Modules, Power Supplies and CarriersUser Manual GFK-1504N

Describes the installation and operation of the Genius NIU. The

Genius NIU interfaces an I/O station of VersaMax modules to a

Genius Network.

Describes the installation and operation of the VersaMax AS-Interface

Network Master module (IC200BEM104), which can be used to

interface a VersaMax PLC or I/O station NIU to an AS-i network.

Scanner, which interfaces a remote node of VersaMax modules to a

PROFINET IO network.

Page 11

1

VersaMax Product Line

The VersaMax product line provides universally-distributed I/O that spans PLC

and PC-based architectures. Designed for industrial and commercial

automation, VersaMax I/O provides a common, flexible I/O structure for local

and remote control applications. The VersaMax PLC provides big-PLC power

with a full range of I/O and option modules. VersaMax I/O Stations with Network

Interface Modules make it possible to add the flexibility of VersaMax I/O to other

types of networks. VersaMax meets UL, CUL, CE, Class1 Zone 2 and Class I

Division 2 requirements.

As a scaleable automation solution, VersaMax I/O combines compactness and

modularity for greater ease of use. The 70-mm depth and small footprint of

VersaMax I/O enables easy, convenient mounting as well as space-saving

benefits. Modules can accommodate up to 32 points of I/O each.

The compact, modular VersaMax products feature DIN-rail mounting with up to

eight I/O and option modules per “rack” and up to 8 racks per VersaMax PLC or

VersaMax I/O Station system. Expansion racks can be located up to 750 meters

from the main VersaMax PLC or VersaMax I/O Station rack. Expansion racks

can include any VersaMax I/O, option, or communications module.

VersaMax provides automatic addressing that can eliminate traditional

configuration and the need for hand-held devices. Multiple field wiring

termination options provide support for two, three, and four-wire devices.

For faster equipment repair and shorter Mean-Time-To-Repair, the hot insertion

feature enables addition and replacement of I/O modules while a machine or

process is running and without affecting field wiring.

GFK-1504N Chapter 1 Introduction 1-3

Page 12

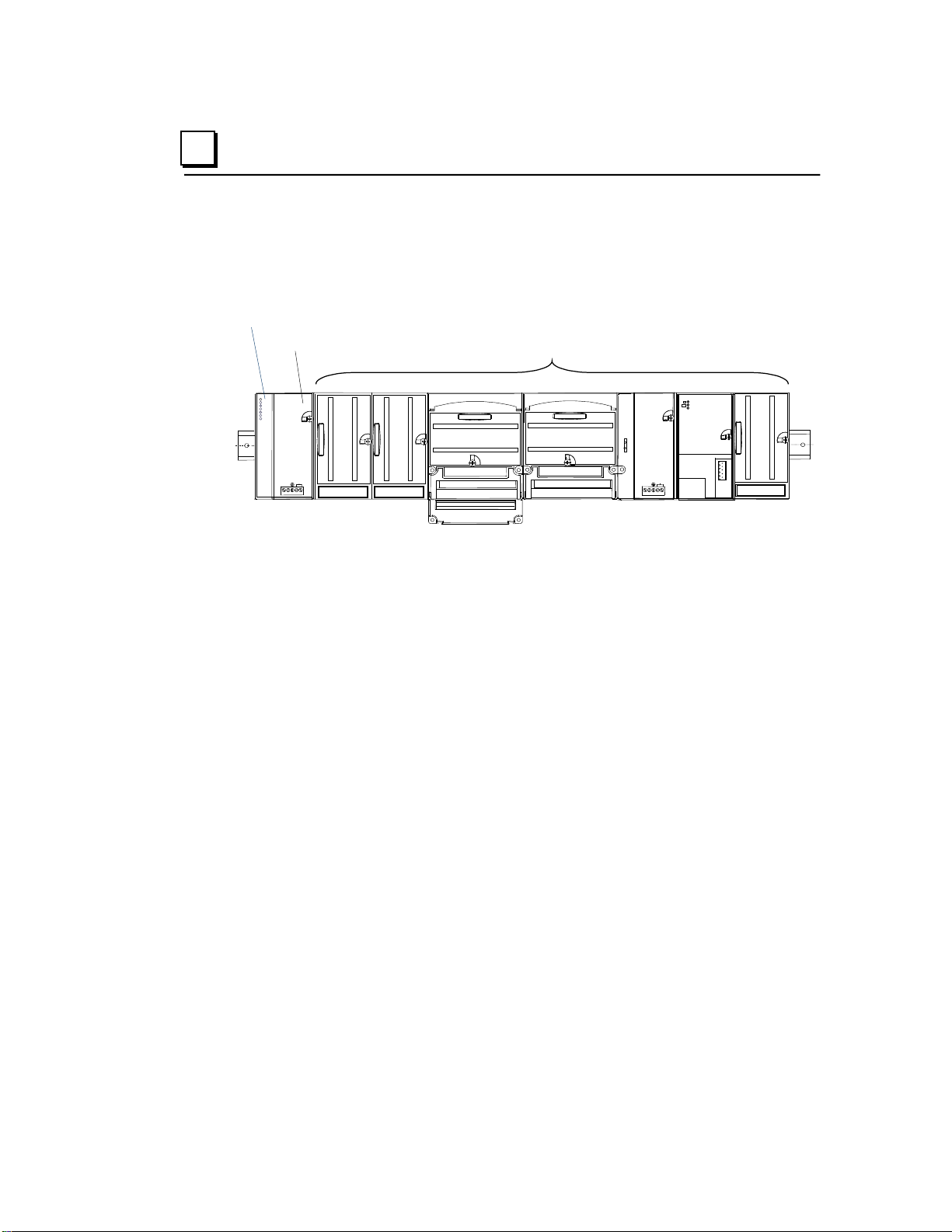

VersaMax PLC CPU

power supply

VersaMax Modules

1

CPU Modules for VersaM ax P LCs

A VersaMax PLC consists of a group of VersaMax modules with a VersaMax

CPU and attached power supply in the first position.

All VersaMax CPUs provide powerful PLC functionality. They are designed to

serve as the system controller for up to 64 modules with up to 2048 I/O points.

Two serial ports provide RS-232 and RS-485 interfaces for SNP slave and RTU

slave communications.

VersaMax CPUs are described in GFK-1503, VersaMax PLC User’s Manual.

This document also provides programming information for the VersaMax PLC.

Basic CPU Features

Programming in Ladder Diagram, Sequential Function Chart, and

Instruction List

Floating point (real) data functions

Non-volatile flash memory for program storage

Battery backup features for program, data, and time of day clock

Super capacitor provides power to memory for 1 hour

Over 1 hour, backup battery protects memory contents up to 6 months.

Backup battery has shelf life of 5 years when not in use.

Run/Stop switch

Embedded RS-232 and RS-485 communications

1-4 VersaMax Modules, Power Supplies and CarriersUser Manual GFK-1504N

Page 13

1

RS485

PORT 2

RS232

PORT 1

CPU001

PORT 2

FORCE

PORT 1

FAULT

RUN

PWR

OK

RS485

PORT 2

RS232

PORT 1

CPU005

FAULT

RUN

PWR

OK

PORT 2

FORCE

PORT 1

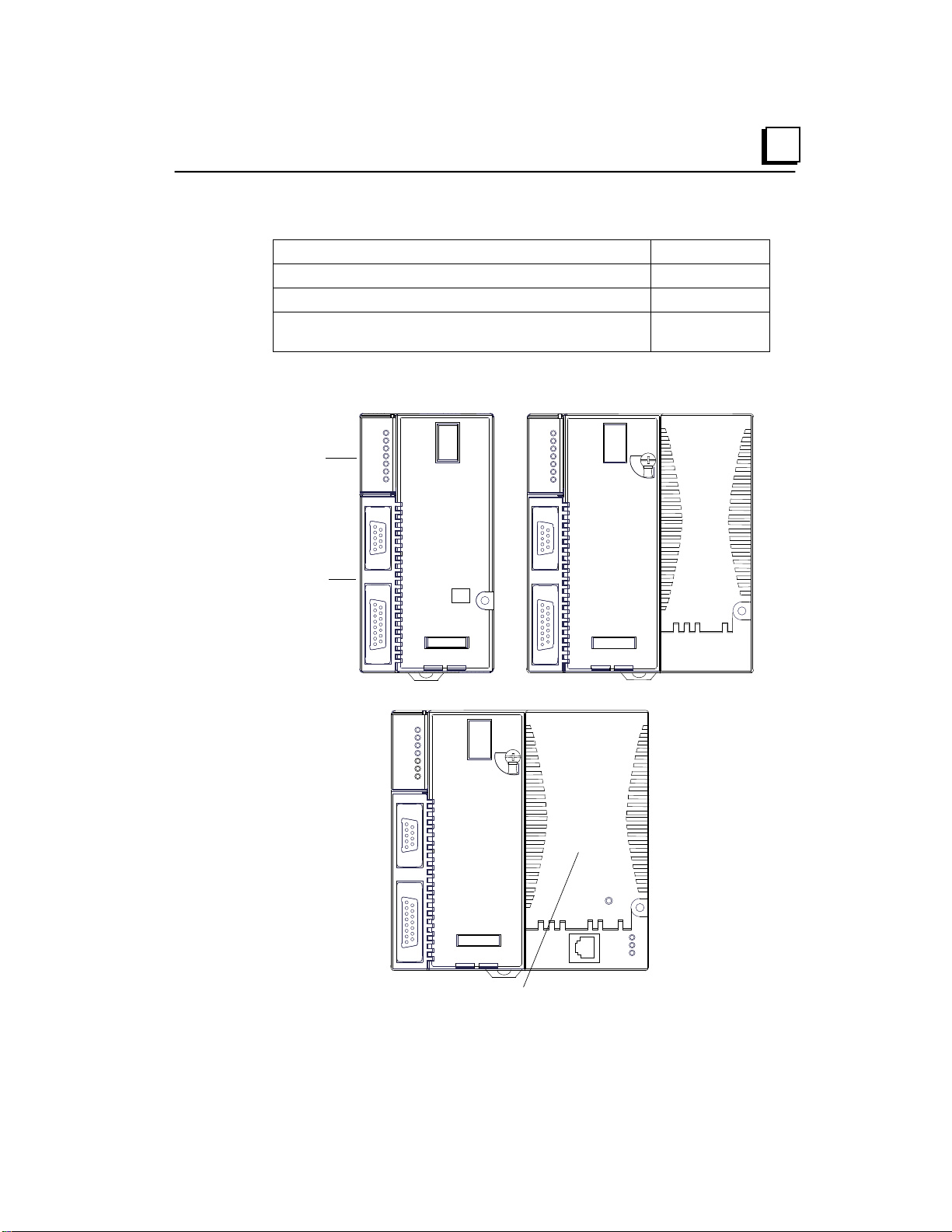

CPU001

CPU002

CPU005

Status LEDs

Serial Ports

RS485

PORT 2

RS232

PORT 1

CPUE05

FAULT

RUN

PWR

OK

PORT 2

FORCE

PORT 1

PORT 1

LAN

STAT

ETHERNET

10 BASE T /

100 BASE TX

ETHERNET

RESTART

CPUE05

Ethernet Interface

Available VersaMax CPUs

CPU with Two Serial Ports, 34kB of Configurable Memory IC200CPU001

CPU with Two Serial Ports, 42kB of Configurable Memory IC200CPU002

CPU with Two Serial Ports, 128kB of Configurable Memory IC200CPU005

CPU with Two Serial Ports and Embedded Ethernet Interface,

128kB of Configurable Memory

IC200CPUE05

GFK-1504N Chapter 1 Introduction 1-5

Page 14

VersaMax NIU

power supply

VersaMax Modules

SHIELD OUT

SERIAL B2

SHIELD IN

SERIAL A2

SHIELD OUT

SERIAL B1

SHIELD IN

SERIAL A1

0

1

0 0 7

6

4

5

8

9

1

1

BAUD

RATE

SBA

X10

3

2

3

2

3

2

GBI001

BUS B

SBA ERR

I/O ENBL

FORCE

PWR

FAULT

OK

SBA

X1

U

N

A

N

Genius® NIU

IC200GBI001

1

Network Interface Uni t s

A VersaMax I/O Station consists of a group of VersaMax modules with a

VersaMax Network Interface Unit (NIU) module and attached power supply in

the first position.

The NIU provides I/O scanning and a communications interface, allowing a

group of VersaMax modules to function as an I/O station on a communications

bus. The power supply on the NIU provides power for the modules in the I/O

Station. Additional “booster” power supplies can be included in the system if

needed for modules with high current requirements.

A NIU module has connectors appropriate for its communications network type

and status LEDs. NIUs also have rotary dials that can be used to set

communications ID information and other parameters.

Genius NIU

1-6 VersaMax Modules, Power Supplies and CarriersUser Manual GFK-1504N

Page 15

1

Available VersaMax NIUs

Ethernet NIU

The Ethernet NIU (IC200EBI001) serves as the connection point between

VersaMax I/O modules and a single 10/100Base-T Ethernet network. The NIU

supports Modbus/TCP protocol. For information about the Ethernet NIU, refer to

GFK-1860, VersaMax System Ethernet Network Communications User’s

Manual.

DeviceNet NIU

The DeviceNet NIU (IC200DBI001) is a DeviceNet slave module. DeviceNet

supports a variety of communication structures including peer to peer, multimaster and master/slave with broadcasting capabilities. Up to 64 nodes can be

connected to a DeviceNet network without bridging or routing. For information

about the DeviceNet NIU, refer to GFK-1533, VersaMax System DeviceNet

Network Communications User’s Manual.

Ethernet NIU IC200EBI001

Profibus NIU IC200PBI001

Genius NIU IC200GBI001

DeviceNet NIU IC200DBI001

Profibus NIU

The Profibus NIU (IC200PBI001) operates as a slave on a Profibus-DP

Network, automatically exchanging I/O, status, control, and diagnostic data with

a master device. The NIU is capable of handling up to 375 bytes of I/O data,

consisting of up to 244 bytes of discrete and analog input data and up to 244

bytes of discrete and analog output data. The system host can be any device

capable of operating as a bus master. For information about the Profibus-DP

NIU, refer to GFK-1534, VersaMax System Profibus Network Modules User’s

Manual (revision A or later).

Genius NIU

The Genius NIU (IC200GBI001) operates as a device on a Genius bus. The

NIU is capable of handling up to 128 bytes of discrete and analog input data and

128 bytes of discrete and analog output data. The system host can be any PLC

or computer capable of controlling the Genius bus. For information about the

Genius NIU, refer to GFK-1535, VersaMax System Genius Network Interface

Unit User’s Manual.

GFK-1504N Chapter 1 Introduction 1-7

Page 16

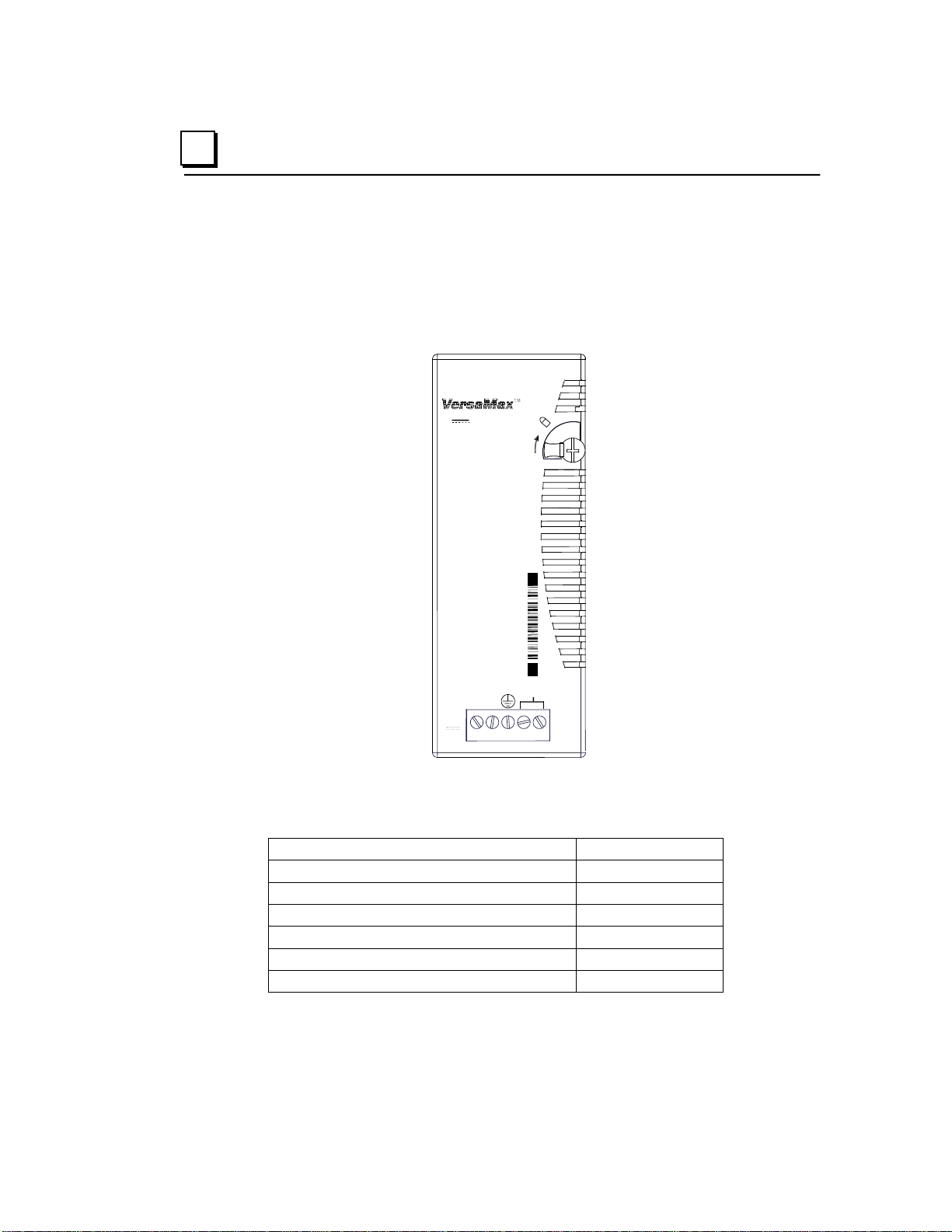

IC200PWR001

VDC

+

INPUT

-

24 VDC, 11 W

POWER SUPPLY

NOT

USED

24VDC Power Supply

IC200PWR001

24VDC Expanded 3.3V Power Supply

IC200PWR002

120/240VAC Power Supply

IC200PWR101

120/240VAC Expanded 3.3V Power Supply

IC200PWR102

12VDC Power Supply

IC200PWR201

12VDC Expanded 3.3V Power Supply

IC200PWR202

Power Supply Booster Carrier

IC200PWB001

1

Power Supplies

An AC or DC Power Supply module installs directly on the CPU or NIU. The

power supply provides +5V and +3.3V power to the modules in the station.

Additional power supplies can be installed on special booster carriers, if

needed, for systems where the number of modules creates the need for a

booster. The AC or DC power supply on the CPU or NIU and the power supply

that resides on the Booster carrier must share the same external power source.

Available Power Supplies and Carrier

1-8 VersaMax Modules, Power Supplies and CarriersUser Manual GFK-1504N

The following table lists the available VersaMax power supplies and carrier.

Power supplies are described in chapter 3 of this manual.

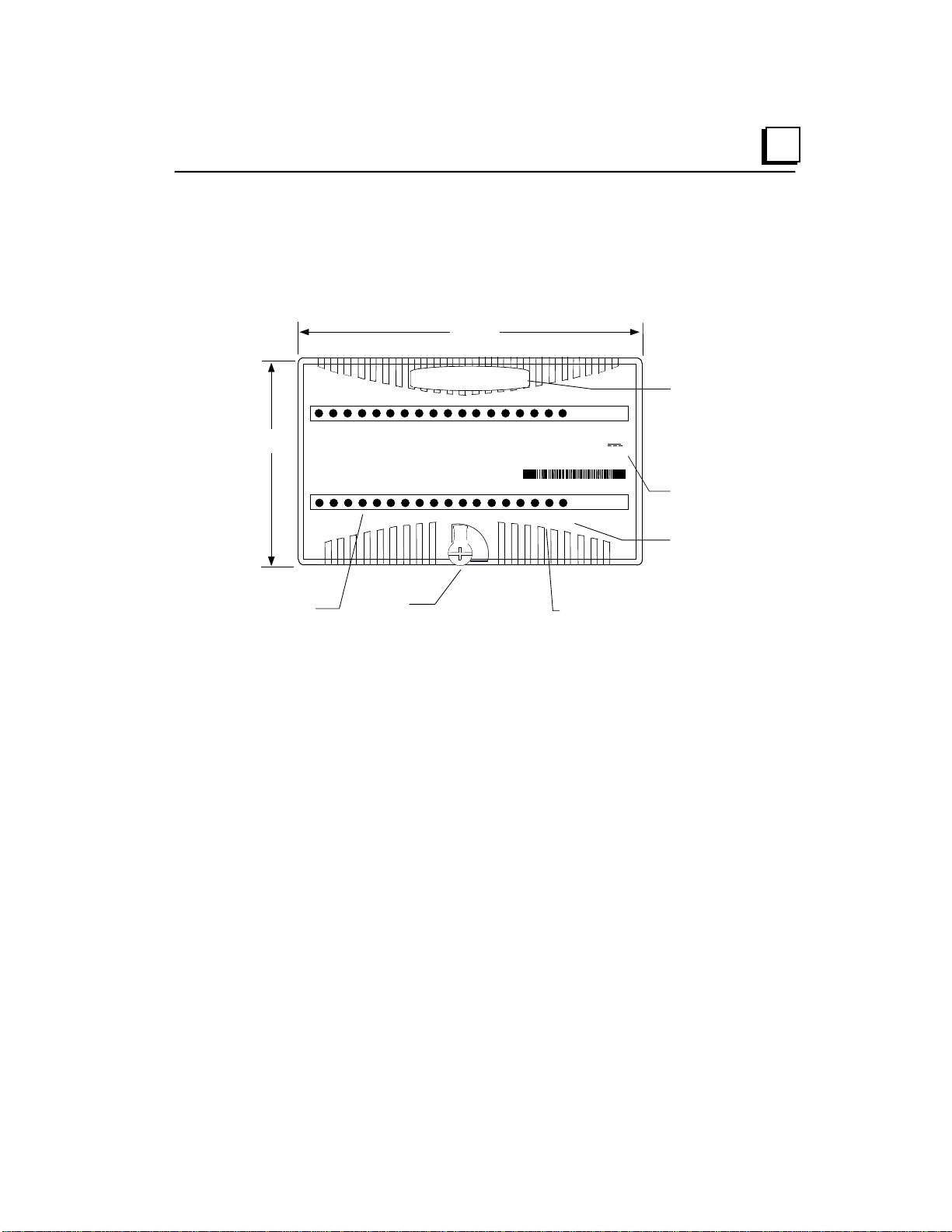

Page 17

1

66.8mm

(2.63in)

110mm

(4.33in)

Latch

Individual Point LEDS

on Discrete Modules

Field Power LED

indicates presence of

power from external

supply

OK LED indicates

presence of power from

VersaMax power supply

Color code:

Red: AC

Blue: DC

Gold: Mixed

Gray: Analog/other

Module

Description

1234567 831

FLD

PWR

OK

IC200MDL750

OUTPUT 12/24VDC

POS GRP .5A 32PT

OK

FLD

PWR

1 2 3 4 5 6 7 8 9 10

11 12 13 14 15 16

Q

Q

17 18 19

20

21 22

23

24 25 26 27 28 29 30 31

32

I/O Modules

VersaMax IO and option modules are approximately 110 mm (4.3 in) by 66.8

mm (2.63 in) in size. Modules can be mounted either horizontally or vertically on

several types of available I/O Carriers. Modules are 50 mm (1.956 in) in depth,

not including the height of the carrier or the mating connectors.

VersaMax I/O modules discussed in this manual are grouped into chapters by

module type. For more information about a specific module, refer to the Table of

Contents or Index for the module description.

Discrete Module Point LEDs

Individual point LEDs on discrete modules provide status information at a

glance. Laser markings on the module identify the LEDs. The positions of the

point LEDs always correspond to the module’s wiring diagram, whether the

module is simple:

GFK-1504N Chapter 1 Introduction 1-9

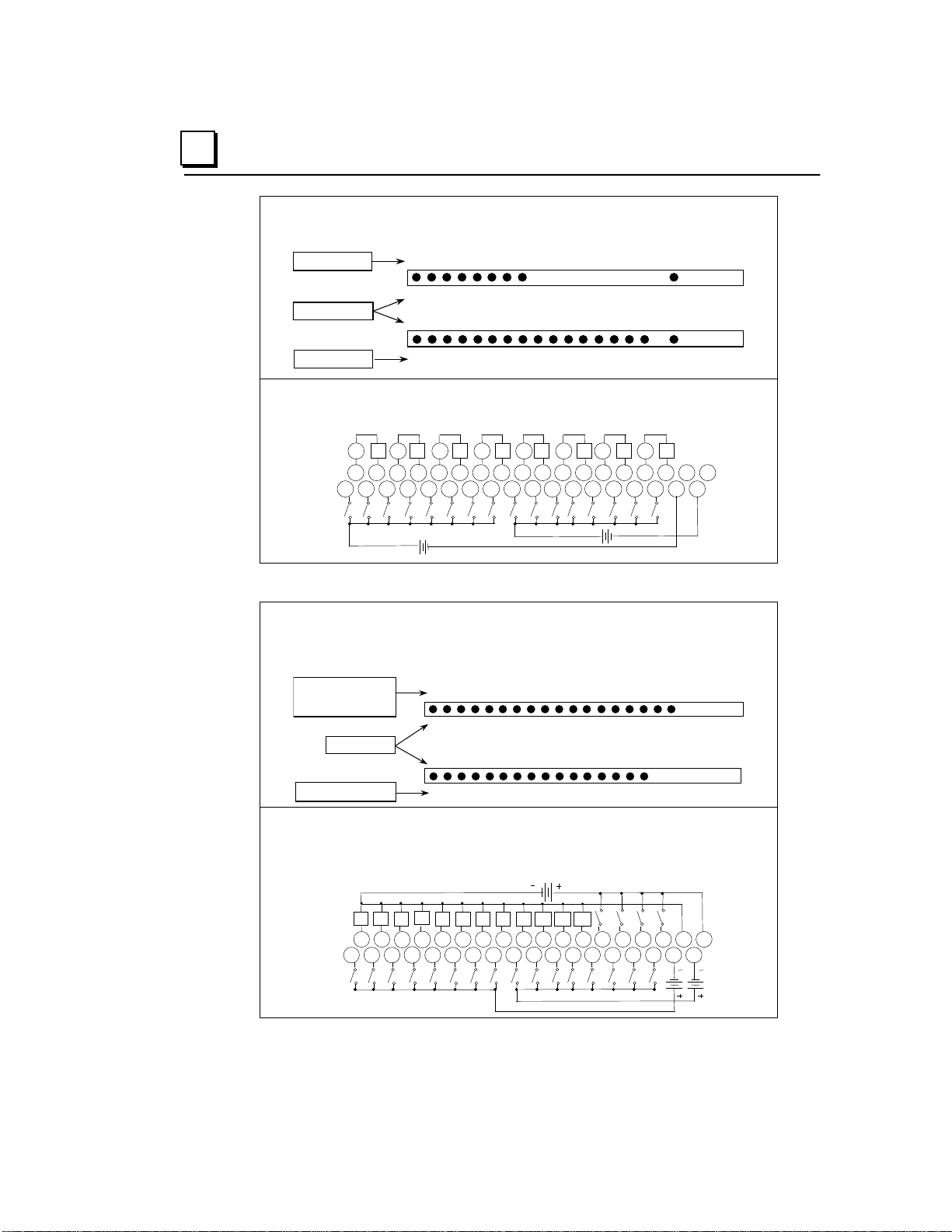

Page 18

Q (output points)

Point numbers

I (input points)

1234567

8

123456789

10111213141516

OK

Q

I

OK

I1 I2 I3 I4 I5 I6 I7 I8 I9 I10 I11 I12 I13 I14 I15 I16

Q1

Q2

Q3

Q4

Q5

Q6

Q7

Q8

v v v v v v v v

1 2 3 4 5 6 7 8 9 11 12 13 14 15 16 17 18

1 2 3 4

5 6 7 8 9 11 12 13 14 15 16 17 18 10

10

B

A

+

-

(+)

(-)

+

-

(+)

(-)

-

(+) - (+)

OK

123456789101112171819

20

123456789101112131415

16

FLD

Q/I

I

Q (Output points 1 - 12)

followed by

I (input points 17 - 20)

Point numbers

I (input points 1 - 16)

1

A B

2

3

4

5

6 7

8

9

1

2

3

4

5

6 7 8

9

11

12

13

14

15

16

17

18

11

12 13

14

15

16

17

18

10

10

I1

I2

I3

I4

I5

I6

I7

I8 9 I10

I11

I12

I13

I14

I15

I16

I17

I18

I19

I20

Q1

Q2

Q3

Q4

Q5

Q6

Q7

Q8

Q9

Q10

Q11

Q12

1

LEDs for Discrete Mixed

Module IC200MDD845

Wiring Diagram for Module

IC200MDD845

or more complex:

LEDs for Discrete Mixed

High-speed Counter Module

IC200MDD841

Wiring Diagram for Mixed

High-speed Counter Module

IC200MDD841

1-10 VersaMax Modules, Power Supplies and CarriersUser Manual GFK-1504N

Page 19

1

Available I/O Modules

Discrete Input Modules

Input Module, 120VAC 8 Points IC200MDL140

Input Module, 240VAC 8 Points IC200MDL141

Input Module, 120VAC Isolated 8 Points IC200MDL143

Input Module, 240VAC Isolated 4 Points IC200MDL144

Input Module, 120VAC 16 Points IC200MDL240

Input Module, 240VAC16 Points IC200MDL241

Input Module, 120VAC Isolated 16 Points IC200MDL243

Input Module, 240VAC Isolated 8 Points IC200MDL244

Input Module, 125VDC Positive/Negative Logic Isolated 8 Points IC200MDL631

Input Module, 125VDC Positive/Negative Logic Isolated 16 Points IC200MDL632

Input Module, 48VDC Positive/Negative Logic Grouped 16 Points IC200MDL635

Input Module, 48VDC Positive/Negative Logic Grouped 32 Points IC200MDL636

Input Module, 24VDC Positive/Negative Logic 16 Points IC200MDL640

Input Module, 5/12VDC Positive/Negative Logic Grouped 16 Points IC200MDL643

Input Module, 5/12VDC Positive/Negative Logic Grouped 32 Point IC200MDL644

Input Module, 24VDC Positive/Negative Logic (32 Points IC200MDL650

Discrete Output Modules

Output Module, 120VAC 0.5 Amp, Isolated 8 Points IC200MDL329

Output Module, 120VAC 0.5 Amp, Isolated 16 Points IC200MDL330

Output Module, 120VAC 2.0 Amp, Isolated 8 Points IC200MDL331

Output Module, 24VDC Positive Logic 2.0 Amps, w/ESCP 8 Points IC200MDL730

Output Module, 12/24VDC Positive Logic 0.5 Amp, 16 Points IC200MDL740

Output Module, 24VDC Positive Logic 0.5 Amp, w/ESCP 16 Points IC200MDL741

Output Module, 24VDC Positive Logic 0.5 Amp, w/ESCP 32 Points IC200MDL742

Output Module, 5/12/24V DC Negative Logic 0.5 Amp, 16 Points IC200MDL743

Output Module, 5/12/24VDC Negative Logic 0.5 Amp, 32 Points IC200MDL744

Output Module, 12/24VDC Positive Logic 0.5 Amp, 32 Points IC200MDL750

Output Module, Relay 2.0 Ampt Isolated Form A 8 Points IC200MDL930

Output Module, Relay 2.0 Amp, Isolated Form A 16 Points IC200MDL940

GFK-1504N Chapter 1 Introduction 1-11

Page 20

Discrete Mixed I/O Modules

Mixed Module, 24VDC Positive Logic Input 20 Points / Output Relay 2.0 Amp 12 Points

IC200MDD840

Mixed Module, 24VDC Positive Logic Input 20 Points / Output 12 Point / (4) High Speed

IC200MDD841

Mixed Module, Output 24VDC Pos. Logic 0.5A Grouped w/ESCP 16 Points / Input 24VDC

Pos/Neg Logic Grouped 16 Points

IC200MDD842

Mixed Module, 24VDC Positive Logic Input Grouped 10 Points / Output Relay 2.0A per Point

Grouped 6 Points

IC200MDD843

Mixed Module, Output 12/24VDC Pos. Logic 0.5A 16 Points / Input 24 VDC Pos/Neg Logic

Grouped 16 Points

IC200MDD844

Mixed Module, Output Relay 2.0A Isolated 8 Points / Input 24VDC Pos/Neg Logic Grouped

16 Points

IC200MDD845

Mixed Module, Output Relay 2.0A per Pt Isolated 8 Points / Input 120VAC Grouped 8 Points

IC200MDD846

Mixed Module, Output Relay 2.0A per Pt Isolated 8 Points / Input 240VAC Grouped 8 Points

IC200MDD847

Mixed Module, Output 120VAC 0.5A per Pt Isolated 8 Points / Input 120VAC Grouped 8

Points

IC200MDD848

Mixed Module Output Relay 2.0A per Pt Isolated 8 Points / Input 120VAC Isolated 8 Points

IC200MDD849

Mixed Module, Output Relay 2.0A per Pt Isolated 8 Points / Input 240VAC Isolated 4 Points

IC200MDD850

Mixed Module, Output 12/24VDC Pos. Grouped 16 Pts / Input 5/12VDC Pos/Neg Grp16 Pts

IC200MDD851

Analog Input Modules

Analog Input Module,12 Bit Voltage/Current 4 Channels

IC200ALG230

Analog Input Module, 16 Bit Voltage/Current, 1500VAC Isolation, 8 Channels

IC200ALG240

Analog Input Module, 12 Bit Voltage/Current 8 Channels

IC200ALG260

Analog Input Module, 15 Bit Voltage Differential 8 Channels

IC200ALG261

Analog Input Module, 15 Bit Current Differential 8 Channels

IC200ALG262

Analog Input Module, 15 Bit Voltage 15 Channels

IC200ALG263

Analog Input Module, 15 Bit Current 15 Channels

IC200ALG264

Analog Input Module, 15 Bit Voltage 15 Channels, SIL2 Rated, Enhanced Diagnostics

IC200ALG265

Analog Input Module, 15 Bit Current 15 Channels, SIL2 Rated, Enhanced Diagnostics

IC200ALG266

Analog Input Module, 16 Bit RTD, 4 Channels

IC200ALG620

Analog Input Module, 16 Bit Thermocouple, 7 Channels

IC200ALG630

Analog Output Modules

Analog Output Module, 12 Bit Current, 4 Channels

IC200ALG320

Analog Output Module, 12 Bit Voltage 0 to 10VDC 4 Channels

IC200ALG321

Analog Output Module, 12 Bit Voltage -10 to +10VDC 4 Channels

IC200ALG322

Analog Output Module, 13 Bit Voltage 8 Channels

IC200ALG325

Analog Output Module, 13 Bit Current 8 Channels

IC200ALG326

Analog Output Module, 13 Bit Voltage 12 Channels

IC200ALG327

Analog Output Module, 13 Bit Current 12 Channels

IC200ALG328

Analog Output Module, 16 Bit Voltage/Current, 1500VAC Isolation, 4 Channels

IC200ALG331

Analog Mixed I/ O Modules

Analog Mixed Module, 12 Bit Input Current 4 Channels and Output Current 2 Channels

IC200ALG430

Analog Mixed Module, 12 Bit 0 to 10VDC Input 4 Channels and Output 2 Channels

IC200ALG431

Analog Mixed Module, 12 Bit +/-10VDC Input 4 Channels and Output 2 Channels

IC200ALG432

1

Counter, PWM, or Pulse Train Configurable Points

1-12 VersaMax Modules, Power Supplies and CarriersUser Manual GFK-1504N

Page 21

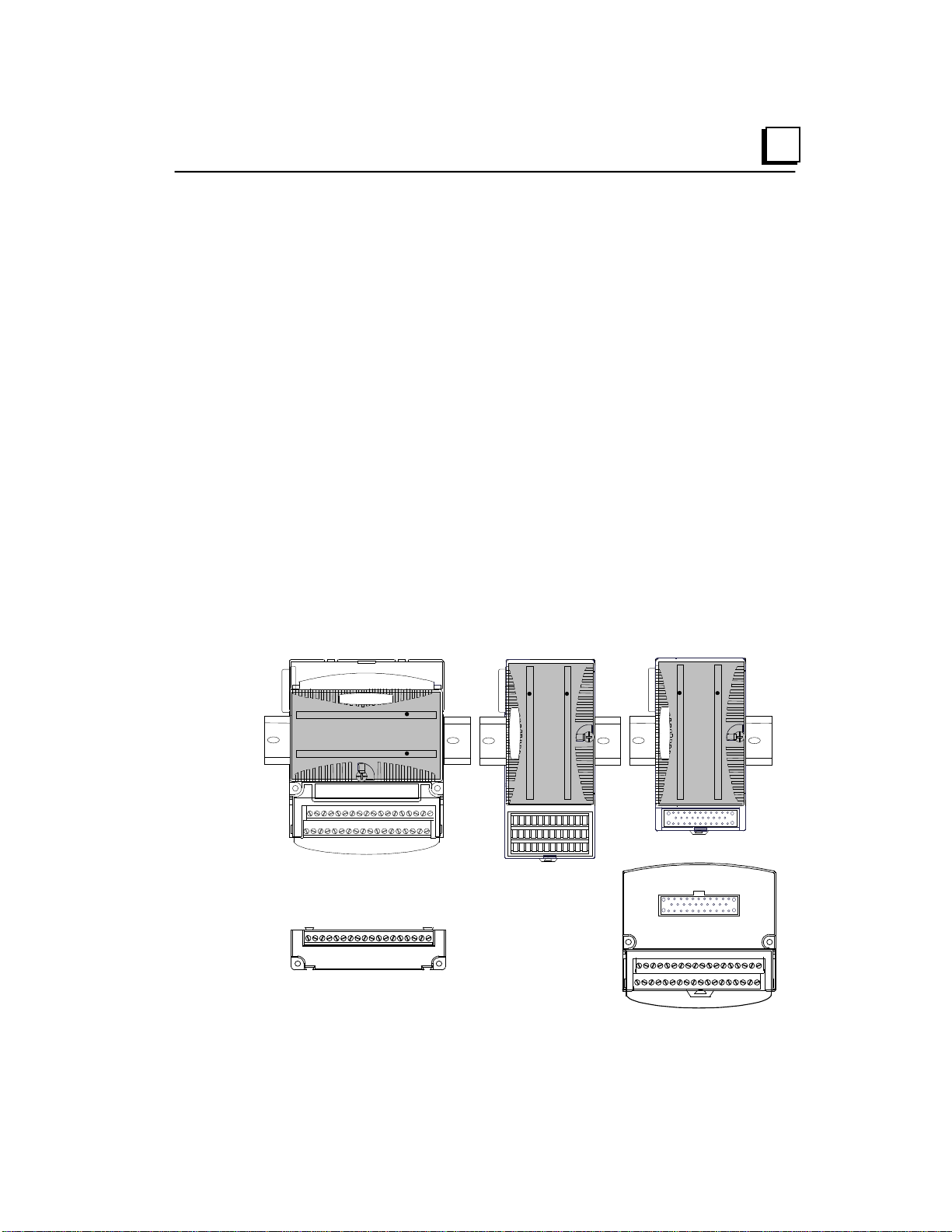

1

Terminal-style I/O

Carrier

Compact Terminal-

style I/O Carrier

Connector-style I/O

Carrier and

Interposing Terminals

Auxiliary I/O

Terminal Strip

Carriers

Carriers provide mounting, backplane communications, and field wiring

connections for all types of VersaMax modules. I/O modules can be installed

on carriers or removed without disturbing field wiring.

There are three basic I/O Carrier types:

Terminal-style I/O carriers. Modules mount parallel to the DIN rail.

Compact Terminal-style I/O Carriers. Modules mount perpendicular to the

DIN rail.

Connector-style I/O Carriers. Modules mount perpendicular to the DIN rail.

These carriers are normally used with Interposing I/O Terminals. One type

of Interposing I/O Terminals is illustrated below; other types are also

available.

Refer to chapter 4 for information about VersaMax I/O Carriers.

Terminal-style I/O carriers have 36 individual terminals for direct connection of

field wiring. Auxiliary I/O Terminal Strips are available for applications requiring

additional wiring terminals. Chapter 5 describes the VersaMax Interposing

Terminals and Auxiliary I/O Terminal Strips.

GFK-1504N Chapter 1 Introduction 1-13

Page 22

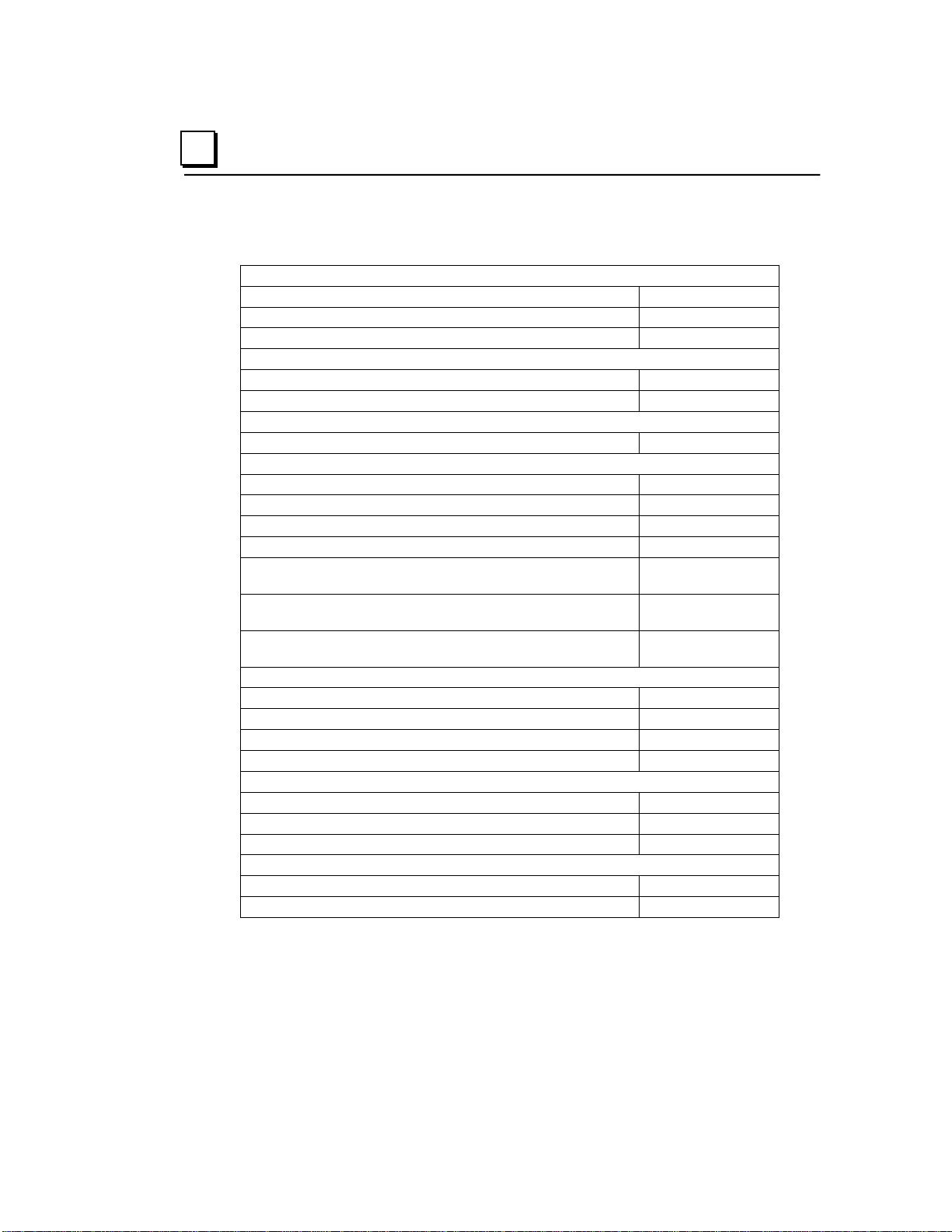

Terminal-Style I/O Carriers

Barrier-Style Terminal I/O Carrier

IC200CHS001

Box-Style Terminal I/O Carrier

IC200CHS002

Spring-Style Terminal I/O Carrier

IC200CHS005

Compact Terminal-Style I/O Carriers

Compact Box-Style I/O Carrier

IC200CHS022

Compact Spring-Style I/O Carrier

IC200CHS025

Connector-Style I/O Carrier

Connector-Style I/O Carrier

IC200CHS003

Interposing Terminals for use wit h Connector-Style Carrier

Barrier-Style Interposing I/O Terminals

IC200CHS011

Box-Style Interposing I/O Terminals

IC200CHS012

Thermocouple-Style Interposing I/O Terminals

IC200CHS014

Spring-Style Interposing I/O Terminals

IC200CHS015

Disconnect-Style Interposing I/O Terminals, Main Base

Disconnect-Style Interposing I/O Terminals, Expansion Base

IC200CHS101

IC200CHS102

Relay-Style Interposing I/O Terminals, Main Base

Relay-Style Interposing I/O Terminals, Expansion Base

IC200CHS111

IC200CHS112

Fuse-Style Interposing I/O Terminals, Expansion Base

IC200CHS122

Cables for use with Connector-Style I/O Carriers

2 connectors, 0.5m, no shield

IC200CBL105

2 connectors, 1.0m, no shield

IC200CBL110

2 connectors, 2.0m, no shield

IC200CBL120

1 connector, 3.0m, no shield

IC200CBL230

Auxiliary I/O Terminal Strips for use with Terminal-style I/O Carriers and Interposing Terminals

Barrier-Style Auxiliary I/O Terminal Strip

IC200TBM001

Box-Style Auxiliary I/O Terminal Strip

IC200TBM002

Spring-Style Auxiliary I/O Terminal Strip

IC200TBM005

Other Carriers

Communications Carrier

IC200CHS006

Power Supply Booster Carrier

IC200PWB001

1

Available I/O Carriers and Terminal Strips

Fuse-Style Interposing I/O Terminals, Main Base

IC200CHS121

1-14 VersaMax Modules, Power Supplies and CarriersUser Manual GFK-1504N

Page 23

1

PS

CPU/NIU

PS

ERM

PS

ERM

ETM

VersaMax ExpansionRack 1

Terminator

Plug

15M with any

IC200ERM002 ERMs

750M with all

IC200ERM001 ERMs

VersaMax PLC or I/O Station Main Rack (0)

VersaMax ExpansionRack 7

IC200CBL601,

602, 615

PS

ERM

VersaMax Expansion Rack

1 M

VersaMax PLC or NIU I/O Station Main Rack

PS

CPU/NIU

IC200CBL601

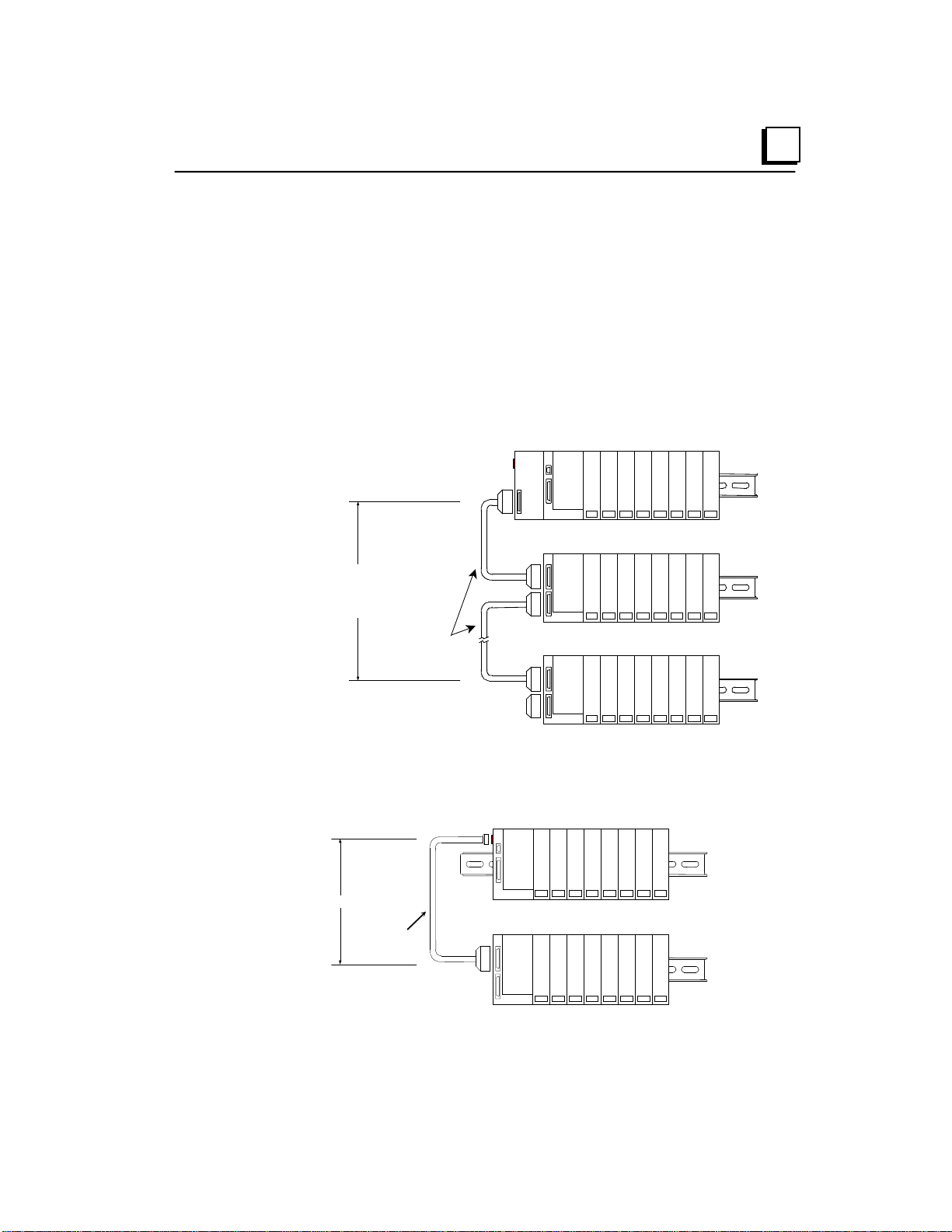

Expansion Modules

There are two basic types of VersaMax I/O expansion systems, Multi-Rack and

Two-Rack Local:

Multi-Rack: A VersaMax PLC or NIU I/O Station with an Expansion

Transmitter Module (IC200ETM001) and one to seven expansion “racks”,

each with an Expansion Receiver Module (IC200ERM001 or

IC200ERM002). If all the Expansion Receivers are the Isolated type

(IC200ERM001), the maximum overall cable length is 750 meters. If the

expansion bus includes any non-isolated Expansion Receivers

(IC200ERM002), the maximum overall cable length is 15 meters.

Two-Rack Local: A CPU or NIU I/O Station connected directly to one

expansion rack with non-isolated Expansion Receiver Module

(IC200ERM002). Maximum cable length is 1 meter.

GFK-1504N Chapter 1 Introduction 1-15

Page 24

Module

Module Revision

IC200ALG320

B or later

IC200ALG321

B or later

IC200ALG322

B or later

IC200ALG430

C or later

IC200ALG431

C or later

IC200ALG432

B or later

1

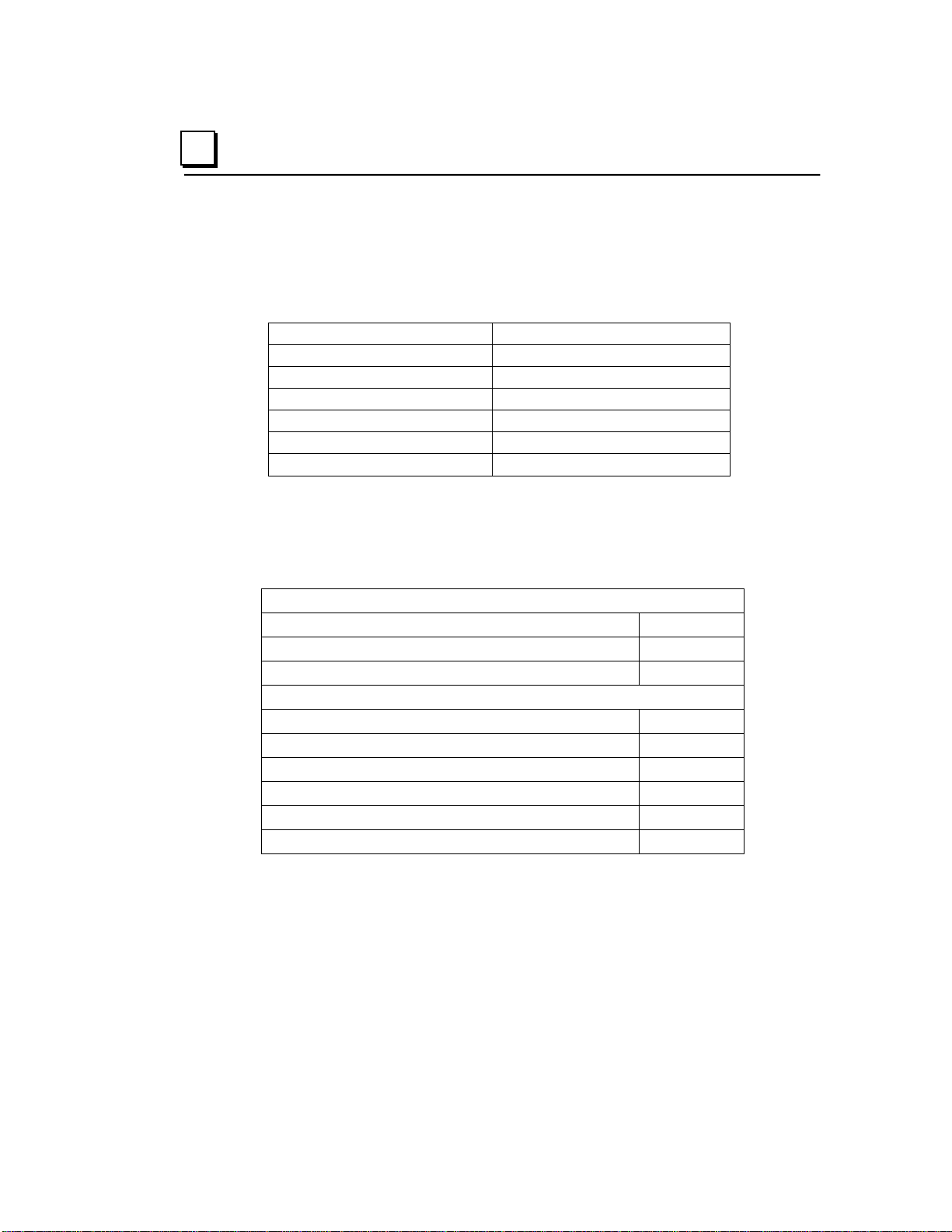

VersaMax Modules for Expansion Racks

All types of VersaMax I/O and communications modules can be used in

expansion racks. Some VersaMax analog modules require specific module

revisions, as listed in the following table.

Available Expansion Module s

Expansion Modules

Expansion Transmitter Module IC200ETM001

Expansion Receiver Module, Isolated IC200ERM001

Expansion Receiver Module, Non-isolated IC200ERM002

Cables

Expansion Cable, Shielded, 1 meter IC200CBL601

Expansion Cable, Shielded, 2 meters IC200CBL602

Expansion Cable, Shielded, 15 meters IC200CBL615

Firmware Update Cable IC200CBL002

Terminator Plug (included with ETM) IC200ACC201

Connector Kit IC200ACC302

Refer to chapter 6 for information about VersaMax Expansion modules.

1-16 VersaMax Modules, Power Supplies and CarriersUser Manual GFK-1504N

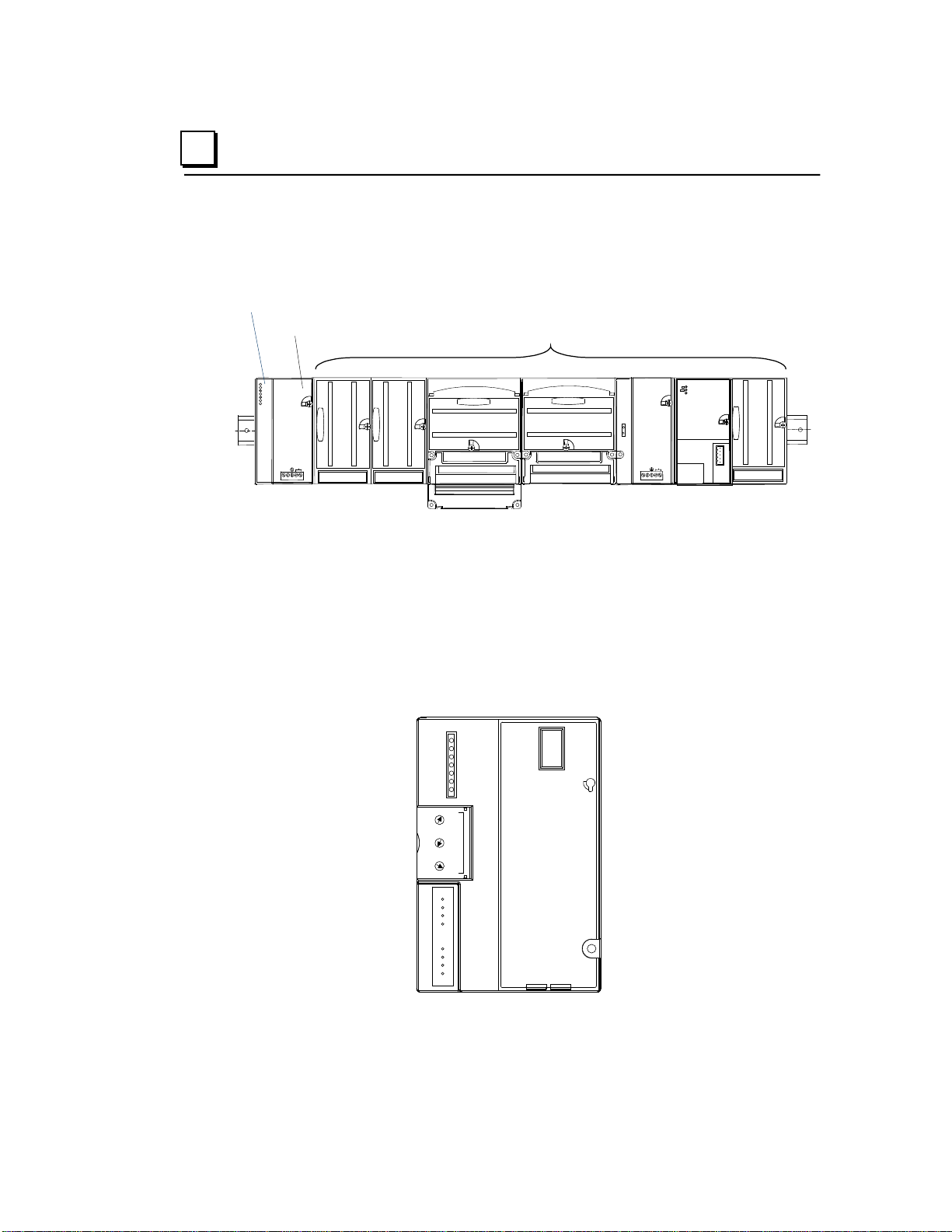

Page 25

1

VersaMax PLC CPU

power supply

Optional booster

power supply

Profibus Network

Slave Module

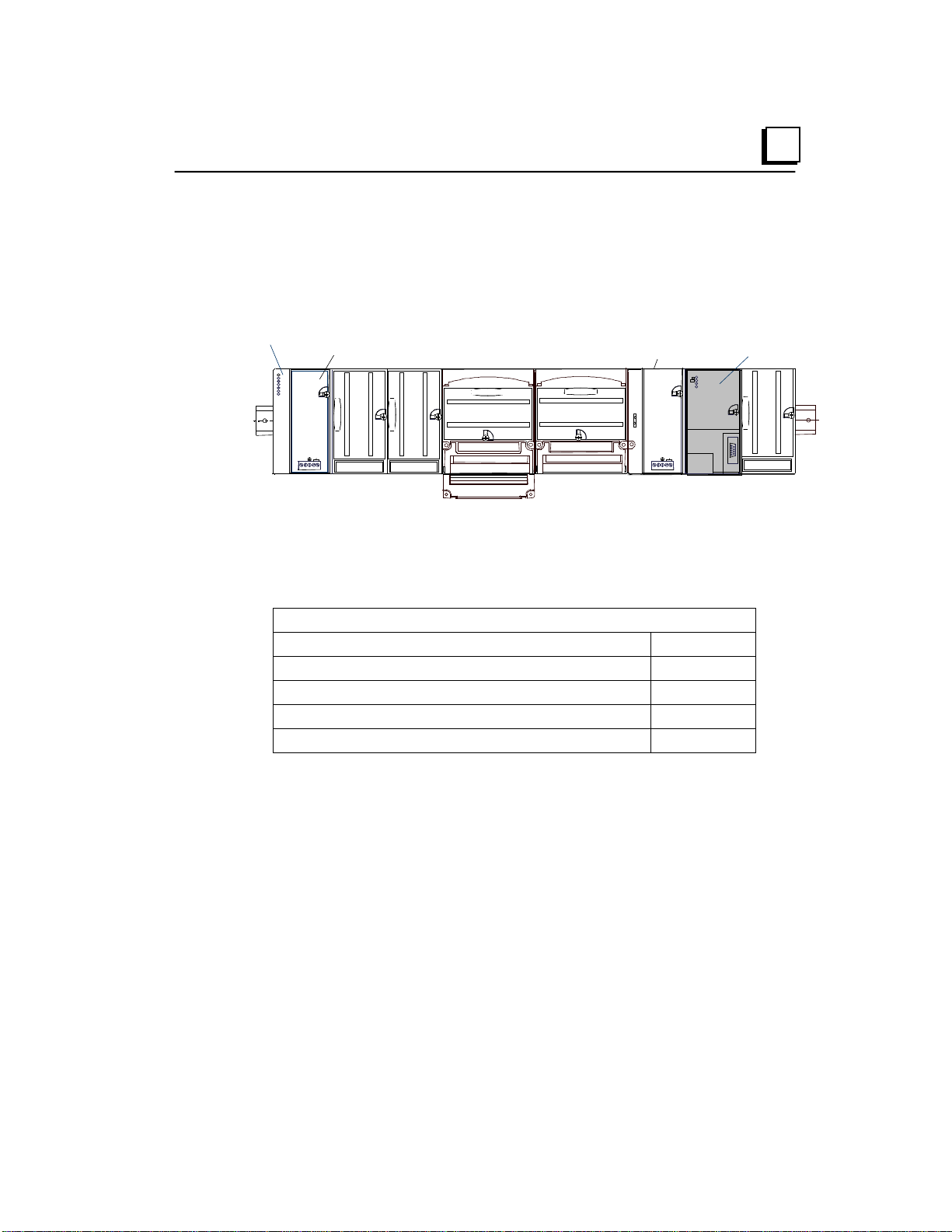

Communications Modules

Communications modules provide additional flexibility for VersaMax systems.

These communications modules install on a VersaMax Communications Carrier.

Power for the communications module comes from the main system power supply

or from a booster supply as displayed in the following figure.

Available VersaMax PLC Communications Modules

Communications Modules

Profibus-DP Network Slave Module IC200BEM002

DeviceNet Network Control Module IC200BEM103

Asi Network Master Module IC200BEM104

Communications Carrier IC200CHS006

Serial Communications Module IC200CMM020

For information about the Communications Carrier, refer to chapter 4.

Profibus-DP Network Slave Module

The Profibus-DP Network Slave Module (IC200BEM002) is a communications

module that exchanges PLC reference table data on the Profibus network. The

VersaMax PLC CPU can read and write this data as though it were conventional

bit- and word-type I/O data.

Multiple Profibus-DP Network Slave Modules may be used in the same

VersaMax PLC. Each one can read up to 244 bytes of data from the network,

and send up to 244 bytes of output data. The total amount of combined inputs

and outputs is 384 bytes.

GFK-1504N Chapter 1 Introduction 1-17

Page 26

1

For information about the Profibus-DP Network Slave Module, refer to GFK1534, VersaMax System Profibus Network Modules User’s Manual (revision A

or later).

DeviceNet Network Control Module

The DeviceNet Network Control Module (IC200BEM103) is a communications

module that can be configured to operate as a master, as a slave, or as both

simultaneously. It can exchange up to 512 bytes of input data and 512 bytes of

output data with other devices on the DeviceNet network. The VersaMax PLC

CPU can read and write this data as though it were conventional bit- and wordtype I/O data.

The Network Control Module operates as a Group 2 Only Client (master) and

can communicate only with Group 2 Slave devices. It can also operate as a

Group 2 Only or a UCMM-capable Server (slave), or as a master and slave

simultaneously.

For information about the DeviceNet Network Control Module, refer to GFK1533, VersaMax System DeviceNet Network Communications User’s Manual.

Asi Network Master Module

The VersaMax AS-Interface Network Master (IC200BEM104) conforms to the

AS-Interface Specification for the master AS-Interface protocol. It can be used

to connect a VersaMax PLC or I/O station NIU to an Actuator-Sensor network.

The AS-Interface module supports communications with up to 31 slave devices,

exchanging to exchange up to 4 bits of input data and 4 bits of output data per

slave address on the Actuator-Sensor network.

For information about the AS-Interface Network Master Module, refer to GFK1697, VersaMax System ASI Network Communications User’s Manual.

Serial Communications Module

The VersaMax Serial Communications Module, IC200CMM020, operates as a

Modbus RTU Master in a VersaMax I/O Station. The Serial Communications

module receives commands from a remote host such as an RX7i PLC.

1-18 VersaMax Modules, Power Supplies and CarriersUser Manual GFK-1504N

Page 27

1

Environmental

Vibration

IEC68-2-6

1G at 57-150Hz, 0.012in p--p at 10-57Hz

Shock

IEC68-2-27

15G, 11ms

0 to +60 deg C ambient

auxiliary I/O terminals

Storage Temperature

-40 to +85 deg C

Humidity

5% to 95%, noncondensing

protection from dust & splashing water

EMC Emission

(Group 1, Class A)

CISPR 22/EN 55022

Information Technology Equipment (Class A)

Radio Devices (Class A)

EMC Immunity

Electrostatic Discharge

EN 61000-4-2

8KV Air, 4KV Contact

rms

100%AM with 200Hz square wave

Fast Transient Burst

EN 61000-4-4

2KV: power supplies, 1KV: I/O, communication

power supplies, I/O [12V-240V]

power supplies, I/O [12V-240V]

modules)

rms

Isolation

Dielectric Withstand

UL508, UL840, IEC664

1.5KV for modules rated from 51V to 250V

Power Supply

Variation for DC ±20%

VersaMax General Product S pecifications

VersaMax products should be installed and used in conformance with productspecific guidelines, as well as the specifications listed in the following table.

Operating Temperature

Enclosure Protection IEC529 Steel cabinet per IP54:

Radiated, Conducted CISPR 11/EN 55011 Industrial Scientific & Medical Equipment

FCC 47 CFR 15 Referred to as FCC part 15,

RF Susceptibility EN 61000-4-3 10V

ENV 50140/ENV 50204 10V

Surge Withstand ANSI/IEEE C37.90a Damped Oscillatory Wave: 2.5KV:

IEC255-4 Damped Oscillatory Wave: Class II,

-40 to +60 deg C ambient for I/O carriers,

communications carrier, interposing I/O terminals, and

/m, 80 to 1000Mhz, 80% AM

/m, 900MHz ±5MHZ

rms

EN 61000-4-5 2 kV cm(P/S); 1 kV cm (I/O and communication

Conducted RF EN 61000-4-6 10V

Input Dips, Variations EN 61000-4-11 During Operation: Dips to 30% and 100%,

GFK-1504N Chapter 1 Introduction 1-19

, 0.15 to 80Mhz, 80%AM

Variation for AC ±10%,

Page 28

Chapter

2

Installation

This section provides the following installation instructions:

Pre-installation Check

Conformance to Standards

Thermal Clearance

DIN Rail and Panel Mounting

Installing Carriers

Expansion System Installation

Installing a Power Supply

System Wiring Guidelines

System Grounding

Installing Wiring for I/O Devices

Installing Modules

GFK-1504N 2-1

Page 29

2

Pre-installation Check

Carefully inspect all shipping containers for damage during shipping. If any part

of the system is damaged, notify the delivery service immediately. The

damaged shipping container should be saved as evidence for inspection by the

delivery service. It is the user’s responsibility to register a claim with the delivery

service for damage incurred during shipment.

After unpacking the VersaMax modules and other equipment, record all serial

numbers. Serial numbers are required if you should need to contact Product

Service during the warranty period of the equipment. All shipping containers and

all packing material should be saved should it be necessary to transport or ship

any part of the system.

Conformance to Standards

Before installing VersaMax products in situations where compliance to

standards or directives from the Federal Communications Commission, the

Canadian Department of Communications, or the European Union is required

please refer to GFK-1179, Installation Requirements for Conformance to

Standards.

▪ Power Supply Modules: Be sure to read the installation instructions

provided with each Power Supply module. These instructions specify the

use of copper conductors for the power supply, wire gauge and type.

▪ Control circuit modules: Be sure to read the installation instructions provided

with the module. These instructions specify the use of copper conductors

and wire gauge and type requirements.

▪ Equipment labeled with reference to Class I, Div. 2, Groups A, B, C and D,

Hazardous Locations is suitable for use in Class I, Div. 2, Groups A, B, C, D

or non-hazardous locations only.

▪ Equipment labeled with reference to Class I, Zone 2, Groups A, B, C and D,

hazardous locations is suitable for use in Class I, Zone 2, Groups A, B, C, D

or non-hazardous locations only.

▪ Battery in CPU Category No. IC200CPU001 and IC200CPU002 is to be

replaced only with Matsushita No. BR2032. The correct battery type is

available as Accessory Kit IC200ACC001.

2-2 VersaMax Modules, Pow er S uppl i es and CarriersUser Manual GFK-1504N

Page 30

2

Installation in Hazardous Locations

▪ WARNING - EXPLOSION HAZARD - SUBSTITUTION OF COMPONENTS

MAY IMPAIR SUITABILITY FOR CLASS I, DIVISION 2;

▪ WARNING - EXPLOSION HAZARD - WHEN IN HAZARDOUS

LOCATIONS, TURN OFF POWER BEFORE REPLACING OR WIRING

MODULES; AND

▪ WARNING - EXPLOSION HAZARD - DO NOT CONNECT OR

DISCONNECT EQUIPMENT UNLESS POWER HAS BEEN SWITCHED

OFF OR THE AREA IS KNOWN TO BE NONHAZARDOUS.

GFK-1504N Chapter 2 Installation 2-3

Page 31

5.1cm

(2.0in)

2.54cm

(1.0in)

5.1cm

(2.0in)

2.54cm

(1.0in)

5.1cm

(2.0in)

2.54cm

(1.0in)

5.1cm

(2.0in)

2.54cm

(1.0in)

CPU or NIU

at Bottom

2

Thermal Considerations

The thermal performance specified for modules in this manual requires a

clearance of 5.1 cm (2 in) above and below the modules and 2.54 cm (1 in) on

each side of the modules as shown below, regardless of the orientation of the

DIN rail.

When using a vertical DIN rail, the CPU or NIU module must be installed at the

bottom.

Individual modules have may additional clearance requirements. Refer to

Appendix A.

2-4 VersaMax Modules, Pow er S uppl i es and CarriersUser Manual GFK-1504N

Page 32

2

Hole for Optional

Panel-Mounting

DIN Rail and Panel Mounting

Each rack in a VersaMax PLC or VersaMax I/O Station must be installed on a

single section of 7.5 mm x 35 mm DIN rail, 1 mm thick. Steel DIN rail is

recommended. “Rack” is the term used for a CPU, NIU, or Expansion Receiver,

plus up to 8 physically-connected I/O carriers. The first rack in a system is

called Rack 0. If there are multiple expansion racks, Rack 0 also includes an

Expansion Transmitter module installed in the leftmost position, before the CPU

or NIU.

The DIN rail used in a VersaMax installation must be electrically grounded to

provide EMC protection. The rail must have a conductive (unpainted) corrosionresistant finish. DIN rails compliant with DIN EN50022 are preferred.

For vibration resistance, the DIN rail should be installed on a panel using

screws spaced approximately 5.24 cm (6 in) apart. DIN-rail clamps (part

number IC200ACC313) can also be installed at both ends of the station to lock

the modules in position.

For applications requiring maximum resistance to mechanical vibration and

shock, the DIN-rail-mounted carriers should also be mounted on the panel.

Panel mount holes can be located on the panel by using the carrier as a

template, or by following the dimensions provided in Appendix A. Pre-drill the

mounting holes and install the CPU, NIU, ERM, and carriers using M3.5 (#6)

screws.

GFK-1504N Chapter 2 Installation 2-5

Page 33

Connector Cover

Connector Cover

2

DIN Rail Installation Steps

VersaMax CPUs, Network Interface Unit (NIU) modules, Expansion Receiver

(ERM) modules, and module carriers snap easily onto the DIN rail. No tools are

required for mounting or grounding to the DIN rail.

Before joining module carriers to a CPU, NIU, or ERM, remove the connector

cover on the right-hand side of the CPU, NIU, or ERM. Do not discard this

cover. You will need to install it on the last carrier.

Slide carriers along the DIN rail to engage the connectors in the sides of

adjacent carriers. To avoid damaging connector pins, do not force or slam

carriers together.

Install the connector cover that was removed over the connector on the last

carrier to protect the connector pins and to provide compliance with standards.

2-6 VersaMax Modules, Pow er S uppl i es and CarriersUser Manual GFK-1504N

Page 34

2

PWR

EXP TX

On indic ates presence of 5VDC power.

Off indicates no 5VDC power.

Blinking or On indicates active

communicati ons on expansion bus.

Off indicates no communications.

Installing an Expansion Transmitter Module

An Expansion Transmitter Module must be installed to the left of a CPU or NIU.

1. Make sure rack power is off.

2. Attach the Expansion Transmitter to DIN rail to the left of the CPU or NIU.

3. Slide the module toward the CPU or NIU and press together until the

connectors are mated.

4. After completing any additional system installation steps, apply power and

observe the module LEDs.

Removing an Expansion Transmitter Module

1. Make sure rack power is off.

2. Slide module on DIN rail away from the CPU or NIU in the main rack.

3. Using a small screwdriver, pull down on the tab on the bottom of the

module and lift the module off the DIN rail.

GFK-1504N Chapter 2 Installation 2-7

Page 35

5

7

6

4

1

3

2

0

PWR

EXP RX

SCAN

On indicates presence of 5VDC power.

Off i ndic ates no 5VDC power.

Blinking or On indicates module is

communicating on expansion bus

Off i ndic ates module not communicating

Green indi cates CPU/NIU is scanning I /O

in expansion racks.

Amber indicates not sc anning.

2

Installing an Expansion Rec eiver Module

An Expansion Receiver Module (IC200ERM001 or 002) must be installed in the

leftmost slot of each VersaMax expansion rack.

1. Insert the label inside the small access door at the upper left corner of the

module.

2. Attach the module to the DIN rail at the left end of the expansion rack.

3. Select the expansion rack ID (1 to 7) using the rotary switch under the

access door at upper left corner of the module. Each rack must be set to a

different rack ID. With a single-ended cable (one expansion rack only), set

the Rack ID to 1.

4. Install a VersaMax Power Supply module on top of the Expansion Receiver.

Refer to the section, Installing a Power Supply.

5. Attach the cables. If the system includes an Expansion Transmitter Module,

attach the terminator plug to the EXP2 port on the last Expansion Receiver

Module.

6. After completing system installation, apply power and observe the module

LEDs.

2-8 VersaMax Modules, Pow er S uppl i es and CarriersUser Manual GFK-1504N

Page 36

2

Removing an Expansion Receiver Module

1. Make sure rack power is off.

2. Un-install the Power Supply module from the Expansion Receiver Module.

3. Slide the Expansion Receiver Module on DIN rail away from the other

modules.

4. Using a small screwdriver, pull down on the tab on the bottom of the module

and lift the module off the DIN rail.

GFK-1504N Chapter 2 Installation 2-9

Page 37

PS

CPU/NIU

PS

ERM

PS

ERM

ETM

VersaMax ExpansionRack 1

Terminator

Plug

15M with any

IC200ERM002 ERMs

750M with all

IC200ERM001 ERMs

VersaMax PLC or I/O Station Main Rack (0)

VersaMax ExpansionRack 7

IC200CBL601,

602, 615

Expansion

Transmitter or

Expansion

Receiver

Module

Transmitting

Port

PIN

2 3

5

6

8

9

12

13

16 17

20 21

24 25

7 23

1

FR AME + FR AME-

RIRQ/+

RIRQ/-

RUN+

RUN-

RERR+

RERR-

IODT + IODT -

RSEL+

RSEL-

IOCL K+ IOCL K-

0V

0V

SHIELD

PIN

2 3

5

6

8

9

12 13

16 17

20

21

24 25

7 23

1

FR AME + FR AME-

RIRQ/+

RIRQ/-

RUN+

RUN-

RERR+ RERR-

IODT +

IODT -

RSEL+

RSEL-

IOCL K+ IOCL K-

0V

0V

SHIELD

26-PIN

FEM AL E

26-PIN

MALE

26-PIN

MALE

26-PIN

FEM AL E

VARIABLE (SEE

TEXT)

Expansion

Receiver

Module

Receiving

Port

2

Connecting the Expansion Cable: RS-485 Differential

For a multiple-rack expansion system, connect the cable from the expansion

port on the Expansion Transmitter to the Expansion Receivers as displayed in

the following figure. If all the Expansion Receivers are the Isolated type

(IC200ERM001), the maximum overall cable length is 750 meters. If the

expansion bus includes any non-isolated Expansion Receivers (IC200ERM002),

the maximum overall cable length is 15 meters.

Install the Terminator Plug (supplied with the Expansion Transmitter module)

into the lower port on the last Expansion Receiver. Spare Terminator Plugs can

be purchased separately as part number IC200ACC201 (Qty 2).

RS-485 Differential Inter-Rack Connection (IC200CBL601, 602, 615)

Building a Custom Expansion Cable

Custom expansion cables can be built using Connector Kit IC200ACC202,

2-10 VersaMax Modules, Pow er Supplies and CarriersUser Manual GFK-1504N

Crimper AMP 90800-1, and Belden 8138, Manhattan/CDT M2483, Alpha

3498C, or equivalent AWG #28 (0.089mm

2

) cable.

Page 38

2

PS

ERM

VersaMax Expansion Rack

1 M

VersaMax PLC or NIU I/O Station M ain Rack

PS

CPU/NIU

IC200CBL600

Connecting the Expansion Cable: Single-ended

For a two-rack local system with one non-isolated expansion rack

(IC200ERM002) and NO Expansion Transmitter, connect the expansion cable

from the serial port on the VersaMax CPU or NIU to the Expansion Receiver as

displayed in the following figure. The maximum cable length is one meter.

Cables cannot be fabricated for this type of installation; cable IC200CBL600

must be ordered separately.

No Terminator Plug is needed in a single-ended installation; however, it will not

impede system operation if installed.

Single-Ended Inter-Rack Connection Cable (IC200CBL600)

GFK-1504N Chapter 2 Installation 2-11

Page 39

2

Installing a Power Supply

I/O and option modules receive power for their operation from the CPU, NIU, or

Expansion Receiver Module through the mating connector on the carrier. The

number of modules that can be supported depends on the power requirements

of the modules (listed in the individual module specifications).

Power Supply Booster Carriers can be used as needed to meet the power

needs of all modules. The AC or DC Power Supply on the CPU or NIU and the

Power Supply that resides on the Booster Carrier must share the same external

power source.

In some cases, the field devices served by an I/O module require additional AC

or DC power, which must be provided using an “external” power supply.

Specifications and connection details for such external power supplies are given

in the module specifications in this manual.

Installing a Power Supply Module

The power supply module installs directly on top of a CPU, NIU, ERM, or

booster carrier. The latch on the power supply must be in the unlocked position.

Align the connectors, tab, and latch post on the power supply to be parallel with

the CPU, NIU, ERM, or carrier. Press the power supply module down firmly,

until the two tabs on the bottom of the power supply click into place. Be sure the

tabs are fully inserted in the holes in bottom edge of the CPU, NIU, ERM, or

booster carrier.

Turn the latch to the locked position to secure the power supply in place.

Note: The VersaMax power supply is not hot-swappable. Hot inserting or

extracting the power supply is an improper method to power-down or power-up.

Hot inserting the power supply can cause a “Corrupted User Memory Fault”

condition. Power-cycling should only be accomplished by switching the main

power going into the power-supply.

2-12 VersaMax Modules, Pow er Supplies and CarriersUser Manual GFK-1504N

Page 40

2

Removing a Power Supply

1. Switch off the external power source to the power supply module.

2

. Turn the latch to the unlocked position.

3

. Press in the tabs on the lower edge of the power supply

4

. Pul l the power supply straight off.

GFK-1504N Chapter 2 Installation 2-13

Page 41

2

System Wiring Guidelines

Four types of wiring may be encountered in a typical factory installation:

Power wiring – the plant power distribution, and high power loads such as

high horsepower motors. These circuits may be rated from tens to

thousands of KVA at 220 V AC or higher.

Control wiring – usually either low voltage DC or 120 V AC of limited energy

rating. Examples are wiring to start/stop switches, contactor coils, and

machine limit switches. This is generally the interface level of discrete I/O.

Analog wiring – transducer outputs and analog control voltages. This is the

interface level to I/O analog blocks.

Communications and signal wiring – the communications network that ties

everything together, including computer LANs, MAP, and field busses.

These four types of wiring should be separated as much as possible to reduce

the hazards from insulation failure, incorrect wiring, and interaction (noise)

between signals. A typical control system may require some mixing of the latter

three types of wiring, particularly in cramped areas inside motor control centers

and on control panels.

In general, it is acceptable to mix the communications bus cable with the I/O

wiring from the blocks, as well as associated control level wiring. All noise

pickup is cumulative, depending on both the spacing between wires, and the

distance span they run together. I/O wires and communications bus cable can

be placed randomly in a wiring trough for lengths of up to 50 ft. If wiring is cord–

tied (harnessed), do not include the bus cable in the harness, since binding

wires tightly together increases the coupling and mechanical stress that can

damage the relatively soft insulation of some serial cable types. Consider using

shielded cable in electrically noisy environments.

External wiring to the equipment and in cable trays should be separated

following National Electrical Code practices.

1

2-14 VersaMax Modules, Pow er Supplies and CarriersUser Manual GFK-1504N

Page 42

2

DC+

DC-

H

N

Installing Power and Ground Wiring

Power Supply terminals accommodate one AWG #14 (avg. 2.1mm2 cross

section) to AWG #22 (avg. 0.36mm

AWG #18 (avg. 0.86mm

2

cross section). Use copper wire rated for 90 deg C.

2

cross section) wire, or two wires up to

When inserting two wires in the same position, the wires must be the same size

and the same type (solid or stranded).

Connect the ground terminal to the conductive mounting panel with a 4 in

maximum length of AWG #14 (avg. 2.1mm

2

) wire. Use hardware such as star

washers to ensure ground integrity.

Grounding DC Power Supplies

DC power supplies are non-isolated. DC- must be grounded to frame / earth

ground. DC- is grounded to frame internally in the Power Supply. As a result,

floating power supplies cannot be used.

Grounding AC Power Supplies

AC power supplies are isolated. Therefore, the AC source does not have to be

grounded. However, it is recommended to only use ground-referenced sources

such as a neutral line or grounded center-tap transformer.

GFK-1504N Chapter 2 Installation 2-15

Page 43

JUMPER

FOR 120V

2

Jumper Installation on an AC Power Supply Module

AC power supply modules (IC200PRW101 and IC200PWR102) can be used

with either 120 V AC or 240 V AC nominal input power. For 120 V AC nominal

operation, install a jumper as marked on the power supply. Use insulated AWG

#14 (avg. 2.1mm

wire.

The power supply operates without a jumper installed; however, the hold-up

specification is not met. If a jumper is not installed for 120 V AC operation, the

power supply will not cause hazardous conditions.

Warnings

DO NOT USE A JUMPER FOR 240V AC OPERATION. If a jumper is used on

the input connector for 240V AC nominal operation, the power s u p p ly will

be damaged and may cause hazardous conditions.

Do not touch the exposed portions of the jumper wire with power applied

to the system. Hazardous voltages are present that could cause personal

injury.

2

cross section) to AWG #22 (avg. 0.36mm2 cross section)

2-16 VersaMax Modules, Pow er Supplies and CarriersUser Manual GFK-1504N

Page 44

2

+

-

DC: +

or

AC: H

DC: -

or

AC: N

Installing Additional Suppression

For agency compliance, external Metal Oxide Varistor (MOV) suppression is

required from both the positive and negative input to frame ground or at the

power line input of a system enclosure. The MOV should be sized to handle

line transients. Examples of suitable MOVs to handle normal line transients

include the following products manufactured by Littelfuse:

V36ZA80 (Non-isolated 24 V DC

V130LA20AP (120 V AC applications)

V275LA40BP (240 V AC applications)

Measurement of actual transients may be required in extreme cases to decide

what MOV is best.

Installing Suppression at the Pow er Supply

The following figure displays typical power and ground connections.

GFK-1504N Chapter 2 Installation 2-17

Page 45

Enclosure

Power

to

Modules

Short Length of

Communications

Bus Cable

2

Installing Suppression for Devi ces in an Enclosure

For a group of devices installed in an enclosure, MOVs can be installed at the

point where the power lines enter the enclosure. Ideally, MOVs should be used

at each cabinet in the system for maximum protection. The following figure

illustrates suppression on both power lines and a communications bus entering

an enclosure.

Periodic Inspection and Replacement of MOVs

MOVs do a good job of absorbing transients on communications, control, and

power lines, provided the total energy of those transients does not exceed the

rating of the device. However, if the energy of the transient exceeds the rating of

the device, the MOV may be either damaged or destroyed. This failure may not

be visibly or electrically evident. MOVs should be regularly inspected for signs

of damage to assure continued protection against transients. For some

applications, periodic replacement of critical MOVs is recommended, even if

they do not show signs of damage.

2-18 VersaMax Modules, Pow er Supplies and CarriersUser Manual GFK-1504N

Page 46

2

Programming

Device

Each Terminal

Block

Motor Drives and

Other Electrical

Control

Equipment

Machinery

Earth

Ground

Central

Ground Point

Signal and power

connections not shown

System Grounding

All components of a control system and the devices it controls must be properly

grounded. Ground conductors should be connected in a star fashion, with all

branches routed to a central earth ground point. This ensures that no ground

conductor carries current from any other branch.

The control panel and enclosure should also be bonded to the plant system

ground per code. Inadequate grounding may compromise system integrity in the

presence of power switching transients and surges.

GFK-1504N Chapter 2 Installation 2-19

Page 47

Return for Isolated

Output Point

Isolated Output

Point

Inductive

Load

100 Ohm

½ Watt

0.1µF

250VAC

Return for Isolated

Output Point

Isolated Output

Point

Inductive

Load

Diode

A18 and/or

B18

Output Point

Inductive

Load

100 Ohm

½ Watt

0.1µF

250VAC

A18 and/or

B18

Output Point

Inductive

Load

Diode

2

Installing Wiring for I/O Devices

Wiring to Inductive Loads

When wiring outputs to inductive loads, use of external suppression circuits is

recommended. If possible, the external suppression circuits should be

connected across the actual load. If that is not possible, external suppression

circuits should be connected to each point that will drive an inductive load.

AC Inductive Loads

For AC inductive loads, the s nubber network

should consist of a 250 V AC, 0.1µF capacitor

connected in series with a 100 Ohm ½ Watt or

higher resistor. A capaci tor with a different

working voltage may be chosen, as appropriat e

for the application.

Recommended snubber pack ages include

104M06QC100 or 104M06RL100 from Paktron.

Isolated Outputs, AC

Grouped Outputs, AC

DC Inductive Loads

For DC inductive loads, a diode should be pl aced

across the load as shown below. Recommended

diodes include:

1N4934 100 V, 1A;

1N4936 400 V, 1A;

1N4937 600 V, 1A.

These diodes are available from most

manufacturers.

Isolated Outputs, DC

Grouped Outputs, DC

2-20 VersaMax Modules, Pow er Supplies and CarriersUser Manual GFK-1504N

Page 48

2

Field Wiring

Terminals

A1A2A3A4A5B5B6B3B4B1B2

A6

A7

A8A9A10

B12B9B10B7B8

A11

A12

A13

A14

A15

A16

B15

B16

B13

B14

B17

B18

A17

A18

B11

Wiring for a Compact I/O Carrier (IC200CHS022, IC200CHS025)