Page 1

IMPORTANT PRODUCT INFORMATION

GFK-2771G

Sep 2019

PACSystems

TM

RSTi

PROFINET NETWORK ADAPTER

(STXPNS001)

Page 2

GFK-2771G Sep 2019

Caution & Warning Notes as Used in this Publication

Warning

Warning notices are used in this publication to emphasize that hazardous voltages, currents,

temperatures, or other conditions that could cause personal injury exist in this equipment or

may be associated with its use. In situations where inattention could cause either personal

injury or damage to equipment, a Warning notice is used.

Caution notices are used where equipment might be damaged if care is not taken.

Notes: Notes merely call attention to information that is especially significant to understanding and operating the equipment.

These instructions do not purport to cover all details or variations in equipment, nor to provide for every possible

contingency to be met during installation, operation, and maintenance. The information is supplied for informational

purposes only, and Emerson makes no warranty as to the accuracy of the information included herein. Changes,

modifications, and/or improvements to equipment and specifications are made periodically and these changes may or

may not be reflected herein. It is understood that Emerson may make changes, modifications, or improvements to the

equipment referenced herein or to the document itself at any time. This document is intended for trained personnel

familiar with the Emerson products referenced herein.

Emerson may have patents or pending patent applications covering subject matter in this document. The furnishing of

this document does not provide any license whatsoever to any of these patents.

Emerson provides the following document and the information included therein as-is and without warranty of any kind,

expressed or implied, including but not limited to any implied statutory warranty of merchantability or fitness for

particular purpose.

Page 3

GFK-2771G Sep 2019

1

Before using the units:

To use the units safely and effectively, please read this document and refer to GFK-2745 & GFK-2746 user manuals for

further details. The most recent user documents are available on the Support website

https://www.emerson.com/Industrial-Automation-Controls/support. Also refer “Installation in Hazardous Areas” for

instructions on safe usage in hazardous locations.

WARNING

• Installing or removing modules or wiring with power applied to the system or field wiring can cause an electrical

arc. This can result in unexpected and potentially dangerous action by field devices. Arcing is an explosion risk

in hazardous locations. Be sure that the area is non-hazardous or remove power appropriately before installing

or removing modules or wiring.

• Potentially dangerous voltages are present on a module’s terminals, even when system power is turned off.

Field power must be turned off when installing or removing a Terminal Block assembly.

• Personnel who install, operate and maintain automation systems that contain these products must be trained

and qualified to perform those functions.

• Overloading power modules or Network adapter can result into electric arc & damage to modules.

• Check the rated voltage and terminal array before wiring.

• Ensure that specified environmental conditions are not exceeded. Avoid placing the module in direct sunlight.

• Review module specifications carefully, and ensure that input and output connections are made in accordance

with the specifications.

• Use specified cables for wiring.

• Field Power Isolators must be used according to the requirements of the 5VDC/24VDC/48VDC or AC Voltage

modules used in the system.

• If system power consumption exceeds the power limits, use system power expansion modules.

• System power and field power must be supplied from separate sources.

• Use Product under pollution degree 2 environment.

• These Devices are open type devices which have to be installed in an enclosure with door or cover which is tool

accessible only.

Specifications: STXPNS001*

Item

Specification

Surrounding Air Temp.

/ Ambient Temp.

Temp./ Ambient Temp.

0℃ to 55℃ for UL applications.

Storage -40℃ to 85℃

Relative Humidity

5% ~ 90%, without condensation

Durable-vib./impact

IEC 60068-2-6:1995

Mount Position

First module of RSTi system

Atmosphere

No excessive dust ; No corrosive gases

Field Supp.Volt.

Class II*** 24VDC, 24VDC (11VDC ~ 28.8VDC)

Field Supply Current

Max. 10A

I/O bus 5Vdc current

Max. 1.5A @ 5VDC

Mount

DIN-Rail

Size

45mm x 99mm x 70mm

Weight

150g

Certification

cULus Ord and HAZLOC, CE, ATEX,PROFINET

CAUTION

Page 4

GFK-2771G Sep 2019

2

Item

Specification

Torque/signal wire

0.8Nm(7lb-in)/1.0mm2 - 2.5mm2(18-14 AWG)

Network Type

PROFINET I/O RT

Network Cable

Ethernet Cable

Cable Length

Upto 100m from Ethernet Hub

Comm. Speed

10**/100Mbps

Max. Station No.

101 Station(Include Master Scanner)

Station Type

PROFIBUS-DP Slave

IO Modules

Max. 32 Module

Max. node

Limited by the IP address

Max. Digital I/O

Input : 2016point / Output : 2016point

Max. Analog I/O

Input : 126Ch / Output : 126Ch

Max. Byte Size

Input: 252 Bytes / Output: 252 Bytes

Topology

Line or Star topology

Power Dissipation

115mA typical @24Vdc

* Specifications and designs may change without advance notice.

** 10Mbps for FTP connections. ***Class II, adjacent to voltage rating (30Vmax.)

Communication & Power Cable Wiring

Value

Description

Factory Setting

0

Device Name of station will be read from

flash memory. (User can assign his own

device name e.g. Device1) IP address will

be read from flash memory.

- Name of station : STXPNS001

- IP address : 192.168.0.254

- Subnet mask : 255.255.255.0

- Gateway : 192.168.0.1

01~99

Device Name of station will be STXPNS001xx. ( xx is the value of Rotary Switch ) IP

address will be read from flash memory.

Page 5

GFK-2771G Sep 2019

3

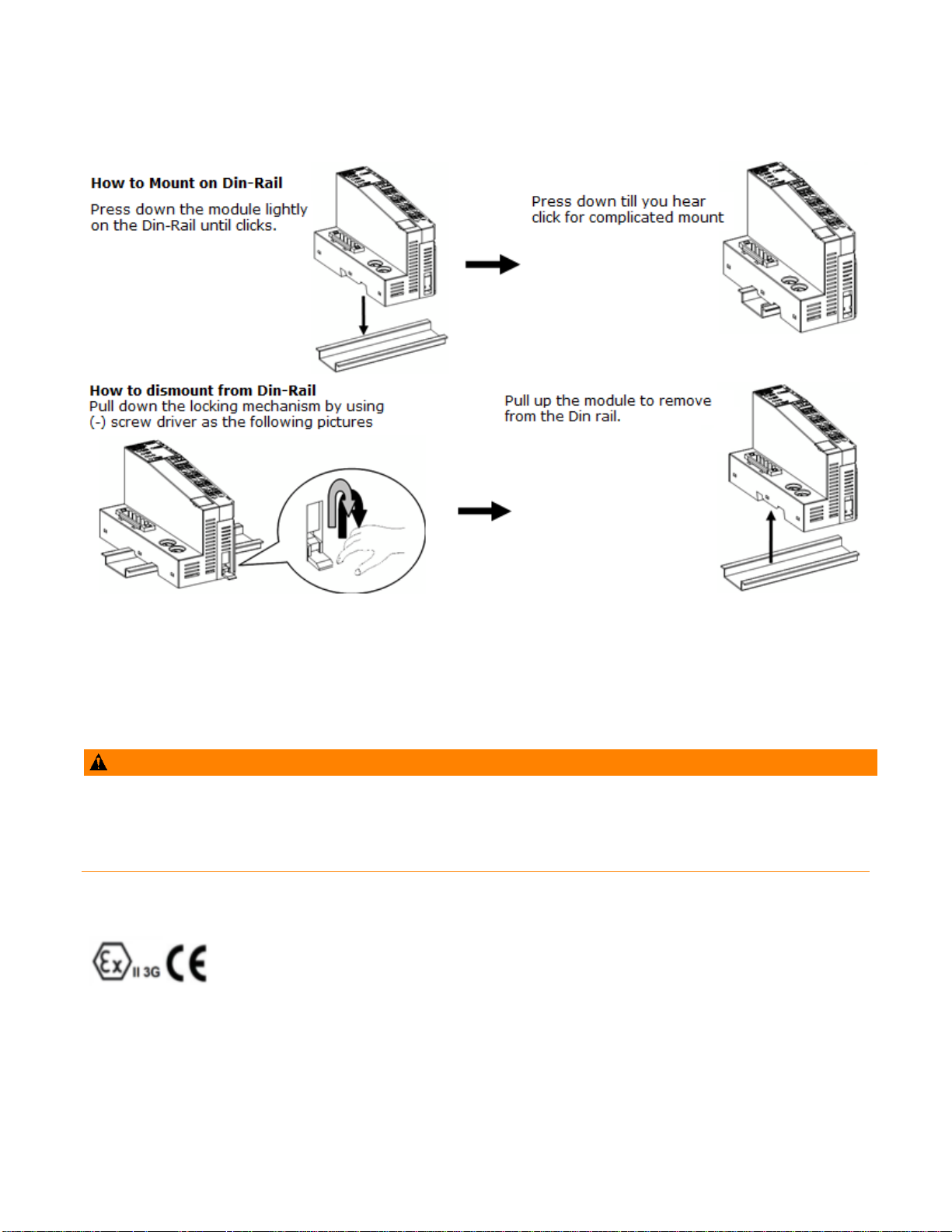

Module Mounting

Installation in Hazardous Area

UL Class 1 Division 2 & ATEX Zone 2 Hazardous Area Warnings

• EQUIPMENT LABELED WITH REFERENCE TO CLASS I, GROUPS A, B, C & D, DIV. 2 OR ZONE 2 HAZARDOUS

LOCATIONS IS SUITABLE FOR USE IN CLASS I, DIVISION 2, GROUPS A, B, C, D, ZONE 2 OR NON-HAZARDOUS

LOCATIONS ONLY.

WARNING

• EXPLOSION HAZARD–SUBSTITUTION OF COMPONENTS MAY IMPAIR SUITABILITY FOR CLASS I, DIVISION 2 &

ATEX ZONE2.

• EXPLOSION HAZARD – TURN OFF POWER BEFORE REPLACING OR WIRING MODULES. DO NOT CONNECT OR

DISCONNECT EQUIPMENT UNLESS POWER HAS BEEN SWITCHED OFF OR THE AREA IS KNOWN TO BE NON–

HAZARDOUS.

ATEX Information

Ambient Range: 0°C ≤ Tamb ≤ 55°C

Certification string: Ex nA IIC T4 Gc (Modules without Relay) & Ex nA nC IIC T4 Gc (Modules with Relay)

Standards Covered: EN 60079-0:2012, EN 60079-15:2010

Special Conditions for Safe Usage:

• The device shall be mounted in an ATEX certified enclosure with a minimum ingress protection rating of at least

IP54 as defined in IEC/EN 60529 and used in an area of not more that pollution degree 2 as defined by IEC60664-

1. Enclosure must utilize a tool removable cover or door.

Page 6

GFK-2771G Sep 2019

4

• Provisions shall be made to prevent the rated voltage being exceeded by the transient disturbances of more than

140%.

• Earthing is accomplished though mounting of modules in rail.

• Subject devices are for operation in Ambient Temperature Range: 0 °C to +55 °C.

LED Status Display

Item

LED is

State

To Indicate

Module Status

LED (MOD)

OFF

Power off

H/W Fault

No Power is supplied to the unit

Solid Red

Invalid boot image

header (Flash), ROM

Boot loader

The unit has occurred unrecoverable fault in selftesting.

- Firmware fault

Flashing Red

(0.5 Sec)

Invalid RAM Image

Invalid RAM Image

Flashing Red

(0.1 Sec)

OS Fatal error is

occurred

OS Fatal error is occurred

Flashing Green (0.1

Sec)

OS Handle Unexpected

Exceptions

OS Handle Unexpected Exceptions

Solid Green

Normal Operation

The unit is operating in normal condition.

NET LED

Off

Power off No

Connection has Been

established with IOcontroller.

Device is not on-line or may not be powered

Flashing Red (0.1 Sec)

Invalid Configuration

Invalid Configuration

Flashing Green (0.1 Sec)

Wait parameters

PROFINET I/O connection has been established.

Wait parameters

Solid Red

PROFINET I/O connection is aborted after a data

exchange has taken place.

Flashing Red (0.5 Sec)

PROFINET I/O connection is aborted before a

data exchange has taken place

Flashing Green (0.5 Sec)

PROFINET I/O Data Exchange stop

Solid Green

PROFINET I/O Data Exchange Run

I/O LED

I/O LED

Off

Not Powered No I/O

Module

Device has no I/O module or may not be powered

Flashing Green

Bus On-line, Do not

Exchanging I/O

Bus operation is normal but does not

exchanging I/O data (Passed the I/O module

configuration).

Solid Green

Bus Connection, Run

Exchanging IO

Exchanging I/O data

Solid Red

Bus connection fault

during exchanging IO

One or more I/O module occurred in fault state.

Changed IO module configuration. Bus

communication failure.

Flashing Red

I/O Configuration Failed

Failed to initialize I/O module - Detected invalid

IO module ID. - Overflowed Input / Output Size Too many I/O module - Initial protocol failure

Port1

Port2

LED

Solid Green

Link is up (Physical connection is established)

Flashing Green

Active is present

Off Link isdown

Field

Power LED

Off

Not Supplied Field

Power

Not Supplied 24Vdc field Power

Solid Green

Supplied Field Power

Supplied 24Vdc field power

Page 7

GFK-2771G Sep 2019

5

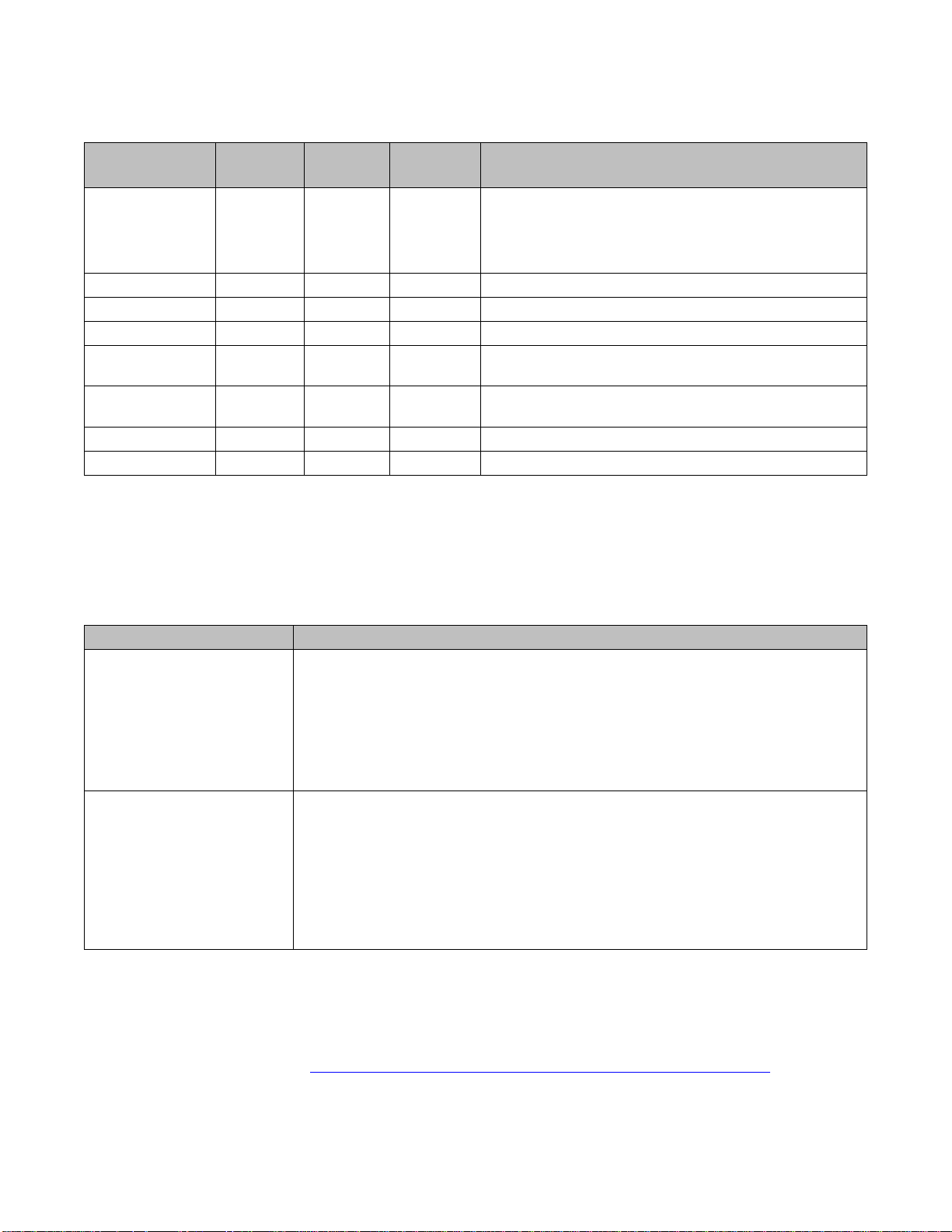

Release Information

Part Number

Hardware

Version

Firmware

Version

Date

Remarks

STXPNS001-DE

20.02

20.220

Sep 2019

Following Emerson’s acquisition of this product, changes

have been made to apply appropriate branding and

registration of the product with required certification

agencies. No changes to material, process, form, fit or

functionality.

STXPNS001-CE

20.02

20.220

May 2019

Firmware updates. No change in form-fit-functionality.

STXPNS001-CD

20.02

20.210

Apr 2019

Firmware updates. No change in form-fit-functionality.

STXPNS001-CC

20.02

20.100

Feb 2016

Firmware updates. No change in form-fit-functionality.

STXPNS001-BC

20.01

20.100

Nov 2013

Atex & Hazloc certification documentation updates. No

change in form-fit-functionality.

STXPNS001-AC

20.00

20.100

Mar 2013

Firmware updates to fix the bugs. No change in form-fitfunctionality.

STXPNS001-AB

20.00

20.010

Apr 2012

Firmware updates. No change in form-fit-functionality.

STXPNS001-AA

20.00

20.000

Mar 2012

Initial Release

Problems Resolved in this Release

None

New Features and Enhancements in this Release

None. Only documentation update.

Restrictions and Open Issues

Subject

Description

Clearing the RX3i controller

memory when a configuration

mismatch fault for a Slice I/O

node exists causes PACSystems

Machine Edition (PME) software

to disconnect and the RX3i

PNC001 to auto reset.

This fault can occur when an RX3i PNC module is connected to a Slice I/O node that has a

STXPNS001 Profinet Network Adapter and I/O modules. If there is a configuration mismatch

of the Slice IO node, a loss of device fault is logged in the I/O fault table. In this situation, if

you try to clear the RX3i CPU user memory, PME disconnects from the RX3i controller. After

the PME connection is lost, if you try to reconnect to the RX3i CPU,the RX3i PNCperforms an

auto reset. To recover from this fault, wait for the PNC to auto reset and the OK LED to glow

solid green, then clear the RX3i CPUuser memory or power cycle the RX3i controller

withoutbattery.Storingavalid configuration restores system operation without faults.

Slice I/O node system power up

sequence issue.

Ifthe NetworkAdapterandST-7xxxPower modules on the same Slice I/O node are

powercycledat differenttimes, the Network Adaptermaypowerup in faultmode. To recover

from the fault, power cycle the node such that Network Adapter andPower modules are

power cycled together or the node is powered up following the sequence such that the power

module farthest from the NetworkAdapterispowered up first. For examplein anode

havingmodules asbelow: STXPNS001+I/O Modules …+ST-7511+I/OModules … +ST7511+I/OModules In the above system power cycle the STXPNS001 and the two ST-7511

modules together or power OFF the entire node andthen powerONthe second ST-7511

andthen the firstST-7511 andthen the STXPNS001.

Upgrades with this release

None

Configuration

Download latest GSDML file from https://www.emerson.com/Industrial-Automation-Controls/support.

Page 8

GFK-2771G Sep 2019

6

Operational Notes

Subject

Description

Loss of device fault occurs when

STXPNS001 Profinet Network

Adaptor isused without I/O

module.

When the Slice I/O Profinet Network Adapter module does not have an I/O module attached,

it will not communicate with the RX3i PNC. The Network Adapter NET LED blinks RED,

indicating invalid configuration and a Loss of device fault is logged in RX3i I/O Fault table. At

least one I/O module has to be present for the NetworkAdapterto establishthe

communication withRX3i PNC.

Page 9

IMPORTANT PRODUCT INFORMATION

GFK-2771G

Sep 2019

Technical Support & Contact Information:

Home link: http://www.Emerson.com/Industrial-Automation-Controls

Knowledge Base: https://www.emerson.com/Industrial-Automation-Controls/support

Note: If the product is purchased through an Authorized Channel Partner, please contact the seller directly for any support.

Emerson reserves the right to modify or improve the designs or specifications of the products mentioned in this manual at any time without notice.

Emerson does not assume responsibility for the selection, use or maintenance of any product. Responsibility for proper select ion, use and

maintenance of any Emerson product remains solely with the purchaser.

© 2019 Emerson. All rights reserved.

Emerson Terms and Conditions of Sale are available upon request. The Emerson logo is a trademark and service mark of Emerson Electric Co. All

other marks are the property of their respective owners.

Loading...

Loading...