Page 1

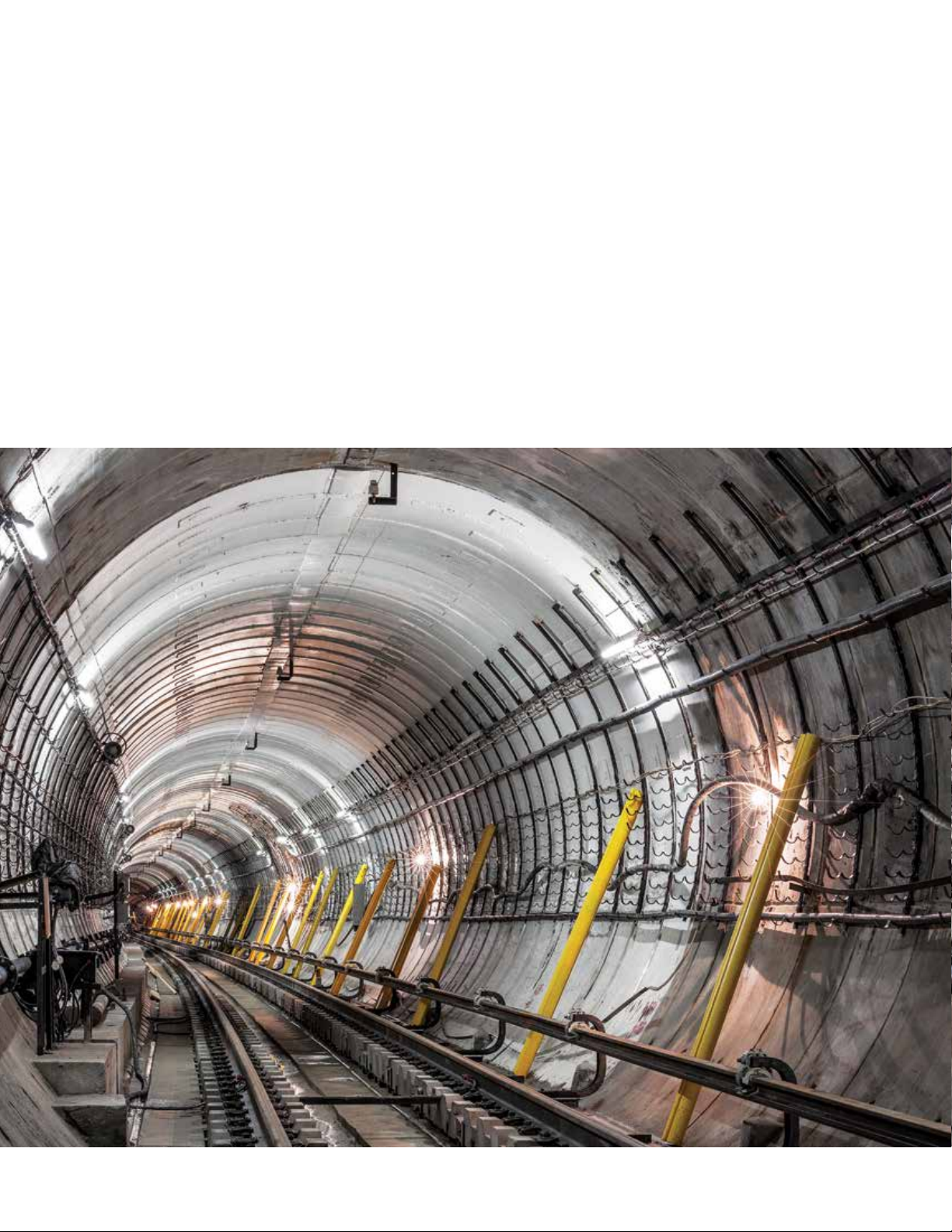

Metro Control

Solutions

Optimizing Your Operations for the Future

geautomation.com

Page 2

One-third of the world’s

major metros use GE

control systems to help get

people where they need to

go, safely and on time.

GE is responsible for the automation and

control of processes that generate onethird of the world’s power. For more than

130 years, we have delivered energy where

it is needed most.

We are also a leading provider of

automation and control products and

services for metro systems. One-third of

the world’s major metros use GE control

systems to help get people where they

need to go, safely and on time. We can help

optimize your equipment performance and

increase the reliability and efficiency of

your metro operations by connecting your

machines, data, insights, and people.

22

Page 3

Industrial Internet Control System for Metro

Unprecedented growth in urban

population is increasing ridership

of existing metro systems and

demand for new and improved

transportation solutions. In 2014,

54% of the global population

lived in urban areas; by 2050,

this number will climb to 66%.

But metro systems throughout

the world are showing their age,

resulting in disruptions, delays,

and even safety risks. Meanwhile,

transit authorities face a shortage

of experienced personnel,

rising costs, and tightening

environmental regulations.

Solutions to Meet Today’s Challenges

In today’s increasingly urban world, to improve your operations you

need a metro control system that is integrated, data-driven, and

accessible from anywhere.

To meet the challenges facing metro operations, GE has developed

integrated control solutions that provide a comprehensive view

and intuitive control of the disparate systems that make up a

subway network. GE’s Industrial Internet Control System (IICS)

makes it possible to actively monitor and dynamically regulate

processes throughout your metro system, reducing strain on

operators and improving overall system reliability.

Why GE?

We have extensive expertise with metro system

automation and control. GE offers:

• BAS Environmental Control (station ventilation,

lighting, conveyance, and other environmental

systems, monitor and control system of tunnel

ventilation)

• Power Monitoring System

• Shielded Gate System

• Traction Distribution Systems

• Subway Station Monitoring Systems

GE metro control systems

• Connect to cloud resources and perform advanced

analytics in the cloud or at edge nodes

• Scale from simplex unit control to high availability

redundant systems all the way to process control

solutions with a single portfolio of products with a

single run-time and toolset

• Include a broad portfolio of complementary products

for integrated solutions

– Fully Integrated VFDs

– Fully integrated industrial Ethernet switches

– IPCs and display panels

– Wireless communications

– Power equipment monitoring

– HMI/SCADA, Historian, and Web visualization

software

– Secure Predix Cloud, local storage, or third-party

cloud connectivity

• Are designed with security in mind, with features like

TPM, secure boot, signed firmware

• Meet industry security standards

• Include built-in software firewalls

3

Page 4

Take your industrial control system

to the next level.

The Industrial Internet Control System

(IICS) helps to improve your operational

efficiency by providing the ability to

access and use data from your facilities

to better understand patterns, trends,

and disparities in your control systems.

This helps to lower overall risk, total cost

of ownership, maintenance expense, and

unplanned downtime while increasing

overall performance and productivity.

Outcome Optimizing Controllers combine

reliable and secure controls with data

acquisition management in a single unit.

Choose to send and manage data onpremise or in the cloud with the flexibility

to use convenient Predix*-enabled

Embedded Field Agent technology or

PACEdge, which enables specific Linuxbased applications and access to your

preferred cloud environment.

(Sources : Morgan Stanle y Research; Globa l Capital Good s, “Insight: C loud Control – Th e Future of Indust rial Automation”, Mar ch 15, 2016”)

Of customers said they have a talent gap for

gathering and consolidating disparate data

The % of industrial companies who believe it’s

important to adopt an Industrial Internet of

Things Strategy the next over the next 5 years

The average % of industrial companies who

indicate big data analytics is the TOP priority for

their company, or in the top 3

4

Page 5

Unlock Hidden Value Through Controls

Optimize Asset & Process Performance

• Securely collect and integrate data across

the plant

• Analyze data on-premise or in the cloud

New Revenue Opportunities for SIs

and OEMs

• Develop new data-driven service offerings

for end customers

• Maintain competitive advantage through

continuous software-based innovation

Maximize Productivity

• Drop in complete, cyber-secure IIoT solutions

or use our Linux-based platform to develop

your own scripts and applications in a

standard Linux environment

• Reduce maintenance cost through

monitoring and diagnostics

Transform the Equipment Lifecyle

• Select the right on-ramp to the Industrial

Internet for either greenfield or brownfield

applications (no retrofit required)

• Eliminate the impact of component

obsolescence through modular hardware,

firmware, and software

Choose from Two Outcome Optimizing Control Options:

CPE400 + Embedded Field Agent

Predix Machine provides:

CPL410 + PACEdge for Linux

PACEdge with Linux provides:

Automated OPC UA Client for data collection from

CPE400 PLC runtime

OPC UA Client for data collection from CPL410 PLC runtime

Hoover data collection and aggregation SQL_Lite database for datacolleciton and aggregation

REST for secure cloud connectivity to PREDIX cloud Webserver with HTTPS Support to connect to your preferred cloud

Predix enabled Edge Applications

Develop your own scripts and applications in a standard Linux

environment

JAVA/C/C++ support for Predix Apps C/C++/Python development environment for Edge Apps

Predix Edge Manager to deploy and manage your devices

Poll for

Insights

Safe, secure

deterministic

control

Predix

Machine

Outcome

Optimizing

Analyze and

Advise

Connect directly to your local storage solution or download

standard tools to connect to your choice of cloud services.

Poll for

Insights

Safe, secure

deterministic

control

PACEdge

Outcome

Optimizing

Analyze and

Advise

Public or Private

Cloud

5

Page 6

66

Page 7

Open Communication Protocols

Open standards allow equipment from

multiple vendors to work together

seamlessly for the end application. This

ease of interoperability allows systems to

be combined, and reduces the skill level

required to do so.

Cyber Security

We understand the risk involved

in securing our customers’ assets

and believe in a defense-in-depth

architecture to help secure from

the hardware layer up, guarding

against potential cyber threats. Our

PACSystems platform has earned

Achilles and TRIMPS certifications. GE

implements a secure design lifecycle,

scrutinizing each components’

hardware and software through

testing and reviews.

At GE, we realize that the control

system must be secure by design and

should have a hardware root of trust

as the foundation of all the security

constructs in the control system. For

our IICS portfolio, all our controllers

now come with Trusted Platform

module (TPM) technology that enables

hardware root of trust. All boot

firmware is signed by GE with the

private key stored in the TPM module

to ensure only GE signed firmware

will run on the hardware. GE supplied

patches are also signed for verification

purposes prior to loading.

Development, deployment,

and commissioning

become easier

• Code can be reused with the ability

to define standard objects and a

fixed, yet flexible, API allows for rapid

development and modifications.

• Metrics and historical data from

disparate vendors and systems are

integrated

Achilles Level 2 Certification

RX3i has been industry-certified to

meet rigorous standards for reliability

and communications robustness. Its

cyber-hardened platform is designed

to help prevent cyber attacks,

reducing operational risks.

Role-Based Access Control

Privileges assigned to users are based

on pre-defined levels of authorization,

enhancing system security. This

provides layered user access, allowing

only specific user access to critical

competitive and customer data.

Secure User Authentication

Access to the controller is

implemented using an authentication

process that does not require

passwords to be passed over

the network. This helps prevent

an attacker from eavesdropping

and collecting credentials from

the network that would provide

unauthorized access to the controller.

Provisions are built-in for

communications security

• Data and associated attributes are

transferred collectively to reduce the

likelihood of a data mix-up

• Common APIs reduce the likelihood of

coding errors, reducing vulnerabilities in

the application

Signed Firmware Updates

Signed firmware updates help ensure

only core operating system software

supplied by GE will run on the PLC and

that it has not been tampered with

since it left the factory. This prevents

code that has been compromised from

entering the controller, protecting

system availability and valuable

operation information.

7

Page 8

Flexible Architectures to Fit Your Needs

Flexible and scalable solutions allow a for

multitude of existing infrastructure and

applications to reap the benefits of our

metro solutions.

• Same tool chain across our solutions:

Manage controls, Industrial Ethernet

Switches, and VFDs from one

integrated tool

• Link to Predix, local storage, or cloud

storage directly for Outcome

Optimizing Control

CIMPLICITY

Client

CIMPLICITY

Redundant Servers

• Simple retrofit on top of any existing

vendor or mix of vendors

• Seamless integration of environmental

and electrical systems with built-in

protocol and power monitoring

• Single HMI solution for local, remote,

and even Web interface with one tool

• Best-in-class high availability solution

for control applications improves

performance, reliability, and availability

Based on Proficy CIMPLICITY Comprehensive Monitoring System

CIMPLICITY

Historian

Fiber Backbone

Industrial Switch Industrial Switch

Optional

Field

Agent

SMS/

Pagers

Redundant

Controllers

• PROFINET System Redundancy enabled

VFDs reduce system installation cost

up to 15% and simplify monitoring and

maintenance of VFD applications

Built-in power protocol and power monitoring

mean seamless integration of environmental

and electrical systems

Mobile Devices

Mobile

Devices

Web/Remote

Maintenance

Power Comms

Controllers

CIMPLICITY

Runtime

Operator

Interface

Based on CIMPLICITY

integrated monitoring

system (station level)

8

Local HMI

Valve

Controls

Drives & Soft Starters

Drives & Soft Starters

Based on PROFINET Ring Architecture - BAS and MCC control system

Local HMI

Valve

Controls

Simplex

Controller

Line

Cabinet

Line

Cabinet

Remote

Line

Cabinet

Based on PACSystems RX3i,

the easy to use control solution

Protection

Device

Smart

Meter

Page 9

Customer Successes

GE customers have successfully deployed our flexible and

scalable metro solutions around the globe.

Major Chinese Metro Line

As usage increases, this metro line will produce more

heat and noxious gas in underground spaces, resulting in

environmental deterioration in the stations.

To address this issue, GE upgraded the BAS system, using

two-level control and real-time monitoring for various

stations, drainage and fire ventilation and air conditioning,

lighting system, elevator and escalator, shielding door,

air defense closed, flood gate and other mechanical

and electrical equipment operation using PACSystems

controllers and VersaMax I/O.

The system is connected to the project control center and

the center stage equipment monitoring system.

European Metro System

The underground public transportation network in this

European capital is the continent’s most-used on a per

capita basis. Comprised of 3 lines, 57 stations and nearly

60 kms of mostly underground railways, this metro system

has relied on GE to help ensure the uptime of its critical

applications for:

• Escalators and elevator controls

• Ventilation systems in the stations and tunnels

• Water drainage

• Electricity supply to stations in the transformer center

A recent modernization and expansion project upgraded

the existing control system with GE’s PACSystems solutions

to help increase performance.This project met customer

requirements for cost effectiveness and ease of migration.

United States Mass Transit System

A major city’s transit authority uses a mix of control

vendors for station automation throughout their metro

network. They turned to GE to help determine the cause

of system failures quickly and reliably, without interrupting

their current controls solution.

GE deployed a monitoring solution on top of the existing

control solution. It consists of CIMPLICITY Historian

software on an IPC for local collection and storage, but

direct connection to the existing SCADA system via

Modbus/TCP from RSTi-EP Remote I/O drops. The solution

provides real-time remote monitoring and diagnostics

from a central control station and emergency local data

storage in the event of network outages.

Large Metropolitan Auto Tunnel

A traffic tunnel in a large American city, consisting of two

tubes with two lanes of traffic each, is over one mile in

length and handles over 27 million vehicles per year. The

tunnel’s two ventilation buildings bring three million cubic

feet of fresh air into the tunnels each minute, and provide

a complete air change every 90 seconds.

Fixing damage caused by a devastating storm, GE

refurbished and updated the tunnel systems, providing

state-of-the art control systems for the ventilation and

parallel switchgear controls using RX3i PLCs, VersaMax

remote I/O, QuickPanel+ for local visualization and

CIMPLICITY Historian software.

9

9

Page 10

GE Power

Automation & Controls

2500 Austin Drive

Charlottesville, VA 22911

1-800 -433-2682 or 1-434-978-5100

www.geautomation.com

© 2018 General Electric. The GE brand and logo are trademarks of General Electric. * Trademark of General Electric. All other trademarks are

the property of their respective owners. Specifications are subject to change without notice.

05.18 GFA2174

Loading...

Loading...