Page 1

GE

g

Automation & Controls

Programmable Control Products

PACSystems* RSTi-EP EPSCPE100

Enhanced performance standalone controller for RSTi-EP Platform

CPU Quick Start Guide

GFK-3012

April 2017

Page 2

Contents

1. User Features ................................................................................................................. 3

1.1. Membrane Run/Stop push button ........................................................................ 4

1.2. LED Indicators (LEDs)........................................................................................... 5

1.3 Ethernet Ports .................................................................................................... 6

2. Hardware Installation................................................................................................... 8

2.1. Initial Checks ...................................................................................................... 8

2.2. Installation Location ........................................................................................... 8

2.3. Grounding .........................................................................................................11

3. Module Start-up ........................................................................................................... 12

3.1. You Will Need: ...................................................................................................12

3.2. Basic Installation Steps:......................................................................................12

4. Programming the EPSCPE100 ................................................................................... 13

4.1. Backwards Compatibility ....................................................................................13

4.2. PROFINET Controller Configuration .....................................................................13

5. Firmware upgrade procedure ................................................................................... 14

6. Product Limitations ..................................................................................................... 16

7. Troubleshooting ........................................................................................................... 17

8. Additional Information ............................................................................................... 18

2 RSTi-EP EPSCPE100 Standalone CPU Quick Start Guide GFK-3012

Page 3

The PACSystems* RSTi-EP EPSCPE100, is an enhanced

performance standalone 1GHz programmable controller

equipped with 1MB of user memory and four Ethernet ports

to run real time deterministic control applications. LAN1 is

dedicated to highspeed Ethernet and LAN2 comprised of 3

switched ports configurable as either an embedded

Ethernet controller or an embedded PROFINET controller,

which provides the PROFINET functionality and supports

only simplex mode of operation. It is a standalone PLC that

supports distributed I/O. From now on in rest of the

document this controller will be referred to as CPE100.

Figure 1: EPSCPE100

Features at a Glance

The CPE100 is programmed and configured over Ethernet

via GE’s Proficy Machine Edition (PME) software. It can

control/process up to 2K I/O points.

Highlights include:

A built-in PACSystems RSTi-EP PLC CPU

o User may program in Ladder Diagram,

Structured Text, Function Block Diagram.

o Contains 1Mbytes of configurable data and

program memory.

o Supports auto-located Symbolic Variables that

can use any amount of user memory.

o Reference table sizes include 2k bits for discrete

%I and %Q and up to 2k words each for analog

%AI and %AQ. Bulk memory (%W) also

supported for data exchanges.

o Supports up to 512 program blocks. Maximum

block size is 128KB.

Supports two independent 10/100 Ethernet LANs. LAN1 has only one port and is

dedicated to highspeed Ethernet and whereas LAN2 comprises of 3 switched

ports configurable as either an embedded Ethernet controller or an embedded

1. User Features

GFK-3012 April 2017 3

Page 4

PROFINET controller. All four ports are located on the front panel, as shown in

Figure 1.

The embedded communications interface has dedicated processing capability,

which permits the CPU to independently support LAN1 and LAN2 with:

o up to 16 combined SRTP Server and Modbus TCP Server connections out

of which Modbus TCP cannot exceed more than 8 connections (or) up to

16 simultaneous SRTP Server connections (or) up to 8 simultaneous

Modbus TCP Server connections.

o 8 Clients are permitted; each may be SRTP or Modbus TCP or a

Combination of both.

o up to 8 simultaneous Class 1 Ethernet Global Data (EGD) exchanges.

o When used in combination for optimal performance, user must not

exceed 4 Channels for Server (Modbus/SRTP) & 4 Channels for client

(Modbus/SRTP), 8 PROFINET nodes and 8 EGD data exchanges.

Ability to display serial number and date code in PME Device Information Details.

Operating temperature range -40C to 70C (-40F to 158F).

STOP/IO

Disabled

RUN/IO

Enabled

1.1. Membrane Run/Stop push button

Pressing Membrane Run/Stop push button briefly, will change the

state of CPU from the state it is in to the next state. Switch operation

state as given in the following state diagram:

The Run/Stop switch is enabled by default; it can be disabled in PME Hardware

Configuration (HWC) settings.

4 RSTi-EP EPSCPE100 Standalone CPU Quick Start Guide GFK-3012

Page 5

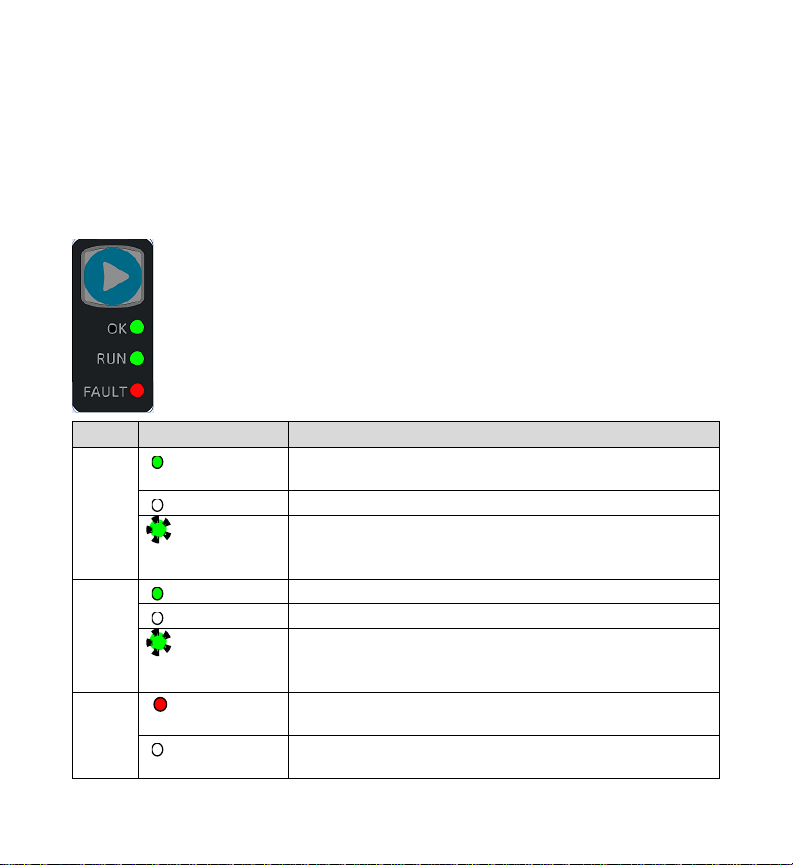

LED

LED State

Operating State

OK

On Green

PLC has passed its power-up diagnostics and is

functioning properly

Off

Power is not applied or PLC has a problem.

Blinking; All

other LEDs

off

PLC in STOP/Halt state; possible watchdog timer fault.

If the programmer cannot connect, cycle power and

refer to the fault tables.

RUN

On Green

PLC is in RUN mode.

Off

PLC is in STOP mode.

Blinking; All

other LEDs

off

Indicates that PLC has encountered a fatal error and is

blinking the error code.

Fault

On Green

PLC is in STOP/Faulted mode: a fatal fault has

occurred.

Off

No fatal faults detected.

1.2. LED Indicators (LEDs)

Ethernet Status Indicators

There are two LEDs (Yellow/Green) for each Ethernet ports of LAN1 and LAN2, which

are embedded in the RJ-45 connectors. The green LED indicates an Ethernet

connection has been established. The yellow LED indicates packet traffic.

Module status Indicators

There are three LEDs and one Membrane Push Button on the front panel

(The one in blue color) as shown in the figure. The below table describes

the behavior of each module LED:

Push Button: Toggles the current mode of the PLC.

GFK-3012 April 2017 5

Page 6

EPSCPE100

LAN1

LAN2

Default IP Address:

192.168.0.100

0.0.0.0

Subnet Mask:

255.255.255.0

0.0.0.0

Gateway:

0.0.0.0

0.0.0.0

1.3 Ethernet Ports

LAN 1 connects to the uppermost RJ-45 connector. It is not switched. LAN2 connects

to the three lower RJ-45 connectors. They are switched internally.

The embedded Ethernet interfaces automatically senses the link data rate (10 Mbps or

100 Mbps), communications mode (half-duplex or full-duplex), and cabling

arrangement (straight-through or crossover).

The embedded Ethernet LAN 1 port may be used to communicate with PME

programming software using the Service Request Transport Protocol (SRTP, a

proprietary GE protocol, used primarily for communication with the programmer).

To establish Ethernet communications between the PME programming package and

the CPU, you first need to set an IP address.

Note: LAN2 will not be operational unless it is configured from the programmer with a

valid IP address.

A typical application will take advantage of the two independent LANs. The dedicated

LAN 1 port will be used for communications with plant-level or supervisory layers. The

6 RSTi-EP EPSCPE100 Standalone CPU Quick Start Guide GFK-3012

Page 7

Figure 2: Typical Multi-Tier LAN Application (supports only Star/Bus network topology)

switched LAN 2 will be used to communicate with devices over PROFINET within the

manufacturing cell or process.

GFK-3012 April 2017 7

Page 8

2. Hardware Installation

2.1. Initial Checks

Upon receiving your equipment, carefully inspect all shipping containers for damage.

If any part of the system is damaged, notify the carrier immediately. The damaged

shipping container should be saved as evidence for inspection by carrier.

As the consignee, it is your responsibility to register a claim with the carrier for damage

incurred during shipment. GE Automation & Controls will fully cooperate with you,

however, should such action be necessary.

After unpacking the equipment, record all serial numbers. Serial numbers are required

if you should need to contact Customer Care during the warranty period. All shipping

containers and all packing material should be saved should it be necessary to

transport or ship any part of the system.

Verify that all components of the system have been received and that they agree with

your order. If the system received does not agree with your order, contact Customer

Care.

2.2. Installation Location

As shipped, the CPE100 is intended for mounting on a DIN rail. An optional panel-mount

adaptor is also available with part number (ICMFAACC001-AA). If panel-mounting is

required, replace the DIN-rail adaptor with the panel-mount adaptor using the screws

supplied with that adaptor. Both adaptors attach to the rear of the CPE100 chassis

using four Torx M3 screws. Torque newly-installed screws to 5.3 in-Ibs (0.6 Nm) if

installing a new adaptor plate.

Thermal Requirements:

When mounting the CPE100, allow a minimum clearance of 50mm on the left & right

side of the unit and a minimum clearance of 100mm on the top & bottom sides.

Instructions to mount the CPE100 on a DIN Rail:

The CPE100 snaps easily onto the DIN rail. No additional tools are required.

(1) Incline the unit so that the upper hooks of the DIN rail adaptor engage with the

upper edge of the DIN rail.

8 RSTi-EP EPSCPE100 Standalone CPU Quick Start Guide GFK-3012

Page 9

(2) Press on the lower part of the unit until you hear a click. The click indicates that the

lower hooks of the DIN rail adaptor have engaged with the lower edge of the DIN rail.

If you need any technical help, please contact Technical Support. For phone numbers

and email addresses, refer to the back cover of this Guide.

Figure 3: Mounting positions of the EPSCPE100 on DIN rail

Instructions to mount the CPE100 on a Panel

(1) Attach the panel mount plate to the rear side of CPE100 using the four M3 screws

supplied with the adapter.

(2) Fasten the tabs of panel mount adapter in the appropriate location of panel with

the four screws. The screw size used for each panel mount tab should not exceed M5.

GFK-3012 April 2017 9

Page 10

Figure 4: Mounting position of the EPSCPE100 in panel

10 RSTi-EP EPSCPE100 Standalone CPU Quick Start Guide GFK-3012

Page 11

2.3. Grounding

Proper grounding of the CPE100 is essential using the provided ground terminal as

shown in the below figure. Use a 16-22 AWG braided wire with lugs to connect the

ground terminal of CPE100 to DIN Rail. The DIN rail into which this product will be

mounted must be grounded as per the instructions provided in RSTi-EP System Manual,

GFK-2958.

Figure 5: Ground Terminal of EPSCPE100

GFK-3012 April 2017 11

Page 12

3. Module Start-up

3.1. You Will Need:

This PACSystems standalone controller RSTi-EP CPE100.

Generic power source which can output 9-30 V DC, 5 W.

A DIN rail, typically mounted in an enclosure, as discussed above. Alternately,

mount the unit using the (optional) compatible panel-mount adaptor.

A computer running Proficy Machine Edition (PME) configuration and

programming software. PME Version 9.50 & SIM 1 or later.

Ethernet cable for connecting the PME programmer computer to the EPSCPE100.

Very small slotted screwdriver (1.4mm jeweler’s size).

3.2. Basic Installation Steps:

For startup and configuration of the EPSCPE100, complete the following steps.

1. Be sure to disconnect the power to EPSCPE100,

2. The ESCPE100 is designed to be DIN-rail-mounted.

3. An external power supply 9- 30 V DC provided by a Class II power supply

marked as "double insulated", Limited Power Source (LPS), or a SELV source

with a minimum 32 V dc listed fuse with 3 A max rating is required to power

the EPSCPE100. Wire sizes: 22 to 16 AWG Screw torque: 2 in-Ib. Temperature

rating for copper wire: 80 °C. Wiring to power input terminals shall be limited

to 30 meters in length.

4. Plug the Ethernet cable for Programmer & Protocol (SRTP, Modbus, EGD) on

LAN 1 port.

5. Plug the Ethernet cable for PROFINET network in LAN 1 port.

6. Apply power to EPSCPE100.

12 RSTi-EP EPSCPE100 Standalone CPU Quick Start Guide GFK-3012

Page 13

4. Programming the EPSCPE100

To configure the CPE100, connect the computer running the PME programming

software to an Ethernet port of LAN1 using the default IP address 192.168.0.100. PME

9.5 SIM 1 or later is required.

Configuration will either start out using the RSTi-EP CPE100 template when creating a

new project, or will convert an existing project to the CPE100 using the Family

Conversion feature in PME.

4.1. Backwards Compatibility

To convert an existing project which uses any other PLC, use the Family Conversion

feature in PME. Be aware of the constraints involved, as will be notified in PME. For

instance, the first PROFINET Controller in an RX3i CPU320 application will be assigned

to the embedded PROFINET Controller feature of the CPE100.

4.2. PROFINET Controller Configuration

An Embedded PROFINET Controller may be configured on LAN2. To enable the

PROFINET Controller in a CPE100 project, select the CPE100 target in the PME Navigator

(Figure 10) and open the Hardware Configuration. On the Settings tab, change the

LAN2 Mode of the selected port to PROFINET. The PROFINET Controller node description

then displays that a PROFINET node exists on the selected LAN (under the CPE100). For

further details, refer to the PACSystems RX3i & RSTi-EP PROFINET IO Controller User

Manual, GFK-2571.

GFK-3012 April 2017 13

Page 14

5. Firmware upgrade procedure

EPSCPE100 comes with the default IP address 192.168.0.100 assigned to the Ethernet

Port of LAN1, user can change the default IP address through PME (Proficy Machine

Edition). Use the Ethernet Port of LAN1 to connect to the webserver of CPE100 through

which user can upgrade the Firmware.

It is always recommended to check if there are any new firmware updates available

for this product at our support site prior to proceeding with upgrading the module

firmware.

Steps are as below (For detailed instructions follow upgrade instructions manual

provided with upgrade kit):

1. Copy the firmware upgrade file (PAC) to any directory on your PC.

2. Use programming software or the controller’s Run/Stop switch place the

Controller module in Stop Disabled mode.

3. If your PC uses a proxy server, it may be necessary to modify your Network

Settings to disable the proxy server (or disable use of automatic proxy

configuration scripts).

4. Open a browser window and go to the EPSCPE100 Controller’s homepage using

the IP address you have configured for Programmer communications (e.g.

http://192.168.0.100).

5. At the EPSCPE100 Controller’s homepage, you will be prompted for a user name

and password. Username is “update” (without the quotes). Password is “sierra”

(without the quotes). Click on Log On.

14 RSTi-EP EPSCPE100 Standalone CPU Quick Start Guide GFK-3012

Page 15

6. Click on “Choose File” and navigate to the location of the firmware update file

obtained and saved earlier. Select the file and click “Open”.

7. Click on “Upload File” to get the file upload started. The

EPSCPE100 Controller’s Firmware Update web page will indicate the upload

progress.

8. The firmware upgrade process may take up to four minutes to complete

depending on the module being upgraded. Do not power cycle the EPSCPE100

Controller during the update process as this may place the module being

updated in an unrecoverable and unusable state. Once the file upload is

completed, EPSCPE100 will automatically reset

9. When the firmware upgrade completes successfully the browser will remain on

the Firmware Update web page and will indicate that the upgrade process is

complete. Note: The processing is complete when the DONE status is displayed.

10. If the firmware upgrade is not successful, a Firmware Update Status page is

displayed with an error status.

11. When you have successfully completed the firmware upgrade:

Close your browser window.

Mark or label your EPSCPE100 to indicate the new firmware version.

Ensure the label does not cover any vents.

12. Return the EPSCPE100 Controller to Run Enabled mode using the programming

software.

GFK-3012 April 2017 15

Page 16

6. Product Limitations

1. MRP (Media Redundancy Protocol) is not supported on Release 1.0.

2. C Toolkit is not supported in Release 1.0.

3. Timed interrupt blocks are not supported.

4. RDSD not supported in Release 1.0.

Note: The above features may be supported in the subsequent FW release. Refer to

the data sheet.

16 RSTi-EP EPSCPE100 Standalone CPU Quick Start Guide GFK-3012

Page 17

7. Troubleshooting

1. Resetting of the IP Address to default one i.e. 192.168.0.100 or to restore the

controller from undermined state, user need to press the Run/Stop switch during

the power-up (till it gets powered up, approx. 60 sec), this action will reset IP

address back to default one i.e. 192.168.0.100 in addition to this it will also clear

the contents of Flash and RAM.

GFK-3012 April 2017 17

Page 18

Proficy* Logic Developer-PLC Getting Started

GFK-1918

PACSystems* RX3i, RX7i and RSTi-EP CPU Reference Manual

GFK-2222

PACSystems* RX3i, RX7i and RSTi-EP TCP/IP Ethernet

Communications User’s Manual

GFK-2224

PACSystems* RX3i System Manual

GFK-2314

PACSystems* RXi, RX3i, RX7i and RSTi-EP Controller Secure

Deployment Guide

GFK-2830

PACSystems* Rx3i & RSTi-EP PROFINET IO-Controller User Manual

GFK-2571

PACSystems* RX3i, RX7i and RSTi-EP CPU Programmer’s

Reference Manual

GFK-2950

RSTi-EP User’s Manual

GFK-2958

8. Additional Information

User manuals, product updates and other information sources are available on the

Support website, https://ge-ip.force.com/communities/CC_Home, under Controllers

and IO, RX3i Controllers.

18 RSTi-EP EPSCPE100 Standalone CPU Quick Start Guide GFK-3012

Page 19

GE Automation & Controls

Contact Information

Americas: 1-800-433-2682 or 1-780-420-2010 (if toll free 800 option is

unavailable)

Global regional phone numbers are available on our web site

www.geautomation.com

* Trademark of General Electric Company and/or its subsidiaries.

All other trademarks are property of their respective holders

g

Copyright © 2017 General Electric Company. All Rights Reserved.

Loading...

Loading...