Page 1

PACSystems*

RSTi-EP CPE115

Programmable Automation Controller

The demand for improved asset

performance and productivity is

increasing in manufacturing and

infrastructure markets. They require

even smaller applications with robust

execution performance and a range

of connectivity options to real-time

application status information and

diagnostics.

GE’s Automation & Controls has

designed a small form factor, high

performance controller that enables

equipment builders to improve

performance and flexibility of their

machines while reducing size,

complexity, and cost.

Small footprint. Big Impact.

Leverage the power and flexibility of

PACSystems in smaller applications. RSTiEP CPUs make it possible to incorporate

the entire PACSystems programming suite

in stand-alone applications or as auxiliary

control in larger process applications

that use RX3i. This simplifies training for

operators and maintenance workers and

streamlines application development and

integration.

CPE115 supports real-time application

status, remote diagnostics and:

• Dual LAN interfaces with four Ethernet

ports

• Built-in RS-232 serial port

• Support for a range of communications

protocols, including PROFINET

• Support of DNP3 Outstation capability for

Remote Terminal Unit (RTU) applications.

• Up to 1.5 MB of non-volatile user memory

All in just 1.5” (38.1mm) of DIN rail space.

Speaking the same language

With CPE115, you can use the same

runtime as existing RX3i controllers and

leverage existing application libraries

and templates while scaling footprint

and performance for smaller application

installations. Fast, easy-to-configure

PACSystems technology and an extensive

range of I/O options support scalable

automation and highly distributed modular

machine designs.

PROFINET advantage

PROFINET I/O solutions from GE can

provide productivity and performance

advantages for virtually any type of

control application in a range of industries.

PROFINET supports a variety of I/O without

compromising system performance and

can operate in high-noise environments.

Connect to any of GE’s purpose-built I/O

families through a PROFINET interface for

advanced flexibility and performance.

Advanced security

Without proper cybersecurity in place,

industrial controls may be vulnerable

to cyber threats. GE enlists defense-indepth architecture to help secure assets

from these threats. The RSTi-EP CPE115

incorporates technologies such as Trusted

Platform Modules and secure, trusted, and

measured boot. Centralized configuration

allows encrypted firmware updates to be

executed from a secure central location.

And, a suite of cybersecurity technology

and tools help prevent unauthorized

updates while built-in security protocols

help protect against man-in-the middle and

denial of service attacks.

geautomation.com

Page 2

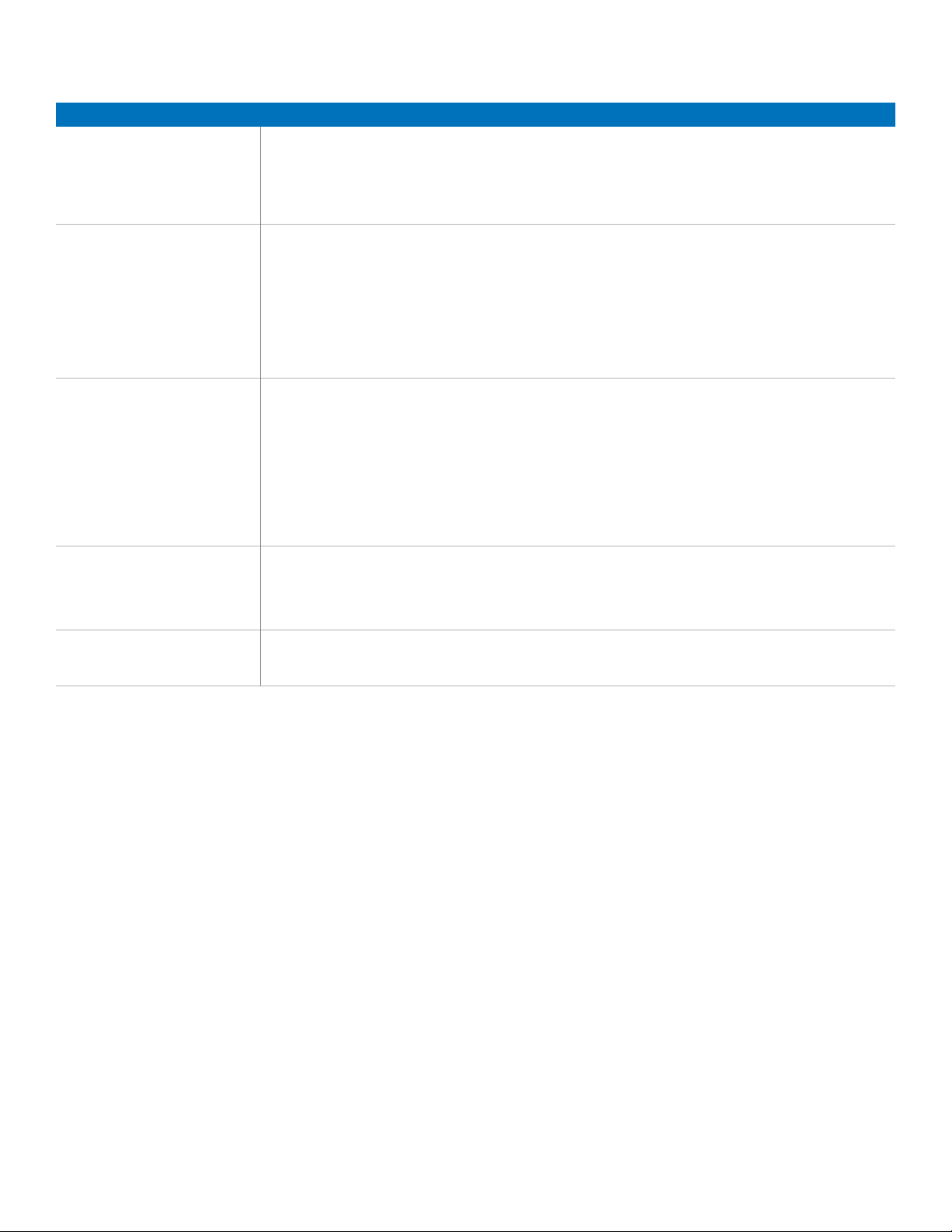

FEATURE BENEFIT

• Latest CPU features integrated System-on-Module processor for reduced latency and

more precise data or I/O control.

High performance

• Full PACSystems library of programming capabilities helps enable quick and convenient

application development.

• Store large amounts of data for better system statistics and analysis.

• Store application files right on the control for fast access to drawings, debug or startup

information, operational notes, and more.

Simplification

• Built-in multiport switch reduces I/O wiring cost and installation time.

• Three-port switch allows for I/O network redundancy via Media Redundancy Protocol and a

connection for local HMI without extra networking equipment.

• Secure-by-design features include Trusted Platform Module and Measured Boot technology to

enable encrypted, digitally signed firmware updates and help stop attempts to introduce malware

onto the CPU. These same technologies are included on the PACSystems RX3i product line.

Security

• Achilles Level 2 certification indicates that it meets industry standards for reliability and

communications robustness.

• Role-based access control assigns user privileges based on pre-defined levels of authorization,

enhancing system security.

• Open standard for high-speed I/O connectivity.

PROFINET distributed

I/O connectivity

• Support for Media Redundancy Protocol for robust operation.

• Replace devices without the need to reconfigure them for improved uptime.

DNP3 Outstation capability

Specifications

Part Number

• EPSCPE115

Form Factor

• Standalone

Storage

• 1.5MB

I/O

• 2k Bits Discrete I/O

• 32k Words for Analog I/O

Field Agent Support

• External

Redundancy Support

• Media Redundancy Protocol (MRP)†

GE Power

Automation & Controls

2500 Austin Dr

Charlottesville, VA 22911

1-800-433-2682 or 1-434-978-5100

www.geautomation.com

• Support of DNP3 Outstation capability for RTU applications in water and wastewater,

transportation, and oil and gas pipeline sectors

Ethernet Port

• 1 – 10/100

• 1 – 3-port switch 10/100

Ethernet Communications

• SRTP Client/Server – (Max 8 Connections)

• Modbus TCP/IP – (Max 8 Connections)

• OPC-UA Server – (Max 8 Clients)†

• EGD – (Max 16 Exchanges)

• PROFINET – (Max 8 IO Devices)

• DNP3 outstation capability over Ethernet

USB Interface

• 1 USB-A 2.0†

Memory Card

• Micro SD†

© 2018 General Electric. The GE brand and logo are trademarks of General Electric. * Trademark of General Electric. All other trademarks are

the property of their respective owners. Specifications are subject to change without notice.

02.18 GFA2153A

Other Interface

• 1 RS-232†

Environmental

• -40°C to 70°C

Power Spec

• 9 VDC – 30 VDC input

• 250mA @ 24 VDC

• 6 W maximum dissipation

† Availabl e later 2018

Loading...

Loading...