Page 1

RSTi-EP User Manual

GFK-2958D

July 2017

Page 2

These instructions do not purport to cover all details or variations in equipment, nor to provide for every possible

contingency to be met during installation, operation, and maintenance. The information is supplied for

informational purposes only, and GE makes no warranty as to the accuracy of the information included herein.

Changes, modifications, and/or improvements to equipment and specifications are made periodically and these

changes may or may not be reflected herein. It is understood that GE may make changes, modifications, or

improvements to the equipment referenced herein or to the document itself at any time. This document is

intended for trained personnel familiar with the GE products referenced herein.

Public – This document is approved for public disclosure.

GE may have patents or pending patent applications covering subject matter in this document. The furnishing of

this document does not provide any license whatsoever to any of these patents.

GE provides the following document and the information included therin as-is and without warranty of any

kind, expressed or implied, including but not limited to any implied statutory warrany of merchantability or

fitness for particular purpose.

Revised: July 2017

Issued: Dec 2015

© 2015 - 2017 General Electric Company.

* Indicates a trademark of General Electric Company and/or its subsidiaries. All other

trademarks are the property of their respective owners.

Page 3

Warning

Indicates a procedure or condition that, if not strictly observed, could result in

personal injury or death.

Caution

Indicates a procedure or condition that, if not strictly observed, could result in

damage to or destruction of equipment.

Attention

Indicates a procedure or condition that should be strictly followed to improve

these applications.

Safety Symbol Legend

Page 4

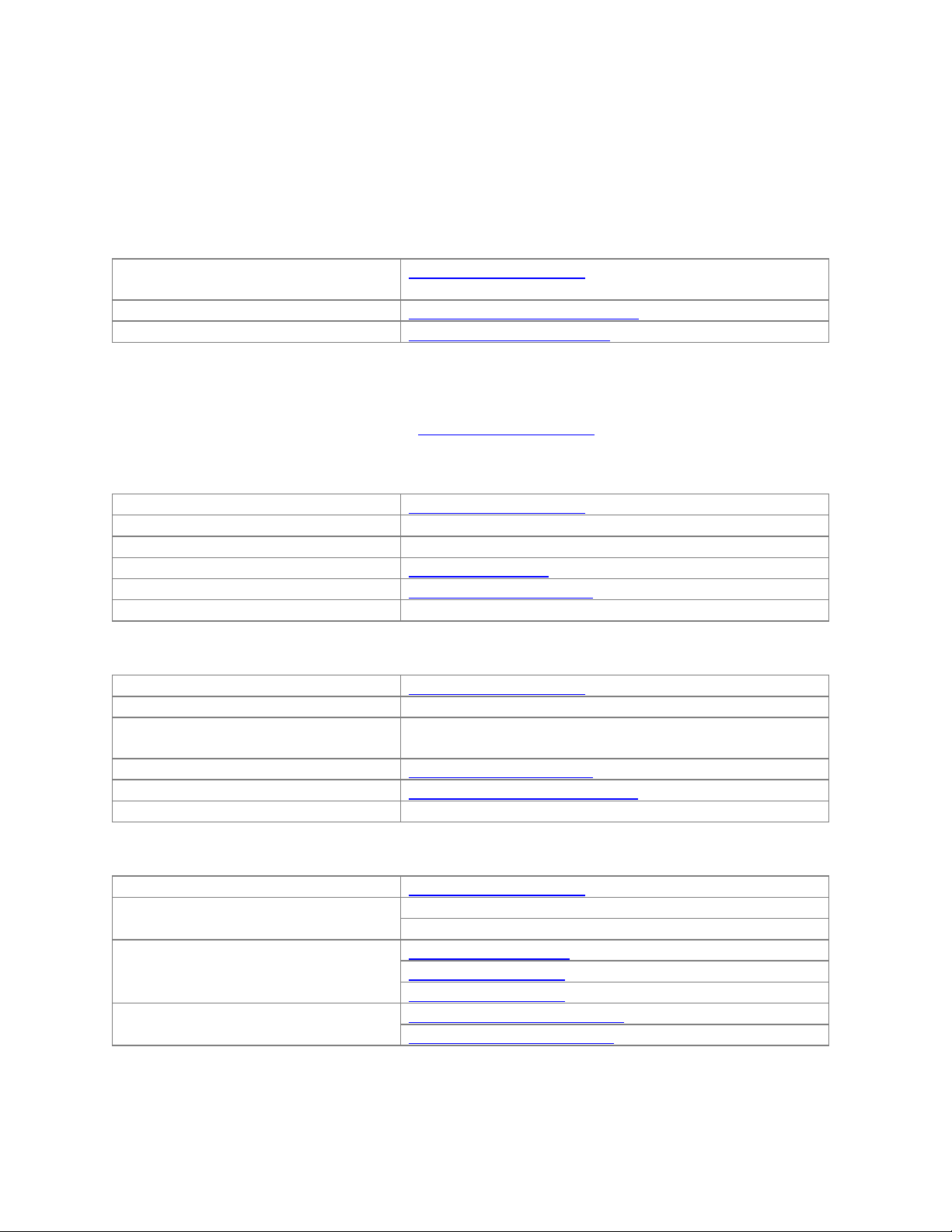

Online technical support and

GlobalCare

http://support.ge-ip.com

Additional information

http://www.geautomation.com/

Solution Provider

solutionprovider.ip@ge.com

Online Technical Support

http://support.ge-ip.com

Phone

1-800-433-2682

International Americas Direct Dial

1-780-420-2010 (if toll free 800 option is unavailable)

Technical Support Email

support.ip@ge.com

Customer Care Email

customercare.ip@ge.com

Primary language of support

English

Online Technical Support

http://support.ge-ip.com

Phone

+800-1-433-2682

EMEA Direct Dial

+420 239015850 (if toll free 800 option is unavailable or if

dialing from a mobile telephone)

Technical Support Email

support.emea.ip@ge.com

Customer Care Email

customercare.emea.ip@ge.com

Primary languages of support

English, French, German, Italian, Czech, Spanish

Online Technical Support

http://support.ge-ip.com

Phone

+86-400-820-8208

+86-21-3877-7006 (India, Indonesia, and Pakistan)

Technical Support Email

support.cn.ip@ge.com (China)

support.jp.ip@ge.com (Japan)

support.in.ip@ge.com (remaining Asia customers)

Customer Care Email

customercare.apo.ip@ge.com

customercare.cn.ip@ge.com (China)

Contact Information

If you purchased this product through an Authorized Channel Partner, contact the seller directly.

General Contact Information

Technical Support

If you have technical problems that cannot be resolved with the information in this manual, contact

us by telephone or email, or on the web at http://support.ge-ip.com

Americas

Europe, the Middle East, and Africa

Asia Pacific

GFK-2958D RSTi-EP User Manual July 2017 iii

Page 5

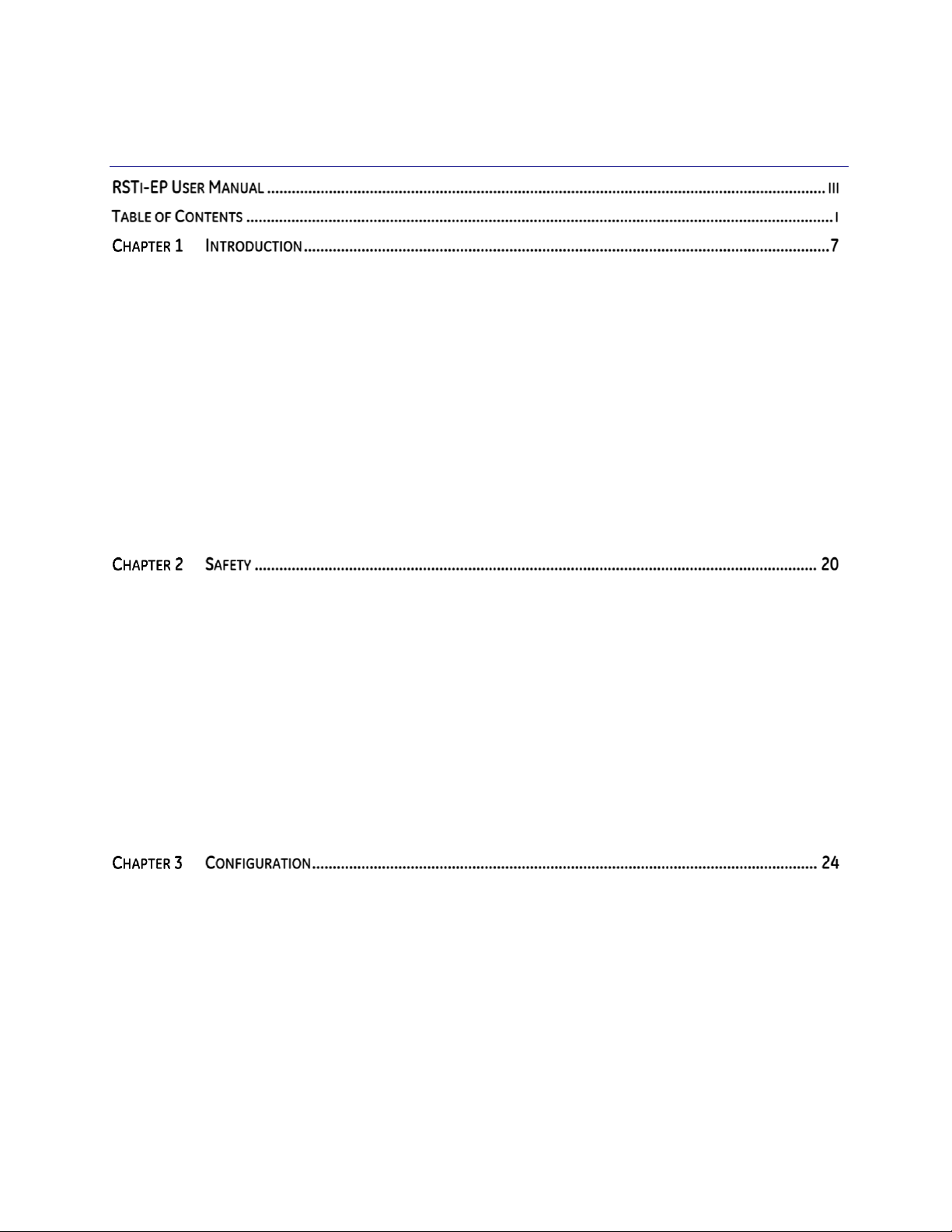

Table of Contents

1.1 DOCUMENT UPDATES ............................................................................................................................................................ 7

1.2 SYSTEM OVERVIEW ................................................................................................................................................................ 8

1.2.1 Double-click Installation ....................................................................................................................................... 9

1.3 GENERAL DESCRIPTION OF THE FIELDBUS NETWORK ADAPTERS ............................................................................... 10

1.4 GENERAL TECHNICAL DATA FOR THE FIELDBUS NETWORK ADAPTER ....................................................................... 11

1.5 GENERAL DESCRIPTION OF I/O MODULES ...................................................................................................................... 13

1.5.1 Standard Connector ............................................................................................................................................ 14

1.5.2 HD Connector EP-8360 ...................................................................................................................................... 14

1.5.3 Cable Protection .................................................................................................................................................... 15

1.6 GENERAL TECHNICAL DATA FOR I/O MODULES ............................................................................................................ 16

1.7 MECHANICAL FIXING ELEMENTS ....................................................................................................................................... 17

1.8 TYPE PLATE ........................................................................................................................................................................... 17

1.9 MARKERS .............................................................................................................................................................................. 18

1.9.1 Swivel Marker ......................................................................................................................................................... 18

2.1 GENERAL SAFETY NOTICE .................................................................................................................................................. 20

2.1.1 Electrostatic Discharge ...................................................................................................................................... 20

2.1.2 Open Equipment ................................................................................................................................................... 20

2.1.3 Fusing......................................................................................................................................................................... 21

2.1.4 Earthing (functional earth FE).......................................................................................................................... 21

2.1.5 Shielding ................................................................................................................................................................... 21

2.1.6 Overcurrent ............................................................................................................................................................. 21

2.2 INTENDED USE ..................................................................................................................................................................... 21

2.3 USE IN A POTENTIALLY EXPLOSIVE ATMOSPHERE .......................................................................................................... 22

2.3.1 ATEX Zone 2 ............................................................................................................................................................ 23

2.3.2 ATEX & IECEx Marking ........................................................................................................................................ 23

2.4 LEGAL NOTICE ...................................................................................................................................................................... 23

2.5 USE OF RSTI-EP STATIONS ABOVE 2000M SEA LEVEL ............................................................................................... 23

3.1 ORDER AND ARRANGEMENT OF THE MODULES ............................................................................................................. 24

3.1.1 Arrangement of Safe Power-feed Modules .............................................................................................. 25

3.1.2 Power Supply Concept ....................................................................................................................................... 26

3.2 INSTALLATION DISTANCES ................................................................................................................................................. 26

3.2.1 Calculation of Space Requirements ............................................................................................................. 28

3.3 USE IN A POTENTIALLY EXPLOSIVE ATMOSPHERE .......................................................................................................... 28

3.3.1 ATEX & IECEx Marking ........................................................................................................................................ 29

3.4 SPRING-STYLE SYSTEM CABLING ...................................................................................................................................... 29

3.5 CURRENT DEMAND AND POWER SUPPLY ....................................................................................................................... 29

3.5.1 Power Supply Derating ...................................................................................................................................... 29

3.6 EXAMPLE CALCULATION FOR THE POWER SUPPLY ........................................................................................................ 31

GFK-2958D RSTi-EP User Manual July 2017 i

Page 6

Contents

3.6.1 Calculation of the Current Demand for the Input Current ................................................................. 31

3.6.2 Calculation of the Current Demand for the Output Current ............................................................. 32

3.7 CALCULATION OF POWER LOSS ........................................................................................................................................ 34

3.7.1 Calculation of Power Loss for Use in a Potentially Explosive Atmosphere ................................ 34

3.8 FEEDBACK ENERGY IN DO MODULES .............................................................................................................................. 34

3.8.1 Calculation of Feedback Energy .................................................................................................................... 35

3.9 PARAMETER OVERVIEW ...................................................................................................................................................... 36

3.10 DATA WIDTH OF I/O MODULE, DEPENDENT ON THE NETWORK ADAPTER USED .................................................... 46

4.1 PROFIBUS DP NETWORK ADAPTER EPXPBS001 ........................................................................................................ 52

4.1.1 LEDs ............................................................................................................................................................................ 53

4.1.2 Addressing ............................................................................................................................................................... 55

4.1.3 Connection Diagrams ......................................................................................................................................... 56

4.1.4 Specifications ......................................................................................................................................................... 57

4.1.5 Supported Modules and Power Supplies ................................................................................................... 59

4.2 PROFINET IRT NETWORK ADAPTER EPXPNS001 .................................................................................................... 61

4.2.1 LEDs ............................................................................................................................................................................ 61

4.2.2 Connection Diagrams ......................................................................................................................................... 63

4.2.3 Specifications ......................................................................................................................................................... 64

4.2.4 Supported Modules and Power Supplies ................................................................................................... 65

4.3 ETHERCAT

®

NETWORK ADAPTER EPXETC001 ........................................................................................................... 67

4.3.1 LEDs ............................................................................................................................................................................ 68

4.3.2 Connection Diagrams ......................................................................................................................................... 69

4.3.3 Specifications ......................................................................................................................................................... 71

4.3.4 RSTi-EP Status Messages .................................................................................................................................. 72

4.3.5 Module Status Messages .................................................................................................................................. 73

4.3.6 Module Diagnosis ................................................................................................................................................. 73

4.3.7 Supported Modules and Power Supplies ................................................................................................... 74

4.4 MODBUS

®

TCP NETWORK ADAPTER EPXMBE001 .................................................................................................... 75

4.4.1 LEDs ............................................................................................................................................................................ 75

4.4.2 Connection Diagrams ......................................................................................................................................... 77

4.4.3 Specifications ......................................................................................................................................................... 78

4.4.4 Configuration of the IP Address ..................................................................................................................... 79

4.4.5 Packed Process Data .......................................................................................................................................... 83

4.4.6 0x1000 – 0x1006 Network adapter Identifier ......................................................................................... 85

4.4.7 0x1000 – 0x1006 Network adapter Status .............................................................................................. 85

4.4.8 0x1010 Process Image Length in Bits for the Output Modules ....................................................... 85

4.4.9 0x1010 Process Image Length in Bits for the Input Modules ........................................................... 85

4.4.10 0x1017 Register – Mapping Revision .......................................................................................................... 85

4.4.11 0x1018 – 0x101B Collective Diagnostics Message for I/O Modules ............................................. 85

4.4.12 0x101C – 0x101F Collective Process Message for I/O Modules ...................................................... 86

4.4.13 0x1028 – 0x102F Module Status ................................................................................................................... 86

4.4.14 0x1030 MODBUS DATA EXCHANGE Watchdog, Current Time ........................................................ 86

4.4.15 0x1120 MODBUS DATA EXCHANGE watchdog, predefined time ................................................... 86

4.4.16 0x1121 MODBUS DATA EXCHANGE Watchdog Reset Register ...................................................... 86

4.4.17 0x1122 Lock force Mode on Web Server ................................................................................................... 86

4.4.18 0x1031 MODBUS CONNECTION Mode Register ..................................................................................... 87

4.4.19 0x1131 MODBUS CONNECTION Timeout in Sec .................................................................................... 87

4.4.20 0x1132 Check Reference List prior to Data Exchange ........................................................................ 87

GFK-2958D July 2017 ii

Page 7

Contents

4.4.21 0x1133 Process Alarm ....................................................................................................................................... 87

4.4.22 0x1134 Diagnostic Alarm ................................................................................................................................. 87

4.4.23 0x1135 Field Bus or Reference List Error Behavior ............................................................................... 87

4.4.24 0x1136 Module Removal Behavior .............................................................................................................. 87

4.4.25 0x1137 Data Format ........................................................................................................................................... 88

4.4.26 0x113C – 0x113F Save Module Parameters ............................................................................................ 88

4.4.27 0x27FE Number of Entries in the Current Module List ......................................................................... 88

4.4.28 0x27FF Number of Entries in the Reference Module List .................................................................... 88

4.4.29 0x2800 – 0x287F Reference Module List ................................................................................................... 88

4.4.30 0x2A00 – 0x2A7F Current Module List ....................................................................................................... 88

4.4.31 0x2B00 – 0x2B7F Module offsets of process data ................................................................................ 88

4.4.32 0x8000 – 0x87FF Process Data Inputs ....................................................................................................... 89

4.4.33 0x9000 – 0x97FF Process Data Outputs ................................................................................................... 89

4.4.34 0xA000 – 0xA7FF Diagnostics ........................................................................................................................ 89

4.4.35 0xB000 – 0xB7FF Process Alarms ................................................................................................................ 89

4.4.36 0xC000 –0xFFFF Parameters .......................................................................................................................... 89

5.1 DIGITAL INPUT MODULE EP-1214 .................................................................................................................................. 90

5.2 DIGITAL INPUT MODULE EP-1218 .................................................................................................................................. 94

5.3 DIGITAL INPUT MODULE EP-1318 .................................................................................................................................. 98

5.4 DIGITAL INPUT MODULE EP-1804 ............................................................................................................................... 102

5.5 DIGITAL INPUT MODULE EP-125F ............................................................................................................................... 108

5.6 DIGITAL INPUT MODULE EP-12F4 ............................................................................................................................... 113

5.6.1 Time Stamp Function ....................................................................................................................................... 117

5.6.2 Structure of an ETS Entry ............................................................................................................................... 117

5.6.3 Example for the Mode of Operation .......................................................................................................... 118

5.7 DIGITAL OUTPUT MODULE EP-2214 ........................................................................................................................... 121

5.8 DIGITAL OUTPUT MODULE EP-2614 ........................................................................................................................... 126

5.9 DIGITAL OUTPUT MODULE EP-2634 ........................................................................................................................... 131

5.10 DIGITAL OUTPUT MODULE EP-2218 ........................................................................................................................... 136

5.11 DIGITAL OUTPUT MODULE EP-225F ........................................................................................................................... 141

5.12 DIGITAL OUTPUT MODULE EP- 2814 .......................................................................................................................... 146

5.13 DIGITAL OUTPUT MODULE EP- 2714 .......................................................................................................................... 151

5.14 DIGITAL OUTPUT MODULE EP- 5111 .......................................................................................................................... 157

5.14.1 Setting Up the Counter .................................................................................................................................... 165

5.14.2 Counter Functions ............................................................................................................................................. 165

5.14.3 Additional Functions Features ..................................................................................................................... 172

5.15 DIGITAL COUNTER MODULE EP- 5112 ....................................................................................................................... 178

5.15.1 Setting Up the Counter .................................................................................................................................... 185

5.15.2 Counter Functions ............................................................................................................................................. 185

5.15.3 Additional Counter Features ......................................................................................................................... 190

5.16 DIGITAL FREQUENCY COUNTER MODULE EP- 5212 ................................................................................................ 196

5.16.1 Function Frequency Counting ...................................................................................................................... 202

5.17 SERIAL COMMUNICATION MODULE EP-5261 ............................................................................................................ 205

5.18 SSI ENCODER INTERFACE MODULE EP- 5311........................................................................................................... 215

5.19 DIGITAL PULSE WIDTH MODULATION OUTPUT MODULE EP- 5422...................................................................... 220

5.20 DIGITAL PULSE WIDTH MODULATION OUTPUT MODULE EP- 5442...................................................................... 225

5.21 ANALOG INPUT MODULE EP- 3164 ............................................................................................................................. 230

5.22 ANALOG INPUT MODULE EP- 3264 ............................................................................................................................. 236

GFK-2958D July 2017 iii

Page 8

Contents

5.23 ANALOG INPUT MODULE EP- 3124 ............................................................................................................................. 243

5.24 ANALOG INPUT MODULE EP-3368.............................................................................................................................. 249

5.25 ANALOG INPUT MODULE EP-3468.............................................................................................................................. 254

5.26 ANALOG OUTPUT MODULE EP-4164.......................................................................................................................... 260

5.27 ANALOG OUTPUT MODULE EP-4264.......................................................................................................................... 266

5.28 ANALOG INPUT MODULE EP-3704.............................................................................................................................. 273

5.29 ANALOG INPUT MODULE EP-3804.............................................................................................................................. 282

5.30 POWER-FEED MODULE FOR INPUT CURRENT PATH EP-7631 ................................................................................ 290

5.31 POWER-FEED MODULE FOR OUTPUT CURRENT PATH EP-7641 ............................................................................ 293

5.32 SAFE FEED-IN MODULES EP-1901, EP-1902, AND EP-1922 ............................................................................. 296

5.33 POTENTIAL DISTRIBUTION MODULE FOR INPUT CURRENT PATH EP-711F .......................................................... 297

5.34 POTENTIAL DISTRIBUTION MODULE FOR OUTPUT CURRENT PATH EP-751F .............................................. 299

5.35 POTENTIAL DISTRIBUTION MODULE FOR FUNCTIONAL EARTH EP-700F .............................................................. 301

5.36 0-V POTENTIAL DISTRIBUTION MODULE FOR INPUT CURRENT PATH EP-710F ............................................. 303

5.37 0-V POTENTIAL DISTRIBUTION MODULE FOR OUTPUT CURRENT PATH EP-750F ............................................ 305

5.38 EMPTY SLOT MODULE EP-8310................................................................................................................................... 307

5.39 TERMINATION KIT EP-8301 .......................................................................................................................................... 308

6.1 PREPARATIONS FOR ASSEMBLY ...................................................................................................................................... 310

6.1.1 Environmental Conditions ............................................................................................................................. 310

6.1.2 DIN Rail ................................................................................................................................................................... 310

6.1.3 Stripping Lengths .............................................................................................................................................. 310

6.1.4 Unpacking and Delivery ................................................................................................................................. 311

6.1.5 Use in a Potentially Explosive Atmosphere ............................................................................................ 311

6.1.6 Installation Position .......................................................................................................................................... 312

6.1.7 Installation Distances ...................................................................................................................................... 312

6.1.8 Calculation of Space Requirements .......................................................................................................... 314

6.1.9 Installation Sequence ...................................................................................................................................... 314

6.1.10 Arrangement of SIL Modules ........................................................................................................................ 315

6.1.11 Preparation and the required tool ............................................................................................................. 315

6.2 ASSEMBLING THE RSTI-EP STATION ............................................................................................................................ 315

6.3 ATTACHING THE MARKER ................................................................................................................................................ 319

6.3.1 Attaching the Swivel Marker ........................................................................................................................ 319

6.4 WIRING .............................................................................................................................................................................. 320

6.4.1 Wiring of Modules with Standard Connectors ..................................................................................... 320

6.4.2 Wiring of Modules with HD Connectors EP-8360 ............................................................................... 321

6.5 INSULATION TEST ............................................................................................................................................................. 322

7.1 EARTHING OF SHIELDED CABLES ................................................................................................................................... 325

7.1.1 Shielded Cables Increase Interference Resistance ............................................................................. 326

7.1.2 Proper Use of Shielded Cables ..................................................................................................................... 326

7.1.3 Effective shielding .............................................................................................................................................. 327

7.2 POTENTIAL RATIOS ........................................................................................................................................................... 329

7.2.1 Basic aspects ....................................................................................................................................................... 329

7.2.2 Potential-free Design ....................................................................................................................................... 329

7.2.3 Non-isolated Design ......................................................................................................................................... 330

7.3 ELECTROMAGNETIC COMPATIBILITY (EMC) .................................................................................................................. 331

7.3.1 Ensuring EMC ...................................................................................................................................................... 331

GFK-2958D July 2017 iv

Page 9

Contents

7.3.2 Earthing of Inactive Metal Parts .................................................................................................................. 331

7.3.3 PE connection ...................................................................................................................................................... 331

7.3.4 Unearthed Operation ....................................................................................................................................... 332

7.3.5 DIN Rails ................................................................................................................................................................ 332

7.3.6 Cabinet Design According to EMC Guidelines ...................................................................................... 333

7.4 SHIELDING OF CABLES ..................................................................................................................................................... 335

7.4.1 Equipotential Bonding ..................................................................................................................................... 336

7.4.2 Inductance wiring.............................................................................................................................................. 336

8.1 REQUIREMENTS ................................................................................................................................................................. 339

8.2 CONFIGURING EPXPNS001 ......................................................................................................................................... 340

8.2.1 Configuring EPXPNS001 Parameters ...................................................................................................... 342

8.2.2 Adding EPXPNS001 Modules to a Remote Node ................................................................................ 344

8.2.3 Configuring EPXPNS001 Module Parameters ...................................................................................... 345

8.3 CONFIGURING EPXPBS001 .......................................................................................................................................... 346

8.3.1 Adding Slaves and Modules .......................................................................................................................... 346

8.3.2 Configuring Module Data Areas ................................................................................................................. 349

8.3.3 Configuring DP-V1 Settings for a Slave ................................................................................................... 350

8.4 CONFIGURING EPXECT001 .......................................................................................................................................... 352

8.5 CONFIGURING EPXMBE001 ......................................................................................................................................... 356

9.1 REQUIREMENTS ................................................................................................................................................................. 358

9.1.1 Operating System .............................................................................................................................................. 358

9.1.2 Browser .................................................................................................................................................................. 358

9.1.3 Device Drivers ..................................................................................................................................................... 358

9.2 INSTALLING THE USB DRIVER ........................................................................................................................................ 358

9.3 STARTING THE WEB SERVER........................................................................................................................................... 359

9.3.1 Activating the Ethernet Socket .................................................................................................................... 360

9.4 SETTING UP REGISTRATION DATA AND PASSWORD PROTECTION ............................................................................ 361

9.5 NAVIGATION AND OPERATING INSTRUCTIONS ............................................................................................................ 363

9.5.1 Setting the Language ...................................................................................................................................... 363

9.5.2 Zooming the View In/Out ............................................................................................................................... 363

9.5.3 Quick View (Tooltip) of Detailed Values .................................................................................................... 364

9.6 DISPLAYING AND EDITING THE NETWORK ADAPTER STATUS ................................................................................... 365

9.6.1 Resetting the Web Server............................................................................................................................... 366

9.6.2 Resetting the Network Adapter to Factory Settings .......................................................................... 366

9.6.3 Accessing Network Adapter Parameters ................................................................................................ 367

9.7 DISPLAYING MODULE DATA AND EDITING PARAMETERS .......................................................................................... 367

9.8 DISPLAYING NODE INFORMATION ................................................................................................................................. 368

9.8.1 Displaying Process Data................................................................................................................................. 369

9.8.2 Displaying Diagnostic Data .......................................................................................................................... 369

9.9 WEB SERVER IN FORCE MODE ....................................................................................................................................... 370

9.9.1 Open the Detail View of the Station in Force Mode ........................................................................... 371

9.9.2 Filtering the Module View .............................................................................................................................. 371

9.9.3 Resetting Filters .................................................................................................................................................. 372

9.9.4 Manually Switching Outputs (Forcing) ..................................................................................................... 372

9.9.5 Modules with Registers ................................................................................................................................... 373

9.9.6 Ending/Deactivating Forced Operations................................................................................................. 373

GFK-2958D July 2017 v

Page 10

Contents

9.10 UPDATING FIRMWARE ..................................................................................................................................................... 374

9.11 WEB SERVER ABOUT HELP ............................................................................................................................................. 377

9.11.1 Exporting Log Data, Saving a Service File .............................................................................................. 377

10.1 REMOVING/REPLACING THE PLUG-IN UNIT................................................................................................................. 379

10.2 REPLACING THE ELECTRONIC UNIT ............................................................................................................................... 380

10.3 REPLACING AN I/O MODULE .......................................................................................................................................... 386

10.4 REMOVING/REPLACING CONNECTORS ......................................................................................................................... 388

10.5 REMOVING/REPLACING CABLES .................................................................................................................................... 390

11.1 DISASSEMBLING THE RSTI-EP STATION ...................................................................................................................... 392

11.2 DISPOSING OF THE RSTI-EP STATION .......................................................................................................................... 393

12.1 FIELDBUS NETWORK ADAPTERS .................................................................................................................................... 395

12.2 I/O MODULES ................................................................................................................................................................... 400

13.1 ACCESSORIES .................................................................................................................................................................... 407

13.2 REPLACEMENT PARTS ...................................................................................................................................................... 407

14.1 HARDWARE INSTALLATION ............................................................................................................................................. 413

14.1.1 Initial Checks ........................................................................................................................................................ 413

14.1.2 Installation Location ......................................................................................................................................... 413

14.2 GROUNDING ...................................................................................................................................................................... 415

14.3 REPLACEMENT OF INTERNAL SUPER CAPACITOR (EPSACC001)............................................................................. 415

14.4 REPLACEMENT OF RTC BATTERY ................................................................................................................................... 416

GFK-2958D July 2017 vi

Page 11

Caution

Prior to hot-swapping I/O modules, refer to section Replacing the

Electronic Unit.

Rev

Date

Description

D

July 2017

Added support for CE100, including the following procedures:

• Replacement of Internal Super Capacitor (EPSACC001)

• Replacement of RTC Battery

C

Sept-2016

Added three new modules:

• Digital Input Module EP-1804

• Serial Communication Module EP-5261

• SSI Encoder Interface Module EP-5311

B

Apr-2016

Changes required as part of ATEX certificate update

A

Feb-2016

Added EtherCat logo after certification

-

Dec-2015

Introduction

This manual describes the RSTi-EP remote I/O system. The products of the RSTi-EP series are

intended for use in industrial automation. A RSTi-EP station with network adapter and connected

modules is intended for the decentralized control of systems or sub-systems. Via the network

adapter every module of a station is integrated into a fieldbus structure and connected to the

primary control unit. The RSTi-EP products conform to protection class IP 20 (in accordance with DIN

EN 60529), they can be used in potentially explosive atmospheres rated as Zone 2 (as per Directive

2014/34/EU) and in safe zones.

The observance of the supplied documentation is part of the intended use. The products described in

this manual may only be used for the intended applications and only in connection with certified

third-party devices or components.

Introductory material may be found in this chapter along with a system overview. Chapter 2 provides

information about safety. Chapter 3 provides configuration instruction. Chapter 4 provides detailed

descriptions of the network adapters. Chapter 5 provides detailed descriptions of the I/O modules.

Chapter 6 provides information on installation and setup. Chapter 7 provides information on earthing

and shielding. Chapter 8 provides information on commissioning. Chapter 9 covers the Web Server.

Chapter 10 provides detailed instructions for replacing components. Chapter 11 describes

disassembly and disposal of the RSTi-EP station. Chapter 12 covers the LEDs and troubleshooting.

Chapter 13 provides ordering information for accessories and replacement parts. Appendix A is a

decimal/hexadecimal conversion table.

1.1 Document Updates

GFK-2958D RSTi-EP User Manual July 2017 7

Page 12

Chapter 1: Introduction

1.2 System Overview

The modular RSTi-EP system supports common fieldbus systems and conforms to IEC 61131-2. Each

station is assigned a bus address in the fieldbus structure. Only the network adapter is fieldbusspecific; the I/O modules are independent of the fieldbus.

Up to 64 active I/O modules can be combined in a RSTi-EP station. The largest expansion possible

depends on the maximum amount of data transmitted by the selected fieldbus, in particular the

configuration, parameter, or process data for the module types provided.

The following components belong to the RSTi-EP product series:

• Fieldbus network adapter (gateway): Head station for converting the respective fieldbus

protocol on the RSTi-EP system bus

• Active I/O modules:

o Modules with digital input (DI) or digital output (DO) with 2, 4, 8 or 16 channels

o Modules with analogue input (AI) or analogue output (AO) with 4 or 8 channels

o Pulse width modulation modules (PWM)

o Digital counter modules (CNT)

• Passive I/O modules (no fieldbus communication)

o 24 V power-feed modules (PF) for input or output current

o Potential distribution modules (AUX)

o Empty modules acting as placeholders (ES)

• Functional safety modules

o Safe power-feed modules (EP-19xx) 24 V for output current, providing one or two

inputs (with two channels each) for safety circuits

• Mechanical fixing elements

o End bracket

o End plate

GFK-2958D RSTi-EP User Manual 8

Page 13

Chapter 1: Introduction

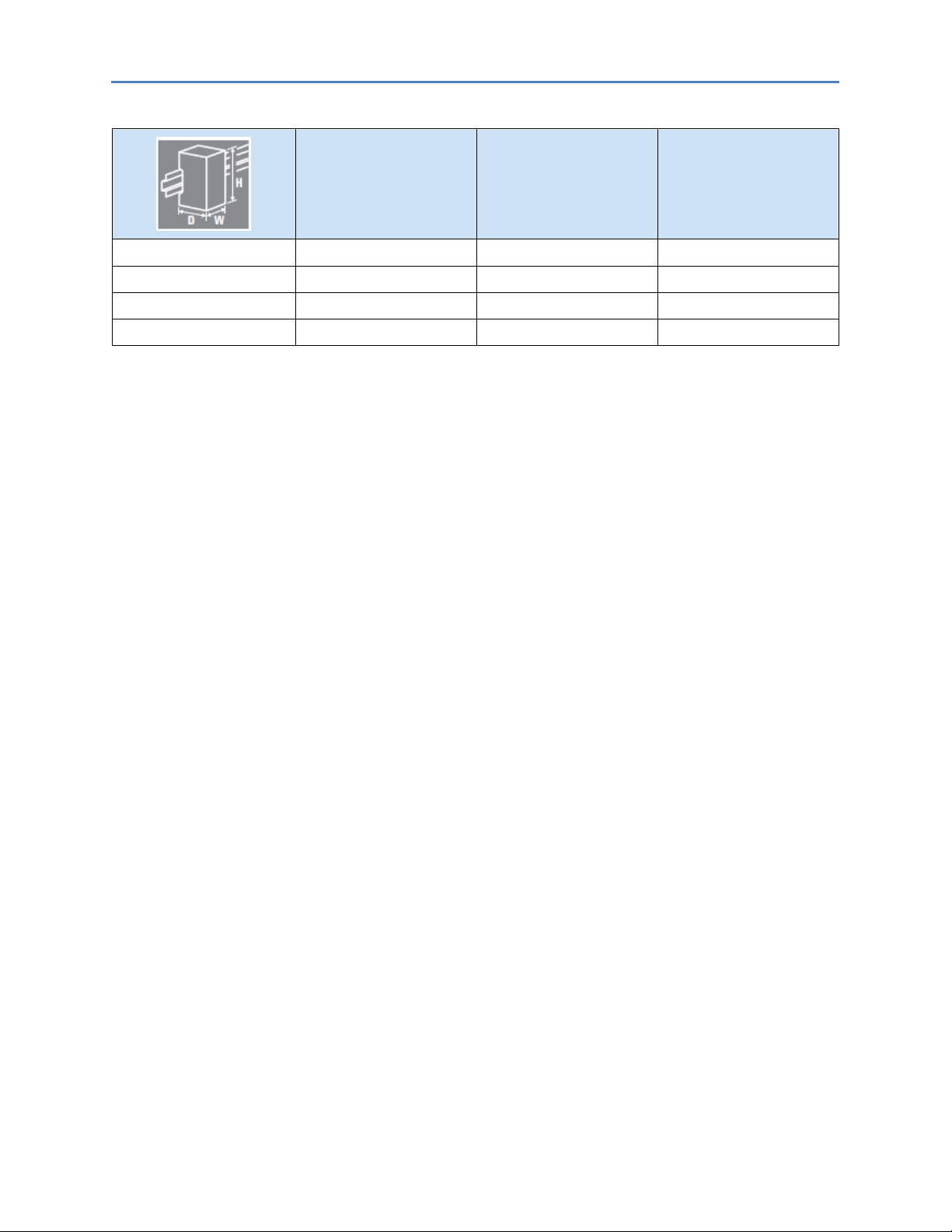

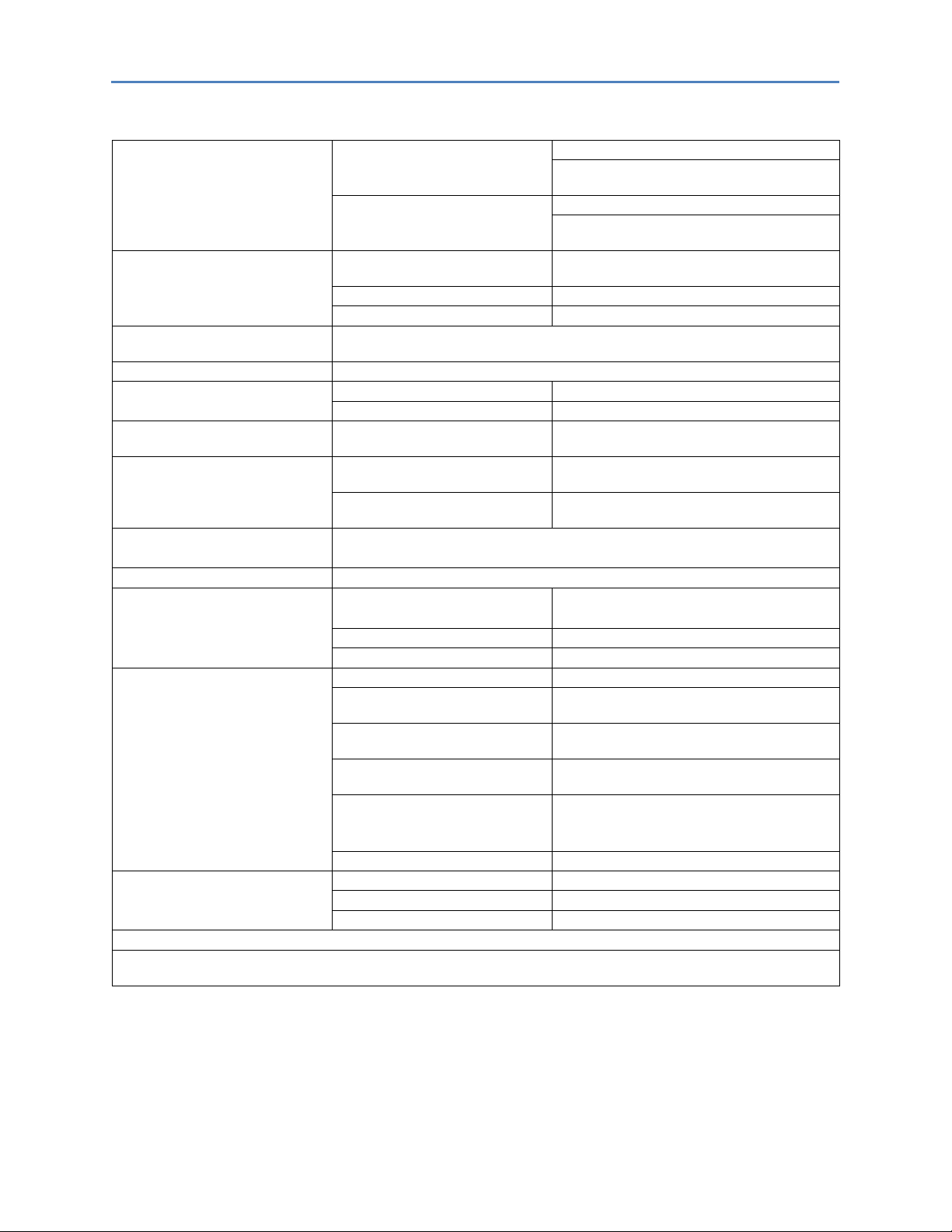

Height (H)

Width (W)

Depth (D)

Network adapter

120.0 mm (4.72 in)

52.0 mm (2.05 in)

76.0 mm (2.99 in)

I/O module

120.0 mm (4.72 in)

11.5 mm (0.45 in)

76.0 mm (2.99 in)

End plate

120.0 mm (4.72 in)

3.5 mm (0.14 in)

76.0 mm (2.99 in)

End bracket

120.0 mm (4.72 in)

8.0 mm (0.32 in)

36.0 mm (1.42 in)

Dimensions of the RSTi-EP Components

1.2.1 Double-click Installation

The RSTi-EP station modules can be installed quickly and simply. When attaching the module to the

DIN rail, a clear clicking noise can be heard, which means that the module has clicked into place. In

the second step, which involves pushing the module being installed together with the neighboring

module, a further clicking noise indicates that the modules have been correctly connected to each

other.

GFK-2958D RSTi-EP User Manual 9

Page 14

Chapter 1: Introduction

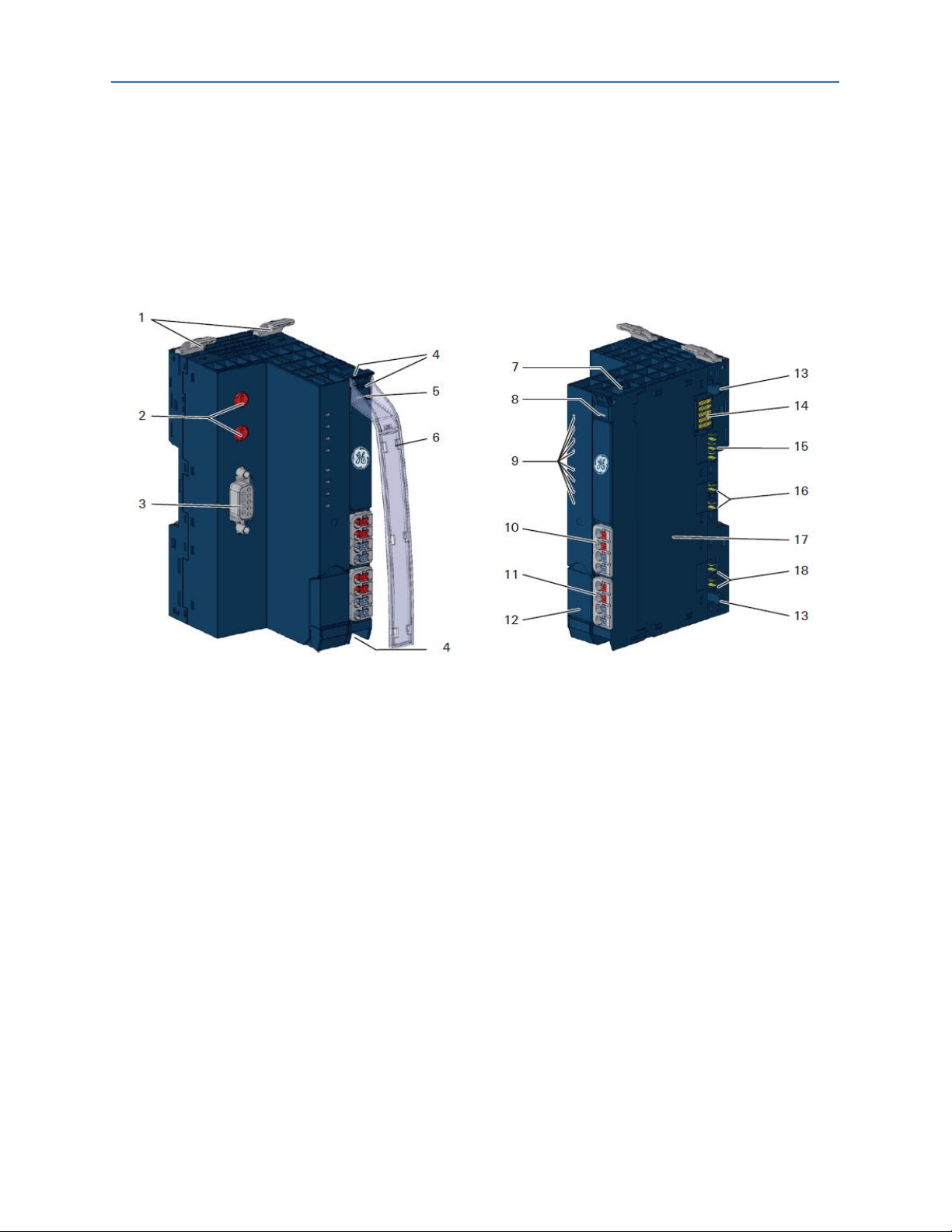

1.3 General Description of the Fieldbus Network Adapters

A fieldbus network adapter is used to connect the station I/O modules to the fieldbus. All of the data

traffic with the programmable logic controller including the diagnostic messages is exchanged via

the network adapter. The integrated power supply provides the network adapter and all connected

modules with power.

A detailed description of the individual network adapter types is available in Chapter 4, Detailed

Descriptions of the Fieldbus Network Adapter.

Fieldbus Network Adapter (example: EPXPNS001)

1 - Catch lever for securing the DIN rail

2 - Rotary switch (only PROFIBUS®)

3 - Data line connection (e.g. SUB-D socket)

4 - Seats for module markers

5 - Type designation

6 - Optional: swivel marker for labelling modules and channels

7 - Connector frame unlocking device

8 - LED power supply network adapter

9 – Network adapter status LEDs

10 - Power supply connector for the system and input modules

11 - Power supply connector for output modules

12 - Service flap

13 - Latching hook for latching onto module sides

14 - System bus

15 - System current path

16 - Input current path

17 - Type plate with block diagram

18 - Output current path

GFK-2958D RSTi-EP User Manual 10

Page 15

Chapter 1: Introduction

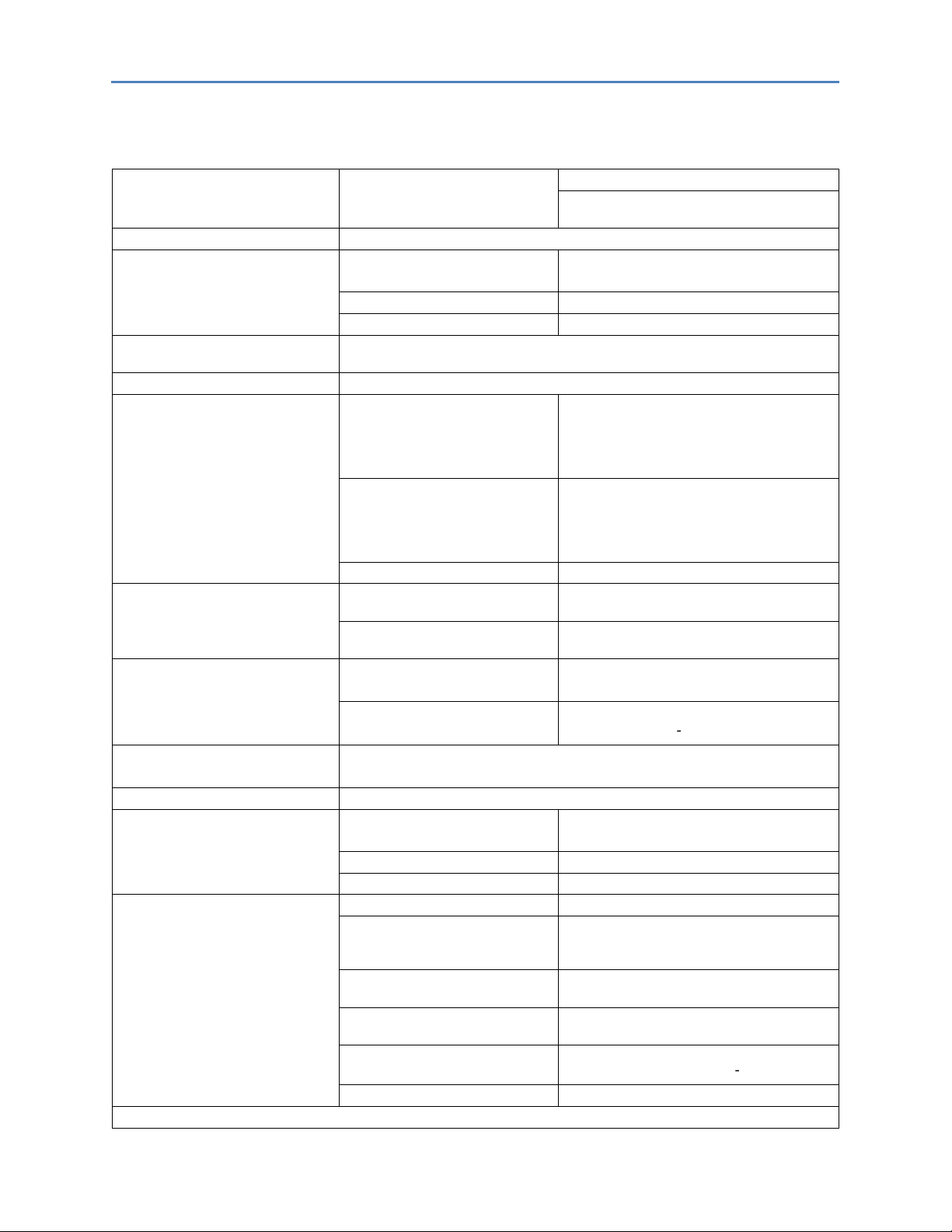

Type of connection

Spring-style

Single-wired, Fine-wired

Conductor cross-section 0.14 – 1.5 mm2

(AWG 16 – 26)

Configuration interface

USB 2.0

Dimensions

Height

120,0 mm (4.72 in)

(with release lever: 128,0 mm / 5,04 in)

Width

52,0 mm (2.05 in)

Depth

76,0 mm (2.99 in)

Protection class (DIN EN

60529)

IP 20

Flammability rating UL 94

V-0

Temperature data (Network

Adapter Power Supply)

Operation (horizontal

installation)

-20°C to +60°C (- 4 to +140 °F)

(8-A power supply)

-20°C to +55°C (- 4 to +131 °F)

(10-A power supply)

Operation (vertical installation)

-20°C to +55°C (- 4 to +131 °F)

(6-A power supply)

-20°C to +50°C (- 4 to +122 °F)

(8-A power supply)

Storage, transport

-40°C to +85°C (- 40 to +185 °F)

Humidity

Operation

95 %, non-condensing as per IEC 611312

Storage, transport

95 %, non-condensing as per IEC 611312

Air pressure

Operation

≥ 795 hPa (altitude ≤ 2000 m)

as per IEC 61131-2

Storage, transport

≥ 700 hPa (altitude ≤ 3000 m)

as per IEC 61131 2

Vibration resistance

5 Hz ≤ f ≤ 8.4 Hz: 3.5 mm amplitude as per IEC 60068-2-6

8.4 Hz ≤ f ≤ 150 Hz: 1 g acceleration as per IEC 60068-2-6

Shock resistance

15 g over 11 ms, half sinewave, as per IEC 60068-2-27

Potential isolation

Test voltage

max. 28,8 V within one channel

500 V DC field/system

Pollution severity level

2

Overvoltage category

II

Approvals and Standards

CULUS

Ordinary Locations

UL 508, CSA C22.2 No. 0-M91

CULUS

Hazardous Locations

Class 1 Division 2, Gr. A, B, C,

D

ISA 12.12.01: 2007

CSA C22.2 No. 213-M1987 (Reaffirmed

2008)

Potentially explosive

atmosphere Zone 2†

ATEX Directive 2014/34/EU

Explosion protection

IEC 60079-0:2012 and IEC 6007915:2010

EMC

IEC 61000 (partial standards as per the

requirements of IEC 61131 2)

FCC Compliance

47 CFR 15: 2011 (Class A)

†

Unless otherwise noted within the product-specific technical data.

1.4 General Technical Data for the Fieldbus Network Adapter

GFK-2958D RSTi-EP User Manual 11

Page 16

Chapter 1: Introduction

All product-specific technical data is available in the corresponding product description in Chapter 4, Detailed

Descriptions of the Fieldbus Network Adapters.

GFK-2958D RSTi-EP User Manual 12

Page 17

Chapter 1: Introduction

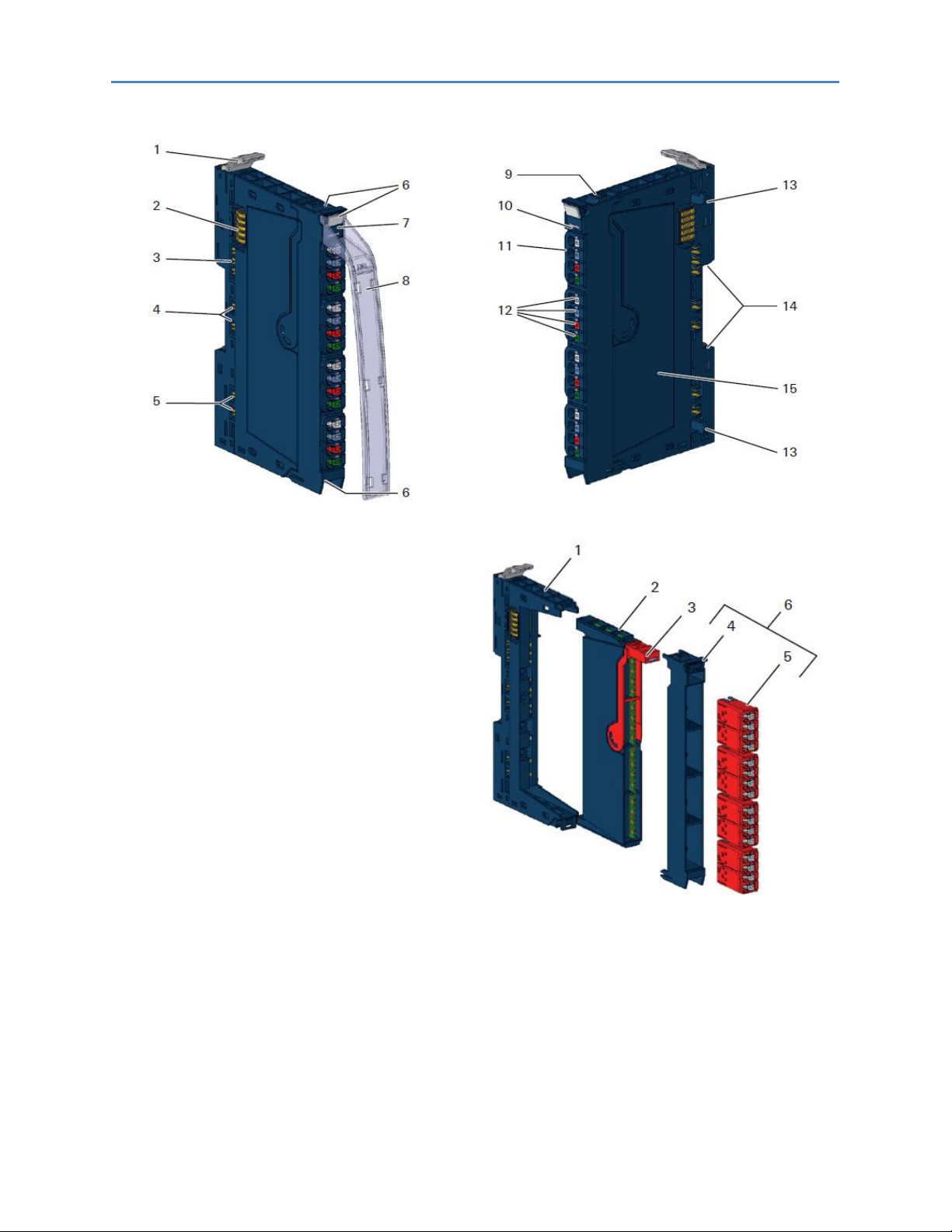

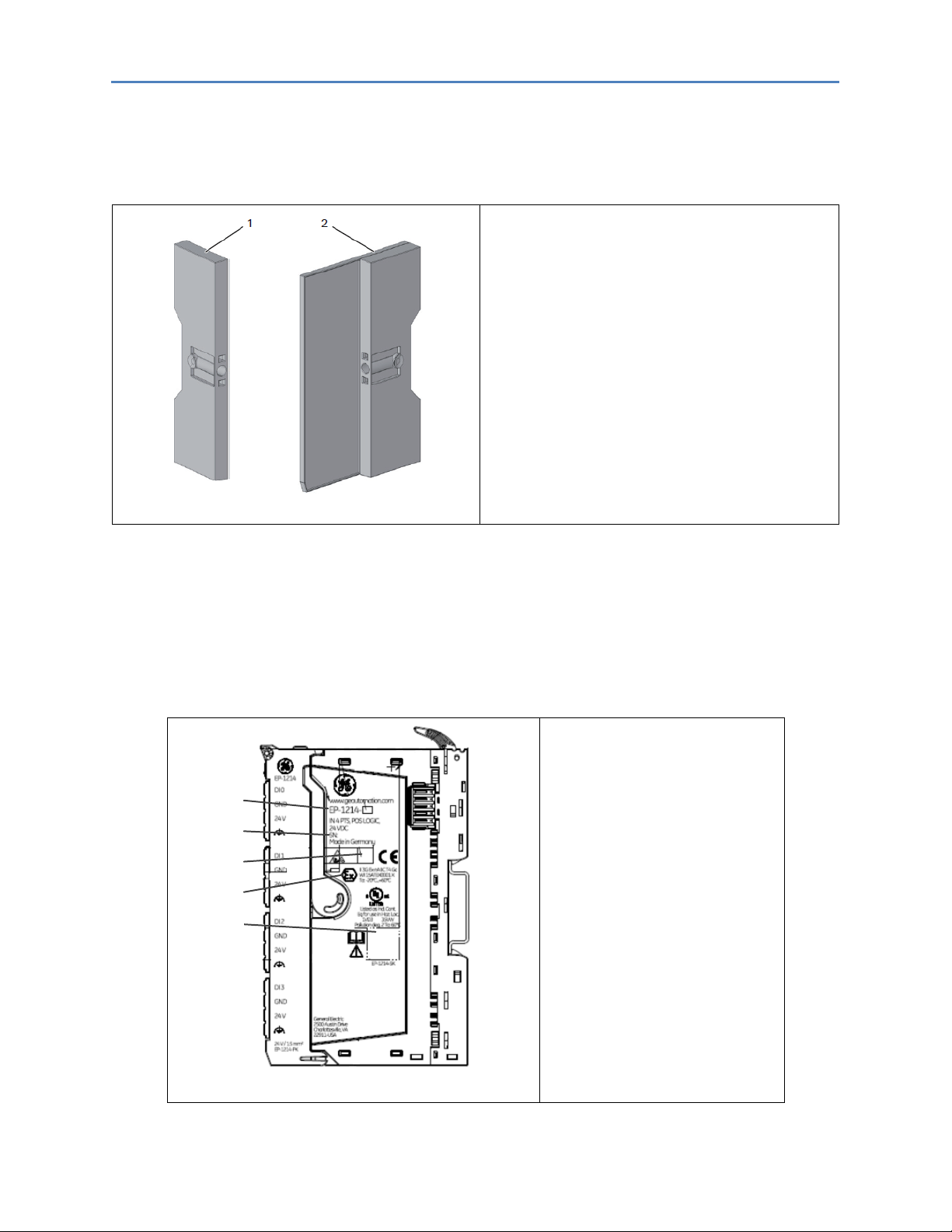

1 Catch lever for securing the DIN rail

2 System bus

3 System current path

4 Input current path

5 Output current path

6 Seats for module markers

7 Type designation

8 Optional: swivel marker for labelling modules and

channels

9 Connector frame unlocking device

10 Module status LED (collective message)

11 Connector

12 Channel status LEDs

13 Latching hook for latching onto module sides

14 DIN rail foot

15 Type plate

I/O Module Components

Color Coding

The removal levers for the electronic unit and the

connectors are color-coded as follows:

• Blue standard

• White power supply

• Red 230 V

• Yellow SIL products

1 Basic module

2 Electronic unit

3 Removal lever for electronic unit

4 Connector frame

5 Connector

6 Plug-in unit

A detailed description of the individual module types is available in Chapter 5, Detailed Descriptions of I/O

Modules.

1.5 General Description of I/O Modules

I/O module (Example EP-1214)

GFK-2958D RSTi-EP User Manual 13

Page 18

Chapter 1: Introduction

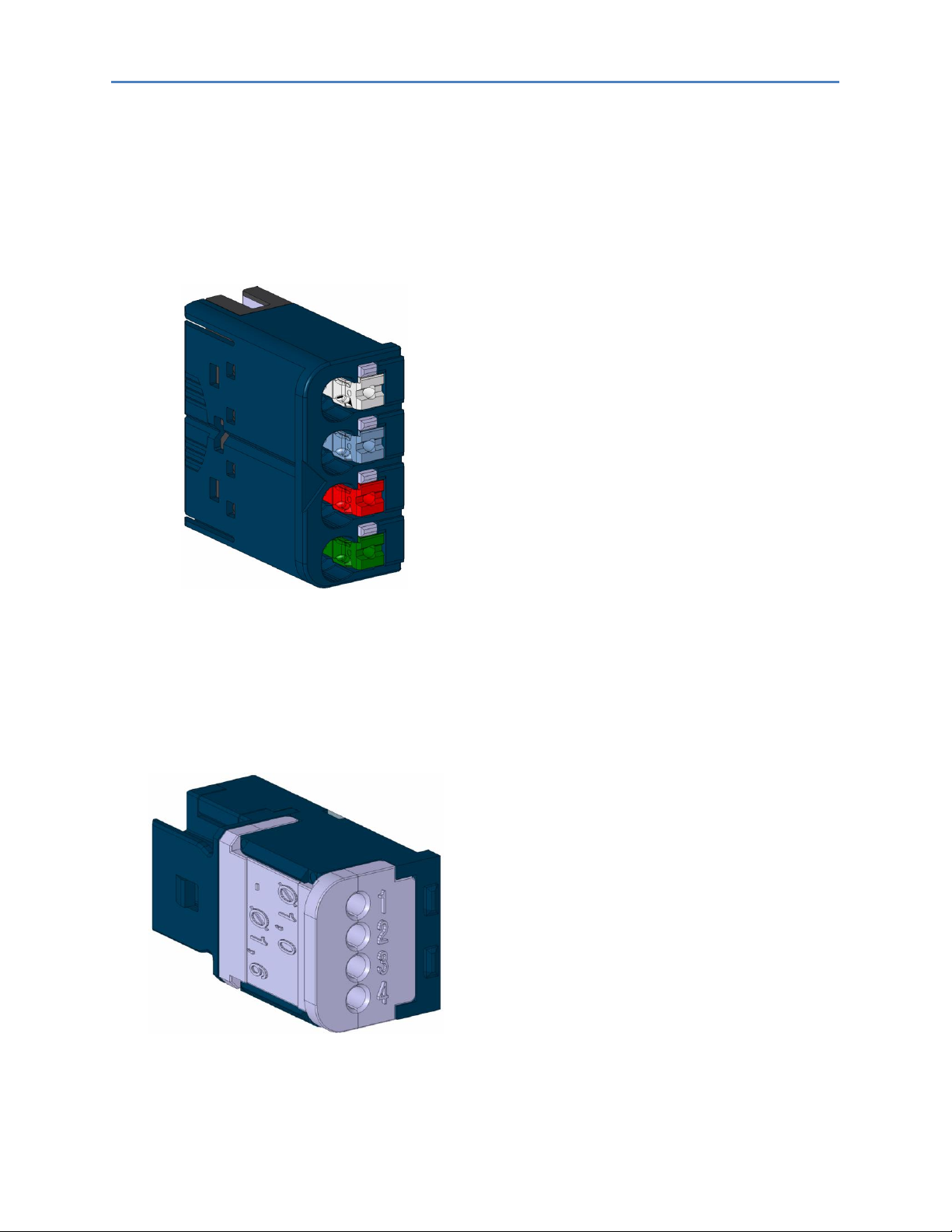

Connector with Four Conductor Connectors

Features and Specifications:

- conductor cross-section 0.14 to 1.5 mm²

(AWG 16 – 26)

- maximum ampacity: 10 A

- 4-pole

The pushers are color-coded for the following

connections:

• White Signal

• Blue GND

• Red 24 V DC

• Green Functional earth (FE)

Connector EP-8360 for HD Modules

Features and Specifications:

- conductor cross-section: 0.14 to 0.35 mm²

(AWG 22-26)

- insulation diameter 1.0 to 1.6 mm (0.04 to

0.06")

- maximum current capacity: 1 A

- 4-pole

1.5.1 Standard Connector

The connection frame can take up to four connectors, and four conductors can be connected to

each connector. Spring-style technology allows for fine-wired conductors with crimped wire-end

ferrules or ultrasonically welded conductors, each with a maximum cross-section of 1.5 mm², to be

inserted easily through the opening in the clamping terminal without having to use tools. To insert

fine-wired conductors without wire-end ferrules, the pusher must be pressed in with a screwdriver

(refer to the section, Wiring).

1.5.2 HD Connector EP-8360

The connection frame can take up to four times two HD connectors EP-8360, and qualified SAI

cables† with a cross-section from 0.14 to 0.35 mm

insulation displacement contact (IDC). (wiring refer to section, Wiring)

GFK-2958D RSTi-EP User Manual 14

2

can be connected to each connector via

Page 19

Chapter 1: Introduction

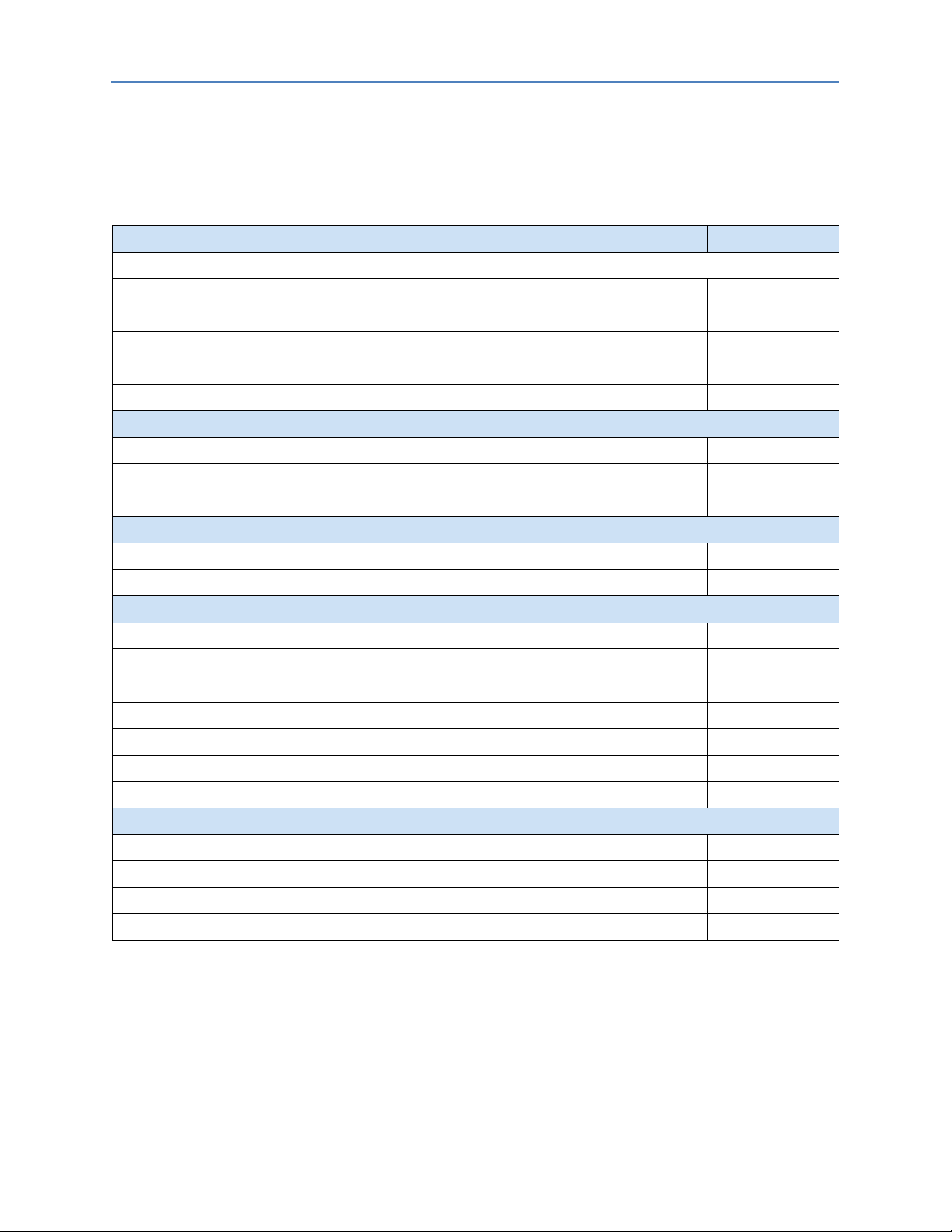

Description

Order No.

Digital input modules

Digital Input, 4 Points, Positive Logic 24VDC, 2,3, or 4 Wire

EP-1214

Digital Input, 8 Points, Positive Logic, 24VDC 2 Wire

EP-1218

Digital Input, 8 Points, Positive Logic, 24VDC 3 Wire

EP-1318

Digital Input, 4 Points, Positive Logic 24VDC, 2,3, or 4 Wire, Time stamp

EP-12F4

Digital Input, 4 Points 110/230 VAC (65 – 277 VAC), 2 Wire, Isolated

EP-1804

Digital output modules

Digital Output, 4 Points, Positive Logic 24VDC, 0.5A, 2,3, or 4 Wire

EP-2214

Digital Output, 4 Points, Positive Logic 24VDC, 2.0A, 2,3, or 4 Wire

EP-2614

Digital Output, 4 Points, Positive/Negative Logic 24VDC, 2.0A, 2,3, or 4 Wire

EP-2634

Analog input modules

Analog Input, 4 Channels Voltage/Current 16 Bits 2, 3, or 4 Wire

EP-3164

Analog Input, 4 Channels Voltage/Current 12 Bits 2, 3, or 4 Wire

EP-3124

Functional modules

2 Channels PWM Output, Positive Logic, 24VDC, 2.0 A

EP-5422

2 Channels PWM Output, Positive Logic, 24VDC, 0.5 A

EP-5442

1 Channel High Speed Counter, AB 100 kHz 1 DO 24VDC, 0.5A

EP-5111

2 Channel High Speed Counter, AB 100 kHz

EP-5112

2 Channel Frequency Measurement, 100 kHz

EP-5212

1 Channel Serial Communications, 232, 422, 485

EP-5261

1 Channel SSI Encoder, BCD or Gray-Code Format, 5/24 VDC

EP-5311

Potential distribution modules

Power Module, 16 Channels 24VDC Potential Distribution +24 VDC from Input Current Path

EP-711F

Power Module, 16 Channels 24VDC Potential Distribution +24 VDC from Output Current Path

EP-751F

Power Module, 16 Channels 24VDC Potential Distribution +0VDC from Input Current Path

EP-710F

Power Module, 16 Channels 24VDC Potential Distribution +0VDC from Output Current Path

EP-750F

1.5.3 Cable Protection

The modules listed in the following table do not have a fused sensor/actuator power supply. Here, all

cables to the connected sensors/actuators must be fused corresponding to their conductor crosssections (as per Standard DIN EN 60204-1, section 12).

GFK-2958D RSTi-EP User Manual 15

Page 20

Chapter 1: Introduction

Type of connection

Spring-style

Single-wired, fine-wired

Conductor cross-section

0.14 – 1.5 mm2 (AWG 16 – 26)

IDC (EP-3368, EP-3468)

Single-wired, fine-wired

Conductor cross-section

0.14 – 0.35 mm2 (AWG 22 – 26)

Dimensions

Height

4.72 in (120.0 mm)

w/ release lever: 128.0 mm (5.04 in)

Width

11.5 mm (0.45in)

Depth

76.0 mm (2.99 in)

Protection class

(DIN EN 60529)

IP 20

Flammability rating UL 94

V-0

Temperature data

Operation

-20°C to +60°C (- 4 to +140 °F)

Storage, transport

-40°C to +85°C (- 40 to +185 °F)

Humidity

Operation, storage, transport

5 % to 95 %, non-condensing

as per IEC 61131-2

Air pressure

Operation

≥ 795 hPa (altitude ≤ 2000 m)

as per IEC 61131-2

Storage, transport

≥ 700 hPa (altitude ≤ 3000 m)

as per IEC 61131-2

Vibration resistance

5 Hz ≤ f ≤ 8.4 Hz: 3.5-mm amplitude as per IEC 60068-2-6

8.4 Hz ≤ f ≤ 150 Hz: 1-g acceleration as per IEC 60068-2-6

Shock resistance

15 g over 11 ms, half sinewave, as per IEC 60068-2-27

Potential isolation

Test voltage

max. 28.8 V within one channel

500 V DC field/system

Pollution severity level

2

Overvoltage category

II

Approvals and Standards

cULus Ordinary Locations

UL 508, CSA C22.2 No. 0-M91

CULUS

Hazardous Locations

Class 1 Division 2, Gr. A, B, C, D

ISA 12.12.01: 2007

CSA C22.2 No. 213-M1987 (Reaffirmed 2008)

Potentially explosive atmosphere

Zone 2†

ATEX Directive 2014/34/EU

Explosion protection

IEC 60079-0:2012 and

IEC 60079-15:2010

EMC

IEC 61000

(partial standards as per the requirements of

IEC 61131-2)

FCC Compliance

47 CFR 15: 2011 (Class A)

Type of connection

Spring-style

Single-wired, fine wired

ICES Compliance

ICES-003:2012 (Class A)

PLC

IEC 61131-2

†

Unless otherwise noted within the product-specific technical data.

All product-specific technical data is available in the corresponding product description in Chapter 5, Detailed Descriptions

of I/O Modules.

1.6 General Technical Data for I/O Modules

GFK-2958D RSTi-EP User Manual 16

Page 21

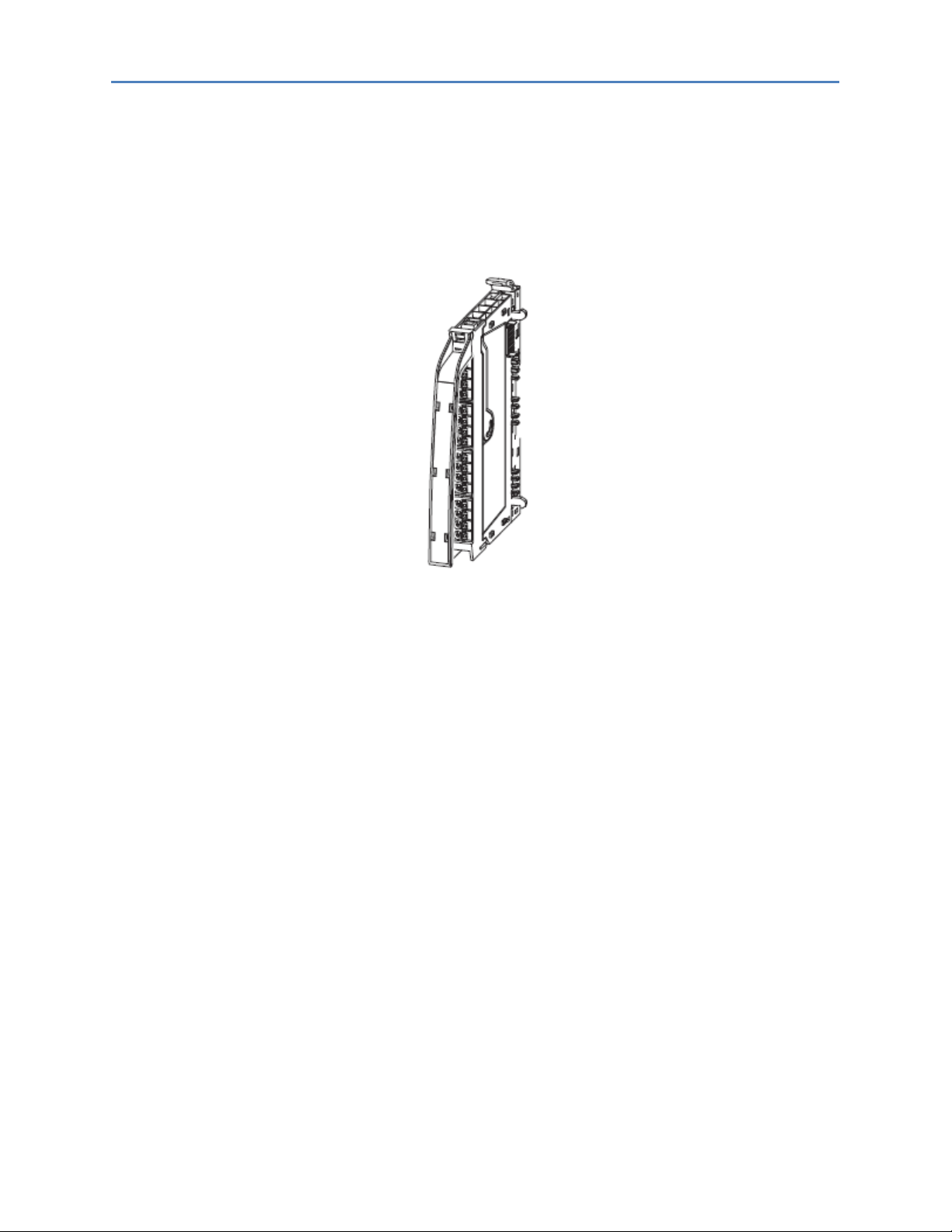

Chapter 1: Introduction

RSTi-EP station fixing elements

1 End bracket (left end, on the network adapter

side)

2 Termination kit with end plate and end

bracket (right end)

For vertical installation, a special end bracket

must also be installed below the station.

5

4

3

2

1

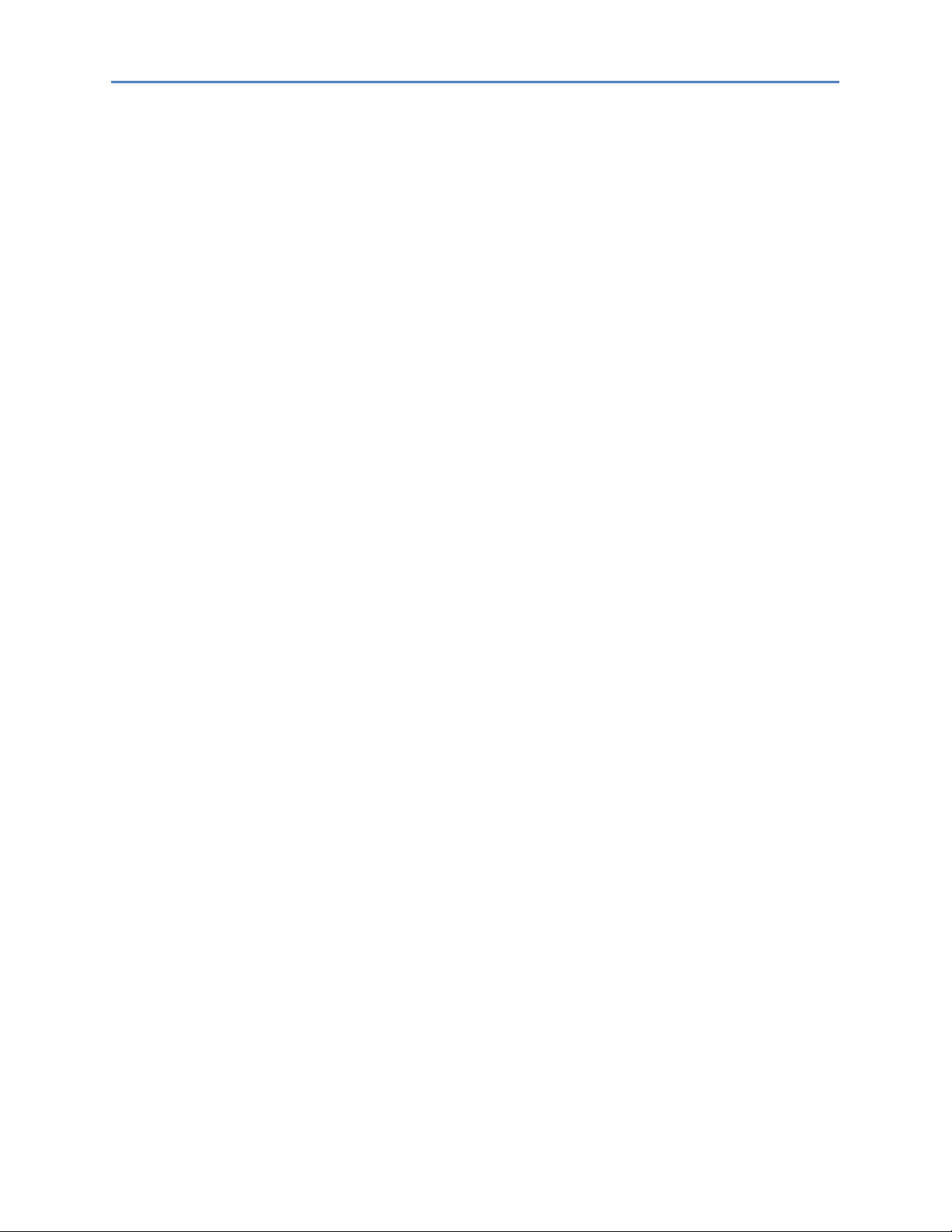

Type Plate (Example of EP-1214)

1 Product number

2 Serial number

3 Manufacturing code

4 ATEX marking

5 QR code

1.7 Mechanical Fixing Elements

The station is fixed in the installation position by an end bracket at either side. The last I/O module is

protected against dust by a cover plate, into which the second end bracket is inserted and screwed

to the mounting rail. Every RTSi-EP network adapter is supplied with a termination kit.

1.8 Type Plate

Each network adapter and each module features a type plate, which includes identification

information, the key technical specifications and a block diagram. In addition, a QR code allows for

direct online access to the associated documentation. The software for reading the QR code must

support inverted QR codes. A breakdown of the serial numbers can be found in the table provided in

the annex.

GFK-2958D RSTi-EP User Manual 17

Page 22

Chapter 1: Introduction

1.9 Markers

A wide range of markers are available as accessories for labelling equipment.

1.9.1 Swivel Marker

RSTi-EP I/O Label Markers (EP-8100) allow for modules and all respective channels and lines to be

labelled in detail. They are attached to the connector frame.

Module with Swivel Marker

The following labels are available for the labelling:

• Paper labels for printing with laser printers (Part No. EP-8101)

o White

o Yellow

GFK-2958D RSTi-EP User Manual 18

Page 23

Chapter 1: Introduction

Notes

GFK-2958D RSTi-EP User Manual 19

Page 24

Safety

This section includes general safety instructions for handling the RSTi-EP system. Specific safety

instructions for specific tasks and situations are given at the appropriate places in the

documentation.

When using remote I/O RSTi-EP modules, refer to the Module for Functional Safety Manual (GFK-2956).

2.1 General Safety Notice

Work on the RSTi-EP products may only be performed by qualified personnel with the support of

trained persons. As a result of their professional training and experience, an personnel is qualified to

perform the necessary work and identify any potential risks.

Before any work is carried out on the products (installation, maintenance, retrofitting), the power

supply must be switched off and secured against being switched on again. Work may be carried out

with safety extra-low voltage.

The manual provided with the equipment shall be followed in detail to assure proper and safe

operation.

A stabilized 24V DC power supply shall be used.

All field wiring intended for connection to the power terminal shall consist of copper conductors with

the insulation locally removed. Additional intermediate connecting parts, other than ferriles, shall not

be used.

When working during continued operations, the emergency stop mechanisms must not be made

ineffective. If you need technical help, contact Technical Support. For phone numbers and email

addresses, refer to the General Contact Information page in the front of this manual.

If a malfunction on a RSTi-EP product cannot be fixed after following the recommended measures

(refer to the Chapter, LED Indicators and Troubleshooting), the product in question must be sent back

to GE. GE does not assume any liability if the base or electronic module has been tampered with.

2.1.1 Electrostatic Discharge

RSTi-EP products can be damaged or destroyed by electrostatic discharge. When handling the

products, the necessary safety measures against electrostatic discharge (ESD) according to IEC

61340-5-1 and IEC 61340-5-2 must be observed.

All devices are supplied in ESD-protected packaging. The packing and unpacking as well as the

installation and disassembly of a device may only be carried out by qualified personnel and in

accordance with the ESD information.

2.1.2 Open Equipment

RSTi-EP products are open equipment (having live electrical parts that may be accessible to users)

that may only be installed and operated in lockable housings, cabinets or electrical operations

rooms. Only trained and authorized personnel may access the equipment.

For applications requiring functional safety or in order to maintain compliance with the ATEX

Directive [Class 1, Zone 2 area (Category 3)], the surrounding housing must meet at least IP 54.

The standards and guidelines applicable for the assembly of switch cabinets and the arrangement of

data and supply lines must be complied with.

GFK-2958D RSTi-EP User Manual July 2017 20

Page 25

Chapter2: Safety

2.1.3 Fusing

The operator must set up the equipment so that it is protected against overloading. The upstream

fuse must be designed such that it does not exceed the maximum load current. The maximum

permissible load current of the RSTi-EP components can be found in the technical data.

In the case of modules without fused sensor/actuator power supplies, all lines to the connected

sensors/actuators must be fused corresponding to their conductor cross-section (as per DIN VDE

0298 Part 4).

To meet UL-specifications in accordance with UL 248-14, a UL-certified automatic fuse or a 10 A fuse

with a medium time-lag must be used.

All connections of the RSTi-EP components are protected against voltage pulses and overcurrent in

accordance with IEC 61131-2, Zone B. The operator has to decide whether additional overvoltage

protection according to IEC 62305 is required. Voltages that exceed +/-30 V may cause the

destruction of network adapters and modules.

A feed-in power supply with secure isolation must be used.

2.1.4 Earthing (functional earth FE)

Each RSTi-EP I/O module is fitted with an FE spring on the underside which creates an electrical

connection to the DIN rail. In order to establish a secure connection, the assembly must be carried

out carefully in accordance with the instructions (refer to Chapter 6, Installation). The module is

earthed by connecting the DIN rail to the protective earth via the earth terminal.

Modules EP-700F, EP-1214, EP-2214, EP-3124 and EP-3164 have connections with green pushers. An

FE potential is also provided at these connections. They must not be used as a PE.

2.1.5 Shielding

Shielded lines are to be connected with shielded plugs and fixed on a shield bus in compliance with

the relevant standard (refer to Chapter 7, Earthing and Shielding).

2.1.6 Overcurrent

Potentials of network adapters and power-feed modules must be disconnected either simultaneously

or in the order 24 V supply first, then the GND potential.

2.2 Intended Use

The products of the RSTi-EP series are intended for use in industrial automation. A RSTi-EP station

with network adapter and connected modules is intended for the decentralized control of systems or

sub-systems. Via the network adapter every module of a station is integrated into a fieldbus

structure and connected to the primary control unit. The RSTi-EP products conform to protection

class IP 20 (in accordance with DIN EN 60529), they can be used in potentially explosive atmospheres

rated as Zone 2 (as per Directive 2014/34/EU) and in safe zones.

The observance of the supplied documentation is part of the intended use. The products described in

this manual may only be used for the intended applications and only in connection with certified

third-party devices or components.

GFK-2958D RSTi-EP User Manual 21

Page 26

Chapter2: Safety

2.3 Use in a Potentially Explosive Atmosphere

If RSTi-EP products are used in potentially explosive atmospheres, the following notes are also

applicable:

• Staff involved in assembly, installation and operation must be qualified to perform safe

work on electrical systems protected against potentially explosive atmospheres.

• The remote I/O-System RSTi-EP shall only be used in an area of not more than pollution

degree 2, as defined in IEC 60664-1.

• For applications in potentially explosive atmospheres, the requirements according to IEC

60079-15 must be observed, in particular the housing enclosing the system must meet

the requirements of explosion protection type Ex n or Ex e and protection class IP54. The

IP54 enclosure must be accessible only by the use of a tool.

• Sensors and actuators that are located in Zone 2 or in a safe zone can be connected to

the RSTi-EP station.

• The ambient temperature range -20°C to +60°C shall not be exceeded.

• When the temperature under rated conditions exceeds 70 °C at the conductor or conduit

entry point, or 80 °C at the contact, the temperature specification of the selected cable

shall be in compliance with the actual measured temperature values.

• A stabilized 24V DC power supply with double or reinforced insulation shall be used.

• When using relay modules EP-2714, EP-2814, and EP-1804 in explosive atmosphere:

o Device shall be installed in an environment free of condensation, corrosives and

conducting dusts.

o If the switching or input voltage exceeds 63V, a transient protection device shall be

provided that limits the transients to a peak voltage of 500V or less.

• For EP-2714 (Relay Module) only:

o Since relays are subject to wear, it must be ensured, by appropriate maintenance

intervals, that the temperatures do not exceed the limits of temperature class T4.

Note: A contact resistance of more than 110 milli-ohm will be considered as a fault.

o Resistive Loads Only

o Transient protection shall be provided that is set at a level not exceeding 140% of the

peak rated voltage value at the supply terminals to the equipment.

• A visual inspection of the RSTi-EP station is to be performed once per year.

• A visual inspection of the RSTi-EP station is to be performed once per year.

• If mounted in other directions than horizontal (reference mounting rail), restrictions to the

max. operating temperature, max. output currents may apply.

• While explosive atmosphere is present:

o No electrical connection shall be separated in energized condition.

o The USB interface shall not be used.

o Dip-switches, binary-switches and potentiometers shall not be actuated.

• Only power supplies with secure isolation shall be used.

• Refer manufacturers manual.

GFK-2958D RSTi-EP User Manual 22

Page 27

Chapter2: Safety

Warning

EXPLOSION HAZARD - SUBSTITUTION OF COMPONENTS MAY IMPAIR

SUITABILITY FOR CLASS I, DIVISION 2.

WHEN IN HAZARDOUS LOCATIONS, TURN OFF POWER BEFORE REPLACING

OR WIRING MODULES; AND

DO NOT CONNECT OR DISCONNECT EQUIPMENT UNLESS POWER HAS

BEEN SWITCHED OFF OR THE AREA IS KNOWN TO BE NONHAZARDOUS.

Altitude (m, ft)

Factor for Temperature Derating

< 2000 m (6561.68 ft)

1

2001 to 3000 m (6564.96 to 9842.52 ft)

0.88

3001 to 4000 m (9845.80 to 13123.36 ft)

0.78

4001 to 5000 m (13126.64 to 16404.20 ft)

0.68

2.3.1 ATEX Zone 2

The module must be mounted in an enclosure certified in accordance with EN60079-15 for use in

Zone 2, Group IIC and rated IP54. The enclosure shall only be able to be opened with the use of a tool.

2.3.2 ATEX & IECEx Marking

WI 15ATEX0001 X

II 3 G Ex nA T4 Gc

II 3 G Ex nA nC T4 Gc

IECEx ULD 16.0022x

Ta: -20°C to +60°C

2.4 Legal Notice

The RSTi-EP series products are CE-compliant in accordance with Directive 2014/30/EU (EMC

Directive) and Directive 2014/35/EU (Low Voltage Directive). They also meet the requirements of the

ATEX Directive 2014/34/EU.

2.5 Use of RSTi-EP Stations Above 2000m Sea Level

The RSTi-EP remote I/O system is able to operate in height >2000 m (6561.68 ft) above sea

level, with the following limitations:

There is a derating for ambient temperatures while the RSTi-EP Station is in operating

mode. Refer to the following derating table.

Example:

Height 3000 m (9842.52 ft): maximum operational temperature is 60° C (140 °F) x 0.88 = 52.8°C

(136.76 °F) at maximum 8A.

GFK-2958D RSTi-EP User Manual 23

Page 28

Configuration

3.1 Order and Arrangement of the Modules

The RSTi-EP system elements are designed to be installed on a profile rail according to EN 60715 [1.4

x 0,26 in (35 × 7.5 mm)], a steel strip in accordance with Annex A of EN 60715, or a tin-plated steel

strip.

Note: A RSTi-EP station may be built up to a maximum length of 3.28 ft (1 m). Therefore, at most

82 modules (including max. 64 active modules) can be aligned on a network adapter.

The RSTi-EP station is usually installed on a horizontally positioned DIN rail.

Installation Position of the RSTi-EP Station on the DIN Rail (Horizontal Installation)

Installation on vertically positioned DIN rails is also possible. In this case however, the heat

dissipation is reduced such that the derating values change (refer to the section Current Demand and

Power Supply). In the case of vertical mounting, the network adapter must always be arranged as the

first module at the bottom and secured with an end bracket for vertical mounting.

GFK-2958D RSTi-EP User Manual July 2017 24

Page 29

Chapter 3: Configuration

Attention

A maximum of three passive modules (potential distribution module, powerfeed module or blank module) may be placed in successive positions. Then at

least one active module must follow.

Installation Position of the RSTI-EP Station on the DIN Rail (Vertical Installation)

A RSTi-EP station may only be installed in this sequence (starting from the left/bottom):

• End bracket

• Network adapter

• Up to 82 modules (including max. 64 active modules)

• End plate and end bracket

3.1.1 Arrangement of Safe Power-feed Modules

A safe power-feed module EP-19xx module can be positioned anywhere in the RSTi-EP station. All the

following output modules (except for the EP-2814 and EP-2714 relay modules) up to the next EP-19xx

module are safely disconnected (safety segment). Multiple EP-19xx modules/safety segments can be

arranged within a station.

Note: When using RSTi-EP EP-19xx modules, also refer to the Modules for Functional Safety Manual

(GFK-2956).

GFK-2958D RSTi-EP User Manual 25

Page 30

Chapter 3: Configuration

Attention

Depending on how the station shielding is implemented, the specified

distances may have to be made larger, where necessary.

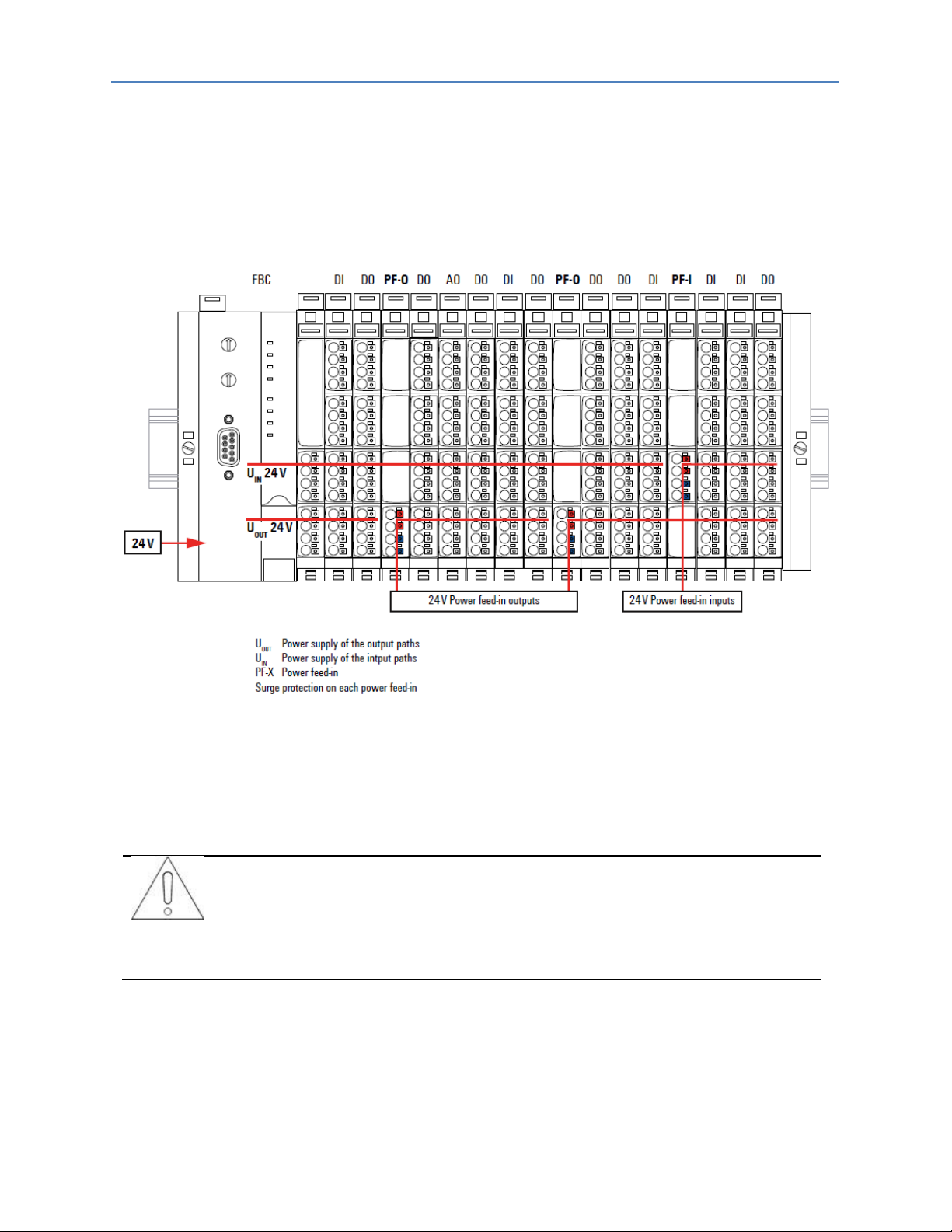

3.1.2 Power Supply Concept

The RSTi-EP system uses three internal current paths as described in the following chapter, Detailed

Descriptions of the Fieldbus Network Adapters. Input and output paths are supplied separately, therefore a

custom-fit refreshing by power-feed modules is easily feasible.

The following figure shows the general supply concept. For detailed description and calculation of the current

demand refer to the sections, Example Calculation for the Power Supply and Calculation of Power Loss of

this manual.

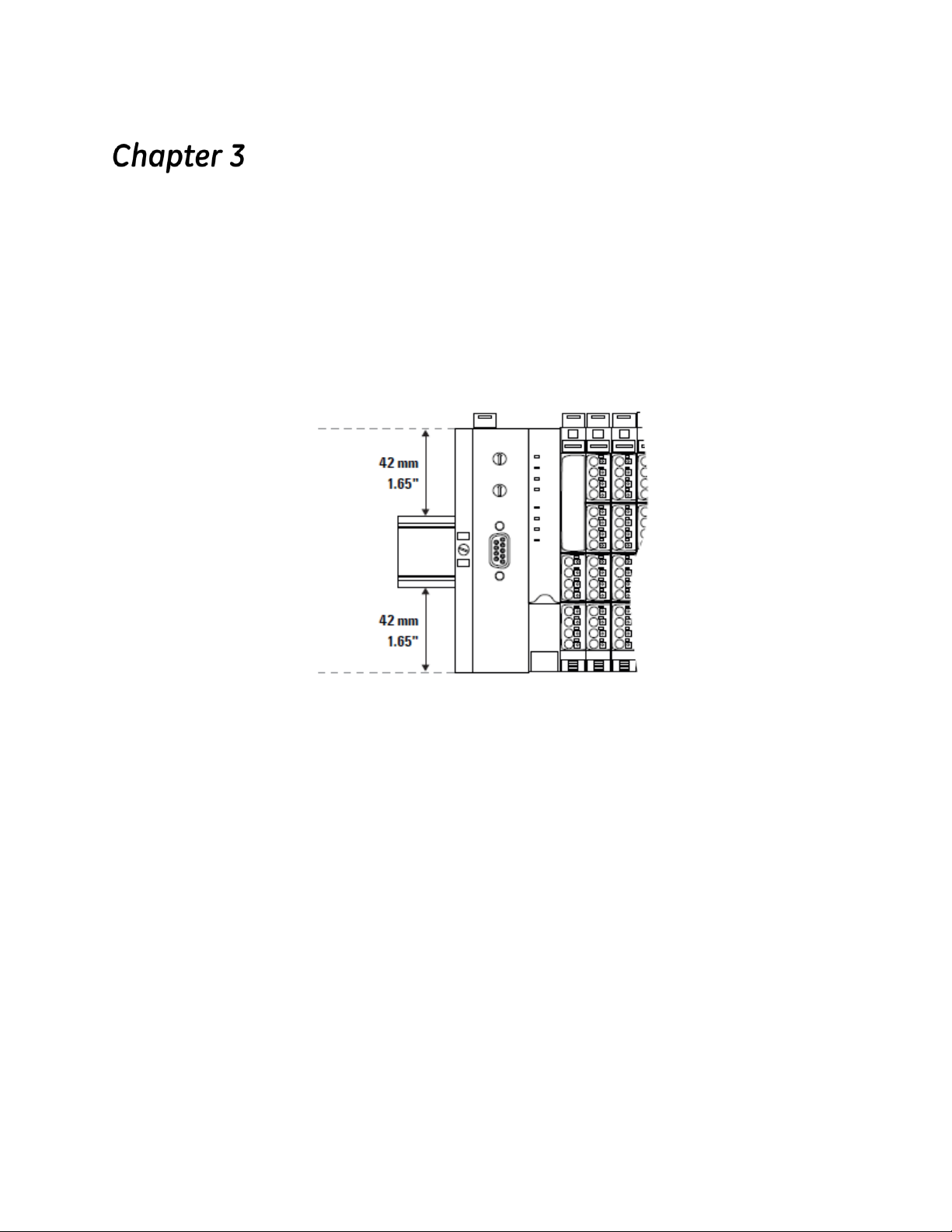

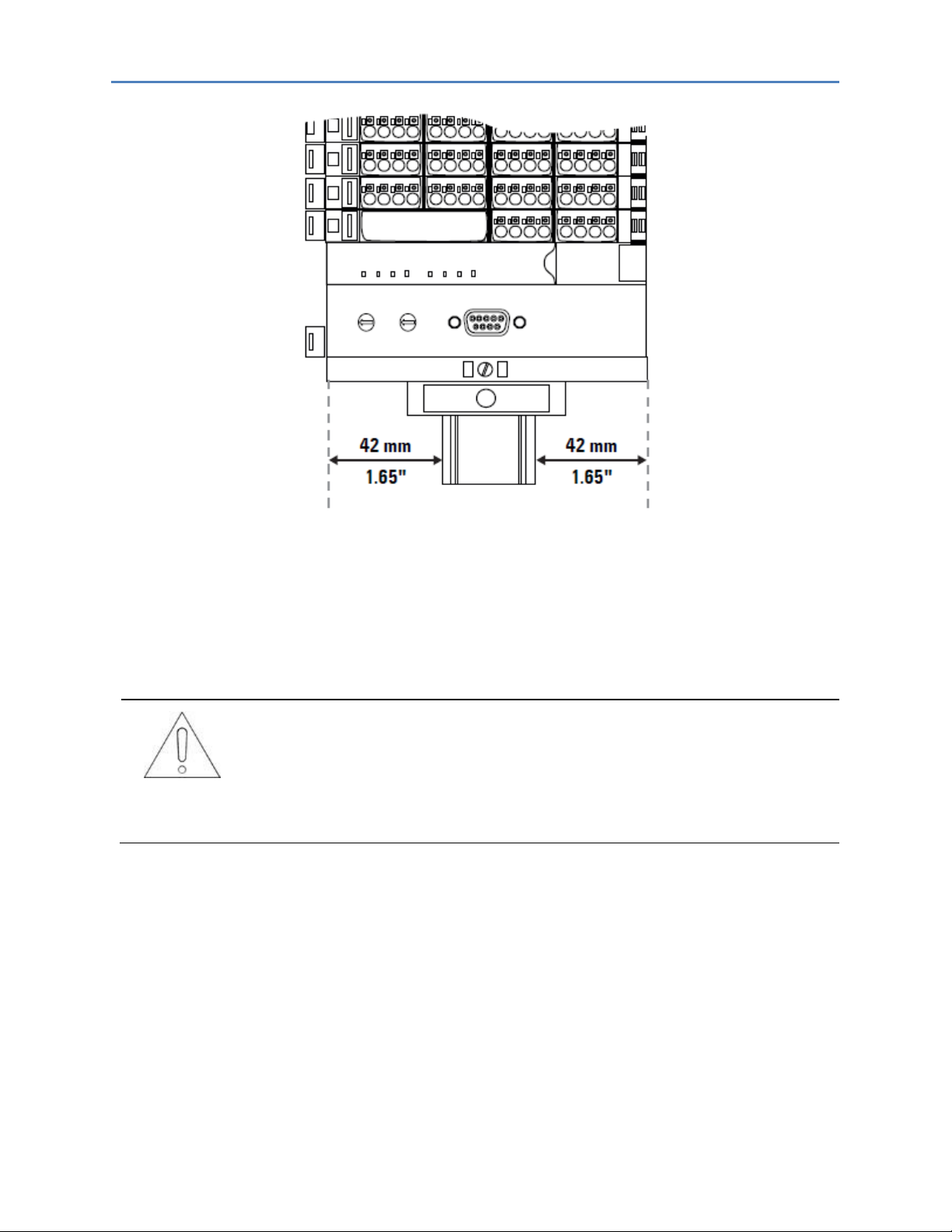

3.2 Installation Distances

In order to be able to carry out the installation and subsequent maintenance work and to ensure

sufficient ventilation, the RSTi-EP station must be installed while observing the following minimum

distances (refer to the following figures).

The minimum permissible conductor bending radii must also be observed. Earth terminals already

installed can be ignored when calculating the distance.

GFK-2958D RSTi-EP User Manual 26

Page 31

Chapter 3: Configuration

Minimum Distances for Horizontal Installation

Minimum Distances for Vertical Installation

Minimum Distance for Electrical Cabinet Door (Without/With Swivel Marker)

GFK-2958D RSTi-EP User Manual 27

Page 32

Chapter 3: Configuration

Height:

120 mm (4.72 in)

+ 40 mm (2 x 1.57 in)

= 200 mm (7.87 in)

distances at top and bottom

Width:

8 mm (1.57 in)

+ 52 mm (2.05 in)

+ n x 11.5 mm (0.45 in)

+ 11.5 mm (0.45 in)

+ 2 x 20 mm (0.79 in)

= 111.5 mm (4.39 in) + n x 11.5 mm (0.45 in)

end bracket

network adapter

n modules

end plate and end bracket

distances to the sides

3.2.1 Calculation of Space Requirements

The space requirements for a RSTi-EP station with n modules (horizontal installation) is calculated as

follows:

For vertical installation interchange height and width. When calculating the width, 4.5 mm (0.18 in)

for the must be added for the end bracket.

3.3 Use in a Potentially Explosive Atmosphere

If the RSTi-EP is used in a potentially explosive atmosphere rated as Zone 2, the housing must meet