Page 1

These Monogram refrigerators and

freezers are designed to be customized

with decorator door and grille panels.

Field installed panels are required.

Custom Options Guide and

Installation

Instructions

With Custom Panel Dimensions

and Trim Kit Installation Instructions

Factory installed trim will

accommodate 1/4" thick custom

panels or optional Lexan ®and stainless

steel panel kits.

Optional trim kits allow an even

broader range of custom appearance

options.

Read this booklet carefu!lg to

accomplish the desired appearance and

to insure a trouble free installation.

This booklet contains information and

illustrations to demonstrate custom

possibilities. Custom door and grille

panel sizes vary to accommodate the

kit being used. Dimensions for each

application are included and can

be faxed or sent to the cabinet

manufacturer so that the panels

can be constructed accuratelg.

36" Refrigerators and 36" Freezers

ZIR36N LH -All Refrigerator

ZlR36N RH - All Refrigerator

ZlF36N LH -All Freezer

ZIF36N RH - All Freezer

monogram.corn

Page 2

Before you begin - Read these instructions completely and carefully.

IMPORTANT - Save these instructions for local inspector's use.

IMPORTANT - OBSERVE ALL GOVERNING CODES AND ORDINANCES.

Note to Installer - Be sure to leave these instructions with the Consumen

Note to Consumer - Keep these instructions with your Owner's Manual for future reference.

This appliance must be properly grounded. See "Grounding the

Refrigerator," page 12.

Cet appareil dolt _tre correctement mis 6 la terre. Consulter <<Mise 6terre du r_frig_rateur >>,page 12.

If you received a damaged product, you should

immediately contact your dealer or builden

Proper installation is the responsibility of the installen

Product failure due to improper installation is not

covered under the GEAppliance Warranty. See the

Owners' Manual for warranty information.

For Monogram local service in your area,

1.800.444.1845.

Use this appliance only for its intended purpose.

Immediately repair or replace electric service

cords that have become frayed or damaged.

Unplug the refrigerator before cleaning or

making repairs.

Repairs should be made by a qualified service

technician.

For Monogram service in Canada,

1.800.561.3344

For Monogram Parts and Accessories,

call 1.800.626.2002.

• II ne faut utiliser cet appareil que pour rusage

pour lequel il a _t_ construit.

• II faut r@arer ou remplacer imm_diatement tout

cordon d'alimentation _lectrique effiloch6 ou

Due to the weight and size of this refrigerator, and

to reduce the risk of personal injury or damage to

the product - THREE PEOPLE ARE REQUIRED FOR

PROPER INSTALLATION.

endommag&

• D6brancher le rdrig_rateur avant le nettoyage

ou toute intervention.

• Les r_parations doivent _tre faites par un

technicien qualifi_.

Contents

cause du poids et de la taille de ce r6frig_rator

et pour r_duire le risque de blessure et de

dommages, IL FAUT TROIS PERSONNES POUR

FAIRE L'INSTALLATION CORRECTEMENT.

Design Information

Flush or Semi-Flush Enclosure Installations ..................3

Enclosure Cutout and Product Dimensions ....................3

Clearances ......................................................................................4

Side By Side Installation of Freezer

and Refrigerator ..........................................................................4

Installation Examples ............................................................4, 5

Frameless Cabinets ....................................................................5

Accessory Panel Kits ..................................................................5

Advance Planning Appearance Options ..........................5

Models Available ..........................................................................6

Trim Kit Descriptions ..................................................................6

Custom Panel Dimensions

Product and Cutout Information ..........................................7

1/4" Thick Custom Panels on 1/4" backing ....................8

3/4" Thick Panels with Supplied Handle ..........................9

3/4" Thick Panels with Custom Handle ..........................10

Side Panel or Filler Options ..................................................11

Trim Kits

ZGC2 Trim Kit, Grille Panel Frame Adjustment ..........19

ZKHR1 Trim Kit (for 1/4" Panels),

Support for Custom Handles ....................................20-21

ZKTR36LH/ZKTR36RH Trim Kit,

3/4" Custom Panels ......................................................22-25

ZKHTR1 Trim Kit (for 3/4" Panels),

Support for Custom Handles ....................................26-28

ZKHRSS1 Trim Kit (for 1/4" Panels),

Tubular Stainless Steel Handles ..............................29-32

ZKHTRSS1 Trim Kit (for 3/4" Panels),

Tubular Stainless Steel Handles ..............................33-34

ZUG75 Trim Kit, Unified 3/4" Grille Panel Kit ......35-40

Installation Instructions ................................................12-18

Page 3

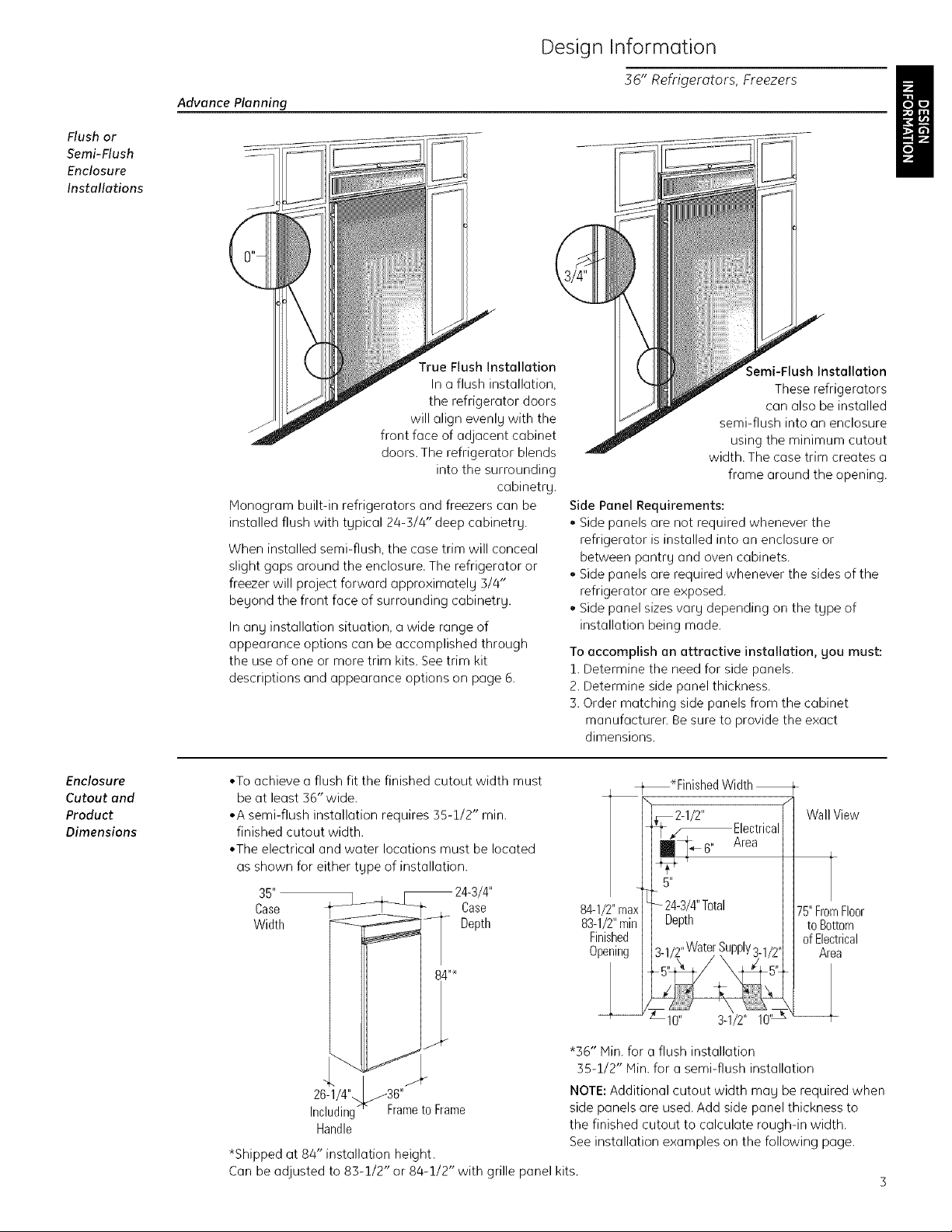

Flush or

Semi-Flush

Enclosure

Installations

Design Information

36" Refrigerators, Freezers

Advance Planning

Enclosure

Cutout and

Product

Dimensions

True Flush Installation

In a flush installation,

the refrigerator doors

will align evenlg with the

J front face of adjacent cabinet

doors. The refrigerator blends

into the surrounding

cabinetrg.

Monogram built-in refrigerators and freezers can be

installed flush with tgpical 24-5/4" deep cabinetry.

When installed semi-flush, the case trim will conceal

slight gaps around the enclosure. The refrigerator or

freezer will project forward approximatelg 5/4"

beyond the front face of surrounding cabinetrg.

In ang installation situation, a wide range of

appearance options can be accomplished through

the use of one or more trim kits. See trim kit

descriptions and appearance options on page 6.

• To achieve a flush fit the finished cutout width must

be at least 56" wide.

oA semi-flush installation requires 55-1/2" min.

finished cutout width.

°The electrical and water locations must be located

as shown for either type of installation.

35" /4"

Case Case

Width Depth

;emi-Flush Installation

These refrigerators

can also be installed

semi-flush into an enclosure

using the minimum cutout

width. The case trim creates a

frame around the opening.

Side Panel Requirements:

,, Side panels are not required whenever the

refrigerator is installed into an enclosure or

between pantr U and oven cabinets.

. Side panels are required whenever the sides of the

refrigerator are exposed.

Side panel sizes var U depending on the tgpe of

installation being made.

To accomplish an attractive installation, you must:

1. Determine the need for side panels.

2. Determine side panel thickness.

3. Order matching side panels from the cabinet

manufacturen Be sure to provide the exact

dimensions.

-t_*Finished Width

_2-1/2" fl Wall View

L_ _Electrical II

84-1/2"max

83-1/2"min

Finished

Opening

2434 Ttal

- / " 0 1175" FromFloor

uepth I I to Bottom

...... II of Electrical

3-1,/2"water ,bupply3-1/2,H Area

*Shipped at 84" installation height.

Can be adjusted to 83-1/2" or 84-1/2" with grille panel kits.

*B6" Min. for a flush installation

35-1/2" Min. for a semi-flush installation

NOTE: Additional cutout width mug be required when

side panels ore used. Add side panel thickness to

the finished cutout to calculate rough-in width.

See installation examples on the following page.

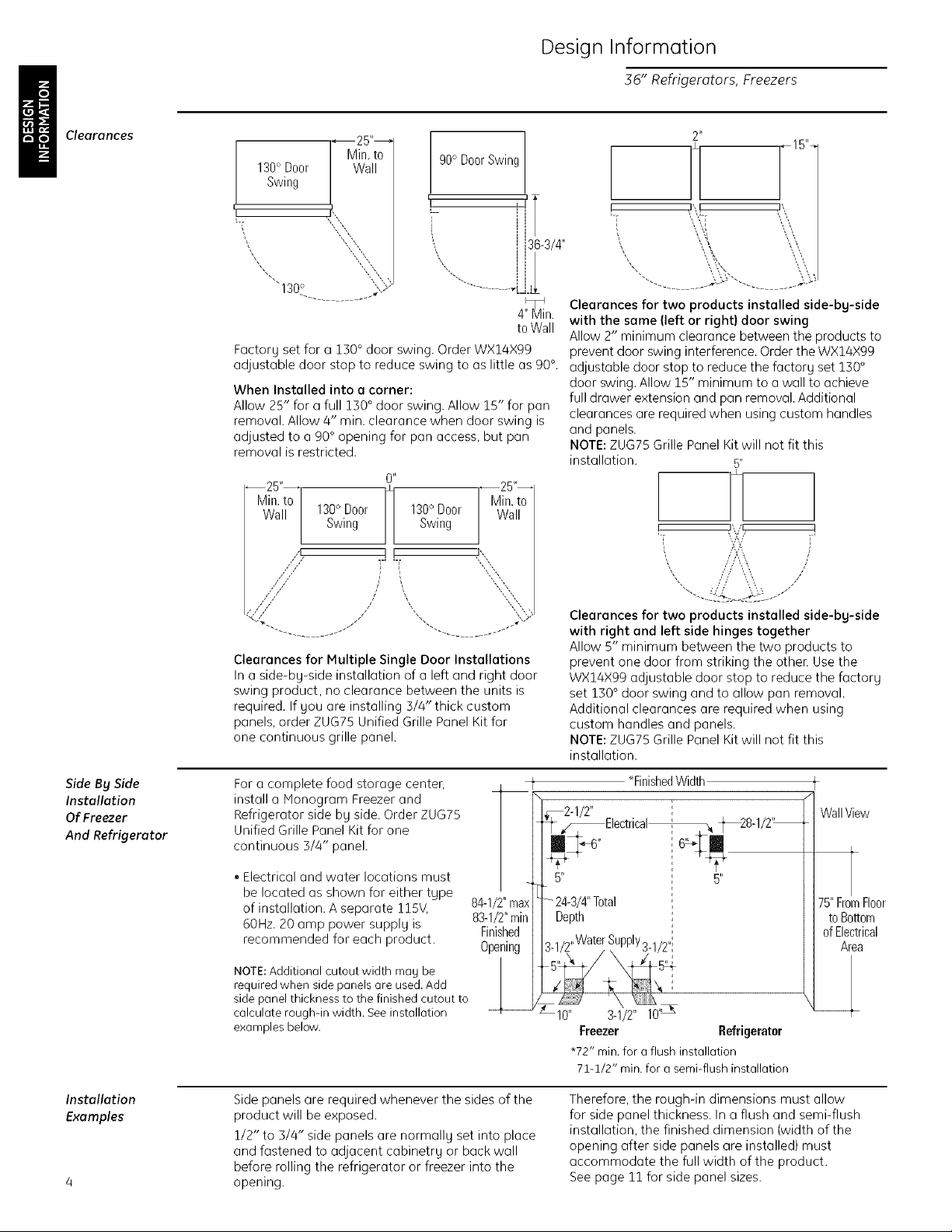

Page 4

Design Information

36" Refrigerators, Freezers

Clearances

1

90° Door Swing /

130°D00rswing[ %'1°

!' i36-3/4"

130° ',.y

4"_Min.

to Wall

Factory set for a 150 ° door swing. Order WX14X99

adjustable door stop to reduce swing to as little as 90°.

When Installed into a corner:

Allow 25" for a full 130 ° door swing. Allow 15" for pan

removal. Allow 4" rain. clearance when door swing is

adjusted to a 90 ° opening for pan access, but pan

removal is restricted.

0 _

%%

Wa

130° Door m 130° Door

Swing m Swing

4 I',

z:ffx "::::-:::,,,,

::::::::z

///

,( ," ',3-"

_q

II

q-' '-F

i

/

/

Z

Clearances for Multiple Single Door Installations

In a side-by-side installation of a left and right door

swing product, no clearance between the units is

required. If you are installing 3/4" thick custom

panels, order ZUG75 Unified Grille Panel Kit for

one continuous grille panel.

--25"--

Min. to

Wall

"X

",',,

2 _

\,,',,,[ '_,',

', \

..... *,, ,,,

Clearances for two products installed side-by-side

with the same (left or right} door swing

Allow 2" minimum clearance between the products to

prevent door swing interference. Order the WX14X99

adjustable door stop to reduce the factory set 130 °

door swing. Allow 15" minimum to a wall to achieve

full drawer extension and pan removal. Additional

clearances are required when using custom handles

and panels.

NOTE: ZUG75 Grille Panel Kit will not fit this

installation. 5"

!

3'

/

", .... X/

ft '

x-.... .......,

Clearances for two products installed side-bg-side

with right and left side hinges together

Allow 5" minimum between the two products to

prevent one door from striking the othel: Use the

WX14X99 adjustable door stop to reduce the factory

set 150 ° door swing and to allow pan removal.

Additional clearances are required when using

custom handles and panels.

NOTE: ZUG75 Grille Panel Kit will not fit this

installation.

Side By Side

Installation

Of Freezer

And Refrigerator

Installation

Examples

For a complete food storage center,

install a Honogram Freezer and

Refrigerator side by side. Order ZUG75

Unified Grille Panel Kit for one

continuous 5/4" panel.

, Electrical and water locations must

be located as shown for either type

of installation. A separate 115V,

60Hz. 20 amp power suppl U is

recommended for each product.

NOTE: Additional cutout width may be

required when side panels are used. Add

side panel thickness to the finished cutout to

calculate rough-in width. See installation

examples below.

Side panels are required whenever the sides of the

product will be exposed.

1/2" to 5/4" side panels are normally set into place

and fastened to adjacent cabinetry or back wall

before rolling the refrigerator or freezer into the

opening.

f _FinishedWidth

84-1/2" maxI_- 24-3/4" Total !

83-1/2"rain I I Depth

Finished II , _ , i

Opening I I I-1/2"vvate_,bupP'Y3-1/2";

_2 3-I/2" 10'_

1_2-1/2" i

I_ _Electrical% _28-1/2 '_

Freezer Refrigerater

*72" rain. for a flush installation

7:[-:[/2" rain. for a semi-flush installation

Therefore, the rough-in dimensions must allow

for side panel thickness. In a flush and semi-flush

installation, the finished dimension (width of the

opening after side panels are installed) must

accommodate the full width of the product.

See page 11 for side panel sizes.

WallView

75"FromFloor

toBottom

ofElectrical

Area

Page 5

Design Information

36" Refrigerators, Freezers

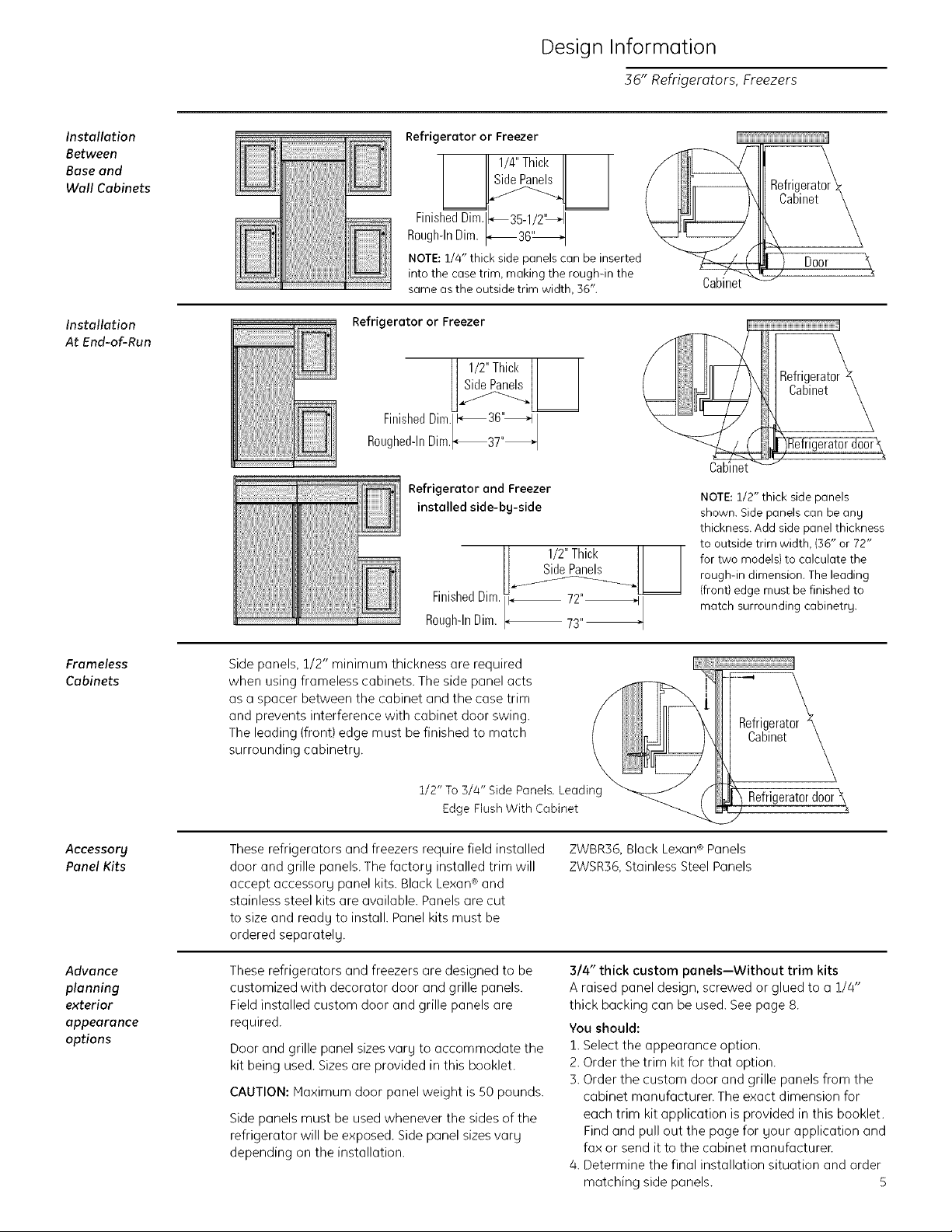

Installation

Between

Base and

Wall Cabinets

Installation

At End-of-Run

Refrigerator or Freezer

R°ugh-lnFinishedDim[lDim._ I_1

NOTE: 1/4" thick side panels can be inserted

into the case trirn, making the rough-in the

same as the outside trim width, 36".

Refrigerator or Freezer

Refrigerator and Freezer

installed side-bg-side

P

Cabi,n

Cab

NOTE: 1/2" thick side panels

shown. Side panels can be ang

thickness. Add side panel thickness

to outside trim width, (36" or 72"

for two models} to calculate the

rough-in dimension. The leading

(front} edge must be finished to

rnatch surrounding cabinetry.

Frameless

Cabinets

Accessory

Panel Kits

Advance

planning

exterior

appearance

options

Side panels, 1/2" minimum thickness are required

when using frameless cabinets. The side panel acts

as a spacer between the cabinet and the case trim

and prevents interference with cabinet door swing.

The leading (front) edge must be finished to match

surrounding cabinetrg. _.

1/2" To 3/4" Side Panels. Leading _

Edge Flush With Cabinet

These refrigerators and fi-eezers require field installed

door and grille panels. The factorg installed trim will

accept accessorg panel kits. Black Lexan ®and

stainless steel kits are available. Panels are cut

to size and readg to install Panel kits must be

ordered separatelg.

These refrigerators and freezers are designed to be

customized with decorator door and grille panels.

Field installed custom door- and grille panels are

required.

Door and grille panel sizes varg to accommodate the

kit being used. Sizes are provided in this booklet

ZWBR36, Black Lexan®Panels

ZWSR36,Stainless Steel Panels

3/4" thick custom panels--Without trim kits

A raised panel design, screwed or glued to a 1/4"

thick backing can be used. See page 8.

You should:

1. Select the appearance option.

2. Order the trim kit for that option.

3. Order the custom door and grille panels from the

CAUTION: Maximum door panel weight is 50 pounds.

Side panels must be used whenever- the sides of the

refrigerator will be exposed. Side panel sizes varg

depending on the installation.

cabinet manufacturer. The exact dimension for

each trim kit application is provided in this booklet.

Find and pull out the page for gour application and

fax or send it to the cabinet manufacturen

4. Determine the final installation situation and order

matching side panels. 5

R ir erat0rk

Cabinet k

Refrigerator door \

Page 6

Design Information

36" Refrigerators, Freezers

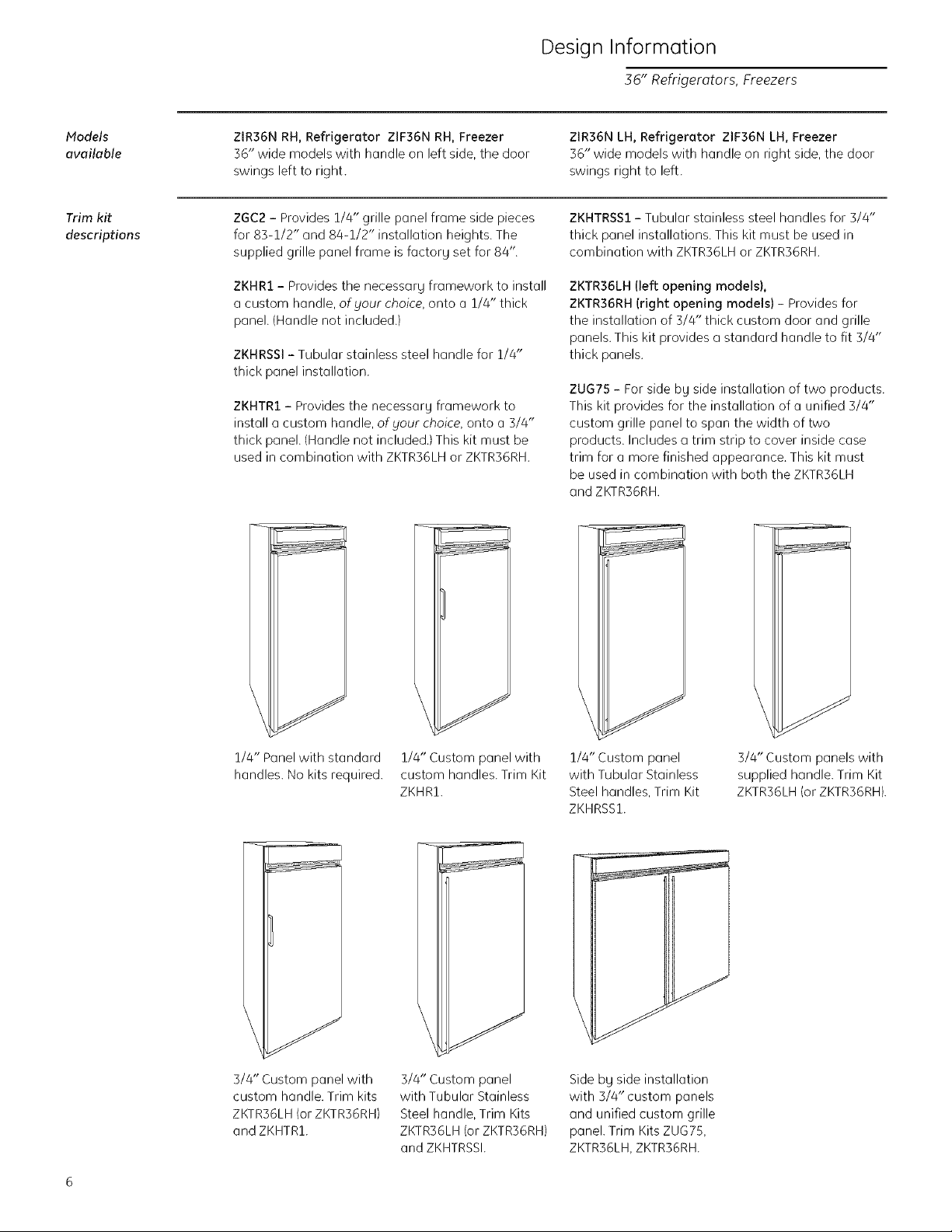

Models

availa61e

Trim kit

descriptions

ZIR36N RH, Refrigerator ZIF36N RH, Freezer

36" wide models with handle on left side, the door

swings left to right.

ZGC2 - Provides 1/4" grille panel frame side pieces

for 83-1/2" and 88-1/2" installation heights. The

supplied grille panel frame is factorg set for 84".

ZKHR1 - Provides the necessarg framework to install

u custom handle, of your choice, onto u 1/4" thick

panel. (Handle not included.)

ZKHRSSl - Tubular stainless steel handle for 1/4"

thick panel installation.

ZKHTR1 - Provides the necessar Uframework to

install a custom handle, ofgour choice, onto a 3/4"

thick panel. (Handle not included.) This kit must be

used in combination with ZKTR36LH or ZKTR36RH.

ZIR36N LH, Refrigerator ZIF36N LH, Freezer

36" wide models with handle on right side, the door

swings right to left.

ZKHTRSS1- Tubular stainless steel handles for 3/4"

thick panel installations. This kit must be used in

combination with ZKTR36LHor ZKTR36RH.

ZKTR36LH (left opening models),

ZKTR36RH (right opening models) - Provides for

the installation of 5/4" thick custom door and grille

panels. This kit provides a standard handle to fit 5/4"

thick panels.

ZUG75 - For side b9 side installation of two products.

This kit provides for the installation of u unified 3/4"

custom grille panel to spun the width of two

products. Includes a trim strip to cover inside case

trim for u more finished appearance. This kit must

be used in combination with both the ZKTR36LH

and ZKTR36RH.

1/4" Panel with standard 1/4" Custom panel with

handles. No kits required, custom handles. Trim Kit

ZKHRZ.

3/4" Custom panel with

custom handle. Trim kits

ZKTR36LH (or ZKTR36RH)

and ZKHTR1.

3/4" Custom panel

with Tubular Stainless

Steel handle, Trim Kits

ZKTR36LH (or ZKTR36RH)

and ZKHTRSSI.

1/4" Custom panel

with Tubular Stainless

Steel handles, Trim Kit

ZKHRSS1.

Side by side installation

with 3/4" custom panels

and unified custom grille

panel. Trim Kits ZUG75,

ZKTR36LH, ZKTR36RH.

3/4" Custom panels with

supplied handle. Trim Kit

ZKTR36LH (or ZKTR36RH).

Page 7

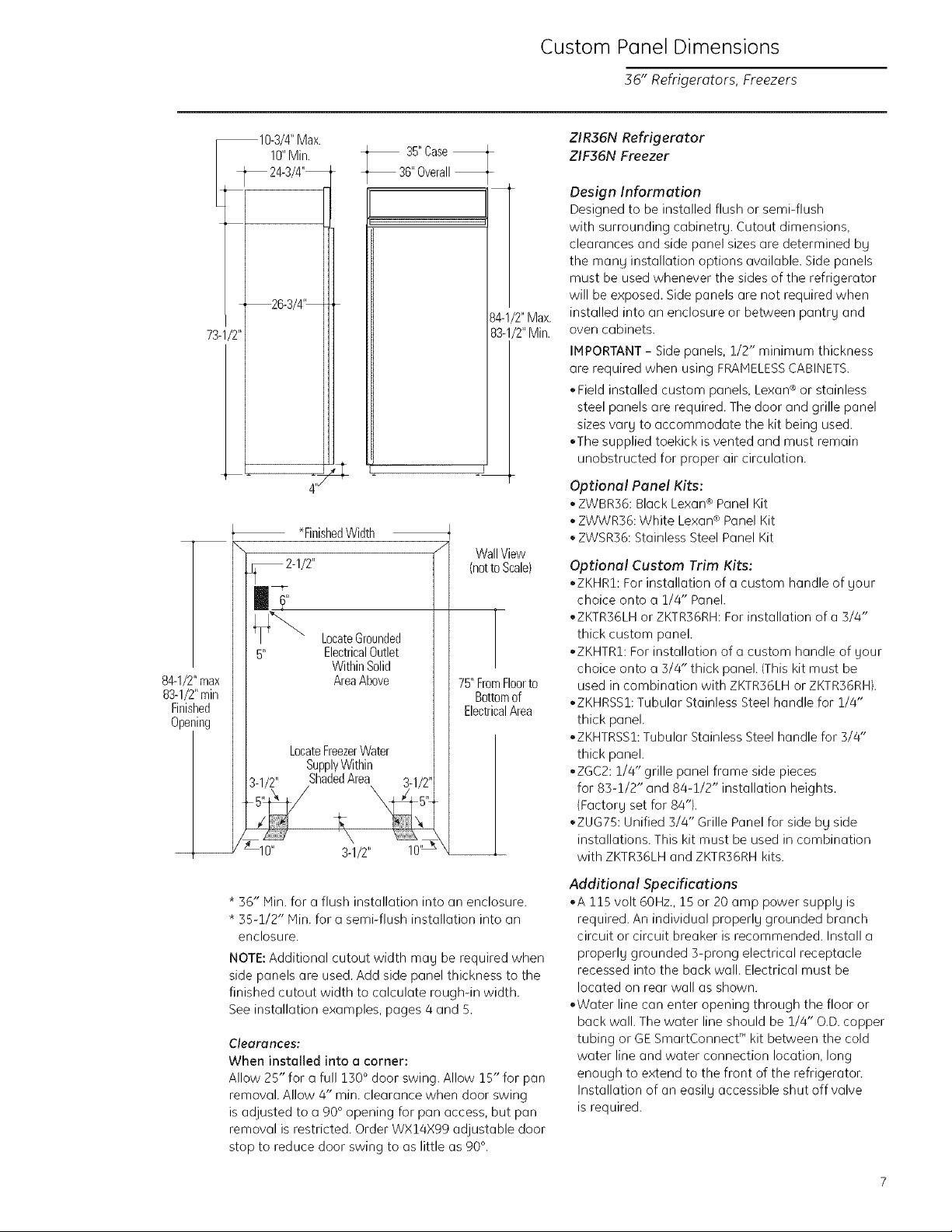

Custom Panel Dimensions

36" Refrigerators, Freezers

10-3/4" Max.

10"Min.

_ 24-3/4"_

26-3/4'--

73-1/2"

35" Case f

36" Overall

4,_

_FinishedWidth

2-1/2"

Ii I I'_ LocateGrounded

I I 5" Electrical0utlet I

84-1/2" max I I AreaAbove I

83-1/2"min I I I

Finished I I I

Opening I I

I I Within Solid I

I I LocateFreezerWater I

I I SupplyWithin I

I I S-1/2" ShadedArea 3-1/2"/

J/_ 10" 3-1/2" 10" = \__

84-1/2"Max.

83-1/2"Min.

Wall View

(n0tt0 Scale)

75"FromFloorto

Bottomof

ElectricalArea

ZIR36N Refrigerator

ZIF36N Freezer

Design Information

Designed to be installed flush or semi-flush

with surrounding cobinetrg. Cutout dimensions,

clearances and side panel sizes are determined bg

the mang installation options available. Side panels

must be used whenever the sides of the refrigerator

will be exposed. Side panels are not required when

installed into an enclosure or between puntr U and

oven cabinets.

IMPORTANT - Side panels, 1/2" minimum thickness

are required when using FRAMELESS CABINETS.

* Field installed custom panels, Lexan ® or stainless

steel panels are required. The door and grille panel

sizes vary to accommodate the kit being used.

,,The supplied toekick is vented and must remain

unobstructed for proper air circulation.

Optional Panel Kits:

* ZWBR36: Black Lexan ® Panel Kit

* ZWWR36: White Lexan ® Panel Kit

* ZWSR36: Stainless Steel Panel Kit

Optional Custom Trim Kits:

*ZKHRI: For installation of a custom handle of gour

choice onto a 1/4" Panel.

*ZKTR36LH or ZKTR36RH: For installation of a 3/4"

thick custom panel.

*ZKHTRI: For installation of a custom handle of your

choice onto a 3/4" thick panel. (This kit must be

used in combination with ZKTR36LH or ZKTR36RH).

*ZKHRSSI: Tubular Stainless Steel handle for 1/4"

thick panel.

*ZKHTRSSI: Tubular Stainless Steel handle for 3/4"

thick panel.

*ZGC2: 1/4" grille panel frame side pieces

for 83-1/2" and 84-1/2" installation heights.

{Factory set for 84'9.

*ZUG75: Unified 3/4" Grille Panel for side by side

installations. This kit must be used in combination

with ZKTR36LH and ZKTR36RH kits.

* 36" Min. for a flush installation into an enclosure.

* 55-1/2" Nin. for e semi-flush installation into an

enclosure.

NOTE: Additional cutout width ma U be required when

side panels are used. Add side panel thickness to the

finished cutout width to calculate rough-in width.

See installation examples, pages 4 and 5.

C]eclrclnces:

When instalJed into a corner:

Allow 25" for a full 130 ° door swing. Allow 15" for pan

removal. Allow 4" rain. clearance when door swing

is adjusted to a 90 ° opening for pan access, but pan

removal is restricted. Order WX14X99 adjustable door

stop to reduce door swing to as little as 90 °.

Additional Specifications

*A 115 volt 60Hz., 15 or 20 amp power supply is

required. An individual properlg grounded branch

circuit or circuit breaker is recommended. Install a

properly grounded 3-prong electrical receptacle

recessed into the back wall. Electrical must be

located on rear wall as shown.

,Water line can enter opening through the floor or

back wall. The water line should be 1/4" O.D.copper

tubing or GE SmartConnect T_'kit between the cold

water line and water connection location, long

enough to extend to the front of the refrigeraton

Installation of an easily accessible shut off valve

is required.

Page 8

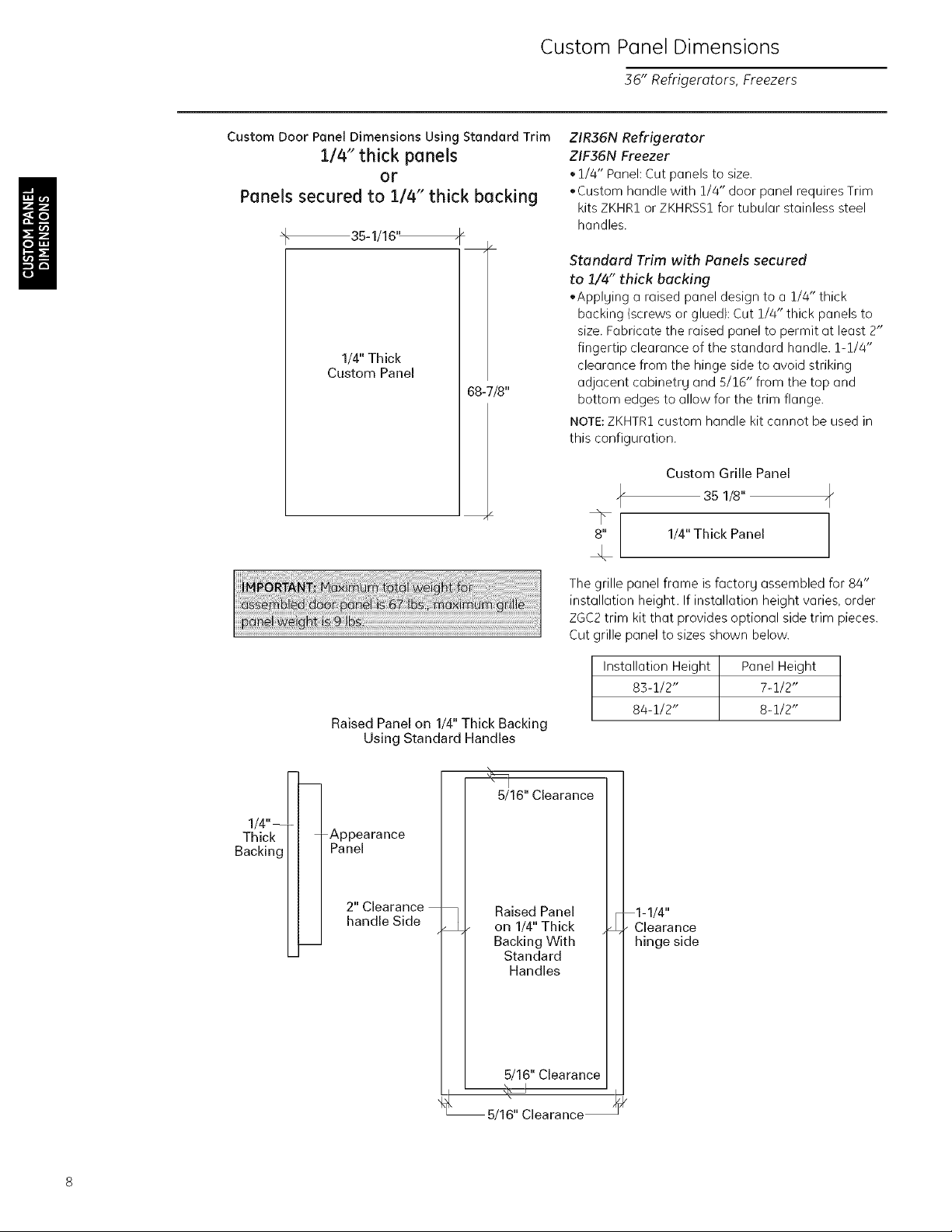

Custom Panel Dimensions

36" Refrigerators, Freezers

Custom Door Panel Dimensions Using Standard Trim

1/4" thick panels

or

Panels secured to 1/4"thickbacking

35-1/16'_

1/4" Thick

Custom Panel

68-7/8"

ZIR36N Refrigerator

ZIF36N Freezer

,1/4" Panel: Cut panels to size.

,Custom handle with 1/4" door pQnel requires Trim

kits ZKHR1 or ZKHRSS1 for tubular stQinless steel

handles.

Standard Trim with Panels secured

to 1/4" thick backing

,Applging a raised panel design to a 1/4" thick

backing (screws or glued): Cut 1/4" thick panels to

size. Fabricate the raised panel to permit at least 2"

fingertip clearance of the standard handle. 1-1/4"

clearance from the hinge side to (]void striking

adjacent cubinetrg and 5/16" from the top and

bottom edges to allow for the trim flange.

NOTE:ZKHTR1custom handle kit cannot be used in

this configuration.

Custom Grille Panel

35 1/8"

8" 1/4" Thick Panel

The grille panel frame is factory assembled for 84"

installation height. If installation height varies, order

ZGC2 trim kit that provides optional side trim pieces.

Cut grille panel to sizes shown below.

Raised Panel on 1/4" Thick Backing

Using Standard Handles

\

_1 "_._/16" Clearance

BTa'!i_i'nkg[ [ T APnPla ra nce

II I 2 Clearance

L_l handle Side _ I Raised Panel

L t on I/4" Thick

| Backing With

/ 5/16 Clearance

t_ 5/16" Clearance

Installation Height Panel Height

83-1/2" 7-1/2"

84-1/2" 8-1/2"

1-1/4"

Clearance

hinge side

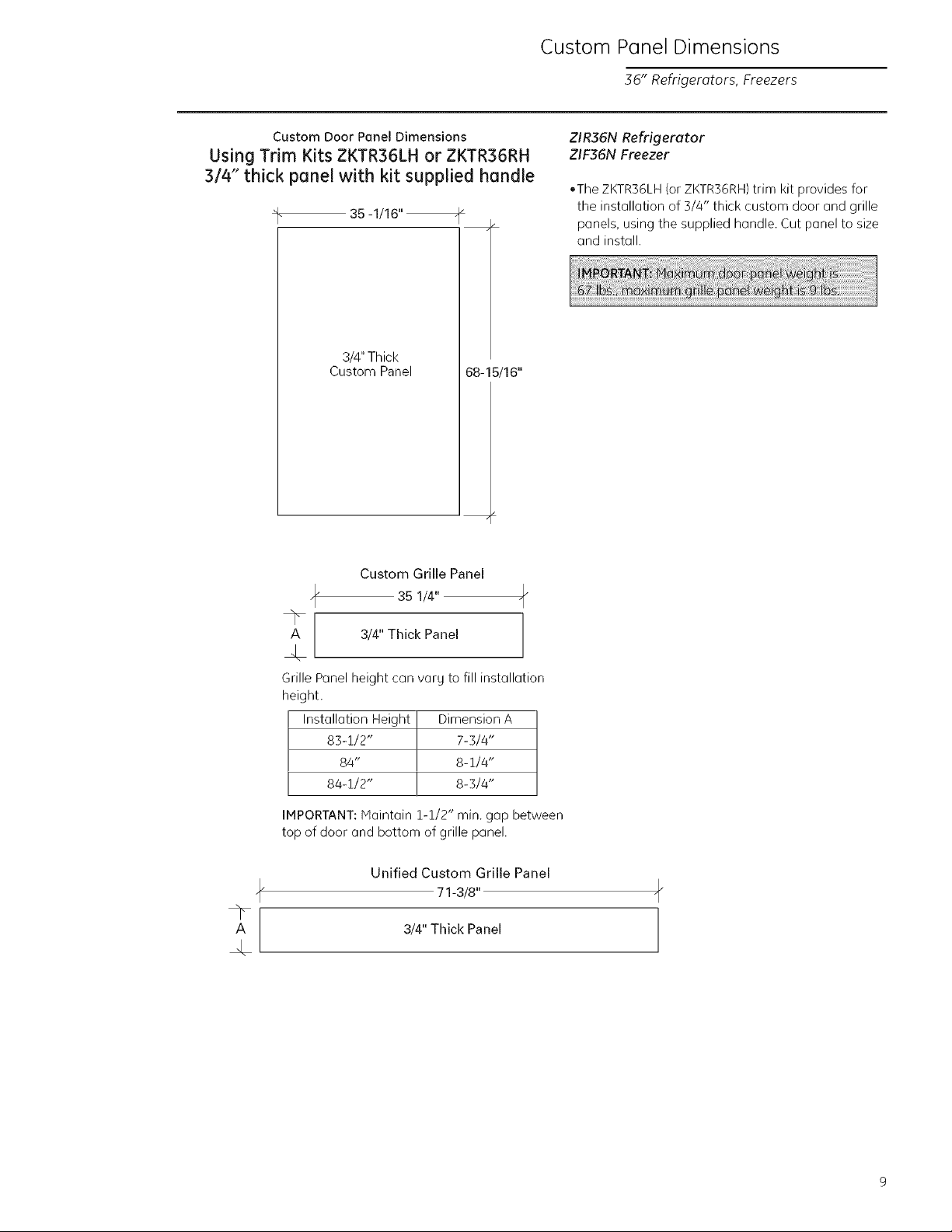

Page 9

Custom Panel Dimensions

36" Refrigerators, Freezers

Custom Door Panel Dimensions

Using Trim Kits ZKTR36LH or ZKTR36RH

3/4" thick panel with kit supplied handle

_F 35 -1/16" _

3/4" Thick

Custom Panel

Custom Grille Panel

35 1/4"

mL

68-15/16"

"r

A 3/4" Thick Panel

ZIR36N Refrigerator

ZIF36N Freezer

.The ZKTR36LH (or ZKTR36RH) trim kit provides for

the installation of 3/4" thick custom door and grille

panels, using the supplied handle. Cut panel to size

and install.

Grille Panel height con vary to fill installation

height.

Installation Height

83-1/2"

84"

84-1/2"

IMPORTANT: Maintain 1-1/2" min. gap between

top of door and bottom of grille panel.

UnifiedCustom Grille Panel

A

Dimension A

7-3/4"

8-1/4"

8-3/4"

71-3/8"

3/4" Thick Panel

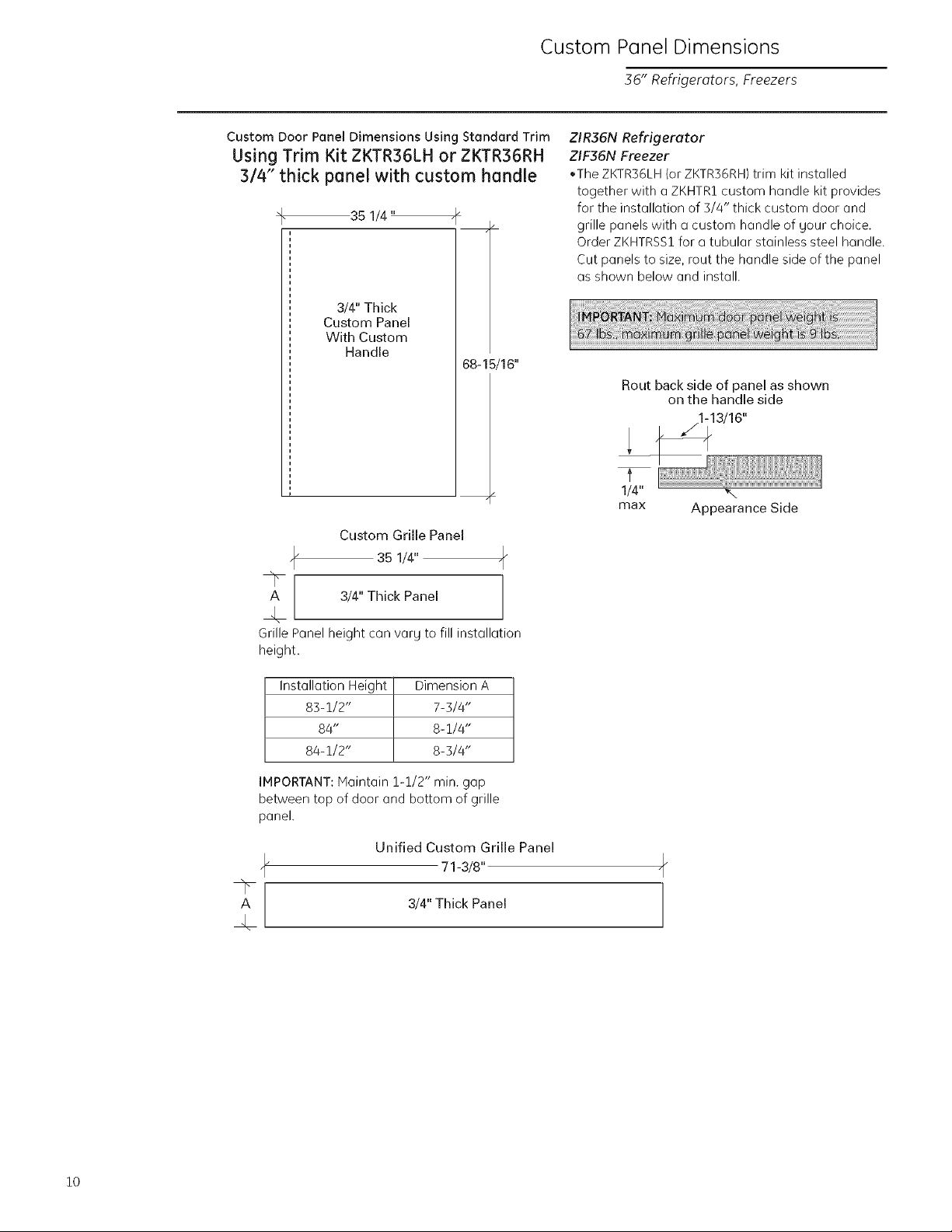

Page 10

Custom Panel Dimensions

36" Refrigerotors, Freezers

Custom Door Panel Dimensions Using Standard Trim

Using Trim Kit ZKTR36LH or ZKTR36RH

3/4" thick panel with custom handle

4" 35 1/4" ._"

3/4" Thick

Custom Panel

With Custom

Handle

68-15/16"

Custom Grille Panel

35 1/4"

ZIR36N Refrigerator

ZIF36N Freezer

.The ZKTR36LH (or ZKTR36RH) trim kit installed

together with a ZKHTR1 custom hQndle kit provides

for the instollQtion of 3/4" thick custom door and

grille panels with a custom handle of gour choice.

Order ZKHTRSS1 for a tubular stainless steel handle.

Cut panels to size, rout the handle side of the panel

as shown below and install.

Rout back side of panel as shown

on the handle side

1/4" ,%

max Appearance Side

A 3/4" Thick Panel

Grille Panel height con varg to fill instollation

height.

Installation Height Dimension A

83-1/2" 7-3/4"

84" 8-1/4"

84-1/2" 8-3/4"

IMPORTANT: Maintain 1-1/2" min. gap

between top of door and bottom of grille

panel.

Unified Custom Grille Panel

71-3/8"

3/4" Thick Panel

10

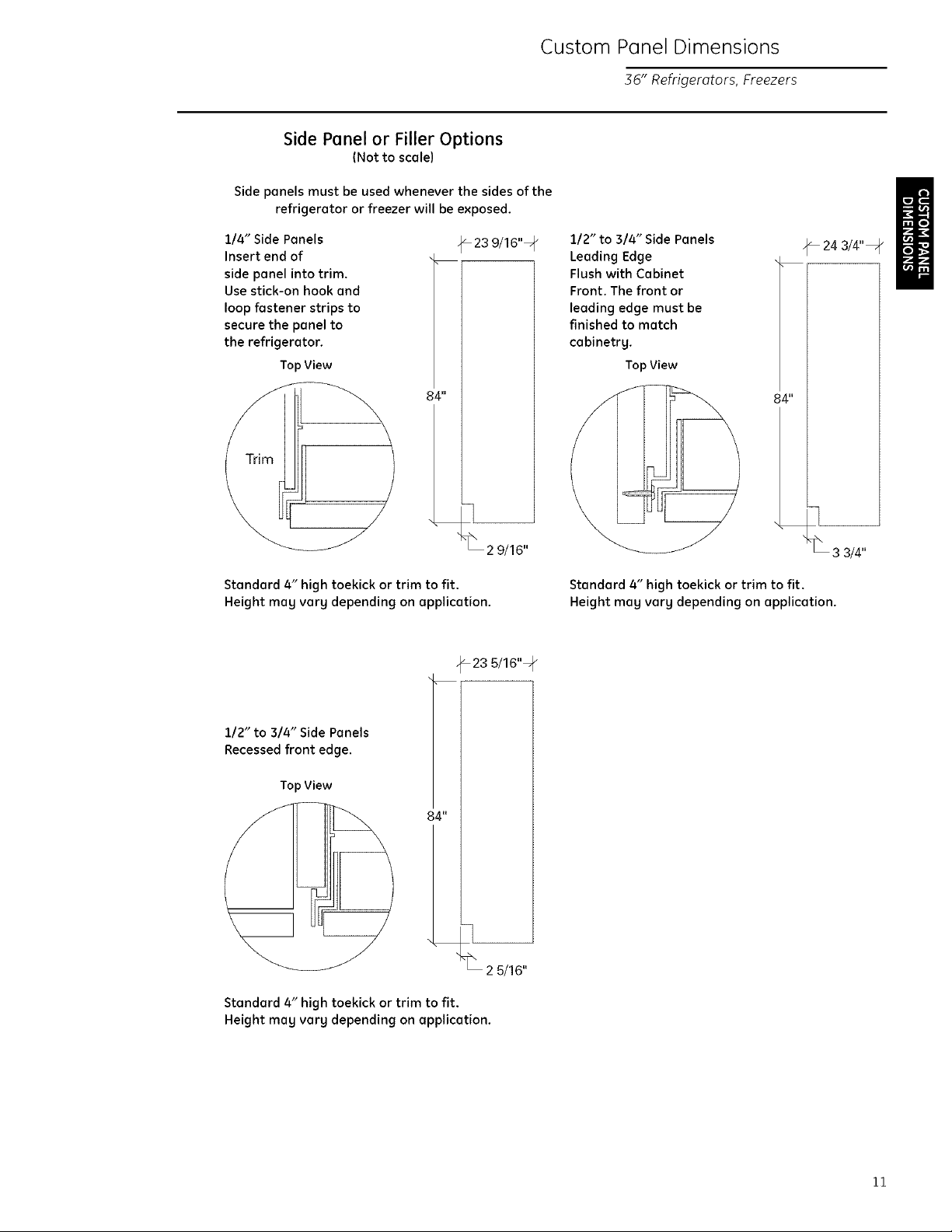

Page 11

Side Panel or Filler Options

(Not to scale)

Side panels must be used whenever the sides of the

refrigerator or freezer will be exposed.

Custom Panel Dimensions

36" Refrigerators, Freezers

114" Side Panels

Insert end of

side panel into trim.

Use stick-on hook and

loop fastener strips to

secure the panel to

the refrigerator.

Top View

84"

Standard 4" high toekick or trim to fit.

Height may vary depending on application.

23 9/16"1 p

2 9/16"

_23 5/16"=

112" to 314" Side Panels

Leading Edge

Flush with Cabinet

Front. The front or

leading edge must be

finished to match

cabinetry.

Top View

84"

Standard 4" high toekick or trim to fit.

Height mag vary depending on application.

_24 3/4"_

1/2" to 3/4" Side Panels

Recessed front edge.

Top View

84"

Standard 4" high toekick or trim to fit.

Height may vary depending on application.

2 5/16"

11

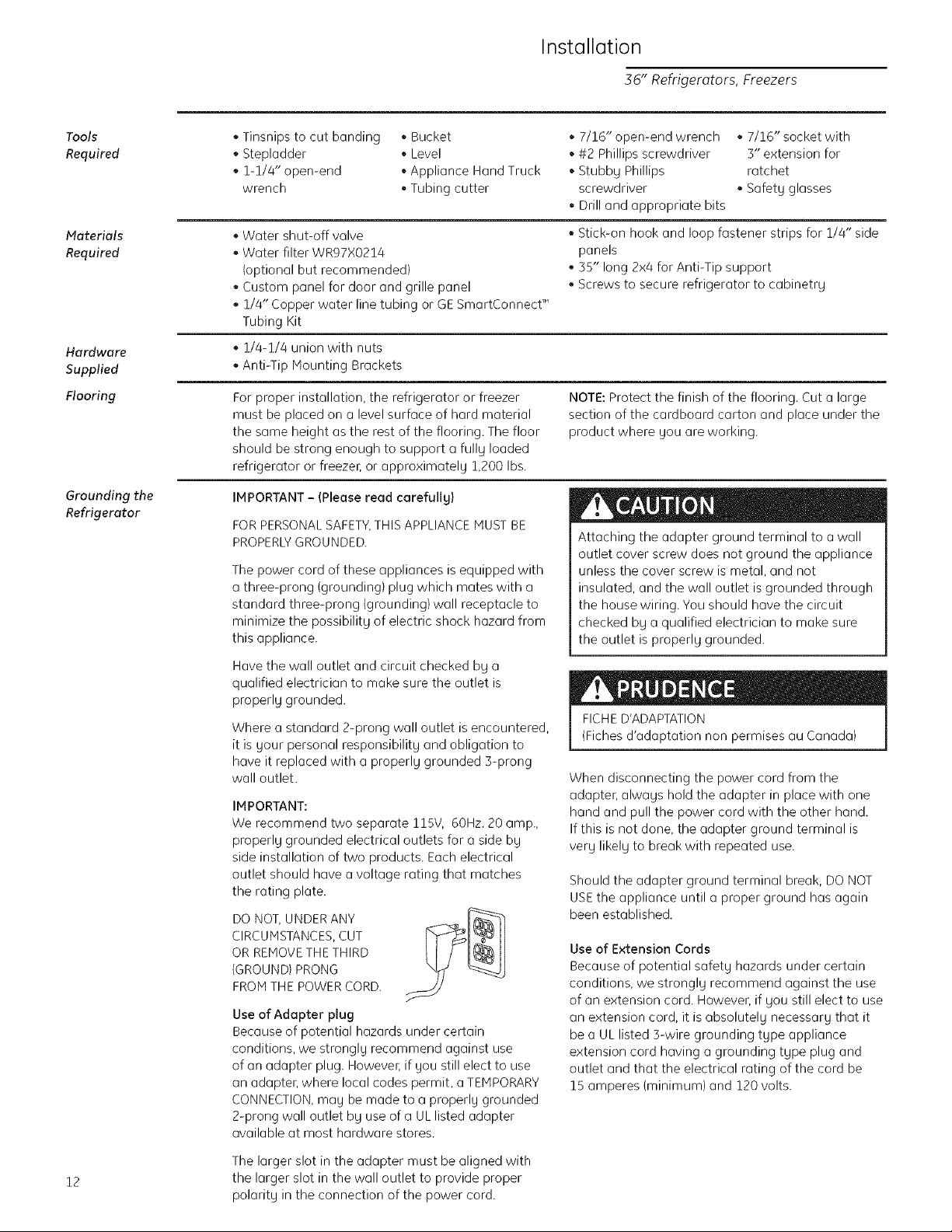

Page 12

Installation

36" Refrigerators, Freezers

Tools

Required

Materials

Required

Hardware

Supplied

Flooring

Grounding the

Refrigerator

, Tinsnips to cut banding , Bucket

, Stepladder , Level

,1-1/4" open-end , Appliance Hand Truck

wrench , Tubing cutter

, Water shut-off valve

, Water filter WRg7X0214

(optional but recommended)

, Custom panel for door and grille panel

,1/4" Copper water line tubing or GE SmartConnecf"

Tubing Kit

,1/4-1/4 union with nuts

, Anti-Tip Mounting Brackets

For proper installation, the refrigerator or freezer

must be placed on a level surface of hard material

the same height as the rest of the flooring. The floor

should be strong enough to support a fullg loaded

refrigerator or freezer, or approximatel U 1,200 Ibs.

IMPORTANT- (Please read carefullg)

FOR PERSONAL SAFETY, THIS APPLIANCE MUST BE

PROPERLYGROUNDED.

The power cord of these appliances is equipped with

a three-prong {grounding) plug which mates with a

standard three-prong {grounding) wall receptacle to

minimize the possibilitg of electric shock hazard from

this appliance.

Have the wall outlet and circuit checked bg a

qualified electrician to make sure the outlet is

properlg grounded.

Where a standard 2-prong wall outlet is encountered,

it is gour personal responsibilitg and obligation to

have it replaced with a properlg grounded 3-prong

wall outlet.

IMPORTANT:

We recommend two separate l15V, 60Hz. 20 amp.,

properlg grounded electrical outlets for a side bg

side installation of two products. Each electrical

outlet should have a voltage rating that matches

the rating plate.

DO NOT, UNDER ANY

CIRCUMSTANCES, CUT

OR REMOVE THE THIRD

{GROUND) PRONG

FROM THE POWER CORD.

Use of Adapter plug

Because of potential hazards under certain

conditions, we stronglg recommend against use

of an adapter plug. However, if gou still elect to use

an adapter, where local codes permit, a TEMPORARY

CONNECTION,mag be made to a properlg grounded

2-prong wall outlet bg use of a UL listed adapter

available at most hardware stores.

,7/16" open-end wrench ,7/16" socket with

, #2 Phillips screwdriver 3" extension for

, Stubbg Phillips ratchet

screwdriver , Safet U glasses

, Drill and appropriate bits

, Stick-on hook and loop fastener strips for 1/4" side

panels

,35" long 2x4 for Anti-Tip support

, Screws to secure refrigerator to cabinetrg

NOTE: Protect the finish of the flooring. Cut a large

section of the cardboard carton and place under the

product where gou are working.

Attaching the adapter ground terminal to a wall

outlet cover screw does not ground the appliance

unless the cover screw is metal, and not

insulated, and the wall outlet is grounded through

the house wiring. You should have the circuit

checked bg a qualified electrician to make sure

the outlet is properlg grounded.

FICHED'ADAPTATION

(Fiches d'adaptation non permises au Canada)

When disconnecting the power cord from the

adapter, alwags hold the adapter in place with one

hand and pull the power cord with the other hand.

If this is not done, the adapter ground terminal is

verg likelg to break with repeated use.

Should the adapter ground terminal break, DO NOT

USE the appliance until a proper ground has again

been established.

Use of Extension Cords

Because of potential safetg hazards under certain

conditions, we stronglg recommend against the use

of an extension cord. However, if gou still elect to use

an extension cord, it is absolutel U necessar U that it

be a UL listed 3-wire grounding tgpe appliance

extension cord having a grounding tgpe plug and

outlet and that the electrical rating of the cord be

15 amperes {minimum) and 120 volts.

12

The larger slot in the adapter must be aligned with

the larger slot in the wall outlet to provide proper

polarit U in the connection of the power cord.

Page 13

Step 1

Remove

Packaging

Refrigerator and freezer is much heavier at the

top than at the bottom - be careful when moving.

When using a hand truck, handle from side only.

Le r6frig_rateur est beaucoup plus Iourd en

haut qu'en bas. II faut &tre prudent Iors des

d_placements. Si un diable est utilis_, il faut

soulever le r_frig_rateur sur le c6t6 seulement.

,, Remove outer carton.

- Carefullg cut banding at the top and bottom.

. Slideout back comer posts (2).

. Slidecarton off top of cabinet.

NOTE:IT ISNOTNECESSARYTOLAYCABINETDOWN

IN ORDERTO REMOVESKID!

. The unit is secured to the skid with 4 slotted tie-

down straps. First remove the 5/16" bolts from the

base channels in the tie-downs, then remove the

7/16" bolts securing the straps to the skid.

. Protect the flooring. Cut a large piece of the

cardboard carton and place under the product.

. Support blocks on the bottom must be removed

before the refrigerator is taken off the skid or

damage will occun Remove support blocks bg

carefullg tilting cabinet to side and sliding out.

Installation

36" Refrigerators, Freezers

7/16"B0k

S

• Lift the refrigerator off the skid with an appliance

dollg. Handle from the sides.

DO NOT ATTEMPT TO ROLL UNIT OFF SKID.

IL NE FAUT PAS ESSAYER DE FAIRE ROULER LE

REFRIGERATEUR POUR UENLEVER DE LAY PALETTE.

13

Page 14

Installation

36" Refrigerators, Freezers

Step 2

Install

Water Line

, A cold water supplg is required for automatic

icemaker operation. The water pressure must be

between 20 and 120 p.s.i.

Route 1/4" OD copper or GESmartConnect TM

tubing between house cold water line and the

water connection location.

Tubing should be long enough to extend to

the front of the refrigerator. Allow enough to

accommodate bend leading into the water valve.

NOTE:The onlg GEapproved plastic tubing is

supplied in the GESmartConnect TM Refrigerator

Tubing kits. Do not use ang other plastic water

supplg line because the line is under pressure at all

times. Other tgpes of plastic mag crack or rupture

with age and cause water damage to gour home.

GE SmartConnect TM Refrigerator Tubing Kits are

available in the following lengths:

2' (.6 m) WXO8XIO002

6' (1.8 m) WXO8XIO006

15'(4.6m}WXO8XIO015

25' (7.6 m} WXO8XlO025

Shut off the main water supplg.

Turn on the nearest faucet long enough to clear the

line of water.

Install a shut-off valve between the icemaker

water valve and cold water pipe in a basement or

cabinet. The shut-off valve should be located where

it will be easilg accessible.

Turn on the main water supplg and flush debris

from the line. Run about a quart of water through

the tubing into a bucket. Shut off water at the

shut-off valve.

Waterline Tubing

Install optional water filter in the water line near the

refrigerator. A water filter is recommended in areas

where water supplg contains sand or particles.

Installation instructions are packed with the filter.

NOTE: Commonwealth of Massachusetts

Plumbing Codes 248CMR shall be adhered to. I

Saddle valves are illegal and use is not permitted in

Massachusetts. Consu t with sour icensed p umberj

14

NOTE:Saddle tgpe shut-off valves are included in

mang water supplg kits, but are not recommended

for this application.

Page 15

Installation

36" Refrigerators Freezers

Step 3

Install

Side Panels

Side panels are not required when the refrigerator

or freezer is installed into an enclosure Skip this

step if gou are installing into an enclosure

Side panels are required whenever the sides of the

refrigerator or freezer will be exposed and when

installed between frameless cabinets See pages

3 and 4

Side panel installation will be determined bg

the design of the side panel gou have previouslg

chosen

Side panels must be installed plumb

Illustration A

I

__)Refrigerator_

Cabinet _

Refrigeratordoor

Cabinet

1/4" Side panels - Insert end of side panel into case

trim. Fasten with stick-on hook and loop strips.

If gou choose to use 1/4"side panels theg should

be inserted into the case trim as illustrated Fasten

the panels to the refrigerator with stick on hook

and loop fastener strips before setting refrigerator

in place See illustration A

1/2" to 3/4" side )anels are normallg set into place

and fastened to adjacent cabinetrg or the back wall

before rolling the refrigerator into the opening See

illustration B

lllustration B

l[ie_rigerator'r_

1/2" to 3/4" Side Panels - Leading edge of side

panel is flush with cabinet front. Fasten to the back

wall using a cleat.

Step 4

Install

Anti-Tip

Brackets

ANTI-TIP PRECAUTIONS

The refrigerator is top-heavg and must be

secured to prevent the possibilitg of tipping

forward.

PRECAUTIONS CONTRE LES BASCULEMENTS

Le r6frig6rateur est beaucoup plus Iourd en

haut et il faut le maintenir en place pour 6viter

la possibilit6 de son basculement vers I'avant.

• Cut a 2" x 4" x 35" block and secure the block to

the mounting brackets provided using #12 or #14

wood screws

• Secure the bracket with wood block to the back

wall so that it is 84" (or gour installation height)

from the finished floon Use #12 or #14 wood

screws See illustration

• Screws must penetrate at least one inch into

vertical wall studs

• Before pushing the refrigerator into the opening

plug the power cord into the receptacle Open the

grille panel and reach into the opening at the back

to grasp the power cord Pull the power cord into

the opening as gou push the refrigerator back

• Gently push refrigerator into the opening with

hands against front corners

Brackets

Required

I

Height

Brackets

NotRequired

Beneatha

Soffit

From

Floor

to

Bottom

ofWood

Block

SideView

2 x 4 Cut _'_

35Length

Installation Mounting

Height Bracket

FromFloor

ScrewsMountedintojJ

VerticalWall Studs

IMPORTANT NOTE: When the refrigerator is installed

under a soffit or if there is not enough height for this

method of security brackets cannot be used Proceed

to step 5 to level the refrigerator and then to step 6 to

secure refrigerator to cabinets The refrigerator must

be secured to prevent tipping

15

Page 16

Installation

36" Refrigerators, Freezers

Step 5

Level

Refrigerator

or Freezer

Step 6

Secure

Refrigerator

or Freezer

to Sides

All models have 4-point leveling. The front is supported

bg leveling legs. the rear is supported bg wheels.

+Adjust rear wheels beneath the product to just barel U

touch the 2x8 block.

.Turn the 7/16" hex nut located above the front

wheels. Turn to raise or lower the refrigerator.

+For front leveling legs. use a 1-1/4" open-end

wrench.

+Adjust carefull U, the refrigerator should be level and

plumb with cabinetr U,and align with toekick height.

The rear leveling wheels and front leveling

legs are limited to a maximum height adjustment

of 1" Ifthe installation requires more than

84 1/2" height the installer should elevate the

refrigerator on a sheet of plgwood or runners

Cabinetrg trim could also be added across the

top of the opening to shorten the opening If gou

attempt to raise the refrigerator more than 1",

gou will damage the front leveling legs and the

rear leveling wheels.

NOTE: Whenever possible, /[7

perform this step for

additional anti-tip securitg.

This step can be used as an

alternate to Step 4, Anti-Tip

bracket installation, whenever

brackets cannot be used.

Hex Nut Adjusts _-_==:_:_=4, I

RearWheels jJ_ll I

Les roues de nivellement arri@re et les pattes

de nivellement avant permettent un r6glage

maximal de 25 mm (1 po). Si I'ouverture pour

le r6frig_rateur a une hauteur sup_rieure

6 2.15 m (84-1/2 po). I'installateur doit _lever

le r6frig&rateur sur une feuille de contre-plaqu_

ou des glissi@res. II est _galement possible

d'ajouter des baguettes de finition des placards

sur le haut de I'ouverture afin de la r6duire.

Lever le r6frig6rateur de plus de 25 mm (1 po)

endommage les pattes de nivellement avant

et les roues de nivellement arri@re.

o _0 ° o

_/ Refrigerator

O00r

Step 7

Connect

Freezer

Water

Supply

16

When using 1/2" to 3/4" side panels, the front flange

of the case trim is attached to the side panel.

+ Open door to access case trim.

+ Drill hole in trim slightlg below the interior opening.

Drive screw through the trim and into the side

panel.

• Locate and bring tubing to the front of the cabinet.

• Turn the water on to flush debris from line. Run

about a quart of water through tubing into a

bucket, then shut-off waten

Copper Tubing:

• Slip a 1/4" nut and ferrule (provided) over both ends

of the copper tubing Insert tube into the union

fitting on the unit and tighten nut to union

• Turn on the water to check for leaks

GE SmartConnect" Tubing:

• Insert the molded end of the tubing into the

refrigerator connection. Tighten the compression

nut until it is just hand tight.

• Tighten one additional turn with a wrench.

Overtightening can cause leaks!

• Turn on the water to check for leaks.

+ Follow the same procedure on the opposite side.

If the product is installed between cabinets with no

side panels or in a custom enclosure, install a spacer

block as shown.

NOTE: Make sure excess tubing length does not

interfere with toekick installation.

Page 17

Installation

36" Refrigerators, Freezers

Step 8

Install I/4"

door panels

Step 9

Check

Power

Step 10

Mount

Top Grille

Panel

If you are using a 3/4" thick custom panel, SKIPTHIS

STEP.See Custom Panel Dimensions pages for panel

sizes with ZKTR36LHor ZKTR36RHtrim kit and other

kits. Refer to trim kit instructions in this booklet.

• Open door to 90° stop. Remove the Phillips head

screws from the aluminum trim door handle.

• Remove handle. Retain all screws and handle.

• Slidecustom panel into the door trim.

• Replace door handle and secure with original

screws.

• Check to make sure power is on bU opening the

door to see if interior lights are on.

If you are using a 3/4" thick custom panel, SKIP THIS

STER See Dimensions and Specifications for grille

panel sizes. Order ZKTR36LH or ZKTR36RH and follow

the installation instructions packed with the kit.

The grille panel frame is factorg assembled for an

84" installation height. If installation height varies,

order ZGC2 trim kit which provides optional side trim

pieces for 83-1/2" and 88-1/2" heights.

Cut 1/4" thick custom panel to fit the frame,

35-1/8" wide, 8" deep {for an 84" installation).

i

Top CaseTrim

Raise T

Installation

Height

To insert custom grille panel into the frame:

, Remove screws (2 on each top corner) and "L"

brackets on each side.

• Slide panel into the frame and reassemble.

• Hount the grille panel bg dropping into slots on the

case trim.

• For shipping purposes, the top case trim is secured

at 84" installation height.

To raise case trim to 84-1/2" or to lower to 83-1/2"

installation height:

, Loosen 2 screws on both sides and raise the top or

lower case trim to meet soffit height or to the top of

adjacent cabinets.

• Tighten all 4 screws.

J

/

IMPORTANT: Maintain 1-1/2" min. gap between top

of doors and bottom of panel frame.

17

Page 18

Installation

36" Refrigerators, Freezers

Step 11

Adjust Door

Alignment

Step 12

Arrange Interior

and Set

Temperature

Controls

Step 13

Start

Icemaker

Check door alignment. The top of the door should

be parallel with the grille panel. If the door appears

to be too high or too low on the handle side,

adjustments can be made by turning the hinge.

• To raise the door, turn adjustable hinge pin

towards the right.

• To lower the dooL turn hinge pin towards the left.

Turn the hinge pin with a 5/16" wrench of-,on some

models, use the 3/16" Allen wrench taped to the

hinge.

• Remove internal packing materials.

• Remove tape from all shelves.

• Set control at "5".

IMPORTANT:Allow 24 hours for temperatures to

stabilize before making adjustments.

• Start the switch to I (on). The green light will come

on and the icemaker will begin operation

automaticallg.

• Be sure nothing interferes with the sweep of the

feeler arm.

• Discard the first few batches of ice cubes.

• To turn the icemaker off, set the switch to O (off).

Allow 45 minutes for the icemaker to resume

operation.

_, oorShouldbeParallel

With Grille Panel

Power Switch

o

3reen Power Light

5/16"Wrench

Step 14

Install

Toekick

18

, A standard toekick is supplied. Install with 2 screws

provided, adjust to desired height and tighten

screws.

IMPORTANT: The vented toekick must remain

unobstructed for proper air circulation and operation.

Page 19

This kit provides optional side trim pieces for the

original grille panel frame to fit 83-1/2" and 84-1/2"

installation heights.

To change grille panel size:

Determine the installation height bU measuring the

enclosure from the floor to the underside of soffit.

When there is no soffit, measure to the top of the

adjacent cabinets.

Adjust refrigerator case trim to desired height.

See Product Installation.

Select the side trim pieces for gour installation

height.

A. Locate original grille panel frame supplied with the

refrigeraton

Remove 8 screws (two on each corner) and "L"

brackets as illustrated.

B. Select correct set of side trim pieces

(2 sets provided).

Secure new side trim pieces to original bottom trim.

_4

Ill ---_- Barrel_ _. .

_:.L Nuts _ u!s,c_a

-_ _,ue ,r,r"_

feces

ZGC2 Trim Kit

Grille Panel Frame Adjustment

E. Mount the assembled panel bg dropping into slots

on the case trim.

/

IMPORTANT: Haintain 1-1/2" min. gap between top of

door and bottom of grille panel

C. Remove barrel nuts from original side trim pieces

(2 each side).

Reinstall the barrel nuts on the new side trim pieces

gou have selected. Discard original side trim.

\

D. Slide custom panel into front slots.

Secure the top trim piece to the frame with "L"

brackets and screws.

19

Page 20

ZKHR1 Trim Kit (For 1/4" Panels)

Support for Custom Handles

Step 1

Remove

handle

Tools and materials required:

#2 Phillips screwdriver

Drill and appropriate bits

Custom door panel

Custom Handle

Safetg glasses

Parts List:

A. Handle side door extrusion (for left hand models)

B. Handle side door extrusion (for right hand models)

This kit provides the necessarg framework to install

a custom handle, of 9our choice, onto a 1/4" thick

custom panel. {Handles not included.) The extrusions

in this kit allow the custom handle to be secured to

the door structure, rather than the door panel.

Select the extrusion for 9our model, discard other

extrusion.

Open door to 90 °. Remove the screws from the full

length aluminum handle.

Retain screws. Discard handle.

Right hand door swing models are illustrated in these

instructions. Follow these instructions for left hand

models.

2O

Page 21

Step 2

Locate

handle

position

ZKHR1 Trim Kit (For 1/4" Panels)

Support for Custom Handles

i.°

3/4" Min.

1-1/2"Max.

Step ._

Assemble

panel

extrusion

and handle

Slide custom panel into the door trim.

Temporaril U secure the new handle extrusion to the

door using at least 2 screws.

The custom handles must be located 3/4" to 1-1/2"

from the edge of the extrusion.

Dec0rat0r_ /

DoorPanel

Handle_ .....

Remove the handle extrusion end custom panel.

Drill 1/16" pilot hole through extrusion.

Drill clearance holes through the panel and

extrusion.

Assemble the door panel, extrusion and custom

handle.

Install screw(s)long enough to pass through the

extrusion, door panel and into the handle.

Slide the assembl U into the door frame until the

new extrusion fits firml U against the steel doon

Reinstall original screws into the door extrusion.

_Extrusi0n

3/a," IVlln.

" Max.

Determine the desired location of the custom

handle and mark centerlines of the screw holes.

Drill 1/16" pilot hole through the panel until it starts

into the aluminum extrusion. This will mark the

matching location for drilling the clearance hole

when assembling the handle, panel and extrusion.

Screw

Decorator

Door _.-/

Panel

21

Page 22

ZKTR36LH/ZKTR36RH Trim Kit

3/4" Custom Ponds

Kit Contents

Right hand door swing models are illustrated in these This kit provides for the installation of 3/4" thick

instructions. Follow these instructions for left hand custom door and grille panels. Handles are included

models, and must replace the supplied handles.

Tools and materials

required:

, #2 Phillips screwdriver

, Drill and appropriate

bits

, Custom door panels

, Putty knife

, Safety glasses

7/16" wrench

Parts List

A.Top trim

B. Handle side trim

C. Hinge side trim

D Bottom trim

E.Support bracket for

custom panel

F.4-3/8" screws for

support brackets

G.Grille support

panel and screws

G

H

P

H. Wood screws #6

1/2" flat head

screws (30)

Step 1

Remove

handles

and trim

NOTE: If you are using a custom handle, see ZKHTR1

installation instructions. For a tubular stainless steel

handle, see ZKHTRSS1 installation instructions.

Open door to 90 °.

Remove the Phillips head screws from the full

length handle, remove and discard handle.

Retain screws.

Open the door fully to stop.

NOTE: Removal of actuator arm allows the door to

be opened wider, giving greater access to hinge

side trim.

Remove the screws from the aluminum trim, top

bottom and hinge side.

Retain screws. Discard original trim and handle.

22

Page 23

ZKTRB6LH/ZKTRB6RH Trim Kit

3/4" Custom Ponds

Step 2

Install

3/4" trim

Step 5

Apply panel

support

brackets

, Attach the new 3/4" trim pieces on the top, hinge

side and bottom using original screws.

, Position support bracket on the back side of the

custom panel, 14-5/16" from the hinge side. Secure

support bracket to panel with screws provided.

I

BackSideCustomPanel

Side

Bottom Edge

Step 4

Install

panels

I ,""

, Place the 3/4" thick panel on the bottom trim with

support bracket tabs inserted into slots. Push the

panel back against the steel door, flush with hinge

side trim.

, Open the door fullg.

, Carefullg drill 4 starter holes using a small drill bit,

through the backside of the trim at the top.

, Install original screws through the trim and into the

panel to secure the panel to the door.

, Drill 6 starter holes through the hinge side and

4 through the bottom trim. Install original screws.

r"

"'% %

23

Page 24

ZKTR36LH/ZKTR36RH Trim Kit

3/4" Custom Ponds

Step 5

Install

handles

Step 6

Adjust

grille

panel height

,, Install new door handle using original screws.

,, For shipping purposes, the top case trim is secured

at the 84" installation height.

. Loosen 2 screws on both sides of the case trim

and raise or lower trim to meet soffit height, from

83-1/2" to 84-1/2".

. Tighten all 4 screws.

IMPORTANT: Haintain 1-1/2" min. gap between top of

door and bottom of grille panel.

iiiiiiiiiiiiiiiiiiiil

TopCaseTrim

RaiseTo1

Installation

Height

Step 7

Secure 3/4"

panel to

grille panel

support

24

. Secure the grille panel support to the bock side of

the 3/4" custom panel with #6 screws.

, Be sure the lip of the support is over the top of the

wood panel.

Panel Support

/

/

/ /

/

/

/

/

/

/

/

Page 25

ZKTR36LH/ZKTR36RH Trim Kit

3/4" Custom Ponds

Step 8

Install

grille panel

,, Install four of the six larger undercut screws so that

the top of the screws ore 1/16" from the surfQce of

the support.

. Attach the assembled panel to the grille opening

by inserting the four protruding screws into the

brQckets on each side.

Back

Grille Panel Support _ "

1/16'_

25

Page 26

ZKHTR1 Trim Kit (For 3/4" Panels)

Support for Custom Handles

Kit Contents

Right hand door swing models are illustrated in these

instructions. Follow these instructions for left hand

models.

Tools and materials required:

, #2 Phillips screwdriver

, Drill and appropriate bits

, Custom door panel

, Custom handle

, Safet U glasses

NOTE: This kit must be used in combination with

ZKTR36LH or ZKTR36RH trim kit for 3/4" panel trim.

Part List:

A. Handle extrusion (for left hand models)

B. Handle extrusion {for right hand models}

This kit provides the necessar U framework to

install a custom handle, of gout choice, onto a 3/4"

thick decorator door panel. (Handles not included.)

The handle extrusion allows the custom handle to be

secured to the door structure, rather than the door

panel.

Select handle extrusion for sour model, discard

other extrusion.

Before

you begin

3/4" custom door panel must be routed to

accommodate these door handle extrusions. Rout

the panel as illustrated, 1/4" deep, and 1-13/16"wide

on the handle side.

Refer to installation instructions for ZKTR36LH or

ZKTR36RH trim kit for 3/4" custom panels:

Follow Step 1 to remove the standard

aluminum trim.

Follow Steps 2 and 3 to attach new 3/4" trim pieces

and to install panel support brackets.

Custom Panel

[_1-13/16"

1/4" Max,_l _ BackSide

I

Handle Side

IMPORTANT: Optimal final appearance depends on

careful routing depth. Do not exceed 1/4" routing depth.

26

Page 27

Step 1

Temporarily

mount door

panel

ZKHTR1 Trim Kit (For 3/4" Panels)

Support for Custom Handles

PIQce the prepared 3/4" custom door pQnel on the

bottom trim with support brqcket tabs inserted into

trim slots.

Push the panel back agQinst the steel door, making

sure the panel is flush with the hinge side trim.

Secure the panel to the trim temporaril U bU

driving 2 screws through the backside of the

trim at the top.

Slide the handle extrusion in between the panel

and steel door.

TemporQril 9 secure the extrusion to the door with

2 screws.

Step 2

Locate

position

of handle

Step

Assemble

panel,

extrusion

and handle

Determine the location of the custom

handles and carefull U mark centerlines

of the screw holes. The hQndles must be

located 3/4" to 1-1/2" from the edge of

the extrusion.

Drill 1/16" pilot hole through the panel until

it starts into the Qluminum extrusion. This

will mQrk the matching location for drilling

a cleQrance hole when assembling the

extrusion, panel and handle.

J

Remove the handle extrusion, the 2 temporarg

screws Qnd custom panel.

Drill 1/16" pilot hole through extrusion.

Drill clearance holes through the panel and

extrusion.

Assemble the panel, extrusion and custom handle.

Install screw(s} long enough to pass through the

extrusion, door panel qnd into the handle.

27

Page 28

Step 4

Mount

assem61ed

panel

I ¢I

Plqce Qssembled pcmel onto the bottom trim with

support bracket tubs inserted into slots.

Push the panel buck against the steel door with

hQndle extrusion flush to handle side of the door.

Open door full Uto stop.

Install original screws qt the top, hinge side and

hqndle side.

ZKHTR1 Trim Kit (For 3/4" Panels)

Support for Custom Handles

• /

4

,t

_z

\

'.. , ", ,,

r

. , ,

28

Page 29

ZKHRSS1 Trim Kit (For 1/4" Panels)

Tubular Stainless Steel Handles

Right hand door swing models are illustrated in these

instructions. Follow these instructions for left hand

models.

NOTE: It is best that 2 people install this kit.

Tools and materials required:

. #2 Phillips screwdriver

Drill and appropriate bits

Custom door panel

Safet U glasses

Center punch

Hasking tape

Hammer

Pencil

1/2" thick 12" x 12" min. piece of plgwood to

protect floor when drilling

For stainless steel panel, wear gloves to protect

against sharp edges.

Parts List:

A. Handle extrusion {for left hand models)

B. Handle extrusion {for right hand models)

C. Door handle

D. 6 Spacer rings (for Stainless Panels ONLY)

(4 required, 2 extra)

E.4 Handle standoffs

F. 6 Screws for mounting handle standoffs

(4 required, 2 extra)

G. 6 Set screws {4 required, 2 extra)

H. 3/32" Allen wrench for set screws

This kit provides for the installation of a Tubular

Stainless Steel handle on 1/4" thick decorator door

panel. The door extrusions allow the handle to be

secured to the door structure, rather than to the

custom panel.

.Select extrusion for 9our model, discard other

extrusion.

Step 1

Remove

handle

Open fresh food door to 90 °. Remove the screws

from the full-length handle.

Retain screws, discard handle.

29

Page 30

ZKHRSS1 Trim Kit (For 1/4" Panels)

Tubular Stainless Steel Handles

Step 2

Match

handle

extrusions

to handle

See Step 2A

for Stainless

Steel panels

• Cut a piece of corrugated to use as a pad to

protect the panel finish. Use 1/2" thick section

of plywood to protect flooring when drilling.

• Place custom panel on the pad, appearance side

down.

• On the back side of the panel-at the handle side,

measure and mark 1/4" below the top edge of the

panel with a pencil.

• Slip panel into new extrusion on the handle side of

the panel.

• Align the extrusion at the pencil mark, 1/4" below

the top of the panel.

• Tape the extrusion to the panel to prevent

movement.

• Center punch and drill 1/8" pilot holes through the

holes in the extrusion and into the panel.

• Turn panel oven On the appearance side, use 9/32"

bit to enlarge clearance hole.

IMPORTANT: Hole locations must be exact to accept

handle standoff and handle assembly.

Custom

Door_ /

Panel

_j_Extrusi0n

I

I

Step 2A If gou are installing handle onto a Stainless Steel

Panel:

Use extreme caution if gou ore drilling through o

stainless steel panel. Stainless steel panels must be

handled gentlg. Do not kneel on the stainless steel

panel. It will leave a permanent dent. Do not remove

protective plastic covering until final installation.

• Place supplied filler panel (corrugated) on floor to

use as a pad.

• On the back side of the panel-at the handle side,

measure and mark 1/4" below the top edge of the

panel.

• Slip panel into the new extrusion, flush against

inner edge, on the handle side.

• Align extrusion to pencil mark as shown in Step 2.

Mark each screw hole location with pencil.

• Tape extrusion to panel to prevent movement.

• Place panel on plgwood section, appearance side

down. Be sure plgwood is clean without nicks and

burrs. Center punch at each screw hole location.

• Drill 1/8" pilot hole. Use 9/32" bit to enlarge

clearance hole.

• Measure and cut a 2" wide strip, top to bottom

off the corrugated panel. This will allow room for

spacer rings between the stainless panel and

extrusion.

30

Page 31

ZKHRSS1 Trim Kit (For 1/4" Panels)

Tubular Stainless Steel Handles

Step 3

Install

standoffs

onto handles

Step 4

Install

handles

and panels

See Step 4A

for stainless

steel panels

. Place a handle standoff onto each attachment post

along the handle. Position the set screw hole on the

standoff to point to the floor.

. Install set screws into the bottom of each standoff,

using the Allen wrench provided. The standoff

should be tight against the handle.

• Slide panel into the door trim. Leave about 4" of the

panel exposed to allow room to install the handle

extrusion.

• Place extrusion onto the back side of the panel,

install mounting screws through the extrusion and

just through the panel.

• Drive screw part wag through the top standoff,

then part wag through the bottom standoff. Install

remaining standoffs part wag.

• Drive all screws until the handle is tight against the

panel.

• Remove tape.

• Slide the assembled panel into the door trim until

the extrusion fits firmlg against the steel door.

Reinstall original screws into the extrusion.

_Screw

Wrench

31

Page 32

Step 4A

Install

handles

and panels

ZKHRSS1 Trim Kit (For 1/4" Panels)

Tubular Stainless Steel Handles

Screw

StainleCs:Ugatet SP!__ _'_ Extrusi0n

Panel ' i

• Crimp top and bottom edges of corrugated

• Slide corrugated into door trim Leave about 1/4"

gap between edge of corrugated and hinge side

trim of the doon

• Slide panel into the door trim. Leave about 4"

of the panel exposed to allow room to install

the handle extrusion.

• Place a spacer ring over each screw hole on the

extrusion. Use tape to hold in place.

NOTE: Panels have a protective plastic covering. Peel

awag just enough to allow panel to slide into trim and to

clear handle mounting screws. The plastic covering will

keep the panel clean during the installation process.

• Place extrusion onto panel. Use a pencil to punch

hole in tape covering spacer rings and align with

screw holes.

• Install mounting screws through the extrusion and

panel.

Be sure to maintain 1/4" gap between corrugated

and hinge side trim.

• Drive screw part wag through the top standoff,

then part wag through the bottom standoff. Install

remaining standoffs part wag.

• Drive screws until the handles are tight against

the panel.

• Slide the assemblg into the door trim until the

extrusion fits firmlg against the steel doon

• Reinstall original screws into the door extrusion.

Raised Panel on 114" Thick Backing:

A raised panel design secured to a 1/4" thick backing

(screwed or glued) can be used with this handle kit. r]-q

• cut the 1/4_' thick panels to size. ,,

Fabricate the raised panel to allow 1-1/4 1/4", Appearance

clearance from the hinge side of the panel to avoid Bacldng FI J

striking

adjucent:- cabinetrg. I I J 5/16

Allow 5/16 clearance at the other edges to allow I LJ Clearance

for the trim flange u handle Side

• Total panel thickness should not exceed 3/4"

• Countertops adjacent to the refrigerator installation

should be mitered 45 °

NOTE: Longer Screws obtained Iocallg will be required

to accommodate panel thickness Use stainless steel

#10 32xl 1/4" truss Phillips head screws

mlcK I I IPanel

Raised Panel on 1/4"Thick Bacldng

II I

5/16"Clearance

Custom Panel

11/4

Clearance

hingeside

5/16" Clearanc_

--5/16"Clearance

32

Page 33

ZKHTRSSl (For 3/4" Panels)

Tubular Stainless Steel Handles

Kit

Contents

Right hand door swing models are illustrated in these

instructions. Follow these instructions for left hand

models.

This kit provides for the installation of a Tubular

Stainless Steel handle on a 3/4" thick decorator door

panel. The door extrusions allow the custom handle

to be secured to the door structure, rather than to

the custom panel.

Select the extrusion for 9our model, discard other

extrusion.

Tools and materials required:

, #2 Phillips screwdriver

, Drill and 1/8", 9/32" bits

, Custom door panel

, Safetg glasses

, Center punch

, Masking tape

, Hammer

_,Pencil

Parts List:

A. Handle extrusion (for left hand models)

B. Handle extrusion (for right hand models)

C. Stainless tubular handle

D. 4 Handle standoffs

E.6 Screws for handle standoffs

(4 required, 2 extra)

F. 6 Set screws (4 required, 2 extra)

G. 3/32" Allen wrench for set screws

This kit must be used in combination with ZKTR36RH

or ZKTR56LH trim kit.

NOTE: It is best that 2 people install this kit.

D E

mmC ,m,,_

Before you

begin:

The 3/4" custom panel must be routed to

accommodate the handle extrusion. Rout the panel

as illustrated, 1/4" deep, and 1-13/16" wide, top to

bottom on the handle side.

Follow the instructions in the ZKTR36RH

(or ZKTR36LH) to install trim onto the door.

Discard the handle supplied with that kit.

Continue the instructions in the ZKTR36RH

(or ZKTR36LH) trim kit to install support brackets

to the bottom of the panel.

Custom Panel

IMPORTANT: Optional final appearance depends on

careful routing depth. Do not exceed 1/4" routing

depth.

33

Page 34

ZKHTRSSl (For 3/4" Panels)

Tubular Stainless Steel Handles

Step 1

Match Handle

Extrusion

to Panel

Step 2

Install

Standoffs

onto Handles

,Cut a piece of corrugated to use as a pad to protect

the panel finish. Additional material ma U be

required to protect flooring when drilling.

Place custom panel on the pad, appearance side

down.

,,Select handle extrusion for uour model, left or right

side extrusion.

Place extrusion against the handle side of the panel.

,Align the extrusion evenlg with the top and bottom

of the panel.

,Tape the extrusion to the panel to prevent

movement.

,Center punch and drill 1/8" pilot holes through the

holes in the extrusion and into the panel.

,,Turn panel oven On the appearance side, use 9/32"

bit to enlarge clearance hole.

• Place a handle standoff on each attachment post

on the handle. Position the screw hole on the

standoff to point to the floon

• Install set screws into the bottom of each standoff,

using the Allen wrench provided. The standoff

should be tight against the handle.

AlignExtrusionEven

With Panel

NOTE: Hole locations must be exact to accept handle

standoff and handle assemblg.

¢

_Screw

Step 3

Install

Mounting

Screws

and Handles

Step 4

Install

Assembled

Panels

• Start mounting screws through the extrusion and

just through the custom panel.

• Stand panel up on the hinge side and hold to

access the appearance side. Place handle against

mounting screws on the appearance side, drive top

screw from the back of the extrusion partially into

the standoff.

• Drive bottom screw partially into the standoff,

and then drive remaining screws partially into

standoffs. Alternate back to the top, driving screws

until the handle is tight against the doon

It is best that 2people perform this step.

• Place assembled panel onto the bottom door trim

with support bracket tabs inserted into slots.

• Push and hold the panel back against the steel

door with door handle extrusion flush to the

handle side of the doon

• Reinstall original screws into the door extrusion.

• Open the door fully to stop.

• Install screws at the top and hinge side.

F

34

Page 35

ZUG75 Trim Kit

Unified 3/4" Custom Grille Panel Kit

Step 1

Install Spacer Pads,

Replace Side Case Trims

This kit provides for the installation of a 3/4" thick

custom grille panel to span the combined width of

a side b 9 side installation. Use this kit in combination

with 3/4" custom panel kits, ZKTR36LH and

ZKTR36RH.

Tools and materials Required:

, #1 and #2 Phillips screwdrivers or sockets

1/4" angled wrench and 1/2" open-ended

wrench

Drill and appropriate bits c

Custom grille panel E

Safetg glasses

Gloves to protect against F

sharp edges

Parts List:

A. Soffit Vent Top

B. Left Side Case Trim

C. Right Side Case Trim

D. Center U-Shape Trim

E.Grille Base Wrap

F. Custom Grille Panel Support

G. Foam Spacer Pads

D

G

CAUTION:Handle parts with care to avoid scratching.

In a side bU side installation, the inside case trim of

both products will be removed and replaced with a

shorter trim.

Lift up to remove the supplied grille panel assembl 9

on both products. Discard both assemblies.

Completion Time: Allow approximatel U 3 hours to

install this kit.

IMPORTANT: 2 People are required to install this kit.

CAUTION: Disconnect power before 9ou begin.

Foam

)Spacer

Pads Remove the Phillips head screws from the inside

AppIg the supplied foam spacer pads to the mating

side of one product as shown.

case trim of each product as shown. Remove and

discard side trim. Retain screws.

Install new side case trim with notches towards the

bottom. Install with original screws.

35

Page 36

ZUG75 Trim Kit

Unified 3/4" Custom Grille Panel Kit

Step 2

Install

Anti-Tip

Brackets

ANTI-TIP PRECAUTIONS

These products are heavg at the top and

must be secured to prevent the possibilitg

of tipping over.

PRECAUTIONS CONTRE LES BASCULEMENTS

Le r_frig_rateur est beaucoup plus Iourd en haut

et il faut le maintenir en place pour _viter

la possibilit_ de son basculement vers I'avant.

Cut a 2"x4" block, 71" long. Secure the 2"x4" to

the 4 mounting brackets provided using #12 or #14

wood screws.

Secure the brackets with wood block to the buck

wall so that it is 84" (or sour installation height)

from the finished floor. Use #12 or #14 wood

screws. See illustration.

Screws must penetrate at least one inch into

vertical wall studs.

Roll Both Products into Opening

. Gentlg push each product into opening with hands

against front corners. Push back into the opening

until it is flush or semi-flush with adjacent cabinets.

Brackets

Required

Height

Brackets

NotRequired

Beneatha

Soffit

From

Floor

to

Bottom

ofWood

Block

m

SideView

2x4Cut_ _-

71" Length ,', ,!

'T÷q

Installation Mounting

Height Bracket

From Floor

ScrewsMountedintoJ

VerticalWall Studs

IMPORTANT NOTE: When the products are installed

under a soffit or if there is not enough height for

this method of securit U, use Step 4 as an alternative.

The refrigerator and freezer must be secured to

prevent tipping.

Step 3

Level Both

Products

36

Both products MUST BE LEVEL AND PLUMB with

each other and adjacent cabinetrg on each side.

Toekick heights should align with cabinetrg.

Adjust carefull U. Both models have 4-point leveling.

The front is supported b9 leveling legs, the rear is

supported b U wheels.

Raise units to the same level, aligning with adjacent

toekick heights.

Adjust rear wheels beneath the product to just

barel9 touch the 2x4 block.

Turn the 7/16" hex nut located above the front

wheels to raise or lower the back of the refrigeraton

To adjust the front leveling legs: Use a 1/4" angled

wrench to turn the top of the leveling leg, or turn

the bottom of the legs with a 1-1/4" wrench.

The rear leveling wheels and front leveling legs

are limited to a maximum height adjustment of

1". If the installation requires more than 84-1/2"

height, the installer should elevate the

refrigerator on a sheet of plgwood or runners.

Cabinetr9 trim could also be added across the

top of the opening to shorten the opening. If gou

attempt to raise the refrigerator more than 1",

gou will damage the front leveling legs and the

rear leveling wheels.

[

HexNut Ad

RearWheels

LevelingLeg

Units must be 1" apart and evenlg aligned at top

and bottom. The inside case trims must align, top

and bottom.

Les roues de nivellement arri_re et les pattes de

nivellement avant permettent un r6glage maximal

de 25 mm 11 po). Si I'ouverture pour le r_frig_rateur

a une hauteur sup6rieure 6 2,15 m (84-1/2 po),

I'instullateur doit _lever le r6frig&-oteur sur une feuille

de contre-plaqu_ ou des glissi&res. II est _galement

possible d'ajouter des baguettes de finition des

placards sur le haut de I'ouverture afin de la r_duire.

Lever le rdrig_rateur de plus de 25 mm (1 po)

endommage les pattes de nivellement avant

et les roues de nivellement arri@re.

Page 37

ZUG75 Trim Kit

Unified 3/4" Custom Grille Panel Kit

Step 4

Secure

Products

To Sides

Step 5

Install Center

Trim Strip

NOTE: This step can be used

as an alternative to Step 2,

Anti-Tip bracket installation,

whenever brackets cannot

be used. Whenever possible,

perform this step for additional

anti-tip securitg.

When using 1/2" to 3/4" thick side panels, the front

flange of the case trim is attached to the side panel.

• Open door to access case trim.

• Drill hole in trim slightlg below the interior opening.

• Drive screw through the trim and into the side

panel.

• Follow the some procedure on the opposite outside

product trim.

• Open doors fullg.

• Starting at the top, press trim strip over inside case

trims of both products.

• Continue pressing trim until gou reach the bottom

of the case trims. The trim will align with the top

and bottom of the case trim.

Stud_Cabinet \

H/Re,r,0erat0r\

OR _

If the product is installed between cabinets with no

side panels or into a custom enclosure, install u

spacer block as shown.

CaseTrim

U-Shape

Trim

Step 6

Remove

Wire Fence

and

Switch Cover

3 Screws

• Remove 5 screws holding the wire fence on both

products. Retain fences and all screws.

j!

i

6rill Base Cover

• Lift off grille base covers. Discard covers.

57

Page 38

Step 7

Install

Grille Base

Cover

Unified Base Cover

• Open doors fully.

• Install the double width grille base cover by

slipping the notched ends over the hinges.

ZUG75 Trim Kit

Unified 3/4" Custom Grille Panel Kit

Place

TrimOver

Hinges

Step 8

Remove

Grille Frame

_%%_%%%%%%%%%%%%%%%%%%%%

°o°Co°o°2222_22_=_! , . , _=9_%%%%%%%%°2o°o°o%° D%%%%%%%%%%%%%%%%%°o%°_Jo%!t

Install

3Screws

• Place wire fence over the grille base cover (textured

side out). Drive original wire fence screws through

the fence, the grille base cover and into the frame.

Screws _!_j

&_€_ _ ° °° °°°° °°°°° °°°°_o22_=O_o%_%%%%_%%%_o_ :_o:_° °° °°°°° °°_o_=o_22_2Z_.... ooooooooooo_C€

• Back out 2 screws on each side of the top

case trim.

• The top piece is secured to the unit with a rubber

dust gasket. Roll the trim upwards to access and

remove end screws as shown. Remove and discard

inside pieces.

• Slide assembly out of the rubber gasket.

jJ

Install

3 Screws

Remove

Screws L_

Remove