Page 1

Installation

Instructions

18” and 24”Built-In Column

Freezers

24” and 30” Built-In Column

Refrigerators

Page 2

Safety Information

BEFORE YOU BEGIN

Read these instructions completely and carefully.

IMPORTANT – Save these instructions for

•

local inspector’s use. Observe all governing codes and

ordinances.

Note to Installer – Be sure to leave these

•

instructions with the Consumer.

• Note to Consumer – Keep these instructions with

your Owner’s Manual for future reference.

If you received a damaged unit, you should immediately

contact your dealer or builder.

Skill Level – Installation of this unit requires basic

mechanical, carpentry and plumbing skills. Proper

installation is the responsibility of the installer. Product

failure due to improper installation is not covered under

the Monogram Warranty. See the Owner’s Manual for

warranty information.

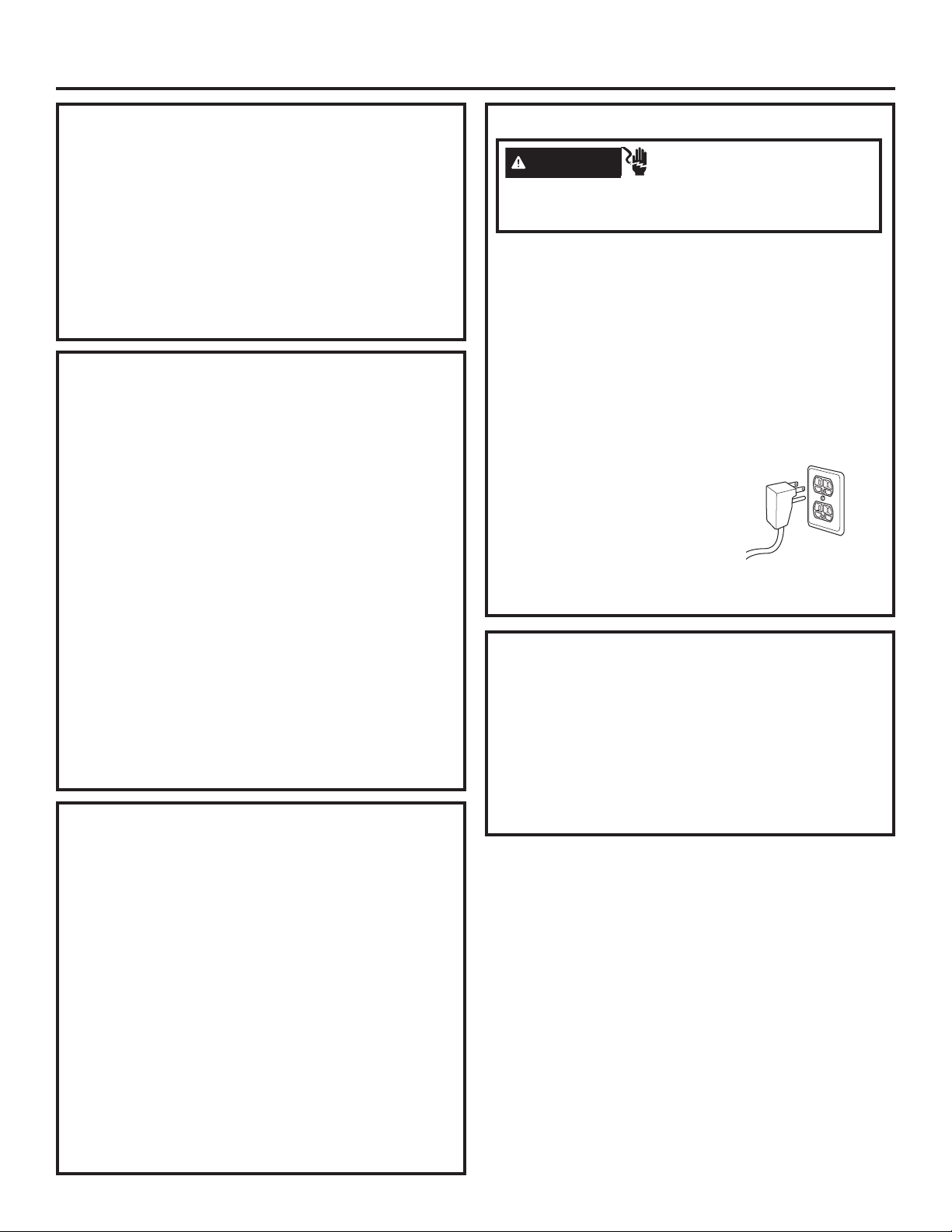

WARNING

Plug into a grounded 3-prong outlet.

Do not remove the ground prong.

Do not use an adapter.

Immediately discontinue use of a damaged supply cord.

If the supply cord is damaged it must be replaced by a

qualified service professional with an authorized service

part from the manufacturer.

WARNING

These appliances are top heavy, especially with any doors open, and must be secured to prevent tipping

forward which could result in death or serious injury. Read and follow the entire installation instructions for

securing the appliance with the anti-tip system.

WARNING

Keep flammable materials and vapors, such as gasoline, away from appliance. Failure to do so can result

in fire, explosion, or death.

WARNING

have access to small parts during the installation of this product.

Electrical Shock Hazard.

Do not use an extension cord with this appliance.

Failure to follow these instructions can result in death,

fire, or electrical shock.

Follow the instructions in the section Grounding the unit.

This appliance must be installed with a means in the

fixed house wiring or circuit breaker for disconnecting the

appliance from the electrical supply after installation.

Tip Over Hazard.

Explosion Hazard.

To reduce the risk associated with choking, do not allow children under 3 years of age to

CAUTION

This unit is very heavy. To reduce the risk of person injury during maneuvering and installing this appliance,

3 people are required for proper installation.

CAUTION

doors and cabinet are necessarily small. Be careful closing doors when children are in the area.

For Monogram local service in your area, call 1.800.444.1845 or visit monogram.com.

For Monogram service in Canada, call 1.800.561.3344

For Monogram Parts and Accessories, call 1.800.444.1845 or visit monogram.com.

Lifting Hazard

Keep fingers out of the “pinch point” areas; clearances between the doors and between the

2

31-49133-1

Page 3

Contents

Safety 2

Design Guide

Dimensions and Clearances 4

Accessories/Kits 5

Instructions for Dual Integrated Installation 6

The Installation Space 6

Tools, Hardware, Materials 8

Grounding the Unit 8

Flooring 8

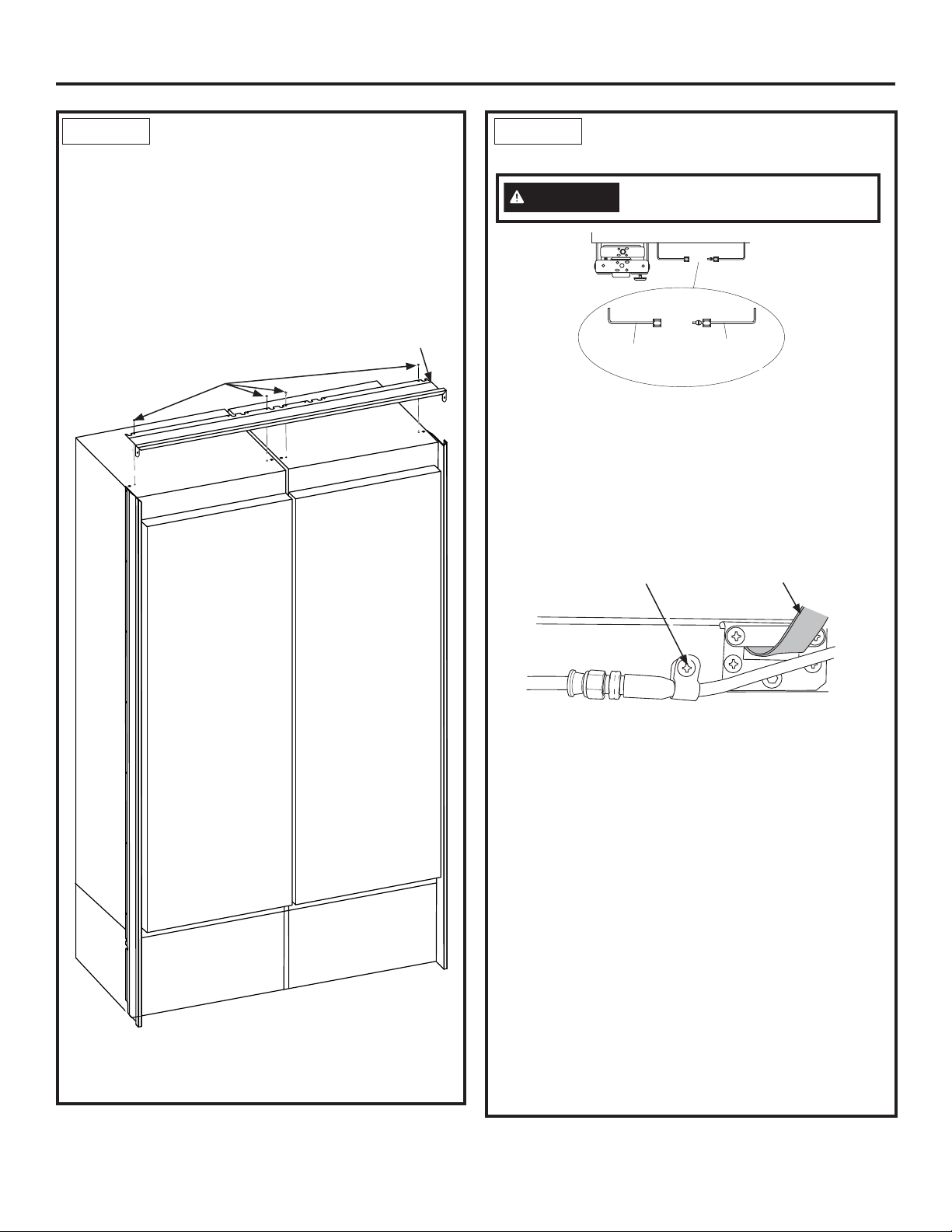

Step 1. Remove Packaging 9

Step 2. Install Water Line 9

Step 3. Preparing Unit for Installation 10

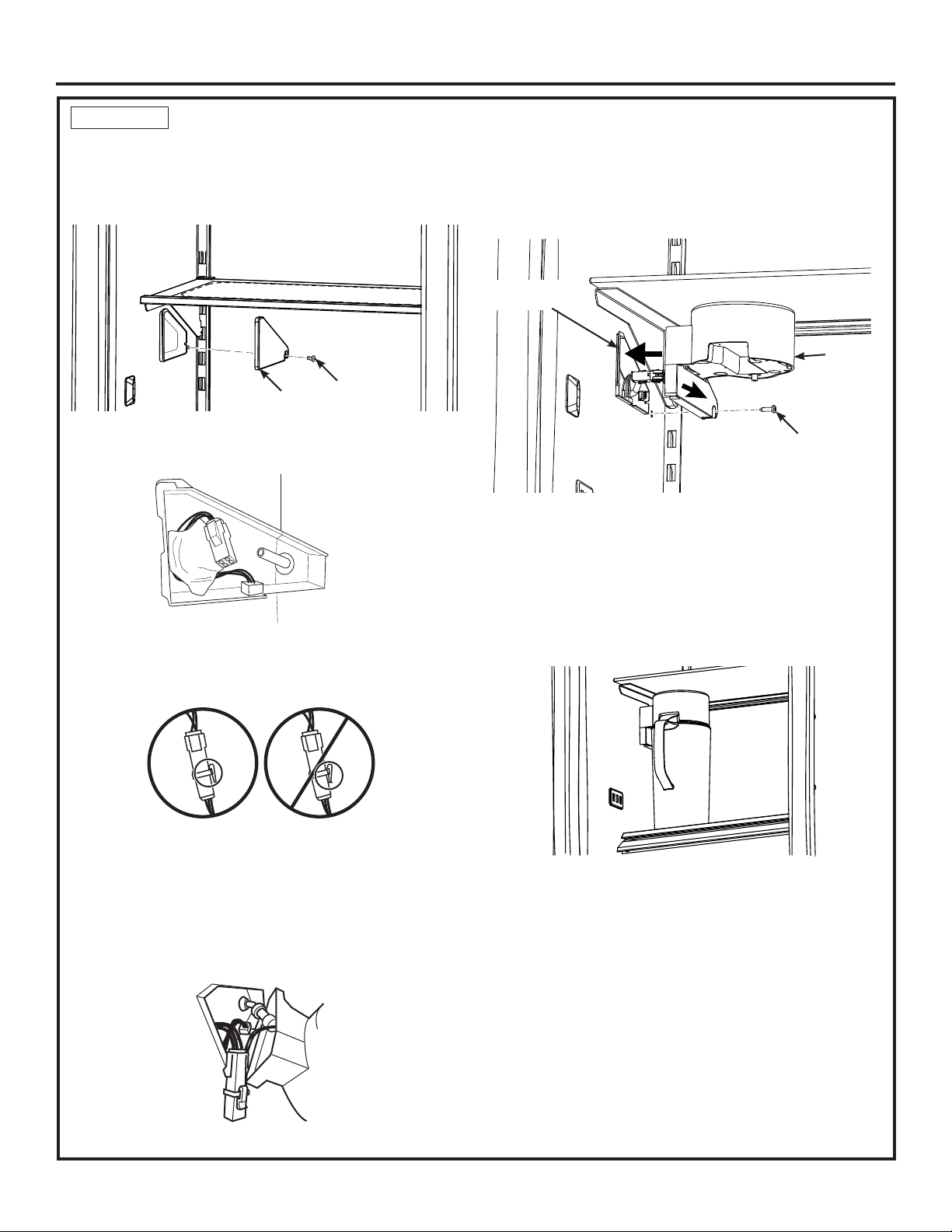

Step 4. Install Anti-tip Bracket 11

Step 5. Joining Dual Installed Units 12

Step 6. Connecting Water Supply 13

Step 7. Inserting/Securing into Cabinet Surround 14

Step 8. Level Unit 15

Step 9. Final External Unit Preparation 15

Step 10. Internal Unit Preparation 16

Step 11. Start Icemaker 16

Step 12. Install AutoFill Pitcher Assembly 17

Instructions for Dual Retro-Fit Installation 18

The Installation Space 19

Tools, Hardware, Materials 20

Grounding the Unit 20

Flooring 20

Step 1. Remove Packaging 21

Step 2. Install Water Line 21

Step 3. Preparing Unit for Installation 22

Step 4. Install Anti-tip Bracket 23

Step 5. Joining Dual Installed Units 24

Step 6. Connecting Water Supply 26

Step 7. Inserting/Securing into Cabinet Surround 27

Step 8. Level Unit 28

Step 9. Final External Unit Preparation 28

Step 10. Internal Unit Preparation 29

Step 11. Start Icemaker 29

Step 12. Install AutoFill Pitcher Assembly 30

Instructions for Single Integrated Installation 31

The Installation Space 32

Tools, Hardware, Materials 33

Grounding the Unit 33

Flooring 33

Step 1. Remove Packaging 34

Step 2. Install Water Line 34

Step 3. Preparing Unit for Installation 35

Step 4. Install Anti-tip Bracket 35

Step 5. Connecting Water Supply 36

Step 6. Inserting/Securing into Cabinet Surround 36

Step 7. Level Unit 37

Step 8. Final External Unit Preparation 38

Step 9. Internal Unit Preparation 38

Step 10. Start Icemaker 38

Step 11. Install AutoFill Pitcher Assembly 39

Reversing the Door Swing 40

Step 1. Remove Door 41

Step 2. Remove Hinge Brackets 41

Step 3. Move Control Assembly 42

Step 4. Hove Light Switch Housing 42

Step 5. Reinstall Hinge Brackets 43

Step 6. Remove Hinges from Door 43

Step 7. Panel Brackets and Hinges 44

Step 8. Reinstall the Door 44

Stainless Steel Door Panel Installation 45

Step 1. Reversing Stainless Panel Door Swing 46

Step 2. Install Stainless Panel 47

Step 3. Adjust Stainless Panel 48

Step 4. Install Hinge Covers 49

Step 5. Install Door Trims 49

Custom Overlay Door Panel Installation 51

Custom Handle Design Guide 52

3/4” Custom Decorative Panel Dimensions 52

Step 1. Overlay Panel Prep 53

Step 2. Install Overlay Panel 54

Step 3. Adjust Overlay Panel 54

Step 4. Install Hinge Covers 55

Step 5. Install Door Trims 55

31-49133-1

3

Page 4

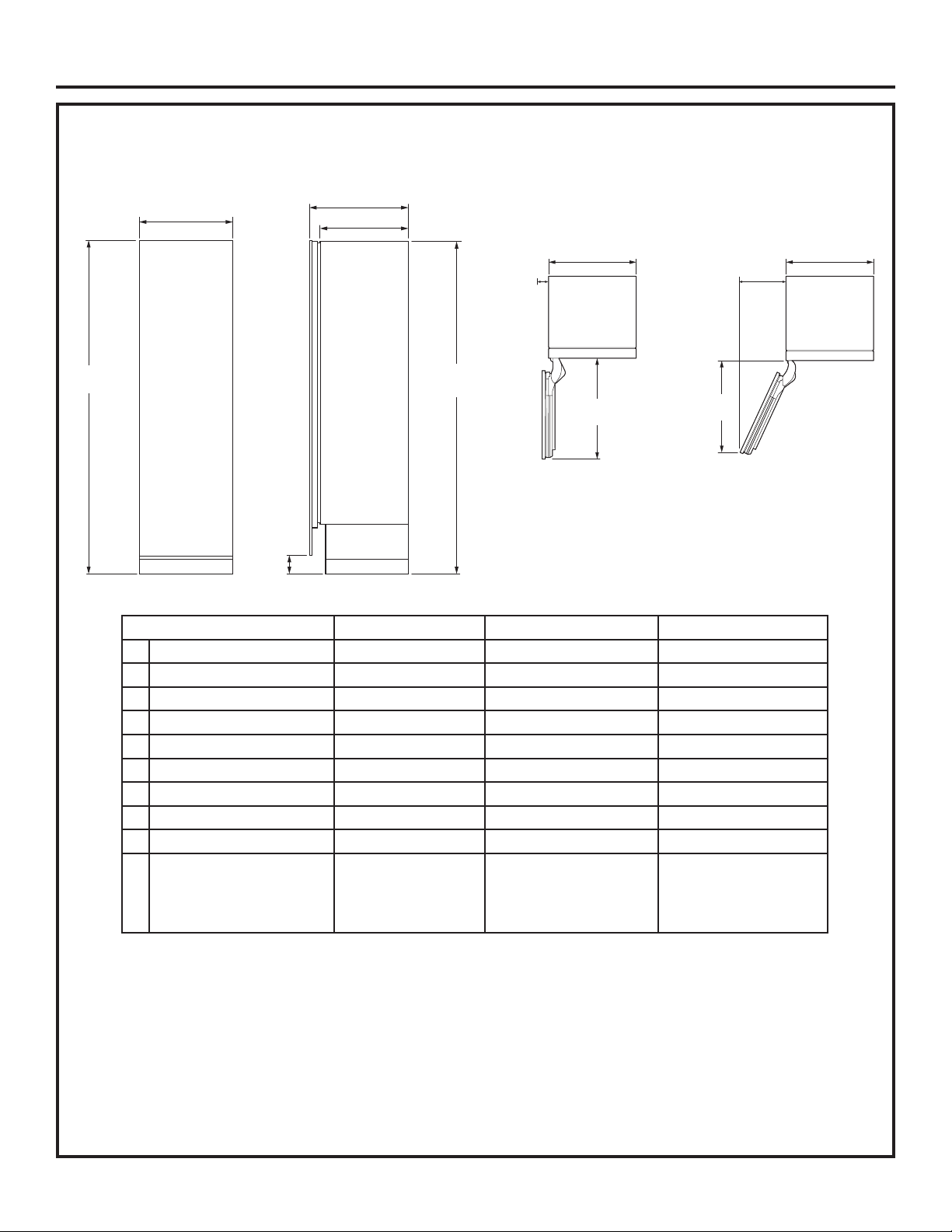

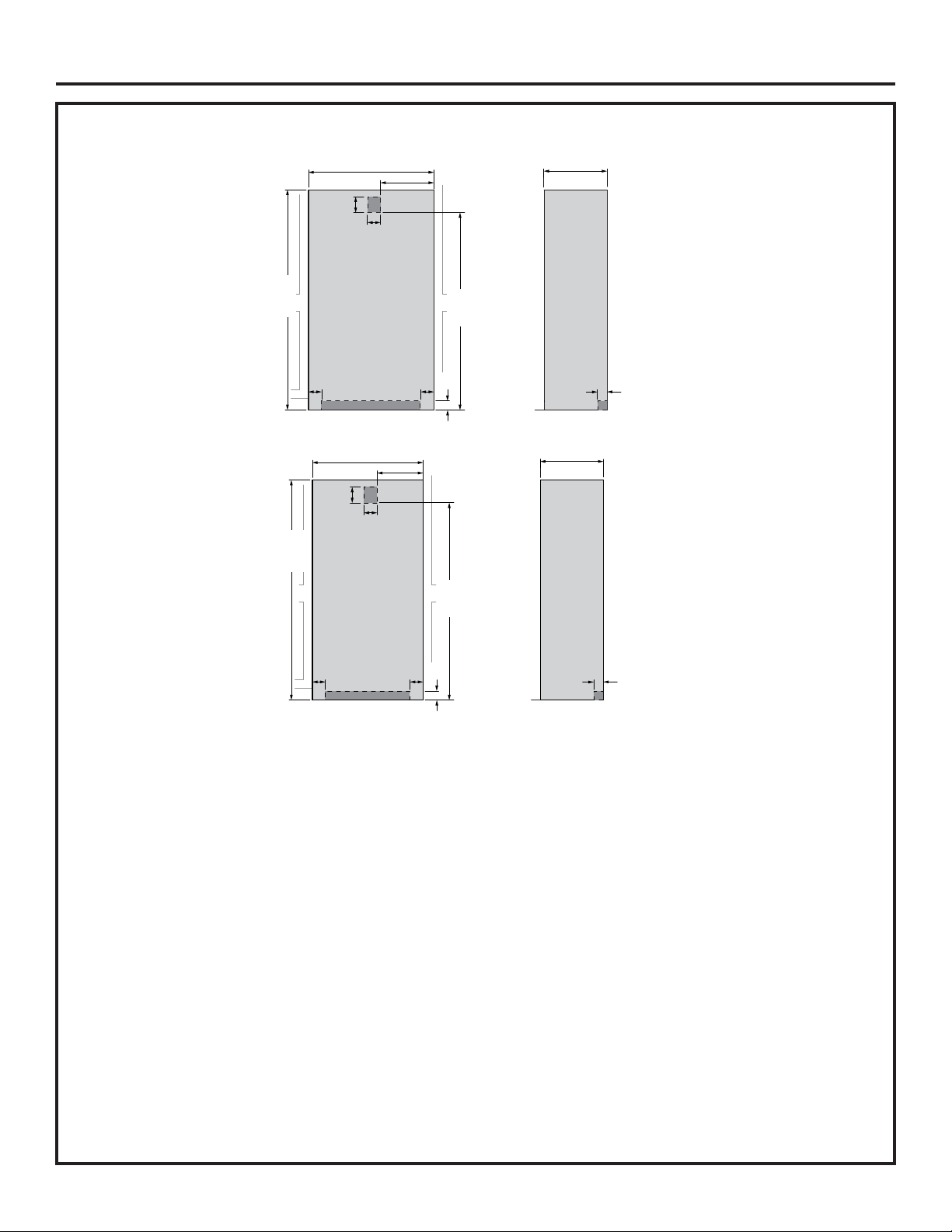

Design Guide

DIMENSIONS AND CLEARANCES

Dimensions in parentheses are in centimeters.

Overall Dimensions

A

C

D

83-3/8"

(211.77)

TOP VIEWS

(38.1)

15"

Minimum

to a Wall

(41.9)

(16.5"

on 30” models)

F

4"

(10.16)

FRONT VIEW SIDE VIEW

83-1/4"

(211.46)

4"

(10.16)

Minimum

to a Wall

B

E

DOOR OPEN 90Û DOOR OPEN 115Û

Dimensions 18” Models 24” Models 30” Models

A Overall Width - Front 17-1/2” (44.5 cm) 23-1/2” (59.7 cm) 29-1/2” (74.9 cm)

B Overall Width - Rear 17-1/4” (43.8 cm) 23-1/4” (59.1 cm) 29-1/4” (74.3 cm)

C Overall Depth 24-3/4” (62.9 cm) 24-3/4” (62.9 cm) 24-3/4” (62.9 cm)

D Case Depth 22-1/16” (56 cm) 22-1/16” (56 cm) 22-1/16” (56 cm)

E Door Clearance at 90° 21-1/4” (53.9 cm) 27-1/4” (62.9 cm) 33-1/4” (84.5 cm)

F Door Clearance at 115° 19-1/16” (48.4 cm) 24-1/2” (62.2 cm) 29-15/16” (76.0 cm)

Cutout Width 17-3/4” (45.1 cm) 23-3/4” (60.3 cm) 29-3/4” (59.7 cm)

Cutout Height 84” (213.4 cm) 84” (213.4 cm) 84” (213.4 cm)

Cutout Depth 25” (63.5 cm) 25” (63.5 cm) 25” (63.5 cm)

Weight 370 lbs

(167.8 kg)

460 lbs (208.7 kg)

(Refrigerator)

510 lbs (231.3 kg)

430 lbs. (195.0 kg)

(Freezer)

B

Shipping height.

The product can be adjusted to fit into a cutout that is

84” (213.36 cm). Use leveling legs and wheels for a

maximum 1” (2.54 cm) height adjustment.

Product Clearances

These units are equipped with a 2-position door stop.

The factory set 115° door swing can be adjusted to 90°

if clearance to adjacent cabinets or walls is restricted.

For a 90° door swing, allow 4” (10.2 cm) minimum

clearance to a wall.

When installed in a corner, allow 15” (38.1 cm) for a full

115° door swing on 18” and 24” models. Allow 16.5”

(41.9 cm) on 30” models.

4

31-49133-1

Page 5

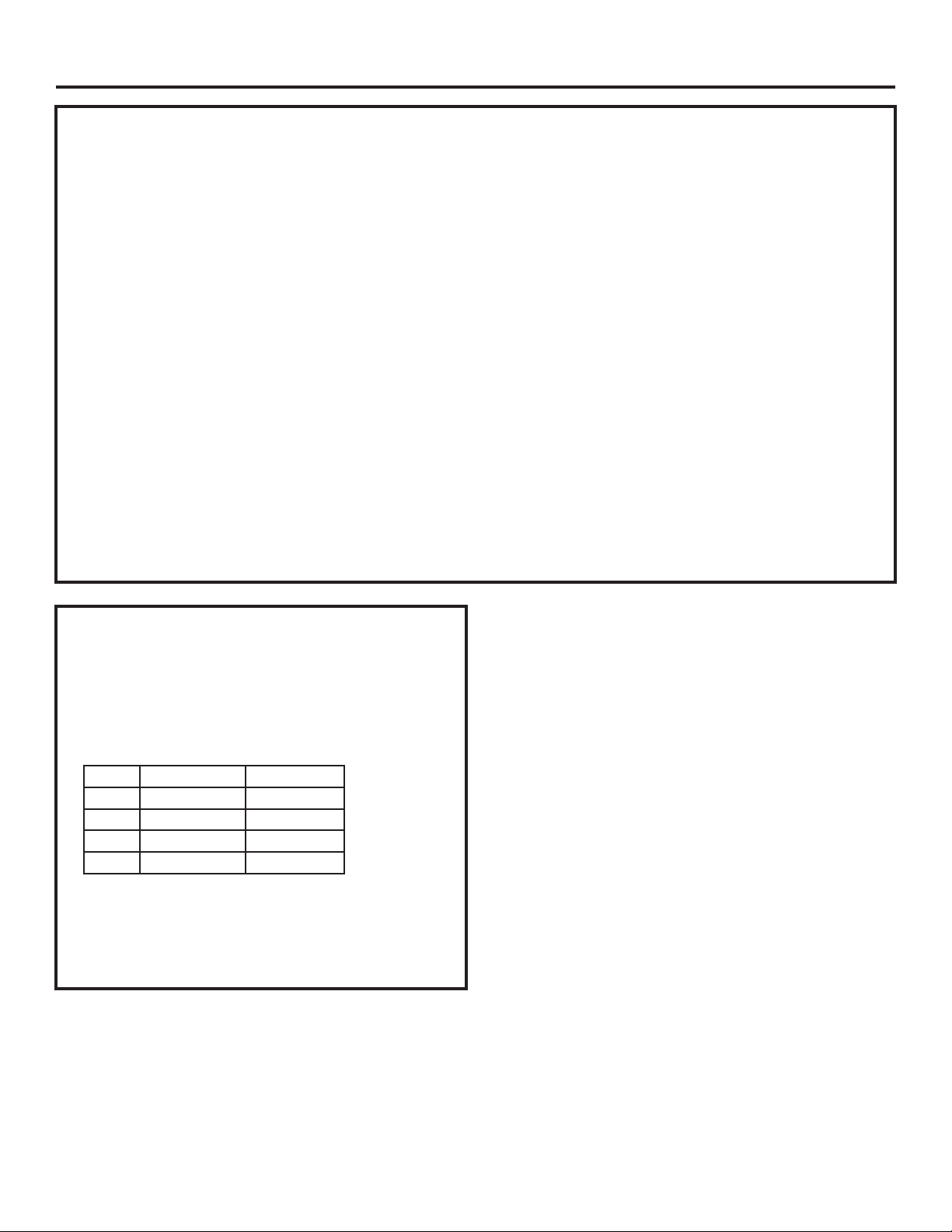

Design Guide

7KH0RQRJUDP&ROXPQVUHIULJHUDWRUVDQGIUHH]HUVFDQEHLQVWDOOHGLQPDQ\FRQ¿JXUDWLRQV

ZLWKGLႇHUHQWLQVWDOODWLRQVLWXDWLRQV7KUHHLQVWDOODWLRQVLWXDWLRQVZLOOEHH[SODLQHGDORQJZLWK

door reversal instructions and two options for door panel installation.

Instructions for Dual Integrated Installation

New construction installation with 25” deep openings

Instructions for Dual Retro Installation

Existing construction installation (existing cutouts) with 24” deep openings that are 41-1/2” or 47-1/2” wide

Instructions for Single Integrated Installation

New construction installation with 25” deep opening

Reversing the Door Swing (all installation types)

Making a refrigerator LH swing and freezer RH swing

Instructions for Stainless Steel Door Panel Installation (all installation types)

Installing Stainless Steel Door Panel Kits

Instructions for Custom Overlay Door Panel Installation (all installation types)

Installing Custom Decorative Panels

ACCESSORIES/KITS

Ŷ ZUGC+HDWHU8QL¿FDWLRQ.LW

Ŷ WX08X10006 8 Ft. Water Line

Ŷ ZTKC42 42” Trim Retro Kit

Ŷ ZTKC48 48” Trim Retro Kit

Ŷ 6WDLQOHVV6WHHO'RRU3DQHO.LWV

Unit Euro Handle Kits Pro Handle Kits

Ǝ/+ ZKCSC184 ZKCSP184

Ǝ/+ ZKCSC249 ZKCSP249

Ǝ5+ ZKCSC244 ZKCSP244

Ǝ5+ ZKCSC304 ZKCSP304

Ŷ Handle Kits for Custom Overlay Door Panels

ZKHCSS: Euro Tubular Stainless Steel Handle

GHVLJQHGWR¿W´RYHUOD\SDQHOV

ZKHPSS1: Pro Tubular Stainless Steel Handle

GHVLJQHGWR¿W´RYHUOD\SDQHOV

31-49133-1

5

Page 6

Instructions for Dual Integrated Installation

New construction installation with 25” deep openings

6

31-49133-1

Page 7

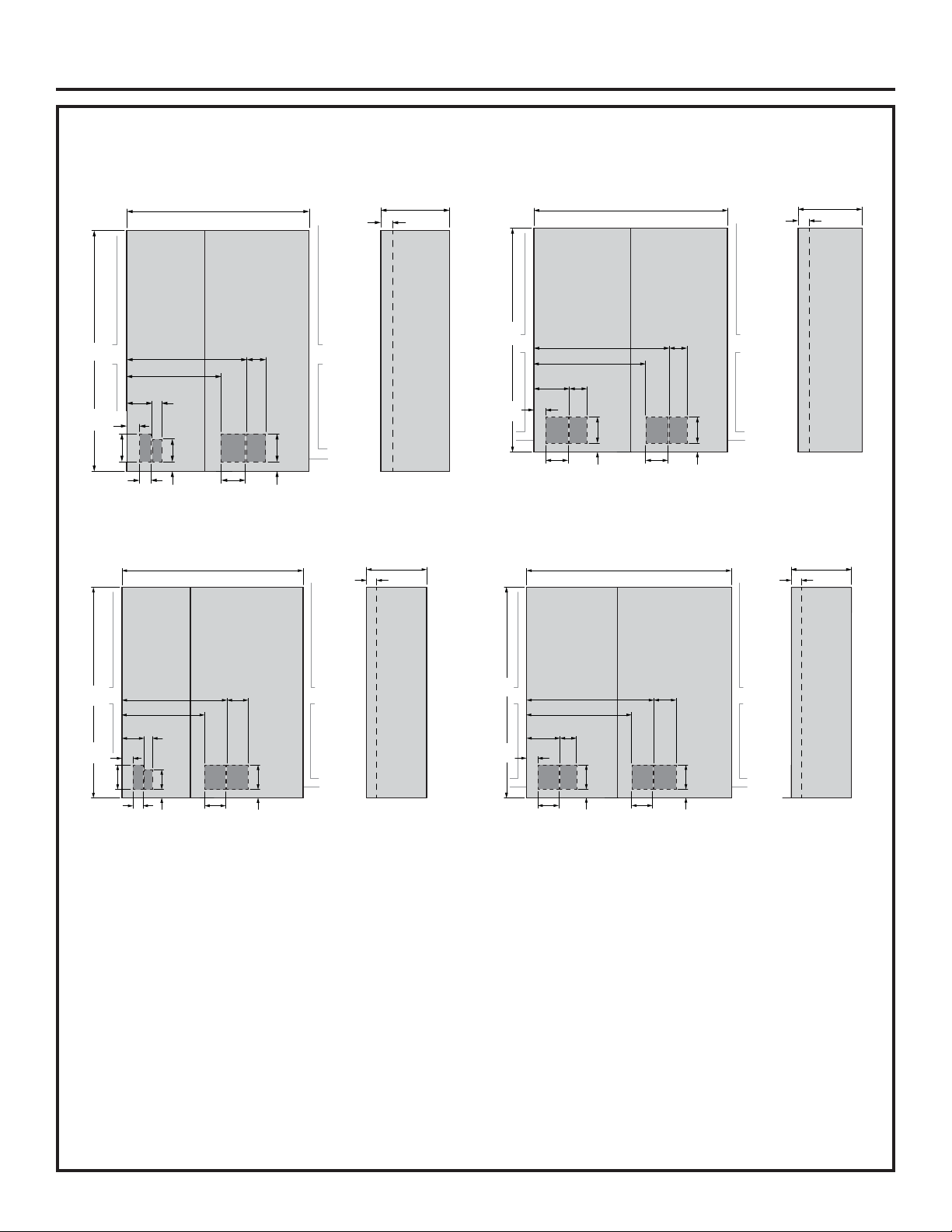

Design Guide - Dual Integrated Installation

DUAL INTEGRATED INSTALLATION SPACE

Dimensions in parentheses are in centimeters.

18” Integrated Freezer

24” Integrated Refrigerator

41 1/2" (105.4)

3 1/2"

(8.9)

Finished

Return

25" (63.5)

24” Integrated Freezer

24” Integrated Refrigerator

47 1/2"

(120.7)

3 1/2"

(8.9)

Finished

Return

25" (63.5)

84"

(213.4)

4 1/8"

(10.5)

3 1/2"

(8.9)

6 3/4"

(17.2)

27 1/4"

(69.2)

22 1/8" (56.2)

7 1/2”

(19.1)

E

W

2"

(5.1)

4"

(10.2)

2 1/2"

(6.4)

FRONT VIEW

(10.2)

ELEC W

(12.7)

4"

6 3/4"

(17.2)

2 1/2"

5"

(6.4)

SIDE VIEW

18” Integrated Freezer

30” Integrated Refrigerator

47 1/2"

(120.7)

84"

(213.4)

4 1/8"

(10.5)

6 3/4"

(17.2)

3 1/2"

(8.9)

22 1/8" (56.2)

7 1/2"

(19.1)

E

28" (71.1)

W

2"

(5.1)

2 1/2"

4"

(10.2)

(6.4)

6 1/4"

(10.2)

ELEC W

5"

(12.7)

FRONT VIEW

6 3/4"

(17.2)

2 1/2"

(6.4)

3 1/2"

(8.9)

Finished

Return

Water And Electrical Locations

Electrical and water supply must be located as shown.

The Cutout Depth Must Be 25”

Cutout is based on installation of 2 products with a leftand-right hand door swing.

Heater Unification Kit ZUGC required.

Product Clearances

These units are equipped with a 2-position door stop.

The factory set 115° door swing can be adjusted to 90°

if clearance to adjacent cabinets or walls is restricted.

For a 90° door swing, allow 4” (10.2 cm) minimum

clearance to a wall.

When installed in a corner, allow 15” (38.1 cm) for a full

115° door swing on 18” and 24” models. Allow 16.5”

(41.9 cm) on 30” models.

25" (63.5)

Back

SIDE VIEW

Back

84"

(213.4)

4 3/8"

(11.1)

9 1/2"

(24.1)

ELEC W

33 1/4" (84.5)

28 1/8" (71.4)

4

2 1/2"

5"

(12.7)

6 3/4"

(17.2)

(6.4)

FRONT VIEW

(10.2)

ELEC W

(12.7)

4"

6 3/4"

(17.2)

2 1/2"

5"

(6.4)

SIDE VIEW

24” Integrated Freezer

30” Integrated Refrigerator

25

25" (63.5)

SIDE VIEW

84"

84"

(213.4)

4 3/8"

(11.1)

9 1/2"

(24.1)

ELEC W

34" (86.4)

28 1/8" (71.4)

4"

(10.2)

5"

(12.7)

53 1/2" (134.6)

6 3/4"

ELEC W

(17.2)

2 1/2"

(6.4)

FRONT VIEW

6 1/4"

(15.9)

5"

(12.7)

6 3/4"

(17.2)

2 1/2"

(6.4)

3 1/2"

(8.9)

Finished

Return

Additional Specifications

• A separate 115 volt 60Hz., 15 or 20 amp power supply

is recommended for each product. An individual

properly grounded branch circuit or circuit breaker is

recommended. Install a properly grounded 3-prong

electrical receptacle recessed into the back wall.

Electrical must be located on rear wall as shown.

• Water line must be located on the back wall as shown.

The water line should be 1/4” O.D. copper tubing or

QuickConnect™ kit (WX08X10006) between the cold

water line and water connection location, long enough

to extend to the front of the unit (8’ [2.4m]). Installation

of an easily accessible shut-off valve in the water line

is required.

• A minimum of 3-1/2” finished return matching cabinet

exterior is recommended on interior on all sides and

top at front of opening.

Back

Back

31-49133-1

7

Page 8

Installation Instructions - Dual Integrated Installation

REFRIGERATOR/FREEZER LOCATION

Ŷ Do not install the refrigerator/freezer where the tem-

perature will go below 55°F (13°C). It will not run

often enough to maintain proper temperatures.

Ŷ Do not install the refrigerator/freezer where

temperatures will go above 100°F (37°C). It will not

perform properly.

Ŷ Do not install the refrigerator/freezer in a location

exposed to water (rain, etc.) or direct sunlight.

Ŷ Install it on a floor strong enough to support it fully

loaded.

TOOLS AND MATERIALS REQUIRED

• Metal shears

• #1, #2 Phillips screwdriver

• Flathead screwdriver

• Putty knife

• Measuring tape

• Drill and 1/16”, 5/64”, 3/16”, 1/2” bits

• 5/32” concrete bit (if installing anti-tip into concrete)

• 1/4”, 3/8”, 7/16” driver/socket

• 7/16” open wrench

• T20, T30 driver/bit

• 5/64”, 1/8”, 1/4” hex driver (allen wrench)

• Level

• Water shut-off valves (optional but recommended)

• 8’ waterline (one per unit requiring water hookup)

• Masking tape

• Rubbing alcohol

• Adjustable wrench

• Center punch

• Heater Unification Kit (ZUGC)

• Stainless Steel Door Kits (if applicable)

• Custom panels for doors (if applicable)

• Handle Kits (if applicable)

HARDWARE SUPPLIED (per unit)

• Water Filter Bypass Plug (if equipped)

• Air filter (if equipped)

• Anti-Tip bracket

• 3 Lag screws

• 3 Tapcon screws

• 3 Toggles with bolts

• 1 Hair Pin Cotter

• 1 Retaining pin

• Panel installation templates

• 2 Door trims

• 2 Door panel brackets

• Set screws

• #6 Phillips head wood screws

• Door Bracket Cover Top

• T30 screws

• 1 Hinge limiter pin

• Center door panel bracket

• Hi-Lo screw and square washer

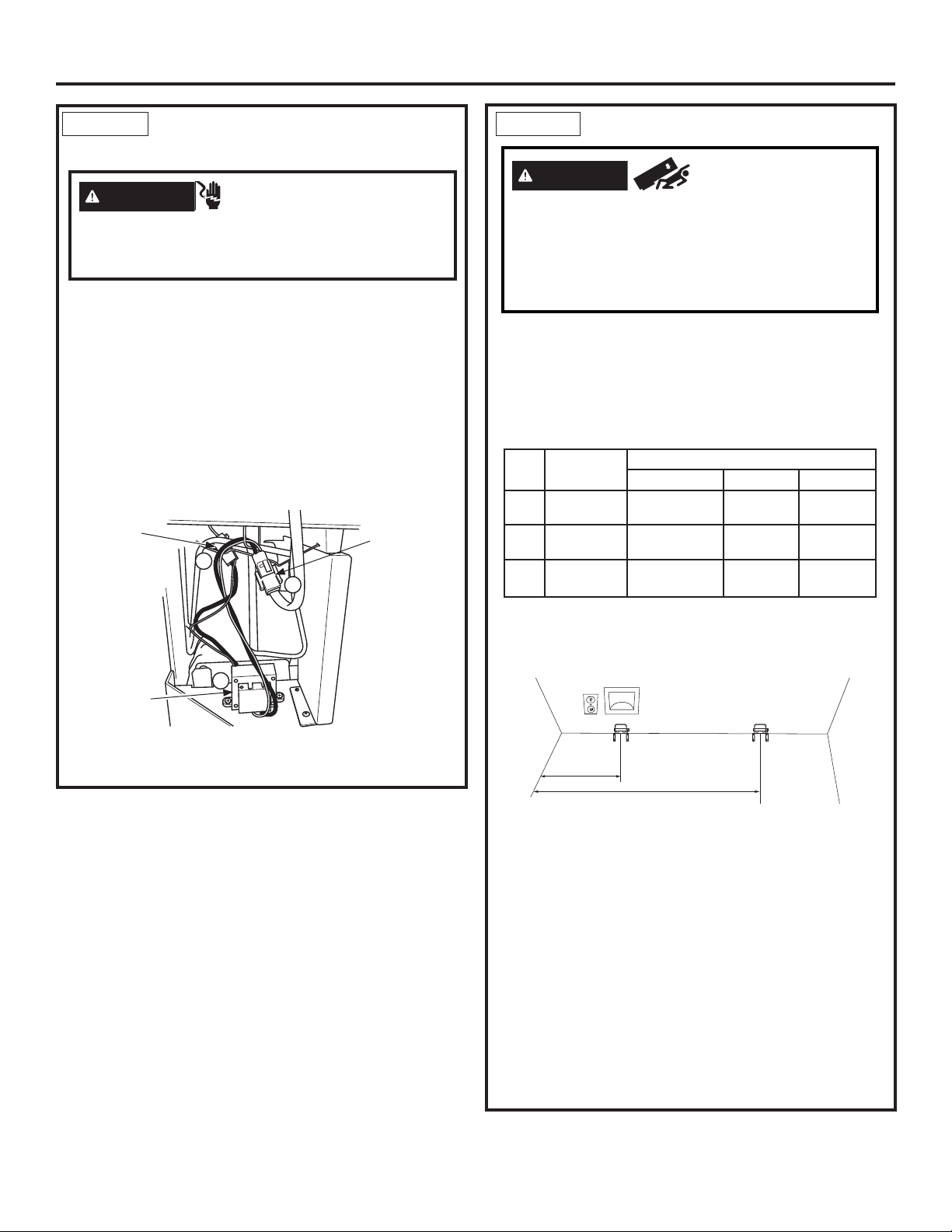

GROUNDING THE UNIT

WARNING

Hazard.

result in death, fire, or electrical shock.

The power cord of this appliance is equipped with a

3-prong (grounding) plug which mates with a standard

3-prong (grounding) wall receptacle to minimize the

possibility of electric shock hazard from this appliance.

Have the wall outlet and circuit checked by a qualified

electrician to make sure the outlet is properly grounded.

Where a standard 2-prong wall outlet is encountered, it

is your personal responsibility and obligation to have it

replaced with a properly grounded 3-prong wall outlet.

DO NOT, UNDER ANY CIRCUMSTANCES, CUT OR

REMOVE THE THIRD (GROUND) PRONG

FROM THE POWER CORD.

DO NOT USE AN ADAPTER

PLUG TO CONNECT THE

REFRIGERATOR TO A 2-PRONG

OUTLET.

DO NOT USE AN EXTENSION

CORD WITH THIS APPLIANCE.

Failure to follow these instructions can

Electrical Shock

FLOORING

For proper installation, this product must be placed

on a level surface of hard material that is at the same

height as the rest of the flooring. This surface should

be strong enough to support a fully loaded refrigerator

or freezer, or approximately 1,200 lbs. per unit.

NOTE: Protect the finish of the flooring.

NOTE: Not recommended for installation on carpeted

flooring.

8

31-49133-1

Page 9

Installation Instructions - Dual Integrated Installation

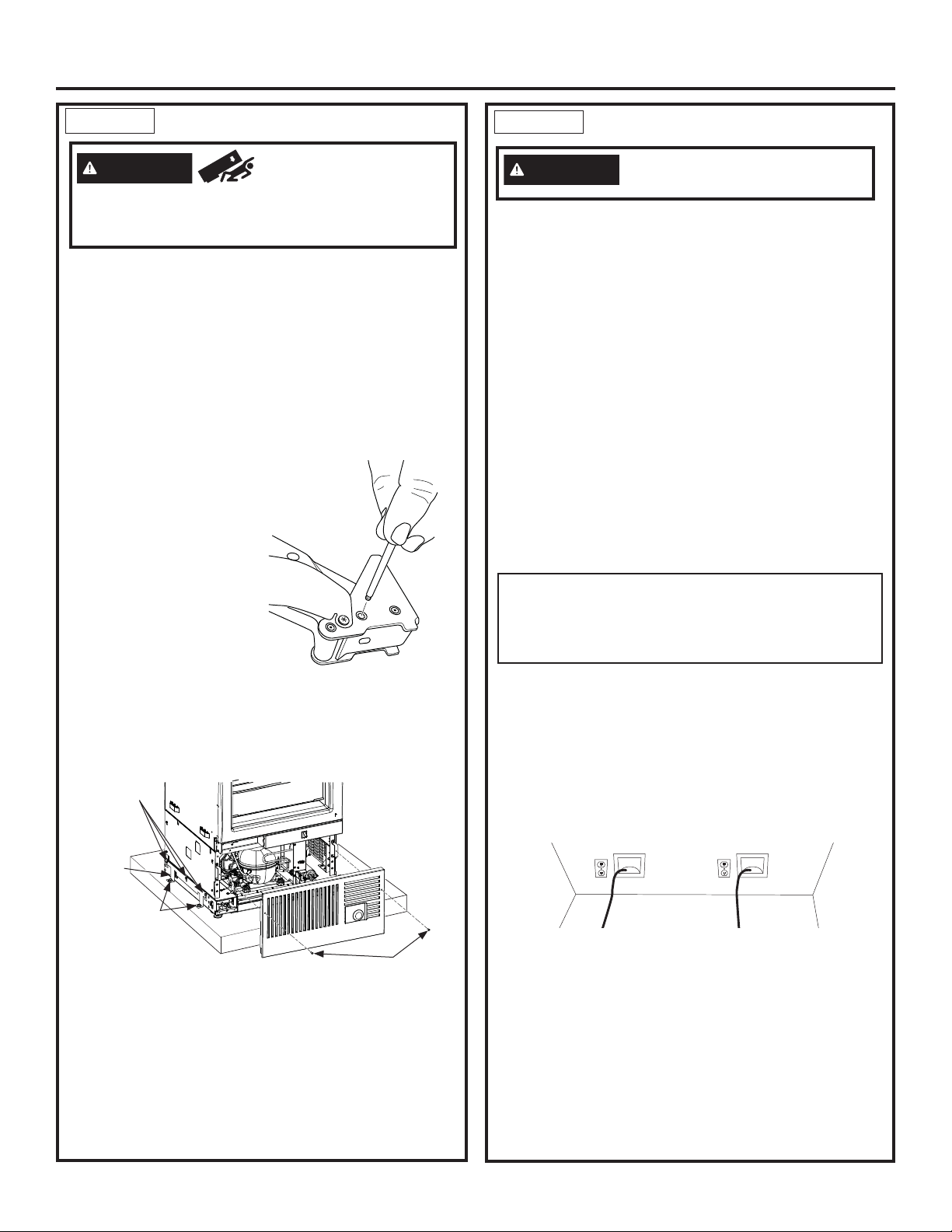

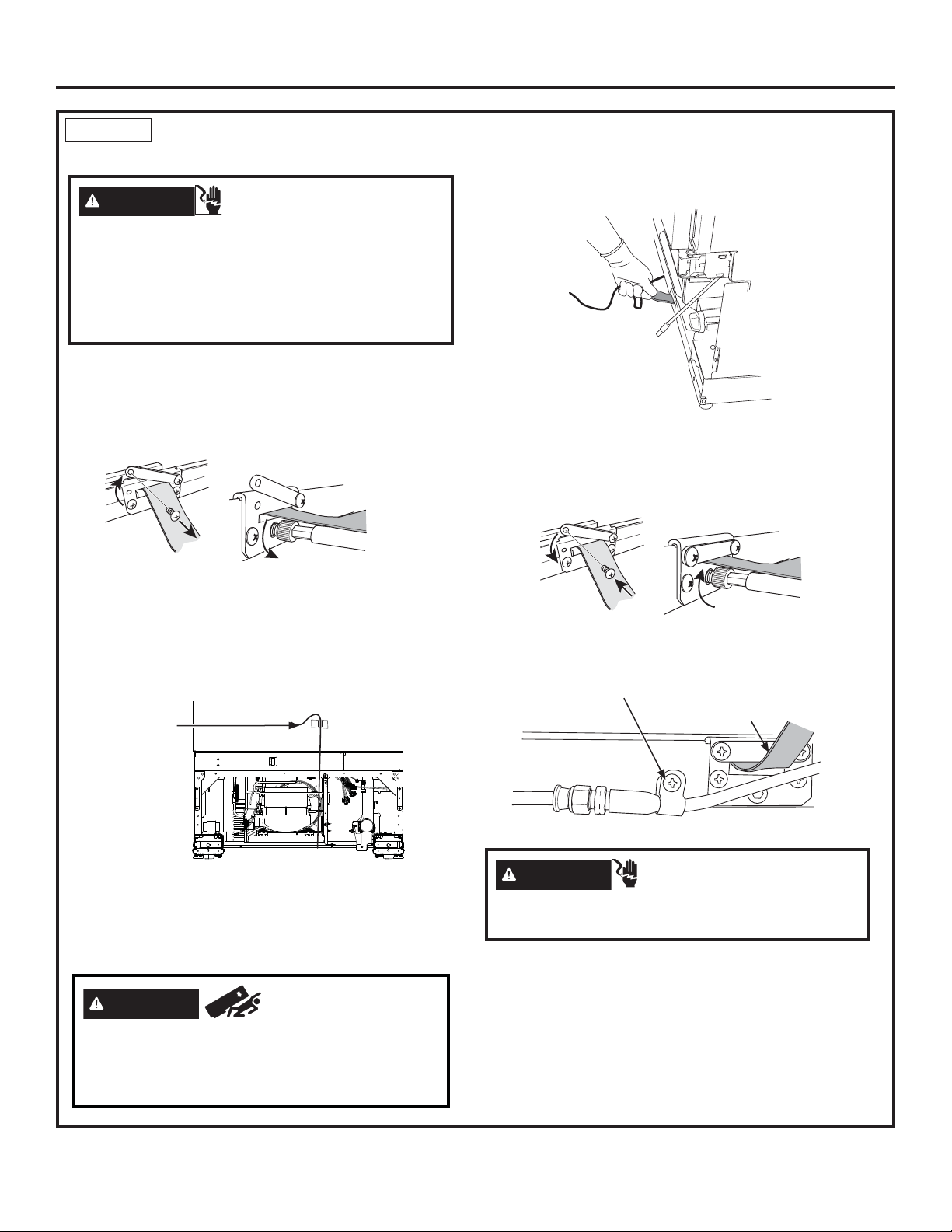

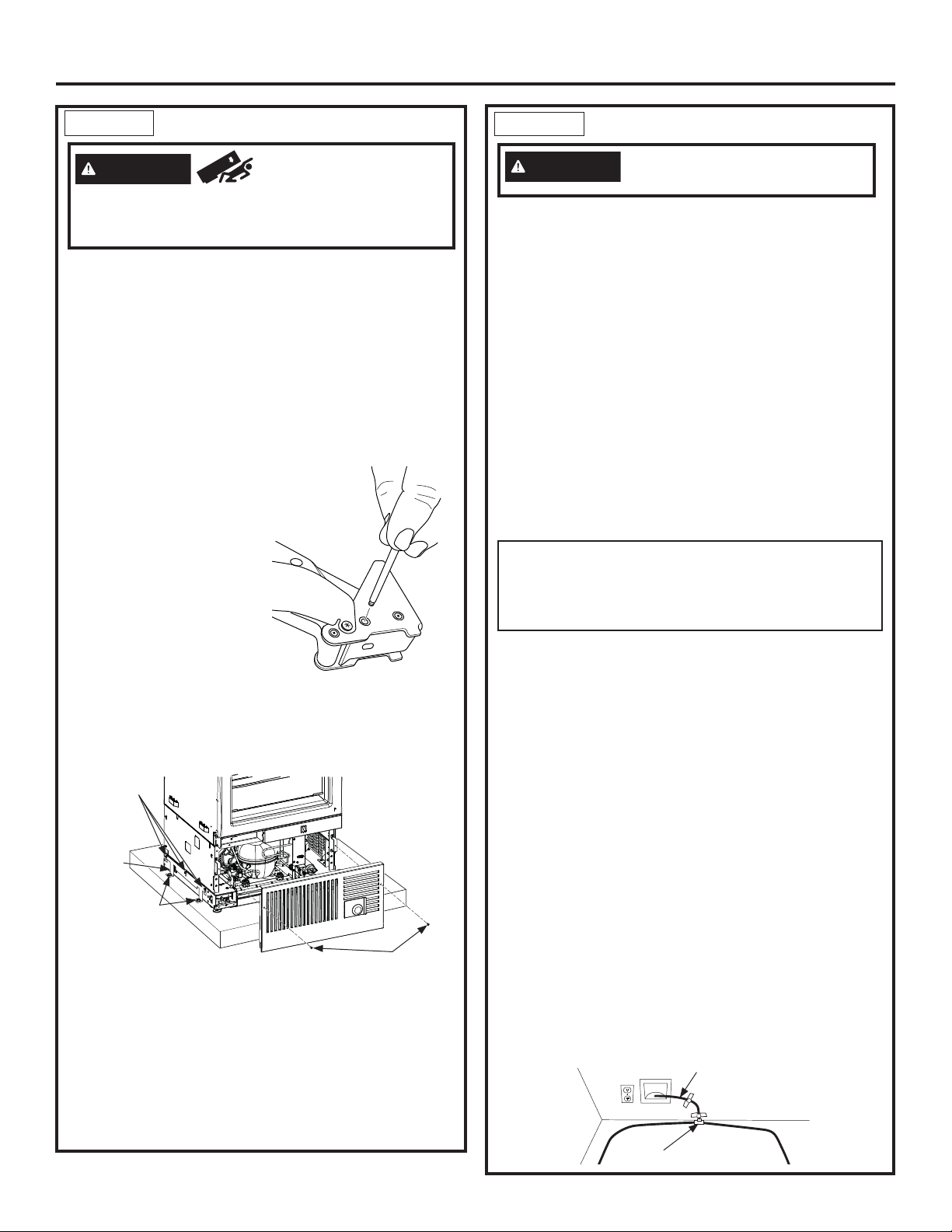

STEP 1 REMOVE PACKAGING

WARNING

appliance is top heavy. Use extreme caution with

moving to prevent tipping over which could result in

death or serious injury.

Ŷ Remove outer carton and external packing from units.

Ŷ Inspect for damage.

Ŷ Ensure the flooring that the units are set is clean/

free of debris that could be collected on to, or

pinched in front of the wheels and damaging the

floor. Additionally, it is recommended that the floor

be protected with a plastic covering through out the

installation process.

Ŷ Remove hardware kit from top drawer.

Ŷ If installation requires a 90° door opening, the

hinge limiter pin must

be installed in the top

hinge BEFORE the unit is

removed from the skid. Pin

is located in the hardware

kit.

- Open the door

approximately 45°, but

no wider than 90°, to

expose the hole in the

back hinge bracket and

install the limiting pin. Pin

must be fully seated in the bracket or the door will

not close properly.

Ŷ Remove front access cover from unit by removing 2

T20 Torx screws. Place the cover and screws to the

side for future installation.

3/8” Drive

Screws

Tip Over Hazard. This

To p

Hinge

STEP 2 INSTALL WATER LINE

WARNING

Ŷ A cold water supply is required for automatic

icemaker and AutoFill pitcher operation. The water

pressure must be between 40 and 120 p.s.i. (275827 kPa).

Shut off the main water supply.

Turn on the nearest faucet long enough to clear the

line of water.

ŶInstall a shut-off valve between the water valve and

cold water pipe in a basement or cabinet. The shutoff valve should be located where it will be easily

accessible.

ŶTurn on the main water supply and flush debris.

Run about a quart of water through the tubing into a

bucket. Shut off water supply at the shut-off valve.

NOTE: Saddle type shut-off valves are included in

many water supply kits. Before purchasing, make sure

a saddle type valve complies with your local plumbing

codes.

NOTE: Commonwealth of Massachusetts Plumbing

Codes 248CMR shall be adhered to. Saddle

valves are illegal and use is not permitted in

Massachusetts. Consult with your licensed plumber.

Ŷ Route 1/4” OD copper or SmartConnect™

(WX08X10006) plastic tubing between house cold

water line and the water connection location at the

front of the unit.

SmartConnect™ Refrigerator Tubing Kits are

available. One 8’ (2.4m) water line (WX08X10006) is

needed for each unit. The waterline(s) will be taped

to the floor using masking tape after anti-tip bracket

installation.

Connect to potable water supply

only.

Shipping

Bracket

7/16” Drive

Screws

T20 Torx

Screws

Ŷ Remove three 3/8” drive screws and two 7/16” drive

screws from each side of the unit to release it from

the skid. Tip the unit from the side enough to remove

the shipping material from under the unit, but above

the skid (both sides)

Ŷ CAREFULLY roll the unit off the back side of the skid.

Ŷ Handle from side only with a hand truck.

31-49133-1

Ŷ Tubing should be long enough to extend to the front

of the unit. Allow enough tubing to accommodate

bend leading into the water line connection. Unit

must be tipped on its side to route waterline

underneath and to the front of the appliance.

NOTE: The only GE Appliances approved plastic

tubing is supplied in the SmartConnect™ Refrigerator

Tubing kits. Do not use any other plastic water supply

line because the line is under pressure at all times.

Other types of plastic may crack or rupture with age

and cause water damage to your home.

9

Page 10

Installation Instructions - Dual Integrated Installation

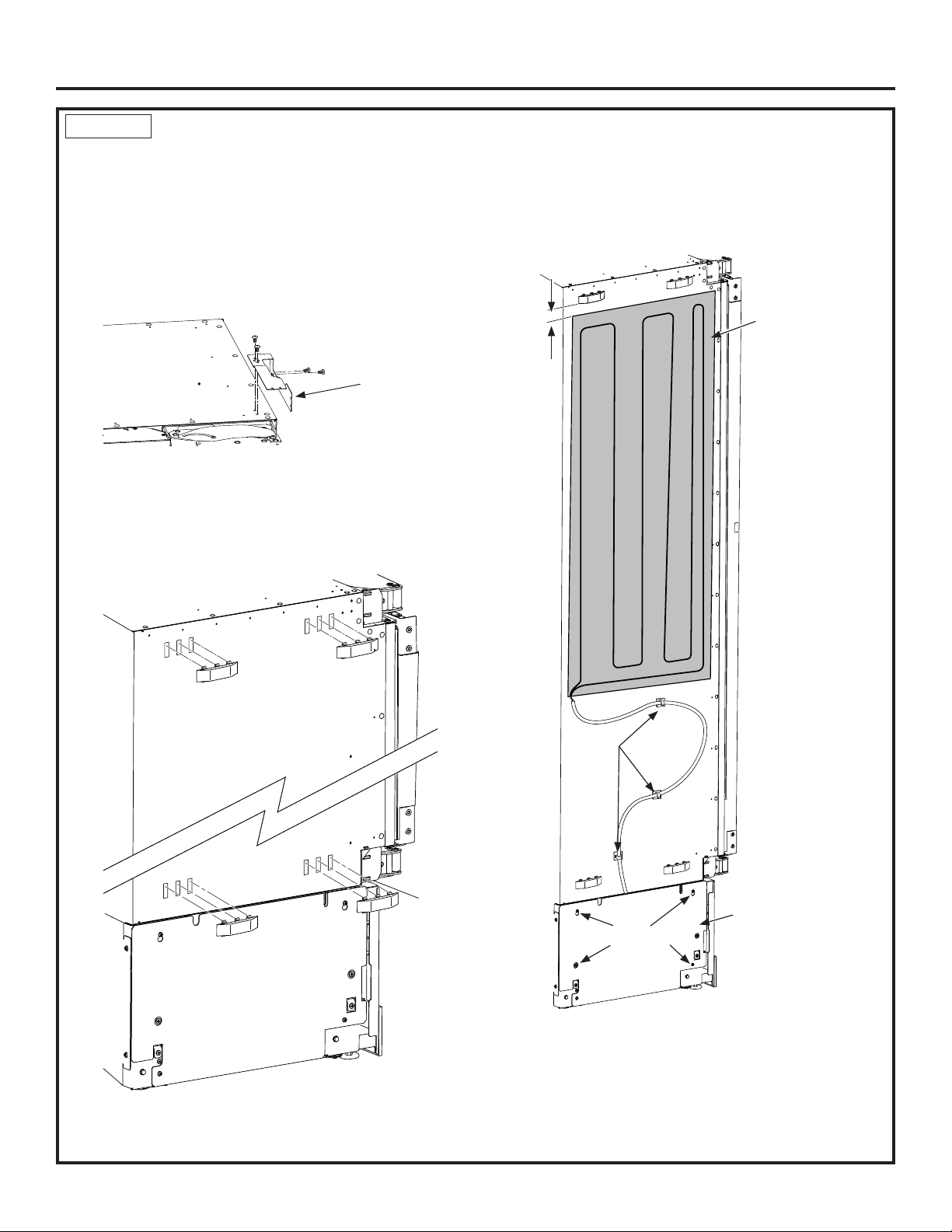

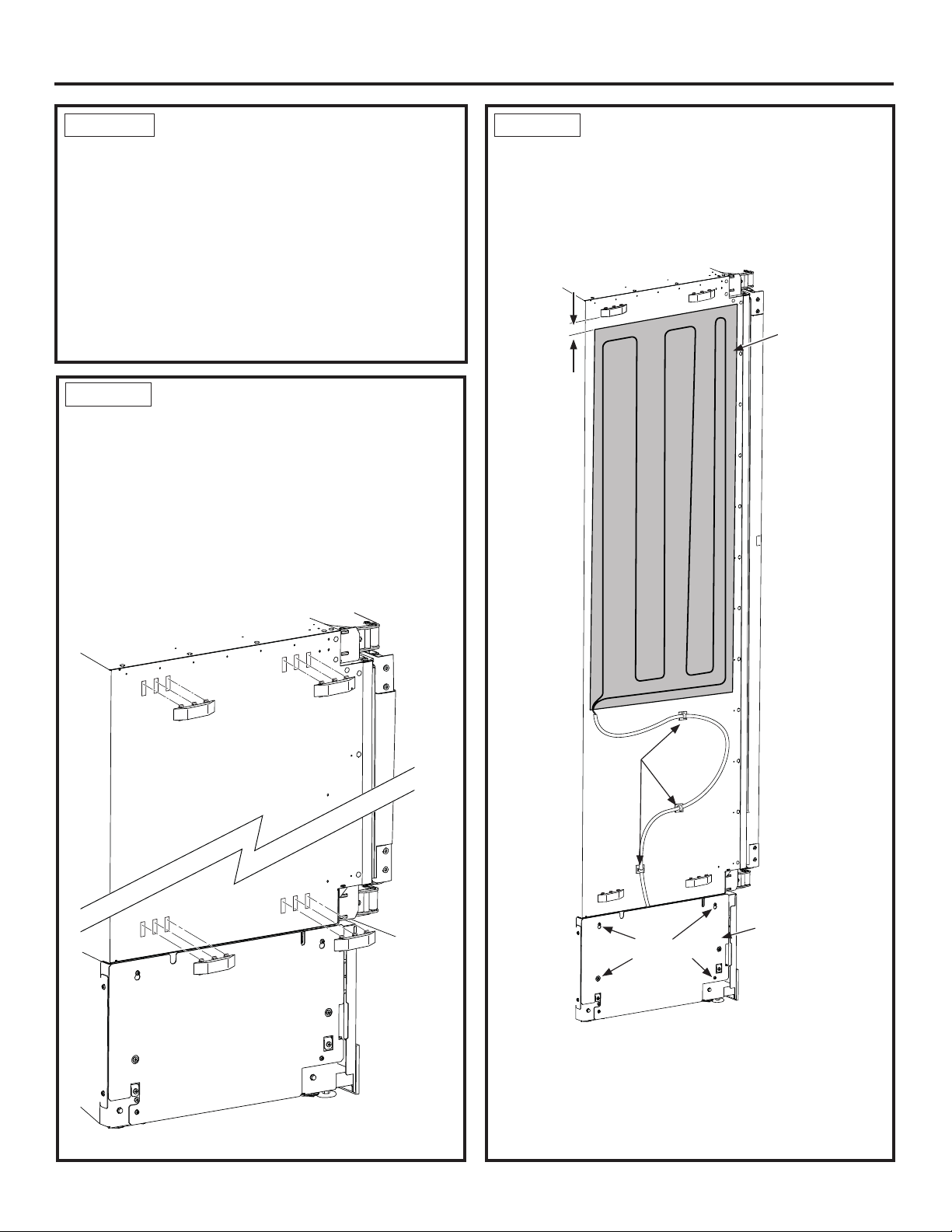

STEP 3 PREPARING UNIT FOR INSTALLATION

Ŷ Place the right hand unit in front of the installation

opening in a way that the unit is in front of the intended

installed location.

Ŷ If doors will be reversed after installing, the stabilization

bracket at the top hinge side of the case will need to

be moved to the opposite side of the case. Remove 4

Phillips head screws, rotate the stabilization bracket

and install on the opposite side of the case.

Stabilization

Bracket

Ŷ Unpack the heater Unification Kit (ZUGC) and make

sure all of the components on the list are included.

Ŷ Install 4 bumper blocks by snapping them to the left

side of the case between the 2 units - 2 on the upper

section of the case wall and 2 on the lower.

Ŷ Install adhesive heater on the outside of the unit to

the left side of the case. Install heater 2” below the top

2 standoff blocks. Heater should be centered front to

back on the metal case. Ensure the heater connector

cord is toward the bottom of the unit when installed.

Ǝ

Adhesive

Heater

Upper bumpers

Lower bumpers

Clips

Left Access

Hex

Screws

Ŷ Remove the left access cover by removing 4 (1/4”) hex

screws. The cover is located at the outside lower left

side of the case.

Ŷ Use clips to adhere loose wire tightly to side of case as

shown. Clean the side using rubbing alcohol to ensure

proper clip adhesion.

Cover

10

31-49133-1

Page 11

Installation Instructions - Dual Integrated Installation

STEP 3 PREPARING UNIT FOR

INSTALLATION (Cont.)

WARNING

Hazard. To avoid the risk of electric shock, make

sure the power cord is not plugged into the wall

outlet.

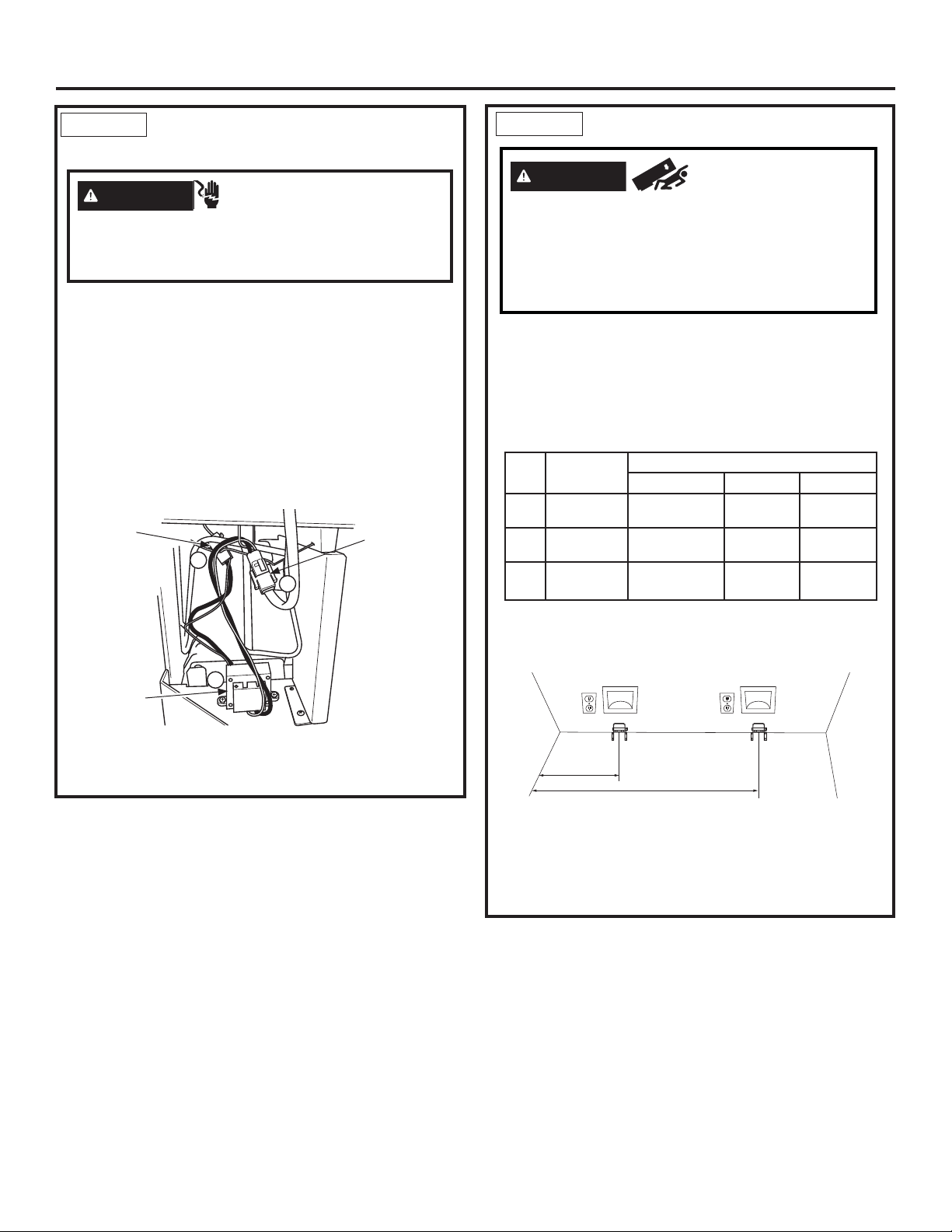

Ŷ Install the transformer into the machine compartment:

1. Plug transformer into the 3 pin connector at the top

of the machine compartment. Make sure locking

tabs are engaged.

2. Place the transformer into the machine compartment

and secure it with the 2 (1/4”) hex screws provided

in ZUGC kit.

3. Connect the 2 pin transformer connector to the

heater connector, make sure locking tabs are

engaged, and place in wire clip at the top of the

machine compartment.

3 Pin

Connector

Electrical Shock

1

2

2 Pin

Connector

to Heater

Connector

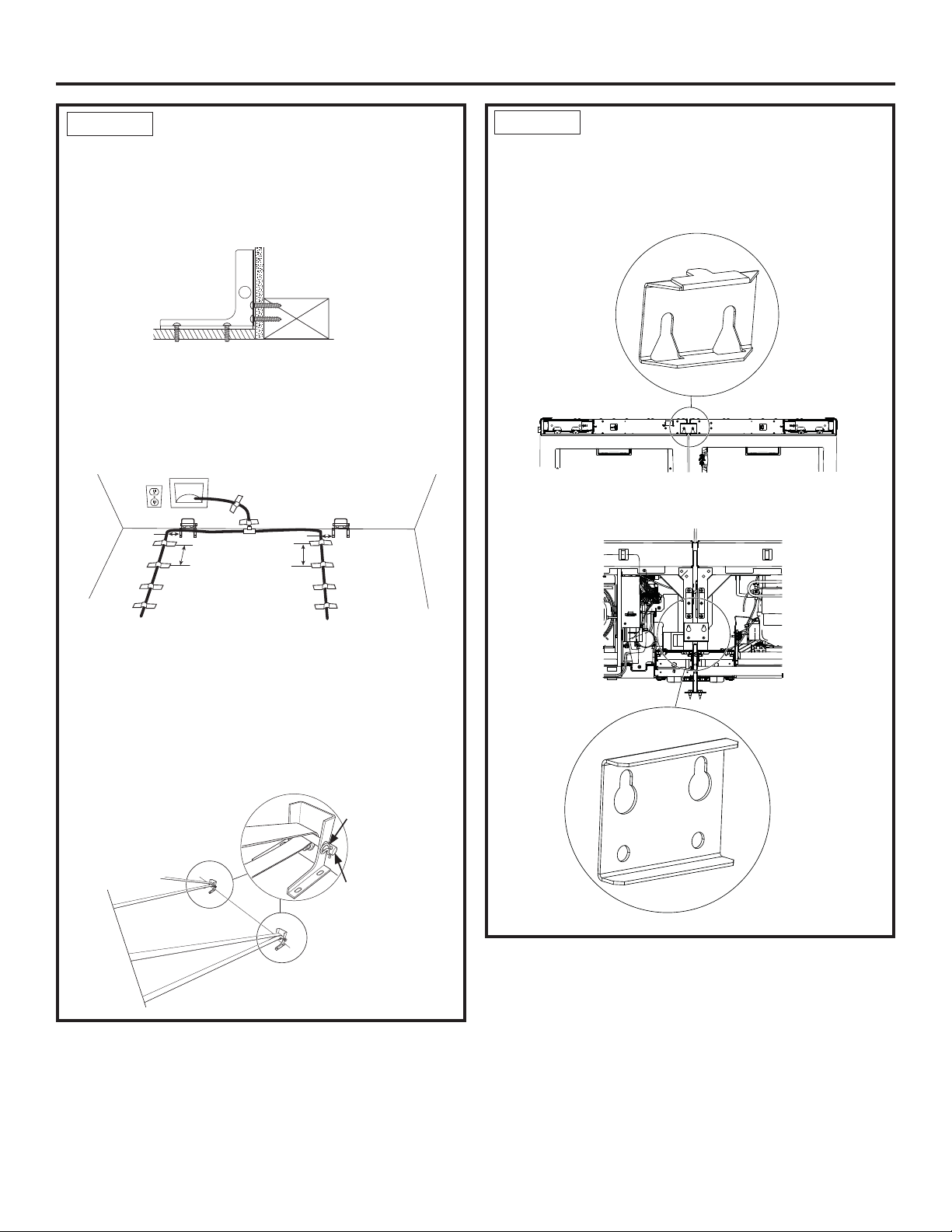

STEP 4

WARNING

INSTALL ANTI-TIP BRACKET

Tip Over Hazard.

These appliances are top heavy, especially with

any doors open, and must be secured to prevent

tipping forward which could result in death or serious injury. Read and follow the entire installation

instructions for securing the appliance with the

anti-tip system.

Ŷ Remove the anti-tip bracket from the hardware kit.

Ŷ Anti-tip bracket should be mounted against the back

wall or up to 27” (68.6 cm) maximum from front of

opening. Use floor mounting method if the bracket is

not against a wall (bracket hardware is provided for

mounting into wood, steel studs and concrete).

Unit LH Unit

18” 10-7/8”

(27.62cm)

24” 14-7/8”

(37.78cm)

30” 18-7/8”

(47.95cm)

18” 24” 30”

29-3/4”

(75.57 cm)

33-3/4”

(85.73 cm)

37-3/4”

(95.89 cm)

RH Units

33-3/4”

(85.73 cm)

39-3/4”

(100.97cm)

45-3/4”

(116.21cm)

37-3/4”

(95.89 cm)

43-3/4”

(110.49cm)

49-3/4”

(126.37cm)

3

Transformer

Ŷ Replace the left access cover and 4 (1/4”) hex

screws.

Ŷ Measure and mark from the LH side of the opening

per the table above depending on the size of the LH

unit you are installing.

LH Unit

RH Unit

Ŷ Measure and mark again from the LH side of the

opening per the table and depending on your

combination of LH and RH units.

For example, if installing an 18” LH unit and a 30” RH

unit, use 10-7/8” and 37-3/4”.

31-49133-1

11

Page 12

Installation Instructions - Dual Integrated Installation

STEP 4

BRACKET

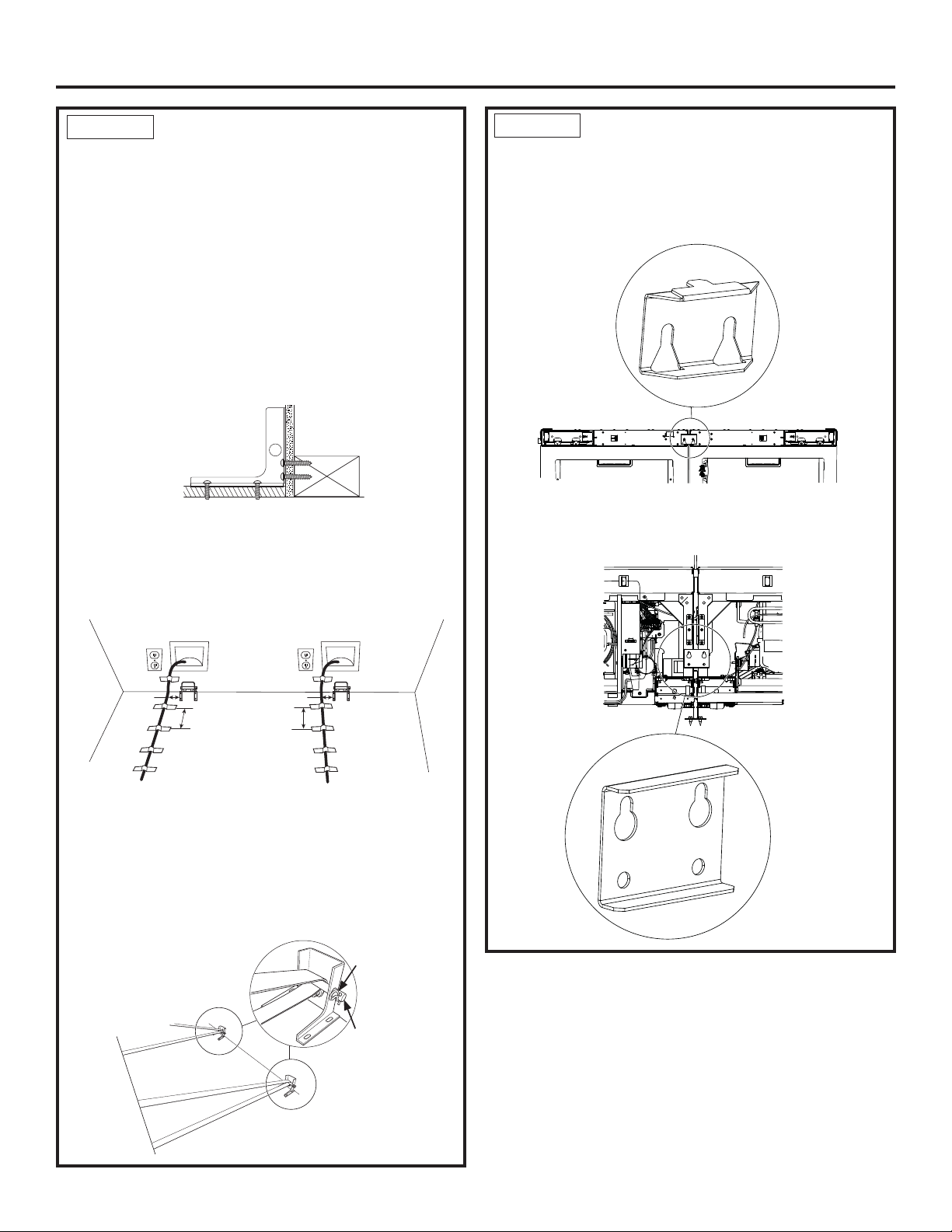

Ŷ Mount the anti-tip bracket centered about the marks

and flush to the floor as shown. Mark 3 holes for wall

mounting or 4 holes for floor mounting.

WOOD MOUNTING: Predrill with 3/16” drill bit, 2”

deep, then install lag bolts with a 7/16” driver.

CONCRETE MOUNTING: Predrill with a 5/32”

concrete bit, 2” deep, then install tapcon screws with

a 7/16” driver.

STEEL MOUNTING: Predrill with a 1/2” drill bit, insert

toggle, then install bolts with a 7/16” driver.

The bracket must be screwed to either the FLOOR or

REAR WALL.

Ŷ Tape the waterline to the wall and floor approximately

3” to the left of the anti-tip bracket. Apply tape about

every 5” toward the front of the opening (tape will

prevent the unit from rolling over the waterline during

installation). Do not tape near the cabinet front in

order to keep tape hidden under the unit.

INSTALLING ANTI-TIP

(Cont.)

STEP 5

JOINING DUAL INSTALLED

UNITS

Ŷ Place the left hand unit in front of the opening.

Ŷ Install top unification bracket between the 2 units by

sliding in place over the two shoulder bolts.

Ŷ Install the bottom unification bracket using a 3/8”

driver (4 screws).

3"

5"

Ŷ Route the strapping coiled up at the back of the unit

through the anti tip bracket.

1. Cut the wire tie holding the strap bundle.

2. Put the strap on the backside of the retaining pin.

3. Secure the retaining pin to the bracket with the

cotter pin.

4. Repeat strap routing on the second unit.

3"

5"

Cotter

Pin

Retaining

Pin

12

31-49133-1

Page 13

Installation Instructions - Dual Integrated Installation

STEP 6

WARNING

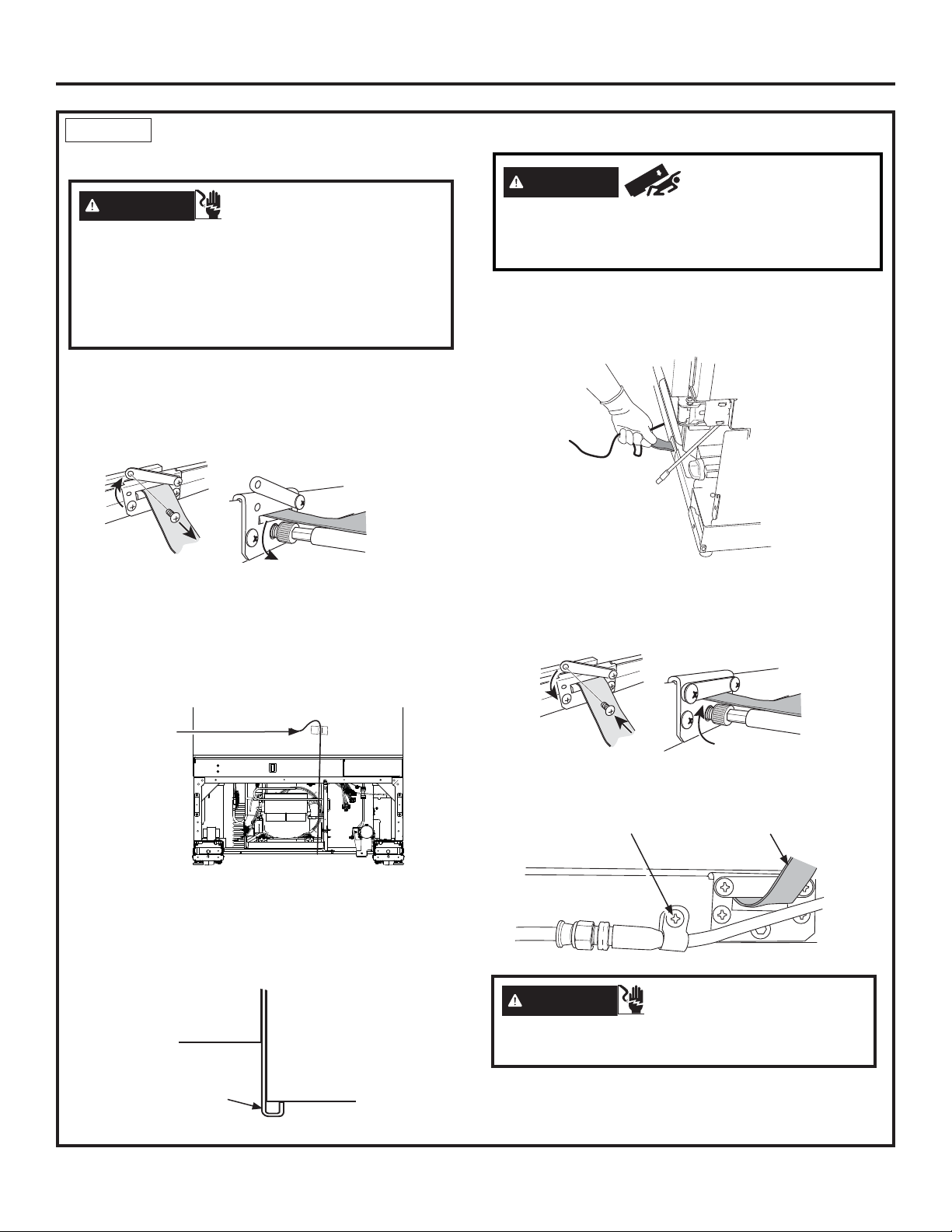

CONNECTING WATER SUPPLY

Connect to potable water supply

only.

House

Water Supply

Refrigerator/

Freezer

Freezer

Water Supply

Water Supply

Ŷ Locate and bring the tubing to the front of the cabinet.

Ŷ Turn the water on to flush debris from the line. Run

about a quart of water through the tubing into a bucket,

then shut off the water.

Ŷ Remove strain relief screw to allow for enough slack

to make a proper water connection. (Screw must be

replaced in the next step.)

Strain Relief

Screw

Anti-tip Strap

Copper Tubing:

Ŷ Slip a 1/4” nut and ferrule (provided) over both ends of

the copper tubing. Insert the tube into the union fitting

on the unit and tighten the nut to the union.

Ŷ Turn on the water to check for leaks.

SmartConnect™ Tubing:

NOTE: The only GE Appliances-approved plastic tubing

is supplied in the SmartConnect™ Refrigerator Tubing

kits. Do not use any other plastic water supply line

because the line is under pressure at all times. Other

types of plastic may crack or rupture with age and cause

water damage to your home.

Ŷ Insert the molded end of the tubing into the refrigerator

or freezer connection. Tighten the compression nut

until it is just hand-tight.

Ŷ Tighten one additional turn with a wrench.

Overtightening can cause leaks!

Ŷ Turn on the water to check for leaks.

31-49133-1

13

Page 14

Installation Instructions - Dual Integrated Installation

STEP 7

Ŷ Plug both units into the outlet in the wall.

WARNING

To reduce the risk of electrical shock, be careful

during the remaining installation steps not to

touch wiring or electrical components inside the

compressor compartment while the appliance is

plugged in and the front access cover is not in

place.

Ŷ Loosen the strap by removing a Phillips head screw

from the top strap bar and the large tensioner 1/4”

allen screw to allow the strap to move freely during

installation. Retain screws for later installation in this

step. Repeat process for both units.

INSERTING/SECURING INTO CABINET SURROUND

Electrical Shock Hazard.

Ŷ As you walk the unit back, pull the anti-tip strap tight.

Secure the strap in the front of the unit. This process

should be completed for each unit.

Ŷ Secure the strap in the front of the unit by replacing the

screw in the top strap bar (do not overtighten) and the

large tensioner screw to prevent the strap from moving.

This process must be completed for both units.

Ŷ Find the installation string that is attached to the door

of the unit; this is to be used as you are pushing the

unit back into the opening. The string is attached to the

power cord; as you walk the unit back into the opening

you should pull the string tight to make sure the power

cord is routed underneath the unit.

Installation

String

Ŷ Slowly walk both units into opening making sure not

to touch the cabinetry on the sides and top to prevent

damage. Both door faces should be 7/8” behind the

front face of surrounding cabinets on either a stainless

or custom panel installation.

WARNING

These appliances are top heavy, especially with

any doors open, and must be secured to prevent

tipping forward which could result in death or

serious injury.

Tip Over Hazard.

Ŷ Replace the waterline strain relief screw.

Strain Relief

Screw

Anti-tip Strap

WARNING

Replace waterline strain relief in front rail location as

shown.

Ŷ Store the excess strapping, string, and water tubing

under the unit.

Electrical Shock Hazard.

14

31-49133-1

Page 15

Installation Instructions - Dual Integrated Installation

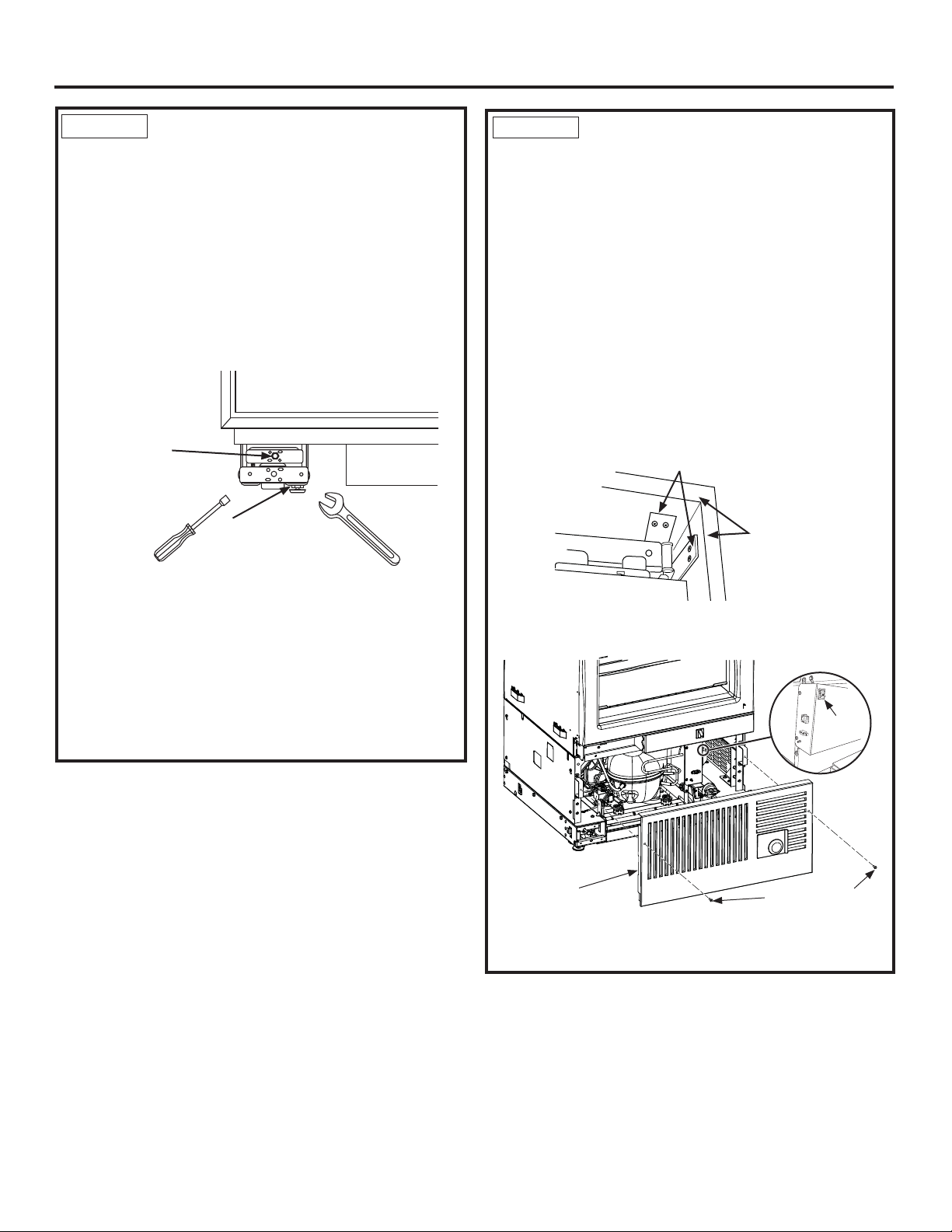

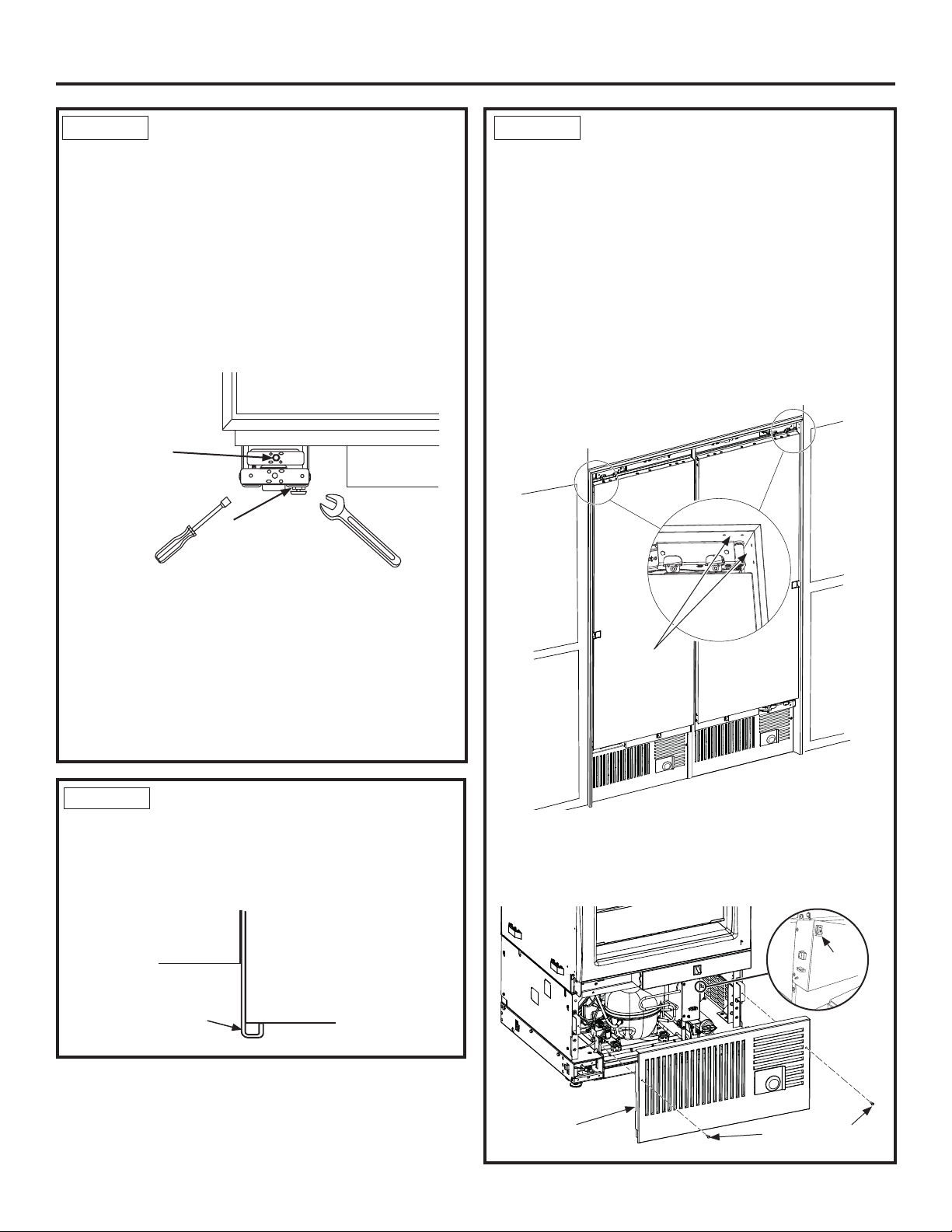

STEP 8 LEVEL UNIT

All models have 4-point leveling. The front is supported

by leveling legs; the rear is supported by adjustable

wheels. Both are accessible from the front of the unit.

Ŷ To level the back of the unit, turn the 7/16” hex nut

located above the front wheels. Turn clockwise to

raise or counterclockwise to lower the unit.

Ŷ For front leveling, use a 7/16” open-end wrench.

Ŷ Adjust height of unit to match installation cutout

opening 84”. The unit should be level and plumb with

cabinetry.

Hex nut adjusts

rear wheels

Open-end wrench

adjusts front

leveling legs

STEP 9

FINAL EXTERNAL UNIT

PREPARATION

Ŷ FOR FLUSH INSTALLATION: Make sure front

surface of the door is 7/8” behind front face of

surrounding cabinets BEFORE securing brackets to

the surrounding cabinetry.

Ŷ Secure stabilization brackets by predrilling 1/16”

holes in both the side and top surround 1/2” deep

through holes in the bracket. Drive 4 No. 6 Phillips

head screws to secure the unit stabilization bracket

to surrounding cabinetry. NOTE: This step does NOT

replace the anti-tip safety hardware. Refer to Step

4 Installing Anti-Tip Bracket and Step 7 Inserting/

Securing into Cabinet Surround for details on

installing the anti-tip hardware. Repeat for the second

unit.

Stabilization Bracket already

installed to unit

Cabinet

surround

NOTICE: The rear leveling wheels and front leveling

legs are limited to a maximum height adjustment of 1”.

If the installation requires more than 84” height, the

installer should elevate the unit on a sheet of plywood

or runners. Cabinetry trim could also be added across

the top of the opening to shorten the opening. If you

attempt to raise the unit more than 1”, you will damage

the front leveling legs and the rear leveling wheels.

Ŷ Open doors to make sure lights are on. If they are

not on, check to make sure the master switch is on.

Master

Switch

Front Access

Cover

Ŷ Install front access covers by replacing 2 T20 Torx

screws on each cover.

T20 Torx Screws

31-49133-1

15

Page 16

Installation Instructions - Dual Integrated Installation

STEP 9

FINAL EXTERNAL UNIT

PREPARATION (Cont.)

Ŷ Install front mullion and access cover trims between

the 2 units. Open the doors and push the flexible

“dart” area of the trims in place between units.

Upper Mullion

Trim

“Dart”

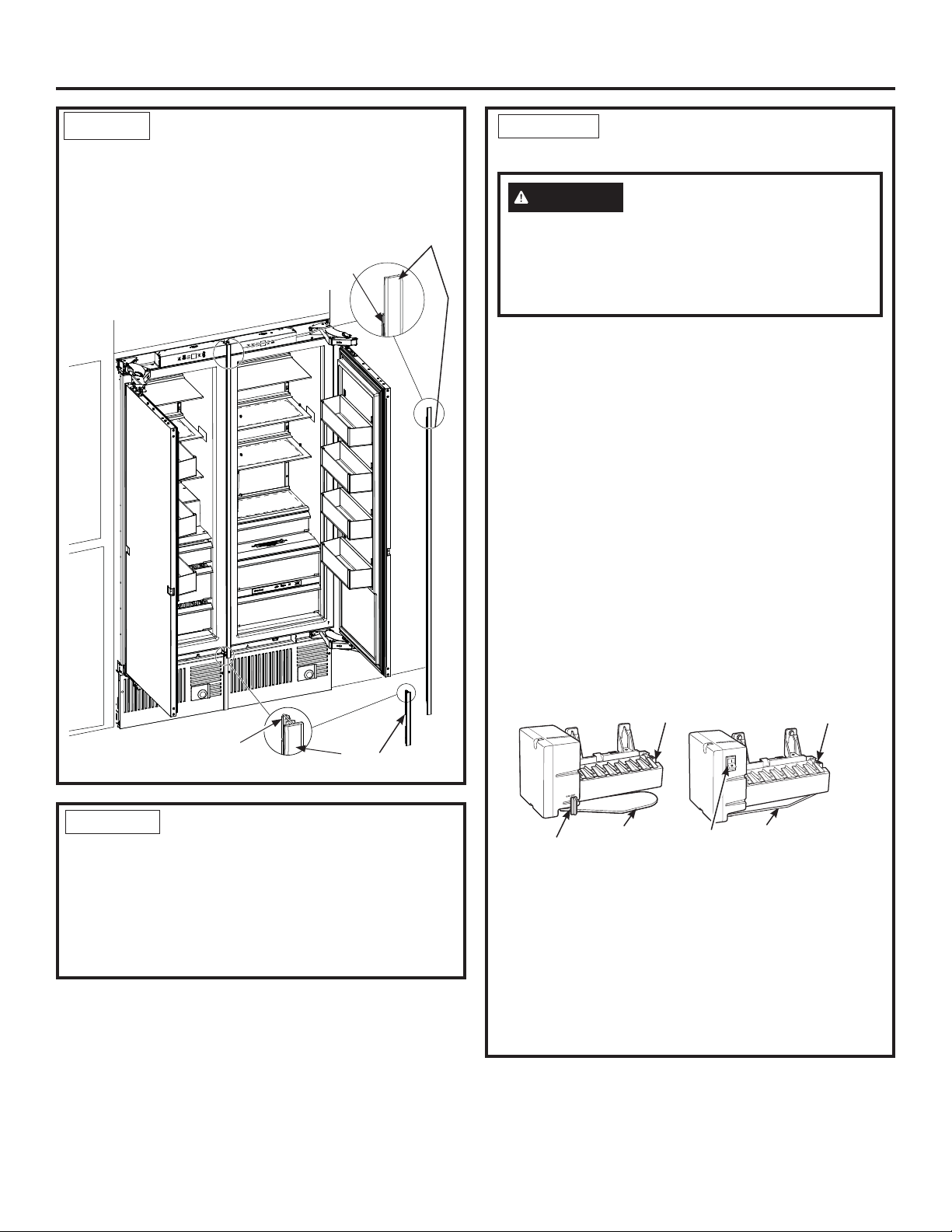

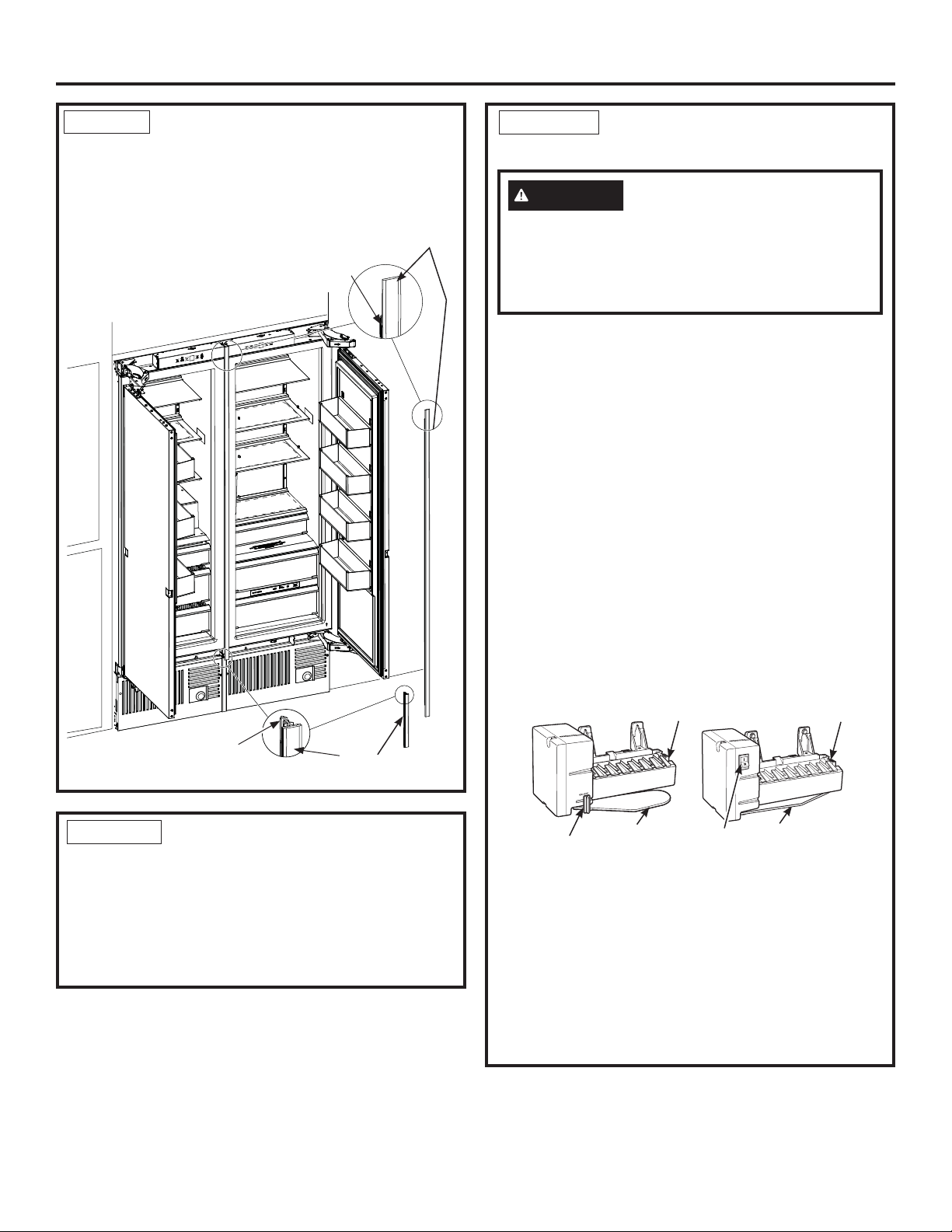

STEP 11 START ICEMAKER

(freezer models)

CAUTION

of the ejector mechanism, or with the heating element

(located on the bottom of the icemaker) that releases

the cubes. Do not place fingers or hands on the

automatic ice making mechanism while the freezer is

plugged in.

A newly-installed freezer may take 12–24 hours to

begin making ice.

The icemaker will produce seven cubes per cycle—

approximately 15 cycles in a 24-hour period,

depending on freezer compartment temperature, room

temperature, number of door openings and other use

conditions.

If the freezer is operated before the water connection

is made to the icemaker, set the power switch to

OFF. Top wire basket must be removed to access the

icemaker power switch.

When the freezer has been connected to the water

supply, set the power switch to ON.

Avoid contact with the moving parts

“Dart”

Lower

Mullion Trim

STEP 10 INTERNAL UNIT

PREPARATION

Ŷ Remove all tape, cardboard, and foam from each

unit.

Ŷ Remove boxed door bins from shelves.

Ŷ Unbox and install door bins.

Throw away the first full bucket of ice to allow the water

line to clear.

Be sure nothing interferes with the sweep of the feeler

arm.

(Appearance may vary)

Icemaker

Power

Switch

When the bin fills to the level of the feeler arm, the

icemaker will stop producing ice.

It is normal for several cubes to be joined together.

If ice is not used frequently, old ice cubes will become

cloudy, taste stale and shrink.

NOTE: Icemaker works best between 40 and 120 PSI

(275-827 kPa) home water pressure.

Feeler Arm

Power

Switch

Icemaker

Feeler Arm

16

31-49133-1

Page 17

Installation Instructions - Dual Integrated Installation

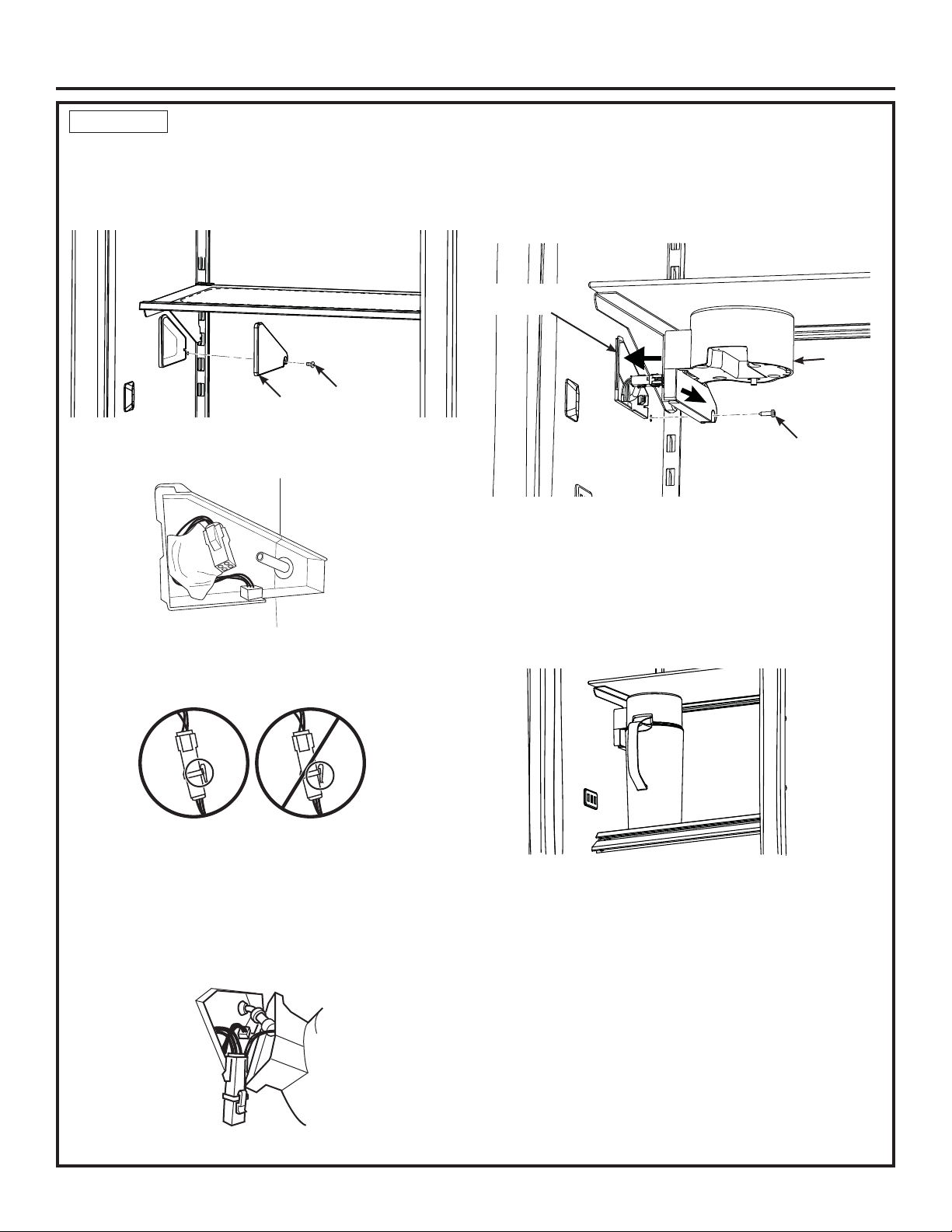

STEP 12 INSTALL AUTOFILL PITCHER ASSEMBLY (Some Refrigerator Models)

Ŷ Locate the AutoFill pitcher cover on the left side of the

refrigerator’s interior. Remove T20 Torx screw holding

the cover in place towards the rear of the cover. Retain

this screw for attachment of AutoFill assembly.

Cover

Ŷ Slide the cover forward to remove. This reveals an

electrical connector and a water tube.

Ŷ Remove the AutoFill assembly from the box. Connect

the 4 pin connector from the AutoFill assembly to the

connector in the compartment wall.

Screw

Ŷ Conceal wires and tubing inside the wall compartment

and place the AutoFill wall assembly onto the forward

end of the mount until flush with the interior wall of the

refrigerator. Slide the assembly toward the back wall

until mounting screw hole is visible.

Mount

Compartment

AutoFill

Assembly

Screw

Ŷ Secure AutoFill assembly with the T20 Torx screw

removed earlier.

Ŷ Ensure supply water is connected to the refrigerator

before proceeding further.

Ŷ Align the pitcher lid to the dispenser guide and slide

the pitcher toward the back of the refrigerator until it

stops. There may be up to a 5 second response time

before water starts to fill the pitcher.

Ŷ Ensure that the locking tab on the connector is fully

engaged.

Ŷ Connect the water line fitting from the AutoFill

assembly to the water tube located in the

compartment. Ensure the water tube is firmly

connected and will not easily become unattached.

Water tube should be inserted to the tubing mark.

31-49133-1

Ŷ Water will fill the pitcher until it reaches a specified

level and will then shut off. It is normal for the water

level to be below the top of the pitcher.

NOTE: After installing the AutoFill pitcher, run 2 gallons

of water (approximately 5 full pitchers) through the

AutoFill dispenser to remove air from the system.

A newly installed filter cartridge will cause water to

spurt and dribble until the air is out of the system. It is

normal for water to appear discolored during the initial

system flush. Water color will return to normal after the

first minutes of dispensing. Wash the AutoFill pitcher

following the initial flush before using.

NOTE: Do not place the pitcher in the dispenser guide

before the water connection is made to the refrigerator.

17

Page 18

Instructions for Dual Retro-Fit Installation

Existing construction installation with 24” deep openings

that are 41-1/2” or 47-1/2” wide

18

31-49133-1

Page 19

Design Guide - Dual Retro-Fit Installation

DUAL RETRO-FIT INSTALLATION SPACE

Dimensions in parentheses are in centimeters.

47 1/2" (120.7)

20" (50.8)

6"

E

(15.2)

5"

(12.7)

83 1/2" min

84 1/2" max

(212.1-214.6)

Trim will overlap

additional 7/16"

5"

(12.7)

WATER

FRONT VIEW SIDE VIEW

(12.7)

75"

(190.5 )

From floor

to bottom

of electrical

area

3 1/2"

5"

(8.9)

24" (61.0)

3/4"

(1.91)

W

41 1/2" (105.4)

18" (45.7)

6"

E

(15.2)

5"

*83 1/2" min

*84 1/2" max

(212.1-214.6)

*Trim will overlap

additional 7/16"

(12.7)

5"

(12.7)

75"

(190.5 )

From floor

to bottom

of electrical

area

3 1/2"

5"

(8.9)

(12.7)

WATER

FRONT VIEW SIDE VIEW

Water And Electrical Locations

Electrical and water supply must be located as shown.

For 24” Deep Cutouts

Trim Retro kits are required for a 41.5”(ZTKC42) or a

47.5” (ZTKC48) wide opening.

Heater Unification Kit ZUGC required

Product Clearances

These units are equipped with a 2-position door stop.

The factory set 115° door swing can be adjusted to 90°

if clearance to adjacent cabinets or walls is restricted.

For a 90° door swing, allow 4” (10.2 cm) minimum

clearance to a wall.

When installed in a corner, allow 15” (38.1 cm) for a full

115° door swing on 18” and 24” models. Allow 16.5”

(41.9 cm) on 30” models.

24" (61.0)

3/4"

(1.91)

W

Additional Specifications

• A separate 115 volt 60Hz., 15 or 20 amp power supply

is recommended for each product. An individual

properly grounded branch circuit or circuit breaker is

recommended. Install a properly grounded 3-prong

electrical receptacle recessed into the back wall.

Electrical must be located on rear wall as shown.

• Water line must be located on the back wall as shown.

The water line should be 1/4” O.D. copper tubing or

QuickConnect™ kit (WX08X10006) between the cold

water line and water connection location, long enough

to extend to the front of the unit (8’ [2.4m]). Installation

of an easily accessible shut-off valve in the water line

is required.

31-49133-1

19

Page 20

Installation Instructions - Dual Retro-Fit Installation

REFRIGERATOR/FREEZER LOCATION

Ŷ Do not install the refrigerator/freezer where the tem-

perature will go below 55°F (13°C). It will not run

often enough to maintain proper temperatures.

Ŷ Do not install the refrigerator/freezer where

temperatures will go above 100°F (37°C). It will not

perform properly.

Ŷ Do not install the refrigerator/freezer in a location

exposed to water (rain, etc.) or direct sunlight.

Ŷ Install it on a floor strong enough to support it fully

loaded.

TOOLS AND MATERIALS REQUIRED

• Metal shears

• #1, #2 Phillips screwdriver

• Flathead screwdriver

• Putty knife

• Measuring tape

• Drill and 1/16”, 5/64”, 3/16”, 1/2” bits

• 5/32” concrete bit (if installing anti-tip into concrete)

• 1/4”, 3/8”, 7/16” driver/socket

• 7/16” open wrench

• T20, T30 driver/bit

• 5/64”, 1/8”, 1/4” hex driver (allen wrench)

• Level

• Water shut-off valves (optional but recommended)

• 8’ waterline (one per unit requiring water hookup)

• Masking tape

• Rubbing alcohol

• Adjustable wrench

• Center punch

• Heater Unification Kit (ZUGC)

• Stainless Steel Door Kits (if applicable)

• Custom panels for doors (if applicable)

• Handle Kits (if applicable)

• 42” (ZTKC42) or 48” (ZTKC48) Trim Retro Kit

GROUNDING THE UNIT

WARNING

Hazard. Failure to follow these instructions can

result in death, fire, or electrical shock.

The power cord of this appliance is equipped with a

3-prong (grounding) plug which mates with a standard

3-prong (grounding) wall receptacle to minimize the

possibility of electric shock hazard from this appliance.

Have the wall outlet and circuit checked by a qualified

electrician to make sure the outlet is properly grounded.

Where a standard 2-prong wall outlet is encountered, it

is your personal responsibility and obligation to have it

replaced with a properly grounded 3-prong wall outlet.

DO NOT, UNDER ANY CIRCUMSTANCES, CUT OR

REMOVE THE THIRD (GROUND) PRONG

FROM THE POWER CORD.

DO NOT USE AN ADAPTER

PLUG TO CONNECT THE

REFRIGERATOR TO A 2-PRONG

OUTLET.

DO NOT USE AN EXTENSION

CORD WITH THIS APPLIANCE.

Electrical Shock

FLOORING

For proper installation, this product must be placed

on a level surface of hard material that is at the same

height as the rest of the flooring. This surface should

be strong enough to support a fully loaded refrigerator

or freezer, or approximately 1,200 lbs. per unit.

NOTE: Protect the finish of the flooring.

NOTE: Not recommended for installation on carpeted

flooring.

HARDWARE SUPPLIED (per unit)

• Water Filter Bypass Plug (if equipped)

• Air filter (if equipped)

• Anti-Tip bracket

• 3 Lag screws

• 3 Tapcon screws

• 3 Toggles with bolts

• 1 Hair Pin Cotter

• 1 Retaining pin

• Panel installation templates

• 2 Door trims

• 2 Door panel brackets

• Set screws

• #6 Phillips head wood screws

• Door Bracket Cover Top

• T30 screws

• 1 Hinge limiter pin

• Center door panel bracket

• Hi-Lo screw and square washer

20

31-49133-1

Page 21

Installation Instructions - Dual Retro-Fit Installation

STEP 1 REMOVE PACKAGING

WARNING

appliance is top heavy. Use extreme caution with

moving to prevent tipping over which could result in

death or serious injury.

Ŷ Remove outer carton and external packing from units.

Ŷ Inspect for damage.

Ŷ Ensure the flooring that the units are set is clean/

free of debris that could be collected on to, or

pinched in front of the wheels and damaging the

floor. Additionally, it is recommended that the floor

be protected with a plastic covering through out the

installation process.

Ŷ Remove hardware kit from top drawer.

Ŷ If installation requires a 90° door opening, the hinge

limiter pin must be installed

in the top hinge BEFORE

the unit is removed from

the skid. Pin is located in

the hardware kit.

- Open the door

approximately 45°, but no

wider than 90°, to expose

the hole in the back hinge

bracket and install the

limiting pin. Pin must be

fully seated in the bracket

or the door will not close properly.

Ŷ Remove front access cover from unit by removing 2

T20 Torx screws. Place the cover and screws to the

side for future installation.

3/8” Drive

Screws

Shipping

Bracket

7/16” Drive

Screws

Ŷ Remove three 3/8” drive screws and two 7/16” drive

screws from each side of the unit to release it from

the skid. Tip the unit from the side enough to remove

the shipping material from under the unit, but above

the skid (both sides)

Ŷ CAREFULLY roll the unit off the back side of the skid.

Ŷ Handle from side only with a hand truck.

Tip Over Hazard. This

Top

hinge

T20 Torx Screws

STEP 2 INSTALL WATER LINE

WARNING

Ŷ

A cold water supply is required for automatic icemaker

and AutoFill pitcher operation. The water pressure

must be between 40 and 120 p.s.i. (275-827 kPa).

Shut off the main water supply.

Turn on the nearest faucet long enough to clear the

line of water.

ŶInstall a shut-off valve between the water valve and

cold water pipe in a basement or cabinet. The shutoff valve should be located where it will be easily

accessible.

ŶTurn on the main water supply and flush debris.

Run about a quart of water through the tubing into a

bucket. Shut off water supply at the shut-off valve.

NOTE: Saddle type shut-off valves are included in

many water supply kits. Before purchasing, make sure

a saddle type valve complies with your local plumbing

codes.

NOTE: Commonwealth of Massachusetts Plumbing

Codes 248CMR shall be adhered to. Saddle

valves are illegal and use is not permitted in

Massachusetts. Consult with your licensed plumber.

Ŷ Connect the jumper water line from the ZTKC42 or

ZTKC48 Trim Retro Kit to the house cold water line.

Tighten the compression nut hand tight, then tighten

one additional turn with a wrench. Overtightening

can cause leaks!

Ŷ Connect the other end of the jumper water line to the

water fitting tee supplied in the trim retro kit. Tighten

the compression nut hand tight, then tighten one

additional turn with a wrench. Overtightening can

cause leaks!

Ŷ Route 1/4” OD copper or SmartConnect™

(WX08X10006) plastic tubing between water fitting

tee and the water connection location at the front of

the unit.

SmartConnect™ Refrigerator Tubing Kits are

available. One 8’ (2.4m) water line (WX08X10006) is

needed for each unit.

Ŷ Tubing should be long enough to extend to the front

of the unit. Allow enough tubing to accommodate

bend leading into the water line connection. Unit

must be tipped on its side to route waterline

underneath and to the front of the appliance.

Connect to potable water supply

only.

Water Line Jumper

31-49133-1

Water Fitting Tee

21

Page 22

Installation Instructions - Dual Retro-Fit Installation

STEP 2 INSTALL WATER LINE

(Cont.)

NOTE: The only GE Appliances approved plastic tubing

is supplied in the SmartConnect™ Refrigerator Tubing

kits. Do not use any other plastic water supply line

because the line is under pressure at all times. Other

types of plastic may crack or rupture with age and

cause water damage to your home.

Ŷ Tape the jumper waterline and water fitting tee to the

back wall. The waterlines will be taped to the floor

using masking tape after anti-tip bracket installation.

STEP 3 PREPARING UNIT FOR

INSTALLATION

Ŷ Place the right hand unit in front of the installation

opening in a way that the unit is in front of the

intended installed location.

Ŷ Unpack the heater Unification Kit (ZUGC) and make

sure all of the components on the list are included.

Ŷ Install 4 bumper blocks by snapping them to the left

side of the case between the 2 units - 2 on the upper

section of the case wall and 2 on the lower.

STEP 3 PREPARING UNIT FOR

INSTALLATION (Cont.)

Ŷ

Install adhesive heater on the outside of the unit to

the left side of the case. Install heater 2” below the top

2 standoff blocks. Heater should be centered front to

back on the metal case. Ensure the heater connector

cord is toward the bottom of the unit when installed.

Ǝ

Adhesive

Heater

Upper bumpers

Lower bumpers

Clips

Left Access

Hex

Screws

Ŷ Remove the left access cover by removing 4 (1/4”)

hex screws. The cover is located at the outside lower

left side of the case.

Ŷ Use clips to adhere loose wire tightly to side of case

as shown. Clean the side using rubbing alcohol to

ensure proper clip adhesion.

Cover

22

31-49133-1

Page 23

Installation Instructions - Dual Retro-Fit Installation

STEP 3 PREPARING UNIT FOR

INSTALLATION (Cont.)

WARNING

Hazard. To avoid the risk of electric shock, make

sure the power cord is not plugged into the wall

outlet.

Ŷ Install the transformer into the machine compartment:

1. Plug transformer into the 3 pin connector at the top

of the machine compartment. Make sure locking

tabs are engaged.

2. Place the transformer into the machine compartment

and secure it with the 2 (1/4”) hex screws provided

in ZUGC kit.

3. Connect the 2 pin transformer connector to the

heater connector, make sure locking tabs are

engaged, and place in wire clip at the top of the

machine compartment.

3 Pin

Connector

Electrical Shock

1

2

2 Pin

Connector

to Heater

Connector

STEP 4

WARNING

INSTALL ANTI-TIP BRACKET

Tip Over Hazard.

These appliances are top heavy, especially with

any doors open, and must be secured to prevent

tipping forward which could result in death or serious injury. Read and follow the entire installation

instructions for securing the appliance with the

anti-tip system.

Ŷ Remove the anti-tip bracket from the hardware kit.

Ŷ Anti-tip bracket should be mounted against the back

wall or up to 27” (68.6 cm) maximum from front of

opening. Use floor mounting method if the bracket is

not against a wall (bracket hardware is provided for

mounting into wood, steel studs and concrete).

Unit LH Unit

18” 10-7/8”

(27.62cm)

24” 14-7/8”

(37.78cm)

30” 18-7/8”

(47.95cm)

18” 24” 30”

29-3/4”

(75.57 cm)

33-3/4”

(85.73 cm)

37-3/4”

(95.89 cm)

RH Units

33-3/4”

(85.73 cm)

39-3/4”

(100.97cm)

45-3/4”

(116.21cm)

37-3/4”

(95.89 cm)

43-3/4”

(110.49cm)

49-3/4”

(126.37cm)

3

Transformer

Ŷ Replace the left access cover and 4 (1/4”) hex

screws.

Ŷ Measure and mark from the LH side of the opening

per the table above depending on the size of the LH

unit you are installing.

LH Unit

RH Unit

Ŷ Measure and mark again from the LH side of the

opening per the table and depending on your

combination of LH and RH units.

For example, if installing an 18” LH unit and a 30” RH

unit, use 10-7/8” and 37-3/4”.

Ŷ Mount the anti-tip bracket centered about the marks

and flush to the floor as shown. Mark 3 holes for wall

mounting or 4 holes for floor mounting.

WOOD MOUNTING: Predrill with 3/16” drill bit, 2”

deep, then install lag bolts with a 7/16” driver.

CONCRETE MOUNTING: Predrill with a 5/32”

concrete bit, 2” deep, then install tapcon screws with

a 7/16” driver.

31-49133-1

23

Page 24

Installation Instructions - Dual Retro-Fit Installation

STEP 4

(Cont.)

STEEL MOUNTING: Predrill with a 1/2” drill bit, insert

toggle, then install bolts with a 7/16” driver.

The bracket must be screwed to either the FLOOR or

REAR WALL.

Ŷ Tape the waterline to the floor approximately 3” to the

left of the anti-tip bracket. Apply tape about every 5”

toward the front of the opening (tape will prevent the

unit from rolling over the waterline during installation).

Do not tape near the cabinet front in order to keep

tape hidden under the unit.

INSTALL ANTI-TIP BRACKET

3"

5"

3"

5"

STEP 5

JOINING DUAL INSTALLED

UNITS

Ŷ Place the left hand unit in front of the opening.

Ŷ Install top unification bracket between the 2 units by

sliding in place over the two shoulder bolts.

Ŷ Install the bottom unification bracket using a 3/8”

driver (4 screws).

Ŷ Route the strapping coiled up at the back of the unit

through the anti tip bracket.

1. Cut the wire tie holding the strap bundle.

2. Put the strap on the backside of the retaining pin.

3. Secure the retaining pin to the bracket with the

cotter pin.

4. Repeat strap routing on the second unit.

Cotter

Pin

Retaining

Pin

24

31-49133-1

Page 25

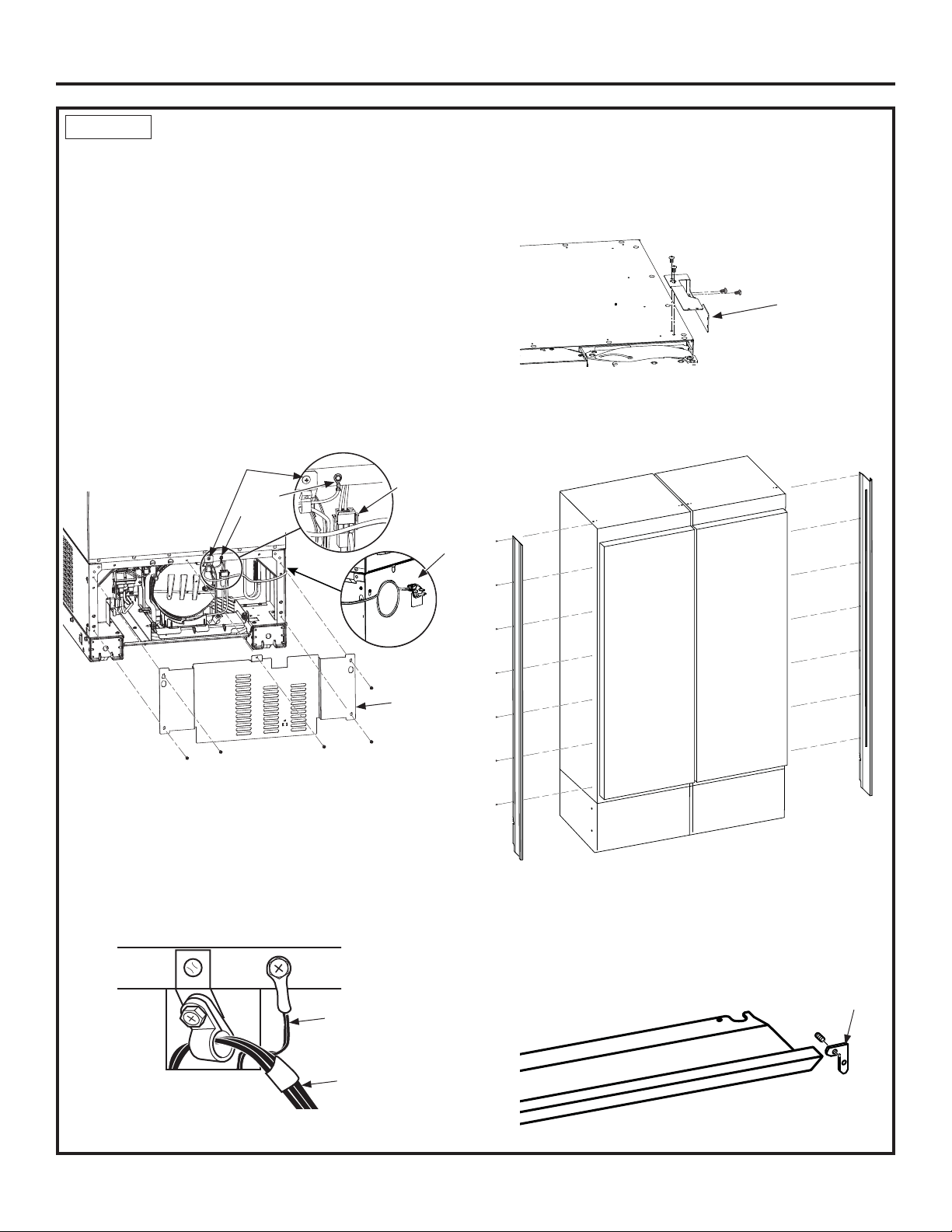

Installation Instructions - Dual Retro-Fit Installation

STEP 5 JOINING DUAL INSTALLED UNITS (Cont.)

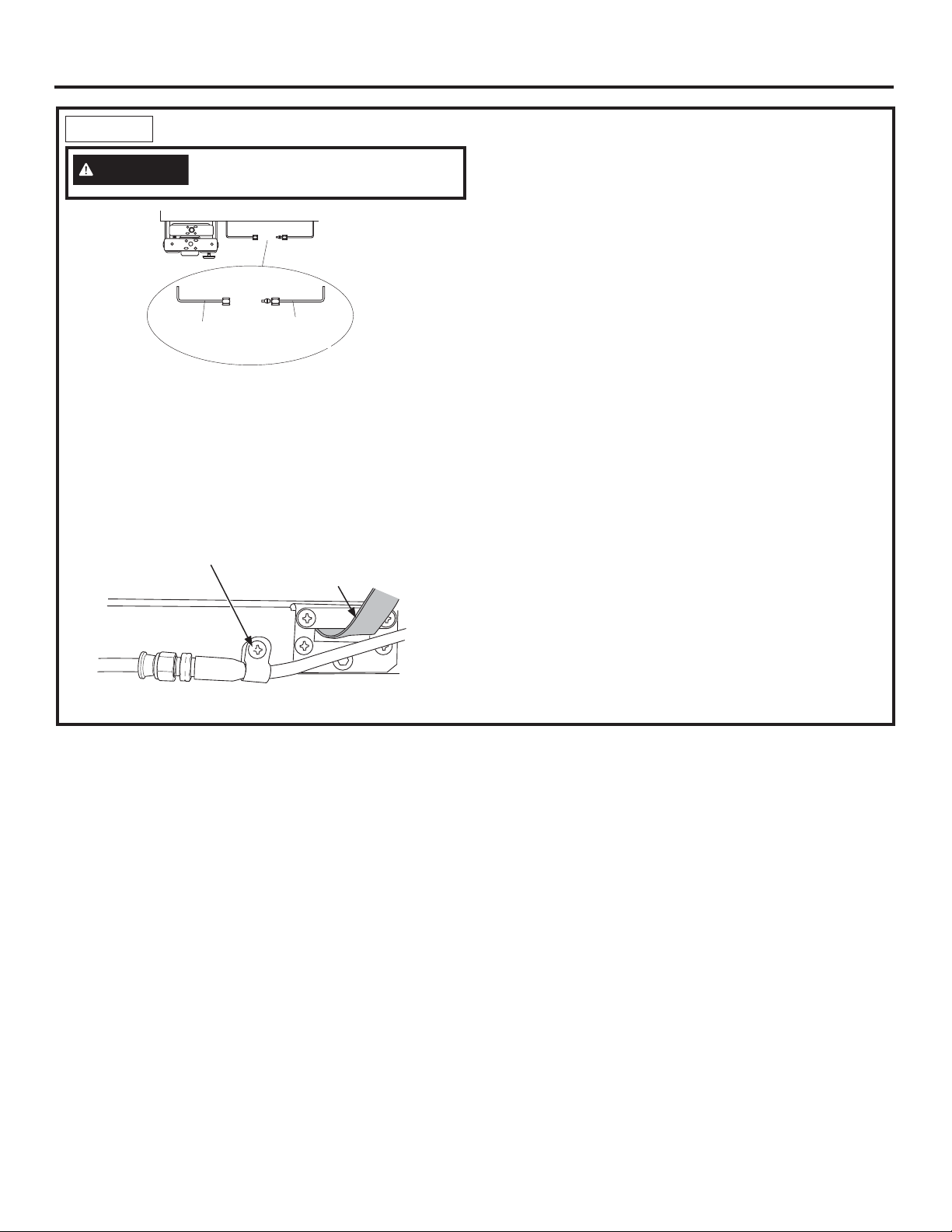

CHANGE POWER CORD

Longer power cords are required for retro fit installation.

Power cords are included in 42” ZTKC42 and 48”

ZTKC48.

Replace power cords on both units. Both units can be

plugged into the same electrical supply receptacle.

Remove existing short power cord with string

assembly:

Ŷ Remove 1/4” hex screws attaching rear access cover.

1. Unplug 3-pin power cord connector inside the

machine compartment (press on sides to release

locking tabs).

2. Remove power cord green ground 1/4” hex screw.

3. Remove strain relief 1/4” hex screw.

Strain Relief

Screw

Green

Ground

Screw

3-Pin

Power Cord

Connector

Power

Cord

CASE TRIM INSTALLATION

Ŷ Remove the stabilization brackets from the hinge side

of each column refrigerator by removing 4 Phillips head

screws per bracket.

Stabilization

Bracket

Ŷ Install the trim kit side rails to the exposed right and left

case walls using the provided #8 Phillips head screws 7 screws per side.

Rear

Access

Cover

Install new longer power cord:

1. Plug in the 3-pin connector (make sure locking tabs

are engaged).

2. Install the power cord green ground screw.

3. Install the power cord strain relief.

Ŷ Replace rear access cover. Make sure the power

cord and ground wire are properly routed through the

access cover cut-out.

Ground

Wire

Power

Cord

Repeat all steps for second unit.

Ŷ Pre-assemble the trim kit top rail and corner keys.

One corner key should be installed to each end of the

top trim. Use the provided 5/64” allen set screw in the

corner key to ensure that the key is snuggly fit to the

top trim, but be sure not to overtighten the screw to

prevent damage to the parts.

Corner

Key

31-49133-1

25

Page 26

Installation Instructions - Dual Retro-Fit Installation

STEP 5 JOINING DUAL INSTALLED

UNITS (Cont.)

CASE TRIM INSTALLATION

Ŷ Fit the top trim and side trim rails together by sliding

the exposed edges of the corner trim into the right

and left trim kit side rails. Press downward on the

top trim until each corner key is fully seated in each

side rail. Use the provided set screws to ensure each

corner key is snugly fit to each trim kit side rail.

Top Trim

with Keys

Screws

STEP 6

CONNECTING WATER

SUPPLY

WARNING

Ŷ Locate and bring the tubing to the front of the cabinet.

Ŷ Turn the water on to flush debris from the line. Run

about a quart of water through the tubing into a

bucket, then shut off the water.

Ŷ Remove strain relief screw to allow for enough slack

to make a proper water connection. (Screw must be

replaced in the next step.)

Connect to potable water supply

only.

House

Water Supply

Strain Relief

Screw

Refrigerator/

Freezer

Freezer

Water Supply

Water Supply

Anti-tip Strap

Ŷ Secure the top trim to the case by using the provided

#8 Phillips head screws (4 screws).

Copper Tubing:

Ŷ Slip a 1/4” nut and ferrule (provided) over both ends

of the copper tubing. Insert the tube into the union

fitting on the unit and tighten the nut to the union.

Ŷ Turn on the water to check for leaks.

SmartConnect™ Tubing:

NOTE: The only GE Appliances-approved plastic tubing

is supplied in the SmartConnect™ Refrigerator Tubing

kits. Do not use any other plastic water supply line

because the line is under pressure at all times. Other

types of plastic may crack or rupture with age and

cause water damage to your home.

Ŷ Insert the molded end of the tubing into the

refrigerator or freezer connection. Tighten the

compression nut until it is just hand-tight.

Ŷ Tighten one additional turn with a wrench.

Overtightening can cause leaks!

Ŷ Turn on the water to check for leaks.

26

31-49133-1

Page 27

Installation Instructions - Dual Retro-Fit Installation

STEP 7

Ŷ Plug both units to the outlet in the wall.

WARNING

To reduce the risk of electrical shock, be careful

during the remaining installation steps not to

touch wiring or electrical components inside the

compressor compartment while the appliance is

plugged in and the front access cover is not in

place.

Ŷ Loosen the strap by removing a Phillips head screw

from the top strap bar and the large tensioner 1/4”

allen screw to allow the strap to move freely during

installation. Retain screws for later installation in this

step. Repeat process for both units.

Ŷ Find the installation string that is attached to the door

of the unit; this is to be used as you are pushing the

unit back into the opening. The string is attached to the

power cord; as you walk the unit back into the opening

you should pull the string tight to make sure the power

cord is routed underneath the unit.

INSERTING/SECURING INTO CABINET SURROUND

Electrical Shock Hazard.

Installation

String

WARNING

These appliances are top heavy, especially with any

doors open, and must be secured to prevent tipping

forward which could result in death or serious injury.

Ŷ As you walk the unit back, pull the anti-tip strap tight.

Secure the strap in the front of the unit. This process

should be completed for each unit.

Ŷ Secure the strap in the front of the unit by replacing the

screw in the top strap bar (do not overtighten) and the

large tensioner screw to prevent the strap from moving.

This process must be completed for both units.

Tip Over Hazard.

Ŷ Slowly walk both units into opening making sure not

to touch the cabinetry on the sides and top to prevent

damage. The back side of the top and side retro trims

should be touching the cabinet surround when the

units are pushed back.

Refrigerator

or Freezer

Retro Trim

31-49133-1

Cabinet

Surround

Ŷ Replace the waterline strain relief screw.

Strain Relief

Screw

WARNING

Replace waterline strain relief in front rail location as

shown.

Ŷ Store the excess strapping, string, and water tubing

under the unit.

Electrical Shock Hazard.

Anti-tip Strap

27

Page 28

Installation Instructions - Dual Retro-Fit Installation

STEP 8 LEVEL UNIT

All models have 4-point leveling. The front is supported

by leveling legs; the rear is supported by adjustable

wheels. Both are accessible from the front of the unit.

Ŷ To level the back of the unit, turn the 7/16” hex nut

located above the front wheels. Turn clockwise to

raise or counterclockwise to lower the unit.

Ŷ For front leveling, use a 7/16” open-end wrench.

Ŷ Adjust height of unit to match installation cutout

opening 84”. The unit should be level and plumb with

cabinetry.

Hex nut adjusts

rear wheels

Open-end wrench

adjusts front

leveling legs

STEP 9

FINAL EXTERNAL UNIT

PREPARATION (Cont.)

Ŷ Secure the trims to the surrounding cabinets to

reduce excess movement to the top of the case

during normal operation.

1. Drill 1/16” pilot holes in the trim (4 per side, see

figure for approximate locations).

2. Drive #6 Phillips head wood screws into the pilot

holes.

NOTE: This step does NOT replace the anti-tip safety

hardware. Refer to Step 4 Installing Anti-Tip Bracket

and Step 7 Inserting/Securing into Cabinet Surround for

details on installing the anti-tip hardware. Repeat for the

second unit.

NOTICE: The rear leveling wheels and front leveling

legs are limited to a maximum height adjustment of 1”.

If the installation requires more than 84” height, the

installer should elevate the unit on a sheet of plywood

or runners. Cabinetry trim could also be added across

the top of the opening to shorten the opening. If you

attempt to raise the unit more than 1”, you will damage

the front leveling legs and the rear leveling wheels.

STEP 9

FINAL EXTERNAL UNIT

PREPARATION

Ŷ For proper case placement after leveling, the back

side of the top and side retro trims should be flush

with the cabinet surround on all sides.

Refrigerator

or Freezer

Retro Trim

Cabinet

Surround

2 at the top

and 2 on the

side in each

corner

Ŷ Open doors to make sure lights are on. If they are not

on, check to make sure the master switch is on.

Ŷ Install front access covers by replacing 2 T20 Torx

screws on each cover.

Master

Switch

28

Front Access

Cover

T20 Torx Screws

31-49133-1

Page 29

Installation Instructions - Dual Retro-Fit Installation

STEP 9

FINAL EXTERNAL UNIT

PREPARATION (Cont.)

Ŷ Install front mullion and access cover trims between

the 2 units. Open the doors and push the flexible

“dart” area of the trims in place between units.

Upper Mullion

Trim

“Dart”

STEP 11 START ICEMAKER

(freezer models)

CAUTION

of the ejector mechanism, or with the heating element

(located on the bottom of the icemaker) that releases

the cubes. Do not place fingers or hands on the

automatic ice making mechanism while the freezer is

plugged in.

A newly-installed freezer may take 12–24 hours to

begin making ice.

The icemaker will produce seven cubes per cycle—

approximately 15 cycles in a 24-hour period,

depending on freezer compartment temperature, room

temperature, number of door openings and other use

conditions.

If the freezer is operated before the water connection

is made to the icemaker, set the power switch to

OFF. Top wire basket must be removed to access the

icemaker power switch.

When the freezer has been connected to the water

supply, set the power switch to ON.

Avoid contact with the moving parts

“Dart”

Lower

Mullion Trim

STEP 10 INTERNAL UNIT

PREPARATION

Ŷ Remove all tape, cardboard, and foam from each

unit.

Ŷ Remove boxed door bins from shelves.

Ŷ Unbox and install door bins.

Throw away the first full bucket of ice to allow the water

line to clear.

Be sure nothing interferes with the sweep of the feeler

arm.

Power

Switch

When the bin fills to the level of the feeler arm, the

icemaker will stop producing ice.

It is normal for several cubes to be joined together.

If ice is not used frequently, old ice cubes will become

cloudy, taste stale and shrink.

NOTE: Icemaker works best between 40 and 120 PSI

(275-827 kPa) home water pressure.

(Appearance may vary)

Icemaker

Feeler Arm

Power

Switch

Icemaker

Feeler Arm

31-49133-1

29

Page 30

Installation Instructions - Dual Retro-Fit Installation

STEP 12 INSTALL AUTOFILL PITCHER ASSEMBLY (Some Refrigerator Models)

Ŷ Locate the AutoFill pitcher cover on the left side of the

refrigerator’s interior. Remove T20 Torx screw holding

the cover in place towards the rear of the cover. Retain

this screw for attachment of AutoFill assembly.

Cover

Ŷ Slide the cover forward to remove. This reveals an

electrical connector and a water tube.

Ŷ Remove the AutoFill assembly from the box. Connect

the 4 pin connector from the AutoFill assembly to the

connector in the compartment wall.

Screw

Ŷ Conceal wires and tubing inside the wall compartment

and place the AutoFill assembly onto the forward end

of the mount until flush with the interior wall of the

refrigerator. Slide the assembly toward the back wall

until mounting screw hole is visible.

Mount

Compartment

AutoFill

Assembly

Screw

Ŷ Secure AutoFill assembly with the T20 Torx screw

removed earlier.

Ŷ

Ensure supply water is connected to the refrigerator

before proceeding further.

Ŷ Align the pitcher lid to the dispenser guide and slide

the pitcher toward the back of the refrigerator until it

stops. There may be up to a 5 second response time

before water starts to fill the pitcher.

Ŷ Ensure that the locking tab on the connector is fully

engaged.

Ŷ Connect the water line fitting from the AutoFill

assembly to the water tube located in the

compartment. Ensure the water tube is firmly

connected and will not easily become unattached.

Water tube should be inserted to the tubing mark.

Ŷ Water will fill the pitcher until it reaches a specified

level and will then shut off. It is normal for the water

level to be below the top of the pitcher.

NOTE: After installing the AutoFill pitcher, run 2 gallons

of water (approximately 5 full pitchers) through the

AutoFill dispenser to remove air from the system.

A newly installed filter cartridge will cause water to

spurt and dribble until the air is out of the system. It is

normal for water to appear discolored during the initial

system flush. Water color will return to normal after the

first minutes of dispensing. Wash the AutoFill pitcher

following the initial flush before using.

NOTE: Do not place the pitcher in the dispenser guide

before the water connection is made to the refrigerator.

30

31-49133-1

Page 31

Instructions for Single Integrated Installation

New construction installation with 25” deep openings

31-49133-1

31

Page 32

Design Guide - Single Integrated Installation

SINGLE INTEGRATED INSTALLATION SPACE

Dimensions in parentheses are in centimeters.

18” Integrated Freezer 30” Integrated Refrigerator

17 3/4" (45.1)

3 1/2"

(8.9)

Finished

Return

25" (63.5)

29 3/4" (75.6)

3 1/2"

(8.9)

Finished

Return

25" (63.5)

84"

(213.4)

4 1/8"

(10.5)

6 3/4"

(17.2)

3 1/2"

(8.9)

7 1/2 2

E

FRONT VIEW

4"

W

(10.2)

2 1/2"

(6.4)

SIDE VIEW

Back

24” Integrated Freezer or Refrigerator

25" (63.5)

Back

SIDE VIEW

84"

(213.4)

9 1/2"

(24.1)4"(10.2)

4 3/8"

(11.1)

ELEC W

FRONT VIEW

23 3/4" (60.3)

5"

(12.7)

6 3/4"

(17.2)

2 1/2"

(6.4)

3 1/2"

(8.9)

Finished

Return

Product Clearances

These units are equipped with a 2-position door stop.

The factory set 115° door swing can be adjusted to 90° if

clearance to adjacent cabinets or walls is restricted.

For a 90° door swing, allow 4” (10.2 cm) minimum

clearance to a wall.

When installed in a corner, allow 15” (38.1 cm) for a full

115° door swing on 18” and 24” models. Allow 16.5”

(41.9 cm) on 30” models.

84"

(213.4)

10 1/4"

6 1/4"

(26.0)

4 3/8"

(11.1)

ELEC W

(12.7)

FRONT VIEW

(15.9)

5"

6 3/4"

(17.2)

2 1/2"

(6.4)

SIDE VIEW

Back

Water And Electrical Locations

Electrical and water supply must be located as shown.

The Cutout Depth Must Be 25”.

Additional Specifications

Ŷ A 115 volt 60Hz., 15 or 20 amp power supply is

required. An individual properly grounded branch circuit

or circuit breaker is recommended. Install a properly

grounded 3-prong electrical receptacle recessed into

the back wall. Electrical must be located on rear wall as

shown.

Ŷ Water line must be located on the back wall as shown.

The water line should be 1/4” O.D. copper tubing or

QuickConnect

™

kit (WX08X10006) between the cold

water line and water connection location, long enough

to extend to the front of the unit (8’ [2.4 m]). Installation

of an easily accessible shut-off valve in the water line is

required.

Ŷ A minimum of 3-1/2” (8.9cm) finished return matching

cabinet exterior is recommended on interior on all sides

and top at front of opening.

Ŷ Installations with 4” (10.2 cm) or less between units

require Heater Kit ZUGC.

32

31-49133-1

Page 33

Installation Instructions - Single Integrated Installation

REFRIGERATOR/FREEZER LOCATION

Ŷ Do not install the refrigerator/freezer where the tem-

perature will go below 55°F (13°C). It will not run

often enough to maintain proper temperatures.

Ŷ Do not install the refrigerator/freezer where

temperatures will go above 100°F (37°C). It will not

perform properly.

Ŷ Do not install the refrigerator/freezer in a location

exposed to water (rain, etc.) or direct sunlight.

Ŷ Install it on a floor strong enough to support it fully

loaded.

TOOLS AND MATERIALS REQUIRED

• Metal shears

• #1, #2 Phillips screwdriver

• Flathead screwdriver

• Putty knife

• Measuring tape

• Drill and 1/16”, 5/64”, 3/16”, 1/2” bits

• 5/32” concrete bit (if installing anti-tip into concrete)

• 1/4”, 3/8”, 7/16” driver/socket

• 7/16” open wrench

• T20, T30 driver/bit

• 5/64”, 1/8”, 1/4” hex driver (allen wrench)

• Level

• Water shut-off valves (optional but recommended)

• 8’ waterline (one per unit requiring water hookup)

• Masking tape

• Rubbing alcohol

• Adjustable wrench

• Center punch

• Heater Unification Kit (ZUGC) (only required with 4”

or less between units)

• Stainless Steel Door Kits (if applicable)

• Custom panels for doors (if applicable)

• Handle Kits (if applicable)

GROUNDING THE UNIT

WARNING

Hazard. Failure to follow these instructions can

result in death, fire, or electrical shock.

The power cord of this appliance is equipped with a

3-prong (grounding) plug which mates with a standard

3-prong (grounding) wall receptacle to minimize the

possibility of electric shock hazard from this appliance.

Have the wall outlet and circuit checked by a qualified

electrician to make sure the outlet is properly grounded.

Where a standard 2-prong wall outlet is encountered, it

is your personal responsibility and obligation to have it

replaced with a properly grounded 3-prong wall outlet.

DO NOT, UNDER ANY CIRCUMSTANCES, CUT OR

REMOVE THE THIRD (GROUND) PRONG

FROM THE POWER CORD.

DO NOT USE AN ADAPTER

PLUG TO CONNECT THE

REFRIGERATOR TO A 2-PRONG

OUTLET.

DO NOT USE AN EXTENSION

CORD WITH THIS APPLIANCE.

Electrical Shock

FLOORING

For proper installation, this product must be placed

on a level surface of hard material that is at the same

height as the rest of the flooring. This surface should

be strong enough to support a fully loaded refrigerator

or freezer, or approximately 1,200 lbs. per unit.

NOTE: Protect the finish of the flooring.

NOTE: Not recommended for installation on carpeted

flooring.

HARDWARE SUPPLIED (per unit)

• Water Filter Bypass Plug (if equipped)

• Air filter (if equipped)

• Anti-Tip bracket

• 3 Lag screws

• 3 Tapcon screws

• 3 Toggles with bolts

• 1 Hair Pin Cotter

• 1 Retaining pin

• Panel installation templates

• 2 Door trims

• 2 Door panel brackets

• Set screws

• #6 Phillips head wood screws

• Door Bracket Cover Top

• T30 screws

• 1 Hinge limiter pin

• Center door panel bracket

• Hi-Lo screw and square washer

31-49133-1

33

Page 34

Installation Instructions - Single Integrated Installation

STEP 1 REMOVE PACKAGING

WARNING

These appliances are top heavy, especially with any

doors open, and must be secured to prevent tipping

forward which could result in death or serious injury.

Ŷ Remove outer carton and external packing from units.

Ŷ Inspect for damage.

Ŷ Ensure the flooring that the units are set is clean/

free of debris that could be collected on to, or

pinched in front of the wheels and damaging the

floor. Additionally, it is recommended that the floor

be protected with a plastic covering through out the

installation process.

Ŷ Remove hardware kit from top drawer.

Ŷ If installation requires a 90° door opening, the hinge

limiter pin must be installed in the top hinge BEFORE

the unit is removed from

the skid. Pin is located in

the hardware kit.

- Open the door

approximately 45°, but no

wider than 90°, to expose

the hole in the back hinge

bracket and install the

limiting pin. Pin must be

fully seated in the bracket

or the door will not close

properly.

Ŷ Remove front access cover from unit by removing 2

T20 Torx screws. Place the cover and screws to the

side for future installation.

3/8” Drive

Screws

Shipping

Bracket

7/16” Drive

Screws

Ŷ Remove three 3/8” drive screws and two 7/16” drive

screws from each side of the unit to release it from

the skid. Tip the unit from the side enough to remove

the shipping material from under the unit, but above

the skid (both sides)

Ŷ CAREFULLY roll the unit off the back side of the skid.

Ŷ Handle from side only with a hand truck.

Tip Over Hazard.

Top

hinge

T20 Torx

Screws

STEP 2 INSTALL WATER LINE

WARNING

Ŷ A cold water supply is required for automatic