GE ZGU36L4DH5SS, ZGU36L4RH3SS, ZGU36L4RH5SS, ZGU36L6H5SS, ZGU36N4DH5SS Installation Guide

...Page 1

Installation

Instructions

ProfessionalGasCooktops

48"Natural

ZGU48N4G

ZGU48N6R

ZGU48N6D

48"LPGas Models

ZGU48L4G

ZGU48L6R

ZGU48L6D

36"Natural

ZGU36N6

ZGU36N4R

ZGU36N4D

36"LPGas Models

ZGU36L6

ZGU36L4R

ZGU36L4D

Gas Models

Gas Models

Monogram°

Page 2

Installation instructions

BEFORE YOU BEGIN

Read these instructions completely and

carefully.

"IMPORTANT- Save these instructions for

local inspector's use.

• IMPORTANT- Observe all governing codes

and ordinances.

• Note to Installer - Be sure to leave these

instructions with the Consumer.

Note to Consumer - Keep these instructions for

future reference.

Skill Level- Installation of this cool<top requires

basic mechanical and electrical skills.

Completion time - 1to 3 hours.

• Proper installation is the responsibility of the installer.

• Product failure due to improper installation is not

covered under the Warranty.

WARNING:

This appliance must be properly grounded.

See "Electric Supply", page 6.

AVERTISSEMENT :

Cet appareil dolt _tre mis _ la terre

ad_quatement. Voir la section {{ Alimentation

_lectrique ))_ la page 6.

For Monogram local service in your area,

1.800.444.1845.

For Monogram Service in Canada, call

1.888.880.3030.

For Monogram Parts and Accessories, call

1.800.626.2002.

If you received a damaged cool<top, you should contact

your dealer.

in the Commonwealth of Massachusetts:

• This product must be installed by a licensed plumber

or gas fitter.

When using ball type gas shut off valves, they shall

be T-handle type.

• A flexible gas connector, when used, must not

exceed 3 feet.

CAUTION'.

THESE COOKTOPSSHOULD BE INSTALLED

IN CONJUNCTION WITH A SUITABLE

OVERHEADVENT HOOD. Due to the high heat capacity

of this unit, particular attention should be paid to the

hood and duct work installation to assure it meets

local building codes.

CES CUISINIF:RESDOIVENT ETRE

MISE EN GARDE :

MONTEES CONJOINTEMENT AVEC UNE

HOTTE_, EVACUATION DE PLAFOND APPROPRIEE.

Etant donn_ la grande capacit_ thermique de cet

appareil, une attention particuli_re dolt _tre port_e

au montage de la hotte et du syst_me de gaines pour

s'assurer qu'il est conforme aux codes du b_timent

Iocaux.

Standard countertop and island installations:

A 1200 CFM hood is recommended for 48" cool<tops.

A 600 CFM hood is recommended for 36" cool<tops.

Hoods should be 24" rain. deep and the same width

as the cool<top.

IsJand instaJJations:

Check local building codes for the proper method of

gas cool<top installation. Local codes vary. Installation,

electrical connections and grounding must comply

with applicable codes. In the absence of local codes,

the cool<top should be installed in accordance with the

National Fuel Gas Code ANSI 223.1-1990 and National

Electrical Code ANSI/NFPA 70-1990.

CAUTION:

These cool<tops are extremely heavy. Due

to the weight and size of the cool<top and

to reduce the risk of personal injury or damage to the

product, TWO PEOPLEARE REQUIREDFOR PROPER

INSTALLATION.

Ces cuisini_res sont extr_mement Iourds.

MISE EN GARDE :

Tout d_montage r_duira consid_rablement

leur poids. En raison du poids et de la taille de la

cuisini_re, dont la manipulation risque d'entrafner

des I_sions corporelles ou des dommages au produit,

DEUX PERSONNES SONT NECESSAIRES POUR

PROCEDERA UN MONTAGE ADEQUAT.

Page 3

CONTENTS

Design Information

Design Information

Models Available ..............................................................3

Accessory Requirements ................................................3

Product Dimensions and Clearances ............................4

Installation Options ..........................................................5

Advance Planning ..........................................................5

Installation Preparation

Tools and Materials Required ........................................6

Power Supply Locations ..................................................6

MODELS AVAILABLE

These cooktops are factory set for either natural

gas or liquid propane gas. Order the model for your

installation situation.

48" Natural Gas Models:

ZGU48N4G -4 gas burners, grill and griddle

ZGU48N6R -6 gas burners and grill

ZGU48N6D -6 gas burners and griddle

48" Liquid Propane Gas Models:

ZGU48L4G- 4 gas burners, grill and griddle

ZGU48L6R- 6 gas burners and grill

ZGU48L6D- 6 gas burners and griddle

Installation Instructions

Step 1, Remove Packaging ..............................................7

Step 2, Cut the Countertop Opening ..............................7

Step 3, Install the Cooktop ..............................................8

Step 4, Connect Cooktop to Gas......................................8

Step 5, Connect Electrical ................................................9

Step 6, Assemble Burners, Check Ignition ....................9

Finalize Installation ..........................................................10

Installation Checklist ......................................................10

Install the Cooktop Backsplash Accessory ................11

36" Natural Gas Models:

ZGU36N4D - 4 gas burners and griddle

ZGU36N4R - 4 gas burners and grill

ZGU36N6 - 6 gas burners

36" Liquid Propane Gas Models:

ZGU36L4D- 4 gas burners and griddle

ZGU36L4R- 4 gas burners and grill

ZGU36L6 - 6 gas burners

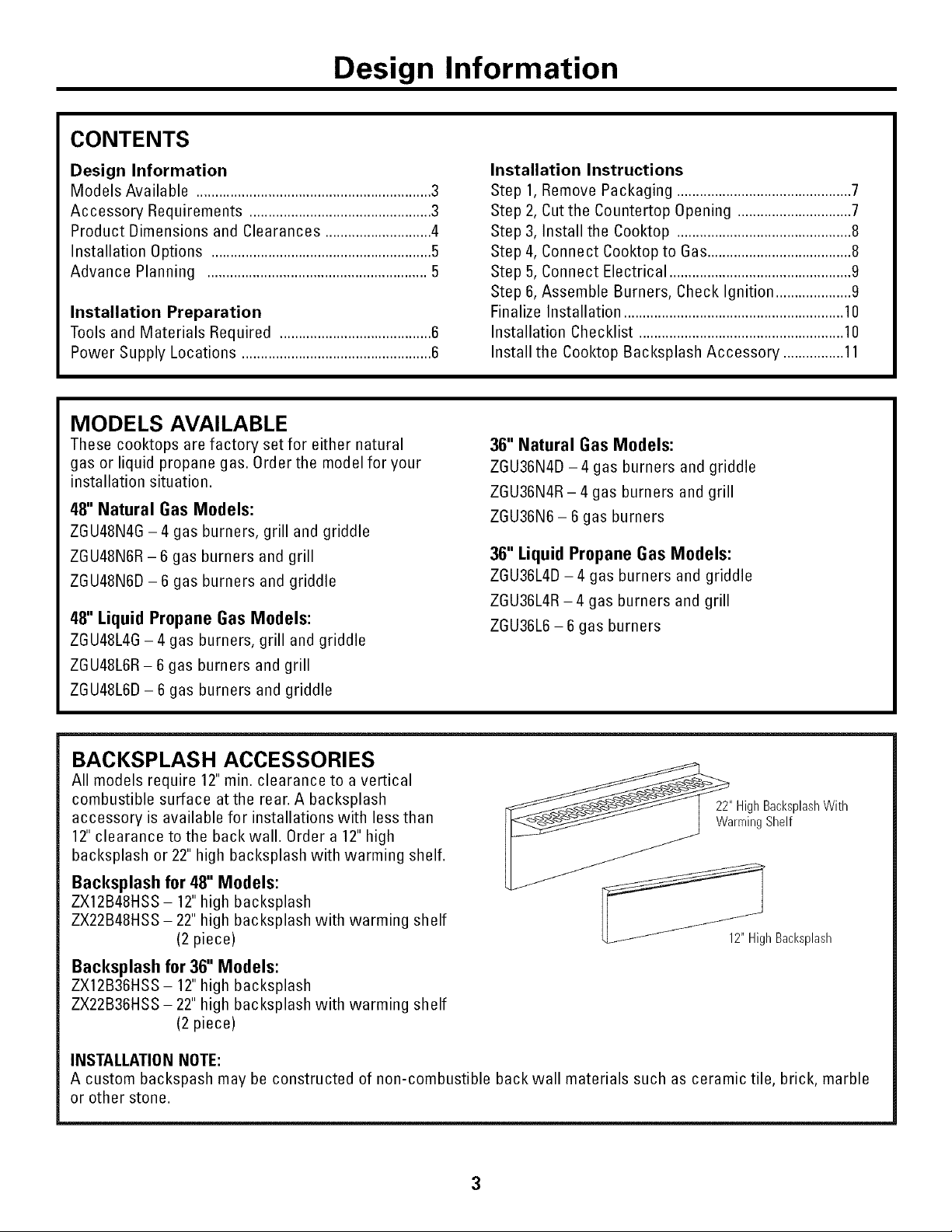

BACKSPLASH ACCESSORIES

All models require 12" min. clearance to a vertical

combustible surface atthe rear. A backsplash

accessory is available for installations with less than

12"clearance to the back wall. Order a 12"high

backsplash or 22" high backsplash with warming shelf.

Backsplash for 48" Models:

ZX12B48HSS - 12"high backsplash

ZX22B48HSS - 22" high backsplash with warming shelf

(2 piece)

Backsplash for 36" Models:

ZX12B36HSS - 12"high backsplash

ZX22B36HSS - 22" high backsplash with warming shelf

(2 piece)

INSTALLATION NOTE:

A custom backspash may be constructed of non-combustible back wall materials such as ceramic tile, brick, marble

or other stone.

" High BacksplashWith

Shelf

12"HighBacl<splash

Page 4

Design Information

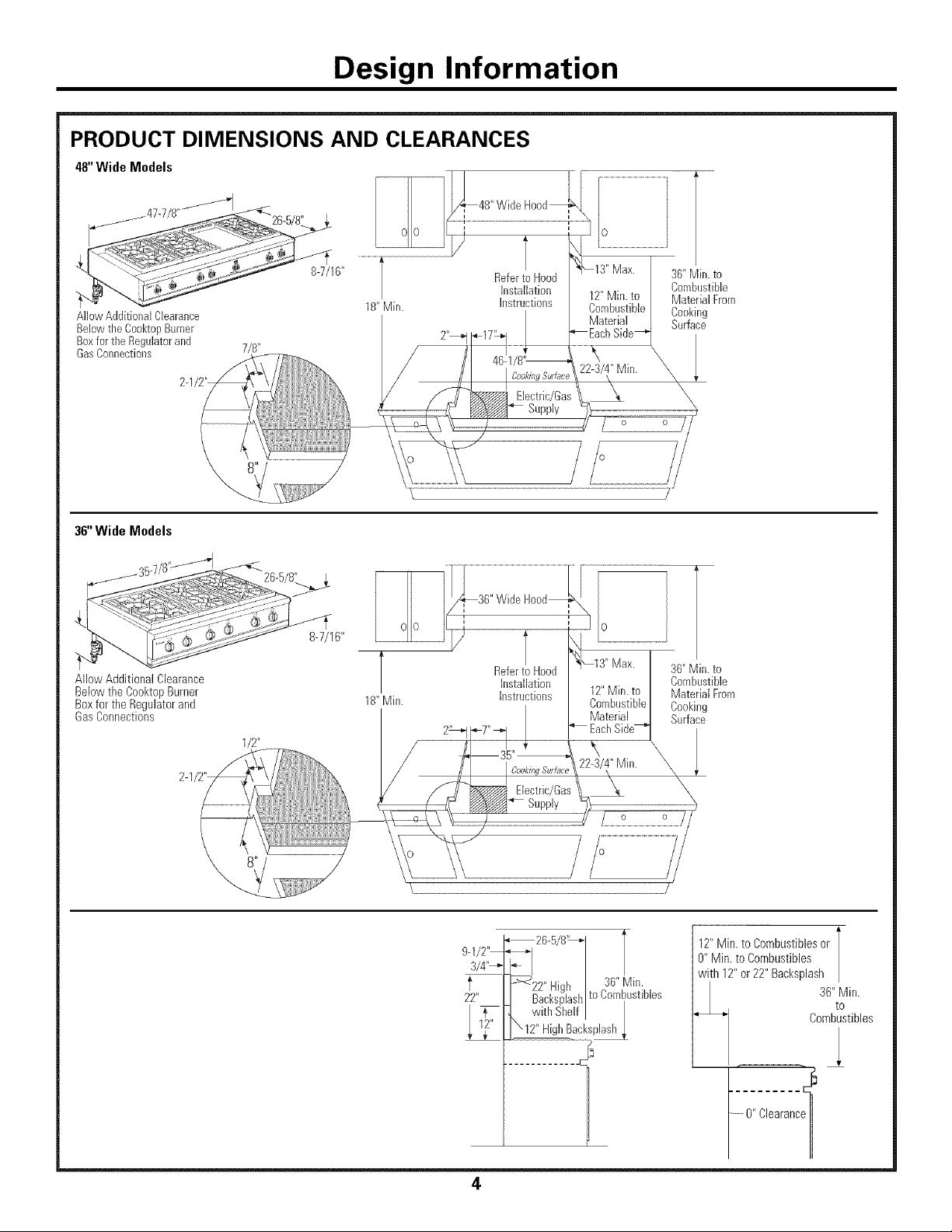

PRODUCT DIMENSIONS AND CLEARANCES

48" Wide Models

477/8 "__

87/16

AllowAdditional Clearance

Belowtile CooktopBurner

Boxfor theRegulatorand

GasConnections 7/8"

18"Min.

Mateda]

\\

22-3/4" Min. \

36" Min. to

Combustible

Material From

Cooking

Surface

\

36"WideModels

Allow Additional Clearance

Below the CooktopBurner

Boxfor the Regulatorand

GasConnections

8-7/16"

9N/2"

3/4"_

t

22,_

,2

_26-5/8'_

_22" High 36" Min.

Backsphsh to Combustibles

witll Shelf

\12 mgl aacks_

12" Min. to Combustiblesor

O"Min. to Combustibles

with 12" or 22" Backsplash

36" Min.

to

Combustibles

4

Page 5

Installation Preparation

INSTALLATION OPTIONS

These cooktops can be installed in standard 24"or

deeper 25" cabinets.

• In 24" deep cabinets, the front of the cooktop will

project approximately 1-7/8" beyond the front of the

countertop.

• In 25" deep cabinets, the cooktop will be flush with

the front of the countertop.

• The stainless surface of the cooktop will be 1/2"

higher than adjacent countertop.

• Cooktop fits flush to rear of cutout; no additional

support is required.

26-5/8"

t

22"

High

Back

Countertop _ 112"

Level _ v

/12" High

22"High

Bacl<splash

with Shelf

Backsplash

ADVANCE PLANNING

Refer to "Dimensions and Clearances" for appropriate

placement and necessary clearances when planning

the installation.

• Cabinetry cannot be installed directly above the

cooktop.

• We recommend the installation of a vent hood above

the cooktop surface.

- The vent hood must be at least 24" deep.

- The vent hood must be at least the same width as

the cooktop.

- For 48" models, we recommend the vent hood

blower be 1200 CFM.

- For 36" models, we recommend the vent hood

blower be 600 CFM.

• Refer to hood installation instructions for height

dimensions.

• Working areas adjacent to the cooktop should have

18"minimum clearance between countertop and

cabinet bottom.

8-7/16"_ 1/2"_

AllowAdditionalClearance

Belowthe BurnerBoxfor

GasConnections

4" to CenterLine_

of GasInlet

on the Left

1/2"

-,23-1/4"

CabinetFace- ProjectingControlPanel_,

CabinetFace-FlushControlPanel

Cooktop

0

FrontProjectsOutwardasShown

FromStandardDepthCabinets.

Cooktop 1/2"AboveAdjacent

0

_22-3/4"

2-1/2'_

1/2"AboveAdjacent

Countertops.

• Clearance between cooktop and side wall or

combustible material must be at least 12" on

each side.

• These cooktops require 8" free space below the

countertop to house the burner box. Additional

clearance is required below the burner box for the

gas regulator and connections. Connections should

be routed to limit interference with drawers or other

cabinetry features.

• Allow 12" min. clearance at the back to combustible

materials.

• Allow 36" min. above the cooking surface to

combustible materials.

• Installation must conform with local codes. In the

absence of local codes, the gas cooktop must comply

with the National Fuel Gas Code, ANSI Z223.1/NFPA.54,

latest edition. In Canada, installation must conform

with the current Natural Gas Installation Code,

CAN/CGA-B149.1 or the current Propane Installation

Code, CAN/CGA-B149.2, and with local codes where

applicable. This cooktop has been design-certified by

CSA International according to ANSI Z21.1, latest

edition and Canadian Gas Association according to

CAN/CGA-I.1 latest edition.

FrontFlushWith Cabinets-a Minimum

of25-3/4" CabinetDepthRequired

CabinetFront

Page 6

Installation Preparation

TOOLS REQUIRED

• Saw

• Measuring tape

• Carpenter's square

• Largeflat-blade screwdriver

• Pipewrench

POWER SUPPLY LOCATIONS

Gas Supply:

• The pressure regulator must be connected in series with the

manifold of the cooktop and must remain in serieswith the

supply line regardless of the type of gas being used.

• Thenatural gas modelsare designedto operate at 5"water

column pressure. A regulator is required atthe natural gas

source to provide a maximumof 7"water pressure to the

cooktop regulator.

• Theliquid propane modelsare designedto operate at 10"

water column pressure. A regulator is required atthe LP

source to provide a maximumof 14"water pressure to the

cooktop regulator.

• These gas cooktops are supplied with 1/2"NPTfemale gas

connection located at the left rear corner.

• A minimum 5/8"dia. metal flexible line is required.

- Use5-foot long 5/8"flexible metaltubing. (Lengthmust

complywith local codes.)

T'for 36" Models

"-. IT' for 48"Models

MATERIALS REQUIRED (not supplied)

• Pipe andfittings as required

• Manual gas line shut-off valve

• Gaspressure regulator (supplied)

• Gas-resistant pipe joint sealant

• 5foot, 5/8"AGA-certified flexible metal gassupply line

(length must comply with local codes)

- If required by local codes,use solid pipefittings.

NOTE:Purchasenew flexible line. DO NOTUSEOLD,

PREVIOUSLYUSEDFLEXIBLELINE.

• For rigid connection, locate the pipe stubwithin area shown.

• Install a manualshut-off valve in the gas line, in an easily

accessible location.

Electric Supply:

These cooktops must be suppliedwith 120volt, 60 Hz.,and

connected to an individual, properly grounded branch circuit

protected bya 15amp circuit breaker or time delay fuse.

The power cord of this appliance is equipped with a

three-prong (grounding) plugwhich mateswith a standard

three-prong grounding wall receptacle to minimizethe

possibility of shock hazardfrom this appliance.

If the electrical service provided does not meetthe above

specifications, it is recommendedthat a licensed electrician

install an approved outlet.

DONOT,UNDERANYCIRCUMSTANCES,CUTORREMOVE

THETHIRD(GROUND)PRONGFROMTHEPOWERCORD.

DONOTUSEAN EXTENSIONCORDWITH THISAPPLIANCE.

• Locatethe electric supplywithin the area shown or within

reach of the cooktop'ssix foot power cord.

• Toavoidtangling cordwith items stored in the cabinet, locate

the receptacle on rear wall, inside the cabinet.

ReceptacleBoxCc

.. to Cookto;

LocateGasSupply

ProtrusionFromWall oronFloor2" FromWall

ThreeProngPlug

\

W _

ThreeProngReceptacle

6

Page 7

STEP 1 REMOVE PACKAGING

Installation

Use a hand-truck to move this cooktop.

• Flatten the carton and use a piece as a pad on the

Before moving the cooktop indoors:

• Remove outer carton and packing.

• Remove the straps holding the cooktop to the skid.

• Remove the grates and drawer, below the knobs

(on grill and griddle models).

• Remove grill and/or griddle covers. DO NOT ATTEMPT

TO REMOVE A GRILL OR GRIDDLE ASSEMBLY.

STEP 2 CUT THE COUNTERTOP OPENING

:" 1/2"

Allow Additional ::

Clearance Below

the Cooktop Burner

Boxfor the Regulator

and Gas Connections :

Install a MatcNng Trim

Strip to Cover the Cut

Edge Below the Cooktop

Install a Matching Trim

Strip to Cover the Cut

Edge Below the Cooktop

bottom and back of the hand-truck. Lift the cooktop onto

the hand-truck standing on its end, with the bottom of

the cooktop resting against the back of the hand-truck.

Move the cooktop indoors:

If door and passageways into the installation location are

less than 30" wide, remove the cooktop knobs.

Allow Additional

Clearance Below

the Cooktop Burner

Boxfor the Regulatol

andGas Connections

48"widemodelsaredesignedtofit in48"orwiderbasecabinets

Measure carefully when cutting the countertop.

Make sure sides of the opening are parallel.

• These cool<tops require 8" free space below the

countertop to house the cooktop burner box.

• Allow additional clearances below the burner box

to install the regulator and make house supply

connections. Use a 90° elbow to route the gas

connections and limit interference with drawers

or other cabinetry features.

* These cool<tops are designed to hang from the

countertop from its rear and side flanges.

* Smooth any rough edges on the countertop before

installing the cool<top.

- Formica countertop edges must befinished.

The countertop must be strong enough to

support the weight of the cool<top.

36" wide models are designed to fit in 36" or wider base cabinets

Adjacent Cabinet _

Counter Sunk

Screws

• Support cleats can be secured to cabinet sides.

OR

• Build a support deck or box inside the cabinet which

will support the weight of the cool<top.

- Build the support box using a solid material, cut a

5"x 5" square in the left rear corner for the gas inlet

and power cord clearances.

* After the cool<top is installed, the bottom front edge of

the cutout may need to be covered. Install a trim strip

from the cabinet manufacturer to match cabinetry.

Page 8

Installation

STEP 3 INSTALL COOKTOP

• Lower the cooktop into the opening. Make sure the

cooktop is evenly seated and supported, A side frame

gasket will seal the cooktop to the countertop.

• "L" brackets with screws are provided to secure the

cooktop to the countertop or to adjacent cabinetry.

- Alternate screw hole locations on the sides of the

cooktop allow for varying thicknesses of countertops

or side cleats,

• Select the bracket location; secure the bracket to the

cooktop with 2 screws.

• Drive one screw through the bottom of the "L" bracket

and into countertop or side cleats.

STEP 4 CONNECT COOKTOP TO GAS

A manual shut-off valve must be installed where

it will be accessible.

Assure that gas is turned off at the shut-off valve.

• Install the supplied pressure regulator onto the end

of the gas inlet,

• You can install a 90° elbow (not supplied)onto the

gas inlet and route the gas connections to avoid

interference with drawers or other cabinetry features.

• Make sure the regulator is installed in the right

direction. See arrow on the underside of the regulator,

NOTE: Instead of using solid piping to connect to

pressure regulator, an approved flexible metal appliance

connector may be used between the pipe stub and the

shut-off valve to the pressure regulator, if local codes

permit,

• Appropriate flare nuts and adapters are required at

each end of the flexible connector.

:::7 lternate Bracket

ScrewHoles

-"L" Bracket

Cool<topBurner Box

Bete: Pipe stub extends I__1

about 1" below burner box. _ Gas Inlet

Regulator

(Supplied)

or Flexible

SolidPiping

Connector

Valve

_ hut-Off

PipeStubFrom

HouseGasSupply

WARNING: Donotuseaflameto

check for gas leaks,

AVERTISSEMENT :II ne faut pas utiliser de flamme pour v_rifier

s'il y a des fuites.

IMPORTANT: Disconnect the cooktop and the individual

shut-off valve from the gas supply piping system during

any pressure testing of that system at test pressures

greater than 1/2 psig. Isolate the cooktop from the gas

supply piping system by closing the individual manual

shut-off valve to the cooktop during any pressure testing

of the gas supply piping system attest pressures equal

to or less than 1/2 psig.

• Turn on gas and check for leaks:

-Use a liquid leak detector at all joints and connections

in the system.

8

Page 9

Installation

STEP 5 CONNECT ELECTRICAL

Plug power cord into properly grounded receptacle.

STEP 6 ASSEMBLE BURNERS, CHECK IGNITION

Assemble burners as shown. Checkto be sure that

burner heads and caps are securely seated. Pin(s) must

completely engage holes to ensure proper assembly.

• Check for proper ignition:

- Push in one control knob and turn 90° to Lite position.

- The igniter will spark and the burner will light; the

igniter will cease sparking when the burner is lit.

- First test mav require some time while air is flushed

out of the gas line.

- Turn knob to OFE

- Repeatthe procedure for each burner.

iMPORTANT: If the igniter electrodes continue to

spark after the burners are lit, check that each

burner component is assembled and seated properly

by observing constant gaps between each layer.

Disassemble and reassemble as required.

Burner flames should be blue and stable with no yellow

or yellow tips, excessive noise or lifting of the flame

from the burner. If any of these conditions exist, check

that the burner ports are not blocked.

BurnerHead-_

_J BurnerCap

(Brass) _

LocatorPins_

BurnerRing

(Aluminum)_

Toaid reassembly,eachbrassburnerheadis

markedwith a clockface. Replacethe burner

headwith the arrowpointingto the rearofthe

cooktop(12o'clockposition).

Page 10

FINALIZE INSTALLATION

Installation

Place the burner grates over the burners. Press corner

of the grate to the cool<top. The grates should be seated

and should not rock.

The grill and griddle are secured with screws atthe

front. They are designed to be stationary and should not

be removed.

INSTALLATION CHECKLIST

[3 Double checkto make sure everything in this manual

has been completed. Rechecking steps will ensure

safe use of the cool<top.

[3 Make sure all controls are left in the OFFposition.

[3 Make sure the flow of combustion and ventilation air

to the cool<top is unobstructed.

[3 The serial plate for your cool<top is located beneath

the ledge trim on the left side, just above the left knob.

In addition to the model and serial numbers, it tells

you the ratings of the burners and the type of fuel

and pressure the cool<top was adjusted for when it

left the factory.

The griddle has two leveling screws beneath the rear

flue cover that can be used to adjust to the desired slope.

The center screw is for shipping purposes only and can

be removed.

[3 When ordering parts, always include the serial

number, model number and a code letter to ensure

proper replacement parts.

Recheck Steps:

Double check to make sure everything in this manual

has been completed. Rechecking steps will ensure

safe use of the cooktop.

10

Page 11

Installation

iNSTALL 9" or 12" HiGH BACKSPLASH

• Install and level the range or cool{top according to the

installation instructions.

Remove the backsplash packaging. Select the back, wall

mount panel with mounting screw slots.

Marl{ a horizontal line on the wall, 1/8" above the

range/cool{top backguard.

Use wood screws or fasteners (not supplied) to secure

the back section to the wall. Slide the panel up or down

to provide the 1/8" gap between the top of the

range/cool{top and the bottom of the backsplash.

This 1/8" gap allows the appearance or front section

to overlap the mounted rear panel.

Secure the appearance panel to the mounted back

section with the #8 self-tapping screws provided.

Install 3 screws on each side and 5 across the top.

iNSTALL 22" HiGH BACKSPLASH

Install and level the range or cooktop according to the

installation instructions.

Remove the backsplash packaging. Select the back, wall

mount panel with mounting screw slots.

• Marl{ a horizontal line on the wall, 1/8" above the

range/cool{top backguard.

Use wood screws or fasteners (not supplied)to secure

the back section to the wall. Slide the panel up or down

to provide the 1/8" gap between the top of the

range/cool{top and the bottom of the backsplash.

This 1/8"gap allows the appearance or front section

to overlap the mounted rear panel.

Attach the shelf to the front section of the backsplash

using screws and nuts supplied.

Secure the appearance panel to the mounted back

section with the #8 self-tapping screws provided.

Install 3 screws on each side and 5 across the top.

Frontsection

Supplied..........\

#8Screws \ section

Back \

Backsection

1/8t

Backl

Frontsection ,

Supplied \

#8 Screws _,

Back_

section

Bac!

section "_.

gackguarld/_

WARNING:

The back section must be securely fastened to

the wall. Failure to do so could cause damage or

personal injury. Maximum shelf weight capability

is 10 Ibs.

Slotsfor Vertical \

Adjustment \

ti °"

I _-_-'_-_--_-_

Holes_

Slotsfor

Vertical

Adjustment

Supplied_

#8Screws

AVERTISSEMENT :

La section arriere doit _tre fix_e solidement

sur lemur. Le d_faut de proc_der ainsi peut

causer des dommages materiels ou des I_sions

corporelles. La capacit_ de charge maximale

de I'_tag_re est de 4,5 kg (10 Ibs ).

11

Page 12

Pub.No.49-80225-3

PartNo.164D4290P377

17713Rev.C

12-06JR

NOTE:While performing installations described in this book,

safety glasses or goggles should be worn.

Iq>rMonog'ram _'_local s_rvh'e i_ )our area, call

1.600.444. l,_4 ).

NOTE:Producl improx(m( nl is a conlinuing endeavor at

General Ele(tric. Thereilnx, malerials, app(aran(_ and

spetif]calions are sul?ject to chmlg( wilhotlr notic(.

@

Monogram:

GEConsumer & I/Idustria/

GEAppliancos

Gono_l FIoc_c _nlpang

Louisville, KY40225

go con)

©2006 GECompany

Loading...

Loading...