Page 1

Installation

Instructions

ProfessionalRanges

48"Natural Gas Models

ZDP48N4G

ZDP48N6R

ZDP48N6D

48"LPGasModels

ZDP48L4G

ZDP48L6R

ZDP48L6D

36"Natural Gas Models

ZDP36N6

ZDP36N4R

ZDP36N4D

36"LPGas Models

ZDP36L6

ZDP36L4R

ZDP36L4D

30"Natural Gas Model

ZDP30N4

30"LPGasModel

ZDP30L4

Monogram._

Page 2

Installation Instructions

BEFORE YOU BEGIN

Read these instructions completely and

carefully.

• IMPORTANT- savethese instructions for

local inspector's use,

• IMPORTANT - Observe all governing codes

and ordinances.

• Note to Installer- Be sure to leave these

instructions with the Consumer.

• Note to Consumer - Keep these instructions for

future reference.

• Skill Level- Installation of this range requires basic

mechanical and electrical skills.

• Completion time - 1to 3 hours,

• Proper installation is the responsibility of the installer,

• Product failure due to improper installation is not

covered under the Warranty,

WARNING:

This appliance must be properly grounded.

See "Electric Supply", page 7.

AVERTISSEMENT :

Cet appareil doit _tre mis _ la terre

ad_quatement. Voir la section, Alimentation

_lectrique _ _ la page 7.

For Monogram local service in your area,

1.800.444.1845.

For Monogram Service in Canada, call

1.888.880.3030.

For Monogram Parts and Accessories, call

1.800.626.2002.

If you received a damaged range, you should contact

your dealer.

In the Commonwealth of Massachusetts:

• This product must be installed by a licensed plumber

or gas fitter.

• When using ball type gas shut off valves, they shall

be T-handle type.

• A flexible gas connector, when used, must not

exceed 3feet.

CAUTION:

THESE RANGES SHOULD BE INSTALLED

IN CONJUNCTION WITH A SUITABLE

OVERHEADVENT HOOD. Due to the high heat capacity

of this unit, particular attention should be paid to the

hood and duct work installation to assure it meets

local building codes.

MISE EN GARDE :

CES CUISINII_RES DOIVENT ETRE

MONTI_ES CONJOINTEMENT AVEC UNE

HOTTE_, I_VACUATION DE PLAFOND APPROPRICE

I_tant donn_ la grande capacit_ thermique de cet

appareil, une attention particuli_re doit _tre port_e

au montage de la hotte et du syst_me de gaines pour

s'assurer qu'il est conforme aux codes du b_timent

Iocaux.

Standard countertop and island installations:

A 1200 CFM hood is recommended for 48" ranges.

A 600 CFM hood is recommended for 30" and 36" Ranges.

Hoods should be 24" min. deep and the same width as

the cooktop.

Check local building codes for the proper method of

gas range installation. Local codes vary. Installation,

electrical connections and grounding must comply

with applicable codes. In the absence of local codes,

the gas range should be installed in accordance with

the National Fuel Gas Code ANSI 223.1,latest

edition and National Electrical Code ANSl/NFPA 70,

latest edition.

CAUTION:

These ranges weigh up to 600pounds.

Some disassembly will reduce the weight

considerably. Due to the weight and size of the range

and to reduce the risk of personal injury or damage

to the product, TWO PEOPLEARE REQUIREDFOR

PROPERINSTALLATION.

MISE EN GARDE :

Ces cuisini_res p_sent jusqu'_

272 kg (600 Ib).Tout d_montage r_duira

consid_rablement leur poids. En raison du poids et

de la taille de la cuisini_re, dont la manipulation risque

d'entrainer des I_sions corporelles ou des dommages

au produit, DEUX PERSONNES SONT NEOESSAIRES

POUR PROCEDERA UN MONTAGE ADI_QUAT.

2

Page 3

Design Information

CONTENTS

Design Information

Models Available ..............................................................3

Accessory Requirements ................................................3

Product Dimensions and Clearances ........................4, 5

Advance Planning ............................................................6

Tools and Materials Required ......................................6

Installation Preparation

Power Supply Locations ..................................................7

MODELS AVAILABLE

These ranges are factory set for either natural

gas or liquid propane gas. Order the model for your

installation situation.

48" Natural Gas Models:

ZDP48N4G -4 gas burners, grill and griddle

ZDP48N6R-6 gas burners and grill

ZDP48N6D -6 gas burners and griddle

48" Liquid Propane Gas Models:

ZDP48L4G - 4 gas burners, grill and griddle

ZDP48L6R- 6 gas burners and grill

ZDP48L6D - 6 gas burners and griddle

Installation Instructions

Step 1, Remove Packaging ..............................................8

Step 2, Level the Range ....................................................9

Step 3, Install Anti-Tip Device ..................................9, 10

Step 4, Connect Range to Gas ......................................11

Step 5, Connect Electrical ..............................................12

Step 6, Slide Range into Position ................................12

Step 7, Replace Oven Doors ..........................................12

Step 8, Assemble and Adjust Burners ........................13

Finalize Installation ..........................................................13

Installation Checklist ......................................................14

Install Backsplash Accessory ......................................15

36" Natural Gas Models:

ZDP36N6 - 6 gas burners

ZDP36N4R - 4 gas burners and grill

ZDP36N4D - 4 gas burners and griddle

36" Liquid Propane Gas Models:

ZDP36L6 - 6 gas burners

ZDP36L4R- 4 gas burners and grill

ZDP36L4D - 4 gas burners and griddle

30" Natural Gas Model:

ZDP30N4

30" Liquid Propane Gas Model:

ZDP30L4

BACKSPLASH ACCESSORIES

All models require 12" rain. clearance to a vertical

combustible surface atthe rear. A backsplash

accessory is available for installations with less

than 12" clearance to the back wall. Order a 12"high

backsplash or 22"high backsplash with warming shelf.

Backsplash for 48" Models:

ZX12B48HSS - 12" high backsplash

ZX22B48HSS - 22" high backsplash with warming shelf

(2 piece)

Backsplash for 36" Models:

ZX12B36HSS - 12" high backsplash

ZX22B36HSS - 22" high backsplash with warming shelf

(2 piece)

INSTALLATION NOTE:

A custom backspash may be constructed of non-combustible back wall materials such as ceramic tile, brick, marble

or other stone.

Backsplash for 30" Models:

ZX9B30HSS - 9" high backsplash

ZX22B30HSS - 22" high backsplash with warming shelf

(2 piece)

HighBacksplashWith

helf

12"HighBacksplash

(9" Highfor30" Models)

3

Page 4

Design Information

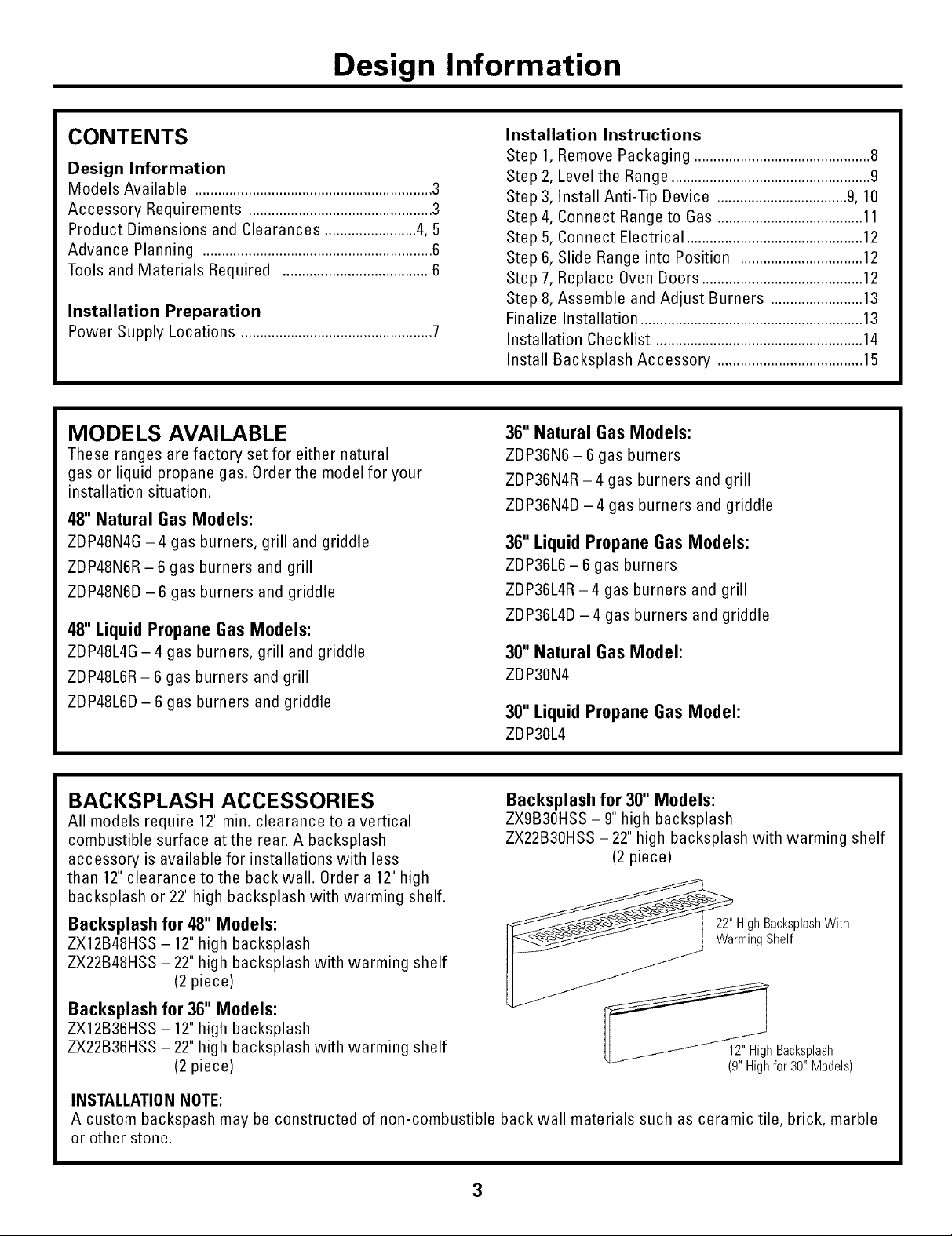

PRODUCT DIMENSIONS AND CLEARANCES

48"Wide RangeModels 36"Wide RangeModels

_:::::::::::::±_:::::::::::::::::_:_:_:::_:_ 22 _

35-1/4"-36-3/4"

<

N

48"and 36"RangeModels

9 1/2"_ 29-1/16''_

-3/4"_ ",_

22" Backsplash

_12" HighBacksplash

J

[_ 31-1/2"_

22"High

with Shelf

45-5/8"

36" Min.

to Combustibles

28-1/4'_ _35-7/8"

12"Min. to Combustiblesor l/'

0" Min. to Combustibles

with 12"or22" Backsplash

._Backguard •

0" Clearance

' r'7 r" "3

NOTE: 12"Min. to Combustibles or

0"Min to Combustibles with any

backsplash accessory or custom

non-combustible back wall.

/

36" Min.

to

Combustibles

4

Page 5

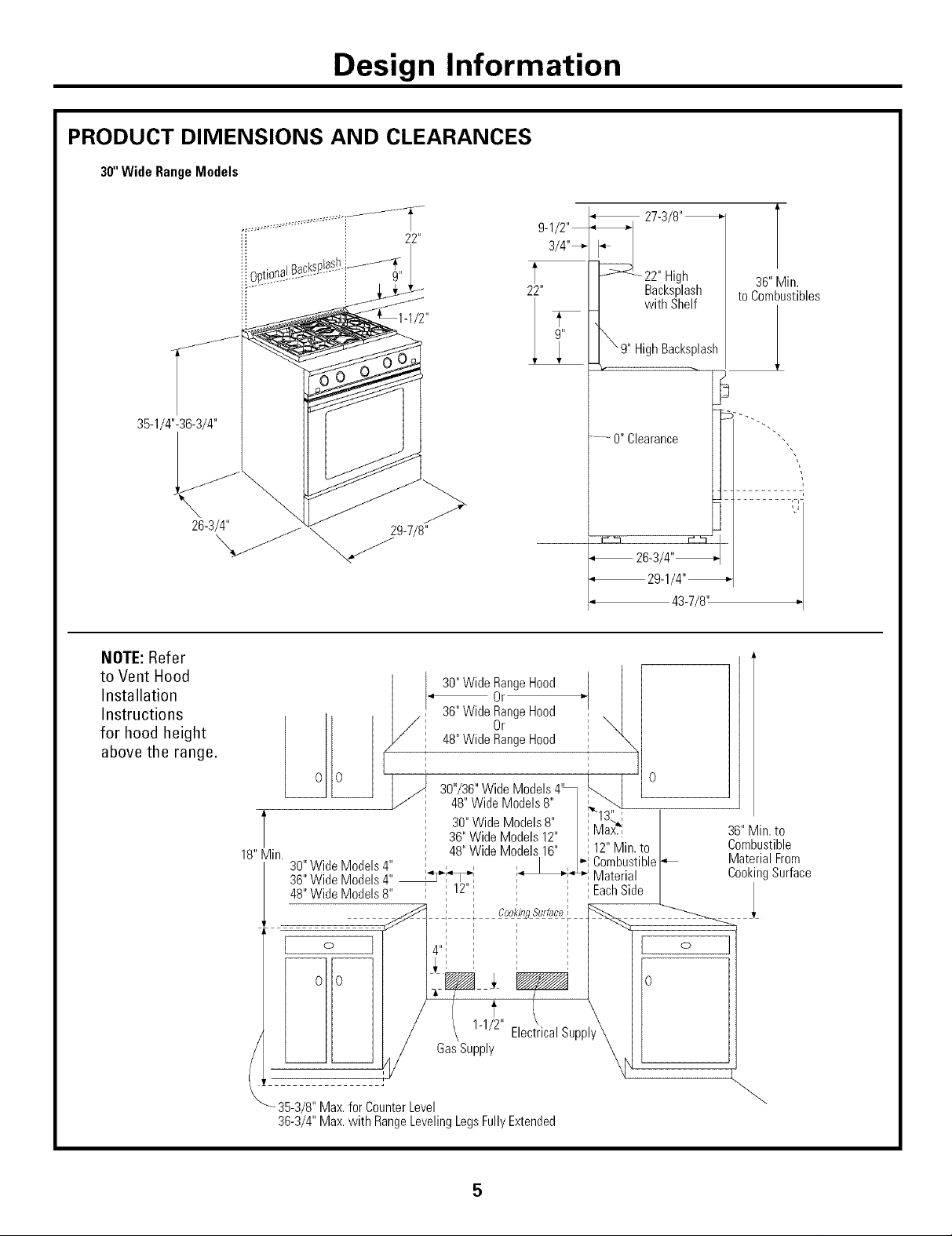

Design Information

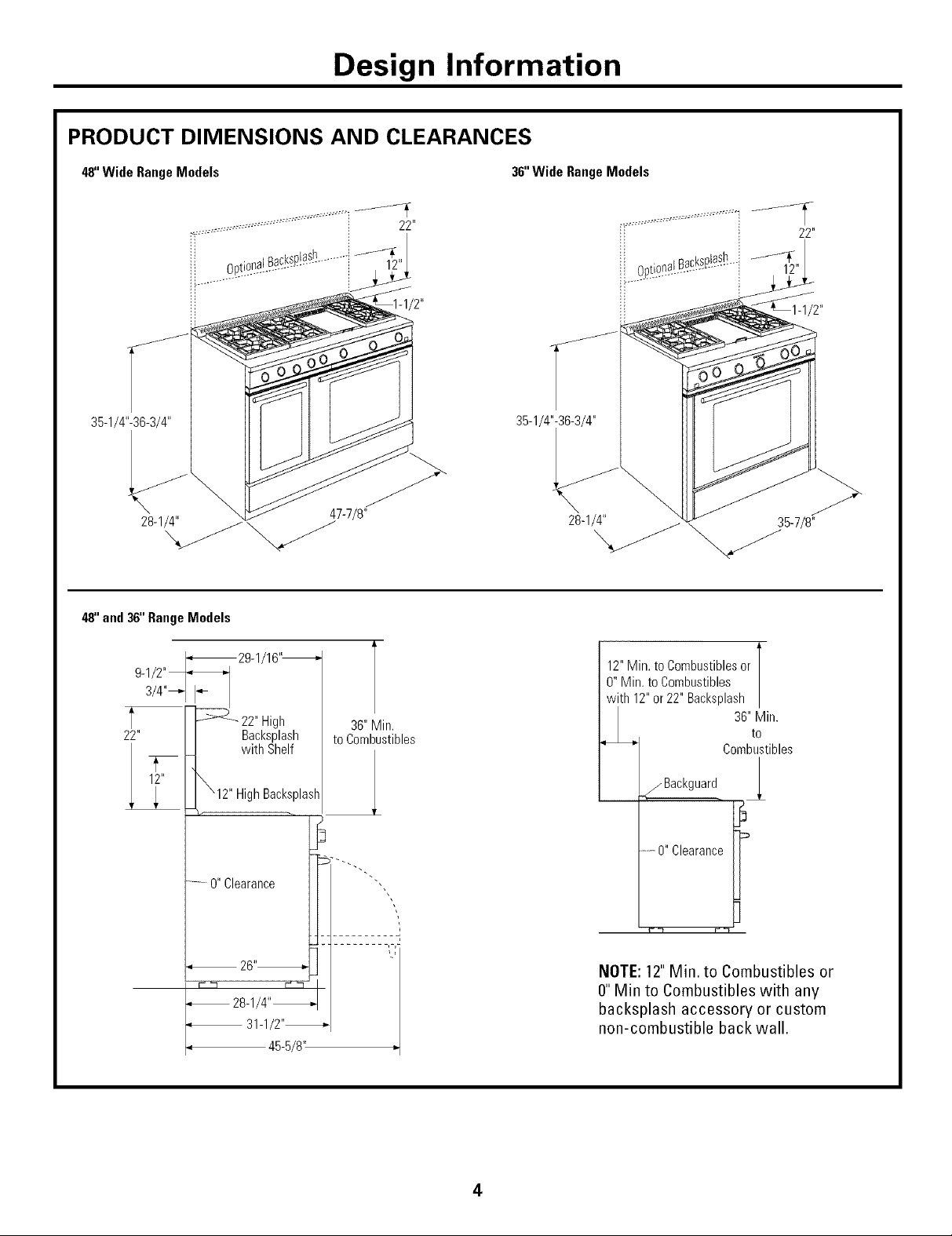

PRODUCT DIMENSIONS AND CLEARANCES

30"Wide RangeModels

NOTE: Refer

to Vent Hood

Installation

Instructions

for hood height

above the range.

22"

9-1/2"

3/4"_

27-3/8"_

_--22" High

Backsplash

with Shelf

Backsplash

[_29-1/4"_

I_ 43-7/8"

36" Min.

to Combustibles

-?I

o

t

1-1/2" ElectricalSupply

GasSupply

[ .................. •

"_ 35-3/8"Max.for CounterLevel

36-3/4"Max.with RangeLevelingLegsFullyExtended

5

o

O

Page 6

Design Information

ADVANCE PLANNING

Refer to "Dimensions and Clearances" for appropriate

placement and necessary clearances when planning

the installation.

• Cabinetry can not be installed directly above the

range.

• We recommend the installation of a vent hood above

the surface.

- The vent hood must be at least 24" deep.

- The vent hood must be at least the same width as

the range.

- For 48"models, we recommend the vent hood

blower be 1200 CFM.

- For 30"and 36" models, we recommend the vent

hood blower be 600 CFM.

• Working areas adjacentto the range should have

18"minimum clearance between countertop and

cabinet bottom.

• Clearance between range and side wall or

combustible material must be at least 12"on

each side.

• Allow 12"min. clearance atthe backto combustible

materials.

TOOLS REQUIRED

• Saw

• Measuring tape

• Carpenter's square

• Pipe wrench

• Large flat-blade screwdriver

• Safety glasses

• Drill and appropriate bits

MATERIALS REQUIRED

(not supplied)

• Pipe and fittings as required

• Manual gas line shut-off valve

• Gas pressure regulator (supplied)

• Gas-resistant pipe joint sealant

• 5 foot, 5/8"AGA-certified flexible metal gas supply line

- If required by local codes, use solid pipe fittings.

NOTE: Purchase new flexible line. DO NOT USE OLD,

PREVl0USLY USED FLEXIBLE LINE.

• Allow 36" min. above the cooking surface to

combustible materials.

• Installation must conform with local codes. In the

absence of local codes, the range must comply with

the National Fuel Gas Code, ANSI Z223.1/NFPA.54,

latest edition. In Canada, installation must conform

with the current Natural Gas Installation Code,

CAN/CGA-B149.1 or the current Propane Installation

Code, CAN/CGA-B149.2, and with local codes where

applicable. This range has been design-certified by

CSA International according to ANSI Z21.1, latest

edition and Canadian Gas Association according

to CAN/CGA-I.1 latest edition.

6

Page 7

Installation Preparation

POWER SUPPLY LOCATIONS

Gas Supply:

• The natural gas models are designed to operate at 5"

water column pressure. A regulator is required at the

natural gas source to provide a maximum of 7" water

pressure to the cooktop regulator,

• The liquid propane models are designed to operate at

10"water column pressure. A regulator is required at

the LP source to provide a maximum of 14" water

pressure to the cooktop regulator,

• These gas ranges are supplied with 1/2" NPT female

gas connection located atthe left rear corner.

• A minimum 5/8" din, metal flexible line is required,

• Locate pipe stub on the back wall as illustrated.

- Use 5-foot, 5/8" long flexible gas supply line.

• Install a manual shut-off valve in the gas line, in an

easily accessible location.

4" for 30"/36" Models

8" Models

2" FlexLine

2" Maximum

Protrusion From

Wall ForGas Supply

iGas Supply

toRange

8" for 30" Models 4" for 30"/36"

12" for 36" Models Models

16" for 48" Models 8" for 48"

"_ Models

i'"-Electrica, | /I

i Supply /

If the electrical service provided does not meet the

above specifications, it is recommended that a

licensed electrician install an approved outlet,

• Locate the electric supply as illustrated.

WARNING: The range isequipped for use with an electrical supply

which uses a separate grounding conductor

(4 wire system).

If this range must be connected to an electrical

system which utilizes a single conductor for ground

and neutral (3 wire system), the grounding jumper at

the terminal block must be connected. The grounding

jumper is located behind the front kick panel.

AVERTISSEMENT :

I_tant donn_ sa conception, la cuisini@e

exige que I'alimentation _lectrique soit

dot_e d'un conducteur de terre distinct (syst_me

4 fils).

Si cette cuisini_re dolt _tre connect_e _ un syst_me

_lectrique qui utilise un conducteur simple pour la

mise _ la terre et le conducteur neutre (syst_me

3 fils), ilfaut alors connecter le cavalier de terre sur

la plaque _ bornes. Le cavalier de terre est situ_

derri@e le panneau de protection frontal.

Receptacle

Electric Supply:

These ranges must be supplied with 208/240 volt, 60 Hz.,

and connected to an individual, properly grounded

branch circuit protected by a circuit breaker or time

delay fuse (50 amp for 48" ranges, 30 amp for 36" ranges

and 25 amps for 30" ranges). The receptacle must be

a NEMA 14-50R device to accept the 4-prong plug

supplied with the range,

jWhite /Black

Co

TerminalBlock

To connect grounding jumper:

• Disconnect restraining clip holding jumper.

• Connect green jumper to open terminal on

neutral (white) portion of the terminal block,

Page 8

Installation

STEP 1 REMOVE PACKAGING

Before moving the range indoors:

• Remove outer carton and packing material from the

shipping base,

KickPanel

• Remove the kick panel by removing 2 screws atthe top

and pulling forward.

LeftRearShipping

Screws

Slot

PulIthe hinge locks

down to unlock.

Remove oven doors:

• Fully open the door.

• Each hinge has a hinge lock, Close the hinge latch

down against the door frame.

• Firmly grasp the door at the top sides.

• Close the door to the near-vertical position.

• Lift the door up and pull straight out.

RangeMust

beUniformly

Supported

onBraces

The range is secured to the skid with 2 bolts in the front

and 2 "L" brackets on the bottom flange of the range

back. Remove bolts and "L" brackets.

To simplify handling and to reduce the weight of

the range:

• Remove the grates and the drawers belowthe knobs

(on grille and griddle models),

• Remove grill and griddle covers. DO NOT ATTEMPT

TO REMOVE A GRILL OR GRIDDLE ASSEMBLY.

• Remove the broiler pans/literature package from

inside oven(s).

LevelingLeg

Due to the weight of these ranges, use a dolly with

soft wheels to move this range.

• Lift the range onto the dolly and move indoors.

• Remove the panel from the rear of the shipping pack.

Lay the panel on the floor directly in front of the

installation location. The range should be placed

on this panel to prevent damage to the floor.

• Remove the two strips from the oven interior. Place

the strips on the floor at the left and right sides of the

installation location, These strips provide a surface

for sliding the range into the final position and will

prevent damage to the floor. The leveling legs must

rest permanently on these runner strips,

Range

Opening 1 _

_rs _C_\ I o

ToSupport _,_\\ II I

LevelingLe

8

Page 9

STEP 2 LEVEL THE RANGE

Installation

NOTE: Rear range leveling legs are not accessible after

installation.

• Check to be sure the adjoining cabinets/countertops

are level, front to back and left to right across the

opening of the range.

• Measure the distance from the floor to the top of the

countertop in the left and right rear corners.

STEP 3 INSTALL ANTI-TIP DEVICE

• All Ranges Can Tip

WARNING:

• Injury Could Result

• Install Anti-Tip Bracket

Provided

• See Instructions

• Adjust the height of the range to countertop height

or higher.

IMPORTANT: The range should always be installed

at countertop height or higher. DO NOT INSTALL THE

RANGE LOWER THAN ADJACENT COUNTERTOP

HEIGHT.

The anti-tip bracket is designed to be installed on

top of the slide (runners) provided with the range.

Any other type of construction may require special

installation techniques to insure adequate fastening

of the anti-tip bracket to the floor or wall.

• The bracket must be properly installed to prevent

tipping of the range.

• Read the AHAM Anti-Tip Safety brochure packed

with the product.

All Ranges must have an anti-tip device correctly

installed according to these instructions.

• Ifthe range is pulled out from the wall for any

reason, make sure that the device is properly

engaged when pushed back against the wall or

installation position.

• Toutes les cuisinieres peuvent

basculer

• Des blessures peuvent en

resulter

antibasculement fourni

• Consultez les instructions

• Montez le support

AVERTISSEMENT:

• Ifthe anti-tip device is not engaged, there is a

possible risk that the range can tip over and

cause injury if you or a child stand, sit or lean on

an open door.

[4]#10 x2" wood

screws

Anti-Tip Bracket

AHAMAnti-Tip

SafetyBrochure

9

Page 10

Installation

STEP 3 INSTALL ANTI-TIP DEVICE

(CONTINUED)

SmallHoleForWood

Installations(2Total)

(2)LargeHolesFor

ConcreteInstallations

SmallHolesForWood

Installations(2

Wood

Slide

Strip

Wood Construction:

• Place the bracket against the back wall, into the right

rear corner of the installation location.

(2)WoodScrewsinto

BackWall

(All Installations)

Back

Wall

Dimension A

1/4"

5/8"

ZDP36

ZDP30

Concrete or Cement Construction:

Hardware Required (not supplied):

[2] sleeve anchors, lag bolts and washers.

• See Dimension A, position the bracket the correct

distance from the right side. Mark the 2 small screw

holes for fastening the bracket to the floor and remove

the bracket.

• Drill two, 1/8"diameter pilot holes.

• Fasten the bracket securely to the floor and wall using

all 4 screws provided.

• Place the bracket against the back wall, into the

right rear corner of the installation location.

• See Dimension A, position the bracket the correct

distance from the right side. Mark the 2 large holes

for fastening the bracket to the floor and remove

the bracket.

• Drill recommended size holes for the hardware.

• Install the sleeve anchors into the holes and then

install the lag bolts through the bracket. The bolts

must be properly tightened as recommended for

the hardware.

• Fasten the bracket securely to the floor.

• Drive wood screws into the back wall.

10

Page 11

Installation

STEP 4 CONNECT RANGE TO GAS

Assure that gas supply is turned off at the shut-off

valve:

• Connect flexible metal connector to incoming gas line

pipe stub located on the left side on the bottom back

of the range.

• Turn on gas and check for leaks:

- Use a liquid leak detector at all joints and

connections in the system.

_k_ CAUTION:

Do not use aflame to check for gas leaks.

MISE EN GARDE :

II ne faut pas utiliser de flamme pour

v_rifier s'il y a des fruites.

NOTE: This range is equipped with a gas shut-off valve

located behind the kick plate, This valve is to be used

in the event that service is required in the future.

o o

o o

I

D

u

11

Page 12

Installation

STEP 5 CONNECT ELECTRICAL

Plug power cord into properly grounded receptacle,

STEP 6 SLIDE RANGE INTO

POSITION

• Carefully, slide the range into position,

- Be careful notto entangle power cord and gas

flexible tubing,

• Be sure the right rear leg is engaged in the slot of the

installed anti-tip bracket,

• Check for proper installation by grasping the range

at the top front edge and carefully attempt to tilt the

range forward,

• Check to be sure the front of the range is level.

Adjust front leveling legs accordingly.

• Replace the front kick panel by reversing the

procedure described in Step 1,

STEP 7 REPLACE OVEN DOOR(S)

IMPORTANT: Do not lift the door by the handle.

To replace the oven doors:

• Firmly grasp the door at the top sides. This is critical.

• Approach the range with the door angled in a vertical

position.

• Guide the hinges into the slots.

• Push the door infirmly while opening,

• Once in position, open the door completely. Push the

hinge locks back in and towards the front frame.

CAUTION:

Take care when replacing the oven doors.

If the hinge latch is not securely locked,

the hinge may snap back and separate. If the hinge

separates, you must apply pressure (possibly with

your foot) to press it back together and then engage

the hinge latch.

MISE EN GARDE :

Soyez prudent Iorsque vous remettez en

place les portes du four. Si le Ioquet de

charni_re n'est pas verrouill_ correctement, la

charni_re peut se d_gager brusquement et se s_parer.

Si c'est le cas, vous devez exercer une pression

(par exemple avec le pied) pour la remettre en place,

puis enclencher le Ioquet.

12

Page 13

Installation

STEP 8 ASSEMBLE AND ADJUST BURNERS

Assemble burners as shown. Checkto be sure that

burner heads and caps are securely seated. Pin(s) must

completely engage holes to ensure proper assembly.

• Check for proper ignition:

- Push in one control knob and turn 90° to LITE

position.

- The igniter will spark and the burner will light; the

igniter will cease sparking when the burner is lit.

- First test may require some time, while air is flushed

out of the gas line.

- Turn knob to OFE

- Repeat the procedure for each burner.

IMPORTANT: If the ignitor electrodes continue to

spark after the burners are lit, check that each burner

component is assembled and seated properly by

observing constant gaps between each layer.

Disassemble and reassemble as required.

• Burner flames should be blue and stable with no

yellow or yellow tips, excessive noise or lifting of the

flame from the burner. If any of these conditions exist,

check thatthe burner ports are not blocked. If one of

these conditions continues, call for service.

(__ _- Burner Cap

BurnerHead._

(Brass) _

LocatorPins_

Toaid reassembly,eachbrassburner

headismarkedwith a clockface.

Replacethe burnerheadwith the

arrow pointingto the rearofthe

cooktop(12o'clockposition).

13

Page 14

FINALIZE INSTALLATION

Installation

Place the burner grates over the burners. Press corner

of the grate to the cooktop. The grates should be seated

and should not rock.

The grill and griddle are secured with screws atthe

front. They are designed to be stationary and should not

be removed.

INSTALLATION CHECKLIST

[] Double checkto make sure everything in this manual

has been completed, Rechecking steps will ensure

safe use of the range.

[] Make sure all controls are left in the OFFposition,

[] Make sure the flow of combustion and ventilation air

to the range is unobstructed,

[] The serial plate is located beneath the ledge trim on

the left side, just above the left knob. In addition to the

model and serial numbers, it tells you the ratings

of the burners and the type of fuel and pressure the

range was adjusted for when it left the factory.

The griddle has two leveling screws beneath the rear

flue cover that can be used to adjust to the desired slope.

The center screw is for shipping purposes only and can

be removed.

[] When ordering parts, always include the serial

number, model number and a code letter to ensure

proper replacement parts.

[] Recheck Steps:

Double check to make sure everything in this manual

has been completed. Rechecking steps will ensure

safe use of the range.

14

Page 15

Installation

INSTALL 9" or 12" HIGH BACKSPLASH

• Install and level the range or cooktop according to the

installation instructions,

• Remove the backsplash packaging, Select the back, wall

mount panel with mounting screw slots.

• Mark a horizontal line on the wall, 1/8" above the

range/cooktop backguard,

• Use wood screws or fasteners (not supplied) to secure

the back section to the wall. Slide the panel up or down

to provide the 1/8" gap between the top of the

range/cooktop and the bottom of the backsplash.

This 1/8"gap allows the appearance or front section

to overlap the mounted rear panel.

• Secure the appearance panel to the mounted back

section with the # 8 self-tapping screws provided. Install

3 screws on each side and 5 across the top.

INSTALL 22" HIGH BACKSPLASH

• Install and level the range or cooktop according to the

installation instructions,

• Remove the backsplash packaging, Select the back, wall

mount panel with mounting screw slots.

• Mark a horizontal line on the wall, 1/8" above the

range/cooktop backguard,

• Use wood screws or fasteners (not supplied) to secure

the back section to the wall, Slide the panel up or down

to provide the 1/8" gap between the top of the

range/cooktop and the bottom of the backsplash.

This 1/8"gap allows the appearance or front section

to overlap the mounted rear panel,

• Attach the shelf to the front section of the backsplash

using screws and nuts supplied.

• Secure the appearance panel to the mounted back

section with the # 8 self-tapping screws provided, Install

3 screws on each side and 5 across the top.

Frontsection

Supplied Back

#BScrews " section\

Supplied\

#BScrews \

\

\

\

\

Backguard_

Slotsfor Vertical \

Adjustment \

/ Slots for

Vertical

Adjustment

Bach

Back

section "\

Backsection

l/B'L

Frontsection ,

Back--

section

II °"

WARNING:

The back section must be securely fastened to

the wall. Failure to do so could cause damage or

personal injury. Maximum shelf weight capability

is 10 Ibs.

Supplied_

#8Screws

AVERTISSEMENT •

La section arri_re doit _tre fix_e solidement

sur lemur. Le d_faut de proc_der ainsi peut

causer des dommages materiels ou des I_sions

corporelles. La capacit_ de charge maximale

de I'_tag_re estde 4,5 kg (10 Ibs ).

15

Page 16

NOTE:While performing installations described in this book,

safety glasses or goggles should be worn.

F<>rMonog'ra_? '_local s_r_Jice h_ )our arm, call

l._S00. 444. l,_4 _.

)

NOTE:] ro(hi(:l iml)l-o'_(m( ill i'_ a (:olHilitling (_ll(l(_a'_'()r _/t

sl)(_(if](:alions m-(_ sul;_j(:(t to (:hmig( Wil[lotlr noti(:(.

Pub.No.49-80222-1

PartNo.164D4290P374

17681Rev.B

12-04JR

Monogram:

GEConsumer & Industrial

Louisville, KY4ll225

©2004 GE Company

Loading...

Loading...