Page 1

Washer* Dryer - 240 Vo#

Instructions

ve

JCt#on$

locol

_en moving the

D sconnec] the powe_ supDly cord_

then tape securely 10the

washer/drier

Tope the drum to the fforfl poneL

Tope the int screen in place, 1ape

the d_yer does elosed_

Wedge a blanket be_ieen the

Ioundry tub ling ar4d cabinet top to

reset ct tub movement,

Turn front leveling legs ali the way in

\

__P_'_34GSg76 ROY A

ifcations are subject tOchonge without notice. Printed tn U.S.A.

Page 2

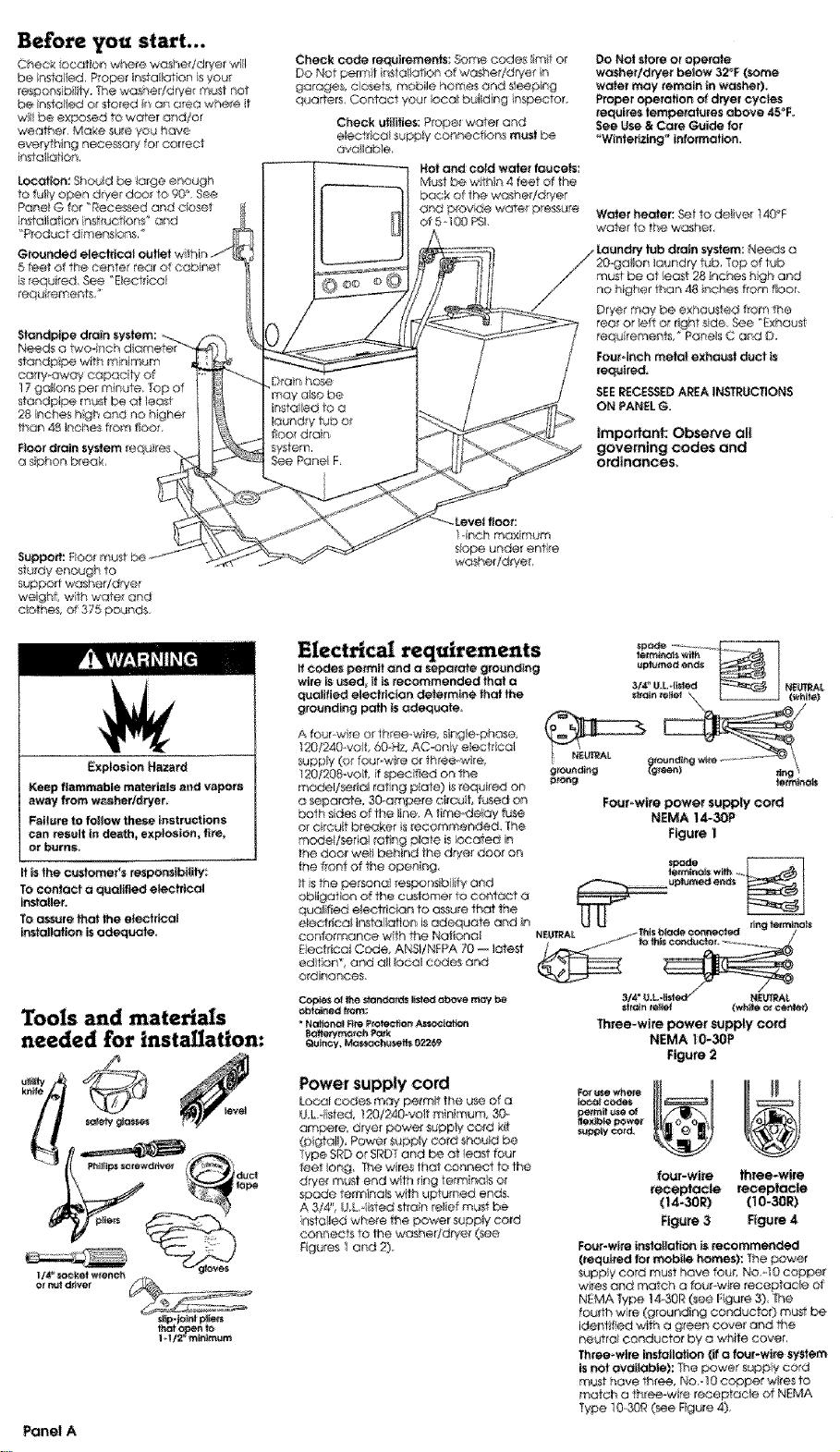

I.oeati_:Shouldbetargeenoagh

tofuhlyopendryerdoo_te_°,See

PanelGfer"Recessedandcbset

insteJtatIonnst_uefions"and

'_P_oductdimensbns,

5 feet ef the center rear of cabinet

is required, See "Electrical

requ rements _

standpipe with m nimum

carry-away cepac t¥ of

17(

standpipe must be of _east

28 Inches high and no highe_

than 48 _nches from floor,

F_or d_in

a sphon break,

Supped': Floe r_ul

sturdy enough to

support washer/dryer

weight, wth water and

ebthes, af 375 pounds

Check c_ requiremetlts: 8©me codes iimit or

Do Not parrot nstaltat_an of washef/d_/e_ n

garage& closets, mobile homes end s!eeplng

quarters, Contact your _oca_building ins_eto_.

Cheek utilities; Proper water and

electrical suppIy connectiens musl be

aveilable,

Not and ¢t.._ water faucets:

MU_ _ce w_h_n 4 _et of the

back of the washer/dryer

cRd prov_t_@water p_sure

of 5 i00 PSk

1-inch maximum

s_ope under entire

washer/dryer,

Do Not siam or operale

w_sherldhler below 32_F (some

w_er may remain in washer),

Proper operation of dwer cycles

requl_es temperatures above 45_F,

See _se & Care Guide for

"Winleilzlng _ lefom_atlon.

Waler heater: _t to deliver t40_F

water to the washer,

rear or taft o I_ghf side, _e _E×haust

requ rements #Par_e_sC and D,

Fourdr'_h melal exhaust duct is

required,

SlOERECESSEDAR_A I_UCTIO_S

ON PANELG.

Important: ObseP,'e all

governing codes and

ordinances.

Explosion Hazard

Keep flammable materials and vapors

away from w_hertdryer,

Faflure to foilew these instru_tions

can tes_lt in de_h_ explosion, fi_,

or burns,

It is the e_fome#s respondbilily

TOconlaet a qualified electrical

I_taller.

tO assure that the e_ectrical

ins_ol|atlan _ adequate,

Tools and materials

needed for installation:

sl_p-je_t p_lecs

tha_ enf_

Panel A

Electrical requirements

If codes permit and a s_arala g_edl_g

_te _ u_d_ It is r_e_meeded that o

quelifie_ electrician determine that the

grounding po_h is adequate,

A four-wire or three-wire singte,.phose,

I20/240 velt 6GoH_AC_enly e_ec_ col

supply (or four, wire Or th_eemvd_e,

120/208 volt, if spec fled on the

model/_edal rating pk_le) is requ red on

a separate_ 30.ampere ci_cu f, tided on

both s_des of the t_ne A time-delay fuse

or circuit bre_ker s reeemmeaded_ The

model/sefial toting plate is leeat_ In

the door welt behind the drye_ door on

the front ot the open ng.

t S the peL_anel respor_s_bii4y and

obliger on of the customer te contact a

qualified electrl¢_n to a_ure that the

e_ctrieat ir_staliation is adequate and n

coniormanee with the National

E@cirtcel Code, ANSI/NFPA 70 -- lat_-st

adrian * and all _oco_c_es and

ordinances,

Ceples el lhe e_r_i_ _t_ above m_y be

"Nal_l ere Pre_io_ Associate

_tte_ym_h P_

Q_ncy, _ch_Iset_s 02269

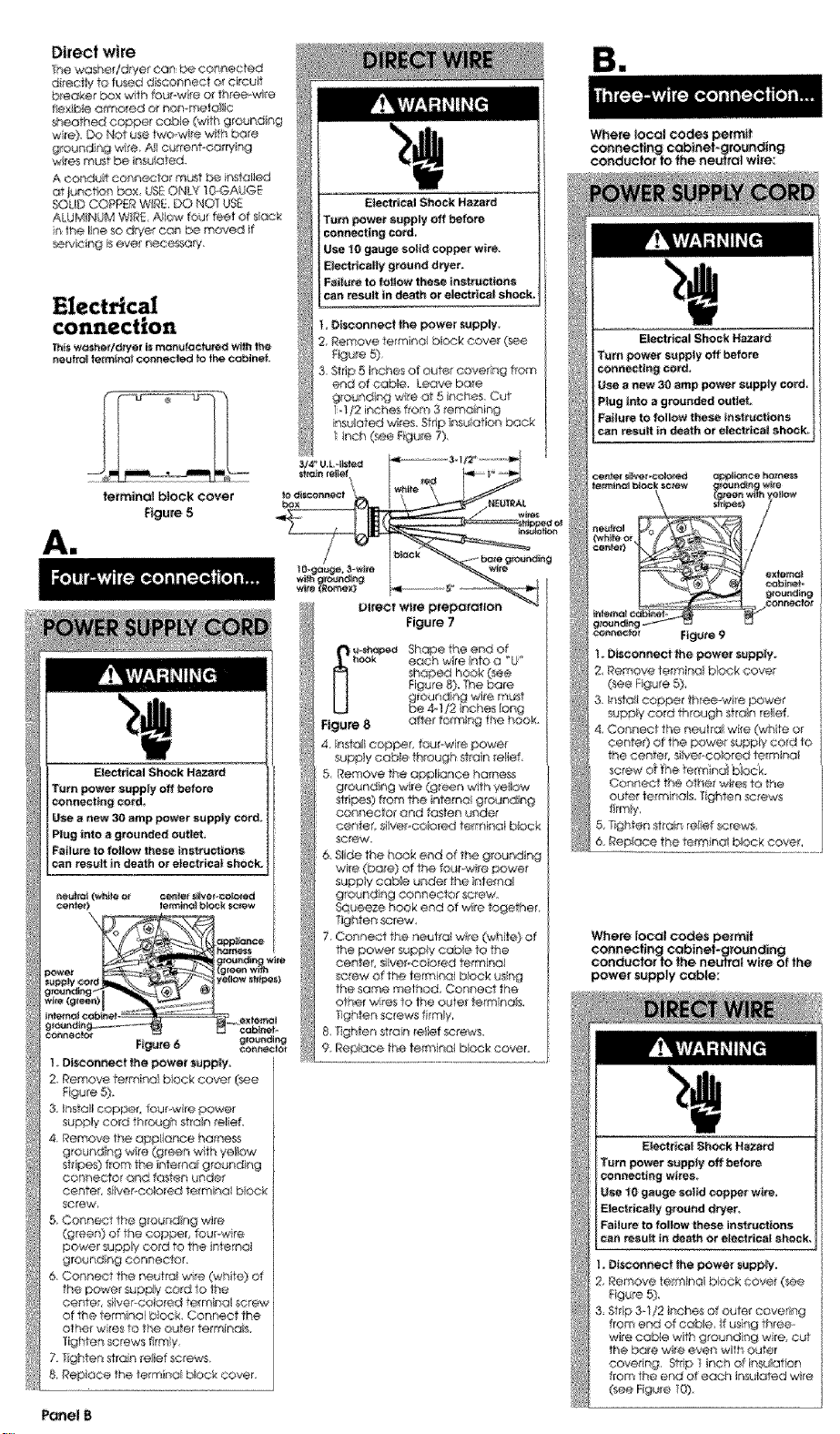

Loca_cedes may' permit the u_ d a

U& dsted, 1X}/24_'_vett m nlmum 30.

ampere, dryer power supply" cord kt_

(pigtail), Power supply co_d shou_

Type SRDof SRDTand be at east fo_3r

leer _ong The w_resthe1 connect to the

dP_,ermust end w/h ling term na}s or

spade Semifinals with upturned ends,

A 3/4", U £ II_ed stron reief must be

insla/_e_Jwhere ihe power supply cord

connects 1o 1he washer/dryer (see

F_gures 1and 2),

dng fe_a_

3/4°e_LoSst N_A_

Three-wire power supply co_d

NEMA _0-30P

Figure 2

_eex_i_e_er

four-wire three-wire

receptacle receptacle

(14-30R) (10-30R)

FIgL_ 3 Figure 4

FouPwi_e installation _ recommended

(required to_ mobile homes): The power

sup_y cosd must hove four, NO_40 copper

wires and match a fo_r wlre receptacle ot

NEMA Type 1_30R (sere Figure 3). _he

fourth wire (grounding conductor) must be

idenfifi_ w'ith a gree_ cover and the

neutral conductor by o white cover,

Three wire Ir_steilatioe (ifa four-wire system

isnet available):The power suppb/cord

must have three_ No,-10 copper wRes to

match a three-w re receptacle of N_MA

_ype 10&OR (see Fk_ure4),

Page 3

Direct wire

The washe_dryer can be eennec_d

_re_y _ fused diseoenect or circuit

bleaker box wth teu_wire er _h_ee-wlre

fie×ib4e @_nored or non-mete II¢

_#_eo_h_ eO_pet cab!e (with gronnd¾_

wre) DO Net u_ two-w re with bare

grounding wire, AI curre_t<orry ng

w_essFTruStbe ir_suo_d_

A conduit connecter re_t _ Ir,_tc_lied

at l_.notion box, USEONLY _GGAUGE

SOUD COP'PERWg_. DO NOT US_

ALUMINUM W_RE.A_IOw fou_ feei ofslack

n the I_neso dryer con be moved }t

servlcir_g is eve_' n@eessory.

_i_ wesher/d_yer is mam_ractu_ed wffh the

r_utfa| terra.at connected to the eobJnet.

tetmtnal block cover

Figure 5

Ai

L Disconnect _e power supply

2, _emove terminal Dock ¢ove_ (see

Rgure 5),

3. Stdp,5 inches of oufe_ eove_ing from

en_ of cable. Leave bare

grounding wi_e at 5 troches Cut

}-}I2 i(_che_ fitom 3 ;erna_-_ing

nsu_ated wires Strip ineJIot on back

inch (_e Rgure 7),

Be

Where local codes permit

co#netting cobtnei-gro_nc|ing

sonde€for to the neu|ral w_re:

Electrical 81tock Hazard

Turn power su_p_:y off before

coenectiag ¢ord_

U_e a new 30 amp power supply cercL

Pl_Jginto _ groencled s-ut_

Failure tofollow these aspect ens

can result in death or ele¢_icaI shock;

cent_ _e_ _ _tew

Figure 6 g_g

I DIscor_nect the power ,1apply=

2 Remove te_mna bbck cove _e

F@jre5),

3. Irfsto_lcoppec four w re,#owe{

supply co_d through stain _@ief

4. Remove the appliance harness

©or/Rector arid fosk:en under

Center, s_ivef*eolo_ed termina block

5, Connect the g[e nding wire

(green) of the copper, fourow re

powe_ sup__y cord to the internal

grout'cling connector,

6. Connect the neutral wits (white} of

the pewe_ supply cart to the

Figure 7

each wre eta a _'U_

[_ Shape the end 0¢

Figure 8

4. e_sta_tscraper, four-wire power

suppy eatNe th_eugh strain _elief

eo_nector and f<_fenunder

wife (bare) of the fourow re powe_

suppy cab._e unde_ the ntemol

ground ng connector screw.

Squeeze hook end dwire legether,

Tighten _re'w

7 Cor_ne_t the neutral wre O_Zhite}of

the power supply cabs to the

cerlter, s@@_-colorod terrtll_'lol

screw of the termino} back using

the some method, Con_ OCtthe

ot_er wkes 10 the outer term nora,

Tghten screws firmly,

S _qghfen s ralnre_ie_screws,

9, Repk_ce the te_miri<:flbksck cover.

Where local codes permit

co,nearing eobinef_gto_nding

conductor Io the neutral wire of _he

Power supply Cable:

_l_rlo_ S_h_;_:kHazard

Tern power s_ppty off before

connectir_g wires

Use tO gauge soi_ copper w_re.

_e_ricalty ground dryer.

Failure to |allow these ir_st_ectiens

can resuR in death or electrical shock.

other wres to _heouter termhl¢_B

T_ghten screws firm}y,

7. lighten strain re}ief _rews

&Repioce the lorraine b_c_s_cover

Panel B

Page 4

4, Install eeppe, three wire pc,wet

super,,* cabe thraugh stran relief

Slide the hook end of the neutrai

Figure _2

(white o_ canto 0 wre from the

three-wit÷ power suppy cable

undo the center, silv®Pco ored

term no_ screw oFthe formica! b:ock,

Squeeze the hook end oF the wire

together Tighten screw,

6 Connect the othe¢ wr_ 1o the outer

terTenas _s_ng the _me method,

i"igt len screws firmly Gee Figure !2)

7. f_ghten _tain relef screws.

love&

4 Remove the appI_ance harness

grounding wie (green with yellow

sir pes) from the hte_d_ gro_nding

conDo©taR

5 Connect the grounding wi_e

(green wlfh yellow stripes) and the

neutral @_hto) wi_e d the power

supply cord o direct wire cable to

the center, siiver co ored terminal

ecew of the terr:nk_ei b_ock,

Connect the other wies to the

alter tem_inals. Tighten screws (see

Fgure 3).

& Connect o sepon_te copper

grounding wire (NO 0 rain mum)

See Connection details*" for

detai ed ns*ructions,

7 Tighlen s#an reief screws.

8 Replace the terraria biock cover.

F_re t4

Use g_ound r_gwre and clamp

e_embty (Ra_t NO,685463) or NO-10

gauge m_r_ihurn eopt_ g_eund ng

wre.

_aust requirement:

Do No_ use non-met@ t@×ibJevent,

metal vent that issmolder than _ou

riches in diameter or exhaust heeds

wth magnet_ latch÷&

Do Not e×hausf draper_nto a chimney

turt-_ace cold ar duc_ attic or oraw_

spaco, or any other duct u_d for

ven_ing

DO Not }nsto i fiex b_event in enclosed

wa_ls, ce_hgs or floes

If using on existing exhaust system,

cleon lint from entire length of exhaust

sys_m. Mo_e sure exhaust hoo_l is not

plugged with tint.

The exhaust system should be inspected

and cleaned yeorly_

I_eplaee any vinyl at melailtzed p_ostte

foilexhaust vent wffh dgid meter ot

flexible metal 'vent,

U_ duct tape _o _al

at* jeints. Do Not use

screws to seeui_ vent

Where toeat codes DO NOT permit

eo_necttng the cabinef._ounding

conduclof tothe neu#al (white) wire:

F{gure 15

Connect ground_ "w_re_ a

grounded cold ware pipe* wth he

e_amp and then to the extemc4

ground ng conneeIOr on the

washed!dryer (see F_gures 14and ! 5)

Do Not ground to a gas supply pipe or

hot water plpe_ Do Not connect the

power supply cord to el_ctrtcal power

supply until the washer ld_¥er is

permanently grounded,

* O_ourlded c_,_ldwater pipe must t _"_ve

meta car4 nui*y to eiectricai grc_._nd

and not be nfe rupted by plastic, tubby)

OIo!her elecff col ir_sulaN-igr;ohPectors

su_chas hoses f fling& washers or gasket_

{ino_x_i_ water meter or pump) Any

electrical ir/_Jlating connector _neuld be

jumped as shewn tr__igure 16 w*lh a

length of No-4 wte _cure y c_amped to

bare rr,e o! at beth e_ds,

Four-inch dgld metal pipe is preferred

Plan installation to u_ the fewest

number of e}bows and _u_ns

Metatilextbie vent should be _uly

extended and supported when the

dr/e _sin iis final position, DO NOT KNK

OR CRUSH T4E VENL The metal flexible

vent must be fullyexten_d toallow

c_equate exhc_uetair to flew,

Allow as much room as possible when

using ebows or makng turns, Bend vent

gradually ra avoia kinkng Remove

excess flex b_e vent to avoid sagg ng

and kink ng that may resutt n reduced

air few,

Panel C

Page 5

Recessed and closet Recessed and closet

Recessed installation

Fire Hazard

Exhaust dryer outside _ installed in a

e_osef

Use Exhaust Deflector Kit 594609

instatled _na recessed arse_

Failure to do so can result in death or

fire.

To prevent large amounls of !lnl and

moisture from accumulating, to

maintain drying e_iotency and to

p_event exposure !e possible health

hazards, lhB washer/dryer should be

exhausted outdoors.

This wosheddryet may be Insta_led in a

rece_d area of closet.

The hstaiiat_on spac rg tsh inches arid

s minimum ai ow_bl÷. Add tiona

spachg should L_econsideied ter ease

of _ns_aIO,%n, servichg artd camp lance

w_th Iooal codes and ordinances

Ifebset door islnslal/ed, the m h_mum

ur_ebstrueled a;r oper_Tr_gsintop and

bOttOm are requ red, Leuvered doo_s

wth equivalent oi_ open rigs are

acceptable _,,t

Other instai ofions must use the _i_imum

dii'nens ons ndicoted

fron_ view side view

Minimum insfallofion _cir_g

spO¢_g co_ b_ O inches

Closet installation

(Shown withlegs extended 1i_¢h from

boffom o_washe_'/dryerJ

rear view

&

t

] front v_ew

U_ob_mc_eda_ _i_ e_e_r_r_m forCiOset

do_r L_ve_l doorwt_ eq_'_ent _ ope_gs

"°?iil I

be needed

side view

324/8 _

,I

side view

Panel G

Page 6

Maximum{eng_of the e£naust system

depends upoe the type at ven_ used.

number of elbows and the _ype of

exhaust hood. the maxim_Jm ength for

bolh red and flexib e vent B shown in

the ehorl

I_6 0

MaimEd,_

Mobile home instal!_ion

This washer/dryer is s_ilable for mobile

home ins_llatiens.The Insteliatlo_of hhe

washer/dryer m_st oonfeFn to the

M_utoo{_ped _ome Constr_ctlon end

Safety, Ti|le 24 C_R, Par_3280 (formerly

the Federal Standard for Mobile Homes

Construction end Safety, Title 24, HUD

Pod 280, latest edition).

• 4 leg_ • 4 |_, ware{_

1 ar_ h_Se ¢{¢1_ hO_e W_l_

2 161t 5_r

_hem_×l_aurnterq_th u_ng_ _ x _ _e_tt_tlg_J_

ventwith 2e_bows_nd a2-1/_ e_ha_t hc_aa}_B_.

_or exhaust eonfigu_..cC,ions olher than

tho_ sled n the chad. the Book

pressure MUS1NO[ exceed 0.2 iehes

water c@umn at _he back of the

washer/dryer. 9_e back pressure shoud

be cheerio by a qua_ifle'a techn cian.

Ser4ee check: The bobk procure n any

e_haust system used must eat exceed

02 nches of water coumn measured

w_th er. ind ned manometer at the

po_r4 _hat the exhaust vent connects to

the dryer

L:×haosttng_he dryer eetside s

recommended Recessed nsta_l@tion

that isr_ot exhausted outside mus_ u_

_xhe,ssl Deflector Kit WE25XO220 %e

W_ecessed and dose_ nstelbfion

nstructiens." Pan@ G for ueo_ssfructed

air opening _equ}remer#s,

Iftheweshei/_eyer isinsta_iecl#ie

confined area S_eh as e bedroom,

bathroom or cleset_ it m_st be

exheested to the Outside and S_o,nsion

mist be made _orenough air tar

venti_olkxs Check governtr g codes and

ordinances AI_4_refer te ft_e 1Recessed

_nd Close_ installer on inshuctions" on

Panel G,

M exhaust hood sho_ld eo_ the

exhaus_ vent to prevent exhausteG air

from re_urnng nro dryer The curie4 o{

the hood must _ at leas112 nches

from the ground or any ob_ec_ that may

be _ the path of the

FoL_r-inchexhaus_

hood ispreferred.

However a 2t/2

exhaust.

inch exhaust !1cod

may be use@ A 2.

1i2-tnch exhaust hood c_eates greater

back pressure than other hood 1spas.

For permanent installation,a stationary

exheest system is req_ired_

enclosed ©red, #oar encJe_ _e_

Extens on be'hand the ene!osure wl!!

pro"vent iet and me sture budup under

the mobile home,

with washer/drye_ in laundw area,

More than one person _sPeqt_ired to

lift, flit or move the washer/dryer

because of its weight sad size.

Foliate to follow this instruction may

result in injury.

Truck only from Pear to prevent prod_ct

damage.

tnjury Hazard

IPLf on safety @asses and @eves.

Numbers

correspond

to steps.

package Check that al parts were

nduded

_eveling _eg inte the hole

in the rear come_ on the

bottom of he

washeUdryen Push _eg n

untl t snaps in_o p!ace_

Do the t_ame same thhg

w_th the ether even@

_eg in the other rear corner,

Stes 4)

legs n hand check the

ridges for a diamond

morking_ That% how for the

1 With one of the front

leg s supposed to go nto

the hole, Staff to scow _he

legs hie the' holes in the

front comers by hand

%

Use slip-joint pliers to finsn turning the

front legs ,_r4you reach the diamond

mark

Slt_ washer/drye_ onto cardboard o_

_rdbeard befo_:emoving ocpe_ floor to

prevent damage to lloor oove_ng_

I Place a pace

Of cardboard or

hardboard n front of

carton, Now stand the:

washeUdryer upright

Side washeqdryer

Panel D

_ p_venl p_cr

d_ge, dO n_

t_ve Com_

p_Is _r_ the

ca_O_ b_e

c_in e,

out the oadon down one comer.

Remav_ cotton,

Page 7

1 Remove

the two _ea[comer

po_stslocated at the

back of the

washer/dryer.

Remove the two

corner pieces

attached to the lower

front of the

wosher/dryer_ Do Net

_emove the foam

s__pping paces

between the washer

and dryer until the

washef/drye_ is in pace

cor4_

pe_

Numbers

correspond

to steps.

9=

1 O, Move

foam shipp ng

pieces outward

iust enough to

c_ea_ the washer

tid. Untape and

open the washer

Id. The latch

under the dryer witl hold Hidopen.

of baskeh Place hoses w_th other parts

11.30.

1 61Attach hose to bottom (hot

water) !nlet valve opening first;then

second hose to tap (paid wateO n_t

valve. T_ghien coup rigs by hand. Use

pliers to make an addiiiona_ two-thirds

turn.

IMPORTANT: THIS PROCEDURE

MUST BEFOLLOWED TO ASSURE

PROPER INSTALLATION.

SI_ woshe_/drye_ onto eo_dboerd or

hardboard before moving across floor fo

avoid damaging floorcove_Ing.

_J_

1

e_het side of the washed/dryer, move

wa_er/drye_ c_ese to final position so

you con e_ib, complete the follow ng

steps. (Go to Step 20.)

tf you ere working in a closer o_

reoet,se_ area, move theewasheridrye_

into flnai posit en ar'd rernove

cardboa_d,!hardboard from undei"

woshe_/dryen _emove the lv,,o foam

shipp#ng pieces bel'ween the wa_qe_

and dryer and place with the o.ine[

sh p_:xng pieces. Remove the two

Philt ps-head screws ocateo of the lop

of the access panel (See _lu_tret on for

Step 25) Remove access panel end set

access ;:_nel and screws aside,

Complete the fat owing steps through

the aoce% a_ea

up on latch_ Case d,

or cable to drye_ See "Electrical

connection, _ Panels B and C. Do Not

plug power supply cord into ouie or

econnect power a,_this time,

Sl_p and FaffHazard

Use new water inlet hoses.

Failure to follow this instrection

could result in he_l injury, broken

benes_ or bruises from sl_pping and

falling le weter on floor.

I _ _eupS_

end of the nlet hoses, Check that

washers are firmy seated in coup rigs,

Panel E

d_i_ hose

1 7I_O _reventthed_oinhose

from comng off at eaking_ it must

instaled per the following nsttuctiens;

1,Wet the inside end of the dron hose

w#h tap wate_ DO NOT USEANY

O_HE_ LUBRICANT,

2 _ueeze ea_ _ drain hose ciamp

wf_ piers to open and place clamp

over the end of the dran ho_.

3 _-dle ho/@r_g clamp epen_ wo_k end

of dralrl hose onto dran ceneeetor.

4. Posit on c_amp ove_ the drain ho_

area ma_ked _clamp" Release

camp, Camp _ould be 1/4 inch

from end of drain hose,

laundry |_tb dt_n system;

Open yellow clamp and

slide over "hook _end of

drain hose to secure the

l/gd and car ugated

_¢ticns togelher

Floor d_ain systemr Do

Not in,all _hook" end of dran hose to

co rugated _c:rion. Consult your

plurn_r _orproper insta lotion.

eta aundry tub o standp pc. Check fo_

proper length of d_oln ho_e.

1 II Before altaching w_er in et

hoses. _un water 1hrough both faucets

into a bucket [_s wil_get rd o por_Jcies

In water lees that migh_ cog hoses.

Mark whic_ is the her water faucet

(inlet marked !4") to hot water faucet

/s_ach top inlet hose (inter marked 'C")

to co_d water fa _cet Tighten coupings

to the faeoefs by hard, Use p_ers lo

mr_ke final two4h rds turn.

Page 8

Move w_her/dtyer to its permanent

locallon_ Remove cardboard/hardboard

from under was,her/dryer,

wosher!d_yer into final position.

* Ti/}the washer/d_yer orward, raLqng

back legs I inch Off }he floor _ that

the rear _ttqeve/ng legs wil_ ad_us}

Gently _ower the washer!dryer to the

floor

, Check tha_ the washer/dryer _slevel

by plae ng a carpenter's eve on top

of the washer, first side to sde. then

front to back,

- It _1b not/eve!, adjust the front legs

up or down,

,-- Ti_tthe wa_ner!dryer forward,

raising back legs 1 inch Off the floo_

so that the rear _lfqeveling legs

will adjust, Gen_y lower the

washer!dryer to the floon

-- Check that the washer/dryer is

love. Repeat _ needed

CHECK THATDRAIN HOSE IS NOr _ISTED

OR KINKED AND iS SECURELYIN PLACE

access p_ne i_ Step g; remove tt_e

1we foam sh pping pieces between the

wa¢*_e_and drye_ ar!_ place wilh the

ether shipping pieces. !f the exhaust

duct cannot be connected from the

s_deof the washer/dryer the exhaust

duct can be reached from the #ant

through the access panel, Remove the

l_vo _hltiips-heod screws located at the

top of the access panel Set acce_

paneq and screws a_de.

exhaust vent that is need_ to connect

the dryer _o the exhaust ho_ (See

_Exhaus} requ fomentS. '_Pcne_s C and D.)

removed alt the shipp ng pieces,

ncludlng the round _fipp n4;_piece,

D_spose of all moter}aB in proper

n_aRne(

if you do net remove the round shlp_ng

piece_ your wosherldryer may "work"

away from its location,

plasSc _d strap

in laundry tub or standp pe Wrap the

Plast c beaded strap around }he drain

hose and aundry tub orstendp pc,

thread _aded end of strap through

keyhote end Puli until st'_op is tight, Slide

strap into narrow end of keyhoie to lock

strap n p_ace See Rgures A-B

If the wate_ intactfaucets and drain

standpipe are _eeessed, t_ghf|y wrap the

past_ beaded strap around the drain

ho_ and route1 body, (Do Not wrap

strap arour'd }he faucet tsandles or

stems) Thread b_aded end of sirap

through ke,/ho_e end Pul unJiI strap is

tight. Side st_ap nto narrow end of

keyhoie to lock s#ap in ptace, D

_e igure C,

Secure the drain hose to the tub

_ stc_rdpipe wt_ the p|a_ic

_mp Faiture to property secure

drain hose could result in water

demage,

If drain hose eatt4_et be ......

strapped _tO ....... _

place, hose most t 2 _\

be cut exactly to I :'

length so hook _ I I i J

endiS held fighW l . _ '!

over _ ot tub or I _ j _ i

star.pipe= See I I J I J

Figure D, b_*_-_r i

Note: If washeE/dryer IS moved to adjust

drain hose, the washer/dryer must be

leveled e_n Repeat Step 23. Race

cardboard under lhe washer/d_er al_

care_}ly move washer/dryer to avoid

_mag_ng _r covering.

,_._sher/dryer and then }o the exhaust

hood.

, Use the _raightesr path posebie to

avoid 90 ° turns.

• U_ duct tape to seal a_ }ants in the

exhaus_ system

• Use eauiking compeund te s(_sl

exter o_ woli open ng areund e×houst

bead,

REQ_I_M_NTS 8E SUREYOU HAVE

CORRECT E_CT_1CAL SUPPLYAND

RECOMMENDED G_O_NIDING METHOD.

Check the instal!arian _n_uctions _ see

that you hove competed each step

Complete any missed steps before you

cent_nue_

9 ISChech that a_ pa#s ere now

nstal e(:L _e pa_ Ist. Pane_ D, If there b

an extra part go back through steps to

see which step was skipped.

t lCheck that you have a_lof

your tools

check for _eake T_ghten couplings if

there is _eaking_ Do Not ovedighten; ff'_is

coud cause damage to faucets,

sure to tighten screws at each end of

the access pa_eL

{_.YL_ to fuly understand "your new

washer/dryer Open dryer door, Check

to be sure lint sereen is in its p_per

positioA. Wipe out drum,

grounded outlet, Reconnect the _._ower

suppay. Now start _e washer and allow

it to complete the regular cycle,

6 n Start dryer and allow It to

comp_te a ful heat cycle to make sure

;t iswe_ng properly

Yell hove seceess_lly inste|lea_your

new washer/dryer_ TOget the most

efficient llse from your new

washer/dryer, read yau_ _s_L_.,_r._

Keep Installation |nstpJattees and

Guide,

Numbers

co_resportd

to steps.

15.

22.

Panel F ......

Loading...

Loading...