Page 1

GE Oil & Gas

GE’s Mooney*

Specialty Regulators

The Handloader, Mity-Mite and

Powereactor Regulators

Page 2

2 | GE Oil & Gas

2 | GE Oil & Gas

Page 3

Mooney* Handloader Regulator

This small volume, high pressure regulator has become the standard of industry and science. These instruments

are often referred to as “Loaders” because of their many years of extensive use maintaining constant, extremely

accurate pressure control in the “loading” of dome regulators. However, their accuracy, trouble-free performance, and versatility have led to hundreds of other applications in static, mobile and airborne services. They

are used in component testing, hydraulic and pneumatic operator systems, safety relief valve actuation, critical

rocket fuel transfer and pressurizing problems encountered in missiles and space vehicle projects, to name only

a few.

Features

Maintains constant, accurate pressure control

Simple effective design

Compact, lightweight, easy to mount

Self-contained, self operating

Bubble-tight shutoff

Repeatability and accuracy of spring loading

Greater sensitivity with flexible diaphragm

Ease of adjustment

Corrosion resistant

Interchangeability of parts

Positive downstream protection

GE’s Mooney Regulators | 3

Page 4

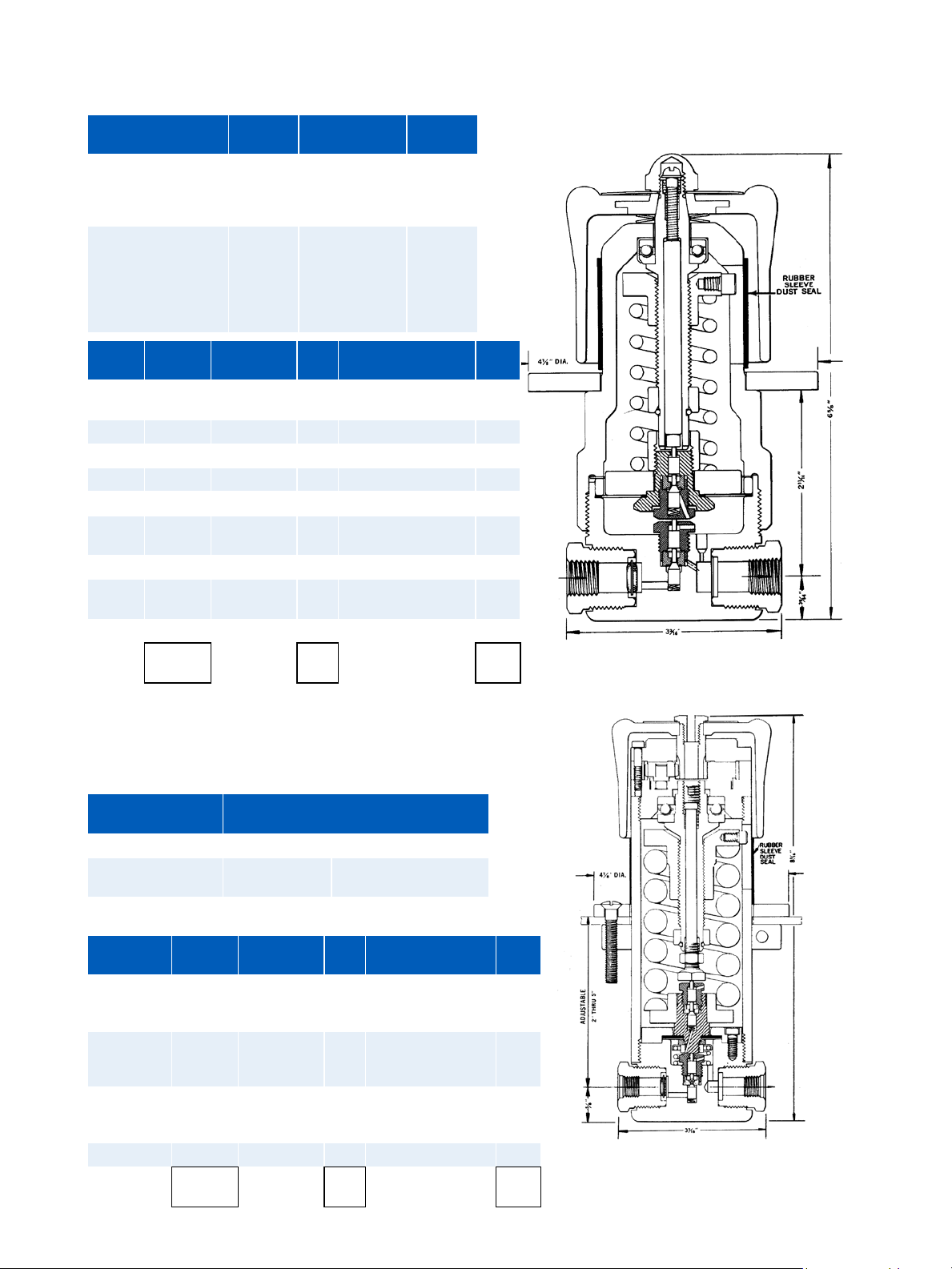

Mooney* Handloader Pressure Reducing Regulator

Model Inlet Pres-

sure

Temperature

Range

C

v

15L w/ Relief System

16 L

15LH w/Relief System

6000 psi -65° to 165° F 0.06

16 LH

15 LX w/Relief

6000 psi

System

16 LX

15 LHX w/Relief

-65° to 165° F 0.06

System

16 LHX

Model Basic

Outlet Range Code End Connection Code

Fig #

15L 10927 2-251 psi A 1/4 Tube MS33649-4

1/4”NPT

L2

P2

16L 11058 3-60 psi B

15 LX 10928 5-150 psi C

16 LX 11089 8-300 psi E

10-750 psi F

15 LH 10929 10-1000 psi H 1/4 Tube MS33649-4

1/4”NPT

L2

P2

16 LH 11059 10-2000 psi K

15 LHX 10930 10-3100

L

psi*

16 LHX 11118

Order

Code =

* Available only in 15LHX and 16LHX models

For all handloaders, add the letter A to the end of the figure number for standard soft

goods (Mylar diaphragm, Nylon seat). For other materials, please contact Oil & Gas.

For example, the complete figure number for a Model 15L with 0-300 psi outlet range and

1/4” FNPT connections and standard soft goods is 10927EP2A.

Model 15L Shown

Mooney* Handloader Pressure Reducing Regulator

Model 15KX w/Relief System

Model 16KX

Inlet Pressure 600 psi 10000 psi

Temperature Range -65° F to +

165° F

Cv 0.018 0.018

Model Basic

Outlet Range Code End Connection Code

Fig #

15KX max

10931 10-2000 psi K 1/4 Tube MS33649-4 L2

Inlet: 6000

psi

16KX max

11060 10-3500 psi M 1/4”NPT P2

Inlet: 6000

psi

15KX max 10932 10-6000 psi P 1/4” Tube AMINCO

16KX max 11229 10-6000 psi

Order

Code =

4 | GE Oil & Gas

-65° F to + 165° F

(for 100000 psi

only)

S2

Model 15KX Shown

Page 5

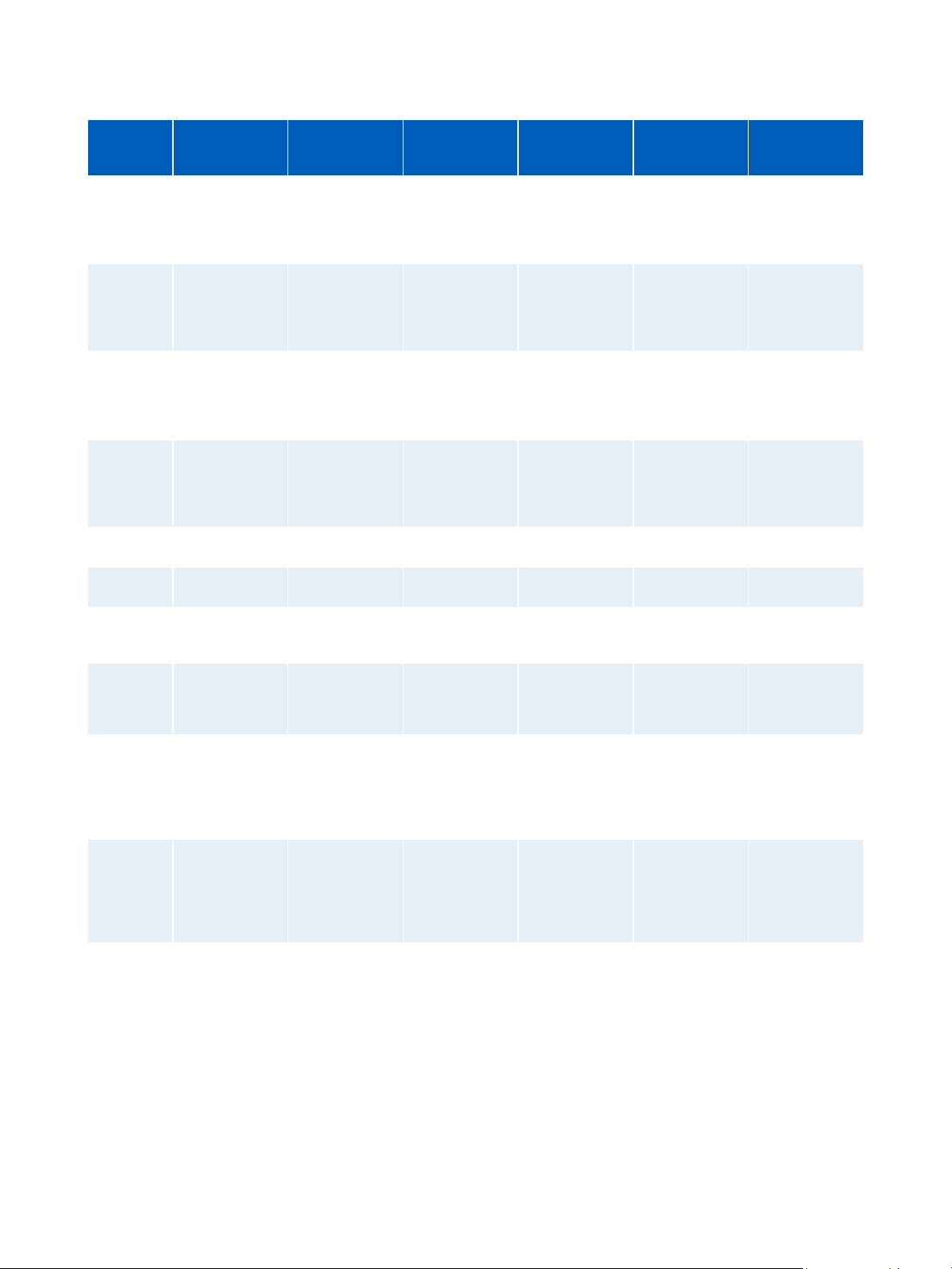

Mooney* Handloader Pressure Reducing Regulator

Model Max Inlet

(psig)

15L 6000

16L 6000

15LX 6000

16LX 6000

15LH 6000

16LH 6000

15LHX 6000

16LHX 6000

6000

15KX

10000

6000

16KX

10000

Outlet Range

(psig)

2-25

3-60

5-150

8-300

10-750

2-25

3-60

5-150

8-300

10-750

2-25

3-60

5-150

8-300

10-750

2-25

3-60

5-150

8-300

10-750

10-1000

10-3100

10-1000

10-3100

10-1000

10-2000

10-3100

10-1000

10-2000

10-3100

10-6000

10-2000

10-3500

10-6000

10-2000

10-3500

10-6000

10-2000

10-3500

10-6000

10-2000

10-3500

10-6000

Relief System C

Yes 0.06

No 0.06

Yes 0.018

No 0.18

Yes 0.06

No 0.06

Yes 0.018

No 0.018

Yes 0.018

No 0.018

v

Outlet Rise/

1000 psig inlet

drop

3

3

3

5.4

11

3

3

3

5.4

11

1

1

1

1.8

3.7

1

1

1

1.8

3.7

33

33

33

33

5.5

11

11

5.5

11

11

6.9

6.9

6.9

6.9

6.9

6.9

6.9

6.9

6.9

6.9

6.9

6.9

6.9

Average Lockup

(psig)

1.7

1.7

1.7

3

6

1.7

1.7

1.7

3

6

1.7

1.7

1.7

3

6

1.7

1.7

1.7

3

6

19

19

19

19

9

19

19

9

19

19

12

12

12

12

12

12

12

12

12

12

12

12

12

input signals.

GE’s Mooney Regulators | 5

Page 6

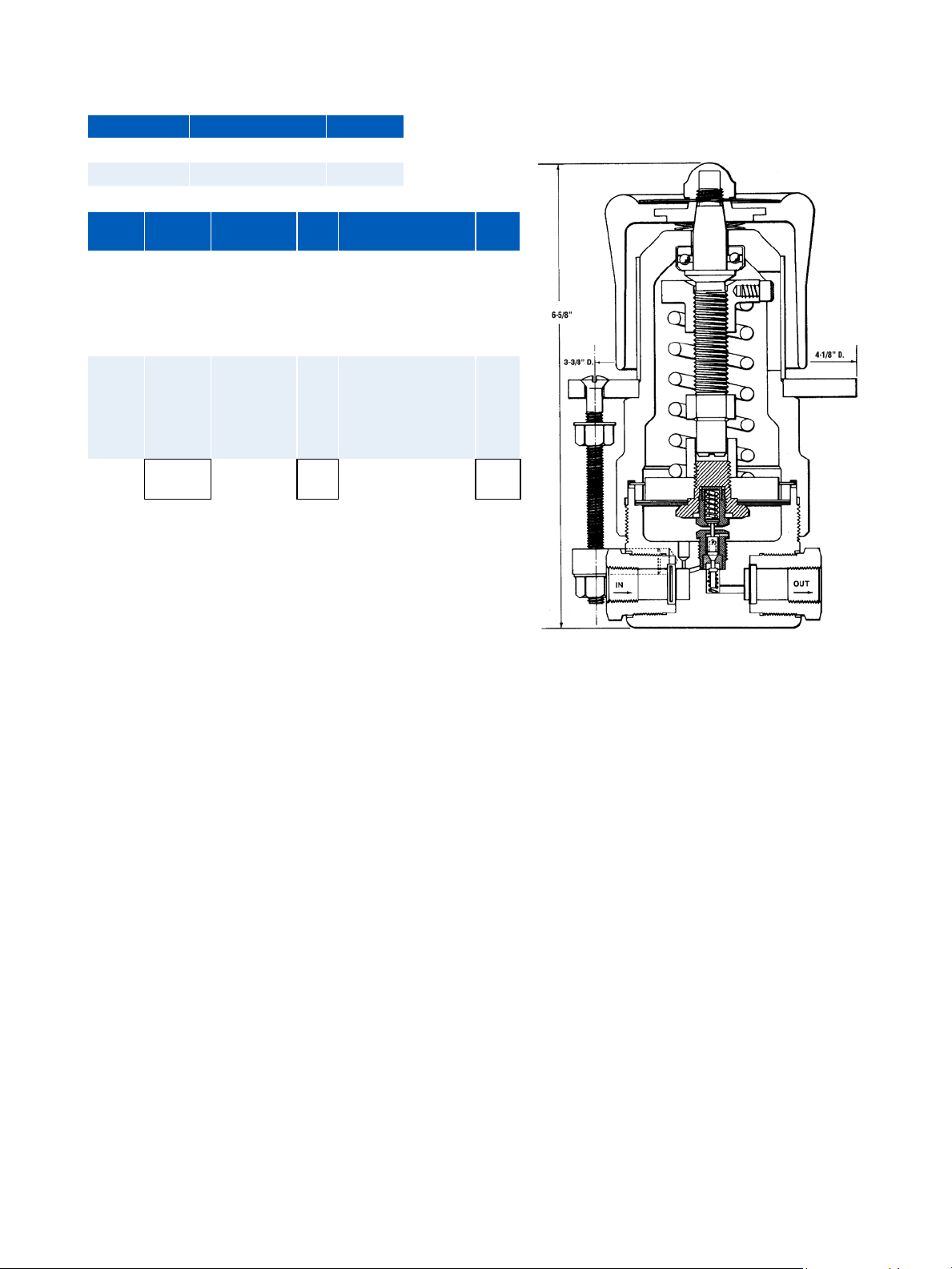

Mooney* Handloader Pressure Reducing Regulator

Model Temperature Range C

v

153 -65° to 165° F 0.17

155 -65° to 165° F 0.04

Model Basic

Outlet Range Code End Connection Code

Fig #

153 11409 2-25 psi

3-60 psi

5-150 psi

8-300 psi

10-750 psi

10-1000 psi

155 11410 2-25 psi

3-60 psi

5-150 psi

8-300 psi

10-750 psi

10-1000 psi

A

B

C

E

1/4”NPT P2

F

H

A

B

C

E

1/4”NPT P2

F

H

Order

Code =

NOTE: Other configurations may be available, please contact Oil & Gas.

P2

Model 15L Shown

6 | GE Oil & Gas

Page 7

Mooney* Mity-Mite Regulator

The Pressure Reducing Mity-Mite is a direct acting, self-contained gas dome regulator of compact design,

weighing approximately 2 lbs. These regulators have a set of integral needle valves for internal dome loading

for gas service. An auxiliary connection is provided in the dome for external dome loading. This port is used

for those applications where the line fluid is a liquid and the dome must be externally loaded from a separate

source of gas pressure, also used for those situations where it is desirable to set the reference dome pressure

form a remote point by means of a Mooney* series 15, combination reducing and relief regulator. Control

pressure is sensed within the regulator.

The Back Pressure Mity-Mite is a an extremely simple, angle

pattern regulator having only one moving part. The diaphragm

senses upstream pressure on the underside and is balanced by

dome pressure on the upper side. In addition, the diaphragm

serves as the valve seal, closing on a nozzle which is an

integral part of the body. This regulator acts to limit upstream

pressure and has no control over outlet pressure. Unlike relief

valves, this unit is designed for continuous throttling service,

maintaining the upstream system pressure between two

pressure levels.

All Mity-Mite back pressure regulators have externally loaded

domes and may be used to control either gases or liquids

providing such fluids do not react chemically with the wetted

regulator materials. The dome must be charged with gas to a

pressure of approximately the desired back pressure setting.

Two connections are provided in the dome. One is intended for

the attachment of a gauge and the other is for dome charging

purposes. An assortment of double needle valve loading

assemblies are available for this purpose as options. Please

contact GE Oil & Gas for details.

Features

Rugged, extremely compact and lightweight

Capacity range equal to conventional regulators

Recommended for small/medium flow conditions

where extreme accuracy is required

Available for pressure reducing and back pressure service

Handles any non-corrosive gas or liquid over a variety of

pressure ranges

Back pressure Mity-Mite series can be applied to corrosive flow media

Materials - Aluminum Alloy/316 SST

GE’s Mooney Regulators | 7

Page 8

Mooney* Mity-Mite Regulator

Model 94

Inlet Pressure 5000 psi

Max. Outlet Pressure 3000 psi

End Connections 1/4” FNPT

Cv 0.1 with 3/32” orifice

Weight Aluminum - 1.6 lbs

0.6 with 3/16’ orifice

Stainless Steel - 4.6 lbs.

Model Dia-

94 2 5000 3000 3/32” 0.14 0.41 1 Yes No Unbal

94 2 5000 3000 3/16’ 0.65 2.3 6.1 Yes No Unbal

Model Basic

94 11486 All Alloy 416 SST 1/4” NPT P2 1/8” 1 3/16” None Nylon PCTFE Nitrile 0 to 165° F A

11233 18-8

Order

Code

=

*All regulators also include options for External Loading or Internal Sensing. External Sensing may be requested on

order for the models specified above for an additional fee.

The Internal Loading option is included at no additional charge for the models specified above.

Fig. #

phragm

Size

(Inches)

Body/

Dome

Material

SST

Max Inlet

(psig)

Trim

Mate-

rial

17-4

PH

SST

Max Outlet

(psig)

End

Conn.

1/4”

MS33649-

4

Orifice C

Code Size Code Orifice Code Valve/

L2 1/4” 2 3/32” 8 Nylon PCTFE Nitrile -65°F to

3/8’ 3 PCTFE PCTFE Nitrile 0 to 165° F E

1/2’ 4 PCTFE PCTFE Nitrile -65°F to

v

Outlet

rise/100 psig

Inlet Drop

Average

Lock up

(psi)

Valve

Seat

PCTFE PCTFE PCTFE 0 to 65°F J

Seat

Gasket

Internal

Loading

Option*

Rubber

Goods

External

Sensing

Option*

Temp Range Code

165°F

165°F

Valve Type

C

G

8 | GE Oil & Gas

Page 9

Mity-Mite Back Pressure Regulator Specifications

Model Connections C

90W

S90W

SD90W

91LW

S91LW

SD91LW

91W

S91W

SD91W

91W

S91W

SD91W

91 1/4” FNPT 0.12 60-6000 psi

Model Basic Fig # Dome Body Diaphragm Temperature

90W

S90W

SD90W

91LW

S91LW

SD91LW

91W

S91W

SD91W

91W

S91W

SD91W

91 M12519-G 316 SST 316 SST FKM 0° F to 200 ° F 60-6000 0.12 4

Order Code = AL = Aluminum

1/4” FNPT 0.44 10-2000 psi

1/4” FNPT 0.44 25-400 psi

1/4” FNPT 0.38 100-2000 psi

1/4” FNPT 0.17 100-3000 psi

10448

11521

11508

10451

11522

11504

10454

11523

11505

10457

11524

11506

316 SST = 316 Stainless Steel

v

Al-Alloy

Al-Alloy

316 SST

Al-Alloy

316 SST

316 SST

Al-Alloy

Al-Alloy

316 SST

Al-Alloy

Al-Alloy

316 SST

Control Range

Al-Alloy

Al-Alloy

316 SST

Al-Alloy

316 SST

316 SST

Al-Alloy

316 SST

316 SST

Al-Alloy

316 SST

316 SST

Nitrile

FKM

FKM

PTFE

PTFE

PTFE

PTFE

PTFE

PTFE

PTFE

PTFE

PTFE

Range

0 to 165° F

0 to 200° F

0 to 200 ° F

-65° F to 200

° F

-65° F to 200

° F

-65° F to 200

° F

Back Pressure

Range (psig)

10-2000 0.44

25-400 0.44

100-2000 0.38

100-3000 0.17

Max

C

v

Weight

(lbs)

1.6

2.5

4

1.6

2.5

4

1.6

2.5

4

1.6

2.5

4

Viton and Teflon are registered trademarks of Dupont.

GE’s Mooney Regulators | 9

Page 10

Mooney* Powreactor Dome Regulator

The Mooney* Powreactors are direct-acting, self-contained, dome-loaded, pressure reducing regulators.

Control pressure sensing is normally accomplished within the Powreactor without the need for external tubing

and valves. This achieves a clean silhouette and minimum envelope size while also making the Powreactor

capable of sustaining much rougher handling than the average regulator.

Features

Instantaneous automatic control

Extremely sensitive to pressure changes

Maintains constant delivered pressure

Balanced valve construction

Ease of cleaning

Avoids chattering and pounding

Positive, tight shutoff

Entirely self-contained

Quick, easy adjustment

Few wearing parts

Fail close on loss of dome pressure

Optional external sensing

10 | GE Oil & Gas

Page 11

As you consider the proper regulator for your application,

please consider the balanced and unbalanced valve

configurations that are available for the Mooney* Specialty

Regulator.

In Unbalanced Valves, the inlet pressure beneath the valve

adds the force needed to open the valve. As the inlet pressure

decreases, the force on the valve decreases, allowing the

valve to open more freely and resulting in higher downstream

pressure. Balanced Valves reduce this effect by equalizing

the pressure above and below the valve, allowing greater

consistency in downstream pressure as the upstream

pressure varies.

Also, consider which outlet pressure sensing configuration is

best for your application. The choices are External Sensing or

Internal Sensing.

The normal configuration of the Mooney* regulator is Internal

Sensing. This method conveys outlet pressure to the bottom

of the diaphragm through an internal sensing passage. This

method provides quick response and accurate control.

Sometimes high-pressure drops across the regulator can

cause turbulence at the outlet port resulting in inaccurate

sensing of the true outlet pressure. This makes the External

Sensing configuration the better choice as the outlet sensing

point is moved away from the turbulence.

Models 202B, 212B, 301B, 311B, 402F, 412F, and 411B can be

converted to external sensing by plugging the internal sense

passage and connecting a tube between the sense volume

and downstream piping.

Model Inlet

Pressure

112B - 3/16” Bal

Valve

112 BR - 3/16”

BR represents relief configuration

6000 psi 6000 psi 0.5

6000 psi 6000 psi 0.5

Max Outlet

Pressure

C

v

Relief Port Relief Material Weight

6 lbs aluminum/

15 lbs stainless

1/4”

MS16142-4

PCTFE 16 lbs

112BR Relief Port:

Internally loaded through integral needle valves

External Dome Loading connection: 1/4” MS16142-4

Model Basic

Fig. #

Body/

Dome

End

Connection

Code Orifice Code Rubber

Goods Seat

Temperature

Range

Code Trim

Material

Material

112B 11220 All Alloy 1/2” FNPT P04 3/16” Bal 9 Nitrile -65° F to 165° FA 18-8 & 17-4

SST

112B 11221 304 SST 1/2” MS33649-8 L04 3/16” Bal 9 EDPM -65° F to 165° FH 18-8 & 17-4

SST

112 BR 11301 304 SST 1/2” & 3/4” GR4 H044 3/16” Bal 9 FKM 0° to 165* F P 18-8 & 17-4

SST

Order

Code =

Seat

Material

PTFE

PTFE

PTFE

GE’s Mooney Regulators | 11

Page 12

Model Inlet Pressure Maximum Outlet

Weight

Pressure

202B 6000 psi 6000 psi 32 lbs.

212B 6000 psi 6000 psi 32 lbs

202F 3500 psi 3500 psi 12 lbs

Internal Sensing with Alternate External Sensing

Connection 3/8” MS16142

Internally loaded through integral needle valves

External Dome Loading connection: 1/4” MS16142-4

Balanced Valve Example

Model Basic

Fig. #

Body/

Dome

Material

Trim

Mate-

rial

202B 11127 304 SST 18-8

& 17-4

SST

212B 11128 304 SST 18-8

& 17-4

SST

202F 11568 Alumi-

num

18-8

SST

Bronze/

Brass

Order

Code =

Unbalanced Valve Example Unbalanced Valve Example

End

Conn.

Code End

Conn

Size

Code Orifice Code Rub-

ber

Goods

Seat

Mate-

rial

Seat

Gasket

Temp Range Code

FNPT P 1/2” 04 1/4” 6 Nitrile PCTFE PCTFE -65°F to

165°F

MS33649-4L 1” 06 3/8” 8 EPDM Kynar PCTFE -65°F to

165°F

1/2” 9 Viton PCTFE PCTFE 0 to 165° F 9

1/2” GR4 Grayloc

1’ GR7 Grayloc

1-1/12” GR14 Grayloc

H044

H067

H0814

FNPT P 1/2” 04 3/16” 5 Nitrile PCTFE PCTFE -65°F to

165°F

MS33649 L 3/4” 05 1/4” 6 EPDM Kynar PCTFE -65°F to

165°F

MS16142 M 1” 06 5/16” 7 Viton PCTFE PCTFE -65°F to

165°F

3/8” 8

1/2” 9

A

H

A

H

P

Internally loaded through integral needle valves

External Dome Loading connection: 1/8” FNPT

Example: A Model 202B with 1/2” MS end connections, a 3/8” orifice, and standard soft goods (Nitrile O-rings and diaphragm,

PCTFE seat and seal gasket), would be Figure No. 11127L048A.

12 | GE Oil & Gas

Page 13

Model Basic

Fig. #

Body/Dome

Material

End

Connection

Code Orifice Code Rubber

301B 11167 All Alloy 1/2” FNPT P04 3/16”

Bal

311B 11221 304 SST 1/2” MS33649-8L04 3/16”

Bal

301B 11213 Carbon

Steel Elect

1-1/2” FNPT

Grayloc

H0814 3/4” 8 KFM P 18-8 & 17-4

Nickel

Coated

311B 11215 Carbon

Steel Elect

3’ x 3” ANSI

2500 RTJ Flg

CJ12 1” Bal

Val

Nickel

Coated

311B 11245 304 SST 2-1/2” - 3” H1225 1-1/2”

Bal

311B 11246 Carbon

Steel Elect

4” FR 31 - 4”

GR31

H1431 1-1/2”

Bal

Nickel

Coated

Order

Code =

301B, 311 B Weights:

1” -1-1/2” = 94 lbs.

3” - 4” = 306 lbs

Internal Sensing (External Sensing Available)

External Dome Loading connection: 1/4” MS16142-4

Goods Seat

Temperature

Range

Code Trim

Material

9 Nitrile -65° F to 165° FA 18-8 & 17-4

SST

9 EDPM -65° F to 165° FH 18-8 & 17-4

SST

SST

9 18-8 & 17-4

SST

9 303 & 17-4

PH SST

9 FKM 0° to 165* F P 303 & 17-4

PH SST

302G Weight: 40 lbs

Internally loaded through integral needle valves

External Dome Loading connection: 1/8” FNPT

Seat

Material

PCTFE

Kynar

PCTFE

PCTFE

PTFE

PTFE

301B Unbalanced

Model Basic

Fig. #

Body/Dome

Material

302G 11567 Aluminum

Bronze/Carbon

Steel

Order

11567

Code =

311B Balanced 302G Unbalanced

End

Connection

Code Orifice Code Rubber

Goods

Temperature

Range

Code Trim

Seat

1/2” FNPT P08 1/4” 4 Nitrile -65° F to 165° FA 18-8 SST

1-1/2’ MS336949-24L08 5/16” 5

3/8” 6

1/2” 7

3/4” 8

1’ 9

GE’s Mooney Regulators | 13

Material

Page 14

Model Basic Fig # Body/Dome

Material

402E 11487P106A Forged Carbon

Steel

11487P107A Forged Carbon

Steel

11487P108A Forged Carbon

Steel

11487P088A Forged Carbon

Steel

11487P086A Forged Carbon

Steel

Order

Code =

402E Weight: 80 lbs

Internal loaded integral needle valves

External Dome Loading connection: 1/8” FNPT

End

Connec-

tion

2’ FNPT 1/2” 3600 1500 0 to 165° F

2’ FNPT 3/4” 3600 1500 0 to 165° F

2’ FNPT 1” 3600 1500 0 to 165° F

1-1/2’

FNPT

1-1/2’

FNPT

Orifice

Size

1/2” 6000 3000 0 to 165° F

1” 6000 3000 0 to 165° F

Max

Inlet

(psi)

Max

Outlet

(psi)

Temperature

Range

Rubber

Goods

Valve Seal

& Gasket

Body

Plug

Gasket

Nitrile PCTFE PCTFE

Nitrile PCTFE PCTFE

Nitrile PCTFE PCTFE

Nitrile PCTFE PCTFE

Nitrile PCTFE PCTFE

Trim

Material

18-8 SST

18-8 SST

18-8 SST

18-8 SST

18-8 SST

Model Basic Fig # Body/Dome

Material

402F 11040P106A Nickel Coated

Carbon Steel

11040P107A Nickel Coated

Carbon Steel

11040P108A Nickel Coated

Carbon Steel

11040P086A Nickel Coated

Carbon Steel

11040P088A Nickel Coated

Carbon Steel

Order

Code =

Model Basic

Body/Dome

Fig. #

411B 11251 304 SST 4’ x 4” ANSI

11252 Aluminum

Bronze/Carbon

Order

11567

Code =

402F Weight: 85 lbs

Internal loaded integral needle valves

External Dome Loading connection: 1/8” FNPT

Material

Steel

Connec-

2’ FNPT 1/2” 3600 3000 -65° F to

2’ FNPT 3/4” 3600 3000 -65° F to

2’ FNPT 1” 3600 300 -65° F to

1-1/2’

FNPT

1-1/2’

FNPT

End

Connection

2500 RGJ Flg

4’ x 4” GR 31

Grayloc

End

tion

Orifice

Size

1/2” 6000 3000 -65° F to

1” 6000 3000 -65° F to

Max

Inlet

(psi)

Max

Outlet

(psi)

Temperature

Range

Code Orifice Code Rubber

Goods

Rubber

Goods

Valve

Seal &

Gasket

165° F Nitrile PCTFE PCTFE

165° F Nitrile PCTFE PCTFE

165° F Nitrile PCTFE PCTFE

165° F Nitrile PCTFE PCTFE

165° F Nitrile PCTFE PCTFE

Temperature

Code Trim

Range

Seat

CJ14 2-1/2” 9 Nitrile -65° F to 165° F A 303 SST and

H1431 2-1/2” 9 EDPM -65° F to 165° F H 303 SST and

FKM 0 to 165° F P 303 SST and

Body

Plug

Gasket

Material

17-4 PH SST

17-4 PH SST

17-4 PH SST

Trim

Material

18-8 SST

17-4 PH

SST

18-8 SST

17-4 PH

SST

18-8 SST

17-4 PH

SST

18-8 SST

17-4 PH

SST

18-8 SST

17-4 PH

SST

Seat

Seal

PTFE

PTFE

PTFE

14 | GE Oil & Gas

411B Weight: 900 lbs

Internally Sensing (External sensing option available)

External Dome Loading connection: 1/2” MS-16142

Page 15

Model Basic Fig # Body/Dome

Material

412E 11489P109A Forged

Carbon Steel

End

Connec-

tion

Orifice

Size

Max

Inlet

(psi)

Max

Outlet

(psi)

Temperature

Range

2’ FNPT 1/2” 3600 1500 0 to 165° F

Rubber

Goods

Valve Seal

& Gasket

Body

Plug

Gasket

Nitrile PCTFE PCTFE

Trim

Material

18-8

SST

412F 11311P109A Nickel Coated

Carbon Steel

Order

Code

=

412E Weight: 80 lbs 412F Weight: 85 lbs

Internal loaded integral needle valves

External Dome Loading connection: 1/8” FNPT

402E Balanced

2’ FNPT 3/4” 6000 3000 -65° F to

165° F

412E Unbalanced

Nitrile PCTFE PCTFE

411B Balanced

18-8

SST

412F Unbalanced

4142F Unbalanced

GE’s Mooney Regulators | 15

Page 16

Powreactor Dome Regulator Chart

Model Diaphragm

Size

94 2 5000 3000 3/32 0.14 0.41 1 Yes No Unbal

94 2 5000 3000 3/16 0.65 2.3 6.1 Yes No Unbal

112B 2 6000 6000 3/16 0.5 0.3 7.1 Yes No Bal

112BR 2 6000 6000 3/16 0.5 0.18 7.1 Yes No Bal

202B 3 6000 6000 3/16 0.7 0.94 2.6 Yes Yes Unbal

202B 3 6000 6000 1/4 1.4 1.5 3.3 Yes Yes Unbal

202B 3 6000 6000 5/16 1.5 2.2 4 Yes Yes Unbal

202B 3 6000 6000 3/8 2.3 2.6 4.4 Yes Yes Unbal

212B 3 6000 6000 1/2 4 0.92 6.7 Yes Yes Bal

202F 3 3500 3000 3/16 0.7 0.94 2.6 Yes No Unbal

202F 3 3500 3000 1/4 1.2 1.5 3.3 Yes No Unbal

202F 3 3500 3000 5/16 1.5 32.2 4 Yes No Unbal

202F 3 3500 3000 3/8 2.4 2.6 4.4 Yes No Unbal

202F 3 3500 3000 1/2 3.4 5 6 Yes No Unbal

301B 5 6000 6000 3/8 2.4 0.99 1.5 No Yes Unbal

301B 5 6000 6000 1/2 5 1.6 1.9 No Yes Unbal

301B 5 6000 6000 3/4 10.7 3.5 2.9 No Yes Unbal

311B 5 6000 6000 1 12.4 0.75 3.7 No Yes Bal

311B 5 6000 6000 1-1/2 26 1 8 No Yes Bal

302G 5 3500 2000 3/8 2.4 0.99 1.5 Yes No Unbal

302G 5 3500 2000 1/2 4.4 1.6 1.9 Yes No Unbal

302G 5 3500 2000 3/4 8.6 3.5 2.9 Yes No Unbal

302G 5 3500 2000 1 11 5.9 3.7 Yes No Unbal

402E 7-3/4 6000 3000 1/2 4 0.62 0.8 Yes No Unbal

402E 7-3/4 6000 3000 3/4 10 1.4 1.1 Yes No Unbal

402E 7-3/4 6000 3000 1 12 2.3 1.5 Yes No Unbal

412E 7-3/4 3600 3000 1-1/2 20 0.55 2.2 Yes Yes Bal

402F 7-3/4 6000 3000 1/2 4 0.62 0.8 Yes Yes Unbal

402F 7-3/4 6000 3000 3/4 10 104 1.1 Yes Yes Unbal

402F 7-3/4 6000 3000 1 12 2.3 1.5 Yes Yes Unbal

412F 7-3/4 3600 3000 1-1/2 20 0.55 2.2 Yes Yes Bal

411B 7-3/4 6000 3000 2-1/2 69 0.65 5.1 No Yes Bal

Max Inlet

(psi)

Max Out-

let (psi)

Orifice

(inches)

C

v

Outlet rise

per 100 psi

Inlet Drop

Average

Lockup (psi)

Internal Load-

ing

Option•

External

Loading

Option•

Valve

Type

* All regulators also include options for External Loading or Internal Sensing. External Sensing may be requested on order for the

models specified above for an additional fee.

The Internal Loading option is included at no additional charge for the models specified above.

16 | GE Oil & Gas

Page 17

Dome Loading Methods

Dome regulators use gas pressure instead of a spring force

to push down on the diaphragm to establish an outlet set

pressure. A pressure down stream that is lower than the

dome pressure results in the diaphragm being pushed

down which opens the valve. Conversely, the valve closes

as the outlet increases above the dome pressure.

The dome loading methods include the use of internal loading needle valves or by the use of a Model 15 Handloader

or other method. By using the Model 15 Handloader,

compensation for variations of pressure changes caused

by increased temperature is carried out by venting gas out

of the dome. Any decrease in dome pressure is maintained

by set point of the Model 15 by adding gas to the dome.

Dome Loaded Regulator uses include:

Propellant transfer systems (pressurization prefabs)

Fuel tank pressurization (test stands)

Test consoles and benches

Jet engine air start sets

Component pressure testing

Hydraulic hoists, power cylinders and presses

High pressure gas wells and pipelines

GE’s Mooney Regulators | 17

Page 18

Regulator Selection Considerations:

Is the flow media liquid or gas?

Is it for pressure reducing or back pressure service?

What is the minimum and maximum inlet pressure?

What is the minimum and maximum outlet pressure?

What is the specific gravity of the media?

What is the minimum and maximum flow rate?

What are the connection requirements?

Other considerations:

Unbalanced Effect = Outlet pressure change affected by the inlet pressure.

Lockup = Normal pressure rise above set pressure required to shut off flow

through the regulator

• Larger diaphragms and smaller valves have lower lockup pressures

Droop = As flow increases through the regulator, the outlet pressure decreases

• Large diaphragms and small orifices have lower droop

Universal Gas Sizing Equation

Q = 520

G•T

Cg =

P1 •

Natural gas@ 60° F

Q = Flow Rate (SCFH)

Cg = Gas Size Coefficient

P1 = Inlet Pressure (psia)

∆P = Pressure Drop Across Valve (∆P = P

P2 = Outlet Pressure (psia)

C1 = Value Recovery Coefficient (C

Cv = Liquid Sizing Coefficient

G = Specific Gravity (0.6 for Natural Gas0 (1.0 for Air)

T = Gas temperature (°Rankine) (T = 460 + °F)

Cg•P1 •sin

520

G•T

Simplifies

1.29

& 0.6 Sg

•sin

3417

[

Q

[

Critical Flow

C

1

P

1 - P2

P

Simplifies

1 = Cg - Cv

1

1.00

1 - P2

∆P

P

1

deg.

]

(psid)

)

]

deg.

Liquid Sizing

Q =CvF

p

∆PA or ∆P Allowable

∆PA = P1 - P

∆PA = .8 (P1 - Pv)

Q = Flow gpm (Gallons per minute)

Cv = Liquid Sizing coefficient (see valve selection)

G = Liquid Specific Gravity

P1 = Inlet Pressure (psia)

P2 = Outlet Pressure (psia)

Pv = Vapor Pressure (psia)

Fp = Piping Swage Factor

2 or

∆PA

G

whichever is less

}

18 | GE Oil & Gas

Page 19

Whether it is the simple operation of the Handloader, the compact Mity-Mite or the configurable

Powreactor, the Mooney* Specialty Regulators provide a stellar history of performance in the

most demanding industrial, laboratory, aero space and defense applications.

PSI

10,000

6,000

5,000

PSI

0.06

Pressure Reducing

For pressure reducing applications, the Mooney* Specialty Regulator line are typically

used for high inlet pressure applications but they work equally well for low inlet

pressures. As seen below, their simple yet durable direct acting design senses down

stream pressure and delivers accurate pressure control over a wide range of inlet

pressures and volumes.

0.6 69

Volume (C )

v

6,000

3,000

2,000

1,000

0.04 0.12 0.17

Back Pressure

The back pressure versions of the Mooney* Specialty Regulator line provide

the same reliability and proven performance and operate by sensing

upstream pressure and throttling the valves to maintain inlet pressure.

0.44

Volume (C )

v

GE’s Mooney Regulators | 19

Page 20

GE Oil & Gas

2822 S. 1030 West

Salt Lake City, UT 84119

T: +1 801.487.2225

F: +1 801.487.2587

Visit us online at: www.ge.com/energy

©2014, General Electric Company

All Rights Reserved

*Trademark of General Electric Company

GEA19588 Mooney Specialty Regulator

Rev 07.2014

Loading...

Loading...