Page 1

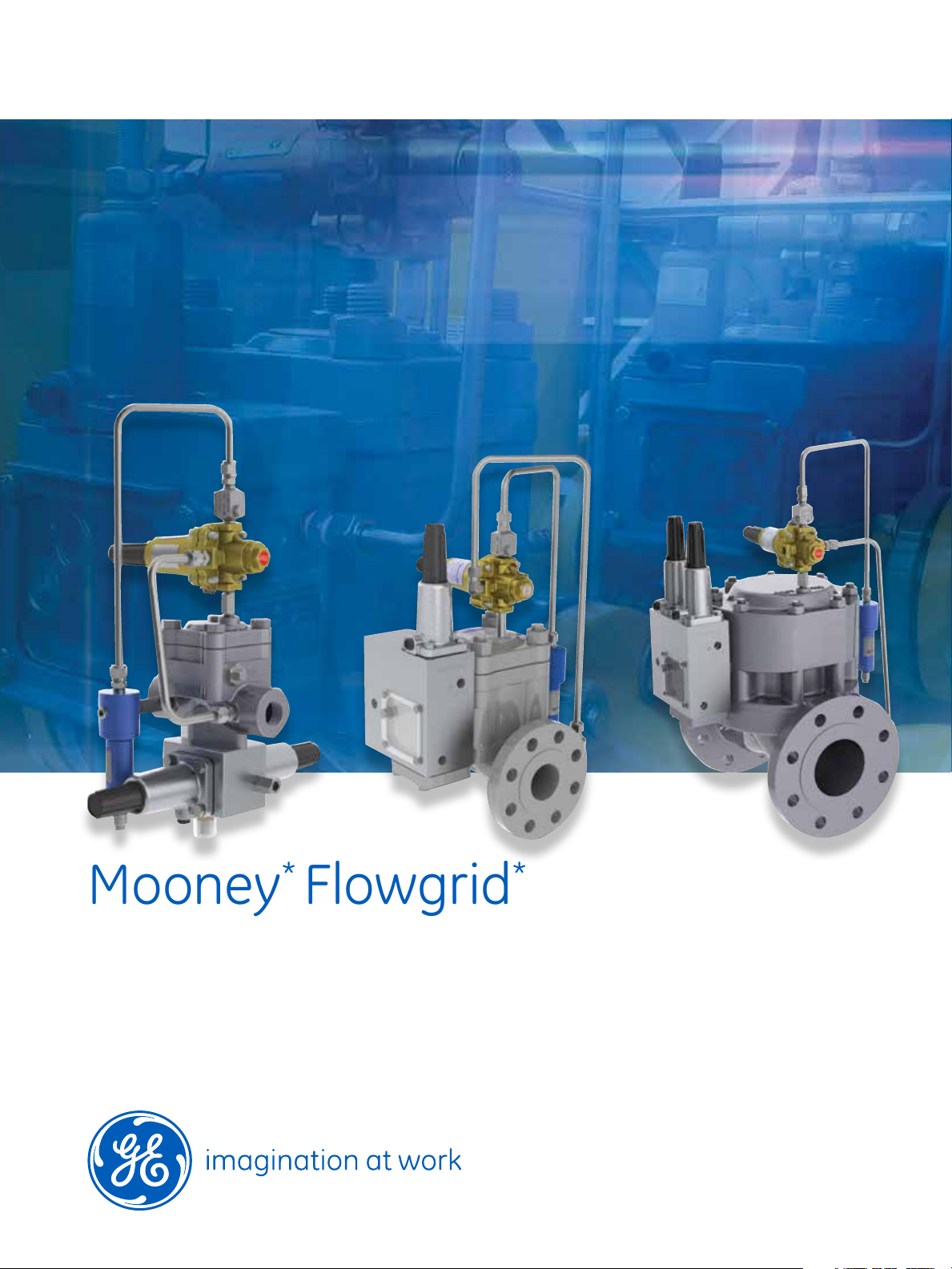

GE Oil & Gas

Mooney* Flowgrid*

Slam Shut Regulator

Delivering accuracy, performance and protection

Page 2

Industries

Gas transmission

Gas distribution

Midstream gas

Gas processing

Applications

Gas pipelines

High occupancy buildings

City gate stations

Point of receipt

Customer Benefits

Easy maintenance with top entry design

High accuracy and performance

Over- or under-pressure protection

Resistant to sticking caused by

freezing or debris

Durable, with only one wear component

Integration with Flowgrid

regulators or can stand alone

Quick response time; fewer than 0.25 seconds

Globally recognized; obtained

EN 14382 certification from DVGW

Latch mechanism eliminates false trips

2

Page 3

Meeting your needs for downstream

pressure protection

GE Oil & Gas has drawn upon our leading product technology and application expertise to develop

the Mooney Flowgrid Slam Shut regulator. The Slam Shut regulator provides accurate, reliable

secondary downstream pressure protection by shutting off the flow of gas when the sense or

outlet pressure in the system either exceeds or drops below the set pressure point. The device

can stand alone or be integrated with a Mooney Flowgrid regulator.

With the Mooney Flowgrid Slam Shut regulator, you get even more than a quality engineered

product. The Slam Shut regulator is backed by dependable technical support from GE and a free

training video that covers principle of operation, installation, maintenance and troubleshooting,

as well as a 3-D model library. Please contact your local representative for more information.

Because GE has an unflagging commitment to quality and safety, we have secured global PED EN

14382 certification for the Slam Shut regulator for sizes 2-4 inch. The certification was

awarded by DVGW (the German Technical and Scientific Association for Gas and Water), one of

the world’s most recognized industry certification bodies and the largest gas and water industry

certification agency in Europe. For more information about other certifications contact your

local representative.

The Flowgrid Slam Shut regulator has earned the trust of our customers around the world.

This advanced technology provides the reliability and security that is necessary for success in

this industry. Because the product’s top entry design allows for easy maintenance, users can be

more productive, which lowers overall costs and yields sustainable energy savings.

3

Page 4

1-inch Flowgrid Slam Shut regulator

The 1-inch Slam Shut is a safety shutoff regulator that closes with a linearly acting plug.

The device has bubble-tight shutoff under all rated conditions and requires no minimum

differential for full shutoff. Set points are adjustable and repeatable regardless of flow rate,

inlet pressure, and temperature variations.

Features

Easy to maintain; only two bolts required to remove the entire Slam Shut assembly

Resistant to sticking caused by freezing water or debris in pipeline

Well-contained moving mechanical parts, which are resistant to vibration effects

Excellent performance and accuracy across a large pressure range by changing only the spring

External visual indicator to show when the unit is tripped

Easy to reset; only three caps need to be removed for complete reset

High cycle applications; only one wear component

No pressure differential requirements for full shutoff

Figure 1 - One inch Mooney Flowgrid Slam Shut

4

Figure 2 - Two inch Mooney Flowgrid Slam Shut

regulator with over or under pressure protection.

Page 5

2-inch to 4-inch Flowgrid Slam Shut regulator

The controller assembly for the Slam Shut can be supplied with either over- or under-pressure

shutoff protection in three basic interchangeable configurations:

1. Series 50 single function controller (Figure 2), which provides either over- or under-pressure

shutoff protection.

2. Series 50D dual function controller (Figure 3), where each function provides either over- or

under-pressure shutoff protection and both functions are controlled by a common sense port

3. Series 50DS dual function controller (Figure 3 and 4), where each function is controlled by an

independent sense port. This allows two independent locations to be monitored for an over- or

under-pressure condition, each with its own set point.

A stand alone Slam Shut consists of a Flowgrid body with valve module and cover mounted on

top. The pressure controller is mounted on the side of the valve module.

Features

Virtually eliminates nuisance trips caused by vibration and sense pressure variation

Retrofitable to existing 2-inch to 4-inch Flowgrid regulators

Pneumatically actuated latch mechanism

Bubble-tight shutoff with floating flapper design

Over- or under-pressure protection, or both

Water tight for below-grade vault installations

Stand alone or integrated into a Flowgrid regulator

Simple reset from front or back without removing covers

Easy maintenance with a top entry design

High accuracy

Proximity Switch signals the open/closed position of the valve

for remote indication (optional feature)

Figure 3 - Two inch Mooney Flowgrid Slam Shut

regulator with over and/or under pressure protection.

A second sense port is optional.

Figure 4 - Four inch Mooney Flowgrid Slam Shut

regulator with over and/or under pressure protection.

A second sense port is optional.

5

Page 6

Table 1 - Specifications

Sizes

Types

Imperial Metric

1-inch NPT & SWE

1.25-inch NPT & SWE

DN 25, DN 32, DN 50, DN 80,

DN 100

2-inch, 3-inch, 4-inch

Stand alone or integrated into Flowgrid regulator

Pressure Protection

Standard: Over

Optional: Over and/or under

Temperature

1

Maximum Operating Inlet Pressure

Operating Sense Pressure

1-inch

2-4 inch

Response Time

1

EN14382 restricts the minimum temperature to -4° F (-20° C).

-20°F to 150°F -29°C to 65°C

740 psig 50 bar

5 to 450 psig

10 psig to 50 psig

<0 .25 seconds

Principle of Operation for 1-inch Slam Shut

This valve has four critical elements:

1. Closing Element

2. Force Reduction Element

3. Tripping Element

4. Sensing Element

The sensing diaphragm will move the trip shaft

when the line pressure goes too high or too low.

At that point, the trip shaft will disengage the force

reduction element, which allows the rotating shaft

to rotate and the spring to push the plug to the seat,

causing full shutoff.

0.35 bar to 31 bar

0.69 bar to 31 bar

1

2

3

Table 2 - Set Point Ranges for 1-inch Slam Shut Table 3 - Set Point Ranges for 2-4 inch Slam Shut

Spring

Color

Red 5 - 10 0.35 - 0.7 10 2.5

Plated 10 - 40 0.7 - 3 5 2.5

Blue 40 - 90 3 - 6 2.5 2.5

Purple 90 - 175 6 - 12 2.5 1.0

Black 175 - 250 12 - 17 2.5 1.0

White/Green 250 - 450 17 - 31 2.5 1.0

2 Preliminary AG Data, Testing per EN 14382

6

Spring Range

psig Bar

Accuracy

(% of Set Point)

Over

Pressure

2

Under

Pressure

Spring

Color

Plated 10 – 40 0.7 – 3 5 5

Blue 40 - 90 3 – 6 2.5 2.5

Purple 90 - 175 6 – 12 2.5 2.5

Black 175 - 250 12 – 17 2.5 2.5

White/Green 250 -450 17 – 31 2.5 2.5

2 Preliminary AG Data, Testing per EN 14382

Spring Range

psig Bar

Accuracy

(% of Set Point)

Over

Pressure

4

2

Under

Pressure

Page 7

Principle of Operation for

2-4 inch Slam Shut

During normal operation the latch mechanism holds the closure element (flapper)

open as shown in Figure 5. The sense or

downstream pressure is monitored by the

over-pressure and under-pressure controller

diaphragms, which convert the sense

pressure into a force proportional to the

pressure. The force is counter-balanced

by the set point adjustment spring located

in the spring case. The adjusting screw is

used to vary the spring force and control

the over-pressure set point or the optional

under-pressure set point.

When the downstream pressure either

exceeds or is less than the pressure set

point, the controller diaphragm and spring

move, opening a valve. The open valve

allows inlet pressure to flow to the

actuator diaphragm, (see Figure 6). The

pressure acts on the diaphragm, which

pushes on the pin. The pin moves the

“L”-shaped pawl lever and releases the

flapper lever. When the flapper lever is

released, a set of springs pushes the

flapper valve closed and provides the

initial force to seal the valve.

Once the flapper valve closes the inlet

pressure is cut off as shown in Figure 7.

To return the system to operation the

technician closes the upstream and

downstream block valves to isolate the

system and bleeds off the isolated section.

Repairs are then made as required to

correct the cause of the over- or underpressure condition. A ½-inch (13 mm) hex

on the back side of the valve and front of

the controller allows Slam Shut to be reset

without removing covers. The Slam Shut is

reset by rotating the flapper valve open and

holding it momentarily while the actuation

pressure bleeds off and the latch engages.

Under Pressure

Trip Control Valve

Under Pressure

Trip Control Valve

Under Pressure

Trip Control Valve

Slam Shut Sense

Restrictor

Over Pressure

Trip Control Valve

Actuator

Vent Valve

Latch Closed

Filter

Type 24

Type 30

Flapper Valve

(Open Position )

Center Port

Vent

Inlet Outlet

Pilot Series 20

Loading

Outlet

Flowgrid Regulator &

Integral Slam Shut Valve

Figure 5 – Valve, Actuator & Latch Mechanism Open

Slam Shut Sense

Restrictor

Over Pressure

Trip Control Valve

Actuator

Vent Valve

Unlatched

Filter

Type 24

Type 30

Flapper Valve

(Between Open & Closed)

Center Port

Vent

Inlet Outlet

Pilot Series 20

Loading

Outlet

Flowgrid Regulator &

Integral Slam Shut Valve

Figure 6 – Valve, Actuator & Latch Mechanism Midway

Slam Shut Sense

Restrictor

Over Pressure

Trip Control Valve

Actuator

Vent Valve

Unlatched

Vent

Filter

Type 24

Type 30

Flapper Valve

(Closed Position)

Center Port

Inlet Outlet

Pilot Series 20

Loading

Outlet

Flowgrid Regulator &

Integral Slam Shut Valve

Pilot Sense

Pilot Sense

Pilot Sense

Figure 7 – Valve, Actuator & Latch Mechanism Closed

7

Page 8

GE Oil & Gas

2822 S. 1030 West

Salt Lake City, UT 84119

T: +1 801.487.2225

F: +1 801.487.2587

Visit us online at: www.ge.com/energy

©2012, General Electric Company

All Rights Reserved

*Trademark of General Electric Company

GEA19398A Mooney Flowgrid Slam Shut

Rev 06.2014

Loading...

Loading...