Page 1

SAFETY INFORMATION ...........3

USING THE HOOD

Downdraft Vent System ..................5

OWNER’S MANUAL &

INSTALLATION

INSTRUCTIONS

CARE AND CLEANING

Downdraft Vent System ..................6

INSTALLATION INSTRUCTIONS ..7

TROUBLESHOOTING TIPS ........ 16

LIMITED WARRANTY ............. 17

ACCESSORIES ..................... 18

Downdraft

CONSUMER SUPPORT ............20

UVD6301S

UVD6361S

Write the model and serial

VENT SYSTEM

GE is a trademark of the General Electric Company. Manufactured under trademark license.

numbers here:

Model # _________________

Serial # _________________

These numbers are also found on

the Product Property Registration

Card sent separately with your

downdraft ventilation system and

on the label located on the front

panel of the unit.

ESPAÑOL

Para consultar una version en

español de este manual de

instrucciones, visite nuestro sitio de

internet GEAppliances.com.

49-2000733 Rev. 1 09-20 GEA

Page 2

THANK YOU FOR MAKING GE APPLIANCES A PART OF YOUR HOME.

Whether you grew up with GE Appliances, or this is your first, we’re happy to have you in the family.

We take pride in the craftsmanship, innovation and design that goes into every GE Appliances

product, and we think you will too. Among other things, registration of your appliance ensures that we

can deliver important product information and warranty details when you need them.

Register your GE appliance now online. Helpful websites and phone numbers are available in the

Consumer Support section of this Owner’s Manual. You may also mail in the pre-printed registration

card included in the packing material.

2 49-2000733 Rev. 1

Page 3

IMPORTANT SAFETY INFORMATION

READ ALL INSTRUCTIONS BEFORE USING

SAFETY INFORMATION

WARNING

ELECTRIC SHOCK OR INJURY TO PERSONS,

OBSERVE THE FOLLOWING:

A. Use this unit only in the manner intended by the

manufacturer. If you have questions, contact the

manufacturer.

B. Before servicing or cleaning unit, switch power off

at service panel and lock the service disconnecting

means to prevent power from being switched

on accidentally. When the service disconnecting

means cannot be locked, securely fasten a

prominent warning device, such as a tag, to the

service panel.

C. Do not use this unit with any solid-state speed

control device.

D. Plug your vent system into a 120-volt grounded

outlet only. Do not remove the round grounding

prong from the plug. If in doubt about the

grounding of the home electrical system, it is your

responsibility and obligation to have an ungrounded

outlet replaced with a properly grounded, three

prong outlet in accordance with the National

Electrical Code. Do not use an extension cord with

this appliance.

TO REDUCE THE RISK OF FIRE,

CAUTION

ONLY. DO NOT USE TO EXHAUST HAZARDOUS

OR EXPLOSIVE MATERIALS AND VAPORS.

WARNING

TO PERSONS IN THE EVENT OF A RANGE TOP

GREASE FIRE, OBSERVE THE FOLLOWING*:

A. SMOTHER FLAMES with a close-fitting lid, cookie

sheet or metal tray, then turn off the burner. BE

CAREFUL TO PREVENT BURNS. If the flames do

not go out immediately, EVACUATE AND CALL

THE FIRE DEPARTMENT.

B. NEVER PICK UP A FLAMING PAN—You may be

burned.

C. DO NOT USE WATER, including wet dishcloths or

towels—a violent steam explosion will result.

D. Use an extinguisher ONLY if:

1. You know you have a Class ABC extinguisher,

and you already know how to operate it.

2. The fire is small and contained in the area where

it started.

3. The fire department is being called.

4. You can fight the fire with your back to an exit.

* Based on “Kitchen Fire Safety” published by NFPA.

FOR GENERAL VENTILATING USE

TO REDUCE THE RISK OF INJURY

WARNING

RANGE TOP GREASE FIRE:

A. Never leave surface units unattended at high

settings. Boilovers cause smoking and greasy

spillovers that may ignite. Heat oils slowly on

medium settings.

B. Always turn hood ON when cooking at high heat or

when flambéing food (i.e. Crepes Suzette, Cherries

Jubilee, Peppercorn Beef Flambé).

C. Clean ventilating fans frequently. Grease should not

be allowed to accumulate on fan or filter.

D. Use proper pan size. Always use cookware

appropriate for the size of the surface element.

TO REDUCE THE RISK OF A

If You Need Service…

Do not attempt to repair or replace any part of the

vent system unless it is specifically recommended in

this manual. All other servicing should be referred to a

qualified technician.

Be sure electrical power is off before servicing the unit.

It may be necessary to remove the vent system blower

system in order to service components such as the

blower motor or air vent mechanism.

Disconnect power to the cooktop and remove it first.

Reverse the steps in the Install Downdraft Vent section

in the Installation Instructions to remove the blower.

Service parts are available from a GE Appliances

Service and Parts Center.

Make sure all fingers are away from the top of the vent

system when it is lowered.

READ AND SAVE THESE INSTRUCTIONS

49-2000733 Rev. 1 3

Page 4

IMPORTANT SAFETY INFORMATION

READ ALL INSTRUCTIONS BEFORE USING

How to Remove Protective Shipping Film and Packaging Tape

Carefully grasp a corner of the protective shipping film

with your fingers and slowly peel it from the appliance

surface. Do not use any sharp items to remove the film.

Remove all of the film before using the appliance for the

first time.

To assure no damage is done to the finish of the

product, the safest way to remove the adhesive from

packaging tape on new appliances is an application of

a household liquid dishwashing detergent. Apply with a

soft cloth and allow to soak.

NOTE: The adhesive must be removed from all parts. It

cannot be removed if it is baked on.

SAFETY INFORMATION

ATTENTION: Please remove the bubble wrap inserted

inside of exhaust before installation. Make sure nothing

is left inside the blower box.

Bubble Wrap

READ AND SAVE THESE INSTRUCTIONS

4 49-2000733 Rev. 1

Page 5

Downdraft Vent System

To Use The Downdraft System

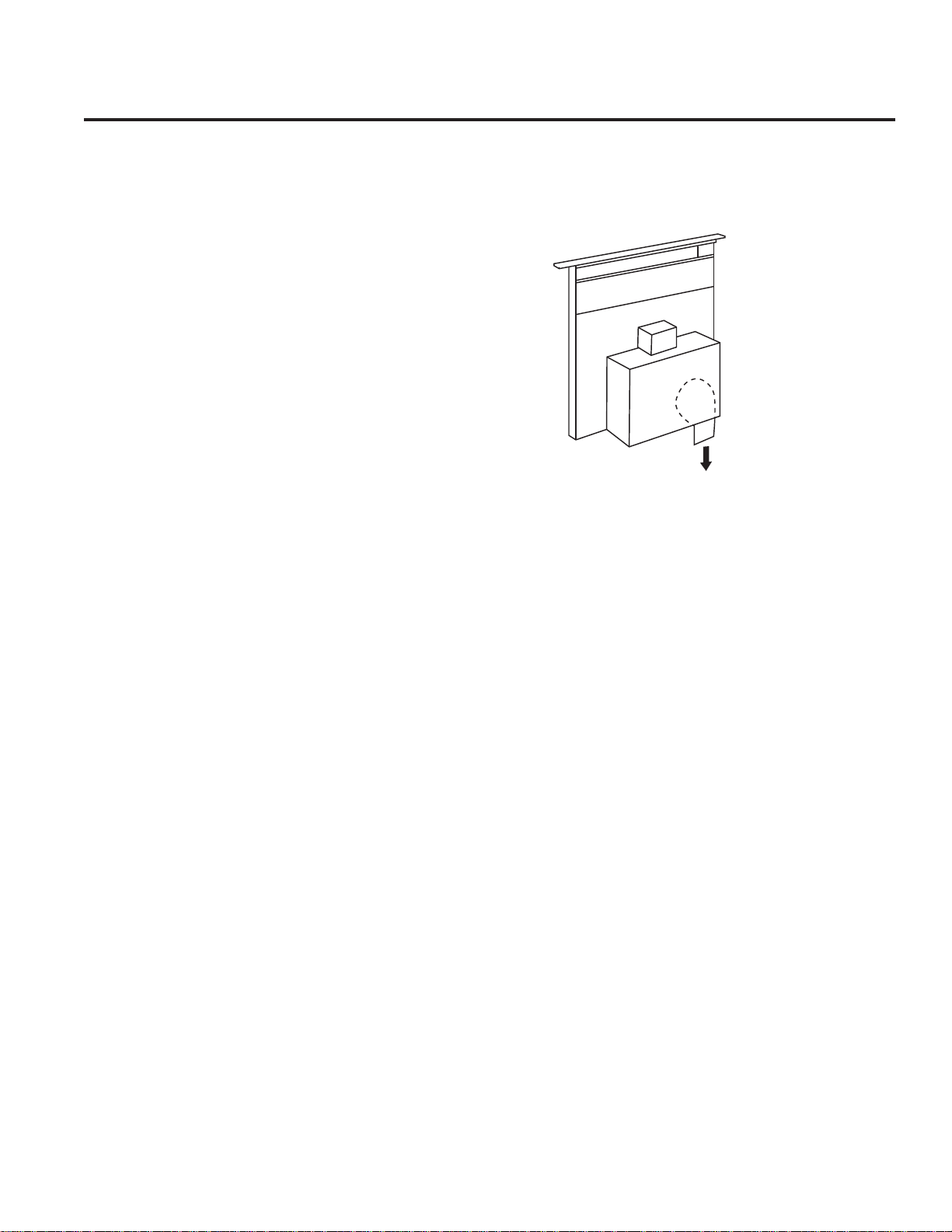

To raise the downdraft vent, press the button on the top

cover. The vent will rise.

Button

When Using The Vent System

USING THE VENT SYSTEM: Downdraft Vent System

The blower can be turned ON or OFF

and the speed can be adjusted with

the recessed knob on the right side of

the air vent. The blower, if left on, will

automatically turn off when the vent is

lowered.

NOTE: For most convenient operation, set the blower to

the speed you use most often. The blower will come on

to this speed whenever the unit is raised.

Lower the downdraft vent by

pressing the button on the top

cover. The vent will go down an

the blower will shut off.

CAUTION

the vent. Be sure pots, pot handles and other objects are

clear of the vent and cannot be struck or tipped by the

vent being raised.

NOTE: There is a slight trim overhang on each side of

the vent.

Ŷ 7RDYRLGLQMXU\EHVXUHILQJHUVDUHFOHDURIWKHYHQW

cover when it is being lowered.

Ŷ .HHSKDQGVDQGILQJHUVDZD\IURPDOOYHQWSDUWV

Be careful when raising or lowering

Cooking Tips

The high air movement of this vent system can increase

the cooking times for some foods. It may take longer to

reach high cooking temperatures if the vent system is

turned to high right away. Adjust the fan speed for best

cooking results.

IMPORTANT: If the vent is obstructed by an object while

it is being raised or lowered, it will stop. Carefully remove

the obstruction and the vent will drop to the lowered

position. Press the button again to return to normal

functons.

For best results when heating oil for deep frying or when

boiling water, use the front surface units or wait until the

water is boiling or the oil is at frying temperatures before

turning on the vent system.

The vent system may not completely capture all the

steam from pans on the front burners.

49-2000733 Rev. 1 5

Page 6

Downdraft Vent System

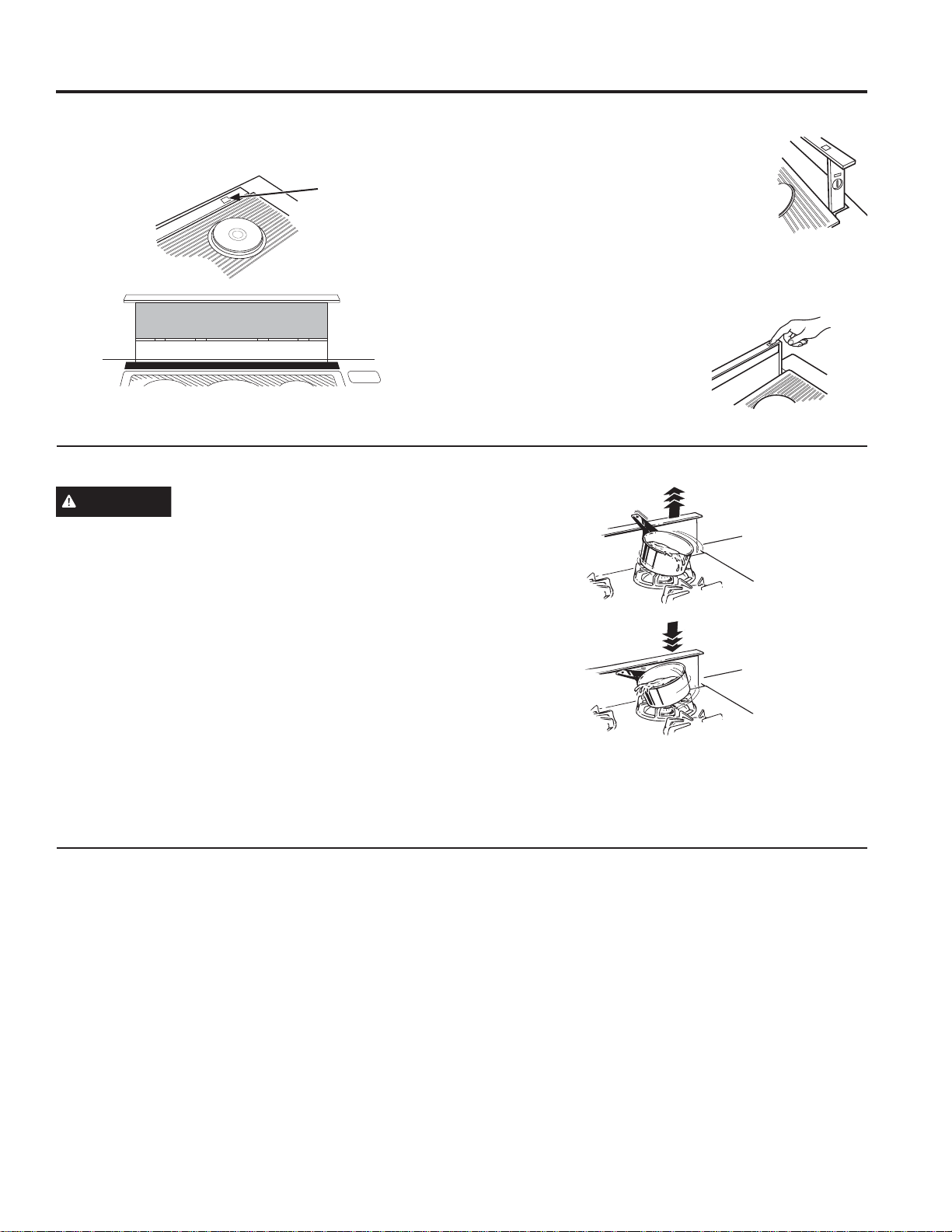

Grease Filters

The efficiency of your vent system depends on a clean

filter. Frequency of cleaning depends on the type of

cooking you do. Grease filters should be cleaned at least

once a month. Never operate the vent system without

the filters in place.

To remove: Remove filters from the air vent by reaching

the filters through the vent openings, pushing down then

pulling out. NOTE: The filters are different sizes. Be sure

to replace them as removed, wider one on the left

To clean: Soak and then agitate in a hot detergent

solution. Light brushing may be used to remove

embedded soil. Rinse, shake and remove moisture

before replacing. Do not clean the filters in the

dishwasher.

With careful handling, the filter will last for years. If

replacement becomes necessary, order the part from

your dealer.

Painted Or Stainless Steel Surfaces

Do not use a steel wool pad; it will scratch the surface.

To clean the stainless steel surface, use warm, sudsy

water or a stainless steel cleaner or polish. Always wipe

the surface in the direction of the grain. Follow the cleaner

instructions for cleaning the stainless steel surface.

For difficult stains on stainless steel, use a cleaner that

contains lactic acid or citric acid.

Filter Tabs

To inquire about purchasing cleaning products including

stainless steel appliance cleaner or polish read the

Assistance and Accessories sections at the beginning of

this manual.

CARE AND CLEANING: Downdraft Vent System

6 49-2000733 Rev. 1

Page 7

INSTALLATION INSTRUCTIONS

Installation

Downdraft Vent Systems

UVD6301S, UVD6361S

Instructions

“If you have questions, call GE Appliances at 800.GE.CARES (800.432.2737)

or visit our website at: GEAppliances.com”

BEFORE YOU BEGIN

Read these instructions completely and

carefully.

•

IMPORTANT — Save these

instructions for local inspector’s use.

•

IMPORTANT — Observe all governing

codes and ordinances.

• Note to Installer – Be sure to leave these

instructions with the Consumer.

• Note to Consumer – Keep these instructions for

future reference.

• Skill level – Installation of this vent hood requires

basic mechanical and electrical skills.

• Proper installation is the responsibility of the

installer.

• Product failure due to improper installation is not

covered under the Warranty.

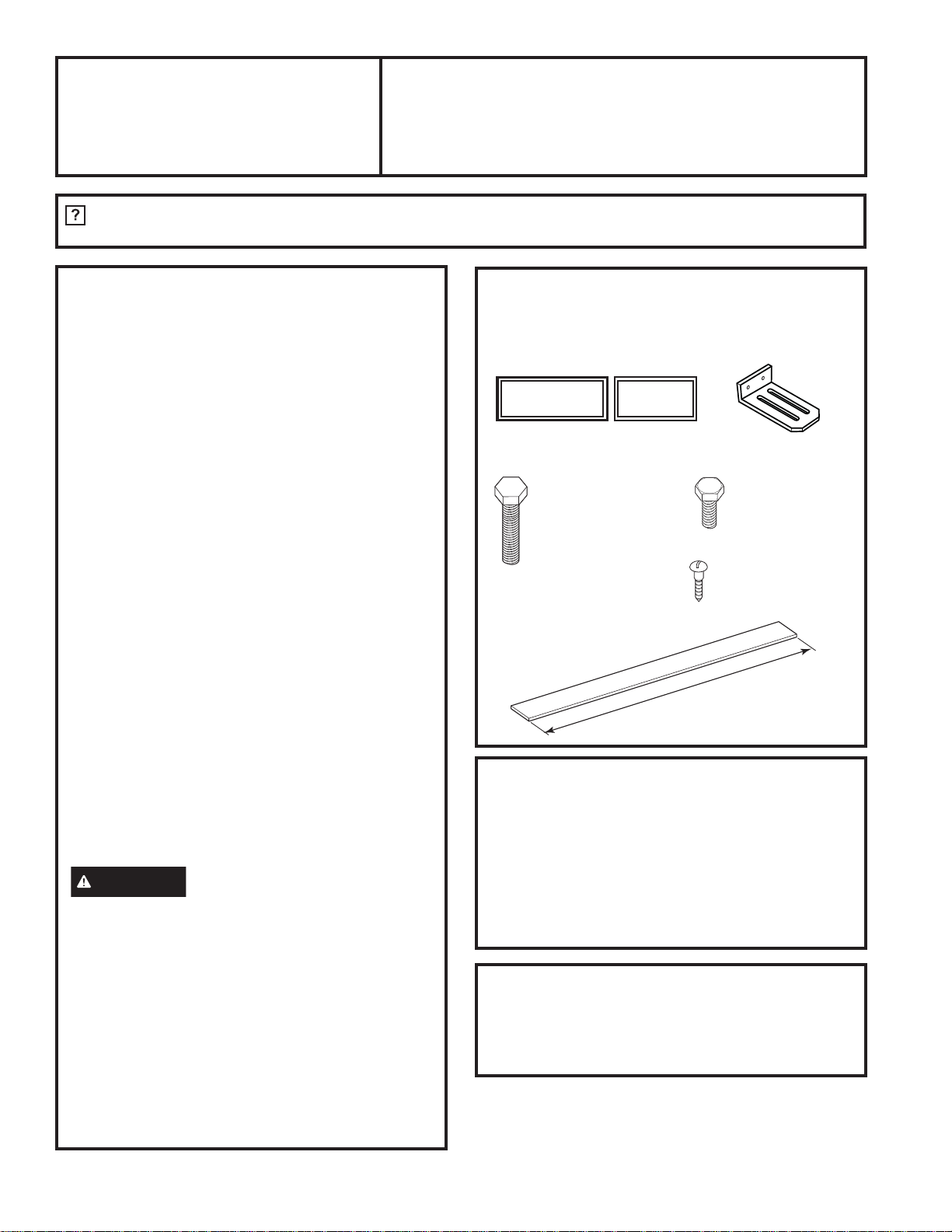

PARTS SUPPLIED

Open the carton and remove parts package.

Check contents to be sure all pieces are

present.

Filters - inside unit

Qty:2

Countertop Mounting

Screw, 1/4-20 x 2.00

Hex Hd

Qty:2

Plastic Template (attached

to product) Qty:1

Stabilizing Brackets

Qty:2

Downdraft

Leveling Screw,

1/4-20 x .50 Hex

Hd - Qty:2

Wood Screw, #8 x

.750 SI Round Hd

- Qty:4

GROUNDING INSTRUCTIONS

This appliance must be grounded. In the event of

an electrical short circuit, grounding reduces the risk

of electric shock by providing an escape wire for

the electric current. This appliance is equipped with

a cord having a grounding wire with a grounding

plug. The plug must be plugged into an outlet that is

property installed and grounded.

WARNING

Improper grounding can result in a risk of electric

shock.

Consult a qualified electrician if the grounding

instructions are not completely understood, or if

doubt exist as to whether the appliance is properly

grounded.

Do not use an extension cord. If the power supply

cord is too short, have a qualified electrician install

an outlet near the appliance.

If you received a damaged vent system, you should

contact your dealer.

28.5” for 30” Models

34” for 36” Models

TOOLS AND MATERIALS REQUIRED

• Safety glasses

• Large flat-blade screwdriver

• Jigsaw

• Carpenter’s square

• Ductwork to suit the installation

• Level

REMOVE PACKAGING

Remove the shipping materials and the carton;

set carton aside. The carton can be used as a

pad when changing or adjusting vent direction.

49-2000733 Rev. 1 7

Page 8

Safety Information

WARNING

ELECTRIC SHOCK OR INJURY TO PERSONS,

OBSERVE THE FOLLOWING:

Ɣ,QVWDOODWLRQZRUNDQGHOHFWULFDOZLULQJPXVWEH

done by qualified person(s) in accordance with all

applicable codes and standards, including fire-rated

construction.

Ɣ6XIILFLHQWDLULVQHHGHGIRUSURSHUFRPEXVWLRQDQG

exhausting of gases through the flue (chimney) of

fuel burning equipment to prevent back drafting.

Follow the heating equipment manufacturer’s

guidelines and safety standards such as those

published by the National Fire Protection Association

(NFPA), the American Society for Heating,

Refrigeration and Air Conditioning Engineers

(ASHRAE) and the local code authorities.

Ɣ:KHQFXWWLQJRUGULOOLQJLQWRZDOORUFHLOLQJGRQRW

damage electrical wiring and other hidden utilities.

Ɣ'XFWHGIDQVPXVWDOZD\VEHYHQWHGWRWKHRXWGRRUV

TO REDUCE THE RISK OF FIRE,

INSTALLATION INSTRUCTIONS

CAUTION

AND TO PROPERLY EXHAUST AIR, BE SURE TO

DUCT AIR OUTDOORS. DO NOT VENT EXHAUST

AIR INTO SPACES WITHIN WALLS OR CEILINGS

OR INTO ATTICS, CRAWL SPACES OR GARAGES.

WARNING

USE ONLY METAL DUCT WORK.

Ɣ:KHQDSSOLFDEOHLQVWDOODQ\PDNHXSUHSODFHPHQW

air system in accordance with local building code

requirements. Visit GEAppliances.com for available

makeup air solutions.

Ɣ39&VHZHUSLSHFDQEHXVHGDVGXFWXQGHUFRQFUHWH

slab if allowed by local code board.

TO REDUCE THE RISK OF FIRE

TO REDUCE THE RISK OF FIRE,

8 49-2000733 Rev. 1

Page 9

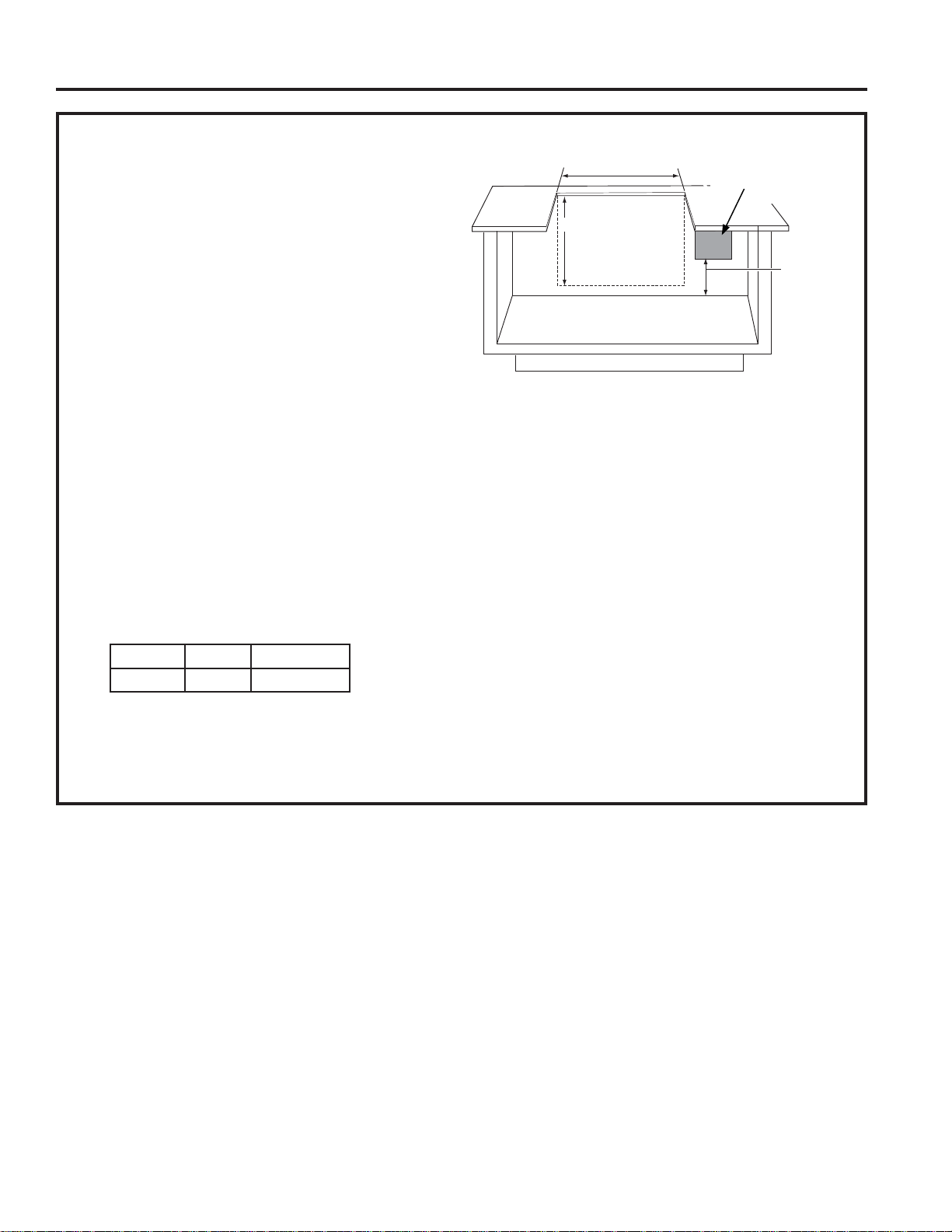

Installation Preparation

INSTALLATION INSTRUCTIONS

POWER SUPPLY

This downdraft vent must be supplied with 120V, 60

Hz. and connected to an individual, properly grounded

branch circuit, protected by a 15- or 20-ampere circuit

breaker or time-delay fuse.

A properly grounded 3-prong receptacle should be

located within reach of the vent’s two-foot power cord.

• Gas Cooktops

If this vent is installed in combination with a GE or

Monogram gas cooktop, it may operate from the same

duplex outlet.

• Electric Cooktops

If this vent is installed in combination with a GE or

Monogram electric cooktop, the vent must operate

from a separate 120V outlet.

Locate the receptacle inside the cabinet on the right side

wall (see illustration). The receptacle cannot be placed

on the back of the cabinet wall where it may interfere

with the downdraft plenum.

The downdraft vent power cord is to be routed beneath

the cooktop and routed away from heat generated by the

cooktop.

Ensure that the cooktop is installed per manufacturer’s

installation instructions.

SPECIFICATIONS

VOLTS AMPS DUCT

120 4.0 3-1/4 X 10

34"(cutout width) for 36" models

28-1/2" (cutout width) for 30" models

29-1/2"

DO NOT Locate

Gas or Electrical

Connections within

this Area

Locate the gas or electrical

connection only within the

shaded area.

Electrical

Outlet 12"

12"

Above

Cabinet

Floor

IMPORTANT

(Please read carefully)

The power cord of this appliance is equipped with

a three-prong (grounding) plug which mates with a

standard three-prong grounding wall receptacle to

minimize the possibility of electric shock. The customer

should have the wall receptacle and circuit checked by

a qualified electrician to make sure the receptacle is

properly grounded and has correct polarity.

• Where a standard two-prong wall receptacle is

encountered, it is the personal responsibility and

obligation of the customer to have it replaced with a

properly grounded three-prong wall receptacle.

Do not, under any circumstances, cut or remove the

third (ground) prong from the power cord.

Do not use an extension cord or adapter plug with this

appliance. Follow National Electrical Code or prevailing

local codes and ordinances.

Location of Rating Label: on front of chassis of vent

system.

49-2000733 Rev. 1 9

Page 10

Installation Preparation

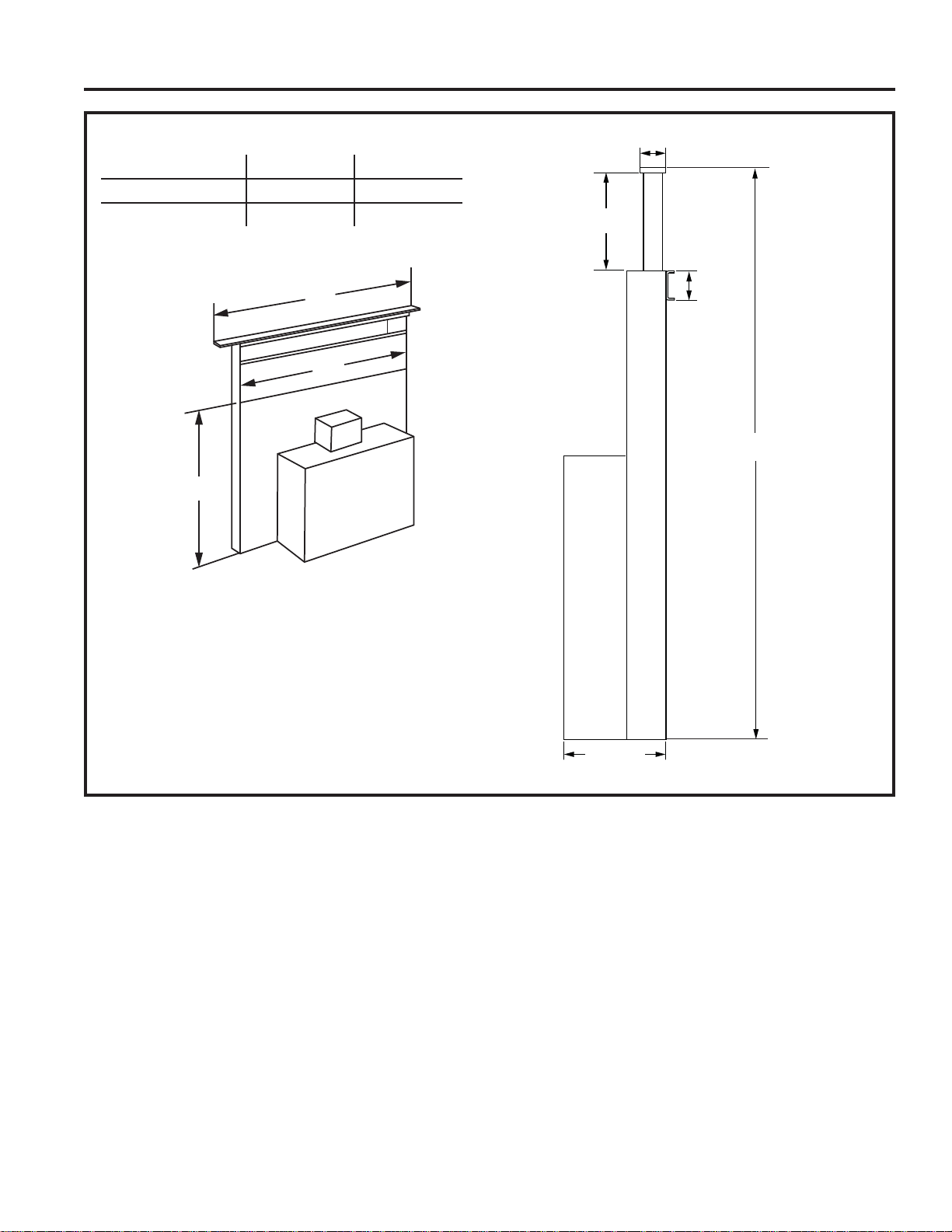

PRODUCT DIMENSIONS

AB

30” Models 30” 26-1/4”

36” Models 36” 32-1/4”

A

B

22.3”

INSTALLATION INSTRUCTIONS

2”

7”

2-1/2”

36-1/2”

7-1/4”

10 49-2000733 Rev. 1

Page 11

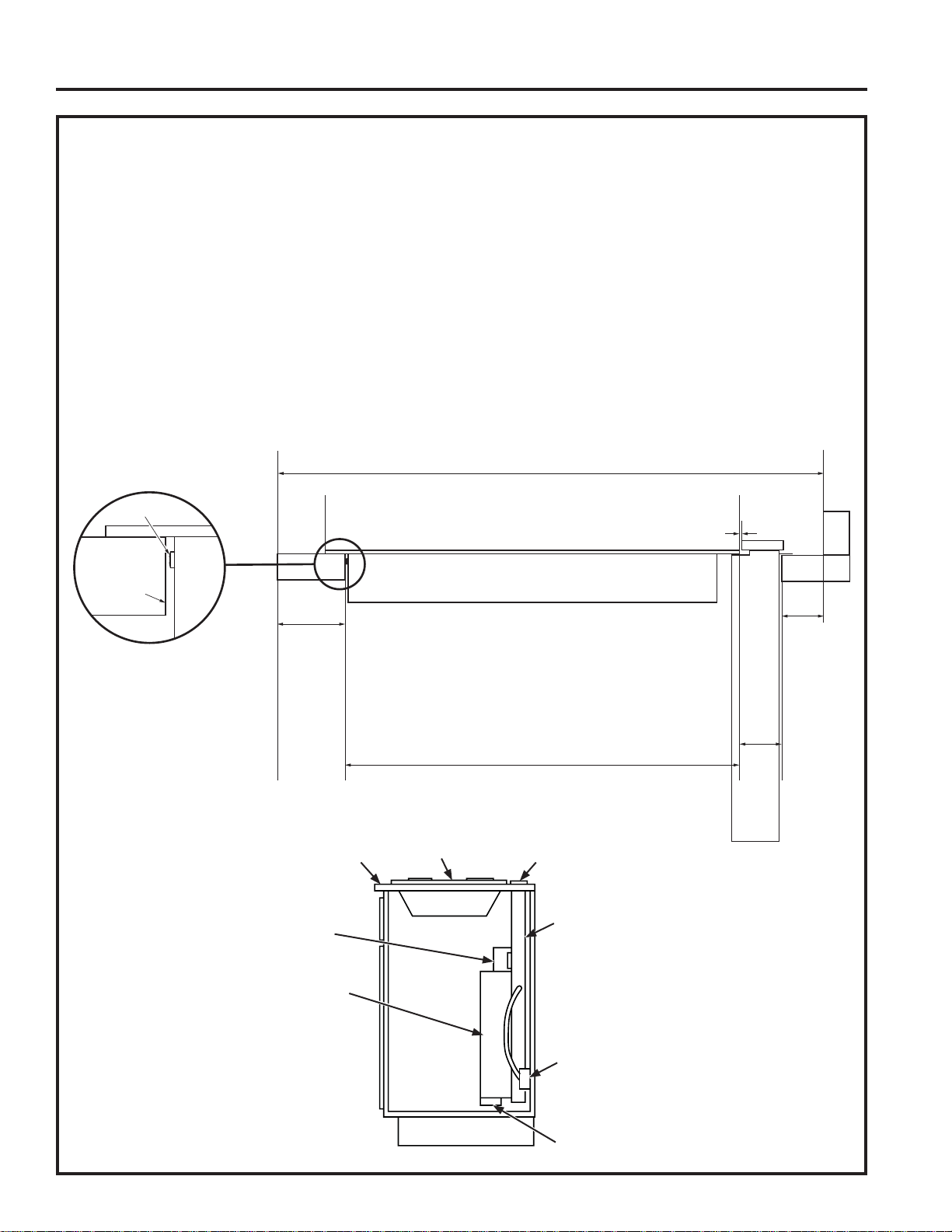

Installation Preparation

PREPARING FOR INSTALLATION

• Unpack the cooktop and read the Installation

Instructions to understand the required countertop

cutout dimensions and location in the countertop,

the cooktop spacing to the front edge of the

countertop, and the required clearances to the

cabinets and walls. The vent system required cutout

width is shown on page 9. Confirm there is enough

side to side counter space to meet the required

spacing and clearances for the cooktop.

• Using the illustrations below and taking

measurements of the cooktop to establish dimension

A, confirm there is enough front to back counter

space (dimension B) to fit both the cooktop and the

vent system. Note the cooktop rear edge will overlap

the vent system front surface (refer to Page 10).

Front

Screw head

edge

cooktop

of

• Refer to the Creative Solutions section on page 13 if

more counter space is needed.

• Using the illustrations on pages 9 through 12 and

taking measurements of the vent system and its

exhaust vent location, confirm the clearances

needed within the cabinet, the exhaust vent

direction, and the alignment of the exhaust vent with

the ducting. If needed for clearance or duct hookup

alignment, reposition the location of the cooktop, or

modify the cabinetry, or modify the ducting.

• Confirm the electrical receptacles and gas lines are

correctly located, and relocate if needed.

B

B is the minimum dimension of the

flat portion of countertop that is needed

Back edge

of cooktop

1/8” minimum

INSTALLATION INSTRUCTIONS

Front of cutout

in countertop

Front edge

of countertop

C

Counter Top

Gear Motor

Cover

Blower Box

COOKTOP

Dimension C is defined in cooktop Installation Instruction

Front of cutout

in countertop

A

A is the dimension from the screw head on the front surface of

the cooktop base to the rear edge of the cooktop. If you cannot find dimension A

in the cooktop installations instructions, then you must measure it.

Depth of cutout is A + 2 1/8”

Minimum counter depth B = A + C + 2.5"

Cook Top Chimney Top

Air Vent

D

o

w

n

d

r

a

f

t

V

e

n

t

3/8”

minimum

2 1/8”

Back of cut

in countertop

120 Vac

Grounded

Outlet

3-1/4" x 10"

Duct Connector

49-2000733 Rev. 1 11

Page 12

Installation Preparation

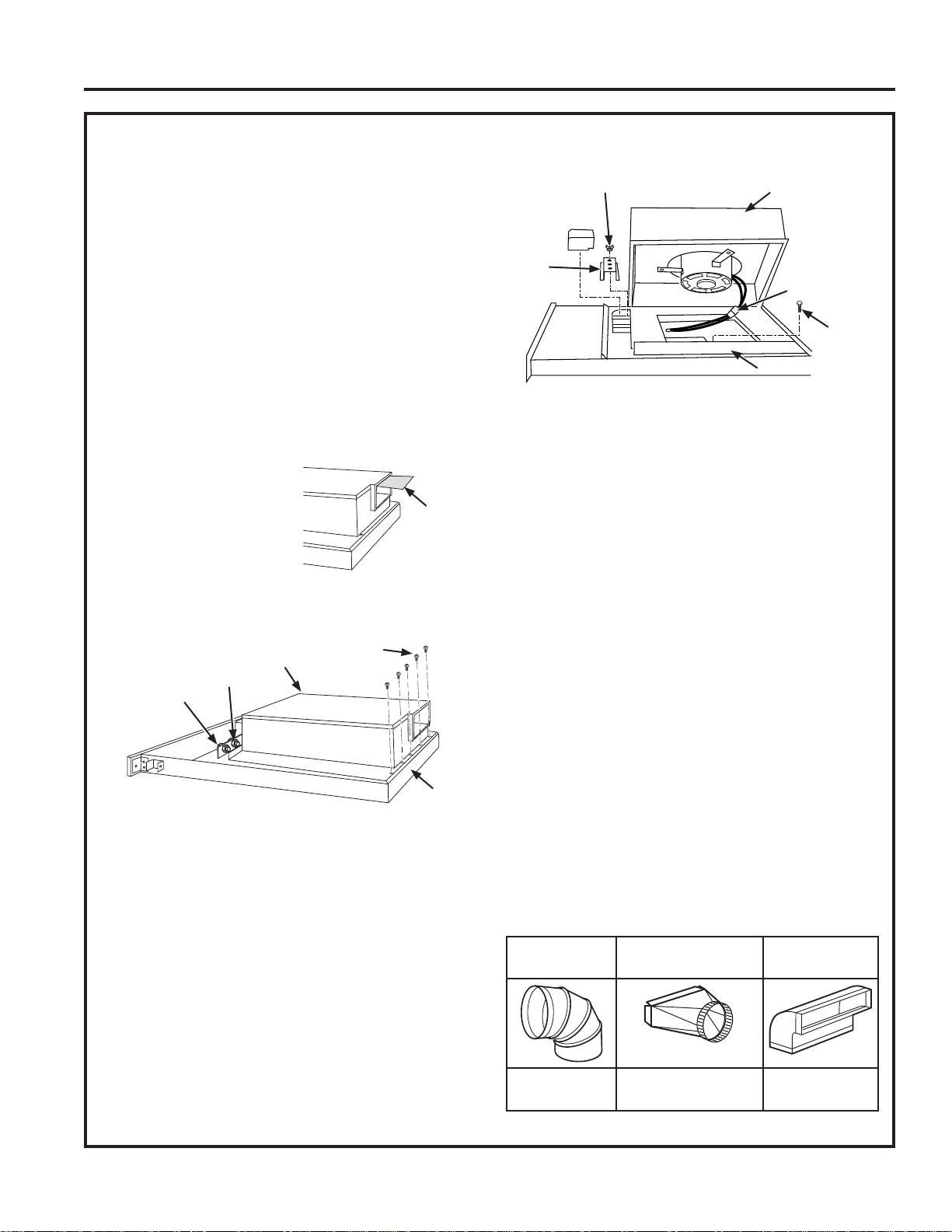

VENTING OPTIONS

• The downdraft vent is shipped with the discharge

outlet pointing straight down and can be changed to

the left or right side. To avoid interference problems,

the downdraft vent cannot be vented to the right

when installed with a GE or Monogram gas cooktop,

or with a GE or Monogram non-induction electric

cooktop.

• The blower outlet is sized for 3-1/4” x 10” and can

be transitioned to 6” round.

The blower is shipped with its discharge facing

DOWN. Follow these steps ONLY if:

• the position of the blower discharge needs to be

moved so ductwork does not interfere with floor

joists, plumbing or wiring below.

• it is necessary to rotate the blower discharge to the

RIGHT or LEFT.

Place the unit on its back on

a table or work surface.

INSTALLATION INSTRUCTIONS

Pull out the bubble wrap

sheet. Make sure nothing is

left inside.

DOWN DISCHARGE - MOVING BLOWER LEFT OR

RIGHT

Sheet Metal

Blower

Clamp

Channel

Nuts

1. Loosen the 4 nuts and 2 clamp channels.

2. Remove the 5 screws on the bottom. These 5

screws are for shipping and do not need to be

re-tightened.

3. Slide blower to desired position.

4. Use supplied cover plate to close open space (if

any).

5. Tighten wing nuts to secure top of blower and use

sheet metal screws through bottom flange to secure

bottom of blower.

Screws

Bubble

Wrap Sheet

Bottom

Flange

LEFT OR RIGHT DISCHARGE

Nut

Clamp

Channel

Blower

Motor Plug

Sheet

Metal

Screw

Cover Plate

1. Remove the 4 nuts and 2 clamp channels.

2. Remove the 5 screws on the bottom. These 5

screws are for shipping and do not need to be

re-tightened.

3. Carefully lift blower and disconnect motor plug if

necessary. Reposition blower and RECONNECT

MOTOR PLUG.

4. Use supplied cover plate to close open space (if

any).

5. Replace clamp channels and use nuts to secure the

blower in its new position.

6. Use sheet metal screws through bottom flange to

secure bottom of blower.

For best performance: Choose the ducting option

which allows the shortest length of ductwork and a

minimum number of elbows and transitions. Check

location of floor joists, wall studs, electrical wiring or

plumbing for possible interference.

NOTE: The unit is shipped with the 3-1/4" x 10"

discharge facing DOWN. See “CHANGING BLOWER

DIRECTION” on page 3, if necessary.

The system will operate most efficiently when the

ductwork does not exceed 40 feet of equivalent duct.

The chart, below, shows equivalent feet of elbows and

transitions. The number of feet of straight duct plus the

equivalent feet of transitions and/or elbows to be used

should equal 40 feet or less.

6" Round

Elbow

3-1/4"x10" to 6"

Round Transition

3-1/4"x10"

90° Elbow

equals 6 ft. of

straight duct

equals 2 ft. of

straight duct

equals 8 ft. of

straight duct

12 49-2000733 Rev. 1

Page 13

Design Information

CREATIVE SOLUTIONS

• When the kitchen

design calls for an

against-the-wall

installation, move

the base cabinet

forward 3” to 5”.

Filler panels or

complementary

moldings can be

added to exposed

cabinet sides.

• In an island or

peninsula, use

an extra-deep

countertop.

The countertop

overhang at the

front can be

adjusted to meet

setback to cutout

requirements.

• When the cutout

to the front edge of the countertop requirement is

more than 2”, add a bullnose trim to the front edge

of the countertop. Include the trim thickness when

measuring the front edge to cutout requirement. By

adding the trim, the cooktop can be moved forward,

Maintain Cutout Clearances

to Front Edge as Specified

Base

Cabinet

Filler Panel

Cover Panel

Base Sink

Filler Panel

Countertop

Overhang

per Cooktop

Clearances

Must be

Maintained

End

Panel

INSTALLATION INSTRUCTIONS

providing additional countertop depth and interior

cabinet space.

• When the distances between the vent and the

inside cabinet side walls are more than 5-1/2” and/

or the inside cabinet back wall is more than 4-1/2”,

false walls should be constructed inside the cabinet

for securing the vent with the stabilizing brackets

(refer to Cutouts and Clearances under Installation

Preparation.)

PREPARING THE COUNTERTOP

Lay out and cut the cooktop cut-out far enough

FORWARD so downdraft will fit behind it.

1. Set cooktop in place and

slide it as far forward as

possible. Center and square

it with edges or countertop.

2. Place the plastic template

against the back flange of

the cooktop and center it.

Trace around template to

mark the downdraft opening.

49-2000733 Rev. 1 13

3. Remove cooktop from countertop.

4. Cut downdraft opening. Be careful not to chip edges

of countertop.

Page 14

Design Information

PREPARE FOR DUCTWORK

Determine the best route for ductwork; it can be routed

in a variety of ways depending on the kitchen layout.

IMPORTANT: The downdraft air discharge outlet

IRUWKLVXQLWLV»´[´UHFWDQJXODU3ODQGXFWLQJ

accordingly.

Typical duct arrangement countertop series.

To maximize the ventilation performance of the vent

system:

1. Minimize the duct run length and number of

transitions and elbows.

2. Maintain a constant duct size.

3. Seal all joints with duct tape to prevent any leaks.

4. Do not use any type of flexible ducting.

Right

Discharge

Left

Discharge

Down

Discharge

(as shipped)

INSTALLATION INSTRUCTIONS

Optional duct arrangement under concrete

slab. PVC duct should be used if installing

under a poured concrete slab.

NOTE: PVC sewer pipe type PSM 12454-B

Schedule 40 ASTM D1785.

Wall Cap

12"

(30 cm)

Min.

6"

(15 cm)

Dia. PVC

Coupling

6" (15 cm) Dia.

PVC Sewer Pipe

Elbow

6" (15 cm)

Dia. 90

Metal Elbow

6" (15 cm) Dia.

Metal Duct

16"

(40.6 cm)

Max.

30'-0" (9.14 m) Max.

Pack tightly with gravel

or sand completely

around pipe

3-1/4" x 10" Rectangular

to 6" Round Transition

Concrete

Slab

6" (15 cm)

Dia. PVC

Sewer Pipe

6" (15 cm) Dia.

PVC Sewer Pipe

Elbow

Install ductwork so the piece of duct nearest the

downdraft unit slots INTO the next piece of the duct.

Secure the joints with self-tapping screws and apply

duct tape around the joints to ensure an airtight seal.

6" (15 cm)

Dia. Metal

Duct

(15 cm)

Dia.

PVC

Coupling

6" (15 cm)

Dia. PVC

Sewer

Pipe

Outside

Inside wall

wall cabinet

cabinet

Up inside wall to roof or

Directly to outside

overhang

6"

Peninsula or island

Peninsula

Between floor joists Through cabinet toe space

Duct Tape

Over Seam and Screw

Air

Flow

Screw

14 49-2000733 Rev. 1

Page 15

Installation Instructions

INSTALLATION INSTRUCTIONS

1

MOUNT THE UNIT

Leveling Bracket -

Flange Facing Out

Mounting Screws

Leveling

Screw

Wood

Screws

Leveling

Screw

Leveling Bracket -

Flange Facing In

Set downdraft into opening. Extend leveling

A

brackets to floor of cabinet so downdraft sits

straight. (NOTE: Leveling brackets can be

removed and re-attached in other positions.

Bottom flange may have to face inward in tight

cabinet installations.)

Secure the downdraft to the countertop as

B

follows: Hold the downdraft against the back of

countertop cut-out and tighten the 2 mounting

screws (one on each end of unit) on underside

of countertop. Use a shim between screw and

underside of granite countertops.

Bracket

1

MOUNT THE UNIT (Cont.)

Screw leveling brackets to bottom of cabinet

C

using the four wood screws (provided with the

unit) on each side.

Tighten leveling screws through leveling

D

bracket slots to the unit on each side.

Place cooktop into the countertop cutout. There

E

should be 1/8" minimum gap between the front

of the vent trim and the rear of the cooktop.

Connect duct. Use a roof or wall cap (with

F

damper) that is intended for use with kitchen

hoods and vent systems.

2

CONNECT POWER

Plug power cord into properly grounded receptacle.

3

INSTALL FILTERS, CHECK

OPERATION

• Press the button on the top cover to raise the

vent.

• Lift the vent straight up and pull forward.

• Slide filter into the retainers and close the vent.

• Turn the knob on the right side of the air vent to

start the blower and adjust the speed.

• To lower the vent, press the button on the top

cover.

NOTE: It is not necessary to turn the fan OFF

before lowering the vent. The fan will automatically

turn off when the vent is lowered. When the fan

is not turned off before lowering the vent, it will

automatically come on at the previously set speed

when the vent is fully raised.

Shim

Countertop

Mounting Screw

The ends of the template may be broken or cut

and used as shims if required.

Break/Cut the Ends

49-2000733 Rev. 1 15

Page 16

TROUBLESHOOTING TIPS

Save time and money! Review the charts on the following pages first and you may not need to call for service.

Problem Possible Cause What To Do

Fan does not work The vent is not fully extended. Press the button on the top cover.

Vent does not work The vent is not plugged into an outlet. Plug the vent into a 120V power outlet.

The button did not engage the lift

motor.

The circuit breaker may have tripped. Check the circuit breaker— reset if necessary.

Sufficient makeup (replacement) air is

required for exhausting appliances to

operate to rating.

Hold down the button for a couple of seconds

to activate the motor.

Check with local building codes, which may

require or strongly advise the use of makeup

air. Visit GEAppliances.com for available

makeup air solutions.

TROUBLESHOOTING TIPS

16 49-2000733 Rev. 1

Page 17

GE Appliances Limited Warranty

GEAppliances.com

All warranty service is provided by our Factory Service Centers, or an authorized Customer Care® technician. To schedule

service online, visit us at GEAppliances.com/service, or call GE Appliances at 800.GE.CARES (800.432.2737). Please

have your serial number and your model number available when calling for service.

Servicing your appliance may require the use of the onboard data port for diagnostics. This gives a GE Appliances factory

service technician the ability to quickly diagnose any issues with your appliance and helps GE Appliances improve its

products by providing GE Appliances with information on your appliance. If you do not want your appliance data to be

sent to GE Appliances, please advise your technician not to submit the data to GE Appliances at the time of service.

For the period of GE Appliances will replace

One year

From the date

of the original

purchase

What GE Appliances will not cover:

Ŷ Service trips to your home to teach you how to use

the product.

Ŷ Improper installation, delivery, or maintenance.

Ŷ Failure of the product if it is abused, misused,

modified, or used for other than the intended purpose

or used commercially.

Ŷ Replacement of house fuses or resetting of circuit

breakers.

Ŷ Damage to the product caused by accident, fire,

floods, or acts of God.

Any part of the cooking product which fails due to a defect in materials or workmanship.

During this limited one-year warranty, GE Appliances will provide, free of charge, all labor

and related service costs to replace the defective part.

Ŷ Incidental or consequential damage caused by

possible defects with this appliance.

Ŷ Damage caused after delivery.

Ŷ Product not accessible to provide required service.

Ŷ Service to repair or replace light bulbs, except for LED

lamps.

LIMITED WARRANTY

EXCLUSION OF IMPLIED WARRANTIES

Your sole and exclusive remedy is product repair as provided in this Limited Warranty. Any implied warranties,

including the implied warranties of merchantability or fitness for a particular purpose, are limited to one year or

the shortest period allowed by law.

This limited warranty is extended to the original purchaser and any succeeding owner for products purchased for

home use within the USA. If the product is located in an area where service by a GE Appliances Authorized Servicer

is not available, you may be responsible for a trip charge or you may be required to bring the product to an Authorized

GE Appliances Service location for service. In Alaska, the limited warranty excludes the cost of shipping or service

calls to your home.

Some states do not allow the exclusion or limitation of incidental or consequential damages. This limited warranty

gives you specific legal rights, and you may also have other rights which vary from state to state. To know what your

legal rights are, consult your local or state consumer affairs office or your state’s Attorney General.

Warrantor: GE Appliances, a Haier company

Louisville, KY 40225

Extended Warranties: Purchase a GE Appliances extended warranty and learn about special discounts that are

available while your warranty is still in effect. You can purchase it online anytime at

GEAppliances.com/extended-warranty

or call 800.626.2224 during normal business hours. GE Appliances Service will still be there after your warranty expires.

If you received a damaged downdraft vent system

Immediately contact the dealer (or builder) that sold you the downdraft vent system.

Staple your receipt here. Proof of the original purchase

date is needed to obtain service under the warranty.

49-2000733 Rev. 1 17

Page 18

Accessories

Looking For Something More?

GE Appliances offers a variety of accessories to

improve your cooking and maintenance experiences!

Refer to the Consumer Support page for phone numbers

and website information.

The following products and more are available:

Parts

ACCESSORIES

Black Stainless Steel Trim (30”)

Black Stainless Steel Trim (36”)

Cleaning Supplies

CitruShine™ Stainless Steel Wipes

Stainless Steel Appliance Cleaner

18 49-2000733 Rev. 1

Page 19

Notes

49-2000733 Rev. 1 19

Page 20

Consumer Support

GE Appliances Website

Have a question or need assistance with your appliance? Try the GE Appliances Website 24 hours a day, any day

of the year! You can also shop for more great GE Appliances products and take advantage of all our on-line support

services designed for your convenience. In the US: GEAppliances.com

Register Your Appliance

Register your new appliance on-line at your convenience! Timely product registration will allow for enhanced

communication and prompt service under the terms of your warranty, should the need arise. You may also mail in

the pre-printed registration card included in the packing material. In the US: GEAppliances.com/register

Schedule Service

Expert GE Appliances repair service is only one step away from your door. Get on-line and schedule your service at

your convenience any day of the year. In the US: GEAppliances.com/service

CONSUMER SUPPORT

or call 800.432.2737 during normal business hours.

Extended Warranties

Purchase a GE Appliances extended warranty and learn about special discounts that are available while your

warranty is still in effect. You can purchase it on-line anytime. GE Appliances Services will still be there after your

warranty expires. In the US: GEAppliances.com/extended-warranty

or call 800.626.2224 during normal business hours.

Remote Connectivity

For assistance with wireless network connectivity (for models with remote enable),

visit our website at GEAppliances.com/connect or call 800.220.6899 in the US.

Parts and Accessories

Individuals qualified to service their own appliances can have parts or accessories sent directly to their homes

(VISA, MasterCard and Discover cards are accepted). Order on-line today 24 hours every day.

In the US: GEApplianceparts.com or by phone at 877.959.8688 during normal business hours.

Instructions contained in this manual cover procedures to be performed by any user. Other servicing

generally should be referred to qualified service personnel. Caution must be exercised, since improper

servicing may cause unsafe operation.

Contact Us

If you are not satisfied with the service you receive from GE Appliances, contact us on our Website with all the

details including your phone number, or write to:

In the US: General Manager, Customer Relations | GE Appliances, Appliance Park | Louisville, KY 40225

GEAppliances.com/contact

20 49-2000733 Rev. 1

Page 21

INFORMACIÓN DE SEGURIDAD ....3

Uso del Sistema de Ventilación

Sistema De Ventilación

De Corriente Descendente ................5

CUIDADO Y LIMPIEZA

Sistema De Ventilación

De Corriente Descendente ................6

INSTRUCCIONES

DE INSTALACIÓN ..................7

CONSEJOS PARA LA SOLUCIÓN

DE PROBLEMAS ................... 16

GARANTÍA LIMITADA .............. 17

ACCESORIOS ........................ 18

SOPORTE PARA

EL CONSUMIDOR ..................20

MANUAL DEL

PROPIETARIO E

INSTALACIÓN

UVD6301S

UVD6361S

de corriente descendente

Escriba los números de modelo y de

serie aquí:

Nº de Modelo ____________

Nº de Serie ______________

Estos números también se encuentran en

la Tarjeta de Registro de Propiedad de

Producto enviada en forma separada con

su sistema de ventilación de corriente

descendente y en la etiqueta que se

encuentra en el panel frontal de la unidad.

SISTEMA DE VENTILACIÓN

GE es una marca registrada de General Electric Company. Fabricado bajo licencia de marca.

49-2000733 Rev. 1 09-20 GEA

Page 22

GRACIAS POR HACER QUE GE APPLIANCES SEA PARTE DE SU HOGAR.

Ya sea que haya crecido usando GE Appliances, o que ésta es su primera vez, nos complace

tenerlo en la familia.

Sentimos orgullo por el nivel de arte, innovación y diseño de cada uno de los electrodomésticos de

GE Appliances, y creemos que usted también. Entre otras cosas, el registro de su electrodoméstico

asegura que podamos entregarle información importante del producto y detalles de la garantía

cuando los necesite.

Registre su electrodoméstico GE ahora a través de Internet. Sitios Web y números telefónicos útiles

están disponibles en la sección de Soporte para el Consumidor de este Manual del Propietario.

También puede enviar una carta en la tarjeta de inscripción preimpresa que se incluye con

el material embalado.

2 49-2000733 Rev. 1

Page 23

INFORMACIÓN IMPORTANTE DE SEGURIDAD

LEA TODAS LAS INSTRUCCIONES ANTES DE USAR

INFORMACIÓN DE SEGURIDAD

ADVERTENCIA

DE INCENDIO, DESCARGA ELÉCTRICA O LESIONES A

PERSONAS, CUMPLA CON LOS SIGUIENTES PUNTOS:

A. Utilice esta unidad sólo de la manera concebida por el

fabricante. Si tiene alguna pregunta, comuníquese con el

fabricante.

B. Antes de realizar reparaciones o limpiar la unidad,

desconecte la energía del panel de servicio y bloquee los

medios de desconexión para evitar el accionamiento de

la energía de manera accidental. Cuando los medios de

desconexión de servicio no pueden bloquearse, coloque

sobre el panel de servicio un dispositivo de advertencia

bien visible, como una etiqueta.

C. No utilice esta unidad con ningún dispositivo de control

de velocidad de estado sólido.

D. Enchufe el sistema de ventilación en un tomacorriente

con conexión a tierra de 120 voltios únicamente. No retire

la pata redonda de conexión a tierra del enchufe. Si tiene

dudas sobre la conexión a tierra del sistema eléctrico

para hogar, es su responsabilidad y obligación contar

con el reemplazo de un tomacorriente sin conexión a

tierra por un tomacorriente de tres patas correctamente

conectado a tierra, de acuerdo con el Código Nacional

de Electricidad. No use prolongadores con este

electrodoméstico.

PARA REDUCIR EL RIESGO

PRECAUCIÓN

VENTILACIÓN GENERAL. NO LO UTILICE PARA

ELIMINAR MATERIALES Y VAPORES PELIGROSOS O

EXPLOSIVOS.

ADVERTENCIA

LESIONES A PERSONAS EN CASO DE UN INCENDIO

DE GRASA SOBRE UNA ESTUFA, CUMPLA CON LOS

SIGUIENTES PUNTOS*:

A. APAGUE LAS LLAMAS con una tapa que ajuste bien,

una plancha para galletas o una bandeja de metal, y

luego apague el quemador. TENGA MUCHO CUIDADO

A FIN DE EVITAR QUEMADURAS. Si las llamas no

se apagan de inmediato, SALGA DE LA VIVIENDA Y

LLAME AL DEPARTAMENTO DE BOMBEROS.

B. NUNCA LEVANTE UNA SARTÉN EN LLAMAS—

Usted puede quemarse.

C. NO UTILICE AGUA, incluyendo repasadores o toallas

húmedos—se provocará una violenta explosión de vapor.

D. Utilice un extintor SÓLO si:

1. Usted sabe que cuenta con un extintor Clase ABC y

ya sabe cómo utilizarlo.

2. El incendio es pequeño y se contuvo en el área donde

comenzó.

3. Se está llamando al departamento de bomberos.

4. Usted puede combatir el incendio con su espalda

dirigida hacia una salida.

* Basado en “Kitchen Fire Safety” publicado por NFPA.

SÓLO PARA USO DE

PARA REDUCIR EL RIESGO DE

ADVERTENCIA

UN INCENDIO DE GRASA SOBRE UNA ESTUFA:

A. Nunca deje unidades de superficie desatendidas en

configuraciones de calor elevadas. Los alimentos que

hierven y se derraman provocan humo y derrames

grasosos que pueden prenderse fuego. Caliente los

aceites lentamente en configuraciones bajas o medias.

B. Siempre encienda el sistema de ventilación cuando

cocine con configuraciones de calor elevadas o cuando

flambee alimentos (por ej., Crepes Suzette, cerezas

Jubilee, carne flambeada a la pimienta en grano).

C. Limpie los ventiladores con frecuencia. No debe

permitirse la acumulación de grasa en el ventilador o en

el filtro.

D. Utilice el tamaño de recipiente adecuado. Siempre utilice

recipientes de cocción apropiados para el tamaño del

elemento de superficie.

PARA REDUCIR EL RIESGO DE

Si necesita servicio técnico…

No intente reparar o cambiar ninguna pieza del sistema

de ventilación, a menos que esté específicamente

recomendado en este manual. Cualquier otro servicio debe

realizarlo un técnico calificado.

Asegúrese de cortar la electricidad antes de efectuar

servicio técnico en el aparato.

Puede resultar necesario quitar el sistema de ventilación

para realizar servicio técnico en componentes tales como el

motor del ventilador o el mecanismo de ventilación de aire.

Desconecte la energía que alimenta la estufa y quítela en

primer término. Invierta los pasos de la sección “Cómo

instalar la ventilación descendente” en las Instrucciones de

instalación para quitar el ventilador.

Las piezas para el servicio técnico se encuentran

disponibles en el Centro de Servicio Técnico y Piezas de GE

Appliances.

Cuando baje la ventilación, mantenga los dedos alejados de

la parte superior del sistema de ventilación.

LEA Y GUARDE ESTAS INSTRUCCIONES

49-2000733 Rev. 1 3

Page 24

INFORMACIÓN IMPORTANTE DE SEGURIDAD

LEA TODAS LAS INSTRUCCIONES ANTES DE USAR

Cómo Retirar la Película Protectora de Envío y la Cinta de Embalaje

Con cuidado tome un extremo de la película protectora

de envío con los dedos y lentamente retire la misma de la

superficie del electrodoméstico. No utilice ningún producto

filoso para retirar la película. Retire toda la película antes de

usar el electrodoméstico por primera vez.

Para asegurar que no haya daños sobre el acabado del

producto, la forma más segura de retirar el adhesivo de la cinta

de embalaje en electrodomésticos nuevos es aplicando un

detergente líquido hogareño para lavar platos. Aplique con una

tela suave y deje que se seque.

NOTA: El adhesivo deberá ser eliminado de todas las partes.

No se puede retirar si se hornea con éste dentro.

ATENCIÓN: Por favor retire el envoltorio de burbujas insertado

en el escape antes de la instalación. Asegúrese de que no

quede nada dentro de la caja del ventilador.

Envoltorio de Burbujas

INFORMACIÓN DE SEGURIDAD

LEA Y GUARDE ESTAS INSTRUCCIONES

4 49-2000733 Rev. 1

Page 25

Sistema De Ventilación De Corriente Descendente

Sistema De Ventilación De Corriente Descendente

A fin de elevar la ventilación descendente, presione el botón

de la tapa superior. La ventilación se elevará.

Botón

Cuando Utilice el Sistema de Ventilación

El ventilador se podrá girar a ON (Encender) y

OFF (Apagar) y la velocidad se podrá ajustar

con la perilla empotrada sobre el lado derecho

de la salida de aire.

ventilador se apagará automáticamente cuando

se baje la ventilación.

NOTA: Para un funcionamiento más

conveniente, configure el ventilador a la velocidad que utilice

más a menudo. El ventilador se accionará a esta velocidad

cuando la unidad se eleve.

Baje la ventilación descendente

presionando el botón de la tapa

superior. La ventilación descenderá y

el ventilador se apagará.

Si se lo deja encendido, el

Uso del Sistema de Ventilación: Sistema de ventilación de corriente descendente

PRECAUCIÓN

la ventilación. Asegúrese de que las cacero las, las manijas

de las cacerolas y otros objetos se encuentren alejados de la

ventilación y que no se golpeen o vuelquen cuando se la eleve.

NOTA: Hay una pequeña saliente en cada lado de la ventilación.

Ŷ 3DUDHYLWDUOHVLRQHVPDQWHQJDORVGHGRVDOHMDGRVGHOD

tapa de la ventilación cuando se la baje.

Ŷ 0DQWHQJDODVPDQRV\ORVGHGRVDOHMDGRVGHWRGDVODV

piezas de la ventilación.

Tenga cuidado al levantar o bajar

Consejos De Cocción

El elevado movimiento de aire de este sistema de ventilación

puede aumentar los tiempos de cocción de algunos alimentos.

Puede tomar más tiempo alcanzar temperaturas de cocción

elevadas si se acciona la ventilación en la configuración “alta”

desde el comienzo. Para mejores resultados de cocción,

ajuste la velocidad del ventilador.

IMPORTANTE: Si la ventilación queda obstruida con un objeto

mientras se la sube o baja, ésta se detendrá. Con cuidado retire

la obstrucción y la ventilación descenderá hasta la posición que

se desea bajar. Vuelva a presionar el botón para regresar a las

funciones normales.

Para mejores resultados cuando caliente aceite para freír o

cuando hierva agua, utilice las unidades de superficie frontales

o espere a que el agua esté hirviendo o a que el aceite

se encuentre a temperatura de fritura antes de accionar el

sistema de ventilación.

Es posible que el sistema de ventilación no capture por

completo todo el vapor proveniente de las ollas de los

quemadores frontales.

49-2000733 Rev. 1 5

Page 26

Sistema De Ventilación De Corriente Descendente

Filtros De Grasa

La eficiencia del sistema de ventilación depende de la

limpieza del filtro. La frecuencia de limpieza depende del tipo

de cocción que realice. Los filtros de grasa deben limpiarse

por lo menos una vez por mes. Nunca opere el sistema de

ventilación si los filtros no están colocados correctamente.

Para quitar:

hasta los mismos a través de la abertura de la ventilación,

presionando hacia abajo y luego hacia afuera. NOTA: Los

filtros poseen diferentes tamaños. Asegúrese de reemplazarlos

una vez retirados, colocando el más ancho sobre la izquierda.

Para limpiar: Sumerja y luego agite en una solución de

detergente caliente. Puede utilizarse un cepillo suave para

quitar la suciedad muy adherida. Enjuague, agite y quite la

humedad antes de volver a colocar. No lave los filtros en el

lavavajillas.

Con una manipulación cuidadosa, el filtro durará muchos años.

Si necesita reemplazarlo, solicite el repuesto a su vendedor.

Superficies Pintadas O De Acero Inoxidable

No utilice almohadillas de acero porque rayan la superficie.

Para limpiar la superficie de acero inoxidable, utilice agua tibia

jabonosa o un limpiador o lustrador para acero inoxidable.

Siempre limpie la superficie en dirección de la veta. Siga las

instrucciones del producto para limpiar la superficie de acero

inoxidable.

En caso de haber manchas difíciles de quitar sobre el acero

inoxidable, use un limpiador que contenga ácido láctico o ácido

cítrico.

Retire los filtros de la salida de aire, llegando

Lengüetas del filtro

Para realizar consultas sobre la adquisición de productos,

incluyendo limpiadores o pulidores para electrodomésticos de

acero inoxidable, lea las secciones de Asistencia y Accesorios,

en el comienzo de este manual.

CUIDADO Y LIMPIEZA: Sistema de ventilación de corriente descendente

6 49-2000733 Rev. 1

Page 27

Instrucciones

INSTRUCCIONES DE INSTALACIÓN

Sistemas de Ventilación

de Aire Descendente

de instalación

¿Preguntas? Llame al 800.GE.CARES (800.432.2737) o visite nuestro sitio Web en: GEAppliances.com

ANTES DE COMENZAR

Lea estas instrucciones por completo y con

detenimiento.

•

IMPORTANTE — Guarde estas instrucciones

para el uso de inspectores locales.

•

IMPORTANTE — Cumpla con todos los códigos

y ordenanzas vigentes.

• Nota al instalador – Asegúrese de dejar estas

instrucciones con el consumidor.

• Nota al consumidor – Conserve estas

instrucciones para referencias futuras.

• Nivel de capacidad – La Instalación de este

electrodoméstico debe ser realizada por un instalador

calificado o por un electricista.

• El instalador tiene la responsabilidad de efectuar una

instalación adecuada.

• La Garantía no cubre las fallas del producto debido a

una instalación incorrecta.

INSTRUCCIONES PARA DESCARGA

PIEZAS PROVISTAS

Abra el cartón y retire el paquete de piezas. Controle los

contenidos a fin de asegurar que todas las piezas estén

presentes.

UVD6301S, UVD6361S

Filtros - unidad interior -

Cant.: 2

Tornillo de Montaje

de la Mesada 1/4-20

x 2.00 Cab. Hex.

Cant.: 2

Plantilla de Plástico

(adherida al producto)

Cant.: 1

Soportes de

Estabilización - Cant.: 2

Tornillo de

Nivelación de

Caída, 1/4-20 x

.50 Cab. Hex. -

Cant.: 2

Tornillo de

madera, nº 8 x.750

SI Redondo -

Cant.: 4

A TIERRA

Este electrodoméstico debe estar conectado a tierra.

En caso de que se produzca un cortocircuito, la

conexión a tierra reduce el riesgo de descarga eléctrica,

brindando un cable de escape de la corriente eléctrica.

Este electrodoméstico está equipado con un cable de

corriente que posee un cable de conexión a tierra con

un enchufe a tierra. El enchufe se deberá colocar en un

tomacorriente instalado y conectado a tierra de forma

adecuada.

ADVERTENCIA

Una conexión a tierra inadecuada puede producir riesgos

de descargas eléctricas.

Consulte a un electricista calificado en caso de

que las instrucciones de conexión a tierra no se

entiendan completamente, o si tiene dudas sobre si

el electrodoméstico está conectado a tierra de forma

apropiada.

No use un prolongador. Si el cable de corriente es

demasiado corto, solicite a un electricista calificado que

instale un tomacorriente cerca del electrodoméstico.

Si el sistema de ventilación que recibió está dañado, se

deberá comunicar con su vendedor minorista.

HERRAMIENTAS Y MATERIALES

REQUERIDOS

• Gafas de seguridad

• Destornillador con cabeza plana largo

• Sierra de vaivén

• Regla de carpintero

• Tubería adecuada para la instalación

• Nivel

QUITE EL EMPAQUE

Retire los materiales embalados y el cartón; deje a un

lado el cartón. El cartón puede ser usado como base al

cambiar o ajustar la dirección de la ventilación.

28.5” para Modelos de 30”

28.5” for 30” Models

34” para Modelos de 36”

34” for 36” Models

49-2000733 Rev. 1 7

Page 28

Información de Seguridad

ADVERTENCIA

PARA REDUCIR EL

RIESGO DE INCENDIO, DESCARGA ELÉCTRICA

O LESIONES A PERSONAS, CUMPLA CON LOS

SIGUIENTES PUNTOS:

• El trabajo de instalación y el cableado eléctrico deben

ser realizados por una persona(s) calificada de acuerdo

con todos los códigos y estándares aplicables, incluyendo

construcciones resistentes al fuego.

• Es necesario contar con suficiente cantidad de aire

para una combustión y salida de gases adecuadas a

través del conducto (chimenea) del equipo de consumo

de combustible, a fin de evitar ráfagas de aire. Siga las

pautas del fabricante del equipo de calefacción y los

estándares de seguridad, tales como aquellos publicados

por la Asociación Nacional de Protección contra

Incendios (National Fire Protection Association, NFPA), la

Sociedad Estadounidense para la Calefacción (American

Society for Heating), los Ingenieros de Refrigeración

y Acondicionadores de Aire (Refrigeration and Air

Conditioning Engineers, ASHRAE) y las autoridades de los

códigos locales.

• Al cortar o perforar una pared o un cielorraso, no dañe el

cableado eléctrico y de otros servicios ocultos.

• Los ventiladores con conducto siempre deben contar con

INSTRUCCIONES DE INSTALACIÓN

ventilación hacia el exterior.

PRECAUCIÓN

PARA REDUCIR EL RIESGO

DE INCENDIO Y PARA ELIMINAR EL AIRE DE

ESCAPE CORRECTAMENTE, ASEGÚRESE

DE DIRIGIR EL AIRE DEL CONDUCTO HACIA

EL EXTERIOR. NO VENTILE EL AIRE DE

ESCAPE EN ESPACIOS DENTRO DE PAREDES

O CIELORRASOS O EN ÁTICOS, HUECOS

SANITARIOS O GARAJES.

ADVERTENCIA

A FIN DE REDUCIR EL

RIESGO DE INCENDIOS, USE SÓLO CONDUCTOS

DE METAL.

• Cuando corresponda, instale un sistema de reposición

(reemplazo) de aire de acuerdo con los requisitos

del código local de construcción. Para acceder a

soluciones relacionadas con la reposición de aire, visite

GEAppliances.com.

• La tubería de cloaca de PVC puede ser usada como

conducto bajo una losa de concreto, si esto lo permite la

junta del código local.

8 49-2000733 Rev. 1

Page 29

Preparación para la instalación

INSTRUCCIONES DE INSTALACIÓN

SUMINISTRO DE ENERGÍA

Esta ventilación de aire descendente debe ser provista con

120V, 60 Hz, y estar conectada a un circuito de empalmes

individual correctamente conectado a tierra, protegido por un

disyuntor o fusible de retardo de 15 o 20 amp.

Un receptáculo de 3 clavijas correctamente conectado a

tierra debe estar dentro del alcance del cable de corriente

de dos pies de la ventilación.

• Superficies de Cocción a Gas

Si esta ventilación es instalada junto con una superficie

de cocción a gas de GE o Monogram, puede funcionar

desde el mismo tomacorriente doble.

• Superficies de Cocción Eléctricas

Si esta ventilación es instalada junto con una superficie

de cocción eléctrica de GE o Monogram, la ventilación

debe funcionar desde un tomacorriente de 120V aparte.

Ubique el receptáculo dentro del gabinete en la pared lateral

derecha (vea la ilustración). El receptáculo no puede ser

colocado en la parte trasera de la pared del gabinete, donde

puede interferir con el plenum de aire descendente.

El cable de corriente de la ventilación de aire descendente

se debe conducir por debajo de la superficie de cocción y

alejado del calor generado por esta última.

Asegúrese de que la superficie de cocción sea instalada de

acuerdo con las instrucciones de instalación del fabricante.

ESPECIFICACIONES

VOLTIOS AMPERIOS CONDUCTO

120 4.0 3-1/4 X 10

34" (ancho del recorte) para modelos de 36”

28-1/2" (ancho del recorte) para modelos de 30”

29-1/2"

NO Ubique las

Conexiones de Gas

o Eléctricas dentro

de esta Área

Ubique la conexión de gas o

electricidad sólo dentro del

área sombreada.

Toma-

corriente

12"

Eléctrico de

12” sobre

el Piso del

Gabinete

IMPORTANTE

(Tenga a bien leer cuidadosamente)

El cable de corriente de este electrodoméstico cuenta

con un enchufe de 3 clavijas (con cable a tierra) que se

conecta a un receptáculo de pared con conexión a tierra

de tres clavijas para minimizar la posibilidad de descargas

eléctricas. El cliente deberá solicitar a un electricista

calificado que controle el receptáculo de pared y el circuito,

a fin de asegurar que el receptáculo esté adecuadamente

conectado a tierra y que cuente con la polaridad correcta.

• En caso de contar con un receptáculo de pared de dos

clavijas, es responsabilidad y obligación del cliente

reemplazarlo por un tomacorriente de pared de tres

clavijas correctamente conectado a tierra.

Nunca, bajo ninguna circunstancia, corte o elimine el

tercer cable (tierra) del cable de corriente.

No use prolongadores ni adaptadores con este

electrodoméstico. Siga el Código Nacional de Electricidad o

los códigos y ordenanzas locales establecidos.

Ubicación de la Etiqueta de Clasificación en el frente del

chasis del sistema de ventilación.

49-2000733 Rev. 1 9

Page 30

Preparación para la instalación

DIMENSIONES DEL PRODUCTO

AB

30" Modelos 30" 26-1/4”

36" Modelos 36" 32-1/4”

A

B

22.3”

INSTRUCCIONES DE INSTALACIÓN

2”

7”

2-1/2”

36-1/2”

7-1/4”

10 49-2000733 Rev. 1

Page 31

Preparación para la instalación

PREPARANDOSE PARA LA INSTALACIÓN

• Desembale la superficie de cocción y lea las Instrucciones

de Instalación a fin de entender las dimensiones

necesarias requeridas para la mesada y su ubicación,

el espacio entre la superficie de cocción y el extremo

frontal de la mesada, y los despejes necesarios con los

gabinetes y paredes. El ancho del espacio requerido

para el sistema de ventilación se muestra en la página 9.

Confirme que haya suficiente espacio entre un lado y otro

para contar con los espacios y despejes necesarios para

la superficie de cocción.

• Utilizando las siguientes ilustraciones y tomando las

medidas de la superficie de cocción para establecer

la dimensión A, confirme que haya suficiente espacio

entre el frente y la parte trasera (dimensión B) para

colocar tanto la superficie de cocción como el sistema

de ventilación. Observe que el extremo trasero de la

superficie de cocción se superpondrá con la superficie

frontal del sistema de ventilación (consulte la Página 10).

Extremo

Cabeza del tornillo

frontal de

la superficie

de cocción

• De ser necesario más espacio para la mesada, consulte

la sección de Soluciones Creativas en la página 13.

• Utilizando las ilustraciones en las páginas 9 y 12 y

tomando las medidas del sistema de ventilación y la

ubicación de la salida de la ventilación, confirme los

espacios necesarios dentro del gabinete, la dirección

del escape de la ventilación, y la alineación del escape

de la ventilación con el conducto. De ser necesario

para el despeje o la alineación del enlace del conducto,

reposicione la ubicación de la superficie de cocción, o

modifique la ubicación de los muebles, o la tubería.

• Confirme que los receptáculos eléctricos y las tuberías de

gas estén correctamente ubicadas, y vuelva a ubicar las

mismas de ser necesario.

B

B es la dimensión mínima de la parte

plana de la mesada que es necesaria

Extremo trasero de

la superficie de cocción

Mínimo de 1/8”

INSTRUCCIONES DE INSTALACIÓN

Frente del recorte

en la mesada

Extremo frontal

de la mesada

C

Mesada

Tapa del Motor

del Engranaje

Caja del

Ventilador

SUPERFICIE DE COCCIÓN

La dimensión C está definida en las Instrucciones

de Instalación de la superficie de cocción

Frente del recorte

en la mesada

A

A es la dimensión desde la cabeza del tornillo en la superficie frontal de la base de la superficie

de cocción hasta el extremo trasero de la superficie de cocción. Si no puede encontrar la dimensión

A en las instrucciones de instalación de la superficie de cocción, entonces deberá medirla.

La profundidad del recorte es A + 2 1/8”

La profundidad mínima de la mesada es B = A + C + 2.5”

Superficie de Cocción

Caperuza de Chimenea

Salida de Aire

V

e

n

t

i

l

a

c

i

ó

n

d

e

A

i

r

e

D

e

s

c

e

n

d

e

n

t

e

Mínimo

de 3/8”

2 1/8”

Parte Trasera

del Recorte

en la mesada

Tomacorriente

con Conexión

a Tierra de 120

VAC

Conector del Conducto

de 3 ¼” x 10”

49-2000733 Rev. 1 11

Page 32

Preparación para la instalación

OPCIONES DE VENTILACIÓN

• La ventilación de aire hacia abajo es enviada con el

tomacorriente de descarga apuntando hacia abajo y

puede ser modificada hacia el lado izquierdo o derecho.

A fin de evitar problemas de interferencias, la descarga

de corriente descendente no podrá ser ventilada hacia la

derecha, cuando se instale con una superficie de cocción

a gas de GE o Monogram, o con una superficie de cocción

eléctrica que no sea de inducción de GE o Monogram.

• El tomacorriente del calefactor está ajustado para la

medida de 3 1/4” x 10” y puede ser modificado hasta 6”.

El ventilador se envía con su descarga mirando hacia

ABAJO. Siga estos pasos ÚNICAMENTE si:

• es necesario mover la posición de descarga del ventilador,

de modo que el conducto no interfiera con viguetas de

pisos, tuberías o cableados que pasen por debajo.

• es necesario rotar la descarga del ventilador hacia la

DERECHA o IZQUIERDA.

Coloque la unidad sobre su parte

trasera en una mesa o superficie

de trabajo.

Haga fuerza hacia afuera para

retirar la lámina del envoltorio de

burbujas. Asegúrese de que no

INSTRUCCIONES DE INSTALACIÓN

quede nada dentro.

DESCARGA DESCENDENTE – MOVIMIENTO DEL

VENTILADOR HACIA LA IZQUIERDA O DERECHA

Tornillos

Ventilador

Canal de la

Abrazadera

1. Afloje las 4 tuercas y los 2 canales de abrazaderas.

2. Retire los 5 tornillos de la parte inferior. Estos 5 tornillos

son de embalaje y no es necesario volver a ajustarlos.

3. Deslice el ventilador hasta la posición deseada.

4. Use la placa de la tapa suministrada para cerrar el

espacio abierto (si lo hay).

5. Ajuste las tuercas de mariposa para asegurar el ventilador

y ajuste los tornillos de la lámina metálica a través de

la brida inferior a fin de asegurar la parte inferior del

ventilador

Tuercas

Metálicos de

la Lámina

Lámina del

Envoltorio

de Burbujas

Brida

Inferior

DESCARGA HACIA LA IZQUIERDA O DERECHA

Tuercas

Canal de la

Abrazadera

1. Retire las 4 tuercas y los 2 canales de abrazaderas.

2. Retire los 5 tornillos de la parte inferior. Estos 5 tornillos

son de embalaje y no es necesario volver a ajustarlos.

3. Con cuidado levante el ventilador y desconecte el enchufe

del motor, de ser necesario. Vuelva a posicionar el

ventilador y RECONECTE EL ENCHUFE DEL MOTOR.

4. Use la placa de la tapa suministrada para cerrar el

espacio abierto (si lo hay).

5. Reemplace los canales de la abrazadera y use las

tuercas para asegurar el soplador en su nueva posición.

6. Use los tornillos de la lámina metálica a través de la brida

inferior a fin de asegurar la parte inferior del soplador.

Para un mejor funcionamiento: elija la opción de tubería que

permita la longitud más corta y el mínimo número de codos

y transiciones. Controle la ubicación de las viguetas del piso,

montajes de pared, cableado eléctrico y plomería para evitar

posibles interferencias.

NOTA: La unidad se envía con la descarga de 3 ¼” x 10"

hacia ABAJO. Consulte el “CAMBIO DE DIRECCIÓN DEL

VENTILADOR” en la página 3, de ser necesario.

El sistema funcionará de forma más eficiente cuando el

conducto no supere los 40 pies del conducto equivalente.

El cuadro que aparece a continuación muestra los pies

equivalentes de los codos y las transiciones. El número de

pies del conducto recto más los pies equivalentes de las

transiciones y/o codos que se usarán deberá ser igual a 40

pies o menos.

Codo

Redondeado

de 6”

Transición

Redondeada de 3

¼” x 10” a 6”

Ventilador

Enchufe del

Motor

Tornillo

Metálicos

de la

Lámina

Brida

Inferior

Codo de 90°

de 3 ¼” x 10”

igual a 6 pies

de conducto

recto

igual a 2 pies de

conducto recto

igual a 8 pies

de conducto

recto

12 49-2000733 Rev. 1

Page 33

Instrucciones de instalación

SOLUCIONES CREATIVAS

• Cuando el diseño de

la cocina requiera

una instalación contra

la pared, mueva el

gabinete de la base

hacia delante entre 3”

y 5”. Los paneles de

relleno o las molduras

complementarias

pueden ser agregadas

a los costados

expuestos de los

gabinetes.

• En una isla o

península, use

una mesada extra

profunda. La parte

saliente del frente

de la mesada puede

ser ajustada para

cumplir con los

requisitos entre el

mueble lindero y el

espacio de recorte.

• Cuando el espacio de recorte requerido hasta el extremo

frontal de la mesada sea superior a 2”, agregue un borde

redondeado al extremo frontal de la mesada. Incluya el

ancho del borde al medir el espacio requerido desde el

extremo frontal hasta el recorte. Al agregar el borde, la

superficie de cocción puede ser movida hacia delante,

Mantenga los Espacios de

Despeje hasta el Extremo Frontal

de Acuerdo con lo Especificado

Gabinete

de la Base

Panel

de Relleno

Panel de Cobertura

Lavabo

de la Base

Se Debe Mantener

la Parte Saliente

de la Mesada para

Contar con los

Despejes de la

Superficie de Cocción

Panel

Final

Panel

de Relleno

INSTRUCCIONES DE INSTALACIÓN

brindando profundidad adicional a la mesada y al espacio

interno de los gabinetes.

• Cuando las distancias entre la ventilación y las paredes

laterales internas de los gabinetes sean superiores a 5

½” y/o la pared trasera del gabinete interno sea superior

a 4 ½”, se deberán construir paredes falsas dentro del

gabinete para asegurar la ventilación con los soportes

de estabilización (consulte los Recortes y Despejes en

Preparación de la Instalación).

PREPARACIÓN DE LA MESADA

Apoye y corte el recorte de la superficie de cocción lo

suficiente HACIA DELANTE de modo que la caída se ajuste

detrás de éste.

1. Configure la superficie de

cocción en su posición y deslice

la misma tan hacia delante

como sea posible. Centre

y cuadre la misma con los

extremos o la mesada.

2. Coloque la plantilla de plástico

contra la brida trasera de la

superficie de cocción y centre

la misma. Realice un trazado

alrededor de la plantilla para

marcar la abertura descendente.

49-2000733 Rev. 1 13

3. Retire la superficie de cocción de la mesada.

4. Corte la abertura descendente. Tenga cuidado de no

astillar los extremos de la mesada.

Page 34

Preparación para la instalación

PREPARACIÓN DEL CONDUCTO

Determine el mejor recorrido para el conducto; el mismo

puede ser conducido de diferentes formas dependiendo del

esquema de la cocina.

IMPORTANTE: La salida de la descarga de aire

descendente para esta unidad es rectangular, y con una

medida de 3 ¼” x 10”. Planifique el recorrido de forma

consecuente.

Serie de mesadas con distribución típica de tuberías.

A fin de maximizar el rendimiento de la ventilación del

sistema de ventilación:

1. Minimice la longitud del conducto y el número de

transiciones y codos.

2. Mantenga un tamaño de conducto constante.

3. Selle todas las juntas con cinta para conductos a fin de

evitar pérdidas.

4. No utilice conductos flexibles de ningún tipo.

Descarga

Derecha

Descarga

Izquierda

Descarga Descendente (como se

envía)

Arreglo opcional del conducto bajo una losa de

concreto. Se deberá usar un conducto de PVC si

INSTRUCCIONES DE INSTALACIÓN

se instalará bajo una losa de concreto.

NOTA: Tubería de cloaca de PVC tipo

PSM 12454-B Norma 40 ASTM D1785.

Codo Metálico de

6” (15 cm) de

Diám. y 90º

Tapa de Pared

Conducto Metálico

de 6” (15 cm) de Diám.

Mín. de

12″(30 cm)

Acople de

PVC de

6″(15 cm)

de Diám.

Codo para Tubería

de Cloaca de

6” (15 cm) de Diám.

Embale de forma bien ajustada

con grava o arena completamente

alrededor de la tubería.

Máx. de

16″(40.6 cm)

Máx. de 30′-0″(9.14 m)

Transición Rectangular

de 3 ¼” x 10” a Circular de 6”

Losa de

Concreto

Tubería de

Cloaca

de PVC

de6″(15 cm)

de Diám.

Codo para Tubería de

Cloaca de 6″(15 cm) de Diám.

Instale la tubería de modo que el trozo de conducto más

cercano a la unidad de ventilación de aire descendente

encaje DENTRO DE la siguiente pieza del conducto.

Asegure las uniones con tornillos autorroscantes y coloque

cinta para conductos alrededor de las uniones, a fin de sellar

la salida de aire.

Conducto

Metálico de

6” (15 cm)

de Diám.

Acople de

6″(15 cm)

Tubería

de Cloaca

de PVC

de 6″(15 cm)

de Diám.

Pared interna hacia arriba hasta

el techo o la parte saliente

Península o una

PVC de

de Diám.

Entre vigas del piso A través del espacio de las

Flujo

de Aire

Pared externa

del gabinete

Pared interna

del gabinete

Directamente hacia el exterior

Península

isla

patas del gabinete

Cinta para Conducto

sobre la Unión y el Tornillo

Tornillo

14 49-2000733 Rev. 1

Page 35

Instrucciones de instalación

INSTRUCCIONES DE INSTALACIÓN

1

MONTA LA UNIDAD

Soporte de Nivelación –

Brida Mirando Hacia Afuera

Tornillos de Montaje

Tornillo de

Nivelación

Tornillos

de Madera

Tornillo de

Nivelación

Soporte de Nivelación

– Brida Mirando Hacia

Configure la caída en la abertura. Extienda los

A

soportes de nivelación hasta el piso del gabinete de

modo que la caída se apoye de forma recta. (NOTA:

Los soportes de nivelación se podrán retirar y

volver a adherir en otras posiciones. Es posible que

la brida inferior mire hacia adentro en instalaciones

de gabinetes ajustadas).

Asegure la caída hasta la mesada del siguiente

B

modo: sostenga la caída contra la parte trasera del

recorte de la mesada y ajuste los 2 tornillos de

montaje (uno en cada extremo de la unidad) sobre la

parte inferior de la mesada. Use una cuña entre el

tornillo y la parte inferior en mesadas de granito.

Adentro

Soporte

1

MONTA LA UNIDAD (Cont.)

Soportes de nivelación de tornillos en la parte inferior

C

del gabinete usando los cuatro tornillos de madera

(provistos con la unidad) a cada lado.

Ajuste los tornillos de nivelación a través de las

D

ranuras del soporte de nivelación a la unidad sobre

cada lado.

Coloque la superficie de cocción en el espacio libre

E

de la mesada. Deberá haber una brecha mínima de

1/8” entre el frente del marco de ventilación y la parte

trasera de la superficie de cocción.

Conecte el conducto. Use una tapa de techo o de

F

pared (con regulador) diseñada para uso con

campanas de cocina y sistemas de ventilación.

2

CONECTE LA CORRIENTE

Enchufe el cable de corriente en un receptáculo

correctamente conectado a tierra.

3

INSTALE LOS FILTROS,

CONTROLE EL FUNCIONAMIENTO

• Presione el botón de la tapa superior para elevar la

ventilación.

• Levante la ventilación hacia arriba y empuje hacia delante.

• Deslice el filtro sobre los tensores y cierre la ventilación.

• Gire la perilla sobre el lado derecho de la salida de

aire para activar el ventilador y ajuste la velocidad.

• A fin de bajar la ventilación, presione el botón de la

tapa superior.

NOTA: No es necesario apagar el ventilador antes de

bajar el nivel de ventilación. El ventilador se apagará de

forma automática cuando la ventilación se baje. Cuando

el ventilador no es apagado antes de bajar el nivel

de ventilación, el mismo irá de forma automática a la

velocidad configurada previamente cuando la ventilación

se incremente hasta el máximo.

Cuña

Mesada

Tornillo de Montaje

Los extremos de la plantilla se podrán romper o ser

cortados y usados como cuñas, de ser necesario.

Rompa/ Corte los Extremos

49-2000733 Rev. 1 15

Page 36

Consejos para la Solución de Problemas... Antes de solicitar el servicio técnico

Ahorre tiempo y dinero! Primero revise los cuadros que aparecen en las siguientes páginas y es posible que no necesite solicitar

reparaciones.

Problema Causa Posible Qué hacer

El ventilador no

funciona

La ventilación no

funciona

El ventilador no está extendido por completo. Presione el botón de la tapa superior.

La ventilación no está enchufada en un

tomacorriente.

Presione el botón de la tapa superior. Mantenga presionado el botón durante un par de

El interruptor de circuitos puede haber

saltado.

Se requiere suficiente reposición (reemplazo)

de aire para que los artefactos con salida

de aire funcionen de acuerdo con sus

calificaciones energéticas.

Enchufe la ventilación en un tomacorriente de 120V.