Page 1

Monitor UV-1

59-7797-01

Edition AG

User Manual

Page 2

Important user information

Reading this entire manual is

recommended for full

understanding and use of

this product.

●

The exclamation mark within an equilateral

triangle is intended to alert the user to the

presence of important operating and

maintenance instructions in the literature

accompanying the instrument.

Should You have any comments on this manual,

we will be pleased to receive them at:

GE Healthcare Bio-Sciences AB

S-75182 Uppsala

Sweden

GE Healthcare Bio-Sciences AB reserves the right to

changes in the specifications without prior

make

notice.

Warranty and Liability

GE Healthcare Bio-Sciences AB guarantees that the

product delivered has been thoroughly tested to

ensure that it meets its published specifications.

The warranty included in the conditions of

delivery is valid only if the product has been

installed and used according to the instructions

supplied by GE Healthcare Bio-Sciences AB.

GE Healthcare Bio-Sciences AB shall in no event be liable

for incidental or consequential damages,

including without limitation, lost profits, loss of

income, loss of business opportunities, loss of

use and other related exposures, however

caused, arising from the faulty and incorrect use

of the product.

Trade marks

FPLC

GE Healthcare Bio-Sciences AB.

In view of the risk of trade mark

degeneration, it is respectfully suggested that

authours wishing to use this designation refer to

its trade mark status at least once in each article.

®

is the exclusive trade mark of

Copyright© 1995 GE Healthcare

Bio-Sciences AB

All rights reserved. No part of this publication

may be reproduced, stored in a retrieval system

or transmitted in any form by any means,

without permission in written form from the

company.

Page 3

Contents

1. Introduction........................................................................................4

2. General Description..........................................................................5

2.1Basic principle.............................................................................5

2.2Optical unit.................................................................................7

2.3Control unit.................................................................................9

3. Installation........................................................................................11

3.1Site requirements......................................................................11

3.2Unpacking.................................................................................11

3.3Electrical connections..............................................................11

3.4Installation of the filter............................................................12

3.5Installation of the flow cell.....................................................13

3.6Connecting the optical unit....................................................14

3.7Connecting a recorder.............................................................14

4. Operation..........................................................................................15

4.1Choice of wavelength..............................................................15

4.2Choice of AU or transmission (%T).......................................15

4.3Conversion table T% to AU and OD.....................................16

4.4Start-up......................................................................................16

4.5Stabilization time......................................................................16

4.6Basic operating procedure - AU.............................................17

4.7Basic operating procedure - Transmission (%T)..................17

4.8Shut down.................................................................................17

5. Maintenance.....................................................................................18

5.1General precautions.................................................................18

5.2Cleaning the flow cell..............................................................18

5.3Changing the flow cell............................................................19

5.4Interference filters....................................................................20

5.5Other optical surfaces..............................................................20

5.6Instrument housing.................................................................20

5.7Lamp and optical system test.................................................20

5.8Changing the mercury lamp...................................................21

5.9Mercury lamp - maximum light adjustment........................22

6. Trouble-shooting..............................................................................23

7. Technical Specifications..................................................................24

8. Accessories and Spare Parts...........................................................25

3

Page 4

1. Introduction

1. Introduction

The UV-1 is a fixed wavelength UV monitor, consisting of a control

unit and an optical unit that can be positioned up to 10 meters apart.

A mercury lamp is the stable light source, furthermore a built-in

reference cell eliminates baseline drift. The output signal can be recorded in either AU or %T. Sensitivity range between 0.01 and 2 AUFS,

or (0-100%T).

The UV-1 offers a range of three detection wavelengths:

254, 280 and 405 nm. In addition, five flow cells are available for

different applications in Standard Chromatography, FPLC and

Industrial applications.

4

Page 5

2. General Description

2. General Description

2.1 Basic principle

GE Healthcare LKB Monitor UV-1 consists of an optical unit

containing the flow cell, lamp, filter assemblies and preamplifiers, and a

control unit containing the signal processing circuits. The two units are

connected via a multi-core cable hardwired from the control unit to

the optical unit. Connection to the recorder and the mains supply is

made via the control unit.

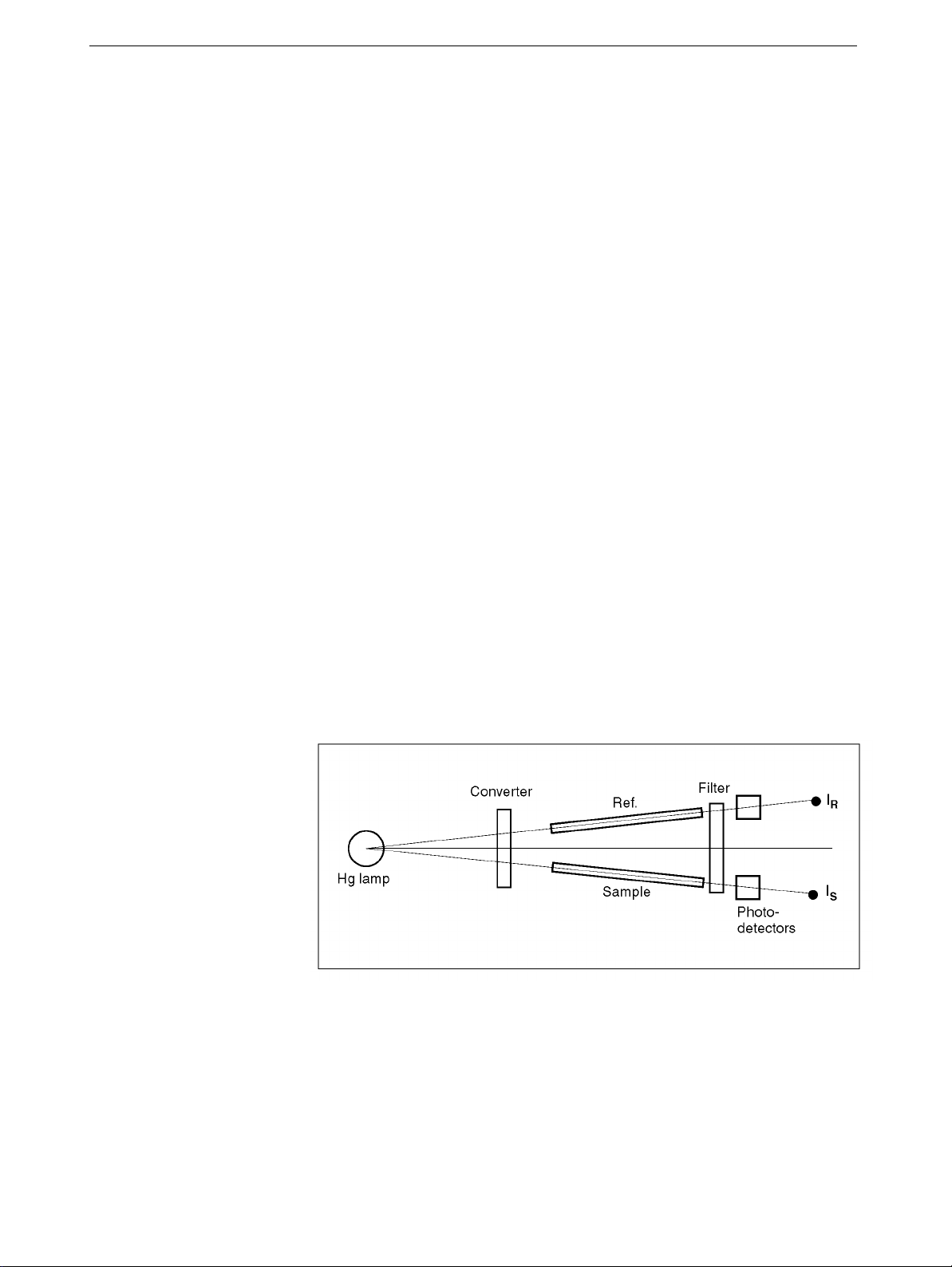

The single path Monitor UV-1 is a dual beam instrument with a

sample cell and a reference cell. Optical path lengths are 10 mm,

3 mm, or 2 mm depending upon the flow cell chosen.

Note:

The sample cell and reference cell are angled to receive light from the

same point in the lamp (Fig. 1) thus assuring a stable base-line by

negating the effects of variations in lamp intensity.

The lamp is powered by a stabilized DC to AC converter operating at

20 kHz to maximize its efficiency. Lamp output is independent of

variations in the line voltage.

Light from the lamp passes through an aperture (254 nm, 405 nm) or

a fluorescence converter (280 nm) and through the reference cell and

sample cell. The light output from each cell passes through an

interference filter and falls onto a solid state photo-detector whose

output is a linear function of the light intensity (Fig. 1 and Fig. 2).

Flow cell S-2 has only the sample cell.

Fig. 1. Optical path.

5

Page 6

2. General Description

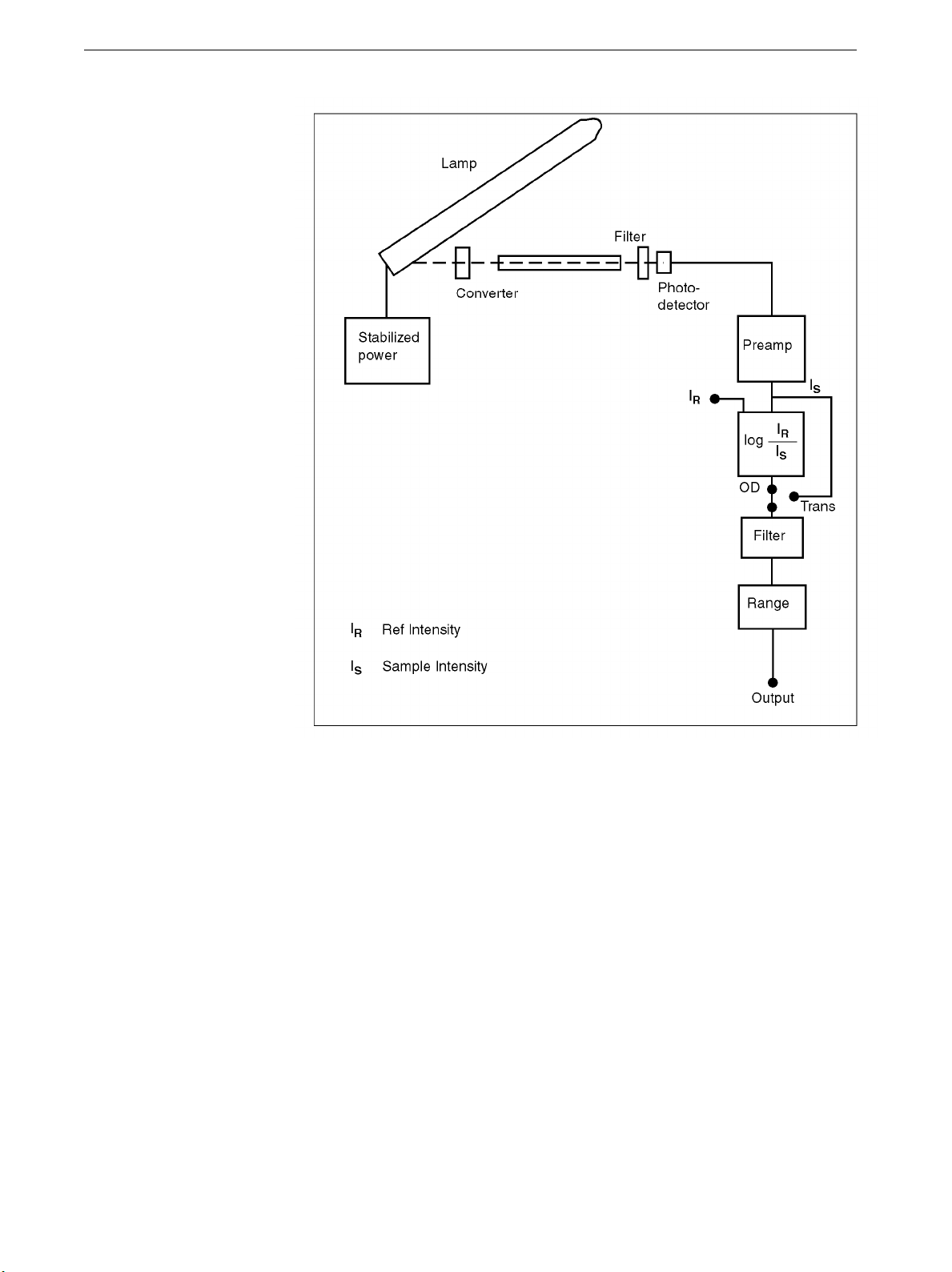

Fig. 2 Block diagram

The photocurrent from each detector is amplified in a pre-amplifier

before passing to the signal processing circuitry in the control unit.

If transmission is to be monitored, the signal passes directly to the

low pass filter. If AU is to be monitored, the reference cell light

intensity (IR) is compared with the sample cell intensity (IS) to form

log (IR/IS) in a logarithmic circuit before passing to the low-pass filter.

The signal finally passes to the range selector before being presented

to the output terminal.

6

Page 7

2. General Description

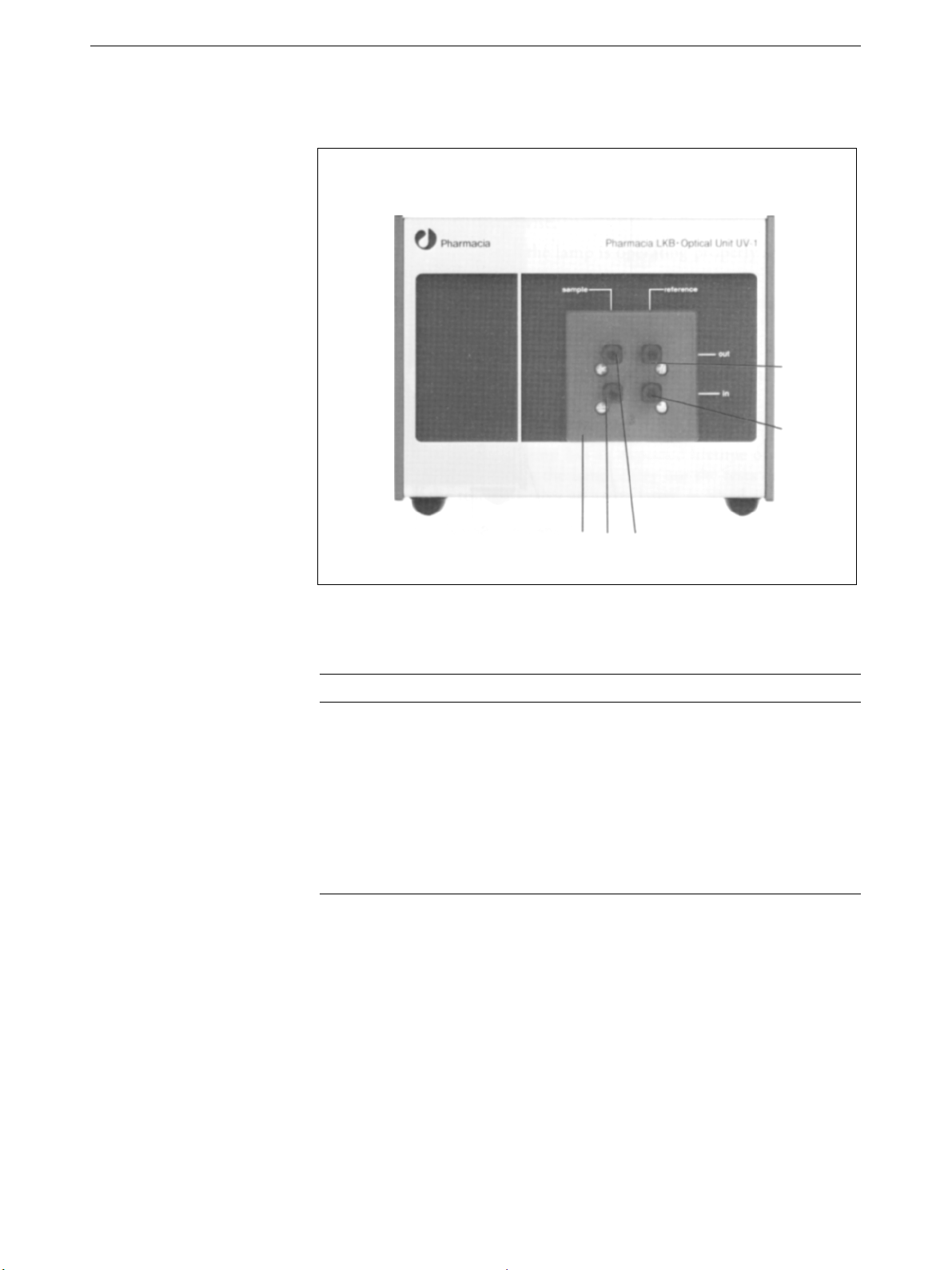

2.2 Optical unit

Front panel controls

12

5

4

3

Fig. 3.

Optical unit. Front panel.

No. Item Description

1 Cell holder The complete cell holder is removed by turning the

locking (Fig. 4:6) knob on the rear panel

2 Sample inlet Inlet for sample flow

3 Sample outlet Outlet for sample flow

4 Reference inlet Inlet for flowing reference liquid. The reference cell

may be operated dry, with static reference liquid

5 Reference outlet Outlet for flowing reference liquid

7

Page 8

2. General Description

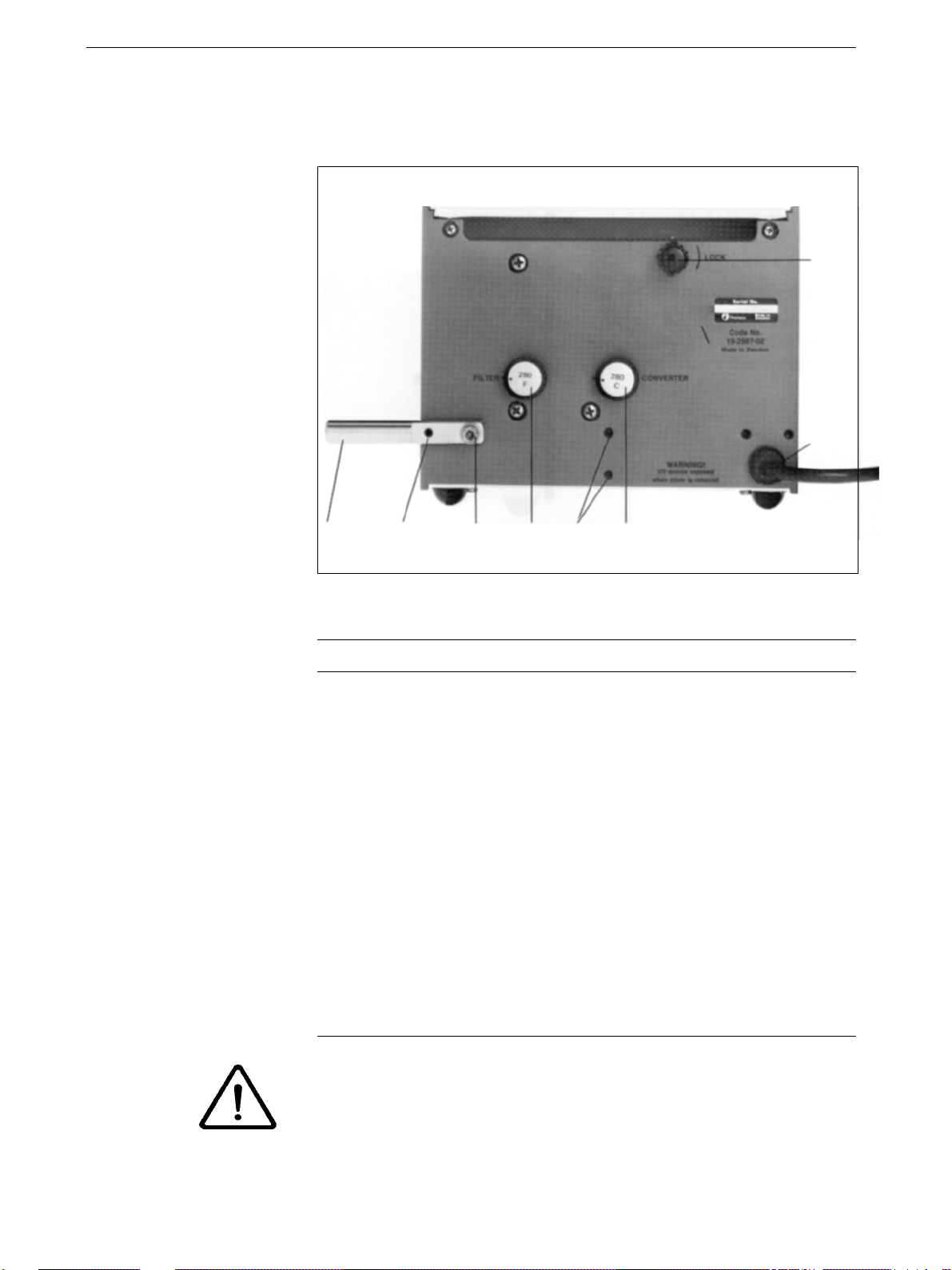

Rear panel controls

6

11

9 Guide pin Screw 7 10 8

Fig. 4.

No. Item Description

6 Locking knob The cell holder is in locked position when the locking

7 Filter inlet Filters, converters or apertures are inserted in the

8 Converter or the arrowhead on the end of the filter or converter

9 Support rod Enables the optical unit to be mounted on laboratory

10 Support rod Alternative position for support rod

11 Multi-core cable Connects the optical unit to the control unit via

Optical unit. Rear panel.

knob is turned fully in the direction of the arrow

positions indicated. When inserting them, align

Aperturewith the arrowhead next to the appropriate

opening. Filters, converters and apertures must be

pressed fully

scaffolding. The rod may be secured in either of two

positions by a screw and a guide-pin

an 11-pin plug with a snap-lock. For disconnection

squeeze the ribbed sides of the plug firmly and pull

Warning: The optical unit contains a UV-source which is exposed

if the cover is removed.

8

Page 9

2. General Description

2.3 Control unit

Front panel controls

12

13

14

15

16

Fig. 5.

Control unit. Front panel.

No. Item Description

12 Absorbance range Selector for the desired absorbance range

selector 0.01, 0.02, 0.05, 0.1, 0.2, 0.5, 1 or 2 AU full scale

deflection. In the position SHORT, the signal output

terminals are disconnected from the rest of the control

circuitry and short-circuited. This position is useful when

setting zero on the recorder.

13 Mode switch The AU / % T switch, enables the UV-1 to be used

AU or %T to monitor the absorbance or transmission of a flowing

liquid. When the UV-1 is used in the AU mode, each of

the other position corresponds to the optical

absorbance which will give a full scale deflection (fsd)

on a recorder with a sensitivity of 10 mV. Absorbances

are measured relative to air or a liquid which is present

in the reference cell

When the recorder is used together with UV-1 in the

% T mode, the absorbance range selector switch is

used, together with baseline adjust, to adjust the

recorder response corresponding to 100 % T

14 Baseline adjust Ten-turn potentiometer to adjust the recorder baseline

15 Indicator lamp Indicates power is on

16 Mains switch The UV-1 is turned on by switching this knob in the ON

(upper) position. The indicator lamp will light to show

that the mains voltage is on

9

Page 10

2. General Description

Rear panel controls

Fig. 6. Control unit. Rear panel.

No. Item

17

18

19

20

21

22

Note:

Description

Mains voltage selector

Fuse holder

Signal outputs

Mains inlet

Optical unit inlet

Ground terminal

Do not attempt to ground the control unit via the recorder

ground as the UV-1 is grounded via the mains ground.

Selects mains voltage 110, 130, 220 and 240 V

Mains fuses:

The output signal is a 10 mV DC signal. The

terminals are connected to a potentiometric

recorder via shielded cables supplied. The

UV-1 is normally earthed via the mains ground

Inlet for the mains cable

Inlet for the optical unit

To connect the shield of an output signal cable

1 x 250 mA for 110-130 V 60 Hz

1 x 125 mA for 220-240 V 50 Hz

10

Page 11

3. Installation

3. Installation

3.1 Site

requirements

3.2 Unpacking

UV-1 should be installed on a stable, flat surface away from all sources of vibration. The atmosphere should be free of both excess humi-

dity and corrosive or contaminated vapours which may form deposits

on the component in the optical path.

UV-1 can be installed either in a coldroom or at ambient temperature

in the laboratory. To minimise drift, the temperature should be kept

constant. UV-1 optical unit should be positioned away from all sources of draught, heat and direct sunlight. UV-1 should be placed away

from any compressor and the fan stream from coldboxes and col-

drooms.

The UV-1 may be operated ambient temperatures in the range

0-40 °C (20-30 °C at full specifications).

One mains power point is required to operate UV-1. Separate power

points are required for all ancillary equipment, such as recorder.

The power consumption of the monitor is max 20 VA.

Note:

It is important that the interference filters and flow cells

should not be handled during unpacking. For protection of

these items they should remain in their packing materials

until required for use.

3.3 Electrical

connections

Carefully unpack the UV-1. Check the contents against the packing

list supplied. Inspect for any damage that may have occurred during

transit. Report any damage immediately to the local

representative and to the transport company concerned. Save

the packing material if future transport can be foreseen.

The instrument is supplied with mains cables and fuses for both

100-130 V and 220-240 V operation.

1.

Ensure that the mains switch (Fig. 5:16) on the front panel of

the control unit is in the OFF position.

2.

Select the correct value of fuse from the fuse kits supplied.

For 110-130 V operation, use the 250 mA fuse supplied.

For 220-240 V operation, use the 125 mA fuse supplied.

Insert the fuse into the fuse cap, and then fit the fuse cap into the

fuse holder on the rear panel (Fig. 6:18) of the instrument.

3.

Check that the mains voltage selector (Fig. 6:17) on the rear

panel of the control unit is set to the mains voltage in the

laboratory. If necessary, turn with a thick bladed screwdriver the

mains voltage setting until appropriate setting is indicated in the

small window.

Note:

Use the 220 V setting for a 230 V mains outlet.

GE Healthcare

11

Page 12

3. Installation

3.4 Installation

of the filter

Mains voltage Voltage selector setting

110 V

130 V

220-230 V

240 V

4.

110

130

125 mA

220

125 mA

240

Select the mains cable corresponding to your mains outlet.

Fuse

250 mA

250 mA

Discard unwanted mains cable immediately. Connect the

instrument to a grounded mains outlet.

Note:

Note:

Do NOT switch on.

Special care must be taken when handling interference

filters. DO NOT touch the filter surface. The filters should

not allowed to come in contact with any liquid or exposed

to temperatures above 60 °C. For directions on cleaning

interference filters, see Section 5.4

1.

Select the appropriate filter for the wavelength to be used.

Insert the filter and converter or aperture in the optical unit

2.

(Fig. 4:7, Fig. 4:8). Each filter is marked with its wavelength and

the letter F. The 280 nm converter is marked 280 C. The

aperture for use with the 254 nm or 405 nm filters is marked 0.

The filter and converter or aperture must be pushed fully home.

Wavelength Filter

254 F

254 nm

280 nm 280 F 280 C

405 nm

405 F

Converter or Aperture

0

0

12

Page 13

3. Installation

3.5 Installation of

the flow cell

Product Material of Path Total dead IlluminatedPressure Application

Code No. wetted parts length volume volume limit area

S-2 Fluoro-plastic, 2 mm 80 µl 2 µl 0.3 MPa Standard

19-4840-02 optical quartz (3 bar) Chromatography

HR-10 Fluoro-plastic, 10 mm 24 µl 8.7 µl 1.0 Mpa FPLC, Standard

19-6254-02 optical quartz,titanium (10 bar) Chromatography

3 mm Fluoro-plastic, 3 mm 50 µl 3 µl 1.0 MPa Preparative FPLC,

19-2503-02 optical quartz (10 bar) Standard Chromatography

10 mm Fluoro-plastic, 10 mm 250 µl 8.7 µl 1.0 MPa Standard

19-2504-02 optical quartz (10 bar) Chromatography

5 mm Silicon rubber, 5 mm 0.2 MPa* Industrial scale

Industrial polypropylene, (2 bar)

19-4510-02 optical quartz

* Flow rate 300 I/h at 0.1 MPa

Monitor UV-1 accepts flow cells for Standard Chromatography, FPLC

and industrial applications.

All flow cell are mounted in the holders, ready to be installed directly

into the cell housing. Release the locking knob (Fig. 4:6) by turning it

against the direction of the arrow and insert the flow cell in its holder

into the optical unit. Lock it in position by turning the locking knob

fully in the direction of the arrow.

For more information please refer to the instruction sheet supplied

with the respectively flow cell.

Fig. 7.

S-2 flow cell

Fig. 8.

HR-10 flow cell

Fig. 9.

3 mm flow cell

Fig. 10.

10 mm flow cell

Fig. 11.

Industrial flow cell

13

Page 14

3. Installation

3.6

Connecting

the optical unit

3.7

Connecting a

recorder

The optical unit may be placed on the bench or mounted on

laboratory scaffolding. For scaffolding mounting, mount the support

rod on the optical unit. The rod may be mounted horizontally or

vertically (Fig. 4:9). Tighten the the Allen screw firmly. The optical

unit should be placed as close as possible to the column outlet.

Connect the cable from the optical unit to the 1 l-pin socket on the

back of the control unit (Fig. 6:21). The plug has a snap lock.

To remove it, squeeze the ribbed sides firmly and pull.

There is one 10 mV signal output port on the rear panel of the

control unit. It is for use with GE Healthcare recorders or similar

instruments. Connect the output terminals to the input of the

recorder, using a signal cable (Fig. 12). Connect the shield of the

signal cable to the grounded terminal port on the rear panel of the

control unit. Choose the 10 mV input range on the recorder for full

scale response.

14

Fig. 12. Connections between the control unit and a dual channel recorder

Recorder REC 102.

Page 15

4. Operation

4. Operation

4.1 Choice of

wavelength

4.2 Choice of AU or

transmission

(%T)

The UV-1 can be operated at either 254 nm, 280 nm or 405 nm.

The choice of wavelength will depend on the spectral properties of

both the eluent and the substances to be detected. Proteins and polypep-tides containing aromatic amino acids are usually best detected at

280 and 254 nm. Nucleic acids and poly-nucleotides are usually best

detected at 254 nm and ferroproteins i.e. hemoglobins, cytochrome

and porphyrin derivatives at 405 nm.

The UV-1 may be set to monitor either the absorbance or %

transmittance of a flowing liquid. Absorbance measurements give

recorder responses which are proportional to the solute concentration

when Lambert Beers Law is obeyed. The AU setting is thus most

appropriate for general use, particularly when quantitative results are

required. However, even with the 3 mm path length cell, there is

always a slight risk that the peak will go off scale. Under these

conditions, peak maxima can still be located by monitoring

transmission.

The relationship between AU and Optical density (OD) is

AU = L x OD

where L is the optical path length in cm.

The relationship between OD and transmission expressed as %T is

T%=

anti log

where L is the optical path length in cm.

100

10

(L.OD)

15

Page 16

4. Operation

4.3

Conversion

table T% to AU

and OD

T%

1

5

10

15

20

25

30

32

35

40

45

50

55

60

63

65

70

75

79

80

85

89

90

95

95.5

97.7

AU OD

(3 mm cell)

2.000

1.301

1.000

0.824

0.699

0.602

0.523

0.500

0.456

0.398

0.347

0.301

0.260

0.222

0.200

0.186

0.155

0.125

0.100

0.097

0.070

0.050

0.046

0.022

0.020

0.010

6.667

4.337

3.333

2.747

2.330

2.007

1.743

1.667

1.520

1.327

1.157

1.003

0.867

0.740

0.667

0.620

0.517

0.417

0.333

0.323

0.233

0.167

0.153

0.073

0.067

0.033

OD

(10 mm cell)

2.000

1.301

1.000

0.824

0.699

0.602

0.523

0.500

0.456

0.398

0.347

0.301

0.260

0.222

0.200

0.186

0.155

0.125

0.100

0.097

0.070

0.050

0.046

0.022

0.020

0.010

4.4 Start-up

4.5

Stabilization

time

Note:

Always ensure that all liquid passing through the flow cell

are degassed to prevent any air bubble formation in the cell.

Liquids must be filtered to remove any particulate material

and prevent any blockage.

1.

Check that the monitor is correctly installed and that the sample

cell is filled with the appropriate eluent. The reference cell may

be left closed with air in the cell unless the UV-1 is used with

eluents showing appreciable UV-absorption. In this case the

reference cell should be filled with eluent.

2.

If the instrument has been switched off, turn on the mains switch

(Fig. 5:16) and refer to Section 4.5, to restabilize the instrument.

Check that the appropriate filter and converter or aperture are in

3.

place and fully inserted.

At normal laboratory temperatures the UV-1 requires 2 hours to

stabilize sufficiently. When the UV- 1 is in constant use, it is

recommended that it remains switched on. UV- 1 can be switched off

when not in use for periods of one week or more.

For coldroom operation below 10 °C , install UV-1 in the coldroom at

the desired running temperature at least 12 hours before the start of a

run. This is necessary to allow the instrument housing to equilibrate

to the temperature of the coldroom. Once equilibration has taken

place, the stabilisation times given for normal temperatures are valid.

16

Page 17

4.6 Basic

operating

procedure -

AU

4.7 Basic

operating

procedure Transmission

(%T)

1.

Switch AU/ %T to AU (Fig. 5:13).

2.

Set the range selector (Fig. 5:12) to SHORT and zero the

recorder with the recorder zero control.

3.

Set the range selector to 2 and adjust the recorder baseline with

the baseline adjust (Fig. 5:14).

4.

Set the range selector to the appropriate range and readjust the

recorder baseline with the baseline adjust (Fig. 5:14). Only

minor adjustment should be necessary.

1.

Switch AU to %T (Fig. 5:13).

2.

Set the range selector (Fig. 5:12) to SHORT and zero the

recorder.

Turn the baseline adjust (Fig. 5:14) fully clockwise.

3.

4.

Set the range selector so that the recorder gives a deflection just

greater than 100%.

4. Operation

4.8 Shut down

Adjust baseline to bring the pen back to 100%.

5.

6.

Exchange the converter for the shutter and zero the recorder

with the recorder zero. This response will correspond to 0%

transmission.

7.

Replace the shutter with the converter. This response will

correspond to 100% transmission. Slight adjustment of baseline

may be required to obtain the response obtained in Step 5.

1.

On completion of the chromatographic run, flush the flow cell

either with pure solvent or the buffer used in the

chromatographic run. To prevent the deposition of salts from

aqueous buffers, flush the cell with distilled water after use, if

necessary after disconnecting the column.

Note:

2.

Never allow aqueous buffers to dry out in the cell. Either

continue to flush through with buffer or leave the cell filled

with distilled water.

Leave the UV-1 switched on. The monitor should only be

switched off if it is not going to be used again for more than one

week.

17

Page 18

5. Maintenance

5.1 General

precautions

5.2 Cleaning the

flow cell

5.

To ensure trouble free running, users are advised to observe the following precautions:

For trouble free operation of the UV-1, it is essential that the flow cell

is free of any particulate matter and contaminant films. Ensure that

the flow cell is never allowed to dry out without having been thoroughly rinsed. Liquids containing dissolved salts, proteins or other

solutes will dry out, leaving contaminants on the inner optical surface

of the flow cell.

Maintenance

All liquids passing through the flow cell should be free of

suspended particles.

All liquids should be degassed to prevent air bubble formation in

the flow cell.

Never allow buffer solutions to dry out in the cell. Always rinse

the flow cell thoroughly with distilled water after use.

Handle interference filters with care. Never touch the optical

surfaces or expose them to temperatures above 60 °C.

The cells may be inspected for particles by removing the cell holder

and examining the light paths with a magnifying glass.

If the cell contains trapped particles proceed as follows:

1.

Remove the cell holder from the optical unit.

2. Connect a syringe to the outlet tubing and squirt a clean solution

of ethanol in distilled water (50% v/v) through the cell in small

aliquots. Examine the cell from time to time to see when the

particles have been washed out.

Rinse the cell with particle-free distilled water (about 100 ml)

3.

and replace it in the optical unit.

4. Reconnect the cell holder to the system to be monitored.

Most non-particulate contaminants e.g. denaturated proteins, salts

etc. can be removed by flushing the cell with the appropriate solvent.

Finally, rinse the cell thoroughly with distilled water or clean solvent.

Oily deposits, which increase the tendency to trap bubbles, can be

removed by rinsing the flow cell first with a non-polar solvent

(e.g. hexane), then with a polar solvent (e.g. isopropanol) and finally

with distilled water or with detergent see procedure described on next

page.

18

Page 19

Cleaning with detergent:

Remove the cell holder from the optical unit.

1.

Pump undiluted cleaning detergent through the cell for at least

2.

2 hours.

Rinse the cell with

3.

a) distilled water (100 ml)

b) ethanol/distilled water (50% v/v, 100 ml)

c) distilled water (100 ml)

Replace the cell in the optical unit and reconnect the system to

4.

be monitored.

Cleaning with chromic acid:

Prepare fresh chromic acid by adding concentrated sulphuric

1.

acid (100 ml) to a saturated solution of sodium dichromate

(3.5 ml).

5. Maintenance

●

5.3 Changing the

flow cell

Warning:

Chromic acid is extremly corrosive. Treat spills

immediately with a large excess of water.

Remove the cell holder from the optical unit.

2.

Connect a glass syringe to the outlet side of the cell and carefully

3.

draw chromic acid into the cell. Do not draw acid into the

syringe.

Allow the acid to remain in the cell for 10-20 minutes. Longer

4.

exposures (several hours) will not harm the cell.

Eject the cleaning solution carefully without splashing and rinse

5.

the cell with

a) distilled water (100 ml)

b) ethanol/distilled water (50% v/v, 100 ml)

c) distilled water (100 ml)

Replace the cell in the optical unit and reconnect the system to

6.

be monitored.

To change the flow cell, follow the instructions below.

1.

Switch the UV-1 off at the control unit.

2.

Disconnect the cell from the system being monitored and empty

it of liquid.

Remove the cell holder from the optical unit.

3.

4. Remove the black cover by undoing the screw on top of the cell

holder. The tubing connections to the cell are now accessible.

Note their positions (Fig. 13).

Loosen the connections using the tool provided. Do not undo.

5.

The cell may now be slipped out.

6.

Before inserting the new cell make sure the tubing ends do not

7.

protrude into the cell compartment.

19

Page 20

5. Maintenance

8. Insert the new cell, being careful not to touch either of the optical

surfaces. See that the inlet and outlet ports are correctly aligned.

9. Retighten the screw washers with the tool provided. Do not use

excessive force.

10. Check for leakage.

11. Replace the black cover.

5.4 Interference

filters

Reference out

Reference in

Fig. 13.

For optimum performance, it is essential that the interference filters

are clean and free of any particulate material. Do not touch the interference filters. Should the filter become contaminated with dust,finger

prints or oil, proceed as follows:

- Carefully take out the filter without touching or scratching the

surface.

- Use lens cleaning tissue dipped in ethanol to gently clean both

sides of the filter surface.

- Place the clean filter back to the UV-1 or its box.

- Interference filters should never be exposed to temperatures

above 60 °C

Flow cell interior showing tubing connections.

Sample out

Sample in

5.5 Other optical

surfaces

5.6 Instrument

housing

5.7 Lamp and

optical system

test

20

Clean all other optical surfaces by wiping the surface with clean, lintfree cloth, moistened with carbon tetrachloride, ethanol, or another

suitable pure solvent.

Wipe the instrument regularly with a damp cloth. Let the instrument

dry completely before use.

Before performing this test see that the filter is clean, that the cell is

clean and free of bubbles or particles and that the cell holder is

correctly inserted and locked in position.

1. Insert the aperture and filter for 254 nm operation or the

converter and filter for 280 nm operation.

2. Set AU / %T to % T.

3. Set the recorder to the 100 mV range.

Page 21

5. Maintenance

4. Set the range selector to SHORT and zero the recorder.

5. Set the range selector as follows:

254 nm, range 1

280 nm, range 0.2

6. Turn Zero fully clockwise.

Response 8 mV or greater: the lamp is operating properly and the

optical system is clean.

Response 0 mV or very close to 0 mV: Contact a GE Healthcare

representative.

Response less than 8 mV but not very close to zero: check that the

cell and filter is clean. If fault persists, the filter or lamp may require

changing (see Section 5.7).

5.8 Changing the

mercury lamp

The low pressure mercury lamp has an expected lifetime of approx.

8000 hours. Before changing the lamp, carry out the tests described in

Section 5.6. If the tests indicates an aging lamp, proceed as follows.

l. Disconnect the control unit from the mains supply and

disconnect the optical unit from the control unit.

Warning: The control unit must be disconnected from the mains

and from the optical unit. If the UV-Iamp is broken

make sure that all mercury is removed.

2. Remove the cell holder.

3. Remove the two screws and locking washers which secure the

case of the optical unit to the bottom of the chassis.

4. Loosen the two Philips screws until the top of the case can be

lifted clear of the catches.

5. Pull the case forward, and remove it (Fig. 14).

Lamp Screw

Screw

Fig. 14.

Stop ring

Optical unit interior with lamp driver circuit board removed

21

Page 22

5. Maintenance

Mercury lamp

5.9

- maximum

light

adjustment

6.

Use an Allen key (2.5 mm) to unscrew the upper of the two

screws securing the lamp holder and the lamp. Note carefully the

positions of the insulation sleeve and washer.

7. Disconnect the lamp from the PC-board.

8. Bend the upper part of the lamp holder slightly (2-3 mm)

upwards and withdraw the mercury lamp from it by gently

pulling the metal socket.

9. Insert the new mercury lamp and connect it to the PC-board.

10. Remount the upper lamp holder screw, ensuring that the

insulations are correctly mounted, reinstall the cell holder and

perform the maximum light adjustment described in Section 5.8.

Warning:

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

During this adjustment stray light may escape from the

UV source and protective glasses must be worn.

Connect the optical unit to the control unit and plug into the

mains supply.

Switch on the instrument and allow to warm up for about

10 minutes.

Insert a filter and the corresponding converter or aperture.

Connect the control unit to a recorder with a full scale response

of 50 mV.

Set the range selector to SHORT and zero the recorder.

Set AU/ %T to % T and turn the baseline adjust fully clockwise.

Select a range giving a pen deflection of approx. 50 % and then

rotate the lamp around its longitudinal axis until maximum pen

deflection occurs.

Set the range selector to SHORT and adjust the recorder zero to

bring the pen to the centre of the chart. Mark this pen position.

Set the range selector to 2 and set AU/ % T to AU.

Adjust the baseline control to its mid-position, five full turns

from either end of its range, by means of a tool, ie. an adjustable

spanner.

22

11.

If necessary, adjust the lamp by turning it slightly to bring the

pen back to the position marked in step 8.

12.

Reassemble the optical unit.

Page 23

6. Trouble-shooting

6. Trouble-shooting

The UV-1 Monitor has been designed for trouble-free use. If good chromatographic practice is

followed, very little difficulty should be experienced. Clean optical surfaces are essential if low noise

levels are to be maintained. The following check list of the most frequent problems is meant to be a

guide in trouble-shooting. If the checks in this section are executed and the UV-1 still does not work

properly, consult your local GE Healthcare representative.

Symptom

Pilot light does not light 1. Mains cord not plugged in Check that mains cord is plugged in

Pilot light on, no recorder 1.

response

Excessive noise

Cause

2. Fuse blown

3. No voltage at mains socket Check by plugging table lamp in

Optical unit not connected

to control unit

2.

Control unit not connected

to recorder

Recorder not operating

3.

4.

Recorder zero not set correctly

5.

Recorder range incorrect

6.

Wrong filter

Filter not pushed in fully

7.

Shutter in place

8.

1.

Poor ground contact

2.

Excess noise on mains supply

3.

Recorder connections

incorrect

4.

Recorder range incorrect

Dirty cell

5.

Deposits on optical surfaces

6.

7.

Solvent with high UV absorption

Lamp not warmed up

8.

Bubbles passing through the cell

8.

Aging lamp

9.

Remedy

Replace fuse. If fuse blows again

immediately consult

Check that connecting cable is

plugged in

Check connection between output

terminals and recorder

Check recorder function

Zero recorder

Set recorder range to 10 mV

Check that the filter corresponds to

converter or aperture

Push in filter

Remove shutter and insert converter

or aperture as appropriate

Check contact to ground

Use alternative power source or

remove source of disturbance

Check connection between

output terminals and recorder

Set recorder on 10 mV range

Clean cell

Clean filter and converter

Relocate optical unit in a clean environment

Change to a more suitable solvent

2 h warm-up, in cold room 12 h

De-gas solvent. Check for leaks

Check lamp and replace if necessary

GE Healthcare representative

Excessive baseline drift 1.

Long term noise, 1. Variations in ambient temperature Relocate optical unit or protect

often regular waves in especially in cold room

recorder reponse

Variable absorbance gradient

2.

Contaminated solvent Use fresh solvent. Check that plastic tubing

3.

Large variation in ambient Relocate optical unit or remove

temperature source of temperature change

4.

Instrument warm-up Allow 2 hours warm-up

5.

Condensation forming in

empty reference

2. Flow rate variations

3. Poor ground contact Check contact to ground

4. Bubbles passing cell De-gas solvent. Check for leaks

5. Dirty cell

6. Deposits on optical surfaces Clean filter and converter

Compensate by use of reference cell

does not leak UV absorbing substances

Flush reference cell with dry gas or

fill it with the appropriate solvent

from draught

Check pump system and column packing

Clean cell

Relocate optical unit in a clean environment

23

Page 24

7. Technical Specifications

7.

Technical Specifications

Wavelength range

Lamp

Filters

Operating modes

Full scale ranges

Noise

Linearity

Temperature drift

Long term drift

Time constant

Recorder output

Environment

Power consumption

Power supply, voltage

frequency

Dimensions (LxWxD)

Weight

254 nm, 280 nm and 405 nm

Hg lamp: for 254, 280, and 405 nm

Life time lamp: 8000 hours

converter: 2000 hours

Interference. Stray light maximum 0,1 %

at 254 nm, maximum 0.8% at 280 nm

AU or Transmission

0.01, 0.02, 0.05, 0.1, 0.2, 0.5, 1 or 2 AUFS

4 x 10-5 AU peak to peak maximum at

254 nm (dry cell)

2 x 10-4 AU peak to peak (typical at

254 nm in flowing liquid)

5 x 10-4 AU peak to peak (typical at

280 nm flowing liquid)

At 254 nm, better than ± 3% to 2 AU

At 280 nm, better than ± 5% to 1 AU

2 x 10-4 AU/°C typical with dry cell at

254 nm

<2

x 10-3 AU/°C typical with dry cell

at 280nm

1 x 10-4 AU/h at 254 nm, constant

temperature after 2 hours warm-up

4 x 10-4 AU/h at 280 nm, constant

temperature after 2 hours warm-up

1.5 s to 90% of FSD at all ranges

0-10 mV

0 to +40 °C , 20-95 % relative humidity,

84-106 kPa (840-1060 mbar) atmospheric

pressure

20 VA

100/120/220-230/240

V-

50-60 Hz

Control unit: 180x145x75 mm

Optical unit: 180x145x75 mm

Control unit: 1.6 kg Optical unit: 1.7 kg

24

EMC standards

Safety standards

This product meets the requirement of the EMC Directive 89/336/EEC through the harmonized standards

EN 50081-2 (emission) and EN 50082-1 (immunity)

Note: This is a class A product. In a domestic environment this product may cause radio interference in which

case the user may be required to take adequate actions.

Note: The declaration of conformity is valid for the instrument when it is:

● used in laboratory locations

● used in the same state as it was delivered from GE Healthcare Bio-Sciences AB except for alteration described in the

User Manual

●

used as “stand alone” unit or connected to other CE labelled GE Healthcare products or other products as

recommended.

This product meets the requirement of the Low Voltage Directive (LVD) 73/23/EEC through the harmonized

standard EN 61010-1.

Page 25

8. Accessories and Spare Parts

8. Accessories and

Spare Parts

Please order accessories and spare parts according to the designation

and code numbers given below.

Designation

Filters

Filter kit, 254 nm

Filter kit, 280 nm

Filter kit, 405 nm

Aperture

Converter 280 nm

Flow cells

Flow cell S-2 complete

with measuring cell

Flow cell 10 mm complete

with measuring cell

Flow cell 3 mm

with measuring cell

Flow cell HR-10

with measuring cell

Flow cell large volume

with measuring cell

Measuring cell, 3 mm

Measuring cell, 10 mm

Code No.

19-2432-01

19-2433-01

19-4724-01

19-2492-01

19-2486-01

19-4840-02

19-2504-02

19-2503-02

19-6254-02

19-4510-02

19-2525-01

19-2524-01

Pieces

1

1

1

1

1

1

1

1

1

1

1

1

Accessories and Spare parts

UV lamp complete

Tubing and fittings

Tubing, PTFE, (pack of 5 m)

Shutter

Allen key

Signal input cable

Mains cable, US

Mains cable, EU

Fuse holder for 125 mA fuse

Fuse holder for 250 mA fuse

Fuse, 125 mA for 220 V

Fuse, 250 mA for 110 V

19-3807-01

19-2505-01

19-0041-01

19-2491-01

19-0379-01

19-2853-01

19-2447-01

19-2448-01

19-2925-01

19-2926-01

19-2367-01

19-2368-01

1

1

1

1

1

1

1

1

1

1

5

5

25

Page 26

Printed in Sweden by SNITS & DESIGN AB/Västra Aros Tryckeri, Nov 1996

Loading...

Loading...