Page 1

y

yrig

g

GE Power Management

L90 Line Differential Rela

UR Series Instruction Manual

L90 Revision:

Manual P/N: 1601-0081-B5 (GEK-106231B)

Cop

ht © 2001 GE Power Management

2.9X

GE Power Management

215 Anderson Avenue, Markham, Ontario

Canada L6E 1B3

Tel: (905) 294-6222 Fax: (905) 294-8512

Internet: http://www.GEindustrial.com/pm

R

E

Manufactured under an

ISO9000 Registered system.

D

G

E

R

I

S

E

T

Page 2

Page 3

g

GE Power Management

ADDENDUM

This Addendum contains information that relates to the L90 relay, version 2.9X. This addendum lists a number of

information items tha t appea r in the i nstruc tion manu al GEK-1 06231B (1 601-00 81-B5) bu t are not i ncluded i n the c urrent L90 operations.

The following functions/items are not yet available with the current version of the L90 relay:

• Signal Sources SRC 3 to SRC 6 (availability is pending for this release)

NOTE:

• The UCA2 specifications are not yet finalized. There will be changes to the object models described in Appendix

C: UCA/MMS.

GE Power Management

215 Anderson Avenue, Markham, Ontario

Canada L6E 1B3

Tel: (905) 294-6222 Fax: (905) 294-8512

Internet: http://www.GEindustrial.com/pm

Page 4

Page 5

TABLE OF CONTENTS

1. GETTING STARTED

1.1 IMPORTANT PROCEDURES

1.1.1 CAUTIONS AND WARNINGS ........................................................................... 1-1

1.1.2 INSPECTION CHE C KL IS T ......................... ... .. ................. ... ... ................. .. ........ 1-1

1.2 UR OVERVIEW

1.2.1 INTRODUCTION TO THE UR RELAY .............. .................................. ..............1-2

1.2.2 UR HARDWARE ARCHITECTURE.................................... ...............................1-3

1.2.3 UR SOFTWARE ARCHITECTURE ................... ..................................... ...........1-4

1.2.4 IMPORTANT UR CONCEPTS........................................................................... 1-4

1.3 URPC SOFTWARE

1.3.1 PC REQUIREMENTS ........................................................................................ 1-5

1.3.2 SOFTWARE INSTALLATION ............................................................................ 1-5

1.3.3 CONNECTING URPC® WITH THE L90............................................................ 1-6

1.4 UR HARDWARE

1.4.1 MOUNTING AND WIRING................................................................................. 1-8

1.4.2 COMMUNICATIONS.......................................................................................... 1-8

1.4.3 FACEPLATE DIS PL A Y ......... ................ ... ... ................. .. ................. ... ................ 1-8

1.5 USING THE RELAY

1.5.1 FACEPLATE KEYPAD.... ................. .. ................. ... ... ................. .. ................. ... .. 1-9

1.5.2 MENU NAVIGATION ......................................................................................... 1-9

1.5.3 MENU HIERARCHY ................................................................ ..........................1-9

1.5.4 RELAY ACTIVATION....................................................................................... 1-10

1.5.5 BATTERY TAB................................................................................................. 1-10

1.5.6 RELAY PASSWORDS..................................................................................... 1-10

1.5.7 FLEXLOGIC™ CUSTOMIZATION................................................................... 1-10

1.5.8 COMMISSIONING ........................................................................................... 1-10

2. PRODUCT DESCRIPTION

2.1 INTRODUCTION

2.1.1 OVERVIEW........................................................................................................ 2-1

2.1.2 FEATURES ........................................................................................................ 2-2

2.1.3 FUNCTIONALITY...............................................................................................2-3

2.1.4 ORDERING........................................................................................................ 2-4

2.2 PILOT CHANNEL

2.2.1 INTER-RELAY COMMUNICATIONS................................................................. 2-7

2.2.2 CHANNEL MONIT OR ..... ... ... ................ ... ................. ... .. ................. ... ................ 2-8

2.2.3 LOOPBACK TEST ................ .. ... ................. ... ................ ... ... ................. ... .......... 2-8

2.2.4 DIRECT TRANSFER TRIPPING ....................................................................... 2-8

2.3 PROTECTION & CONTROL FUNCTIONS

2.3.1 CURRENT DIFFERENTIAL PROTECTION ......................................................2-9

2.3.2 BACKUP PROTECTION.................................................................................... 2-9

2.3.3 MULTIPLE SETTINGS GROUPS...................................................................... 2-9

2.3.4 USER PROGRAMMABLE LOGIC ..................................................................... 2-9

2.3.5 CONFIGURABLE INPUTS AND OUTPUTS...................................................... 2-9

2.4 METERING & MONITORING FUNCTIONS

2.4.1 METERING ...................................................................................................... 2-10

2.4.2 EVENT RECORDS .......................................................................................... 2-10

2.4.3 OSCILLOGRAPHY .......................................................................................... 2-10

2.4.4 CT FAILURE / CURRENT UNBALANCE ALARM......................................... ..2-10

2.4.5 TRIP CIRCUIT MONITOR ......................................... ......................................2-10

2.4.6 SELF TEST ...................................................................................................... 2-10

2.5 OTHER FUNCTIONS

2.5.1 ALARMS .......................................................................................................... 2-11

2.5.2 LOCAL USER INTERFACE ............................................................................. 2-11

2.5.3 TIME SYNCHRONIZATION.............................................................................2-11

2.5.4 FUNCTION DIAGRAMS..................................................................................2-11

2.6 TECHNICAL SPECIFICATIONS

2.6.1 PROTECTION EL E M ENT S ............... ... ................. ... ................. .. ... ................. 2-13

2.6.2 USER PROGRAMMABLE ELEMENTS ........................................................... 2-16

2.6.3 MONITORING..................................................................................................2-16

2.6.4 METERING ...................................................................................................... 2-17

GE Power Management

L90 Line Differential Relay i

Page 6

TABLE OF CONTENTS

2.6.5 INPUTS.............................................................................................................2-17

2.6.6 POWER SUPPLY.............................................................................................2-18

2.6.7 OUTPUTS.........................................................................................................2-18

2.6.8 COMMUNICATIONS ........................................................................................2-18

2.6.9 INTER-RELAY COMMUNICATIONS................................................................2-19

2.6.10 ENVIRONMENTAL...........................................................................................2-19

2.6.11 TYPE TESTS....................................................................................................2-20

2.6.12 PRODUCTION TESTS..................................................................... ................2-20

2.6.13 APPROVALS ....................................................................................................2-20

2.6.14 MAINTENANCE................................................................................................2-20

3. HARDWARE

4. HUMAN INTERFACES

3.1 DESCRIPTION

3.1.1 PANEL CUTOUT................................................................................................3-1

3.1.2 MODULE WITHDRAWAL / INSERTION............................................................3-4

3.1.3 REAR TERMINAL LA Y OU T ............................. ... ................. .. ... ................. ... .....3-5

3.1.4 REAR TERMINAL AS S IGNMENTS.... ... ... ................ ... ................. ... ................. ..3-5

3.2 WIRING

3.2.1 TYPICAL WIRING DIAGRAM.............................................................................3-6

3.2.2 DIELECTRIC STRENGTH RATINGS AND TESTING........................................3-7

3.2.3 CONTROL POWER............................................................................................3-7

3.2.4 CT/VT MODULES...... ... ... .. ................. ... ................. .. ................. ... ... ................. ..3-8

3.2.5 CONTACT INPUTS/OUTPUTS ........................................................................3-10

3.2.6 TRANSDUCER INP U TS/OUTPUTS................. ... ... ................ ... ................. ... ...3-16

3.2.7 RS232 FACEPLATE PROGRAM PORT ..........................................................3-17

3.2.8 CPU COMMUNICATION PORTS.....................................................................3-17

3.2.9 IRIG-B...............................................................................................................3-19

3.3 L90 CHANNEL COMMUNICATION

3.3.1 DESCRIPTION .................................................................................................3-20

3.3.2 FIBER: LED & ELED TRANSMITTERS............................................................3-21

3.3.3 FIBER-LASER TR ANSMITTERS ............... ... ... ................. ... ................ ... ... ......3-21

3.3.4 G.703 INTERFACE...........................................................................................3-22

3.3.5 RS422 INTERFACE .........................................................................................3-25

3.3.6 RS422 & FIBER INTERFACE ..........................................................................3-28

3.3.7 G.703 & FIBER INTERFACE............................................................................3-28

4.1 URPC® SOFTWARE INTERFACE

4.1.1 GRAPHICAL USER INTERFACE.......................................................................4-1

4.1.2 CREATING A SITE LIST ....................................................................................4-1

4.1.3 URPC

4.1.4 URPC

®

SOFTWARE OVERVIEW......................................................................4-1

®

SOFTWARE MAIN WINDOW ...............................................................4-3

4.2 FACEPLATE INTERFACE

4.2.1 FACEPLATE.......................................................................................................4-4

4.2.2 LED INDICATORS..... ... ... ................ ... ... ................. .. ................. ... ... ................. ..4-5

4.2.3 CUSTOM LABELING OF LEDs..........................................................................4-7

4.2.4 CUSTOMIZING THE DISPLAY MODULE..........................................................4-7

4.2.5 DISPLAY.............................................................................................................4-8

4.2.6 KEYPAD .............................................................................................................4-8

4.2.7 BREAKER CONTR OL ................... .. ... ................. ... ................ ... ... ................. ... ..4-9

4.2.8 MENUS..... ... ... ................. .. ................. ... ... ................ ... ................. ... ... .............. 4 - 10

4.2.9 CHANGING SETTINGS ................ ................ ... ... ................. .. ................. ... ... ...4-11

5. SETTINGS

5.1 OVERVIEW

5.1.1 SETTINGS MAIN MENU ....................................................................................5-1

5.1.2 INTRODUCTION TO ELEMENTS......................................................................5-3

5.1.3 INTRODUCTION TO AC SOURCES..................................................................5-4

5.2 PRODUCT SETUP

5.2.1 PASSWORD SECURITY....................................................................................5-7

ii L90 Line Differential Relay

GE Power Management

Page 7

TABLE OF CONTENTS

5.2.2 DISPLAY PROPERTIES.................................................................................... 5-8

5.2.3 COMMUNICATIONS.......................................................................................... 5-8

5.2.4 MODBUS

5.2.5 REAL TIME CLOCK......................................................................................... 5-15

5.2.6 FAULT REPORT.............................................................................................. 5-15

5.2.7 OSCILLOGRAPHY .......................................................................................... 5-16

5.2.8 DATA LOGGER .................... ................ ... ... ................. .. ................. ... .............. 5 - 18

5.2.9 DEMAND ... ................ ... ... ................. .. ................. ... ... ................. .. ... ................. 5-18

5.2.10 USER-PROGRAMMABLE LEDS................ ................. .. ................. ... .............. 5 - 20

5.2.11 FLEX STATE PARAMETERS.......................................................................... 5-21

5.2.12 USER-DEFINABLE DISPLAYS ....................................................................... 5-21

5.2.13 INSTALLATION................................................................................................ 5-23

®

USER MAP.................................................................................... 5-15

5.3 SYSTEM SETUP

5.3.1 AC INPUTS ...................................................................................................... 5-24

5.3.2 POWER SYSTEM............................................................................................ 5-25

5.3.3 SIGNAL SOURCES ......................................................................................... 5-26

5.3.4 L90 POWER SYSTEM..................................................................................... 5-28

5.3.5 LINE ................................................................................................................. 5-30

5.3.6 BREAKERS...................................................................................................... 5-31

5.3.7 FLEXCURVES™.............................................................................................. 5-34

5.4 FLEXLOGIC™

5.4.1 INTRODUCTION TO FLEXLOGIC™...............................................................5-35

5.4.2 FLEXLOGIC™ RULES .................................................................................... 5-43

5.4.3 FLEXLOGIC™ EVALUATION.......................................................................... 5-43

5.4.4 FLEXLOGIC™ PROC EDURE EXAMPLE.......................................................5-43

5.4.5 FLEXLOGIC™ EQUATION EDITOR............................................................... 5-48

5.4.6 FLEXLOGIC™ TIMERS................................................................................... 5-48

5.4.7 FLEXELEMENTS™ ......................................................................................... 5-49

5.5 GROUPED ELEMENTS

5.5.1 OVERVIEW...................................................................................................... 5-53

5.5.2 SETTING GROUP ....... ... ... ................ ... ................. ... ... ................ ... ................. 5-53

5.5.3 LINE DIFFERENTIAL ELEMENTS .................................................................. 5-53

5.5.4 CURRENT DIFFERENTIAL............................................ ................................ .5-54

5.5.5 STUB BUS ..... ................. ... ................ ... ... ................. ... ................ ... ... .............. 5 - 57

5.5.6 LINE PICKUP................................................................................................... 5-58

5.5.7 DISTANCE ....................................................................................................... 5-60

5.5.8 POWER SWING DETECT ............................................................................... 5-72

5.5.9 LOAD ENCROACHMENT....................................................................... .. .. .....5-78

5.5.10 CURRENT ELEMENTS ........................................ .. .........................................5-80

5.5.11 INVERSE TIME OVERCURRENT CURVE CHARACTERISTICS ..................5-81

5.5.12 PHASE CURRENT ..................... ........................................... .. ........................5-86

5.5.13 NEUTRAL CURRENT......................................................................................5-92

5.5.14 GROUND CURRENT.......................................................................................5-99

5.5.15 NEGATIVE SEQUENCE CURRENT .............................................................5-101

5.5.16 BREAKER FAILU R E............... ... ... ................. .. ................. ... ... ................. .. ....5-103

5.5.17 VOLTAGE ELEMENTS.................................................................................. 5-112

5.5.18 PHASE VOLTAGE......................................................................................... 5-113

5.5.19 NEUTRAL VOLT AG E ........ ................ ... ................. ... ................. .. ................. . 5 - 1 15

5.5.20 AUXILIARY VOLTAGE .................................................................................. 5-116

5.5.21 SUPERVISING ELEMENTS .......................................................................... 5-118

5.6 CONTROL ELEMENTS

5.6.1 OVERVIEW.................................................................................................... 5-125

5.6.2 SETTING GROUP S ........ ................. .. ... ................. ... ................. .. ... ............... 5 - 1 25

5.6.3 SYNCHROCHECK.........................................................................................5-126

5.6.4 AUTORECLOSE ....... ................. ... ................. .. ... ................. ... ................. .. ... . 5-130

5.6.5 DIGITAL ELEMENTS..................................................................................... 5-137

5.6.6 DIGITAL COUNTERS.................................................................................... 5-140

5.6.7 MONITORING ELEMENTS ...........................................................................5-142

5.6.8 BREAKER ARCING CURRENT....................................................................5-142

5.6.9 CONTINUOUS MONITOR ............................................................................. 5-144

5.6.10 CT FAILURE DETECTOR .............................................................................5-145

5.6.11 VT FUSE FAILURE........................................................................................5-147

5.6.12 PILOT SCHEMES ...................... ... ................. .. ... ................. ... ................. .. ... . 5-148

5.7 INPUTS / OUTPUTS

5.7.1 CONTACT INPUTS........................................................................................ 5-151

GE Power Management

L90 Line Differential Relay iii

Page 8

TABLE OF CONTENTS

5.7.2 VIRTUAL INPUTS ..........................................................................................5-153

5.7.3 UCA SBO TIMER ...........................................................................................5-154

5.7.4 CONTACT OUTPUTS ....................................................................................5-154

5.7.5 VIRTUAL OUTPUTS ......................................................................................5-155

5.7.6 REMOTE DEVICES........................................................................................5-155

5.7.7 REMOTE INPUTS ..........................................................................................5-156

5.7.8 REMOTE OUTPUTS: DNA BIT PAIRS ..........................................................5-157

5.7.9 REMOTE OUTPUTS: UserSt BIT PAIRS.......................................................5-158

5.7.10 DIRECT INPUTS /OUTPUTS ........... ................. ... ... ................ ... ................. ... .5-158

5.7.11 RESETTING .................................. .. ... ................. ... ................ ... ... ................. . 5 - 1 60

5.8 TRANSDUCER I/O

5.8.1 DCMA INPUTS ...............................................................................................5-161

5.8.2 RTD INPUTS ................ ... ................ ... ... ................. .. ................. ... ... ............... 5 - 1 62

5.9 TESTING

5.9.1 TEST MODE... ... .. ................. ... ................. .. ... ................. ... ................. .. ... .......5-163

5.9.2 FORCE CONTACT IN P U TS.... ... ... .. ................. ... ................. .. ... ................. ... .5-163

5.9.3 FORCE CONTACT OU TPUTS.............. ... ................ ... ................. ... ............... 5 - 1 63

5.9.4 CHANNEL TESTS ..... ... ................. .. ................. ... ... ................ ... ................. ... .5-164

6. ACTUAL VALUES

6.1 OVERVIEW

6.1.1 ACTUAL VALUES MAIN MENU .........................................................................6-1

6.2 STATUS

6.2.1 CONTACT INPUTS ............................................................................................6-3

6.2.2 VIRTUAL INPUTS ..............................................................................................6-3

6.2.3 REMOTE INPUTS ..............................................................................................6-3

6.2.4 DIRECT INPUTS ............... ... ... ................. .. ... ................. ... ................. .. ... ...........6- 4

6.2.5 CONTACT OUTPUTS ........................................................................................6-4

6.2.6 VIRTUAL OUTPUTS ..........................................................................................6-4

6.2.7 AUTORECLOSE.................................................................................................6-5

6.2.8 REMOTE DEVICES STATUS ............................................................................6-5

6.2.9 REMOTE DEVICES STATISTICS......................................................................6-5

6.2.10 CHANNEL TESTS ..... ... ................. .. ................. ... ... ................ ... ................. ... ... ..6-6

6.2.11 DIGITAL COUNTERS.........................................................................................6-7

6.2.12 FLEX STATES....................................................................................................6-7

6.2.13 ETHERNET ........................................................................................................6-7

6.3 METERING

6.3.1 METERING CONV E N TIO N S ..... ................ ... ... ................. ... ................ ... ...........6-8

6.3.2 87L DIFFERENTIAL CURRENT.......................................... .. ...........................6-11

6.3.3 SOURCES................................................................. .......................................6-12

6.3.4 SYNCHROCHECK................................................ .. .......................... .. .. ...........6-15

6.3.5 TRACKING FREQU E N CY.... ... ... ................ ... ... ................. ... ................ ... ... ......6-16

6.3.6 FLEXELEMENT S ™............................... ... ................ ... ... ................. ... .............. 6 - 16

6.3.7 TRANSDUCER I/O .... ... ................. .. ................. ... ... ................ ... ................. ... ...6-17

6.4 RECORDS

6.4.1 FAULT REPORTS............................................................................................6-18

6.4.2 EVENT RECORDS...........................................................................................6-20

6.4.3 OSCILLOGRAPHY...........................................................................................6-20

6.4.4 DATA LOGGER............................. .. ................. ... ... ................ ... ................. ... ...6-20

6.4.5 MAINTENANC E.................... ... ... ................ ... ................. ... ................. .. ............6-21

6.5 PRODUCT INFORMATION

6.5.1 MODEL INFORMATION...................................................................................6-22

6.5.2 FIRMWARE REVISIONS..................................................................................6-22

7. COMMANDS AND

TARGETS

7.1 COMMANDS

7.1.1 COMMANDS MENU...........................................................................................7-1

7.1.2 VIRTUAL INPUTS ..............................................................................................7-1

7.1.3 CLEAR RECORDS.............................................................................................7-1

7.1.4 SET DATE AND TIME ..... .. ... ................. ... .. ................. ... ................. ... ................7-2

7.1.5 RELAY MAINTENANCE.....................................................................................7-2

iv L90 Line Differential Relay

GE Power Management

Page 9

TABLE OF CONTENTS

7.2 TARGETS

7.2.1 TARGETS MENU............................................................................................... 7-3

7.2.2 RELAY SELF-TESTS......................................................................................... 7-3

8. THEORY OF OPERATION

8.1 OVERVIEW

8.1.1 INTRODUCTION................................................................................................8-1

8.1.2 ARCHITECTURE ............................................................................................... 8-1

8.1.3 REMOVAL OF DECAYING OFFSET................................................................. 8-2

8.1.4 PHASELET COMPUTATION............................................................................. 8-2

8.1.5 ADAPTIVE STRATEGY..................................................................................... 8-3

8.1.6 DISTURBANCE D ET EC TION.................. ... ... ................ ... ................. ... ... .......... 8-3

8.1.7 FAULT DETECTION.......................................................................................... 8-3

8.1.8 CLOCK SYNCHRONIZATION...........................................................................8-5

8.1.9 FREQUENCY TRACKING AND PHASE LOCKING.......................................... 8-6

8.1.10 FREQUENCY DETECTION............................................................................... 8-6

8.1.11 PHASE DETECTION ......................................................................................... 8-7

8.1.12 PHASE LOCKING FILTER .............................................................................. 8-10

8.1.13 CLOCK IMPLEMENTATION............................................................................ 8-12

8.1.14 MATCHING PHASELETS................................................................................ 8-12

8.1.15 START-UP ....................................................................................................... 8-13

8.1.16 HARDWARE AND COMMUNICATION REQUIREMENTS ............................. 8-13

8.1.17 ON-LINE ESTIMATE OF MEASUREMENT ERRORS ....................................8-13

8.1.18 CT SATURATION DETECTION ...................................................................... 8-14

8.1.19 CHARGING CURRENT COMPENSATION.....................................................8-14

8.1.20 DIFFERENTIAL ELEMENT CHARACTERISTICS........................................... 8-16

8.1.21 RELAY SYNCHRONIZATION..........................................................................8-16

8.2 OPERATING CONDITION CALCULATIONS

8.2.1 DEFINITIONS .................................................................................................. 8-18

8.2.2 2 TERMINAL MODE ........................................................................................ 8-18

8.2.3 TRIP DECISION EXAMPLE............................................................................. 8-22

8.2.4 TRIP DECISION TEST .................................................................................... 8-22

9. APPLICATION OF

SETTINGS

9.1 L90 CT REQUIREMENTS

9.1.1 INTRODUCTION................................................................................................9-1

9.1.2 CALCULATION EXAMPLE 1 ............................................................................. 9-1

9.1.3 CALCULATION EXAMPLE 2 ............................................................................. 9-2

9.2 CURRENT DIFFERENTIAL (87L) SETTINGS

9.2.1 INTRODUCTION................................................................................................9-3

9.2.2 CURRENT DIFF PICKUP...................................................................... ............9-3

9.2.3 CURRENT DIFF RESTRAINT 1......................................... ...............................9-3

9.2.4 CURRENT DIFF RESTRAINT 2......................................... ...............................9-3

9.2.5 CURRENT DIFF BREAK PT.................................... .. ........................................9-3

9.2.6 CT TAP .............................................................................................................. 9-4

9.3 DISTANCE BACKUP/SUPERVISION

9.3.1 DESCRIPTION................................................................................................... 9-5

9.3.2 PHASE DISTANCE............................................................................................ 9-6

9.3.3 GROUND DISTANCE ........................................................................................9-6

9.4 POTT SIGNALING SCHEME

9.4.1 DESCRIPTION................................................................................................... 9-7

9.5 SERIES COMPENSATED LINES

9.5.1 DISTANCE SETTINGS ON SERIES COMPENSATED LINES ......................... 9-8

9.6 LINES WITH TAPPED TRANSFORMERS

9.6.1 DESCRIPTION................................................................................................... 9-9

9.6.2 TRANSFORMER LOAD CURRENTS....................................................... .........9-9

9.6.3 FAULTS AT THE LV SIDE OF THE TRANSFORMER(S)............................... 9-10

9.6.4 EXTERNAL GROUND FAULTS......................................................................9-10

GE Power Management

L90 Line Differential Relay v

Page 10

TABLE OF CONTENTS

10. COMMISSIONING

10.1 PRODUCT SETUP

10.1.1 PRODUCT SETUP............................ .. ................................................... .. ........10-1

10.2 SYSTEM SETUP

10.2.1 SYSTEM SETUP ..............................................................................................10-8

10.2.2 FLEXCURVE™ A ...........................................................................................10-10

10.2.3 FLEXCURVE™ B ...........................................................................................10-11

10.3 FLEXLOGIC™

10.3.1 FLEXLOGIC™ ................................................................................................10-12

10.4 GROUPED ELEMENTS

10.4.1 GROUPED ELEMENTS .................................................................................10-21

10.5 CONTROL ELEMENTS

10.5.1 SETTINGS TABLE .........................................................................................10-27

10.6 INPUTS / OUTPUTS

10.6.1 CONTACT INPUTS ........................................................................................10-32

10.6.2 VIRTUAL INPUTS ..........................................................................................10-33

10.6.3 UCA SBO TIMER ...........................................................................................10-33

10.6.4 CONTACT OUTPUTS ....................................................................................10-34

10.6.5 VIRTUAL OUTPUTS ......................................................................................10-35

10.6.6 REMOTE DEVICES........................................................................................10-36

10.6.7 REMOTE INPUTS ..........................................................................................10-37

10.6.8 REMOTE OUTPUTS ......................................................................................10-38

10.6.9 DIRECT MESSAG ING..... .. ................. ... ... ................ ... ................. ... ... ............1 0 - 39

10.6.10 RESETTING ... ... ................ ... ................. ... .. ................. ... ................. ... .. ..........10- 39

10.7 TRANSDUCER I/O

10.7.1 DCMA INPUTS ...............................................................................................10-40

10.7.2 RTD INPUTS ................ ... ................ ... ... ................. .. ................. ... ... ............... 1 0 - 41

10.8 TESTING

10.8.1 FORCE CONTACT IN P U TS /OUTPUTS................... ... ................. ... ... ............1 0 - 42

10.8.2 CHANNEL TESTS ..... ... ................. .. ................. ... ... ................ ... ................. ... .10-42

10.9 L90 COMMISSIONING TESTS

10.9.1 CHANNEL TESTING. ................. ... .. ................. ... ................. .. ... ................. ... .10-43

10.9.2 CLOCK SYNCHRONIZATION TESTS ...........................................................10-44

10.9.3 CURRENT DIFFERENTIAL............................................................................10-45

10.9.4 LOCAL-REMOTE RELAY TESTS..................................................................10-46

A. FLEXANALOG

PARAMETERS

B. MODBUS® RTU PROTOCOL

A.1 PARAMETER LIST

A.1.1 FLEXANALOG PARAMETER LIST................................................................... A-1

B.1 OVERVIEW

B.1.1 INTRODUCTION. ..............................................................................................B-1

B.1.2 PHYSICAL LAYER ............................................................................................ B-1

B.1.3 DATA LINK LAYER ........................................................................................... B-1

B.1.4 CRC-16 ALGORITHM.......................................................................................B-3

B.2 FUNCTION CODES

B.2.1 SUPPORTED FUNCTION CODES...................................................................B-4

B.2.2 03/04H: READ ACTUAL VALUES/SETTINGS.................................................. B-4

B.2.3 05H: EXECUTE OPERATION ........................................................................... B-5

B.2.4 06H: STORE SINGLE SETTING....................................................................... B-5

B.2.5 10H: STORE MULTIPLE SETTINGS ................................................................B-6

B.2.6 EXCEPTION RESPONSES............................................................................... B-6

B.3 FILE TRANSFERS

B.3.1 OBTAINING UR FILES USING MODBUS® PROTOCOL ................................. B-7

B.3.2 MODBUS

®

PASSWORD OPERATION............................................................. B-8

B.4 MEMORY MAPPING

B.4.1 MODBUS® MEMORY MAP .............................................................................. B-9

vi L90 Line Differential Relay

GE Power Management

Page 11

TABLE OF CONTENTS

B.4.2 MODBUS® MEMORY MAP DATA FORMATS................................................B-46

C. UCA/MMS

D. IEC 60870-5-104

E. DNP

F. MISCELLANEOUS

C.1 UCA/MMS OVERVIEW

C.1.1 UCA....................................................................................................................C-1

C.1.2 MMS...................................................................................................................C-1

C.1.3 UCA REPORTING .............................................................................................C-6

D.1 IEC 60870-5-104 POINTS LIST

D.1.1 INTEROPERABILTY DOCUM E NT .... ... ................. ... ... ................ ... ................. ..D-1

D.1.2 POINTS LIST .......... .. ................. ... ... ................ ... ................. ... ................. .. ... ...D-10

E.1 DNP DEVICE PROFILE

E.1.1 DNP V3.00 DEVICE PROFILE ..........................................................................E-1

E.2 DNP IMPLEMENTATION TABLE

E.2.1 IMPLEMENTATION TABLE...............................................................................E-4

E.3 DNP POINT LISTS

E.3.1 BINARY INPUT POINTS....................................................................................E-8

E.3.2 BINARY OUTPUT AND CONTROL RELAY OUTPUT ....................................E-13

E.3.3 COUNTERS .....................................................................................................E-14

E.3.4 ANALOG INPUTS............................................................................................E-15

F.1 CHANGE NOTES

F.1.1 REVISION HISTORY ......................... ... ................. ... ... ................ ... ... ................ F-1

F.1.2 CHANGES TO L90 MANUAL ............................................................................ F-1

F.2 STANDARD ABBREVIATIONS

F.2.1 ABBREVIATIONS .............................................................................................. F-4

F.3 TABLES AND FIGURES

F.3.1 LIST OF TABLES............................................................................................... F-6

F.3.2 LIST OF FIGURES.............................................................................................F-7

F.4 WARRANTY

F.4.1 GE POWER MANAGEMENT WARRANTY.....................................................F-10

GE Power Management

L90 Line Differential Relay vii

Page 12

TABLE OF CONTENTS

viii L90 Line Differential Relay

GE Power Management

Page 13

1 GETTING STARTED 1.1 IMPORTANT PROCEDURES

1 GETTING STARTED 1.1 IMPORTANT PROCEDURES

Please read this chapter to help guide you through the initial setup of your new relay.

1.1.1 CAUTIONS AND WARNINGS

Before attempting to install or use the relay, it is imperative that all WARNINGS and CAUTIONS in this manual are reviewed to he lp prev ent pe rs ona l injury, eq uipm ent da ma ge, an d/

WARNING CAUTION

• Open the relay packaging and inspect the unit for physical damage.

• Check that the battery ta b is inta ct on the power sup ply mo dule (for more details , see th e secti on BATTERY T AB in this

chapter).

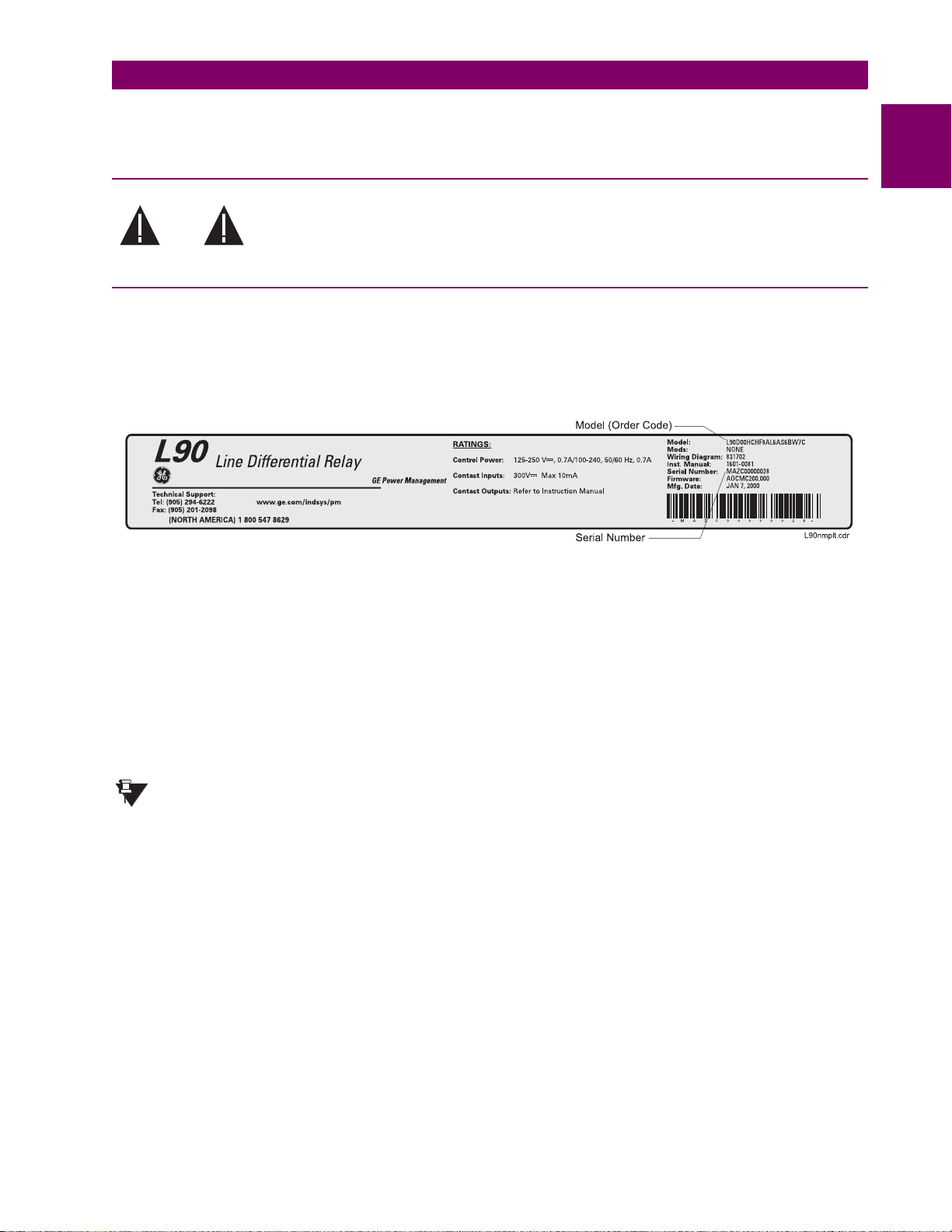

• View the rear name-plate and verify that the correct model has been ordered.

or downtime.

1.1.2 INSPECTION CHECKLIST

1

Figure 1–1: REAR NAME-PLATE (EXAMPLE)

• Ensure that the following items are included:

• Instruction Manual

• Products CD (includes URPC software and manuals in PDF format)

• mounting screws

• registration card (attached as the last page of the manual)

• Fill out the registration form and mail it back to GE Power Management (include the serial number located on the rear

nameplate).

• For product information, instruction manual updates, and the latest software updates, please visit the GE Power Man-

agement Home Page.

If there is any noticeable physical damage, or any of the contents listed are missing, please contact GE

Power Management immediately.

NOTE

GE POWER MANAGEMENT

GE Power Management

215 Anderson Avenue

Markham, Ontario

Canada L6E 1B3

TELEPHONE: (905) 294-6222, 1-800-547-8629 (North Ame ric a only )

FAX: (905) 201-2098

E-MAIL: info.pm@indsys.g e.c om

HOME PAGE: http://www.GEindustrial.com/pm

CONTACT INFORMATION AND CALL CENTER FOR PRODUCT SUPPORT:

GE Power Management

L90 Line Differential Relay 1-1

Page 14

1.2 UR OVERVIEW 1 GETTING STARTED

1.2 UR OVERVIEW 1.2.1 INTRODUCTION TO THE UR RELAY

1

Historically, substation protection, control, and metering functions were performed with electromechanical equipment. This

first generation of equipment was gradually replaced by analog electronic equipment, most of which emulated the singlefunction approach of their electromechanical precursors. Both of these technologies required expensive cabling and auxiliary equipment to produce functioning systems.

Recently, digital electronic equipment has begun to provide protection, control, and metering functions. Initially, this equipment was either single function or had very limited multi-function capability, and did not significantly reduce the cabling and

auxiliary equipment required. However, recent digital relays have become quite multi-functional, reducing cabling and auxiliaries significantly. These devices also transfer data to central control facilities and Human Machine Interfaces using electronic communications. The functions performed by these products have become so broad that many users now prefer the

term IED (Intelligent Electronic Device).

It is obvious to statio n desig ners that the amou nt of cabl ing and au xilia ry eq uipme nt inst alled in station s can be even furth er

reduced, to 20% to 70% of the levels common in 1990, to achieve large cost reductions. This requires placing even more

functions within the IEDs.

Users of power equipment are also interested in reducing cost by improving power quality and personnel productivity, and

as always, in increasing system reliability and efficiency. These objectives are realized through software which is used to

perform functions at both the station and supervisory levels. The use of these systems is growing rapidly.

High speed communications are required to meet the data transfer rates required by modern automatic control and monitoring systems. In the near future, very high speed communications will be required to perform protection signaling with a

performance target response time for a command signal between two IEDs, from transmission to reception, of less than 5

milliseconds. This has been established by the Electric Power Research Institute, a collective body of many American and

Canadian power utilities, in their Utilities Communications Architecture 2 (MMS/UCA2) project. In late 1998, some European utilities began to show an interest in this ongoing initiative.

IEDs with the capabilities outlined above will also provide significantly more power system data than is presently available,

enhance operations and maintenance, and permit the use of adaptive system configuration for protection and control systems. This new generation of equipment must also be easily incorporated into automation systems, at both the station and

enterprise levels. The GE Power Management Universal Relay (UR) has been developed to meet these goals.

1-2 L90 Line Differential Relay

GE Power Management

Page 15

1 GETTING STARTED 1.2 UR OVERVIEW

1.2.2 UR HARDWARE ARCHITECTURE

Input Elements

Contact Inputs Contact Outputs

Virtual Inputs

Analog Inputs

CT Inputs

VT Inputs

Remote Inputs

Input

Status

Table

CPU Module Output Elements

Protective Elements

Logic Gates

Pickup

Dropout

Operate

Output

Status

Table

Virtual Outputs

Analog Outputs

Remote Outputs

-DNA

-USER

LAN

Programming

Device

Figure 1–2: UR CONCEPT BLOCK DIAGRAM

a) UR BASIC DESIGN

The UR is a digital-based device containing a central processing unit (CPU) that handles multiple types of input and output

signals. The UR can communicate over a local area network (LAN) with an operator interface, a programming device, or

another UR device.

The CPU module contains firmware that provides protection elements in the form of logic algorithms, as well as programmable logic gates, timers, and latches for control features.

Input elements accept a variety of analog or digital signals from the field. The UR isolates and converts these signals into

logic signals used by the relay.

Output elements con vert and isolate the logic signa ls gene rated by th e rela y into di gital or an alog si gnals that can be used

to control field devices.

Operator

Interface

827822A1.CDR

1

b) UR SIGNAL TYPES

The contact inputs and outputs are digital signals associated with connections to hard-wired contacts. Both ‘wet’ and

‘dry’ contacts are supported.

The virtual inputs and outputs are digital signals associated with UR internal logic signals. Virtual inputs include signals

generated by the local user interface. The virtual outputs are outputs of FlexLogic™ equations used to customize the UR

device. Virtual outputs can also serve as virtual inputs to FlexLogic™ equations.

The analog inputs an d outpu ts are si gnals that are associat ed w i th tra ns duc ers , s uch as R esi st anc e Temperature Detectors (RTDs).

The CT and VT inputs refer to ana log current tran sfor mer and vo ltage tra nsform er signals us ed to moni tor AC power lines .

The UR supports 1A and 5 A CTs.

The remote inputs and outputs provide a means of sharing digital point state information between remote UR devices.

The remote outputs interface to the remote inputs of other UR devices. Remote outputs are FlexLogic™ operands inserted

into UCA2 GOOSE messages and are of two assignment types: DNA standard functions and USER defined functions.

GE Power Management

L90 Line Differential Relay 1-3

Page 16

1.2 UR OVERVIEW 1 GETTING STARTED

c) UR SCAN OPERATION

1

Read Inputs

Protection elements

serviced by sub-scan

Protective Elements

Solve Logic

Set Outputs

Figure 1–3: UR SCAN OPERATION

The UR device operates in a cyclic scan fashion. The UR reads the inputs into an input status table, solves the logic program (FlexLogic™ equati on), and then s ets e ach ou tput to the ap propriat e state in an ou tput st atus ta ble. An y resu lting t ask

execution is priority interrupt-driven.

PKP

DPO

OP

827823A1.CDR

1.2.3 UR SOFTWARE ARCHITECTURE

The firmware (software embedded in the relay) is designed in functional modules which can be installed in any relay as

required. This is achieved with Object-Oriented Design and Programming (OOD/OOP) techniques.

Object-Oriented techniques involve the use of ‘objects’ and ‘classes’. An ‘object’ is defined as “a logical entity that contains

both data and code that manipulates that data”. A ‘class’ is the generalized form of similar objects. By using this concept,

one can create a Protec ti on Cla ss w ith the Protec ti on El em ents as obj ec ts o f the cl ass s uch as Time Overcurrent, Instantaneous Overcurrent, Current Differential, Undervoltage, Overvoltage, Underfrequency, and Distance. These objects represent completely self-contained software modules. The same object-class concept can be used for Metering, I/O Control,

HMI, Communications, or any functional entity in the system.

Employing OOD/OOP in the software architecture of the Universal Relay achieves the same features as the hardware

architecture: modularity, scalability, and flexibility. The application software for any Universal Relay (e.g. Feeder Protection,

Transformer Protection, Distance Protection) is constructed by combining objects from the various functionality classes.

This results in a ’common look and feel’ across the entire family of UR platform-based applications.

1.2.4 IMPORTANT UR CONCEPTS

As described above, the arch itecture of th e UR rela y is different from prev ious de vice s. In orde r to achie ve a gen eral und erstanding of this device, some sections of Chapter 5 are quite helpful. The most important functions of the relay are contained in "Elements". A description of UR elements can be found in the INTRODUCTION TO ELEMENTS section. An

example of a simple element, and some of the organization of this manual, can be found in the DIGITAL ELEMENTS

MENU section. An explanation of the use of inputs from CTs and VTs is in the INTRODUCTION TO AC SOURCES section.

A description of how digital signals are used and routed within the relay is contained in the INTRODUCTION TO FLEXLOGIC™ section.

1-4 L90 Line Differential Relay

GE Power Management

Page 17

1 GETTING STARTED 1.3 URPC SOFTWARE

1.3 URPC SOFTWARE 1.3.1 PC REQUIREMENTS

The Faceplate keypad and display or the URPC software interface can be used to communicate with the relay.

The URPC software interface is the preferred method to edit settings and view actual values because the PC monitor can

display more information in a simple comprehensible format.

The following minimum requirements must be met for the URPC software to properly operate on a PC.

Processor: Intel

RAM Memory: 64 MB minimum (128 MB recommended)

Hard Disk: 50 MB free space required before installation of URPC software

O/S: Windows

Device: CD-ROM drive

Port: COM1(2) / Ethernet

Refer to the following procedure to install the URPC software:

1. Start the Windows

2. Insert the URPC software CD into the CD-ROM drive.

3. If the installation program does not start automatically, choose Run from the Windows® Start menu and type

D:\SETUP.EXE. Press Enter to start the installation.

4. Follow the on-screen instructions to install the URPC software. When the Welcome window appears, click on Next to

continue with the installation procedure.

5. When the Choose Destination Location window appears and if the software is not to be located in the default direc-

tory, click Browse and type in the complete path name including the new directory name.

6. Click Next to continue with the installation procedure.

7. The default program group where the application will be added to is shown in the Select Program Folder window. If it

is desired that the application be added to an already existing program group, choose the group name from the list

shown.

8. Click Next to begin the installation process.

9. To launch the URPC application, click Finish in the Setup Complete window.

10. Subsequently, double click on the URPC software icon to activate the application.

Refer to the HUMAN INTERFACES chapter in this manual and the URPC Software Help program for more

information about the URPC software interface.

NOTE

®

Pentium 300 or higher

®

NT 4.x or Windows® 9x/2000

®

operating system.

1.3.2 SOFTWARE INSTALLATION

1

GE Power Management

L90 Line Differential Relay 1-5

Page 18

1.3 URPC SOFTWARE 1 GETTING STARTED

1.3.3 CONNECTING URPC® WITH THE L90

1

This section is intended as a quick start guide to using the URPC software. Please refer to the URPC Help File and the

HUMAN INTERFACES chapter for more information.

a) CONFIGURING AN ETHERNET CONNECTION

Before starting, verify that the Ethernet network cable is properly connected to the Ethernet port on the back of the relay.

1. Start the URPC software. Enter the password "URPC" at the login password box.

2. Select the Help > Connection Wizard menu item to open the Connection Wizard. Click "Next" to continue.

3. Click the "New Interface" button to open the Edit New Interface window.

• Enter the desired interface name in the Enter Interface Name field.

• Select the "Ethernet" interface from the drop down list and press "Next" to continue.

4. Click the "New Device" button to open the Edit New Device Window.

• Enter the desired name in the Enter Interface Name field.

• Enter th e Modbus address o f the relay (fr om

PROTOCOL

• Enter the IP address (from

the

5. Click the " 4.1 Read Dev ice Inf ormation" button the n "OK" when the relay in formati on has been re ceiv ed. C lick "Next" to

continue.

6. Click the "New Site" button to open the Edit Site Name window.

• Enter the desired site name in the

7. Click the "OK" b utt on then click "F inish ". The ne w Site Lis t tree wil l be ad ded to th e Site Li st wi ndow (or O nline window)

located in the top left corner of the main URPC window.

The Site Device has now been configured for Ethernet communications. Proceed to Section c) CONNECTING TO THE

RELAY below to begin communications.

Ö

MODBUS SLAVE ADDRESS) in the

Enter TCPIP Address

SETTINGS Ö PRODUCT SETUP ÖØ COMMUNICATIONS ÖØ NETWORK Ö IP ADDRESS) in

field.

Enter Site Name

SETTINGS

Enter Modbus Address

field.

Ö

PRODUCT SETUP ÖØ COMMUNICATIONS ÖØ MODBUS

field.

b) CONFIGURING AN RS232 CONNECTION

Before starting, verify that the RS232 serial cable is properly connected to the RS232 port on the front panel of the relay.

1. Start the URPC software. Enter the password "URPC" at the login password box.

2. Select the

3. Click the "New Interface" button to open the Edit New Interface window.

• Enter the desired interface name in the

• Select the "RS232" interface from the drop down list and press "Next" to continue.

4. Click the "New Device" button to open the Edit New Device Window.

• Enter the desired name in the

• Enter the PC COM port number in the

5. Click "OK" then click "Next" to continue.

6. Click the "New Site" button to open the Edit Site Name window.

• Enter the desired site name in the

7. Click the "OK" b utt on then click "F inish ". The ne w Site Lis t tree wil l be ad ded to th e Site Li st wi ndow (or O nline window)

located in the top left corner of the main URPC window.

The Site Device has now been configured for RS232 communications. Proceed to Section c) CONNECTING TO THE

RELAY below to begin communications.

Help > Connection Wizard

Enter Interface Name

menu item to open the Connection Wizard. Click "Next" to continue.

Enter Interface Name

COM Port

Enter Site Name

field.

field.

field.

field.

1-6 L90 Line Differential Relay

GE Power Management

Page 19

1 GETTING STARTED 1.3 URPC SOFTWARE

c) CONNECTING TO THE RELAY

1. Select the Display Properties window through the Site List tree as shown below:

1

2. The Display Properties window will open with a flashing status indicator.

• If the indicator is red, click the Connect button (lightning bolt) in the menu bar of the Displayed Properties window.

3. In a few moments, the flashing light should turn green, indicating that URPC is communicating with the relay.

Refer to the HUMAN INTERFACES chapter in this manual and the URPC Software Help program for more

information about the URPC software interface.

NOTE

GE Power Management

L90 Line Differential Relay 1-7

Page 20

1.4 UR HARDWARE 1 GETTING STARTED

1.4 UR HARDWARE 1.4.1 MOUNTING AND WIRING

1

Please refer to the HARDWARE chapter for detailed relay mounting and wiring instructions. Review all WARNINGS AND

CAUTIONS.

1.4.2 COMMUNICATIONS

The URPC software communicates to the relay via the faceplate RS232 port or the rear panel RS485 / Ethernet ports. To

communicate via the faceplate RS232 port, a standard “straight-through” serial cable is used. The DB-9 male end is connected to the relay and the DB-9 or DB-25 female end is connected to the PC COM1 or COM2 port as described in the

HARDWARE chapter.

Figure 1–4: RELAY COMMUNICATIONS OPTIONS

To communicate through the L90 rear RS485 port from a PC RS232 port, the GE Power Management RS232/RS485 converter box is required. This device (catalog number F485) connects to the computer using a "straight-through" serial cable.

A shielded twisted-pair (20, 22, or 24 AWG) connects the F485 converter to the L90 rear communications port. The converter terminals (+, –, GND) are connected to the L90 communication module (+, –, COM) terminals. Refer to the CPU

COMMUNICATION PORTS section in the HARDWARE chapter for opti on details. The line shou ld b e te rmi nated with an RC network (i.e. 120 Ω, 1 nF) as described in the HARDWARE chapter.

1.4.3 FACEPLATE DISPLAY

All messages are display ed on a 2 × 20 characte r vacuum fluo rescen t displa y to make them visi ble unde r poor lighti ng conditions. Messages are displayed in English and do not require the aid of an instruction manual for deciphering. While the

keypad and display are not actively being used, the display will default to defined messages. Any high priority event driven

message will automatically override the default message and appear on the display.

1-8 L90 Line Differential Relay

GE Power Management

Page 21

1 GETTING STARTED 1.5 USING THE RELAY

1.5 USING THE RELAY 1.5.1 FACEPLATE KEYPAD

Display messages are organized into ‘pages’ under the following headings: Actual Values, Settings, Commands, and Targets. The key navigates through these pages. Each heading page is broken down further into logical subgroups.

The MESSAGE keys navigate through the subgro ups. The VALUE keys scroll increment or decreme nt

numerical setting values when in programming mode. These keys also scroll through alphanumeric values in the text edit

mode. Alternatively, values may also be entered with the numeric keypad.

The key initiates and adv ance to the next chara cte r in te xt e dit mod e or e nters a decimal poin t. The key may be

pressed at any time for context sensitive help messages. The key stores altered setting values.

1.5.2 MENU NAVIGATION

Press the key to select the desired header display page (top-level menu). The header title appears momentarily followed by a header display page menu item. Each press of the key advances through the main heading pages as

illustrated below.

Ö

Ö

ACTUAL VALUES SETTINGS COMMANDS

ØØØØ

ACTUAL VALUES

STATUS

SETTINGS

PRODUCT SETUP

Ö

Ö

COMMANDS

VIRTUAL INPUTS

Ö

Ö

TARGETS

No Active

Targets

1

Ö

Ö

USER DISPLAYS

when in use

(

Ø

User Display 1

The setting and actual value messages are arranged hierarchically. The header display pages are indicated by double

scroll bar characters (

pages represent the highest level of the hierarchy and the sub-header display pages fall below this level. The MESSAGE

and keys move within a group of headers, sub-headers, setting values, or actual values. Continually pressing the

MESSAGE key from a header display displays specific information for the header category. Conversely, continually

pressing the MESSAGE key from a setting value or actual value display returns to the header display.

HIGHEST LEVEL LOWEST LEVEL (SETTING VALUE)

SETTINGS

PRODUCT SETUP

SETTINGS

SYSTEM SETUP

)

1.5.3 MENU HIERARCHY

), while sub-header pages are indicated by single scroll bar characters (

PASSWORD

SECURITY

ACCESS LEVEL:

Restricted

). The head er displ ay

GE Power Management

L90 Line Differential Relay 1-9

Page 22

1.5 USING THE RELAY 1 GETTING STARTED

1.5.4 RELAY ACTIVATION

1

The relay is defaulted to the "Not Programmed" state when it leaves the factory. This safeguards against the installation of

a relay whose settings have not been entered. When powered up successfully, the TROUBLE indicator will be on and the

IN SERVICE indicator off. The relay in the "Not Programmed" state will block signaling of any output relay. These conditions will remain until the relay is explicitly put in the "Programmed" state.

Select the menu message

RELAY SETTINGS:

Not Programmed

To put the relay in the "Programmed" state, press either of the VALUE keys once and then press . The faceplate TROUBLE indicator will turn off and the IN SERVICE indicator will turn on. The settings for the relay can be programmed manually (refer to the SETTINGS chapter) via the faceplate keypad or remotely (refer to the URPC Help file) via

the URPC software interface.

The battery tab is installed in the power supply module before the L90 shipped from the factory. The battery tab prolongs

battery life in the event the relay is powered down for long periods of time before installation. The battery is responsible for

backing up event records, oscillography, data logger, and real-time clock information when the relay is powered off. The

battery failure self-te st error gen erated by the relay is a m inor and s hould no t af fect the rel ay functio nality. When the relay is

installed and ready for co mmis sioni ng, the tab sh ould be rem oved. The battery tab should be re-inserte d if the relay is powered off for an extended period of time. If required, contact the factory for a replacement battery or battery tab.

SETTINGS Ö PRODUCT SETUP ÖØ INSTALLATION Ö RELAY SETTINGS

1.5.5 BATTERY TAB

1.5.6 RELAY PASSWORDS

It is recommended that passwords be set up for each security level and assigned to specific personnel. There are two user

password SECURITY access levels:

1. COMMAND

The COMMAND access level restricts the user from making any settings changes, but allows the user to perform the following operations:

• operate breakers via faceplate keypad

• change state of virtual inputs

• clear event records

• clear oscillography records

2. SETTING

The SETTING access level allows the user to make any changes to any of the setting values.

Refer to the CHANGING SETTINGS section (in the HUMAN INTERFACES chapter) for complete instructions

on setting up security level passwords.

NOTE

1.5.7 FLEXLOGIC™ CUSTOMIZATION

FlexLogic™ equation editing is required for setting up user-defined logic for customizing the relay operations. See section

FLEXLOGIC™ in the SETTINGS chapter.

1.5.8 COMMISSIONING

Templated tables for charting all the required settings before entering them via the keypad are available in the COMMISSIONING chapter, which also includes instructions for commissioning tests.

1-10 L90 Line Differential Relay

GE Power Management

Page 23

2 PRODUCT DESCRIPTION 2.1 INTRODUCTION

2 PRODUCT DESCRIPTION 2.1 INTRODUCTION 2.1.1 OVERVIEW

The L90 relay is a digital current differential relay system with an integral communications channel interface.

The L90 is intended to provide complete protection for transmission lines of any voltage level. Both three phase and single

phase tripping schemes are available. Models of the L90 are available for application on both two and three terminal lines.

The L90 uses per phase differential at 64 kbps transmitting 2 phaselets per cycle. The current differential scheme is based

on innovative patented techniques developed by GE. The L90 algorithms are based on the Fourier transform–phaselet

approach and an adaptive statistical restraint. The restraint is similar to a traditional percentage differential scheme, but is

adaptive based on relay measurements. When used with a 64 kbps channel, the innovative “phaselets” approach yields an

operating time of 1.0 to 1.5 cycles typical. The adaptive statistical restraint approach provides both more sensitive and

more accurate fault sensin g. This al lows the L90 to dete ct relati vely higher im pedan ce sin gle line to gro und f aults th at existing systems may not. The basic current differential element operates on current input only. Long lines with significant

capacitance can ben efit from charg ing cu rrent com pens ation i f termin al vol tage me asurem ents a re appli ed to the relay. The

voltage input is also used for some protection and monitoring features such as directional elements, fault locator, metering,

and distance backup.

The L90 is designed to operate over different communications links with various degrees of noise encountered in power

systems and communications environments. Since correct operation of the relay is completely dependent on data received

from the remote end, special attention must be paid to information validation. The L90 incorporates a high degree of security by using a 32-bit CRC (cyclic redundancy code) inter-relay communications packet.

In addition to current differential protection, the relay provides multiple backup protection for phase and ground faults. For

overcurrent prot ect ion , th e time overcurrent c urve s may be s ele cte d fro m a selection of stan dard cu rve shapes or a custom

FlexCurve™ for optimum co-ordination. Additionally, one zone of phase and ground distance protection with power swing

blocking, out-of-step tripping, line pickup, load encroachment, and POTT features is included.

The L90 incorporates charging current compensation for applications on very long transmission lines without loss of sensitivity. The line capacitive current is removed from the terminal phasors.

The relay uses a sampling rate of 64 samples per cycle to provide metering values and flexible oscillography.

Voltage and current metering is included as a standard feature. Additionally, currents are available as total RMS values.

Power, power factor and frequency measurements are also provided.

Diagnostic feature s inc lude a seque nce of record s of 10 24 tim e-tagge d eve nts. Th e intern al cl ock u sed fo r time-tagg ing ca n

be synchronized with an IRIG-B signal. This precise time stamping allows the sequence of events to be determined

throughout the system. Events can also be programmed (via FlexLogic™ equations) to trigger oscillography data capture

which may be set to record the measured parameters before and after the event for viewing on a portable computer (PC).

These tools will significantly reduce troubleshooting time and simplify report generation in the event of system faults.

A faceplate RS232 port may be used to connect a PC for programming settings and for monitoring actual values. A variety

of communications modules are available. Two rear RS485 ports are standard to allow independent access by operating

and engineering staff. All serial ports use the Modbus

puters with baud rates up to 115.2 kbps. The RS232 port has a fixed baud rate of 19.2 kbps. Optional communications

modules include a 10BaseF Eth ern et interfa ce whic h can b e used t o provi de fast, reliabl e commu nicati ons in noisy enviro nments. Another option provides two 10BaseF fiber optic ports for redundancy. The Ethernet port supports MMS/UCA2 protocol.

The relay uses flash memory technology which allows field upgrading as new features are added.

The testing features can be used to verify and test settings and operations.

®

RTU protocol. The RS485 ports may be connected to system com-

2

GE Power Management

L90 Line Differential Relay 2-1

Page 24

2.1 INTRODUCTION 2 PRODUCT DESCRIPTION

2.1.2 FEATURES

LINE CURRENT DIFFERENTIAL:

• Phase segregated, high-speed digital current differential system

• Overhead and underground AC transmission lines, series compensated lines

• Two and three terminal line applications

2

• Zero-sequence removal for application on lines with tapped transformers connected in a grounded Wye on the line

side

• GE phaselets approach based on Discrete Fourier Transform with 64 samples per cycle and transmitting 2 timestamped phaselets per cycle

• Adaptive restraint approach improving sensitivity and accuracy of fault sensing

• Increased security for trip decision using Disturbance Detector and Trip Output logic

• Continuous clock synchronization via the distributed synchronization technique

• Increased transient stability through DC decaying offset removal

• Accommodates up to 5 times CT ratio differences

• Peer-to-Peer (Master-Master) architecture changing to Master-Slave via DTT (if channel fails) at 64 kbps

• Charging current comp ens ati on

• Interfaces direct fiber, multiplexed RS422 and G.703 connections with relay ID check

• Per phase line differential protection Direct Transfer Trip plus 8 user-assigned pilot signals via the communications

channel

• Secure 32-bit CRC protection against communications errors

BACKUP PROTECTION:

• DTT provision for pilot schemes

• 1 zone distance protection with POTT scheme, power swing blocking/out-of-step tripping, line pickup, and load

encroachment

• 2-element TOC and 2-element IOC directional phase overcurrent protection

• 2-element TOC and 2-element IOC directional zero sequence overcurrent protection

• 2-element TOC and 2-element IOC negative sequence overcurrent protection

• Undervoltage and overvoltage protection

ADDITIONAL PROTECTION:

• Breaker failure protection

• Stub bus protection

• VT and CT supervision

• GE "Sources" approach allowing grouping of different CTs and VTs from multiple input channels

• Open pole detection

• Breaker trip coil supervision and "seal-in" of trip command

• FlexLogic™ allowing creation of user-defined distributed protection and control logic

CONTROL:

• 1 and 2 breakers configuration for 1½ and ring bus schemes, pushbutton control from the relay

• Auto-reclosing and synchrochecking

• Breaker arcing current

2-2 L90 Line Differential Relay

GE Power Management

Page 25

2 PRODUCT DESCRIPTION 2.1 INTRODUCTION

MONITORING:

• Oscillography of current, voltage, FlexLogic™ operands, and digital signals (1× 128 cycles to 31 × 8 cycles config-

urable)

• Events recorder - 1024 events

• Fault locator

METERING:

• Actual 87L remote phasors, differential current and channel delay at all line terminals of line current differential protec-

tion

• Line current, voltage, real power, reactive power, apparent power, power factor, and frequency

COMMUNICATIONS:

• RS232 front port - 19.2 kbps

• 1 or 2 RS485 rear ports - up to 115 kbps

• 10BaseF Ethernet port supporting MMS/UCA2.0 protocol

2.1.3 FUNCTIONALITY

The following SINGLE LINE DIAGRAM illustrates relay functionality using ANSI (American National Standards Institute)

device numbers

2

52

Monitoring

50DD

(via Dedicated Communications)

79

CLOSE TRIP

51P(2)

51_2(2)

50_2(2)

50P(2)

Data From/To Remote End

L90 Line Differential Relay

Figure 2–1: SINGLE LINE DIAGRAM

50BF(2)

87L 21P

67P(2)

FlexElement

50G(2)

68

51G(2)

TM

78

Metering

50N(2)

51N(2)

Transducer

Inputs

59X

3V_0

21G67N/G

59P

27P(2)

59N

27X

25(2)

831706AS.CDR

GE Power Management

L90 Line Differential Relay 2-3

Page 26

2.1 INTRODUCTION 2 PRODUCT DESCRIPTION

T able 2–1: DEVICE NUMBERS AND FUNCTIONS

2

DEVICE

NUMBER

21G Ground Distance 51N Neutral Time Overcurrent

21P Phase Distance 51P Phase Time Overcurrent

25 Synchrocheck 51_2 Negative Sequence Time Overcurrent

27P Phase Undervoltage 52 AC Circuit Breaker

27X Auxiliary Undervoltage 59N Neutral Overvoltage

50BF Breaker Failure 59P Phase Overvoltage

50DD Adaptive Fault Detector

50G Ground Instantaneous Overcurrent 67P Phase Directional Overcurrent

50N Neutral Instantaneous Overcurrent 68 Power Swing Blocking

50P Phase Instantaneous Overcurrent 78 Out-of-step Tripping

50_2 Negative Sequence Instantaneous Overcurrent 79 Automatic Recloser

51G Ground Time Overcurrent 87L Segregated Line Current Differential

FUNCTION DEVICE

(sensitive current disturbance detector)

Table 2–2: ADDITIONAL DEVICE FUNCTIONS

FUNCTION FUNCTION FUNCTION

Breaker Arcing Current (I

Breaker Control FlexLogic™ Equations Pilot Scheme (POTT)

Contact Inputs (up to 96) L90 Channel T ests Setting Groups (8)

Contact Outputs (up to 64) Line Pickup Stub Bus

CT Failure Detector Load Encroachment Transducer I/O

Data Logger Metering: Current, Voltage, Power,

Digital Counters (8) User Programmable LEDs

Digital Elements (16) Virtual Inputs (32)

Direct Inputs (8 per L90 comms channel) MMS/UCA Communications Virtual Outputs (64)

DNP 3.0 MMS/UCA Remote I/O ("GOOSE") VT Fuse Failure

Event Recorder ModBus Communications

Fault Locator ModBus User Map

Fault Reporting O pen Pole Detector

2

T) FlexElements™ Oscillography

NUMBER

FUNCTION

59X Auxiliary Overvoltage

67N Neutral Directional Overcurrent

Energy, Frequency, Demand,

Power Factor, 87L differential

current, local & remote phasors

User Definable displays

2.1.4 ORDERING

The relay is available as a 19-inch rack horizontal mount unit or as a reduced size (¾) vertical mount unit, and consists of

power supply, CPU, Digital Input/Output, Trans ducer I/O an d L90 C ommunic ations modul es. Eac h of these can be supp lied

in a number of configurations which must be specified at the time of ordering. The information required to completely specify the relay is provided in the followin g table.

2-4 L90 Line Differential Relay

GE Power Management

Page 27

2 PRODUCT DESCRIPTION 2.1 INTRODUCTION

Table 2–3: ORDER CODES

L90 L90 -

Base Unit

CPU

Software

Mount /

Faceplate

Power

Supply

CT/VT

DSP

Digital I/O

Transducer

I/O (max of 4

per unit)

Inter-Relay

Communications

L90

00 - H C

00 - V F

| | ||| | | | | | | |

| | | | | | | | | | |

A

| | | | | | | | | | |

C

| | | | | | | | | | |

D

00

-F

- H

-F

||| | | | | | | |

| | | | | | | |

H C

| | | | | | | |

V F

|||||||

H

|||||||

L

8A

8C |

- L

- H

- L

| | | | | |

|

6A 6A 6A 6A 6A

6B 6B 6B 6B 6B

6C 6C 6C 6C 6C

6D 6D 6D 6D 6D

6E 6E 6E 6E 6E

6F 6F 6F 6F 6F

6G 6G 6G 6G 6G

6H 6H 6H 6H 6H

6K 6K 6K 6K 6K

6L 6L 6L 6L 6L

6M 6M 6M 6M 6M

6N 6N 6N 6N 6N

6P 6P 6P 6P 6P

6R 6R 6R 6R 6R

6S 6S 6S 6S 6S

6T 6T 6T 6T 6T

6U 6U 6U 6U 6U

5C 5C 5C 5C 5C |

5E 5E 5E 5E 5E |

5F 5F 5F 5F 5F |

N

S

|

XX XX XX XX

N

| | | |

_ _

U

For Full Sized Horizontal Mount

W

For Reduced Size Vertical Mount

R

Base Unit

RS485 + RS485 (ModBus RTU, DNP)

RS485 + 10BaseF (

RS485 + Redundant 10BaseF (

No Software Options

Horizontal (19” rack)

Vertical (3/4 size)

125 / 250 V AC/DC

24 to 48 V (DC only)

Standard 4CT/4VT

Standard 8CT

No Module

|

2 Form-A (Volt w/ opt Curr) & 2 Form-C outputs, 8 Digital Inputs

|

2 Form-A (Volt w/ opt Curr) & 4 Form-C Outputs, 4 Digital Inputs

|

8 Form-C Outputs

|

16 Digital Inputs

|

4 Form-C Outputs, 8 Digital Inputs

|

8 Fast Form-C Outputs

|

4 Form-A (Voltage w/ opt Current) Outputs, 8 Digital Inputs

|

6 Form-A (Voltage w/ opt Current) Outputs, 4 Digital Inputs

|

4 Form-C & 4 Fast Form-C Outputs

|

2 Form-A (Curr w/ opt Volt) & 2 Form-C Outputs, 8 Digital Inputs

|