GE TMQV Installation Instructions Manual

Effective November 2016DEH41188 Installation Instrucitons

Installation Instructions for TMQV

Circuit Breakers and Molded Case Switches

Contents

Description Page

Introduction . . . .... . . . . ..... ..... ... ..... 2

Installation . . . .... . . . . .... . . ... .... .... . . 2

Manual Operation ... . . . . ..... .... ...... . . 4

Inspection and Field Testing ... ....... ..... . 4

DEH41188 Installation Instructions

Effective November 2016

Installation Instructions for TMQV

Circuit Breakers and Molded Case Switches

WARNING

DO NOT ATTEMPT TO INSTALL OR PERFORM M AINTENANCE ON EQUIPMENT WHILE IT IS ENERGIZED. DEATH, SEVERE PERSONAL INJURY OR

SUBST ANTIA L PROPERTY DAMAGE CAN RESULT FROM CONTACT WITH

ENERGIZED EQUIPMENT. ALWAYS VERIFY THAT NO VOLTAGE IS PRESENT

BEFORE PROCEEDING WITH THE TASK, AND ALWAYS FOLLOW GENERALLY

ACCEPTED SAFETY PROCEDURES.

GE IS NOT LIABLE FOR THE MISAPPLICATION OR MISINSTALLATION

OF ITS PRODUCTS.

The user is cautioned to observe all recommendations, warnings

and cautions relating to the safety of personnel and equipment, as

well as all general and local health and safety laws, codes, and procedures .

1. Introduction

2. Installation

The installation procedure consists of inspecting and mounting the

circuit breaker, connecting and torquing the line and load terminations, and attaching terminal shields or barriers, when supplied . To

install the circuit breaker perform the following steps:

ote :N TMQVV circuit breakers are factory sealed. UL489 requires that internal

accessories be installed at the factory. Where local codes and standards permit and UL listing is not required, internal accessories can be field installed .

Accessory installation should be done before the circuit breaker is mounted

and connected .

Mounting hardware and unmounted terminations (where required)

are supplied in separate packages.

2-1. Make sure that the circuit breaker is suitable for the installation

by comparing nameplate data with system requirements . Inspect

the circuit breaker for completeness and check for damage before

mounting .

WARNING

BEFORE MOUNTING THE CIRCUIT BREAKER IN AN ELECTRICAL SYSTEM,

MAKE SURE THERE IS NO VOLTAGE PRESENT WHERE WORK IS TO BE

PERFORMED. THE VOLTAGES IN ENERGIZED EQUIPMENT CAN CAUSE

INJURY OR DEATH.

2-2. Depending on the equipment configuration, the circuit breaker

can be mounted using different styles of hardware. The following

steps describe how to mount the circuit breaker using standard

hardware. When special hardware is needed (for example, with the

electrical operator), the instruction leaflet describing the accessory

also describes the special mounting arrangements .

ote :N Before mounting the circuit breaker, check if the termination devices

should be installed first. See terminations instructions .

2-3. To mount the circuit breaker, perform the following steps:

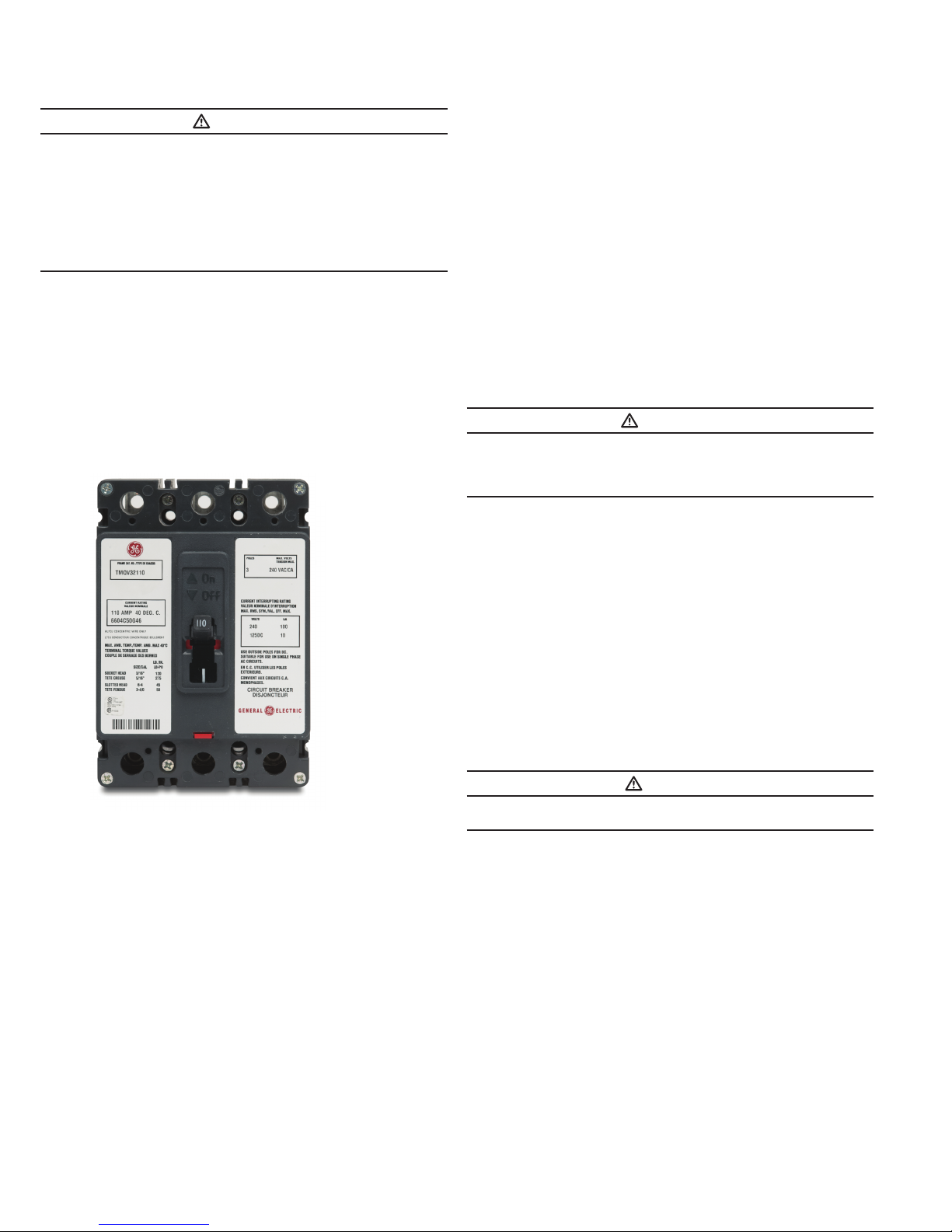

Figure 1. TMQV Circuit Breaker and Molded Case Switches

TMQV

The circuit breakers (Fig. 1) are rated from 60A to 225A continu ous current and are available as thermal-magnetic circuit breakers

and molded case switches . (Molded case switches are available rated at 225A .) Circuit breakers are listed in accordance with

Underwriters Laboratories, Inc. Standard UL489 . Molded case

switches are listed in accordance with UL489 . For this publication,

the term circuit breaker also includes molded case switches and QV

is used to cover all of the circuit breakers and molded case switches

associated with this instruction sheet..

a. For individual mounting panels, make sure that mounting panel is

predrilled using bolt drilling plan (Fig . 2). For panelboard mounting,

only load end support mounting holes are required. For deadfront

cov

er applications make sure panel cover is cut out to correct

escutcheon dimensions (Fig .3) .

CAUTION

DO NOT EXCEED CONNECTOR/BUS CAPACITY IN THE APPROVED PANEL

ASSEMBLY .

b. If circuit breaker includes factory installed internal accessories,

make sure accessory wiring can be reached when the circuit

breaker is mounted .

c. Position circuit breaker on mounting surface.

d. Install mounting screws, washers, and nuts . Tighten screws

firmly, but do not exceed 28 pound-inches (3.16 N.m)

2

Loading...

Loading...