Page 1

May 2003

Process Control Instruments

Model TMO2D-TC

Thermal Conductivity Analyzer

User’s Manual 910-146A2

Page 2

May 2003

TMO2-TC Thermal Conductivity Transmitter with TMO2D

iii

Page 3

May 2003

Warranty Each instrument manufactured by GE Panametrics is warranted to be

free from defects in material and workmanship. Liability under this

warranty is limited to restoring the instrument to normal operation or

replacing the instrument, at the sole discretion of GE Panametrics. Fuses

and batteries are specifically excluded from any liability. This warranty

is effective from the date of delivery to the original purchaser. If GE

Panametrics determines that the equipment was defective, the warranty

period is:

• one year for general electronic failures of the instrument

• one year for mechanical failures of the transducers

If GE Panametrics determines that the equipment was damaged by

misuse, improper installation, the use of unauthorized replacement parts,

or operating conditions outside the guidelines specified by GE

Panametrics, the repairs are not covered under this warranty.

The warranties set forth herein are exclusive and are in lieu of

all other warranties whether statutory, express or implied

(including warranties or merchantability and fitness for a

particular purpose, and warranties arising from course of

dealing or usage or trade).

Return Policy If a GE Panametrics instrument malfunctions within the warranty period,

the following procedure must be completed:

1. Notify GE Panametrics, giving full details of the problem, and

provide the model number and serial number of the instrument. If the

nature of the problem indicates the need for factory service, GE

Panametrics will issue a RETURN AUTHORIZATION NUMBER

(RAN), and shipping instructions for the return of the instrument to a

service center will be provided.

2. If GE Panametrics instructs you to send your instrument to a service

center, it must be shipped prepaid to the authorized repair station

indicated in the shipping instructions.

3. Upon receipt, GE Panametrics will evaluate the instrument to

determine the cause of the malfunction.

Then, one of the following courses of action will then be taken:

• If the damage is covered under the terms of the warranty, the

instrument will be repaired at no cost to the owner and returned.

• If GE Panametrics determines that the damage is not covered under

the terms of the warranty, or if the warranty has expired, an estimate

for the cost of the repairs at standard rates will be provided. Upon

receipt of the owner’s approval to proceed, the instrument will be

repaired and returned.

iv

Page 4

May 2003

Table of Contents

Chapter 1: Features and Capabilities

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

System Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

TMO2-TC Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

Sample System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

TMO2D-TC Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

Extra Cable (optional). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

Typical Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-10

Chapter 2: Installation

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Mounting the TMO2-TC Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Mounting the Sample System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

Manual, 2-Port (Sealed Reference Gas) Sample System . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

Manual, 4-Port (Flowing Reference Gas) Sample System . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Automatic, 2-Port (Sealed Reference Gas) Sample System . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Mounting the TMO2D-TC Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Wiring the TMO2-TC Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

Wiring the TMO2D-TC Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

Chapter 3: Operation

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Powering Up the TMO2D-TC Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Establishing a Flow of Sample Gas. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Operating the TMO2D-TC Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

LCD Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Chapter 4: Programming

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Key Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

Entering Programming Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Menu Navigation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

The Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

The Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

The Recorders Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-13

The Alarms Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-15

The Tests Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-16

The Calibration Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-19

v

Page 5

May 2003

Table of Contents (cont.)

Chapter 5: Calibration

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Required Equipment and Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Preparing the Transmitter for Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

2-Port (Sealed Reference Gas) Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

4-Port (Flowing Reference Gas) Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Checking/Changing Switch and Jumper Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Chapter 6: Specifications

TMO2-TC Transmitter Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Performance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Functional . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Physical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

TMO2D-TC Display Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Performance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Functional . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Physical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Chapter 7: Ordering Information

Appendix A: Relative Thermal Conductivity of Common Gases

Appendix B: Applications

H2 in N2 in Heat Treat Furnace Atmospheres. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Problem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Basic Operating Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Permanent Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

Detailed Operating Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

H2 Purity in H2 Electricity Generator Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-7

Problem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-7

Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-7

Basic Operating Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-8

How Previously Handled. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-10

Permanent Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-10

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-10

Detailed Operating Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-10

vi

Page 6

May 2003

Table of Contents (cont.)

Appendix C: Installation and Maintenance Drawings

Appendix D: Menu Flow Diagrams

Appendix E: Special Programming

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-1

Entering the Hidden Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-1

Select Gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-2

LabCal Recorders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-3

Manual Offset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-4

Erase RAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-5

Appendix F: Calibration Procedure and Adjustment Locations for Older Versions

Calibration Procedure for PCB #703-1036 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F-1

2-Port (Sealed Reference Gas) Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F-1

4-Port (Flowing Reference Gas) Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F-4

Checking/Changing Switch and Jumper Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F-6

Calibration Procedure for PCB #703-867 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F-7

2-Port (Sealed Reference Gas) Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F-7

4-Port (Flowing Reference Gas) Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F-9

Appendix G: Sample TMO2D-TC Calibration Sheet

Appendix H: Installation Instructions for CE Mark Compliance

Installation Instructions for CE Mark Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . H-1

vii

Page 7

Chapter 1

Page 8

Features and Capabilities

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Theory of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

System Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

Typical Applications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-10

Page 9

May 2003

Overview This chapter will introduce you to the features and capabilities of the

GE Panametrics TMO2D-TC Thermal Conductivity Analyzer. You

will find the following topics discussed:

• Introduction — A discussion of the TMO2D-TC Analyzer features

and capabilities.

• Theory of Operation — Details on TMO2-TC Transmitter

construction and how the measurement is made.

• System Description — A detailed description of the basic

TMO2D-TC Analyzer and available options, and sample systems.

• Typical Applications — A brief discussion of industries and

applications where the TMO2D-TC can be used, along with two

common applications and the required TMO2D-TC

configurations.

TMO2D-TC technical specifications can be found in Chapter 6,

Specifications. Ordering information can be found in Chapter 7,

Ordering Information.

Introduction The GE Panametrics TMO2D-TC is an analyzer that measures the

thermal conductivity of a binary (or pseudo-binary) gas mixture,

determines and displays the concentration of one of the gases in the

mixture, and also provides 0/4-20 mA and RS232C outputs and alarm

relays for process control requirements. The TMO2D-TC consists of

two main components — the TMO2-TC Transmitter and the

TMO2D-TC Display.

The TMO2-TC Transmitter offers several unique design features:

• Ultra-stable thermistors and a temperature-controlled measuring

cell (55

span stability, as well as insensitivity to ambient temperature

variations.

o

C standard, or 70 oC optional) provide excellent zero and

• The measuring cell design makes it resistant to contamination and

essentially flow insensitive. Since it has no moving parts, the

transmitter can handle the shock and vibration found in many

industrial applications.

• You can select a 2-port version for measurement of zero-based gas

mixtures using a sealed reference gas (air), or 4-port version for

measurement of zero-suppressed gas mixtures (and some other

special calibrations) using a flowing reference gas.

Features and Capabilities 1-1

Page 10

11/1/95

Introduction (cont.) • The TMO2-TC modular construction means that the unit can be

field-calibrated quickly and easily; or the plug-in measuring cell

can be replaced with a pre-calibrated spare in minutes.

• The TMO2-TC Transmitter, with weatherproof and explosion-

proof packaging, is designed to be installed as close as possible to

the process sample point. It can be located up to 2,800 feet (850

meters) from the TMO2D-TC Display using inexpensive,

unshielded cable.

The TMO2D-TC Display offers several advanced features:

• The microprocessor-based TMO2D-TC electronics unit features a

two-line, backlit LCD display, full keypad, and menu-driven

software to provide easy access to a variety of features, including

user-selectable gas range, recorder output range, alarm settings,

and automatic calibration (Auto Cal).

• Standard 0/4-20 mA output and dual Form C alarm relays, coupled

with optional dual isolated 0/4-20 mA outputs and dual relays for

Auto Cal, provide excellent flexibility for process control

applications.

• Long-term, hands-off performance is provided by Auto Cal. When

re calibration is desired, the TMO2D-TC controls solenoid valves

in the sample system to bring zero and span gases to the TMO2-TC

Transmitter. Then, TMO2D-TC software compares the Auto Cal

readings with factory calibration data and makes any necessary

corrections -automatically - so manual re calibration requirements

can be reduced significantly.

• The TMO2D-TC Display, with bench, rack, panel, weatherproof,

and explosion-proof packaging options, can be located adjacent to

the TMO2-TC Transmitter, or up to 2,800 feet (850 meters) away

using inexpensive, unshielded cable.

1-2 Features and Capabilities

Page 11

11/1/95

Theory of Operation The TMO2-TC Transmitter measures the concentration of a gas in a

binary gas mixture by measuring the thermal conductivity of the

sample gas and comparing it to the thermal conductivity of a selected

reference gas.

Two ultra-stable, glass-coated thermistors are used: one in contact

with the sample gas, and the other in contact with a selected reference

gas. The thermistors are mounted so that they are in close proximity

to the stainless steel walls of the sample chamber. The entire sensor is

o

heated to 55

sensor temperature using a constant current source. The thermistors

lose heat to the walls of the sample chamber at a rate that is

proportional to the thermal conductivity of the gas surrounding them.

Thus, each thermistor will reach a different equilibrium temperature.

The temperature difference between the two thermistors is detected in

an electrical bridge circuit. It is amplified and converted to a 4-20 mA

output proportional to the concentration of one of the constituents of

the binary gas mixture.

C (or 70 oC) and the thermistors are heated above the

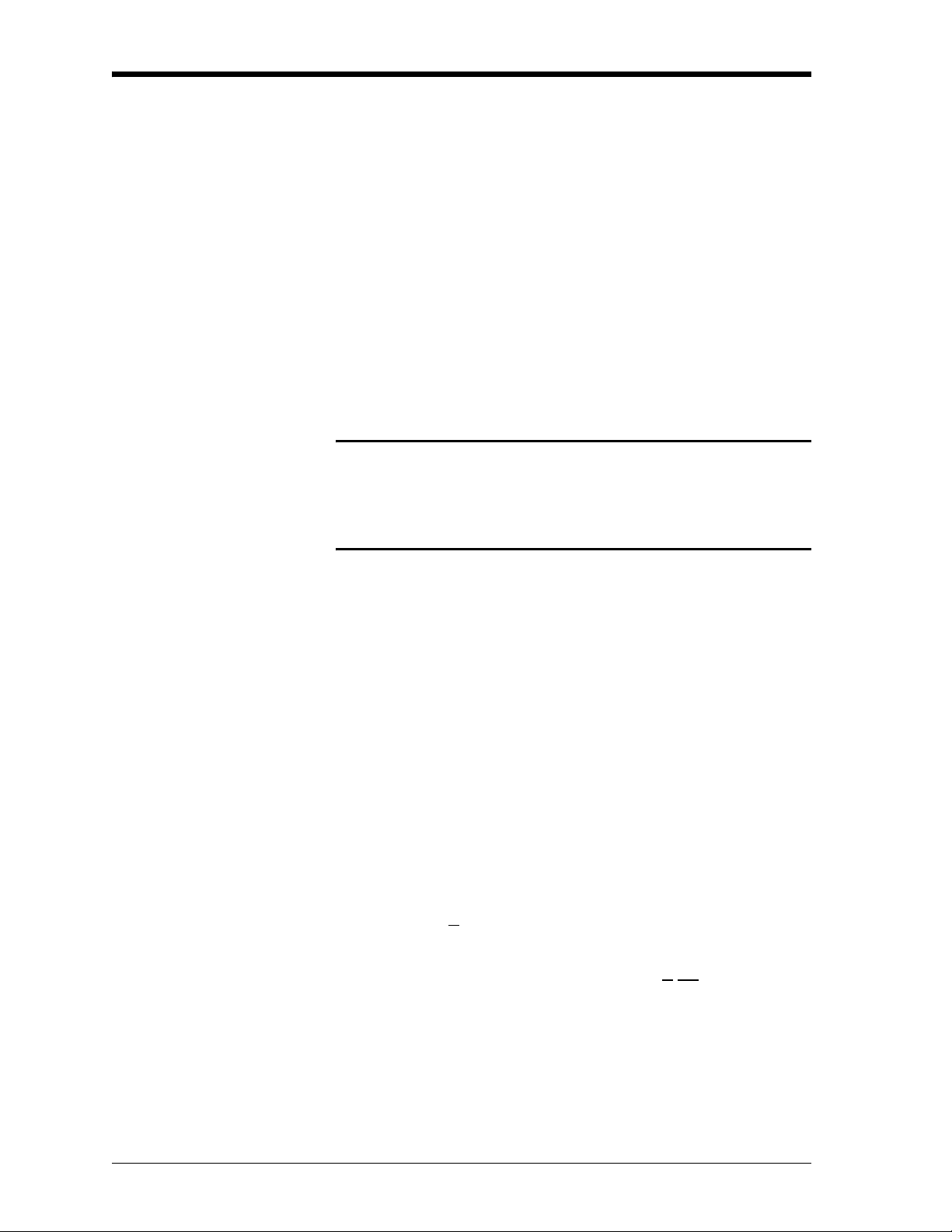

Appendix A contains a Table of Relative Thermal Conductivity of

Common Gases. Figure 1-1 on the next page shows several of these

values graphically. In order to measure 0 to 25% H

in N2, the

2

reference gas would be air (2-port version, sealed reference gas), and,

for calibration, the zero gas would be 100% N

span gas 25% H

, the reference gas would be 100% H2 (4-port version, flowing

N

2

(balance N2). In order to measure 90-100% H2 in

2

reference gas), the zero gas would be 90% H

span gas 100% H

(the same as the reference gas).

2

(i.e., 0 % H2) and the

2

(balance N2), and the

2

The TMO2-TC has a polarity adjustment switch which permits the

measurement of gases (such as CO

) with relative thermal

2

conductivity less than the background gas.

Features and Capabilities 1-3

Page 12

11/1/95

Theory of Operation

(cont.)

Air/N

2

SO

CO

2

C4-C

6

2

CH4Ne

He

H

2

Figure 1-1: Relative Thermal Conductivity of Several Common Gases

1-4 Features and Capabilities

Page 13

May 2003

System Description The basic TMO2D-TC measurement system consists of a TMO2-TC

Transmitter mounted in a sample system and connected to a TMO2DTC Display. The sample system is mandatory, and can be provided by

GE Panametrics or constructed according to our recommendations.

The TMO2D-TC is supplied with a standard 10 ft. (3 m), 3-wire cable

for connecting the transmitter to the display module. Lengths up to

2,800 ft. (850 m) are optionally available.

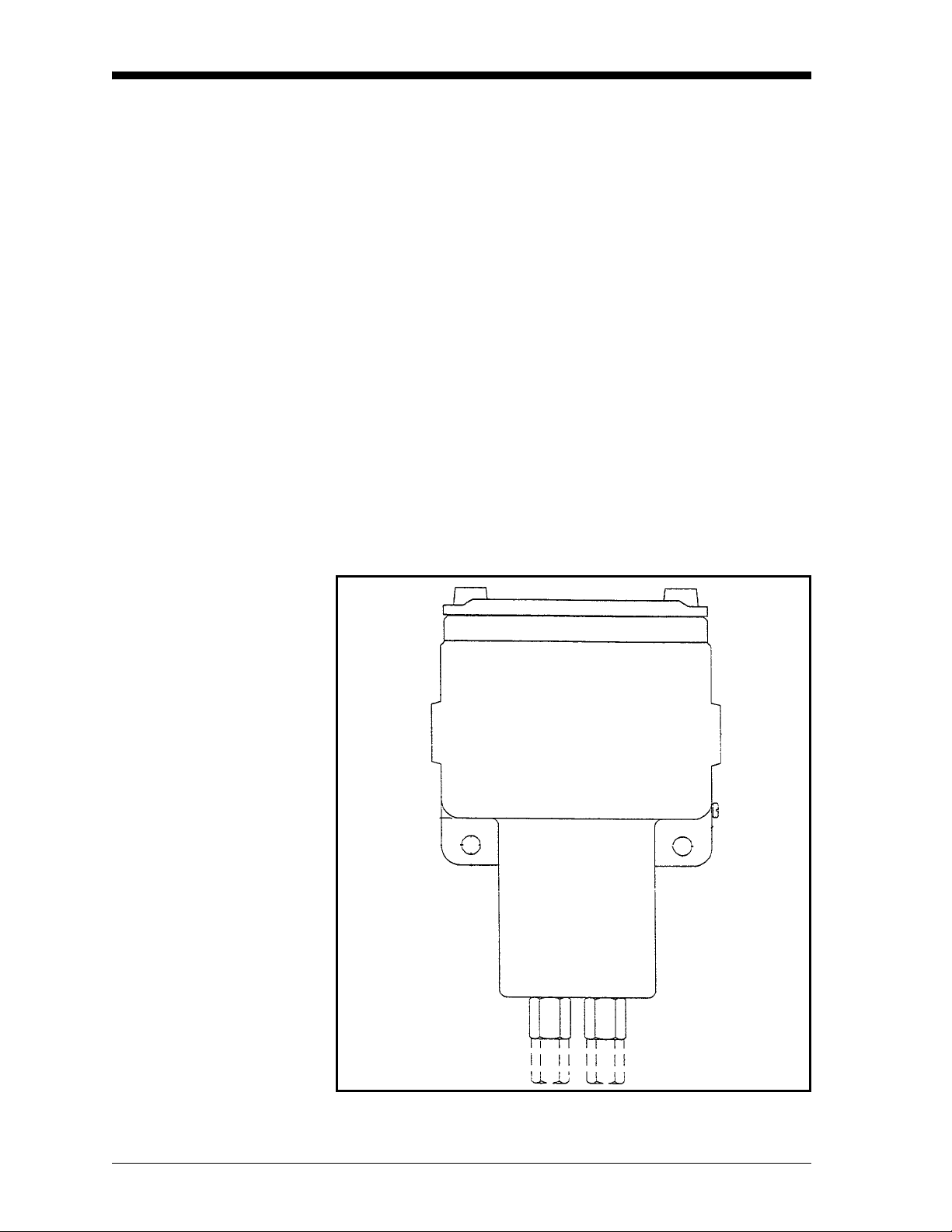

TMO2-TC Transmitter The TMO2-TC Transmitter is self-contained, consisting of the

thermal conductivity sensor and associated electronics. It requires 24

VDC power (1 amp maximum at power-up), which it receives from

the TMO2D-TC Display. It provides a 4-20 mA output signal to the

display module proportional to the thermal conductivity of the sample

gas and to the concentration of one of the gases in the binary mixture.

The TMO2-TC is designed to be installed in a sample system as close

as possible to the process sample point. Thus, it is available in two

environmental packages — weatherproof (NEMA-4X; IP65) and

explosion-proof (Class I, Groups C,D, Div. 1; Cenelec EEx d II C T6)

with the addition of flame arrestors to the sample/reference gas inlet

and outlet.

Each environmental package is available in a standard 2-port (sealed

reference gas) version, or optional 4-port (flowing reference gas)

version.

Features and Capabilities 1-5

Page 14

11/1/95

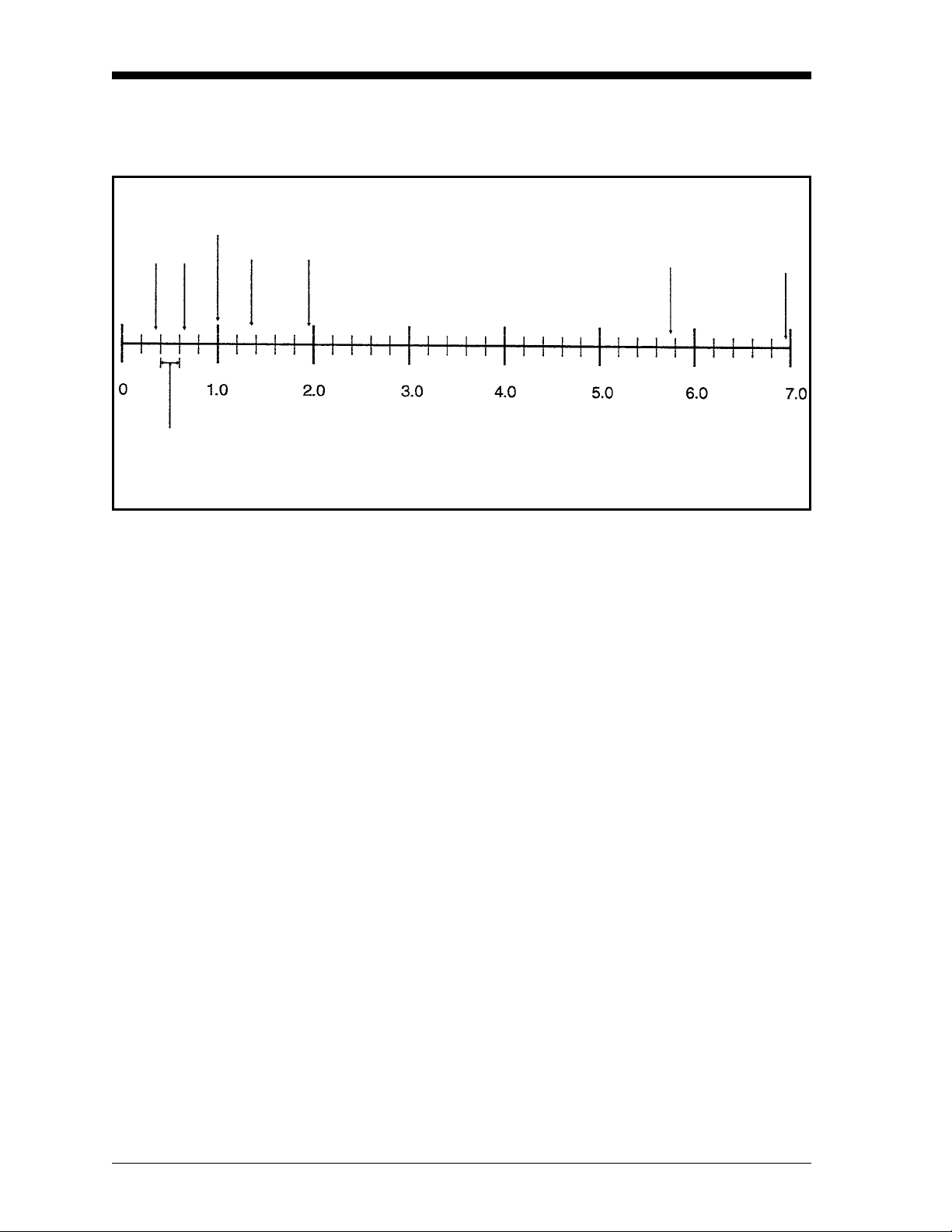

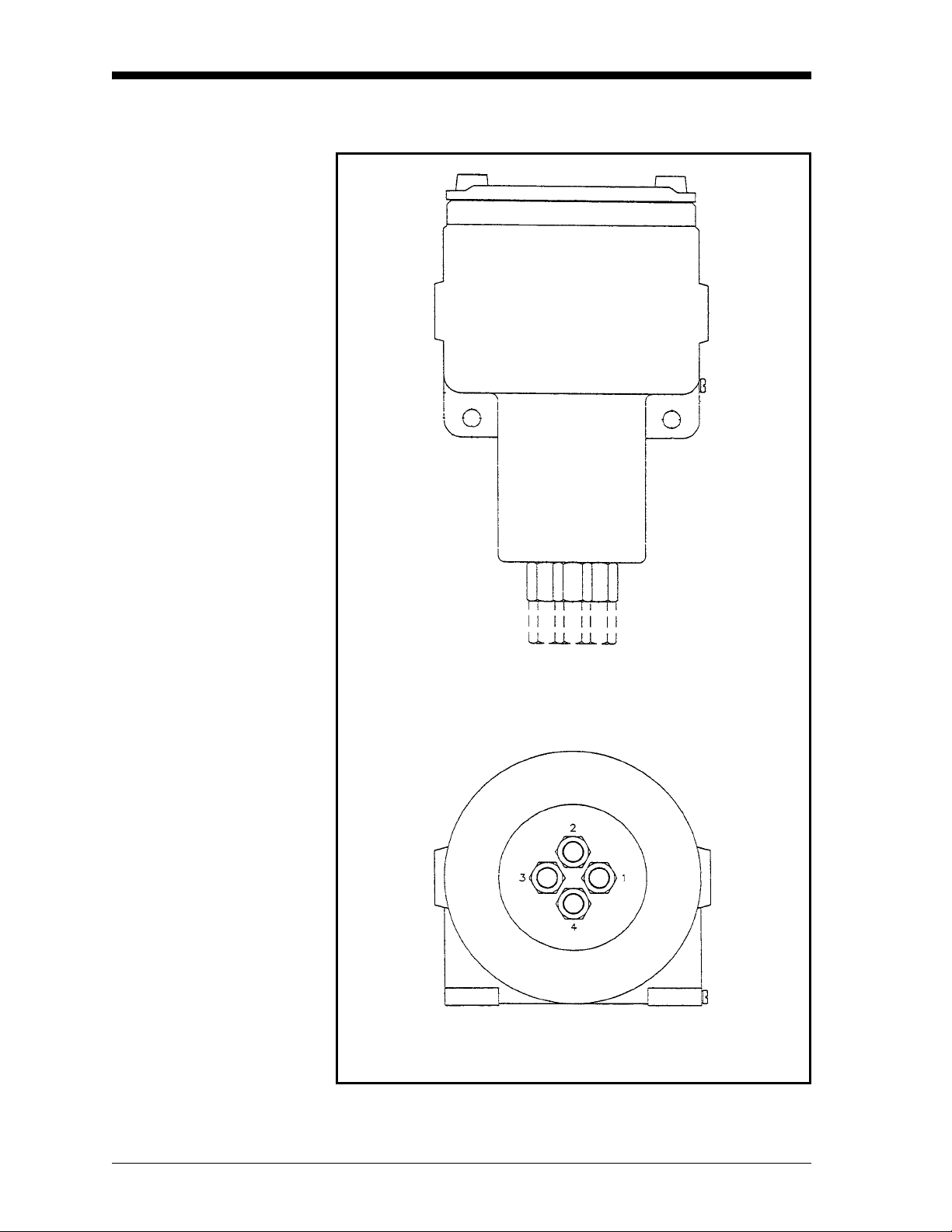

2-Port (Sealed Reference Gas) Version

This standard configuration (see Figure 1-2 below) is used for zerobased ranges with air or nitrogen at atmospheric pressure as the

balance or background gas. It utilizes air with desiccant in a factorysealed chamber as the reference gas. The following standard ranges

and gases are provided:

0 to 1%

0 to 2%

0 to 5%

0 to 10%

0 to 25%

0 to 50%

0 to 100%

in N

H

2

2

CO2 in N2 (minimum range 0 to 5% CO2)|

in Air (minimum range 0 to 5% CO2)

CO

2

He in N

He in Air

2

Figure 1-2: 2-Port (Sealed Reference Gas) TMO2-TC

1-6 Features and Capabilities

Page 15

11/1/95

4-Port (Flowing Reference Gas) Version

This optional configuration (see Figure 1-3 on the following page) is

used for zero-suppressed ranges and some other special applications.

Typically, a flowing reference gas of 100% H

following standard ranges and gases are provided:

90 to 100%

80 to 100%

in N

H

2

2

CO2 in N2/Air

He in N

2

/Air

Note: For factory calibration pricing on the standard ranges and

gases, or for pricing on other zero-suppressed ranges and

gases, please consult the factory.

The TMO2-TC is supplied with a standard measurement cell

o

operating temperature of 55

C. An optional 70 oC cell operating

temperature is available.

or CO2 is used. The

2

Note: The 70

high temperature applications, since it will result in reduced

sensitivity.

o

C operating temperature should be selected only for

Features and Capabilities 1-7

Page 16

11/1/95

4-Port (Flowing Reference Gas) Version (cont.)

Top View

Bottom View

Figure 1-3: 4-Port (Flowing Reference Gas) TMO2-TC

1-8 Features and Capabilities

Page 17

May 2003

Sample System A sample system is mandatory for use with the TMO2-TC. The

design of the sample system will depend on the conditions of the

sample gas and the requirements of the application. In general, a

sample system must deliver a clean, representative sample to the

TMO2-TC at a temperature, pressure, and flow rate that are within

acceptable limits. Standard TMO2-TC sample conditions are as

follows:

• Less than 50

temperature)

o

C (122 oF) temperature (for 55 oC cell operating

• Atmospheric pressure

• 0.5 SCFH (250 cc/min) flow rate

GE Panametrics offers sample systems for a wide variety of

applications. Three standard sample systems for the TMO2-TC are

shown in Chapter 2, Installation. For assistance in designing your

own sample system, please consult the factory.

TMO2D-TC Display The TMO2D-TC Display receives a 4-20 mA signal from the TMO2-

TC Transmitter proportional to the concentration of one of the gases

in the binary mixture (the sample gas). It then displays the

concentration (and other information) on a 2-line x 24 character,

backlit LCD.

It requires 100/120/220/240 VAC power (35 watts max.), and

provides 24 VDC power to the TMO2-TC Transmitter. The standard

TMO2D-TC provides a 0/4-20 mA analog output; an RS232C digital

output; and dual Form C, SPDT relays for process monitoring and

control. Dual isolated 0/4-20 mA outputs and a second pair of relays

for Auto Cal are available as options.

The TMO2D-TC can be located adjacent to the TMO2-TC

Transmitter or as far as 2,800 ft. (850 m) away. It is provided in

bench, rack, panel, weatherproof (NEMA 4X; IP65), or explosionproof mounting configurations. The standard TMO2D-TC is suitable

for use in general purpose areas. A package suitable for use in Class I,

Div. 2 hazardous areas is available as an option. This package

includes hermetically-sealed alarm relays.

Extra Cable (optional) GE Panametrics provides a 10 ft. (3 m) length of 3-wire, color-coded

cable with each TMO2D-TC to connect the transmitter to the display

module. The same cable is available in lengths up to 2,800 ft (850 m).

If you are using your own cable, refer to Chapter 2, Table 2-2, Cable

Requirements, for recommendations.

Features and Capabilities 1-9

Page 18

11/1/95

Typical Applications The TMO2D-TC can be used in a wide variety of industrial

applications where it is necessary to measure the concentration of one

component of a binary gas mixture. It can also be used in pseudobinary gas mixtures where the ratio of concentrations of the

background gas components remains constant, and in gaseous

mixtures where the thermal conductivity of the gas of interest is

significantly different from that of the background gas. Some typical

industries and applications include:

• Metals Industry —

H

in heat treat furnace atmospheres

2

• Electric Power Industry —

in generator cooling systems

H

2

• Gas Production Industry —

Purity monitoring of argon, hydrogen, nitrogen, helium

• Chemical Industry —

in ammonia synthesis gas

H

2

H

in methanol synthesis gas

2

in chlorine plants

H

2

• Food Industry —

CO

in fermentation processes

2

Ethylene Oxide (ETO) sterilization

• Steel Industry —

in blast furnace top gas

H

2

• Petroleum Industry —

in hydrocarbon streams

H

2

Two very common applications are as follows:

in N2 in heat treat furnace atmospheres - Zero-based 0-25%

1. H

2

, 2-Port (sealed reference gas, air)

H

2

purity in H2 electricity generator cooling - Zero-suppressed,

2. H

2

80-100% H

For more details on these applications, refer to Appendix B,

Applications. For details on applications not shown in Appendix B, or

if you wish to discuss your own application, please consult the

factory.

, 4-Port (flowing reference gas, 100% H2)

2

1-10 Features and Capabilities

Page 19

Chapter 2

Page 20

Installation

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Mounting the TMO2-TC Transmitter . . . . . . . . . . . . . . . . . . . . . . . .2-2

Mounting the Sample System . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

Mounting the TMO2D-TC Display . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Wiring the TMO2-TC Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

Wiring the TMO2D-TC Display . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

Page 21

May 2003

Overview This chapter will describe how to mount and wire the TMO2-TC

Transmitter and its sample system, and the TMO2D-TC Display. You

will find the following topics discussed:

• Introduction — A brief discussion of installation steps.

• Mounting the TMO2-TC Transmitter — How to mount the

transmitter in a sample system.

• Mounting the Sample System — Mounting and plumbing a GE

Panametrics sample system. Includes drawings of basic 2-Port and

4-Port sample systems, and an automatic 2-Port sample system.

• Mounting the TMO2D-TC Display — How to mount the different

TMO2D-TC packaging configurations.

• Wiring the TMO2-TC Transmitter — How to connect the

transmitter to the display module.

• Wiring the TMO2D-TC Display — Connecting 100/120/220/240

VAC power, 0/4-20 mA output and alarm relay wiring to the

TMO2D-TC.

!WARNING!

TO ENSURE THE SAFE OPERATION OF THE

TMO2D-TC, YOU MUST INSTALL AND OPERATE IT

AS DESCRIBED IN THIS MANUAL. IN ADDITION, BE

SURE TO FOLLOW ALL APPLICABLE SAFETY

CODES AND REGULATIONS FOR INSTALLING

ELECTRICAL EQUIPMENT IN YOUR AREA.

PROCEDURES SHOULD BE PERFORMED BY

TRAINED SERVICE PERSONNEL.

!ATTENTION EUROPEAN CUSTOMERS!

IN ORDER TO MEET CE MARK REQUIREMENTS,

YOU MUST INSTALL CABLES AS DESCRIBED IN

APPENDIX H.

Note: Different versions of the TMO2D-TC display have different

PC boards. In Appendix C refer to the appropriate drawings,

as follows:

• Serial numbers 101 through 749, schematic 700-997 and

PCB assembly drawing 703-997.

• Serial numbers 750 or greater, schematics 700-1226 and

PCB assembly drawing 703-1226.

Installation 2-1

Page 22

May 2003

Introduction Installation of the TMO2D-TC analyzer typically consists of five

steps:

1. Mounting the TMO2-TC Transmitter in a sample system. (If you

purchased your sample system from GE Panametrics, this step has

already been done for you.)

2. Mounting, plumbing (and possibly wiring) the sample system.

3. Mounting the TMO2D-TC Display.

4. Making wiring connections between the transmitter and the

display module.

5. Making wiring connections to the TMO2D-TC Display for power,

outputs, and alarms.

Mounting the TMO2-TC Transmitter

This section applies only if you are mounting the TMO2-TC

Transmitter to a sample system that has not been supplied by GE

Panametrics.

Your sample system should deliver a clean, representative sample to

the TMO2-TC at the proper temperature, pressure and flow rate. This

usually means a clean, dry sample (free of solid and liquid

particulates) at atmospheric pressure; a temperature no greater than

o

C (122 oF); and a flow rate of approximately 0.5 SCFH (250 cc/

50

min). Factory calibration of the sensor is at atmospheric pressure and

0.5 SCFH - higher or lower operating pressures may necessitate field-

calibration adjustment.

A simple sample system for a 2-Port TMO2-TC might have an inlet

and/or outlet flow regulating needle valve; a flow meter; and a

pressure gauge, in addition to the TMO2-TC Transmitter.

The TMO2-TC Transmitter should be mounted in the sample system

o

so that it is upright and level to within +/- 15

. Also, provide at least

9" of clearance above the top cover of the transmitter to allow access

to the transmitter printed circuit board (PCB) for calibration and

maintenance. For a 2-Port TMO2-TC, connect the sample system

Sample Inlet and Sample Outlet portions to the appropriate TMO2TC port (see Drawing 712-225 in Appendix C for port location). For a

4-Port system, also connect the Reference Inlet and Reference Outlet

portions to the appropriate TMO2-TC port (see Drawing 712-226 in

Appendix C for port location).

!WARNING!

FOR EXPLOSION-PROOF UNITS, BE SURE TO

CONFORM TO ALL SAFETY AND ELECTRICAL

CODE REQUIREMENTS.

2-2 Installation

Page 23

May 2003

Mounting the Sample System

Manual, 2-Port (Sealed Reference Gas) Sample System

You can order a complete sample system, which includes the TMO2TC Transmitter and all necessary components and sample tubing

mounted on a metal panel, from GE Panametrics. Several standard

sample systems are available; and custom-designed sample systems

can be built to your exact specifications. Following are descriptions

of three standard sample systems:

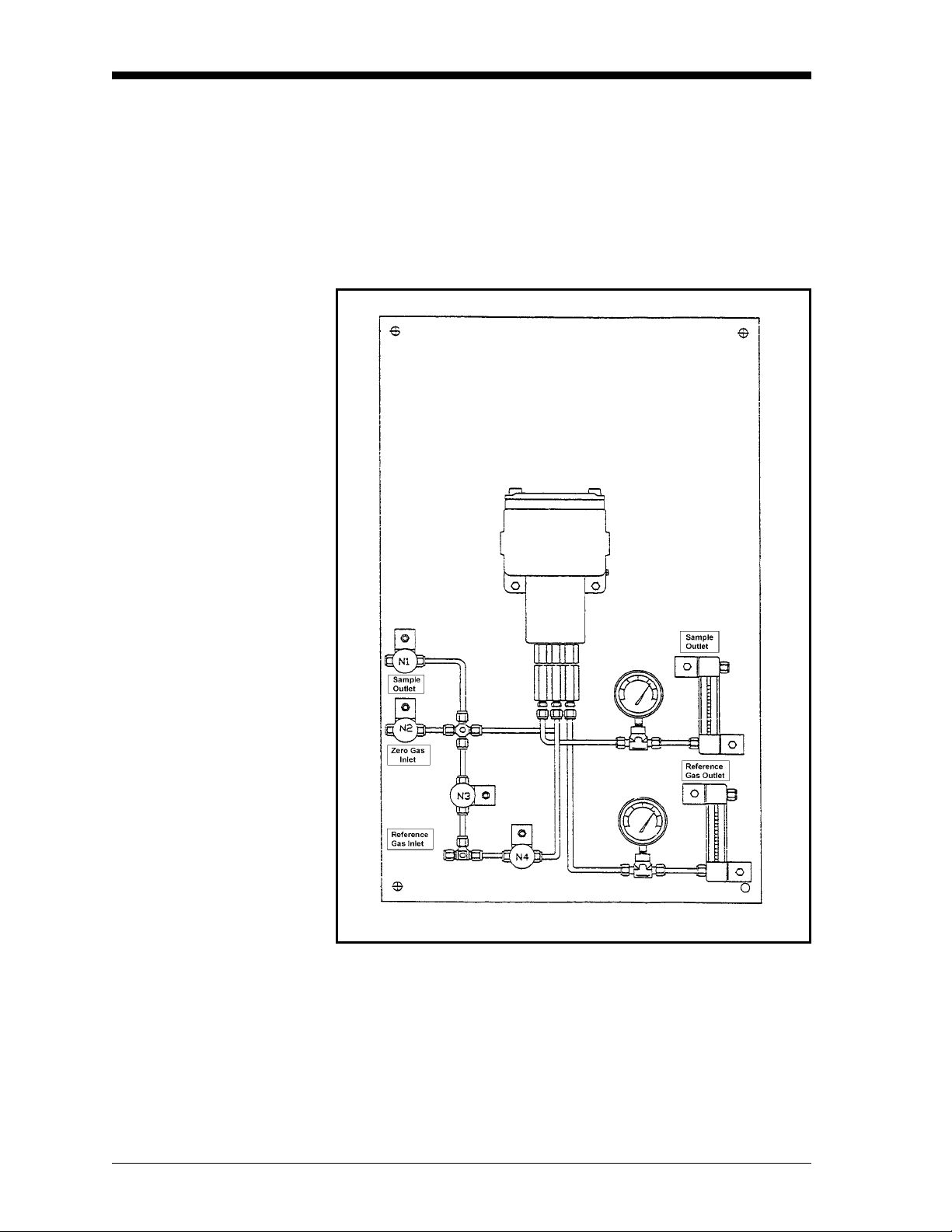

Figure 2-1 below shows a basic sample system for a 2-Port (sealed

reference gas) TMO2-TC. This sample system consists of inlet needle

valves for sample, zero, and span gases; a ball valve; a 2-port TMO2TC; a pressure gauge; and a flow meter. All components are mounted

on a painted steel plate. Other components could be added for

filtration (filter/coalescer), pressure control (regulator), or flow

control (pump).

Figure 2-1: Basic Sample System for a 2-Port TMO2-TC

Installation 2-3

Page 24

May 2003

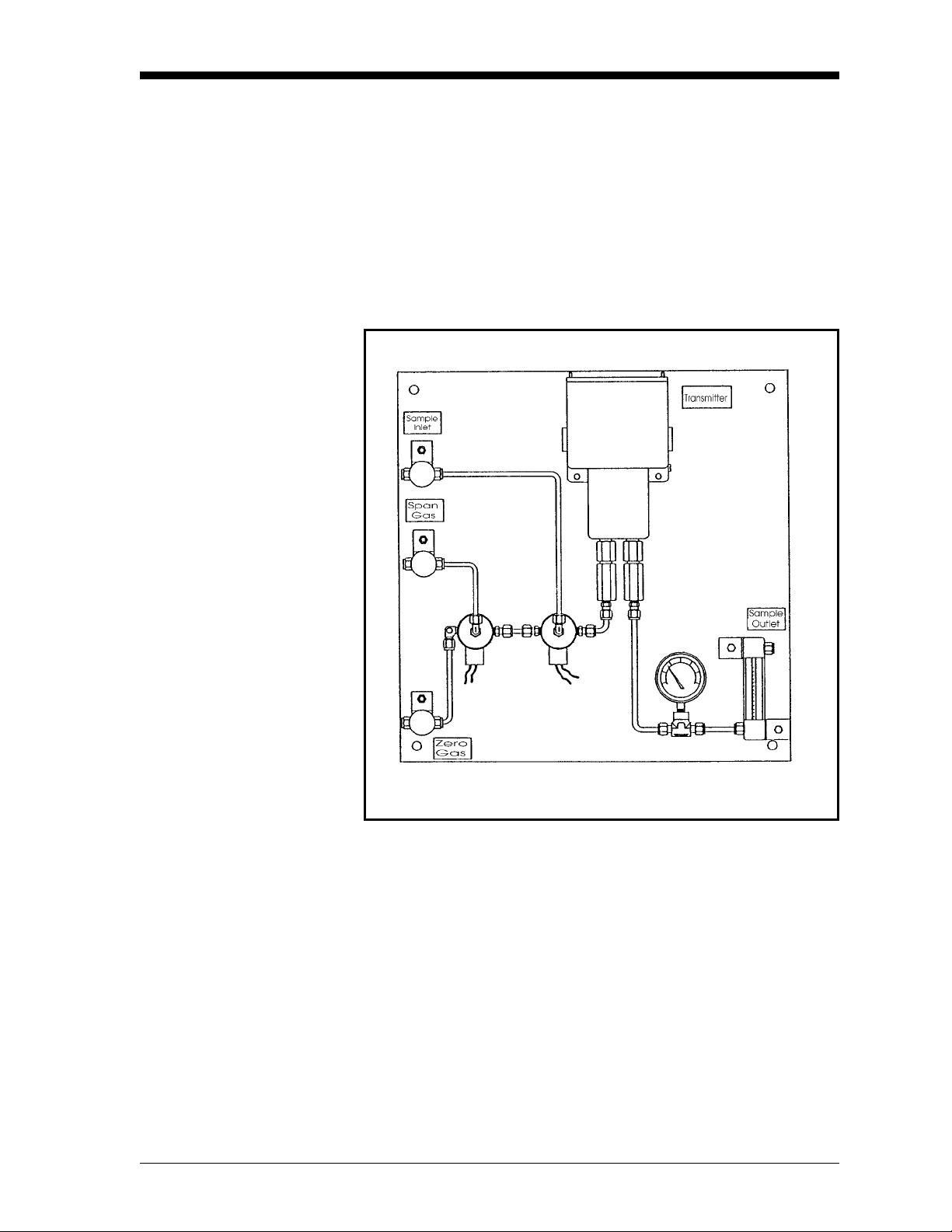

Manual, 4-Port (Flowing Reference Gas) Sample System

Figure 2-2 below shows a basic sample system for a 4-Port (flowing

reference gas) TMO2-TC. This sample system consists of inlet needle

valves for sample, reference, and calibration gases; a 4-port TMO2TC; two pressure gauges; and two flow meters. All components are

mounted on a painted steel plate. Other components could be added

for filtration (filter/coalescer), pressure control (regulator), or flow

control (pump).

Figure 2-2: Basic Sample System for a 4-Port TMO2-TC

2-4 Installation

Page 25

11/1/95

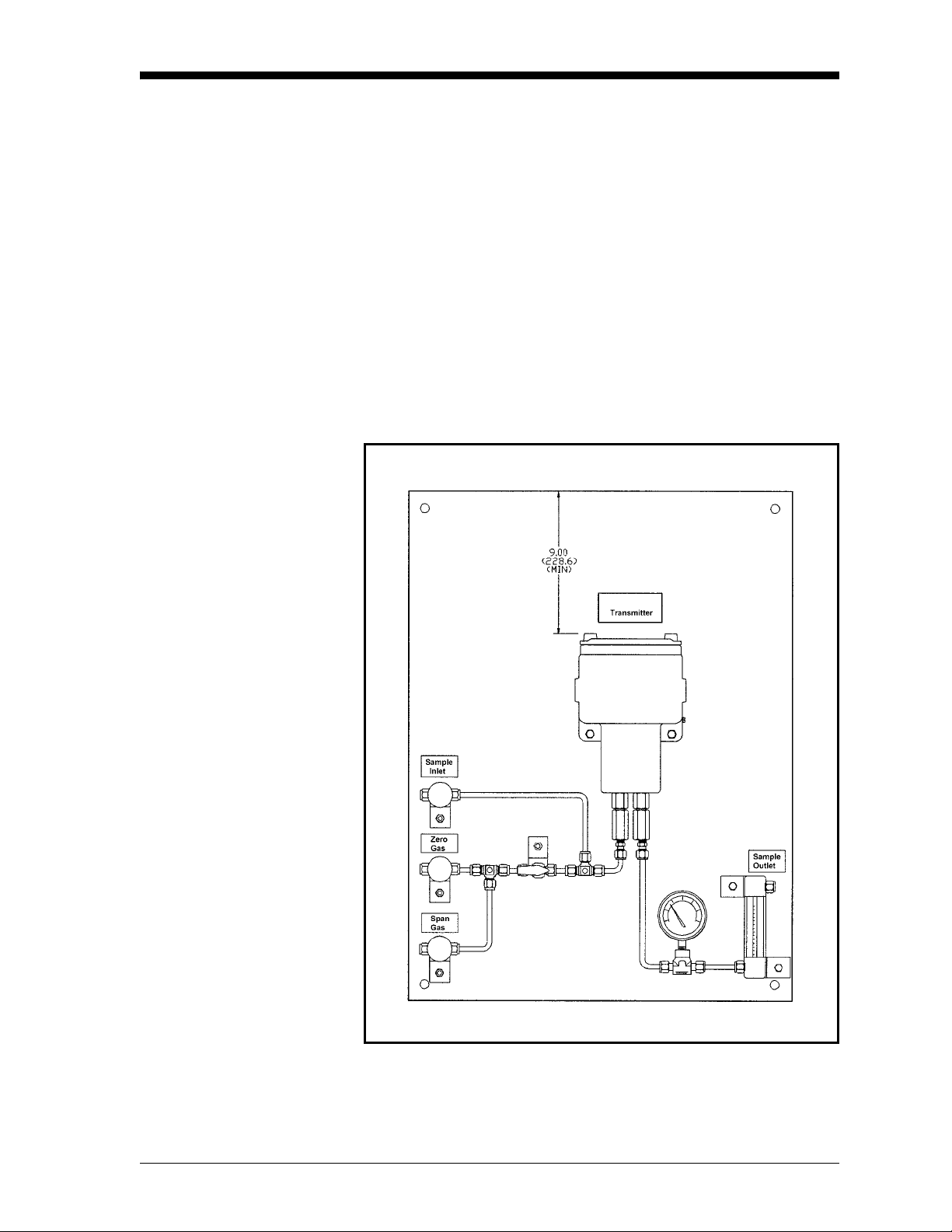

Automatic, 2-Port (Sealed Reference Gas) Sample System

Figure 2-3 below shows an automatic sample system for a 2-Port

(sealed reference gas) TMO2-TC. This sample system requires the

Auto Cal option on the TMO2D-TC Display. It consists of inlet

needle valves for sample, zero, span, and optional calibration gases;

two electrically-actuated solenoid valves for gas selection; a 2-Port

TMO2-TC; a pressure gauge; a flowmeter; a regulating needle valve;

and a sample pump. All components are mounted on a painted steel

plate. Other components could be added for filtration (filter/

coalescer), or pressure control (regulator).

Figure 2-3: Automatic Sample System

for a 2-Port TMO2-TC

Installation 2-5

Page 26

May 2003

Automatic, 2-Port

(Sealed Reference Gas)

Sample System (cont.)

Mounting the TMO2DTC Display

When used in conjunction with the TMO2D-TC Display with the

Auto Cal option, the above sample system allows automatic

switching of sample, zero, and span gases during calibration. Refer to

Appendix B, Applications, for details on sample systems designed by

GE Panametrics for specific applications.

Mount the sample system as close as possible to the process sample

point. Once the sample system is mounted, connect all inlet and outlet

lines via the fittings on the sample system (1/4" compression). The

sample line leading from the process to the sample system should be

of 1/4" stainless steel tubing, and as short as possible in order to

insure a representative sample.

The TMO2D-TC Display is available in five mounting

configurations: bench, rack, panel, weatherproof, and explosionproof. See Appendix C, Outline and Installation Drawings, for

dimensional drawings for each configuration, as well as rack/panel

cutout dimensions.

No special mounting requirements are needed for the TMO2D-TC

Display.

!WARNING!

FOR EXPLOSION-PROOF AND CLASS I, DIV. 2

UNITS, BE SURE TO CONFORM TO ALL SAFETY

AND ELECTRICAL CODE REQUIREMENTS.

!WARNING!

TO ENSURE THE SAFE OPERATION OF THE

TMO2D-TC, YOU MUST INSTALL AND OPERATE IT

AS DESCRIBED IN THIS MANUAL. IN ADDITION, BE

SURE TO FOLLOW ALL APPLICABLE SAFETY

CODES AND REGULATIONS FOR INSTALLING

ELECTRICAL EQUIPMENT IN YOUR AREA.

PROCEDURES SHOULD BE PERFORMED BY

TRAINED SERVICE PERSONNEL.

2-6 Installation

Page 27

1/20/97

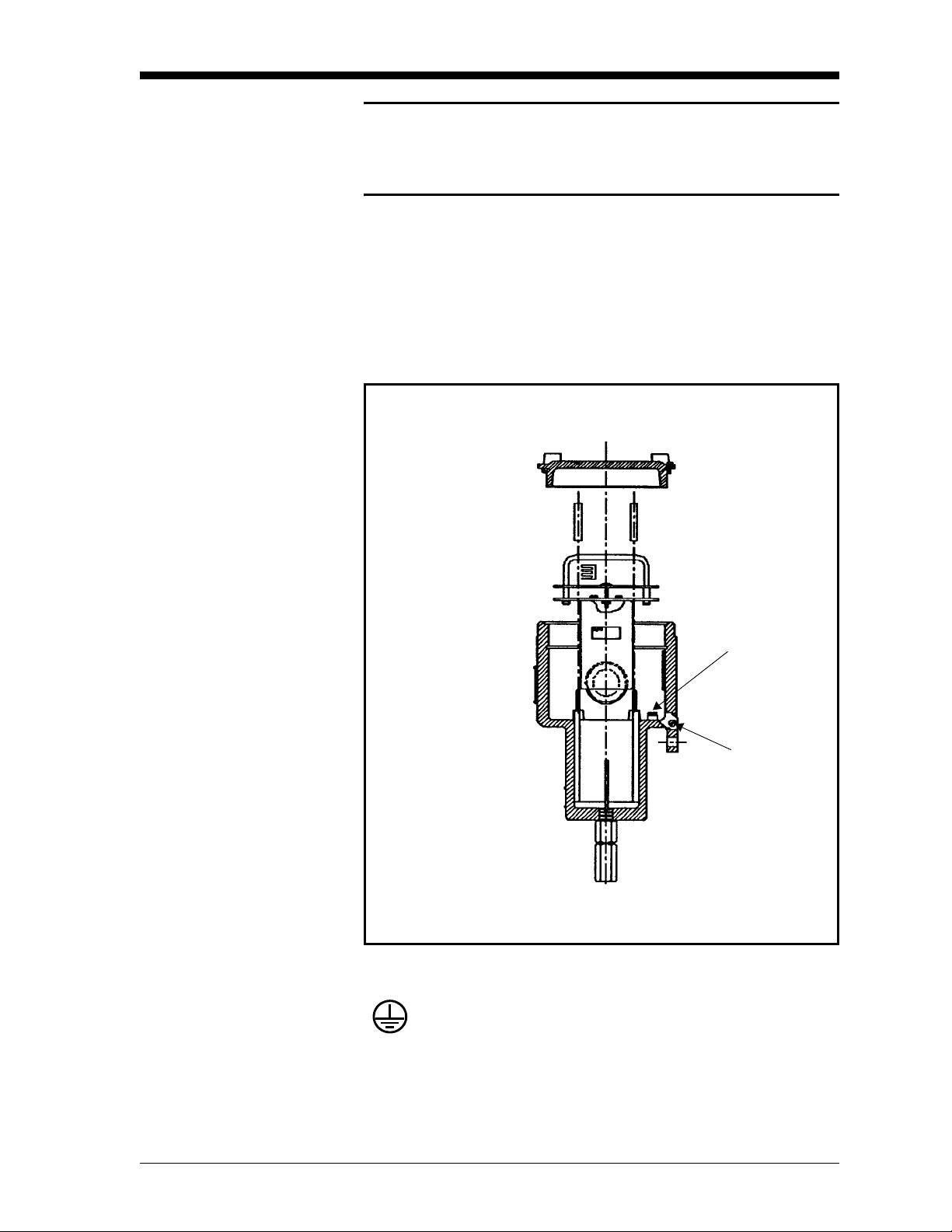

Wiring the TMO2-TC Transmitter

Caution!

Always bring power to the TMO2-TC immediately after

installation, especially when it is mounted outdoors or in

a humid area.

This section describes how to wire the TMO2-TC Transmitter to the

TMO2D-TC Display. First, the transmitter enclosure must be

grounded. This can be done using an external ground screw on the

TMO2-TC, or, if required, an internal ground screw located below the

transmitter PCB. See Figure 2-4 below for the location of both ground

screws.

Figure 2-4: Location of Ground Screws

= Protective Conductor Terminal

Internal

Ground

Screw

External

Ground

Screw

Installation 2-7

Page 28

11/1/95

Wiring the TMO2-TC

Transmitter (cont.)

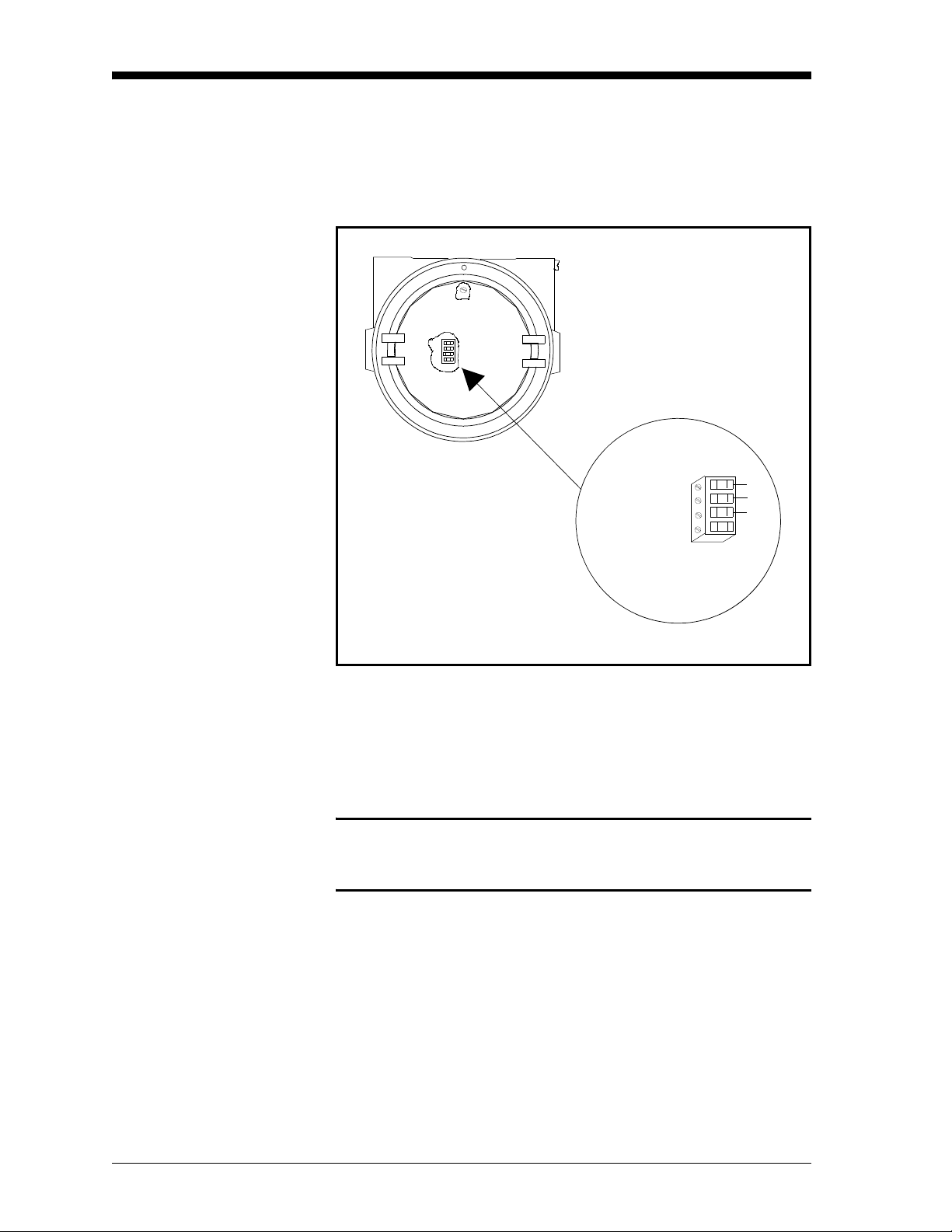

Wiring connections to the TMO2-TC Transmitter are made to

terminal block TB1, which is accessed by removing the TMO2-TC

cover. See Figure 2-5 below for the location and pin designations for

TB1. Also refer to Appendix C, Outline and Installation Drawings.

1

2

3

4

+24 VDC/1Amp

Return

Output Signal

No Connection

1

2

3

4

Red

Blk

Wht

Figure 2-5: TMO2-TC Wiring Connections

Wiring connections to the TMO2D-TC Display are made to the

terminal block labeled OXYGEN CELL at the rear of the TMO2DTC. See Figure 2-6 on the following page for the location of the

OXYGEN CELL terminal block.

Caution!

Do not make any connections to unassigned or unused

terminals.

2-8 Installation

Page 29

Wiring the TMO2-TC

Transmitter (cont.)

11/1/95

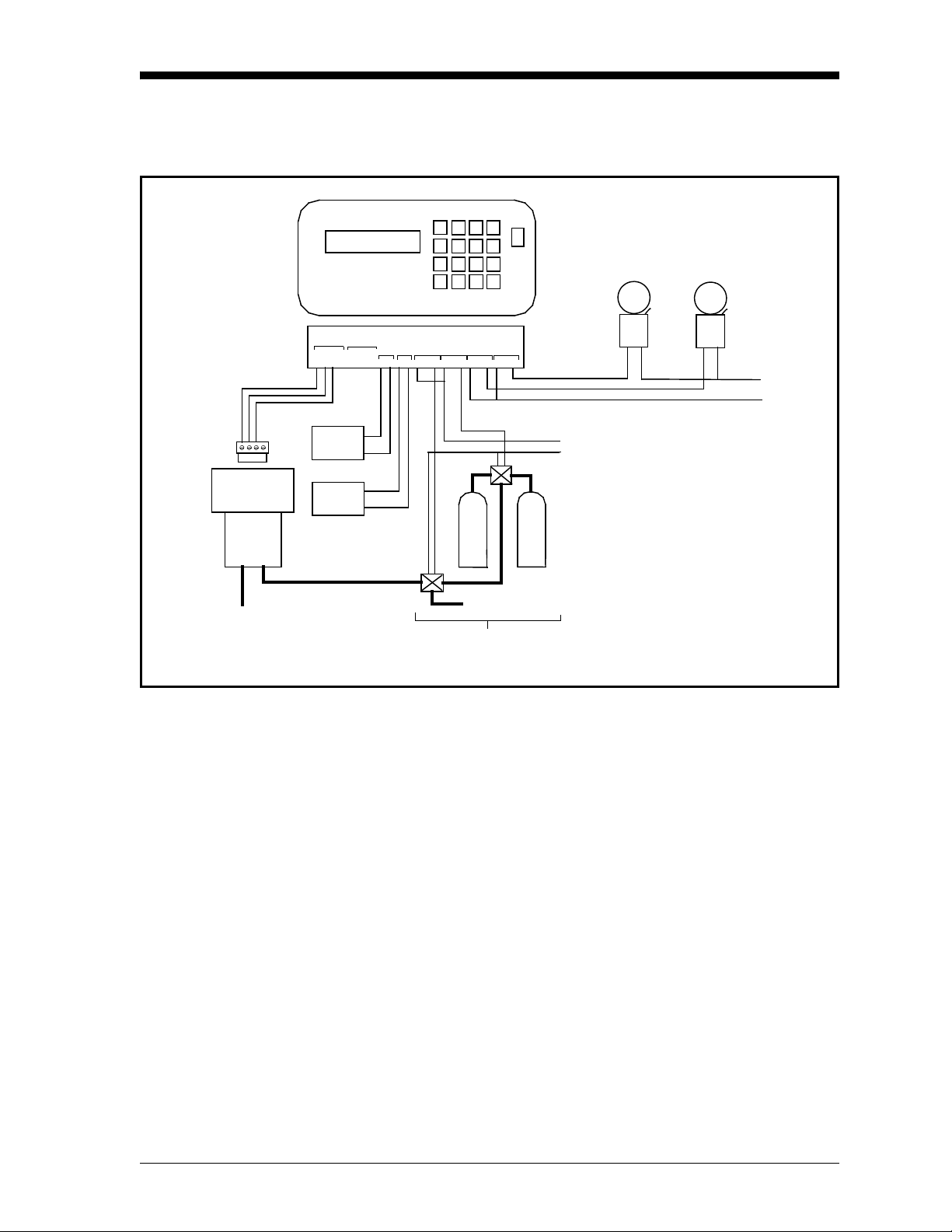

14

32

TMO2-TC

Outlet

TMO2D-TC

OXYGEN

SPARE

Cell

+24V

RTN

REC

REC

B

RECORDERS

INPUTS

COMP

0/4-20 mA

+24V

RTN

REC A REC B

IN2

IN1

OX

+

-

+

_

A

+

_

+

-

AUTOCAL

PROCESS CAL

C NC NO

C NC NO

ALARMS

LOW HIGH

C NC NOC NC NO

Zero

Gas

Span

Gas

Process Gas Inlet

Auto-Calibration System

High

Alarm

Solonoid Valve

Power

Low

Alarm

Alarm

Power

Figure 2-6: TMO2D-TC Wiring Connections

Installation 2-9

Page 30

May 2003

Wiring the TMO2-TC

Transmitter (cont.)

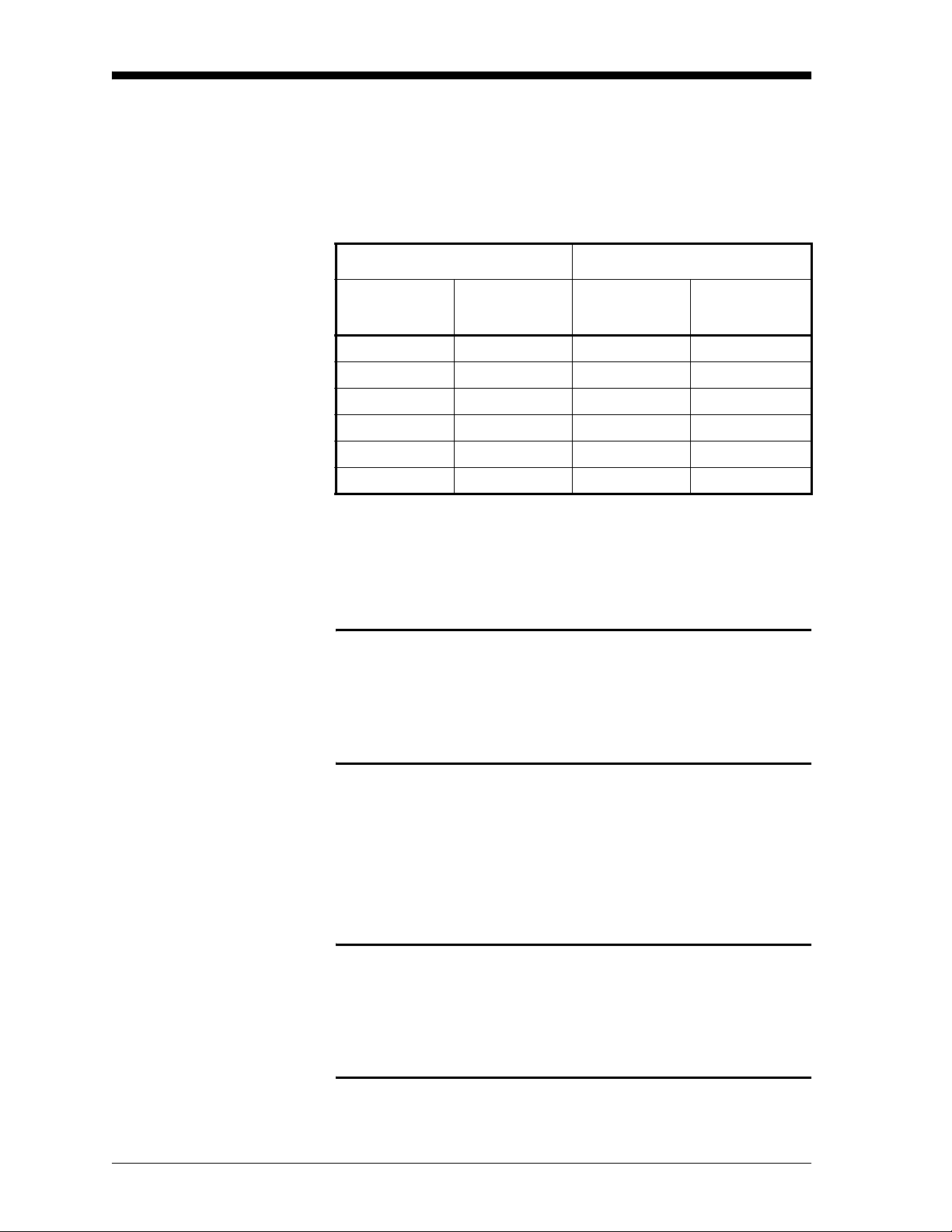

Table 2-2 below shows the transmitter to display module wiring

connections using the standard GE Panametrics TMO2D-TC cable.

This cable can be used for distances up to 2,800 ft (850 m). If you are

using your own cable, refer to Table 2-2 for cable requirements.

Table 2-1: Cable Requirements

Max Cable Length Cable Size

Sq.

Feet Meters AWG

450 130 22 0.35

700 200 20 0.6

1,050 320 18 1.0

1,700 500 16 1.2

2,800 850 14 2.0

4,000 1,200 12 3.0

Use the following steps to make the proper connections:

Millimeters

1. Route the cable into the transmitter through one of the 3/4"

conduit holes.

!WARNING!

BE SURE TO PLUG UP THE UNUSED CONDUIT

HOLE ON THE SIDE OF THE TRANSMITTER IN

ORDER TO MAINTAIN THE APPROPRIATE

WEATHERPROOF OR EXPLOSION-PROOF

RATING.

2. Unplug TB1 by carefully pulling it directly up without bending the

pins attached to the PCB.

3. Loosen the TB1 side screws and insert the colored wires into the

corresponding openings on top of TB1. See Table 2-1 above for

color-coded pin designations.

!WARNING!

BE SURE THAT +24 VDC (RED WIRE) IS

CONNECTED TO TERMINAL TB1-1. CONNECTING

+24 VDC POWER TO ANY OTHER TERMINAL WILL

DAMAGE THE TMO2-TC PCB, REQUIRING

FACTORY REPAIR.

2-10 Installation

Page 31

11/1/95

Wiring the TMO2-TC

Transmitter (cont.)

Table 2-2: Transmitter Power and Output Connections

Transmitter

Wire Color Gage

+24 VDC Red 14 AWG Pin 1 +24V

Return Black 14 AWG Pin 2 RTN

Signal White 22 AWG Pin 3 OX

4. Tighten the side screws, and carefully plug TB1 back onto the

PCB.

5. Connect the other end of the cable in a similar manner to the

OXYGEN CELL terminal block located on the rear panel of the

TMO2D-TC Display. See Table 2-1 on the previous page for

color-coded pin designations.

TB1 Display

Installation 2-11

Page 32

1/20/97

Wiring the TMO2D-TC Display

Figure 2-6 on page 2-9 shows possible output wiring connections

between the TMO2D-TC Display and recorders, alarms, and

automatic sample systems. Note that the standard TMO2D-TC has a

single, non-isolated 0/4-20 mA output (RCDR A) and dual Form C

SPDT alarm relays (ALARMS). Dual isolated 0/4-20 mA outputs

(RCDR A/RCDR B) and dual auto calibration (Auto Cal) relays are

optional.

The alarm relays can be wired in a “fail-safe” configuration that will

allow a contact closure when the H

level falls below a certain point

2

or rises above a certain point, or when a power failure occurs. For

example, to have a contact closure when the H

level falls below 1%

2

or rises above 5%, or in the event of a power failure, do the following:

TMO2D-TC Alarm Wire Program For Use As

LOW COM/NC 5% H

HIGH COM/NC

1% H

2

2

HIGH

LOW

Note: See Chapter 4, Programming the TMO2D-TC, The Alarms

Menu, for information on programming the alarm set points.

When the LOW alarm is wired and programmed as above, a loss of

power or an H

reading greater than 5% causes a contact closure that

2

can be used as a HIGH or “fail-safe” alarm.

When the HIGH alarm is wired and programmed as above, a loss of

power or an H

reading less than 1% causes a contact closure that can

2

be used as a LOW or “fail-safe” alarm.

!ATTENTION EUROPEAN CUSTOMERS!

IN ORDER TO MEET CE MARK REQUIREMENTS,

YOU MUST SHIELD AND GROUND ELECTRICAL

CABLES AS DESCRIBED IN APPENDIX H.

!WARNING!

TO ENSURE THE SAFE OPERATION OF THE

TMO2D-TC, YOU MUST INSTALL AND OPERATE IT

AS DESCRIBED IN THIS MANUAL. IN ADDITION, BE

SURE TO FOLLOW ALL APPLICABLE SAFETY

CODES AND REGULATIONS FOR INSTALLING

ELECTRICAL EQUIPMENT IN YOUR AREA.

PROCEDURES SHOULD BE PERFORMED BY

TRAINED SERVICE PERSONNEL.

2-12 Installation

Page 33

1/20/97

Wiring the TMO2D-TC

Display (cont.)

The TMO2D-TC also has a bi-directional, industry standard RS232C

serial port, which can be connected to a terminal or PC that supports

the RS232C protocol. Figure 2-7 below shows the wiring pin

designations. The 25-pin, male D connector is located at the right on

the rear of the TMO2D-TC Display.

J8

Pin 14

Pin 1

Pin 2 = Transmit

(from)

Pin 3 = Receive (to)

Pin 7 = Return (ground)

Figure 2-7: RS232C Wiring Connections

Installation 2-13

Page 34

1/20/97

Wiring the TMO2D-TC

Display (cont.)

The TMO2D-TC Display is connected to 100/120/220/240 VAC

power using the supplied power cord.

Caution!

The interconnecting wiring between the TMO2-TC

Transmitter and TMO2D-TC Display must be completed

before powering up.

Note: The power cord is the main disconnect device.

Note: = Protective Conductor Terminal

IMPORTANT: To comply with the European Low Voltage Directive,

you must install a switch or circuit breaker on the

input power line. For greatest safety, locate the

circuit breaker or switch near the unit that the line

serves.

2-14 Installation

Page 35

Chapter 3

Page 36

Operation

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Powering Up the TMO2D-TC Analyzer . . . . . . . . . . . . . . . . . . . . . .3-1

Establishing a Flow of Sample Gas . . . . . . . . . . . . . . . . . . . . . . . .3-2

Operating the TMO2D-TC Display. . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Page 37

1/20/97

Overview This chapter provides information on operating the TMO2D-TC

analyzer. You will find the following topics discussed:

• Introduction — A brief discussion of operational considerations.

• Powering Up the TMO2D-TC Analyzer — How to start the

TMO2D-TC.

• Establishing a Flow of Sample Gas — Basic sample gas

considerations.

• Operating the TMO2D-TC Display — A description of the

TMO2D-TC LCD display and keypad.

Introduction The TMO2D-TC operation consists of only three steps:

1. Supplying power to the analyzer and turning it on.

2. Establishing a flow of sample gas through the system.

Powering Up the TMO2D-TC Analyzer

3. Operating the display module.

If you have not already done so, please read Chapter 2, Installation,

for details on mounting and wiring the TMO2-TC Transmitter, the

sample system, and the TMO2D-TC Display.

The TMO2D-TC Display has a power switch located at the top right

of the front panel. It will begin operation as soon as it is turned to the

ON position.

Note: The power cord is the main disconnect device.

Note: If your TMO2D-TC was supplied in a weatherproof enclosure

or was modified for use in Class I, Div. 2 hazardous areas, the

power switch will be inoperative. The TMO2D-TC will begin

operating as soon as it is connected to a 100/120/220/240

VAC power source.

The TMO2D-TC Display will provide 24 VDC power to the TMO2TC Transmitter. Because the transmitter is controlled at a constant

o

C (131oF) operating temperature, allow 30 minutes for the unit to

55

warm up and reach temperature stability. During this time, you can

establish a sample gas flow through the sample system.

IMPORTANT: To comply with the European Low Voltage Directive,

you must install a switch or circuit breaker on the

input power line. For greatest safety, locate the

circuit breaker or switch near the unit that the line

serves.

Operation 3-1

Page 38

May 2003

Powering Up the

TMO2D-TC Analyzer

(cont.)

Establishing a Flow of Sample Gas

When the display module is first turned on, it will show the firmware

version installed. For example:

GE Panametrics

TMO2D STD.00X.X

Next it will do some internal testing:

GE Panametrics

Testing RAM ... Passed.

The above sequence should take about 10 seconds. The display

module then begins taking measurements from the transmitter, and

the LCD displays the gas concentration, the time, and the Alarm

status. Allow the transmitter 30 minutes to warm up before accepting

data from the TMO2D-TC.

Open the necessary valves to establish a sample gas flow of 0.5 SCFH

(250 cc/min) at atmospheric pressure. Make sure that nothing

obstructs the flow of sample gas, thereby causing a pressure build-up

in the sensing chamber. For proper operation, the TMO2-TC

Transmitter should be vented to atmosphere.

Note: Unless otherwise specified, the TMO2-TC is factory

calibrated at atmospheric pressure and 0.5 SCFH (250 cc/

min) and should therefore be operated at atmospheric

pressure. Operating the TMO2-TC at any other pressure will

necessitate a field calibration at that pressure in order to

maintain accuracy. See Chapter 5, Calibration.

If you are using the 4-Port (flowing reference gas) configuration,

open the necessary valves to establish a reference gas flow of 0.5

SCFH (250 cc/min) at atmospheric pressure. Note that you can use a

reference gas flow as low as 5 cc/min in order to conserve gas.

3-2 Operation

Page 39

May 2003

Operating the TMO2DTC Display

The TMO2D-TC Display has a 2-line x 24 character backlit Liquid

Crystal Display (LCD) screen, and a 16-key keypad (see Figure 3-1).

After displaying the firmware version and testing RAM, the display

module enters Operate Mode.

Figure 3-1: TMO2D-TC Display and Keypad

LCD Display In Operate Mode, the left side of the top line of the LCD shows the

name of the gas being measured (e.g., H

the factory according to initial specifications. If you should need to

change the name of the gas, refer to Appendix E, Special

Programming. This manual will refer to the gas being measured as

. The left side of the bottom line shows the gas concentration in %

H

2

(see Figure 3-1 above).

The right side of the top line is a clock. When the TMO2D-TC is

powered up, this clock will start from 00:00:00. The current time (and

date) can be entered in Programming Mode (see Chapter 4,

Programming the TMO2D-TC). However, if power to the TMO2DTC is interrupted, the clock will be reset to 00:00:00.

The right side of the bottom line displays the alarm status. The word

“Alarm:” is displayed. If the HIGH alarm is activated, an “H” will be

displayed in reverse lettering. If the LOW alarm is activated, an “L”

will be displayed.

, N2, SO2, CO2). It was set at

2

Keypad Except for the No key, which is used to enter Programming Mode, the

keypad does not function in Operate Mode. Pressing any other key

will activate the display backlight.

Operation 3-3

Page 40

Chapter 4

Page 41

Programming

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Key Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

Entering Programming Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Menu Navigation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

The Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

Page 42

11/1/95

Overview This chapter provides information on programming the TMO2D-TC

Display using either the 16-key keypad or the RS232C serial port.

You will find the following topics discussed:

• Introduction — A brief overview of the TMO2D-TC user program.

• Key Functions — Keypad key functions and their RS232C

equivalents when in Programming Mode.

• Entering Programming Mode — How to enter Programming Mode

from Operate Mode in order to access the user program.

• Menu Navigation — How to navigate the TMO2D-TC menu

structure.

• The Main Menu — A description of the Main menu functions.

• The Setup Menu — A description of the Setup menu functions.

• The Recorders Menu — A description of the Recorders menu

functions.

• The Alarms Menu — A description of the Alarms menu functions.

• The Tests Menu — A description of the Tests menu functions.

• The Calibration Menu — A description of the Calibration menu

functions.

Programming 4-1

Page 43

11/1/95

Introduction The TMO2D-TC Display contains an interactive, user-friendly

program that allows the user to customize the TMO2D-TC to their

application and change operating parameters as desired. The program

is accessed through the TMO2D-TC keypad and LCD display, or the

RS232C serial port using an ASCII terminal or PC.

Data entered into the TMO2D-TC by the user overrides any

previously entered data, and is retained in memory for several years,

even if power to the TMO2D-TC is interrupted.

Note: The time in the TMO2D-TC is reset to 00:00:00 if power is

interrupted. The date information is retained if power is

interrupted, but may be incorrect if power is not restored

immediately. Both date and time should be re-entered in the

event of power interruption.

!WARNING!

IF THE CABLE CONNECTING THE TMO2D-TC

DISPLAY TO THE TMO2-TC TRANSMITTER IS

DISCONNECTED WHILE THE TMO2D-TC IS

POWERED UP, DATA MAY BE LOST. ALWAYS

REMOVE POWER FROM THE DISPLAY MODULE

BEFORE DISCONNECTING THE TMO2D-TC TO

TMO2-TC CABLE.

4-2 Programming

Page 44

11/1/95

Key Functions When the TMO2D-TC is in Operate Mode, it will ignore all keys

except the No key. On receipt of a No, the LCD will display Enter

Code:, and await the user program entry code, 1 2 3. During code

entry, the TMO2D-TC continues to update the data display, alarm

status, and recorder output.

If the correct code is entered, the TMO2D-TC switches to

Programming Mode. While it is in Programming Mode, data

collection is suspended, and alarm status and recorder outputs are

held at their current values.

In Programming Mode, the keypad keys are divided into three

groups: Yes/No, Selector, and Data Entry:

Ye s / No : The Yes key is used to select a displayed menu option

or to confirm a numeric entry. The No key is used to

scroll forward to the next menu option or to clear a

numeric entry.

Selector: The Left and Right Arrow keys are used as selector

keys. The Left Arrow key is used to step backward

through a displayed list of menu options, or as a backspace (erase) key during numeric entry. The Right

Arrow key is used to step forward through a displayed

list of menu options. It is equivalent to the No key.

Data

The 0-9, -, and . keys are used to enter numeric values.

Entry:

All keypad and most display operations can be performed remotely

on the RS232C serial port using a terminal or PC that supports the

RS232C protocol. Table 4-1 on the next page provides a list of

keypad keys (left column) and their ASCII (center column) and

terminal/PC (right column) equivalents.

Programming 4-3

Page 45

11/1/95

Key Functions (cont.)

Table 4-1: TMO2D-TC RS232C Serial Port

Corresponding Keys

TMO2D-TC

Keypad ASCII Terminal/PC Keys

0 030 0

1 031 1

2 032 2

3 033 3

4 034 4

5 035 5

6 036 6

7 037 7

8 038 8

9 039 9

-02D-

.02E.

Y00DENTER_

N 01B ESCAPE

←

008 BACKSPACE

→

020 SPACE BAR

4-4 Programming

Page 46

11/1/95

Entering Programming Mode

When the TMO2D-TC is turned on, it enters Operate Mode (after

approx. 10 seconds). In order to enter data into the user program or to

check previously entered values, the TMO2D-TC must be switched to

Programming Mode. To enter Programming Mode:

1. Press the No key.

2. The top line of the display will show Enter Code:

3. Key in the code 1 2 3, pressing each key slowly and firmly. The

display will show an * after each digit is entered.

Note: If an incorrect code is entered, or a non-numeric (Yes/No or

Arrow) key is pressed, or the keys are pressed too quickly, the

TMO2D-TC will return to Operate Mode, and the user must

press No again to re-enter the code.

4. The display will now show:

MAIN MENU

Setup?

5. The TMO2D-TC is now in Programming Mode, ready for user

input.

Menu Navigation When a menu item is being displayed, the first line of the LCD shows

the title of the current menu in capital letters. The second line shows

the current menu option followed by a question mark. Press Yes to

select a displayed option, No or Right Arrow to move on to the next

option, or Left Arrow to move back to the previous option.

Note: The menu options are circular — skipping over the last option

in the list returns to the first option.

Programming 4-5

Page 47

11/1/95

The Main Menu The Main menu consists of six submenus: Setup, Recorders, Alarms,

Tests, Calibration, and Resume. Selecting Resume returns the

TMO2D-TC to Operate Mode. Refer to Appendix D, Menu Flow

Diagrams, for a flow diagram of the Main menu.

The Setup Menu The Setup menu consists of seven options: Set Time, Set Date, Set

Backlight, Set Display, Set Communications, Set Error Handling, and

Done. These options allow the user to change basic operating

parameters. Selecting Done returns the TMO2D-TC to the Main

menu. Refer to Appendix D, Menu Flow Diagrams, for a flow

diagram of the Setup menu.

Set Time

Set Time sets the current time in 24-hour format. For example, to

enter 1:15 PM (13.15 in 24-hour time):

MAIN MENU

Setup?

SETUP MENU

Set Time?

Enter 24 hour time:

HH.MM [XX.XX]: 13.15

SETUP MENU

Set Time?

Press Yes to enter the Setup

menu.

Press Yes to set the time.

Use the Data Entry keys to enter

13.15 (the X’s represent the

previous entry). Press Yes to

confirm the entry; then press Yes

again to exit.

Press No to move to the next

option on the Setup menu.

4-6 Programming

Page 48

11/1/95

Set Date

Set Date sets the current date in USA (month, day, year) format. For

example, to enter August 12, 1994:

SETUP MENU

Set Date?

Enter Date (MM.DD.YY):

XX.XX.XX]: 08.12.94

Press Yes to set the date.

Use the Data Entry keys to enter

08.12.94 (the X’s represent the

previous entry). Press Yes to

confirm the entry; then press Yes

again to exit.

SETUP MENU

Set Date?

Press No to move to the next

option on the Setup menu.

Set Backlight

The LCD contains an electro-luminescent (EL) panel to enhance the

readability of the screen in dim light. EL panels have a finite life

span, dimming with use. To maintain the life of the EL backlight, the

TMO2D-TC will automatically turn the backlight off after a

predetermined time period. The backlight time-out period can be set

from 0 (never on) to 60 minutes. The default is 3 minutes. For

example, to enter a time-out of 10 minutes:

SETUP MENU

Set Backlight?

SETUP MENU

Remain ON (min) [XX]: 10

Press Yes to set the backlight

time-out period.

Use the Data Entry keys to enter

10 (the X’s represent the

previous entry). Press Yes to

confirm the entry; then press Yes

again to exit.

SETUP MENU

Set Backlight?

Press No to move to the next

option on the Setup menu.

Set Display

This option is not applicable to the TMO2D-TC and should not be

used.

SETUP MENU

Set Display?

Press No to move to the next

option on the Setup menu.

Programming 4-7

Page 49

11/1/95

Set Communications

The Set Communications menu consists of three options: Set Baud

Rate, Set Update Rate, and Done. These options allow the user to

change RS232C communications parameters. Selecting Done returns

the TMO2D-TC to the Setup menu. Refer to Appendix D, Menu Flow

Diagrams, for a flow diagram of the Set Communications menu.

Set Baud Rate

The TMO2D-TC supports communications rates of 9600, 4800,

2400, 1200, and 300 baud. The default setting is 9600 baud, Word

size is fixed at 8 bits, 1 stop bit, NO parity.

Note: The use of 300 baud greatly limits the computation speed of

the TMO2D-TC, and is not recommended. It is provided solely

for compatibility with older equipment.

SETUP MENU

Set Communications?

SET COMMUNICATIONS

Set Baud Rate?

SELECT BAUD RATE

9600 baud?

Press Yes to enter the Set

Communications menu.

Press Yes to set the baud rate.

Use the No or Arrow keys to

scroll through the choices (9600,

4800, 2400, 1200, 300). Press

Yes to select the desired baud

rate and exit to the Set

Communications submenu.

Note: The baud rate can also be changed via a terminal/PC

connected to the RS232C port; however, this practice is not

recommended. Since the TMO2D-TC will immediately change

to the new baud rate, the display and keyboard operation will

not be correct until the baud rate of the terminal/PC is

changed to match the new baud rate set in the TMO2D-TC.

4-8 Programming

Page 50

11/1/95

Set Update Rate

This option is used to change the interval at which data is sent to the

RS232C serial port. The data update rate can be set from 0 (no data

sent) to 300 seconds. The default rate is 1 second. For example, to set

an update rate of 180 seconds:

SETUP MENU

Set Update Rate?

SET COMMUNICATIONS

Data Interval [XXX]: 180

SET COMMUNICATIONS

Set Update Rate?

SET COMMUNICATIONS

Done?

SETUP MENU

Set Communications?

Press Yes to set the update rate.

Use the Data Entry keys to enter

180 (the X’s represent the

previous entry). Press Yes to

confirm the entry; then press Yes

again to exit.

Press No to move to the next

option on the SET

COMMUNICATIONS

submenu.

Press Yes to exit to the Setup

menu.

Press No to move to the next

option on the Setup menu.

Programming 4-9

Page 51

11/1/95

Set Error Handling

The Set Error Handling option is used to program the LCD, output(s),

and alarms to respond to an invalid H

over-range) that occurs when the TMO2D-TC is in Operate mode. An

invalid measurement occurs if the H

mA or greater.

measurement (under-range or

2

reading is 1 mA or less, or 24

2

Note: Error handling for an invalid H

measurement is independent

2

of error handling for Auto Cal (see “Auto Cal Parameters” in

the Calibration menu). If both error conditions occur

simultaneously, error handling for the invalid H

2

measurement will take precedence.

Follow the steps below to enable Error Handling, set the LCD, and

select the output and alarm responses:

SETUP MENU

Set Error Handling?

Enable Error Handling:

[YES] no

Press Yes to select the Set Error

Handling option.

Press the No or the Arrow keys

to select YES. Press Yes to

confirm.

Note: If you select NO and press Yes to confirm, you will be

immediately returned to the Setup menu.

SYSTEM ERROR EFFECTS

Set Display Response?

Press Yes to set the LCD

response.

Display System Error?

yes [NO]

Press the No or the Arrow keys

to select your choice. Press Yes

to confirm.

SYSTEM ERROR EFFECTS

Set Display Response?

Press No to move to the next

option on the System Error

Effects menu.

SYSTEM ERROR EFFECTS

Set Alarm Response?

4-10 Programming

Press Yes to set the alarm

response.

Page 52

Set Error Handling (cont.)

11/1/95

Select Alarm Effect?

No Effect?

Select Alarm Effect?

Trip High?

Select Alarm Effect?

Trip Low?

Select Alarm Effect?

Trip Both?

SYSTEM ERROR EFFECTS

Set Alarm Response?

SYSTEM ERROR EFFECTS

Set Recorder Response?

Select Recorder Effect?

No Effect?

Select Recorder Effect?

Force High?

Use the No or Arrow keys to

scroll through the choices and

press Yes at your choice.

Press No to move to the next

option on the System Error

Effects menu.

Press Yes to set the recorder

output(s) response.

Use the No or Arrow keys to

scroll through the choices and

press Yes at your choice.

Select Recorder Effect?

Force Low?

Select Recorder Effect?

Hold Last Value?

SYSTEM ERROR EFFECTS

Set Recorder Response?

SYSTEM ERROR EFFECTS

Done?

Press No to move to the next

option on the System Error

Effects menu.

Press Yes to return to the Setup

menu.

Programming 4-11

Page 53

11/1/95

Set Error Handling (cont.)

SETUP MENU

Set Error Handling?

SETUP MENU

Done?

MAIN MENU

Setup?

Press No to move to the next

option on the Setup menu.

Press Yes to return to the Main

menu.

Press No to move to the next

option on the Main menu.

4-12 Programming

Page 54

11/1/95

The Recorders Menu The Recorders menu is used to scale the 0/4-20 mA analog output(s).

Selecting A allows the user to scale the first analog output. Selecting

B allows the user to scale the second analog output (if one is present).

Selecting Done returns the TMO2D-TC to the Main menu. Refer to

Appendix D, Menu Flow Diagrams, for a flow diagram of the

Recorders menu.

The TMO2D-TC provides a choice of one non-isolated 0/4-20 mA

output, or two isolated 0/4-20 mA outputs. Both recorder options can

be set for a 0-20 mA or 4-20 mA response, and can be scaled

anywhere within the range of the transmitter.

Note: The TMO2D-TC user program will accept settings for two

outputs, A and B. However, if the TMO2D-TC has been

purchased with only a single, non-isolated 0/4-20 mA output,

only recorder A is effective.

Use the steps in the following example to set up recorders A and B.

We will set recorder A for a 4-20 mA output, with 4 mA equal to 0%

and 20 mA equal to 100% H2.

H

2

MAIN MENU

Setup?

MAIN MENU

Recorders?

Select Recorder to set:

[A] B done

Rcd A Output (mA):

0-20 [4-20]

Recorder A 4 mA Value

%H2 [XX.XX]: 0.00

Recorder A 20 mA Value

%H2 [XXX.XX]: 100.00

Press No or Right Arrow until

Recorders? appears.

Press Yes to enter the Recorders

menu.

Press No or the Arrow keys to

select A. Press Yes to confirm

the entry.

Press No or the Arrow keys to

select 4-20. Press Yes to confirm

the entry.

Use the Data Entry keys to enter

0.00 (the X’s represent the

previous entry). Press Yes to

confirm the entry; then press Yes

again to exit.

Use the Data Entry keys to enter

100.00 (the X’s represent the

previous entry). Press Yes to

confirm the entry; then press Yes

again to exit.

Programming 4-13

Page 55

11/1/95

The Recorders Menu

(cont.)

Select Recorder to set:

[A] B done

MAIN MENU

Recorders?

Recorder B is scaled in the same

manner. After Recorder B is

scaled, use the No or Arrow keys

to select DONE. Press Yes to

return to the Main menu.

Press No to move to the next

option on the Main menu.

4-14 Programming

Page 56

11/1/95

The Alarms Menu The TMO2D-TC is provided with two single-pole double throw

(SPDT), Form C alarm relays for use in activating alarm devices. See

Chapter 6, Specifications, for details on relay specifications, and

Chapter 2, Installation, for wiring recommendations. Both relays

provide a normally-open (NO) and a normally-closed (NC) set of

contacts. The alarms are addressed as HIGH or LOW. The HIGH

alarm relay will change state when the current reading becomes

greater than or equal to the HIGH alarm set point. The LOW alarm

relay will change state when the current reading becomes less than or

equal to the LOW alarm set point. Refer to Appendix D, Menu Flow

Diagrams, for a flow diagram of the Alarms option.

Use the steps in the following example to set the HIGH and LOW

alarm relays. We will set the HIGH alarm relay to 75% H

LOW alarm relay to 25% H

.

2

, and the

2

MAIN MENU

Setup?

MAIN MENU

Alarms?

Select Alarm to set:

[HIGH] low done

Enter Alarm Setpoint:

High %H

Select Alarm to set:

[HIGH] low done

Enter Alarm Setpoint:

Low %H

Select Alarm to set:

high [LOW] done

MAIN MENU

Alarms?

[XX.XX]:

2

[XX.XX]:

2

Press No or Right Arrow until

Alarms? appears.

Press Yes to enter the Alarms

menu.

Press No or the Arrow keys to

select HIGH. Press Yes to

confirm the entry.

Use the Data Entry keys to enter

75.00 (the X’s represent

the previous entry). Press Yes to

confirm the entry; then press Yes

again to exit.

Press No or the Arrow keys to

select LOW. Press Yes to

confirm the entry.

Use the Data Entry keys to enter

25.00 (the X’s represent the

previous entry). Press Yes to

confirm the entry; then press Yes

again to exit.

Press No or the Arrow keys to

select DONE. Press Yes to return

to the Main menu.

Press No to move to the next

option on the Main menu.

Programming 4-15

Page 57

11/1/95

The Tests Menu The Tests menu consists of four options: DVM Test, Recorder

Calibrate, Alarms Test, and Done. These options allow the user to

perform operational tests on the analog outputs and alarm relays, and

to directly measure the raw signal from the TMO2-TC Transmitter.

Selecting Done returns the TMO2D-TC to the Main menu. Refer to

Appendix D, Menu Flow Diagrams, for a flow diagram of the Tests

menu.

DVM Test

The DVM test allows the TMO2D-TC to operate as a simple, digital

voltmeter to measure, in milliamps, the signal being received from

the TMO2-TC Transmitter. The TMO2D-TC is updated

approximately twenty times per second, facilitating connection and

calibration of the TMO2-TC Transmitter.

Follow the steps below to test the input signal from the TMO2-TC

Transmitter:

MAIN MENU

Setup?

MAIN MENU

Te st s?

TESTS

DVM Test?

Select DVM Input:

[GAS] comp done

Press No or Right Arrow until

Tests? appears.

Press Yes to enter the Tests

menu.

Press Yes to enter the DVM test

option.

Press No or the Arrow keys to

select GAS. Press Yes to

confirm.

Note: The COMP option is not applicable to the TMO2D-TC, and

should not be used. If you select COMP by mistake, you

should see:

H2 DVM TEST

0.00 mA

Press any key to exit.

4-16 Programming

Page 58

The Tests Menu (cont.)

11/1/95

H2 DVM TEST

XX.XX mA

The X’s represent the mA signal

from the TMO2-TC Transmitter,

which will update continuously.

Press any key to exit.

Select DVM Input:

[GAS] comp done

Press No or the Arrow keys to

select DONE. Press Yes to exit

to the Tests menu.

TESTS

DVM Test?

Press No to move to the next

option on the Tests menu.

Recorder Calibrate

The Recorder Calibrate test allows a selected % gas composition to

be output to the recording device to facilitate adjustment of the

device’s zero and span.

For example, to enter a %H

TESTS

Recorder Calibrate?

Select Recorder to test:

[A] B done

Set Recorder A to:

%H

[XX.XX]: 36.39

2

Select Recorder to test:

[A] B done

TESTS

Recorder Calibrate?

of 36.39 to be output to recorder A:

2

Press Yes to enter the Recorder

Calibrate option.

Press No or the Arrow keys to

select A. Press Yes to confirm

the entry.

Use the Data Entry keys to enter

36.39 (the X’s represent the

previous entry). Press Yes to

confirm the entry; then press Yes

again to exit.

Recorder B (if present) is tested

in the same manner. After you

are done, press No or the Arrow

keys to select DONE. Press Yes

to exit to the Tests menu.

Press No to move to the next

option on the Tests menu.

Programming 4-17

Page 59

11/1/95

Alarms Test

The Alarms test enables you to trip and reset the alarm relays using

the keypad, in order to test the operation of external alarm devices

and circuits. For example, to test the HIGH alarm relay:

TESTS

Alarms Test?

Select Alarm to test:

[HIGH] low done

Press Yes to enter the Alarms test

option.

Press No or the Arrow keys to

select HIGH. Press Yes to

confirm the entry.

Turn High Alarm:

[ON] off done

Press No or the Arrow keys to

select ON. Press Yes to confirm.

Note: Upon selecting the ON option and pressing Yes, the HIGH

alarm relay will turn on, and the brackets will automatically

move to OFF.

Turn High Alarm:

on [OFF] done

Press Yes to turn the HIGH

alarm off.

Note: Upon selecting the OFF option and pressing Yes, the HIGH

alarm relay will turn off and the brackets will automatically

move to ON.

Turn High Alarm:

[ON] off done

Select Alarm to test:

[HIGH] low done

Press No or the Arrow keys to

select DONE. Press Yes to exit.

The LOW alarm is tested in

the same manner. After you

are done, press No or the Arrow

keys to select DONE. Press Yes

to exit to the Tests menu.

TESTS

Alarms Test?

TESTS

Done?

MAIN MENU

Te st s?

4-18 Programming

Press No to move to the next

option on the Tests menu.

Press Yes to return to the Main

menu.

Press No to move to the next

option on the Main menu.

Page 60

May 2003

The Calibration Menu The Calibration menu consists of three options: Auto Cal Parameters,

Edit Calibration Data, and Done. These options allow the user to

perform automatic zero and span calibration of the TMO2D-TC, and

to enter measurement parameters and calibration data. Selecting Done

returns the TMO2D-TC to the Main menu. Refer to Appendix D,

Menu Flow Diagrams, for a flow diagram of the Calibration menu.

Auto Cal Parameters

The TMO2D-TC can be programmed to perform an automatic

calibration procedure (Auto Cal) at specified time intervals ranging

from minutes to months. By performing measurements on two

calibration gases (zero and span), the TMO2D-TC can automatically