Page 1

GE

ROADWAY LIGHTING

g

Lighting Solutions

GUIDE FORM SPECIFICATIONS

TIGER ™ ROADWAY LUMINAIRE

GENERAL DESCRIPTION

The totally enclosed and weather-resistant luminaire designated

_______ (identify) shall be a GE TIGER™ ROADWAY LIGHTING luminaire,

ordering number _______ (specify TGSM (with SnapDrive™) TCSM/

TGTM (tray mounted ballast), plus ordering number logic from catalog)

designed, to operate one _______ (specify 250, 400) watt high pressure

sodium or _______ (specify 250, 400) watt metal halide mogul base

lamp from a nominal _______ (specify 120, 208, 240, 277, 347 or 480)

volt , 60 Hertz power source. The luminaire shall include an integral

prewired SnapDrive™ ballast assembly or removable power tray (magnetic Regulator) and optical assembly that shall produce a _______

(specify narrow, medium, forward throw, staggered, opposite wide,

extra wide) distribution. The luminaire shall have UL/cUL1598 Listed

SUITABLE FOR WET LOCATIONS with SnapDrive™. The luminaire shall be

equipped with an activated charcoal breath-way for clean ventilation

and long term maintained foot-candle levels. Ballast , housing, optical,

and luminaire assembly shall all be built to GE Lighting Systems specifications.

MECHANICAL CONSTRUCTION

The luminaire shall include an astethically pleasing heavy duty die-cast

aluminum alloy housing with thermoset electrocoat primer applied inside and out. Finish paint shall be TGIC polyester powder paint applied

100% to the outside surface up to a thickness of .008". The luminaire

shall have a thermal and impact resistant glass lens that is sealed to

the door frame with continuous wet applied bead of silicone rubber

gasketing. The luminaire access door shall be sealed to the back housing with continuous molded silicone foam gasket . Entire housing and

optical sealed to IP65. Entry to the luminaire shall be accomplished via

hand operated latches (tool-less entry). The door frame shall be hinged

to the luminaire via hinging screws and can be loosened for quick

and simple removal when desired. No electricals shall be mounted on

the door. All threaded hardware shall be corrosion resistant chromate

washed, zinc-nickel alloy plated carbon steel. The luminaire shall have

provision for a factory installed photoelectric control receptacle.

The luminaire shall be equipped with a 4-bolt slipfitter for mounting

(specify H4 mounting in catalog logic) to horizontal mast arms. It shall

be made of cast aluminum with a thermoset electrocoat primer with

finish paint of TGIC polyester powder paint applied to 100% of the

exterior surface to match luminaire. The slipfitter shall be mounted internally to the housing with four 3/8" bolts. It shall have adjustment of

± 5 degrees for leveling and shall have two galvanized clamps with four

3/8" bolts to secure luminaire to a standard 2" mast arm (2-3/8"OD). All

hardware shall be zinc-nickel coated for corrosion protection. OR

The luminaire shall be supplied with an adjustable tenon mounting

slipfitter (specify 1K-low tilt or 2K-high tilt in catalog logic). Slipfitter

shall consist of three, cast aluminum components- mounting adaptor,

tenon slipfitter and terminal board cover. Components shall be made

of cast aluminum with a thermoset electrocoat primer with finish coat

of TGIC polyester powder paint applied to 100% of the exterior surface

to match luminaire. Assembly shall be internally attached to luminaire

housing via two 3/8" hex-head bolts. Tenon slipfitter shall accept

standard 2" tenon (2-3/8" OD) and be capable of field adjustment of

the aiming angles from 0° to 45° There shall be a dead-back terminal

board with tunnel type connectors suitable for #6 conductor mounted

on top of the slipfitter. All hardware shall be zinc-nickel coated for corrosion protection. OR

The luminaire shall be equipped with a non-adjustable external slipfitter (specify ES in catalog logic) for mounting to horizontal mast arms.

Slipfitter shall be made of schedule 40 steel pipe and secure 2" mast

arm via four 3/8" set screws. It shall be attached internally via two

3/8" hex head bolts. It shall have a thermoset electrocoat primer with

matching finish coat of TGIC polyester powder paint applied to 100%

of the exterior surface to match luminaire. All hardware shall be zincnickel coated for corrosion protection.

The luminaires shall be certified that samples have been tested for vibration resistance at 2 g' s for 100,000 cycles in each of the three major

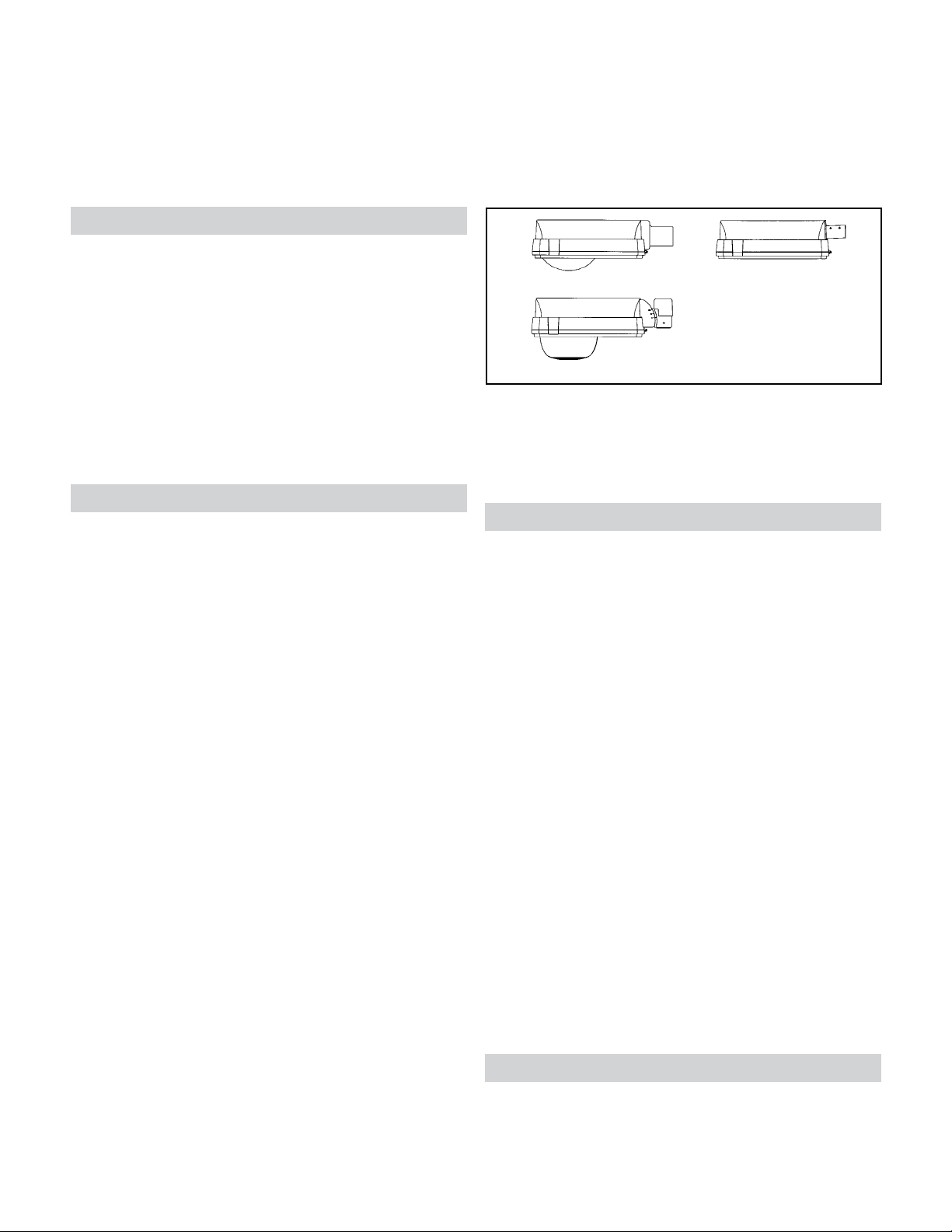

Shallow Glass

Flat Glass

Prismatic Glass

axes, at or below the first harmonic, followed by a 4 g' s test for a period of 5,000 cycles in the axis with the most displacement without any

major mechanical failures. Integral mounting features to add shielding.

BALLAST OPERATION

TGSM

Ballast , ignitor, capacitor and printed circuit board wiring shall be

installed onto a modular SnapDrive™ Electrical System that snaps

in and out of the luminaire without tools. Voltage changes, wattage

changes (250 or 400 watt only), the addition of optional EZAdd™ quartz

switching device and optional EZAdd™ 400 watt bi-level switching

shall be accomplished with the use of quick-change jumpers that shall

be located on the ballast printed circuit board (Contact factory for

application availability). SnapDrive™ Electrical Systems shall be interchangeable into other luminaires in the Criterion™ family of the same

wattage size. The luminaire shall contain a standard Auto-regulator

(CWA) ballast . Optional factory installed fusing shall be available for

all discrete voltages and wattages. The ballast shall be compliant with

ANSI specifications and lamp manufacturers specifications at the time

of manufacture. The ballast shall reliably start and operate the lamp in

ambient temperatures down to -20 degrees F for metal halide and -40

degrees F for high pressure sodium. Pulse start metal halide ballasts

shall be available from 250 - 400 watts.

TGTM

The luminaire shall contain a standard _______ (specify) type ballast

in full compliance with lamp-ballast specifications available to the fixture manufacturer from the lamp manufacturers at the time of fixture

manufacture.

The ballast shall reliably start and operate the lamp in ambient temperatures down to -20°F for mercury and metal halide or

-40°F for HPS.

The luminaire and ballast shall be from the same manufacturer.

The ballast shall be prewired to the lamp socket and dead-back termi-

nal board, requiring connection of power supply leads to the terminal

board only. A plug-in ignitor shall be available and shall be removable

without the use of tools. Shutoff device protected ignitor option available.

The ballast components including ballast , dead-back terminal board

and ignitor shall be mounted on an easily removable power tray. The

tray shall be held in place by three key-hole slot screws.

OPTICAL ASSEMBLY

The optical assembly shall be either precision hydroformed aluminum

reflector that has a chemically bonded lightweight non-breakable

®

ALGLAS

cally brightened, anodized and sealed segmented reflector.

Flat lens enclosures shall be 0.125" thick, heat and impact resistant

tempered soda lime glass. Shallow and prismatic enclosures shall be

0.25" thick heat and impact resistant molded borosilicate glass.

finish on all surfaces for precise light control or electro-chemi-

Guide Form Specifications – 2011

Page 2

g

GE Lighting Solutions • 1-888-MY-GE-LED • www.gelightingsolutions.com

1 6 9 4 3 5 3 3- - -- 8 8 8

GE Lighting Solutions is a subsidiary of the General Electric Company. Evolve and other trademarks belong to GE Lighting Solutions. The GE brand and logo are trademarks of the General Electric Company.

© 2011 GE Lighting Solutions. Information provided is subject to change without notice. All values are design or typical values when measured under laboratory conditions.

Loading...

Loading...