Page 1

GE

g

READ THOROUGHLY BEFORE INSTALLING

Lighting Solutions

WARNING

Risk of electric shock

• Turn power off before servicing

– see instructions

WARNING

Risk of fire

• Use supply wire specified on

nameplate

GENERAL

This luminaire is designed for outdoor lighting applications,

and should not be used in areas of limited ventilation, or in high

ambient temperature enclosures. For optimum performance, it

should be installed and maintained according to the following

recommendations.

UNPACKING

This luminaire has been properly packed so that no parts

should have been damaged during transit. Inspect to confirm.

INSTALLATION

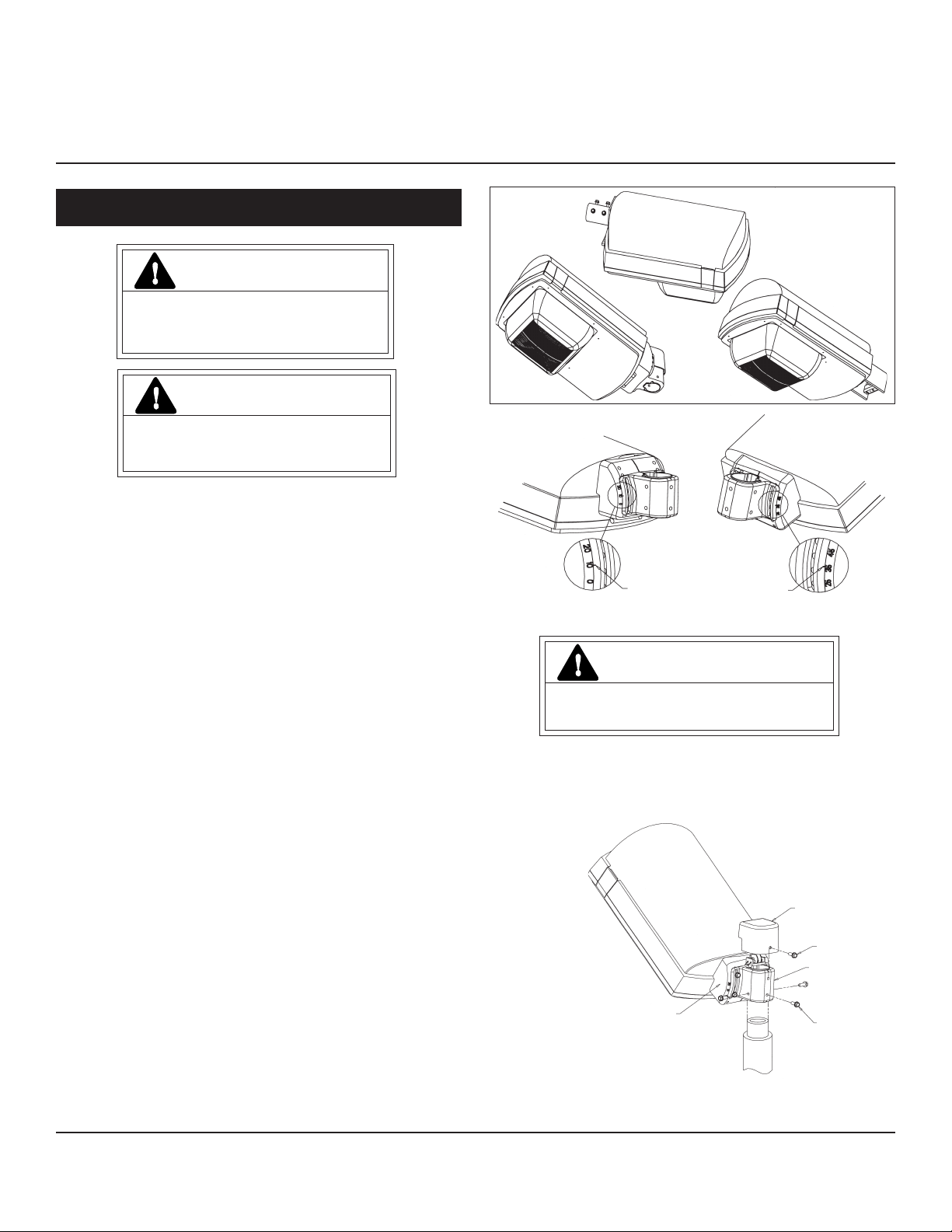

This luminaire has several mounting arrangements - adjustable

pole-top tenon mounting and two horizontal slipfitters. The nonadjustable version allows for mounting to 2-3/8” OD mounting

arms. The adjustable version is equipped with two pipe clamps and

four mounting bolts. The adjustable, tenon mounting adapter has

two ranges of adjustments. See section A for specific mounting

instruction.

If ordered with the adjustable tenon mounting it has been

shipped as ordered in either the low or high position and exact

angular setting can be accomplished in the field. Verify that the

aiming indicator is on the appropriate side of the slip fitter adapter

for the desired tilt (see Figure 1). For ease of installation, it is

recommended that adjustment to tilt be done for before mounting.

Four slipfitter bolts should be separated as far as possible in the slot

and torque to 10-12 ft-lbs.

Caution: Correct tightening of bolts is important to

ensure proper function of system.

GEH-5944D

INSTRUCTIONS

Tiger™ Fixture

250-400 Watt

Figure 1

A. MOUNTING

AIMING INDICATOR AIMING INDICATOR

CAUTION

Unit will fall if not installed properly

• Follow installation instructions

For adjustable tenon mounting insert 2-inch tenon into the

bottom opening of slip fitter until it rest on center stop. Secure in

place by tightening (3) 3/8” slip fitter mounting bolts. Torque

bolts to 10-12 ft-lbs. Remove cover, connect customer wiring to

luminaire wiring or optional terminal board (See Figure 2).

COVER

COVER SCREW

SLIPFITTER

If aiming indicator is not on the desired side, remove the bolts

securing slip fitter to adapter, cover, terminal board, and slip

fitter mounting bolts. Invert adapter to desired orientation.

Adjust tilt to desired position and secure 3/8” bolts. Reattach the

terminal board, and cover to the top of slip fitter, and the three

mounting bolts in the bottom.

These instructions do not purport to cover all details or variations in equipment nor to provide for every possible contingency to be met in connection with installation, operation or

maintenance. Should further information be desired or should particular problems arise which are not covered sufficiently for the purchaser’s purposes, the matter should be referred

to GE Lighting Solutions.

Figure 2

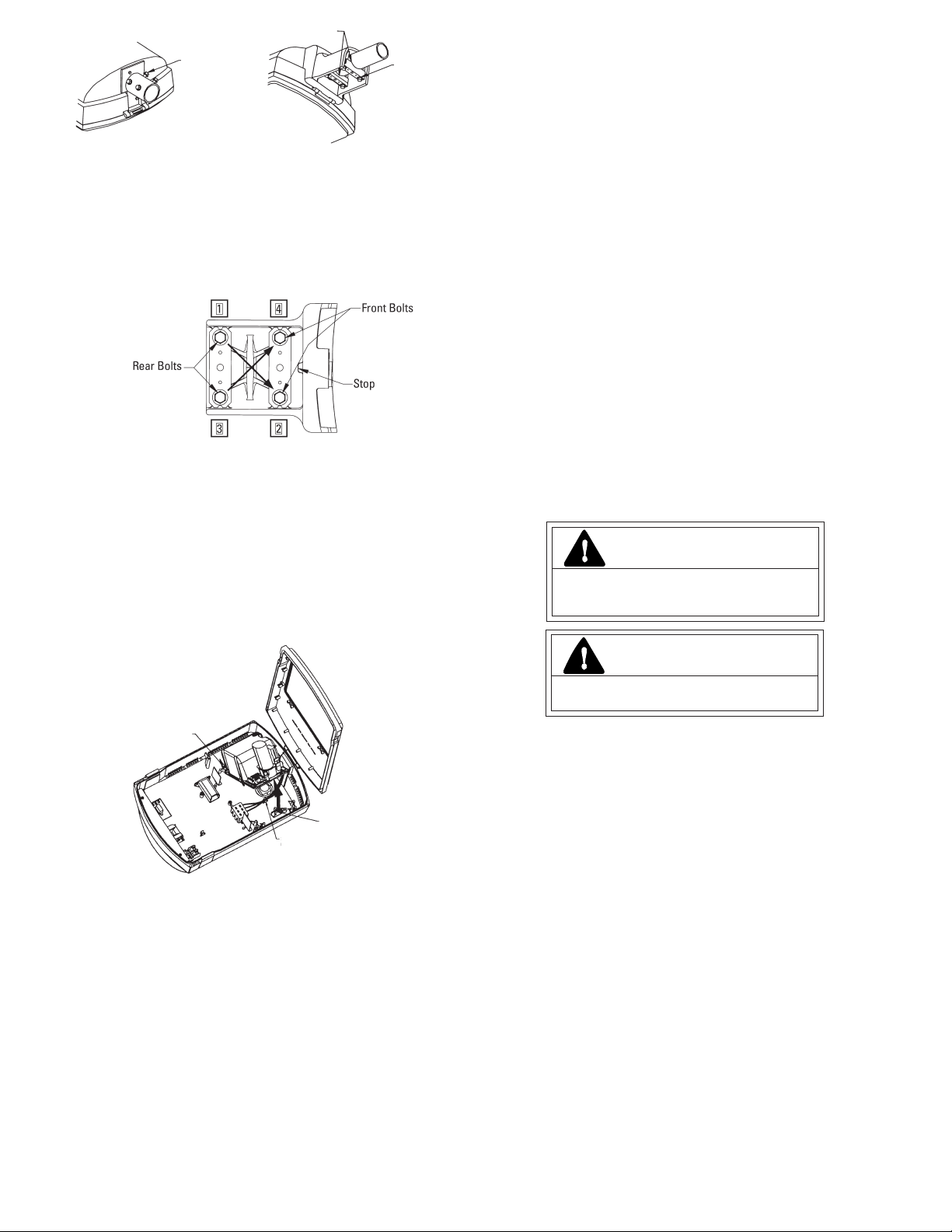

For luminaires equipped with non-adjustable slipfitter, install

luminaire on the 2-3/8” OD arm and tighten four set-screws (see

Figure 3). Torque screws 10-12 ft-lbs.

SLIPFITTER ADAPTER

(3) MOUNTING SCREWS

Page 2

PIPE CLAMPS

SET SCREWS

Figure 3

For luminaires equipped with the adjustable slipfitter, install

luminaire on the 2-3/8” OD arm. Arm should be in contact with

“stop” located on the upper front surface of the slipfitter (see

Figure 5). The edges of both pipe clamps must be fully seated

on the arm.

Tighten rear bolts equally to bring leveling ball to center (if

so equipped) or until top housing is level. Tighten front bolts

equally to a torque of 5-12 foot-pounds. Tighten rear bolts to a

torque of 10-20 foot-pounds. Confirm torque using a crossing

pattern (see Figure 5)

Figure 4

BOLTS

Figure 5

B. WIRING

Make all electrical connections in accordance with all

applicable code requirements (National Electrical Code,

Canadian Electrical Code and applicable local Codes).

Verify that supply voltage is correct by comparing it to nameplate.

Supply wiring entering from pole to interior terminal board

must be routed through the wiring clips and maintain one-

half inch (1/2”) (113mm) minimum spacing to SnapDrive (see

Figure 6).

Connect ground lead to the green lead, green ground screw

on housing or terminal block provided.

IF MULTIVOLT (120/208/240/277 volts):

Connect the tray mounted ballast lead with the insulated

terminal to the desired voltage terminal as indicated on the

ballast terminal nameplate.

IF MULTI-WATT

Tray mounted multi-watt ballasts are available in various

combinations of wattage. See wiring instructions on wiring tag

inside the luminaire.

The SnapDrive is equipped with a multi-volt ballast. Ballast

has been wired to the voltage indicated on the nameplate. Verify

that supply voltage is correct by comparing it to nameplate. If

another voltage is desired, place the voltage selection jumper onto

the appropriate voltage position as indicated on the wiring

diagram. Optional features such as fusing, switched quartz safety

lights and photocontrols are voltage specific. Do not change

jumper positions if fixture is equipped with these features.

This will damage or destroy these optional parts and will void

the safety listing (UL, CUL, CSA, etc.) of the fixture.

The SnapDrive is equipped with a multi-watt ballast. Ballast

and jumper have been configured as indicated on the nameplate.

If another wattage is desired, place the wattage selection jumper

onto the appropriate position as indicated on the wiring diagram.

Do not change the wattage jumper position if fixture is

equipped with fusing. Fuses have been sized to the wattage

that was ordered. Changing wattage may damage the fuses and

will void the safety listing (UL, CUL, CSA, etc.) of the fixture.

Replace power fuses only with fuses of the same type and ratings.

To complete installation refer to MOUNTING.

LAMP INSTALLATION

CAUTION

Risk of burn

• Allow lamp/fixture to cool before

handling

SNAPDRIVE

HINGE

SNAPDRIVE

SPRING CLIP

Figure 6

The luminaire comes supplied with either an electrical tray or

a SnapDrive electrical module.

If unit is designated as multi-volt or multi-watt, follow specific

instruction below. Do not remove insulated connectors from wires

not needed for required voltage connection. When changing

voltage on reconnectable units, move only the lead with the

insulated connector.

SUPPLY WIRE

CLIP

IF SINGLE VOLTAGE:

All single voltage, tray mounted ballasts are pre-wired such

that user need only connect the supply conductors.

GE Lighting Solutions • 1-888-MY-GE-LED • www.gelightingsolutions.com

16943533----888

GE Lighting Solutions is a subsidiary of the General Electric Company. Evolve and other trademarks belong to GE Lighting Solutions. The GE brand and logo are trademarks of the General Electric Company.

© 2011 GE Lighting Solutions. Information provided is subject to change without notice. All values are design or typical values when measured under laboratory conditions.

g

WARNING

Risk of burn

• Do not touch operating luminaire

Use only lamps specified on nameplate. Observe lamp manufacturer’s

recommendations and restrictions on lamp operation, particularly ballast

type, burning position, etc. Replace blackened lamps immediately.

Lamp Tightness-Mogul Base Lamp: The lamp should be securely

inserted to the NEMA-EEI specified torque of 35 inch-pounds (3.95 N•m),

which is best achieved by very firm tightening sufficient to fully

depress and load the center contact of the socket.

MAINTENANCE AND CLEANING

It will occasionally be necessary to clean the outside of the refractor

to maintain light levels. Frequency of cleaning will depend on ambient

dirt level and minimum light level which is acceptable to the user.

The refractor should be washed in a solution of warm water and any

mild, nonabrasive household detergent, rinsed with clean water and

wiped dry. Should the optical assembly become dirty on the inside,

wipe the reflector and clean the refractor in the above manner.

The light output of a luminaire is also dependent on the age of

the lamp. In applications where the light level is critical, it may be

desirable to replace lamps before they burn out. The lamp

manufacturer can provide data showing how the lamp light output

decreases with use.

35-201578-137 (1/05)

Loading...

Loading...