Page 1

GE Healthcare

Instructions 71-7149-00 AN HiTrap ion exchange columns

HiTrap SP HP, 1 ml and 5 ml

HiTrap Q HP, 1 ml and 5 ml

HiTrap™ SP HP and HiTrap Q HP are prepacked, ready to use cation and anion

exchange columns for method scouting, group separations, sample concentration

and sample clean-up of charged biomolecules. HiTrap SP HP and HiTrap Q HP provide

fast, reproducible, and easy separations in a convenient format.

The columns can be operated with a syringe, peristaltic pump or liquid

chromatography system such as ÄKTAdesign

™

or FPLC™ System.

Page 2

Code No. Designation No. supplied

17-1151-01 HiTrap SP HP 5 x 1 ml

17-1152-01 HiTrap SP HP 5 x 5 ml

17-1153-01 HiTrap Q HP 5 x 1 ml

17-1154-01 HiTrap Q HP 5 x 5 ml

Connectorkit

Connectors supplied Usage No. supplied

1/16” male/luer female Connection of syringe to top of

HiTrap column 1

Tubing connector Connection of tubing (e.g. Peristaltic

flangeless/M6 female Pump P1) to bottom of HiTrap column* 1

Tubing connector Connection of tubing (e.g. Peristaltic

flangeless/M6 male Pump P1) to top of HiTrap column** 1

Union 1/16” female/ Connection to original FPLC Sys tem

M6 male through bottom of HiTrap column 1

Union M6 female/ Connection to original FPLC Sys tem

1/16” male through top of HiTrap column 1

Stop plug female, 1/16” Sealing bottom of HiTrap column 2, 5 or 7

* Union 1/16” fe male/M6 male i s also needed .

** Union M6 fema le/1/16” male is als o needed.

Table of contents

1. Description 3

2. Selection of ion exchanger and conditions 5

3. Operation 9

4. Optimization 12

5. Choice of gradient type 13

6. Determination of binding capacity 15

7. Scaling up 17

8. Storage 17

9. Ordering Information 17

p. 2

Page 3

1. Description

Media properties

SP Sepharose™ High Per formance and Q Sepharose High Performance

are strong cation and strong anion exchangers respectively. Both remain

charged and maintain high capacity over broad pH ranges. The functional

groups are coupled to the matrix via chemically stable ether linkages.

Characteristics of HiTrap SP HP and HiTrap Q HP, 1 and 5 ml columns are

listed in Table 1.

Column

HiTrap Q HP and HiTrap SP HP are 1 ml and 5 ml columns made of

polypropylene, which is biocompatible and non-interactive with

biomolecules. The top and bottom frits are manufactured from porous

polyethylene. It is delivered with a stopper on the inlet and a snap-of f end

on the outlet.

The separation can be easily achieved using a syringe together with the

supplied luer adaptor, a peristaltic pump, or in a chromatography system

such as ÄKTA

Note: To prevent leakage it is essential to ensure that the adaptor is tight.

The column cannot be opened or refilled.

™

or FPLC.

p. 3

Page 4

Table 1. HiTrap SP HP and HiTrap Q HP columns characteristics

Column volumes 1 ml or 5 ml

Column dimensions 0.7 × 2.5 cm (1 ml) and 1.6 × 2.5 cm (5 ml)

Total ionic capacity 0.14–0.20 mmol (Cl

0.15–0.20 mmol (H

–

)/ml medium (Q)

+

)/ml medium (SP)

Dynamic binding capacity SP: approx. 55 mg ribonuclease/ml medium

(0.1 M sodium acetate, pH 6.0 at 1 ml/min)

Q: approx. 50 mg HSA/ml medium (20 mM Tris-HCl,

pH 8.2 at 1 ml/min)

Mean particle size 34 μm

Bead structure 6% highly cross-linked spherical agarose

Maximum flow rates HiTrap 1 ml: 4 ml/min, HiTrap 5 ml: 20 ml/min

Recommended f low rates HiTrap 1 ml: 1 ml/min, HiTrap 5 ml: 5 ml/min

Maximum backpressure 0.3 MPa, 3 bar, 42 psi

Chemical stability All commonly used buffers

Charged group SP: – CH

Q: – CH2N+(CH3)

pH stability*

2CH2CH2SO3

3

Sho rt term SP: 3–14, Q : 1–14

Working SP: 4–13, Q: 2–12

Long term SP: 4–13, Q: 2–12

Storage temperature +4° to +30 °C

Storage buffer SP: 20% ethanol, 0.2 M sodium acetate

Q: 20% ethanol

Avoid SP: Oxidizing agents, cationic detergents and

buffers

Q: Oxidizing agents, anionic detergents and

buffers

* Th e ranges given are estimates b ased on our knowledg e and experience.

Pleas e note the follow ing:

pH stability, long term refers to the pH i nterval where the medium is s table over

a long pe riod of time wit hout advers e eff ects on its subsequent chromatographic

performance.

pH stability, short term refers to the pH interval for regeneration, cleaning-in-place and

sanitization procedures.

p. 4

Page 5

2. Selection of ion exchanger and conditions

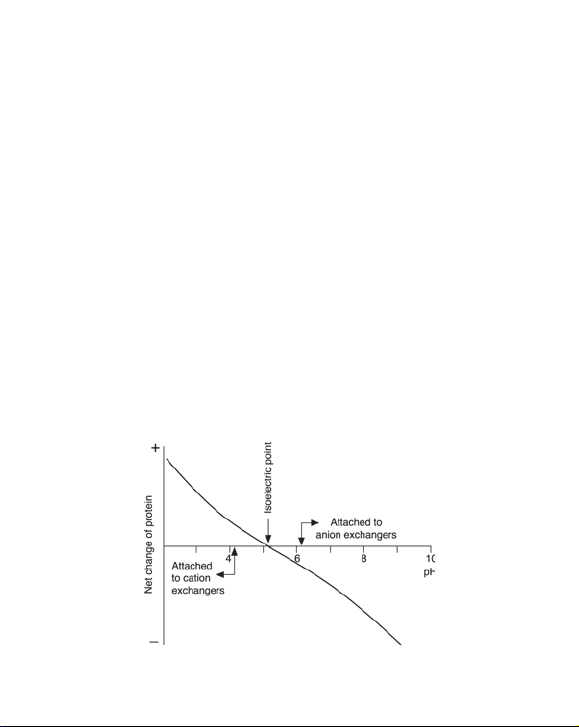

Ion exchange chromatography is based on adsorption and reversible

binding of charged sample molecules to oppositely charged groups

attached to an insoluble matrix. The pH value at which a biomolecule carries

no net charge is called the isoelectric point (pI). When exposed to a pH below

its pI, the biomolecule will carry a positive charge and will bind to a cation

exchanger (SP). At pH’s above its pI the protein will carry a negative charge

and will bind to an anion exchanger ( Q). If the sample components are most

stable below their pI’s, a cation exchanger should be used. If they are most

stable above their pI´s, an anion exchanger is used. If stability is high over a

wide pH range on both sides of pI, either type of ion exchanger can be used

(Figure 1).

Selection of buff er pH and ionic strength

Buffer pH and ionic strength are critical for the binding and elution of

material (both target substances and contaminants) in ion exchange

chromatography. Selection of appropriate pH and ionic strength for

the start and elution buffers allows the use of three possible separation

strategies.

Fig 1. The net charge or a protein as a function of pH.

p. 5

Page 6

Strategy 1. Binding and elution of all sample components

Binding is achieved by choosing a start buffer with a low pH for HiTrap SP

HP or a high pH for HiTrap Q HP. The ionic strenght should be kept as low as

possible to allow all components to bind to the ionic exchange (<5 mS/cm).

This results in a concentration of the target substance and a complete

picture of the whole sample. The drawback of this strategy is that the

binding capacity of the ion exchanger for the target substance is dependent

on the amount of contaminant in the sample. Strongly binding contaminants

can also displace bound target protein if a large volume of sample is loaded.

Note: Start conditions are subject to the stability of the sample

components.

Strategy 2. Enrichment of target protein

This is achieved by choosing a start buffer with a pH optimized to allow

maximal binding of target protein, and as high as possible ionic strength

to suppress binding of sample contaminants. This strategy results in a

concentration of the target substances.

Strategy 3. Binding of sample contaminants

This is achieved by choosing a start buffer with a pH and ionic strength

that promotes the binding of some or all contaminating substances but

allows the substance of interest to pass through the column. The drawback

of this approach is that the target substance is not concentrated and the

sample volume applied to the ion exchanger is dependent on the amount of

contaminants in the sample.

Start buff er

The concentration of buf fer required to give effective pH control varies

with the buffer system. A list of suitable buffers and suggested starting

concentrations is shown in Tables 2 and 3, Figs 2 and 3. In the majority of

cases a concentration of at least 10 mM is required to ensure adequate

buffering capacity. The ionic strength of the buf fer should be kept low

(< 5 mS/cm) so as not to interfere with sample binding. Salts also play a

role in stabilizing protein structures in solution and it is important the ionic

strength should not be so low that protein denaturation or precipitation

occurs.

p. 6

Page 7

The buf fering ion should carry the same charge as the ion exchange group

and should have a pKa within 0.5 pH units of the pH used in the separation.

Buffering ions of opposite charge may take par t in the ion exchange process

and cause local disturbances in pH.

Starting pH

Cation exchangers (SP): At least 1 pH unit below the pI of substance to be

bound.

Anion exchangers (Q): At least 1 pH unit above the pI of substance to be

bound.

Table 2. Buffers for cation exchange chromatography.

pH inter val Subst ance Conc . (mM) Counter-ion pKa (25 °C)

1.4–2.4 Mal eic acid 20 Na+ 1.92

2.6–3.6 Methyl malonic acid 20 Na

2.6–3.6 Citric acid 20 Na

3.3–4.3 Lactic acid 50 Na

3.3–4.3 Formic acid 50 Na

3.7–4.7; 5.1–6.1 Succinic acid 50 Na

4.3–5.3 Acetic acid 50 Na

5.2–6.2 Methyl malonic acid 50 Na

5.6–6.6 MES 50 Na

6.7–7.7 Phosphate 50 Na

7.0–8.0 HEPES 50 Na

7.8 – 8 . 8 B I CIN E 50 N a

1

Ref: Handboo k of chemistry a nd physics, 83rd edition, CRC, 2002–2003.

+

or Li+ 3.07

+

3.13

+

3.86

+

or Li+ 3.75

+

4.21; 5.64

+

or Li+ 4.75

+

or Li+ 5.76

+

or Li+ 6.27

+

7.2 0

+

or Li+ 7.5 6

+

8.33

1

p. 7

Page 8

Table 3. Buffers for anion exchange chromatography.

pH inter val Substance Conc. ( mM) Counter-ion pKa (25 °C)

4.3–5.3 N-Methylpiperazine 20 Cl- 4.75

4.8–5.8 Piperazine 20 Cl

5.5–6 .5 L-Histidine 20 Cl

6.0–7.0 bis-Tris 20 Cl

6.2–7.2; 8.6–9.6 bis-Tris propane 20 Cl

7.3–8.3 Triethanolamine 20 Cl

7.6 – 8 .6 Tr i s 20 Cl- 8.07

8.0–9.0 N-Methyldiethanolamine 20 SO

8.0–9.0 N-Methyldiethanolamine 50 Cl

8.4–9.4 Di ethanolamine 20 at pH 8.4 Cl

50 at pH 8.8

8.4–9.4 Propane 1,3-Diamino 20 Cl

9.0–10.0 Ethanolamine 20 Cl

9.2–10.2 Piperazine 20 Cl

10.0–11.0 Propane 1,3-Diamino 20 Cl

10.6–11. 6 Pip eri din e 20 Cl

1

Ref: Handboo k of chemistry a nd physics, 83rd edition, CRC, 2002–2003.

-

or HCOO- 5.33

-

6.04

-

6.48

-

6.65; 9.10

-

or CH3COO- 7.76

2-

8.52

4

-

or CH3COO- 8.52

-

8.88

-

8.88

-

9.50

-

9.73

-

10.55

-

11.12

pH

Fig 2. Recommended buffer substances for cation exchange chromatography.

1

p. 8

Page 9

Fig 3. Recommended buffer substances for anion exchange chromatography.

The columns can be operated with a syringe, peristaltic pump or a

chromatography system.

3. Operation

Buff er preparation

Water and chemicals used for buffer preparation should be of high purity. It

is recommended to filter the buffers by passing them through a

0.22 μm filter immediately before use. See Tables 2 and 3, Figs 2 and 3 for

recommended buffers.

Sample preparation

The sample should be adjusted to the composition of the start buffer.

This can be done by either diluting the sample with start buffer or by

buffer exchange using HiTrap Desalting, HiPrep

column. The sample should be filtered through a 0.22 μm or 0.45 μm filter or

centrifuged immediately before it is applied to the column. See Table 4.

™

26/10 Desalting or PD-10

p. 9

Page 10

p. 10

>5000).

r

>5000).

r

a syringe or pump

to run.

17-5087-01 HiPrep Up to 15–20 ml Prepacked with For desalting and

26/10 15 ml Sephadex G-25 buffer exchange of

Desalting Fine. Requires a protein extracts

pump to run. (M

Table 4. Prepacked columns for desalting and buffer exchange.

Code No Column Loading volume Elution volume Comments Application

17-1408-01 HiTrap 0.1–1.5 ml 1.3–4.0 ml Prepacked with For desalting and buffer

Desalting Sephadex™ G-25 exchange of protein

Superfine. Requires extracts (M

17-0851-01 PD-10 2.5 ml 3.5 ml Prepacked with For desalting and

>5000)

r

>5000).

r

17-0855-01 NICK™ 0.1 ml 0.4 ml Prepacked with For separation of

Sephadex G-25. proteins (M

and nicktranslated

Desalting Sephadex G-25. buffer exchange

Requires only of protein extracts

gravity to run. (M

DNA from radiolabelled

>5000),

r

nucleotides not shorter

than 120 mers, and

similar separations.

17-0853-01 NAP™-5 0.5 ml 1.0 ml Prepacked with For purification of

17-0854 -01 NAP-10 1 .0 ml 1.5 ml Sephadex G-25 proteins (M

17-0852-01 NAP-25 2.5 ml 3.5 ml DNA grade. DNA and oligo -

Requires only nucleotides greater

gravity to run. than 10 bases in length.

Page 11

Purifi cation

1. Fill the syringe or pump tubing with start buffer (low ionic strength).

Remove the stopper and connect the column to the syringe (with the

provided adaptor), “drop to drop” to avoid introducting air into the

column.

2. Remove the snap-off end at the column outlet.

3. Wash out the preservatives with 5 column volumes of start buffer, at

1 ml/min for the 1 ml column and 5 ml/min for the 5 ml column.

4. Wash with 5 column volumes of elution buffer (start buffer with

1 M NaCl).

5. Finally equilibrate with 5–10 column volumes of start buffer.

6. Apply the sample at 1 or 5 ml/min for the 1 ml and 5 ml columns

respectively, using a syringe fit ted to the luer adaptor or by pumping it

onto the column.

7. Wash with at least 5 column volumes of start buffer or until no material

appears in the effluent.

8. Elute with 5–10 column volumes of elution buffer (see section “Choice of

gradient type”).

9. The purif ied fractions can be desalted using a HiTrap Desalting,

HiPrep 26/10 Desalting or a PD-10 columns if necessary.

10. After the completed elution, regenerate the column by washing with

5 column volumes of regeneration buffer (start buffer with 1 M NaCl)

followed by 5–10 column volumes of start buffer. The column is now

ready for a new sample.

For a first experiment the following conditions are recommended:

Flow rate: 1 ml/min using HiTrap 1 ml column

5 ml/min using HiTrap 5 ml column

Start buffer: See Tables 2 and 3

Elution buffer: Start buffer + 1 M NaCl

Gradient volume: 20 ml

p. 11

Page 12

Note: If a P1-pump is used a max flow rate of 1–3 ml/min can be run on

a HiTrap 1 ml column packed with Sepharose High Performance

media.

4. Optimization

If sample composition is unknown, a simple screening test with the aid

of a syringe or pump can be per formed to optimize starting pH and ionic

strength.

1. Set up a series of buf fers with different pH´s, in the range 4–8 (SP) or 5–9

(Q), with 0.5–1 pH unit intervals between each buffer. Make one series

with 1 M NaCl included in the buffers (regeneration buffer) and the other

without NaCl (start buffer).

2. Equilibrate the column, see Purification.

3. Adjust the sample to the chosen start buffer, see Sample preparation.

4. Apply a known constant amount of the sample at 1 or 5 ml/min for the

1 ml and 5 ml columns respectively. Collect eluate.

5. Wash with at least 5 column volumes start buffer or until no material

appears in effluent. Collect eluate.

6. Elute bound material with elution buf fer. 3–5 column volumes is usually

sufficient. Other volumes may be required, depending on the chosen

operational conditions. Collect eluate.

7. Analyze all eluates for example by activity assay and SDS-PAGE and

determine the purity and the amount bound to the column.

8. Perform steps 2–7 for the next buffer pH.

9. Decide which pH should be used for the selected purification strategy.

10. To decide on starting ionic strength conditions, a similar screening is

done, but the buf fer pH is held constant and the ionic strength is varied

in the interval 0–0.5 M, with intervals of 0.05 to 0.1 M salt between each

buffer.

p. 12

Page 13

Further optimization

The recommendations given above will give a sound basis for developing an

efficient purification step. Details of how flow rate, sample loading, particle

size and elution scheme may be optimized to meet the special needs can

be found in the handbook, Ion Exchange Chromatography & Chromatofoucsing, Principles and Methods, Code No. 11-0004-21.

GE Healthcare supplies a wide range of ion exchange chromatography

media for purif ication of biomolecules at all scales. See Ordering information

and visit www.gehealthcare.com/hitrap.

5. Choice of gradient type

1. Stepwise gradients are easy to produce and require minimal equipment.

Eluted peaks are very sharp and elution volumes minimal. However,

care must be exercised in the design of the steps and the interpretation

of results for substances eluted by a sharp change in pH or small

differences in ionic strength. Peaks tend to have sharp fronts and

pronounced tailing since they frequently contain more than one

component.

2. Continuous salt gradients are the most frequently used type of elution.

Many types of gradient forming systems are available. Two buffers of

differing ionic strength, the start and elution buf fer (start buffer

+ 1 M NaCl or higher buffer salt concentration), are mixed together and if

the volume ratio is changed linearly, the ionic strength changes linearly.

Note: Another, but less common, method to desorb bound material is to

increase (SP) or decrease (Q) the pH of the eluent. Continuous pH

gradients are difficult to produce at constant ionic strength, since

simultaneous changes in ionic strength, although small, also occur

(buffering capacities are pH dependent).

p. 13

Page 14

Elution with stepwise ionic strength gradients

Stepwise elution is the sequential use of the same buffer at different ionic

strengths. It is technically simple and fast, and is suitable for syringe

operation. It is often used for sample concentration and sample clean-up.

Stepwise elution gives small peak volumes and the resolution depends on

the difference in elution power between each step.

1. Choose starting conditions as outlined under Optimizing starting

conditions.

2. Equilibrate the column, see Purification.

3. Adjust the sample to the choosen starting pH and ionic strength, see

Sample preparation.

4. Apply the sample at 1 or 5 ml/min for the HiTrap 1 ml or 5 ml column

respectively. Collect eluate.

5. Wash with at least 5 column volumes of start buffer or until no material

appears in effluent. Collect eluate.

6. Elute with the first step ionic strength buffer. The volumes required for

stepwise elution depend on the operating conditions. However, 3–5

column volumes is usually sufficient. Collect eluate.

7. Elute with next ionic strength buffer. Collect eluate.

8. After completed elution, regenerate the column by washing with 5

column volumes of regeneration buffer (start buffer with 1 M NaCl)

followed by 5–10 column volumes of start buffer. The column is now

ready for a new sample.

Elution with continuous ionic strength gradients

Continuous salt gradient elution is the most frequently used type of

elution in ion exchange chromatography. It is very reproducible and leads

to improved resolution, since zone sharpening occurs during elution.

Continuous gradients can be prepared in different ways, depending on

available equipment.

p. 14

Page 15

– A peristaltic pump and a gradient mixer e.g. pump P-1, gradient mixer

GM-1.

– A one pump system, e.g. ÄKTAprime™ plus.

– A two pump system, e.g FPLC or ÄKTA.

1. Choose starting conditions as outlined under Optimizing starting

conditions.

2. Equilibrate the column, see Purification.

3. Adjust the sample to the chosen starting pH and ionic strength, see

Sample preparation.

4. Apply the sample at 1 or 5 ml/min for the HiTrap 1 or 5 ml column

respectively. Collect eluate.

5. Wash with 5–10 column volumes of star t buffer or until no material

appears in effluent.

6. Start the gradient elution. A gradient volume of 10–20 column volumes

and an increase in ionic strength to 0.5 M NaCl is usually sufficient.

7. Regenerate the column by washing with 5 column volumes of start

buffer with 1 M NaCl followed by 5–10 column volumes of star t buffer.

The column is now ready for a new sample.

6. Determination of binding capacity

The amount of sample which can be applied to a column depends on the

capacity of the column and the degree of resolution required. The capacity

is dependent on the sample composition, choosen starting conditions of pH

and ionic strength and the flow rate at which the separation is done. The

influence of flow rate and pH on the capacity for some model proteins are

shown in Figure 4.

Samples were applied until 5% of the start material appeared in the eluent.

The column was then washed with 10 ml start buffer (20 mM Tris-HCl, pH 8.2

or 9.0) before elution with elution buffer (20 mM Tris-HCl, 1.0 M NaCl, pH 8.2

or 9.0).

1. Equilibrate the column, see Purification.

2. Adjust the sample to the chosen starting pH and ionic strength, see

Sample preparation.

3. Determine the concentration of the specific proteins by UV, SDS- PAGE,

ELISA or other appropriate techniques.

p. 15

Page 16

Fig 4. Binding capacity of human IgG, HSA and human transferrin at dif ferent pH´s

on HiTrap Q HP, 1 ml.

4. Apply the sample solution to the column with a pump or a syringe, at a

flow rate equal to the flow rate to be used in the purification method.

Collect fractions and continue sample application until the column is

saturated.

5. Wash the column with 5–10 column volumes start buffer or until no

material appears in the effluent.

6. Elute bound proteins with 3–5 column volumes of elution buffer (start

buffer with 1 M NaCl) and collect eluate.

7. Analyse fractions and eluates from steps 4 and 6 for the specific protein

and determine the breakthrough profile (sample concentration as a

function of the amount of sample applied). The dynamic capacity is the

amount that can be applied without any significant breakthrough. The

total capacity for the specific protein is determined from step 6.

p. 16

Page 17

7. Scaling up

For quick scale-up of purifications (back pressure will increase), two or three

HiTrap ion exchange columns of the same type can be connected in series.

For further scale-up SP Sepharose High Performance and Q Sepharose High

Performance are available in prepacked HiLoad

packs. See Ordering Information.

™

columns or bulk media

8. Storage

HiTrap SP HP: Rinse with water and then wash with 5 column volumes of

20% ethanol, 0.2 M sodium acetate.

HiTrap Q HP: Rinse with water and then with 5 column volumes of 20%

ethanol.

Seal the column with the supplied stoppers. The recommended storage

temperature is +4 to +30 °C.

9. Ordering Information

Produc t No. Supplied Code No.

HiTrap SP HP 5 x 1 ml 17-1151-01

HiTrap SP HP 5 x 5 ml 17-1152-01

HiTrap Q HP 5 x 1 ml 17-1153-01

HiTrap Q HP 5 x 5 ml 17-1154-01

p. 17

Page 18

Related products No. Supplied Code No.

HiTrap IEX Selection Kit 7 x 1 ml 17-6002-33

HiTrap Desalting 5 x 5 ml 17-1408- 01

HiTrap Desalting 100 x 5 ml* 11-0003-29

HiPrep 26/10 Desalting 1 x 53 ml 17-5087-01

HiPrep 26/10 Desalting 4 x 53 ml 17-5087-02

PD-10 Desalting column 30 17-0851-01

HiLoad 16/10 SP Sepharose High Performance 1 x 20 ml 17-1137-01

HiLoad 26/10 SP Sepharose High Performance 1 x 53 ml 17-1138-01

HiLoad 16/10 Q Sepharose High Performance 1 x 20 ml 17-1064-01

HiLoad 26/10 Q Sepharose High Performance 1 x 53 ml 17-1066-01

SP Sepharose High Performance 75 ml 17-1087-01

Q Sepharose High Performance 75 ml 17-1014-01

* Specia l pack size deliv ered on specif ic order.

Accessories No. Supplied Code No.

1/16” male/luer female* 2 18-1112-51

Tubing connector flangeless/M6 female* 2 18-1003-68

Tubing connector flangeless/M6 male* 2 18-1017-98

Union 1/16” female/M6 male* 6 18-1112-57

Union M6 female /1/16” male* 5 18-3858-01

Union luerlock female/M6 female 2 18-1027-12

HiTrap/HiPrep, 1/16” male connector for ÄKTAdesign 8 28-4010-81

Stop plug female, 1/16”

Fingertight stop plug, 1/16”

* One c onnector inc luded in each Hi Trap pac kage.

† Two, five, o r seven stop plu gs female inclu ded in HiTrap pack ages dependi ng on the produc t.

‡

O ne finger tight stop plu g is connected t o the top of each Hi Trap colu mn at delivery .

†

5 11-0004-64

‡

5 11-0003-55

p. 18

Page 19

Realated literature

Ion Exchange Chromatography & Chromatofocusing

Handbook, Principles and Methods 1 11-0004-21

Ion Exchange Columns and Media,

Selection Guide 1 18-1127-31

Convenient Protein Purification,

HiTrap Column Guide 1 18-1129-81

p. 19

Page 20

www.gehealthcare.com/hitrap

www.gehealthcare.com

GE Healthcare Bio-Sciences AB

Björkgatan 30

751 84 Uppsala

Sweden

HiTrap, Sepharose, Sephadex, FPLC, ÄKTA, ÄKTAprime, ÄKTAdesign, Drop Design, NICK, NAP, HiPrep and HiLoad are

trademarks of GE Healthcare companies. GE, imagination at work and GE monogram are trademarks of General Electric

Company.

All goods and services are sold subject to the terms and conditions of sale of the company within GE Healthcare which

supplies them. GE Healthcare reserves the right, subject to any regulatory and contractual approval, if required, to make

changes in specifi cations and features shown herein, or discontinue the product described at any time without notice or

obligation. Contact your local GE Healthcare representative for the most current information.

© 2006 General Electric Company – All rights reserved.

GE Healthcare AB, a General Electric Company.

GE Healthcare Europe GmbH

Munzinger Strasse 5

D-79111 Freiburg

Germany

GE Healthcare UK Ltd

Amersham Place

Little Chalfont

Buckinghamshire, HP7 9NA

UK

GE Healthcare Bio-Sciences Corp

800 Centennial Avenue

P.O. Box 1327

Piscataway, NJ 08855-1327

USA

GE Healthcare Bio-Sciences KK

Sanken Bldg.

3-25-1, Hyakunincho

Shinjuku-ku, Tokyo 169-0073

Japan

71-7149-00 AN 08/2006

Elanders Östervåla 2006

Loading...

Loading...