Page 1

GE Healthcare

Solar™ 8000M/i patient monitor

Service Manual

Software Version 5

Solar™ 8000M/i patient monitor

English

2026266-004 (CD)

2026264-042C (paper)

© 2007 General Electric Company

All rights reserved.

Page 2

NOTE: The information in this manual applies to Solar 8000i and Solar 8000M Patient Monitors. Due to

continuing product innovation, specifications in this manual are subject to change without notice.

NOTE: For technical documentation purposes, the abbreviation GE is used for the legal entity name, GE

Medical Systems Information Technologies.

Listed below are GE Medical Systems Information Technologies trademarks. All other trademarks contained

herein are the property of their respective owners.

APEX, DASH, MUSE, RSVP, SOLAR, TRAM, TRIM KNOB, and UNITY NETWORK are trademarks of GE

Medical Systems Information Technologies registered in the United States Patent and Trademark Office.

CARESCAPE is a trademark of GE Medical Systems Information Technologies.

T-2 Solar 8000M/i patient monitor 2026265-075C

30 November 2007

Page 3

Contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Manual information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Intended audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Ordering manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Responsibility of the manufacturer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Warnings, cautions, and notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Equipment symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Service information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Service requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Equipment identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

2 Equipment overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

System components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Solar 8000M/i patient monitoring system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Solar 8000M/i patient monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

iPanel computer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

UnityView remote display controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Tram-rac housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Patient Data Module (PDM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Connectivity devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

PRN 50/PRN 50-M digital writer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

Laser printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Remote control or keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Remote displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

Device compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Acquisition modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Peripheral devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

Unity Network devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-11

Interfacing with other peripheral devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

Theory of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Block diagram of internal connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Processor board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-22

Speaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

2026265-075C Solar 8000M/i patient monitor i

Page 4

3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Back panel connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

TRAM-NET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

ETHERNET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

VGA VID 1 and 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

DFP VID 1 and 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

RS-232 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

RS-232 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Front panel connectors and indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

M-Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

Power up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

TRAM-NET communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Internal hub . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Ethernet communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

About ethernet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-12

Twisted pair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Network terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

4 Maintenance and checkout . . . . . . . . . . . . . . . . . . . . . . . 4-1

Maintenance schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Manufacturer recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Manufacturer responsibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Preventive maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Visual inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Cleaning precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Exterior cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Cleaning, disinfecting and storing GE ECG cables and leadwires . . . . . . . . . . . . 4-5

Electrical safety tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Set up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Power outlet test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Ground (earth) integrity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Ground (earth) wire leakage current tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

Enclosure leakage current test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-12

Patient (source) leakage current test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Patient (sink) leakage current test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-14

Test completion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

ii Solar 8000M/i patient monitor 2026265-075C

Page 5

Checkout procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

Required tools and equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

Set up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Parameter tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

Completion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-36

Maintenance Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-37

“Visual inspection” on page 4-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-37

“Cleaning” on page 4-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-37

“Electrical safety tests” on page 4-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-37

“Checkout procedure” on page 4-16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-37

Repair Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-39

5 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Terms used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Abort (main code) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

Boot loader or boot code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Cold start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Continue (main code) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Monitor memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Protected memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Power cycle or reboot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Service mode (main code) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Service menu (boot code) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Warm start (boot code) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Country selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Set language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Service menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Boot code Service Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Main code SERVICE MODE menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Fault analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

AC line voltage test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

120 VAC, 50/60 Hz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

240 VAC, 50/60 Hz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Troubleshooting procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

Problems and solutions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

LED troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-16

Troubleshooting software updates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

2026265-075C Solar 8000M/i patient monitor iii

Page 6

Error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

Reviewing error/event logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-22

Accessing error/event logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-22

Useful error data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-23

Get error logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-27

Get logs via PC using netUpdate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-27

6 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Configuring a patient monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Set unit name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Set bed number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-3

Patient monitor type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Set graph locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Admit Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Set line frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Set defib sync voltage and pulse width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Set country selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Set language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Calibrate touchscreen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Completion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Advanced user procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Set time and date . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Change software level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-10

Enable options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

Transfer monitor defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

Change Ethernet address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

Set internet address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

Power cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

7 Field replaceable units . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Ordering parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Field replaceable units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Hardware kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Keypads and remote controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

iv Solar 8000M/i patient monitor 2026265-075C

Page 7

Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

Disassembly procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

Appendix A – Technical specifications . . . . . . . . . . . . . . A-1

Solar 8000M/i patient monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Tram-rac 2 and 4A module housings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

Tram modules and Solar parameter functionality . . . . . . . . . . . . . . . . . . . . . . . . . A-7

Dual temperature module (400 and 700 series) . . . . . . . . . . . . . . . . . . . . . . . . . . A-15

Capnostat mainstream CO

module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-18

SvO

2

ICG module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-19

BIS/EEG module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-20

Patient Data Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-21

Solar SpO

Solar 8000M/i display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-22

Masimo SET module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-21

2

Purchaser’s responsibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-22

Medical-grade displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-22

Non-medical grade displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-23

Required specifications for non-medical grade CRT displays . . . . . . . . . . . . . . .A-24

Recommended specifications for non-medical grade CRT displays . . . . . . . . . .A-25

Required specifications for non-medical grade digital flat panel displays . . . . . .A-26

Recommended specifications for non-medical grade digital flat panel displays .A-27

module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-16

2

Appendix B – Electromagnetic compatibility . . . . . . . . . B-1

Electromagnetic compatibility (EMC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Guidance and manufacturer’s declaration — electromagnetic emissions . . . . . . .B-2

Guidance and manufacturer’s declaration — electromagnetic immunity . . . . . . . .B-3

Recommended separation distances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-5

Compliant cables and accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-6

2026265-075C Solar 8000M/i patient monitor v

Page 8

vi Solar 8000M/i patient monitor 2026265-075C

Page 9

1 Introduction

2026265-075C Solar 8000M/i patient monitor 1-1

Page 10

Manual information

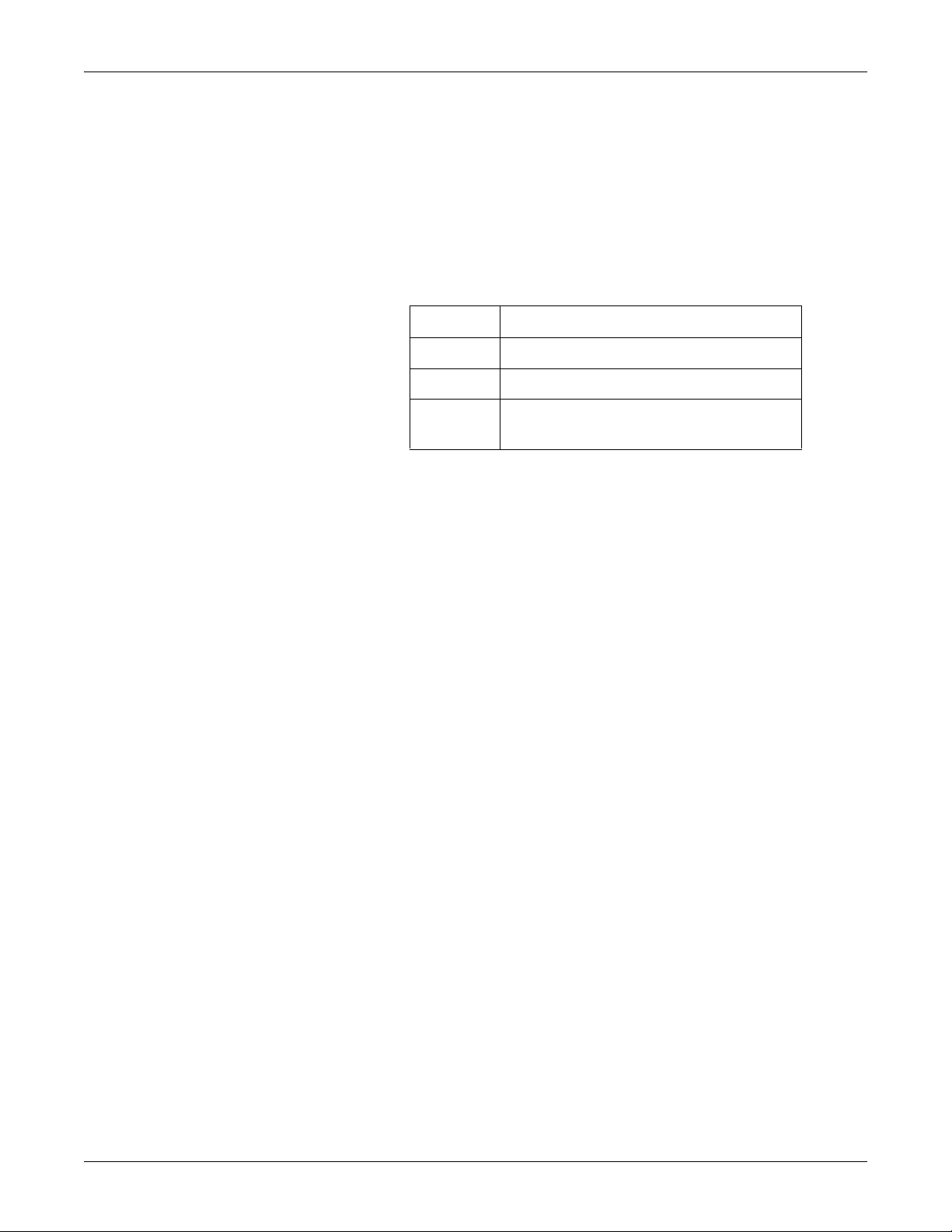

Revision history

Each page of the document has the document part number and revision

letter at the bottom of the page. The revision letter changes whenever

the document is updated.

Intended use

Introduction: Manual information

Revision Comment

A Initial release

B Updated document with editorial changes.

C Updated document with cpu and related hardware

changes.

Intended audience

Ordering manuals

This manual supplies technical information for service representatives

and technical personnel so they can maintain the equipment to the

assembly level. Use it as a guide for maintenance and electrical repairs

considered field repairable. Where necessary the manual identifies

additional sources of relevant information and technical assistance.

See the operator’s manual for the instructions necessary to operate the

equipment safely in accordance with its function and intended use.

This manual is intended for service representatives and technical

personnel who maintain, troubleshoot, or repair this equipment.

A paper copy of this manual will be provided upon request. Contact your

local GE representative and request the part number on the first page of

the manual.

1-2 Solar 8000M/i patient monitor 2026265-075C

Page 11

Introduction: Safety information

Safety information

Responsibility of the manufacturer

GE is responsible for the effects of safety, reliability, and performance

only if:

Assembly operations, extensions, readjustments, modifications, or

repairs are carried out by persons authorized by GE.

The electrical installation of the relevant room complies with the

requirements of the appropriate regulations.

The equipment is used in accordance with the instructions for use.

General

This device is intended for use under the direct supervision of a licensed

health care practitioner.

This device is not intended for home use.

Federal law restricts this device to be sold by or on the order of a

physician.

Contact GE for information before connecting any devices to the

equipment that are not recommended in this manual.

Parts and accessories used must meet the requirements of the applicable

EN 60601 series safety standards, and/or the system configuration must

meet the requirements of the EN 60601-1-1 medical electrical systems

standard.

Periodically, and whenever the integrity of the device is in doubt, test all

functions.

The use of accessory equipment not complying with the equivalent safety

requirements of this equipment may lead to a reduced level of safety of

the resulting system. Consideration relating to the choice shall include:

use of the accessory in the patient vicinity; and

evidence that the safety certification of the accessory has been

performed in accordance to the appropriate EN 60601-1 and/or EN

60601-1-1 harmonized national standard.

If the installation of the equipment, in the USA, will use 240V rather

than 120V, the source must be a center-tapped, 240V, single-phase

circuit.

2026265-075C Solar 8000M/i patient monitor 1-3

Page 12

Introduction: Safety information

Warnings, cautions, and notes

The terms danger, warning, and caution are used throughout this

manual to point out hazards and to designate a degree or level or

seriousness. Familiarize yourself with their definitions and significance.

Hazard is defined as a source of potential injury to a person.

DANGER indicates an imminent hazard which, if not avoided, will

result in death or serious injury.

WARNING indicates a potential hazard or unsafe practice which, if not

avoided, could result in death or serious injury.

CAUTION indicates a potential hazard or unsafe practice which, if not

avoided, could result in minor personal injury or product/property

damage.

NOTE provides application tips or other useful information to assure

that you get the most from your equipment.

1-4 Solar 8000M/i patient monitor 2026265-075C

Page 13

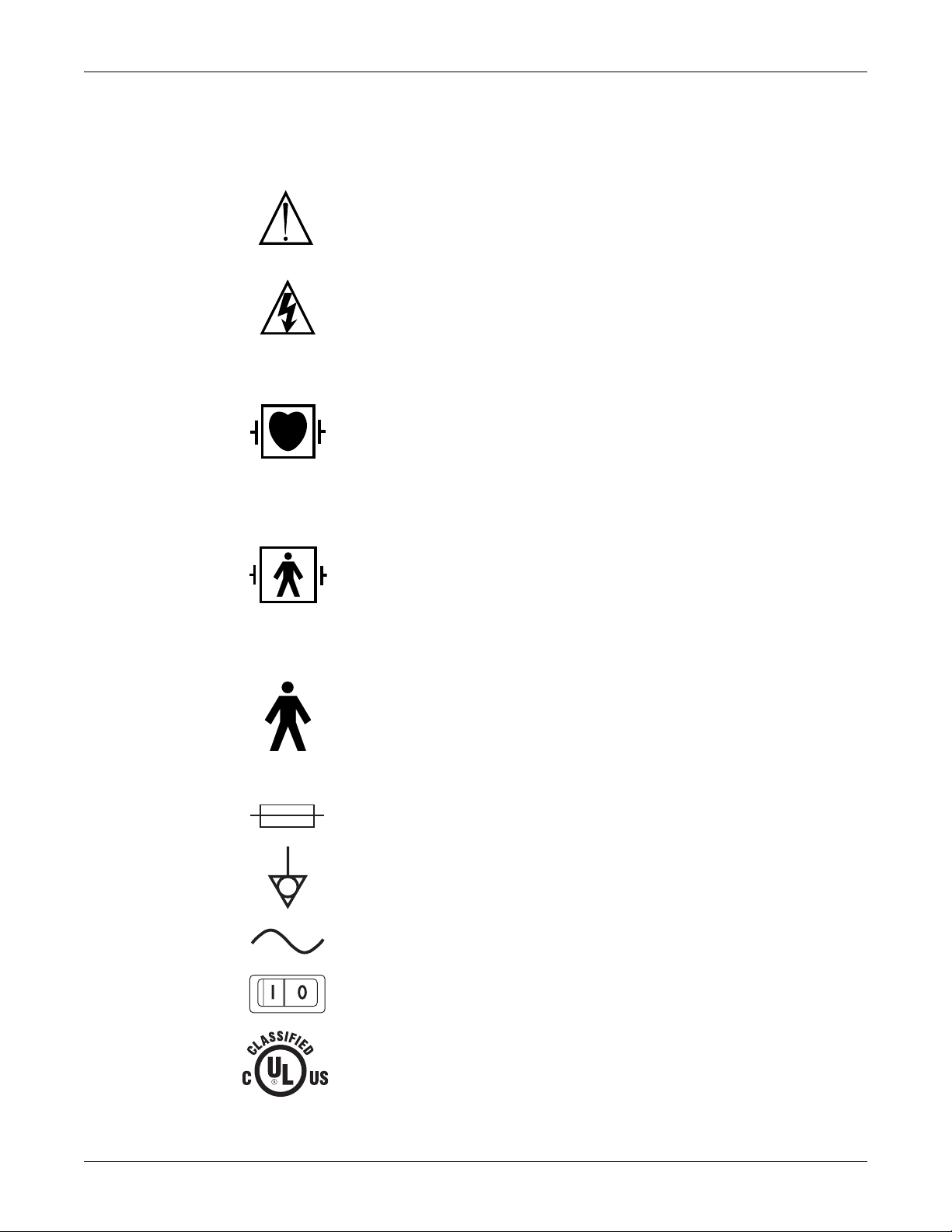

Equipment symbols

Introduction: Safety information

NOTE: Some symbols may not appear on all equipment.

ATTENTION: Consult accompanying documents.

CAUTION: To reduce the risk of electric shock, do not remove cover. Refer servicing to

qualified service personnel.

NOTE: The rating of protection against electric shock (indicated by symbol for CF or BF) is

achieved only when used with patient applied parts recommended by GE.

TYPE CF APPLIED PART: Isolated (floating) applied part suitable for intentional external and

internal application to the patient including direct cardiac application. “Paddles” outside the

box indicate the applied part is defibrillator proof.

[Medical Standard Definition:] F-type applied part (floating/isolated) complying with the

specified requirements of IEC/EN/UL 60601-1 Medical Standards to provide a higher degree

of protection against electric shock than that provided by type BF applied parts.

TYPE BF APPLIED PART: Isolated (floating) applied part suitable for intentional external and

internal application to the patient excluding direct cardiac application. “Paddles” outside the

box indicate the applied part is defibrillator proof.

[Medical Standard Definition:] F-type applied part (floating/isolated) complying with the

specified requirements of IEC/EN/UL 60601-1 Medical Standards to provide a higher degree

of protection against electric shock than that provided by type B applied parts.

TYPE B APPLIED PART: Non-isolated applied part suitable for intentional external and

internal application to the patient excluding direct cardiac application.

[Medical Standard Definition:] Applied part complying with the specified requirements of IEC/

EN/UL 60601-1 Medical Standards to provide protection against electric shock, particularly

regarding allowable leakage current.

Fuse

Equipotential Stud: A ground wire from another device can be tied here to ensure the devices

share a common reference.

Alternating current (AC)

Power; I = ON; O = OFF

Medical Equipment

With respect to electric shock, fire and mechanical hazards only in accordance with UL

60601-1, CAN/CSA C22.2 NO. 601.1, IEC 60601-1, IEC 60601-2-27, IEC 60601-2-30, IEC

4P41

2026265-075C Solar 8000M/i patient monitor 1-5

60601-2-34, and IEC 60601-2-49.

Page 14

2006-04

Introduction: Safety information

This symbol indicates that the waste of electrical and electronic equipment must not be

disposed as unsorted municipal waste and must be collected separately. Please contact an

authorized representative of the manufacturer for information concerning the

decommissioning of your equipment.

This symbol indicates the date of manufacture of this device. The first four digits identify the

year and the last two digits identify the month.

Non-ionizing electromagnetic radiation: To indicate elevated, potentially dangerous, levels of

non-ionizing radiation. Note - In case of application in a warning sign the rules according to

ISO 3864-1 shall be adhered to.

IEC 60878 note: See safety sign ISO 7010 - W005 “Warning, non-ionizing radiation”.

Manufacturer name and address.

European authorized representative.

NOTE

The following symbols (required by China law only) are

representative of what you may see on your equipment.

The number in the symbol indicates the EFUP period in years, as explained below. Check the

symbol on your equipment for its EFUP period.

This symbol indicates the product contains hazardous materials in excess of the limits

established by the Chinese standard SJ/T11363-2006 Requirements for Concentration Limits

for Certain Hazardous Substances in Electronic Information Products. The number in the

symbol is the Environment-friendly User Period (EFUP), which indicates the period during

which the toxic or hazardous substances or elements contained in electronic information

products will not leak or mutate under normal operating conditions so that the use of such

electronic information products will not result in any severe environmental pollution, any bodily

injury or damage to any assets. The unit of the period is “Year”.

In order to maintain the declared EFUP, the product shall be operated normally according to

the instructions and environmental conditions as defined in the product manual, and periodic

maintenance schedules specified in Product Maintenance Procedures shall be followed

strictly.

Consumables or certain parts may have their own label with an EFUP value less than the

product. Periodic replacement of those consumables or parts to maintain the declared EFUP

shall be done in accordance with the Product Maintenance Procedures. This product must not

be disposed of as unsorted municipal waste, and must be collected separately and handled

properly after decommissioning.

This symbol indicates that this electronic information product does not contain any toxic or

hazardous substance or elements above the maximum concentration value established by

the Chinese standard SJ/T11363-2006, and can be recycled after being discarded, and

should not be casually discarded.

1-6 Solar 8000M/i patient monitor 2026265-075C

Page 15

Service information

Service requirements

Follow the service requirements listed below.

Refer equipment servicing to GE authorized service personnel only.

Any unauthorized attempt to repair equipment under warranty voids

It is the user’s responsibility to report the need for service to GE or to

Failure on the part of the responsible individual, hospital, or

Regular maintenance, irrespective of usage, is essential to ensure

Equipment identification

Introduction: Service information

that warranty.

one of their authorized agents.

institution using this equipment to implement a satisfactory

maintenance schedule may cause undue equipment failure and

possible health hazards.

that the equipment will always be functional when required.

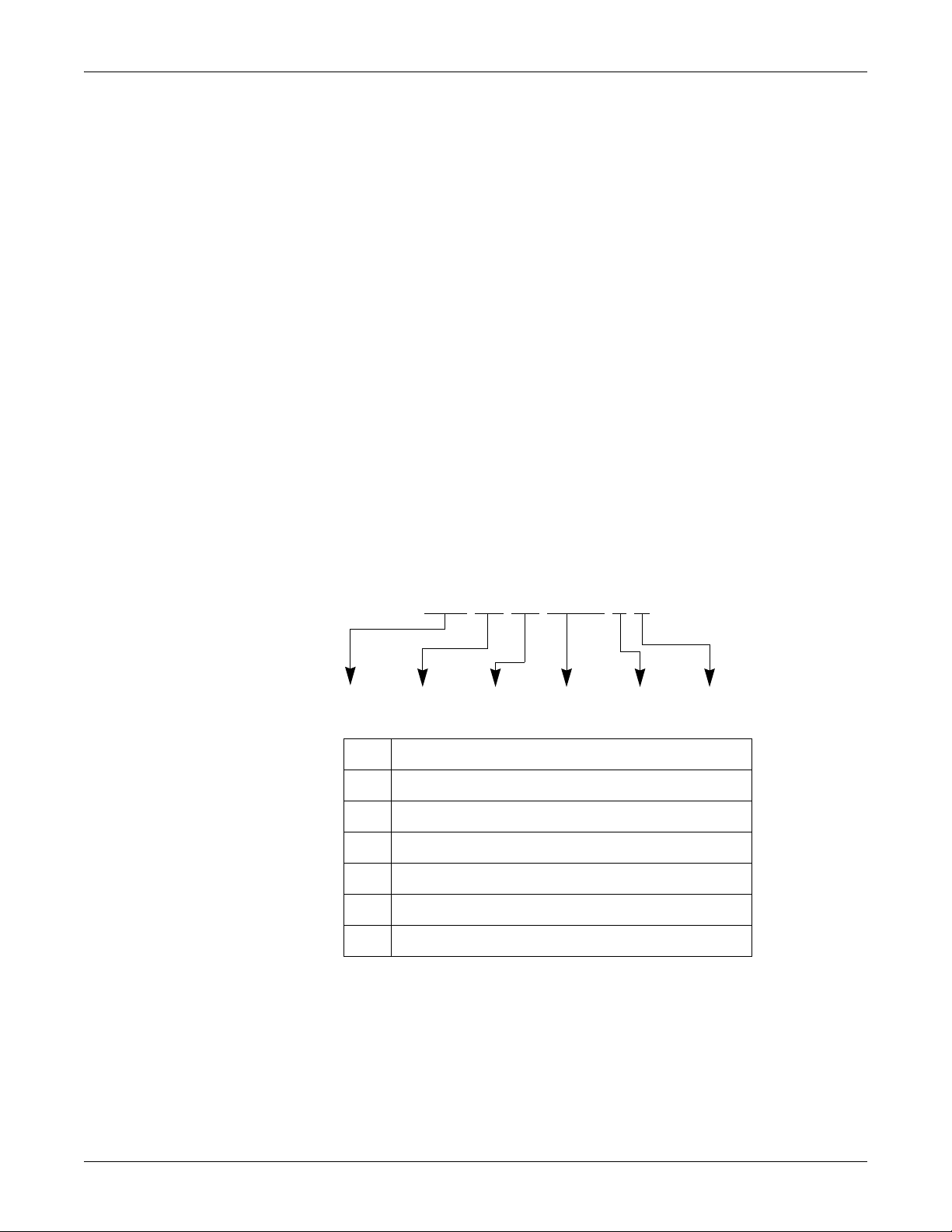

Every GE device has a unique serial number for identification. A sample

of the information found on a serial number label is shown below.

### ## ## #### # #

ABCDEF

Description

A product code

B year manufactured

C fiscal week manufactured

D production sequence number

E manufacturing site

F miscellaneous characteristic

2026265-075C Solar 8000M/i patient monitor 1-7

Page 16

Introduction: Service information

1-8 Solar 8000M/i patient monitor 2026265-075C

Page 17

2 Equipment overview

2026265-075C Solar 8000M/i patient monitor 2-1

Page 18

Equipment overview: System components

System components

Solar 8000M/i patient monitoring system

The Solar 8000M/i patient monitoring system consists of the following

standard components:

Solar 8000M/i processing unit

Display

Keypad and/or remote control

Two possible acquisition devices:

Tram-rac housing with acquisition module(s)

Patient Data Module (also referred to as PDM)

Optional components include:

iPanel™ computer

Clinical Information Center (central station)

Remote display, VGA and DFP

NOTE

Available on Solar 8000M and Solar 8000i patient monitors with

dual display capability.

Printer PRN 50/PRN 50-M

Unity Network™ ID connectivity device

2-2 Solar 8000M/i patient monitor 2026265-075C

Page 19

Equipment overview: System components

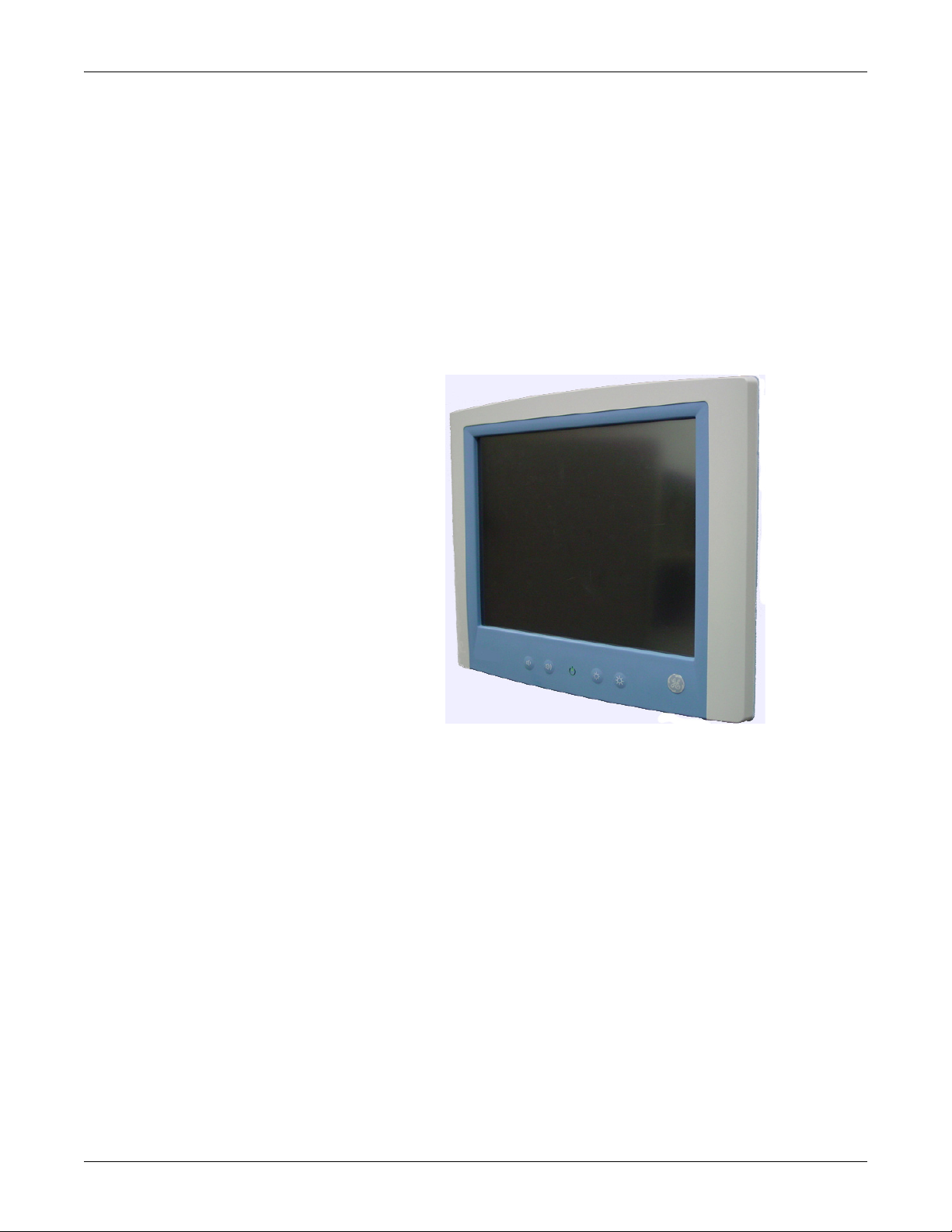

Solar 8000M/i patient monitor

The patient monitor consists of a Solar 8000M/i processing unit with

compatible display purchased from GE or another vendor.

The processing unit is the center of the Solar 8000M/i patient monitoring

system. It provides the user controls, the processors to communicate with

various patient monitoring modules, and it analyzes patient data. It can

display up to eight different waveforms at one time. System software

may be updated using a laptop computer connected to the Solar 8000M/i

processing unit or the Unity Network or from a Clinical Information

Center (CIC) on the Unity Network.

001C

042B

2026265-075C Solar 8000M/i patient monitor 2-3

Page 20

iPanel computer

Equipment overview: System components

The iPanel computer is a self contained medical grade computer with flat

panel display for use in the patient area. The iPanel contains the iPanel

software that provides one touch access to patient data on the enterprise

network. The iPanel application is compatible with the following patient

data web portals:

Centricity CIV

Centricity CV Cardiology Web

MUSE CV Web

Centricity Enterprise Web

UnityView remote display controller

The UnityView remote display controller consists of a remote display

controller with a compatible display purchased from GE or another

vendor. The controller connects to the Unity Network and may be

configured to display any patient waveforms broadcasted on the network

for better visibility as a remote full-view display, or as an in-room

telemetry display.

037A

2-4 Solar 8000M/i patient monitor 2026265-075C

Page 21

Tram-rac housing

Equipment overview: System components

The Tram-rac housing (remote acquisition case) acquires patient data for

the patient monitor. There are two Tram-rac housings available for the

monitor:

Tram-rac 2 housing — holds one Tram module.

Tram-rac 4A housing — holds one Tram module and two additional

single-high modules.

See the Tram-rac Housing Service Manual for additional information.

Shown below is a Tram-rac 4A housing with a Tram module and two

single parameter modules inserted.

005B

2026265-075C Solar 8000M/i patient monitor 2-5

Page 22

Equipment overview: System components

Patient Data Module (PDM)

The Patient Data Module (PDM) acquires patient data for the patient

monitor. See the Patient Data Module service manual for additional

information.

061A

Connectivity devices

The Unity Network ID connectivity device acquires digital data from

eight individually isolated serial ports. The data is collected from up to

eight peripheral devices (not necessarily manufactured by GE), then the

device transmits the formatted data to the Solar 8000M/i patient

monitor. See the appropriate connectivity device service manual for

additional information.

002B

2-6 Solar 8000M/i patient monitor 2026265-075C

Page 23

Equipment overview: System components

PRN 50/PRN 50-M digital writer

The PRN 50/PRN 50-M digital writer thermally records patient data on a

paper strip. Any parameter or trace that can be monitored on a monitor

can be graphed by the writer. Graphs initiate automatically when an

alarm is activated, or they can be initiated manually from the monitor.

Laser printer

003C

NOTE

The PRN 50-M digital writer is an M-Port device. To make an

AutoPort device (such as PRN 50) M-Port compatible, use the

AutoPort to M-Port adapter, pn 2001973-001.

An optional laser printer can be connected directly to the monitor via one

of the M-Ports. The laser printer must have a serial port, and an

interface adapter is required for the cable between the laser printer and

the monitor. Refer to the instructions provided in Laser Printer Support

Kit, pn 2013421-001, for details on the interface adapter and installing a

serial card in a laser printer.

WARNINGS

SHOCK HAZARD. Laser printers are UL 60950/EN

60950 certified equipment, which may not meet the

leakage current requirements of patient care equipment.

This equipment must not be located in the patient

vicinity unless the medical system standard EN

60601-1-1 is followed.

Do not connect a laser printer to a multiple portable

socket outlet (MPSO) supplying patient care equipment.

The use of an MPSO for a system will result in an

enclosure leakage current equal to the sum of all the

individual earth leakage currents of the system if there is

an interruption of the MPSO protective earth conductor.

2026265-075C Solar 8000M/i patient monitor 2-7

Page 24

Equipment overview: System components

Remote control or keypad

The remote control or keypad provides all patient monitor controls on a

portable component with a TRIM KNOB control, and allows the user to

operate the patient monitor from across a room. Eighteen hard keys are

configured for adult, neonatal, or operating room applications. The

keypad can be mounted on the display or on a separate holster that has

various mounting configurations.

Remote displays

004B

Depending on your Solar 8000M/i configuration, there are up to two VGA

(CRT/analog flat panel) ports and two DFP (digital flat panel) ports for

remote viewing.

2-8 Solar 8000M/i patient monitor 2026265-075C

Page 25

Equipment overview: Device compatibility

Device compatibility

The tables in this section are current as of the publication date of this

manual and are subject to change. For current information, contact your

Service or Sales Representative.

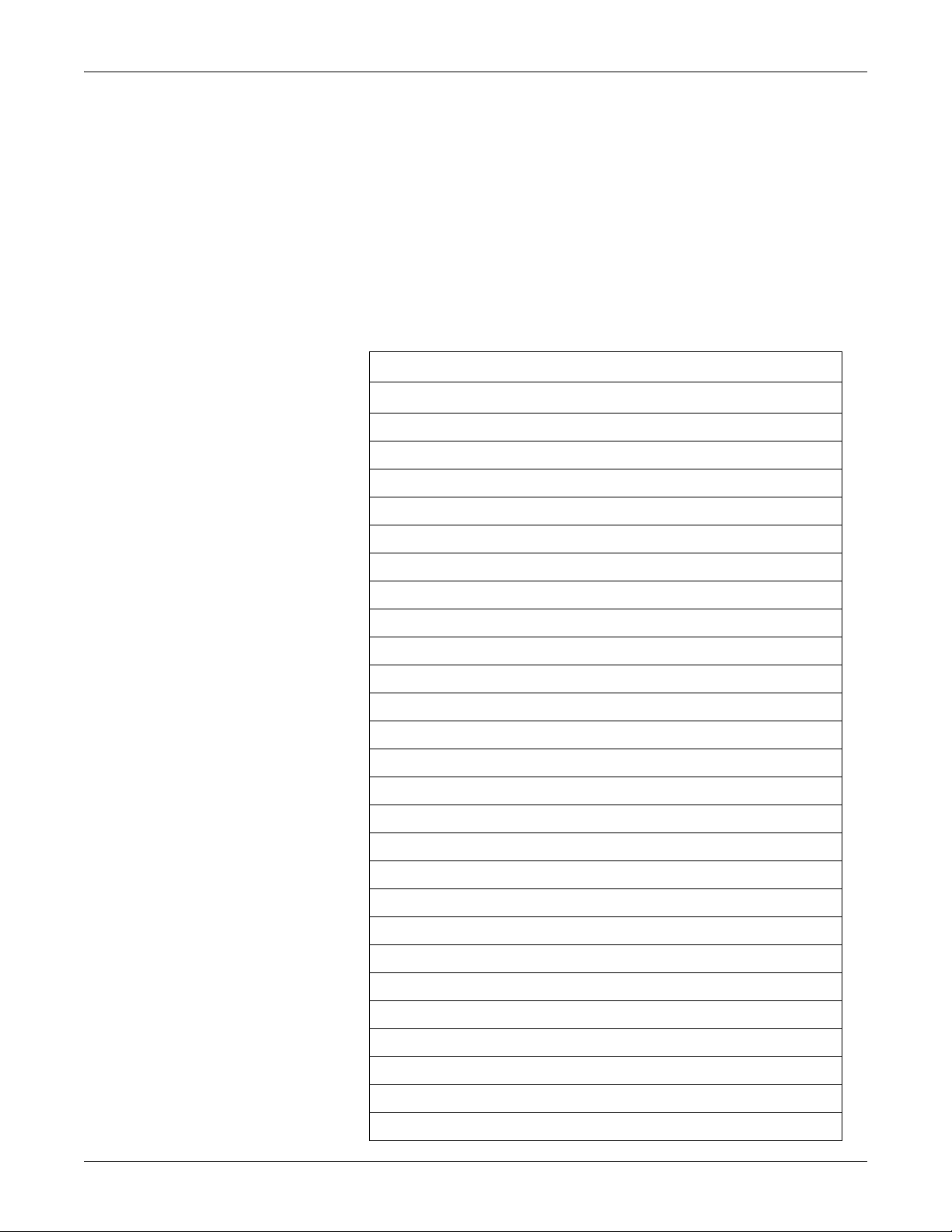

Acquisition modules

The Solar 8000M/i patient monitor is compatible with the following

acquisition modules.

Patient Data Module (Nellcor OxiMax SpO

Patient Data Module (Masimo SpO

SvO2 Module

Dual Temp Module, Series 700

Dual Temp Module, Series 400

Dual BP Module

BP Module

BP/Dual Temp Module

GE SpO2 Module

Masimo SET SpO2 Module

Capnostat Mainstream EtCO2 Module

Capnostat Mainstream Module

Capnostat Dual CO2 Module

Pryon Mainstream Module

Pryon Sidestream Module

SAM Module

)

2

)

2

SAM80 Module

Tram Module w/ECG, Resp, CO, 2 BP, NIBP, SpO2

Tram Module w/ECG, Resp, CO, 3 BP, NIBP, SpO2

Tram Module w/ECG, Resp, CO, 4 BP, SpO2

Tram Module w/ECG, Resp, CO, NIBP, SpO2

Tram Module w/ECG, Resp, CO, 4 BP, NIBP, SpO2 (GE)

Tram Module w/ECG, Resp, CO, 4 BP, NIBP, SpO2 (Nellcor)

Tram Module w/ECG, Resp, CO, 4 BP, NIBP, SpO2 (Nellcor OxiMax)

Tram Module w/ECG, Resp, CO, 4 BP, NIBP, SpO2 (Masimo)

Tram Module w/ECG, Resp, CO, SpO2 (GE)

Tram Module w/ECG, Resp, CO, SpO2 (Nellcor)

Tram Module w/ECG, Resp, CO, SpO2 (Nellcor OxiMax)

2026265-075C Solar 8000M/i patient monitor 2-9

Page 26

Peripheral devices

Equipment overview: Device compatibility

Tram Module w/ECG, Resp, CO, SpO2 (Masimo)

tcpO2/pCO2 Module

Respiratory Mechanics Module

Impedance Cardiograph Module

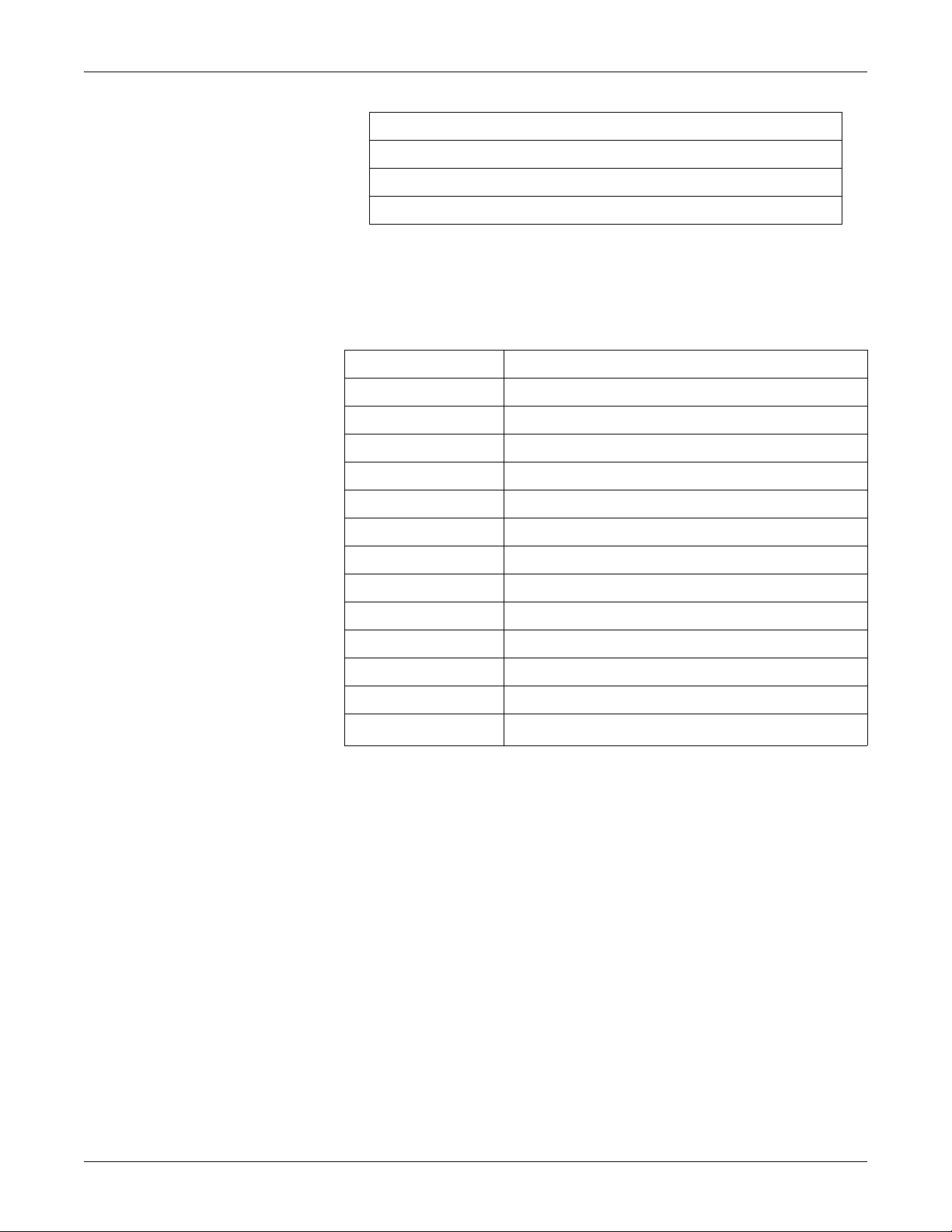

The Solar 8000M/i patient monitor is compatible with the following

peripheral devices.

Device Interface

Solar 8000M/i Remote M-Port

Solar 8000M/i Keypad M-Port

PRN 50 M-Port with M-Port compatible PRN50

RAC 4A Comm TRAM-NET

RAC 4A DAS TRAM-NET

RAC 2 TRAM-NET

Unity Network ID M-Port

RM Module M-Port with M-Port compatible RM module

Serial download RS-232 1

Elo Touchscreen RS-232 2

Remote Alarm M-Port

Laser printer M-Port

iPanel Computer

1. Solar 8000i patient monitor only.

RS-232 1

1

2-10 Solar 8000M/i patient monitor 2026265-075C

Page 27

Unity Network devices

Equipment overview: Device compatibility

The Solar 8000M/i patient monitor is compatible with the following

Unity Network devices.

Device Device

ADU/Pager LAN MARS 5000/8000

ApexPro MUSE

Aware Gateway Octacomm

CDT-LAN QS

CIC RSVP

CIC Pro C Solar 7000/8000

Dash 2000 Solar 8000M

Dash 3000/4000/5000 Solar 9000/9500

Eagle 3000 ST Guard

Eagle 4000 Tramscope 12

HL7 Outbound Auto View

ICMMS/Service Web CO2 Module

StatView Transcutaneous Module

iPanel Unity Network ID interface

Impact Pager Unity Network IS Patient Viewer

Managed Care Unity Network Patient Data Server

2026265-075C Solar 8000M/i patient monitor 2-11

Page 28

Equipment overview: Device compatibility

Interfacing with other peripheral devices

The Solar 8000M/i patient monitor can interface with other peripheral

bedside monitoring devices through an Unity Network ID connectivity

device. For a list of supported devices, see the Unity Network Interface

Device (ID) Service Manual.

2-12 Solar 8000M/i patient monitor 2026265-075C

Page 29

Equipment overview: Theory of operation

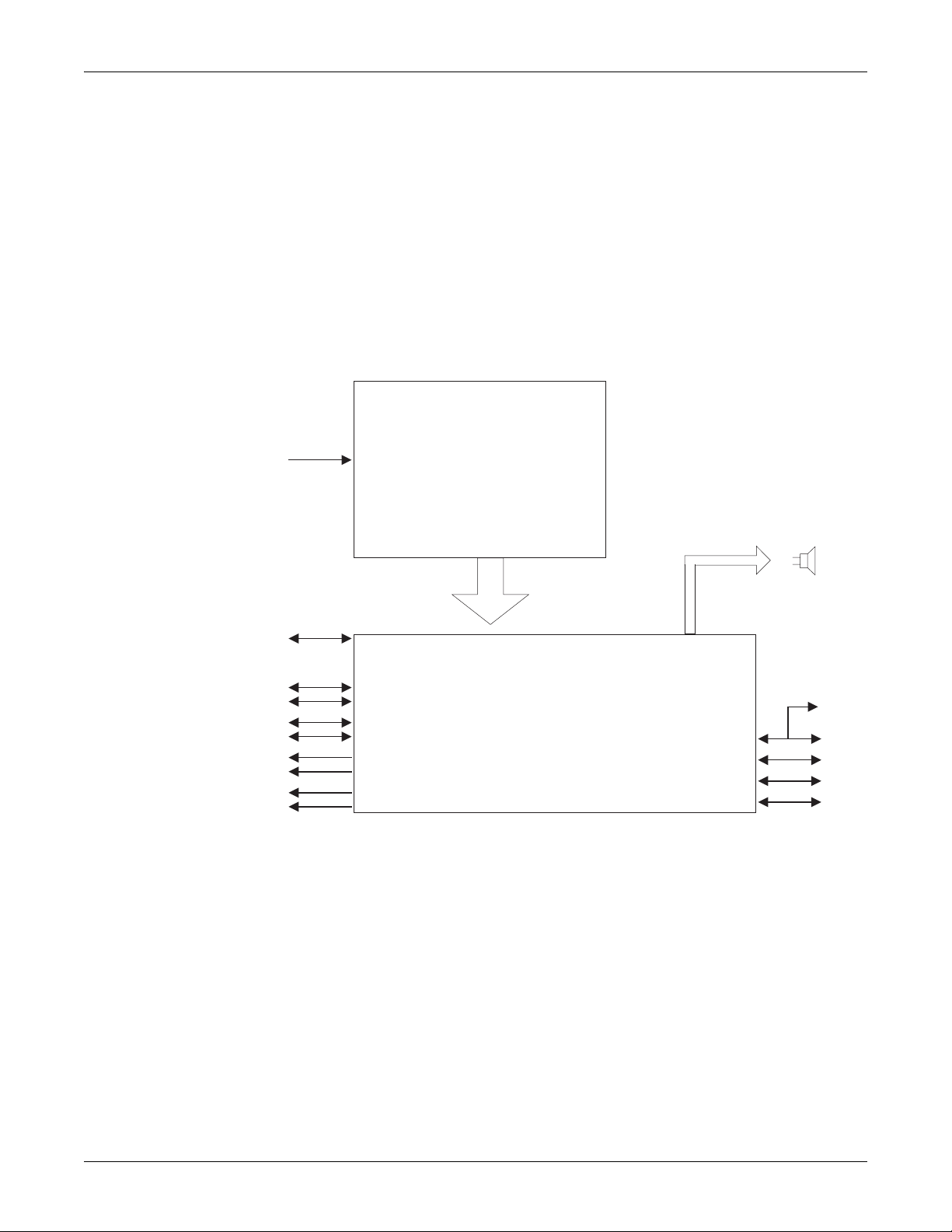

t

t

t

t

d

e

Theory of operation

The Solar 8000M/i patient monitor consists of a processor board, a power

supply board, and a speaker. Software running on the processor board

processes incoming data, services the communication channels and

performs the general functions. System software may be updated using a

laptop computer connected to the Solar 8000M/i processing unit or the

Unity Network or from a Clinical Information Center (CIC) on the Unity

Network.

The following theory of operation provides an overview of the various

functional circuit boards in the monitor.

AC Power

Ethernet

TRAM-NET 1

TRAM-NET 2/ePort*

Serial Port 1

Serial Port 2

DFP 1

DFP 2

VGA 1

VGA 2

*ePort available on 801586-003 only.

Power Supply

Power

harness

Processor Board

Speak

Keypa

M-Por

M-Por

M-Por

M-Por

034B

2026265-075C Solar 8000M/i patient monitor 2-13

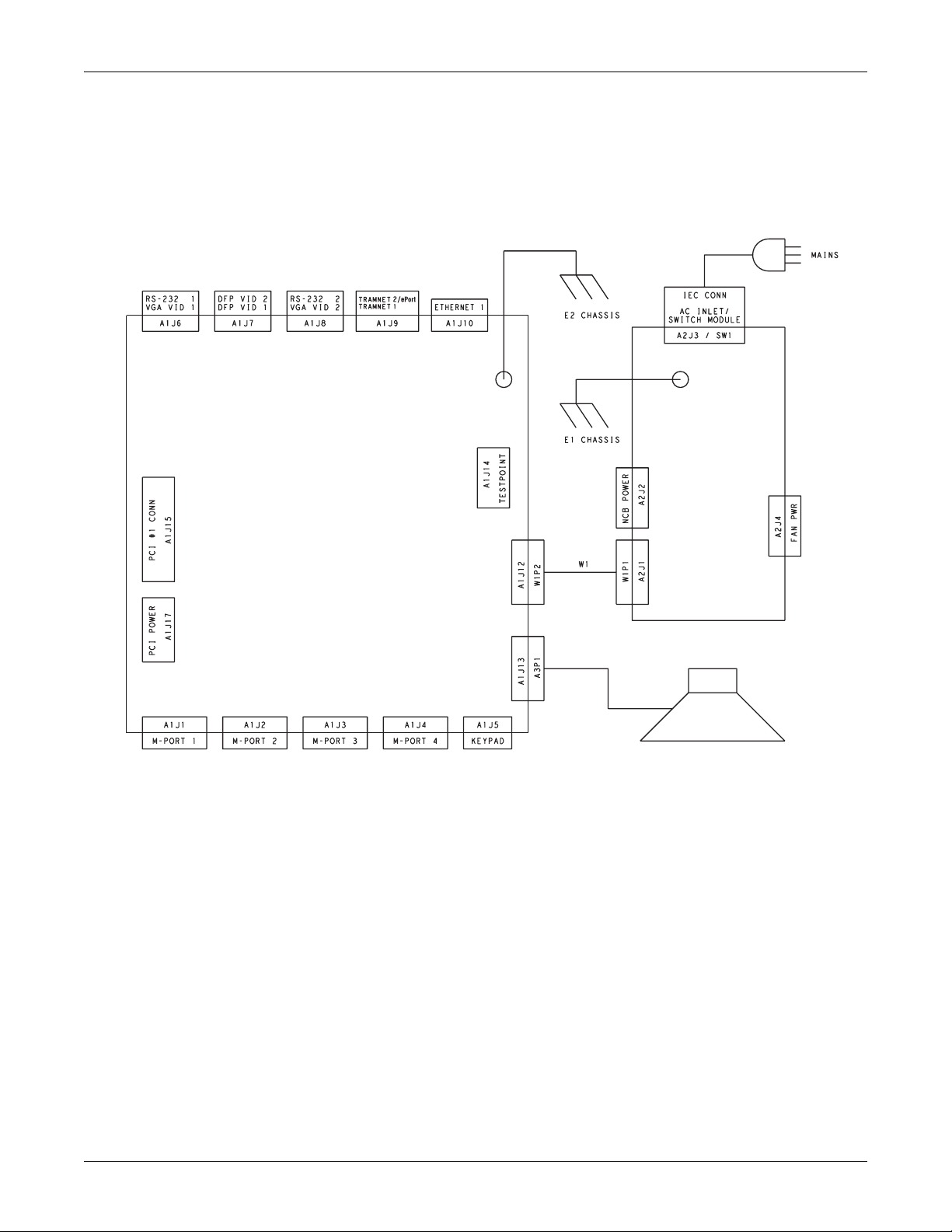

Page 30

Equipment overview: Theory of operation

Block diagram of internal connections

Power Supply

Assembly

Processor

Board

Speaker

036B

2-14 Solar 8000M/i patient monitor 2026265-075C

Page 31

Processor board

Equipment overview: Theory of operation

The processor board processes acquired data for the generation of

displayed information, audible alarms, and supports communication

channels for the acquisition system, serial peripherals and the Unity

Network.

035B

2026265-075C Solar 8000M/i patient monitor 2-15

Page 32

Core processing system

Equipment overview: Theory of operation

The core processing system of the processor board is the microprocessor,

the memory subsystem and the peripheral set.

The microprocessor

The Motorola PowerPC MPC860P, operating internally at 66.66 MHz

and 33.33 MHz externally, is the microprocessor used in the Solar

8000M/i processor PCB. The MPC860P consists of a PowerPC core with a

System Interface Unit (SIU) and Communications Processor Module

(CPM).

The main facilities integrated into the MPC860P include:

PowerPC Core including:

16k of Dual ported RAM for registers and microcode

A Memory Management Unit (MMU)

16 kByte Instruction Cache

8 kByte Data Cache

System Integration Unit (SIU) including:

Memory Controller and Wait State Generator via Eight(8)

General Purpose Chip-Select Machines (GPCM) and two(2)

Universal Programmable Machines (UPM)

Development Port/Background Debug Monitor

System Configuration and Protections such as the Bus Monitor,

Software Watchdog Timer, and Periodic Interrupt Timer

PLL Clock synthesizer

Communication Processor Module (CPM) including:

One (1) Fast Ethernet Channel (Media Independent Interface)

Four SCCs, all of which can do IEEE 802.3 Ethernet

Two SMCs (UARTs)

One SPI Interface

One I2C Interface

Seven IRQ lines

I/O port pin banks, some of which can be programmed to

generate an interrupt when a condition is present

A Development Port, commonly referred to as a Background Debug

Monitor (BDM) debug port on other processors, is resident in the

MPC860 to assist in debugging and troubleshooting the processor

operation.

NOTE

The MPC860 is +5V I/O tolerant on all of its pins except for the clock

input. This is important because the signals from the TRAM-NET

Hub are +5V signal levels.

2-16 Solar 8000M/i patient monitor 2026265-075C

Page 33

Equipment overview: Theory of operation

Memory subsystem

The processor PCB provides the memory resources necessary for code

storage and execution, and nonvolatile and configuration data storage by

providing the following:

FLASH Memory for Boot Code, Main Code and Parametric (TMSS)

Storage Memory,

DRAM Memory for Code Execution and Volatile Data Storage, and,

SRAM Memory that is battery backed for Nonvolatile Data Storage.

EEPROM Memory for network configuration data.

The memory subsystem utilizes the memory controller facility of the

MPC860. This allows for the addresses, strobe generation and wait

stating to be under software control.

Peripheral set

Clock Source – The central clock source for the processor PCB is a

crystal oscillator with a frequency of 14.7456 MHz.

Power monitor, watchdog and battery switch – The MAX793

provides the following facilities:

Power-on reset

Battery switchover

Battery charge level indication (battery OK)

Power going away indication (Low Line)

SRAM chip select gating

Manual reset input

Watchdog facility

Real time clock – The Epson RTC-8593AA is the Real Time Clock

(RTC) used. It is an I2C RTC with an internal crystal and can operate

with a supply voltage of +3.3V. The storage of the year will have to be

done in another location since this RTC has only 2 bits for storage of the

year. The RTC must be battery backed to insure that the time is

continued to be kept during power down periods. The I2C address for the

RTC is “1011xxxx”.

Serial EEPROM – The serial EEPROM used is a Xicor X24165. The

X24165 is a 16k bit part organized as 2k x 8, I2C compatible and a +3.3V

part. The data stored in the EEPROM would be the Ethernet Address, IP

Address, Software level, product type, year and Power-Applied

Indication. The I2C address for the EEPROM is “1010001x”.

NOTE

The serial EEPROM on the Solar 8000M/i processor PCB is not

removable.

Audio tone generation and output amplifier – The Solar 8000M/i

processor PCB provides audio output for alarm and parameter tones.

2026265-075C Solar 8000M/i patient monitor 2-17

Page 34

Video system

Equipment overview: Theory of operation

FPGA logic chip – The Processor PCB has one (1) Field Programmable

Gate Array logic chip on the board to provide the PCI host bridge

interface, the TRAM-NET strobe processing, the M-port support and a

revision port. The FPGA used is an Altera 6016 FLEX FPGA. The FPGA

is configured at power up by the Boot Code startup software loading the

FPGA configuring data into the FPGA. Therefore the FPGA does not

contain any functionality that is needed to allow the MPC860 to access

and execute Boot Code or any other necessary facilities needed to get the

processor PCB initialized at startup. In addition, any signal lines that

the FPGA drives must be able to accommodate the fact that at power up

the FPGA lines are high impedance until the FPGA is programmed.

NOTE

The FPGA must be 5V I/O tolerant since it is interfacing the older

+5V technology parts such as the TRAM-NET Hub.

The video system consists of one video accelerator and two duplicate sets

of CRT and flat panel buffers. A maximum of two analog and two digital

flat panel displays can be used.

A 65.00 MHz clock oscillator is used to drive the video system. The

MPC860 accesses the video systems over the PCI Bus using the Host

Bridge implementation within the FPGA.

Video system components

The video system has a video graphics chip, some discretes and

connectors for VGA (RGB) and DFP (Digital Flat Panel) video displays as

well as a RS-232 serial port to provide for a Touchscreen input.

Video graphics chip – The video graphics accelerator chip has the

following facilities:

4 Mbytes of internal memory

A bandwidth of 800 Mbytes/second minimum

RAMDAC for direct VGA/RGB output

Flat Panel Drive (using SiI164 components)

Programmable Ports Pins

VGA video output – The RGB output from the graphics accelerator is

used to generate the video signals output on the 15 pin VGA video

connectors.

DFP video output – Flat Panel drive signals from the video accelerator

are interfaced to a Silicon Image SiI164’s.The SiI164’s convert signals to

transition Minimized Differential Signaling (TMDS) levels before

connection to the 20 pin MDR DFP connectors.

RS-232 serial ports

The RS-232 serial ports provide the interface to the iPanel computer

(RS-232 1) and serial communication devices such as a touchscreen

display. See the Communication System for detailed discussion.

2-18 Solar 8000M/i patient monitor 2026265-075C

Page 35

Communication system

Equipment overview: Theory of operation

PCI bus implementation

The PCI Bus is used to communicate with the video accelerator and two

(2) expansion slots. The PCI Bus is a 32 bit, 33MHz implementation. The

PCI Bus interface to the MPC860 Bus was accomplished by

implementing a purchased Intellectual Property (IP) design in the FPGA

for a Host Bridge and PCI Bus Arbiter.

Ethernet for unity

The Processor PCB provides one (1) IEEE 802.3 10BaseT compliant

Ethernet port. This port is implemented using an SCC within the

MPC860 and an LXT905 Serial Interface Adapter. An Ethernet Port

Address label is affixed to the connector bracket and visible to the user

without disassembly.

Processor SCC channel – The first Serial Communication Controller

(SCC) is used to implement the Ethernet channel.

Serial interface adapter – The LXT905 is used as the Serial Interface

Adapter (SIA) for each Ethernet channel.

TRAM-NET (2 ports)

The Processor PCB provides an interface to the GEHC proprietary

Carrier Sense Multiple Access/Collision Detection (CSMA/CD) network,

TRAM-NET, by providing a TRAM-NET Controller (TNC) and a Hub

facility. The TRAM-NET 1 port provides TRAM-NET communication

only for connection to the Tram-rac 4A or Tram-rac 2. The TRAM-NET

2/ePort port provides TRAM-NET communication or ePort

communication for connection to the PDM with an ePort cable. When the

TRAM-NET 2/ePort connector is connected to PDM, the connection

uses ethernet through the Broadcom ethernet switch.

Processor SCC channel – The MPC860 fourth Serial Communication

Controller (SCC) is used to implement the TRAM-NET Controller. This

is done by operating the SCC in transparent mode and using software to

provide the functionality that was originally provided by an external

communications processor.

Hub – The Hub chip is the Solar 9000 FPGA implementation. It

accommodates the TNC port as well as four (4) external ports functioning

as a “Header Hub”. The Header Hub “turns the signal around” by

sending the “Up” signal out on the “down” path, generates the carrier

sense signal so that the TNC will not cause an “out of window” collision,

generates Collision Presence signals at the detection of a collision, and

retimes the bits.

NOTE

The signals out of the Hub are at +5V signal levels, so any +3.3V

devices interfacing to the Hub must be +5V tolerant.

Drivers and receivers – The DS8923 Dual Differential Driver/Receiver

pair is used to convert the signals between the TRAM-NET differential

RS-422 level and TTL levels.

2026265-075C Solar 8000M/i patient monitor 2-19

Page 36

Equipment overview: Theory of operation

Isolation – The TRAM-NET signals are electrically isolated with signal

transformers. The TRAM-NET power source is not isolated before being

delivered to the TRAM-NET network.

ESD protection scheme – The typical diode/transzorb pair is employed

to clamp the TRAM-NET connector pins to the common return plane.

Since the TRAM-NET is really not an electrically isolated network, the

need for maintaining isolation in the ESD protection scheme is not

present.

M-Ports (4)

ID signal – The ID Signal is generated using a Dallas Semiconductor 1Wire Line Driver chip, DS2480. The DS2480 is interfaced by the

MPC860's SCC3, which is multiplexed in the FPGA across the four (4) MPorts. The benefit of the DS2480 is that it relieves the MPC860 of doing

most of the timing for the interface to the 1-Wire memory device, such as

the DS2430 out in the DIDCA device. Also it improves noise immunity by

reading at the latest possible time and it minimizes emissions by driving

the line with a controlled edge rate and controlled drive current. The rate

at which the DS2480 can receive new commands or transfer additional

bytes of data is synchronized by the MPC860 waiting for a received

character interrupt response from the DS2480 before it can load the next

character. The ID signal has its own Return line. The ID Signal and its

Return share the RJ-45 connector pins that the M-Port Ethernet 10 Base

T Transmit differential pair uses. The functionality of the shared

connector pins is determined by a relay under software control.

RS-232/UART interface – The M-Port RS-232 interface is provided by

a Philips SC28L194 Quad UART (one UART per M-Port) and an Analog

Devices ADM202E RS-232 Driver/Receiver. The SC28L194 Quad UART

has sixteen (16) byte FIFO's on both the receiver and transmitter and I/O

port pins that function as status LED drive signals. The benefit of the

FIFOing is to reduce the overhead to the MPC860 to service the UART's.

The Quad UART uses the auto vectored interrupt on level 3.

Ethernet facility – A Broadcom Ethernet Switch provides each M-Port

with Ethernet capability. With the relay in the Ethernet position, pins 3

and 6 in the RJ-45 connector provide the Ethernet Differential Transmit

pair. The Ethernet receive pair are provided on pins 1 and 2 of the RJ-45

connector.

NOTE

The M-Port provides Host or Hub pinouts, not device side pin outs, so

that a one-to-one Category 5 cable can be used to connect any

Ethernet device up using an M-Port.

2-20 Solar 8000M/i patient monitor 2026265-075C

Page 37

Equipment overview: Theory of operation

The Serial Management Interface (SMI) to the Broadcom Ethernet

Switch is provided by reprogramming SCC3 in the MPC860 to be an

HDLC controller and setting the appropriate MPC860 port pins to get

the proper muxing action within the FPGA. The use of the SMI is to

determine which M-Ports have a functioning 10BaseT Ethernet

connection on them without having to switch the relay back to ID mode

and interrogate for a One-Wire interface.

NOTE

The clock source for the SMI is selected by the MPC860 to be either

sourced by itself or by the Broadcom Ethernet Switch under software

control.

M-Port power sourcing – Each M-Port is capable of providing

+5V +/- 5% @ 100mA into an external load.

Isolation – Per the M-Port Specification, Basic Insulation for 250Vac is

provided between each M-Port and any other isolated facility and from

earth ground.

ESD protection scheme – The M-Port connectors are ESD protected

by using the planar capacitance method since they are isolated from an

earth connection. The typical diode/transzorb pair is employed to clamp

the connector pin to its isolated return plane. The impedance of the

connector contact, the ferrite bead and the copper traces form an

impedance divider with the 'planar' capacitor formed by the dielectric

material in the PCB layer between the copper of the isolated return

plane and the copper of the common (earthed) plane. The expectation is

that the physical impedance divider formed by the bead/trace/connector

inductance and the planar capacitor will accomplish the following two

results:

Limit the rate of rise of the voltage across the isolation barrier, i.e.,

across the planar capacitor, and

Limit the peak amplitude to which the voltage across the barrier

rises to.

RS-232 serial ports

Both RS-232 serial ports are associated to a video set as described earlier

to accommodate a touchscreen. However, the serial ports are not limited

to being a touchscreen interface only. The RS-232 1 port also interfaces

to the iPanel computer and either of these serial ports are capable of

providing a polled data service facility or can be used as a service port.

Processor SMC channels – The RS-232 1 uses the SMC1 and the RS232 2 will use SMC2 in the MPC860.

Isolation – The serial ports are not isolated with respect to earth

ground.

ESD protection scheme – The typical diode/transzorb pair is employed

to clamp the RS-232 serial port connector pins to the common return

plane. Since the serial ports are not electrically isolated, the need for

maintaining isolation in the ESD protection scheme is not present.

2026265-075C Solar 8000M/i patient monitor 2-21

Page 38

Power supply

Speaker

Equipment overview: Theory of operation

I2C bus

The I2C bus is used to interface to the Real Time Clock and the Serial

EEPROM.

SPI interface

The SPI is used to program the FPGA.

The power supply generates DC voltages necessary to power the

processor board and the communication channels (M-ports and devices

connected to TRAM-NET). It consists of a mains (AC line) PWM

converter, that creates a 16.75 output voltage bus from which two

outputs are developed. The main 16.75V output also provides external

power to the RAC, data acquisition modules, and plug-in modules.

The speaker generates sound for alarms, QRS detection, and SpO2 pulse

tones.

2-22 Solar 8000M/i patient monitor 2026265-075C

Page 39

3 Installation

2026265-075C Solar 8000M/i patient monitor 3-1

Page 40

Installation: Back panel connections

Back panel connections

Connect the power cord to the power supply inlet on the back of the Solar

8000M/i patient monitor. If using a Tram-rac with power supply, connect

the power cord as shown.

007A

Power switch

Ethernet connector RS-232 connectorsPower switch

Voltage select

Ethernet connector RS-232 connectors

TRAM-NET connectors Video connectorsPower cord

008C

Digital flat panel

connectors

Solar 8000M

Power cord Voltage select TRAM-NET/ePort connectors

Solar 8000i

Video connectors Digital flat panel

connectors

010C

NOTE

The number of video connectors varies by configuration.

3-2 Solar 8000M/i patient monitor 2026265-075C

Page 41

TRAM-NET

Installation: Back panel connections

CAUTION

Equipment damage. Connect all peripheral equipment

before plugging the power cord into an AC outlet.

Otherwise, connectors may be damaged.

TRAM-NET provides the network for communication with bedside

peripherals and acquisition modules.

NOTE

If two Tram-racs are connected in any configuration, one must have a

power supply.

The following devices connect to either of the two TRAM-NET ports on

the Solar 8000M/i monitor. The connector is a 9-pin, D-type.

Tram-rac 4a housing with or without power supply

Tram-rac 2 housing

Tram-rac 4 housing with or without power supply

Tram-rac 3 housing with or without power supply

Patient Data Module (PDM) connects to TRAM-NET 2/ePort

connector only.

Tram-rac 4a housing

Tram-rac 2 housing

009C

011A

2026265-075C Solar 8000M/i patient monitor 3-3

Page 42

Installation: Back panel connections

Tram-rac 4a housings with and without power supply

CAUTION

Equipment damage. Connect the Tram-rac housing to the

Solar 8000M/i patient monitor before plugging the power

cord into an AC outlet. Connecting these devices to a

powered Solar 8000M/i patient monitor could damage

connectors.

One Tram-rac must have a

power supply.

013C

Patient Data Module

The Patient Data Module (PDM) is an acquisition device that connects to

the Solar 8000i patient monitor via the ePort cable.

940B

Connect one end of the ePort cable to the TRAM-NET2/ePort connector

and the other end to the Patient Data Module.

3-4 Solar 8000M/i patient monitor 2026265-075C

Page 43

ETHERNET

Installation: Back panel connections

One Tram-rac must have a

power supply.

043B

The ETHERNET connector provides an ANSI/IEEE 802.3 10BaseT

Ethernet standard interface to the Unity Network using a Category 5

network cable. The connector is an 8-pin, RJ-45 type.

VGA VID 1 and 2

NOTE

The number of video connectors varies by configuration.

The two VGA connectors provide an interface to analog (VGA) displays.

The connector is a 15-pin, high density D type.

WARNING

Do not connect a monochrome display to the Solar

8000M/i patient monitor. Visual alarm indictors may not

appear properly, resulting in a hazard to the patient.

014D

2026265-075C Solar 8000M/i patient monitor 3-5

Page 44

DFP VID 1 and 2

Installation: Back panel connections

Two DFP (Digital Flat Panel) connectors provide an interface to digital

displays. The connector is a 20-pin, MDR type.

014C

RS-232 1

RS-232 2

The RS-232 1 serial connector provides an interface to the iPanel

computer. If not using an iPanel, it interfaces to a PC for software

upgrades or polled-parameter service. The connector is a 9-pin, D type.

The RS-232 2 serial connector provides a touchscreen interface. The

connector is a 9-pin, D type.

NOTE

Use cable 2006733-00X for touchscreen connection. The cable

supplied with the display will not work.

3-6 Solar 8000M/i patient monitor 2026265-075C

Page 45

Installation: Front panel connectors and indicators

Front panel connectors and indicators

The front panel connectors consist of four M-Ports. The Solar 8000M also

has a keypad connector. Each port has a LED indicator.

M-Port LED indicators Power LED indicator

M-Ports

M-Port connectors

015A

Solar 8000i

015B

Solar 8000M

Keypad connector

M-Port means multi-protocol and supports Ethernet 10BaseT, RS-232, 1

wire identification, and is MIB (Medical Information Bus) compliant.

M-Ports support AutoPort devices, but an AutoPort to M-Port adapter,

PN 2001973-001, is required. The adapter must connect to the AutoPort

device, not the M-Port host (the Solar 8000M/i patient monitor).

The following devices connect directly to the M-Ports. The connector is an

8-pin RJ-45 type.

Solar 8000M/i remote control

Solar 8000M/i keypad

PRN 50-M digital writer

RM-M respiratory mechanics module

Remote Alarm Terminal (Nurse Call and Alarm Light System)

Laser printer (requires a serial port on the printer and an interface

adapter to connect to the monitor)

Unity Network ID connectivity device

2026265-075C Solar 8000M/i patient monitor 3-7

Page 46

Remote control or keypad

Installation: Front panel connectors and indicators

The following devices connect to M-Port hosts using AutoPort to M-Port

adapter PN 2001973-001.

PRN-50 digital writer with AutoPort

Respiratory mechanics module with AutoPort

NOTE

AutoPort to M-Port adapter PN 2001973-001 is required for

connecting AutoPort devices to M-Ports. Plug the adapter end

labeled AutoPort into the AutoPort device.

The remote control or keypad is DIDCA programmed for specific care

areas (adult, neonatal, or operating room). A keypad holster mount is

available for mounting under the display.

NOTE

The Solar 8000M/i requires an interface (remote control or keypad)

with all display types.

NOTE

The error message WARNING: REMOTE MISMATCHED WITH

MONITORING MODE displays if a mismatched keypad/remote

control is connected to the Solar 8000M/i patient monitor.

PRN-50 digital writer and respiratory mechanics module

The figure below shows the PRN-50-M digital writer connected to one of

the M-Ports. The RM-M respiratory mechanics module has similar

connections.

AutoPort or M-Port connector.

Note: If this is a PRN 50 or RM module with

AutoPort, then adapter PN 2001973-001 is

required.

016A

3-8 Solar 8000M/i patient monitor 2026265-075C

Page 47

Installation: Front panel connectors and indicators

Unity Network ID connectivity device

The figure below shows the Unity Network ID connectivity device

connected to one of the M-Ports.

NOTE

This connection requires that the Unity Network ID connectivity

device IP address is a 10.X.X.X address. Refer to the Unity Network

ID connectivity device service manual for more details.

Ethernet connector

Laser printer

017A

Refer to the instructions provided in Laser Printer Support Kit, pn

2013421-001, for details on interconnection using the interface adapter

and installing a serial card in a laser printer.

WARNING

SHOCK HAZARD. Laser printers are UL 60950/EN

60950 certified equipment, which may not meet the

leakage current requirements of patient care equipment.

This equipment must not be located in the patient

vicinity unless the medical system standard EN

60601-1-1 is followed.

Do not connect a laser printer to a multiple portable

socket outlet (MPSO) supplying patient care equipment.

The use of an MPSO for a system will result in an

enclosure leakage current equal to the sum of all the

individual earth leakage currents of the system if there is

an interruption of the MPSO protective earth conductor.

2026265-075C Solar 8000M/i patient monitor 3-9

Page 48

Indicators

Power up

Installation: Power up

A green LED indicates that the unit is connected to an AC power source

and the power switch is turned on. There is a green/yellow LED above

each M-Port indicating the M-Port status.

Solid green indicates the device is communicating properly.

Slow flashing yellow indicates the device has been identified, but

there is no communication.

Quick flashing yellow indicates that too many identical devices are

connected or the device cannot be identified.

Refer to Chapter 5, “Troubleshooting” if an LED is not green.

NOTE

Check power voltage at your location and set power to either 120 V or

240V.

After making all connections, plug the power cord into an AC wall outlet,

turn the power switch to 1 (on), and turn on the display. The power LED

illuminates and after about 10 seconds a display appears.

If the Solar 8000M/i patient monitor does not work properly, refer to

Chapter 5, “Troubleshooting” .

3-10 Solar 8000M/i patient monitor 2026265-075C

Page 49

Installation: TRAM-NET communication

TRAM-NET communication

Overview

The Solar patient monitor uses two distinct local area networks:

TRAM-NET communication, and

Ethernet communication.

Consider TRAM-NET as a small area network (SAN) contained in one

room or at the patient bedside. Consider Ethernet as the local area

network (LAN) for room-to-room communication or communication

between patient monitors, central stations, and other GE equipment

throughout the hospital.

NOTE

GE highly recommends using a ‘private’ LAN to connect Unity

products. The purpose of the Unity Network is to connect only Unity

devices for the exchange of patient data and room-to-room

communication. Adding non-Unity devices (PCs, laptops, desktops,

etc.) may compromise the ability of the Unity Network to meet its

intended use.

Internal hub

A ‘private’ LAN is not the same as a private IP address.

This local area network links all patient monitors, central stations, and

other GE equipment throughout the hospital.

The TRAM-NET connector makes a TRAM-NET small area network

available for the peripheral devices. The TRAM-NET controller resides

within the main processor which provides efficient data transfer by

sharing main memory.

TRAM-NET is a small network that offers ample flexibility, a high rate

of communication, and relatively inexpensive cabling. Data is

transmitted at the rate of 921.6K bits per second. It uses a star topology,

sometimes referred to as a rooted tree topology. This means that the

wiring of the network can be pictured as a star or a series of stars. The

center of each star is called a hub, and the points of the star are called

nodes. There are cables between the nodes and the hubs, but no cables

exist between nodes.

Data is acquired at a node, and is transmitted through a hub to all the

other nodes. Each node has an address so data will be received by the

node with the correct destination address. It is impossible for a node to

communicate with another node without the data going through a hub

somewhere along its journey. The hub controls all of the data ‘traffic’ in

the system.

In a TRAM-NET system, the head hub is contained in the patient

monitor, but there will be intermediate hubs in the Tram-rac housing

and Tram module as well.

2026265-075C Solar 8000M/i patient monitor 3-11

Page 50

Installation: Ethernet communication

Ethernet communication

About ethernet

The GE Unity Network uses Ethernet for device-to-device

communications. This local area network links all patient monitors,

clinical information centers, and other GE equipment throughout the

hospital. Depending on the construction of the hospital, thick-net, thinnet, or CAT-5 twisted pair cabling is used. The Solar 8000M/i is designed

to be used with twisted-pair cabling. Consult GE when trying to interface

with either thick-net or thin-net cabling. The real-time GE Unity

Network operates at 10 Mbps, half-duplex.

Twisted pair

Twisted pair is the most popular cabling because it is easy to install and

flexible to work with. It uses the star topology with a switch as the hub of

the segment. A maximum of 100 meters or 328 feet is the longest length

of twisted pair cable allowed. The maximum number of devices on the GE

Unity Network is 1,000.

CIC Pro

CIC Pro

Solar 8000M/i

Printer

Segment

Solar 8000M/i

Switches

1 to n

041A

3-12 Solar 8000M/i patient monitor 2026265-075C

Page 51

Network terms

Node

MAC address

Switch

Installation: Ethernet communication

Each network device or node is assigned a MAC address number and

requires a network connection to interface between the network device

and the network.

A 48-bit address assigned by the manufacturer to uniquely identify a

node of the network. This is also known as the Ethernet address.

To implement the star topology, each network device is connected to a

network switch. The switch passes all network data between each

network device in the star segment. Typically, the switch supports 12 to

48 network devices and may be linked to other switches to form larger

networks.

Segment

IP address

Subnet

A network segment is comprised of all devices connected to 1 or many

switches which are in-turn connected together to form a larger network.

The boundaries of the segment are defined by networking equipment

that regulate the flow of packets into and out of the segment (e.g. routers

and switches).

A 32-bit (IPv4) address assigned by the user (either statically or

dynamically from a server) to uniquely identify the packets from a device

for routing purposes.

A subnet is a logical segment of a larger network that shares a common

IP address range as defined by a subnet mask. Proper subnetting can

improve the performance and security of a network. Solar 8000 series

monitors support classful subnetting.

2026265-075C Solar 8000M/i patient monitor 3-13

Page 52

Installation: Ethernet communication

3-14 Solar 8000M/i patient monitor 2026265-075C

Page 53

4 Maintenance and

checkout

2026265-075C Solar 8000M/i patient monitor 4-1

Page 54

Maintenance and checkout: Maintenance schedule

Maintenance schedule

Manufacturer recommendations

To help ensure the equipment remains in proper operational and

functional order, adhere to a good maintenance schedule. The

manufacturer recommends that the following be performed by service

personnel upon receipt of the equipment, every 12 months thereafter,

and each time the unit is serviced:

Visual Inspection

Cleaning

Electrical Safety Tests

Checkout Procedure

Clearing the Stored Patient Data Memory: Admit and discharge a

test patient every 12 months to clear the monitor’s stored patient

data memory.

Manufacturer responsibility

Preventive maintenance

The message “EC1” will appear on the monitor to the left of the ECG