SIGNA Voyager

Pre-Installation

OPERATING DOCUMENTATION

5680008–1EN

Revision 2

SIGNA Voyager Pre-Installation

Direction 5680008–1EN, Revision 2

2

Important Information

LANGUAGE

SIGNA Voyager Pre-Installation

Direction 5680008–1EN, Revision 2

ПРЕДУПРЕЖДЕНИЕ

(BG)

警告

(ZH-CN)

警告

(ZH-HK)

Това упътване за работа е налично само на английски език.

Ако доставчикът на услугата на клиента изиска друг език, задължение на

•

клиента е да осигури превод.

Не използвайте оборудването, преди да сте се консултирали и разбрали

•

упътването за работа.

Неспазването на това предупреждение може да доведе до нараняване на

•

доставчика на услугата, оператора или пациентa в резултат на токов удар,

механична или друга опасност.

本维修手册仅提供英文版本。

如果客户的维修服务人员需要非英文版本,则客户需自行提供翻译服务。

•

未详细阅读和完全理解本维修手册之前,不得进行维修。

•

忽略本警告可能对维修服务人员、操作人员或患者造成电击、机械伤害或其他形式的

•

伤 害。

本服務手冊僅提供英文版本。

倘若客戶的服務供應商需要英文以外之服務手冊,客戶有責任提供翻譯服務。

•

除非已參閱本服務手冊及明白其內容,否則切勿嘗試維修設備。

•

不遵從本警告或會令服務供應商、網絡供應商或病人受到觸電、機械性或其他的危

•

險。

警告

(ZH-TW)

UPOZORENJE

(HR)

Important Information 3

本維修手冊僅有英文版。

若客戶的維修廠商需要英文版以外的語言,應由客戶自行提供翻譯服務。

•

請勿試圖維修本設備,除非 您已查閱並瞭解本維修手冊。

•

若未留意本警告,可能導致維修廠商、操作員或病患因觸電、機械或其他危險而受

•

傷。

Ovaj servisni priručnik dostupan je na engleskom jeziku.

Ako davatelj usluge klijenta treba neki drugi jezik, klijent je dužan osigurati prijevod.

•

Ne pokušavajte servisirati opremu ako niste u potpunosti pročitali i razumjeli ovaj

•

servisni priručnik.

Zanemarite li ovo upozorenje, može doći do ozljede davatelja usluge, operatera ili

•

pacijenta uslijed strujnog udara, mehaničkih ili drugih rizika.

SIGNA Voyager Pre-Installation

Direction 5680008–1EN, Revision 2

VÝSTRAHA

(CS)

ADVARSEL

(DA)

WAARSCHUWING

(NL)

Tento provozní návod existuje pouze v anglickém jazyce.

V případě, že externí služba zákazníkům potřebuje návod v jiném jazyce, je zajiště‐

•

ní překladu do odpovídajícího jazyka úkolem zákazníka.

Nesnažte se o údržbu tohoto zařízení, aniž byste si přečetli tento provozní návod a

•

pochopili jeho obsah.

V případě nedodržování této výstrahy může dojít k poranění pracovníka prodejního

•

servisu, obslužného personálu nebo pacientů vlivem elektrického proudu, respektive

vlivem mechanických či jiných rizik.

Denne servicemanual findes kun på engelsk.

Hvis en kundes tekniker har brug for et andet sprog end engelsk, er det kundens

•

ansvar at sørge for oversættelse.

Forsøg ikke at servicere udstyret uden at læse og forstå denne servicemanual.

•

Manglende overholdelse af denne advarsel kan medføre skade på grund af elektrisk

•

stød, mekanisk eller anden fare for teknikeren, operatøren eller patienten.

Deze onderhoudshandleiding is enkel in het Engels verkrijgbaar.

Als het onderhoudspersoneel een andere taal vereist, dan is de klant verantwoorde‐

•

lijk voor de vertaling ervan.

Probeer de apparatuur niet te onderhouden alvorens deze onderhoudshandleiding

•

werd geraadpleegd en begrepen is.

WARNING

(EN)

HOIATUS

(ET)

Indien deze waarschuwing niet wordt opgevolgd, zou het onderhoudspersoneel, de

•

operator of een patiënt gewond kunnen raken als gevolg van een elektrische schok,

mechanische of andere gevaren.

This service manual is available in English only.

If a customer's service provider requires a language other than English, it is the cus‐

•

tomer's responsibility to provide translation services.

Do not attempt to service the equipment unless this service manual has been con‐

•

sulted and is understood.

Failure to heed this warning may result in injury to the service provider, operator or

•

patient from electric shock, mechanical or other hazards.

See teenindusjuhend on saadaval ainult inglise keeles.

Kui klienditeeninduse osutaja nõuab juhendit inglise keelest erinevas keeles, vastu‐

•

tab klient tõlketeenuse osutamise eest.

Ärge üritage seadmeid teenindada enne eelnevalt käesoleva teenindusjuhendiga

•

tutvumist ja sellest aru saamist.

Käesoleva hoiatuse eiramine võib põhjustada teenuseosutaja, operaatori või pat‐

•

siendi vigastamist elektrilöögi, mehaanilise või muu ohu tagajärjel.

4 Important Information

SIGNA Voyager Pre-Installation

Direction 5680008–1EN, Revision 2

VAROITUS

(FI)

ATTENTION

(FR)

WARNUNG

(DE)

Tämä huolto-ohje on saatavilla vain englanniksi.

Jos asiakkaan huoltohenkilöstö vaatii muuta kuin englanninkielistä materiaalia, tar‐

•

vittavan käännöksen hankkiminen on asiakkaan vastuulla.

Älä yritä korjata laitteistoa ennen kuin olet varmasti lukenut ja ymmärtänyt tämän

•

huolto-ohjeen.

Mikäli tätä varoitusta ei noudateta, seurauksena voi olla huoltohenkilöstön, laitteis‐

•

ton käyttäjän tai potilaan vahingoittuminen sähköiskun, mekaanisen vian tai muun

vaaratilanteen vuoksi.

Ce manuel d’installation et de maintenance est disponible uniquement en anglais.

Si le technicien d'un client a besoin de ce manuel dans une langue autre que l'an‐

•

glais, il incombe au client de le faire traduire.

Ne pas tenter d'intervenir sur les équipements tant que ce manuel d’installation et

•

de maintenance n'a pas été consulté et compris.

Le non-respect de cet avertissement peut entraîner chez le technicien, l'opérateur

•

ou le patient des blessures dues à des dangers électriques, mécaniques ou autres.

Diese Serviceanleitung existiert nur in englischer Sprache.

Falls ein fremder Kundendienst eine andere Sprache benötigt, ist es Aufgabe des

•

Kunden für eine entsprechende Übersetzung zu sorgen.

Versuchen Sie nicht diese Anlage zu warten, ohne diese Serviceanleitung gelesen

•

und verstanden zu haben.

ΠΡΟΕΙΔΟΠΟΙΗΣΗ

(EL)

FIGYELMEZTETÉS

(HU)

Wird diese Warnung nicht beachtet, so kann es zu Verletzungen des Kundendienst‐

•

technikers, des Bedieners oder des Patienten durch Stromschläge, mechanische

oder sonstige Gefahren kommen.

Το παρόν εγχειρίδιο σέρβις διατίθεται μόνο στα αγγλικά.

Εάν ο τεχνικός σέρβις ενός πελάτη απαιτεί το παρόν εγχειρίδιο σε γλώσσα εκτός των

•

αγγλικών, αποτελεί ευθύνη του πελάτη να παρέχει τις υπηρεσίες μετάφρασης.

Μην επιχειρήσετε την εκτέλεση εργασιών σέρβις στον εξοπλισμό αν δεν έχετε

•

συμβουλευτεί και κατανοήσει το παρόν εγχειρίδιο σέρβις.

Αν δεν προσέξετε την προειδοποίηση αυτή, ενδέχεται να προκληθεί τραυματισμός

•

στον τεχνικό σέρβις, στο χειριστή ή στον ασθενή από ηλεκτροπληξία, μηχανικούς ή

άλλους κινδύνους.

Ezen karbantartási kézikönyv kizárólag angol nyelven érhető el.

Ha a vevő szolgáltatója angoltól eltérő nyelvre tart igényt, akkor a vevő felelőssége

•

a fordítás elkészíttetése.

Ne próbálja elkezdeni használni a berendezést, amíg a karbantartási kézikönyvben

•

leírtakat nem értelmezték.

Ezen figyelmeztetés figyelmen kívül hagyása a szolgáltató, működtető vagy a beteg

•

áramütés, mechanikai vagy egyéb veszélyhelyzet miatti sérülését eredményezheti.

Important Information 5

SIGNA Voyager Pre-Installation

Direction 5680008–1EN, Revision 2

AÐVÖRUN

(IS)

AVVERTENZA

(IT)

警告

(JA)

Þessi þjónustuhandbók er aðeins fáanleg á ensku.

Ef að þjónustuveitandi viðskiptamanns þarfnast annas tungumáls en ensku, er það

•

skylda viðskiptamanns að skaffa tungumálaþjónustu.

Reynið ekki að afgreiða tækið nema að þessi þjónustuhandbók hefur verið skoðuð

•

og skilin.

Brot á sinna þessari aðvörun getur leitt til meiðsla á þjónustuveitanda, stjórnanda

•

eða sjúklings frá raflosti, vélrænu eða öðrum áhættum.

Il presente manuale di manutenzione è disponibile soltanto in lingua inglese.

Se un addetto alla manutenzione richiede il manuale in una lingua diversa, il cliente

•

è tenuto a provvedere direttamente alla traduzione.

Procedere alla manutenzione dell'apparecchiatura solo dopo aver consultato il pre‐

•

sente manuale ed averne compreso il contenuto.

Il mancato rispetto della presente avvertenza potrebbe causare lesioni all'addetto al‐

•

la manutenzione, all'operatore o ai pazienti provocate da scosse elettriche, urti mec‐

canici o altri rischi.

このサービスマニュアルには英語版しかありません。

サービスを担当される業者が英語以外の言語を要求される場合、翻訳作業はその業

•

者の責任で行うものとさせていただきます。

このサービスマニュアルを熟読し理解せずに、装置のサービスを行わないでくださ

•

い。

경고

(KO)

BRĪDINĀJUMS

(LV)

この警告に従わない場合、サービスを担当される方、操作員あるいは患者 さんが、

•

感電や機械的又はその他の危険により負傷する可能性があります。

본 서비스 매뉴얼은 영어로만 이용하실 수 있습니다.

고객의 서비스 제공자가 영어 이외의 언어를 요구할 경우, 번역 서비스를 제공하는

•

것은 고객의 책임입니다.

본 서비스 매뉴얼을 참조하여 숙지하지 않은 이상 해당 장비를 수리하려고 시도하지

•

마십시오.

본 경고 사항에 유의하지 않으면 전기 쇼크, 기계적 위험, 또는 기타 위험으로 인해 서

•

비스 제공자, 사용자 또는 환자에게 부상을 입힐 수 있습니다.

Šī apkopes rokasgrāmata ir pieejama tikai angļu valodā.

Ja klienta apkopes sniedzējam nepieciešama informācija citā valodā, klienta pienā‐

•

kums ir nodrošināt tulkojumu.

Neveiciet aprīkojuma apkopi bez apkopes rokasgrāmatas izlasīšanas un sapraša‐

•

nas.

Šī brīdinājuma neievērošanas rezultātā var rasties elektriskās strāvas trieciena, me‐

•

hānisku vai citu faktoru izraisītu traumu risks apkopes sniedzējam, operatoram vai

pacientam.

6 Important Information

SIGNA Voyager Pre-Installation

Direction 5680008–1EN, Revision 2

ĮSPĖJIMAS

(LT)

ADVARSEL

(NO)

OSTRZEŻENIE

(PL)

Šis eksploatavimo vadovas yra tik anglų kalba.

Jei kliento paslaugų tiekėjas reikalauja vadovo kita kalba – ne anglų, suteikti vertimo

•

paslaugas privalo klientas.

Nemėginkite atlikti įrangos techninės priežiūros, jei neperskaitėte ar nesupratote šio

•

eksploatavimo vadovo.

Jei nepaisysite šio įspėjimo, galimi paslaugų tiekėjo, operatoriaus ar paciento suža‐

•

lojimai dėl elektros šoko, mechaninių ar kitų pavojų.

Denne servicehåndboken finnes bare på engelsk.

Hvis kundens serviceleverandør har bruk for et annet språk, er det kundens ansvar

•

å sørge for oversettelse.

Ikke forsøk å reparere utstyret uten at denne servicehåndboken er lest og forstått.

•

Manglende hensyn til denne advarselen kan føre til at serviceleverandøren, oper‐

•

atøren eller pasienten skades på grunn av elektrisk støt, mekaniske eller andre

farer.

Niniejszy podręcznik serwisowy dostępny jest jedynie w języku angielskim.

Jeśli serwisant klienta wymaga języka innego niż angielski, zapewnienie usługi tłu‐

•

maczenia jest obowiązkiem klienta.

Nie próbować serwisować urządzenia bez zapoznania się z niniejszym podręczni‐

•

kiem serwisowym i zrozumienia go.

ATENÇÃO

(PT-BR)

ATENÇÃO

(PT-PT)

Niezastosowanie się do tego ostrzeżenia może doprowadzić do obrażeń serwisan‐

•

ta, operatora lub pacjenta w wyniku porażenia prądem elektrycznym, zagrożenia

mechanicznego bądź innego.

Este manual de assistência técnica encontra-se disponível unicamente em inglês.

Se outro serviço de assistência técnica solicitar a tradução deste manual, caberá ao

•

cliente fornecer os serviços de tradução.

Não tente reparar o equipamento sem ter consultado e compreendido este manual

•

de assistência técnica.

A não observância deste aviso pode ocasionar ferimentos no técnico, operador ou

•

paciente decorrentes de choques elétricos, mecânicos ou outros.

Este manual de assistência técnica só se encontra disponível em inglês.

Se qualquer outro serviço de assistência técnica solicitar este manual noutro idio‐

•

ma, é da responsabilidade do cliente fornecer os serviços de tradução.

Não tente reparar o equipamento sem ter consultado e compreendido este manual

•

de assistência técnica.

O não cumprimento deste aviso pode colocar em perigo a segurança do técnico, do

•

operador ou do paciente devido a choques eléctricos, mecânicos ou outros.

Important Information 7

SIGNA Voyager Pre-Installation

Direction 5680008–1EN, Revision 2

ATENŢIE

(RO)

ОСТОРОЖНО!

(RU)

UPOZORENJE

(SR)

Acest manual de service este disponibil doar în limba engleză.

Dacă un furnizor de servicii pentru clienţi necesită o altă limbă decât cea engleză,

•

este de datoria clientului să furnizeze o traducere.

Nu încercaţi să reparaţi echipamentul decât ulterior consultării şi înţelegerii acestui

•

manual de service.

Ignorarea acestui avertisment ar putea duce la rănirea depanatorului, operatorului

•

sau pacientului în urma pericolelor de electrocutare, mecanice sau de altă natură.

Данное руководство по техническому обслуживанию представлено только на

английском языке.

Если сервисному персоналу клиента необходимо руководство не на

•

английском, а на каком-то другом языке, клиенту следует самостоятельно

обеспечить перевод.

Перед техническим обслуживанием оборудования обязательно обратитесь к

•

данному руководству и поймите изложенные в нем сведения.

Несоблюдение требований данного предупреждения может привести к тому,

•

что специалист по техобслуживанию, оператор или пациент получит удар

электрическим током, механическую травму или другое повреждение.

Ovo servisno uputstvo je dostupno samo na engleskom jeziku.

Ako klijentov serviser zahteva neki drugi jezik, klijent je dužan da obezbedi prevodi‐

•

lačke usluge.

UPOZORNENIE

(SK)

ATENCION

(ES)

Ne pokušavajte da opravite uređaj ako niste pročitali i razumeli ovo servisno uputst‐

•

vo.

Zanemarivanje ovog upozorenja može dovesti do povređivanja servisera, rukovaoca

•

ili pacijenta usled strujnog udara ili mehaničkih i drugih opasnosti.

Tento návod na obsluhu je k dispozícii len v angličtine.

Ak zákazníkov poskytovateľ služieb vyžaduje iný jazyk ako angličtinu, poskytnutie

•

prekladateľských služieb je zodpovednosťou zákazníka.

Nepokúšajte sa o obsluhu zariadenia, kým si neprečítate návod na obluhu a nepor‐

•

ozumiete mu.

Zanedbanie tohto upozornenia môže spôsobiť zranenie poskytovateľa služieb, ob‐

•

sluhujúcej osoby alebo pacienta elektrickým prúdom, mechanické alebo iné ohroze‐

nie.

Este manual de servicio sólo existe en inglés.

Si el encargado de mantenimiento de un cliente necesita un idioma que no sea el

•

inglés, el cliente deberá encargarse de la traducción del manual.

No se deberá dar servicio técnico al equipo, sin haber consultado y comprendido

•

este manual de servicio.

La no observancia del presente aviso puede dar lugar a que el proveedor de servi‐

•

cios, el operador o el paciente sufran lesiones provocadas por causas eléctricas,

mecánicas o de otra naturaleza.

8 Important Information

SIGNA Voyager Pre-Installation

Direction 5680008–1EN, Revision 2

VARNING

(SV)

OPOZORILO

(SL)

DİKKAT

(TR)

Den här servicehandboken finns bara tillgänglig på engelska.

Om en kunds servicetekniker har behov av ett annat språk än engelska, ansvarar

•

kunden för att tillhandahålla översättningstjänster.

Försök inte utföra service på utrustningen om du inte har läst och förstår den här

•

servicehandboken.

Om du inte tar hänsyn till den här varningen kan det resultera i skador på servicete‐

•

knikern, operatören eller patienten till följd av elektriska stötar, mekaniska faror eller

andra faror.

Ta servisni priročnik je na voljo samo v angleškem jeziku.

Če ponudnik storitve stranke potrebuje priročnik v drugem jeziku, mora stranka za‐

•

gotoviti prevod.

Ne poskušajte servisirati opreme, če tega priročnika niste v celoti prebrali in razu‐

•

meli.

Če tega opozorila ne upoštevate, se lahko zaradi električnega udara, mehanskih ali

•

drugih nevarnosti poškoduje ponudnik storitev, operater ali bolnik.

Bu servis kılavuzunun sadece ingilizcesi mevcuttur.

Eğer müşteri teknisyeni bu kılavuzu ingilizce dışında bir başka lisandan talep

•

ederse, bunu tercüme ettirmek müşteriye düşer.

Servis kılavuzunu okuyup anlamadan ekipmanlara müdahale etmeyiniz.

•

Bu uyarıya uyulmaması, elektrik, mekanik veya diğer tehlikelerden dolayı teknisyen,

•

operatör veya hastanın yaralanmasına yol açabilir.

Important Information 9

This page left intentionally blank.

SIGNA Voyager Pre-Installation

Direction 5680008–1EN, Revision 2

10 Important Information

Revision History

Revision Date Description

1 Feb 18, 2016 Initial Release

2 Aug 31, 2016 Update the weight of ISC and Patient Table.

SIGNA Voyager Pre-Installation

Direction 5680008–1EN, Revision 2

Update the dimension of Minimum Magnet Service Area(Top review)

Update some dimensions in Table 2–1 System Minimum Room inside Clear Space Di‐

mensions

Correct some typing error

Revision History 11

This page left intentionally blank.

SIGNA Voyager Pre-Installation

Direction 5680008–1EN, Revision 2

12 Revision History

SIGNA Voyager Pre-Installation

Direction 5680008–1EN, Revision 2

Table of Contents

Chapter 1 INTRODUCTION...................................................................................................................19

1 Pre-Installation Manual Introduction..............................................................................................19

1.1 Document Purpose...............................................................................................................19

1.2 Intended User.......................................................................................................................19

1.3 Document Overview............................................................................................................. 20

Chapter 2 GENERAL SYSTEM LEVEL................................................................................................. 21

1 System Components..................................................................................................................... 21

1.1 Magnet Room.......................................................................................................................21

1.2 Equipment Room..................................................................................................................21

1.3 Control Room....................................................................................................................... 21

1.4 Accessories.......................................................................................................................... 21

2 MR Suite Minimum Room Size Requirement................................................................................23

3 IEC EMC Compliance....................................................................................................................27

4 MR Seismic Requirements............................................................................................................28

5 MR Suite Acoustic Specifications..................................................................................................29

6 MR Suite Magnetic Field Specifications........................................................................................ 30

6.1 Magnet Fringe Field.............................................................................................................30

6.2 Interference from Changing Magnetic Fields.......................................................................33

6.3 Electrical Current..................................................................................................................36

6.4 Non-MR System Equipment Sensitivity to Magnetic Fields..................................................37

6.5 Magnet Shield.......................................................................................................................38

7 Multiple MR System Requirements............................................................................................... 40

7.1 Multiple Magnets.................................................................................................................. 40

7.2 Shared Equipment Rooms................................................................................................... 41

8 MR Suite Temperature and Humidity............................................................................................ 42

8.1 Temperature and Humidity Requirements............................................................................42

8.2 Equipment Heat Output Specifications.................................................................................43

9 MR Coolant Requirements............................................................................................................ 44

9.1 Integrated Cooling Cabinet (ICC) Coolant Requirements.................................................... 44

Table of Contents 13

SIGNA Voyager Pre-Installation

Direction 5680008–1EN, Revision 2

9.2 Emergency Facility Coolant Requirements.......................................................................... 47

10 MR Suite Electrical Requirements...............................................................................................49

10.1 General Electrical Requirements........................................................................................49

10.2 Main Disconnect Panel (MDP) Requirements....................................................................52

11 MR System Shipping and Receiving........................................................................................... 54

11.1 Receiving Requirements.................................................................................................... 54

11.2 Facility Delivery Route Requirements................................................................................ 54

11.3 MR System Component Shipping Specifications............................................................... 55

Chapter 3 MAGNET ROOM...................................................................................................................59

1 Magnet Room Introduction............................................................................................................ 59

2 Magnet Room Structural Requirements........................................................................................ 61

2.1 Overview...............................................................................................................................61

2.2 Environmental Steel Limits...................................................................................................61

2.3 Vibration Requirements........................................................................................................62

3 Magnetic Shielded Room Requirements.......................................................................................64

4 Acoustic Room Specifications....................................................................................................... 65

5 RF Shielded Room Requirements.................................................................................................66

5.1 RF Shielded Room Purpose.................................................................................................66

5.2 RF Definitions.......................................................................................................................66

5.3 Customer Responsibilities....................................................................................................67

5.4 Requirements....................................................................................................................... 68

5.4.1 RF Shield Requirements..............................................................................................68

5.4.2 RF Shield Test Report................................................................................................. 69

5.4.3 Dock Frame Anchor Mounting Requirements..............................................................70

5.4.4 RF Shielding Integrity Reliability Requirements ..........................................................71

6 Finished Room Requirements.......................................................................................................72

6.1 Walls.....................................................................................................................................72

6.2 Penetration Wall Closet........................................................................................................72

6.3 Doors, Magnet Access Openings and Patient Viewing Windows.........................................73

6.4 Finished Ceiling....................................................................................................................73

14 Table of Contents

SIGNA Voyager Pre-Installation

Direction 5680008–1EN, Revision 2

6.5 Magnet Room Floors............................................................................................................76

7 Magnet Room Equipment Specification........................................................................................ 79

7.1 Magnet with Enclosure (MAG)..............................................................................................79

7.2 Patient Table (PT)................................................................................................................ 80

7.3 Magnet Rundown Unit (MRU).............................................................................................. 81

8 Magnet Room Venting Requirements........................................................................................... 83

8.1 Venting System Requirements.............................................................................................83

8.2 HVAC Vent Requirements....................................................................................................83

8.3 Emergency Exhaust Vent Requirements..............................................................................83

8.4 Pressure Equalization Vent Requirement.............................................................................85

8.5 Cryogenic Venting................................................................................................................ 85

8.6 Vent Requirements Inside the Magnet Room ......................................................................86

8.6.1 General........................................................................................................................86

8.6.2 Vent Size..................................................................................................................... 87

8.6.3 Vent Materials..............................................................................................................87

8.6.4 Cryogen Vent Support................................................................................................. 88

8.6.5 Construction.................................................................................................................88

8.7 Vent Requirements Outside the Magnet Room....................................................................90

8.7.1 Cryogen Vent Support................................................................................................. 90

8.7.2 Vent Construction........................................................................................................ 90

8.7.3 Vent Exit...................................................................................................................... 91

8.8 Combined Vent.....................................................................................................................93

9 Magnet Room Electrical and Grounding Requirements................................................................ 95

9.1 Electrical Line and Filter Requirements................................................................................95

9.2 Lighting Requirements..........................................................................................................95

9.3 Grounding Requirements..................................................................................................... 95

Chapter 4 EQUIPMENT ROOM.............................................................................................................97

1 Equipment Room Overview...........................................................................................................97

1.1 Equipment Room Layout......................................................................................................97

1.2 Components in Equipment Room.........................................................................................98

Table of Contents 15

SIGNA Voyager Pre-Installation

Direction 5680008–1EN, Revision 2

2 Equipment room hardware components....................................................................................... 99

2.1 Integrated System Cabinet (ISC)..........................................................................................99

2.2 Integrated Cooling Cabinet (ICC)....................................................................................... 102

2.3 Magnet Monitor (MON) Requirements and Specifications................................................. 105

2.3.1 Requirements............................................................................................................ 105

2.3.2 Specifications.............................................................................................................105

2.4 Main Disconnect Panel (MDP) Option................................................................................107

2.5 Magnetic Resonance Elastography (MRE) Option.............................................................108

2.5.1 Requirements............................................................................................................ 108

2.5.2 Specifications.............................................................................................................108

3 ISC and ICC Construction Requirements....................................................................................109

4 ISC and ICC Wall Opening Requirements.................................................................................. 112

Chapter 5 OPERATOR ROOM............................................................................................................ 121

1 Operator Workspace (OW1)........................................................................................................121

2 Pneumatic Patient Alert (PA1).....................................................................................................125

3 Oxygen Monitor (OXY) Option.....................................................................................................126

Chapter 6 SYSTEM INTERCONNECTIONS....................................................................................... 129

1 MR System Interconnects Specifications.................................................................................... 129

1.1 Component Designator Definitions.....................................................................................129

1.2 Usable Cable Lengths........................................................................................................ 130

1.3 Long / Short cable selection guidance................................................................................131

1.4 Magnetic Resonance Elastography (MRE) Option.............................................................132

2 MR System Interconnects Routing Requirements...................................................................... 133

2.1 General Requirements....................................................................................................... 133

2.2 Magnet Room Requirements..............................................................................................134

2.2.1 Recommended Cable Groupings.............................................................................. 135

2.2.2 Cable Tray Requirements and Examples..................................................................135

2.3 Equipment Room Requirements........................................................................................ 138

3 MR System Cable Specifications................................................................................................ 140

4 Facility Supplied System Interconnects Specifications............................................................... 144

16 Table of Contents

SIGNA Voyager Pre-Installation

Direction 5680008–1EN, Revision 2

Chapter 7 APPENDIX.......................................................................................................................... 147

1 Glossary...................................................................................................................................... 147

2 MR Site Vibration Test Guidelines...............................................................................................150

2.1 Test Measurements............................................................................................................150

2.2 Equipment (Spectral Analyzer) Set-Up...............................................................................150

2.3 Data Collection................................................................................................................... 151

2.3.1 Ambient Baseline Condition.......................................................................................151

2.3.2 Normal Condition.......................................................................................................151

2.4 Presentation/Interpretation of Results................................................................................ 151

3 RF Shielding Effectiveness and Ground Isolation Testing.......................................................... 157

3.1 Ambient Radio Frequency Interference (RFI).....................................................................157

3.2 Introduction.........................................................................................................................157

3.2.1 Discrete RF Interference............................................................................................157

3.2.2 Broadband RF Interference....................................................................................... 157

3.2.3 Ambient Radio Frequency Interference (RFI) Site Survey........................................ 157

3.3 RF Shielding Effectiveness (SE) and Ground Isolation Test Methods............................... 158

3.3.1 Introduction................................................................................................................158

3.3.2 Test Set-Up for RF Shielded Room ..........................................................................159

3.3.3 Shielding Effectiveness (SE)..................................................................................... 159

3.3.4 Reference Level and Dynamic Range.......................................................................159

3.3.5 Test Equipment..........................................................................................................159

3.3.6 Test Frequency..........................................................................................................160

3.3.7 Measurement Procedure........................................................................................... 160

3.3.7.1 Shielding Effectiveness Measurement..............................................................161

3.3.7.2 Reference Level Measurement.........................................................................161

3.3.7.3 Attenuated Level Measurement........................................................................163

3.3.7.4 Shielding Effectiveness calculation...................................................................164

3.3.8 RF shielded Room Ground Isolation Resistance Measurement Method ..................164

3.3.9 RF Shield Test Report............................................................................................... 165

4 Acoustic Background and Design Guidelines............................................................................. 167

Table of Contents 17

SIGNA Voyager Pre-Installation

Direction 5680008–1EN, Revision 2

4.1 Acoustic Background..........................................................................................................167

4.1.1 Airborne..................................................................................................................... 167

4.1.2 Structureborne...........................................................................................................167

4.2 Acoustic Design Guidelines................................................................................................168

4.2.1 Magnet Room............................................................................................................ 168

4.2.2 Inter-Spacial Areas.................................................................................................... 168

4.2.2.1 Wall Construction..............................................................................................168

4.2.2.2 High Bay RF Room...........................................................................................170

4.2.2.3 Miscellaneous Plumbing, RF Windows and RF Doors..................................... 170

5 Sample Calculation AC Power Equipment Minimum Distance................................................... 172

6 Selecting Magnet Anchor Size.................................................................................................... 173

7 Magnet Cryogenic Venting Pressure Drop Reference Tables.................................................... 175

18 Table of Contents

Chapter 1 Introduction

1 Pre-Installation Manual Introduction

WARNING

EQUIPMENT FAILURE OR PERSONNEL INJURY

FAILURE TO IMPLEMENT ALL REQUIREMENTS AND ADHERE TO ALL

SPECIFICATIONS IN THIS MANUAL MAY RESULT IN PERSONAL INJURY,

EQUIPMENT DAMAGE, SCAN FAILURE, OR WARRANTY VOID.

THE IMPLEMENTATION OF ALL REQUIREMENTS AND ADHERENCE TO ALL

SPECIFICATIONS IN THIS MANUAL IS THE RESPONSIBILITY OF THE

CUSTOMER OR ITS ARCHITECT AND ENGINEERS. REFER ANY

QUESTIONS TO THE GE HEALTHCARE PROJECT MANAGER OF

INSTALLATION (PMI).

NOTICE

The customer is responsible for compliance with all local and National codes and

regulations.

SIGNA Voyager Pre-Installation

Direction 5680008–1EN, Revision 2

1.1 Document Purpose

This pre-installation manual provides the necessary information to prepare a site for system

installation. Specifically, this manual provides information:

To define system requirements and interactions

1.

2. For the effective arrangement and interconnection of system components

1.2 Intended User

The primary user of this manual is the installation or architectural planner who has knowledge of

the following:

National and local building codes

1.

2. Customer site procedures (medical, MR, safety, etc.)

Any special architectural requirements (e.g., seismic codes)

3.

Chapter 1 Introduction 19

1.3 Document Overview

This manual describes requirements and specifications for the following:

General System Requirements

1.

Magnet Room

2.

3. Equipment Room

4. Operator Room

System Interconnections

5.

SIGNA Voyager Pre-Installation

Direction 5680008–1EN, Revision 2

20 1 Pre-Installation Manual Introduction

Chapter 2 General System Level

1 System Components

The SIGNA Voyager 1.5T system consists of the following components: Refer to Illustration 2-1.

1.1 Magnet Room

1. 1.5T LCC RD Magnet with Enclosure (MAG) and VibroAcoustic Dampening Kit

Patient Transport Table (PT)

2.

Magnet Rundown Unit (MRU). Note: An optional remote MRU may be located outside the

3.

magnet room.

1.2 Equipment Room

1. Main Disconnect Panel (MDP) (GE Option or customer supplied)

Integrated System Cabinet (ISC)

2.

Integrated Cooling Cabinet (ICC)

3.

SIGNA Voyager Pre-Installation

Direction 5680008–1EN, Revision 2

4. Magnet Monitor (MON)

Optional: Magnetic Resonance Elastography (MRE)

5.

1.3 Control Room

1. Operator Workspace Equipment (OW1)

Pneumatic Patient Alert System (PA1)

2.

Optional: Oxygen Monitor (OXY)

3.

1.4 Accessories

1. Patient accessories, including phantoms, cushions, sponges, straps, and wedges

Gating accessories, including patient cardiac leads, peripheral gating probe, and respiratory

2.

bellows

Chapter 2 General System Level 21

Illustration 2-1: System Overview

SIGNA Voyager Pre-Installation

Direction 5680008–1EN, Revision 2

22 1 System Components

2 MR Suite Minimum Room Size Requirement

CAUTION

Procedure Failure

The minimum service area shown must be kept clear of permanent or installed

cabinetry, mill work, shelving, coil storage fixtures, furniture, etc. Ceiling service

area should be kept clear of overhead items, including soffits, HVAC, plumbing

compnent and brackets

Permanent or installed objects in this area may prevent or delay magnet service

or operation.

Room dimensions shown in the table below lists the minimum finished room space

requirements to properly and safely operate and service the MR system. The items listed below

are not included in the minimum area dimensions:

1. Building code requirements (e.g., exit routes, door placement, local and national electrical

codes, etc.)

SIGNA Voyager Pre-Installation

Direction 5680008–1EN, Revision 2

NOTE:

The customer must provide Equipment and Magnet Room evacuation routes to

comply with facility emergency procedures.

2. System requirements, including cable run locations, cryogen venting, patient observation

requirements, and penetration panel placements (e.g., the Equipment room and Magnet

room must share a common wall to allow penetration panel installation)

Penetration panel closet and all associated areas (must be outside the minimum finished

3.

room dimensions)

4. Non-GEHC equipment options (such as additional AC or water cooling equipment in the

Equipment room)

5. Accessory storage. Refer to the

Customer Site Storage Requirements

manual (document

number 5182674) or contact the GE Healthcare Project Manager of Installation (PMI) for

any additional accessory storage requirements

Table 2-1: System Minimum Room Inside Clear Space Dimensions

W x D

in. (mm)

107.7 x 70.9

(2735 x 1800)

Equipment Room

Area ft2 (m2)

52.9

(4.92)

Ceiling Height

In. (mm)

114

(2896)

W x D

In. (mm)

145.8 x

228.8

(3704 x

5812)

See Note

1,2,3

Magnet Room Control Room

Area

ft2 (m2)

201.4

(18.7)

Ceiling

Height

in. (mm)

98.5

(2500)

See Note 4

W x D

In. (mm)

83.9 x 59.8

(2130 x

1520)

Area

ft2 (m2)

34.8

(3.24)

Total System

Area

ft2(m2)

293.2

(27.24)

Chapter 2 General System Level 23

SIGNA Voyager Pre-Installation

Direction 5680008–1EN, Revision 2

NOTE: 1. Must locate center of the magnet to keep minimum service area described in

Illustration 2-2.

Minimum dimensions are for service only. Room size may grow due to local

2.

constraints including magnetic field containment

Minimum Magnet Room dimensions do not contain 5 gauss line to room. If fringe

3.

field containment is needed, see Chapter 3, Magnetic Shielded Room

Requirement .

4. Magnet Room minimum ceiling height is 98.5 in. (2500mm) when M7000GM 2.5m

Ceiling Kit-Passive is installed. If suspended ceiling height is between 98.5 in.

(2500 mm) and 105 in. (2667 mm), 2.5M Low Ceiling Kit-Passive, M7000GM is

required. Contact the PMI for preparation.

24 2 MR Suite Minimum Room Size Requirement

SIGNA Voyager Pre-Installation

Direction 5680008–1EN, Revision 2

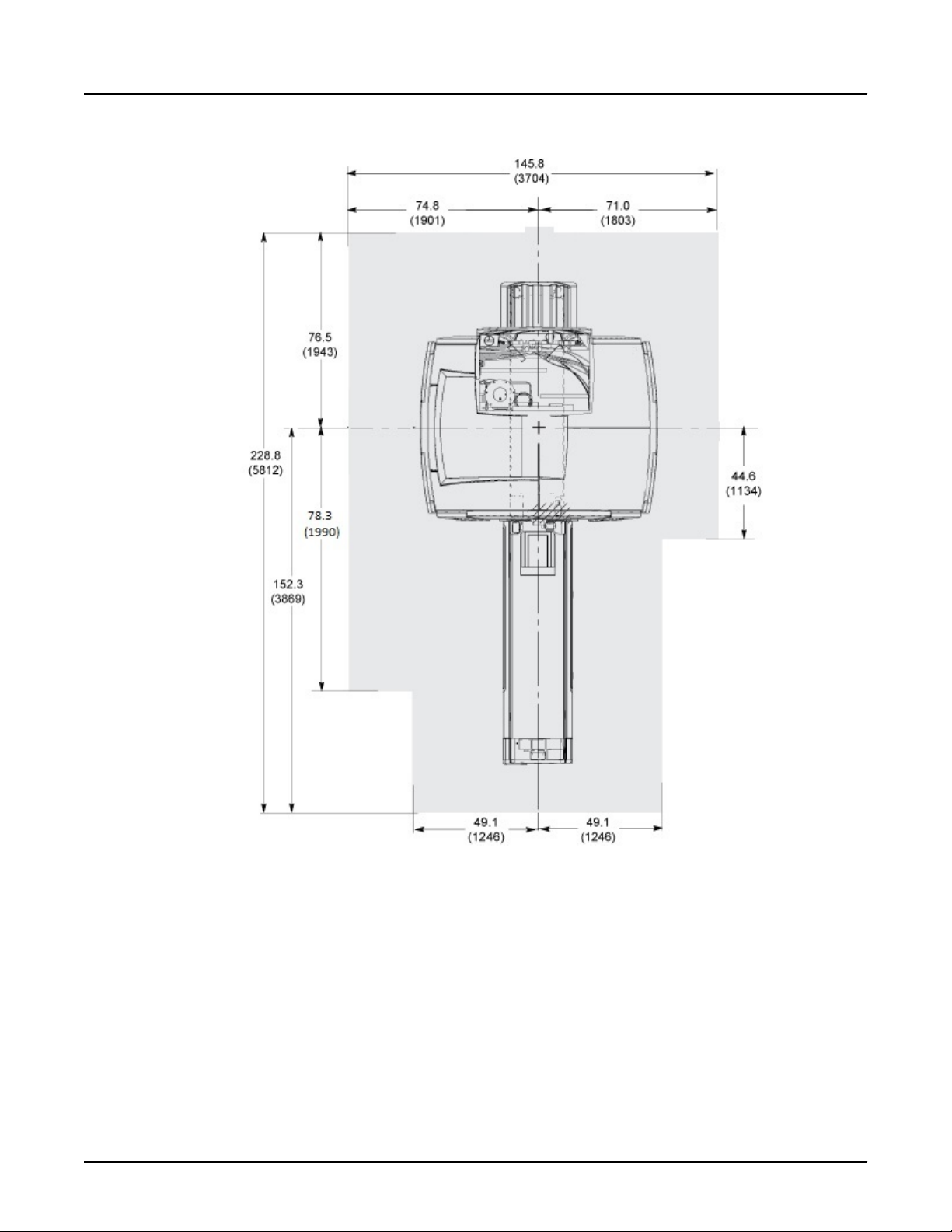

Illustration 2-2: Minimum Magnet Service Area (Top View)

NOTE: 1. All dimensions are in inches; bracketed dimensions are in millimeters

2. Shaded area indicates minimum service area

Chapter 2 General System Level 25

SIGNA Voyager Pre-Installation

Direction 5680008–1EN, Revision 2

Illustration 2-3: Minimum Magnet Ceiling Height (Top View)

NOTE:

1. All dimensions are in inches; bracketed dimensions are in millimeters

2. Shaded area indicates floor to ceiling minimum height of 98.5 (2500)

26 2 MR Suite Minimum Room Size Requirement

3 IEC EMC Compliance

Per IEC 60601-1-2 Medical Electrical Equipment requires special precautions regarding

Electromagnetic Compatibility (EMC) and must be installed and put into service according to the

EMC information provided in the following tables. Full declaration is stored on-site in the user

manual delivered with the system.

The MR system is designed and tested to the following standards:

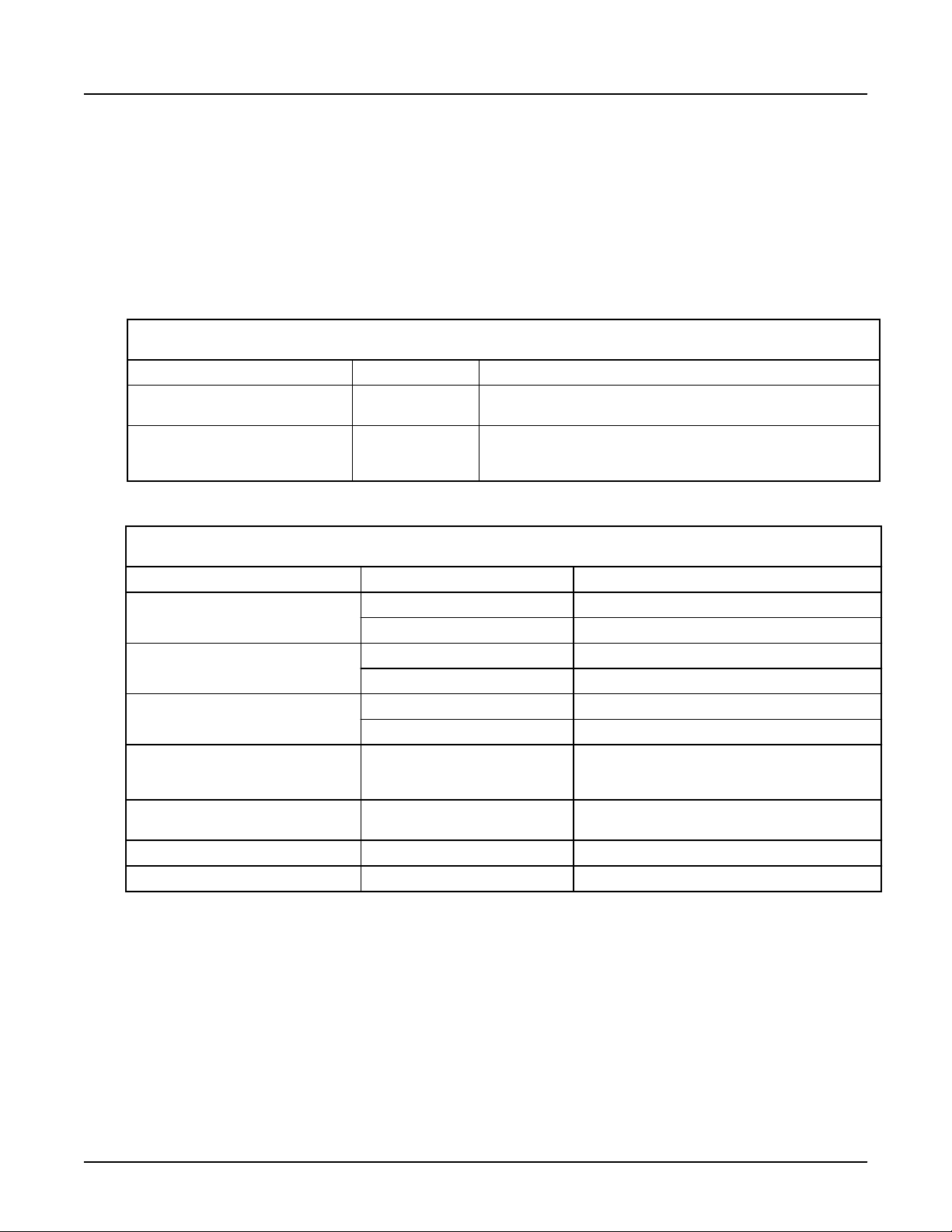

Table 2-2: Guidance And Manufacturer’s Declaration – Electromagnetic Emissions

The system is intended for use in the electromagnetic environment specified below. The customer or the user of the system should

assure that it is used in such an environment.

Emissions Test Compliance Electromagnetic Environment – Guidance

RF Emissions CISPR 11 Group 2 The system must emit electromagnetic energy in order to perform its

RF Emissions CISPR 11 Class A The system is suitable for use in all establishments other than domestic

Table 2-3: Guidance And Manufacturer’s Declaration – Electromagnetic Immunity

SIGNA Voyager Pre-Installation

Direction 5680008–1EN, Revision 2

intended function. Nearby electronic equipment may be affected

and those directly connected to the public low-voltage power supply

network that supplies buildings used for domestic purposes

The system is intended for use in the electromagnetic environment specified below. The customer or the user of the system should

assure that it is used in such an environment.

Immunity test IEC 60601 test level Compliance Level

Electrostatic discharge (ESD) IEC

61000-4-2

Electrical fast transient / burst IEC

61000-4-4

Surge IEC 61000-4-5 ±1 kV line(s) to line(s) ±1 kV differential mode

Voltage dips, short interruptions and volt‐

age variations on power supply input

lines IEC 61000-4-11

Power Frequency (50/60Hz) magnetic

field IEC 61000-4-8

Conducted RF IEC 61000-4-6 3 Vrms 150 kHz to 80 MHz 3 Vrms

Radiated RF IEC 61000-4-3 3 V/m 80 MHz to 2,5 GHz 3 V/m

±6 kV contact ±6 kV contact

±8 kV air ±8 kV air

±2 kV for power supply lines ±2 kV for power supply lines

±1 kV for input/output lines ±1 kV for input/output lines

±2 kV line(s) to earth ±2 kV common mode

<5 % UT (>95 % dip in UT) for 5 sec.

3 A/m 3 A/m

<5 % UT (>95 % dip in UT) for 5 sec.

Chapter 2 General System Level 27

4 MR Seismic Requirements

Contact the Project Manager of Installation for any questions regarding MR system seismic

requirements or specifications.

The customer is responsible for seismic anchoring of GE components

1.

Center of gravity, weight, physical dimensions, and attachment points are provided for

2.

seismic calculations.

SIGNA Voyager Pre-Installation

Direction 5680008–1EN, Revision 2

28 4 MR Seismic Requirements

5 MR Suite Acoustic Specifications

The following table lists the acoustic output of GE Healthcare equipment:

Table 2-4: Acoustic Specifications (Under Ambient Conditions)

SIGNA Voyager Pre-Installation

Direction 5680008–1EN, Revision 2

GE Equipment Acoustic Output

Control Room ≦ 80dBA 20 to 20k Hz

Equipment Room ≦ 80dBA 20 to 20k Hz

Magnet Room

Frequency

Refer to Acoustic Background and Design Guidelines for guidance to contain the noise within

the magnet room .

NOTE:

All GE equipment acoustic output values are for base equipment configuration in each

room.

Chapter 2 General System Level 29

6 MR Suite Magnetic Field Specifications

6.1 Magnet Fringe Field

Illustration 2-4, Illustration 2-5, Illustration 2-6 are the fringe field plots for the 1.5T LCC RD

Magnet. These plots illustrate the three-dimensional area of magnetic field without the influence

of any nearby ferrous objects or the earth's ambient magnetic field. Actual magnetic field

intensity at given locations will vary from these plots due to the following effects:

Ferrous materials used in building construction which will become permanently magnetized

•

when in close proximity to the MR generated magnetic field.

Earth's magnetic field - about 0.5 gauss in strength and unidirectional.

•

Therefore, these plots are only approximations of actual field intensities found at points

surrounding the magnet. These plots should be used as an aid in reviewing the location of MR

and hospital equipment and services (i.e. elevators, vehicular traffic, computer monitors, etc.).

Refer to Proximity Limits for the sensitivities of various equipment within the magnetic field.

Potential Exists Under fault conditions that the 5 gauss line may expand to 19.86 ft (6.0m)

Radially and 24.60ft (7.5m) axially for 2 seconds or less.

SIGNA Voyager Pre-Installation

Direction 5680008–1EN, Revision 2

30 6 MR Suite Magnetic Field Specifications

SIGNA Voyager Pre-Installation

Direction 5680008–1EN, Revision 2

Illustration 2-4: 1.5 Tesla LCC RD Magnetic Isogauss Line Plot - Top View

Chapter 2 General System Level 31

SIGNA Voyager Pre-Installation

Direction 5680008–1EN, Revision 2

Illustration 2-5: 1.5 Tesla LCC RD Magnetic Isogauss Line Plot - Front View

32 6 MR Suite Magnetic Field Specifications

SIGNA Voyager Pre-Installation

Direction 5680008–1EN, Revision 2

Illustration 2-6: 1.5 Tesla LCC RD Magnetic Isogauss Line Plot - Side View

6.2 Interference from Changing Magnetic Fields

Metal objects moving within the magnet sensitivity lines can produce a field disturbance during

clinical imaging. If the metal object is moving it will produce a fluctuating dipole type of field

which cause image artifacts. As an example, a car driven inside the moving metal line will act as

a dipole and produce a time varying field which change the magnet's main field during the

imaging time. The same vehicle may park within the moving metal line and remain parked

during clinical scanning without impact to the main field. See Illustration 2-7 and Illustration 2-8 .

Chapter 2 General System Level 33

SIGNA Voyager Pre-Installation

Direction 5680008–1EN, Revision 2

Illustration 2-7: Magnet Moving Metal Sensitivity Line Plot (Side View)

Illustration 2-8: Magnet Moving Metal Sensitivity Line Plot (Top View)

34 6 MR Suite Magnetic Field Specifications

Table 2-5: Magnet Moving Metal Requirements

SIGNA Voyager Pre-Installation

Direction 5680008–1EN, Revision 2

Steel Objects Category Definition Of Distance Location Minimum Distance Radial X Axial ft (m)

Objects 100 - 400 lbs distance from isocenter radial x axial (See Note 1) 3 Gauss line

Cars, Minivans, Vans, Pickup Trucks,

Ambulances

Bus, Trucks (Utility, Dump, Semi) distance from isocenter measured to center of driving or

Objects > 400 lbs, Elevators, Trains,

Subways

Notes

1. Radial distances are magnet X and Y axis. Axial distances are magnet Z axis.

EXAMPLE: For Moving Metal Requirements of objects > 400 lbs category you can use the time history of the occurrence to determine

2.

what milligauss level to use.

a. If the site has elevators/counter weights near the magnet and the elevator can stop on the floors for longer than 20 seconds (which

is usually the case), peak-to-peak milligauss reading must be less than 4.43.

If the site has a subway nearby and the field disturbance is less than 5 seconds, the peak-to-peak milligauss reading must be less

b.

than 8.39.

c. Use 4.43 milligauss peak-to-peak.

distance from isocenter measured to center of driving or

parking lane radial x axial (See Note 1)

parking lane radial x axial (See Note 1)

Place a directional probe (e.g. flux gate sensor) at isocen‐

ter of proposed magnet location aligned along the Z-axis.

Measure p-p magnetic field change (dc).

See Illustration 2-9 and see Example in

See Note 1

15.5 x 21 (4.72 x 6.40)

18.1 x 24.5 (5.52 x 7.47)

Note 2

Chapter 2 General System Level 35

SIGNA Voyager Pre-Installation

Direction 5680008–1EN, Revision 2

Illustration 2-9: Actual Axial Shielding Performance

6.3 Electrical Current

1. Electrical current in high voltage power lines, transformers, motors, or generators near the

magnet may affect magnetic field homogeneity

36 6 MR Suite Magnetic Field Specifications

SIGNA Voyager Pre-Installation

Direction 5680008–1EN, Revision 2

2. Magnetic field interference at 50 or 60 Hz must not exceed 40 milligauss RMS respectively

at the magnet location (refer to Illustration 2-10)

The following equation can be used as a general guide in determining allowable current in

3.

feeder lines at a given distance from the magnet isocenter:

a.

For 1.5T LCC RD Magnet: I= (20X2)/S

I = Maximum allowable RMS single phase current (in amps) or maximum allowable RMS

b.

line current (in amps) in three phase feeder lines

c. S = Separation (in meters) between single phase conductors or greatest separation

between three phase conductors

d. X = Minimum distance (in meters) from the feeder lines to isocenter of the magnet

Illustration 2-10: Magnet Allowable Milligauss vs. Line Frequency for AC Equipment

Refer to Chapter 7, Sample Calculation AC Power Equipment Minimum Distance for additional

examples.

6.4 Non-MR System Equipment Sensitivity to Magnetic Fields

This section lists equipment known to be sensitive to high magnetic fields. Recommended limits

given are based on general MR site planning guidelines. Actual susceptibility of specific devices

Chapter 2 General System Level 37

SIGNA Voyager Pre-Installation

Direction 5680008–1EN, Revision 2

may vary significantly depending on electrical design, orientation of the device relative to the

magnetic field, and the degree of interference considered unacceptable.

Site plans must include consideration for magnetic field interaction with all customer equipment.

Use the table for reference only. The gauss limits in the table are approximate for that type of

equipment. Refer to OEM manuals for the equipment at your site to determine the actual Gauss

limits.

Table 2-6: Magnetic Proximity Limits

Gauss (mT) Limit Equipment

0.5 gauss (0.05mT) Nuclear camera

1 gauss (0.1mT) Positron Emission Tomography scanner Video display (tube)

Linear Accelerator CT scanner

Cyclotrons Ultrasound

Accurate measuring scale Lithotriptor

Image intensifiers Electron microscope

Bone Densitometers

3 gauss (0.3mT) Power transformers Main electrical distribution transformers

5 gauss (0.5mT) Cardiac pacemakers Biostimulation devices

Neurostimulators

10 gauss (1mT) Magnetic computer media Telephone switching stations

Hard copy imagers Water cooling equipment

Line printers HVAC equipment

Video Cassette Recorder (VCR) Major mechanical equipment room

Film processor Credit cards, watches, and clocks

X-ray tubes

Large steel equipment, including:

Emergency generators Air conditioning equipment

Commercial laundry equipment Fuel storage tanks

Food preparation area Motors greater than 5 horsepower

50 gauss (5mT) Metal detector for screening Telephones

LCD panels

No Limit Digital Detectors

6.5 Magnet Shield

NOTICE

If a site has an existing magnetic shield and an upgrade to the LCC RD magnet

is being performed, the existing shield must be evaluated by the GE Healthcare

MR Siting And Shielding Group.

Magnetic shielding is used to reduce the fringe field around the magnet. Refer to Section 6.1 for

the fringe field plots for the Magnet.

38 6 MR Suite Magnetic Field Specifications

SIGNA Voyager Pre-Installation

Direction 5680008–1EN, Revision 2

Magnetic shielding can also be used to reduce the magnetic field disturbance from moving

metal objects which can improve the moving metal capability.

Room magnetic shielding generally consists of iron plates in the room walls, floor, and ceiling.

Special consideration should be given when selecting a magnet site location due to the expense

and effort required to provide magnetic shielding.

Designing a magnetic shield requires a comprehensive computer analysis which predicts the

effect the shield will have on the magnetic field as well as the effect of the shield on the

homogeneity of the magnet. The structural capacity of the site and space availability are

important factors in the design of the shield. The GE Healthcare MR Siting & Shielding Group

has the capability to design magnetic shields which meet a broad range of site requirements.

Chapter 2 General System Level 39

7 Multiple MR System Requirements

7.1 Multiple Magnets

When installing multiple magnets, the 3 gauss lines must not intersect or the magnets will be

interactive. Contact the GE Healthcare Project Manager of Installation (PMI) for any questions

regarding magnetic field interaction.

Illustration 2-11: Two Magnet Installation

SIGNA Voyager Pre-Installation

Direction 5680008–1EN, Revision 2

40 7 Multiple MR System Requirements

7.2 Shared Equipment Rooms

When installing multiple MR systems in a shared equipment room, the following conditions must

be met:

The other system’s cabinet with RF amp must be separated from ISC by at least 79 in.

1.

(2000 mm).

2. The other system’s Penetration panel must be separated from Penetration Wall of ISC by at

least 118 in (3000 mm).

Cables from different MR systems must not be routed together

3.

SIGNA Voyager Pre-Installation

Direction 5680008–1EN, Revision 2

Chapter 2 General System Level 41

8 MR Suite Temperature and Humidity

CAUTION

Equipment Failure

Failure to maintain the required temperature or humidity at all times (i.e., both

working and non-working hours) may result in equipment failure, scanning failure,

or warranty void.

Ensure the HVAC system has the correct capacity for the room size, equipment

heat output, and environmental conditions to maintain proper temperature and

humidity.

This section provides temperature and humidity requirements for the MR suite. Specific

construction requirements for each room can be found in the following sections:

Magnet Room

•

Equipment Room

•

Operator Room

•

SIGNA Voyager Pre-Installation

Direction 5680008–1EN, Revision 2

8.1 Temperature and Humidity Requirements

Table 2-7: Room Temperature and Humidity Requirements

Room

Equipment Room (at Inlet to Equip‐

ment)

Magnet Room 59-69.8 (15-21) 5 (3) 30-60 5

Operator Room 59-89.6 (15-32) 5 (3) 30-75 5

Notes:

1. Operating temperature gradient limits shall be between -5° F/Hr (-3° C/Hr) and 5° F/Hr (3° C/Hr), when averaged over 1 hour

Operating humidity gradient limits shall be between -5% RH/hour and 5% RH/hour, when averaged over 1 hour

2.

Maximum ambient temperature is derated by 1 degree C per 300 m above 2000 m (not to exceed 2600 m)

3.

Range °F (°C)

59-89.6 (15-32)

1. The customer is responsible for HVAC system design, purchase, and installation

The temperature requirements must not be exceeded at any point during the day (both

2.

working or non-working hours)

3. A separate thermostat must be provided for the Magnet room

Temperature Humidity

Change °F/Hr (°C/Hr)

3

5 (3) 30-75 5

1

Range %RH

Change %RH/Hr

2

42 8 MR Suite Temperature and Humidity

8.2 Equipment Heat Output Specifications

This section details the heat output for specific components. These heat outputs define the

maximum condition. Actual heat output and room temperature may vary due to environmental

factors, room insulation, actual usage, and any non-GE Healthcare equipment used in the MR

suite. Also, due to large variations in heat loads, the HVAC system may require unloaders, hot

gas bypass, and reheat to maintain humidity levels.

Table 2-8: System Heat Output for Air Cooling

SIGNA Voyager Pre-Installation

Direction 5680008–1EN, Revision 2

Component Magnet Room

Maximum Average

Magnet (MAG) and Patient

Transport Table (PT)

Main Disconnect Panel (MDP,

optional)

Integrated System Cabinet

(ISC)

Heat Exchanger Cabinet (ICC) 3,412

Cryocooler Compressor (CRY)

Magnet Monitor (MON) 205 (60) 205 (60) 205 (60)

Operator Workspace equip‐

ment (OW)

8,189

(2,400)

BTU/hr (W)

4,095

(1,200)

Idle

1,915

(561)

Equipment Room

BTU/hr (W)

Maximum Average

901 (264) 450 (132)

24,232

(7,100)

(1,000)

1,706 (500)

7,270*

(2,130)

1,706*

(500)

1,706

(500)

Idle

450

(132)

955*

(280)

0* (0)

1,706

(500)

Control Room

BTU/hr (W)

Maxi‐

mum

4,947 (1,450)

Aver‐

age Idle

NOTE: For ISC and ICC, Average value is calculated using Standby mode and Idle value is

calculated using Night Mode (Power Off Mode).

Table 2-9: System Options Heat Output for Air Cooling

Component

MR Elastography

Magnet

Room

BTU/hr

(W)

Equipment

Room

BTU/hr (W)

480 (141)

Control

Room

BTU/hr (W)

Chapter 2 General System Level 43

9 MR Coolant Requirements

NOTICE

Equipment Failure. A continuous supply of facility liquid coolant to the Integrated

Cooling Cabinet (ICC) is required at all times for proper system operation. Failure

to provide liquid coolant with the requirements listed in this section may cause

equipment failure.

9.1 Integrated Cooling Cabinet (ICC) Coolant Requirements

1. The facility must provide liquid coolant to the Integrated Cooling Cabinet (ICC)

The facility must provide pipe/hose, filter, and connectors to the ICC

2.

The facility must provide an uninterrupted supply of liquid coolant to the ICC at magnet

3.

delivery

4. The ICC, ISC and CRY must be located on the same level.

5. The customer must provide and install an in-line flow meter on either the supply or return

facility coolant hose. The flow meter must be capable of visually displaying volumetric flow

between 10.5 and 26.4 gpm (40 and 100 L/min) and configured for the properties of the

cooling fluid in use

SIGNA Voyager Pre-Installation

Direction 5680008–1EN, Revision 2

Table 2-10: Facility Liquid Coolant Requirements

Parameter Requirements

Availability Continuous

Antifreeze 0-40% propylene glycol

Minimum Flow 13.2 gpm (50 L/min)

Maximum Flow 21.1 gpm (80 L/min)

Typical Flow 17.2 gpm (65 L/min)

Maximum Pressure Drop in ICC at Mini‐

mum Flow

Maximum Pressure Drop in ICC at Maxi‐

mum Flow

Maximum Inlet Pressure to ICC 80 psi (5.52 bar)

Chiller Size Minimum 36 KW

Condensation Protection Facility Plumbing to the ICC must be properly routed and insulated to prevent equipment damage or safety

Minimum Continuous Heat Load 7.5 KW

Inlet Temperature 41 to 59°F (5 to 15°C) measured at the inlet to the ICC

Customer supplied feeder hose (from

main water supply to ICC)

26.1 psi (1.8 bar) with 40% propylene glycol-water; 1021 kg/m3 density

49.3 psi (3.4 bar) with 40% propylene glycol-water; 1021 kg/m3 density

hazards

1 inch (25.4 mm) minimum hose inside diameter

If Hose length is over 10m less than 30m, it is recommended to use 1.25 inch (31.75 mm) minimum hose in‐

side diameter. If using 1.25 inch (31.75 mm) hose, prepare adapter to reduce inner diameter to 1 inch (25.4

mm) for ICC connection

44 9 MR Coolant Requirements

Table 2-11: Facility Water Quality Requirements

pH Value 6.5 to 8.2 at 77 °F (25 °C)

Electrical Conductivity < 0.8 mmho/cm

Chloride Ion < 200 ppm

Sulfate Ion < 200 ppm

M-Alkalinity < 100 ppm

Total Hardness < 200 ppm

Calcium Hardness < 150 ppm

Ionic Silica < 50 ppm

Iron < 1.0 ppm

Copper < 0.3 ppm

Sulfide Ion None, not detectable

Ammonium Ion < 1.0 ppm

Residual Chlorine < 0.3 ppm

Free Carbon Dioxide < 4.0 ppm

Stability Index 6.0 to 7.0

Suspended Matter < 10 ppm

Particle Size < 100 micron (with field changeable filter)

SIGNA Voyager Pre-Installation

Direction 5680008–1EN, Revision 2

Chapter 2 General System Level 45

SIGNA Voyager Pre-Installation

Direction 5680008–1EN, Revision 2

Illustration 2-12: MR System Water Cooling Block Diagram

46 9 MR Coolant Requirements

9.2 Emergency Facility Coolant Requirements

The facility may provide an optional backup coolant supply:

Cryocooler operation only: Backup coolant may be routed to ICC backup water port for the

Cryocooler compressor with the following requirements:

The facility is responsible for coolant, 1/2” pipe/hose, filters, and connectors to supply the

1.

coolant to the ICC back up port for the CRY.

The emergency coolant to Cryocooler Compressor must be drained to the facility through

2.

customer supplied 1/2” hose and must not back-feed to the ICC

3. Coolant must meet all other ICC coolant requirements listed in and Table 2-11

4. The charts in Illustration 2-13 shows the coolant flow rate and temperature requirements for

the Cryocooler Compressor:

SIGNA Voyager Pre-Installation

Direction 5680008–1EN, Revision 2

Chapter 2 General System Level 47

SIGNA Voyager Pre-Installation

Direction 5680008–1EN, Revision 2

Illustration 2-13: Cryocooler Water Cooling Requirements

48 9 MR Coolant Requirements

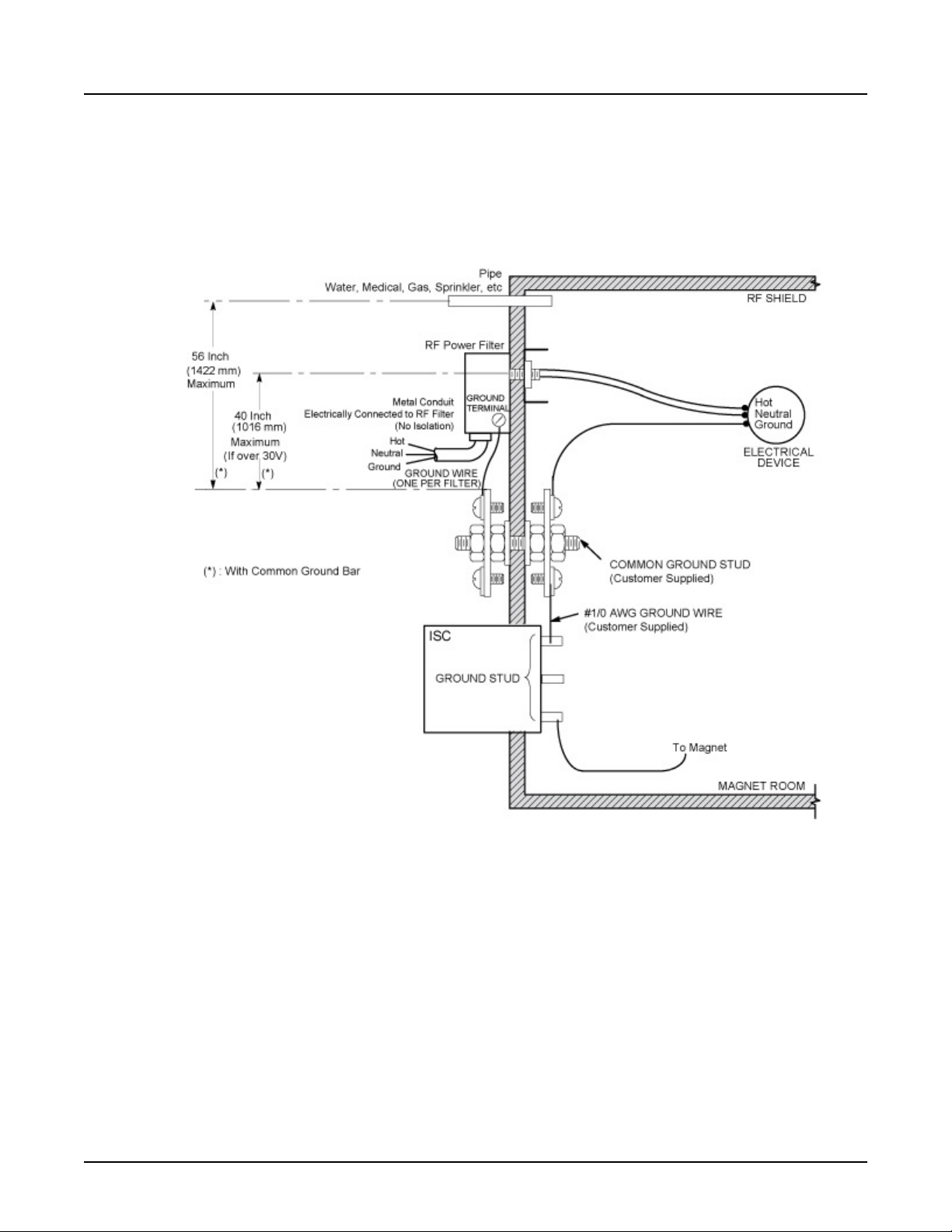

10 MR Suite Electrical Requirements

10.1 General Electrical Requirements

1. Customer is required to install a Main Disconnect Panel (MDP).

NOTE: GE MDP is orderable OR the customer can procure their own.

Refer to Section 10.2 for MDP Design Requirements

a.

Refer to Illustration 2-14 for Main Disconnect Panel (MDP) Set-Up

b.

2. The facility must provide system power to the MDP

3. All associated transformers and cables must be correctly sized for system power

requirements

4. The facility must provide cabling from the MDP to the PDU in Integrated System Cabinet

and from the MDP to the Cryocooler Compressor (F-50) in Integrated Cooling Cabinet (ICC)

5. For the power of facility backup cooling and compressor, it is customer’s responsibility to

prepare.

SIGNA Voyager Pre-Installation

Direction 5680008–1EN, Revision 2

Table 2-12: Facility Power Requirements

Component Parameter Requirements

At Main Dis‐

connect Pan‐

el (MDP)

Voltage / Frequency

Daily Voltage Variation Customer to provide +7.5% / -10% from nominal at MDP input under all line and load

Phase

Phase Balance Difference between the highest phase line-to-line voltage and the lowest phase line-

Power Quality Recommended THD of less than 2.5%

Facility Zero Voltage

Reference Ground

480 VAC 60 ±3 Hz

415 VAC 50 ±3 Hz, 60 ±3 Hz

400 VAC 50 ±3 Hz, 60 ±3 Hz

380 VAC 50 ±3 Hz, 60 ±3 Hz

conditions. This includes variation of power source and transmission losses up to the

MDP.

Input power to the MDP may use one of the following configurations:

A 3 phase solidly grounded WYE with Ground (4-wire system)

•

If a neutral wire exists, it must be terminated prior to or inside the MDP

A 3 phase floating DELTA with Ground (4-wire). Do not connect a corner

•

grounded DELTA source

Note: Some UPS options may require a neutral (refer to manufacturer documentation

for requirements).

to-line voltage must not exceed 2%

The facility ground for the MR system must originate at the system power source

•

(i.e., transformer or first access point of power into the facility) and be continu‐

ous to the MR system Main Disconnect Panel (MDP) in the room.

Main facility ground conductor to Main Disconnect Panel (MDP) must be appro‐

•

priately sized insulated copper wire.

The main facility ground to the Main Disconnect Panel (MDP) must meet local

•

codes.

Chapter 2 General System Level 49

SIGNA Voyager Pre-Installation

Direction 5680008–1EN, Revision 2

Component Parameter Requirements

Service re‐

ceptacle in

Magnet

Room

Power Availability Continuous, facility power is required at all times for operation of the Cryocooler

Voltage / Frequency

Phase 1

Maximum Amps 2.0

(CRY) to minimize cryogen consumption.

100-120 VAC 50/60 Hz Receptacle required for small power tools. Local volt‐

age and portable transformers for voltage values.

Table 2-13: System Power Demand

Equipment Power Draw (kVA)

ISC PDU Continuous Power 55

ISC PDU 5 Second Power 65

Cryo Compressor Continuous Power 9

Total System 5 Second Power 77

Total system Continuous Power 64

Standby Consumption (no scan) (PDU, CRY) < 17

Table 2-14: Power Consumption

Power Consumption Sleep Mode 5.7kW

Power Consumption Standby(no scan) 11.1kW

Power Consumption Typical consumption 16.1kW

50 10 MR Suite Electrical Requirements

SIGNA Voyager Pre-Installation

Direction 5680008–1EN, Revision 2

Illustration 2-14: Main Disconnect Panel (MDP) Set-Up

Chapter 2 General System Level 51

10.2 Main Disconnect Panel (MDP) Requirements

WARNING

PERSONNEL INJURY OR EQUIPMENT DAMAGE

CUSTOMER SUPPLIED MDP MUST HAVE CORRECTLY SIZED WIRES AND

RATED COMPONENTS TO MEET THE MR SYSTEM POWER

REQUIREMENTS.

WARNING

PERSONNEL INJURY OR EQUIPMENT DAMAGE

IF THE MDP POWERS THE CRYO COMPRESSOR, THE MDP EMERGENCYOFF FUNCTION MUST DISABLE THE AUTO RESTART FUNCTIONALITY

WHEN ACTUATED.

1. MDP to provide Auto-Restart. Auto-Restart to provide power to the Cryo compressor. See

Table 2-13

2. Manual Restart Capability

a. A low voltage release feature to disconnect the PDU upon power loss

SIGNA Voyager Pre-Installation

Direction 5680008–1EN, Revision 2

The PDU circuit must require a manual restart when power is reapplied to the main

b.

panel

3. Emergency Off Circuit

a. The MDP must have an emergency off control circuit that disables power to the entire

MR system

The emergency off circuit must be actuated by remotely located push button(s) (see

b.

Illustration 2-14)

c. The wire size for the emergency-off circuit is 12–22 AWG and is supplied by the

customer.

The manual reset must be required to restore power to the entire system

d.

e. Two sets of isolated, normally closed contacts that open when an emergency off button

is actuated must be provided for optional accessories

4. Lock-out/Tag-out

a. The MDP break must have capability to lock-out for single point Lock-out/Tag-out

requirements

A standard sized hasp for lock-out

b.

5. The MDP must be marked as required by national/local regulations

6. The MDP must provide terminations for all grounds entering, leaving and residing within the

panel

7. The MDP must provide terminations of appropriate size for all power wiring entering and

leaving the panel

Terminal blocks that can accept 3/0 AWG or larger on the main panel

a.

52 10 MR Suite Electrical Requirements

SIGNA Voyager Pre-Installation

Direction 5680008–1EN, Revision 2

b. Terminal blocks to accept 12 AWG (E0009) on the Cryocooler

c. Terminal blocks to accept 1 or 2 AWG on the PDU in ISC

The optional GE Healthcare MDP consists of the following:

8.

a.

A 3-pole 200A main circuit breaker rated for the total current of all the sub-breaker

circuits

A 3-pole 150A circuit breaker rated for the current of the PDU circuit

b.

A Customer Supplied 3-pole 30A circuit breaker is required for Cryocooler circuit outside

c.

of MDP

d. All circuit breakers have a short circuit current interrupting rating of 25000 Amps

Auto restart on the Cryocooler circuit

e.

f. Emergency off circuit including 2 pushbuttons to be installed external to the MDP

g. Terminal blocks that can accept 3/0 AWG maximum size on the main, 8 AWG maximum

size on the 30A Customer Supplied Breaker for Cryocooler circuit, and 1 or 2 AWG on

the PDU in ISC.

NOTE:

12 AWG (Cable RUN # E0009) will be connected between the 30A Customer

Supplied Breaker and the Cryocooler.

h. Isolated neutral terminal block for termination

i. Multiple ground terminal blocks as required by panel design

Listed and labeled by a Nationally Recognized Testing Lab (NRTL) in accordance with

j.

UL 508A and IEC/EN 60204–1 and bear the CE Marking in accordance with the EU Low

Voltage Directive (2006/95/EC) and Electromagnetic Compatibility Directive (2004/108/

ED).

Power on indicators

k.

l. Two isolated, normally open contact pairs that open when e-OFF is pressed for use with

optional accessories

Chapter 2 General System Level 53

11 MR System Shipping and Receiving

NOTICE

All shipping dimensions and weights are approximate and may vary based on

ship-to location, required rigging, or other requirements. Some shipping or

access routes may have requirements in addition to those listed in this section.

Contact the GE Healthcare Project Manager of Installation (PMI) to verify magnet

shipping, rigging, and access.

11.1 Receiving Requirements

1. The customer must provide an area for unloading system components from the truck and

delivering to the MR suite

SIGNA Voyager Pre-Installation

Direction 5680008–1EN, Revision 2

NOTE:

Contact the GE Healthcare Project Manager of Installation (PMI) for a list of

experienced rigging companies.

2. The customer is responsible for ensuring:

a.

All floors along the route will support the weight of the magnet (GE Healthcare

recommends a structural analysis)

Doors or other openings are sufficiently wide to allow passage

b.