Page 1

GE

Measurement & Control

Krautkramer Testing Machines

Full Body Volumetric Inspection Of Round Bars

ROWA-B Series

The ROWA-B is an ultrasonic phased

array test system for detection

of core and longitudinal surface/

subsurface flaws in round bars.

The ultrasonic coupling is realized

by a rotating water jacket,

generated by tangentially flowing

coupling water (GE patent). Due

to the compact dimensions of the

mechanics, the ROWA-B system can

be seamlessly integrated into an

existing inspection line.

The bars are fed into the test

chamber one by one on linear

tracks by means of a guiding and

transport device. A lifting/shifting

table is required for installation

of the test mechanism within the

guiding and transport line.

ROWA-B test mechanics

Page 2

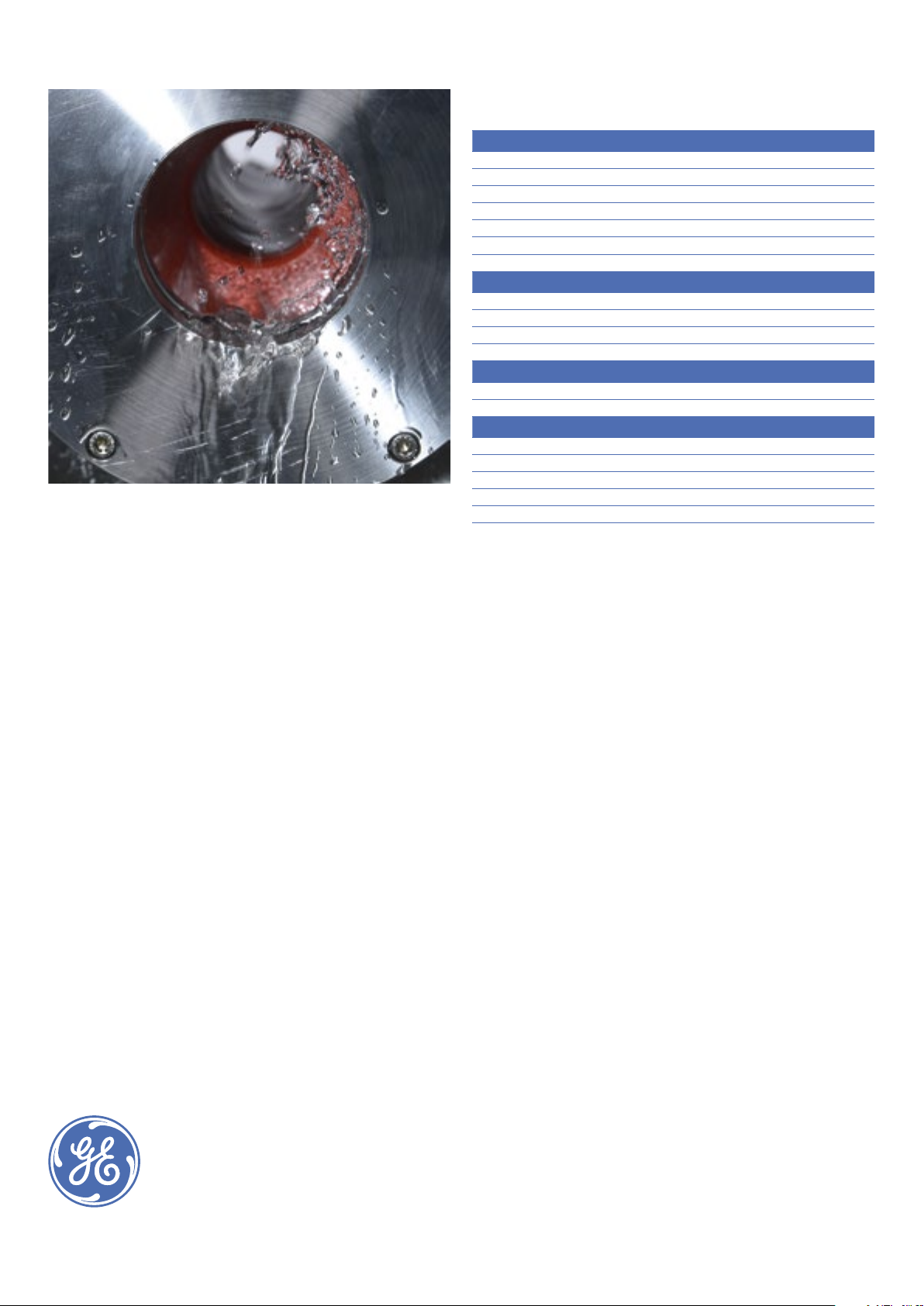

Rotating water jacket

System Overview

System Electronics – Type VPA

Windows operating system

Max. 20 kHz PRF in full parallel operation

VME bus controller

Parameter storage

Automatic sensitivity check/adjustment

Extensive monitoring functions, self-test and diagnostic support

State of the art PC technology

Options

Pre-wetting system

Water circulation system

Guiding and transport device

Shifting table

Test Specifications

AMS 2154 class AA

Various end user specific standards

Technical Specifications

Longitudinal surface/subsurface flaw testing

Core flaw testing

Material dia. Ø 10 – 250 mm

100 % coverage

Test speed up to 120 m/min

Dimension dependent guiding bushes at the inlet and outlet

sides keep the water jacket within the test chamber and

determine its free diameter. Rubber sealings prevent water

leakage during test and remove the water from the test

object’s surface after the test.

Depending on the application and object diameter, 4-18

phased array probes with up to 128 elements each are

arranged circumferentially in a chamber.

For testing, a multiple number of neighbouring elements

are controlled in parallel and form virtual probes. Due to

sequential activation of virtual probes along the circumference, the ROWA-B achieves 100% coverage of the rotating

sound beam without mechanical probe rotation. The system

does not contain any moving parts which results in overall

robustness and easy maintenance.

One key advantage of the ROWA-B is a short changeover

time. Within a wide dimension range, no mechanical probe

adjustment is necessary. Probes are adjusted electronically

by recalling stored parameters – only the guiding bushes and

the seals have to be changed according to the diameter of

the material under test.

The field proven and reliable GE ultrasonic electronics

processes all signals and carries out a separate evaluation

according to flaw type and position.

GEIT-60024EN (04/13)

© 2013 General Electric Company. All Rights Reserved. Specifications are subject to change without notice. GE is a registered trademark of General Electric Company. Other company or product names

mentioned in this document may be trademarks or registered trademarks of their respective companies, which are not affiliated with GE.

Loading...

Loading...