Page 1

SPECIFICATIONS

ROOTS™TRI-NADO™TM Truck-Mount,

Tri-Lobe Vacuum Blowers

Frame 1125

The ROOTS TRI-NADO™ TM Truck-Mount, Tri-Lobe

Vacuum Blowers have been redesigned to incorporate

the latest technology for reduced noise and vibration.

These features include:

• Cast-Foot Design for Reduced Vibration

• Stronger Construction for Minimum Noise

and Vibration

• Progressive Chamber Design That Reduces Noise

and Features Cooler Operation.

CASING - The casing is of one piece close-grained

cast iron construction. The casing is heavily ribbed

to prevent distortion under the most severe operating

conditions and incorporates the ROOTS Whispair™

feature for reduced pulsation, horsepower and

noise levels.

TIMING GEARS - The impellers are timed by a pair of

alloy steel spur gears that operate in an oil bath.

IMPELLERS - The closed-end impellers are made from

ductile iron with high tensile strength, and operate

without liquid sealing or lubrication.

SHAFTS - The shafts are 3” diameter alloy steel forgings

flange connected to the impeller body.

BEARINGS - The impeller/shaft assemblies are supported

at each end by antifriction bearings.

LUBRICATION - A patented jet spray oil slinger system

provides lubrication to gears and bearings.

PERFORMANCE TABLE

6” HgVac 15” HgVac 21” HgVac 24” HgVac 27” HgVac 28” HgVac

Speed CFM BHP CFM BHP CFM BHP CFM BHP CFM BHP CFM BHP

750 1768 28 1376 69.1 962 96.7 526 110.7 Blank Off 124.3

1200 3064 44 2672 110.5 2258 154.7 1822 176.8 508 198.9

1400 3640 52 3248 128.9 2834 180.5 2398 206.3 1084 232.1

1600 4216 59 3824 147.4 3410 206.3 2974 235.8 1660 265.3

1800 4792 74.4 4400 170.9 3986 235.1 3550 267.3 2236 299.4 Blank Off 310

2000 5368 84.8 4976 191.2 4562 262.1 4126 297.5 2812 333 Blank Off 344

Note: Vacuum ratings based on inlet air at standard temperature of 68º F, discharge pressure

of 30” Hg and specific gravity of 1.0.

S-8134B99 rev.0708

Page 2

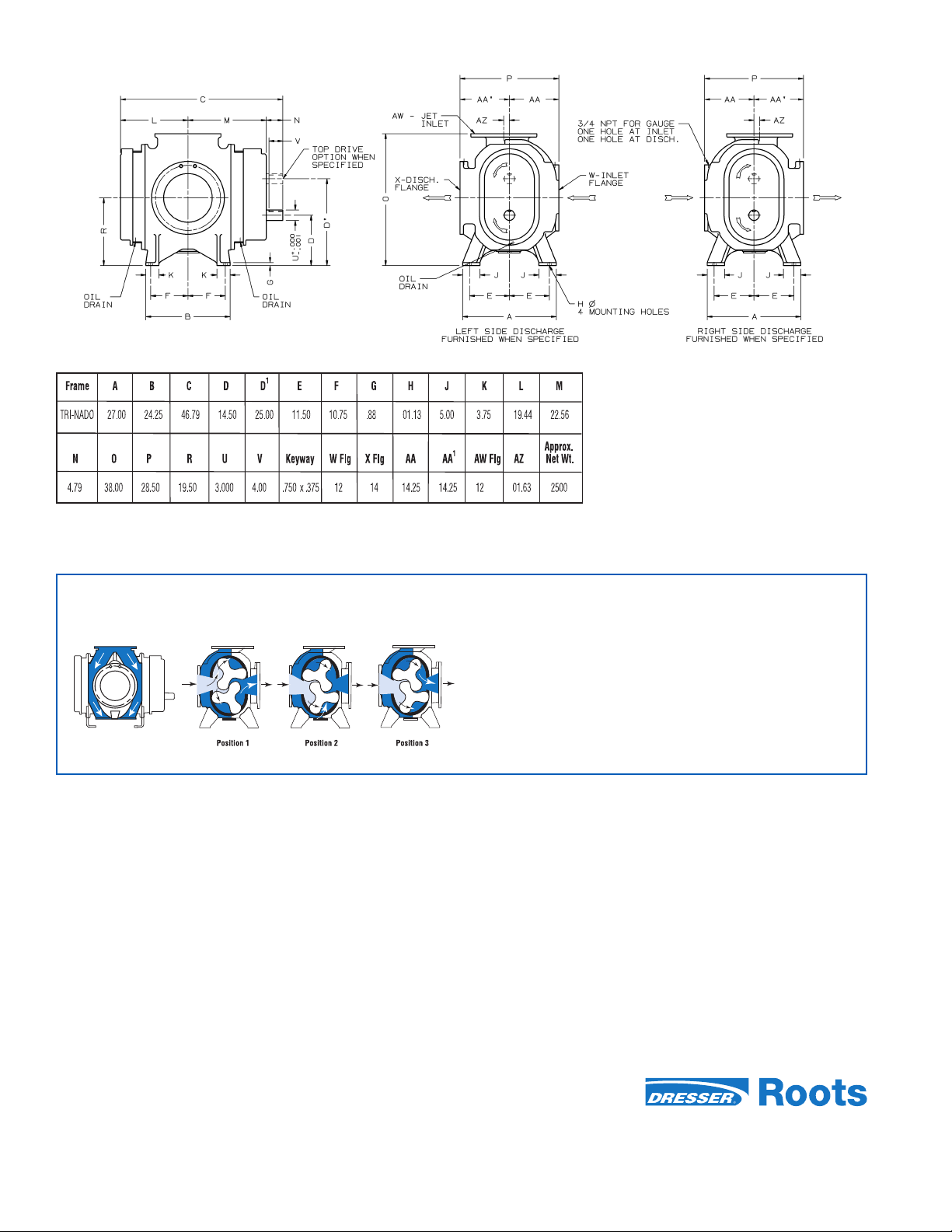

TRI-NADO™ TM DIMENSIONS

NOTES:

1. Unless otherwise specified,

dimensions are in inches.

2. Do not use for construction.

PRINCIPLE OF OPERATION

Shaded blue areas indicate air pressure variations from intake to

atmosphere discharge.

Position 1 - Incoming air is trapped between the impellers and the

case, producing a vacuum in the application system.

Simultaneously, air is discharged (right) from the vacuum blower.

Position 2 - As the impeller passes the jet plenum, atmospheric air

flows into the space between the impeller and the case. This cools

the trapped air, aids impeller movement and reduces shock and

power loss.

Position 3 - The trapped air is then moved to the discharge flange

(right). Backflow is reduced, resulting in lower discharge noise

relative to conventional rotary vacuum blowers.

TESTING

Each ROOTS rotary lobe vacuum blower is given a complete mechanical run at full speed and vacuum to ensure

mechanical integrity and verify performance. The units are operated at maximum rated vacuum level for a minimum of

one hour after temperatures have stabilized. Performance readings are recorded during the test, and each unit must

meet vibration in three planes before being certified as acceptable.

Dresser Roots

Houston, Texas Headquarters • U.S. Toll Free Phone: 1-877-363-ROOT(S) (7668) • Direct Phone: +1 832-590-2600

Connersville, Indiana Operations • U.S. Toll Free Phone: 1-877-442-7910 • Direct Phone: +1 765-827-9285

United Kingdom Operations • Phone: +44 (0) 1695 52600

USA/Canada Sales • Phone: +1 773-444-3360

Houston, Texas Factory Service • Phone: +1 713-896-4810

Mexico City Sales and Factory Service • Phone: +52 55 5889 5811

Dubai Sales and Factory Service • Phone: +971 4-8830831

Malaysia Sales • Phone: +60 3 2163 0480

China Sales • Phone: +86 10 8486 2440

Shanghai Factory Service • Phone: +86 21 5858 7638

©2007 Dresser, Inc. all rights reserved. • Printed in the U.S.A. • All information subject to change

without notice. • Universal RAI and EasyAir are registered trademarks of Dresser, Inc. • ROOTS,

RAM X, and WHISPAIR, are trademarks of Dresser, Inc.

www.dresser.com/roo tsblowers

S-8134B99 rev.0708

Loading...

Loading...